Oil stain decomposition and adsorption device for oil-containing waste gas treatment

A waste gas treatment and adsorption device technology, which is applied in the direction of combination device, separation method, dispersed particle separation, etc., to achieve the effect of avoiding adsorption clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

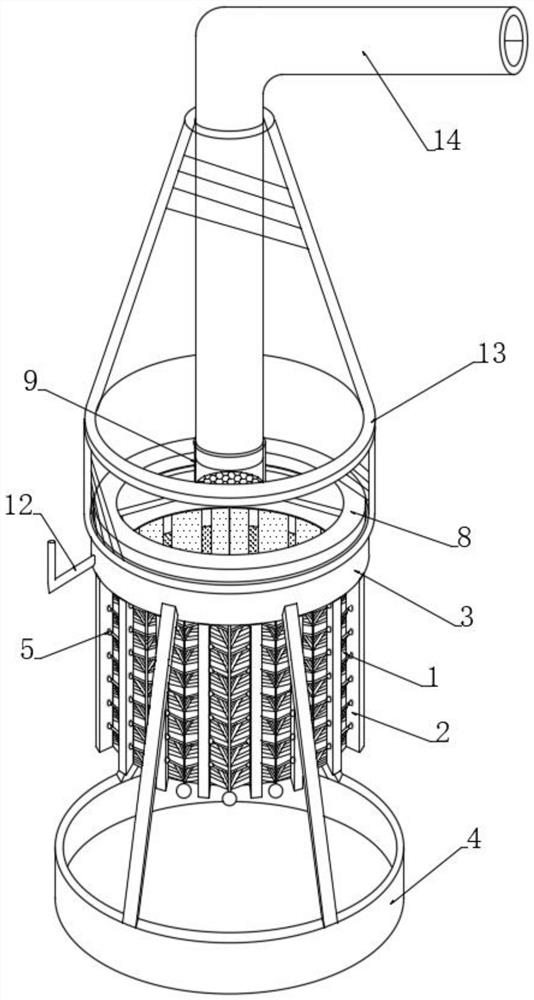

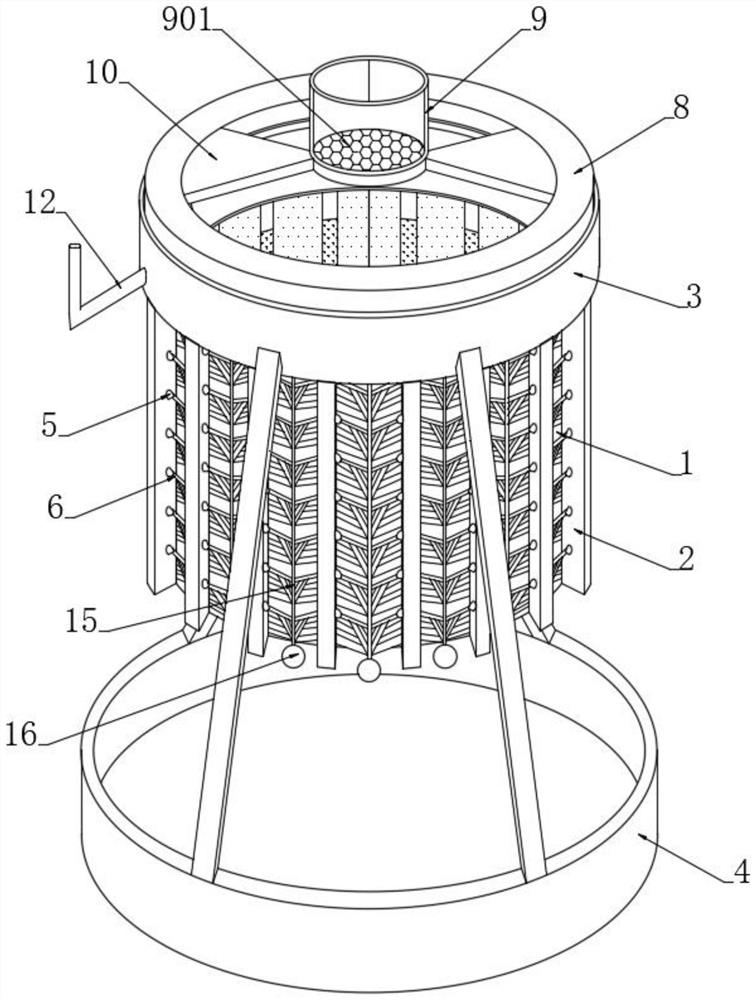

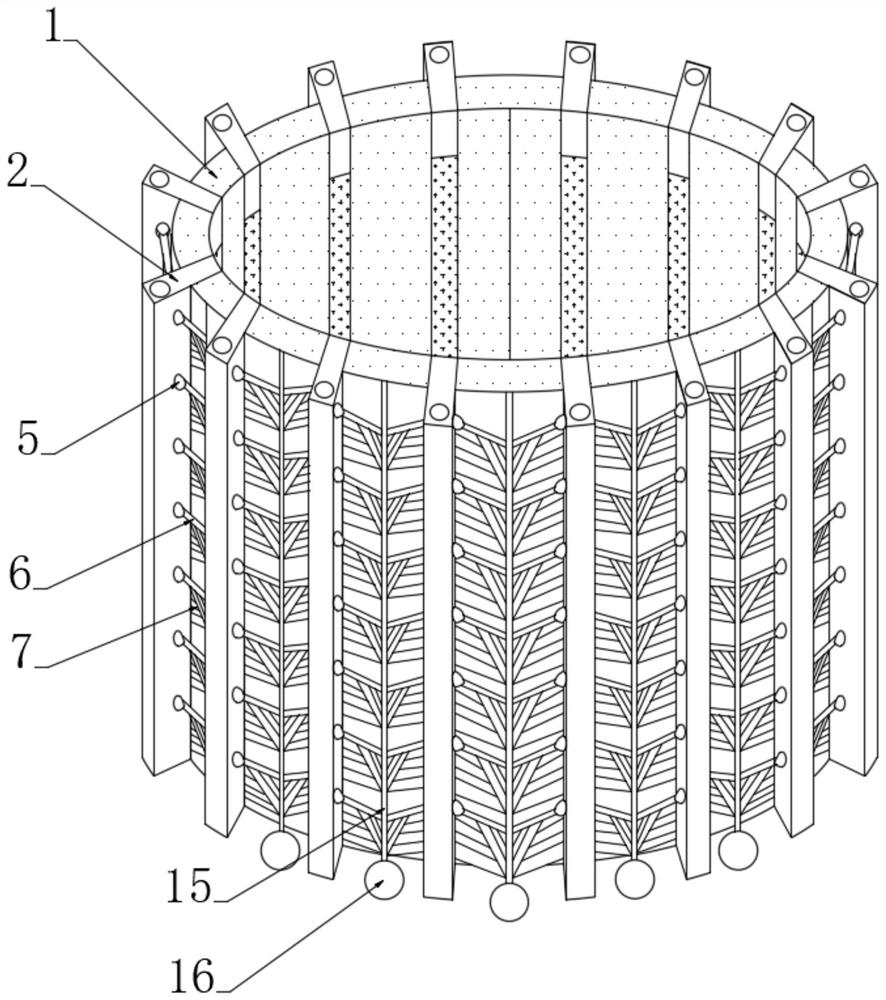

[0038] see Figure 1-2 , an oil stain decomposition and adsorption device for oily waste gas treatment, comprising a filler skeleton 1 and a plurality of strip-shaped arc-shaped embedded plates 2 embedded and connected to the side walls around the filler skeleton 1, the strip-shaped arc-shaped embedded plates 2 are Porous ceramic filler skeleton, the porous ceramic filler skeleton is filled with biochar, the thickness of the porous ceramic filler skeleton is 1.5-3cm, the top of the filler skeleton 1 is fixedly connected with a plurality of strip-shaped arc-shaped embedded plates 2 internally communicated Ring-shaped feed pan 3, the four corners of the lower end of the ring-shaped feed pan 3 are fixedly connected with a disc base 4 through a support frame, and the top end of the annular feed pan 3 is slidably and sealedly connected with an annular squeeze disc 8, and the ring-shaped squeeze disc 8 The top end is connected with a push-down mechanism, and the ring-shaped feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com