Patents

Literature

126results about How to "Even drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

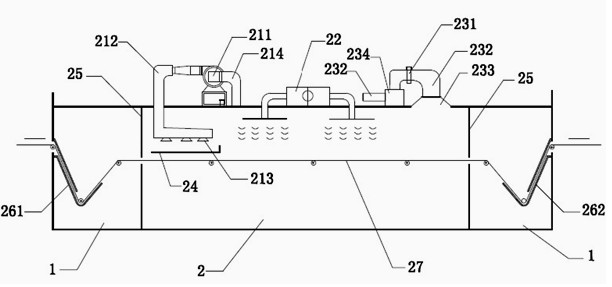

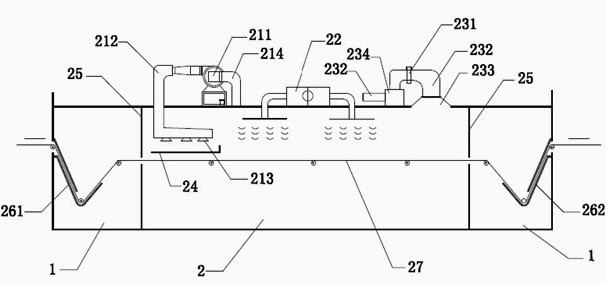

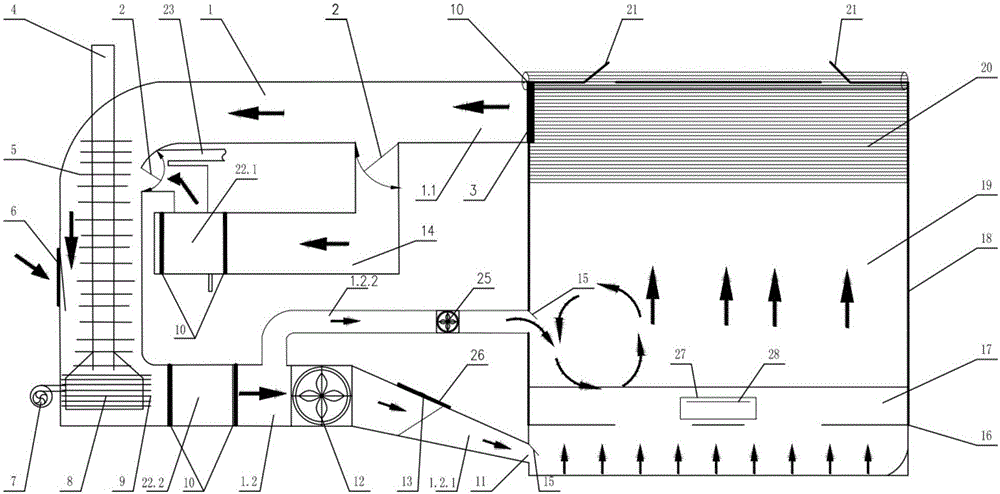

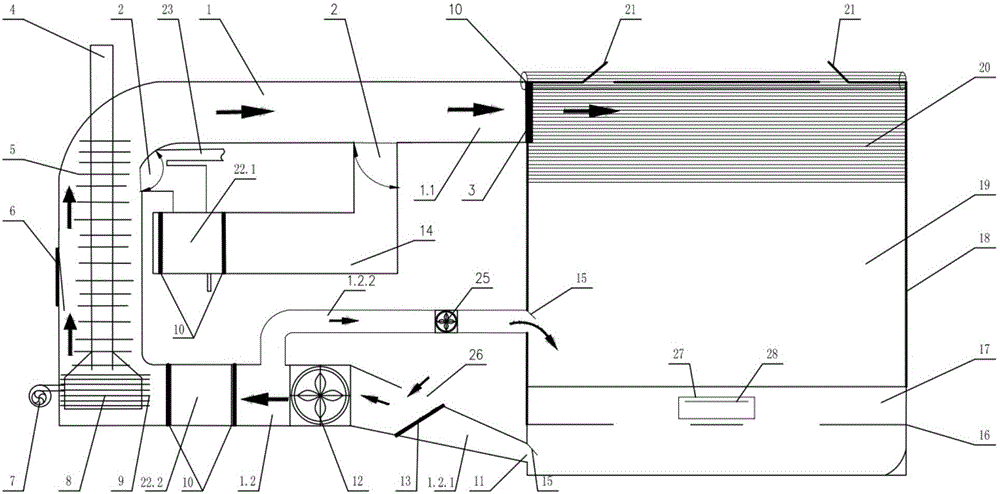

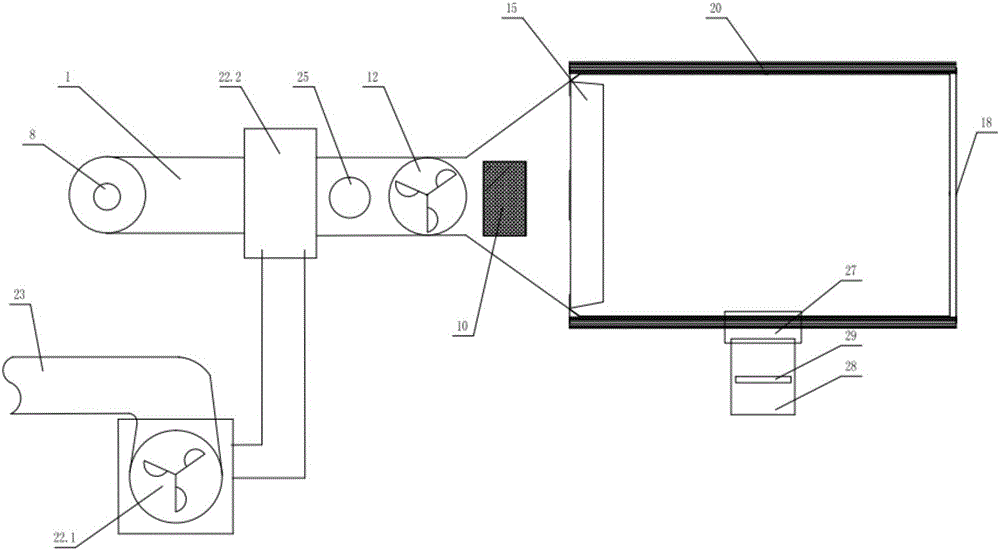

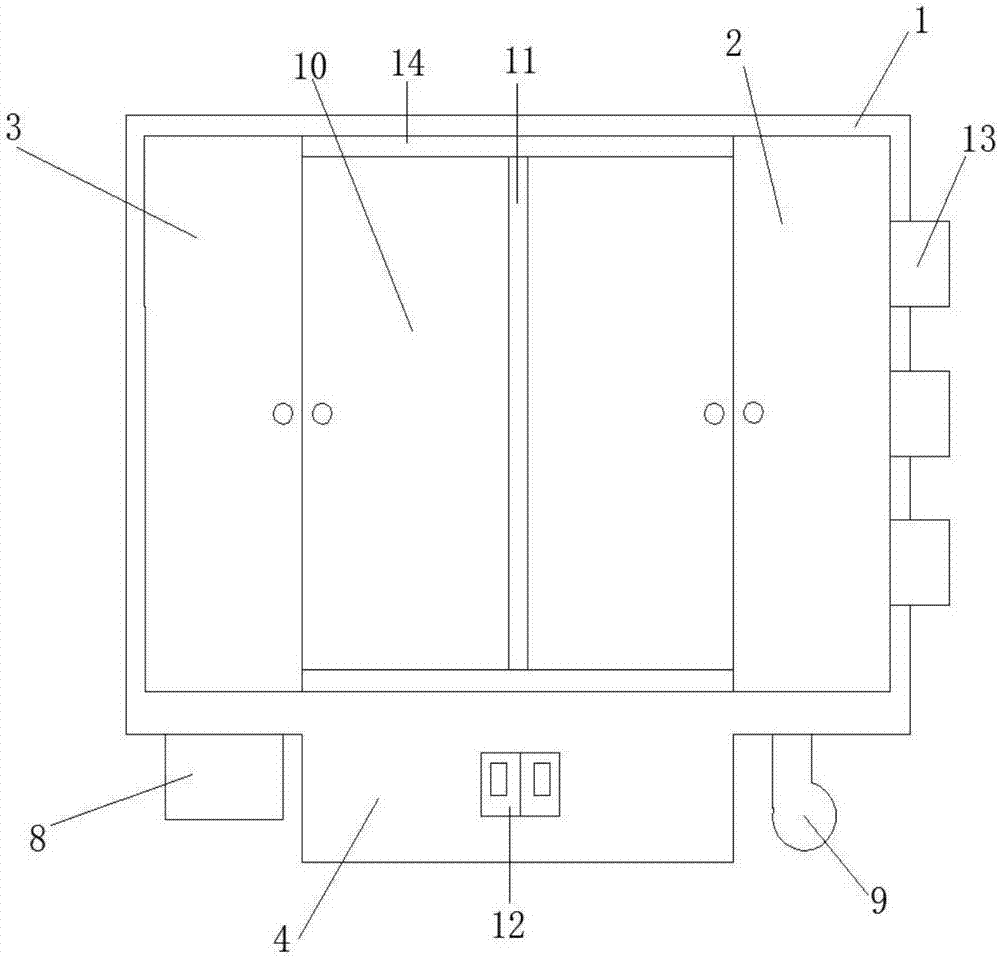

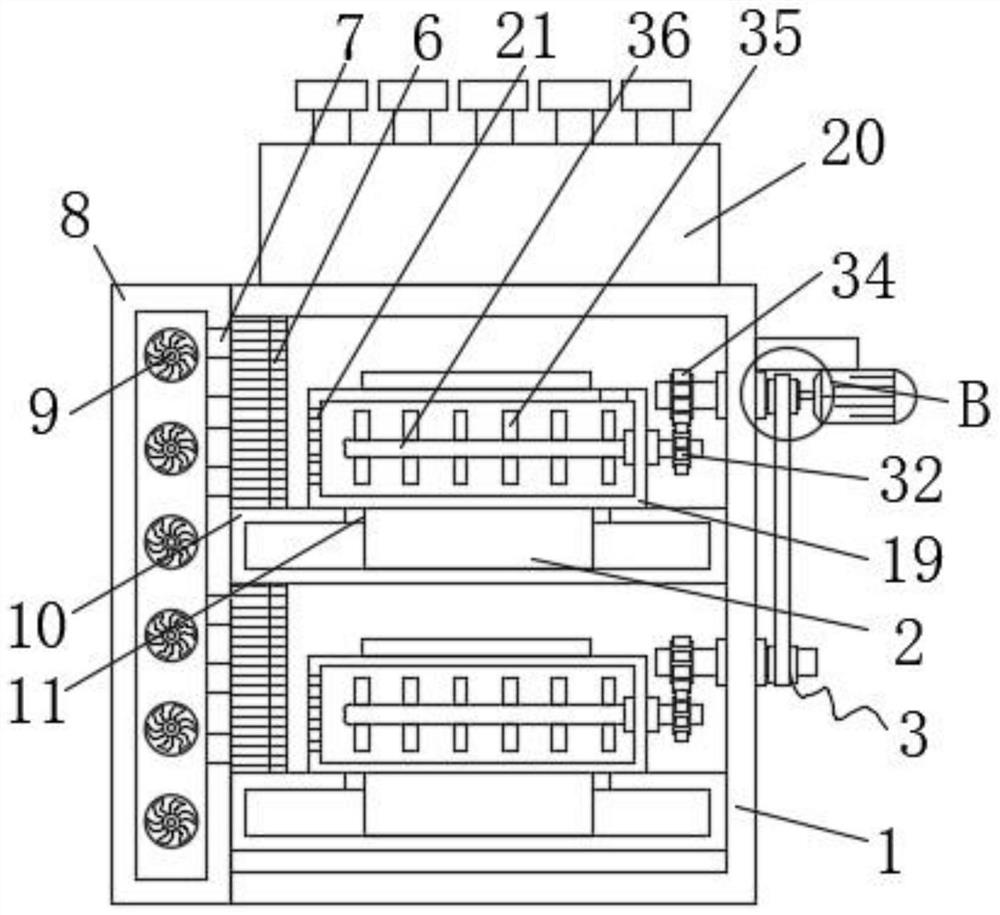

Intelligent hot-air drying control device

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

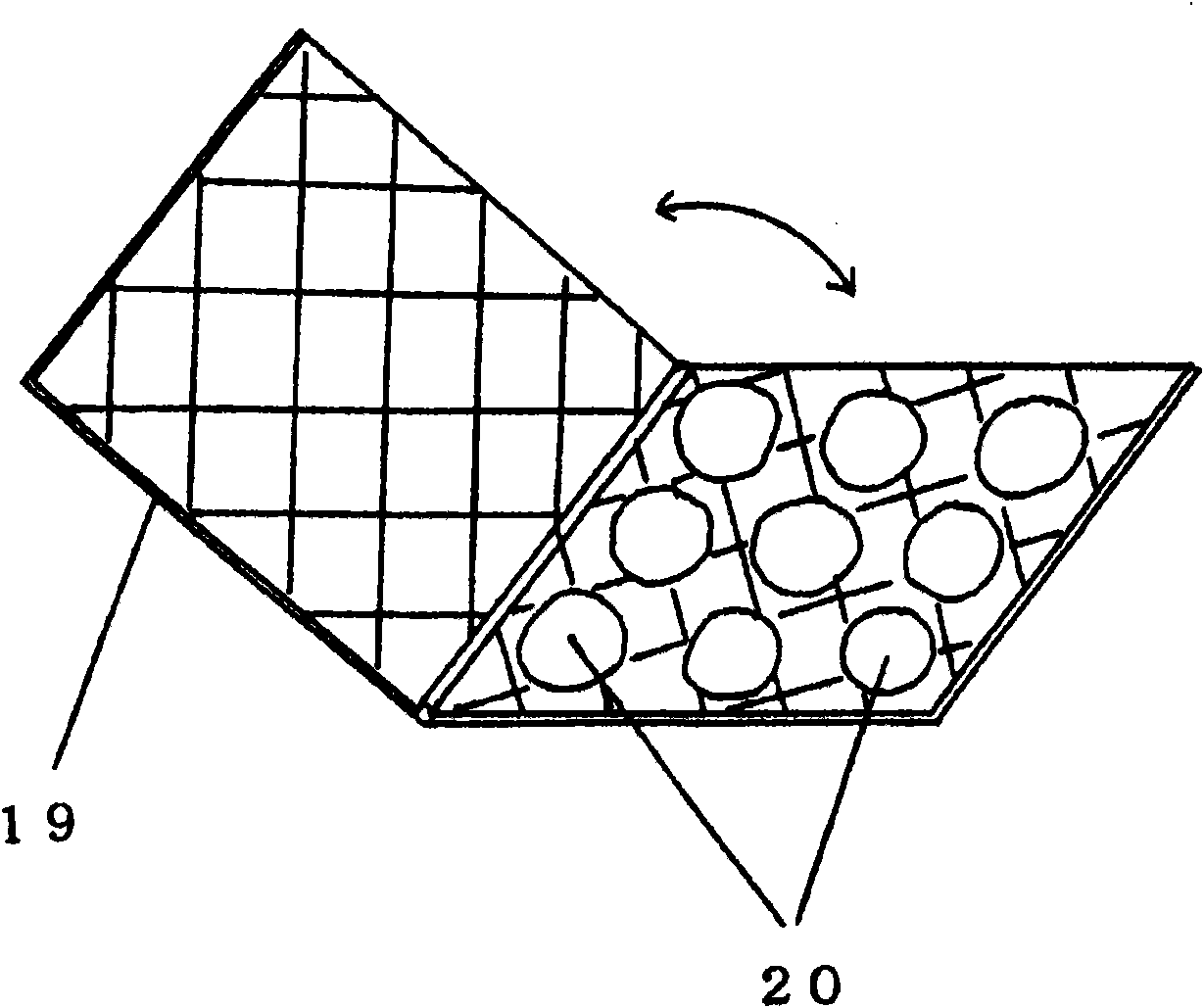

Preparation method of dried day lily

ActiveCN103918775AMaintain nutrientsBalance internal and external moistureFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationCooking & bakingFlavor

The invention belongs to the field of food processing, and particularly relates to a preparation method of dried day lily. The dried day lily is prepared by the working procedures of with fresh day lily buds as raw materials, destemming, rinsing by running water, leaching, putting into dishes, carrying out microwave heating for deactivating enzymes, cooling, carrying out once microwave drying for dehydrating, cooling, carrying out secondary microwave drying for dehydrating, cooling, carrying out three-segment far infrared rotary baking, and packaging. According to the invention, microwave heating for deactivation of enzymes for three times, dehydration and three-segment far infrared rotary baking and drying modes are adopted, the day lily is subjected to enzyme deactivation, dehydration and drying, and sterilization, and the prepared dried day lily can be directly eaten or can be eaten after rehydrated. The method provided by the invention is beneficial to preservation of the dried day lily, also keeps the color, fragrance, flavor and shape of the day lily well, and effectively solves the problem of nutritional ingredient loss in the processes of deactivating enzymes and drying. The dried day lily prepared by the method provided by the invention is straight and uniform in shape, is golden yellow and green in color, and can be preserved for 18 months with perfect packages under the normal temperature condition.

Owner:渠县琦鑫源花卉苗木开发有限公司

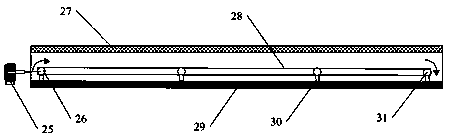

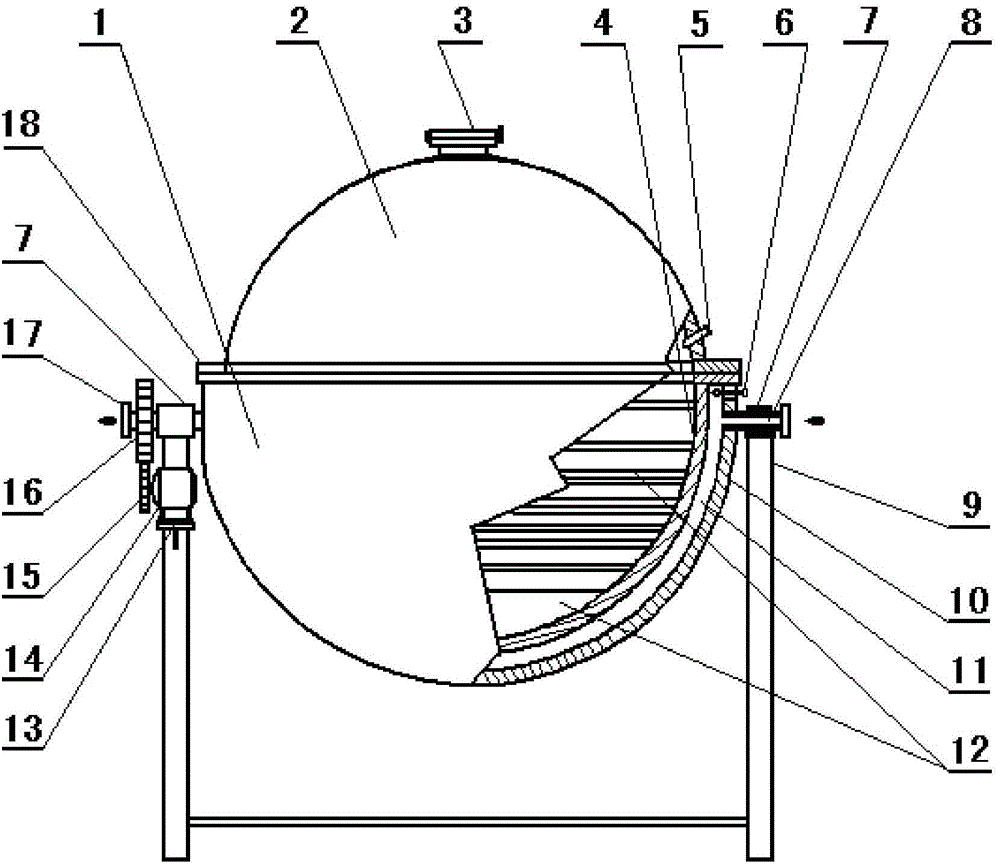

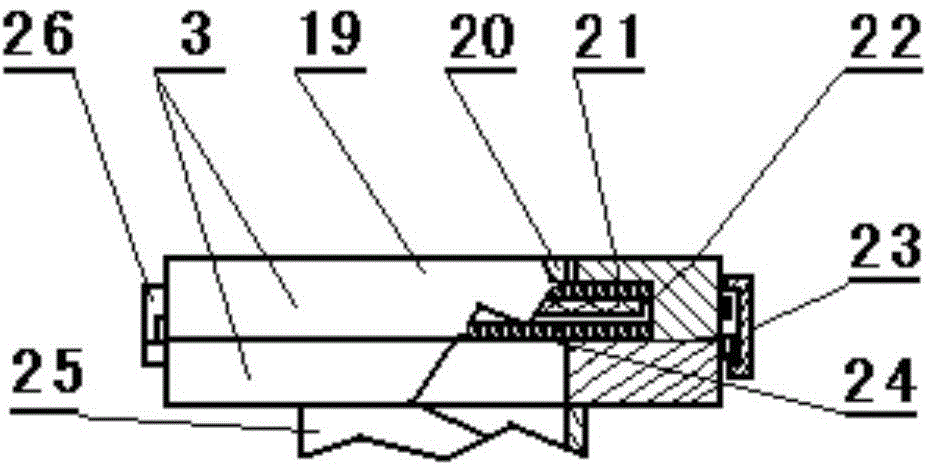

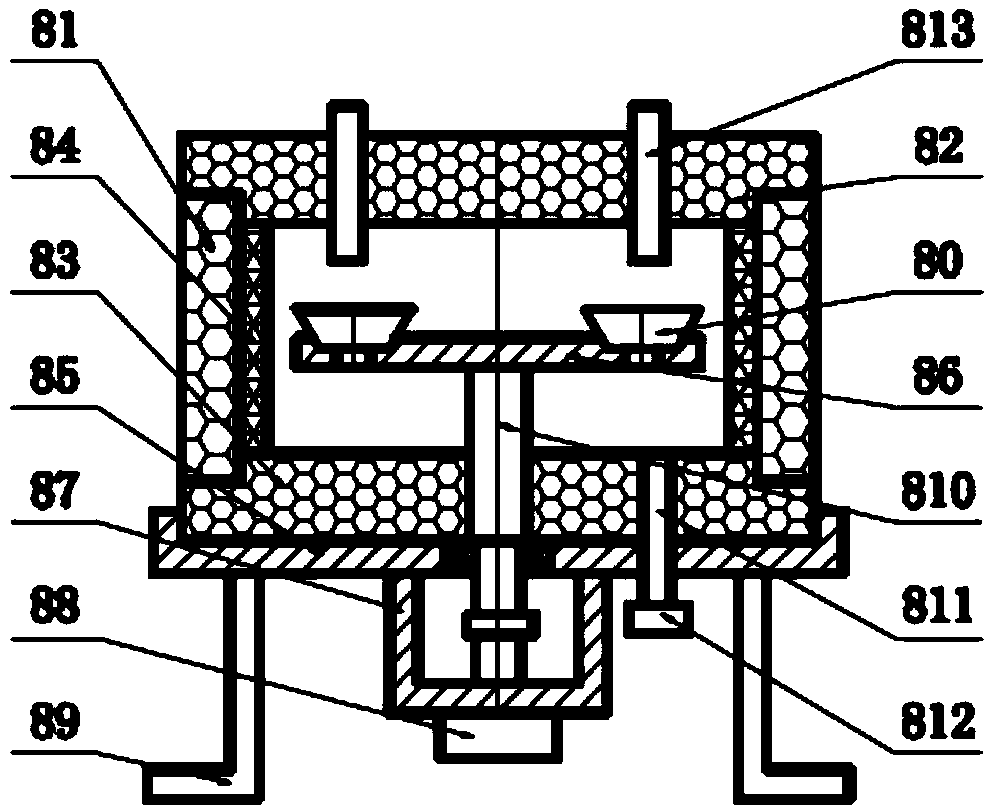

High-nitrogen steel pressure welding device and method for welding high-nitrogen steel by using same

InactiveCN106346171AImprove mechanical propertiesGood application effectWelding/cutting auxillary devicesAuxillary welding devicesWelding power supplyMixing chamber

The invention discloses a high-nitrogen steel pressurized welding device and a method for welding high-nitrogen steel by using the device, comprising an airtight welding chamber, a gas mixing chamber, and a vacuum pump; the airtight welding chamber communicates with the gas mixing chamber and the vacuum pump respectively through gas pipelines ;The airtight welding room is equipped with bracket, welding power supply, welding wire frame, wire feeding mechanism and welding torch; the cooling plate is arranged above the bracket; the welding wire sleeve is connected under the wire feeding mechanism; the welding power supply is connected with the welding wire sleeve and the bracket through electrode wires respectively The cold source is set in the cooling plate; the welding base metal is placed on the cooling plate; the raw material gas is mixed in the gas mixing chamber and then input into the airtight welding room; the position of the welding wire and the welding torch is adjusted, the welding power is turned on, and welding is carried out. By controlling the system shielding gas composition, system total pressure and cooling parameters, the nitrogen content in the high-nitrogen steel weld can be fixed, and the mechanical properties of the high-nitrogen steel weld can be improved. Using the system of the present invention for high-nitrogen steel welding, the nitrogen content of the weld can reach More than 95% of the base material.

Owner:SUZHOU UNIV

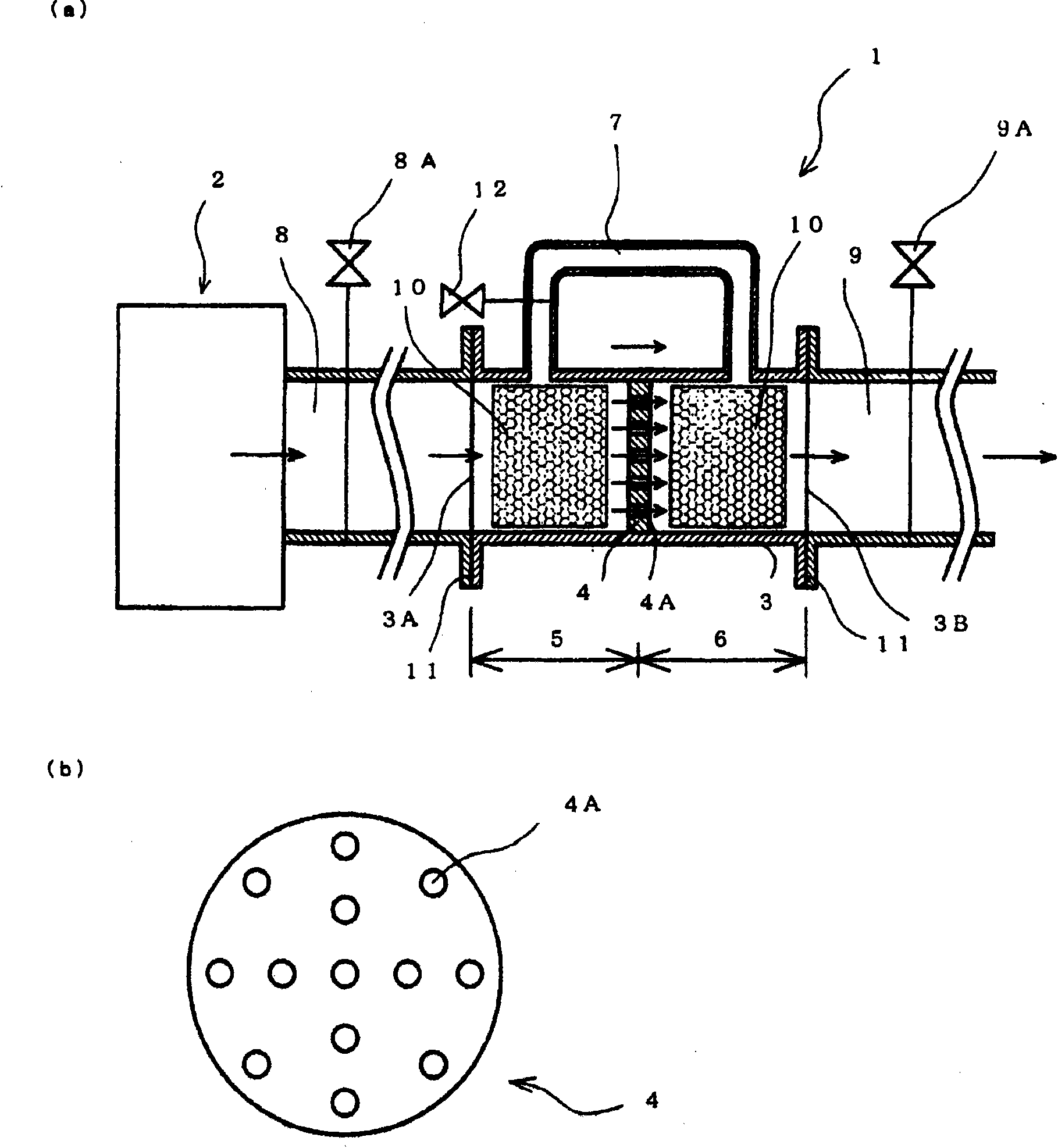

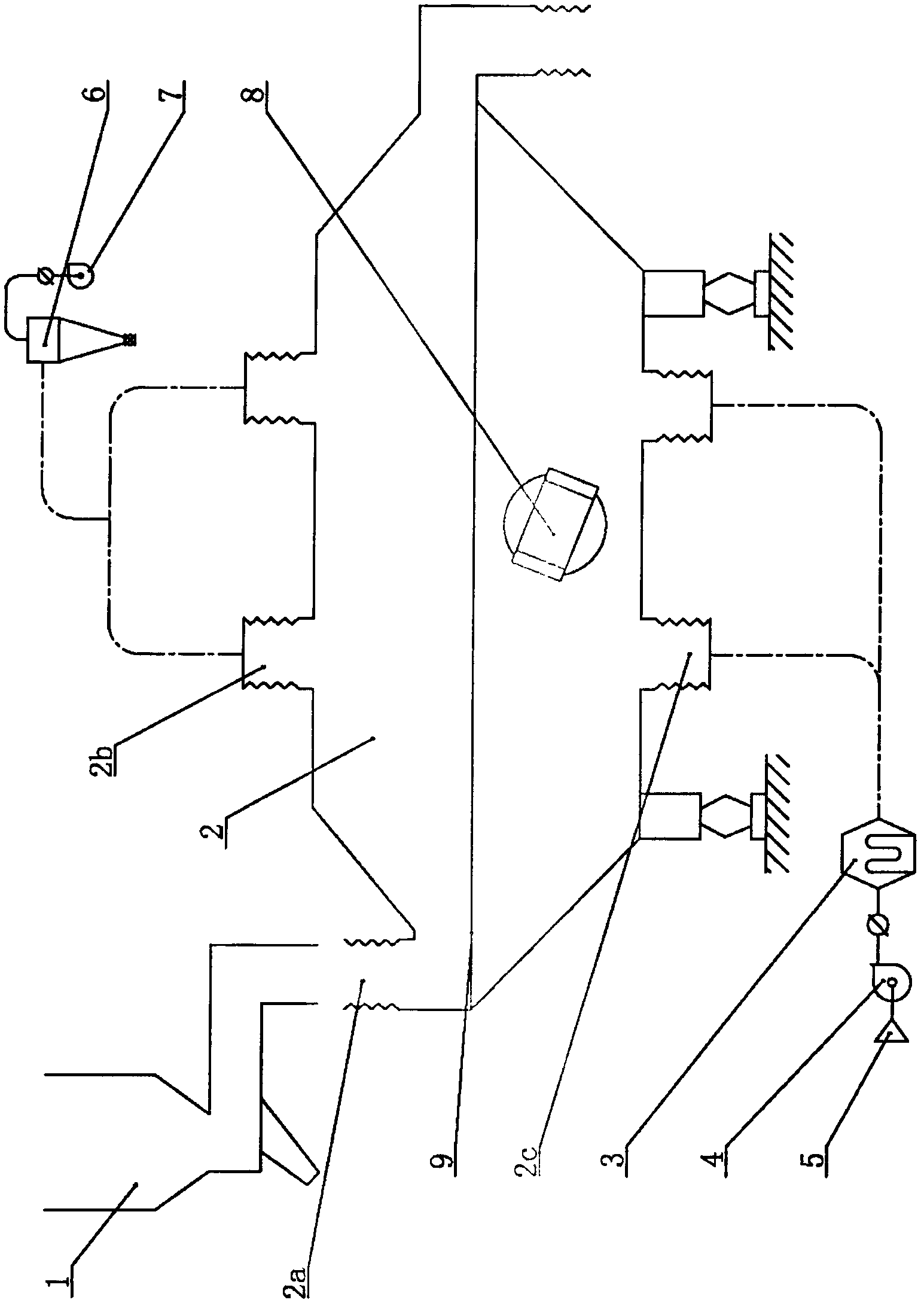

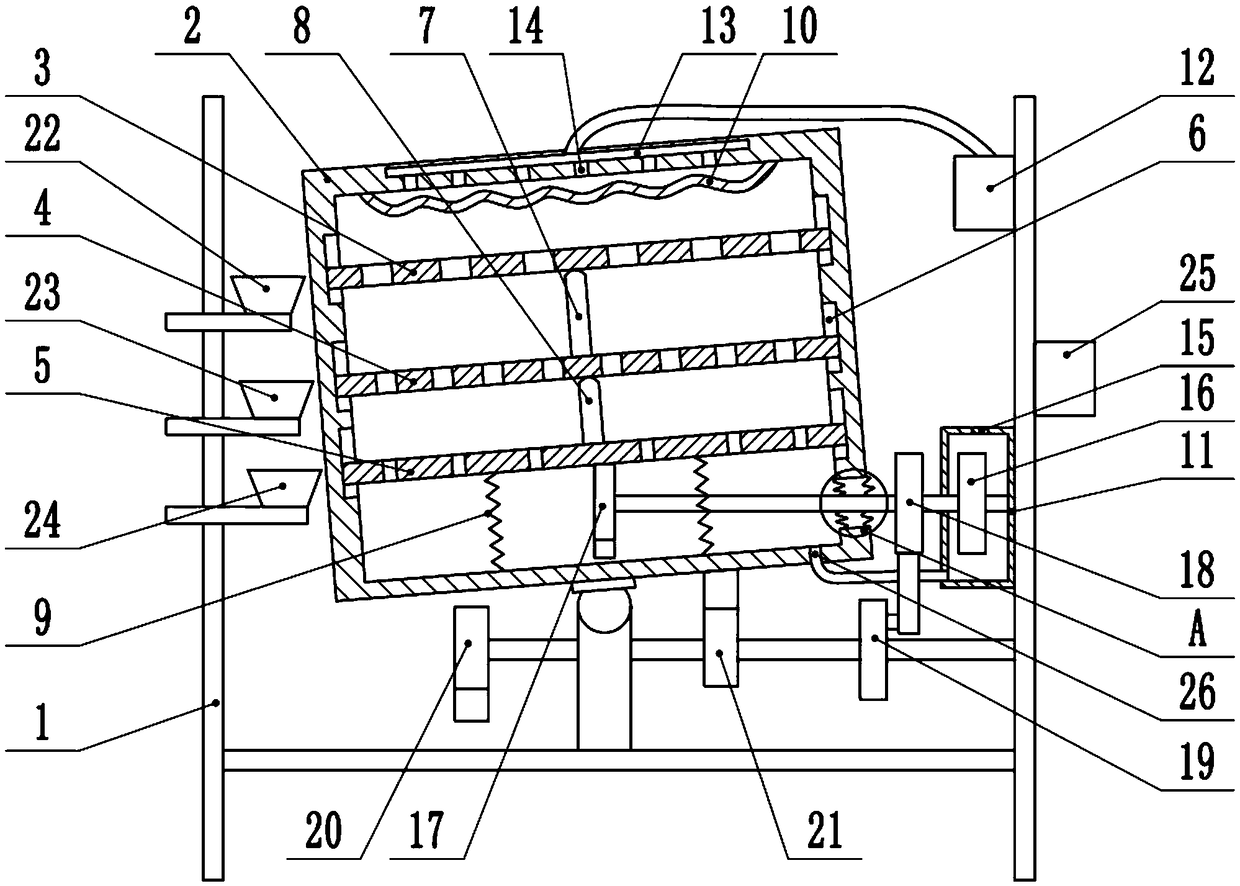

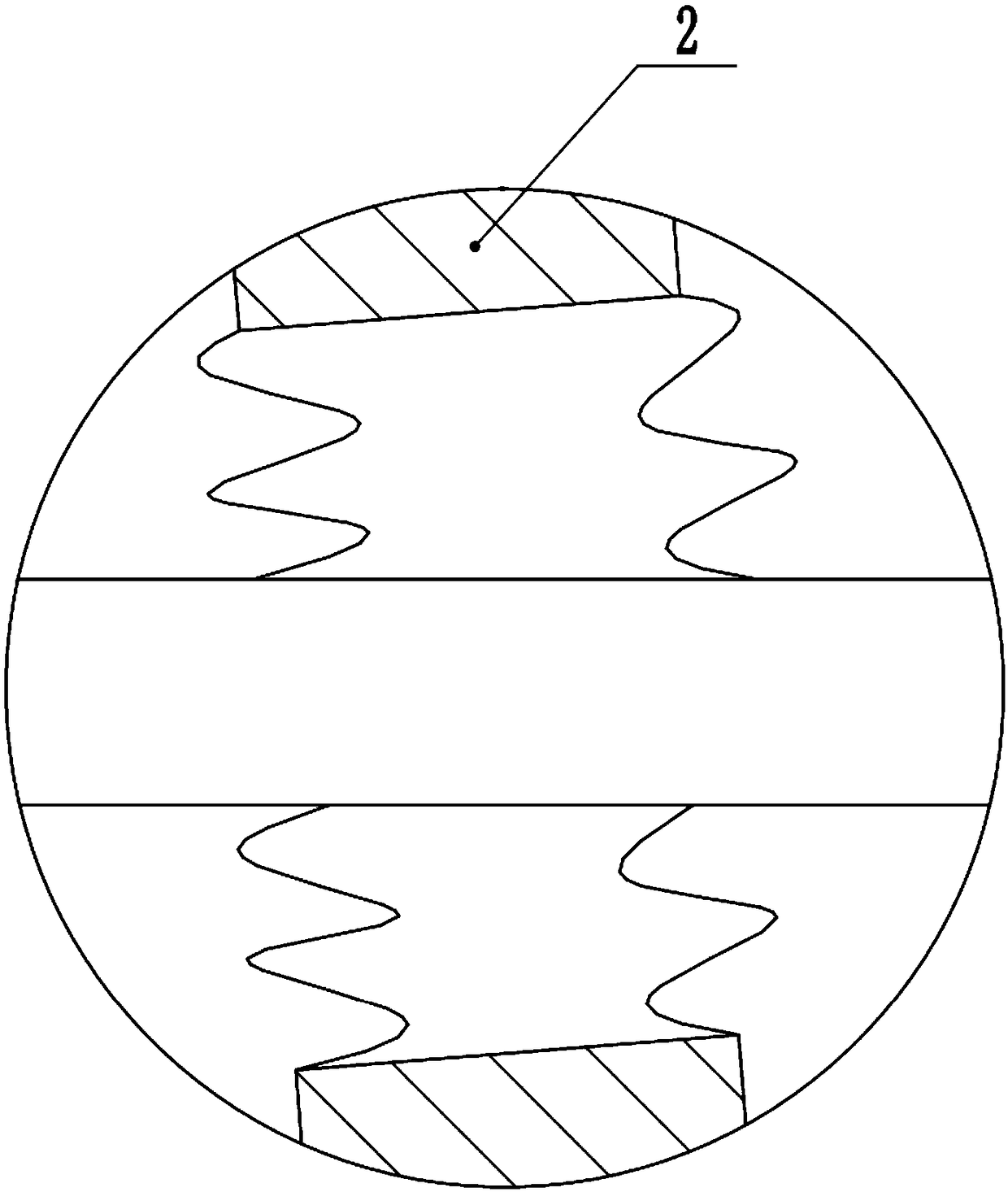

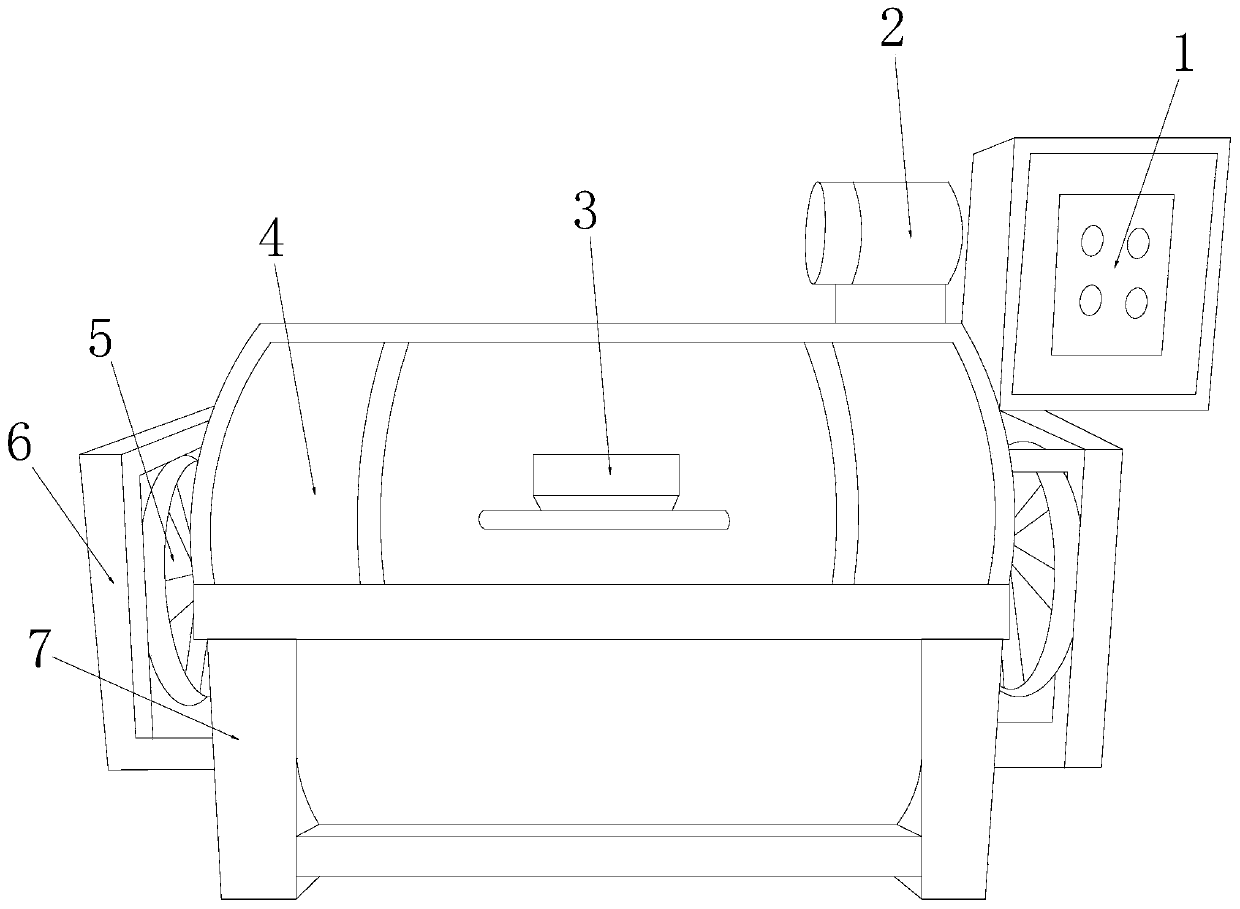

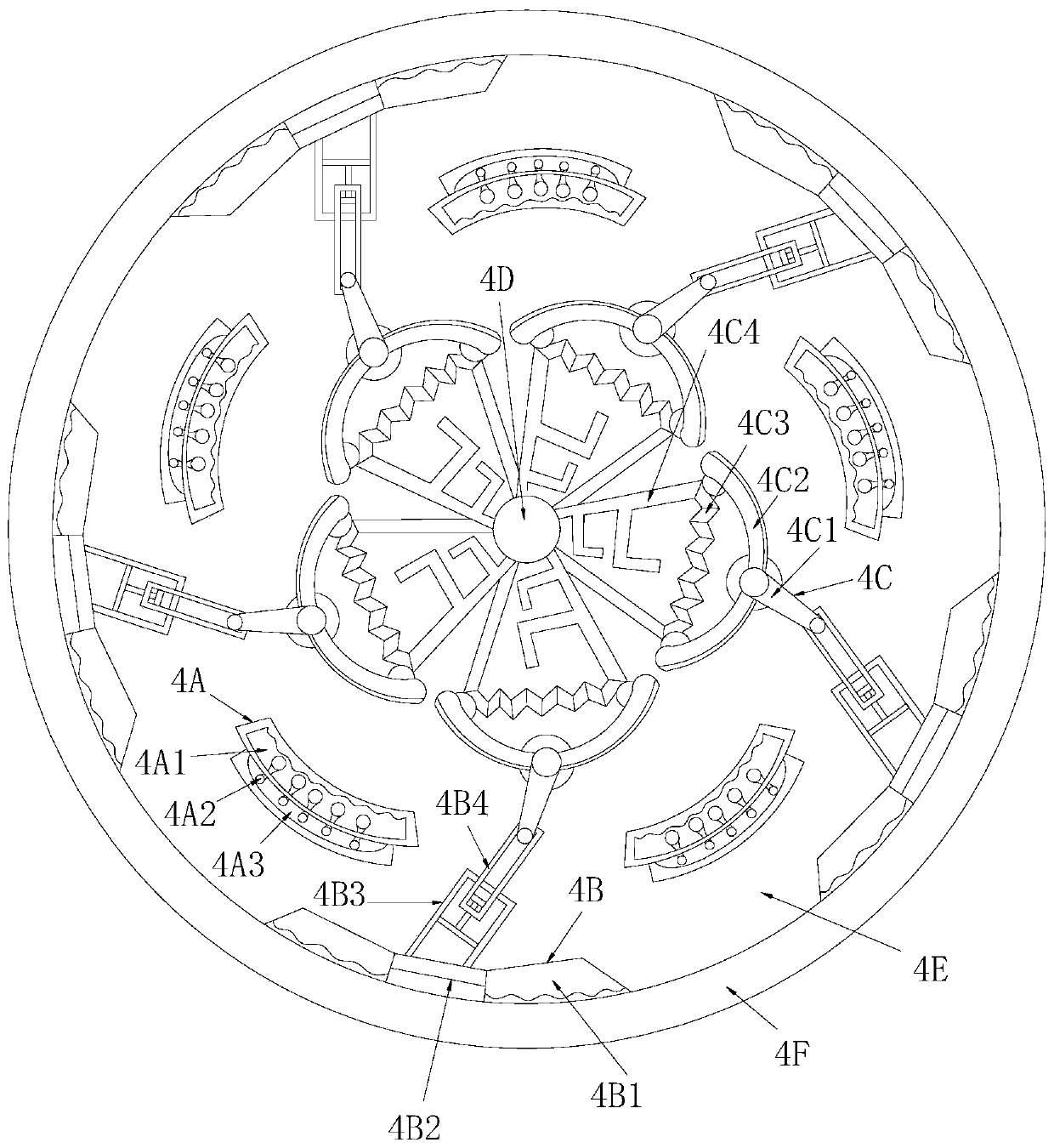

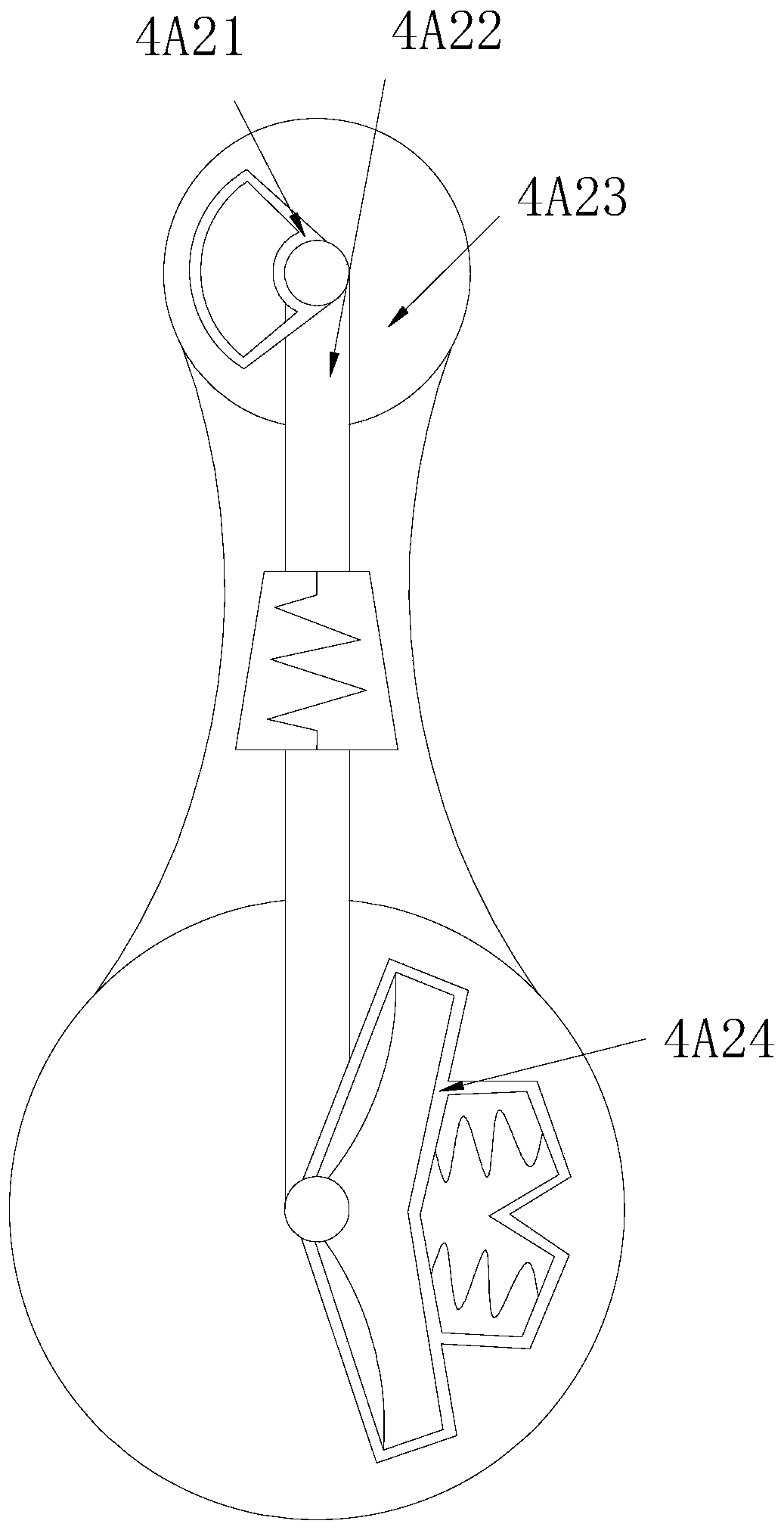

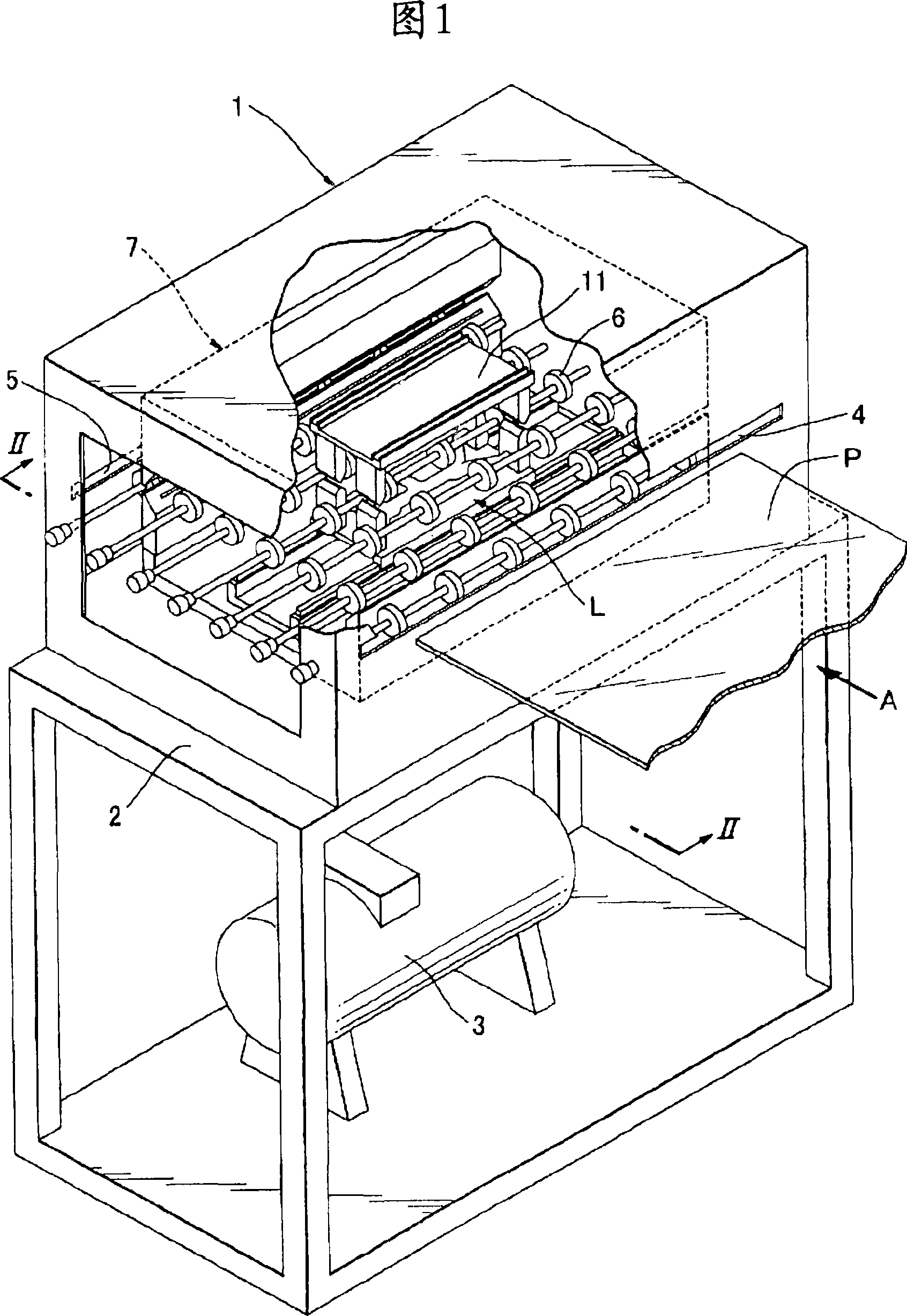

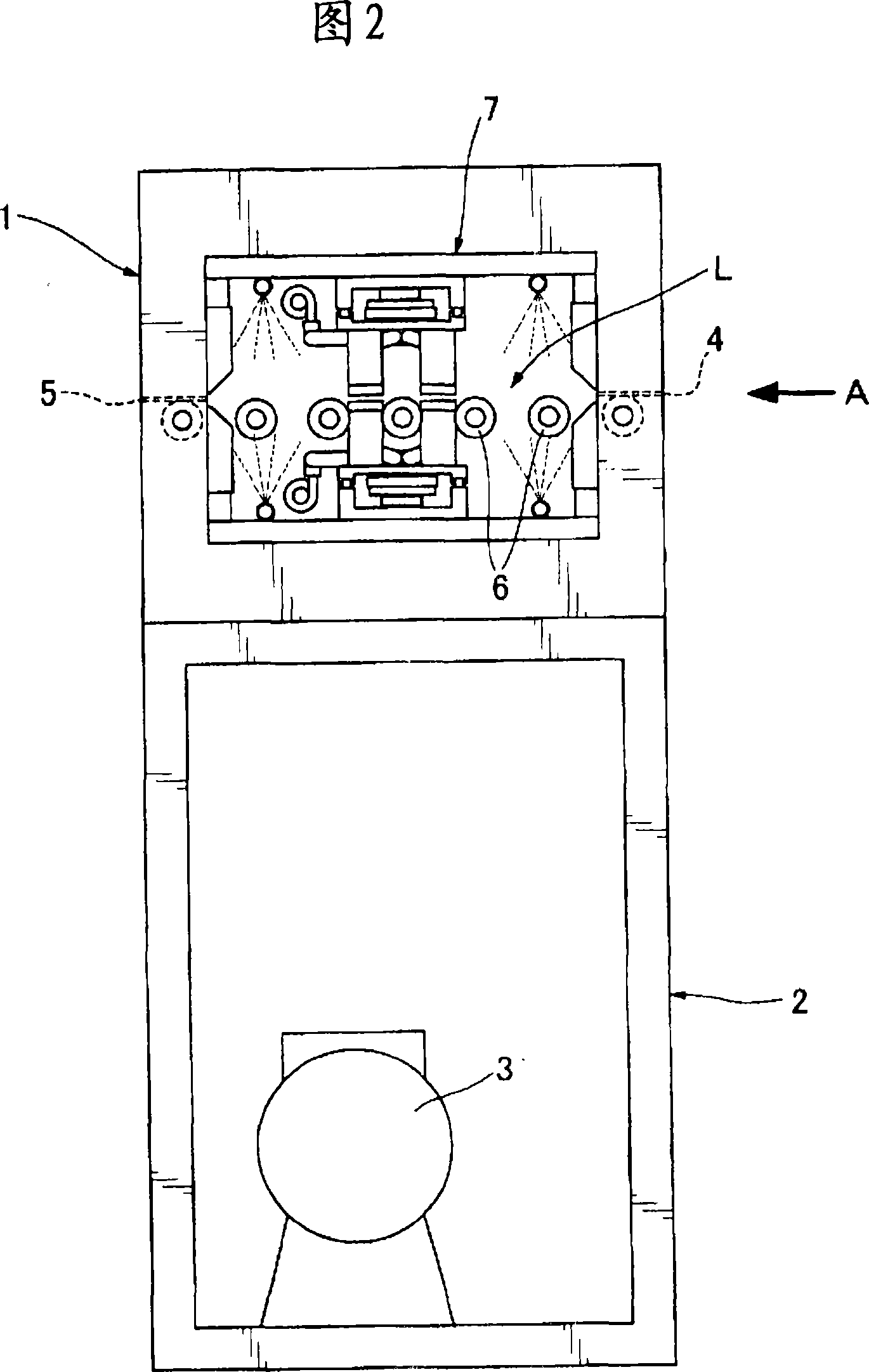

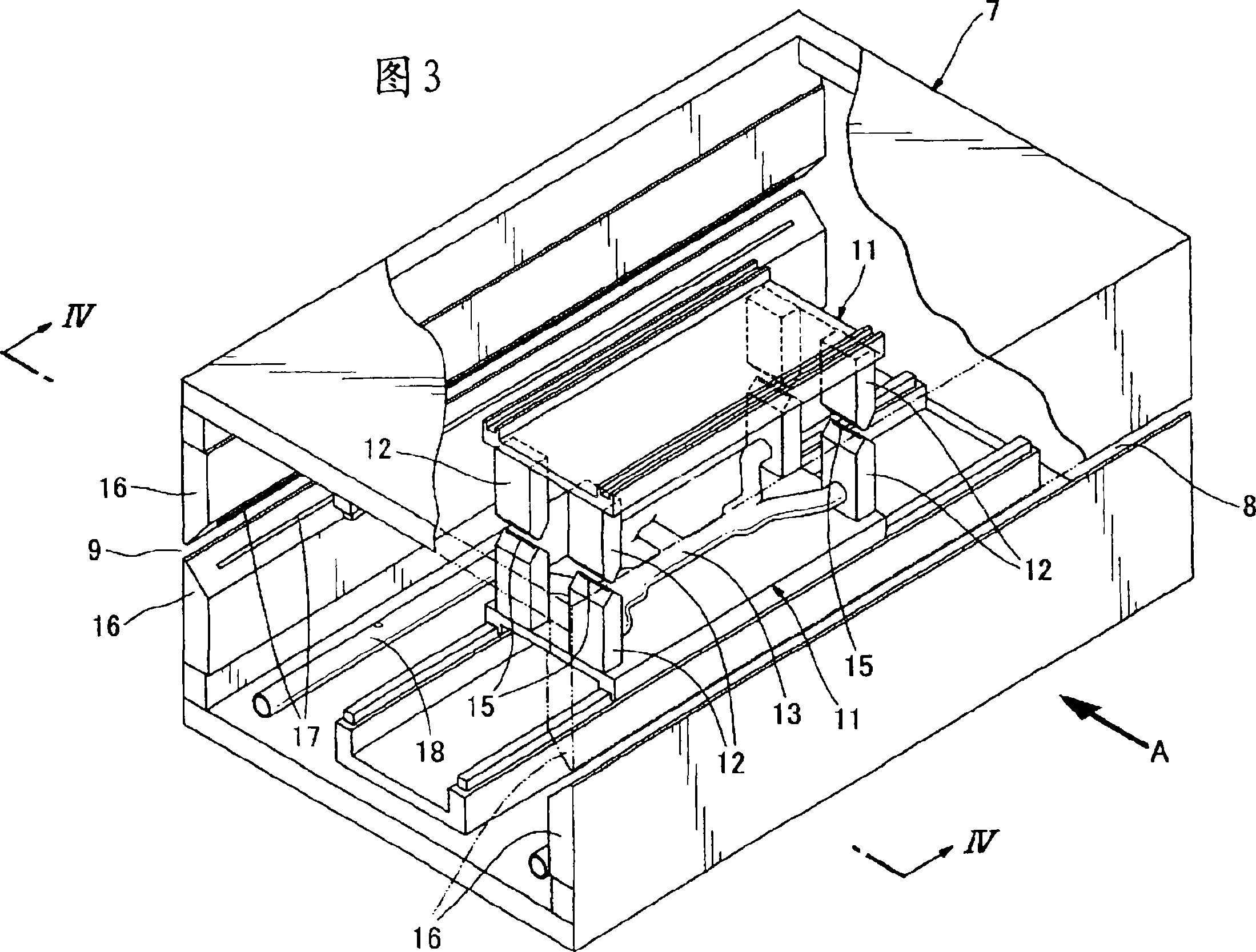

Overheated compressed hot air stream producing method and device, object processed by overheated compressed hot air stream, processing method, and processing apparatus

InactiveCN101910748ADry evenlyEven drying effectLiquid fuel feeder/distributionDrying solid materials with heatWater qualityEngineering

A method and device for producing a minus-ion air similar to a heated compressed hot air stream, electromagnetic waves in the far-infrared and submilimeter region (hereinafter referred to as ''terahertz wave'') by regulating the discharge pressure and the discharge temperature. The device is excellent in versatility, small in size, and low in cost. An object processed by using the method and device, a processing method, and a processing apparatus are also provided. Air is sent from a blower or an air compressor (2) through an air pipe (8) to a heated compressed air regulator (vessel (3)). The air sealed in the heated compressed airregulator (1) regulated under a predetermined discharge pressure (for example, 30 kPa to 150 kPa) and at a temperature (40 DEG C to 250 DEG C) is passed through a through hole (4A) of a circular plate (4) to produce a heated compressed air. In the produced hot air stream, a resonance electromagnetic wave resonating with the natural frequency of the water molecule is generated by a terahertz wave and a generated thermal shock wave, thereby the hydrogen bond of the water molecules in the air is cut, and electrons are released from hydrogen atoms, thus also producing a minus-ion air stream. A processed object, a processing method, and a processing apparatus are so constituted that the produced hot air stream is used for drying, production of a functional water by exposing water to the hot air stream, production of an aqueous fuel, beauty / health appliances, air / water quality improvement devices, combustion efficiency enhancement devices for internal combustion engines, and so forth.

Owner:SUZUYAELECTRIC SERVICE

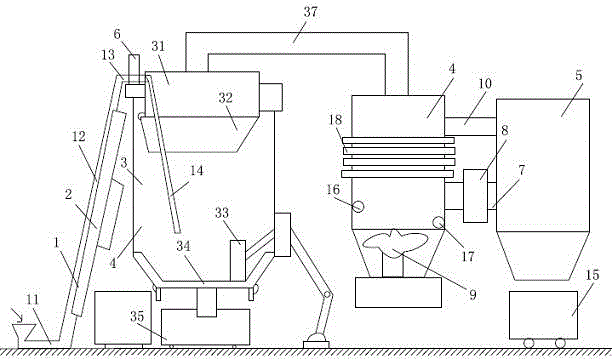

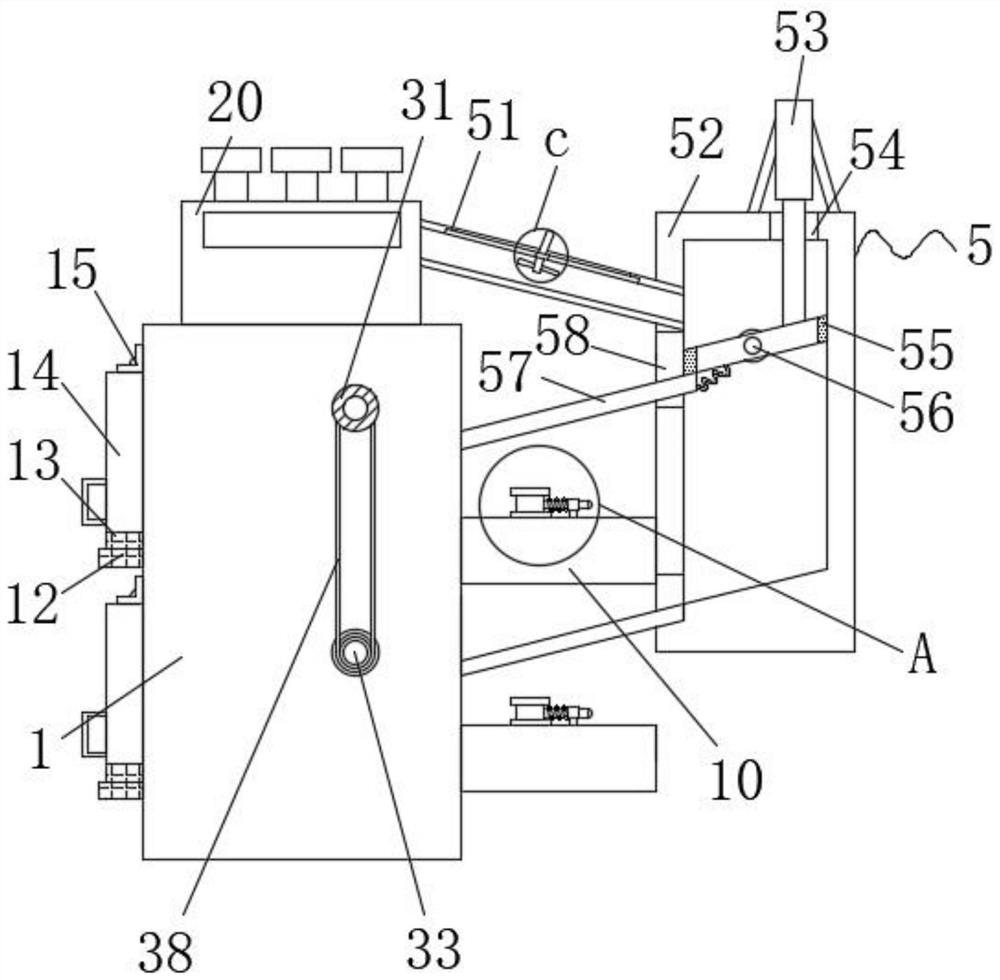

Drying cooler of fluidized bed

InactiveCN103017498AImprove efficiencyHigh efficiency drying effectDrying using combination processesDrying gas arrangementsFluidized bed dryingAir filter

The invention discloses a drying cooler of a fluidized bed in the field of feed processing devices. The drying cooler comprises a material feeder connected with a feeding hole of a drying bin, wherein the drying bin is internally provided with a conveyer belt which is provided with air holes, a vibrator controlling the vibration of the conveyer belt is arranged below the conveying belt in the drying bin, an air inlet is formed in the lower part of the drying bin, an air outlet is in the upper part of the drying bin, the air outlet is connected with an exhaust fan through a deduster, the air inlet is connected with an outlet of a heat exchanger, an inlet of the heat exchanger is connected with an outlet of an air feeder, and an inlet of the air feeder is connected with an air filter. According to the invention, by means of the working action of vibration and hot air, materials advance in a wavy manner on the conveyer belt, so that the heat transfer effect is good, the drying efficiency is high, the humidity distribution is uniform, and the drying cooler is simple in structure and lower in investment cost and can be applied to drying of granular materials.

Owner:陶仁

Coating drying technology and device thereof

The invention discloses a coating drying technology and device thereof. The technology is used for drying a coating by combining a microwave drying technology with a circulating air-supply type drying technology, and a mode of heating the microwave dried coating from inside to outside is combined with a mode of drying the microwave dried coating with circulating air from outside to inside so that the purpose of more rapidly thoroughly drying the coating is achieved. The coating drying technology disclosed in the invention has the characteristics of uniform heating, high drying speed, high heat efficiency, good product quality and the like; and the circulating air can be used for immediately eliminating a solvent evaporated by the coating in a microwave heating process, thus the problems of local overheating caused by high microwave heating speed and incapability of immediately eliminating the solvent is avoided, the quality of the coating is ensured, and the thorough and uniform drying effect is obtained. The device has simple structure, can obtain better drying effect of the coating, and can improve the drying speed, thereby greatly saving the production period, improving the production efficiency and being capable of effectively avoiding microwave leakage.

Owner:惠州市德赛聚能电池有限公司

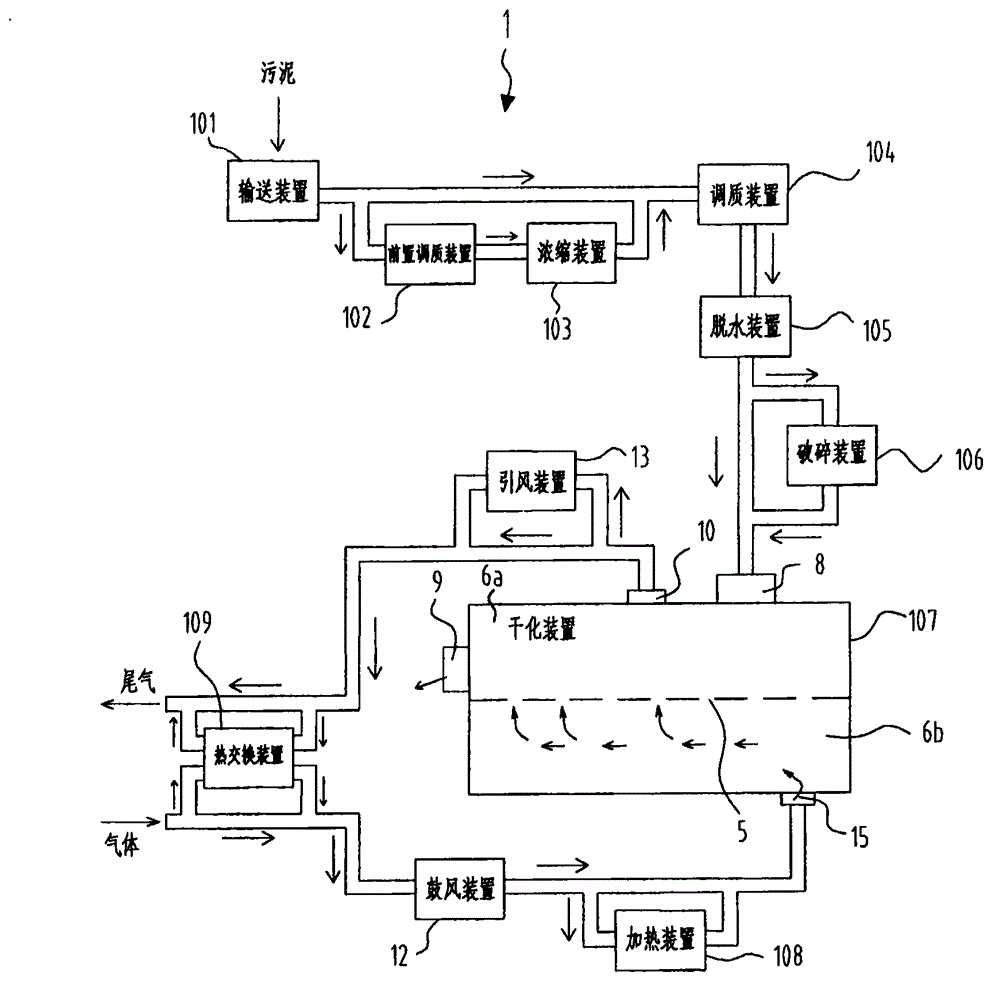

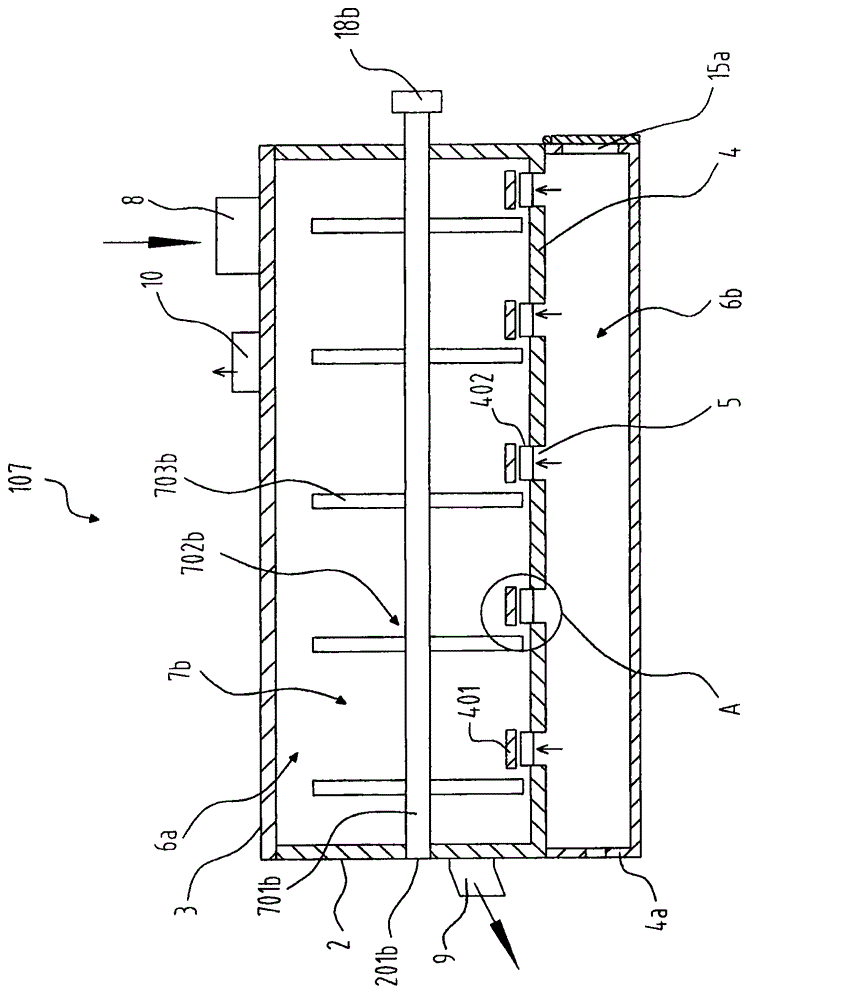

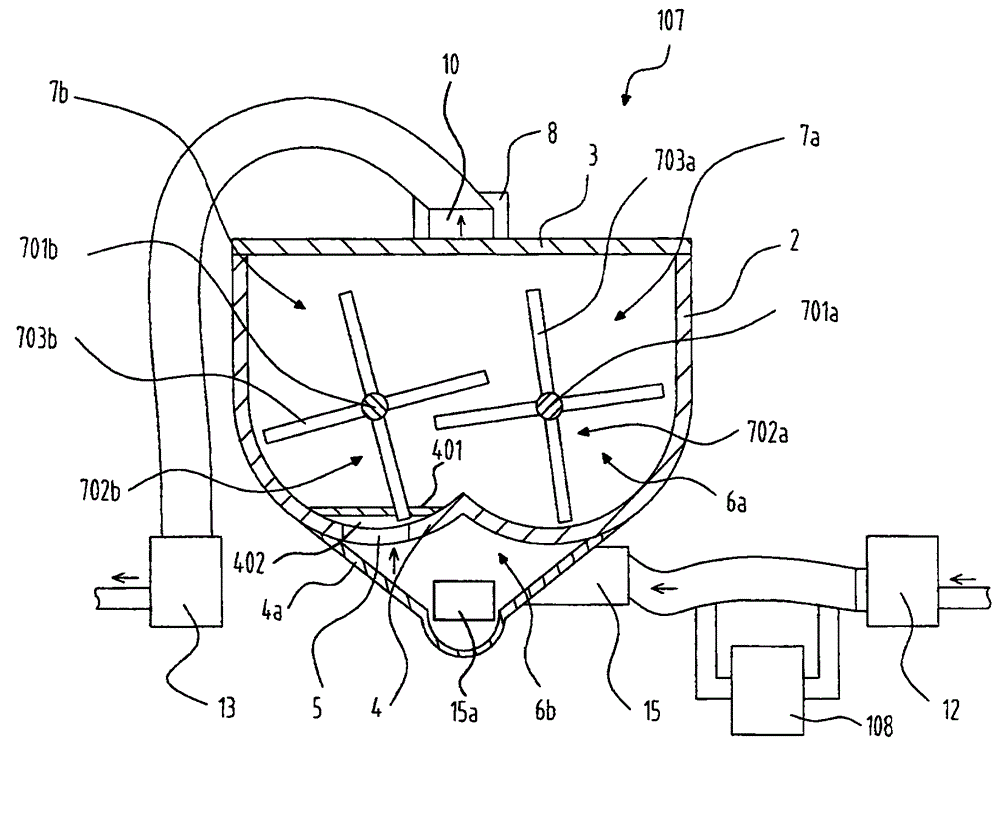

Sludge drying system and sludge drying method

PendingCN105819652AReduce moisture contentMore separationSludge treatment by de-watering/drying/thickeningDrying machinesSludgeDehydration

The invention provides a sludge drying system, which comprises a conveying apparatus, a tempering apparatus, a dehydration apparatus and a drying apparatus. The drying apparatus comprises a housing, the housing comprises a separation wall used for dividing the housing into a first drying chamber and a second drying chamber, and a communication port is formed on the separation wall and used for communicating the first drying chamber with the second drying chamber. A feed inlet and an air outlet are arranged on the upper part of the first drying chamber, and a discharge hatch is arranged on the circumferential wall of the first drying chamber. An air inlet is arranged on the circumferential wall of the second drying chamber. A stirring apparatus is arranged in the first drying chamber, wherein, the stirring apparatus comprises a rotation shaft and a stirring component fixed on the rotation shaft, and the stirring component is used for scraping the sludge near the communication port. An air blast apparatus is capable of communicating with the second drying chamber when passes through the air inlet. The invention also provides a sludge drying method by using the sludge drying system.

Owner:广州正晟科技有限公司

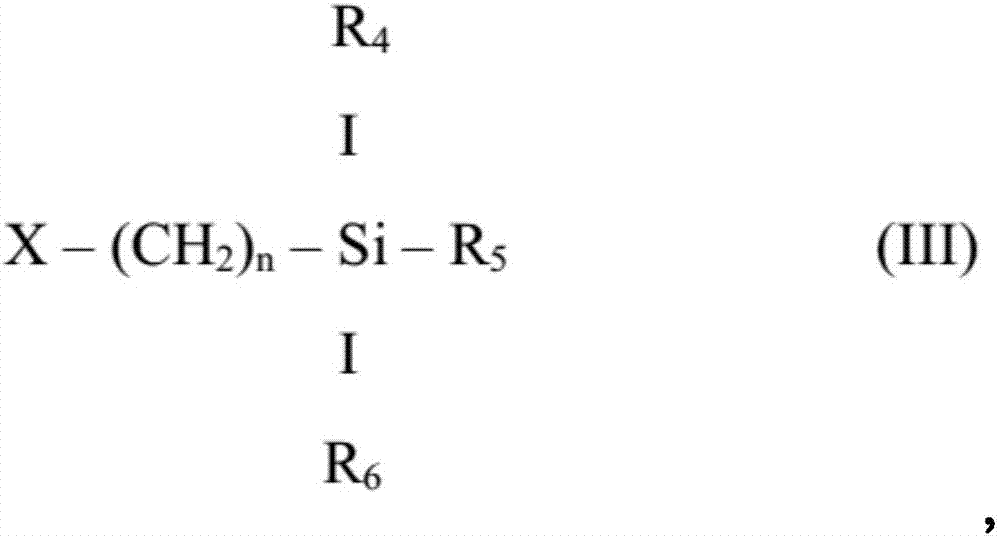

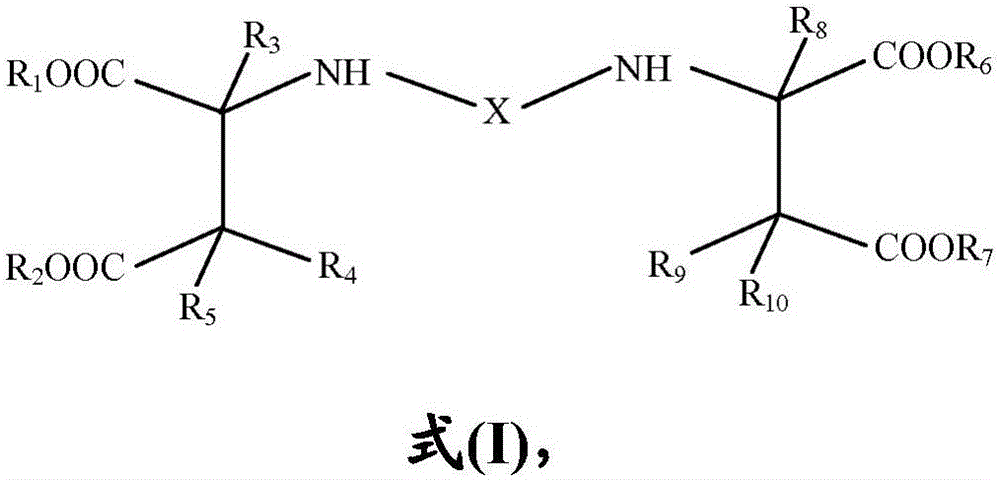

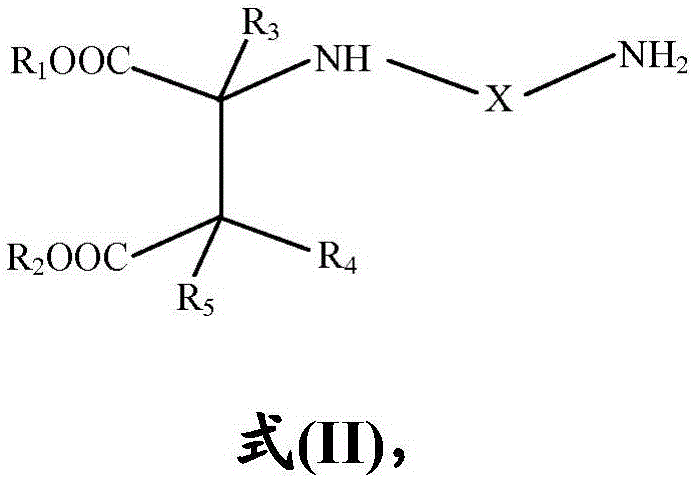

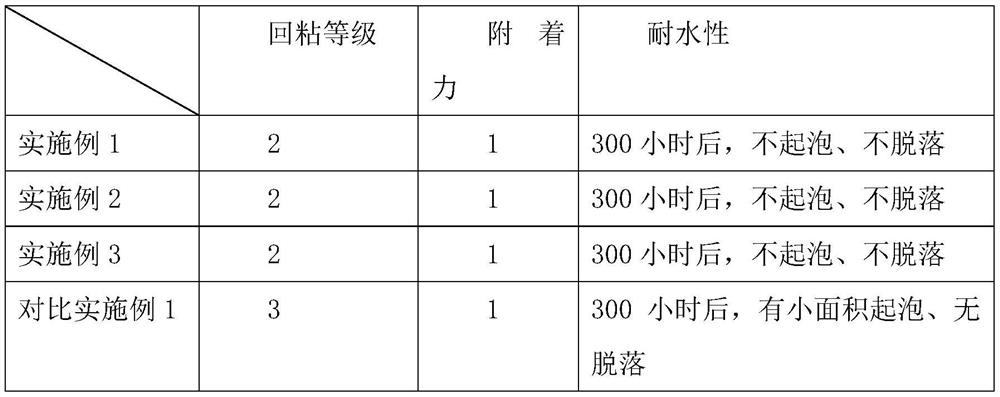

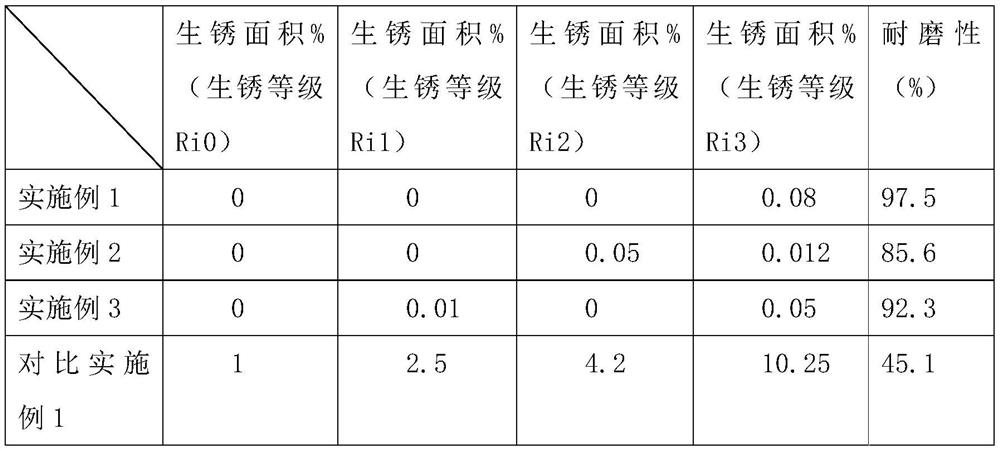

Coating compositions including a polyisocyanate chain extended NH functional pre-polymer

ActiveCN106947372AEven drying effectExcellent mechanical propertiesPolyurea/polyurethane coatingsPrepolymerPolymer chemistry

This disclosure relates to a coating composition including a polyisocyanate chain extended NH functional pre-polymer, a method for coating of a metallic or plastic substrate as well as the use of the polyisocyanate chain extended NH functional pre-polymer for improving the adhesion of a coating composition on a metallic or plastic substrate and / or for improving the adhesion between two adjacent layers of multiple layers and the use of the coating composition in a one-component coating composition or two-component coating composition.

Owner:AXALTA COATING SYST GMBH

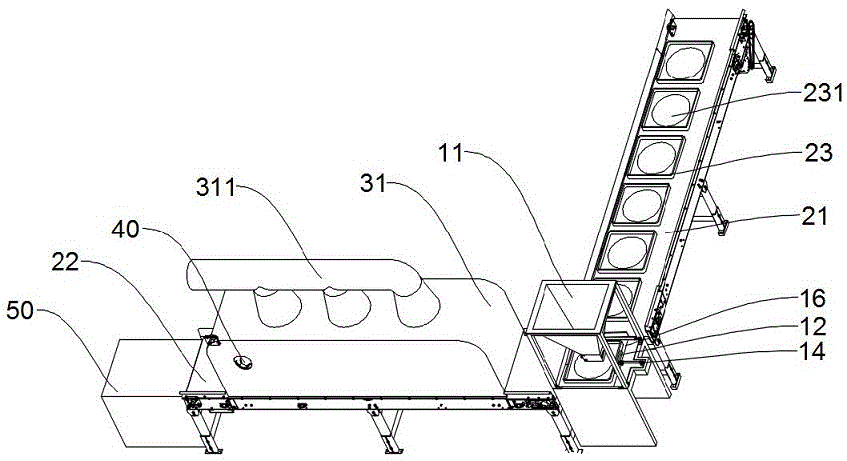

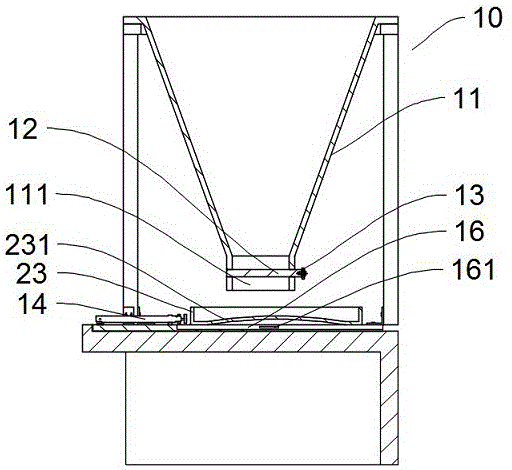

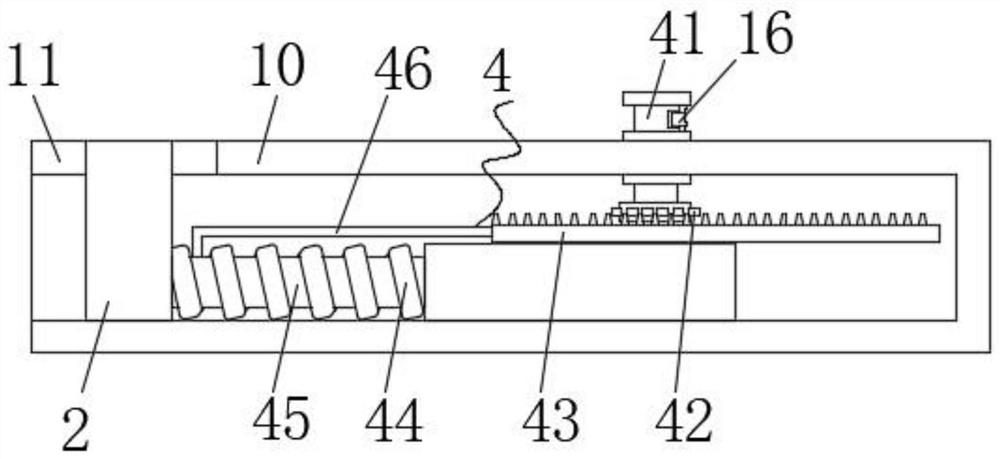

Aquatic product drying machine and control method

InactiveCN106568315AShorten production timeLabor savingDrying chambers/containersDrying machines with progressive movementsMicrowaveControl system

Disclosed is an aquatic product drying machine. The aquatic product drying machine comprises a feeding unit, a conveying unit and a microwave drying unit. The conveying unit comprises a first conveying belt and a second conveying belt, and a plurality of trays are placed on the first conveying belt. The feeding unit comprises a feeding funnel, a push plate, a feeding cylinder, a tray pushing cylinder, a first stopping cylinder and a tray base plate. The push plate is arranged at a lower opening of the feeding funnel. The feeding cylinder and the push plate are connected to be used for controlling the lower opening to be opened and closed. The tray base plate is arranged below the push plate. The first stopping cylinder is arranged between the tray base plate and the first conveying belt. The microwave drying unit is arranged on the second conveying belt and comprises a box body, a microwave generator, a capacitive sensor and a second stopping cylinder. The microwave generator is arranged inside the box body. The second stopping cylinder is arranged at an outlet of the box body. The capacitive sensor is arranged on a support corresponding to the second conveying belt and is used for detecting the reaching positions of the trays and sending signals to a control system, and thus the second stopping cylinder and the outlet of the box body are controlled to be opened and closed.

Owner:XIAMEN UNIV OF TECH

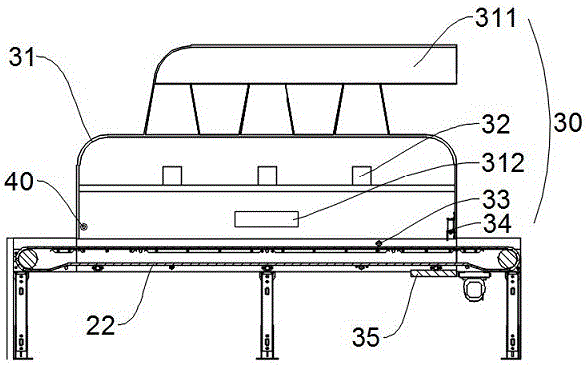

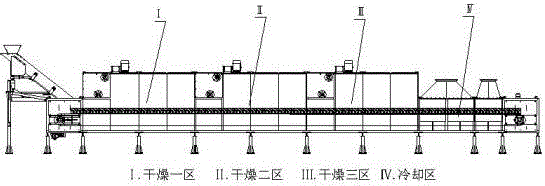

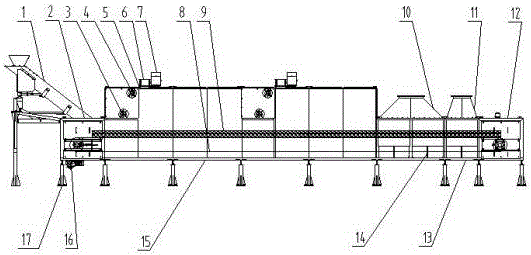

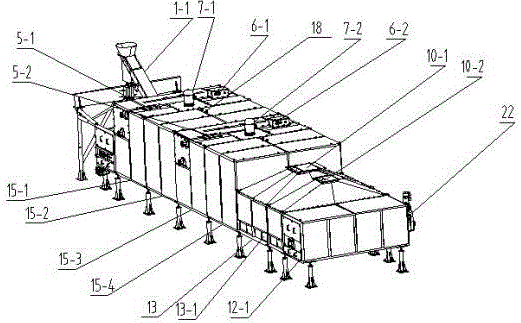

Belt-type dry cooler

ActiveCN106839730AConsider moisture uniformityUniform moistureDrying gas arrangementsDrying solid materialsEngineeringVariable frequency control

The invention relates to a belt-type dry cooler which comprises a distributing device, a feeding section, a drying section, a cooling section and a discharging section. The distributing device is communicated with the feeding section through a distributing-device hosepipe connected on the distributing device, and a conveying belt in the dry cooler sequentially penetrates the feeding section, the drying section, the cooling section and the discharging section; the drying section comprises at least one drying area, and an air supplement port, an air outlet, a circulating fan, a hot-air inlet, a temperature sensor and a heat exchanger are independently arranged on the upper portion of each drying area; the cooling section comprises at least one cooling area, each cooling area is provided with an independent air duct, an exhaust fan and an air inlet, a second wind screen is arranged between every two neighboring drying areas, and a third wind screen is arranged between the drying section and the cooling section. The distributing device is under variable frequency control, hot air is capable of operating in a more balanced and stable manner through reasonable air-inlet and-outlet arrangement and a tight sealing structure, and dried materials are ensured to be uniform in moisture.

Owner:JIANGSU MUYANG HLDG

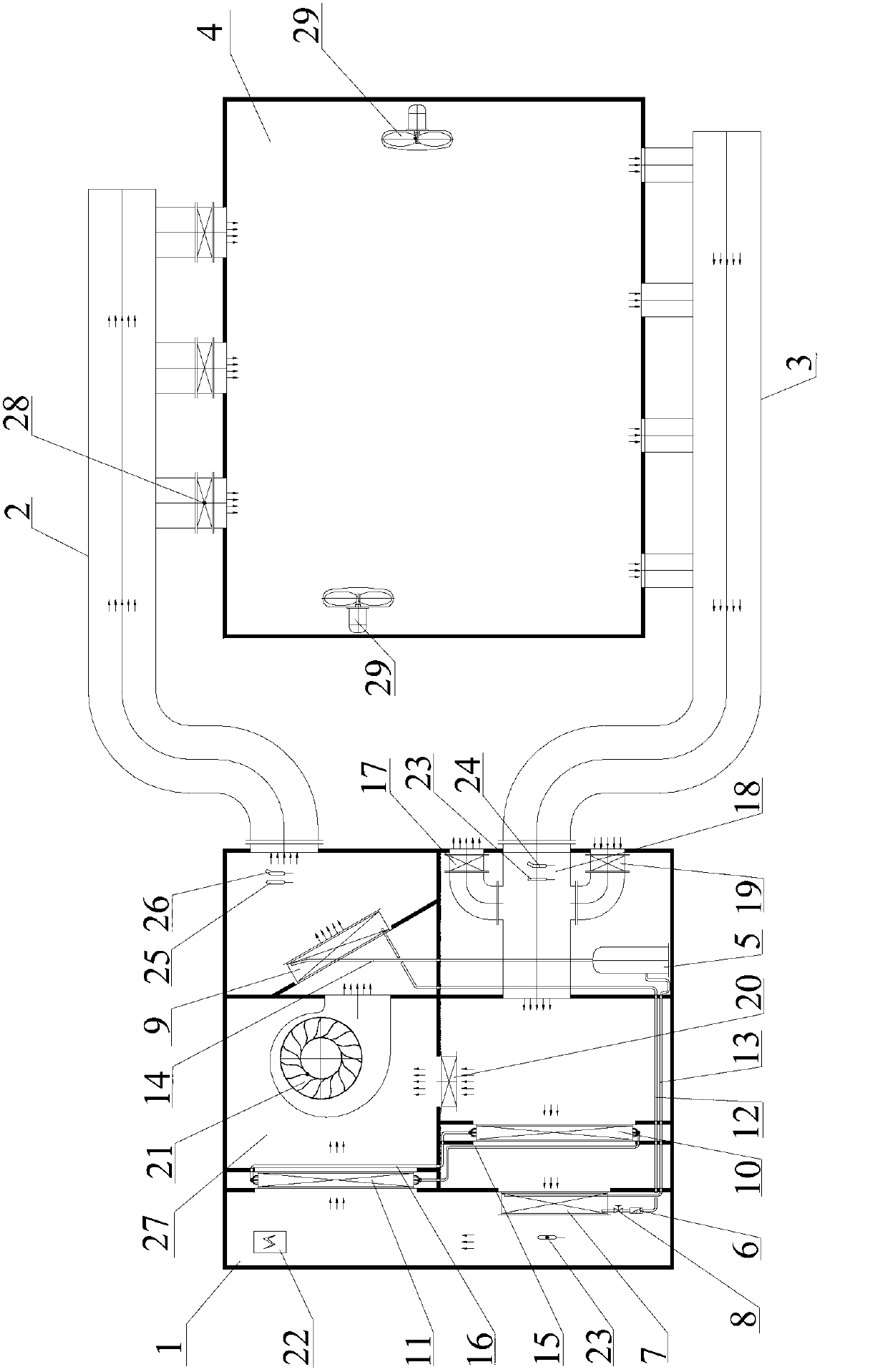

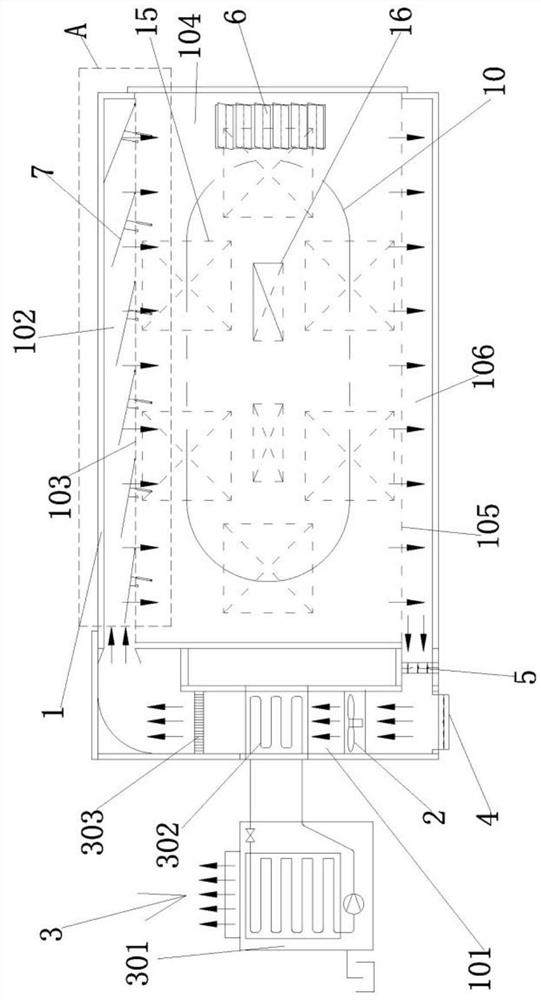

Double-source closed type efficient and energy-saving drying system

InactiveCN106196913AHeating up fastIncrease wind speedDrying gas arrangementsDrying solid materialsAutomatic controlMaterial quality

The invention discloses a double-source closed type efficient and energy-saving drying system. The double-source closed type efficient and energy-saving drying system is characterized in that the system comprises a drying chamber, a burner, a heat pump and a circulating air pipe; the circulating air pipe comprises an air outlet pipe and an air inlet pipe, the air inlet pipe is connected with an air inlet of the drying chamber, and the air outlet pipe is connected with an air outlet of the drying chamber; the heat pump is arranged on the air inlet pipe, and an air heat exchanger is arranged between the air outlet pipe and the air inlet pipe; and the air heat exchanger is connected with the burner and heated through the burner. A full-automatic constant-temperature high-air-volume low-humidity drying process is adopted by the system, temperature rise is fast since the burner and the heat pump are combined, and drying time is shortened; a dehumidifier of a traditional drying system is replaced by the internal heat pump, so that efficiency is higher and more energy is saved; and the circulating air volume is randomly set in sealed space, and turbulent flow is formed by bottom air guiding and an auxiliary fan, so that no dead corner exists in drying, and the uniform drying effect is guaranteed. Because of closed circulating drying, external pollution is avoided, mosquitoes and dust cannot enter the system easily, and the material quality is guaranteed. No dead angle exists because of strong wind convection, materials do not need to be overturned, and full-automatic control is achieved.

Owner:四川自然道节能科技有限公司

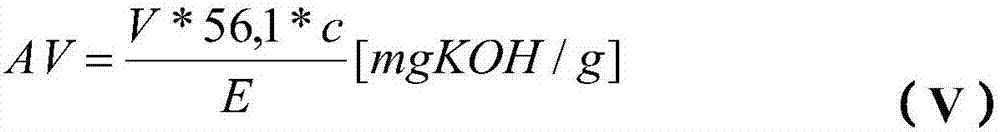

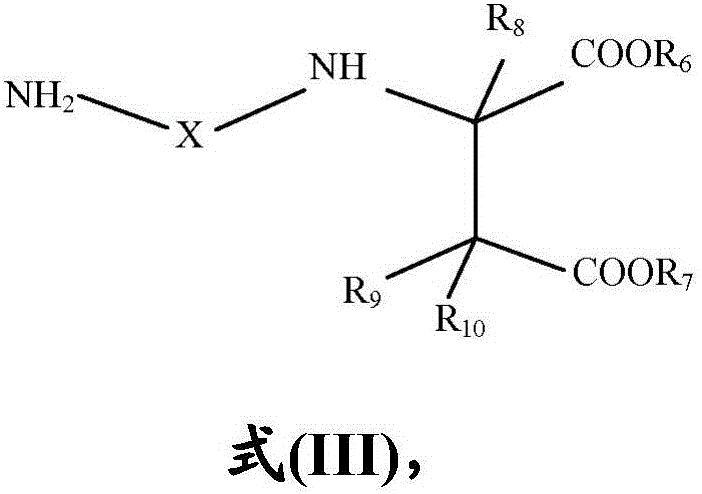

Coating compositions comprising diisocyanate chain extended bisaspartates

ActiveCN106029729AEven drying effectExcellent mechanical propertiesLiquid surface applicatorsPolyurea/polyurethane coatingsPrepolymerIsocyanate

This invention relates to a coating composition, a method for coating of a metallic substrate as well as the use of a chain-extended aspartate prepolymer for improving the early hardness of the coating composition and in a two-component coating composition.

Owner:AXALTA COATING SYST GMBH

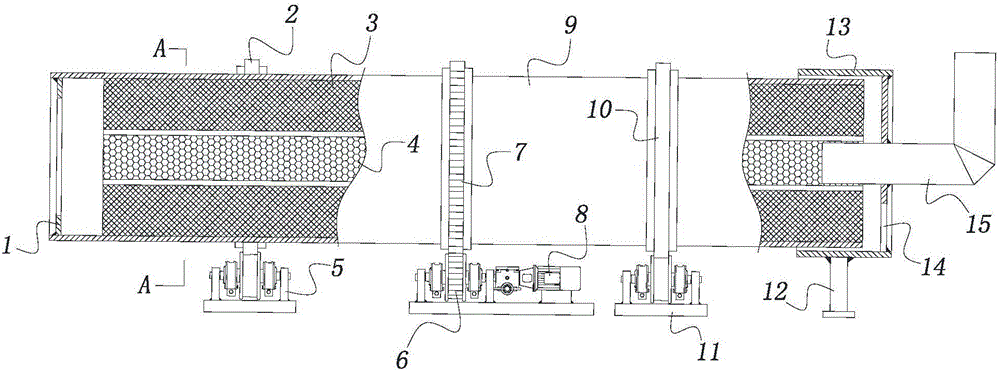

Tea leaf classified drying machine

The invention relates to the technical field of tea leaf processing, and discloses a tea leaf classified drying machine. The tea leaf classified drying machine comprises a machine frame, wherein a drying box body is connected to the machine frame in a swinging manner; a first mesh screen, a second mesh screen and a third mesh screen are sequentially in slip connection to the inner part of the drying box body from top to bottom, wherein hole diameters of the first mesh screen, the second mesh screen and the third mesh screen are sequentially reduced; springs are connected between the third meshscreen and the bottom wall of the drying box body; a heating element is arranged on the top wall in the drying box body; a wind guiding chamber which communicates with the drying box body and a windsupplying box which communicates with the drying box body through the top wall of the drying box body are arranged on the machine frame; an air outlet is formed in the wind guiding chamber; a turbineis rotatably connected to the inner part of the wind guiding chamber; a first cam which is propped to the third mesh screen and a driving mechanism for driving the drying box body to swing are coaxially connected to the turbine; a first push rod which is propped to the first mesh screen is fixedly connected to the second mesh screen; and a second push rod which is propped to the second mesh screenis fixedly connected to the third mesh screen. Through the adoption of the tea leaf classified drying machine disclosed by the invention, classified drying and collecting of the tea leaves can be realized.

Owner:FENGGANG XIUGU TEA CO LTD

Cement production line fine powder grinding equipment

ActiveCN106622603AUniform temperatureEven drying effectCement productionGrain treatmentsHorizontal transmissionProduction line

The invention discloses cement production line fine powder grinding equipment which comprises an inclined spiral feed device, a drying device, a hot air device, a pulverizer, a powder screening machine and a fine powder collector which are sequentially connected, wherein the pulverizer comprises a discharge pipe, a primary fan, a grader, a swing roller, an abrasive disk, a speed reducer and a motor which are sequentially connected from top to bottom; the inclined spiral feed device comprises a horizontal feed inlet, an obliquely upward spiral transmission section, a horizontal transmission section and an inclined feed section which are sequentially connected; the obliquely upward spiral transmission section is connected with the drying device, and the horizontal transmission section is connected with the hot air device; furthermore, the temperature of hot air blown out of the hot air device is kept below 45 DEG C; in addition, the pulverizer is connected to the top position of the powder screening machine through the discharge pipe; a smashing device is further arranged at the bottom of the powder screening machine, and the powder screening machine is connected with the fine powder collector through a collection pipe which is arranged at the top of the powder screening machine. The cement production line fine powder grinding equipment has the advantages of high production efficiency, higher cement evenness and higher fineness quality.

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG

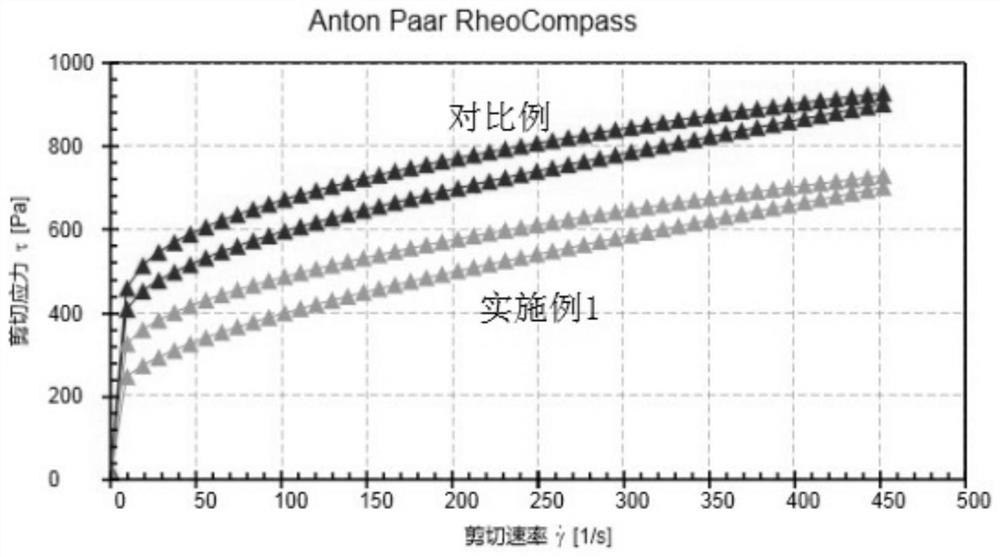

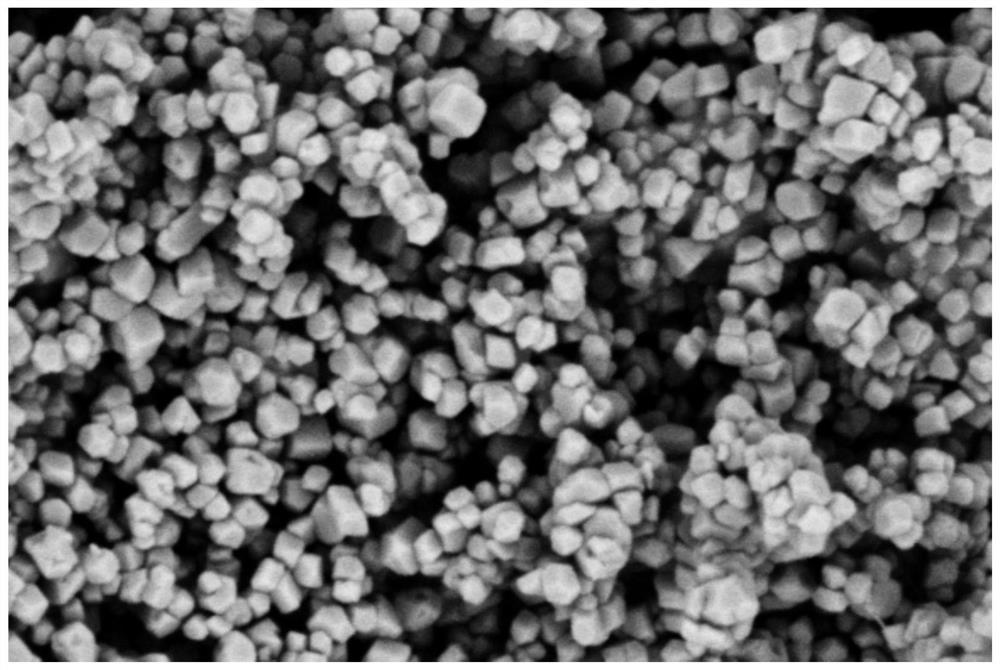

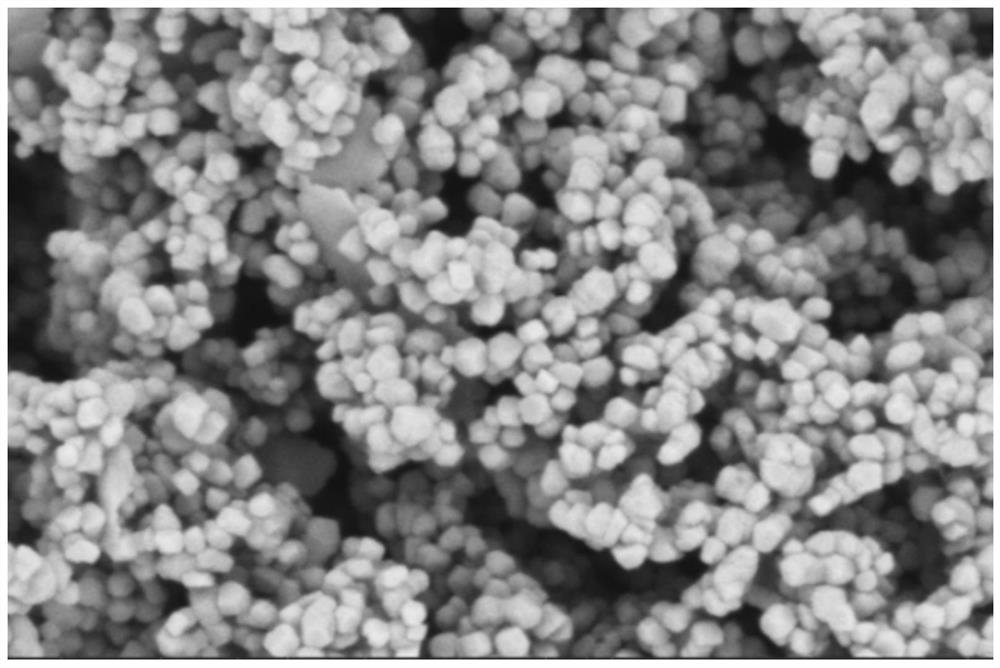

Surface treatment method of nano calcium carbonate for impact-resistant automobile chassis coating

ActiveCN112724708AHigh viscoelasticityImprove rheologyCalcium/strontium/barium carbonatesMaterial nanotechnologySodium stearateCarbonization

The invention discloses a surface treatment method of nano calcium carbonate for an impact-resistant automobile chassis coating, which comprises the following steps of diluting lime milk to obtain slurry, regulating the specific gravity, and carbonating the slurry in a carbonating tower, measuring conductivity through an instrument, adding a crystal form control agent at the lowest point of gelatinization conductivity at the initial stage of carbonization, and stirring to react until the pH value is less than or equal to 7 to obtain calcium carbonate suspension, carrying out oleophylic surface treatment on the calcium carbonate suspension, stirring, and adding a compound treatment agent consisting of a sodium stearate saponification solution and flaxseed gum, polyhexamethylene glycol, sodium dodecyl benzene sulfonate and isopropyl triisostearoyl titanate for surface treatment, and carrying out filter pressing, microwave vacuum drying and sieving to obtain the nano calcium carbonate. The nano calcium carbonate particles prepared through the method are regular in morphology, have the advantages of being good in stability, good in rheological property, high in impact resistance, low in moisture absorption capacity and the like, and can improve the impact resistance and sagging resistance of PVC paste when applied to filling of the automobile chassis coating PVC paste.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

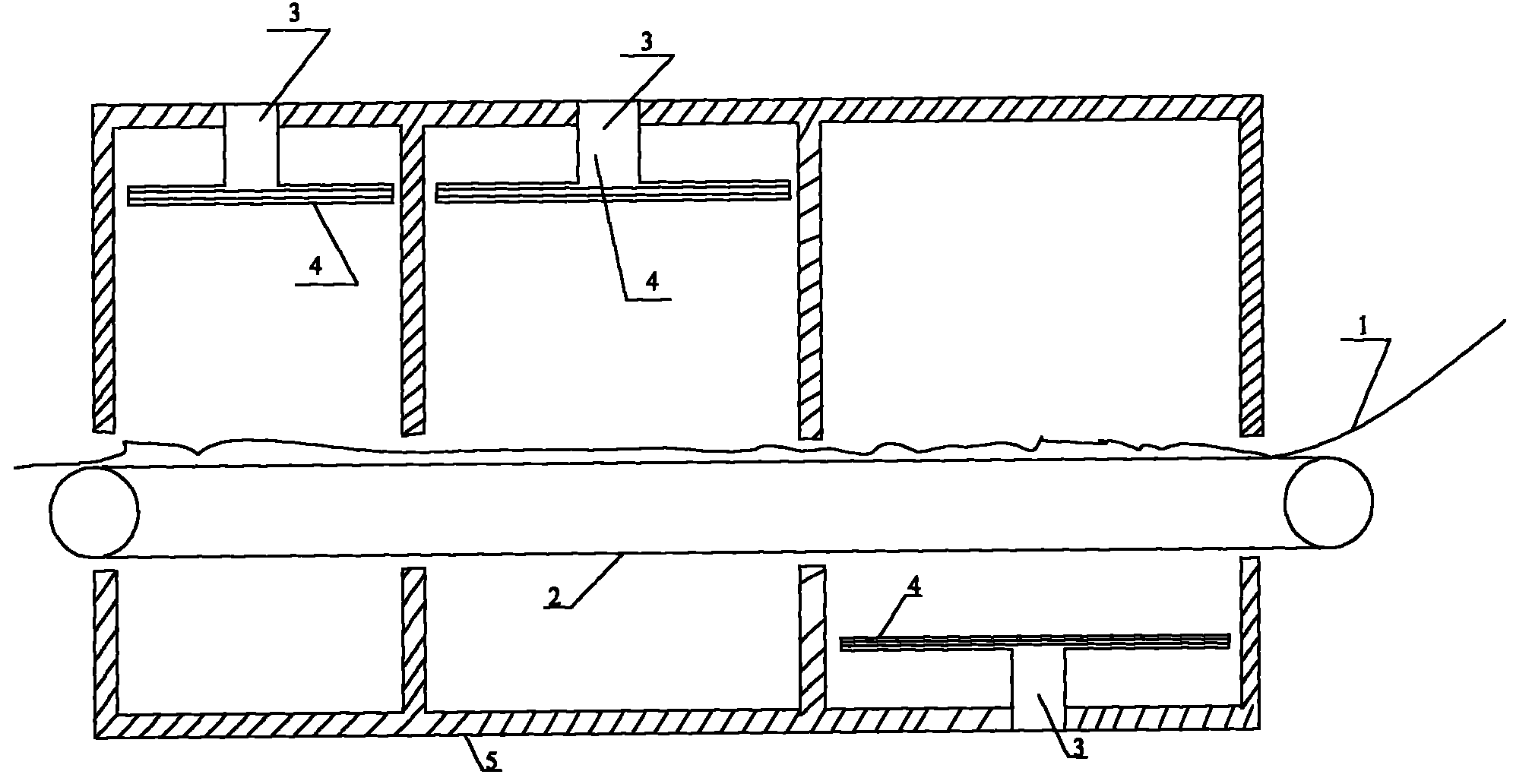

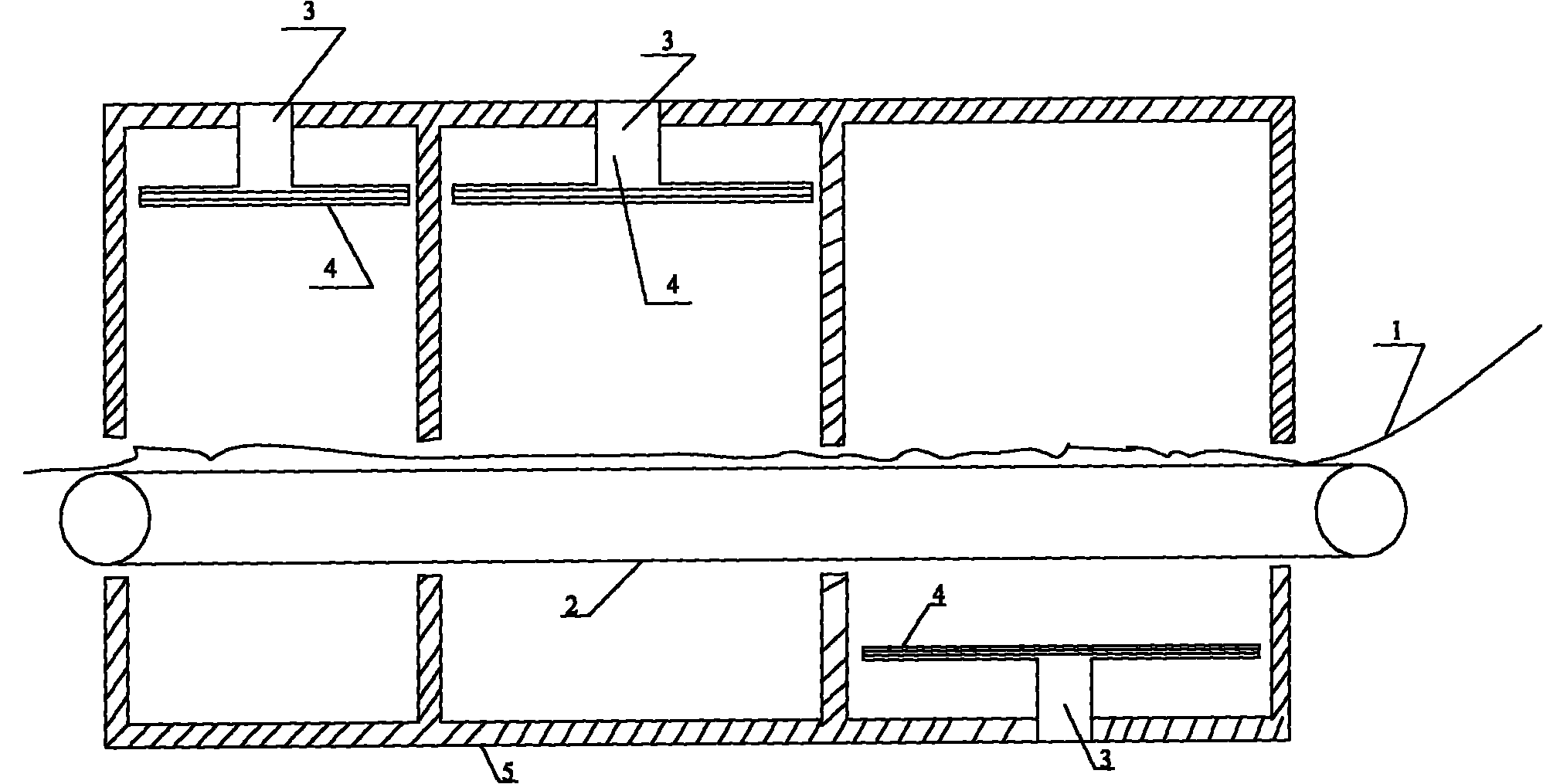

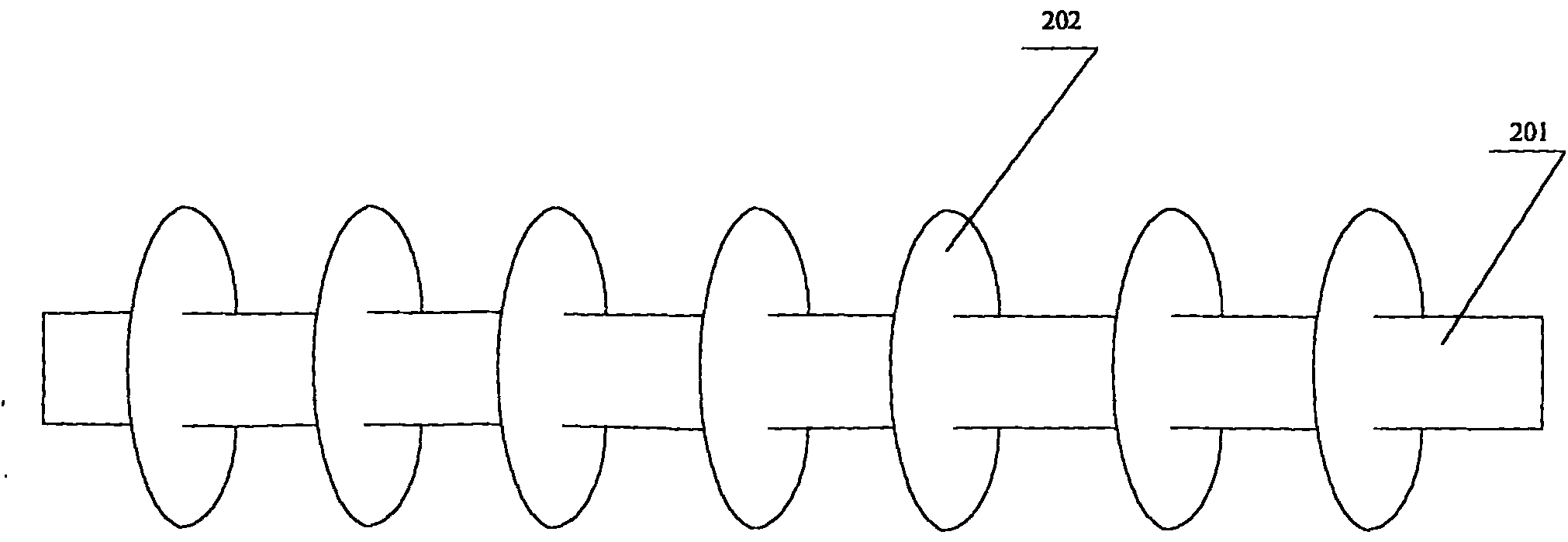

Device for drying chemical fiber

InactiveCN101813407APerformance impactEven drying effectDrying solid materials with heatDrying machines with progressive movementsFiberEngineering

The embodiment of the invention provides a device for drying chemical fiber, which comprises a heat-insulation chamber, a chemical fiber conveyor belt, a first drier, a second drier and a third drier, wherein the chemical fiber conveyor belt having a reticular structure and transports the chemical fiber to pass through the heat-insulation chamber, so as to carry out the drying process; a first drying chamber, a second drying chamber and a third drying chamber are sequentially arranged in the traveling direction of the chemical fiber conveyor belt in the heat-insulation chamber; the first drier is arranged above the chemical fiber conveyor belt in the first drying chamber; and the second drier and the third drier are arranged below the chemical fiber conveyor belt in the second drying chamber and the third drying chamber. Accordingly, the device of the invention is capable of drying the chemical fiber in a more reasonable manner, thus preventing the performance of the chemical fiber from being affected by the incomplete drying or non-uniform heating of the chemical fiber.

Owner:杨珍芬

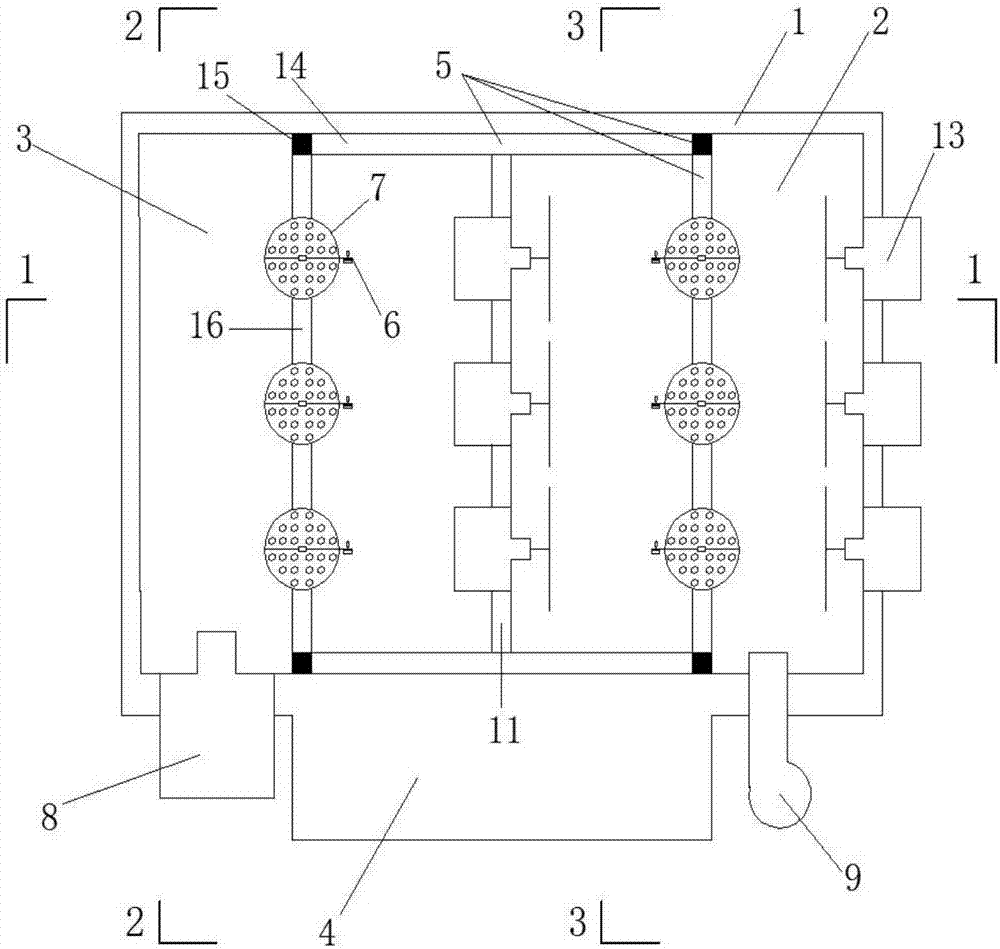

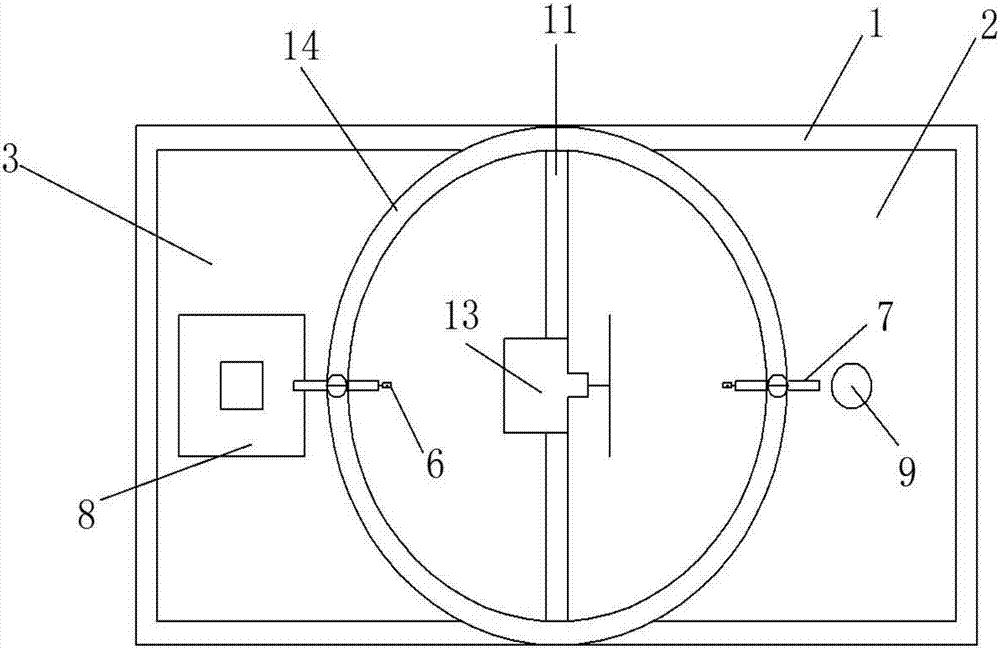

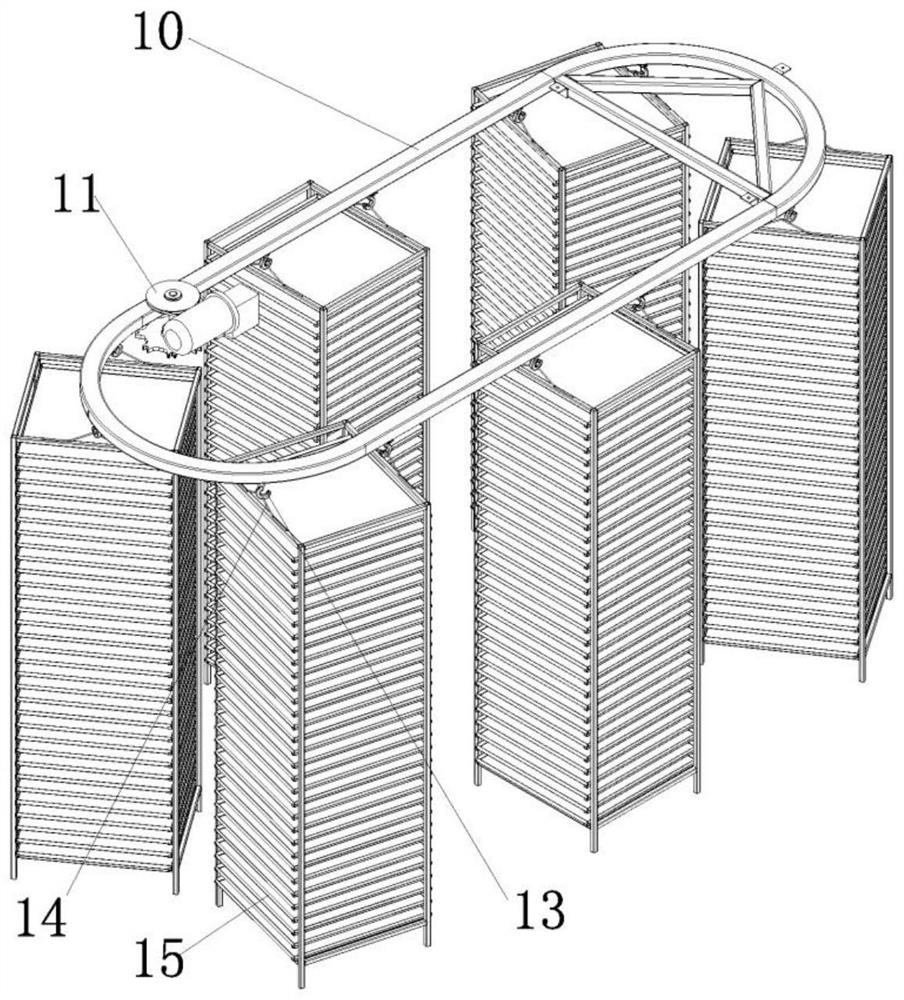

Dry-wet cycle testing device capable of monitoring moisture content of soil in real time

A dry-wet cycle testing device capable of monitoring moisture content of soil in real time comprises a drying tank, a saturation tank, a power supply tank, a rotating device and a reading control device, wherein the drying tank promotes drying of soil samples by means of fans and a blower; the saturation tank performs humidification saturation on the soil samples by means of a humidifier; the power supply tank is located at the bottom of the device; the rotating device is divided into a self-rotating device and an around-circular-ring-track rotating device; the reading control device monitors the moisture content of the soil samples in real time. The dry-wet cycle testing device has the advantages that dry-wet cycle can be performed on the multiple soil samples with different water content ranges simultaneously, saturation and drying are more uniform by means of the special rotating device in the dry-wet cycle process, the moisture content of the soil samples can be monitored at any time, indication lamps can be lightened when preset moisture content is reached, and the dry-wet cycle on the soil samples is performed precisely.

Owner:GUANGXI UNIV

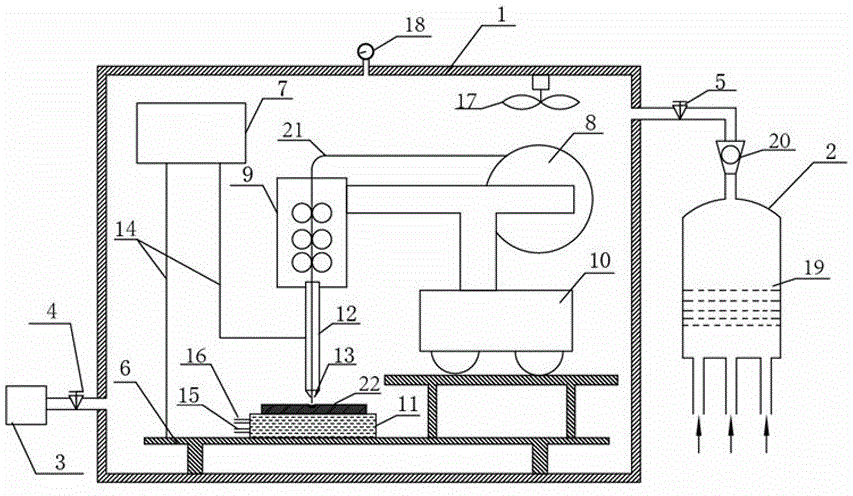

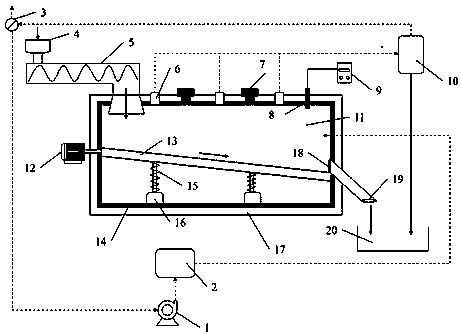

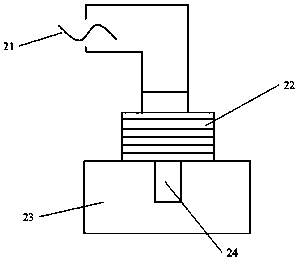

Device and method for drying lignite in a combined mode through microwave and hot air

PendingCN110411151ASimple structureLow investment costDrying solid materials with heatDrying gas arrangementsSmall footprintContinuous production

The invention discloses a device and a method for drying lignite in a combined mode through microwave and hot air, and belongs to the technical field of lignite drying equipment. The device comprisesa feeding device, a vibration transmission mechanism, a hot air generating device, microwave generating devices, a drying cavity, a temperature measuring system and a tail gas treatment device, wherein the feeding device comprises a feeding hopper and a spiral feeder, the hot air generating device comprises a blower and a hot blast stove; more than one microwave generating device and more than oneexhaust port are arranged above the drying cavity; a heat preservation layer and a metal shell capable of shielding microwaves are arranged in the cavity, the vibration transmission mechanism is connected with a vibration motor outside a cavity, and the tail end of the vibration transmission mechanism is provided with a drawable baffle and a discharge port. The method for drying lignite in a combined mode through microwave and hot air comprises the following steps of crushing raw coal, and carrying out the sieving treatment; carrying out the feeding through the spiral feeder, starting the hotair generating device and the microwave generating device; carrying out the vibration and conveying through the vibration transmission mechanism, drying the brown coal in the microwave drying cavitythrough microwave hot air, and obtaining a finished product through drying, and collecting the finished product in the finished product coal bin through a movable baffle. The device is simple in structure, low in investment cost, small in occupied area, high in operation efficiency and capable of realizing continuous production; the method for drying in a combined mode through the microwave and the hot air is capable of improving the heat efficiency of materials and high in drying speed, capable of recycling waste heat, high in energy utilization rate, capable of reducing energy consumption, and environment-friendly.

Owner:YUNNAN MINZU UNIV

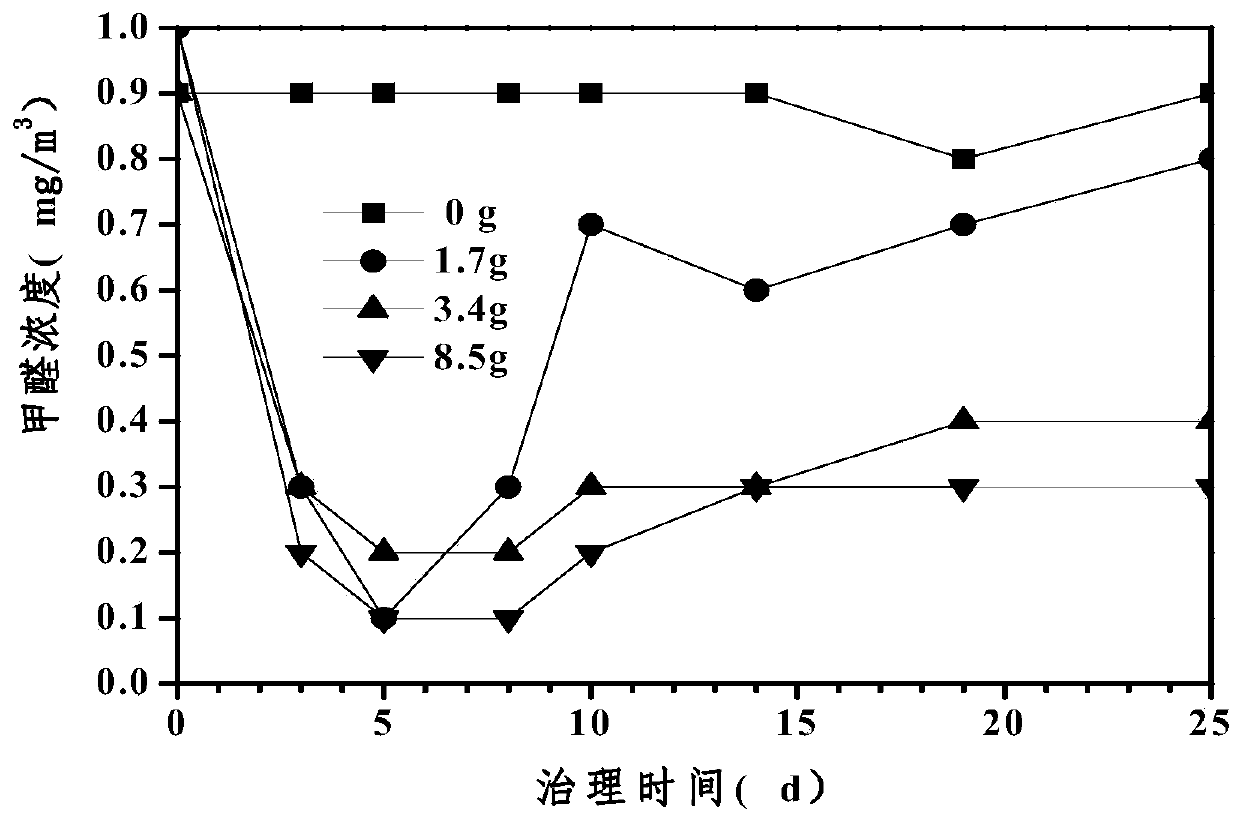

Formaldehyde scavenger and preparation method thereof

ActiveCN110860179ASolve the problemsNo dust problemGas treatmentOther chemical processesFiberCarbon fibers

The invention relates to the technical field of formaldehyde air pollution treatment, in particular to a composite formaldehyde scavenger of activated carbon fiber loaded amino acid and a preparationmethod thereof. The formaldehyde scavenger is activated carbon fiber loaded amino acid, the mass ratio of the amino acid to the activated carbon fiber is 0.001-0.4:1, the amino acid comprises at leastone of glycine, alanine, arginine, lysine, proline and serine, and the activated carbon fiber carrier is activated carbon fiber honeycomb filter cotton or activated carbon fiber felt. The preparationmethod includes: firstly, dissolving amino acid in water to obtain a solution with a concentration of 0.01-20%; and putting an activated carbon fiber product into the solution, conducting soaking for0.5-24h for adsorption loading, then taking the activated carbon fiber product out of the solution, and conducting drying to obtain the formaldehyde scavenger. The formaldehyde scavenger provided bythe invention has no dust problem, provides a barrier-free network type carrier material with a large specific surface area for amino acid, can be for repeated loading, and is efficient, safe, simpleand convenient.

Owner:上海置顶环境科技有限公司

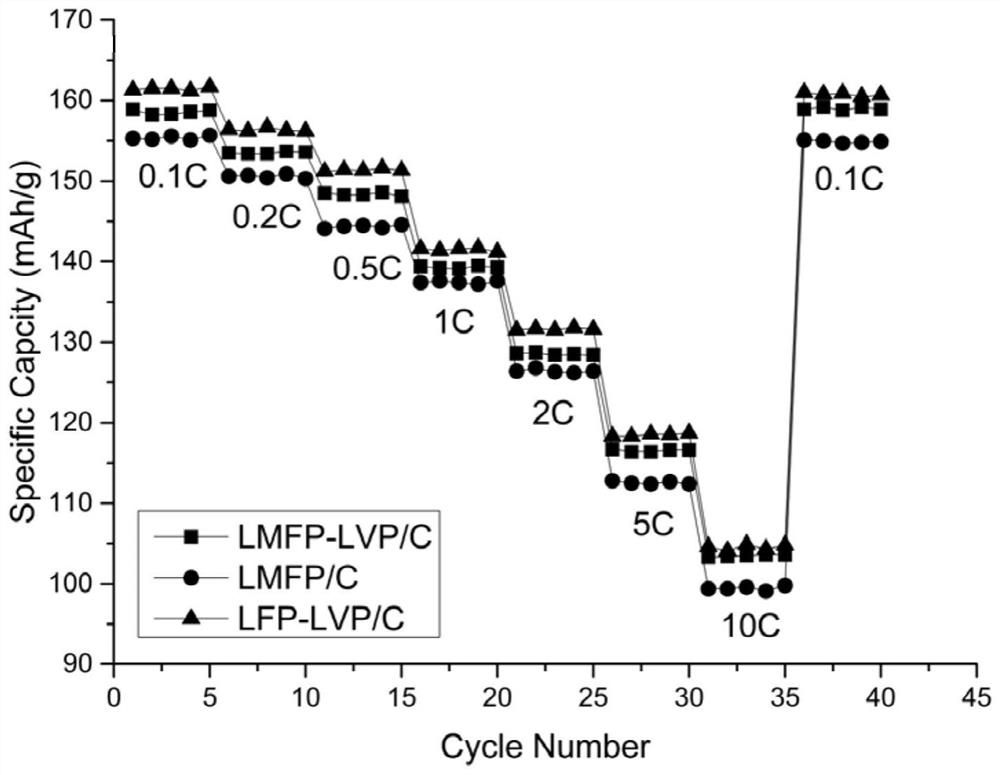

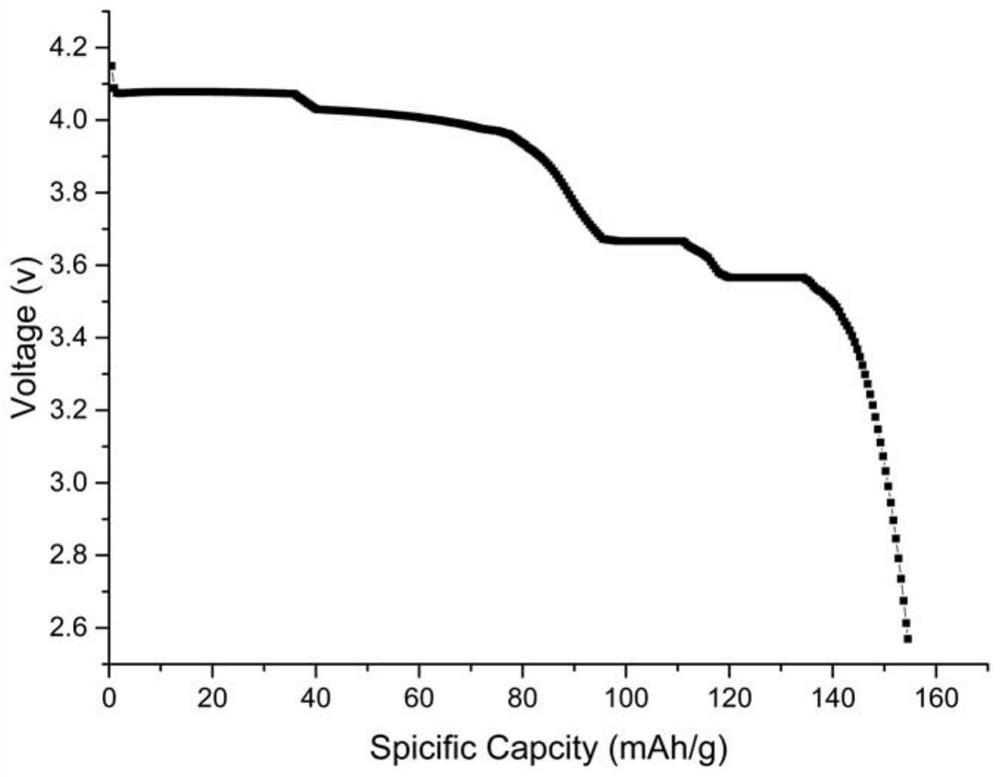

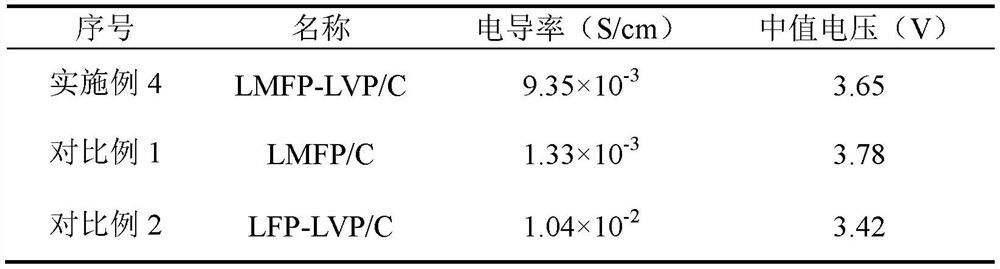

Preparation method of composite multi-element lithium iron manganese vanadium phosphate positive electrode material

InactiveCN113078323AReduce oxidationIncrease working voltageSecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a preparation method of a composite multi-element lithium iron manganese vanadium phosphate positive electrode material. The method comprises the following steps: 1) mixing a lithium source, an iron source, a manganese source, a vanadium source, a phosphorus source and a carbon source according to a certain proportion, and fully grinding and refining in a grinding machine to obtain slurry a; 2) carrying out microwave drying on the slurry a in a microwave oven for a certain time, cooling to room temperature, and taking out to obtain a precursor b; and 3) adding the precursor b into an atmosphere sintering furnace for high-temperature sintering for a certain time, and cooling to room temperature to obtain the lithium ferric manganese vanadium phosphate positive electrode material. The method is easy to operate, high in controllability and suitable for industrial mass production, and the lithium ion battery positive electrode material with multiple advantages is synthesized at low cost.

Owner:天津斯科兰德科技有限公司

Spherical jacketed kettle for drying or mixing powdery materials

InactiveCN104983568AIncrease the heating surfaceImprove heat transfer efficiencyFood processingFood preservationSocial benefitsPolymer science

The invention discloses a spherical jacketed kettle for drying or mixing powdery materials. The jacketed kettle comprises a lower kettle body, an upper kettle body, a feeding port cover, a heat transmission layer, a medium pipe or / and a support pipe, a bearing frame, lower kettle body material stir-fry plates, a motor, a driven wheel, a driving wheel and a coupler. The spherical jacketed kettle for drying or mixing powdery materials can heat, dry or mix materials by means of circulated liquid or steam, and can dry materials without heating and mixing the materials, the material drying / mixing time is short, the spherical jacketed kettle has a good effect and has substantial economic benefit and social benefit, energy is saved, and the spherical jacketed kettle is suitable for drying or mixing powdery materials in the pharmacy industry and the foodstuff industry.

Owner:唐婧婵

Air drying equipment for wig fibers

PendingCN110940171ADry fastEasy to storeDrying gas arrangementsDrying machines with progressive movementsFiberElectric machinery

The invention discloses air drying equipment for wig fibers. A wind box is included. The whole wind box is a cuboid cabinet body structure. An exhaust cavity is arranged in a top of a cabinet body. The exhaust cavity is connected with the outside world through an air exhaust pipe. Openings for hair to penetrate through are correspondingly arranged in two opposite side walls of the wind box. An airinlet pipe is arranged at a lower section of a side surface of the wind box. A hair dispersion component is arranged at a hair inlet of the wind box. The hair dispersion component comprises an installation frame, an extrusion roller component and a hair dispersion row. The extrusion roller component and the hair dispersion row are arranged on the installation frame. The extrusion roller componentis rotatably arranged on an outer side of the hair dispersion row, the extrusion roller component is used for extruding moisture in hair and comprises an upper extrusion roller and a lower extrusionroller, and a driving motor is installed at one end of the lower extrusion roller. The device is uniform in drying effect, the hair cannot be damaged, and operation efficiency can be effectively improved.

Owner:禹州市金博发制品有限公司

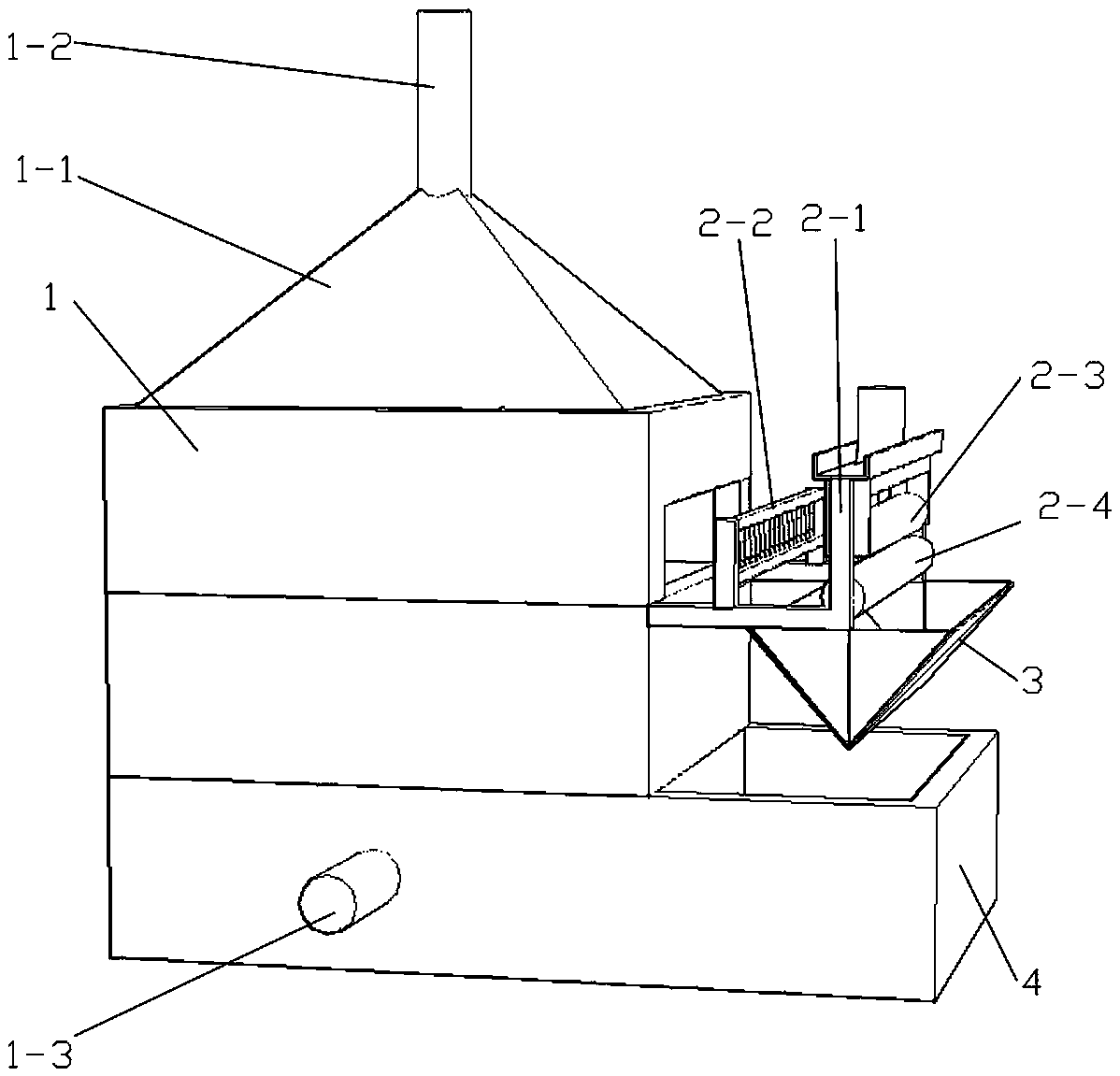

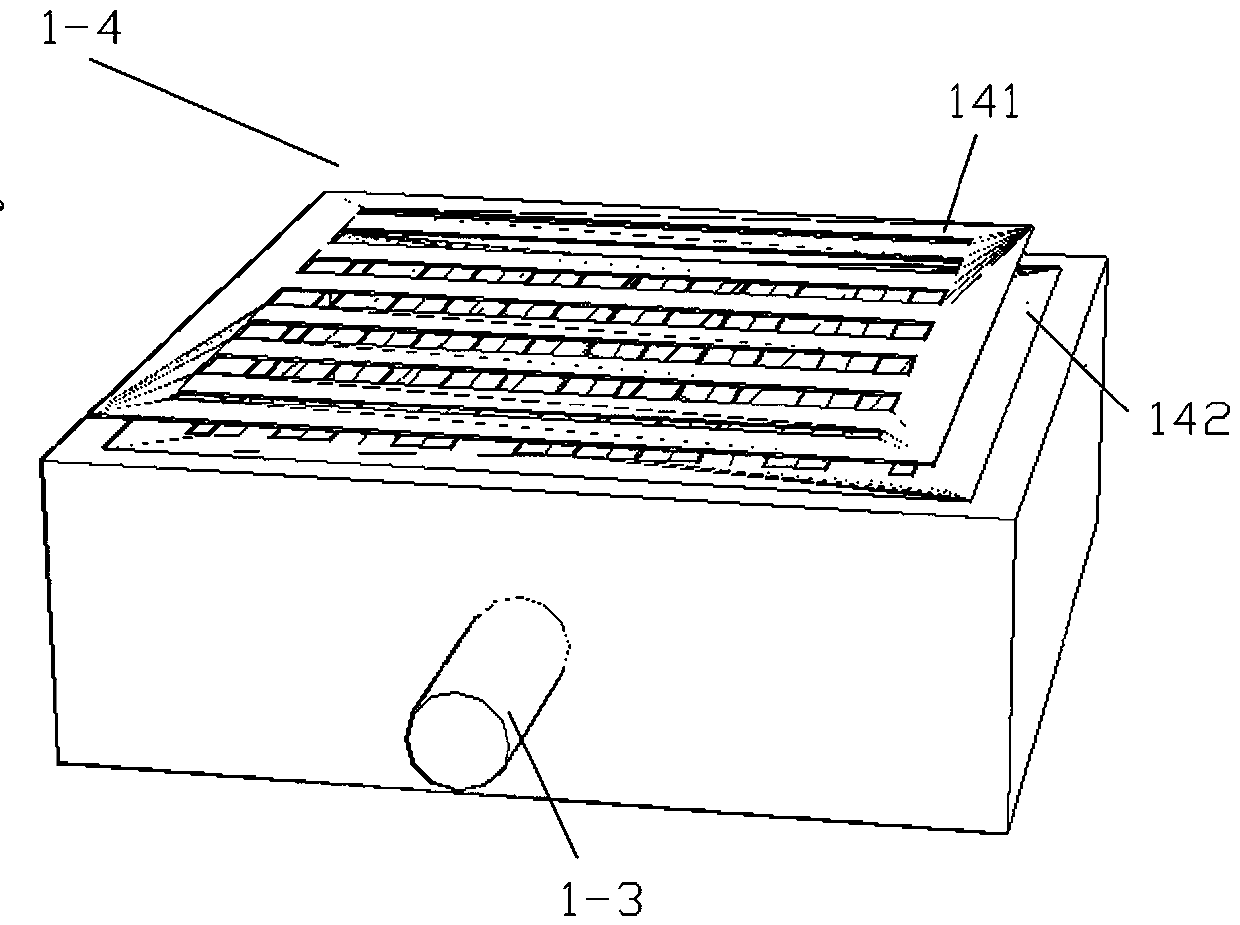

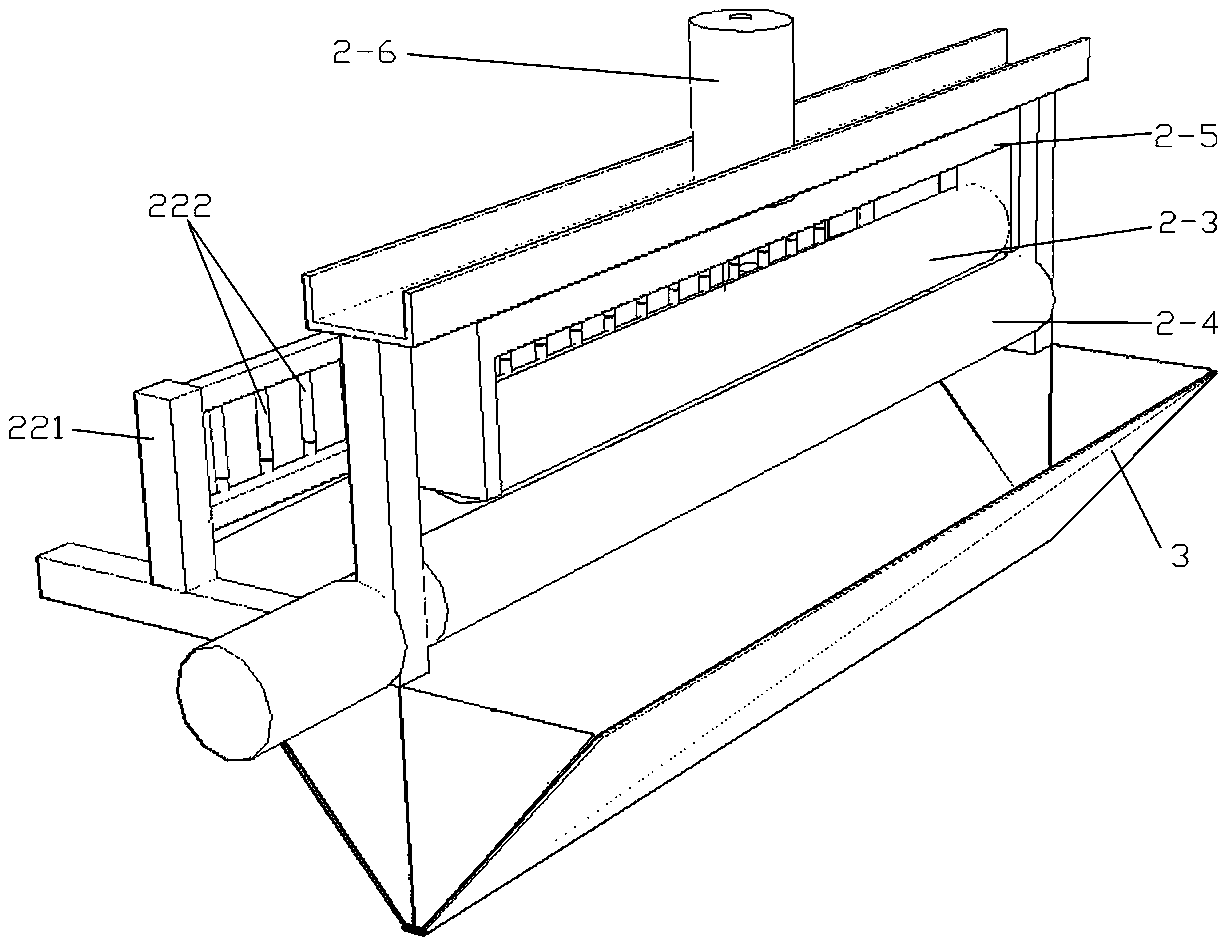

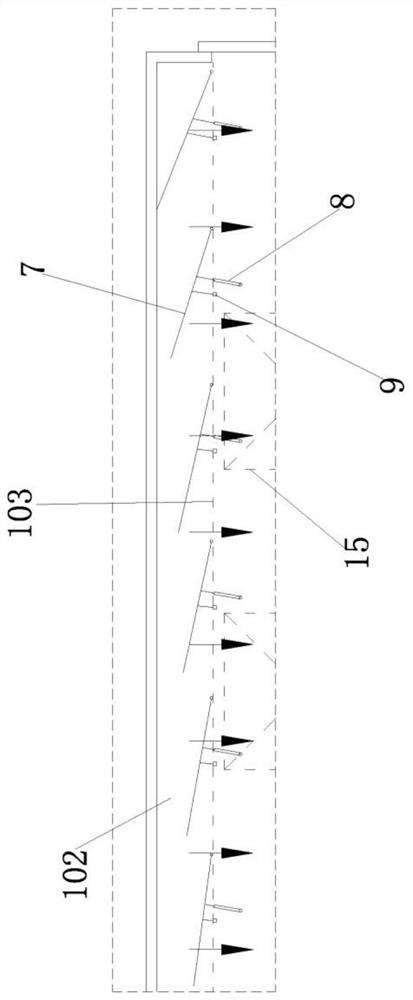

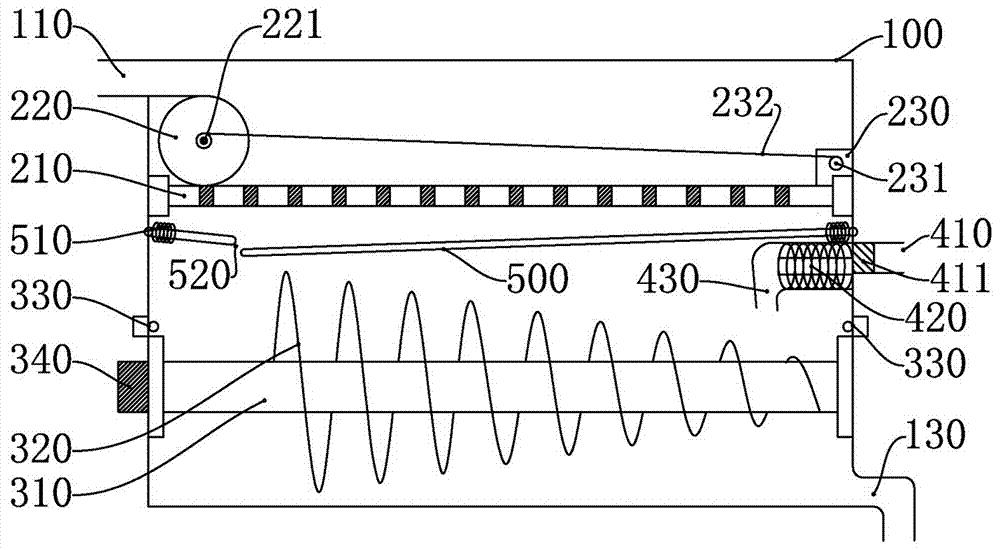

Tray frame fixed rail moving dryer based on side ventilation structure

PendingCN111780534AEvenly distributedSolve the problem of uneven dryingDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention relates to a tray frame fixed rail moving dryer based on a side ventilation structure in the technical field of agricultural product drying. A fan chamber, an air inlet chamber, a dryingchamber and an air return chamber communicate according to a circulating airflow sequence; an intake air side punching plate is arranged between the air inlet chamber and the drying chamber; an exhaust air side punching plate is arranged between the drying chamber and the air return chamber; multiple air guide plates with automatically adjusted opening angles are uniformly distributed in the horizontal direction of the intake air side punching plate, so that drying airflow can reach a relatively uniform state in the horizontal direction; and as the vertical section structure of the fan chamber is a rectangular structure, all fans are arranged as a vertical column in the height direction of the fan chamber at equal intervals, and the drying airflow can keep a relatively uniform state in the vertical direction. Such schemes as vertical ventilation of an axial flow fan set, air distribution and homogenization of multi-grade air guide plate combination and movement of a tray frame along aguide rail are adopted to solve the problems of nonuniform ventilation and drying in the vertical direction and the horizontal direction.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

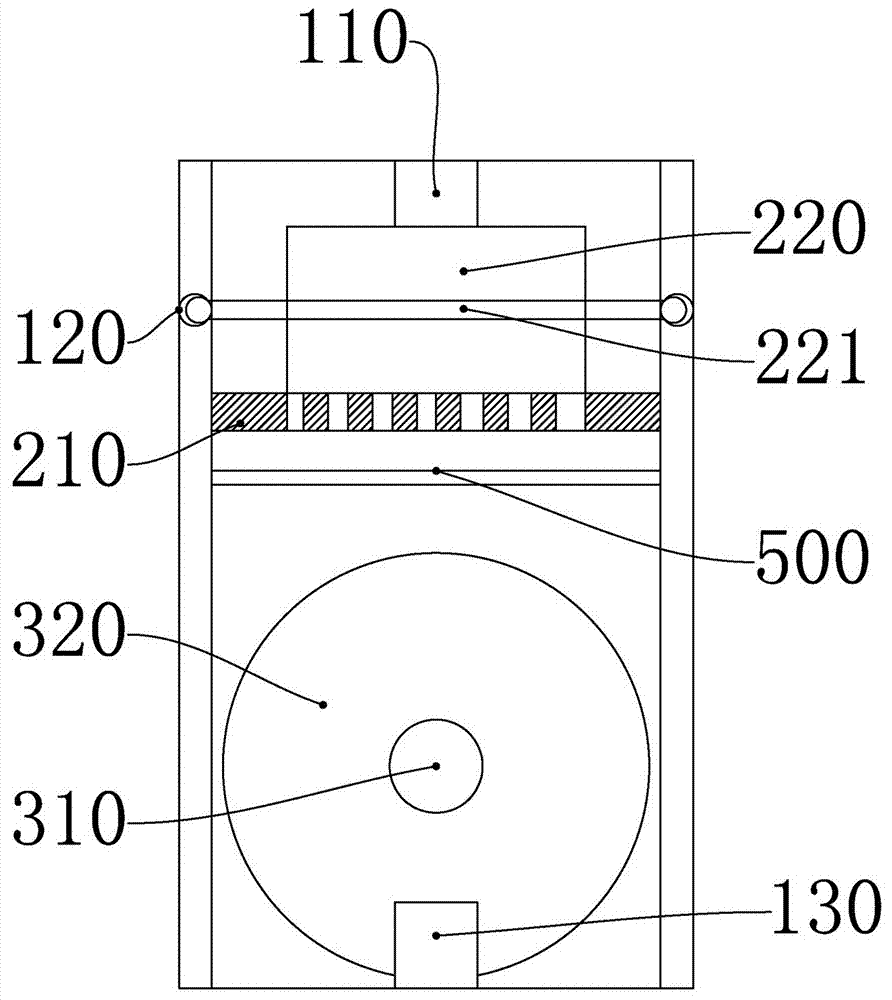

Novel gauze drying and rapid winding equipment

InactiveCN111268472AImprove uniformityImprove the fluency of undertakingLiquid/gas/vapor removalDrying machines with progressive movementsYarnElectric machine

The invention discloses novel gauze drying and rapid winding equipment. The equipment structurally comprises an electric control box, a shaft driving motor, a pull rod handle, a drying and winding sliding lining frame barrel, a traction wheel frame, limiting frame blocks and a front coaming frame. According to the novel gauze drying and rapid winding equipment, the drying and winding sliding lining frame barrel is matched with the traction wheel frame, a roller groove body and a thin frame ring rotate around a rolling shaft column, and then a hot drying sliding frame seat and an arc liner creel are driven to form a cloth pulling effect of peripheral hot drying and liner ejecting supporting, so that an arc brush frame plate groove gets a better separating, adjusting, needle threading, sliding pulling and internal pressing effect in the whole yarn bundling process; and whole gauze drying surfaces are overlapped to form a side gradient gap pulling distance, a uniform air drying effect isconveniently formed by a gap internal flow air path, the internal environment airflow circulation effect of hot air exhaust after hot drying is guaranteed, bonding of the upper gauze face and the lower gauze face of a hot drying twisted wire is avoided, well-layered quality guarantee is improved, the lifting position face and the layering position face in the rolling sliding pulling process are improved, the sliding lining operation effect is synchronized, and the maintaining treatment effect of a winding rack on gauze is achieved.

Owner:程金海

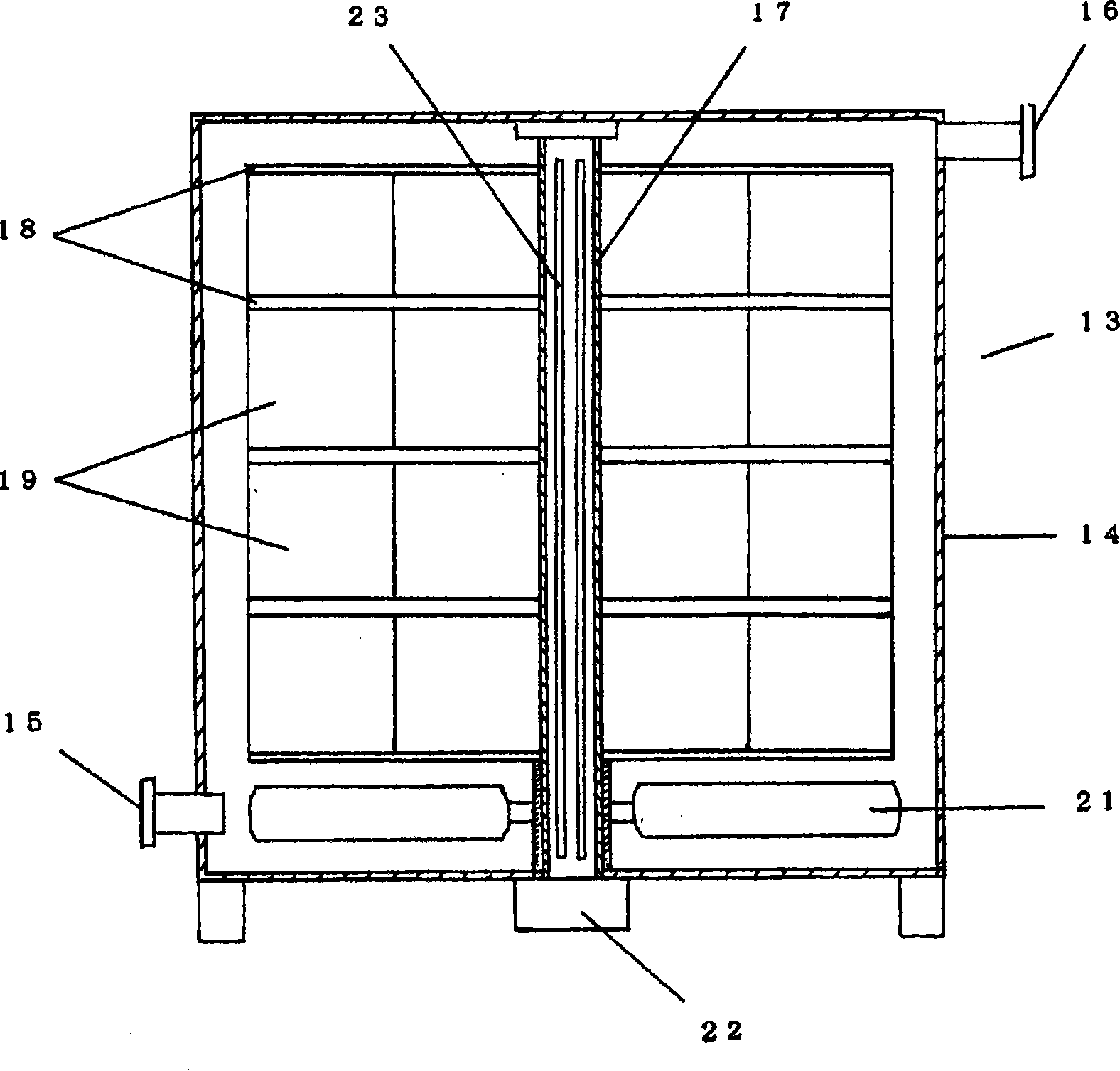

Drying apparatus

InactiveCN101163936AKeep dryFull drying effectDrying gas arrangementsSemiconductor/solid-state device manufacturingSpray nozzleLinear drive

A drying device has a linear drive device for linearly moving, in a drying box, a spray nozzle in a direction orthogonal to a conveyance direction of an object to be washed, and an ejection opening of the spray nozzle is formed as a slit stretching in the conveyance direction. A pair of nozzles is arranged at an inlet and outlet of the drying device, and each nozzle has a slit extended in the direction orthogonal to the conveyance direction, by the width of the object to be washed. Those surfaces of the nozzles that face each other are each inclined from an inner edge to an outer edge so that the distance between the inner edges of the nozzles is greater than the distance between the outer edges.

Owner:KYOWA KAKO KABUSHIKI KAISHA

Traditional Chinese medicine decoction piece drying device

InactiveCN112197507AImprove drying efficiencyImprove practicalityDrying gas arrangementsMetal working apparatusEngineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicine decoction piece drying device, and belongs to the field of drying devices. The traditional Chinese medicine decoction piece drying device comprises a placing shell, wherein two fixing shells are fixedly connected to the inner wall of the placing shell, and pushing mechanisms are arranged in the fixing shells. According to the traditional Chinese medicine decoction piece drying device, two storage boxes are arranged, the purpose of drying different traditional Chinese medicine decoction pieces at the same time can be achieved by utilizing the two storage boxes, the drying efficiency of the traditional Chinese medicine decoction pieces is improved, and the situation that the different traditional Chinese medicine decoction pieces are mixed when being placed into the same drying device is avoided; and then a sliding rod, a third rotating shaft, a third bearing and a telescopic rod are arranged, the limitation on the third rotating shaft can be relieved by utilizing the sliding of the sliding rod, so that a rack moves under the elastic force action of the telescopic rod and a first spring, a push plate can be pushed by utilizing the extension of the telescopic rod, the storage boxes are driven to move out through a first bin door, then people can conveniently and rapidly put in or take out the traditional Chinese medicine decoction pieces, and the practicability of the device is greatly improved.

Owner:深圳市和顺本草药业有限公司

Sodium pyrosulfite drying machine

ActiveCN108007070ADry evenlyWarm up evenlyDrying gas arrangementsPreliminary solid treatment for dryingSodium sulfiteSulfite salt

The invention relates to the technical field of chemical equipment, in particular to a sodium pyrosulfite drying machine. The sodium pyrosulfite drying machine comprises a machine shell, a heating assembly and a drying assembly, and the heating assembly and the drying assembly are installed in the machine shell. The sodium pyrosulfite drying machine is characterized in that the machine shell further internally comprises a preheating assembly, the preheating assembly comprises a screening plate and a roller, and the roller is arranged above the screening plate and is tangential to the screeningplate; the machine shell is provided with a feeding pipe, and the wall of the feeding pipe is tangential to the outer surface of the roller; and the two opposite shell walls of the machine shell areprovided with sliding grooves, and the two ends of the roller are installed in the sliding grooves separately. The drying machine is specially used for drying sodium pyrosulfite products step by step,and the drying effect is uniform.

Owner:上海嘉定马陆化工厂有限公司

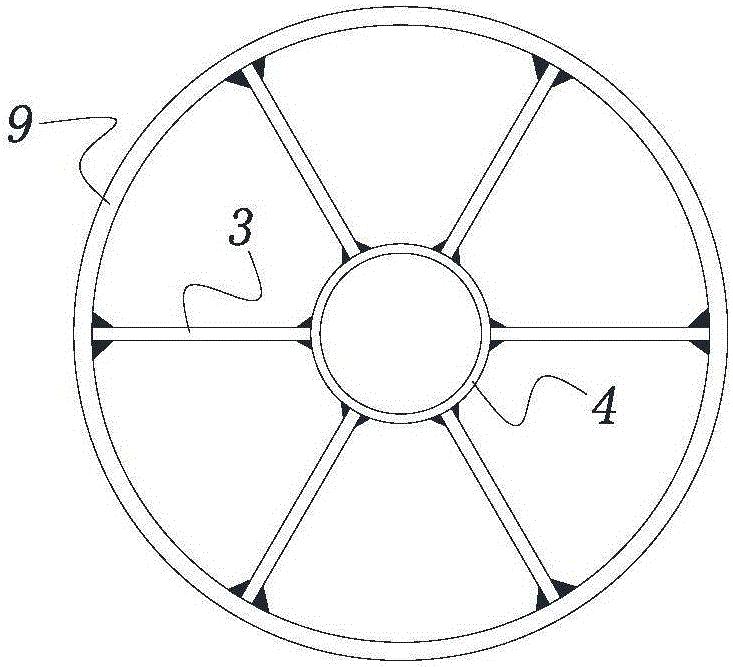

Device for drying water purifying filter material particles

InactiveCN104990377AFast dryingEven drying effectDrying machines with non-progressive movementsFiltration separationEngineeringFilter material

The invention relates to a device for drying water purifying filter material particles. The device comprises a straight roller slightly inclining. A gear ring is fixedly connected to and installed in the middle of the outer wall of the straight roller. A first annular track is installed between the head end and the gear ring. A second annular track is arranged between the tail end and the gear ring. The device further comprises a first riding wheel fixedly installed on the ground, a drive device and a second riding wheel. The first riding wheel is matched with the first annular track, and the second riding wheel is matched with the second annular track. The drive device comprises a speed reducer and a driving gear driven by the speed reducer, and the driving gear is in meshing transmission with the gear ring. A core pipe made of a hole plate is arranged in the center of the straight roller. A plurality of partition plates which extend in the axial direction and are made of hole plates are arranged between the outer wall of the core pipe and the inner wall of the straight roller. The device further comprises a sleeve which is supported by a stand column and arranged at the tail end of the straight roller in a sleeving mode, and the outer end of the sleeve is closed. A discharging port is formed in the bottom of an outer end plate of the sleeve. The device further comprises a hot air pipeline fixedly connected to the center of the outer end plate of the sleeve, and the inner end of the hot air pipeline is inserted in the tail end of the core pipe.

Owner:天津市彤泰成科技有限公司

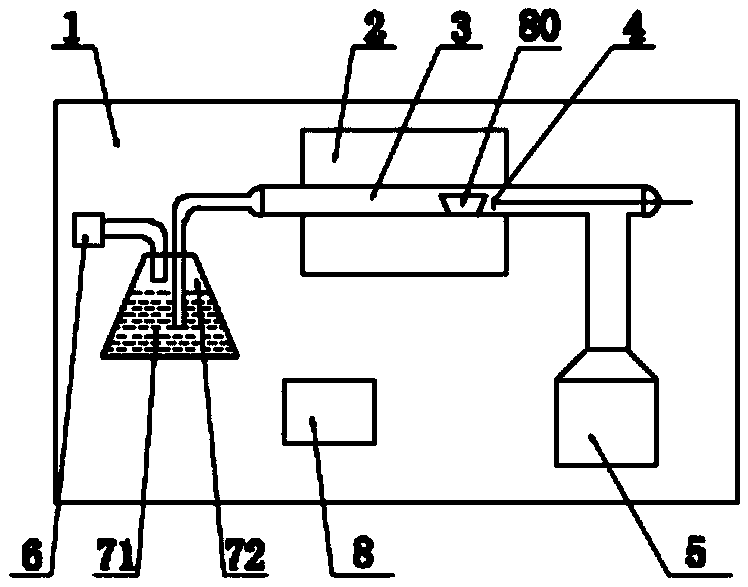

Neutralization sulphur meter with function of automatic drying

InactiveCN105510515AKeep dryEven drying effectChemical analysis using combustionPreparing sample for investigationCombustionNickel cadmium

The invention discloses a neutralization sulphur meter with a function of automatic drying and belongs to the field of coal sulfur content automatic measuring equipment. The neutralization sulphur meter comprises a combustion furnace and a drying device fixed to a base plate, a combustion tube, a nickel-cadmium push rod, an oxygen bottle and a gas collection bottle with a sodium hydroxide solution, and a sucking pump connected to the gas collection bottle through a gas-guide tube. The oxygen bottle and the gas collection bottle are respectively connected to two ends of the combustion tube through gas-guide tubes. The drying device comprises a drying tank of which the inner wall is provided with a resistance wire, an upper end cover, a lower end cover, a positioning plate, a rotation disc arranged in the drying tank, a rotation shaft of which the upper end is provided with the rotation disc, a temperature sensor and a blower. The neutralization sulphur meter has a simple and compact structure and a high automation degree, can fast dry a sample and has an automatic drying function.

Owner:CHANGZHOU UNIV

Water-based anticorrosive coating and preparation method thereof

InactiveCN112795250AImprove the efficacy of absorbing UV raysImprove the quality of useAnti-corrosive paintsPolyurea/polyurethane coatingsPolyurethane dispersionWeather resistance

The invention relates to an anticorrosive coating and a preparation method thereof, and particularly discloses a water-based anticorrosive coating which comprises the components in parts by weight: 15-25 parts of a water-based acrylic emulsion, 10-20 parts of a water-based polyurethane dispersion body, 5-8 parts of a film-forming agent, 1-3 parts of an anti-rust agent, 0.1-0.5 part of an anti-rust pigment, 8-12 parts of a filler, 5-10 parts of a wear-resistant anti-aging agent, 4-7 parts of an auxiliary agent and the balance being deionized water. The anticorrosive coating disclosed by the invention has good weather resistance, yellowing resistance, high hardness, good gloss and excellent permeability, further improves the ultraviolet absorption effect of the coating, can prevent the photodegradation of the coating, reduces the photoinduced color development speed, improves the use quality of the coating, prolongs the service life of the coating, improves the smoothness and self-cleaning property of the surface of the coating, and further improves the coating scratch-resistant wear resistance and other properties; and the coating disclosed by the invention is low in odor, good in anti-corrosive effect, excellent in wear resistance and aging resistance, simple and convenient in preparation process and high in coating performance stability.

Owner:扬州郎康汽车水性涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com