High efficient electric furnace steel-making system

An electric furnace steelmaking and high-efficiency technology, applied in the direction of electric furnace, furnace, furnace type, etc., can solve the problems of inconvenient use and inconspicuous effect, and achieve the effects of reducing production costs, improving the quality of steelmaking products, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with embodiment.

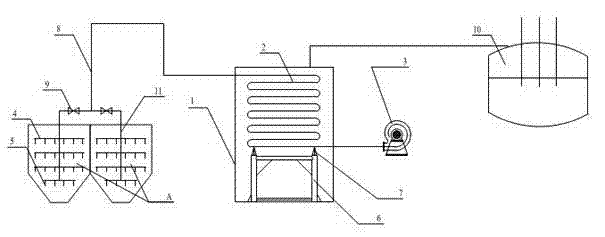

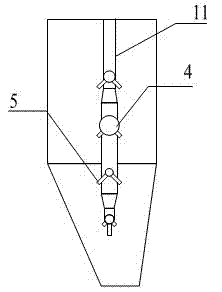

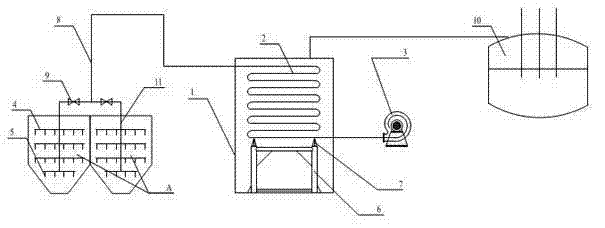

[0024] Such as figure 1 As shown, a high-efficiency electric furnace steelmaking system includes an electric furnace 10 with a flue gas outlet, a settling chamber 1 connected to the flue gas outlet of the electric furnace 10, and two auxiliary material bins A. The bottom of the settling chamber 1 is fixed with a support 6, and the support 6 is fixedly connected to the heat exchange pipeline 2 through a triangular bottom plate 7, the inlet of the heat exchange pipeline 6 is connected to a high-pressure centrifugal fan 3, and the outlet is connected to the exhaust system through the main pipe 8, and the exhaust system is arranged in the auxiliary material bin A. The main pipe 8 is provided with a regulating valve 9, and the outer surface adopts asbestos insulation to ensure that the hot air enters the temperature of the auxiliary material bin A. According to the historical temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com