Patents

Literature

157results about How to "Act as a squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

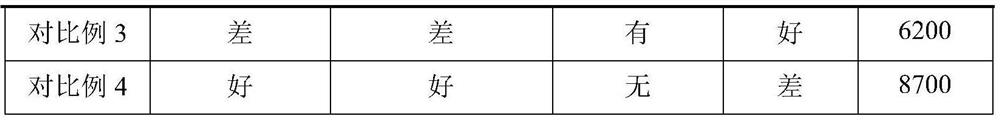

Centrifugation and pressure filtration double sludge dewatering method

InactiveCN104016565AReduce moisture contentGuaranteed uptimeSludge treatment by de-watering/drying/thickeningLiquid layerFiltration

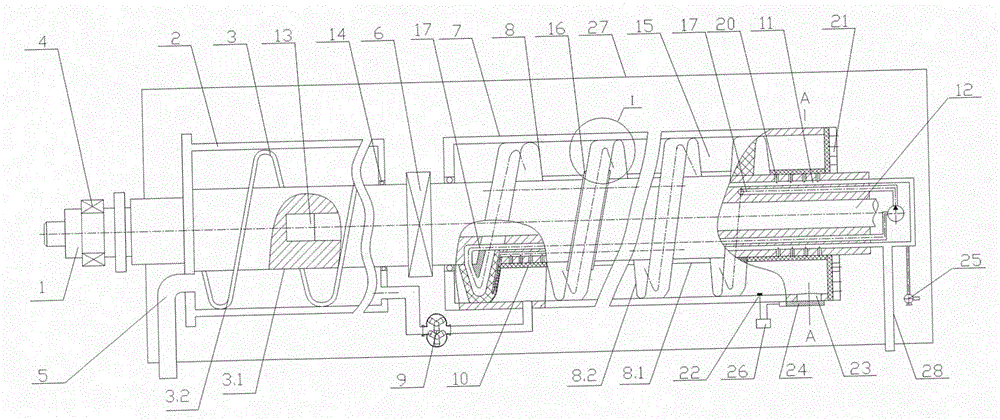

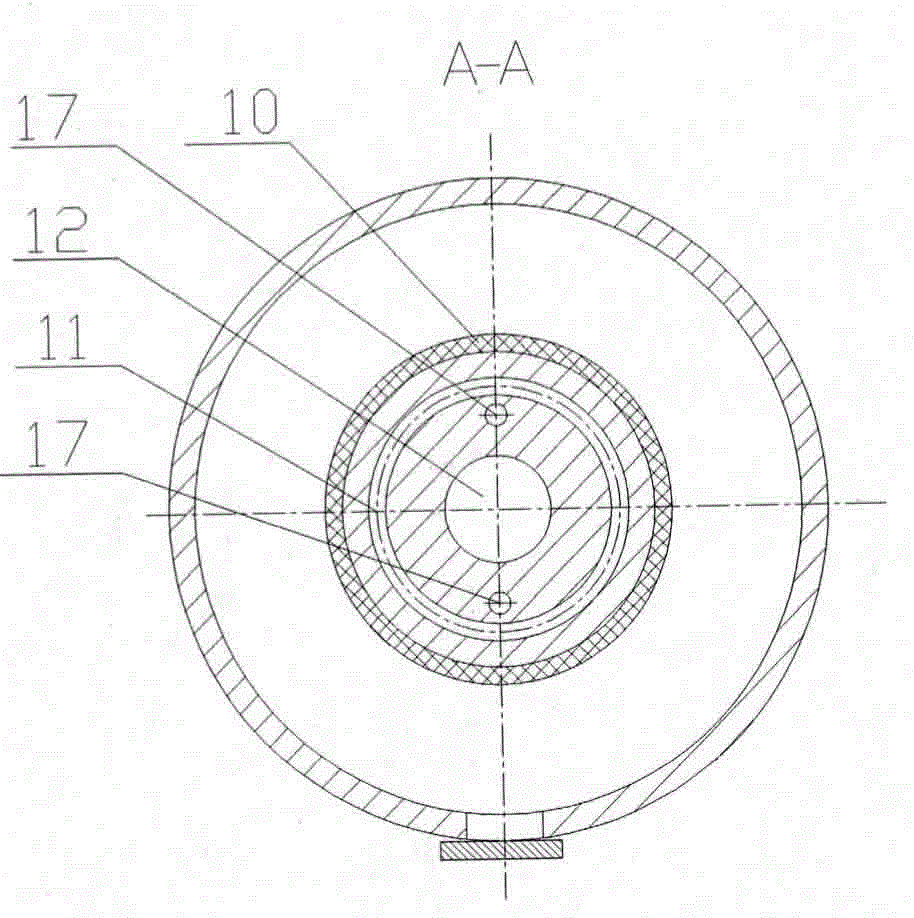

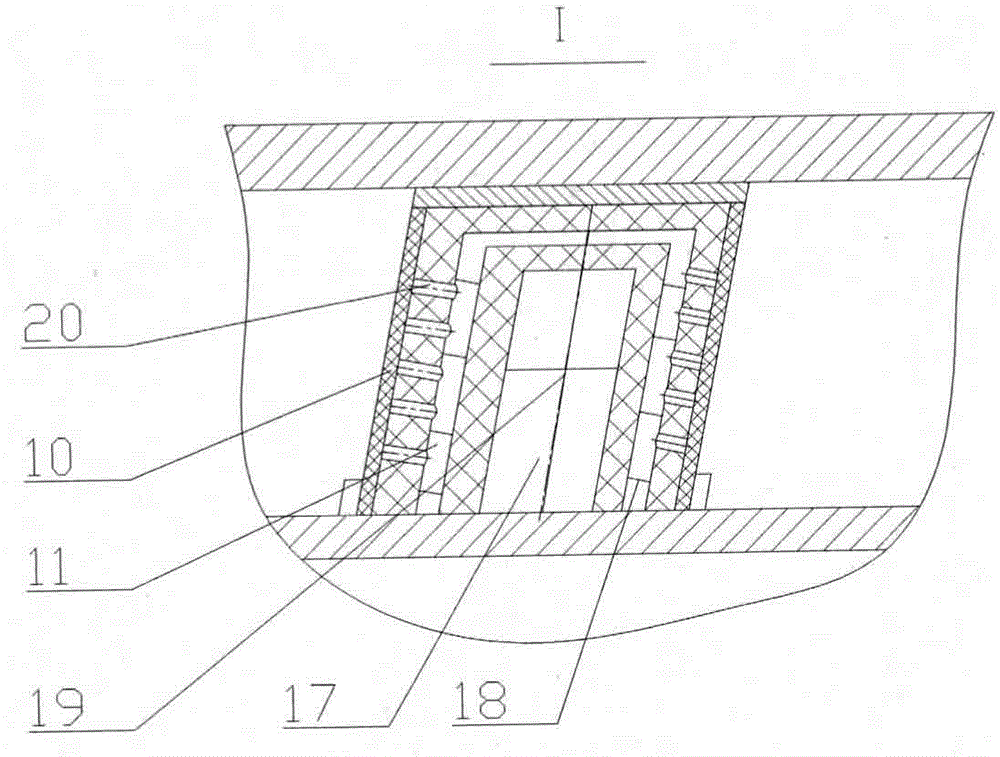

The invention discloses a centrifugation and pressure filtration double sludge dewatering method. The method comprises the steps: sewage is conveyed into a first rotary drum (2) through a pipeline, the first rotary drum (2) and a spiral pusher (3) are in differential rotation, sludge is thrown to the internal wall of the first rotary drum (2) under the action of centrifugal force, so as to form a solid layer, and a liquid layer is formed at the inner side of the solid layer by water; the sludge treated by a front-section dewatering device is conveyed into a second rotary drum (7) of a rear-section dewatering device, a plurality of chambers are formed between a spiral press filter (8) and the second rotary drum (7), spiral pressure filtration blades (8.2) are made from elastic materials, high-pressure fluid is introduced into the spiral pressure filtration blades, so as to expand the spiral pressure filtration blades, and the expanded spiral press filter rotates and extrudes the sludge. According to the centrifugation and pressure filtration double sludge dewatering method, the front-section dewatering device is mainly used for filtering moisture out of the sewage by means of centrifugation, and the rear-section dewatering device is used for carrying out further treatment on the sewage by means of centrifugation and pressure filtration, so that continuous operation can be carried out, the production efficiency is high, and the moisture content is low after dewatering.

Owner:CHINA JILIANG UNIV

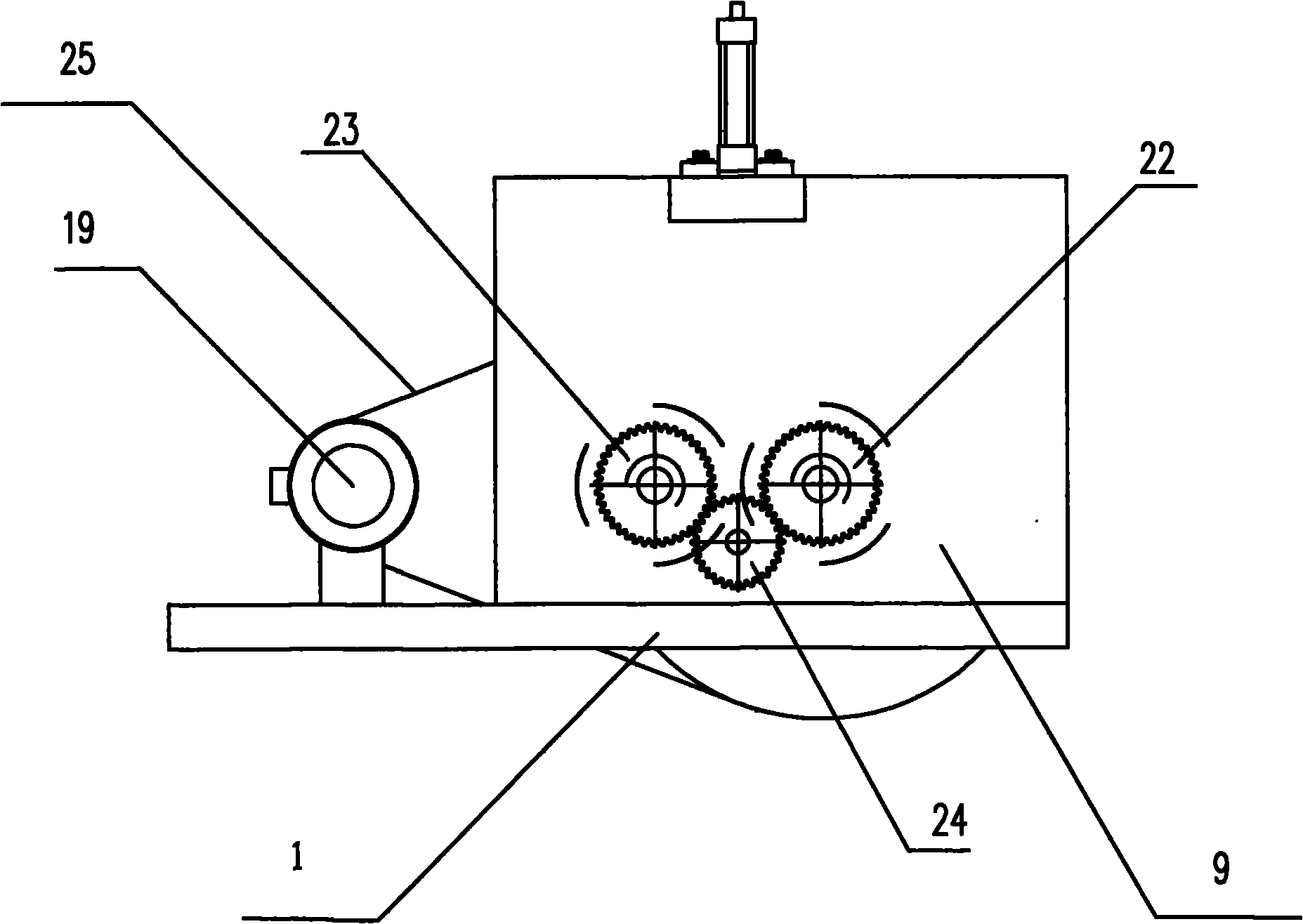

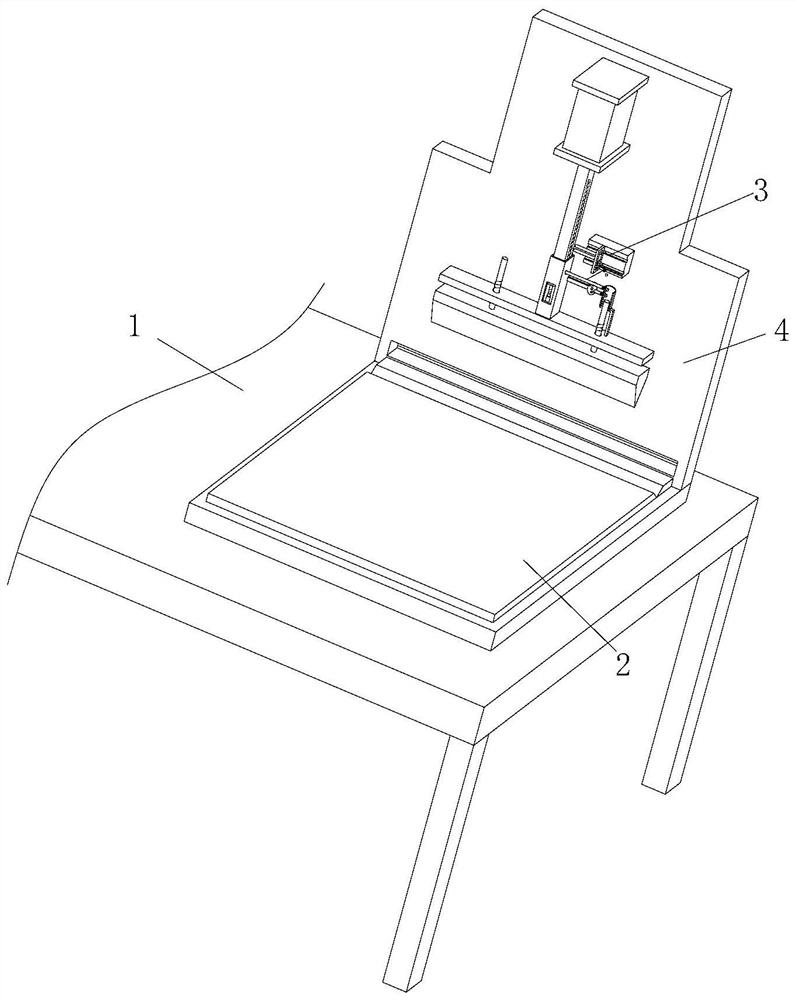

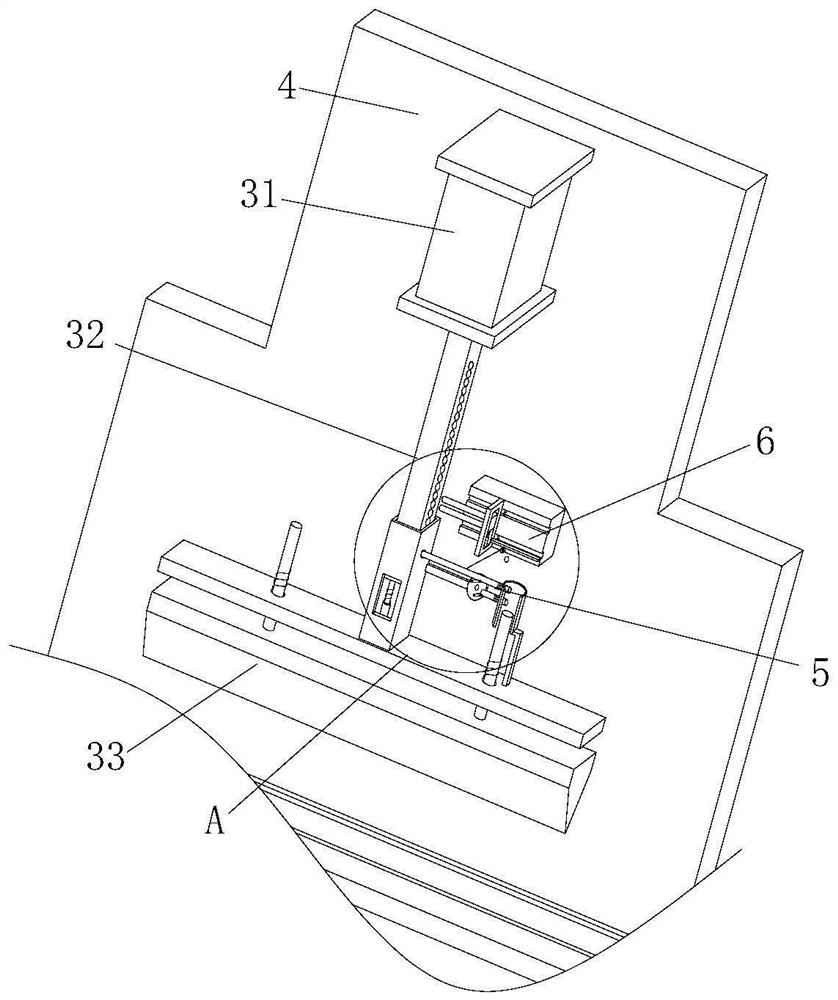

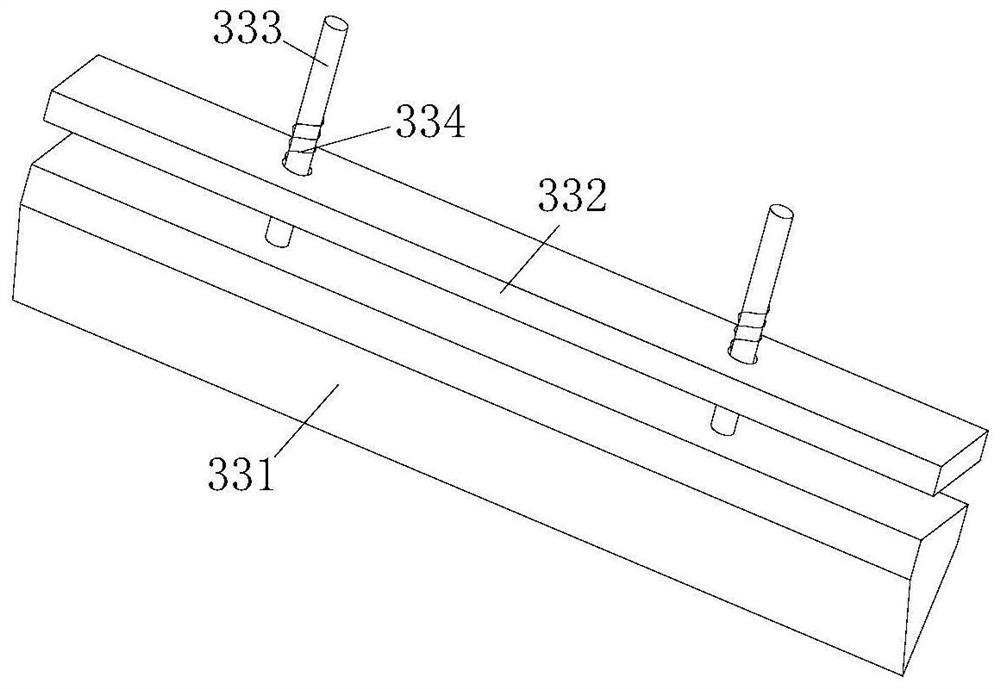

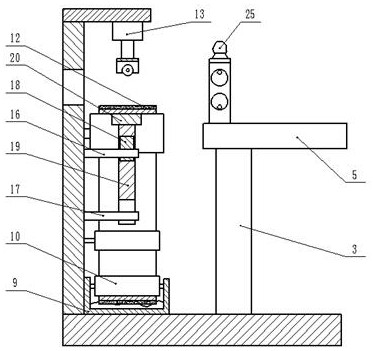

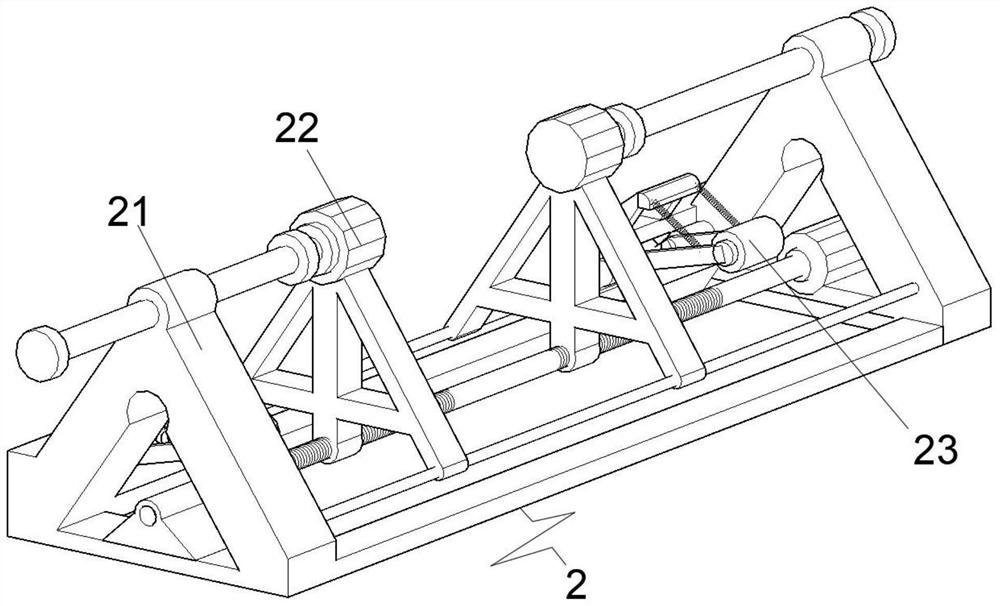

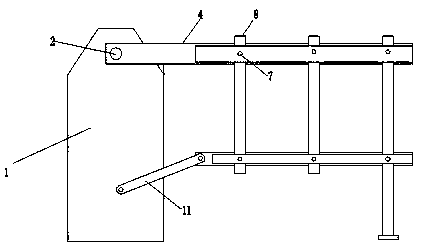

Metal pipe welding device capable of adjusting spacing

InactiveCN111151938AGood limit fixation effectSpacing is easy to adjustWelding/cutting auxillary devicesAuxillary welding devicesGear wheelCooling effect

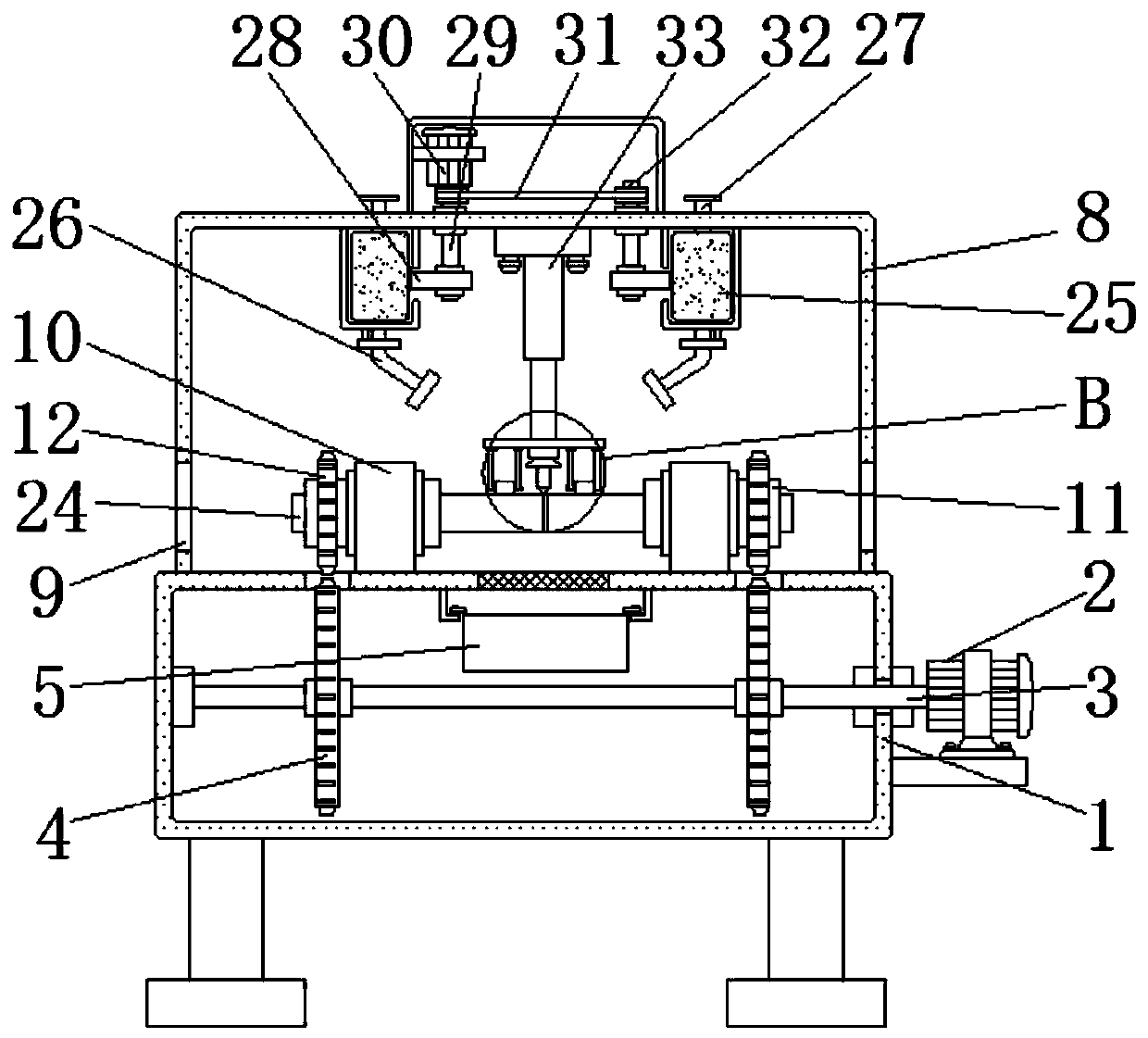

The invention discloses a metal pipe welding device capable of adjusting spacing. The metal pipe welding device comprises a fixing base, a first servo motor, a second servo motor and a welding head; and the first servo motor is fixed to the right side of the fixing base through bolts, the edge side of a transmission rod is connected with a gear through a bearing, a rubber water bag is mounted at the upper end in a working box, an electric push rod is fixed to the middle of the upper end in the working box through bolts, a transverse plate is fixedly mounted at the lower end of the electric push rod, the welding head is mounted in the middle of the lower end of the transverse plate, and a supporting rod is fixed to the edge side of the lower end of the transverse plate through bolts. According to the metal pipe welding device capable of adjusting the spacing, the spacing between a metal pipe and the welding head can be conveniently adjusted, meanwhile collision between the welding headand the metal pipe can be avoided, good limiting and fixing effects on the metal pipe can be achieved, and meanwhile a certain cooling effect on a welded position of the metal pipe can be achieved after welding work is completed.

Owner:广西高新美管业科技股份有限公司

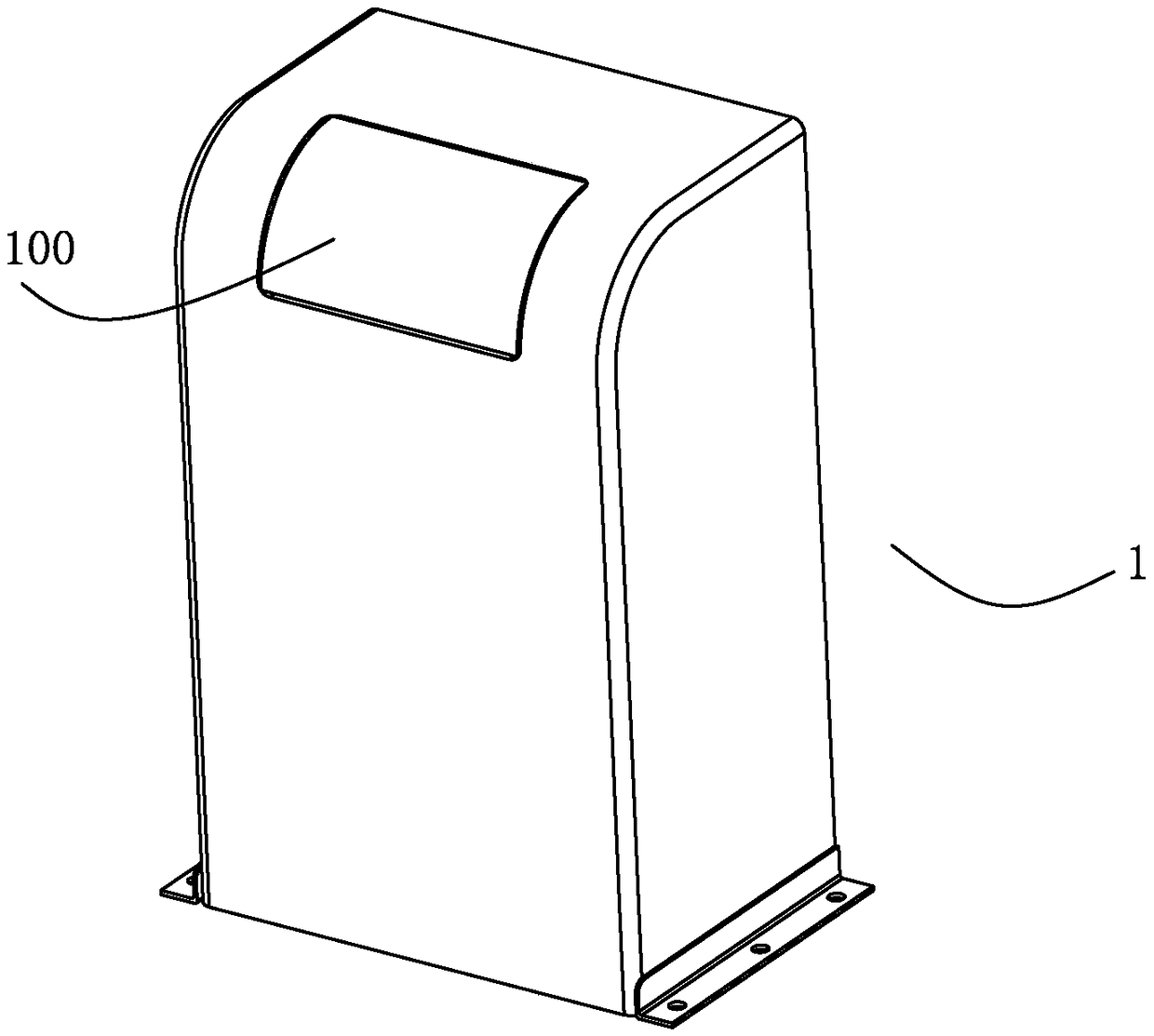

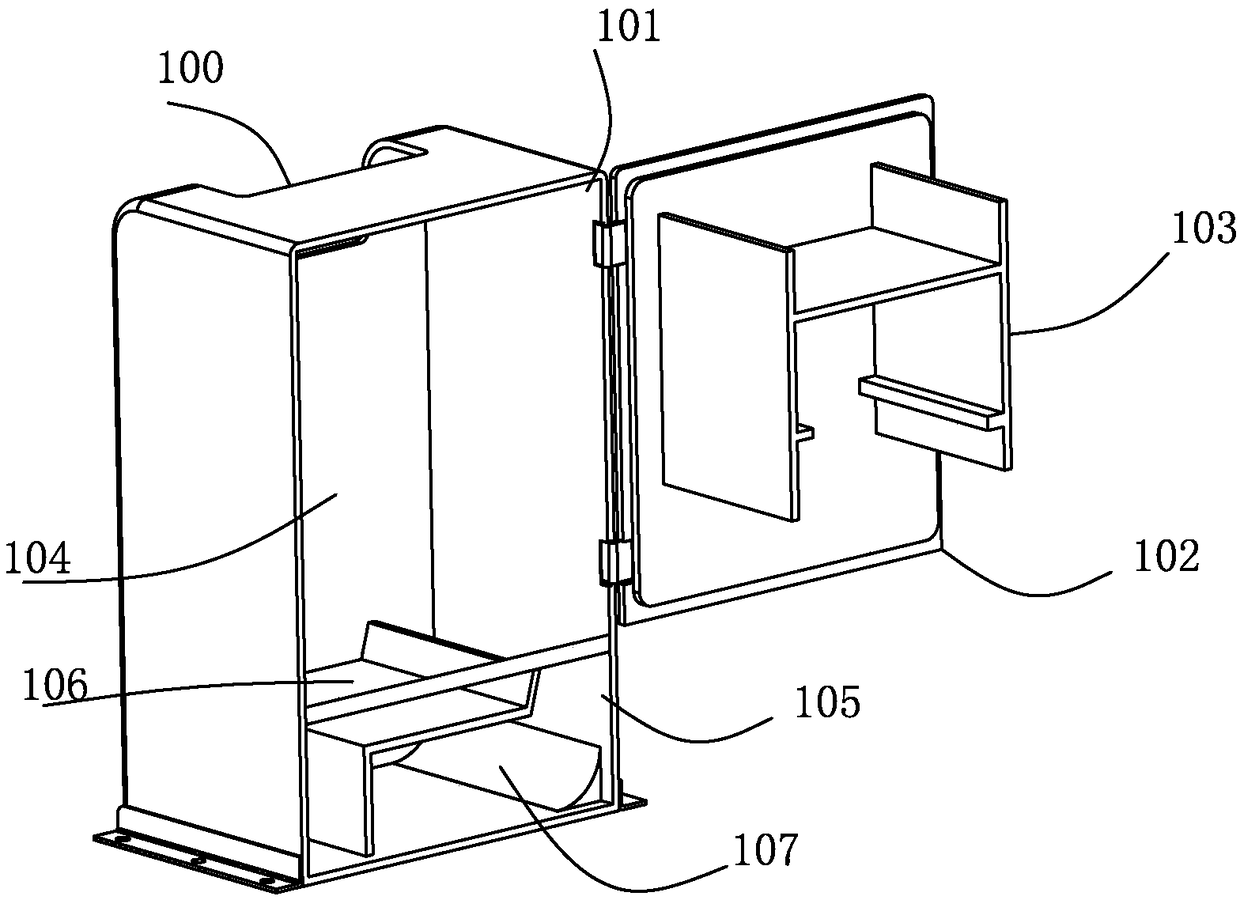

Environment-friendly garbage can

InactiveCN108773613ASmall footprintAvoid safety hazardsRefuse receptaclesWaste collectionDrive motor

The invention discloses an environment-friendly garbage can. The environment-friendly garbage can comprises a garbage can body; an inner cavity, a garbage feeding opening and a garbage discharging opening are formed in the garbage can body, and a garbage conveying device, a crushing mechanism, a screening mechanism, a compressing mechanism, a driving motor and at least two garbage collecting siloscommunicating with the garbage discharging opening are arranged in the inner cavity of the garbage can body; the garbage conveying device is arranged below the garbage feeding opening, the crushing mechanism is arranged below the output end of the garbage conveying device; the screening mechanism is arranged below the crushing mechanism, and a plurality of leaking holes are formed in the screening mechanism to sort the garbage into two types; and the compressing mechanism is used for compressing the lightweight garbage falling from the lower end of the screening mechanism. The environment-friendly garbage can is compact and simple in structure, the burden of the follow-up garbage disposal can be reduced, the garbage can be compressed, the garbage occupying space is saved, the amount of the garbage storage is improved, and the garbage sorting collection and cleaning are facilitated.

Owner:叶于诚

High-efficiency crushing machine for pharmacy

The invention discloses a high-efficiency crushing machine for pharmacy. The high-efficiency crushing machine comprises a machine body, the inner wall of the left side of the machine body is fixedly connected with a power box, the inner wall of the left side of the power box is fixedly connected with a stepper motor, the inner wall of the left side of the power box is fixedly connected with two limiting rods which are disposed on two sides of the stepper motor and are symmetric to each other, and an output end of the right side of the stepper motor is fixedly connected with a screw rod. The high-efficiency crushing machine is provided with an electric hydraulic propeller, an installation plate and an extruding block, thereby playing a role in extruding the medicine, and achieving an effectfor facilitating the subsequent crushing operation; and by arranging an asynchronous motor, a rotating rod and a crushing cutter blade, an effect for crushing the extruded medicine can be realized, the overall processing efficiency can be improved by adopting the two steps, i.e., the extruding step and the crushing step, the processing quality of the extruding step and the crushing step is also improved, and the efficiency is improved, and the quality is improved.

Owner:肖叶

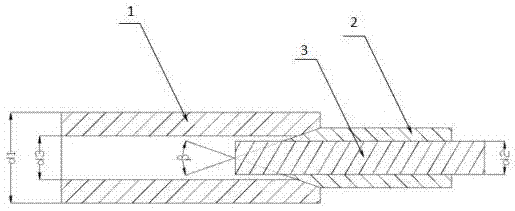

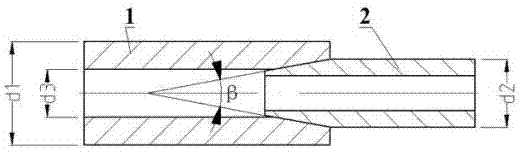

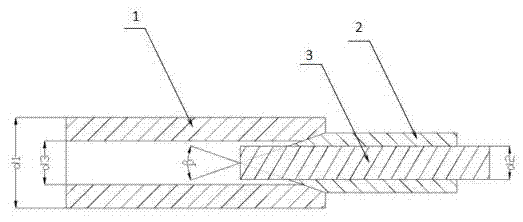

Method for manufacturing copper-aluminum welded joint of capillary tube and copper end sleeved aluminum capillary tube

ActiveCN102672326AReduce in quantityStable supportRigid pipesWelding/soldering/cutting articlesAluminiumWelding joint

The invention relates to a method for manufacturing a copper-aluminum welded joint of a capillary tube, and a copper end sleeved aluminum capillary tube which is manufactured by the method. The method comprises the following steps of inserting a core into a copper tube, wherein the core is exposed from two ends of the copper tube; one end of the copper tube is made to be a conical head by a precise roller forging machine, and thinning the wall of the copper tube, so that the core is clamped at the conical head; preassembling the conical end of the copper capillary tube with the core into an aluminum tube; and welding and pulling the core out. Gaps in contact parts of the copper tube and the aluminum tube are small, so that an aluminum bead cannot be generated, and the flow of the capillary tube cannot be influenced.

Owner:左铁军 +1

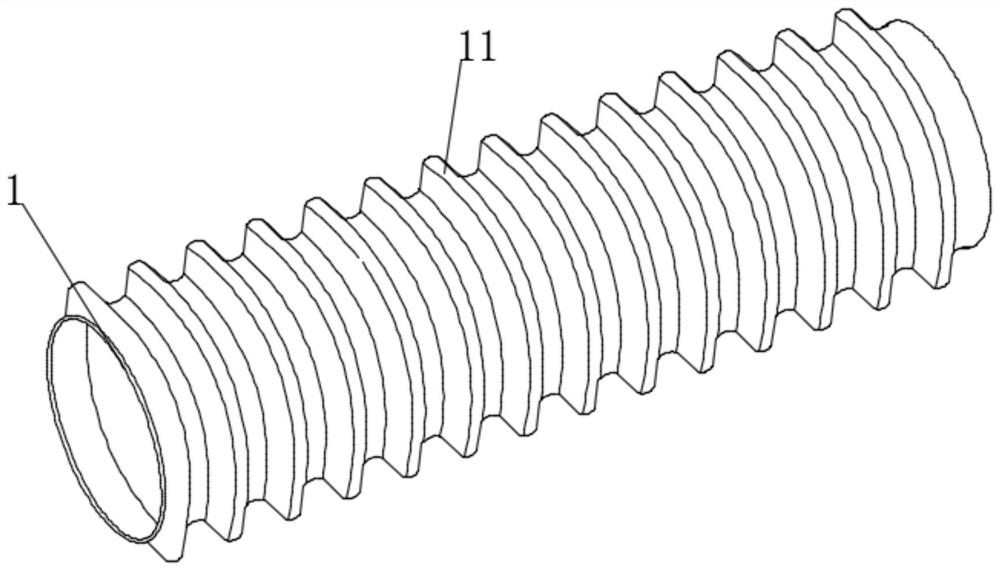

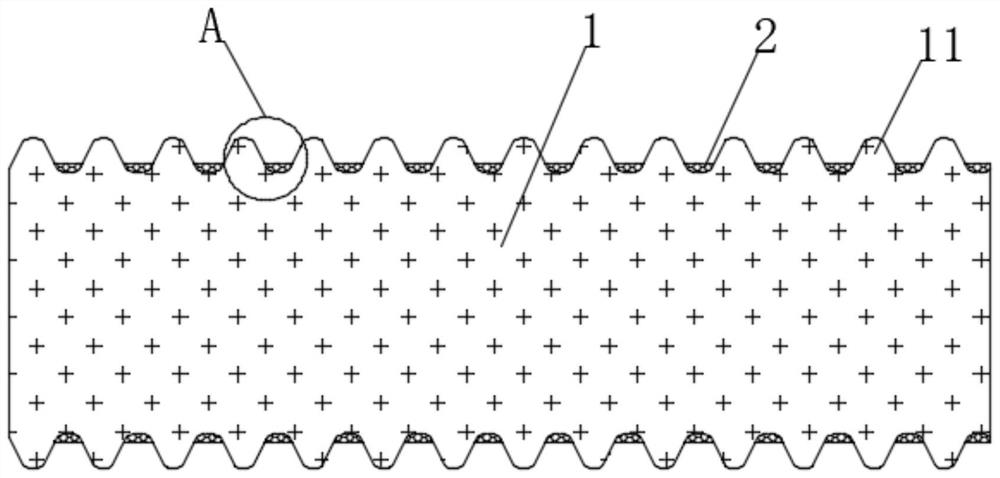

Air contact type self-condensation repaired electric corrugated pipe

ActiveCN112186665AHigh strengthPlay the role of water stopApparatus for repairing insulation/armouring cablesBending forceElectric power

The invention discloses an air contact type self-coagulation repair electric power corrugated pipe, belongs to the field of electric power pipes, and provides the air contact type self-coagulation repair electric power corrugated pipe with the advantages that through the arrangement of an air contact layer, on one hand, a certain anti-seismic force unloading effect is realized, and the partial extrusion force can be effectively protected; on the other hand, when the bamboo-shoot-shaped convex joints are subjected to large bending force, the air contact layer is extruded, so that the embedded extending pieces are extruded to a certain extent, the sides, facing the inner liquid storage ball, of the embedded extending pieces expand and deform, and the folded parts of the embedded extending pieces are unfolded, so that the bamboo-shoot-shaped convex joints are prevented from being broken. The inner contact pricking point can make contact with the inner liquid storage ball and prick the inner liquid storage ball, a repairing agent in the inner liquid storage ball overflows, and when the bamboo-shoot-shaped convex joint is locally broken, the repairing agent can flow out along the brokenposition in time, so that self-repairing of the broken position or the cracked position is achieved, and the situation of electric leakage caused by breaking is remarkably reduced.

Owner:成得建设集团有限公司

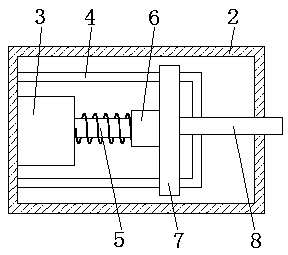

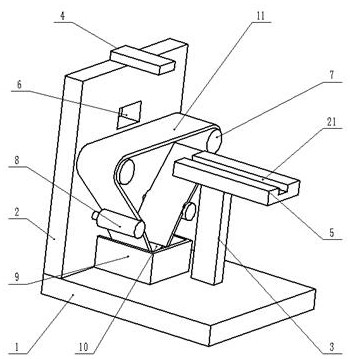

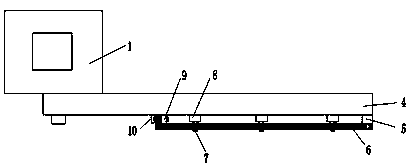

Adjustable grinding device

InactiveCN103506933APlay a grinding roleAct as a squeezeLapping machinesLapping toolsSurface roughnessEngineering

The invention discloses an adjustable grinding device which comprises a left nut, an outer sleeve, an adjusting shaft and a right nut. An inner tapered hole of the outer sleeve is combined with an outer tapered face of the adjusting shaft in a sleeved mode. The left nut and the right nut are relatively fixed on the adjusting shaft through bolts at the two ends of the adjusting shaft. Multiple straight grooves are formed in the periphery of the outer sleeve and boart sand is evenly cohered to the outer wall. When the grinding device is used for grinding, the grinding device penetrates into an inner hole of a metal part to be ground to rotate relatively and the grinding device and the metal part relatively move back and forth along the axis of the metal part so as to finish grinding. The adjustable grinding device is used for grinding and the inner hole of the metal part is not only ground, but also extruded. The inner hole of the metal part is smooth and possessed of higher surface roughness and precision. Grinding agents will not retain in pores of the surface of the inner hole of the metal part.

Owner:泰州市恒久转向器厂

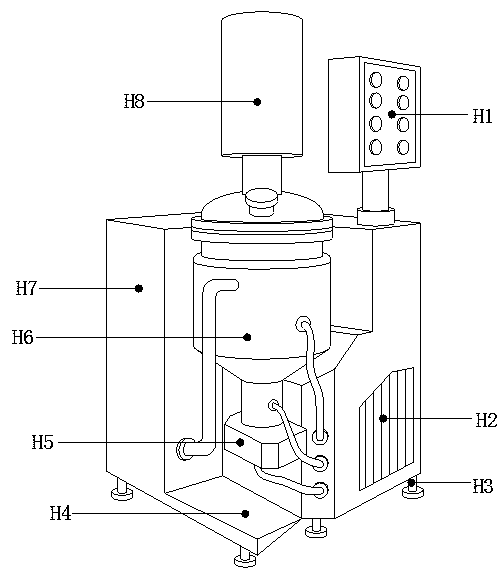

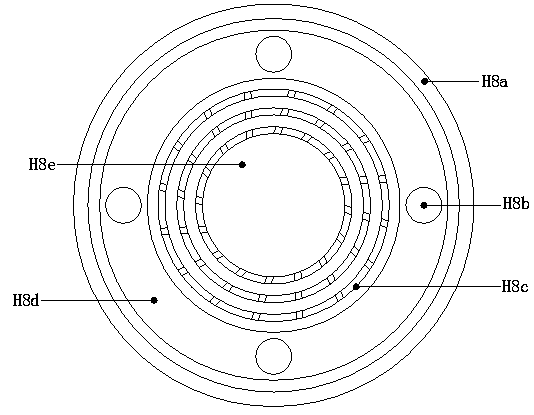

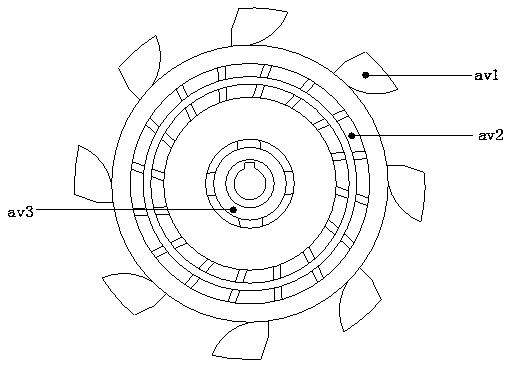

Preparation device for graphene-doped hydrogen storage material

ActiveCN110282601AAvoid Hydrogen Permeability DropsPrevent raw materials from cakingHydrogenGrapheneCvd grapheneProcess engineering

The invention discloses a preparation device for a graphene-doped hydrogen storage material; the structure of the device comprises a controller, a heat dissipation groove, fixed foot margins, a material holding table, a preparation port, a preparation tank, a control main engine, and a doping tank. Graphene raw materials in the doping tank uniformly pass through a material scraping groove when entering; the material scraping groove and a discharge ring are fixedly arranged; the raw materials are guided to an area in which the discharge ring and a grinding embedded ring are matched for pulverization treatment through poking blocks when a grinding mechanism rotates, and then enter a dispersion component for dispersed blanking; the decrease of hydrogen permeability caused by stacked blanking can be avoided; a gas compression mechanism can generate gas to pneumatically control the dispersion component under the driving of a built-in drive shaft; the clogging of the graphene raw materials is avoided; high-precision pulverization can be performed on flake graphite after the whole use; the raw materials are effectively prevented from agglomerating in the blanking process; a state of powdery falling is formed; the permeability of hydrogen doping is greatly improved; the hydrogen storage effect is higher.

Owner:GUIZHOU UNIV OF ENG SCI

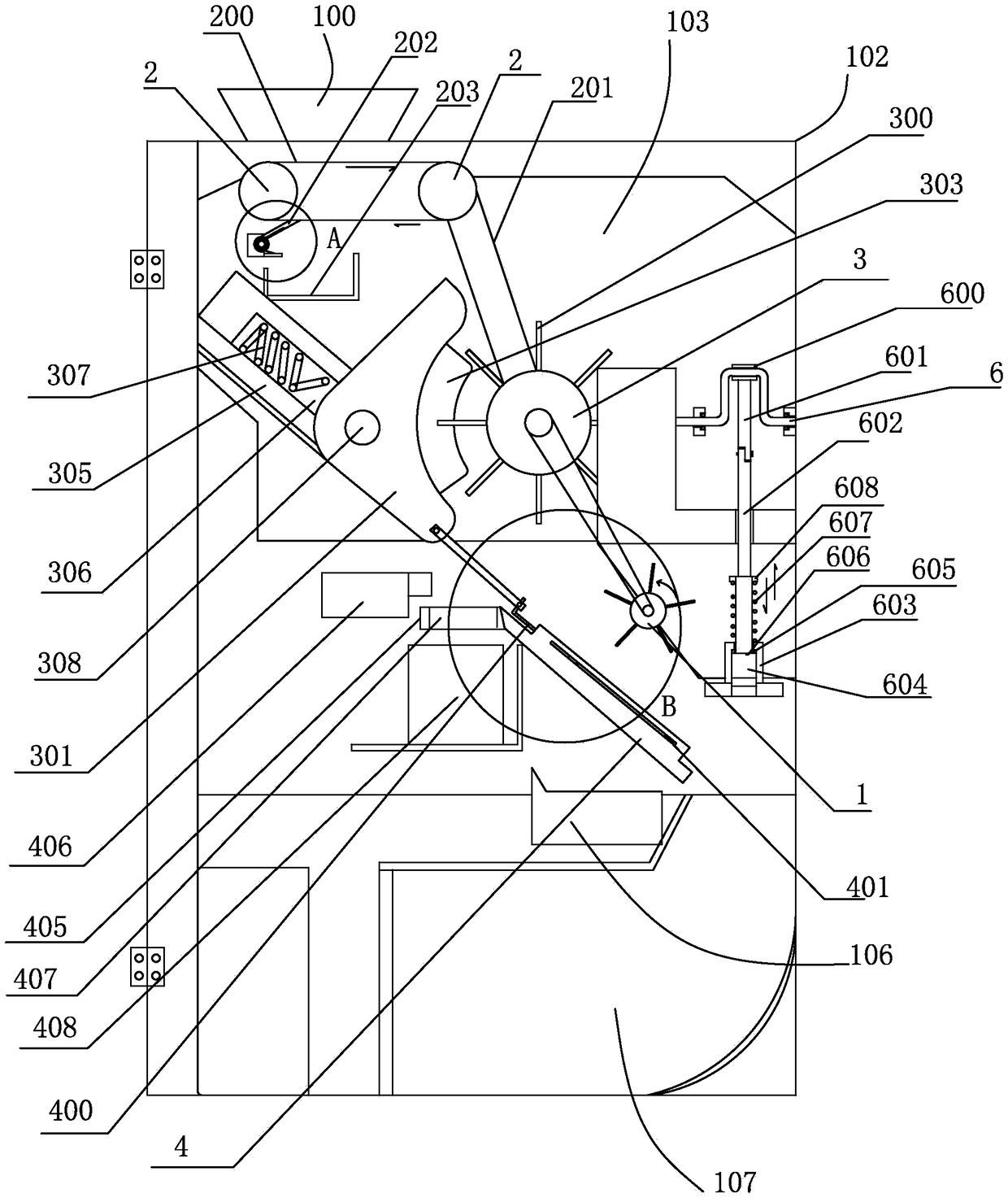

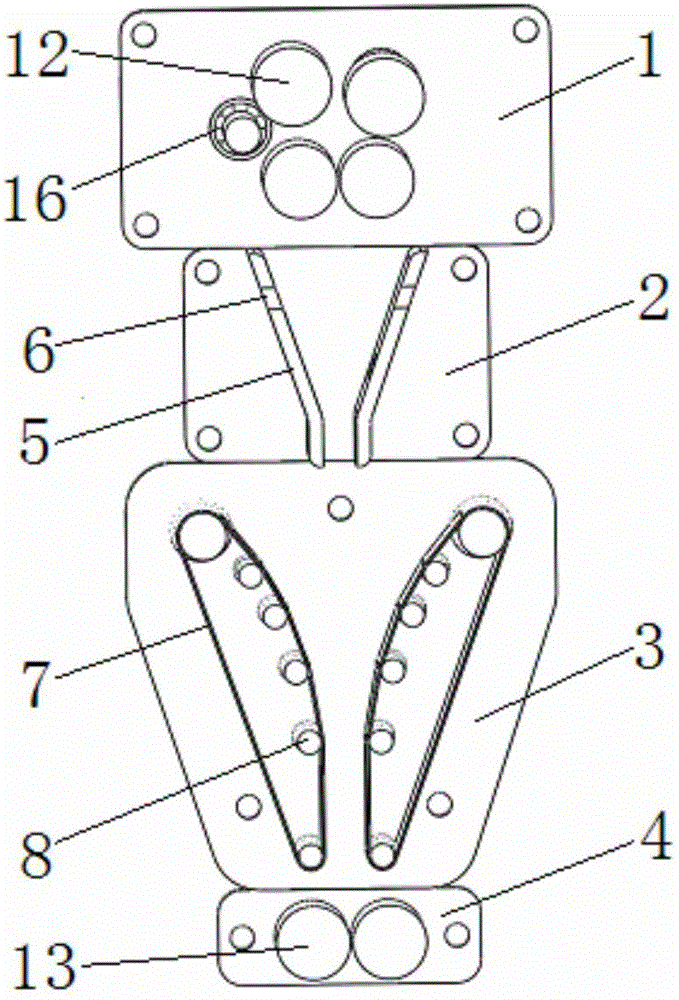

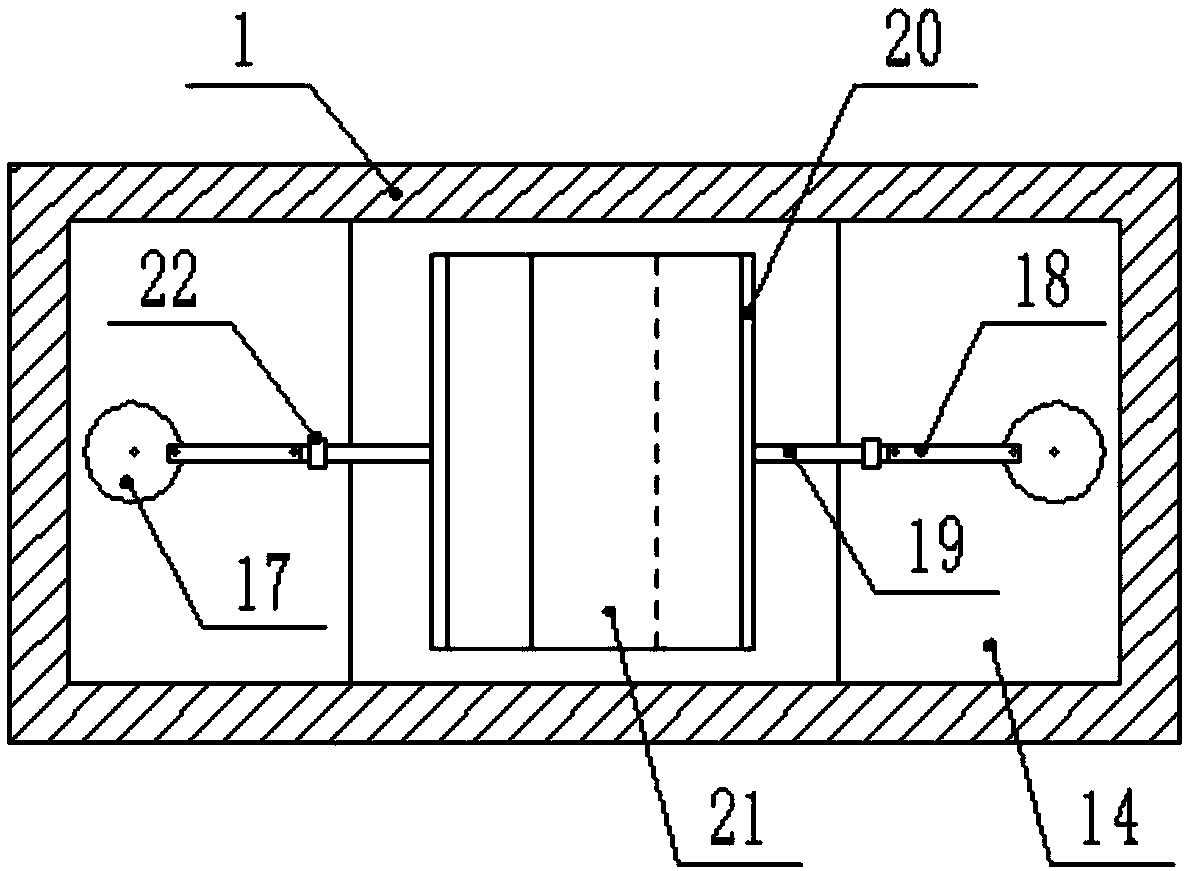

Paper currency unfolding arrangement device

The invention provides a paper currency unfolding arrangement device. The paper currency unfolding arrangement device comprises a first conveying unit, a wetting unit, an unfolding unit and a second conveying unit which are sequentially mounted in the paper currency conveying direction. The size of the wetting unit in the paper currency conveying direction is smaller than the length of paper currency, and the wetting unit comprises wetting side plates, mounting plates and ultrasonic atomizers; the unfolding unit comprises unfolding side plates and two sets of unfolding assemblies which are symmetrically arranged with the paper currency conveying direction as the axis; each unfolding assembly is composed of an unfolding motor, a coupler, a rolling shaft set and a track with brushes, wherein each track with the brushes is arranged on the corresponding rolling shaft set in a sleeving manner, and the distance between two rolling shafts, with the opposite positions, in each rolling shaft set is gradually decreased in the paper currency conveying direction; and each track with the brushes is composed of a rubber track body and the brushes. The brushes are perpendicular to the paper currency conveying direction to be fixed to the outer surfaces of the rubber track bodies, and the rotating speed of the unfolding motors is larger than the rotating speed of a first motor and smaller than the rotating speed of a second motor; and according to the device, paper currency with folded corners or in the wrinkling state can be subject to wetting-flat brushing treatment, and in the treatment process, the paper current is not damaged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

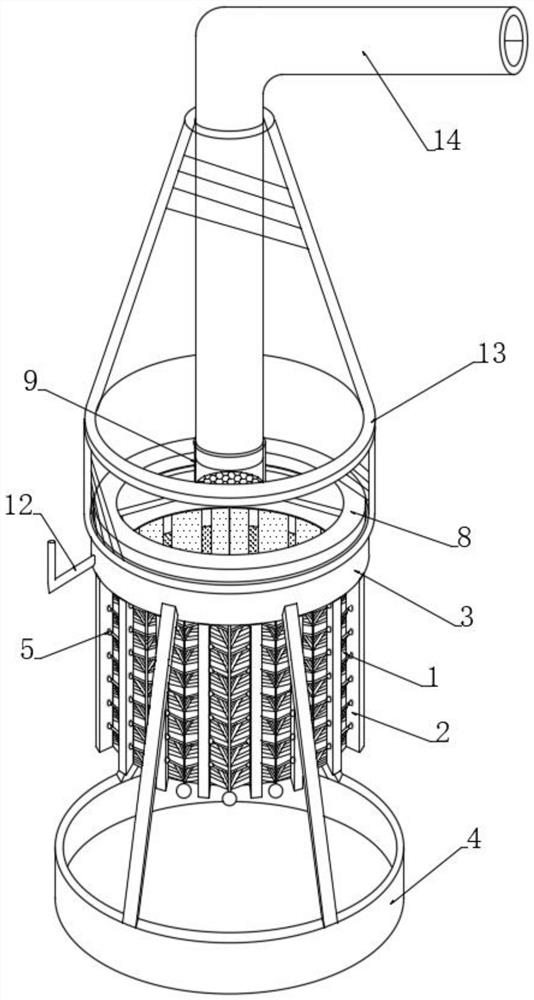

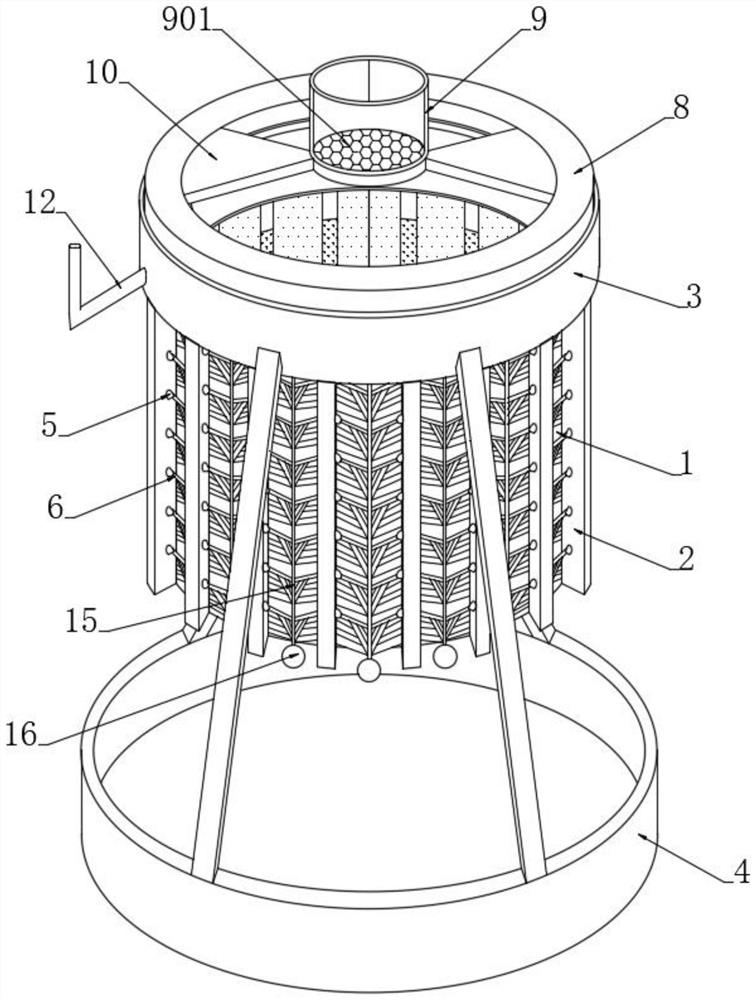

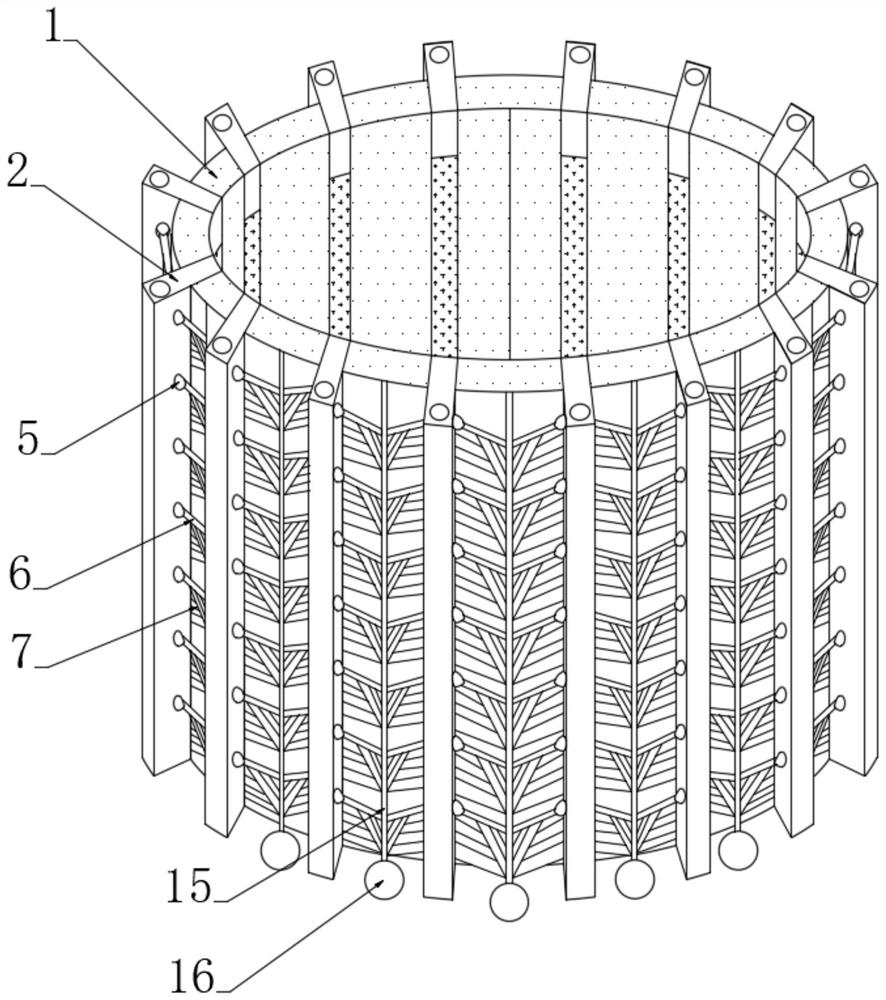

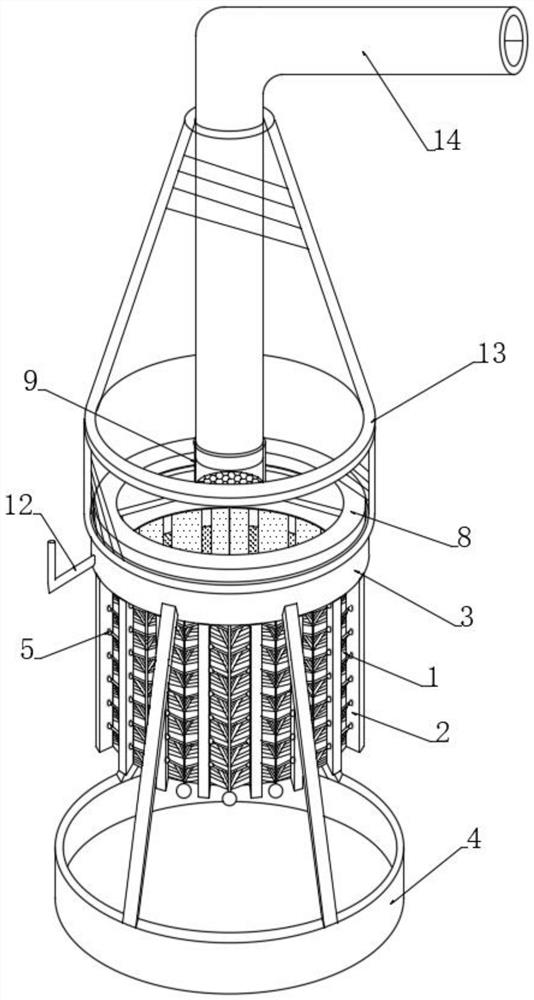

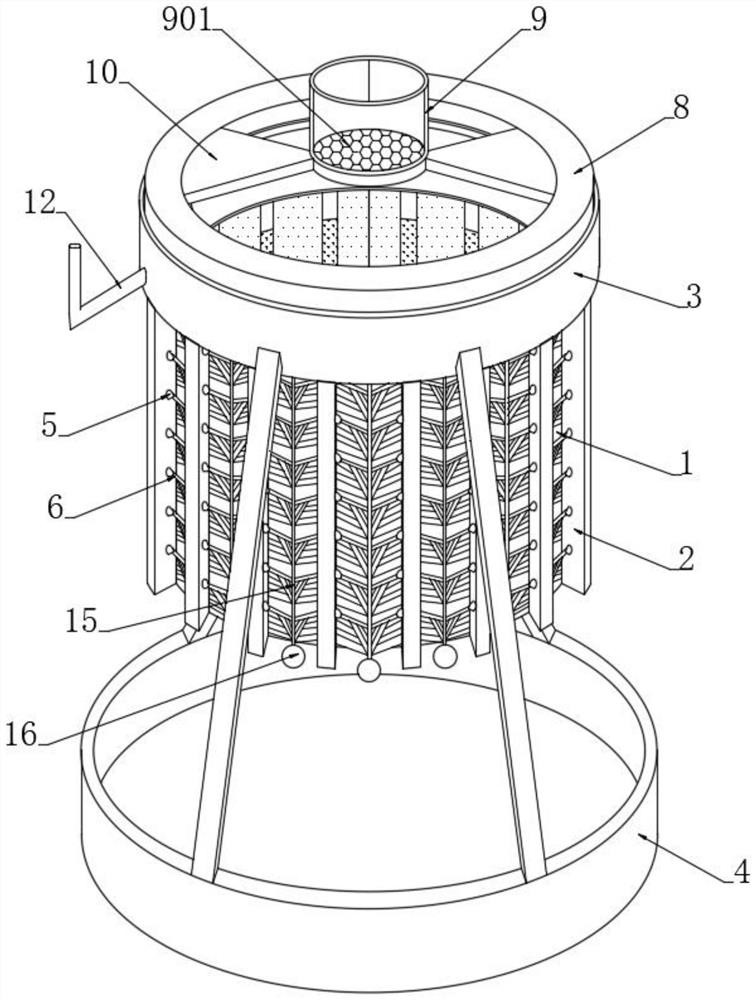

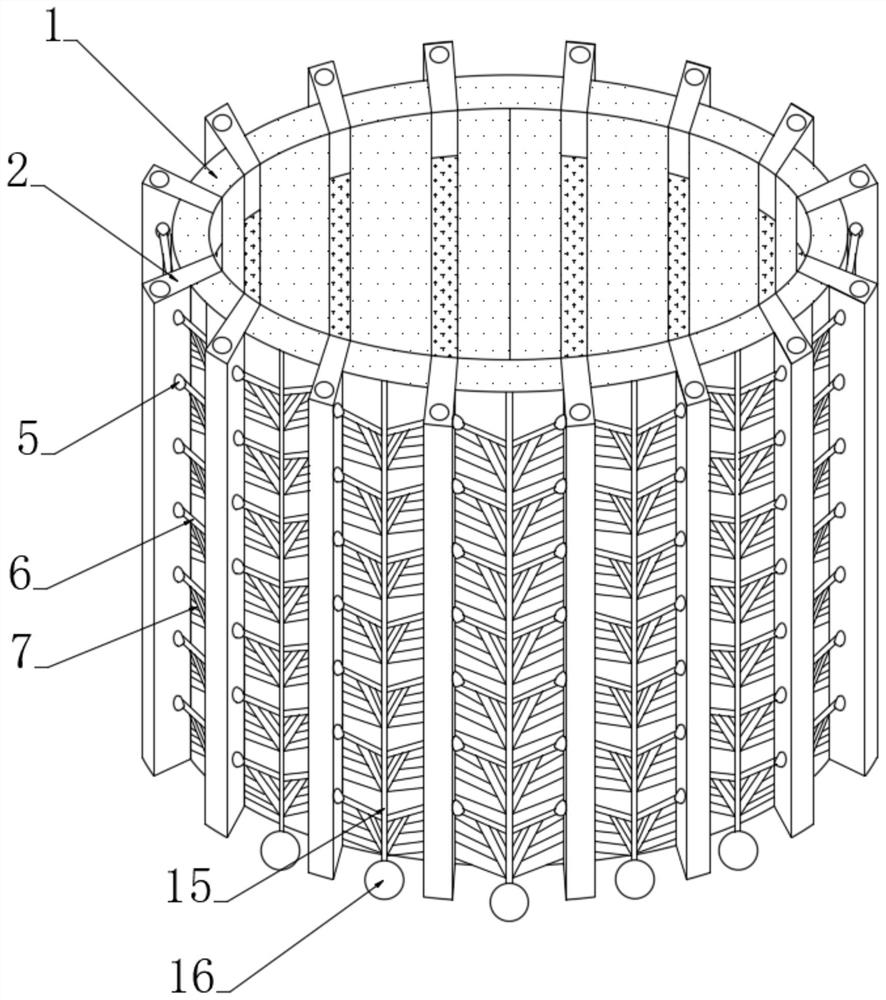

Oil stain decomposition and adsorption device for oil-containing waste gas treatment

The invention discloses an oil stain decomposition and adsorption device for oil-containing waste gas treatment, and belongs to the technical field of waste gas treatment. The pushing force during waste air intake is utilized; an oil stain dispersing agent in an annular feeding disc is pushed into a plurality of strip-shaped arc-shaped embedding plates to permeate outwards by a plurality of elastic telescopic feeding bags; the oil stain dispersing agent which permeates outwards is dispersed on a filler framework through a feeding diffusion mechanism, and is used for decomposing and diffusing oil stains attached to the filler framework. Blockage caused by excessive oil stains attached to the filler framework is effectively avoided; besides, an elastic bag layer filled with an expansion gaslayer is arranged at the inner end of the strip-shaped arc-shaped embedding plate, when guided-in waste gas diffuses outwards through the filler framework, the waste gas with certain impact force canplay a certain role in extruding the elastic bag layer, so that the oil stain dispersing agent permeates outwards more easily, and under the condition that the waste gas is not guided in, the elastictelescopic feeding bags reset and contract, so that the oil stain dispersing agent is effectively prevented from permeating outwards.

Owner:戚永团

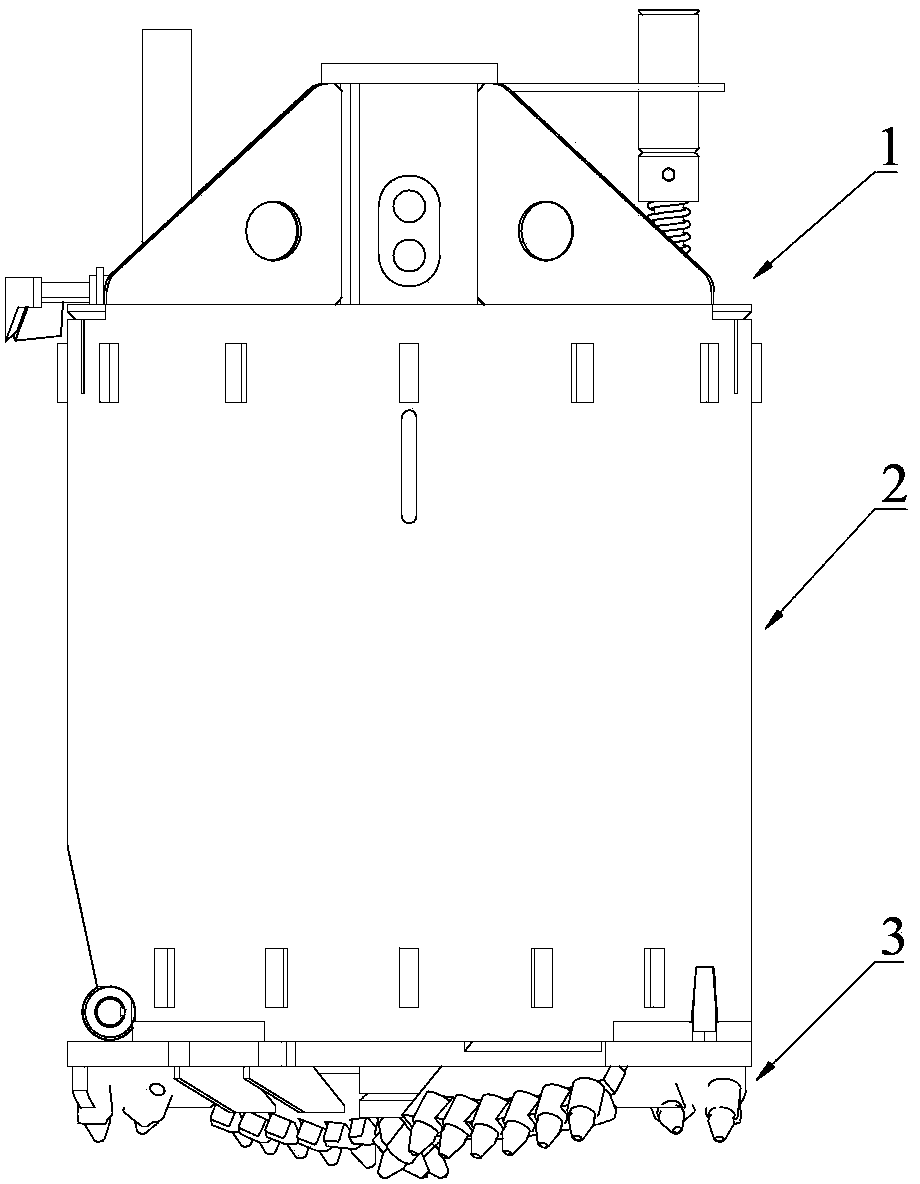

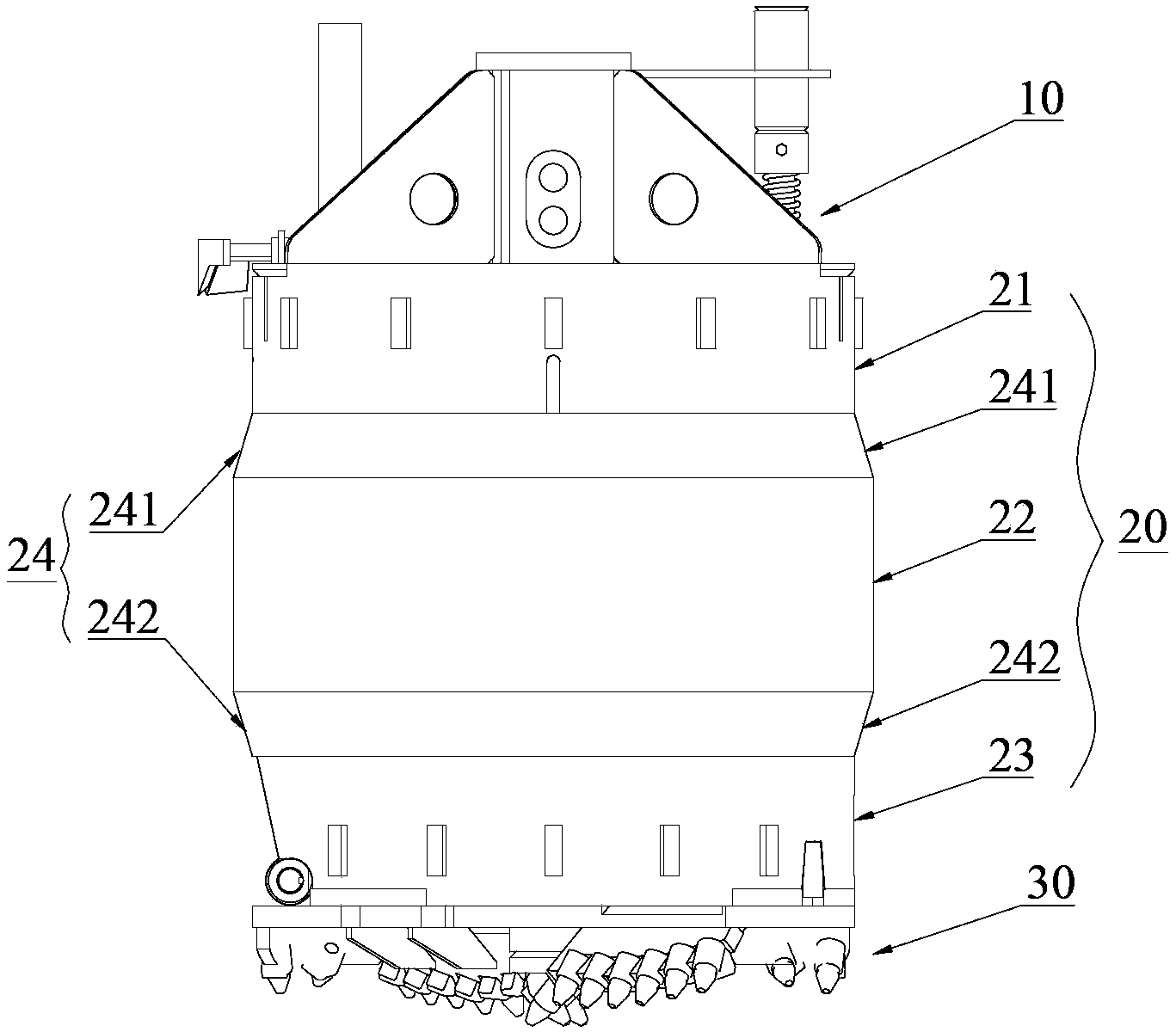

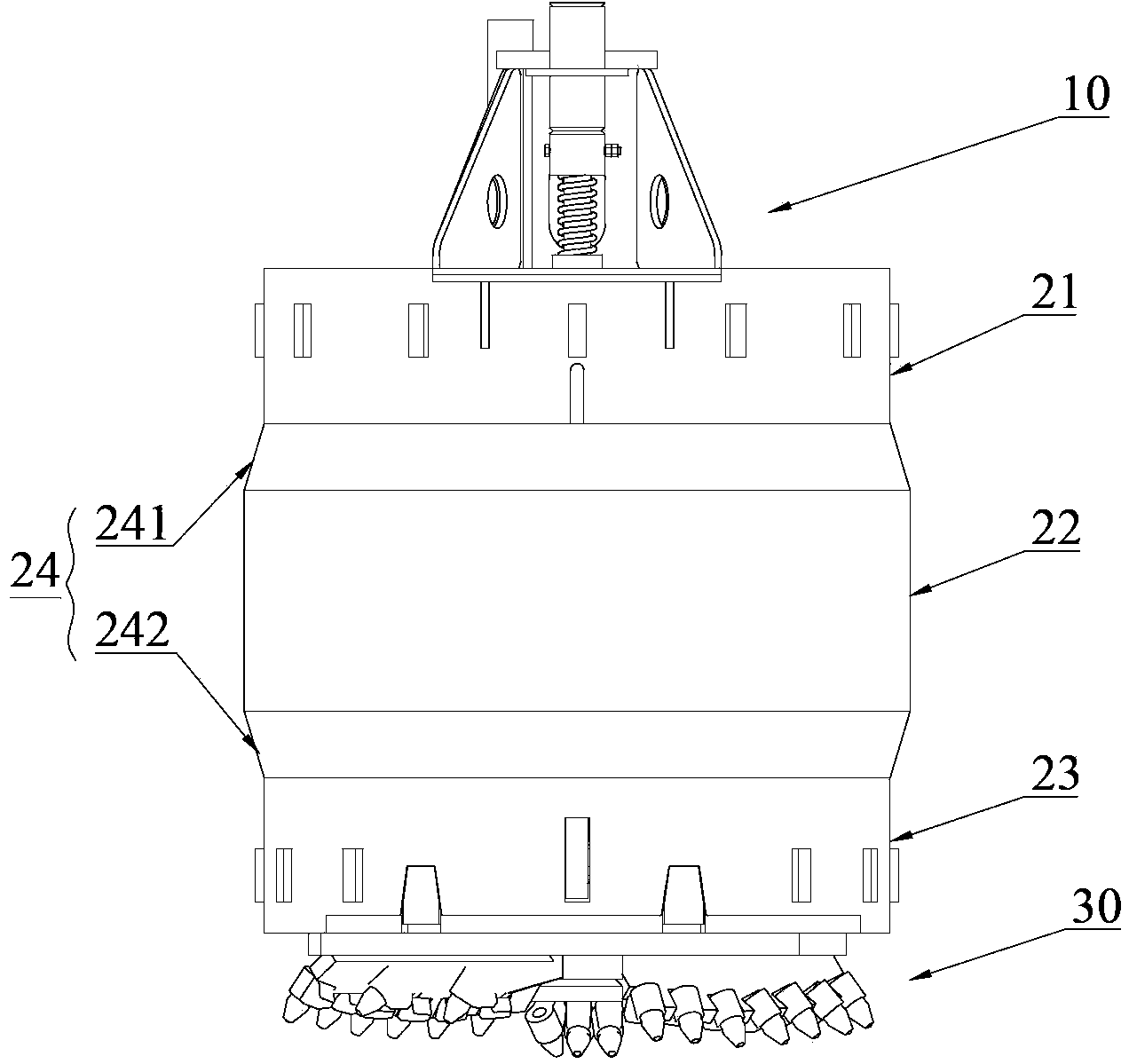

Drilling bucket and rotary drilling rig

The invention discloses a drilling bucket and a rotary drilling rig, wherein the drilling bucket comprises a drilling bucket upper bottom part, a drilling bucket lower bottom part, and a drilling bucket barrel connecting the drilling bucket upper bottom part with the drilling bucket lower bottom part, and the maximum diameter of the drilling bucket barrel is larger than the maximum diameter of the drilling bucket upper bottom part and the maximum diameter of the drilling bucket lower bottom part. The drilling bucket provided by the invention adopts the invention of unequal diameters, the maximum diameter of the drilling bucket barrel is designed to be larger than the maximum diameter of other parts of the drilling bucket, then the drilling bucket barrel can be in tight fit with the hole wall in the drilling process and has certain drilling guide effect, the problem of deflective drilling is effectively solved, the impact on the drilling bucket and the lateral force transmitted upwards to structures like a drilling rod and a mast are reduced, the working stability of a main engine structure of the rotary drilling rig is improved, and meanwhile, the hole wall is fixed. The rotary drilling rig provided by the invention also has the benefits.

Owner:BEIJING SANY HEAVY MASCH CO LTD

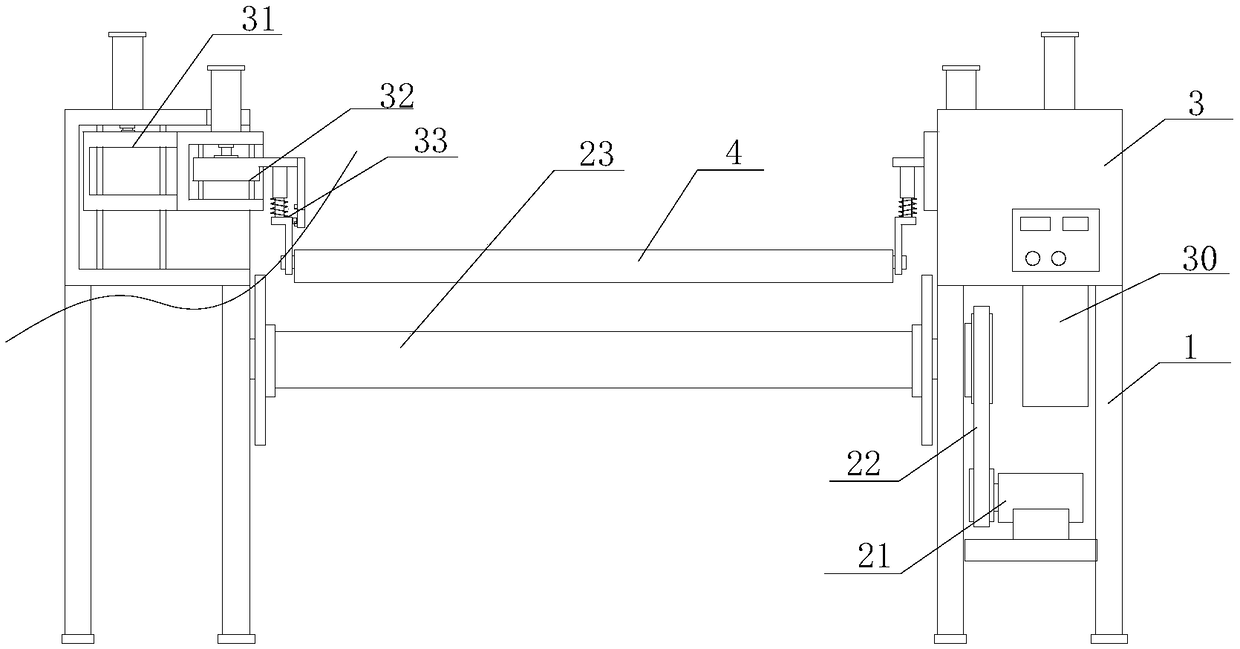

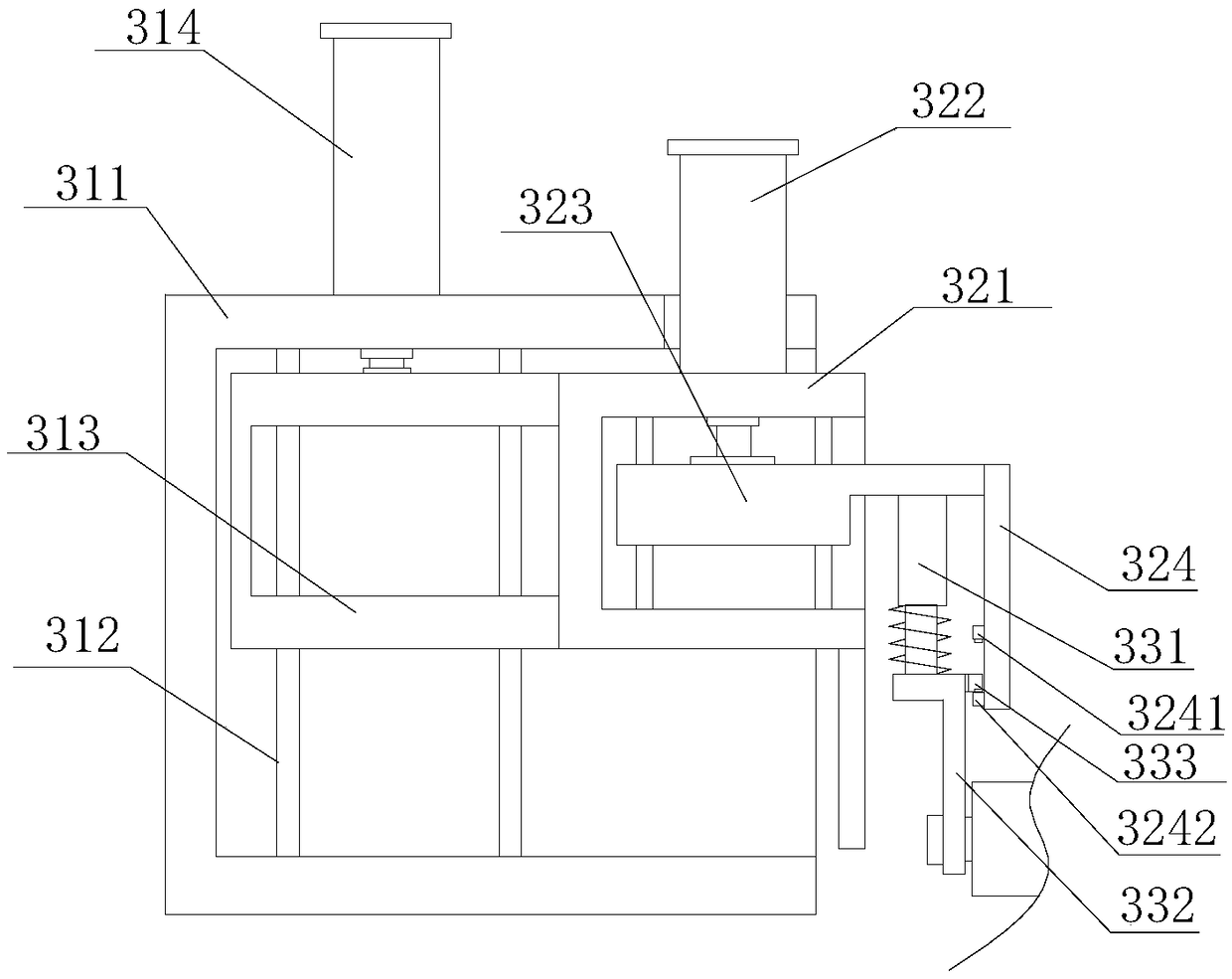

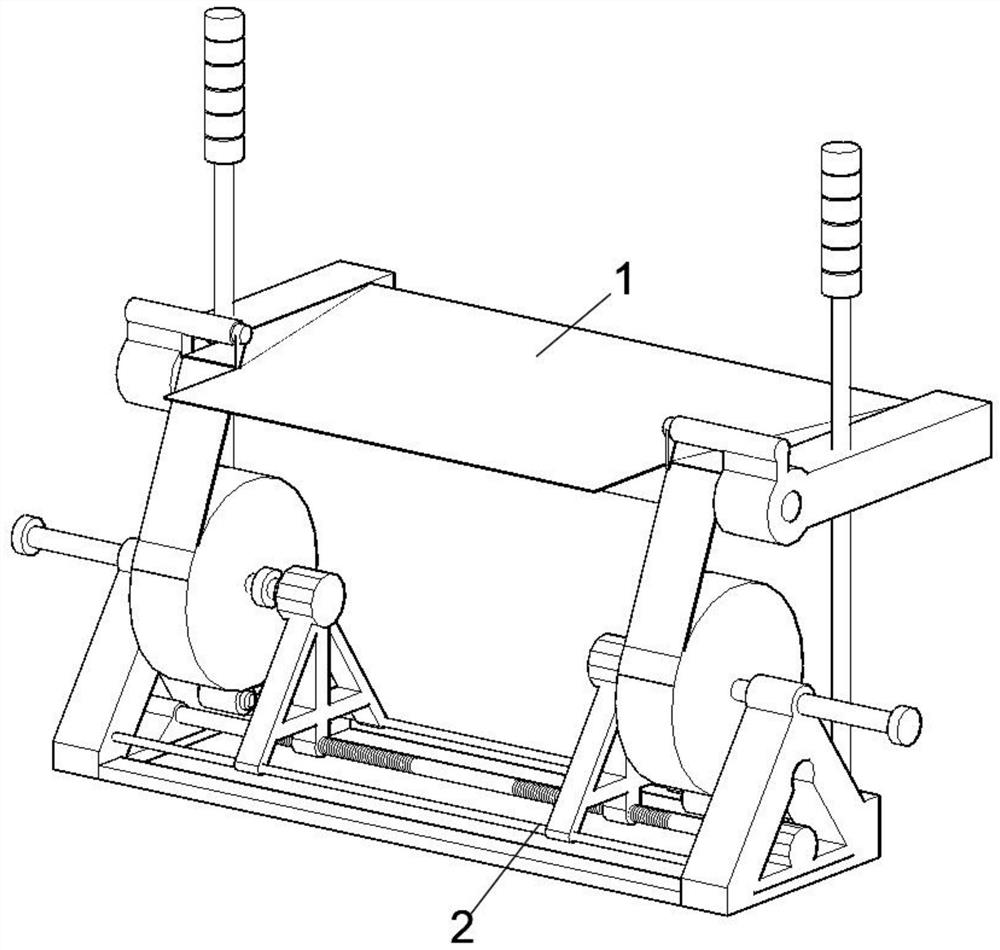

Silk winding device

The invention discloses a silk winding device. The silk winding device comprises machine frames, a winding roller mechanism, a driving compression mechanism, a compression roller mechanism, a cuttingworkbench and a shut-off mechanism. The winding roller mechanism and the compression roller mechanism are mounted between the machine frames, and a control system, a lifting control mechanism, a pressure regulation mechanism and a compression roller mounting mechanism are arranged on the driving compression mechanism. The pressure regulation mechanism is mounted on the lifting control mechanism, the compression roller mounting mechanism is arranged on the pressure regulation mechanism, and two ends of the compression roller mechanism are mounted on the compression roller mounting mechanism. Anauxiliary guide roller is arranged between the winding roller mechanism and the cutting workbench, the shut-off mechanism is arranged above the cutting workbench, a compression roller capable of automatically regulating pressure is adopted to effectively abut against a winding roller, the compression roller plays an extrusion role on a greige cloth wound to a coiling roller, and it is ensured that the winding is level and tight; and the shut-off mechanism with a press plate is adopted to shut off plus materials, and notches are ensured to be parallel and level.

Owner:浙江华越丝绸制品有限公司

Batch-type asphalt cold-recycling blending technology

ActiveCN105803898AQuality improvementGuaranteed uniformityRoads maintainenceBitumen emulsionProcess engineering

The invention discloses a batch-type asphalt cold-recycling blending technology.The technology comprises the steps that 1, an old asphalt mixture is conveyed to a crushing and screening chamber through a first conveying channel; 2, the old asphalt mixture is crushed and screened in the crushing and screening chamber, and the screened old asphalt mixture enters a stirring chamber; 3, novel aggregates and construction aggregates are added into the stirring chamber to be stirred to obtain a mixture; 4, a certain amount of emulsified asphalt is sprayed to the mixture, a certain amount of water is sprayed to the mixture, and second stirring heads inside the stirring chamber are turned on at the same time for primary stirring; cement is added into the stirring chamber, and the second stirring heads are used for secondary stirring; remaining emulsified asphalt and water are sprayed to the mixture, and the second stirring heads are used for tertiary stirring, and a cold-recycling mixture is obtained.According to the batch-type asphalt cold-recycling blending technology, the problems that crushing is not thorough, spraying is not uniform, and the cold-recycling mixture is poor in quality are solved.

Owner:NANFANG HIGH TECH ENG TECH CO LTD

Steel pipe polishing equipment with scrap removing and reminding functions

InactiveCN114406888AAvoid scratchesIncrease gas pressureGrinding carriagesPolishing machinesPolishingPipe

The invention relates to the technical field of steel pipe machining, and discloses scrap-removing and reminding steel pipe polishing equipment which comprises a rack, a clamping mechanism, a steel pipe and a supporting rod, and a polishing barrel is fixedly connected to the top of the supporting rod. By designing the polishing barrel, the moving block, the sliding cavity, the sliding block, the polishing block and the air bag, when a steel pipe is polished, the telescopic rod is used for controlling the moving block to slide to extrude the air bag, so that air in the air bag enters the sliding cavity, and the sliding block is promoted to drive the polishing block to move downwards; meanwhile, heat generated by friction between the steel pipe and the polishing block during polishing is used for promoting the gas pressure in the sliding cavity to be increased, the sliding block is promoted to drive the polishing block to be attached to the steel pipe more tightly, and the steel pipe is polished; and high-pressure gas in the sliding cavity is exhausted, powder and chippings generated when the steel pipe is polished are blown away, and the polished outer surface is prevented from being scratched.

Owner:冯星星

Three-directional roll riveting equipment of through-flow fan blade

The invention discloses three-directional roll riveting equipment of a through-flow fan blade, and belongs to the technical field of the roll riveting equipment of the through-flow fan blade. The three-directional roll riveting equipment comprises a base, a roll riveting system, a fixing and driving system, a guiding system and a conduction system, wherein the roll riveting system comprises a roller row; the roller row is arranged parallel to the base and comprises an upper roller row, a lower front roller row and a lower rear roller row; the upper roller row is arranged over a machined blade wheel and is provided with an upper roll riveting hob set of which a hob edge is vertically downward; the lower front roller row and the lower rear roller row are symmetrically arranged at two sides of a vertical plane on which a center line of the machined blade wheel is positioned and are provided with a lower front roll riveting hob set and a lower rear roll riveting hob set of which hob edges are obliquely upward respectively; and the upper roll riveting hob set, the lower front roll riveting hob set and the lower rear roll riveting hob set form a three-directional roll riveting structure. During machining, the blade wheel is uniformly stressed in three directions so as to ensure that machining pressure is always aligned with the center, the coaxial heights of central discs of the blade wheel are consistent, and the blade wheel is prevented from performing circular runout.

Owner:宁波市天超通风设备有限公司

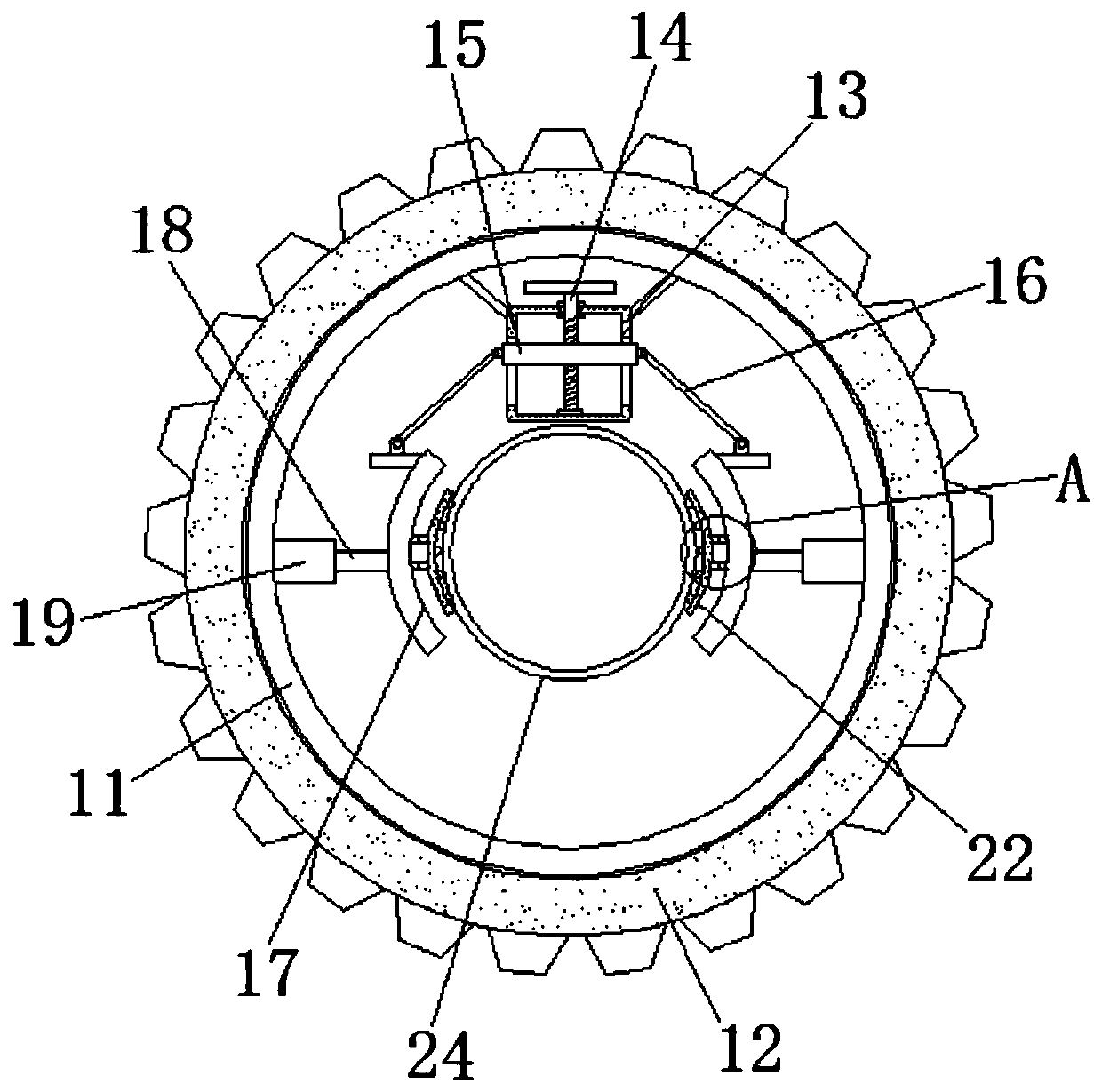

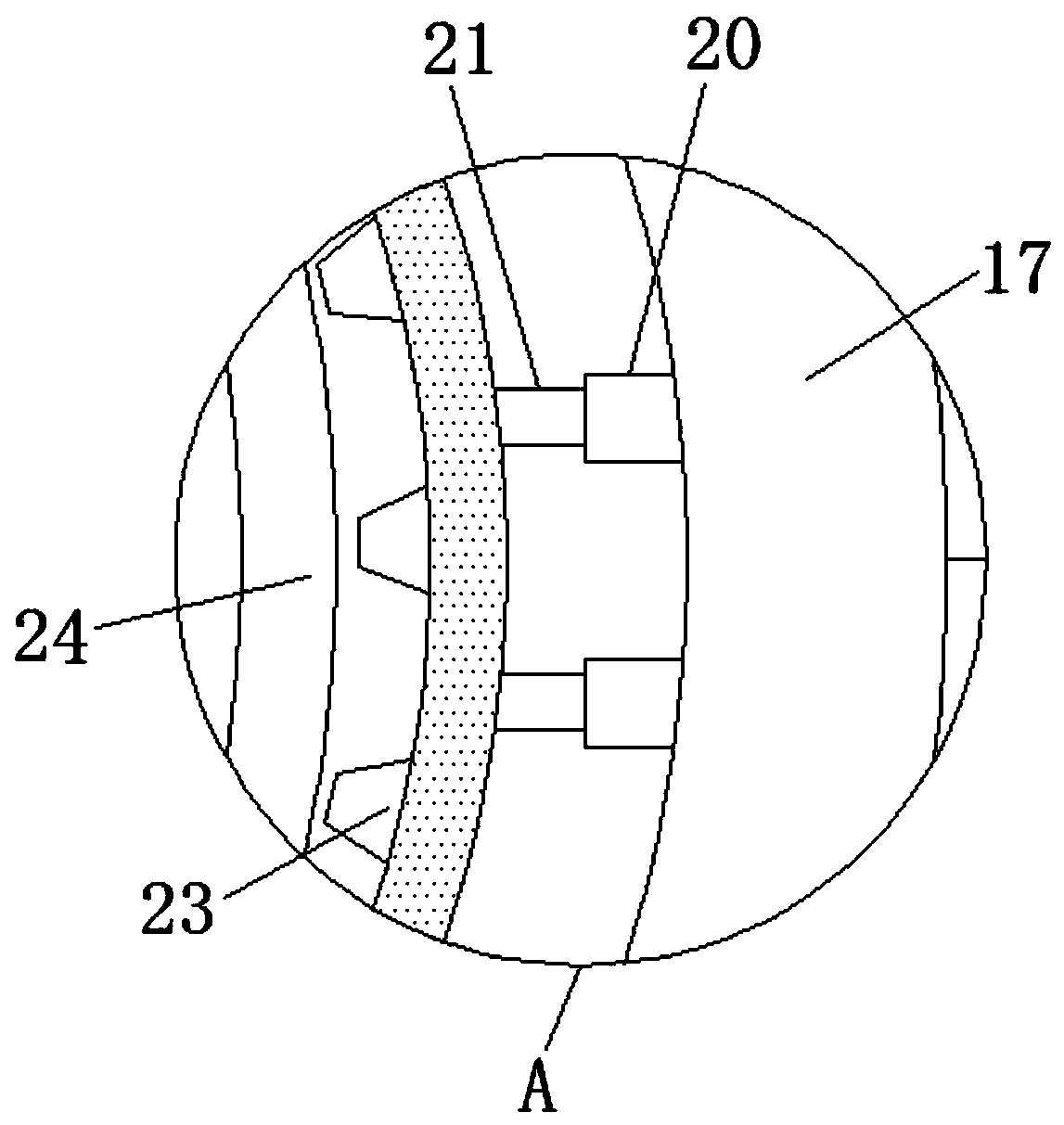

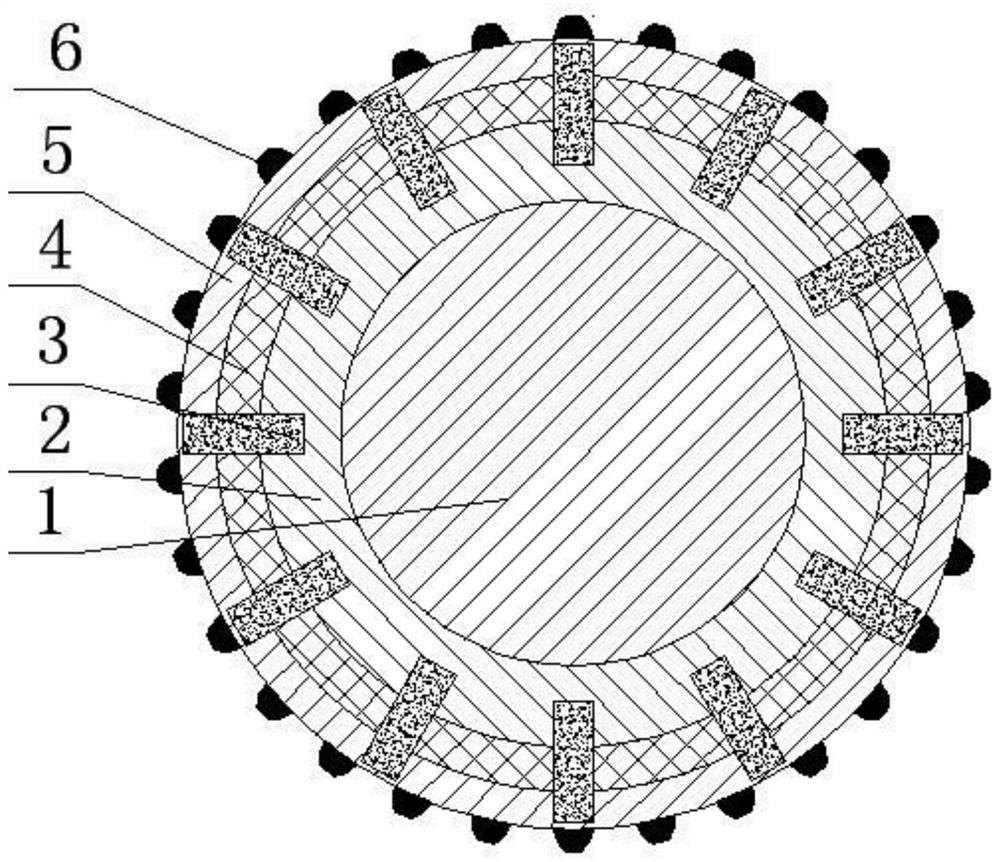

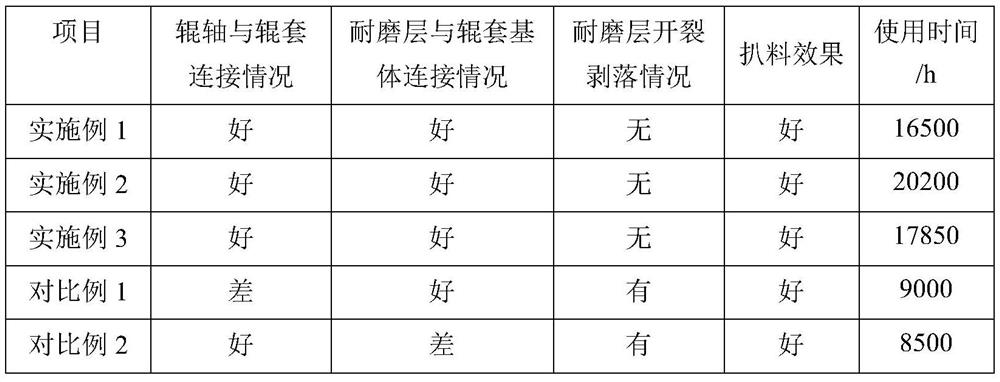

Preparation method of wear-resistant extrusion roller

PendingCN113926994AReduce the hazards of stress concentrationNot easy to crackFoundry mouldsFurnace typesBonding strengthManufacturing engineering

The invention belongs to the field of preparation of industrial crushing machinery, and provides a preparation method of a wear-resistant extrusion roller. The method comprises the steps of cavity preparation, wear-resistant stud placement, mother liquid pouring, heat treatment, inner hole machining, hot charging, transition layer surfacing, wear-resistant layer surfacing and pattern surfacing. Steel-bonded alloy wear-resistant studs have good impact resistance, wear resistance and weldability, stress concentration can be reduced, a base body does not easily crack, the skeleton supporting effect is achieved, and a transition layer and a wear-resistant layer are not peeled off in a large area; the transition layer improves the weldability of a roller sleeve base body, enhances the metallurgical bonding strength of the wear-resistant layer and the roller sleeve base body, and reduces the crack generation tendency; before surfacing of the transition layer, the wear-resistant layer and wear-resistant patterns, a roll shaft and a roll sleeve are subjected to hot charging so that the phenomena that the roll shaft and the roll sleeve are not firmly connected and the wear-resistant layer and the wear-resistant patterns are easily peeled off due to hot charging after welding are changed; and the service life of the wear-resistant extrusion roller prepared by the method is prolonged by more than one time compared with that of the extrusion roller with a conventional structure.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

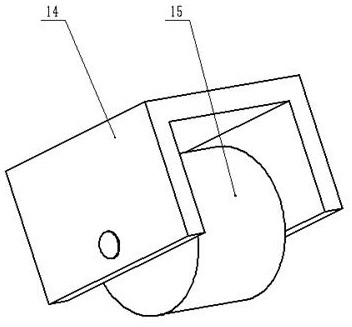

Dendrobium candidum processing equipment

InactiveCN106491360AFully heat and dryAct as a squeezePharmaceutical product form changeDomestic articlesDendrobium candidumBiochemical engineering

The invention relates to dendrobium candidum processing equipment. The equipment comprises a driving motor and a feeding tank, the feeding tank is connected with a forming tube, a forming screw is arranged on the front section of the forming tube, the forming screw is connected with the driving motor through a coupling, an electric heating wire is arranged on the outer side of the middle section of the forming tube, and a discharge hole is formed in the lower portion of the rear section of the forming tube. The equipment has the advantages that dendrobium candidum can be made to be curled in a spiral mode effectively through the forming screw, manual operation is omitted, heating and coiling are conducted simultaneously, and the process of lifting and twisting simultaneously in a traditional technology is met; dendrobium candidum is dried for shaping through the electric heating wire after being curled, the length of the forming tube can be effectively reduced by means of a block, sufficient heating and drying of dendrobium candidum can be guaranteed in the forming tube with limited length, a extruding effect on dried dendrobium candidum is achieved, and further forming is promoted.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

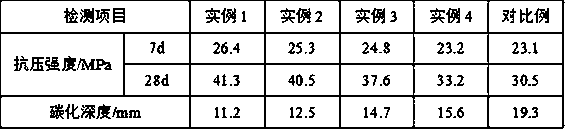

Durable concrete curing agent

The invention discloses a durable concrete curing agent, and belongs to the technical field of building materials. The durable concrete during agent is prepared through the following steps: stirring and mixing, by weight, 20-30 parts of a calcium nitrate solution, 40-50 parts of a chitosan solution, 10-20 parts of urea and 20-30 parts of Bacillus pasturii, then adding a sodium sulfate solution with the volume 0.2-0.3 times that of the chitosan solution, performing stirring and mixing, cooling the obtained solution, dropwise adding a glutaraldehyde solution with the volume 0.3-0.4 times that ofthe chitosan solution, continuously performing stirring and mixing, adjusting the pH value of the obtained solution, filtering the solution, and performing drying to obtain modified microcapsules; and stirring and mixing the modified microcapsules, a peach gum solution, an Arabic gum solution, a surfactant, phospholipids, a silane coupling agent, modified maifanite and water to obtain the durableconcrete curing agent. The durable concrete curing agent prepared by the technical scheme of the invention can significantly improve the mechanical properties and the durability of concrete.

Owner:GUANGZHOU KRYSTIC BUILDING MATERIALS CO LTD

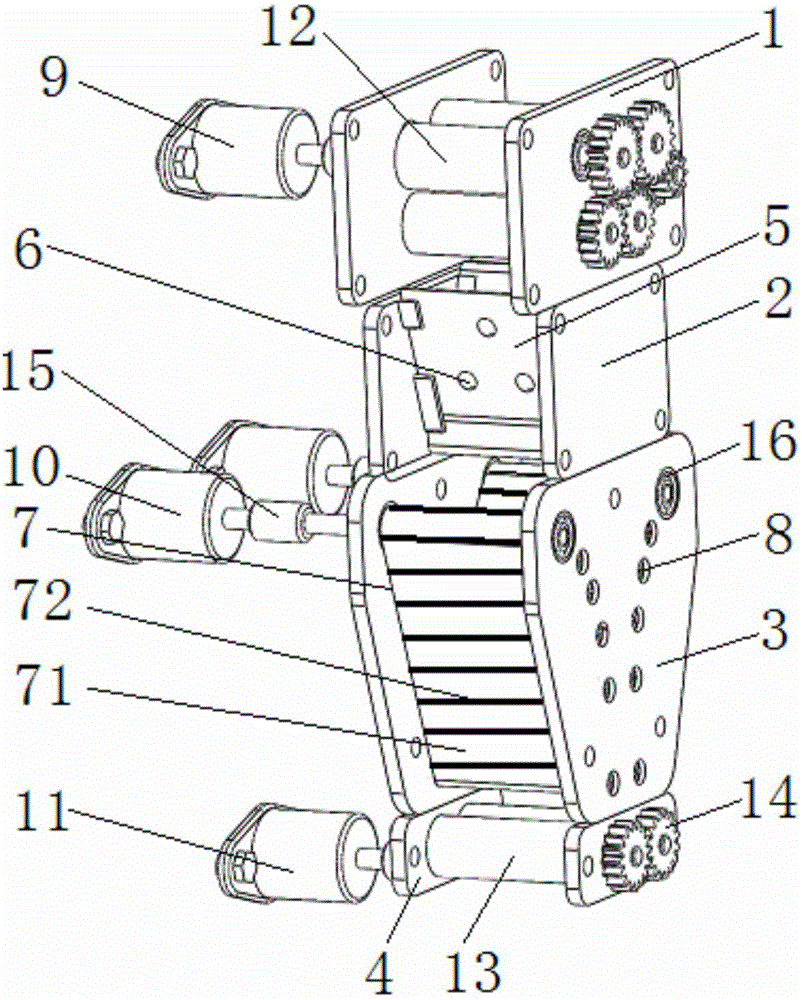

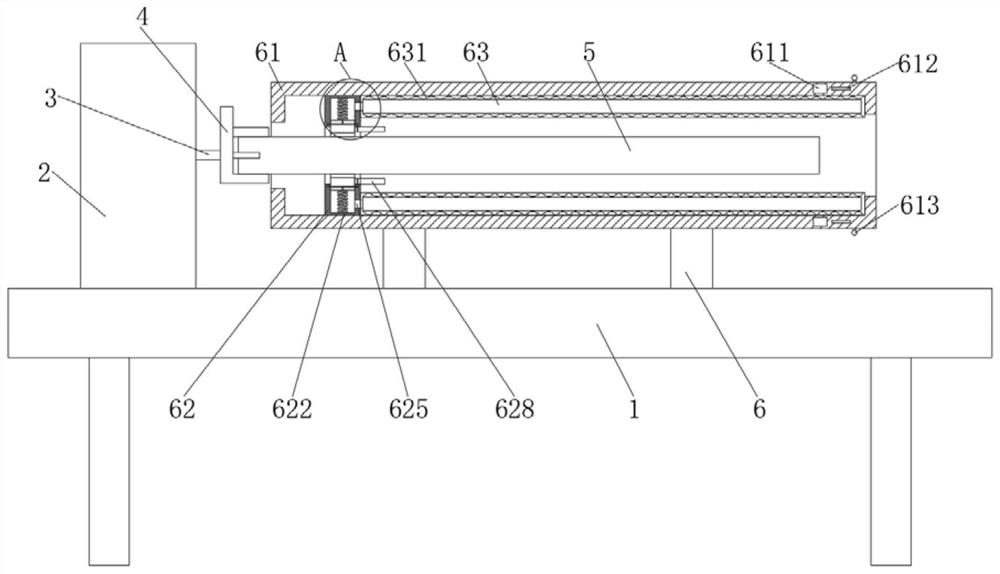

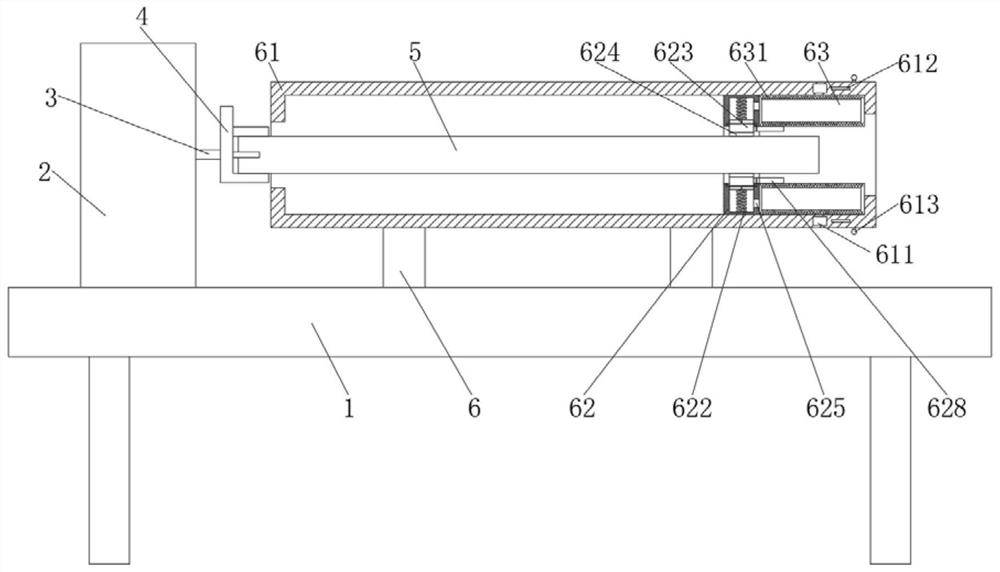

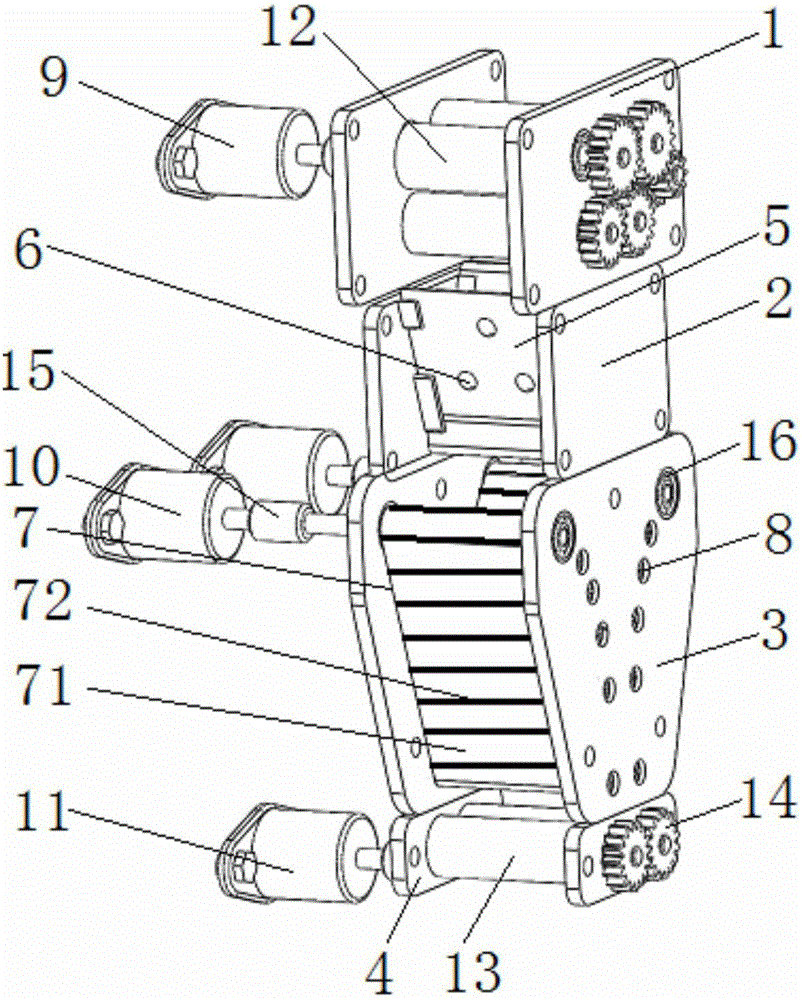

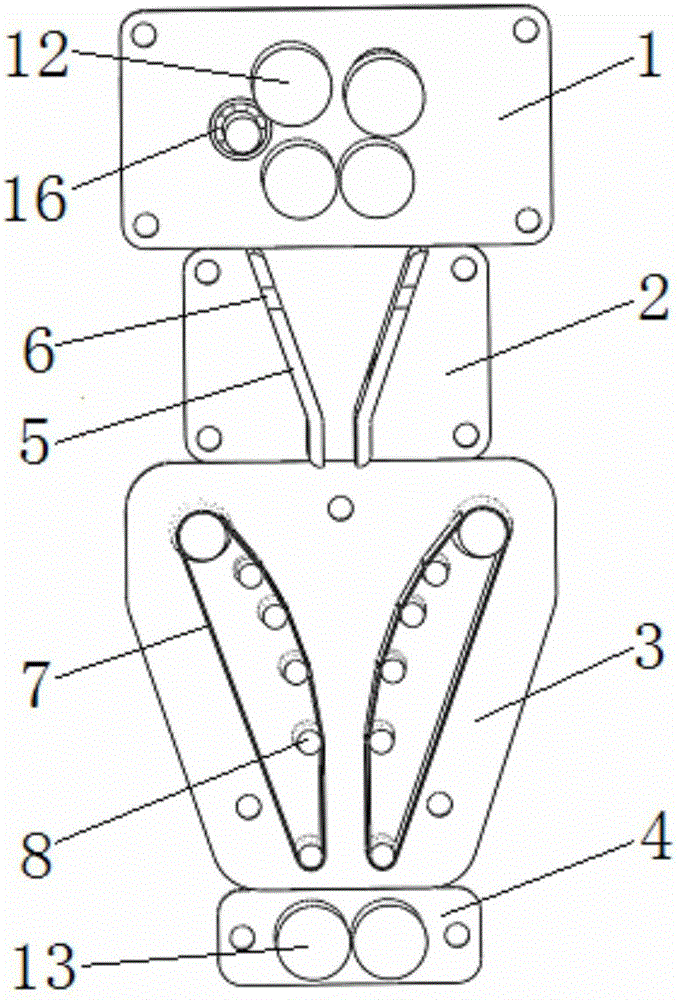

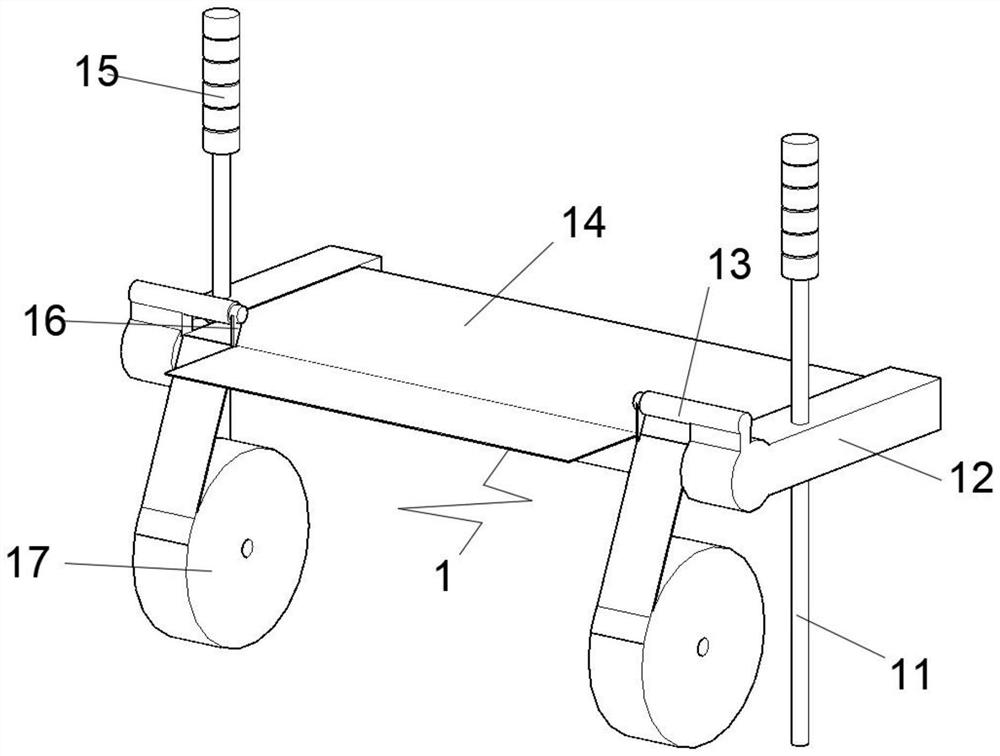

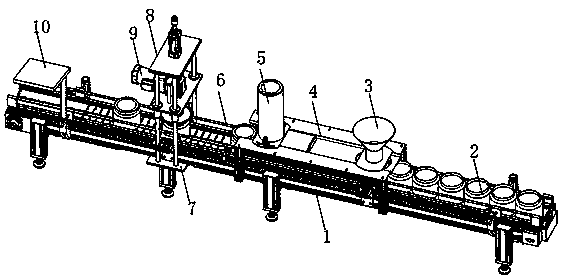

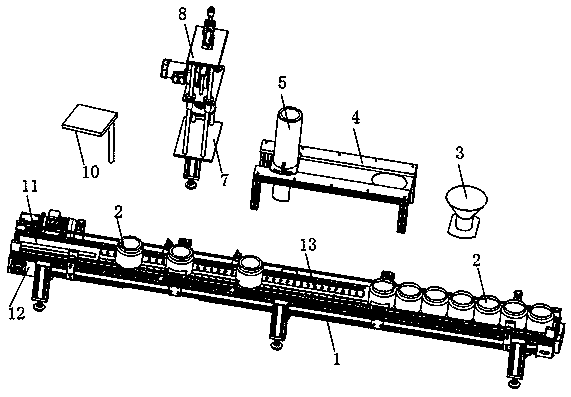

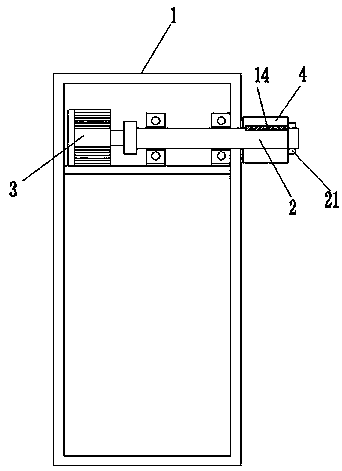

A banknote unfolding and sorting device

InactiveCN105692267BGuaranteed flattening effectAct as a squeezeArticle feedersCouplingPulp and paper industry

The invention provides a paper currency unfolding arrangement device. The paper currency unfolding arrangement device comprises a first conveying unit, a wetting unit, an unfolding unit and a second conveying unit which are sequentially mounted in the paper currency conveying direction. The size of the wetting unit in the paper currency conveying direction is smaller than the length of paper currency, and the wetting unit comprises wetting side plates, mounting plates and ultrasonic atomizers; the unfolding unit comprises unfolding side plates and two sets of unfolding assemblies which are symmetrically arranged with the paper currency conveying direction as the axis; each unfolding assembly is composed of an unfolding motor, a coupler, a rolling shaft set and a track with brushes, wherein each track with the brushes is arranged on the corresponding rolling shaft set in a sleeving manner, and the distance between two rolling shafts, with the opposite positions, in each rolling shaft set is gradually decreased in the paper currency conveying direction; and each track with the brushes is composed of a rubber track body and the brushes. The brushes are perpendicular to the paper currency conveying direction to be fixed to the outer surfaces of the rubber track bodies, and the rotating speed of the unfolding motors is larger than the rotating speed of a first motor and smaller than the rotating speed of a second motor; and according to the device, paper currency with folded corners or in the wrinkling state can be subject to wetting-flat brushing treatment, and in the treatment process, the paper current is not damaged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

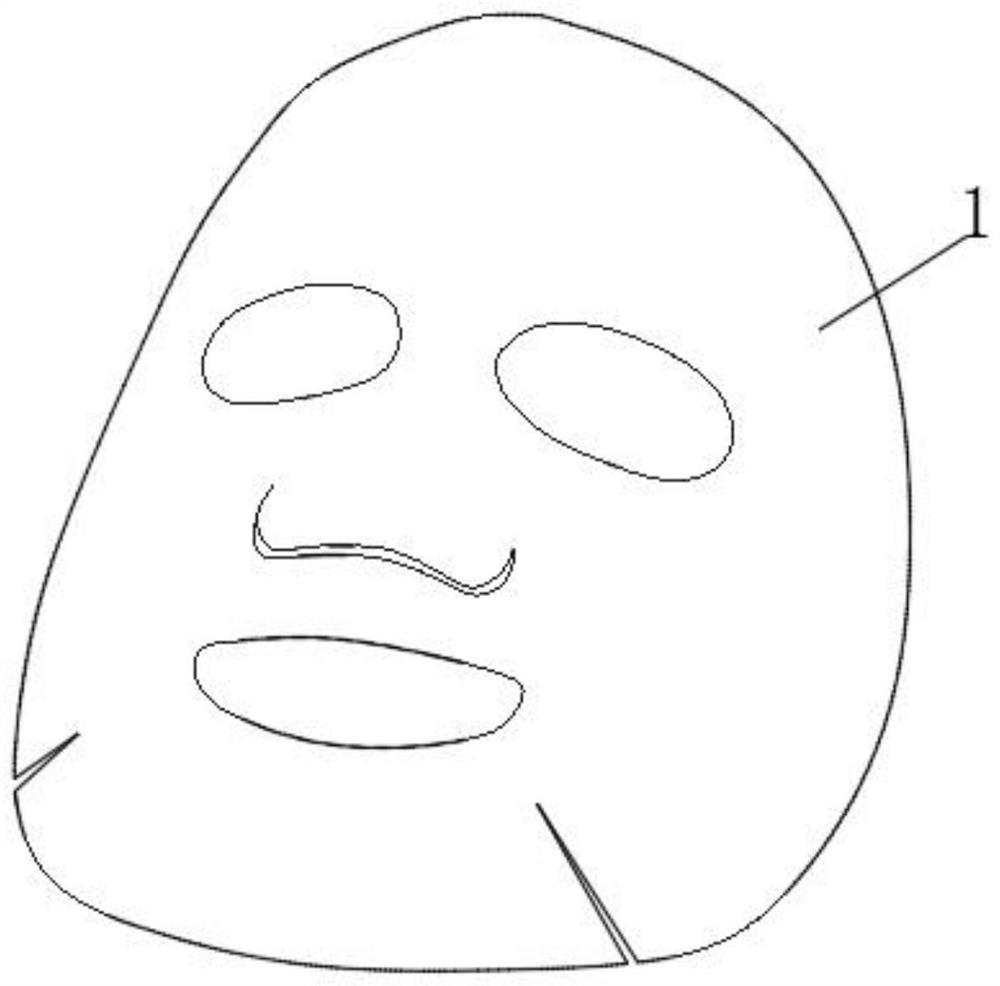

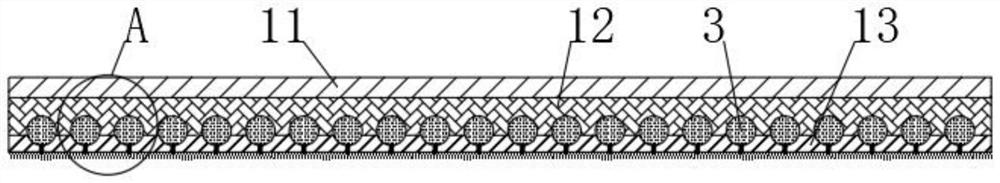

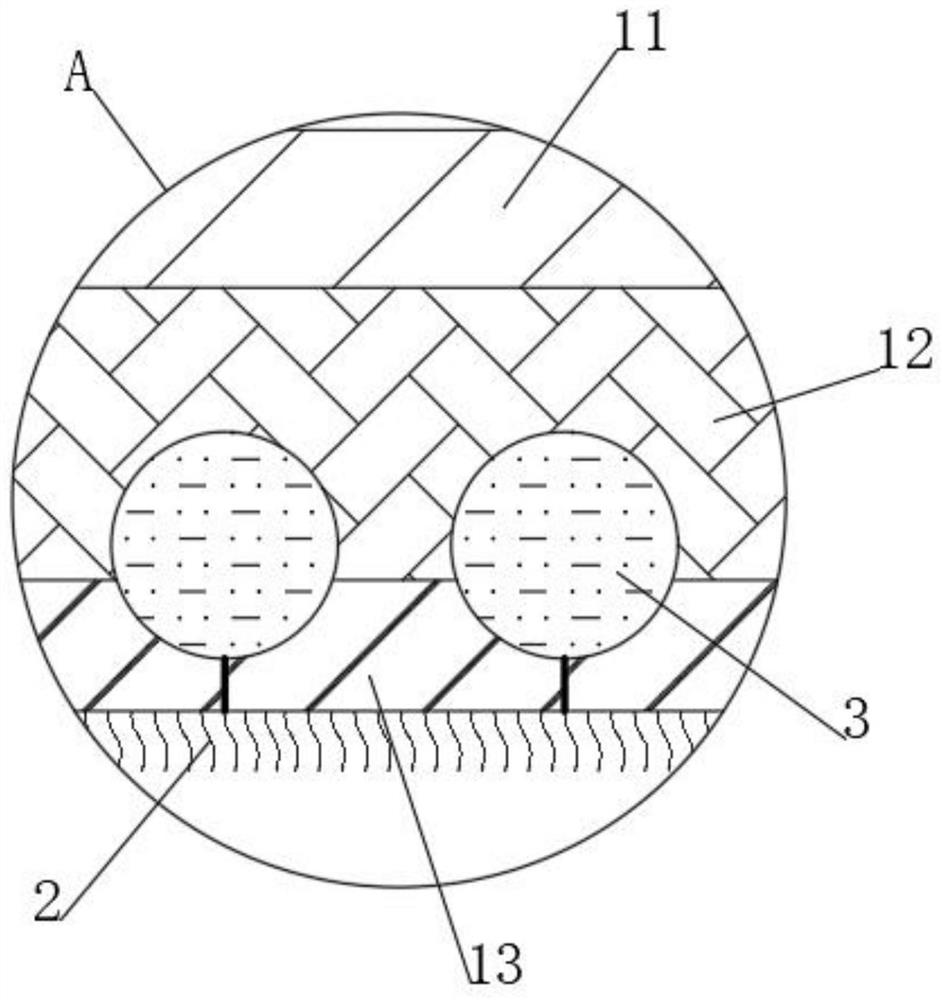

Self-fluid-supplementing micro-seismic mask

InactiveCN112353695AMoisturizing effect is obviousFast absorptionCosmetic preparationsToilet preparationsPhysicsEngineering

The invention discloses a self-supplementing micro-vibration mask, belongs to the field of masks, and particularly relates to a self-supplementing micro-vibration mask which is characterized in that aself-supplementing air vibration ball is arranged, and water mist is sprayed to the face coated with the mask after the mask is used for a period of time, so that the water mist is absorbed by a water guide cotton rod and enters the self-supplementing air vibration ball; the gas storage particles in the self-supplementing gas vibration ball make contact with water to generate gas, on one hand, the self-supplementing gas vibration ball is expanded, essence in the self-supplementing gas vibration ball overflows towards the liquid storage layer under extrusion of the gas, the effect of self-supplementing the essence is achieved, and use convenience is improved, and on the other hand, when the gas in the gas storage particles overflows, a certain impact force is generated on a sealed pinball,the position of the pinball is moved, and then the mask presents a micro-vibration effect. Compared with the prior art, the facial mask has the advantages that the absorption speed of the essence bythe face is remarkably increased, the overall duration of applying the facial mask is shortened, the absorption rate of the essence in the facial mask is effectively increased, and the use effect of the facial mask is better.

Owner:李艳秋

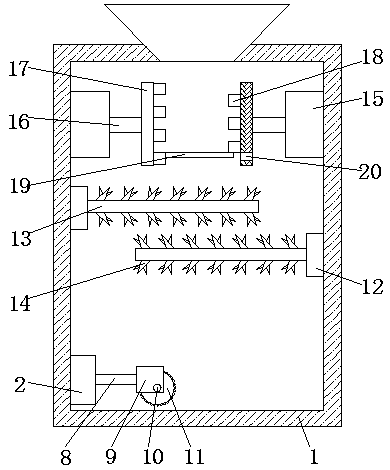

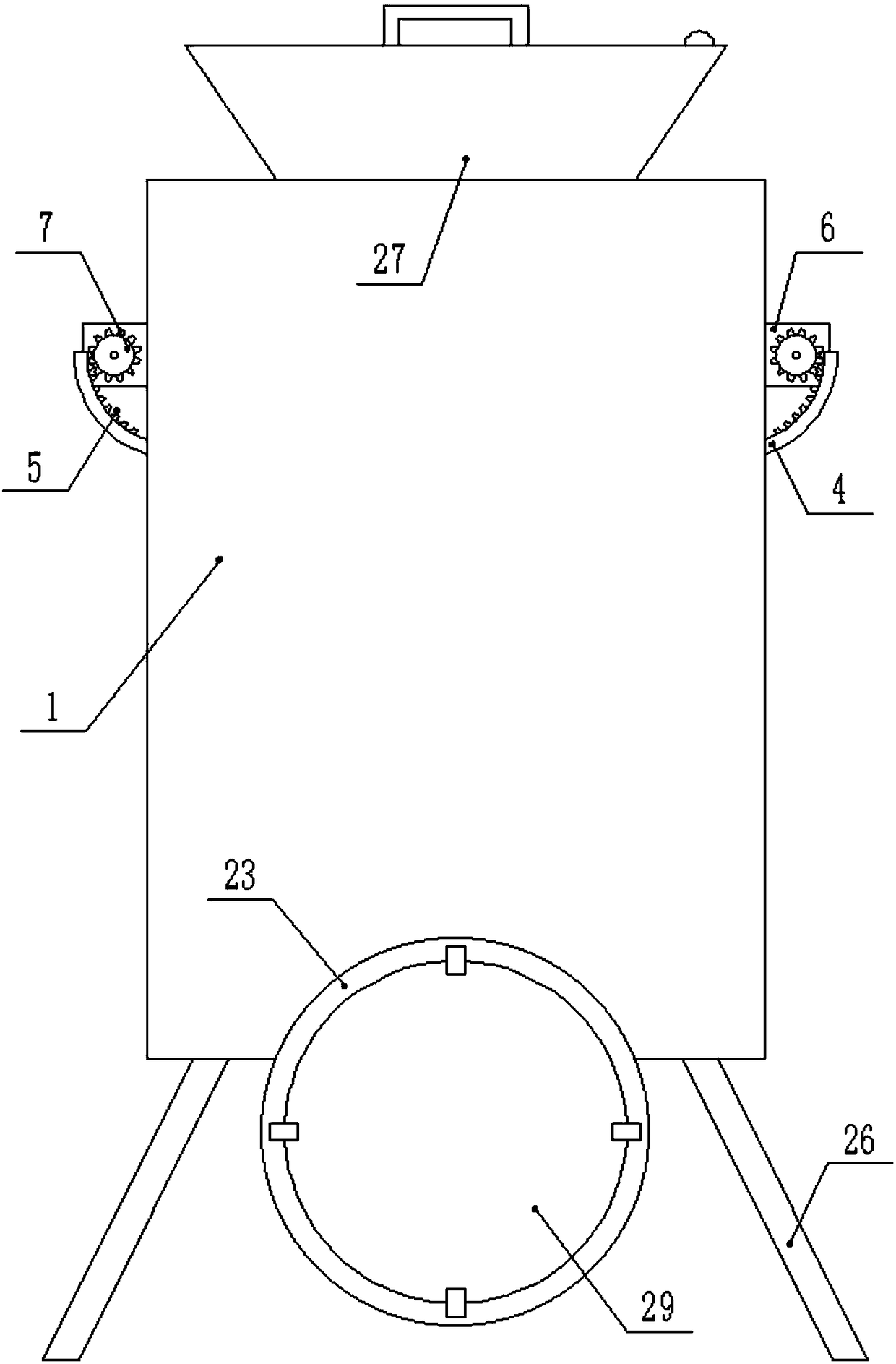

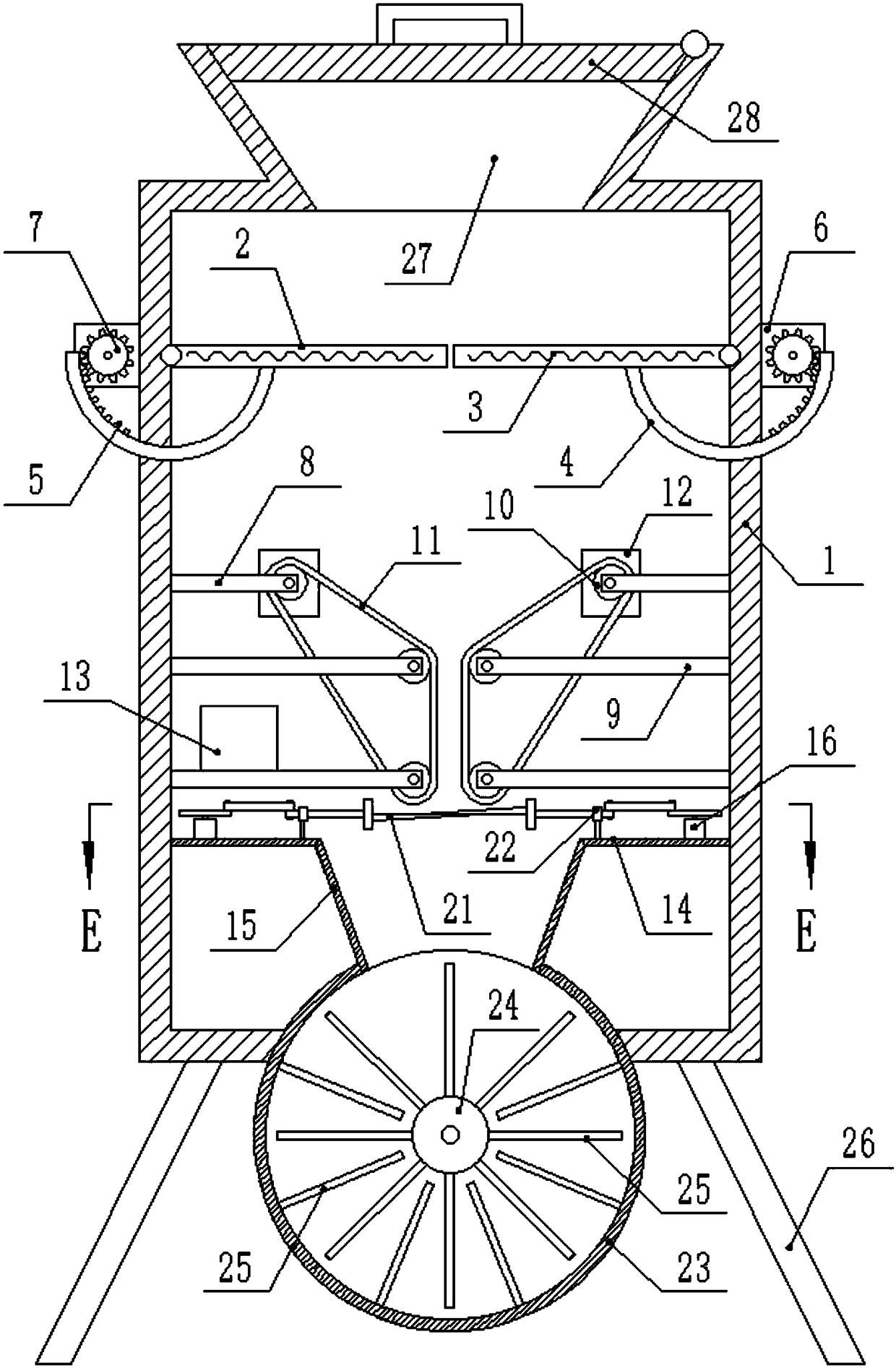

Baby diaper collecting treatment device and method

The invention discloses a baby diaper collecting treatment device and method. The baby diaper collecting treatment device comprises a box body; transverse plates are symmetrically hinged to the two ends of the inner wall of the box body, electric heating wires fixedly connected with the transverse plates are arranged in the transverse plates, the transverse plates are made of a ceramic material, and semi-circular rods which are concentric with the hinged positions the transverse plates and the semi-circular rods are fixed to the edges of the lower ends of the transverse plates; the semi-circular rods penetrate through the side wall of the box body and are slidably connected with the side wall of the box body; the portions, arranged outside the box body, of the semi-circular rods are provided with a plurality of uniformly distributed bulging teeth, and the bulging teeth are arranged on the inner arc surfaces of the semi-circular rods; first motors are symmetrically fixed to the two endsof the outer wall of the box body, and gears are fixed to rotary shafts of the first motors and engaged with the bulging teeth on the semi-circular rods; dried baby diapers can be conveniently subjected to smashing cutting, meanwhile, most of peculiar smell and germs can be eliminated, after the baby diapers are pressed and flattened by rollers and belts, crushing treatment is facilitated, the cut baby diapers can be conveniently smashed, the time is saved, the efficiency is improved, and the cost is reduced; and the baby diapers are thoroughly smashed through cutting blades rotating rapidly,the space is saved, and transporting, storing and recycling are facilitated.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

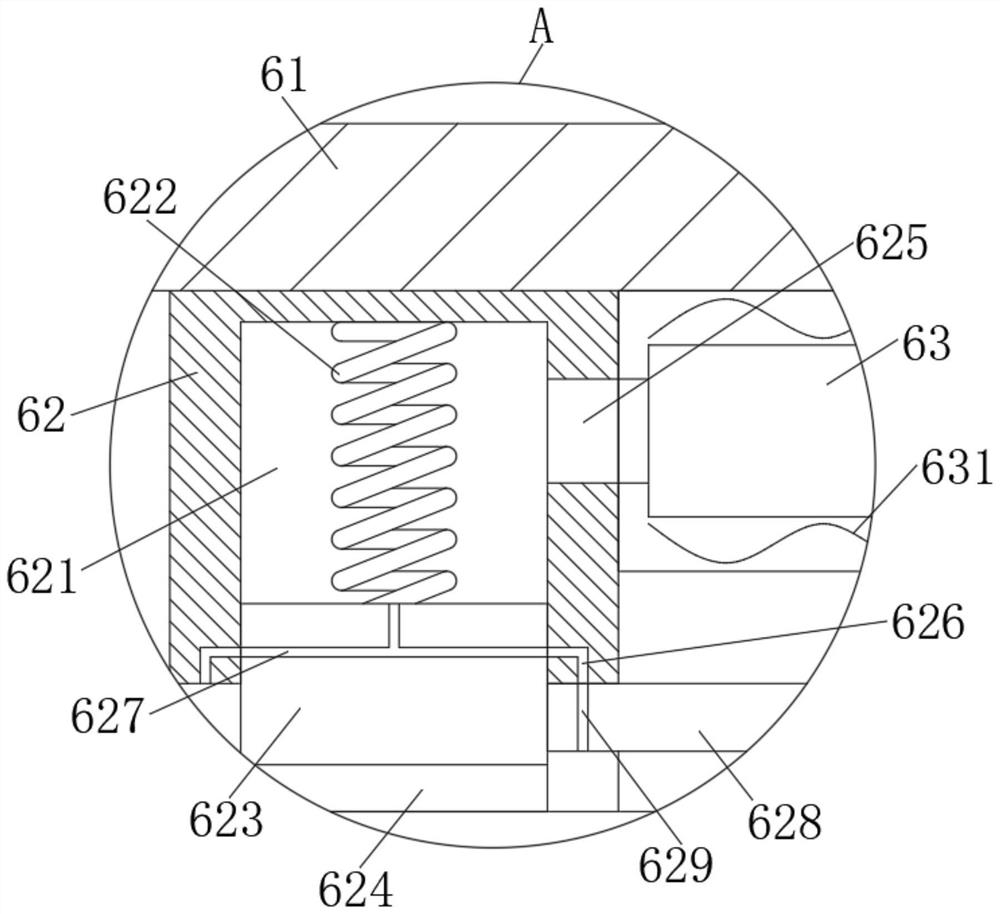

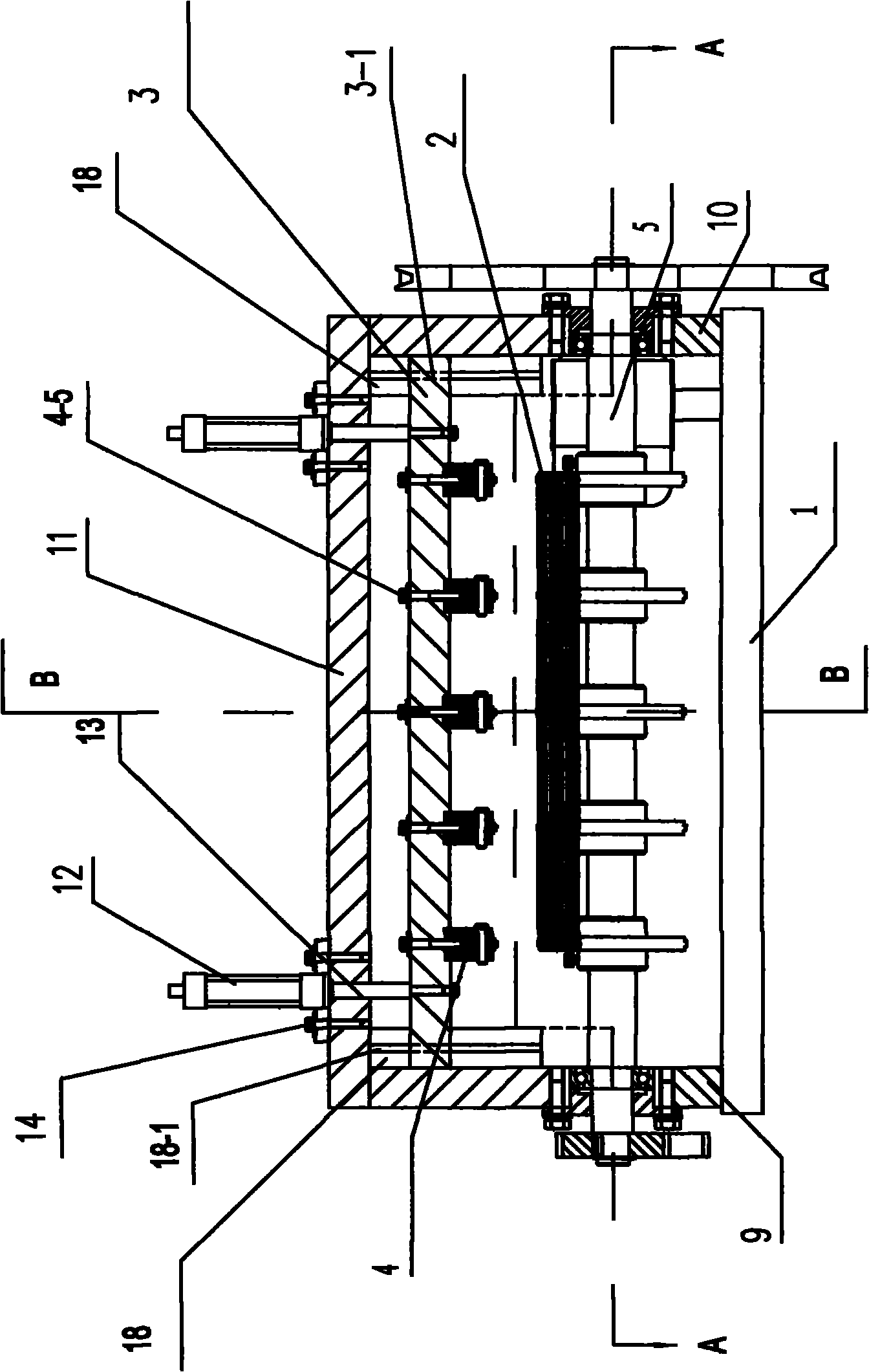

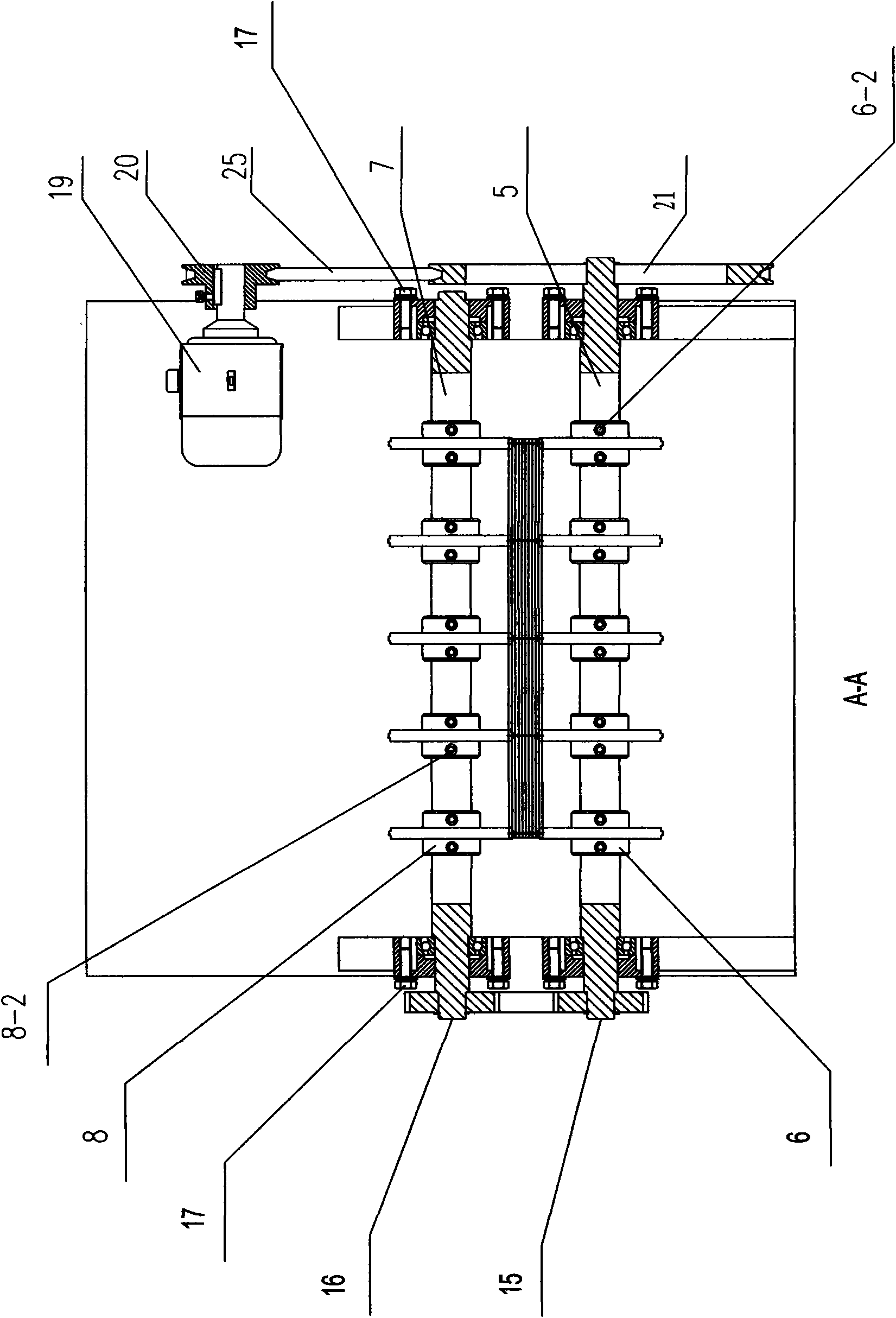

Pressing and rolling mechanism for cold-rolled aluminum

InactiveCN112845763AAct as a squeezePlay a protective effectShaping toolsShaping safety devicesStructural engineeringWorkbench

The invention relates to a pressing and rolling mechanism for cold-rolled aluminum. The pressing and rolling mechanism comprises a workbench and a cold rolling groove, wherein the cold rolling groove is fixedly formed in the upper end surface of the workbench, a pressing and rolling mechanism body is arranged directly above the cold rolling groove and arranged on the side wall of a supporting side plate, and the supporting side plate is fixedly arranged on the upper end surface of the cold rolling groove. According to the pressing and rolling mechanism disclosed by the invention, the structure of an existing cold rolling head is optimized, a buffer structure is additionally arranged on the basis of the existing cold rolling head, and in the actual working process, after cold rolling of an aluminum component is completed, the buffer structure acts along with continuous movement of a driving cylinder, so that continuous driving force is avoided, the cold rolling head is extruded, the cold rolling head is protected, the service life of the cold rolling head is prolonged, the production cost can be reduced, the maintenance and replacement frequency can be reduced, and the pressing and rolling mechanism has higher practical value.

Owner:孙洪达

Oil stain decomposition and adsorption device for oil-containing waste gas treatment

The invention discloses an oil stain decomposition and adsorption device for oil-containing waste gas treatment, and belongs to the technical field of waste gas treatment. The pushing force during waste air intake is utilized; an oil stain dispersing agent in an annular feeding disc is pushed into a plurality of strip-shaped arc-shaped embedding plates to permeate outwards by a plurality of elastic telescopic feeding bags; the oil stain dispersing agent which permeates outwards is dispersed on a filler framework through a feeding diffusion mechanism, and is used for decomposing and diffusing oil stains attached to the filler framework. Blockage caused by excessive oil stains attached to the filler framework is effectively avoided; besides, an elastic bag layer filled with an expansion gaslayer is arranged at the inner end of the strip-shaped arc-shaped embedding plate; when guided-in waste gas diffuses outwards through the filler framework, the waste gas with certain impact force canplay a certain role in extruding the elastic bag layer, so that the oil stain dispersing agent permeates outwards more easily, and under the condition that the waste gas is not guided in, the elastictelescopic feeding bag resets and contracts, so that the oil stain dispersing agent is effectively prevented from permeating outwards.

Owner:戚永团

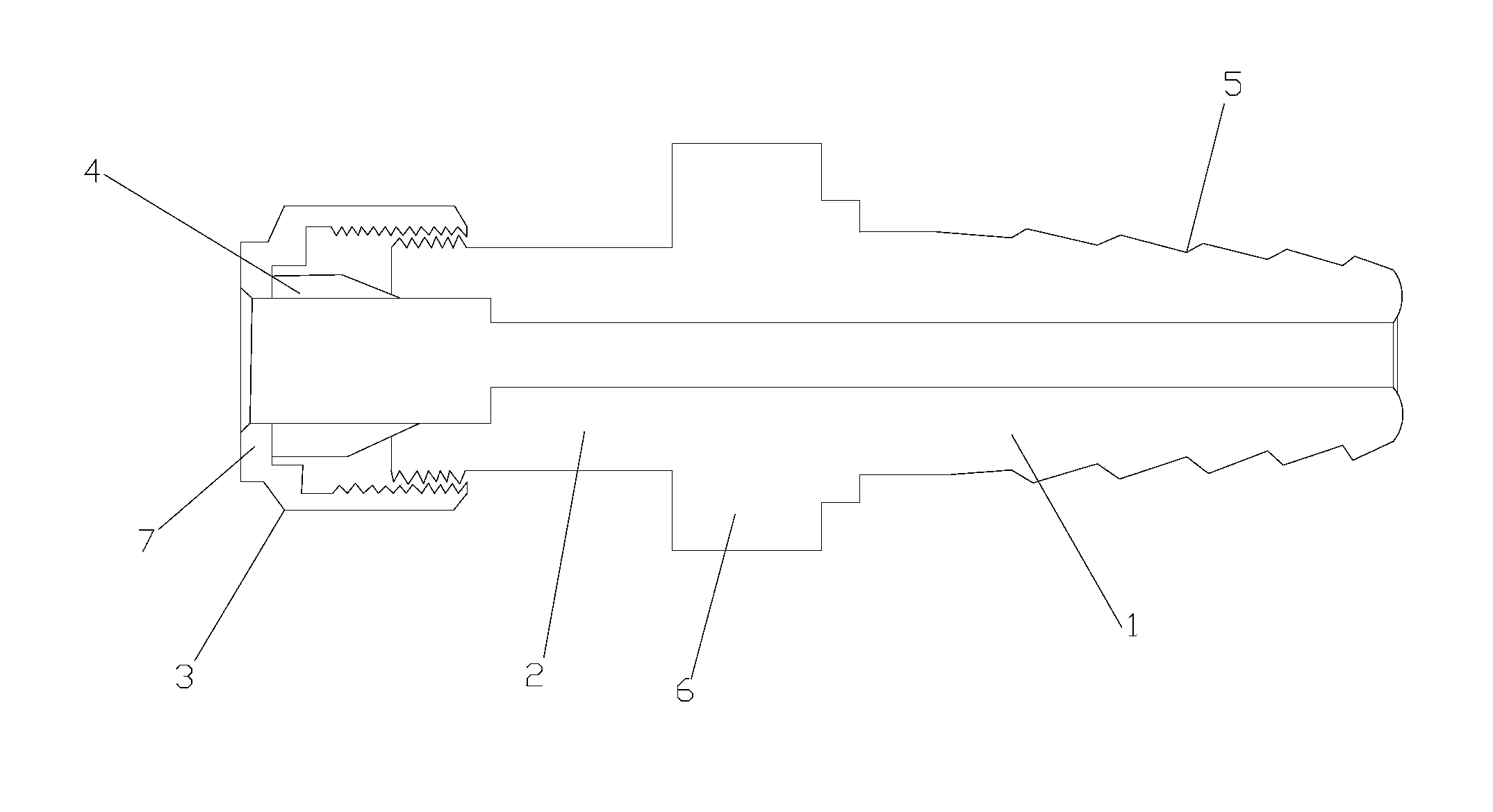

Hose coupler

InactiveCN103697268APlay a role in anti-slipAct as a squeezeHose connectionsBiochemical engineeringScrew thread

Owner:天津渤海晟机械设备配件有限公司

Middle core wire oiling device for wire and cable production

ActiveCN112435803AGuaranteed reflowReduce wasteClimate change adaptationCable/conductor manufactureDrive shaftStructural engineering

The invention discloses a middle core wire oiling device for wire and cable production, and relates to the technical field of wire and cable production equipment, the middle core wire oiling device comprises a bottom plate, a vertical plate and a support plate, the vertical plate is fixedly connected to the left end of the bottom plate, and the upper end of the vertical plate is fixedly welded with a transverse plate and fixedly connected to the bottom plate; a guide plate is fixedly connected to the upper end of the support plate; and the vertical plate is provided with a wire inlet, the right side of the vertical plate is rotationally connected with main belt rollers which are symmetrical front and back, and auxiliary belt rollers are arranged below the main belt rollers. Compared with the prior art, the oiling device has the beneficial effects that through rotation of the driving shaft of the lead mechanism, the driving lever intermittently keeps the conveying belt at different positions under the action of the eccentric wheel to oil a central core wire, the oil immersion roller enables the conveying belt and the oil cloth to be stained with oil in the opening box, and meanwhile, the auxiliary belt rollers on the two sides play a role in extrusion; and by means of the mode, oiling is even, waste of oil is effectively reduced, and production cost is saved.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV

Preparation method for optical polyester film

ActiveCN112938606APlay a supporting roleStable supportArticle deliveryWebs handlingThin membranePolyester

The invention relates to the technical field of film preparation methods, in particular to a preparation method for an optical polyester film. According to the preparation method, preparation equipment comprises a film production device and a collecting device, the collecting device is fixedly arranged right below the film production device, a conveying frame is fixedly arranged in the film production device, a fixing rod is welded to the upper surface of the conveying frame, leftover material rolls are fixedly connected to the two side edges of the polyester film, a supporting rod is fixedly arranged in the conveying frame in an inserted mode, an alarm lamp is fixedly connected to the top end of the supporting rod, a supporting base is fixedly arranged in the collecting device, winding devices are symmetrically and movably arranged at the two ends of the interior of the supporting base, and triggering devices are symmetrically and movably arranged at the bottom edges of the two ends of the supporting base. The preparation method has the advantages that real-time winding of leftover materials of the polyester film can be realized, workers can conveniently conduct centralized cleaning on the leftover materials of polyester film, and the situation that normal operation of the production equipment is affected due to the fact that the leftover materials of the polyester film is stacked on the ground can be avoided.

Owner:深圳市巨城光电科技有限公司

Concrete impermeability test structure and test method thereof

The invention discloses a concrete impermeability test structure comprising a worktable and a loading cylinder, wherein the upper part of the worktable is installed with a conveyor belt along the length direction, one end of the worktable is rotatably mounted with a loading plate along the length direction, one end of the loading plate close to the conveyor belt is connected to both sides in the worktable through a rotating shaft, the bottom of the worktable is horizontally welded with a base below the loading plate, a plurality of hydraulic columns are mounted on the top of the base, and thetops of the hydraulic columns and the bottom of the loading plate are in rotary connection. Concrete can be solidified under different environments to simulate different laying environment temperatures in actual use of concrete. The loading cylinder can be quickly received using a rotating loading plate and is easily detached from the conveyor belt.

Owner:东莞市交港建材有限公司

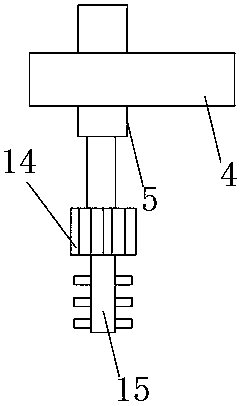

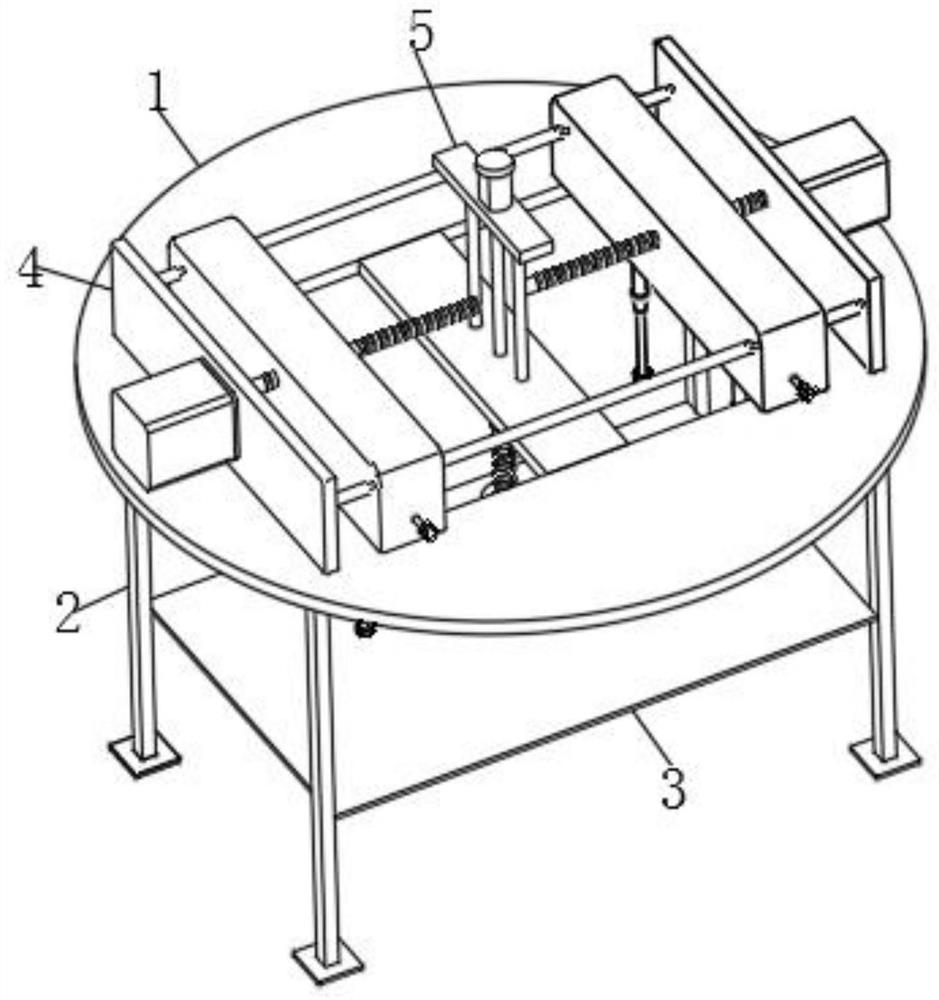

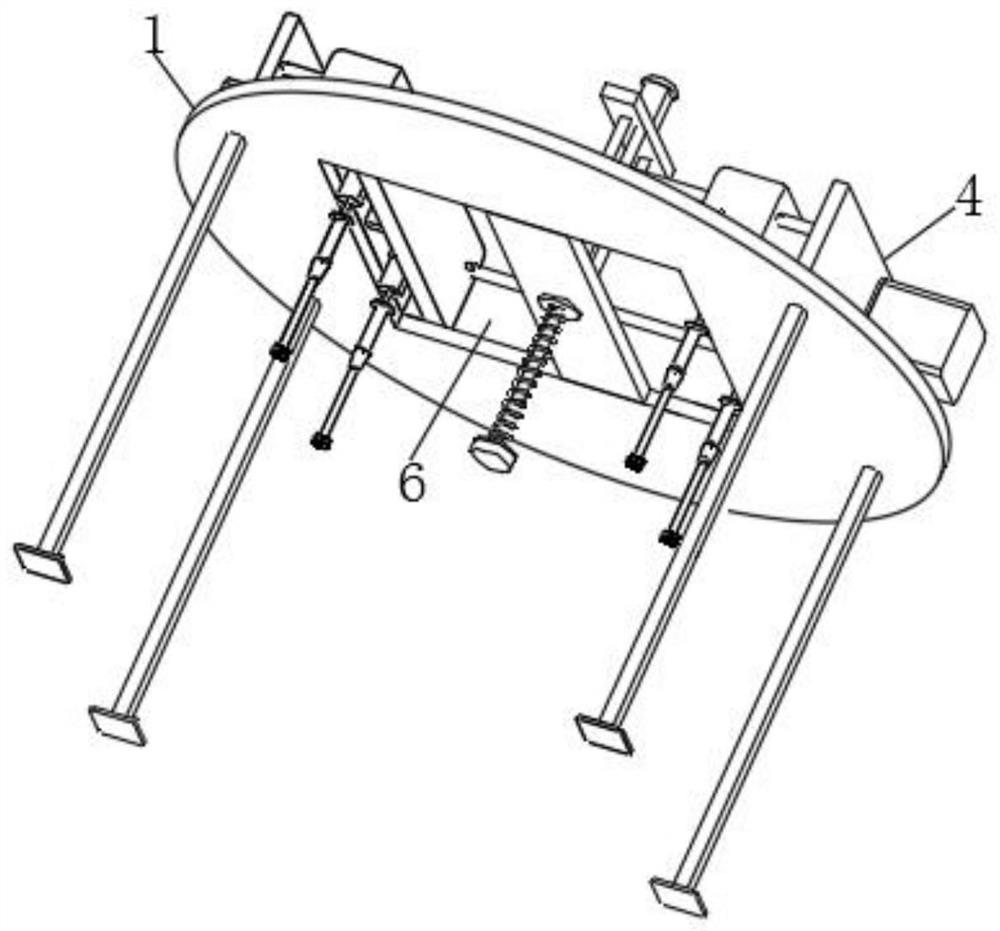

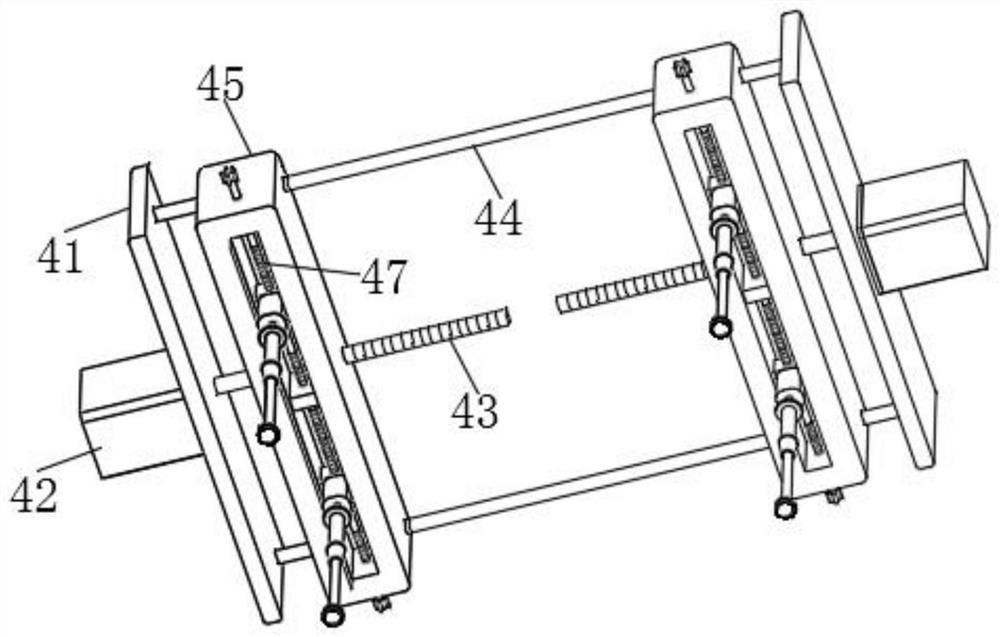

Rotating disc mechanism for cosmetic cap screwing equipment

InactiveCN112374435ATwist the cap to facilitateAct as a squeezeCapsThreaded caps applicationCircular discElectric machinery

The invention relates to the technical field of cosmetic processing, and discloses a rotating disc mechanism for cosmetic cap screwing equipment. The rotating disc mechanism comprises a supporting disc. Two first adjusting mechanisms are symmetrically mounted at the upper end of the supporting disc, a square groove is formed between the two first adjusting mechanisms at the upper end of the supporting disc, and an anti-falling device is mounted at the upper end of the interior of the square groove. Each first adjusting mechanism comprises a side plate, wherein a first motor is mounted at one end of the side plate, a lead screw is connected to an output shaft of the first motor in a manner of penetrating through the side plate, and positioning sliding rods are arranged at the positions, infront and back of the lead screw, of the other end of the side plate. According to the rotating disc mechanism for the cosmetic cap screwing equipment, a bottle cap can be prevented from falling off from a cosmetic bottle during screwing, the bottle cap is subjected to the downward pressure of a spring, screwing of the bottle cap is facilitated, and the working efficiency is improved; the rotatingdisc mechanism is suitable for screwing of bottle caps of cosmetic bottles with different heights; and the front-and-back positions and the left-and-right positions of rubber columns can be adjusted,so that bottle caps with different sizes and different shapes can be screwed.

Owner:程红梅

Barrier gate convenient to demount, mount and combine

InactiveCN109338933AEasy to installEasy to disassembleTraffic restrictionsOptical axisArchitectural engineering

The invention discloses a barrier gate convenient to demount, mount and combine. The barrier gate comprises a control box, a rotating shaft, transverse gate rods and a positioning ring; the interior of the control box is connected with the rotating shaft through a bearing seat, one end of the rotating shaft is fixedly connected with an output shaft of a motor, and one of the transverse gate rods is arranged at the end, extending out of the control box, of the rotating shaft; a connecting rod is hinged to the bottom end of the obverse side of the control box, the other transverse gate rod is fixed to the connecting rod, and the end, extending out of the transverse gate rod, of the rotating shaft is in threaded connection with the positioning ring; and first fixing blocks are fixed to the right sides of the obverse sides of the transverse gate rods correspondingly, baffles are hinged to the first fixing blocks, polished shafts are evenly fixed to the obverse sides of the transverse gaterods, the polished shafts are rotatably connected with vertical gate rods, second fixing blocks are fixed to one sides of the obverse sides of the transverse gate rods, and the baffles and the vertical gate rods are fixed through fastening screws. The barrier gate convenient to mount and demount can be freely combined into a polished-rod type barrier gate or a fence type barrier gate, thus the barrier gate can intercept vehicles and can also intercept pedestrians, demounting and mounting are convenient, the production efficiency is effectively improved, and meanwhile, carrying and maintainingare convenient.

Owner:江苏艾华美陈科技股份有限公司

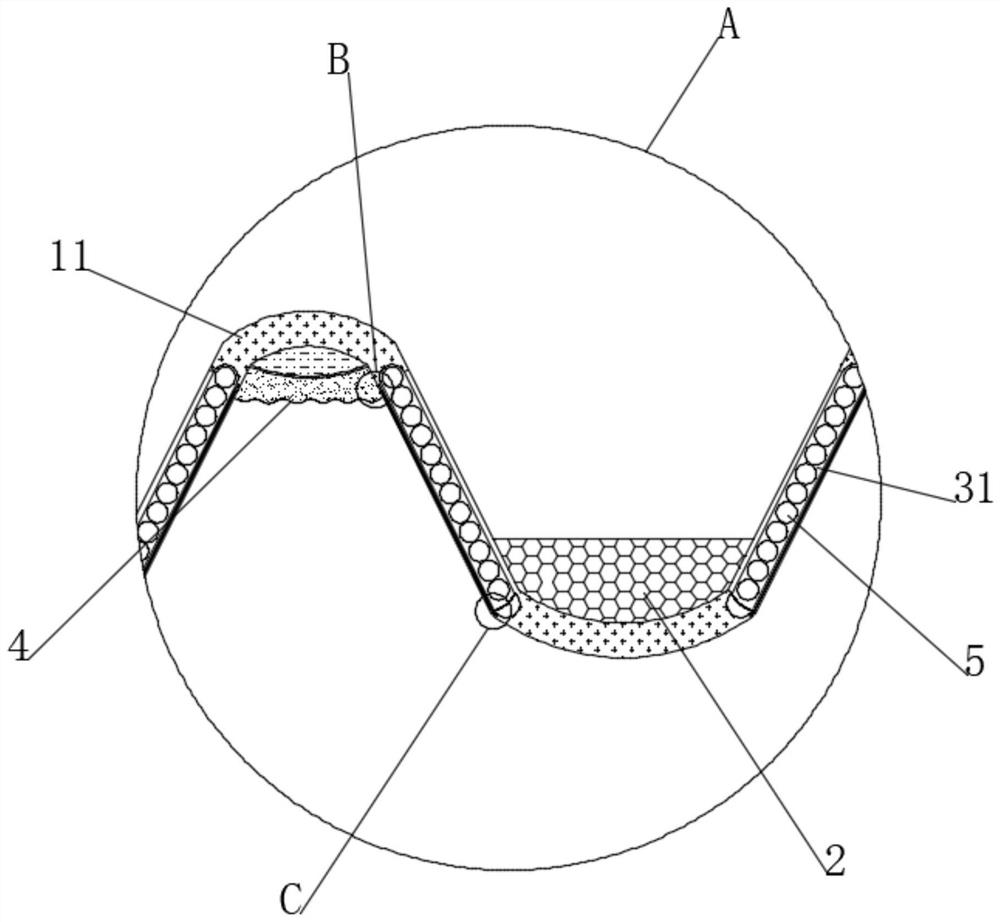

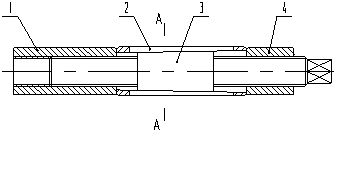

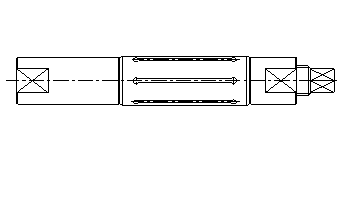

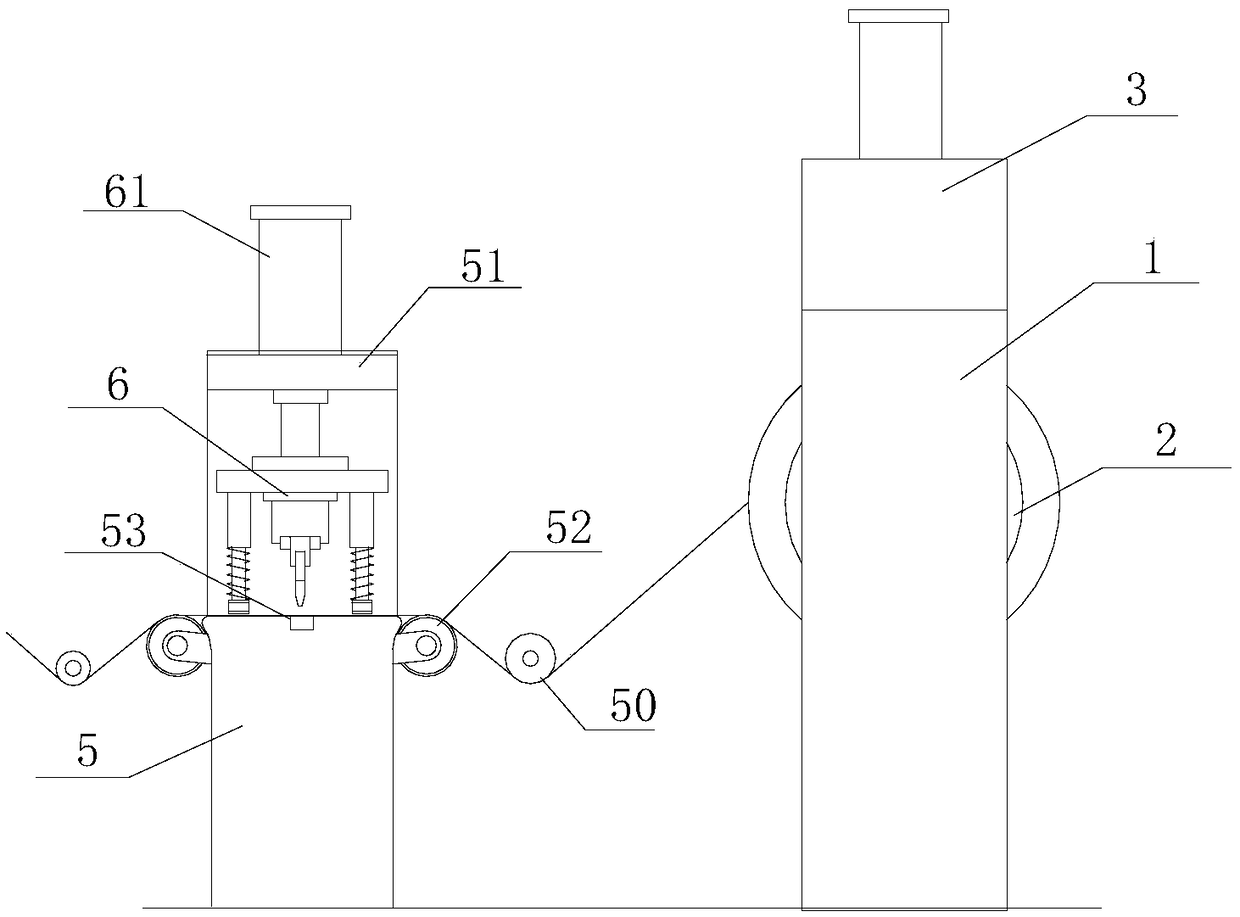

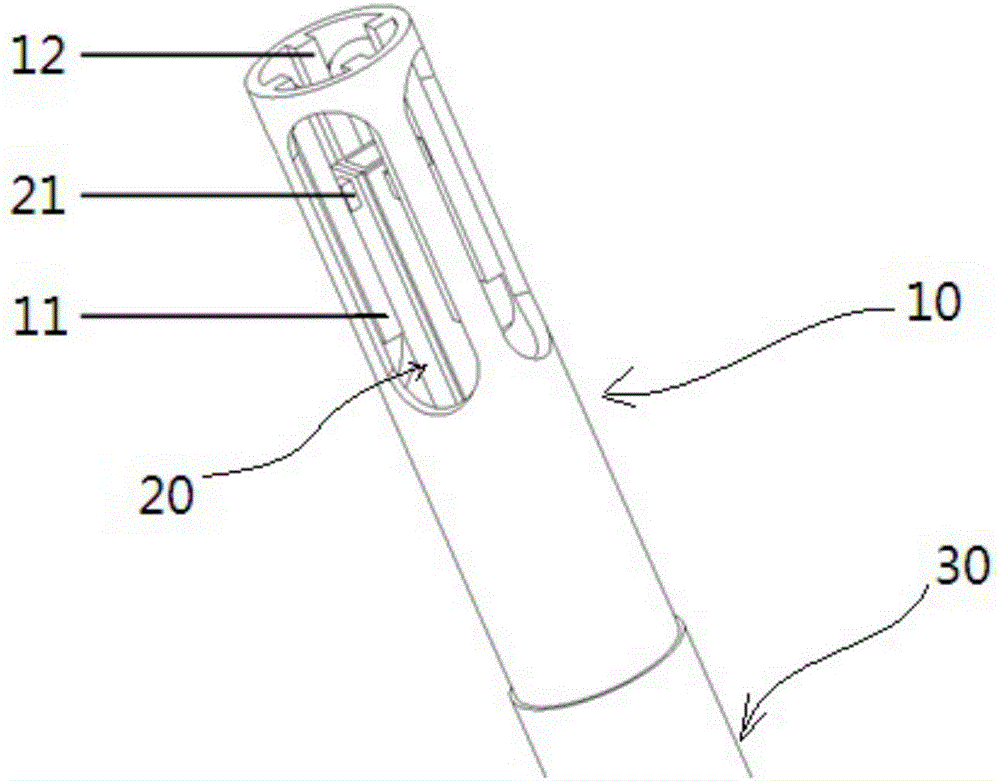

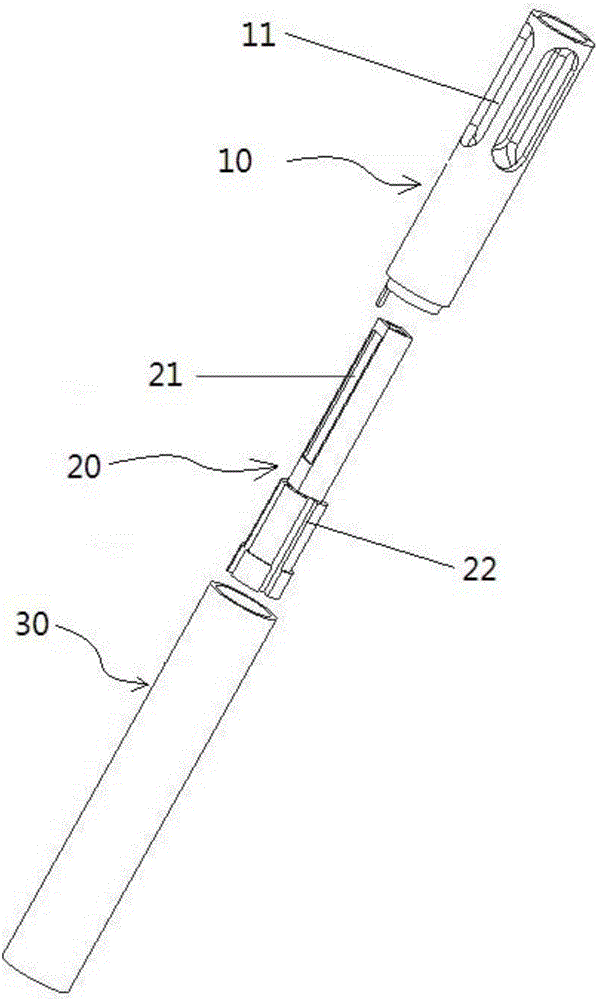

Packaging structure for mass point vibration velocity measurement sensor

ActiveCN105841799AHigh measurement sensitivityImprove signal-to-noise ratioSubsonic/sonic/ultrasonic wave measurementUsing electrical meansEngineeringSound pressure

The invention relates to a packaging structure for a mass point vibration velocity measurement sensor. The packaging structure comprises an upper housing (10), an inner core (20), and a lower housing (30). A plurality of windows (11) are opened at the upper part of the upper housing (10) in a peripheral direction. The inner core (20) is accommodated into an inner cavity formed by the upper housing (10) and the lower housing (30) jointly; the upper end of the inner core (20) is a rectangular-column-shaped body; and three mass point vibration velocity sensors (21) are arranged at three planes perpendicular to each other. Front amplification circuit boards of the sensors (21) are arranged at the lower housing (30). Long-strip-shaped cylinders (12) are arranged at the two sides of each window (11) of the upper housing (10); and the three mass point vibration velocity sensors (21) arranged at the three adjacent side surfaces of the rectangular-column-shaped body at the upper end of the inner core (20) are close to the long-strip-shaped cylinders (12) in a face-to-face mode without any contact. Because the long-strip-shaped cylinders are arranged opposite to the mass point vibration velocity sensors in the upper housing and play a role in extrusion of the mass point flow of the sound field, so that the mass points flowing through the mass point vibration velocity sensors can flow fast on the condition of the same sound pressure at the same sound field and thus the measurement sensitivity of the mass point vibration velocity sensors can be improved effectively.

Owner:THE THIRD RES INST OF CHINA ELECTRONICS TECH GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com