Dendrobium candidum processing equipment

A kind of processing equipment, the technology of iron maple bucket, applied in the field of iron maple bucket processing equipment, can solve the problems of unreachable, unfavorable processing and production, complex structure of winding device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

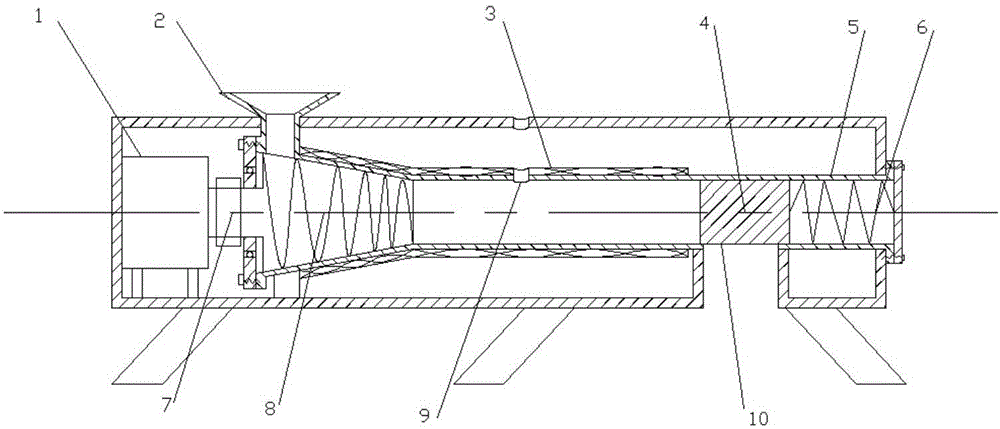

[0014] Example: such as figure 1 , a kind of iron maple bucket processing equipment, including a driving motor 1, a feed trough 2, the feed trough 2 is connected with a forming pipe 5, the front section of the forming pipe 5 is provided with a forming screw 8, and the forming screw 8 is connected to the driving motor through a coupling 7 1 connection, the outer side of the forming tube 5 is provided with a heating wire 3, and the lower part of the forming tube 5 is provided with a discharge hole 10. The end section of the forming tube 5 is provided with a spring 6, and the stopper 4 connected with the spring 6 is located above the discharge hole 10 without external force. The forming tube 5 is provided with ventilation holes 9 .

[0015] When it is necessary to process the iron maple bucket, pour the stem of Dendrobium candidum obtained after softening treatment and cutting according to a certain length into the feeding tank 2, and the forming screw 8 will make the stem of De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com