Coating compositions including a polyisocyanate chain extended NH functional pre-polymer

A technology of polyisocyanate and composition, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient pot life and characteristics, and achieve the effect of excellent mechanical properties, balanced mechanical properties, and balanced optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0040] Examples include 2-[2-(2-aminoethoxy)ethoxy]ethylamine (e.g. Jeffamine XTJ-504, available from Huntsman), 3-[2-(3-aminopropoxy)ethoxy ]propylamine (for example Etheramine NDPA 10, available from Tomah Products), 3-[3-(3-amino-propoxy)propoxy]propylamine (for example Etheramine NDPA 11, available from Tomah Products), 3-[4- (3-amino-propoxy)butoxy]propylamine (e.g. Etheramine NDPA 12, available from Tomah Products), 3-{2-[2-(3-aminopropoxy)ethoxy]ethoxy } Propylamine (eg EtheramineDPA-DEG, available from Tomah Products; or BASF TTD, available from BASF).

[0041] The NH functional prepolymers are also prepared from at least one disubstituted maleate and / or disubstituted fumarate.

[0042] The term "at least one" disubstituted maleate and / or disubstituted fumarate in the sense of the present disclosure means that the disubstituted maleate and / or the disubstituted fumarate respectively comprise one or more A plurality of disubstituted maleates and / or disubstituted fumarat...

Embodiment

[0165] Measurement methods

[0166] The following measurement methods were used to evaluate the parameters given in the examples and claims.

[0167] Hazen Chroma

[0168] Colorimetry was measured on the Hazen scale (based on ASTM D1209) with a BYK LCSIII device.

[0169] viscosity

[0170] ・The viscosity of the resin depends on Method determination. Measurements are carried out based on DIN 53015 at 25°C.

[0171] - Determine the viscosity of the activated clearcoat with a DIN 4 flow cup at room temperature (20±3°C). This method is based on DIN53211.

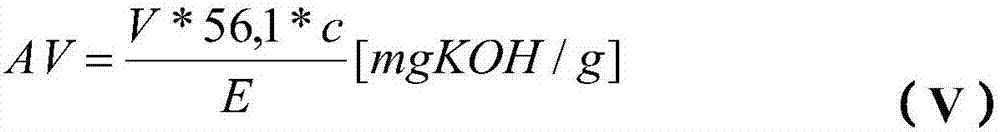

[0172] Applicable period

[0173] The pot life of the composition is measured by measuring the viscosity (DIN 4 cup) increase as a function of time. The pot life is defined as the time required to increase the initial viscosity to 1.5 times. Pot life defines the period of time during which the clearcoat composition remains readily sprayable.

[0174] hardness

[0175] The coating was applied to glass at a dry film t...

Embodiment 5

[0242] Embodiment 5: preparation is based on the transparent coating of comparative example 1, comparative example 2 and comparative example 3 and invention example 4

[0243] Clear coating compositions have been prepared by first activating the products obtained in Comparative Examples 1, 2 and 3 and Inventive Example 4 with a polyisocyanate activator based on 65% (aliphatic polyisocyanate HDI terpolymer, 90% solids, Bayer), 32.37% n-butyl acetate, epoxy functional silane (2.4% from Momentive), 0.2% p-toluenesulfonyl isocyanate (pTSI 96% from Aldrich) and 0.27% DBTDL catalyst (TINSTAB BL 277 from Akcros Chemicals). The product and activator were mixed manually in such a ratio that the ratio of NCO to NH was kept constant at 1.26. The total solids content of the activated mixture has also been kept constant at 57% by weight, based on the total weight of the mixture.

[0244] Clearcoats 5A, 5B, 5C and 5D were formulated with the components shown in Table 1 below.

[0245] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equivalent weight | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com