Patents

Literature

1422results about How to "Improve the quality of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment protecting wood wax oil

InactiveCN101550316ANo pollution in the processMeet environmental protection requirementsCoatingsWood impregnation detailsWaxVegetable oil

The present invention relates to an environment protecting wood wax oil which comprises the following main components by weight: 75-85 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 11-22 parts of rosin resin, 1-2 parts of drier and 0.1-1 part of cosolvent. The preparing method of the wood wax oil comprises the following steps: heating and melting the vegetable oil and wax mixing system, reducing the temperature and adding other materials, and mixing to uniform for obtaining the wood wax oil. The wood wax oil related to the invention can totally penetrate into the wood. The wood wax oil of the invention is remarkably different with the traditional paint with the existence of paint skin. The surface of wood wax oil has an open texture effect. The different woods can represent different real tactile sensation. Furthermore the wood with the environment protecting wood wax oil can be partially restored and retrofitted without mark. The wood wax oil can preserve various excellent performances of wood and effectively prevent the seasoning cracking of wood. The wood is caused to possess the excellent performances of ventilation, drying, corrosion resistance, worm resistance, flame resistance, etc. The using quality of wood can be increased comprehensively.

Owner:TIANJIN XIANDAIREN RE EMPLOYMENT SERVICE

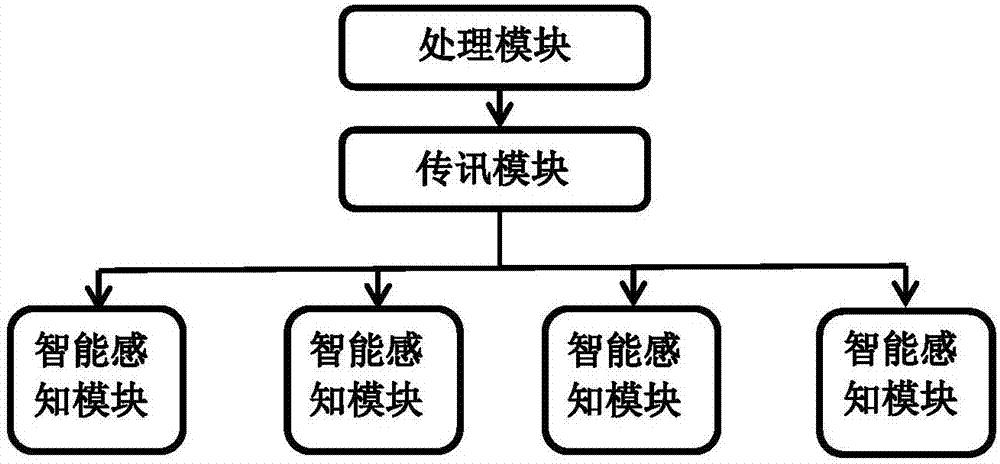

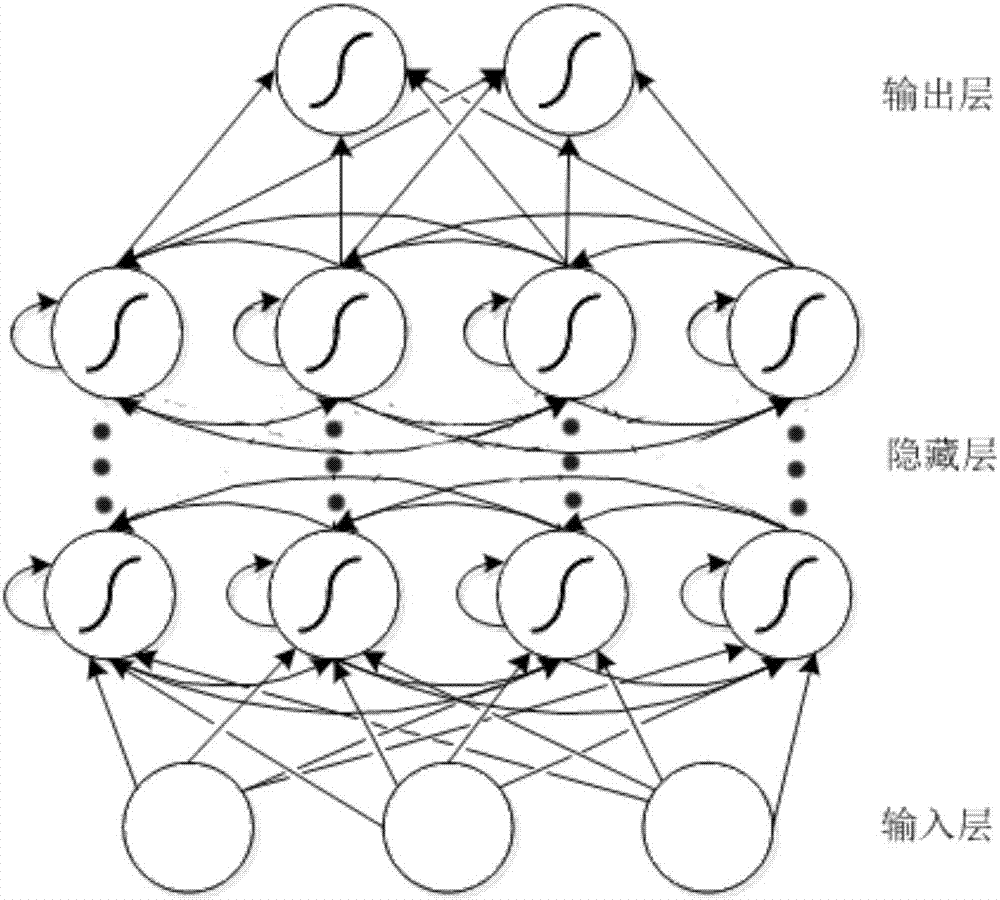

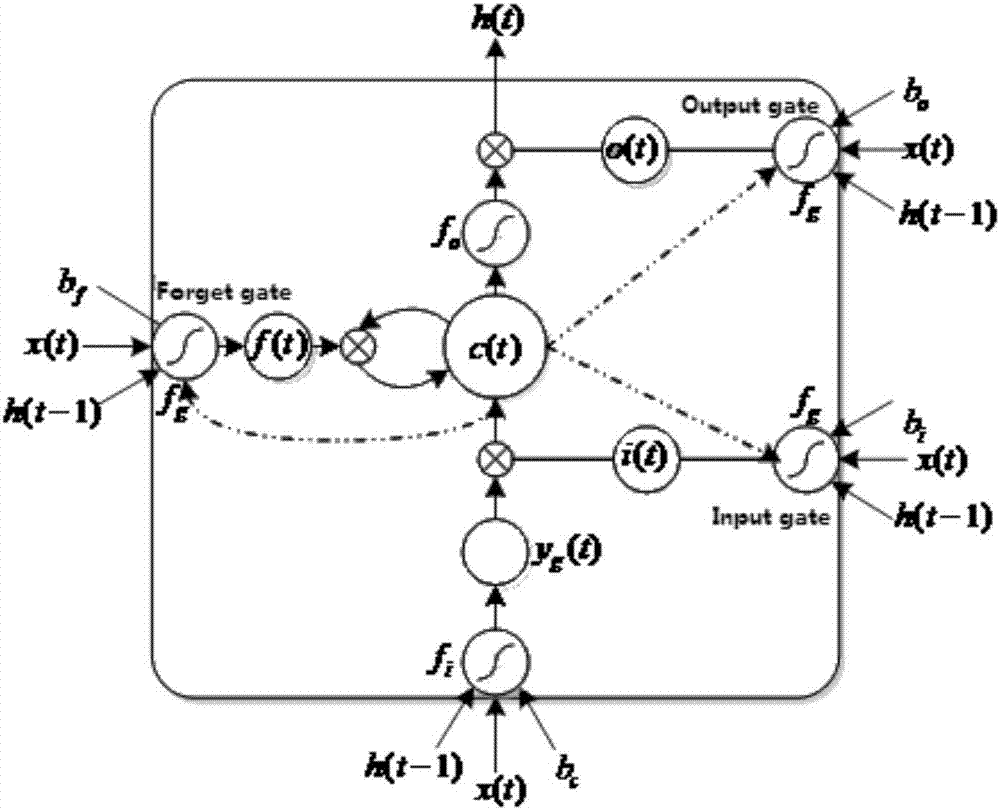

Electric quantity consumption predicting method based on deep learning

InactiveCN107239852AImprove the quality of useGood forecastForecastingNeural architecturesError tolerancePower grid

The invention discloses an electric quantity consumption predicting method based on deep learning. According to the invention, a deep learning model is able to train a BP network according to the historical data as of now so as to achieve a better predicting effect. The reasons behind choosing the deep learning for electric quantity predicting are that it has a non-linear adaptive information processing ability unique to the neural network, that it has a strong error tolerance, and that it can be applied to the dynamic analysis for electric quantity consumption and meets a plurality of integrated factors such as time regularity and event suddenness. In the method, first, the intelligently sensed current and voltage data are calculated as electric quantity consumption amount for the training of a neural network so as to predict the electric quantity consumption at a next period. The predicted electric quantity consumption amount and the statistic power using duration are fed back to the user so as to guide him or her to conserve power. The method of the invention is simple and practical in use and can be applied to a smart home system connected via Wifi, and the method can also be used to predict the electric quantity consumption in regional and urban power grids.

Owner:NANJING UNIV OF POSTS & TELECOMM

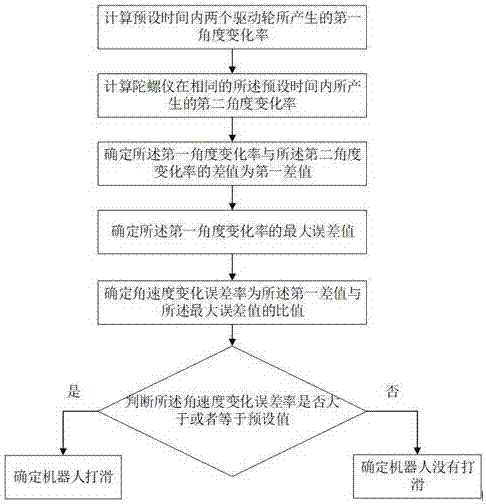

Detecting method of barrier collision by intelligent robot and mapping method

The invention relates to a detecting method of barrier collision by an intelligent robot and a mapping method. The method includes steps of detecting and calculating the bias rate of the angle speed change of the robot through a milemeter on the existing driving wheel of a robot, a gyroscope and a processor in a machine body, and judging if the robot is slipped through the bias rate of the angle speed change; then confirming if the robot collides the barrier through judging if the current variance generated by the driving wheel is more than or equal to the setting value on the basis of the slippage of the robot. According to the detecting method of the barrier collision by the intelligent robot and the map structuring on the basis of the method detection result, the cost is relatively low, and the detecting method is not influenced by the mass or structure design of these special sensors, thus the robot structure is simplified, the production processing difficulties are reduced, and the service life and quality of the robot are improved.

Owner:AMICRO SEMICON CORP +1

Tungsten titanium target material with high purity and high tungsten-rich phase, and preparation method thereof

ActiveCN101748365AUniform densityHigh strengthVacuum evaporation coatingSputtering coatingHigh densityRefractory

The invention relates to a refractory alloy tungsten titanium target material and a preparation method thereof, in particular to a tungsten titanium target material with high purity and high content of tungsten-rich phase, and a hot-pressing preparation method thereof, which belongs to the technical field of refractory alloy target materials. The method prepares high-density tungsten alloy targetmaterial by taking high-purity W powder and Ti powder, as well as high-purity Mo, Cr, Ta, Nb and other additive metal powder as raw materials and adopting a high-temperature high-pressure hot-pressing molding process, wherein the relative density of the target material reaches 95 to 99 percent, and the content of tungsten-rich phase reaches 80 to 93 percent. Relative to the prior art, the method adds part of high-purity Nb, Mo, Cr, Ta and other metal powder while mixing materials so as to stabilize the tungsten-rich phase in alloy, increase the content of the tungsten-rich phase in the alloy and improve the using quality of the target material.

Owner:有研资源环境技术研究院(北京)有限公司

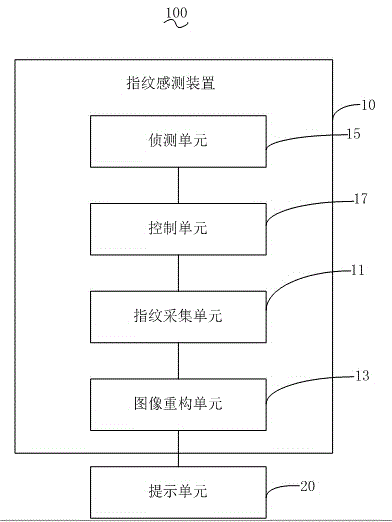

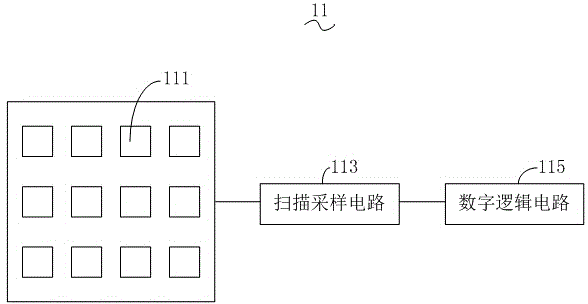

Fingerprint sensing device, electronic product and fingerprint sensing method thereof

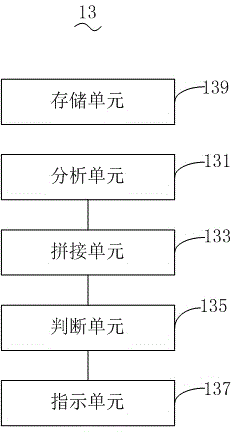

InactiveCN104615991AImprove the quality of useFacilitate fingerprint recognitionMatching and classificationPattern recognitionCorrelation analysis

The invention discloses a fingerprint sensing device, a product with a fingerprint sensing function and a fingerprint sensing method of the product. The fingerprint sensing device comprises a fingerprint acquisition unit and an image reconstruction unit. The fingerprint acquisition unit is used for acquiring a fingerprint image of a finger, pressing the fingerprint acquisition unit, of a user. The image reconstruction unit is used for instructing the finger to conduct corresponding movement operation on the fingerprint acquisition unit according to the fingerprint image acquired by the fingerprint acquisition unit so as to acquire different secondary fingerprint images; the image reconstruction unit conducts correlation analysis on the secondary fingerprint images acquired by the fingerprint acquisition unit, conducts splicing on the secondary fingerprint images according to the analysis result, and judges whether a fingerprint image formed through splicing meets predetermined requirements or not, and if not, the image reconstruction unit continues instructing the finger to conduct corresponding movement operation on the fingerprint acquisition unit according to the fingerprint image formed through splicing until the situation that the fingerprint image formed through splicing meets the predetermined requirements is determined.

Owner:SHENZHEN SUNWAVE TECH

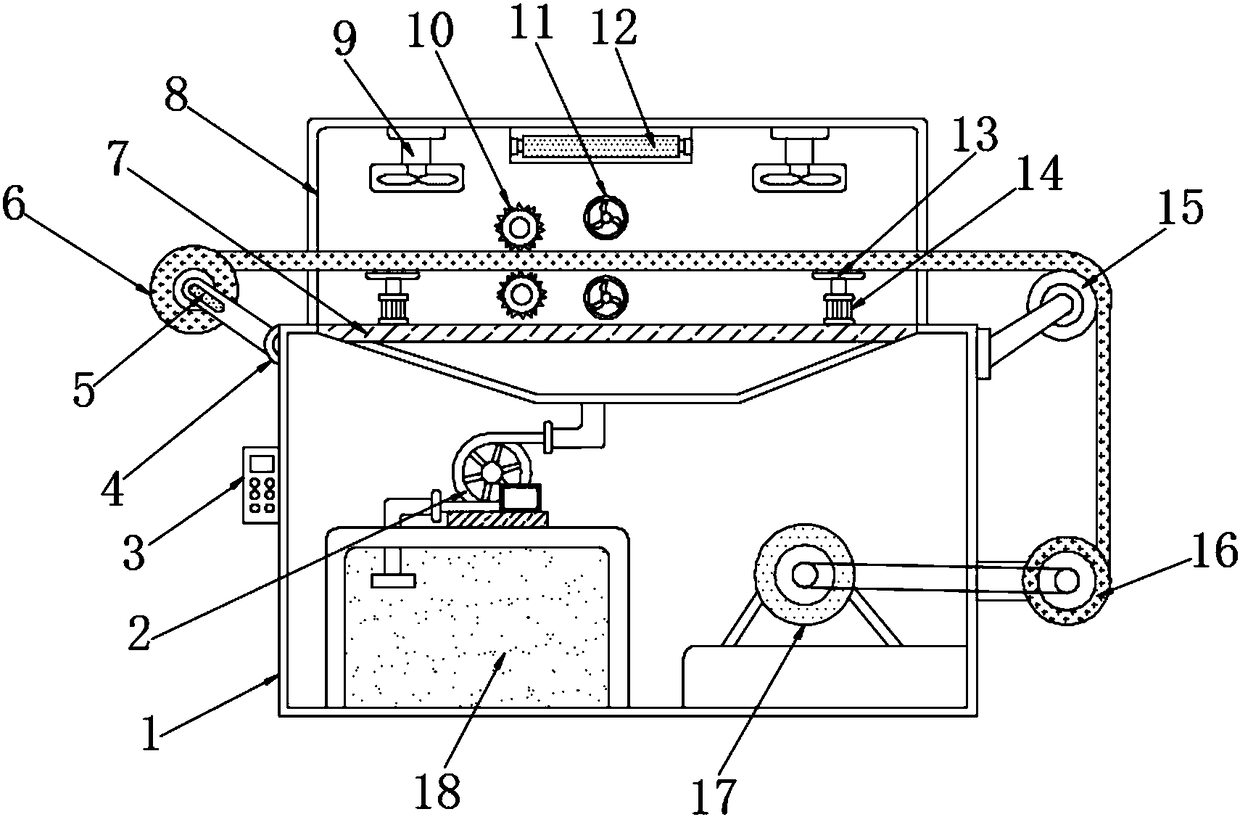

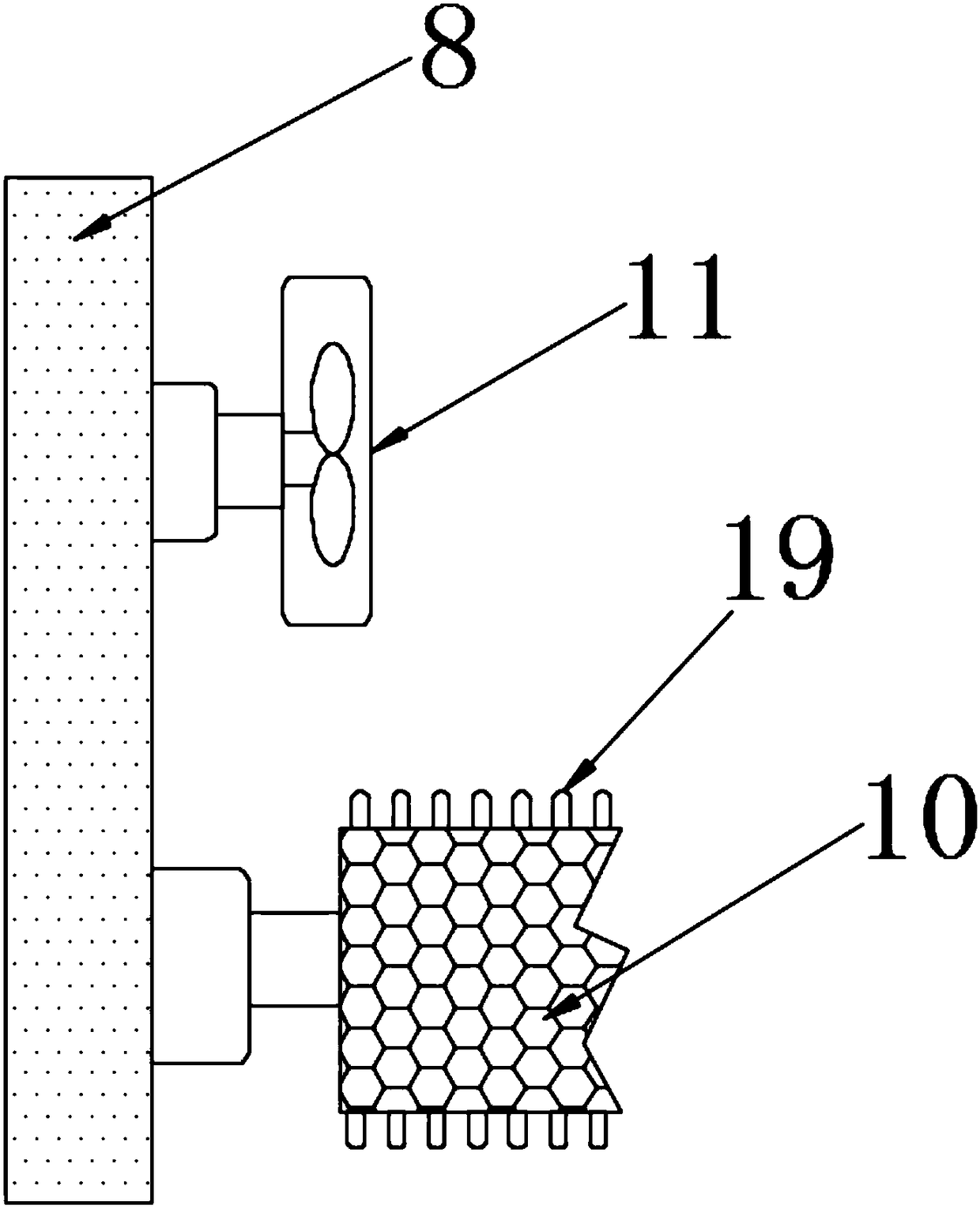

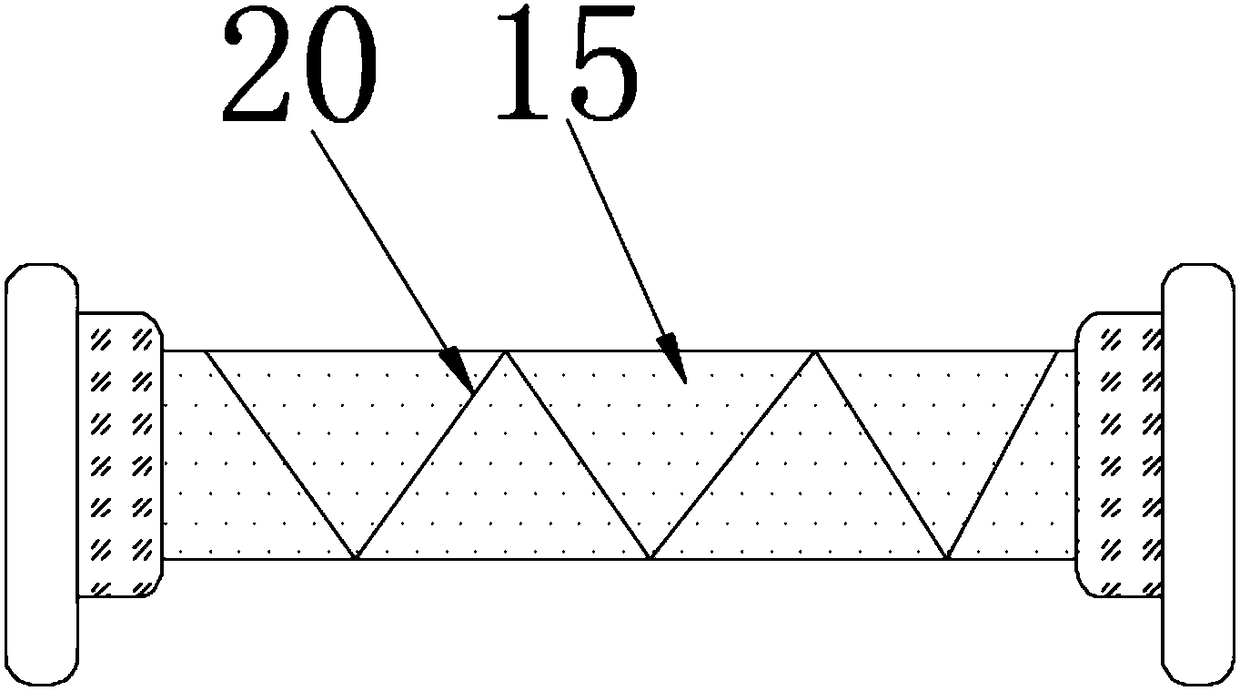

Dust removing device for textile use

InactiveCN108130702AAvoid problems that cannot be blown offImprove the quality of dust removalMechanical cleaningPressure cleaningEngineeringVirus

The invention discloses a dust removing device for textile use, comprising a case. A dust box is arranged inside the case. A grille is arranged on the upper end of the case. A vibration motor is arranged on the upper end of the grille. A shaking board is arranged on the upper end of the vibration motor. A cover is arranged on the upper end of the shaking board. The vibration motor and the shakingboard cooperate with a dust removing fan to shake textile cloth in order to remove the dust impurities on the textile cloth. The dust impurities on the texture cloth can be brushed off through a dustremoving brush roll and the grille, and the dust impurities can be easily collected. The bacteria and viruses on the texture cloth can be killed conveniently through an ultraviolet lamp tube, and willnot affect the sanitary quality of the textile cloth. The textile cloth can be heated and dehumidified conveniently through a cloth guide roll and a heating wire. Moreover, the texture cloth can alsobe ironed and prevented from wrinkling, and thus, the textile cloth looks more beautiful.

Owner:响水县嘉亿纺织有限公司

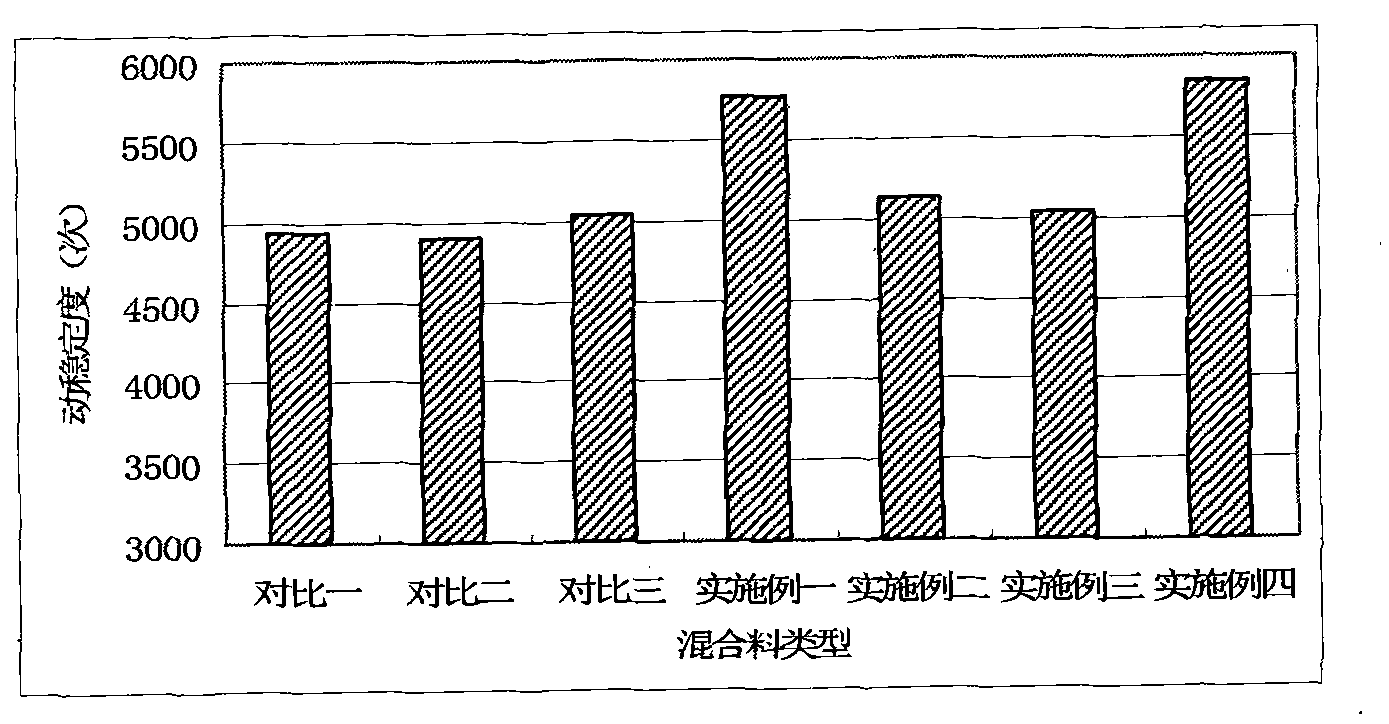

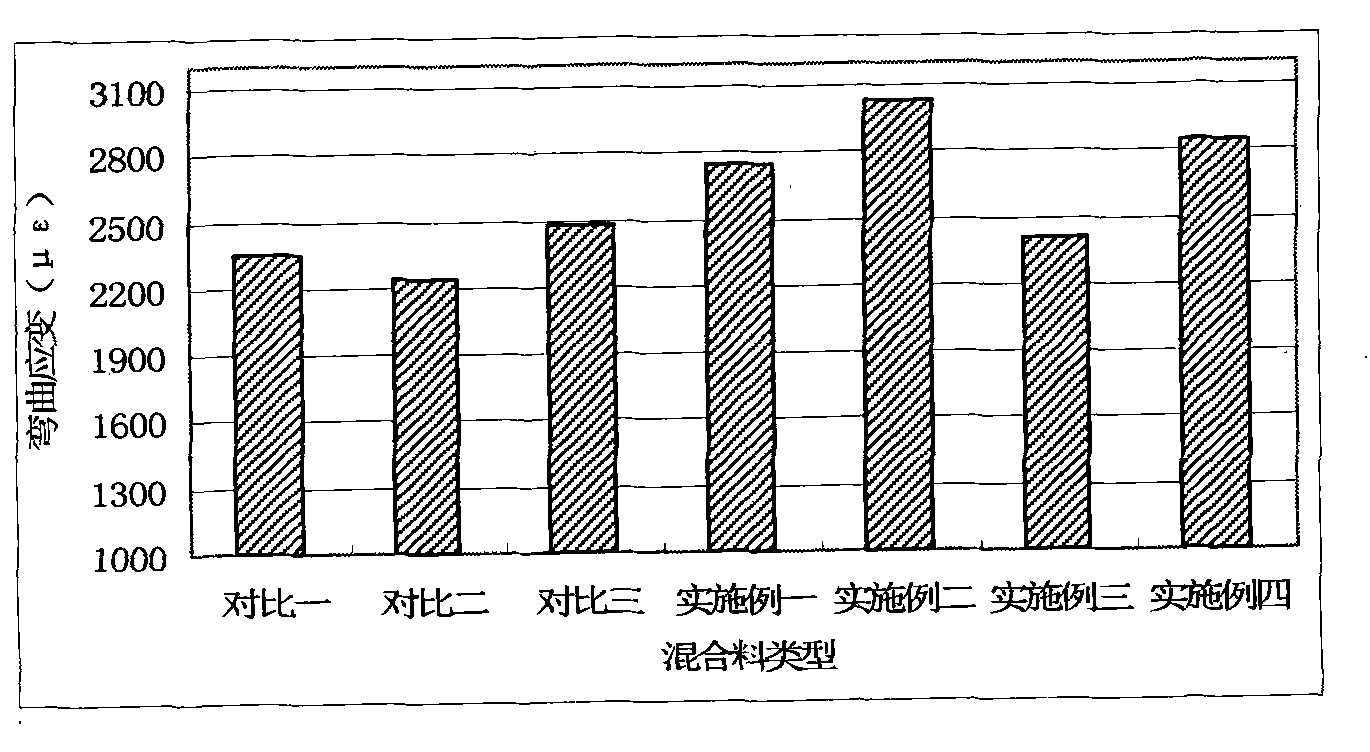

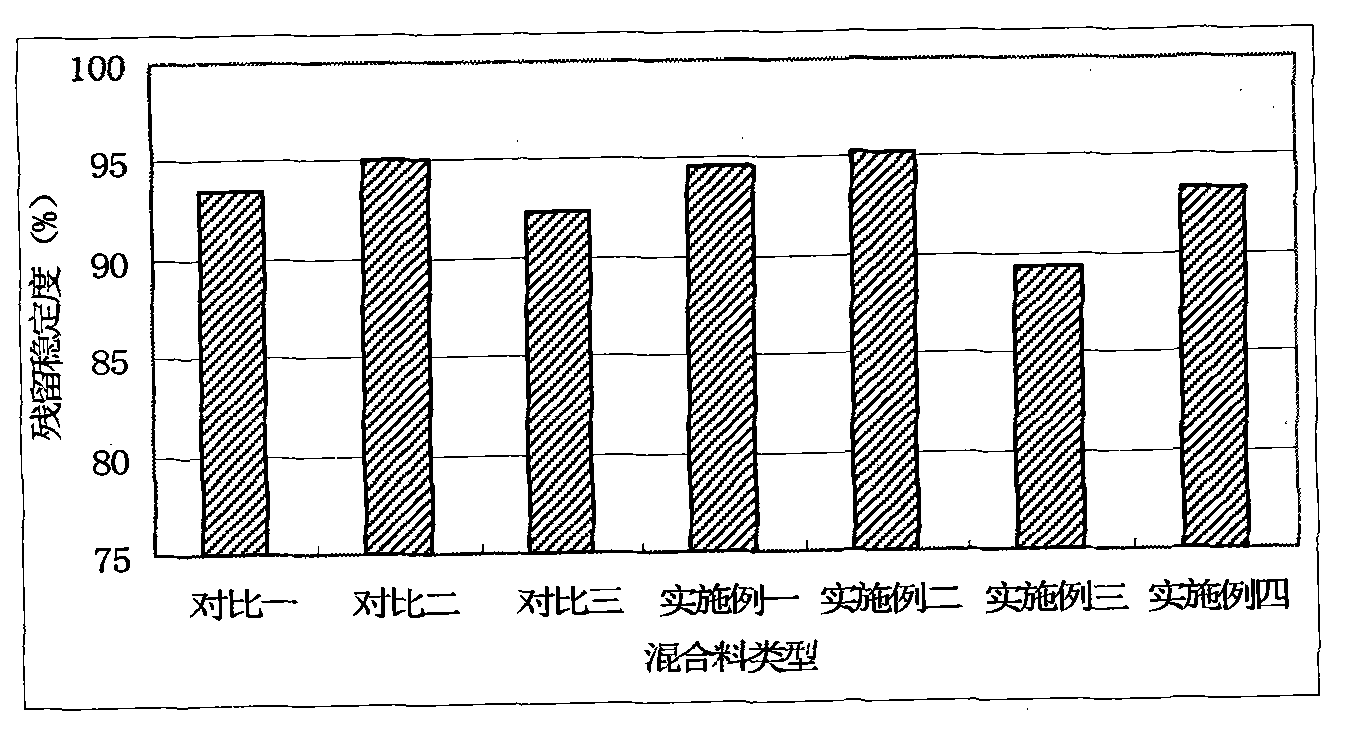

Rubber modified asphalt mixture and preparation and construction methods thereof

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methodshave the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by blackpollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

Design and manufacturing method of porous grid structure material

InactiveCN105499575AManufacturing flexibilityImprove performance qualityAdditive manufacturing apparatusTissue regenerationLaser scanningSize ratio

The invention discloses a design and manufacturing method of a porous grid structure material and aims to solve the problems of blindness and uncertainty in traditional manufacturing of a porous material and apply an effective design concept for the porous material to practical manufacturing. The design and manufacturing method comprises the following steps: obtaining a data image based on topological optimization simulation; performing three-dimensional rebuilding on the data image on Solid Works; importing to magics software as a unit grid structure; filling into various three-dimensional models of specific parts which need to adopt the grid structure at any size ratio; afterwards manufacturing the parts. According to the design and manufacturing method, firstly, the three-dimensional model of each part is imported to a computer on a worktable; the printing angle and the printing position are set according to the three-dimensional graph structure; a powder layer is sintered into a corresponding two-dimensional shape on the layer; powder with the same thickness is repeatedly laid on the worktable on which one layer of graph is sintered; laser scanning is still performed according to the scanning route of the layer until the overall three-dimensional graph is completed. The design and manufacturing method disclosed by the invention has the advantages of reducing the elasticity modulus of the part and realizing good mechanical properties.

Owner:BEIJING UNIV OF TECH

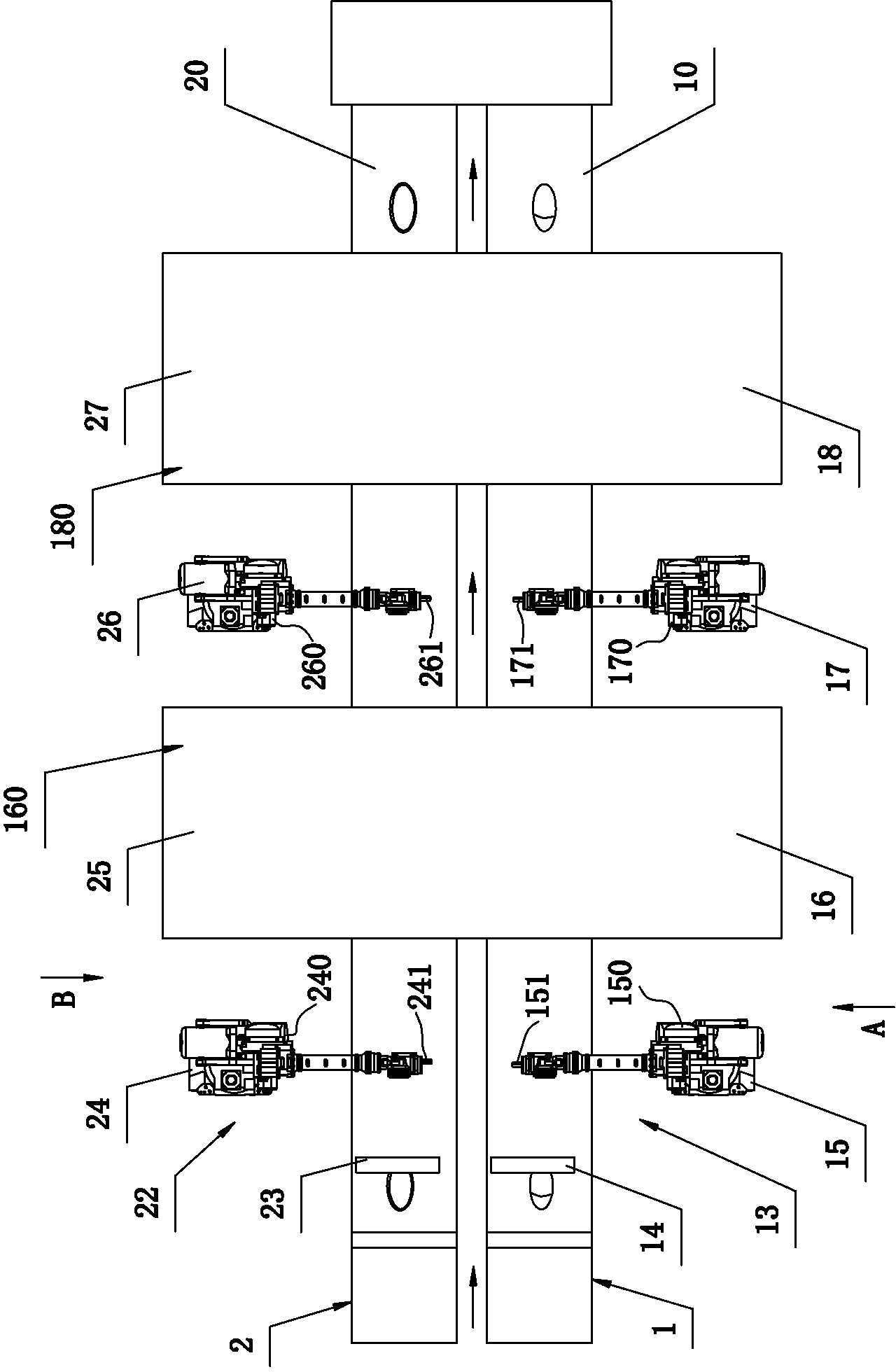

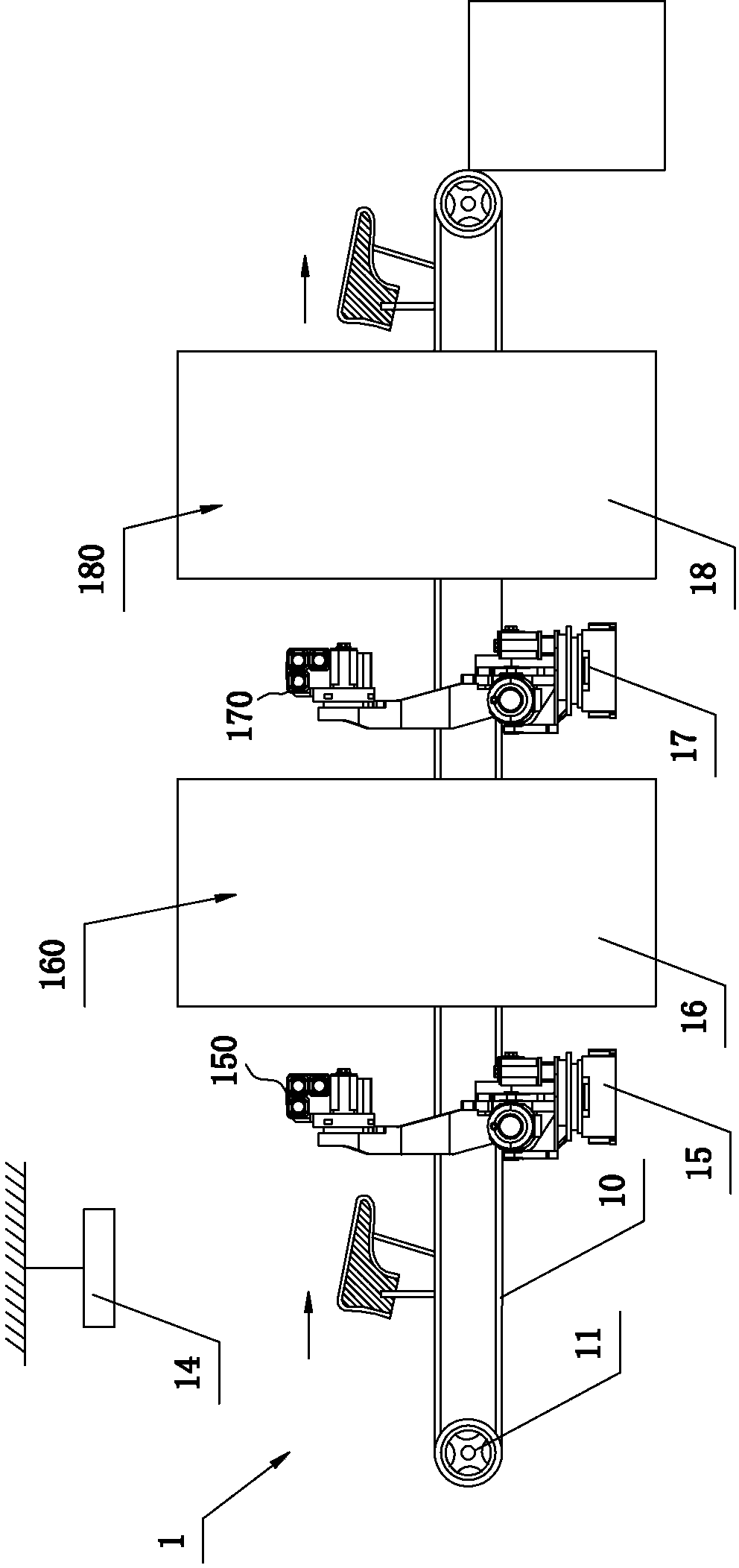

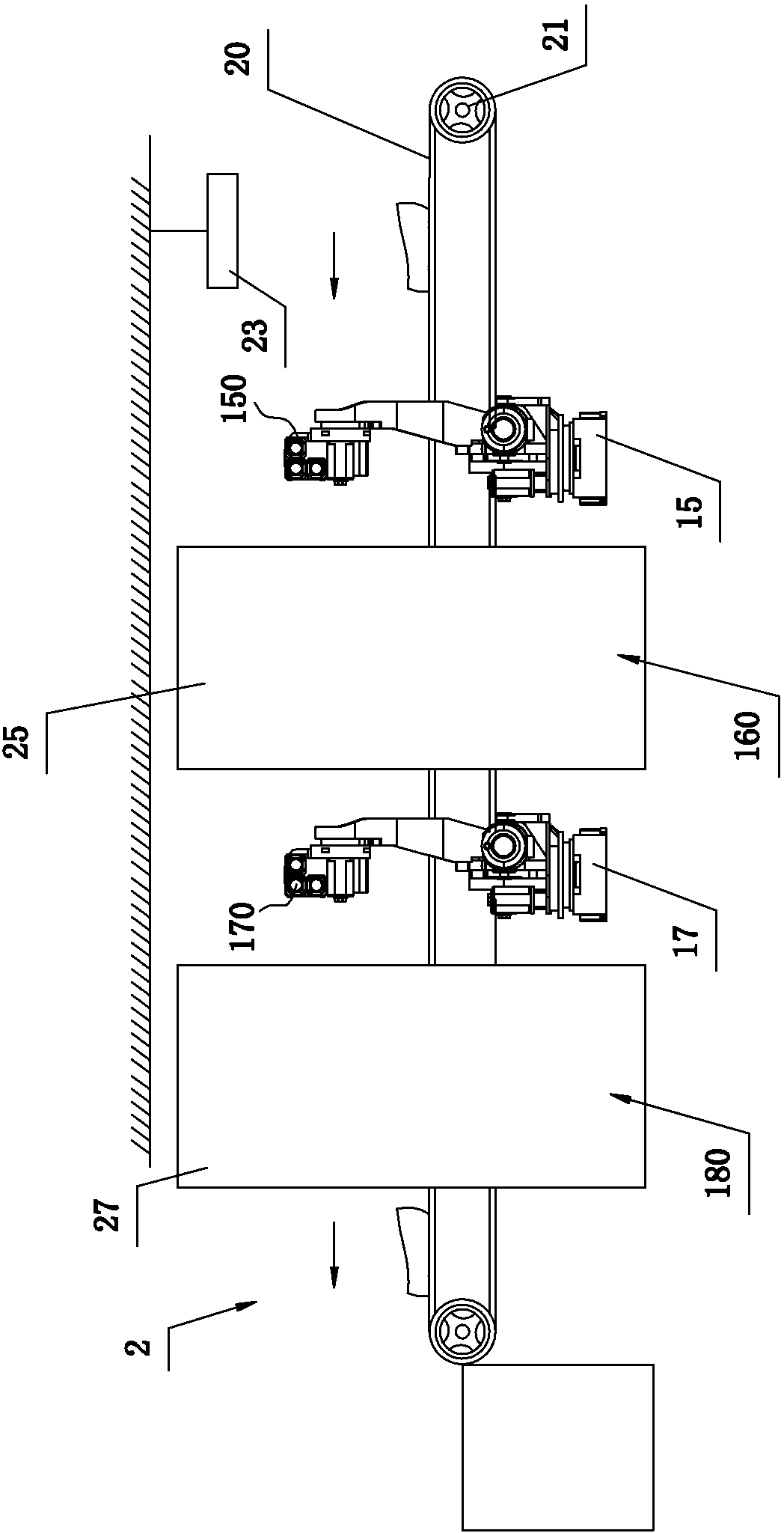

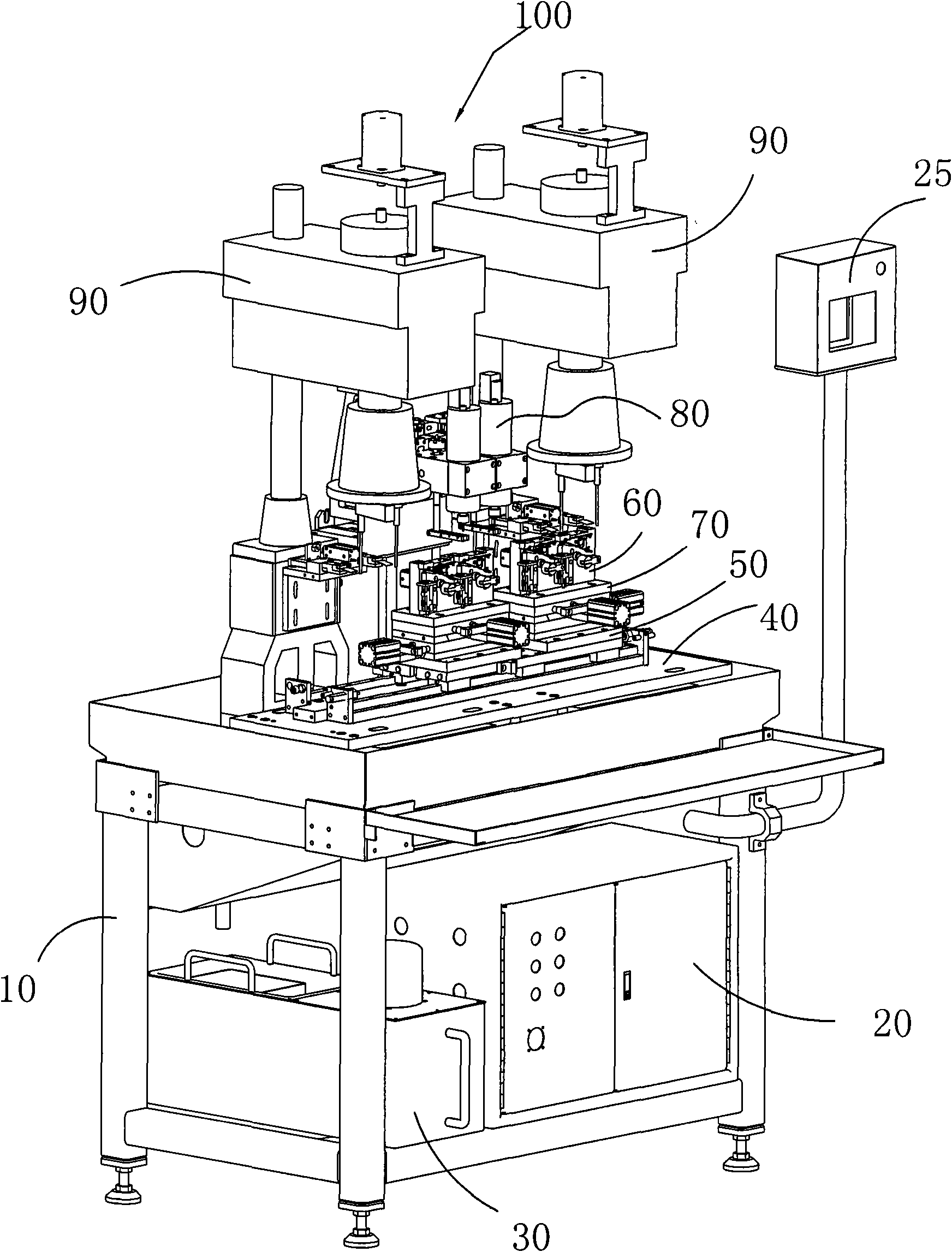

Automatic manufacturing method and automatic production line for shoes

InactiveCN104161355AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingProduction lineManipulator

The invention relates to an automatic production line for shoes. The automatic production line comprises an automatic vamp gluing device and an automatic sole gluing device. The automatic vamp gluing device comprises a first conveying belt, a first driving assembly and a first automatic glue spraying control assembly. The first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first processing water spraying mechanism, a first processing water drying mechanism, a first glue spraying executing mechanism and a first glue drying mechanism, wherein the three-dimensional scanning mechanism, the first processing water spraying mechanism, the first processing water drying mechanism, the first glue spraying executing mechanism and the first glue drying mechanism are located above the first conveying belt and adjacently connected in sequence. The first glue spraying executing mechanism comprises a controller, a first six-degree-of-freedom mechanical hand and a first spray gun, wherein the enable end of the controller is connected with the three-dimensional scanning mechanism, and the first spray gun is installed on the arm of the first six-degree-of-freedom mechanical hand. The invention further relates to an automatic manufacturing method for the shoes. According to the automatic production line and the automatic manufacturing method for the shoes, glue wastage can be greatly reduced, the vamp glue spraying effect consistency is improved, then the follow-up vamp and sole gluing firmness degree is improved, the service life of the shoes is prolonged, and the quality of the shoes is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

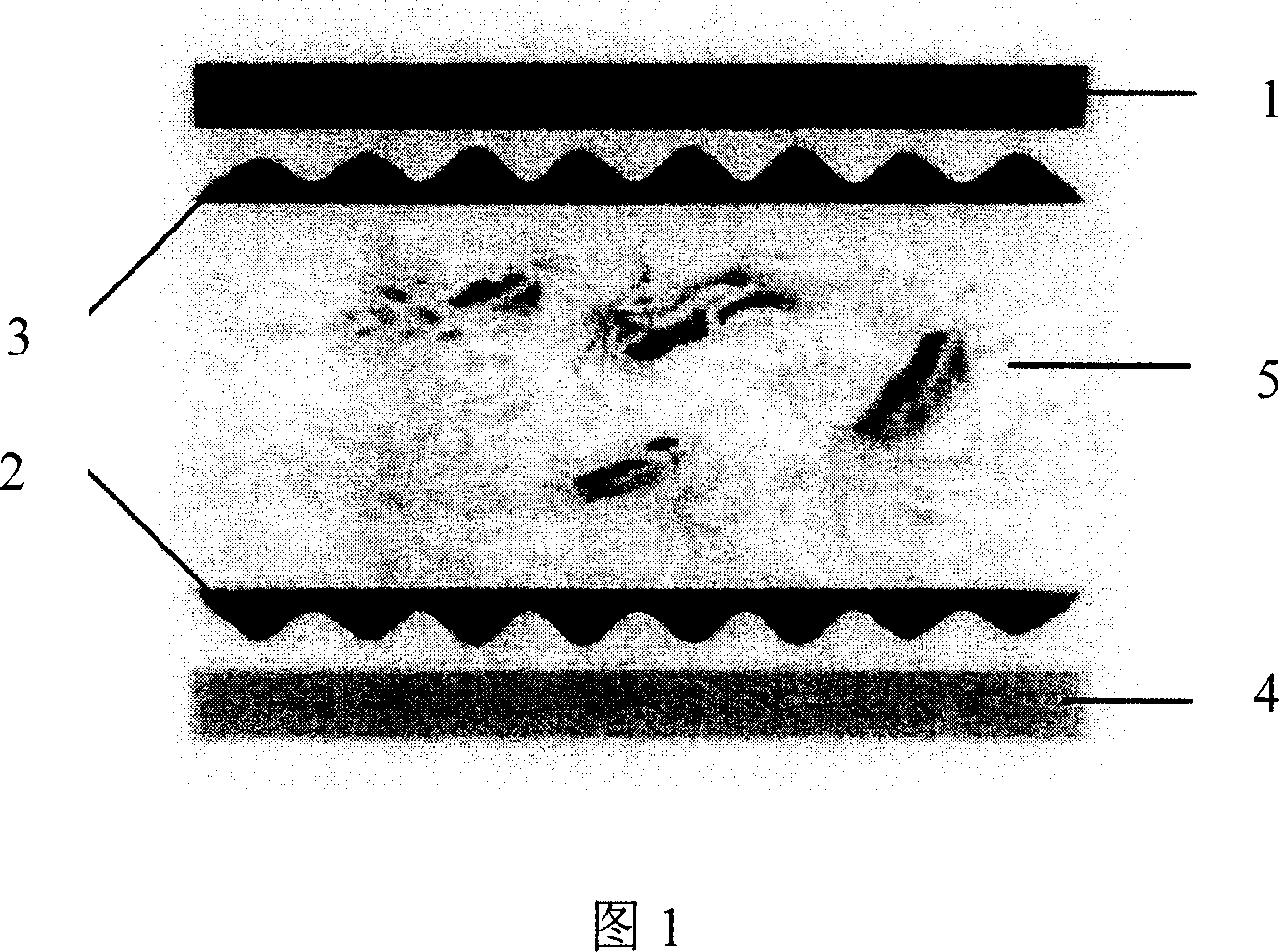

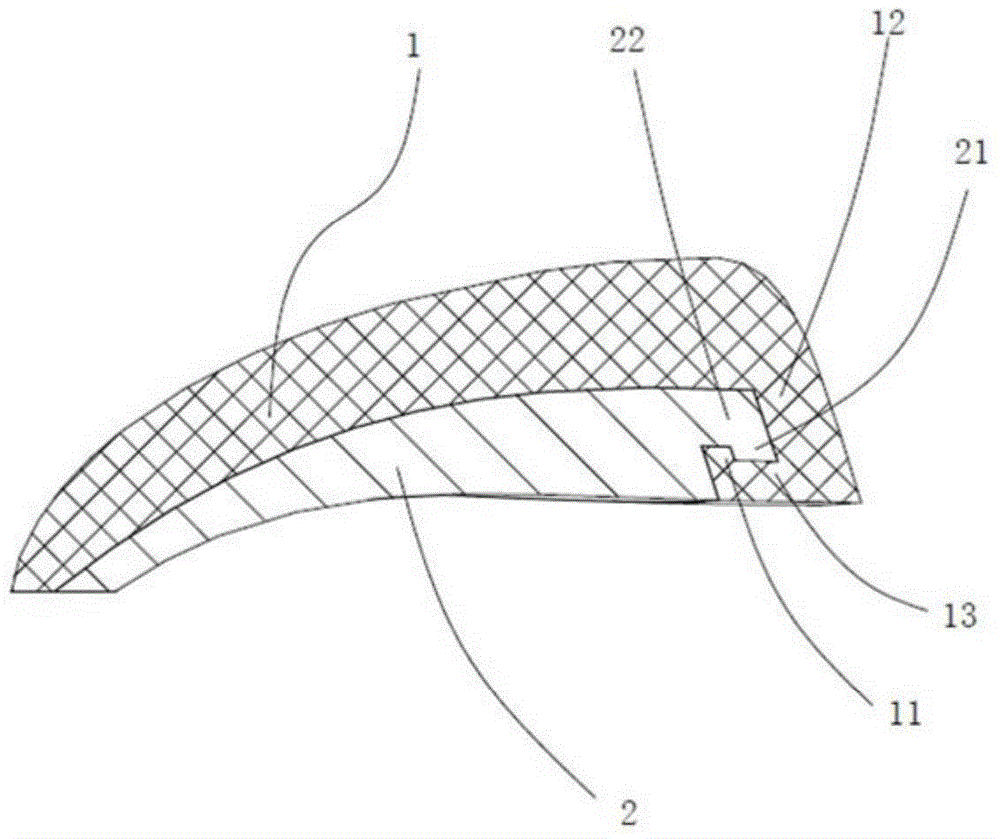

Down and feather garment with effect for locking down, and technique for processing locked down

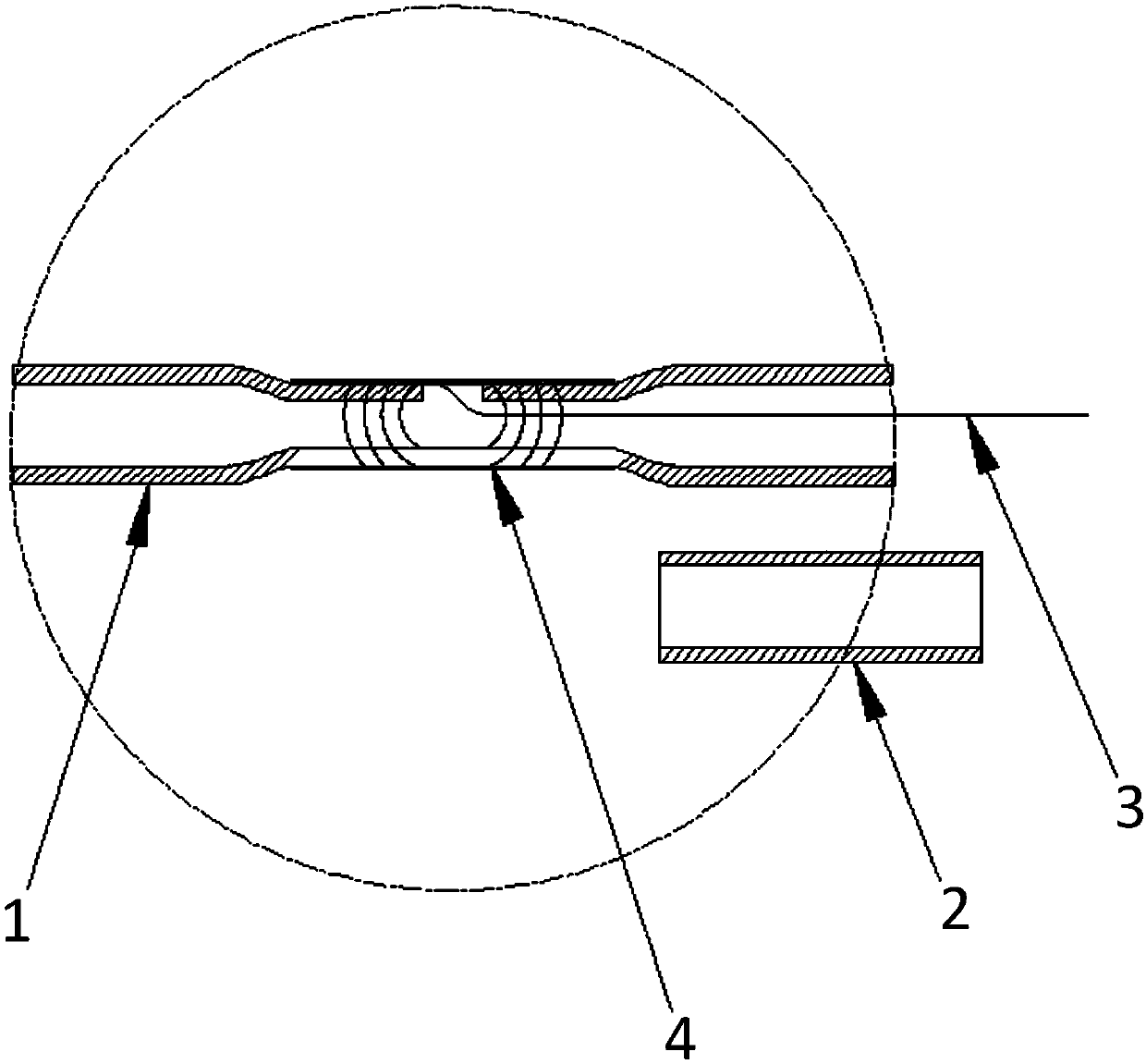

ActiveCN1957782AExtended service lifeImprove the quality of useOvergarmentsProtective garmentMechanical engineeringComposite material

A down-padded jacket without down escape is composed of an external surface fabric layer, the first and the second liner fabric layers, a down layer between said first and second liner fabric layers, and an internal surface fabric layer. Its treating technology for preventing escape of down is also disclosed.

Owner:ZHEJIANG ERAL DOWN PRODS

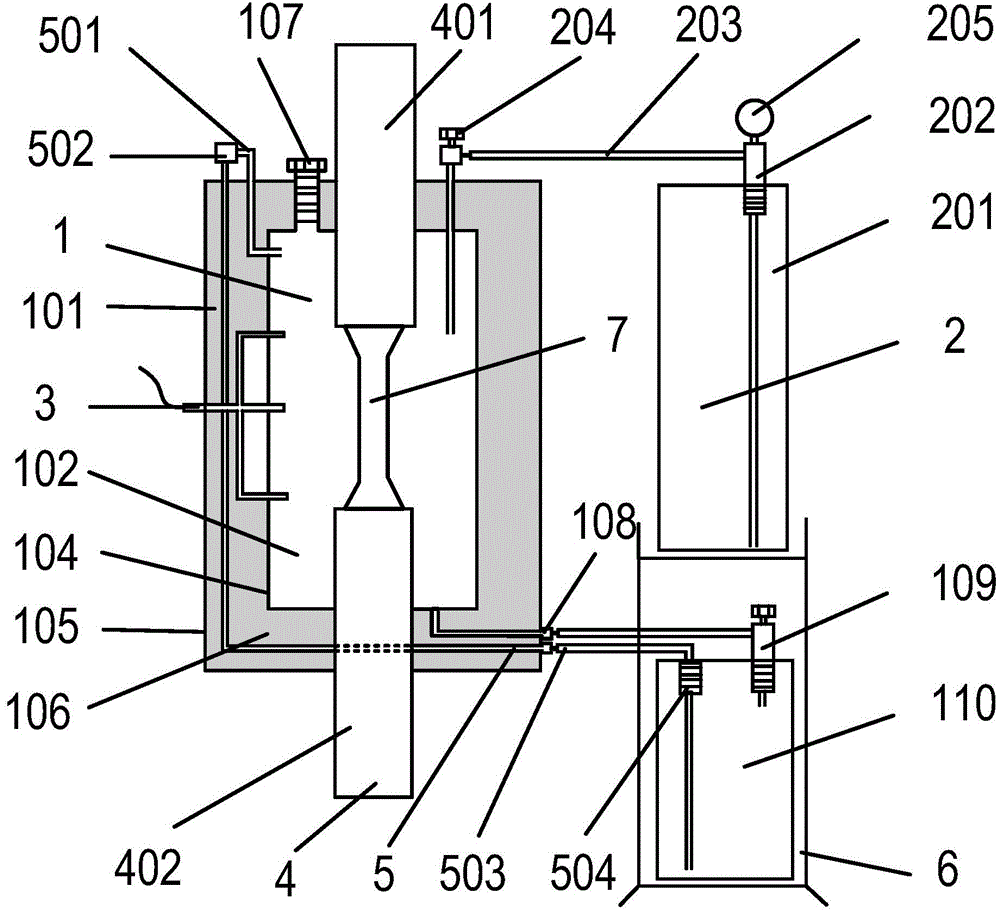

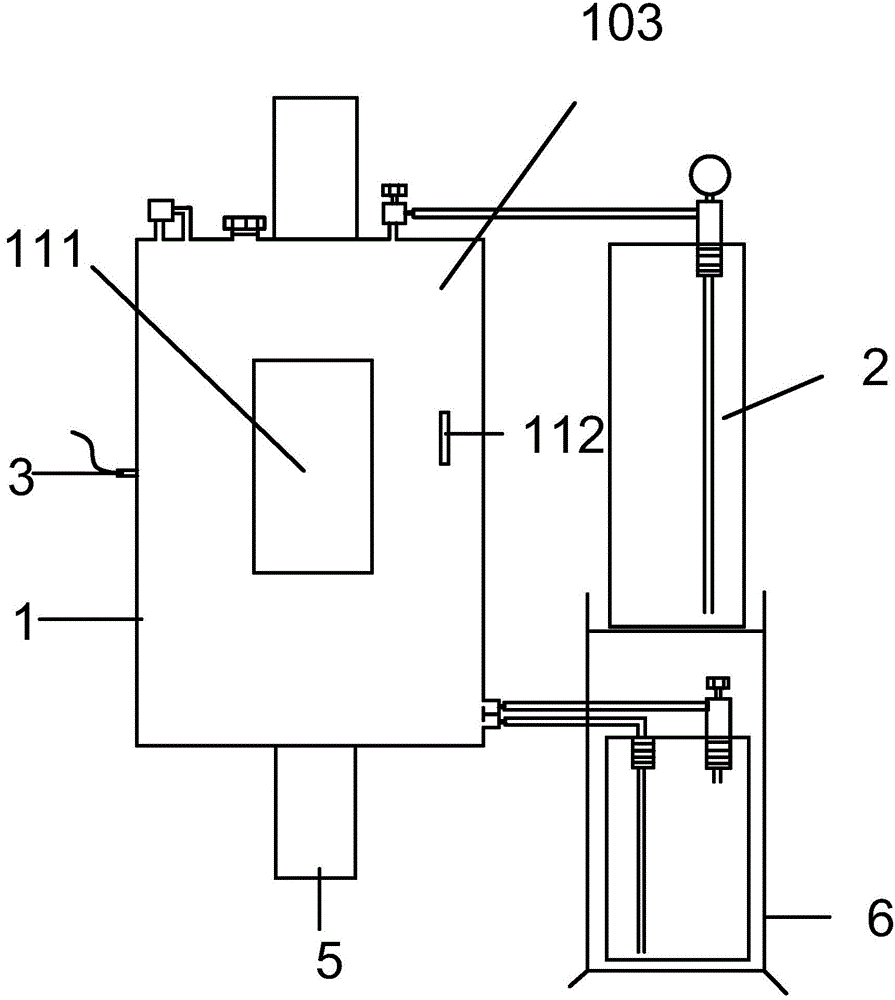

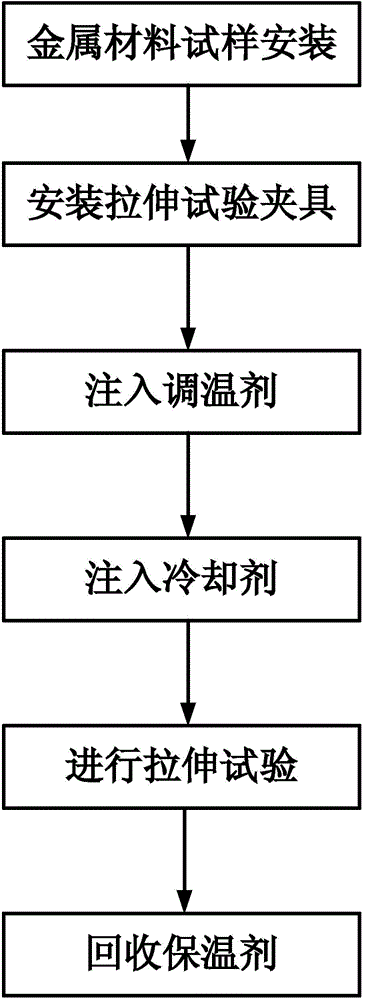

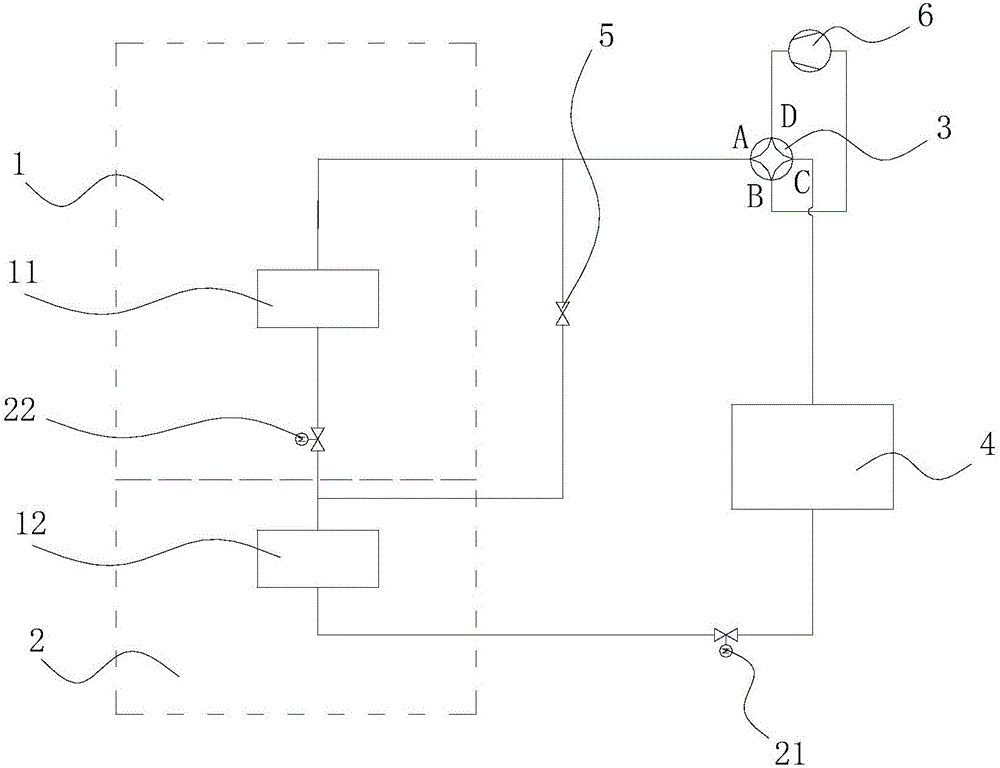

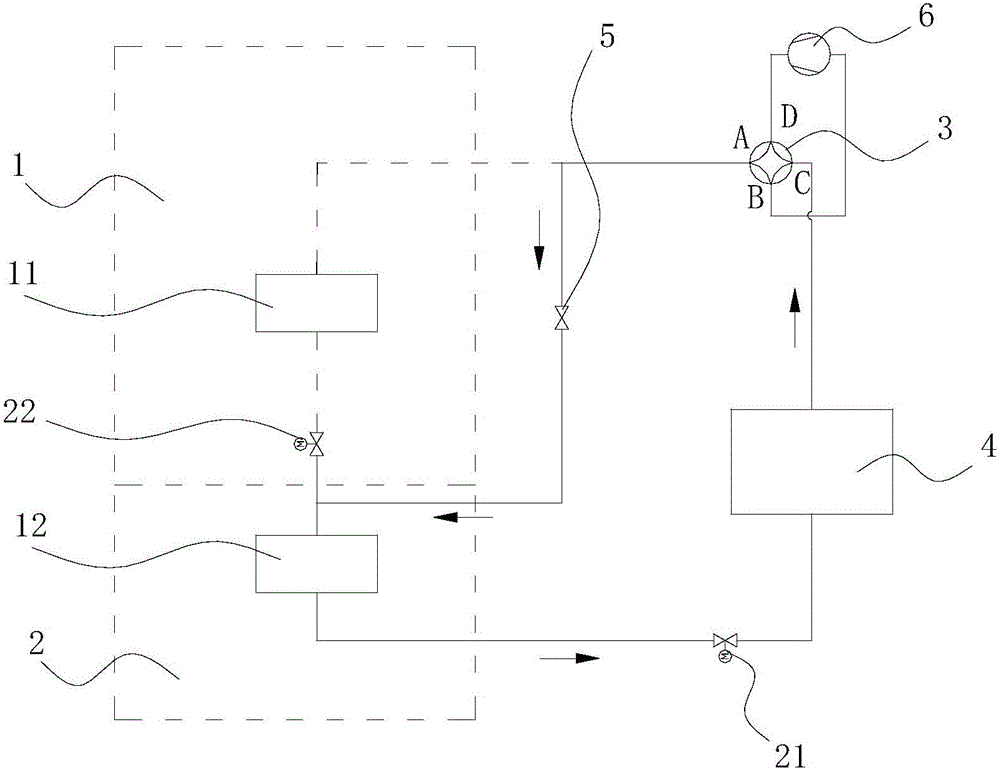

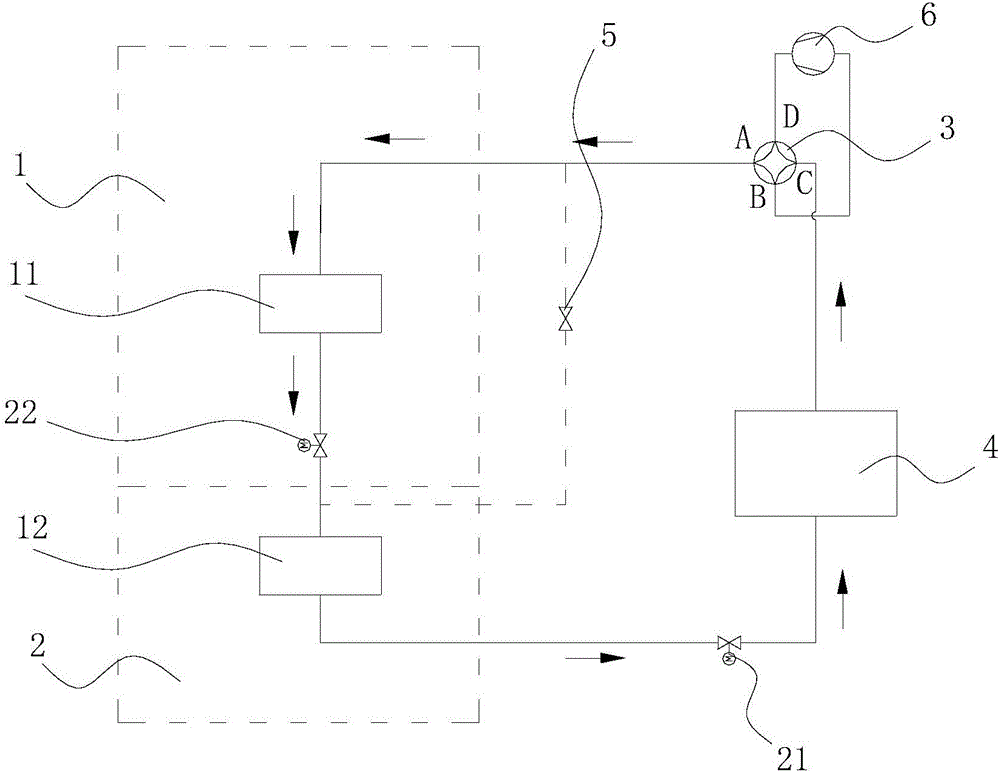

Metal material low-temperature tensile test device and test method

InactiveCN104142273AGood temperature control abilityEven and stable temperature regulationMaterial strength using tensile/compressive forcesMetallic materialsEngineering

The invention discloses a metal material low-temperature tensile test device. The metal material low-temperature tensile test device comprises a temperature measuring device, a low temperature box, a low-temperature box refrigerating device which is communicated with the low temperature box and tensile test clamps which are connected with a tensile testing machine, wherein the low temperature box comprises a box body, a box internal working space and a box door which is arranged on the box body, and the box body consists of an inner shell, an outer shell and a heat preserving layer which is arranged between the inner shell and the outer shell; the tensile test clamps include an upper clamp and a lower clamp, which are symmetrically arranged on the top and the bottom of the box body, both the upper clamp and the lower clamp respectively stretch into the box internal working space, and the axis of the upper clamp is overlapped with that of the lower clamp; the temperature measuring device with temperature measuring end stretching into the box internal working space is arranged on the middle part of the side wall of the box body; the upper part of the box body is provided with a temperature regulating agent injection opening, a temperature regulating agent discharging pipe which is communicated with the box internal working space and stretches out of the box body is arranged on the bottom of the box body, and the temperature regulating agent discharging pipe outside the box body is provided with a temperature regulating agent discharging pipe valve. The metal material low-temperature tensile test device is simple for controlling the temperature, good in temperature control effect and accurate and effective in test results.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cabinet air conditioner, cabinet air conditioner system and air conditioner control method

InactiveCN105953334AImprove experienceSmall footprintMechanical apparatusSpace heating and ventilation safety systemsEngineeringEvaporator

The invention belongs to the field of air conditioners and control methods thereof and discloses a cabinet air conditioner, a cabinet air conditioner system and an air conditioner control method to solve the problem that multiple sets of household appliances used are overlarge in floor space. The cabinet air conditioner comprises a refrigerating-heating chamber and a clothes and shoe drying chamber. A first evaporator is arranged in the refrigerating-heating chamber; a second evaporator is arranged in the clothes and shoe drying chamber; one end of the first evaporator is connected to a compressor assembly, and the other end of the first evaporator is connected to the second evaporator; the second evaporator is connected to a condenser; and the condenser is connected to the compressor assembly. According to the cabinet air conditioner, the cabinet air conditioner system and the air conditioner control method, an existing air conditioner, a clothes dryer and a shoe dryer which are separately arranged are integrated together, the floor space is reduced, an outdoor unit is integrated, the cost is reduced, the use quality is improved, and the use experience is good.

Owner:GREE ELECTRIC APPLIANCES INC

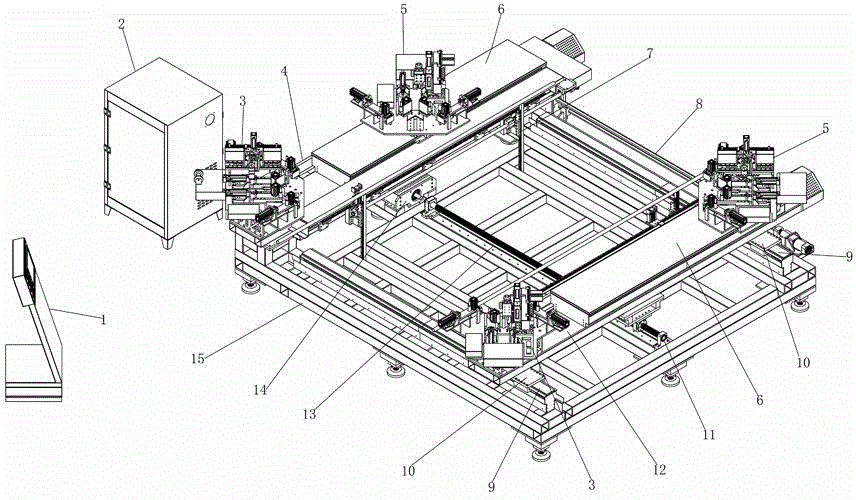

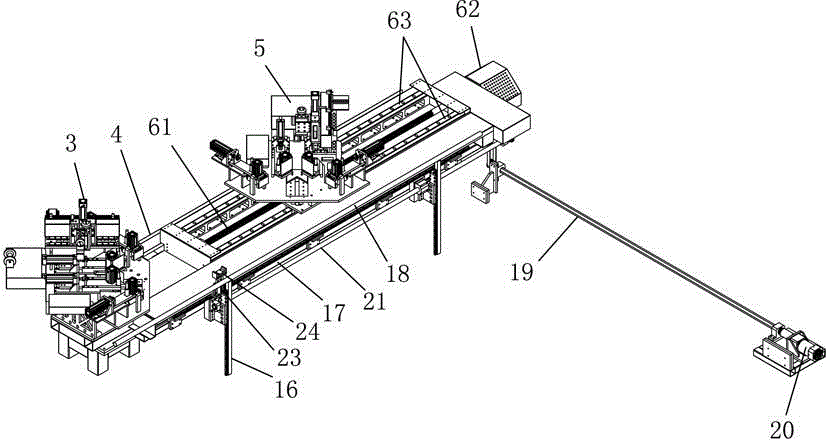

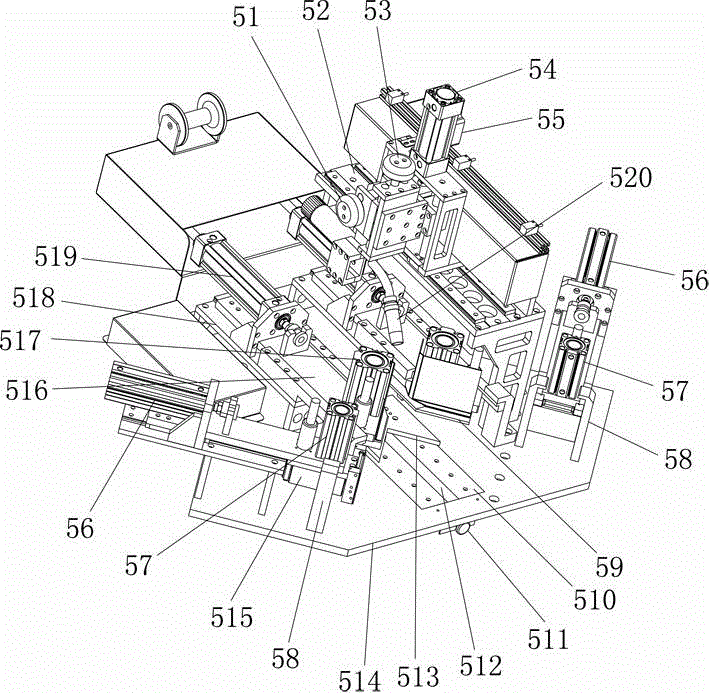

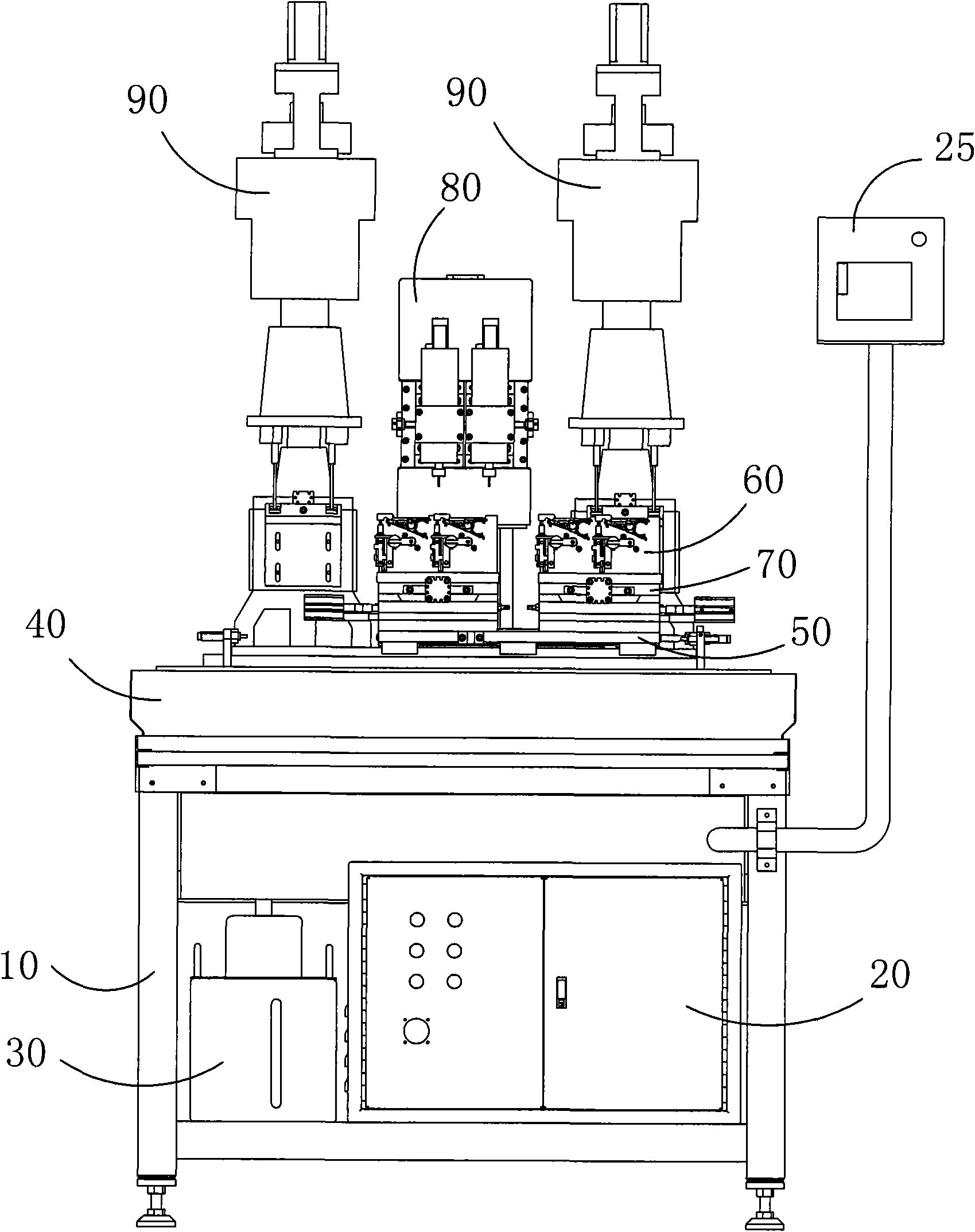

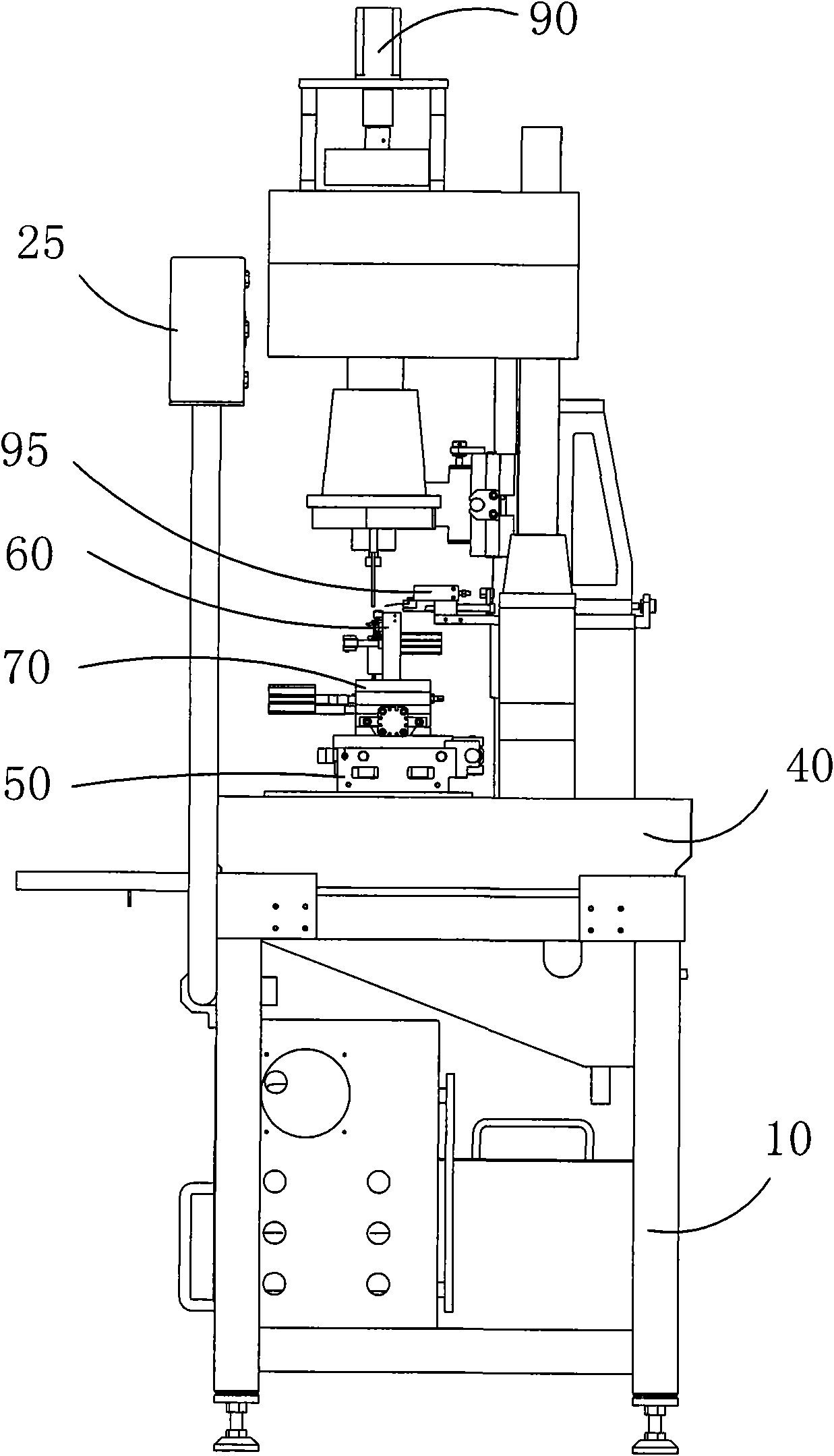

Numerical-control full-automatic positioning and forming welding machine for aluminum-clad wooden doors or windows

ActiveCN103817474AOvercome the high costHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesWeld seamFixed frame

The invention discloses a numerical-control full-automatic positioning and forming welding machine for aluminum-clad wooden doors or windows. The numerical-control full-automatic positioning and forming welding machine comprises a control system, an underframe, a fixed frame, a movable frame, a feeding mechanism and a discharging mechanism. The fixed frame and the movable frame are respectively arranged on two sides of the underframe; the feeding mechanism and the discharging mechanism are disposed between the fixed frame and the movable frame; both the movable frame and the fixed frame are provided with positioning and forming welding devices and longitudinal moving mechanisms; the positioning and forming welding devices arranged on the longitudinal moving mechanisms are capable of moving thereon; the movable frame is driven to slide along transverse guide rails by a transverse driving mechanism. By the aid of the numerical-control full-automatic positioning and forming welding machine, automatic welding of four corners of rectangular aluminum-clad wooden doors or windows is realized rapidly with attractive and smooth weld joints, the defect that wood is affected with damp is overcome; after welding, the aluminum-clad wooden doors or windows are integrated with no spliced seams but smooth and non-defective surfaces, are long in service lives and high in quality; production efficiency is high while production cost is low.

Owner:HUIZHOU YILONG MACHINERY & EQUIP

BIM technology-based curtain wall mounting design method

InactiveCN108460189AEliminate biasImprove installation accuracyGeometric CADDesign optimisation/simulationPoint cloudEngineering

The invention discloses a BIM technology-based curtain wall mounting design method. The method comprises the following steps of (1) importing a two-dimensional drawing of a curtain wall to BIM software Revit, and building three-dimensional models of to-be-mounted curtain wall unit members according to modeling specifications; (2) exporting detail drawings according to the three-dimensional modelsof the to-be-mounted curtain wall unit members, and performing processing production according to the detail drawings of the curtain wall unit members by a factory; (3) building three-dimensional point cloud models of the curtain wall unit members by utilizing fixed point cloud information; (4) adjusting information of the curtain wall unit members by using a processing device; and (5) simulatingwhole pre-mounting of the curtain wall in the Revit according to the three-dimensional point cloud models of the curtain wall unit members meeting specification requirements, and according to a pre-mounting process, performing entity member mounting. The BIM technology-based curtain wall mounting design method solves the problems of high field mounting difficulty, low mounting efficiency and low precision of the curtain wall.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

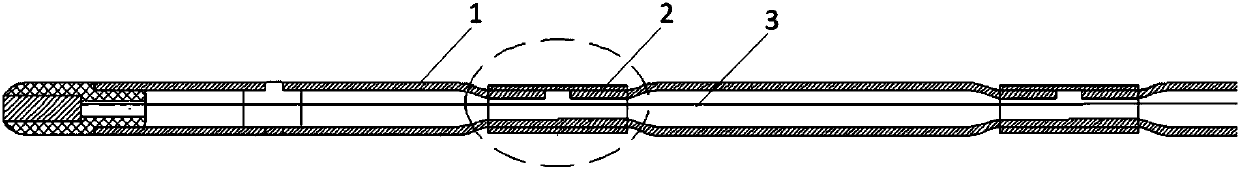

Novel medical pH (potential of Hydrogen) electrode catheter

PendingCN107752983AImprove the stability of useImprove the quality of useCatheterDiagnostic recording/measuringHydrogenBiomedical engineering

The invention discloses a novel medical pH (potential of hydrogen) electrode catheter, which comprises a catheter, an impedance ring and conducting wires, wherein the catheter is a hollow pipe body; further, the conducting wires are arranged in the pipe body; the impedance ring is mounted at a preset position of the pipe body; the preset position where the impedance ring is mounted is provided with a wire leading hole; further, the impedance ring is connected with the conducting wires led out from the wire leading hole in a butting manner. When the novel medical pH electrode catheter is applied, the conducting wires are firstly completely threaded into the catheter; the single conducting wire is taken out from a corresponding mounting vacancy of the impedance ring; the conducting wire is wound on the catheter, and afterwards, is threaded into the impedance ring; the impedance ring is fixedly arranged at the position of the conducting wire; finally, the closing-in location is carried out on the impedance ring by adopting a necking process; thus, the assembly of the whole pH electrode catheter is completed. In comparison with a segment-by-segment connection method adopted in the prior art, the novel medical pH electrode catheter adopts the integrated assembly for the catheter and the impedance ring; the water-leakage problem is thoroughly solved and meanwhile, the pH electrode catheter is enhanced in use stability and quality and has a better clinical use effect.

Owner:重庆金山医疗技术研究院有限公司

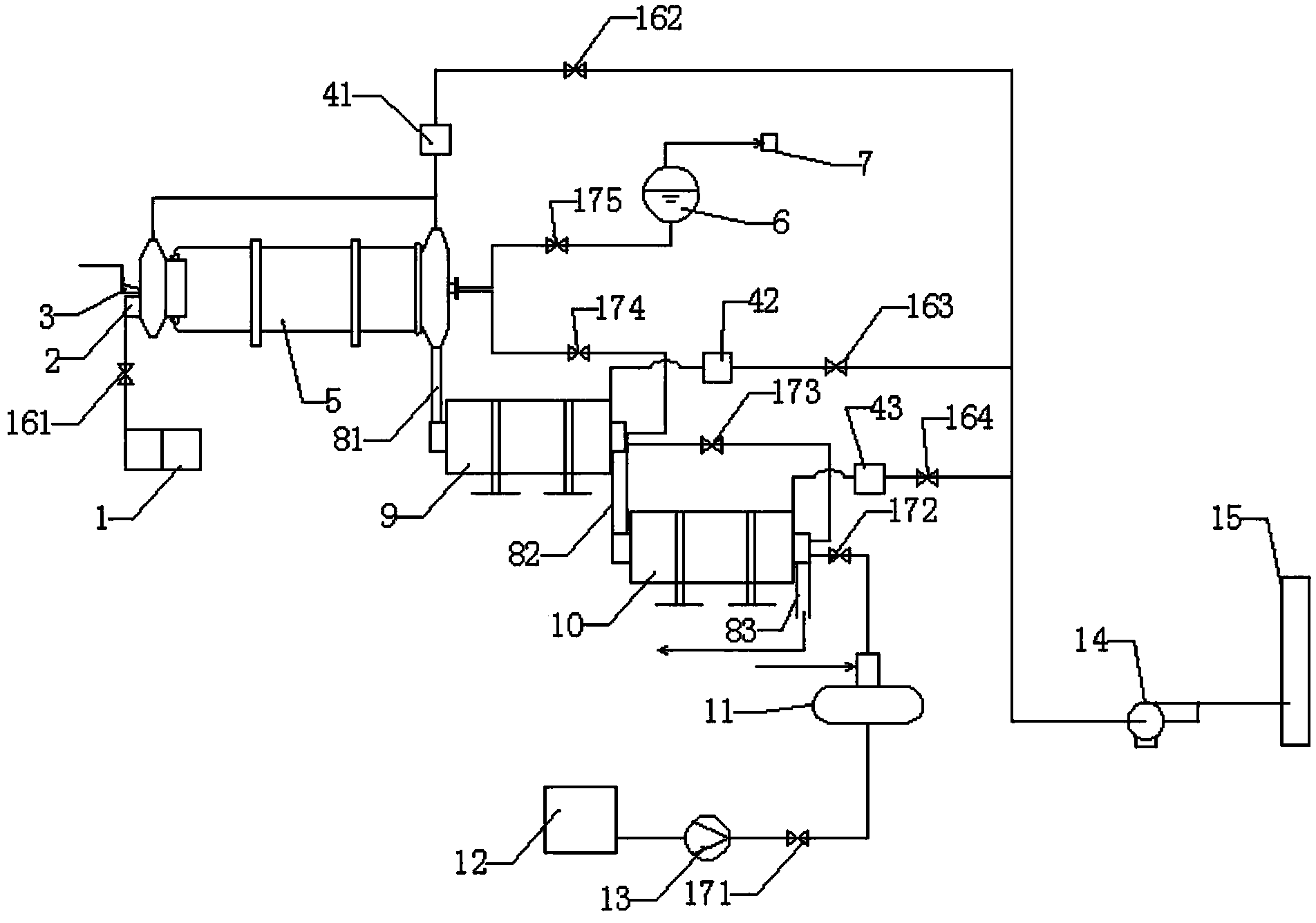

Liquid state blast furnace slag granulation and multi-roller residual heat recovery system

ActiveCN103642956ARealize cascade utilizationRaise the gradeRecycling and recovery technologiesSteam generation using hot heat carriersLiquid stateSlag

The invention discloses a liquid state blast furnace slag granulation and multi-roller residual heat recovery system. The liquid state blast furnace slag granulation and multi-roller residual heat recovery system comprises a first level vaporized roller granulation bin, a second level vaporized roller storage bin, a third level roller cooler and a residual heat recovery system, wherein a material inlet of the first level vaporized roller granulation bin is provided with a liquid state slag flow groove and a granulation device; the first level vaporized roller granulation bin, the second level vaporized roller storage bin and the third level roller cooler are connected in series, and are all provided with vapor-water inlets and outlets; the residual heat recovery system comprises a water feeding pump, an oxygen removing device and a vapor bag which are communicated through water pipes. According to the invention, high-grade saturated steam can be produced by utilizing residual heat of a blast furnace slag in a gradient mode, and the waste slag utilization grade is improved by the rapid cooling of solid slags; the continuous running in the integral process is not affected by the resting period of a blast furnace.

Owner:无锡市东方环境工程设计研究所有限公司

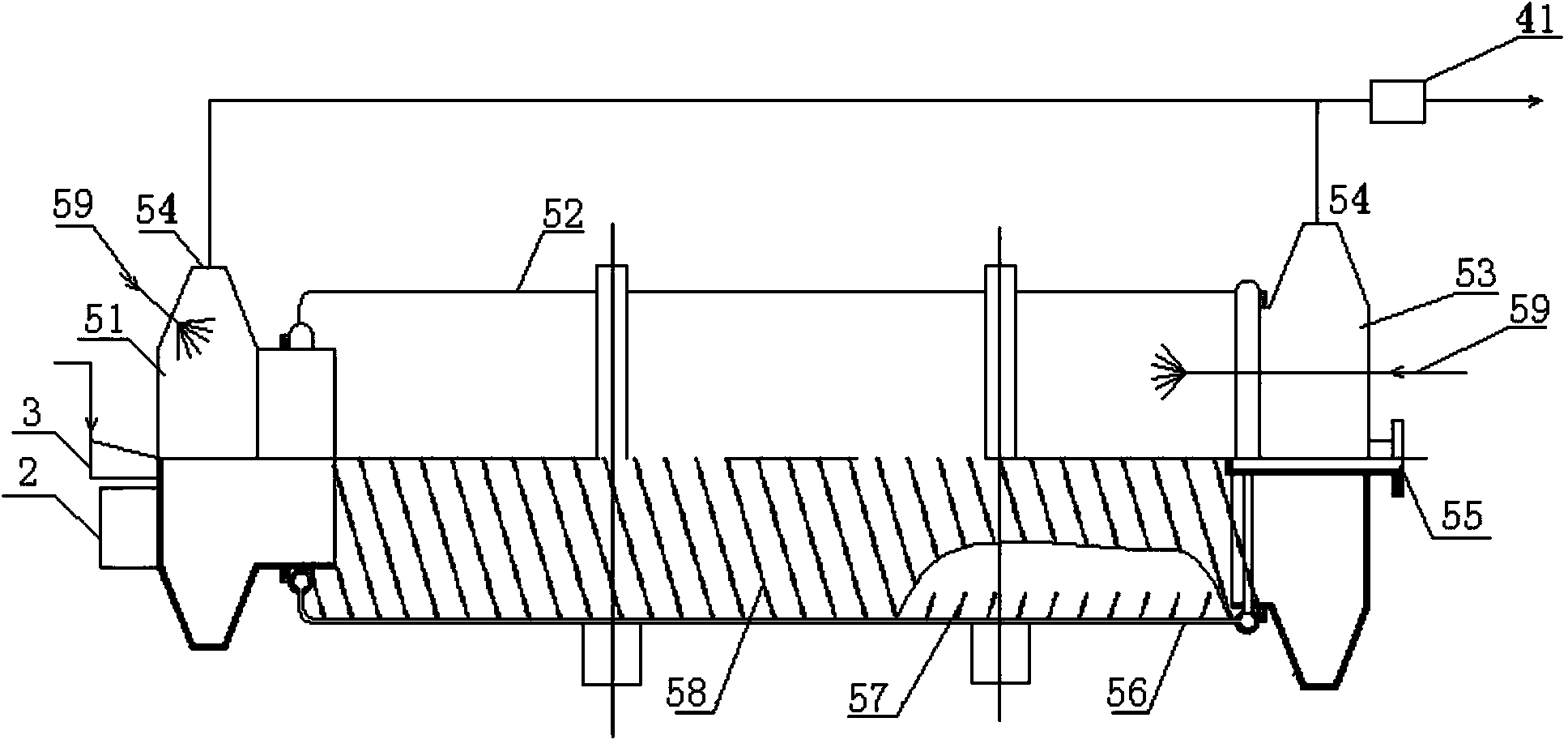

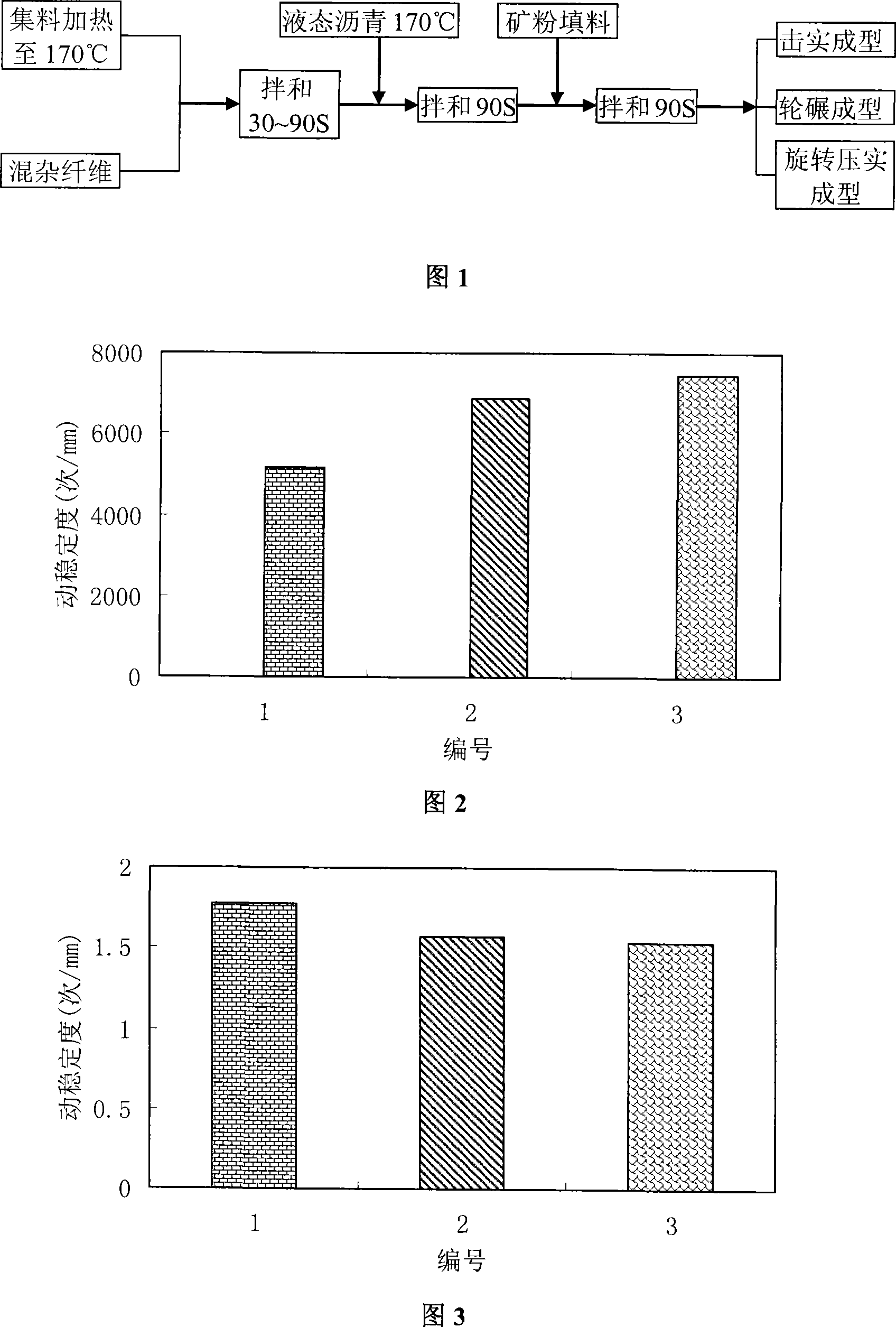

Multi-component fibre composite asphalt concrete and preparing method thereof

InactiveCN101215123AReduce project costImprove performanceSolid waste managementFiberMaterials science

The invention relates to a multicomponent fiber composite asphaltic concrete and the preparing process thereof. The concrete comprises rough aggregates, fine aggregates, powdered ore filler, asphalt and multicomponent fiber material, the blending amount of the multicomponent fiber material is 0.2-0.4% wt of the mass of the multicomponent fiber composite asphaltic concrete. The preparing process of the concrete is firstly heating the aggregates to 170 DEG C to blend with the multicomponent fiber, then to blend with asphalt with temperature of 150 DEG C to 170 DEG C, then adding powdered ore filler to mix evenly and employing Marshall compacting process to compact each of the two sides of the multicomponent fiber composite asphaltic concrete 75 times, or employing rolling method for molding, rolling back and forth for 15-18 times, or employing rotary compacting method to select rotary compacting times for molding as the case might be. The invention has important economic and social sequences in terms of large-scaled popularization and application of multicomponent fiber composite asphaltic concrete on pavement with high grades, decreasing the cost of construction projects, improving running quality of pavement and the like.

Owner:WUHAN UNIV OF TECH

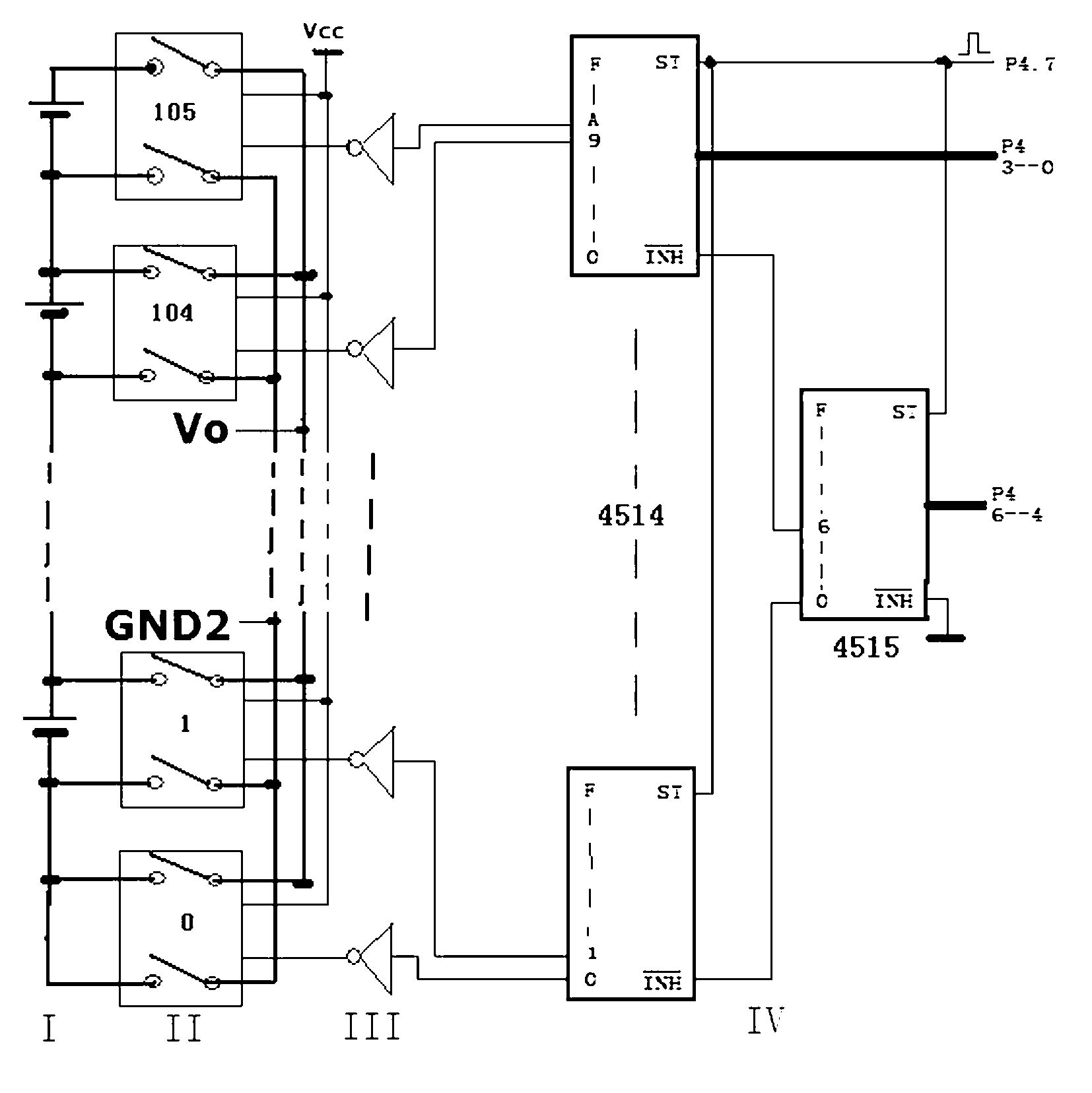

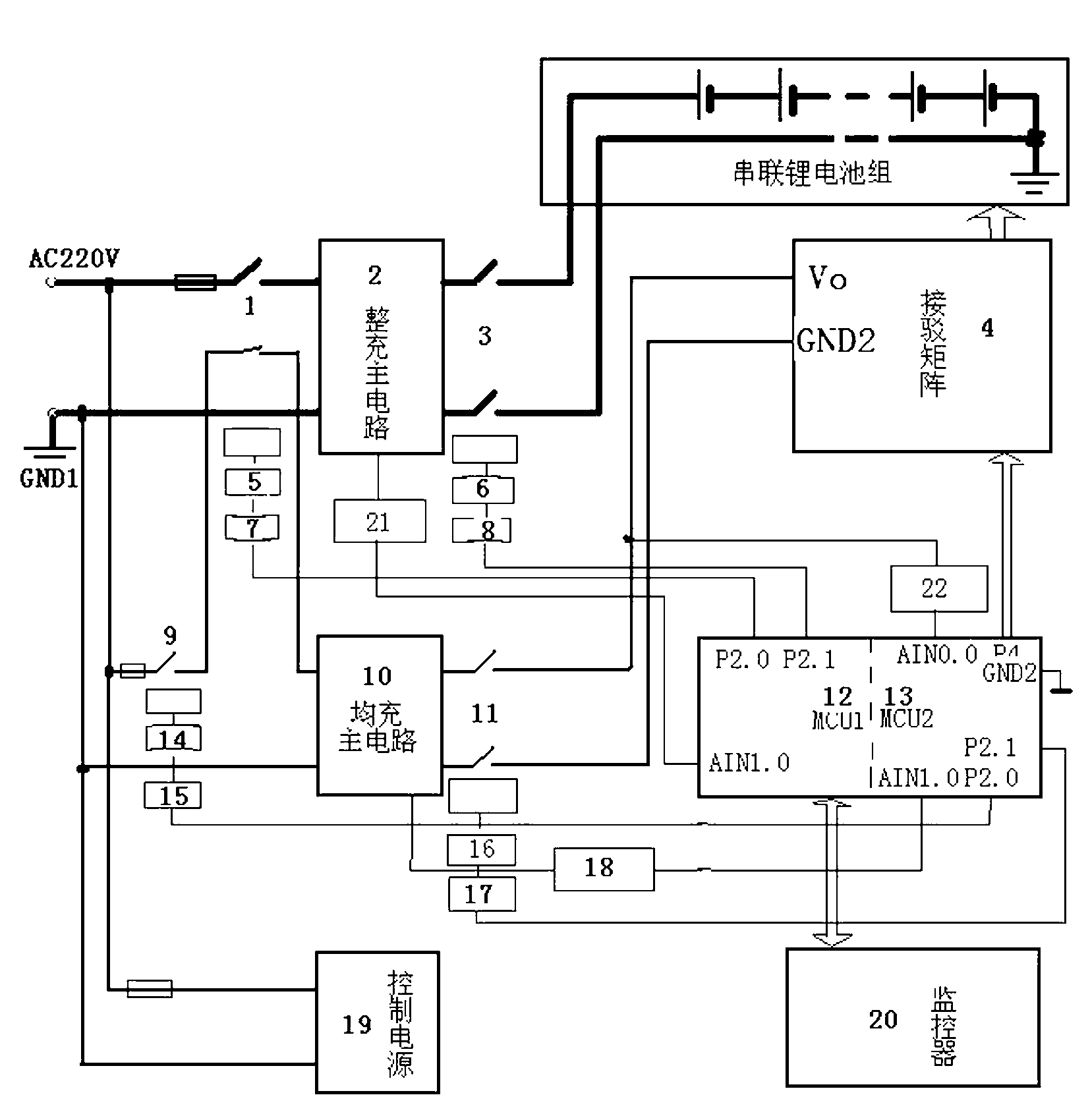

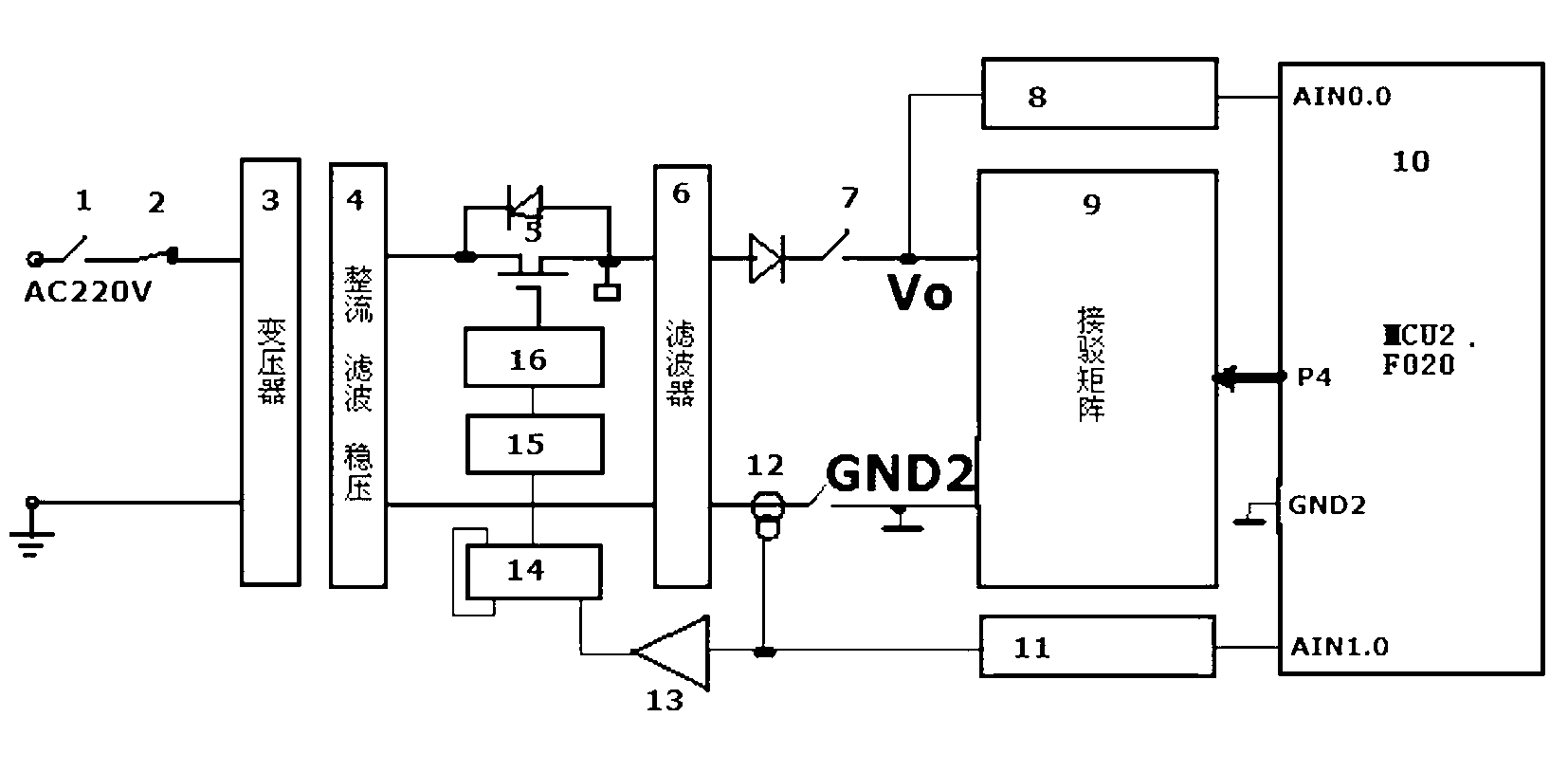

Uniform charging method and uniform charging device for lithium battery packs

ActiveCN103066671AImprove the quality of useExtended service lifeBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

The invention relates to a battery charging technology, and in particular relates to a uniform charging method and a uniform charging device for lithium battery packs. The method comprises the steps that: firstly, the lithium battery pack is overall charged; the voltage of each battery cell is basically detected in real time in the overall charging process; the charging process can be accelerated by virtue of the overall charging manner; the overall charging process is stopped when the voltage of any battery cell reaches a preset threshold; the voltage of each battery cell of the battery pack is ordered from small to large; the voltage of the backmost battery cell with the highest voltage is used as a reference voltage of the uniform charging process; the uniform charging process is started from the headmost battery cell with the lowest voltage till the voltage of the headmost battery cell reaches the reference voltage; then each battery cell with the voltage lower than the reference voltage is uniformly charged in sequence from small to large till the voltage of the battery cell reaches the reference voltage; and thus far, the charging operation is ended. The uniform charging method and the uniform charging device have the advantages of reasonable structure, simplicity and convenience in operation, reliable work and the like.

Owner:威海威能商用机器有限公司

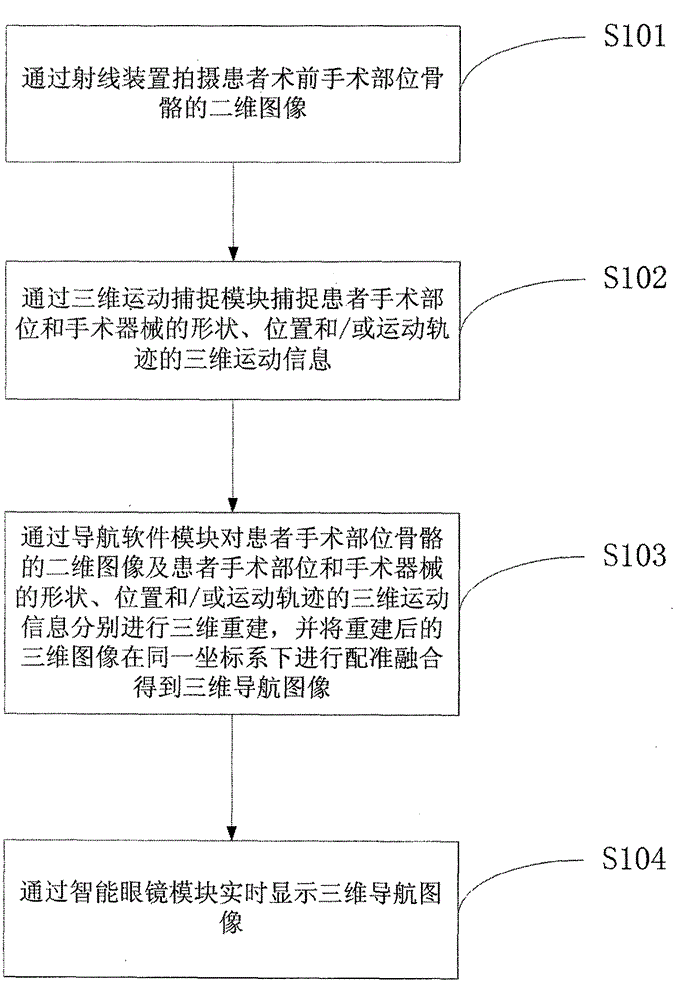

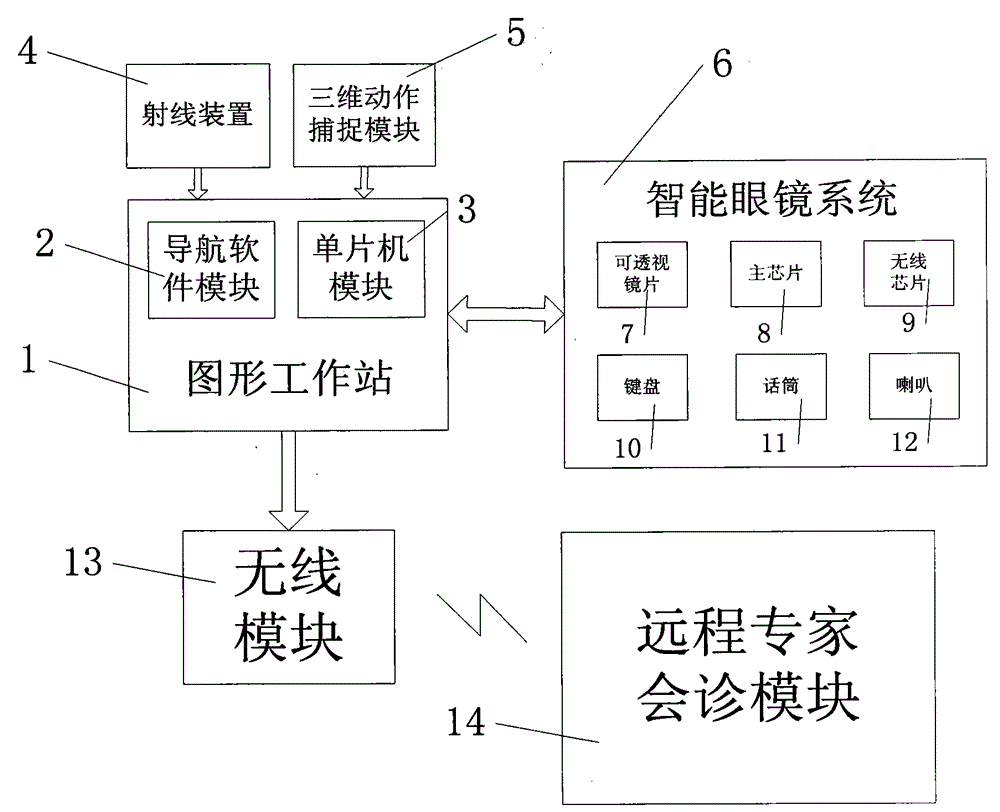

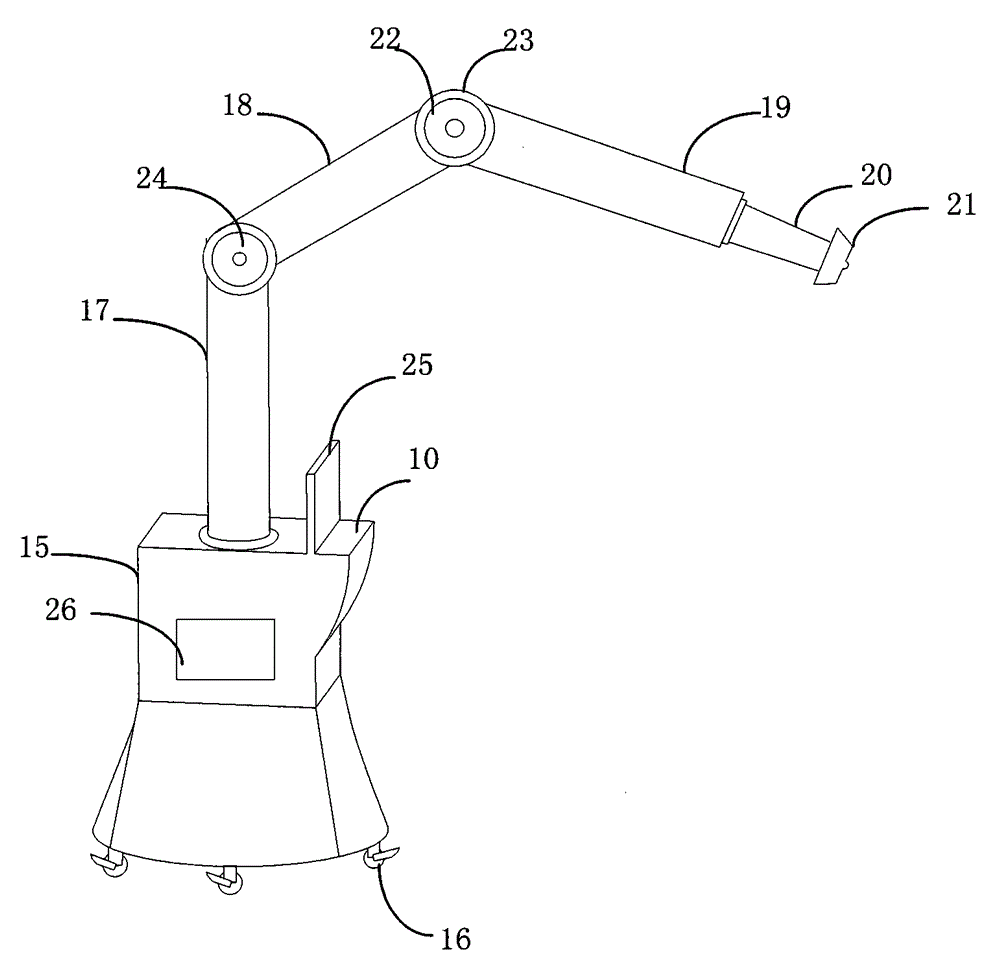

Navigating system and method for orthopedic operation

InactiveCN104586505AEasy to observeEasy to operateDiagnosticsSurgeryGraphics workstationSurgical site

The invention relates to a navigating system and method for an orthopedic operation. The navigating system for the orthopedic operation comprises an orthopedic operation navigating module and an orthopedic operation navigating device, and the orthopedic operation navigating module is installed in the orthopedic operation navigating device. In the orthopedic operation navigating module, a graphic workstation is used for operation of software and comprises a navigation software module and a single-chip microcomputer module. The navigating software module is used for conducting three-dimensional reconstruction on a two-dimensional image, photographed before the operation of a patient, on the skeleton of the operative part and three-dimensional movement information of the shapes, the positions and the movement tracks of the operative part of the patient and an operation instrument, and registration and fusion are conducted on two reconstructed three-dimensional images under the same coordinate system, and a three-dimensional navigating image is obtained; the single-chip microcomputer module has the storage function. According to the navigating system and method for the orthopedic operation, the intelligence degree can be easily improved, the use quality is improved, the maintenance cost is lowered, the service life is prolonged, and the operation can be completed more safely, more accurately and more efficiently.

Owner:张巍

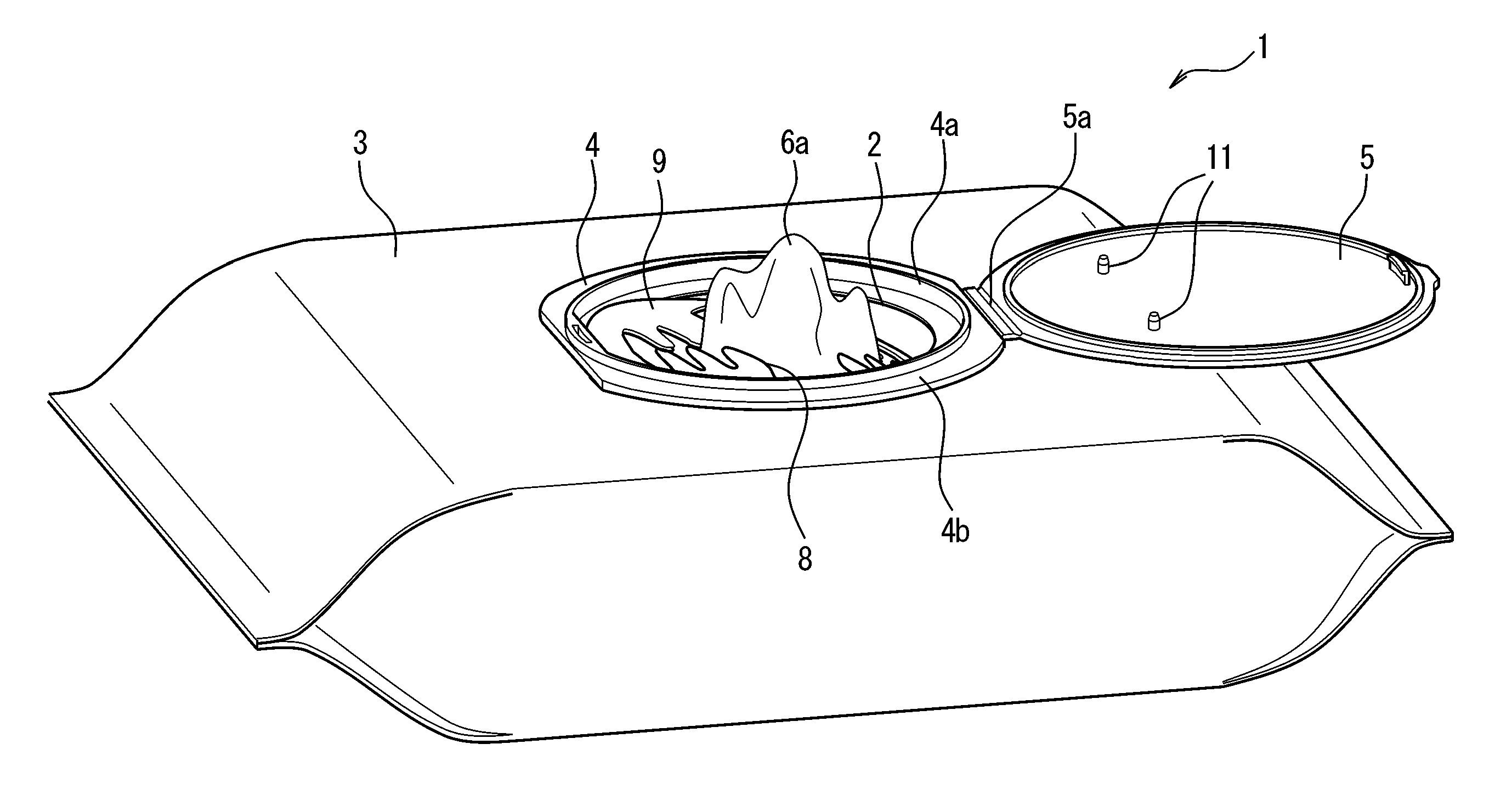

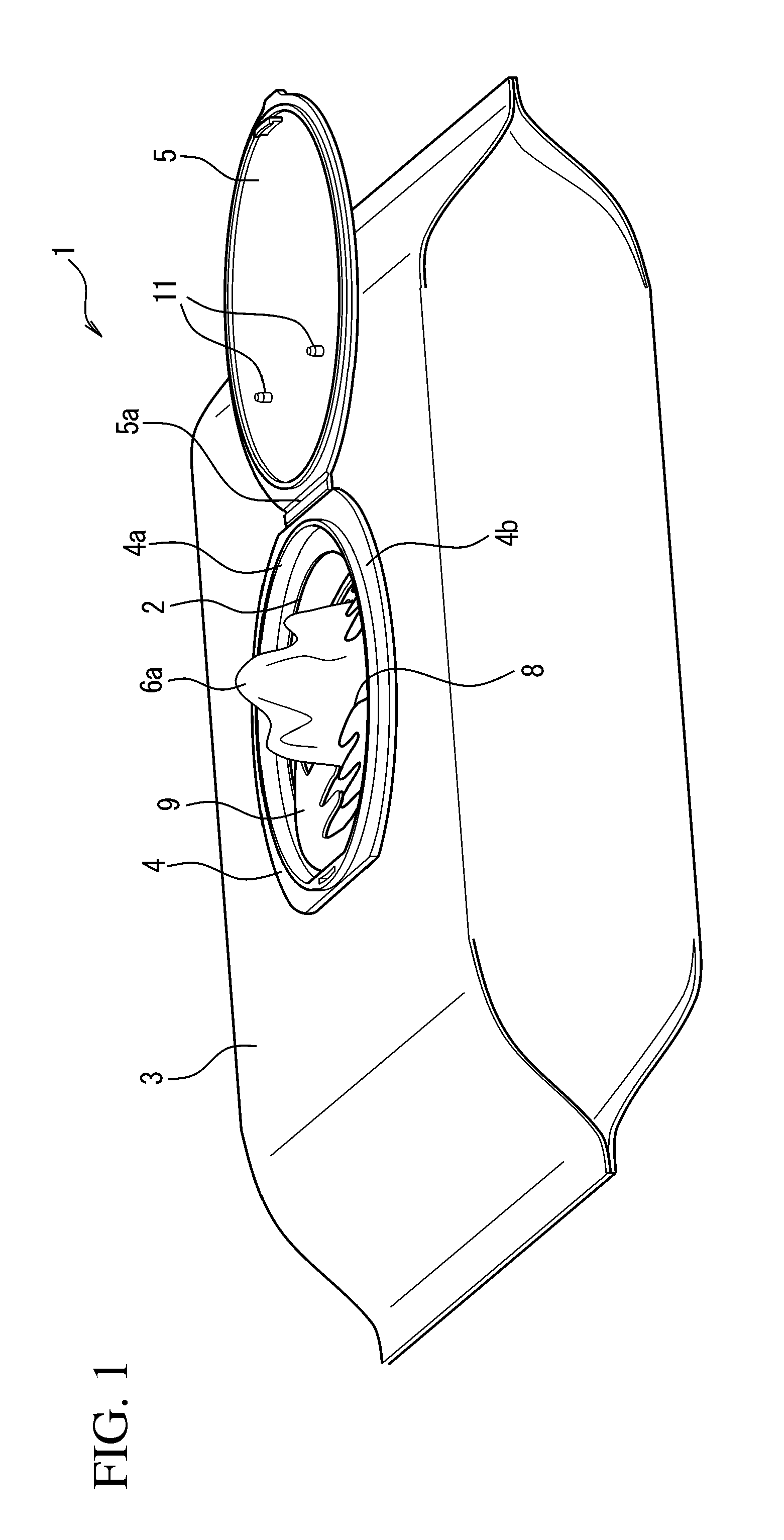

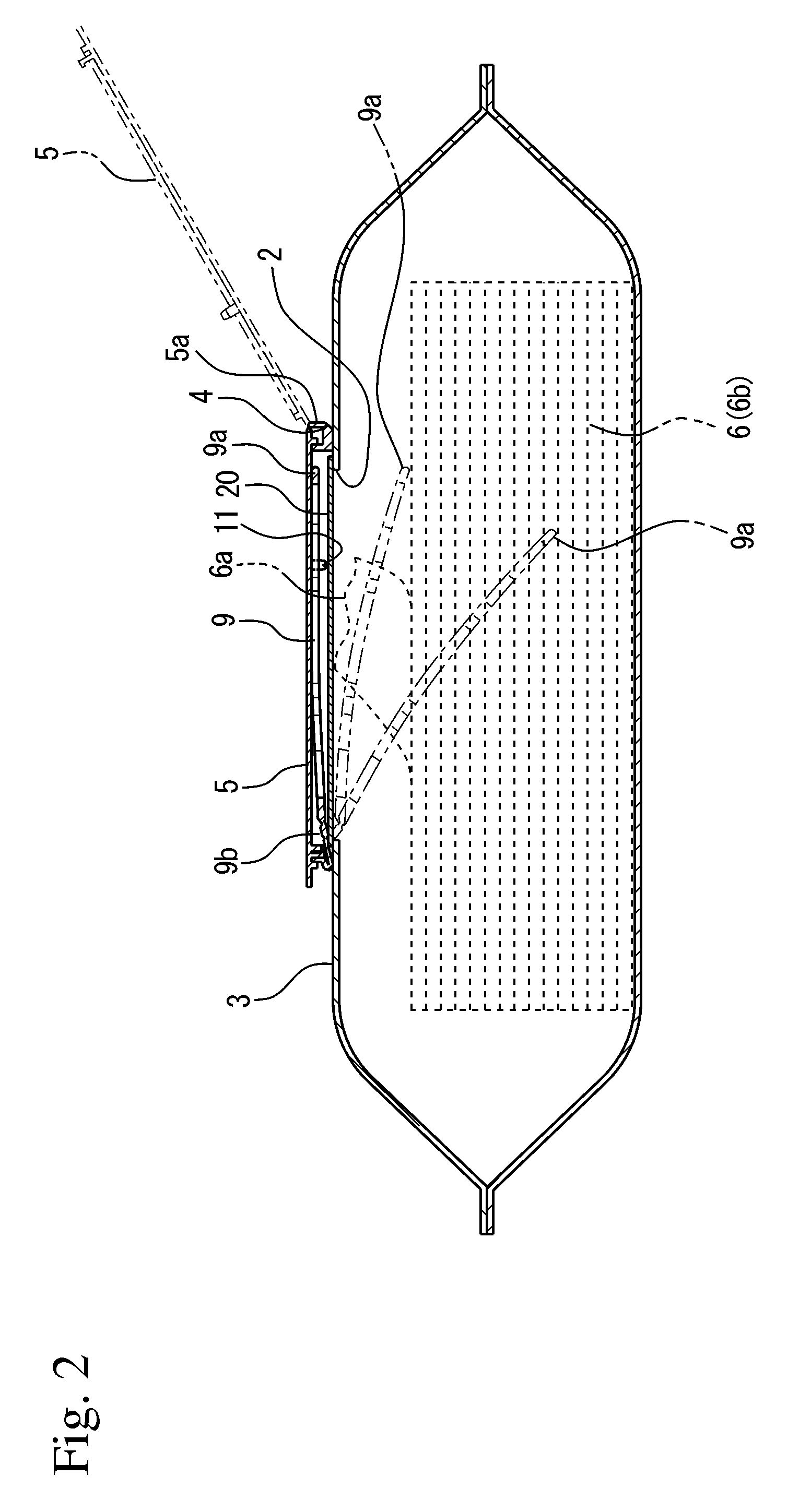

Wet wipe packaging body

ActiveUS20160113450A1Easy to implementImprove the quality of useCoin-freed apparatus detailsClosure with auxillary devicesWet wipeEngineering

Exemplary embodiments of a wet wipe packaging body are designed to improve use quality as to press resistance application member against front surface of wet wipe stacked body at all times when bulk of wet wipe stacked body in bag body is reduced. Exemplary embodiments of the wet wipe packaging body include an outlet port frame body for wet wipes that pulled out from an opening portion provided in a bag body. A resistance application member, which is biased in direction in which resistance is applied to the wet wipe continuous body, is provided on an outlet port side of the outlet port frame body, and lower surface side of outlet port frame body is attached on an outer surface side of bag body so as to surround an opening portion of the bag body.

Owner:YAMADA KIKUO

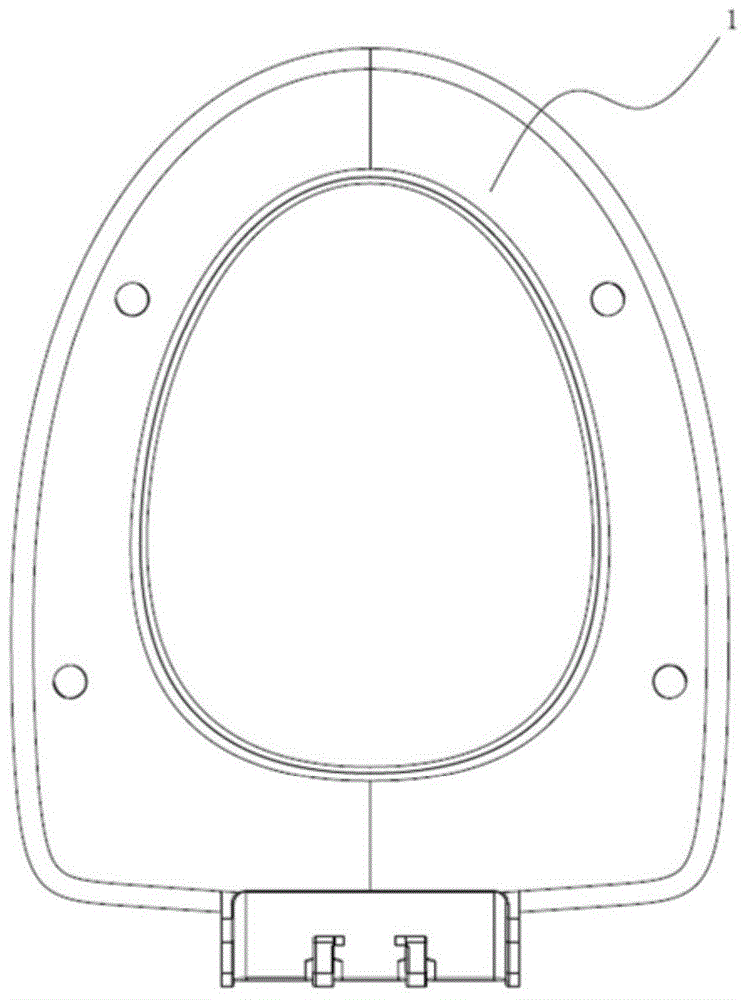

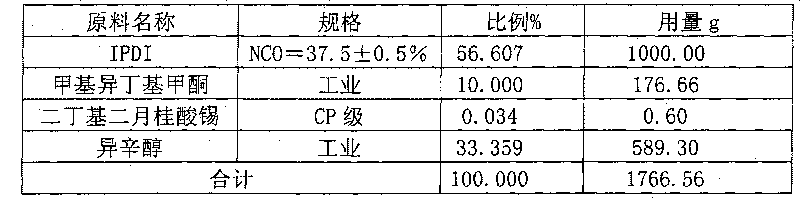

Compound type polyurethane toilet seat and preparation technology thereof

ActiveCN104545656AReduce usage costsReduce processing costsBathroom coversDomestic articlesAbrasive blastingEngineering

The invention discloses a compound type polyurethane toilet seat, including a surface coating layer, a positioning structure and a seat cushion support, wherein the surface coating layer of made of polyurethane and seamlessly wraps the outer surface of the seat cushion support by the positioning structure. The preparation technology includes the steps of: 1, spraying mold release agents and intramode paint in a mold cavity; 2, cleaning the surface of the seat cushion support; 3, polishing or abrasive blasting; 4, thermally processing seat cushion support; 5, spraying the mold release agent in the mold cavity, and installing the seat cushion support in the mold cavity; 6, injecting polyurethane material into the mold cavity, and shaking the mold; 7, foaming the polyurethane material; 8, after the polyurethane is cured in the mold, opening the mold to take out the product, and thereby completing the whole preparation technology of the product. The compound type polyurethane toilet seat achieves the one-time composite molding of the polyurethane toilet seat, optimizes the processing technology, saving the use cost, increases the bonding intensity of the product, and improves the use quality of the product.

Owner:FINEHOPE POLYUREHTHANE PROD

Biological enzyme preparation and preparing method thereof

InactiveCN103651663AImprove qualityImprove featuresPre-baking dough treatmentFood preparationProteaseSieve

The invention relates to a biological enzyme preparation. The biological enzyme preparation comprises, by weight, 1.2-1.5 parts of dextranase, 2.5-8 parts of amylase, 1-5.3 parts of lipase, 1.8-4.5 parts of protease, 1.5-3.8 parts of oxidase, 0.8-1.6 parts of glutamine transaminase, 0.5-1.2 parts of phytase, 1.5-5.0 parts of emulgator, 1.0-5.0 parts of water retention agents and 0.5-3.5 parts of flour gluten fortifier. By means of the biological enzyme preparation, the dough performance can be adjusted obviously, the bread size is increased, the bread stiffness is obviously improved, and the bread softness is improved. A preparing method of the biological enzyme preparation includes the steps of weighing the above raw materials by weight to be stirred and evenly mixed, passing through an 80-mesh sieve, further stirring and even mixing until the raw materials are completely and evenly mixed, and obtaining the biological enzyme preparation.

Owner:ZHONGSHAN NAIDE BIOTECH

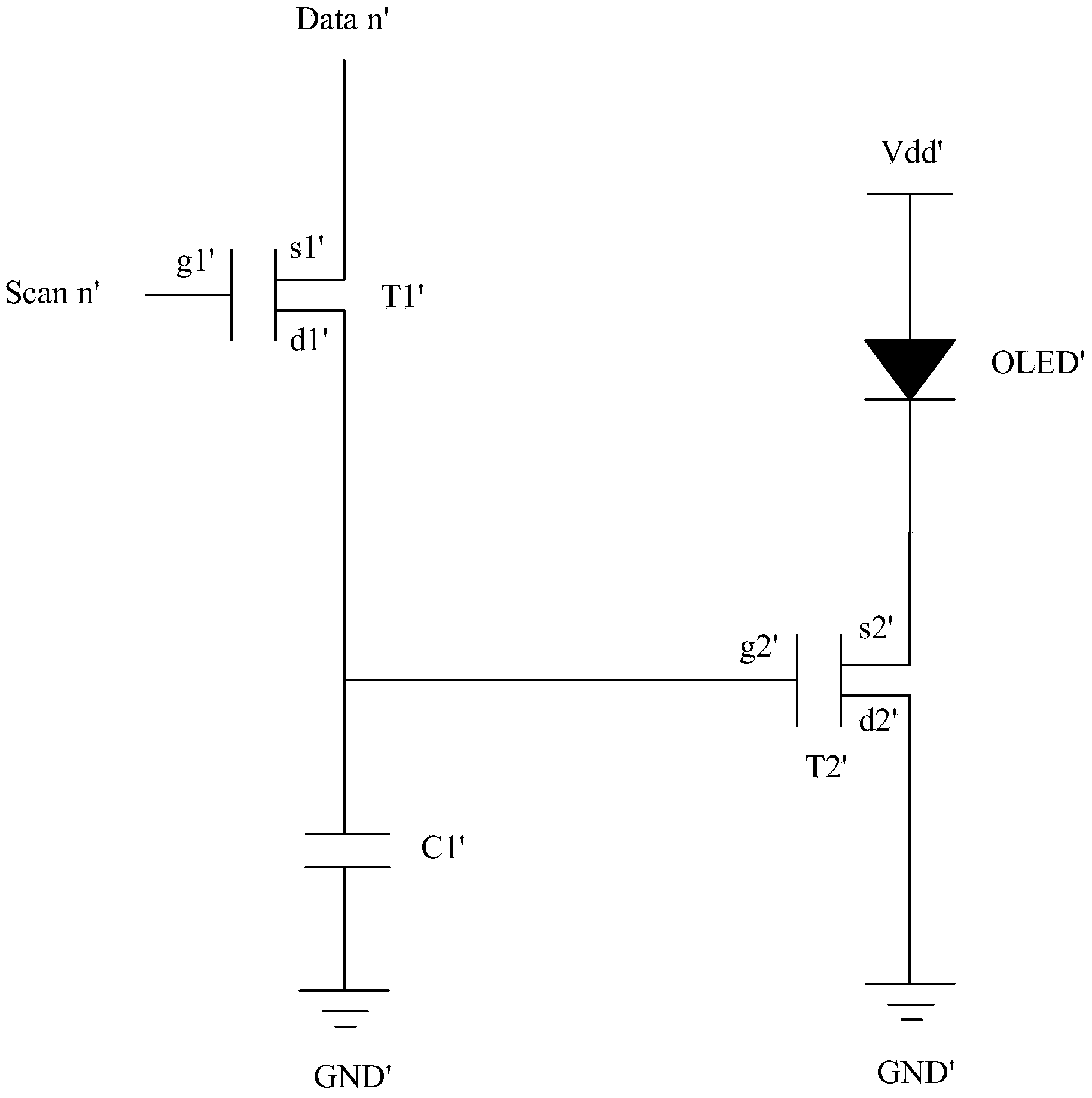

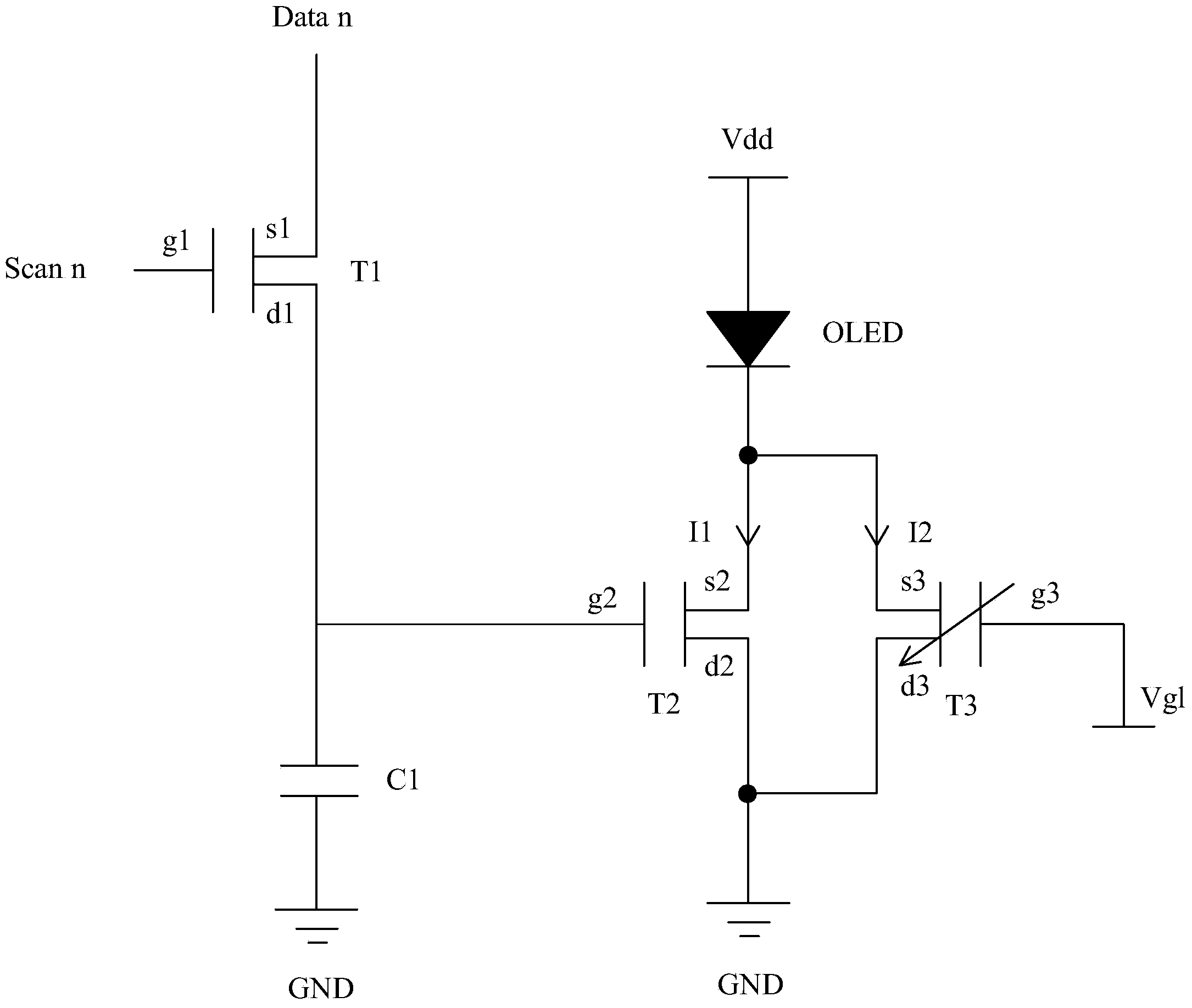

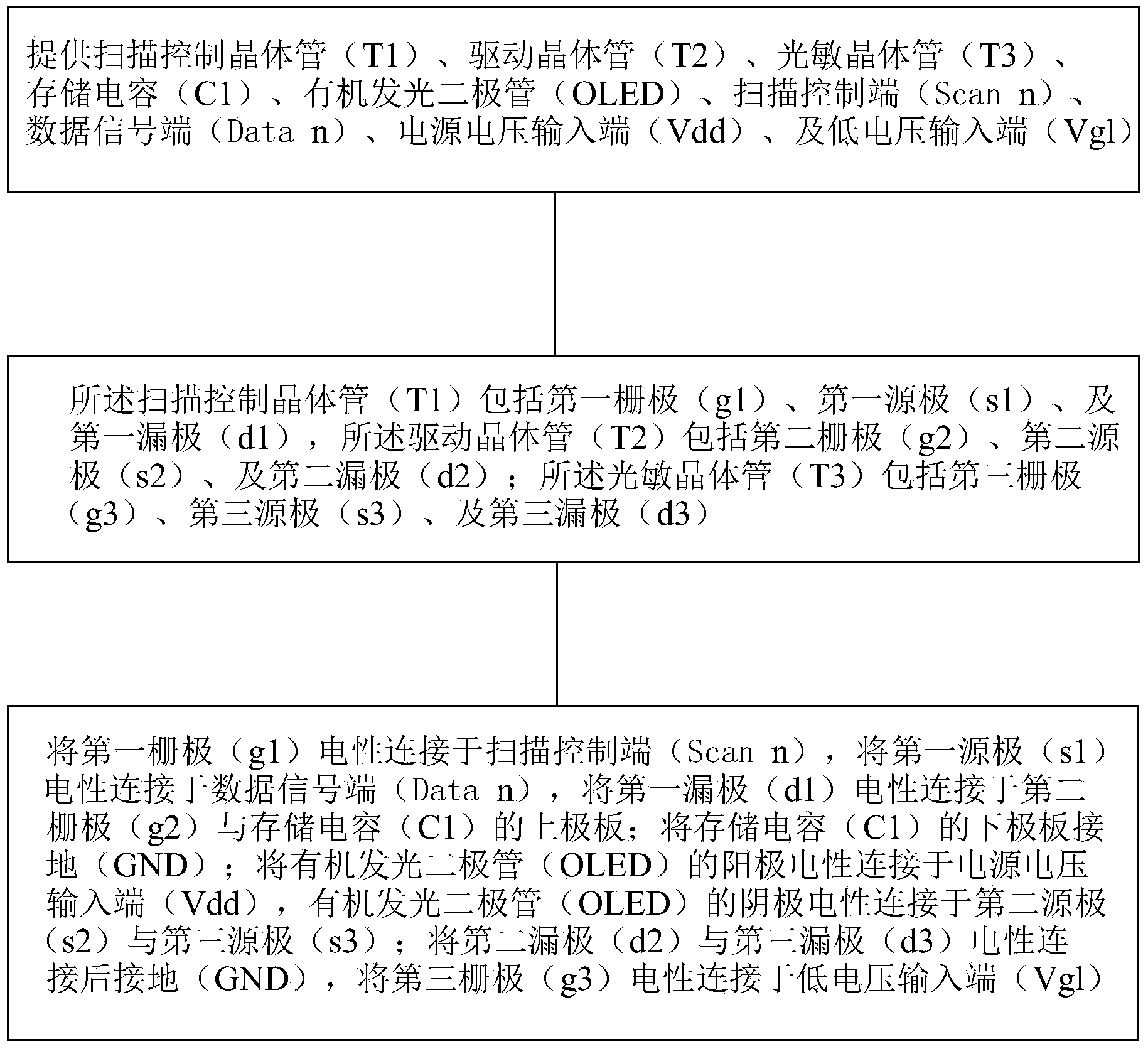

Panel drive circuit and panel drive method

ActiveCN103956142AReduce drive power consumptionExtended service lifeStatic indicating devicesCapacitanceDriving current

The invention provides a panel drive circuit and a panel drive method. The panel drive circuit comprises a scanning control transistor (T1), a drive transistor (T2), a photo-transistor (T3), a storage capacitor (C1) and an OLED. The panel drive circuit further comprises a scan control end (Scan n), a data signal end (Data n), a power voltage input end (Vdd) and a low voltage input end (Vgl). The drive currents of the drive transistor (T2) are gray-scale currents (I1), the currents of the photo-transistor (T3) are environment lighting currents (I2), the gray-scale currents (I1) depend on gray-scale voltages stored in the storage capacitor (C1), and the environment lighting currents (I2) depend on environment lighting. The luminance of a panel depends on the sum of the gray-scale currents (I1) and the environment lighting currents (I2).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

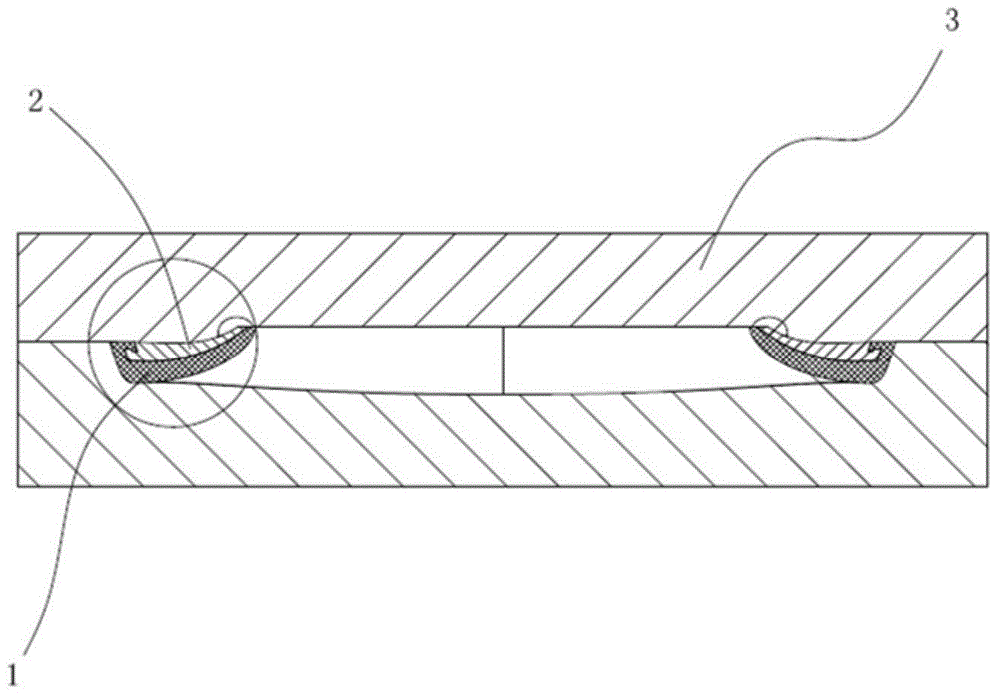

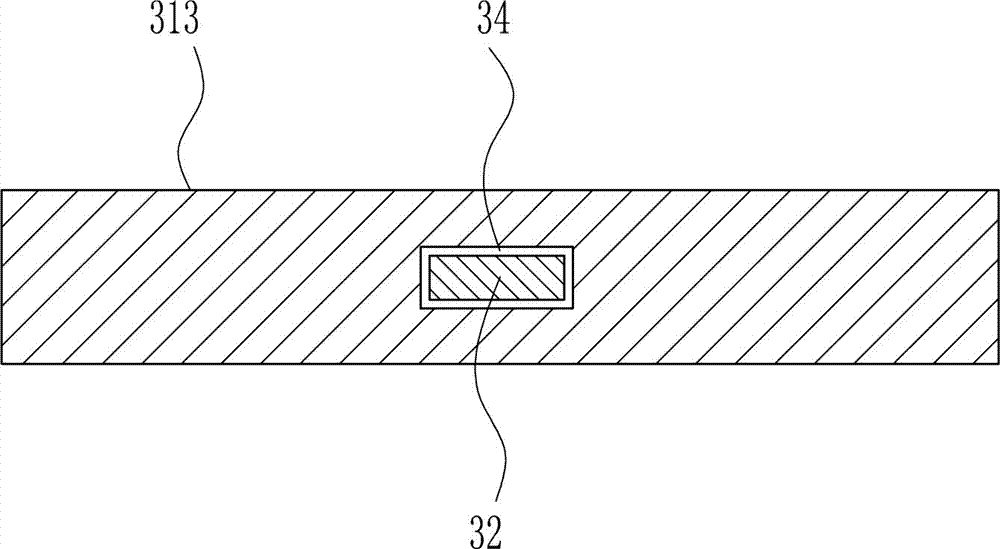

Core-board with new structure and its production process

InactiveCN1346734AHigh yieldImprove production siteWood veneer joiningWood layered productsEngineeringUltimate tensile strength

A core-board with novel structure features that its both surface plys and core ply are all the single board with the thickness of more than 4 mn. Its production method includes using the rotating cutter to cut timber for obtaining single board with more than 4 mm of thickness, drying for 1-4 days, gluing their together to obtain three-ply board, abrading both surfaces, and gluing veneer. Its advantages are high utilization rate of timber (80-90%), saving electric energy by 60% or more, simple method, and high performance and quality of product.

Owner:滕恩荣

Method for self-repairing shape memory effect based joint sealant for concrete pavement through two steps

InactiveCN106337349AExtended service lifeImprove the quality of usePaving detailsCross-linkStrain energy

The invention provides a method for self-repairing a shape memory effect based joint sealant for a concrete pavement through two steps, belongs to the technical field of the joint sealant for the concrete pavement, and solves the problems of one-time repairing, poor repeatability, and microfracture repairing only of a current repairing method. A pre-deformation method is firstly used to give a shape memory function to the joint sealant in the horizontal direction, a prepressing strain energy is stored, the shape restoration force of the joint sealant mounted in a joint of the cement pavement is closed on a macrostructure scale when the temperature rises, a thermoplastic polymer nano-particle embedded in the joint sealant in advance is melt to implement cross-linked polymerization and curing reaction, then the self-repairing on a molecular scale is conducted, the conditions of a fracture or damage closure on the structure scale are observed, the self-healing process of the fracture or damage closure on the macrostructure scale is known, the interfacial energy of two free surfaces is measured, and the self-repairing effect of the two free surfaces on the molecular scale is evaluated. The method repeatedly implements self-repairing of the fracture of the joint sealant on the macro scale, and the durability of the joint sealant is improved.

Owner:NANJING FORESTRY UNIV

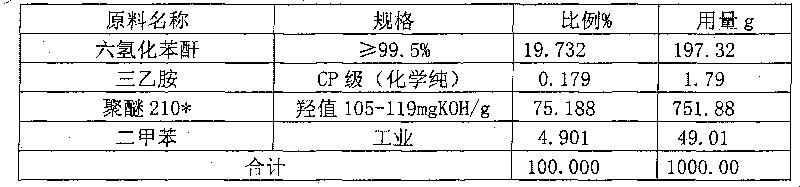

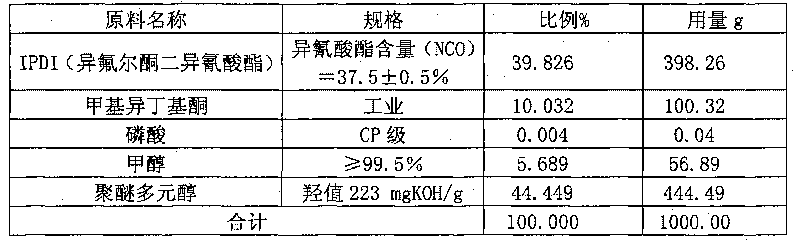

Cathode electrophoretic coating composition and preparation method thereof

InactiveCN101760126AGood anti-ultraviolet aging performanceImprove supporting yellowingPolyurea/polyurethane coatingsPaints for electrolytic applicationsAlcoholEmulsion

The invention relates to a cathode electrophoretic coating composition and a preparation method thereof, wherein the cathode electrophoretic coating composition contains the following components of: a component A comprising water-dispersing emulsion in which cycloaliphatic resin is added, wherein the water-dispersing emulsion accounts for 70-90 parts of the total weight of the composition; and a component B comprising colorant in which cycloaliphatic resin is added, wherein the colorant accounts for 10-30 parts of the total weight of the composition; and the cycloaliphatic resin is selected from an esterified reaction product of hexahydro-anhydride and C1-10 alkyl alcohol or alcohol ether and a closure of isophorone diisocyanate. The invention also provides a method for preparing the cathode electrophoretic coating composition.

Owner:上海金力泰化工股份有限公司

Efficient paint spraying device for leather shoe manufactory

ActiveCN107138313APlay a supporting rolePlay a guiding rolePretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to a paint spraying device, in particular to an efficient paint spraying device for a leather shoe manufactory. The efficient paint spraying device for the leather shoe manufactory aims to achieve the effects of being high in paint spraying work efficiency and full and uniform in paint spraying. The efficient paint spraying device for the leather shoe manufactory comprises an installation frame and the like. A paint spraying mechanism used for leather shoe paint spraying treatment, a swinging mechanism used for swinging a paint spraying component and a rotating mechanism used for rotating a fixing component and a leather shoe are all fixed to the top of the installation frame. The swinging mechanism is located between the paint spraying mechanism and the rotating mechanism. A fixing mechanism used for fixing the leather shoe is fixed to the rotating mechanism. A drying mechanism used for drying the leather shoe is fixed to the inner top of the installation frame. The efficient paint spraying device for the leather shoe manufactory achieves the effects of high paint spraying work efficiency and full and complete paint spraying. The rotating mechanism can drive the fixing mechanism to rotate, so that the leather shoe is driven to rotate.

Owner:嘉兴久珥科技有限公司

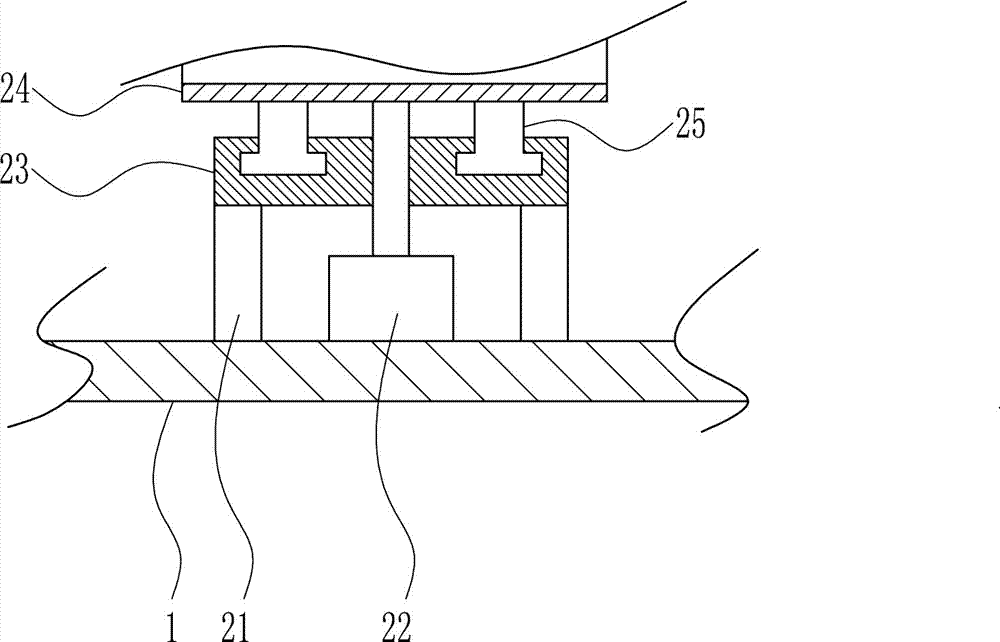

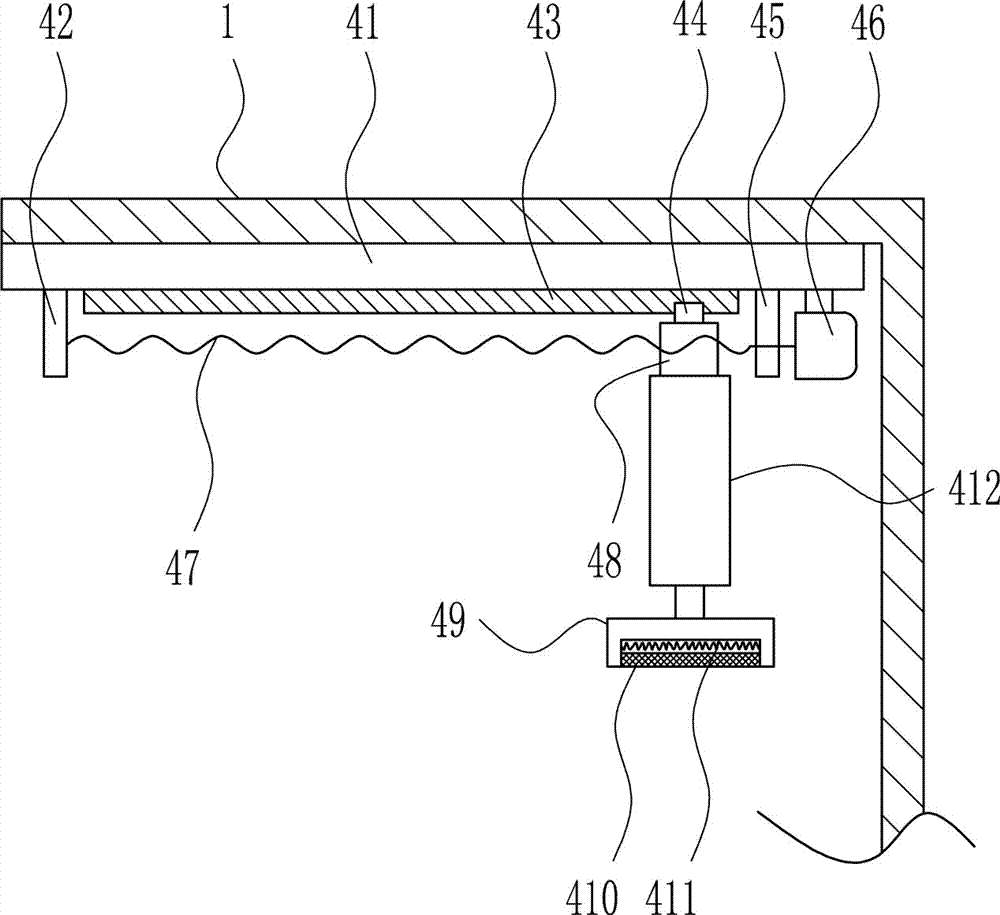

Drilling and tapping machine

InactiveCN102371484AExtended service lifeImprove the quality of useOther manufacturing equipments/toolsEngineeringDrill bit

The invention relates to a drilling and tapping machine, which is used for drilling and tapping workpieces. The drilling and tapping machine comprises a machine frame, a tapping drilling clamp which is arranged on the machine frame and is used for clamping and fixing the workpieces, a drilling device which is arranged above the tapping drilling clamp and is used for drilling, two servo tapping devices which are arranged on left and right sides of the drilling device and are used for tapping and an electric cabinet for controlling the drilling device and the servo tapping devices. In the drilling device of the drilling and tapping machine, two drills are respectively controlled to drill holes by a double-high-accuracy electric main shaft so as to ensure the stability of bottom holes; and a tapping cutter is controlled to tap by using the servo tapping devices, and machining parameters can be set by combining actual conditions, so the service life of the tapping cutter can be prolonged greatly, and the quality of threads can be improved greatly.

Owner:福群科技集团有限公司

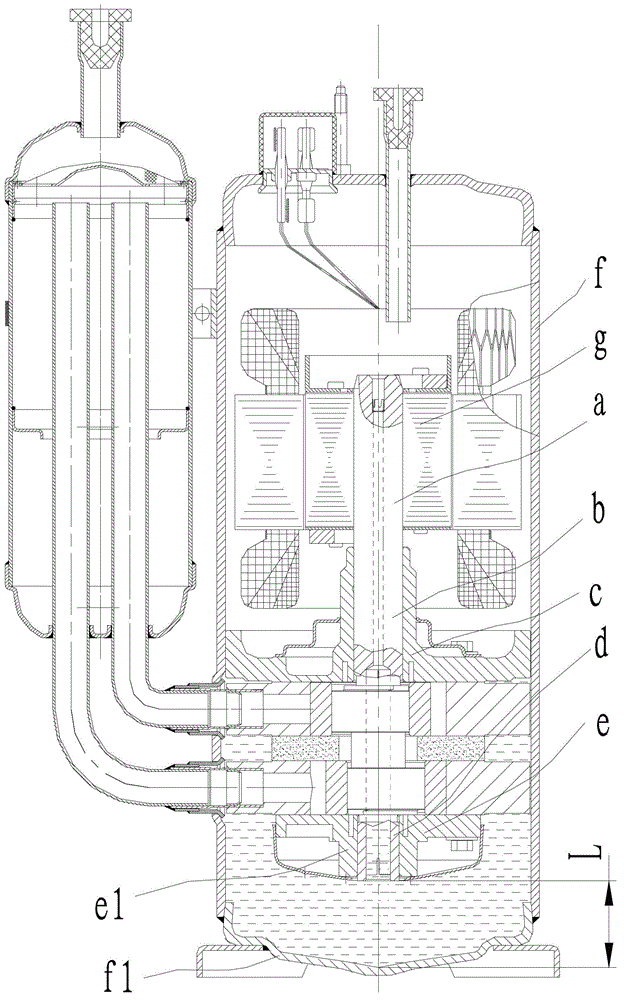

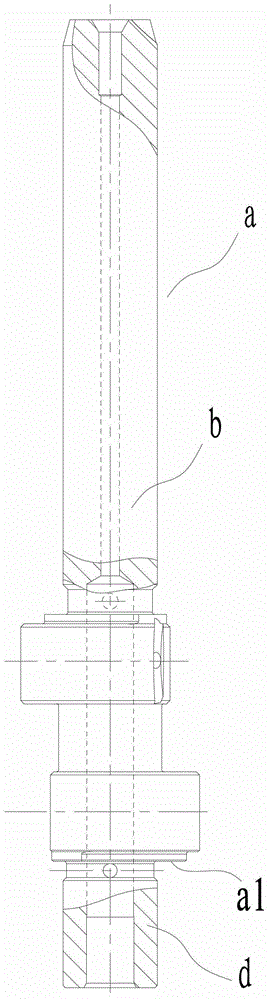

Double-cylinder rotating compressor and eccentric assembling method thereof

ActiveCN103147987AReduce manufacturing costLower the altitudeRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringCrankshaft

The invention discloses a double-cylinder rotating compressor which comprises a shell body, a motor, an upper flange, an upper air cylinder, a crank shaft, an upper running pulley, a partition plate, a lower running pulley, a lower air cylinder and a lower flange. The radius of a cylinder matched segment of the portion in which the crank shaft is matched with an inner hole of the partition plate is larger than biggest eccentric radiuses of an upper eccentric portion and a lower eccentric portion of the crank shaft, the cylinder matched segment of the crank shaft is matched with the inner hole of the partition plate in a sliding mode to form an auxiliary bearing of the compressor, the bottom end face of the lower eccentric portion of the crank shaft is arranged in an alignment mode corresponding to the bottom end face of the lower air cylinder, and the corresponding lower flange is a plane plate. The lower flange enables the lower running pulley and the lower eccentric portion of the crank shaft to be blocked in the lower air cylinder in an alignment mode, an original short shaft of the crank shaft is removed, the height of the shell body is reduced, frozen oil filling injection amount is reduced, and power consumption of the compressor is reduced. The invention further discloses an eccentric assembling method of the double-cylinder rotating compressor, a combined centering assembling mode from top to bottom is adopted by the method, and the problem that coaxiality difference of the long shaft and the short shaft of the existing crank brings problem for a gap of the lower cylinder is solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

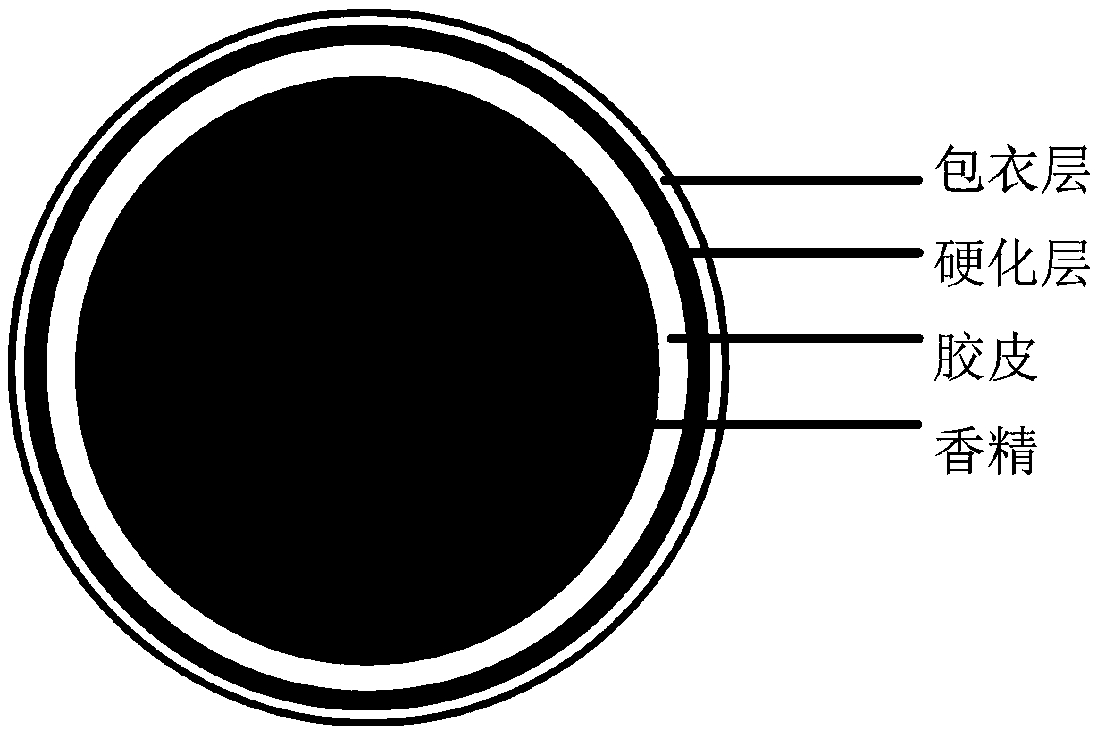

Moisture-proof and embrittling treatment method of cigarette capsules and product obtained by treatment method

InactiveCN105495686AImprove brittlenessImprove appearance qualityTobacco smoke filtersEnvironmental healthMoisture

The invention relates to a moisture-proof and embrittling treatment method of cigarette capsules and a moisture-proof embrittling cigarette capsule. The treatment method comprises steps: preparing cigarette capsules, post-treating cigarette capsules, preparing a coating liquid and a coating and the like. The moisture-proof and embrittling treatment method of the cigarette capsules enables improved brittleness for cigarette capsules, an improvement of 25.0-37.9 % in moisture-proof effect, an improvement in capsule surface gloss and thereby improvements in cigarette capsule appearance and quality of use.

Owner:YUNNAN XINYUN TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com