A roller heating device for textile

A heating device and roller technology, which is used in textile processing machine accessories, processing textile material drums, textiles and paper making, etc., can solve the problems that the cloth cannot be reciprocated, the cloth debris cannot be removed in time, and the impact of the subsequent use of the cloth can be solved. , to achieve the effect of improving the drying effect, improving the drying effect and avoiding the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

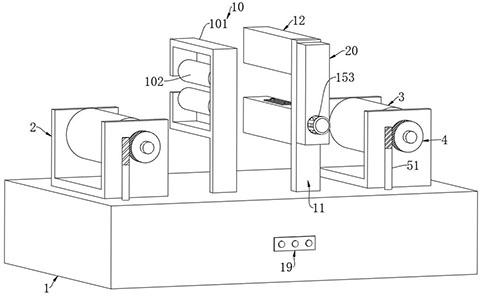

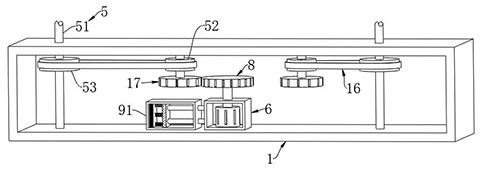

[0025] Such as Figure 1-5 As shown, a roller-type heating device for textiles includes a support platform 1, two brackets 2 are fixedly connected to the support platform 1, and retractable rollers 3 are rotatably connected to the two brackets 2. The rollers 3 are coaxially fixedly connected with the first worm gear 4 , the supporting platform 1 is hollow, and the supporting platform 1 is provided with a transmission mechanism 5 matched with the first worm gear 4 .

[0026] The transmission mechanism 5 includes a first worm 51, a first synchronous wheel 52 and a second synchronous wheel 53, the first worm 51 is rotatably arranged in the support table 1, and the upper end of the first worm 51 passes through the support table 1 and is connected to the corresponding first The worm gear 4 is meshed, the second synchronous wheel 53 is sleeved on the first worm 51, the first synchronous wheel 52 is rotatably arranged in the support table 1, and the synchronous belt 16 is passed betw...

Embodiment 2

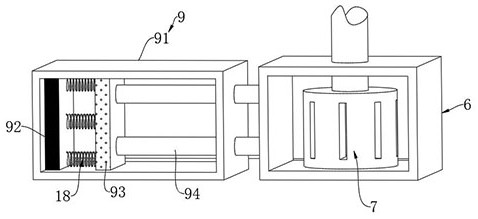

[0036] for Figure 6 The second embodiment shown is different from the first embodiment in that two T-shaped gear bars 23 are slidably connected in the dust removal box 12, and a plurality of stretching rods are fixedly connected between the upper end of the T-shaped gear rods 23 and the dust removal box 12. Spring 24, and the lower end of T-shaped gear bar 23 is fixedly connected with vibrating ball 25, and the incomplete gear 26 that is meshed with T-shaped tooth bar 23 is sleeved on the second worm screw 141, through the T-shaped tooth bar 23 that is set, pull The mutual cooperation of the extension spring 24 and the incomplete gear 26 enables the T-shaped gear rod 23 to cooperate with the rotation and reciprocating sliding of the second worm 141, so that the T-shaped gear rod 23 can drive the vibrating ball 25 to strike the cloth back and forth, causing the cloth to vibrate. And then make the cloth scraps that may adhere on the cloth be vibrated, so that the suction fan 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com