Water-based anticorrosive coating and preparation method thereof

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor anti-corrosion performance, poor gloss, unsatisfactory weather resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

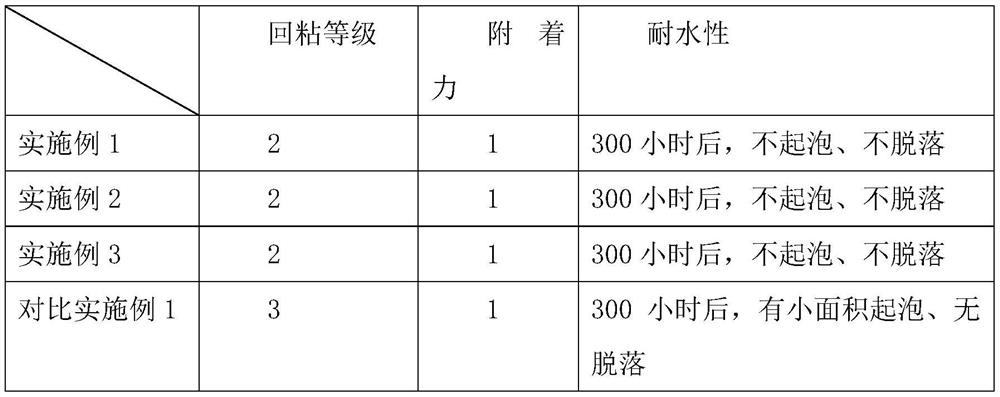

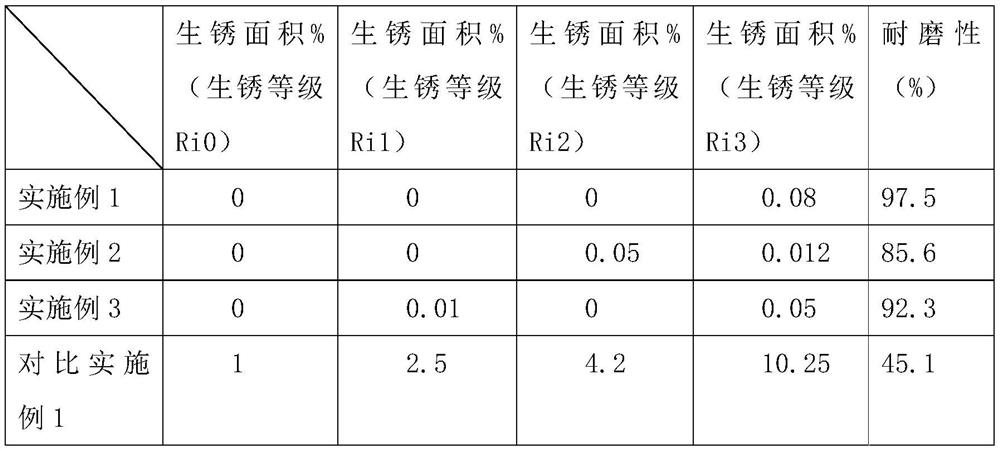

Examples

preparation example Construction

[0027] In the embodiment of the present invention, water-based anti-corrosion coating and preparation method, the preparation method of water-based anti-corrosion coating is the following steps:

[0028] B1. Put the water-based acrylic emulsion and water-based polyurethane dispersion into the reaction tank for full stirring, and add a certain amount of film-forming agent. The temperature is controlled at 30-40°C, mixed evenly for 10-15min, and the speed is controlled at 1200-1500r / min, get the mixture;

[0029] B2. Then add the rust-removing pigment, anti-rust agent and filler into the mixture obtained above, and add a certain amount of deionized water, heat up to 45-55°C, rotate at 1500-1800r / min, stir and mix for 15-20min , add the wear-resistant anti-aging agent and additives, and continue to stir evenly for 20-40 minutes to obtain a water-based anti-corrosion coating;

[0030] Wherein, the antirust agent is one of zinc phosphate, zinc molybdate, aluminum tripolyphosphate...

Embodiment 1

[0041] Water-based anti-corrosion coating, the composition of this anti-corrosion coating comprises by weight: 15 parts of water-based acrylic emulsion, 10 parts of water-based polyurethane dispersion, 5 parts of film-forming agent, 1 part of anti-rust agent, 0.1 part of anti-rust pigment, 8 parts of filler, 5 parts of wear-resistant and anti-aging agent, 4 parts of auxiliary agent, and the balance is deionized water.

[0042] The filler is composed of 6 parts by weight of talcum powder, 3 parts of mica powder, 2 parts of porous quartz powder, 1 part of calcium carbonate, and 0.1 part of zinc stearate;

[0043] The preparation method of the filler is as follows: After drying the talc powder, mica powder and porous quartz powder, put them into the mixing tank and mix them evenly, then add calcium carbonate and zinc stearate in sequence, and continue to stir for 10-30 minutes to prepare got filler;

[0044]The wear-resistant and anti-aging agent is composed by weight: 5 parts o...

Embodiment 2

[0047] Water-based anti-corrosion coating, the composition of this anti-corrosion coating comprises by weight: 25 parts of water-based acrylic emulsion, 20 parts of water-based polyurethane dispersion, 8 parts of film-forming agent, 3 parts of antirust agent, 0.5 part of antirust pigment, 12 parts of filler, 10 parts of wear-resistant and anti-aging agent, 7 parts of auxiliary agent, and the balance is deionized water.

[0048] The filler is composed of 10 parts by weight of talcum powder, 5 parts of mica powder, 6 parts of porous quartz powder, 3 parts of calcium carbonate, and 0.5 part of zinc stearate;

[0049] The preparation method of the filler is as follows: After drying the talc powder, mica powder and porous quartz powder, put them into the mixing tank and mix them evenly, then add calcium carbonate and zinc stearate in sequence, and continue to stir for 10-30 minutes to prepare got filler;

[0050] The wear-resistant and anti-aging agent is composed by weight: 10 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com