Patents

Literature

464results about How to "Improve performance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Streaming Media System and Method

ActiveUS20070180137A1Improve output qualityImprove performance qualityMultiple digital computer combinationsTransmissionLoudspeakerWaiting time

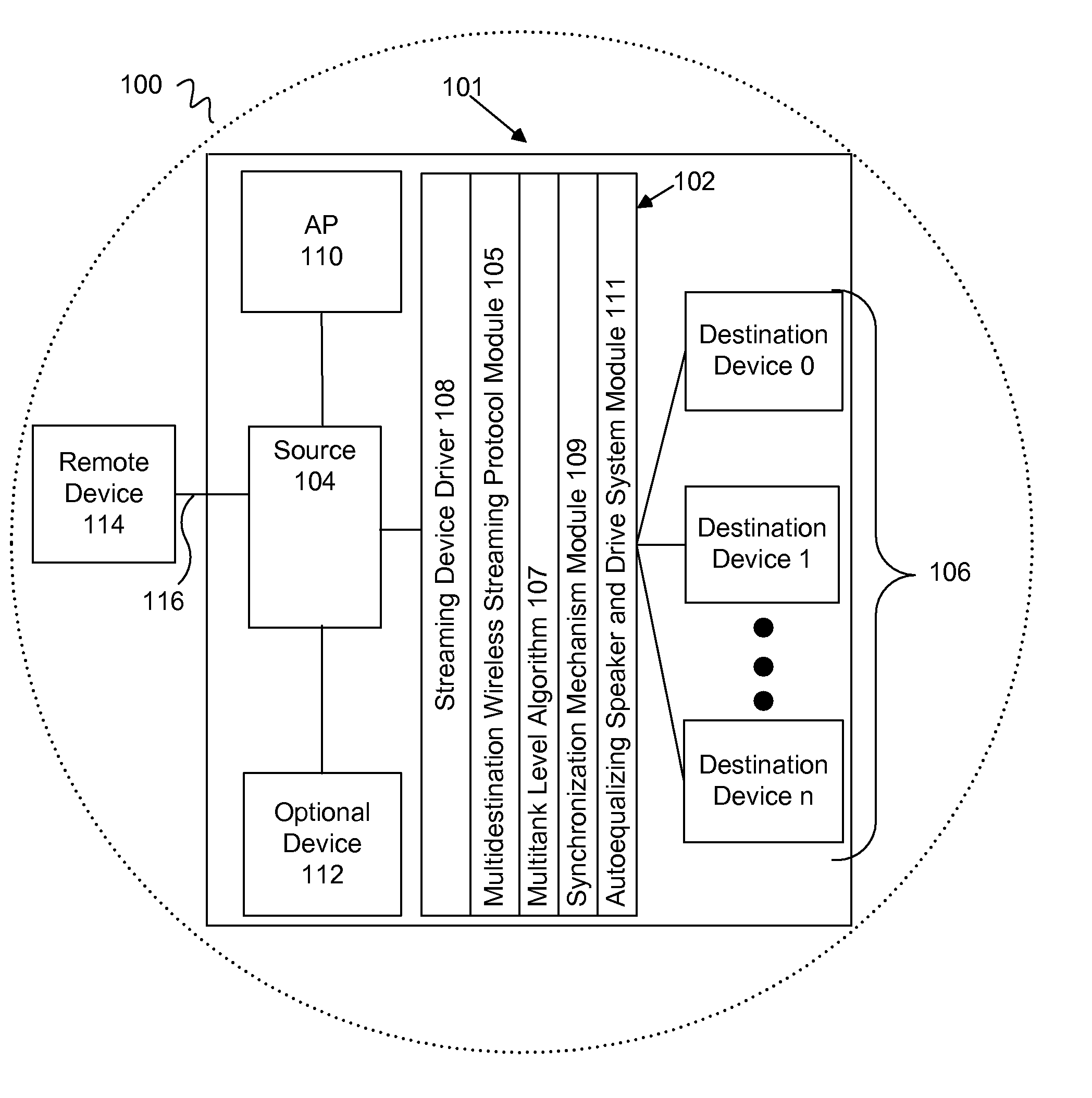

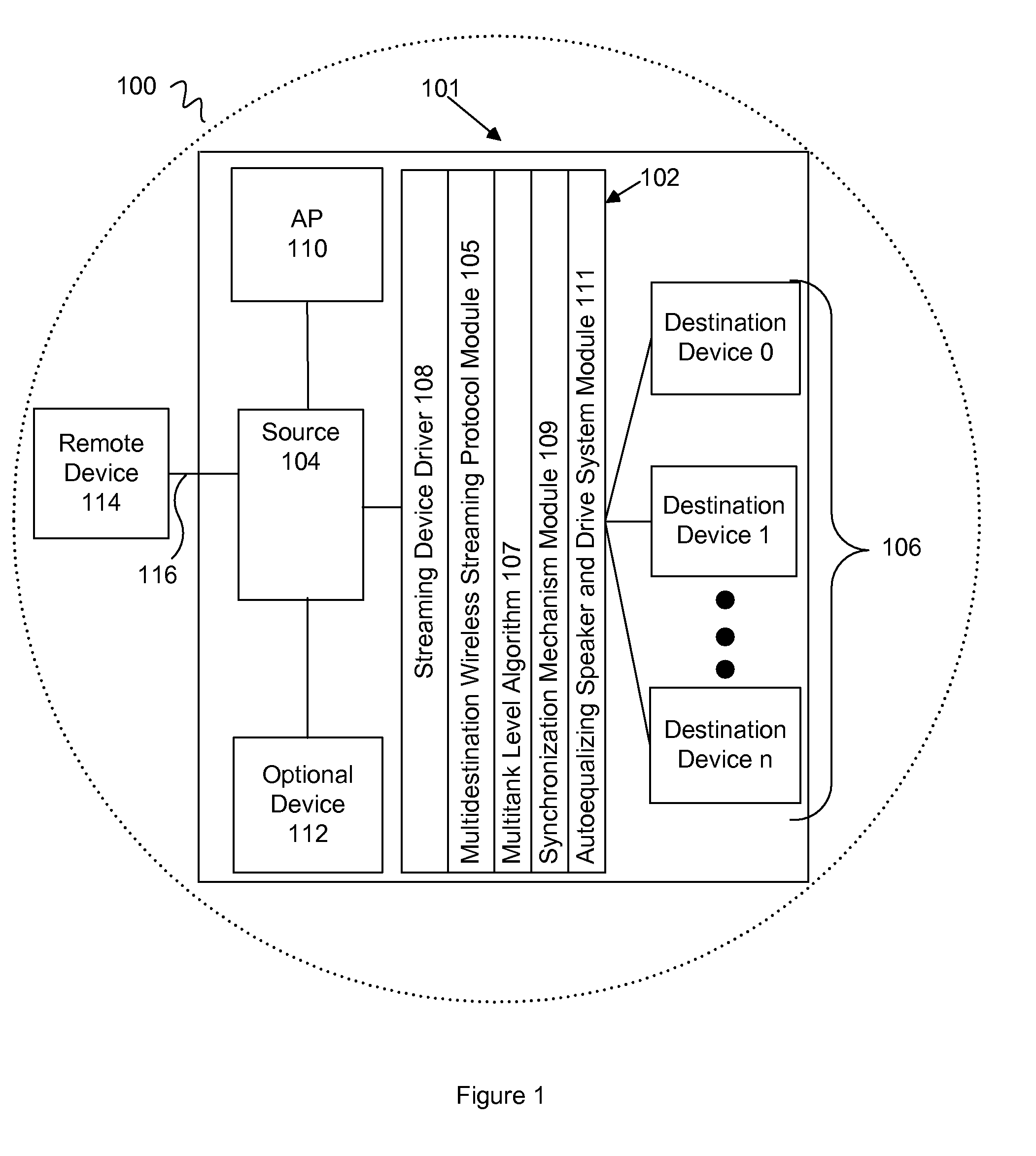

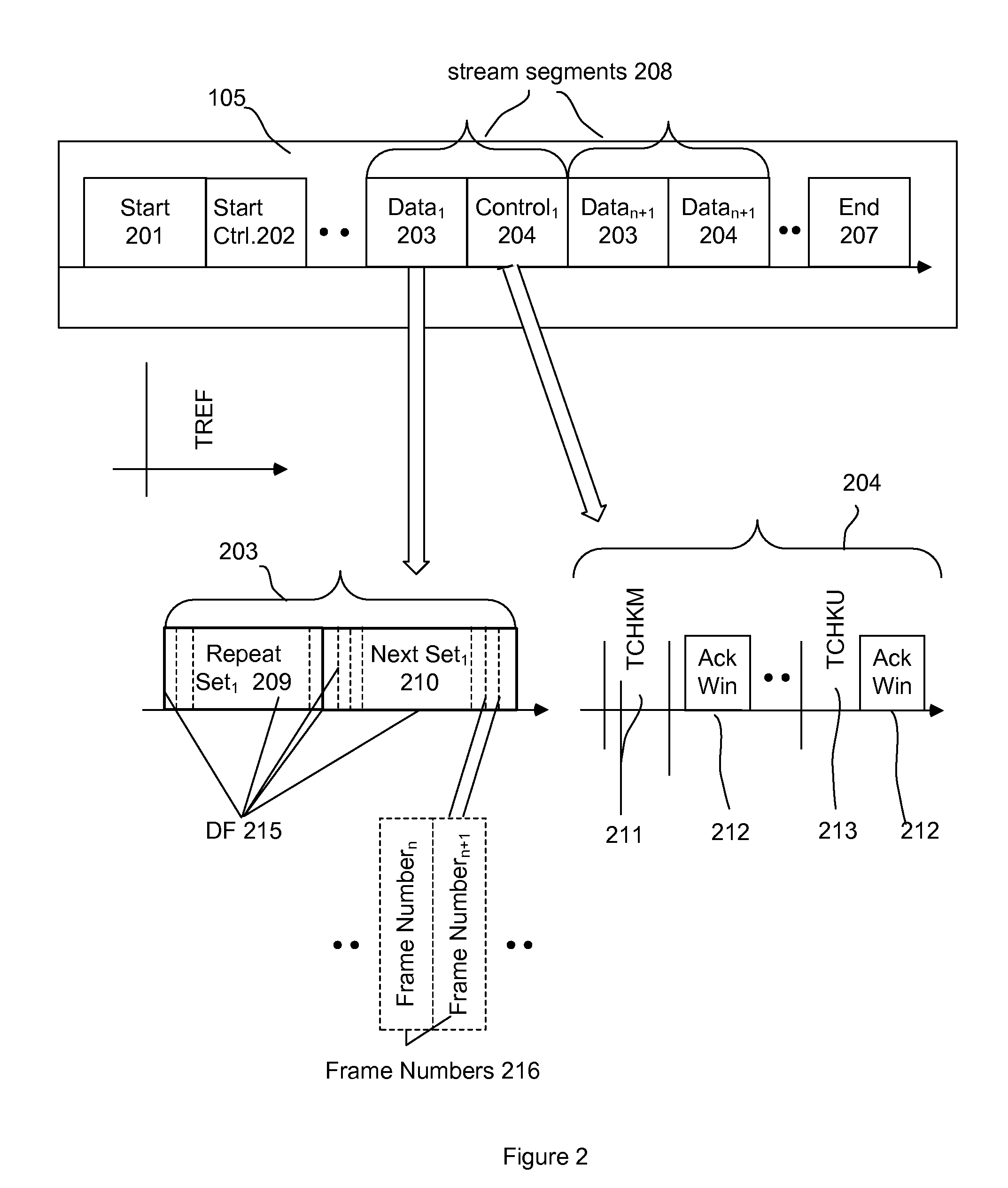

A system and method for streaming media on a wireless network is provided. In one aspect, the system includes a streaming device driver; a multidestination wireless streaming protocol module, a multitank level algorithm module, a synchronization mechanism module, and an autoequalizing speaker and drive system module. The system and method minimize latency, dropout, jitter, and synchronization issues associated with media streaming while optimizing performance and output quality of the media.

Owner:ROKU INCORPORATED

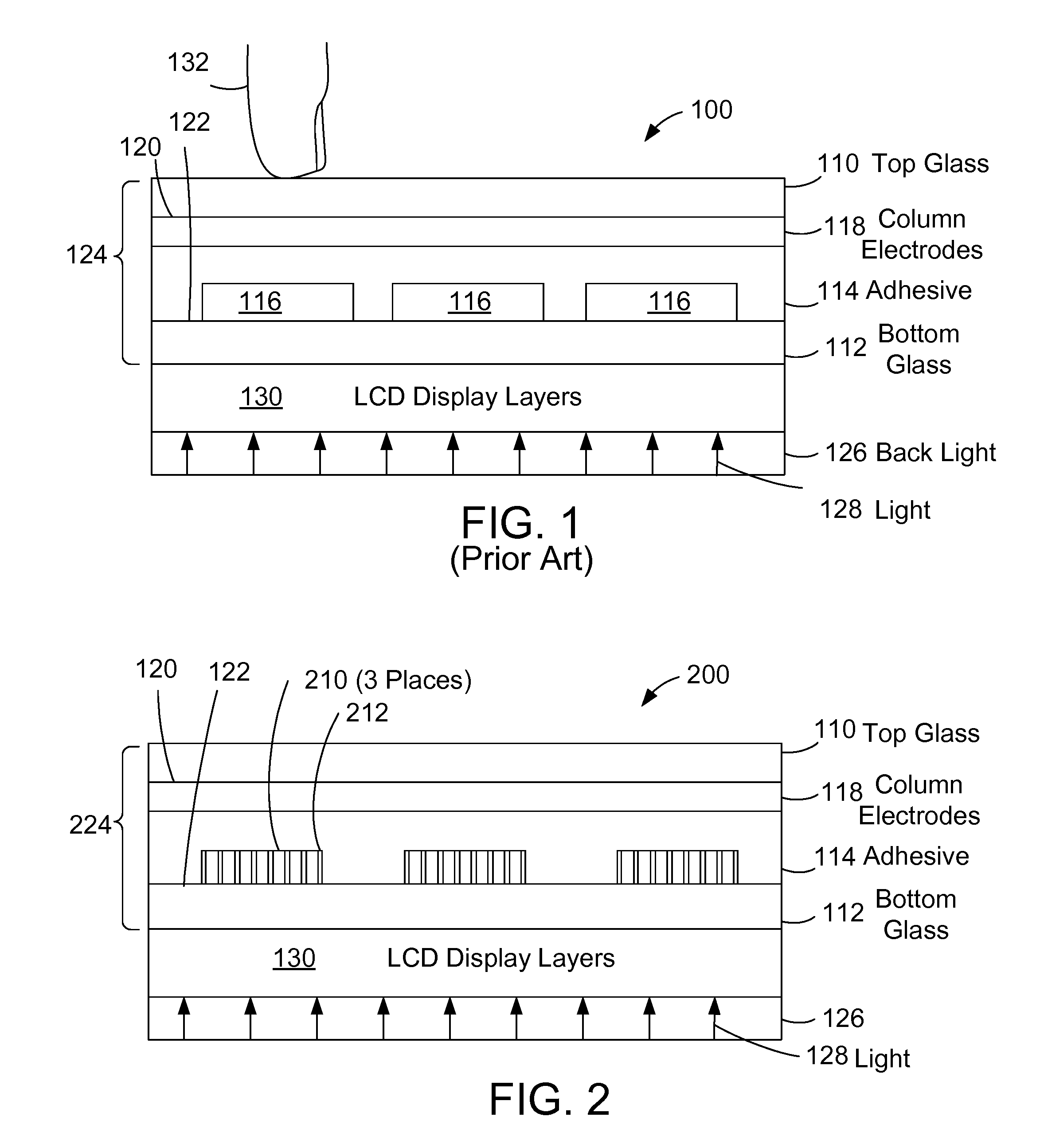

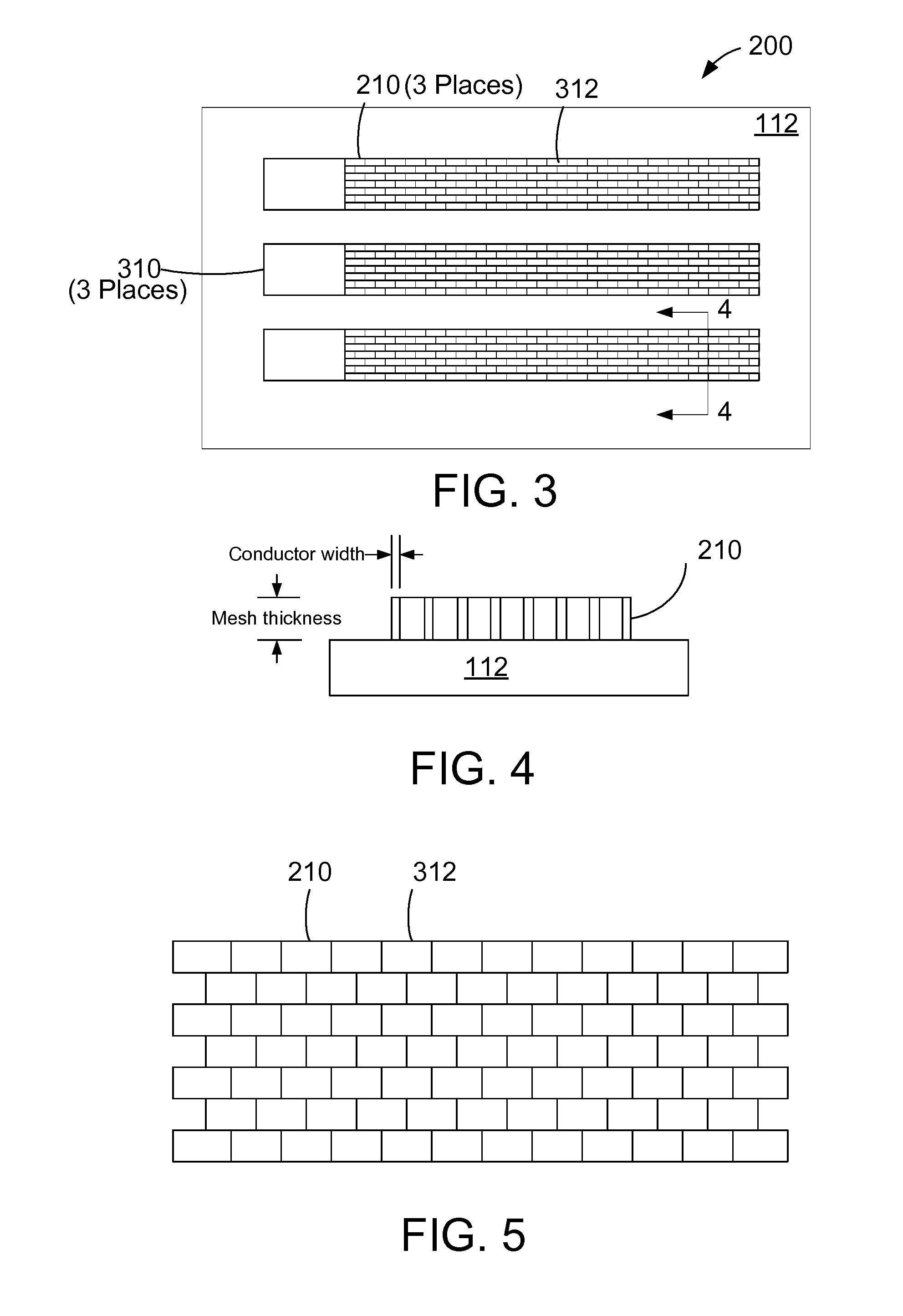

Capacitive touch screen with a mesh electrode

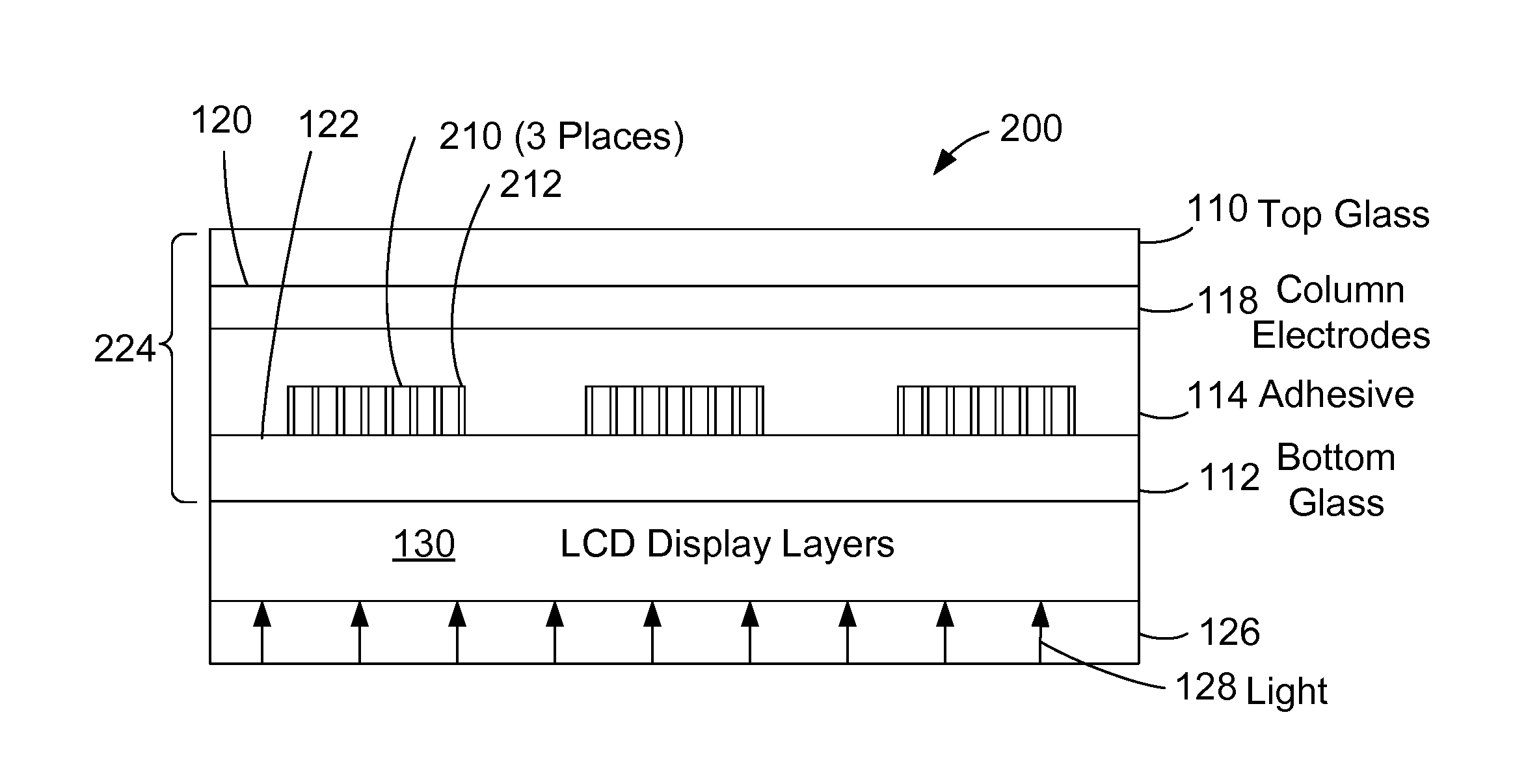

InactiveUS20110007011A1Improve electrical performanceImprove optical qualityInput/output processes for data processingElectrical resistance and conductanceConductive materials

An improved touch screen provides enhanced electrical performance and optical quality. The electrodes on the touch screen are made of a mesh of conductors to reduce the overall electrode resistance thereby increasing the electrical performance without sacrificing optical quality. The mesh electrodes comprise a mesh pattern of conductive material with each conductor comprising the mesh having a very small width such that the conductors are essentially invisible to the user of the touch screen.

Owner:OCULAR LCD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

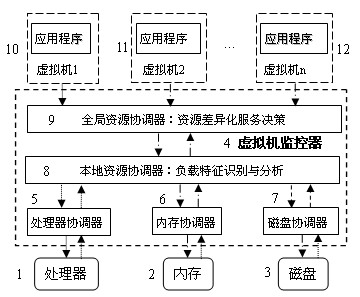

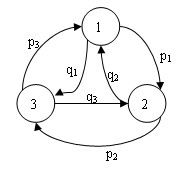

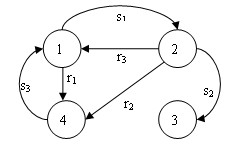

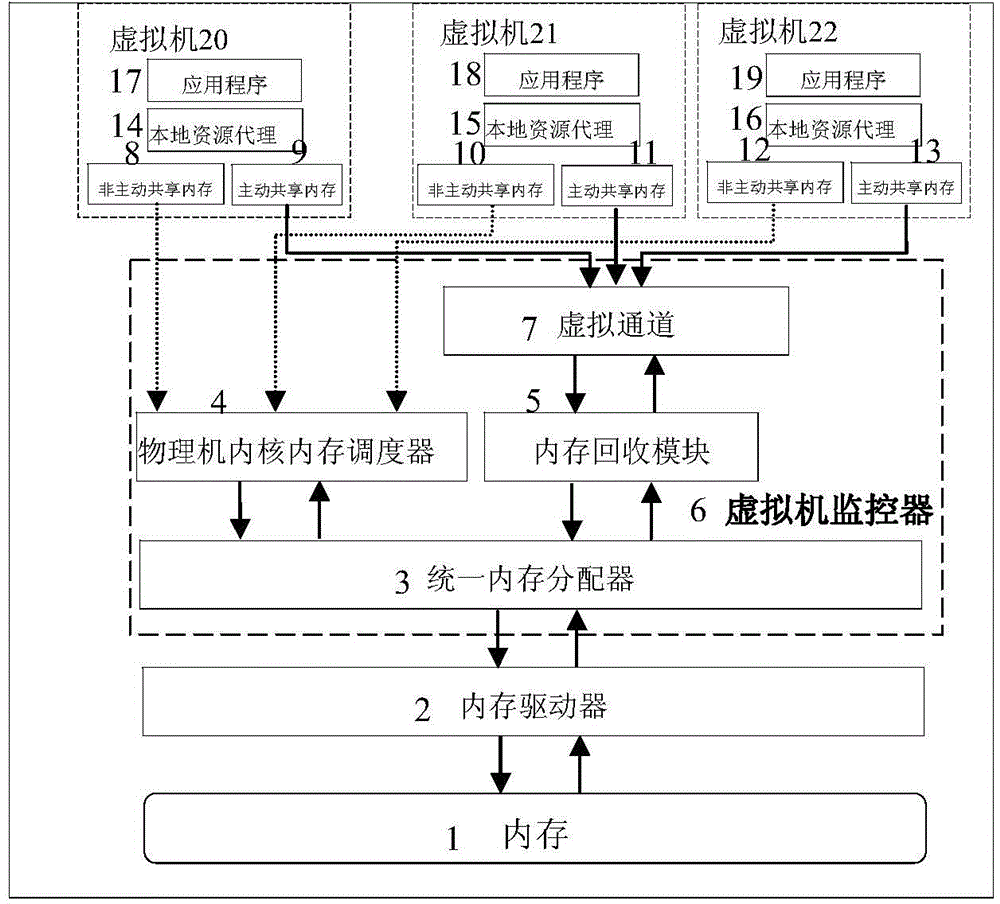

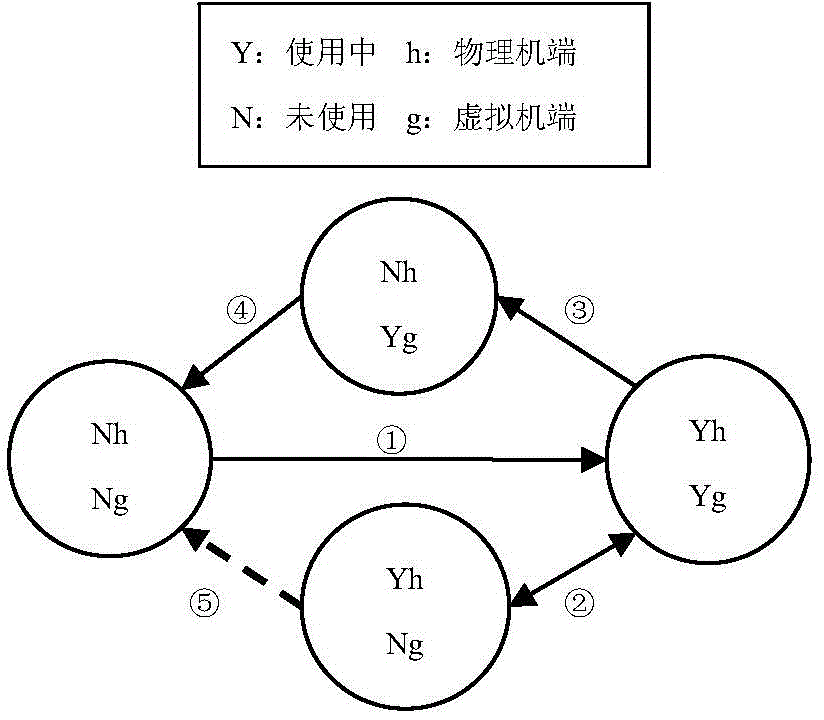

Differential serving method for virtual system competition resources

InactiveCN102156665AImprove performance qualityImprove service qualityResource allocationSoftware simulation/interpretation/emulationVirtualizationDifferentiated service

The invention relates to a differential serving method for virtual system competition resources. Resource application features of a specific virtual machine application program are not differentiated in the conventional virtual machine monitor software and operating system, so that service quality of an important application program and a client operating system cannot be guaranteed. The method comprises three parts of contents: a Markov model used by the virtual system resources, a response time based service quality evaluation model of a multi-virtual machine system and a competition resource differential serving method based on the two models. Through the differential serving method for the virtual system competition resources, provided by the invention, competition degree of the system resources can be effectively relieved under the condition of high competition of the system, so that performance and service quality of the entire virtual system are obviously improved.

Owner:HANGZHOU DIANZI UNIV

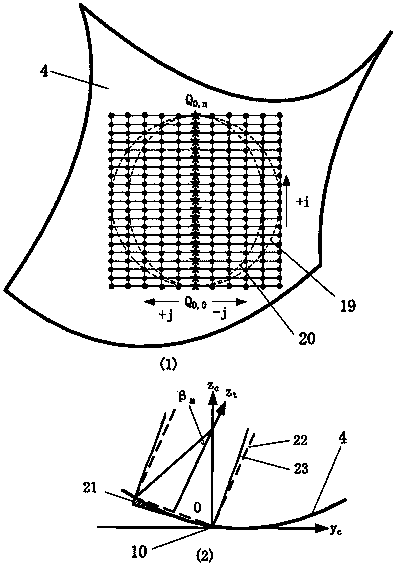

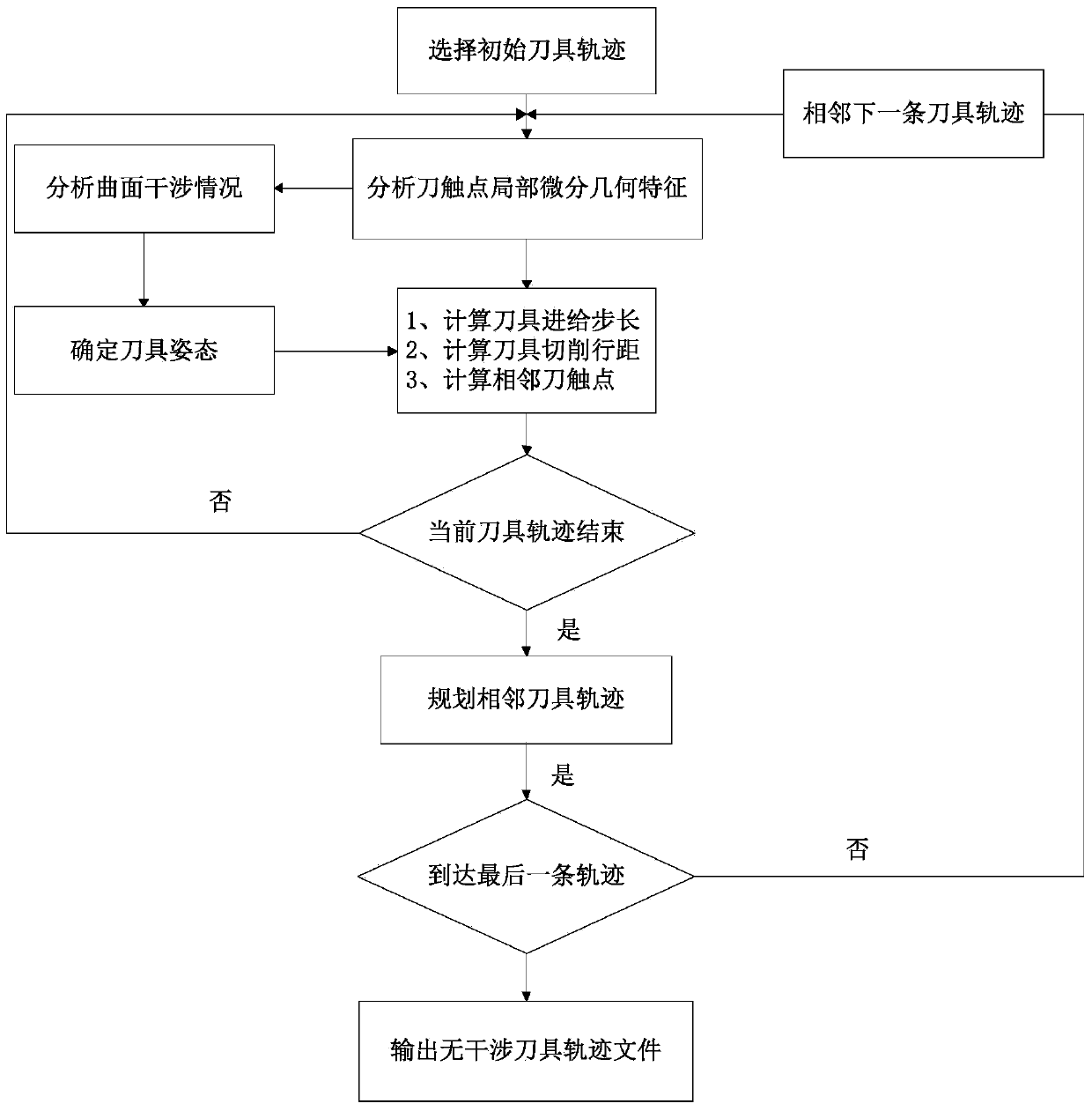

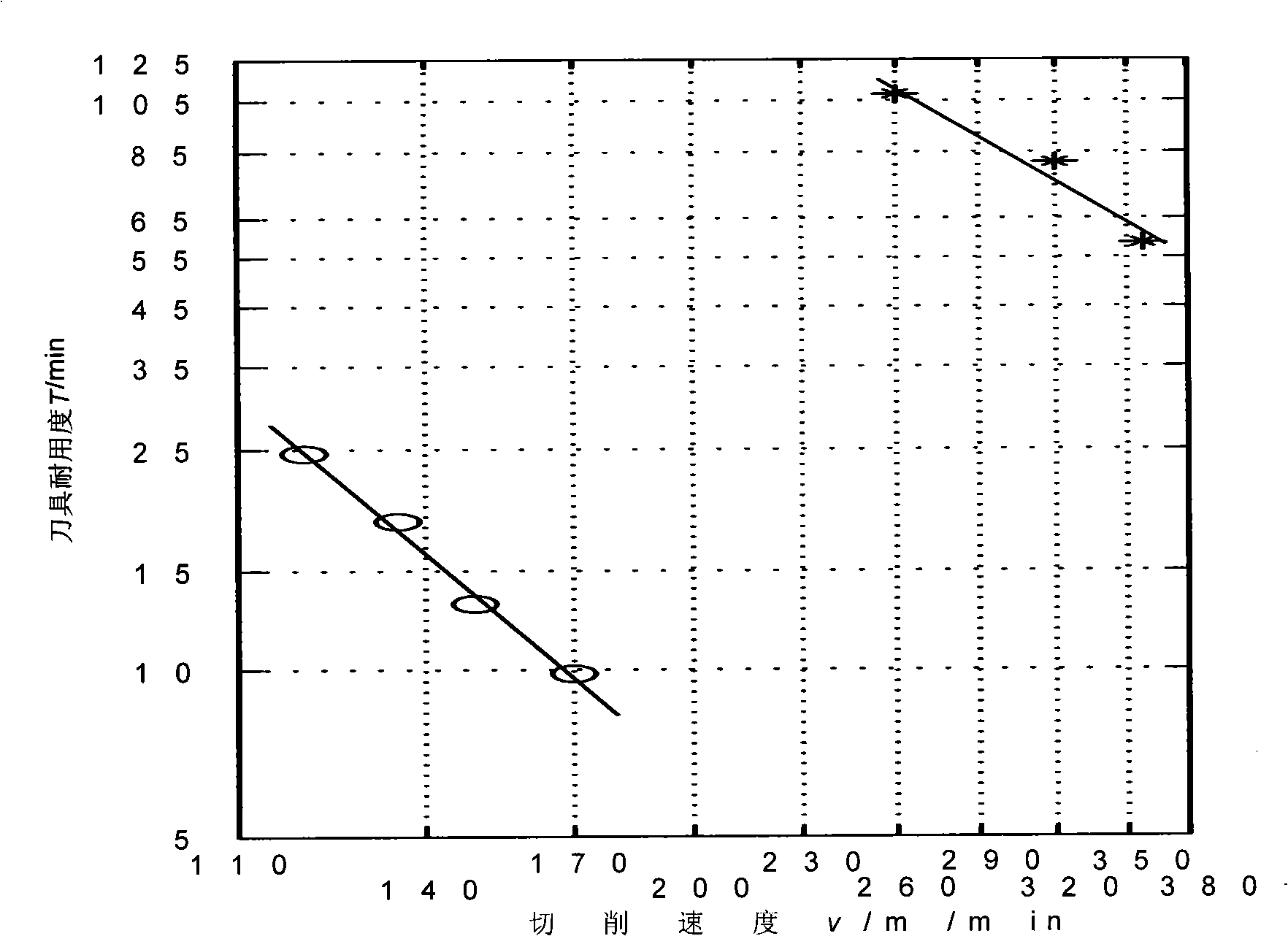

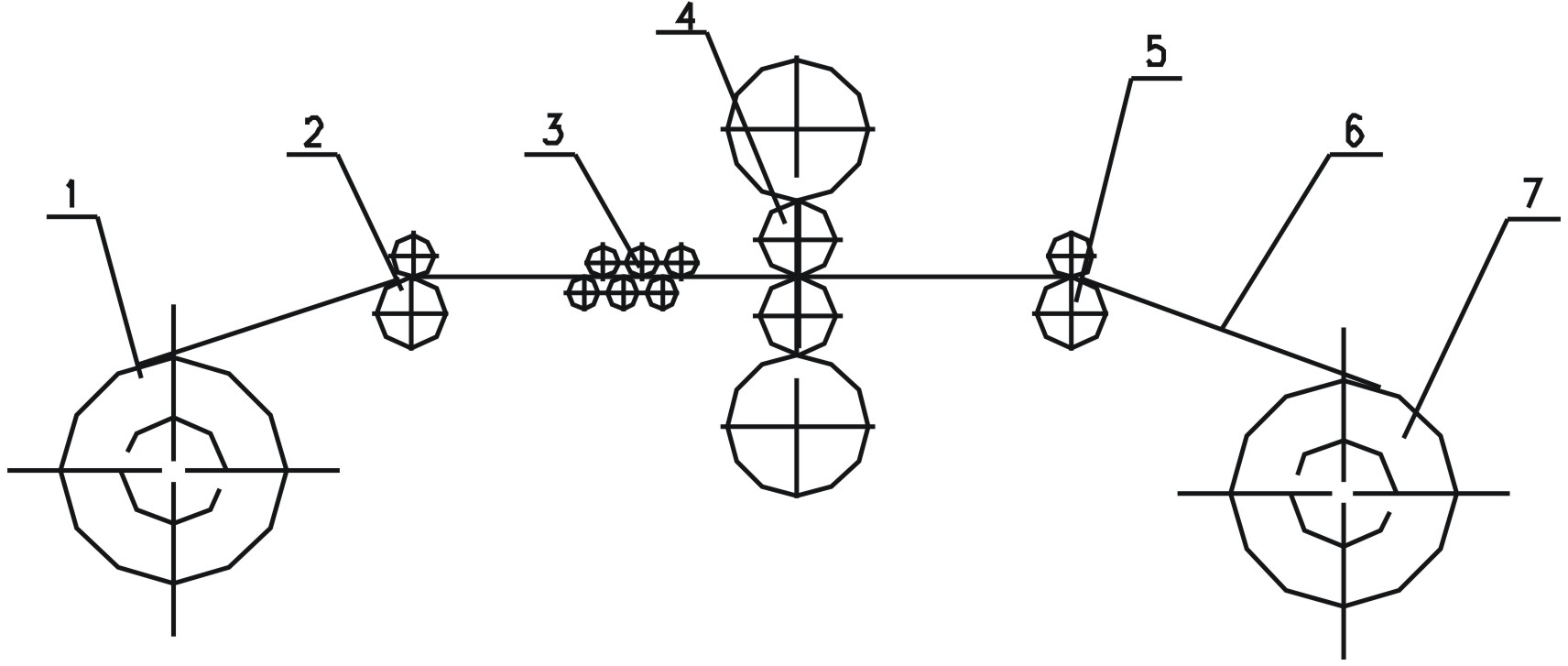

Interference-free tool path generation method in machining of transitional surfaces by flat-end milling cutter

InactiveCN103744349AImprove processing efficiencyReduce surface roughnessNumerical controlMilling cutterPath generation

The invention discloses a method for generating interference-free flat-end milling cutter process path along the ridge direction of transitional surfaces. The method comprises the following steps: (1) initial machining tool path is set, a tool is processing along the ridges of transitional surfaces, a current tool contact is calculated to obtain effective curvature of the machining tool at the tool contact; (2) curvature interference analysis of transitional surface machining is carried out according to the effective curvature of the machining tool at the tool contact, tool bottom interference is analyzed, and the angle of the tool is deflected at the tool contact to obtain interference-free tool posture; (3) parameter calculation is carried out on the adjusted tool path so as to obtain step-length and cut row distance; and (4) adjacent tool path lines are calculated, including calculation of adjacent tool contacts and calculation of tool location data, and interference-free tool path is finally obtained. By the method, automatic planning of interference-free tool path can be realized; large cut row distance is obtained; cutting efficiency is high; machining surface roughness is low; surface fairness is good; and problems of low cutting efficiency, poor machining surface quality and the like by machining of a ball-end milling cutter are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

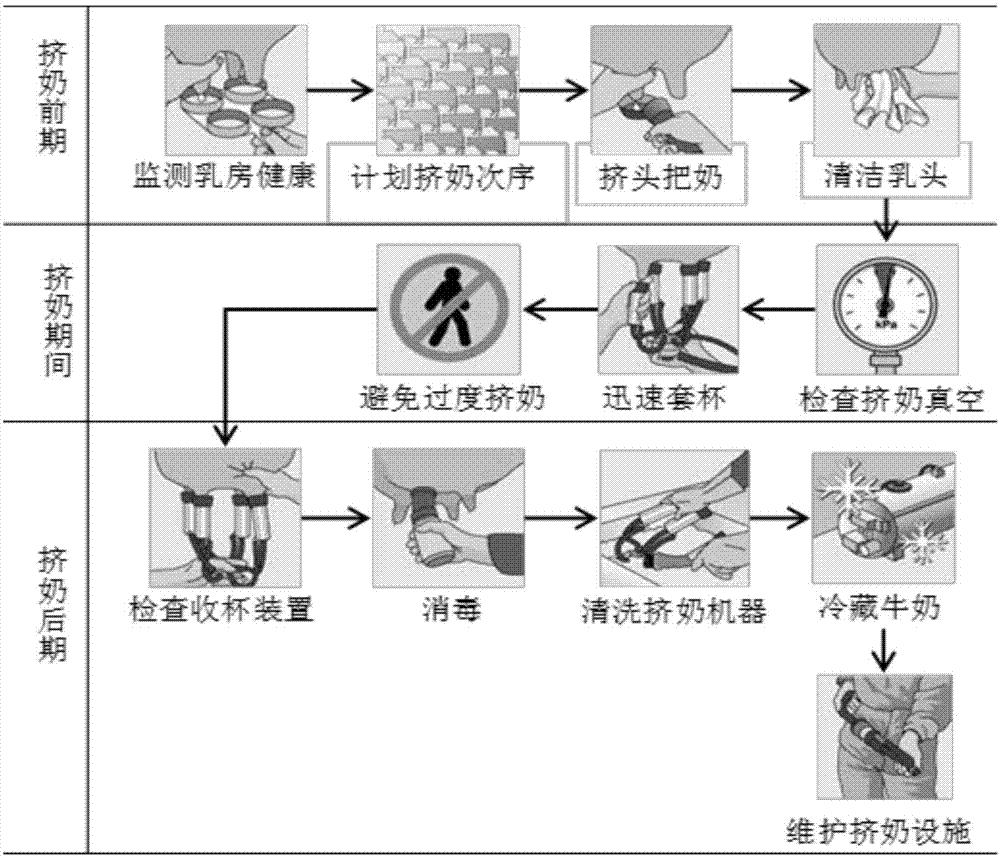

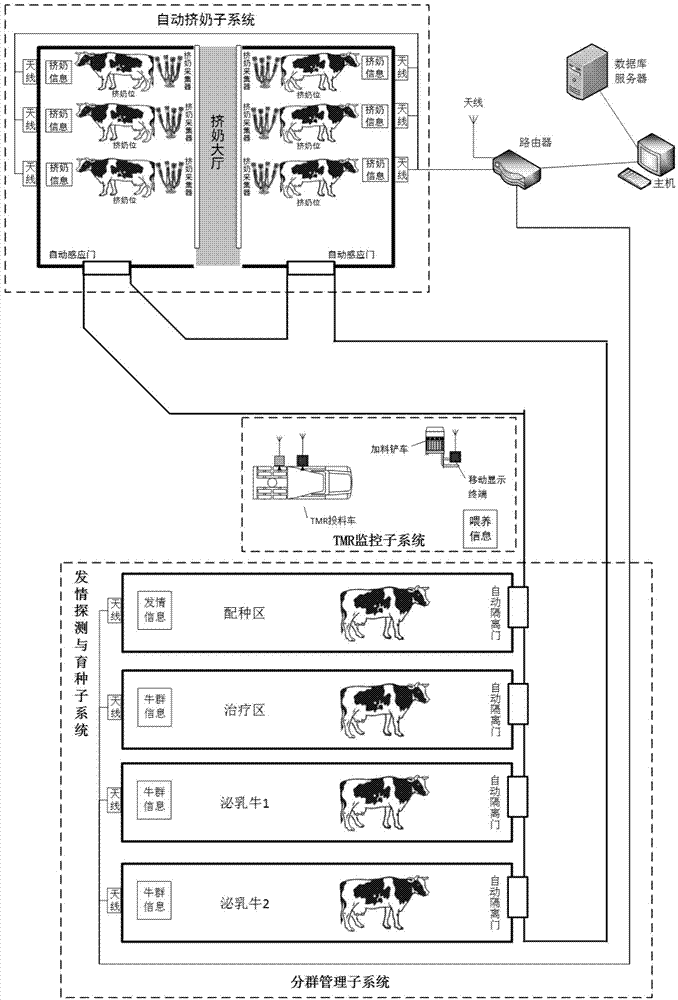

Cow fine breeding method based on RFID technology

ActiveCN103782954AImplement dynamic configurationImprove efficiencyClimate change adaptationCo-operative working arrangementsAgricultural scienceBusiness function

The invention discloses a cow fine breeding method based on the RFID technology. The method includes the following steps that 1, the milk production of cows is recorded through an automatic milk production recording subsystem where the RFID technology and milking are combined; 2, automatic clustering management is performed on the cows through an automatic cow isolation door based on the RFID technology; 3, appropriate nutritious daily ration is prepared for cow groups through a TMR monitoring subsystem based on the RFID technology; 4, cow movement and oestrus sensors are installed on cow neckbands so as to monitor movement conditions of the cows in real time. In the cow fine breeding method, the cow breeding management business relates to various fields of milking management and fodder management, and the cow fine breeding method is applied and deployed from the aspects of automatic milk production counting, clustering management, fodder management and oestrus hybridization management according to different business functions of cow farms.

Owner:GUANGDONG YANTANG DAIRY

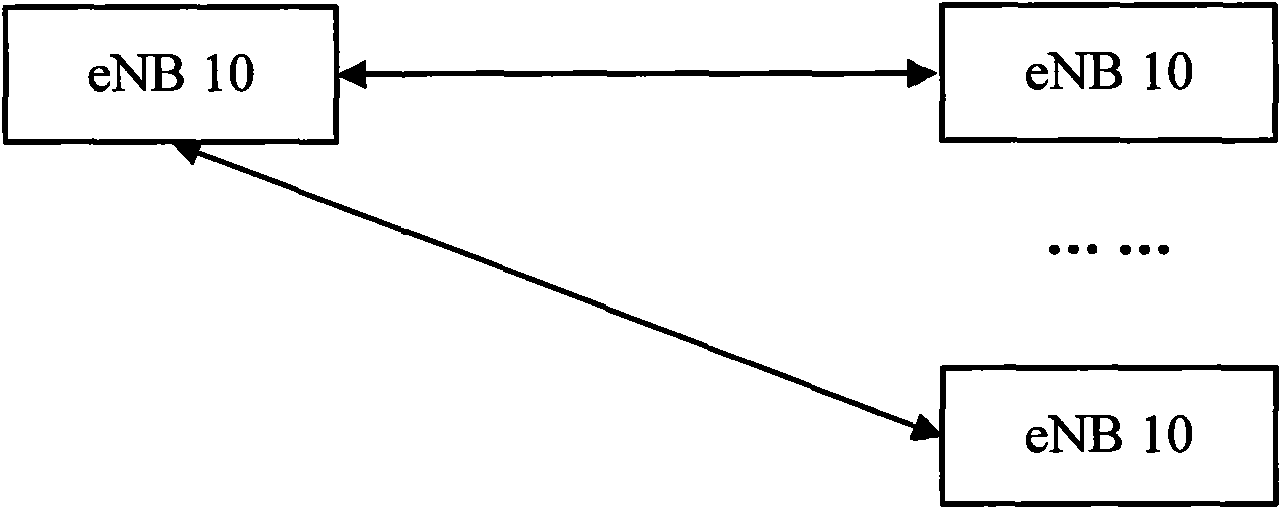

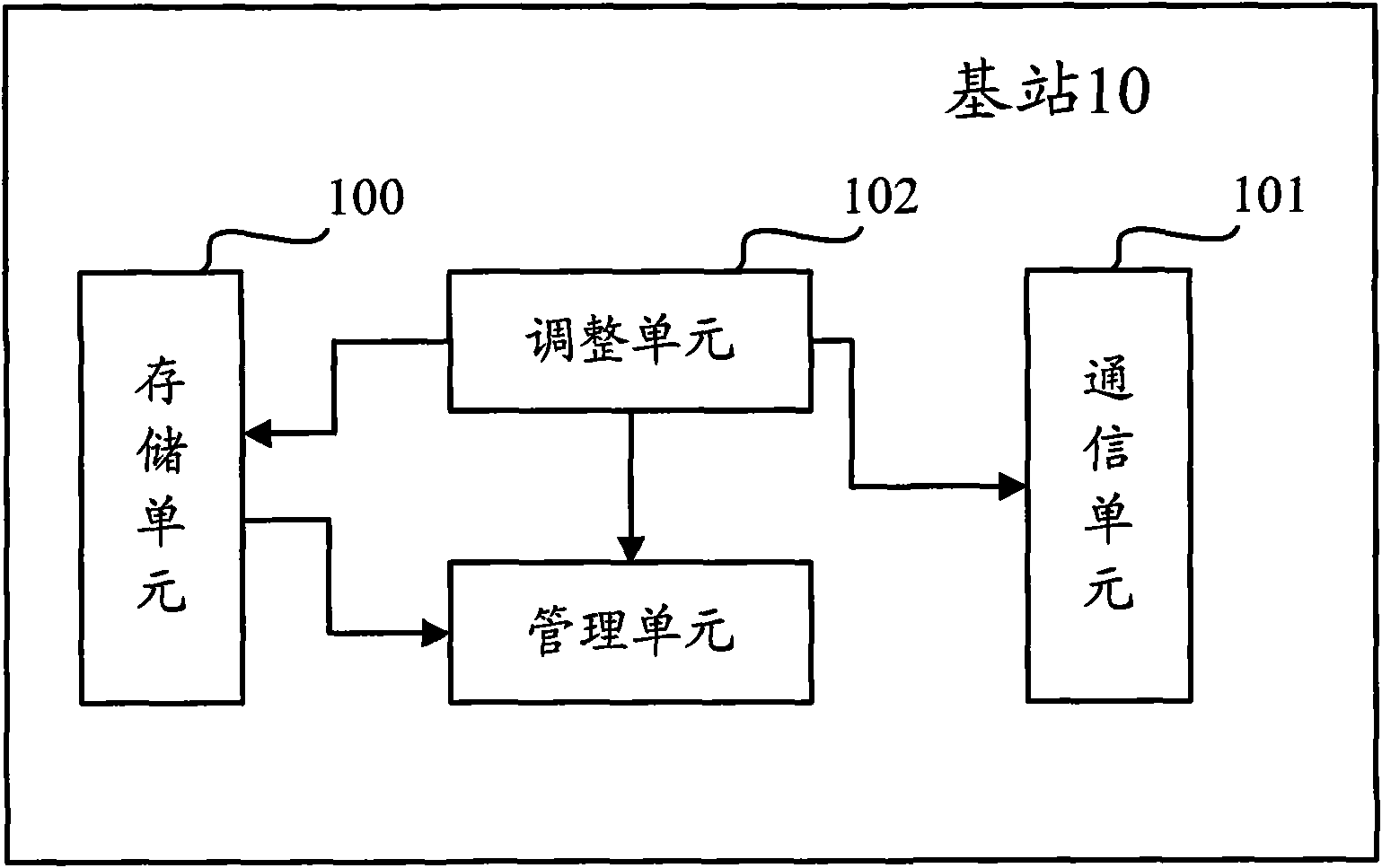

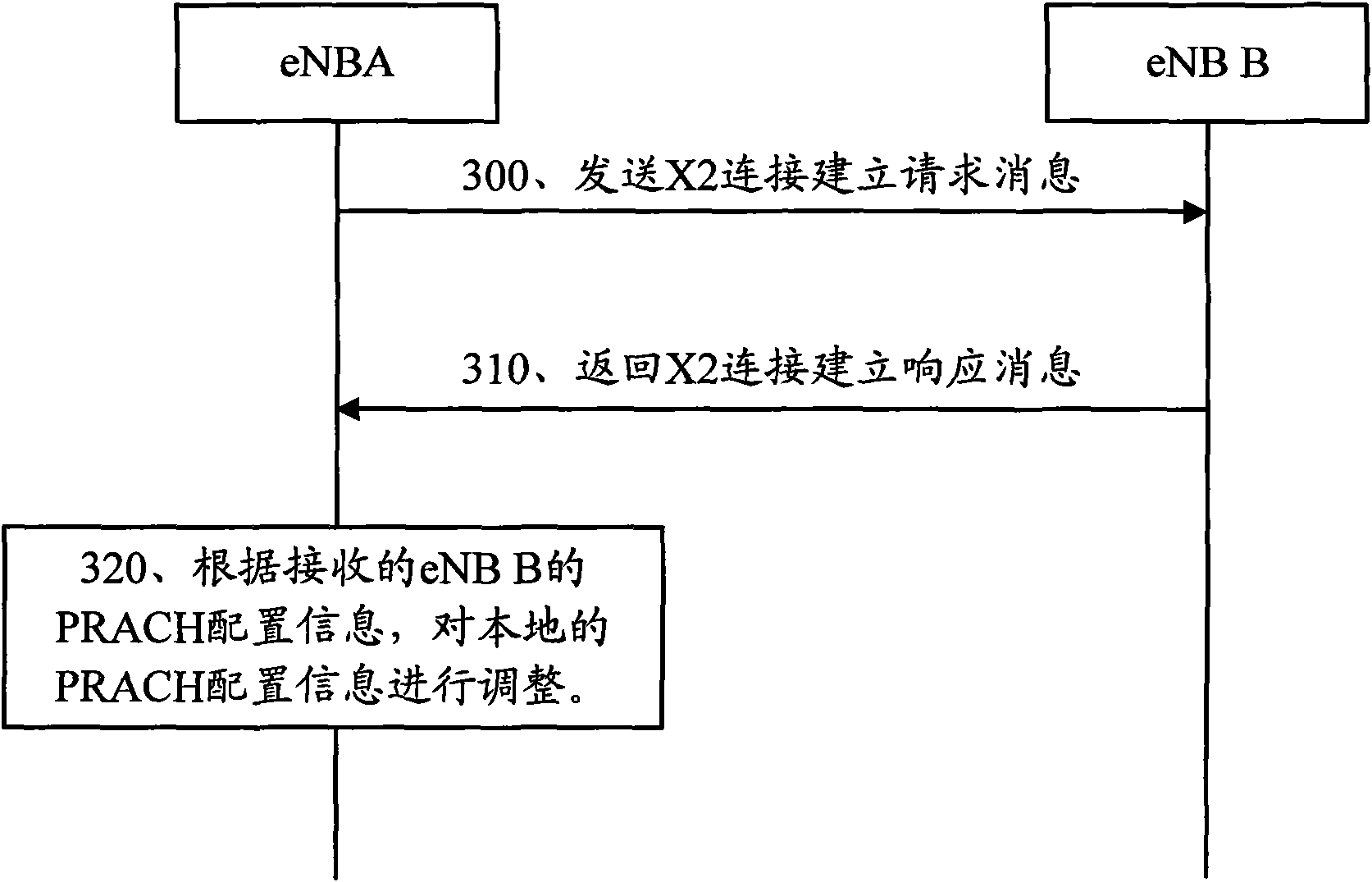

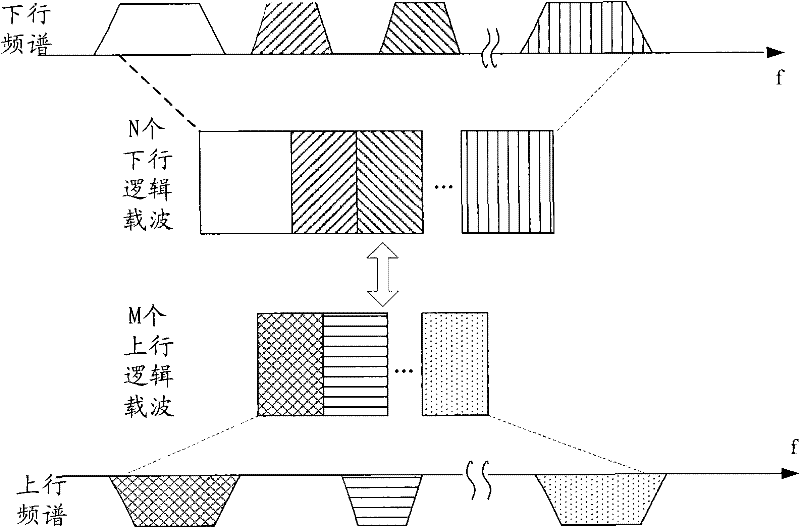

Method, device and system for adjusting PRACH configuration information

ActiveCN101873712AImprove random access success rateReduce distractionsConnection managementQuality of serviceComputer science

The invention discloses a method for adjusting physical random access PRACH configuration information; the method comprises the following steps that: in a long-termed evolution LTE system, when in work, a first base station receives the PRACH configuration information sent by at least one second base station which is adjacent to the first base station; the PRACH configuration information at least comprises an initial root sequence index, a cyclic shift parameter index zero correlation zone config and a prach-config index which are used by the second base station; the first base station correspondingly adjusts the local PRACH base station configuration information according to the received PRACH configuration information of the at least one second base station so as to reduce the interference between a community under the jurisdiction of the first base station and the community under the jurisdiction of the at least one second base station. Consequently, the invention reduces the interference of the adjacent communities, improves the random access success rate of a user so as to improve the performance and the service quality of the whole system. Simultaneously, the invention discloses the base station and the LTE system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

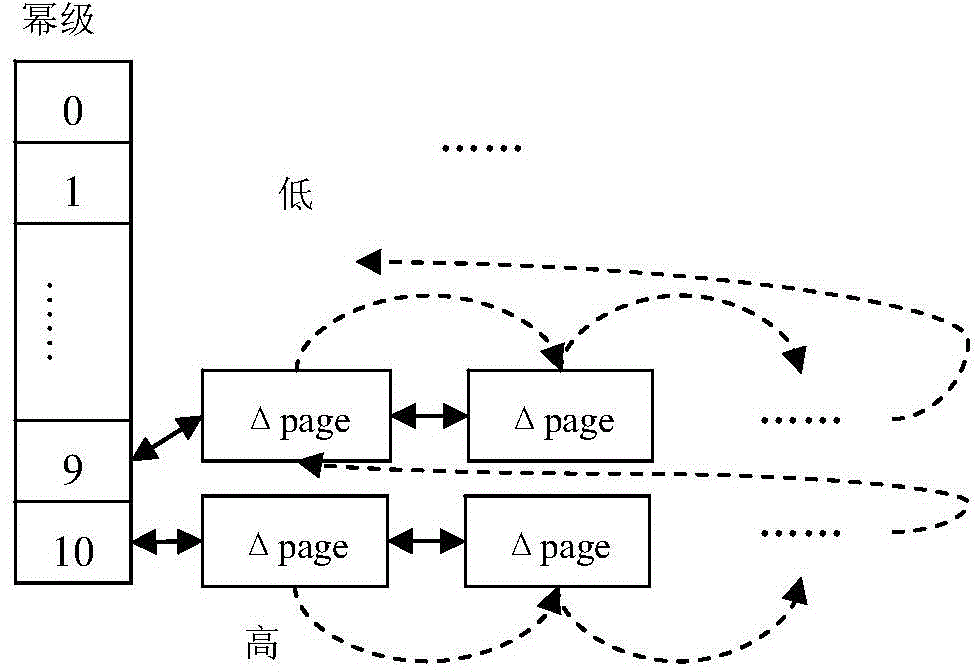

Active sharing memory excessive allocation method in multi-virtual machine system

ActiveCN104915151AMaximize the best performanceImprove performance qualityInput/output to record carriersMemory adressing/allocation/relocationVirtualizationPeak value

The invention relates to an active sharing memory excessive allocation method in a virtual system. A traditional virtual system adopts an excessive allocation strategy for a memory in order to meet the peak value performance of a client virtual machine, and the waste of memory resources under low load is always caused. The method comprises three parts of content: a client virtual machine memory page marking method based on a tile record method and a residual quantity linked list record method, an active memory sharing method based on a virtual channel and a multi-virtual machine memory excessive allocation method based on the above two methods. According to the active sharing excessive allocation method of the virtual system, a competition degree of system resources can be effectively alleviated under a condition that the system memory is highly competitive, and the performance and the service quality of the client virtual machine system under the whole multi-tenant cloud computing environment can be obviously improved.

Owner:HANGZHOU DIANZI UNIV

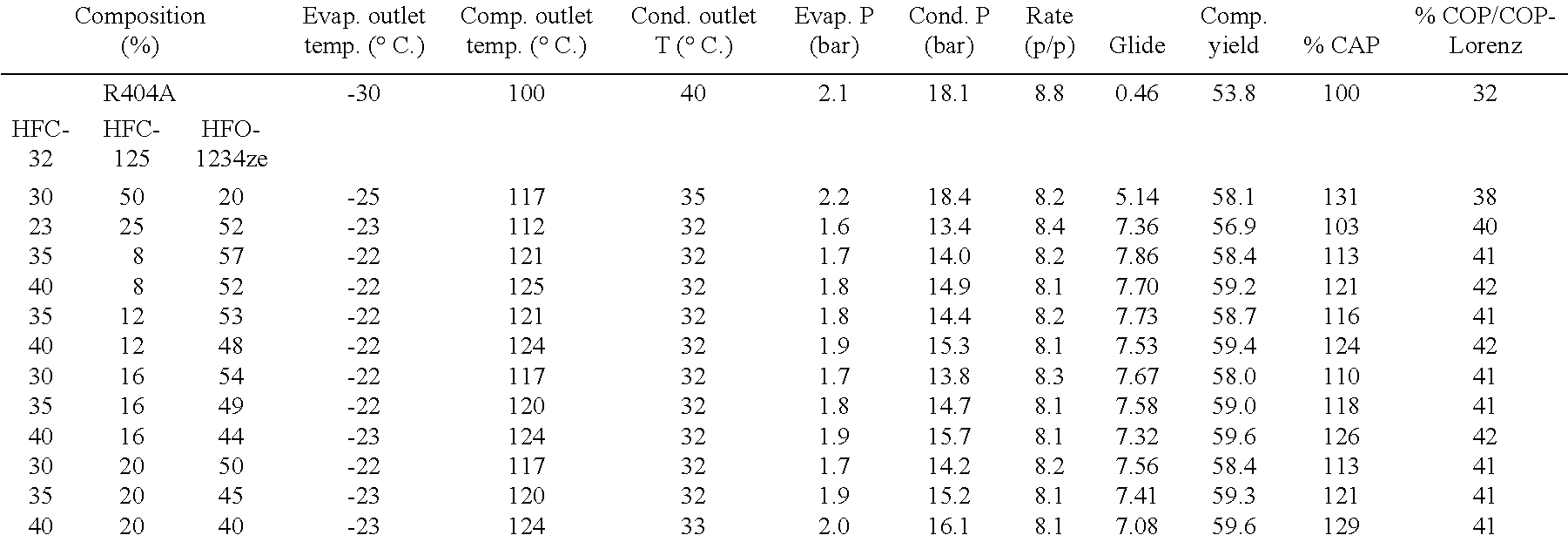

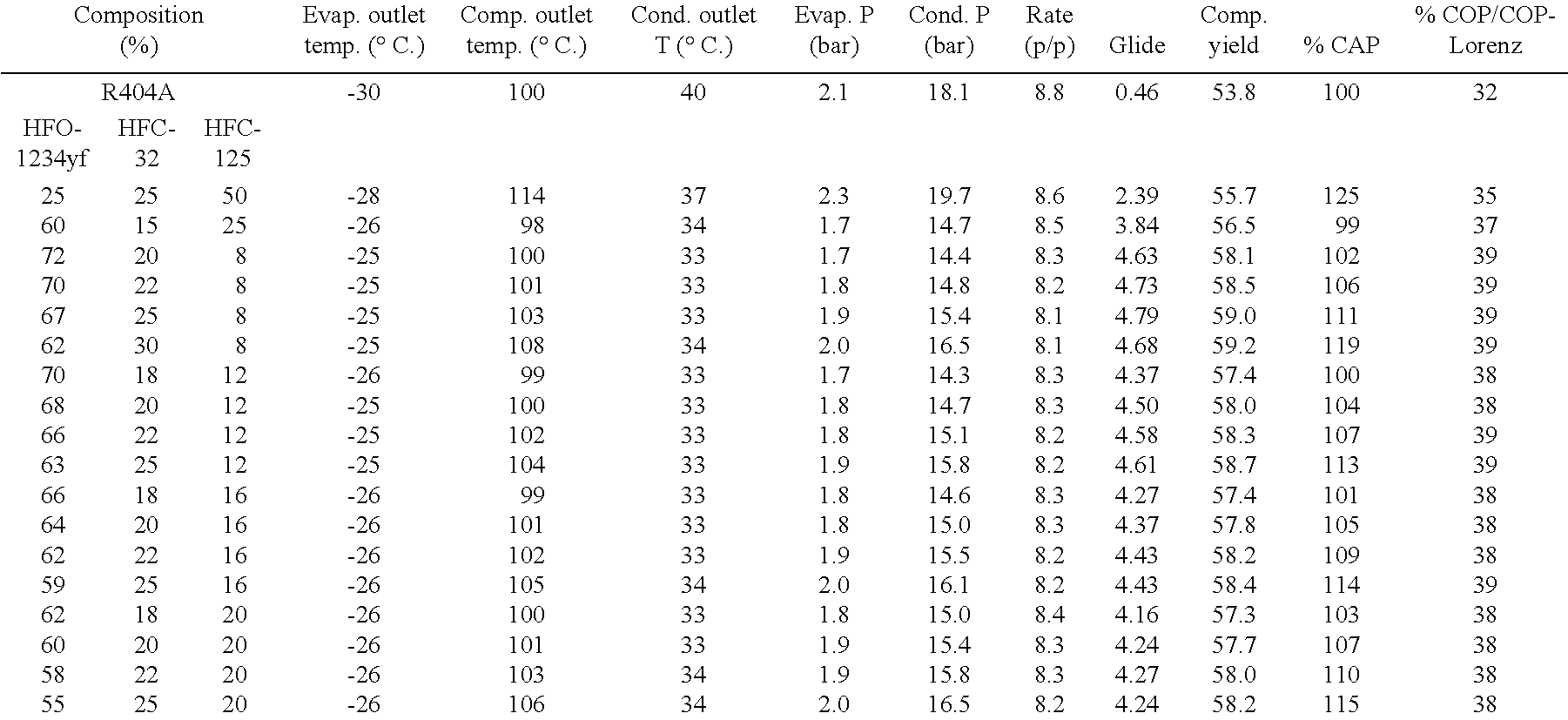

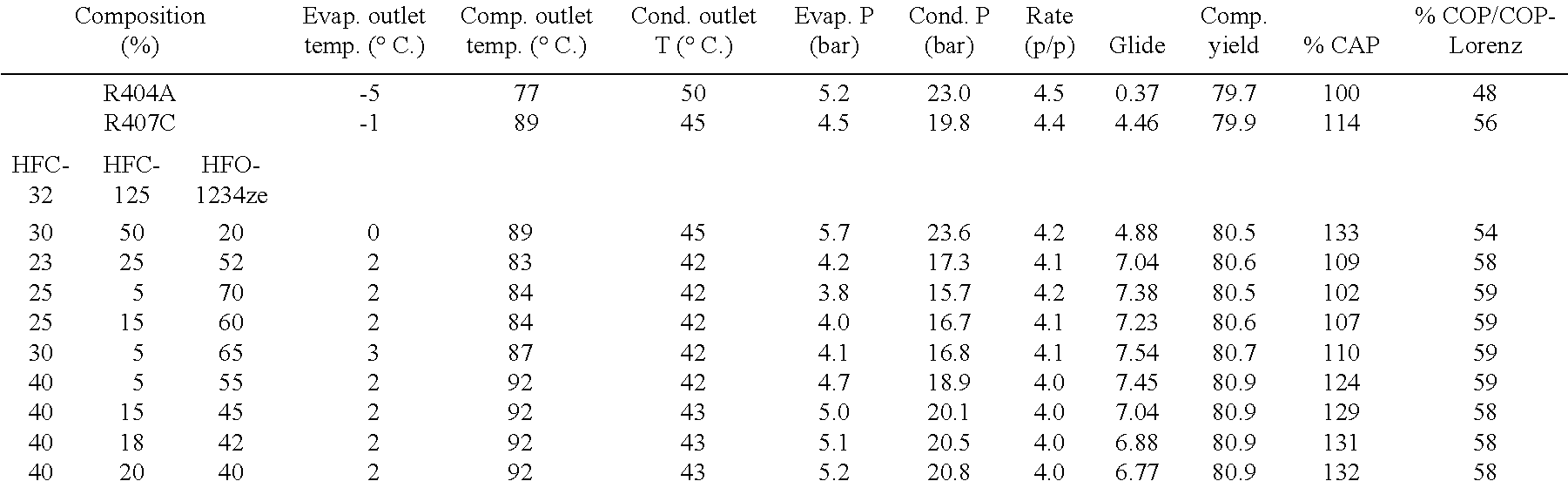

Ternary heat-transfer fluids comprising difluoromethane, pentafluoroethane and tetrafluoropropene

InactiveUS20130055738A1Reduce the impact of heatLow GWPHeat-exchange elementsRefrigeration componentsThermodynamicsMaterials science

The invention relates to a ternary composition comprising: from 5 to 50% of difluoromethane;—from 2 to 20% of pentafluoroethane; and—from 30 to 90% of tetrafluoropropeae. The tetrafluoropropeae may be 1,3,3,3-tetrafluoropropene or 2,3,3,3-tetrafluoropropene. This composition can he used as a heat-transfer fluid in vapor compression circuit.

Owner:ARKEMA FRANCE SA

Easy-cutting untempered steel and method for manufacture thereof

InactiveCN101255535AEasy to shapeAdverse effects of improved mechanical propertiesProcess efficiency improvementElectric furnaceHeating timeHeating furnace

The invention discloses a Ca-S composite free-cutting non-quenched and tempered steel for cutting which has high cutting property and the manufacturing method thereof. The steel is composed of 0.44% to 0.49% of C, 0.30% to 0.60% of Si, 1.20% to 1.50% of Mn, 0.08% to 0.12% of V, no more than 0.30% of Cr, Ni and Cu, 0.040% to 0.065% of S, no more than 0.035% of P, 0.001% to 0.010% of Ca, 0.01% to 0.03% of Al, and the balance Fe and unavoidable impurity. According to the method, the compositions of inclusion in steel are controlled by ladle argon blowing and Ca-S composite processing, casting blank is poured by continuous casting, the average temperature for heating billet in a heating furnace is 1180 DEG C to 1220 DEG C, the heating time is 2 to 3 hours, the rolling starting temperature is 1100 DEG C to 1150 DEG C, the rolling finishing temperature is 850 DEG C to 1000 DEG C, the cooling speed of the rolled steel is 1.5 DEG C per second to 2.5 DEG C per second, the cooling bed cooing in pile temperature is 600 DEG C to 700 DEG C. The steel has superior mechanical property and free-cutting property.

Owner:SHANDONG IRON & STEEL CO LTD

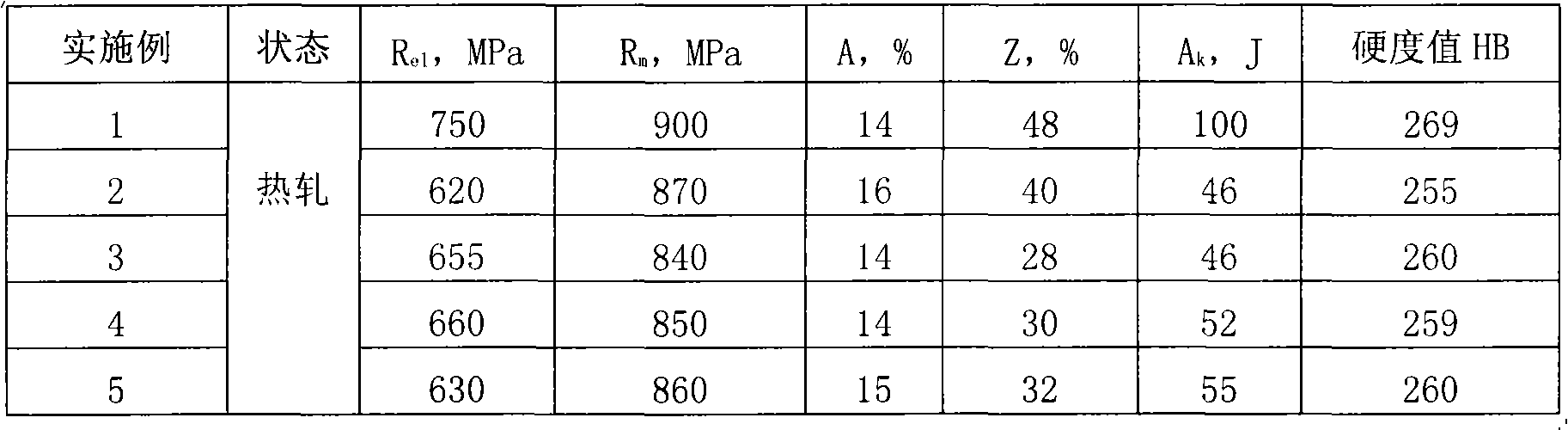

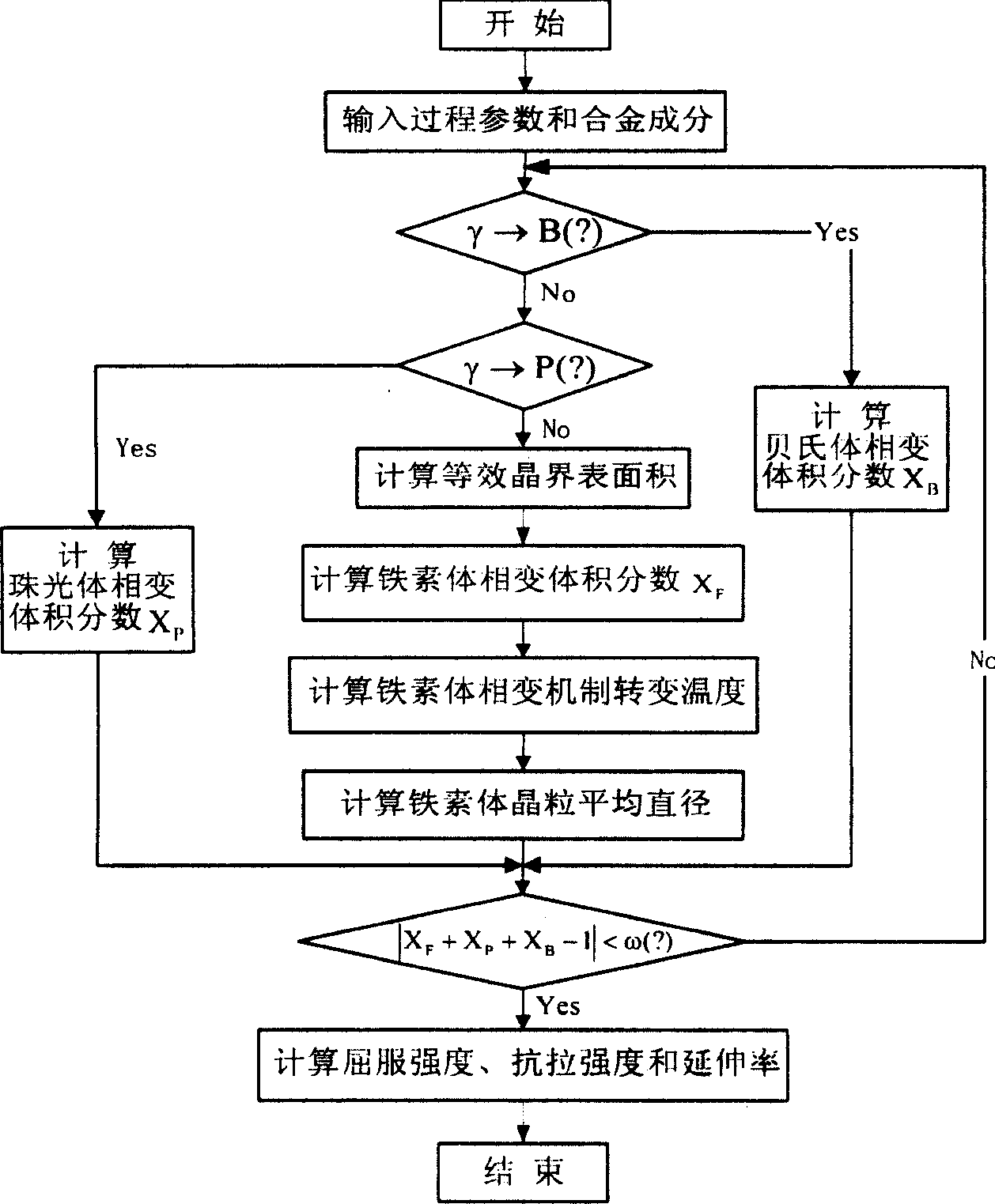

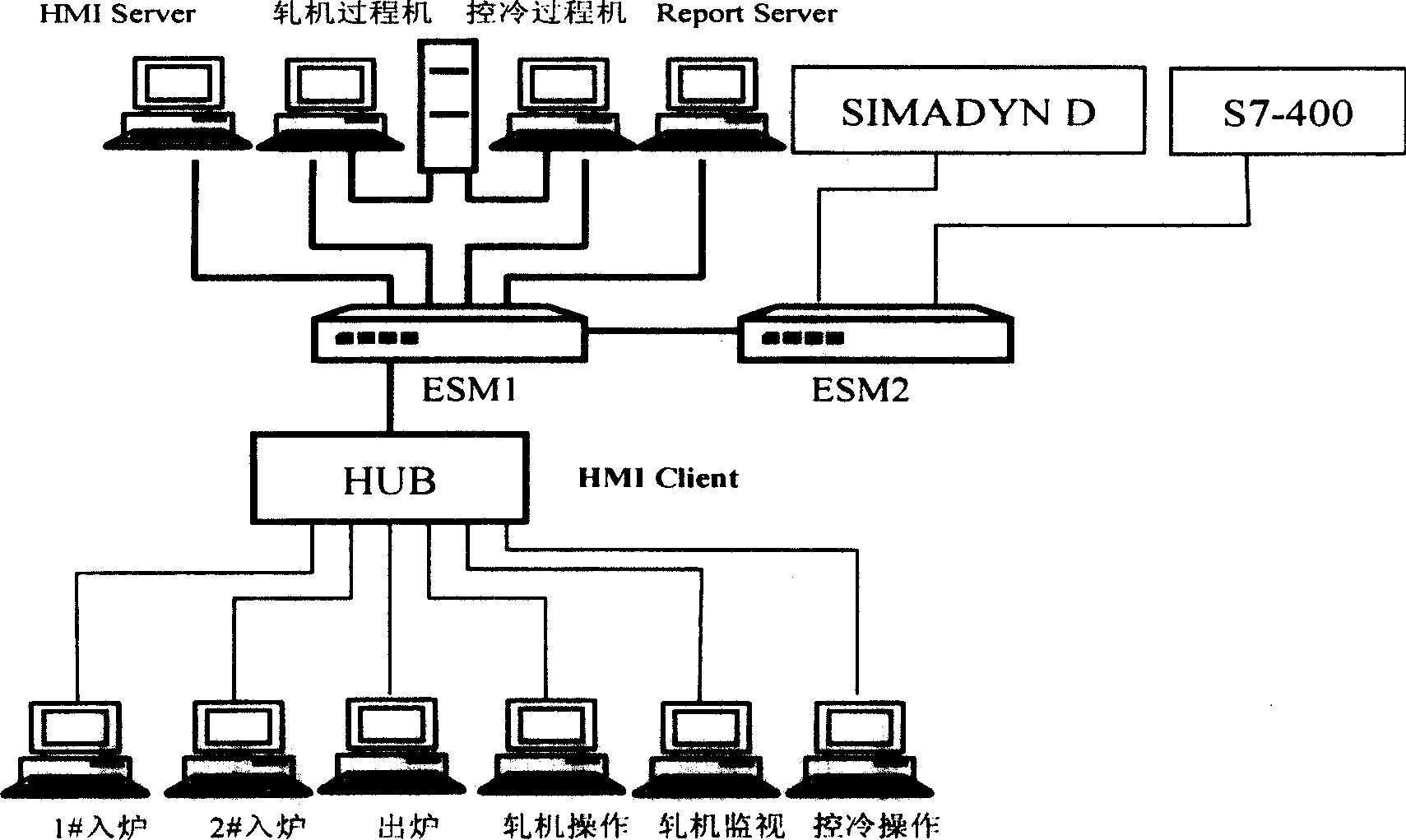

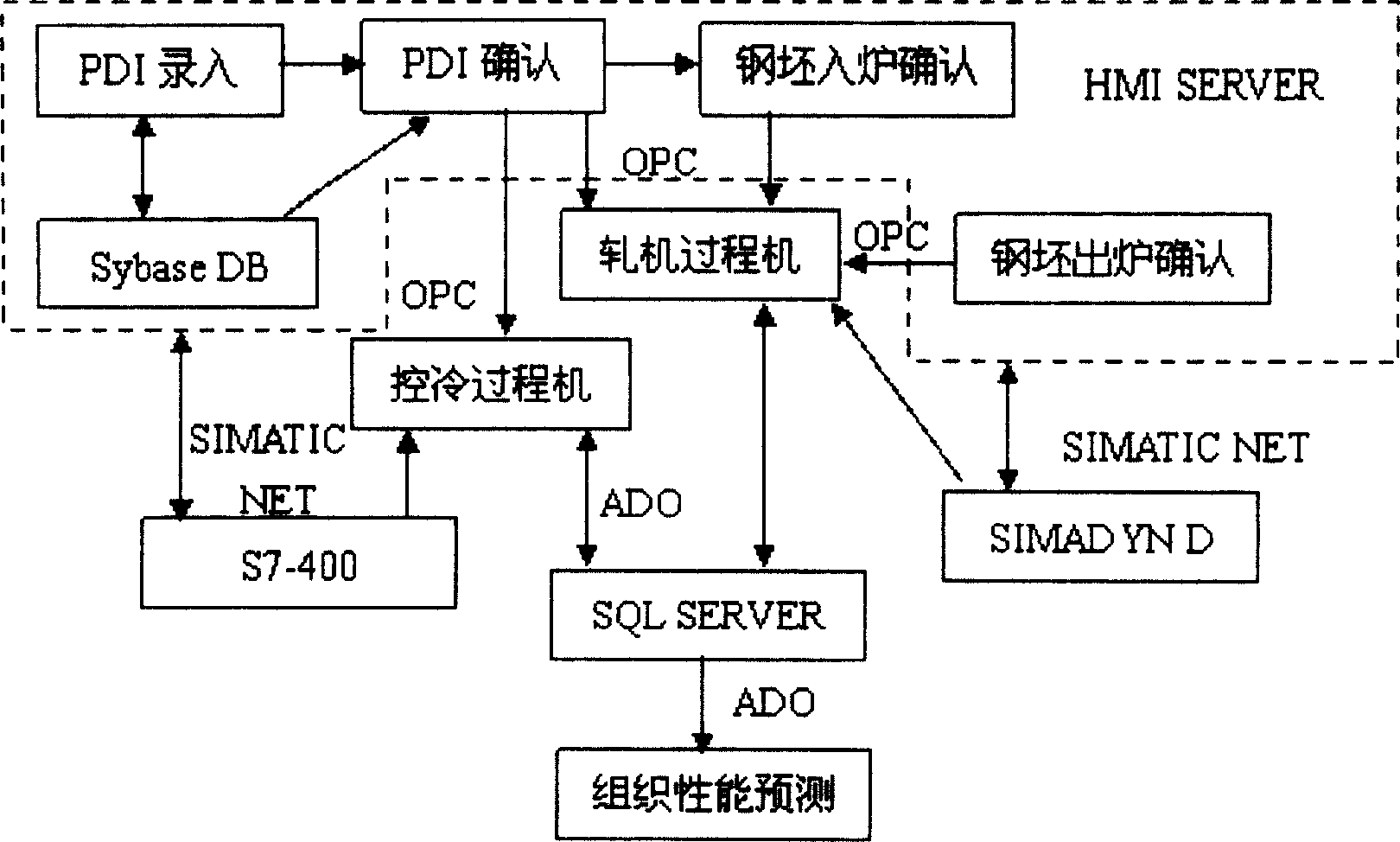

Method for online test of steel plate mechanic property during rolling process

InactiveCN1664550ASufficient reliabilityHigh precisionInvestigating material ductilityInvestigating material hardnessOnline testModel parameters

The invention relates to a method for testing the mechanical of the steel plate on line when rolling, providing a comprehensiveness on-line predicting method based on the physico-metallurgy model and combined with the database, information technology through setting up a corresponding model of microscopic structure, finished size, art component to the mechanical. The method including the following steps: (a) selecting and confirming the parameter of the model; (b) setting up the real-time traffic to the processing machine, calling the art parameter and alloying component dynamic data from the processing database; (c) predicting the ferrite grain size and temperature (d) predicting mechanical of the finished plate. The invention is used specially for low-carbon steel and mini alloyed steel, the adaptive process is heavy and medium plate mill or big mill and finisher in rolling process.

Owner:NORTHEASTERN UNIV

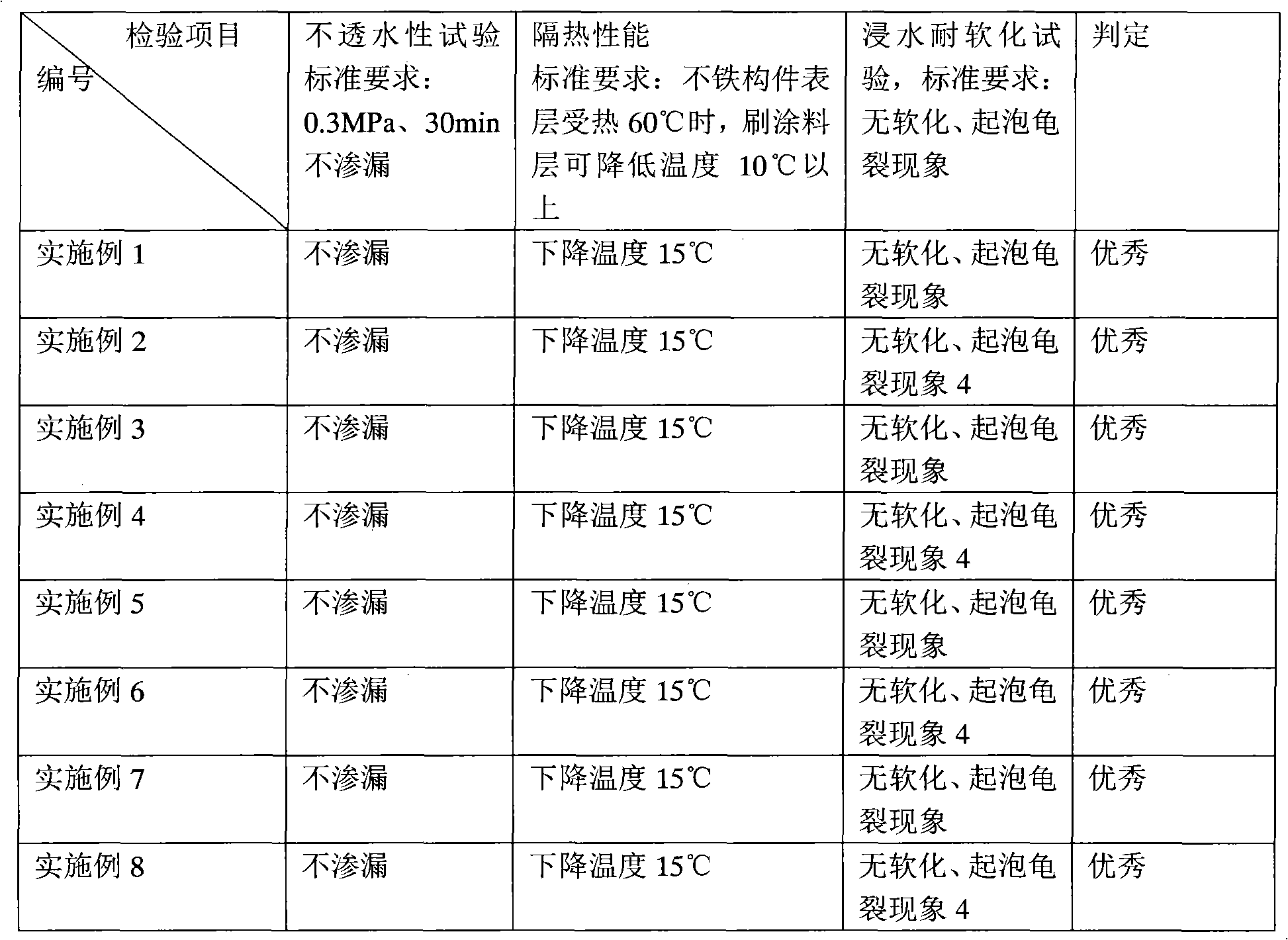

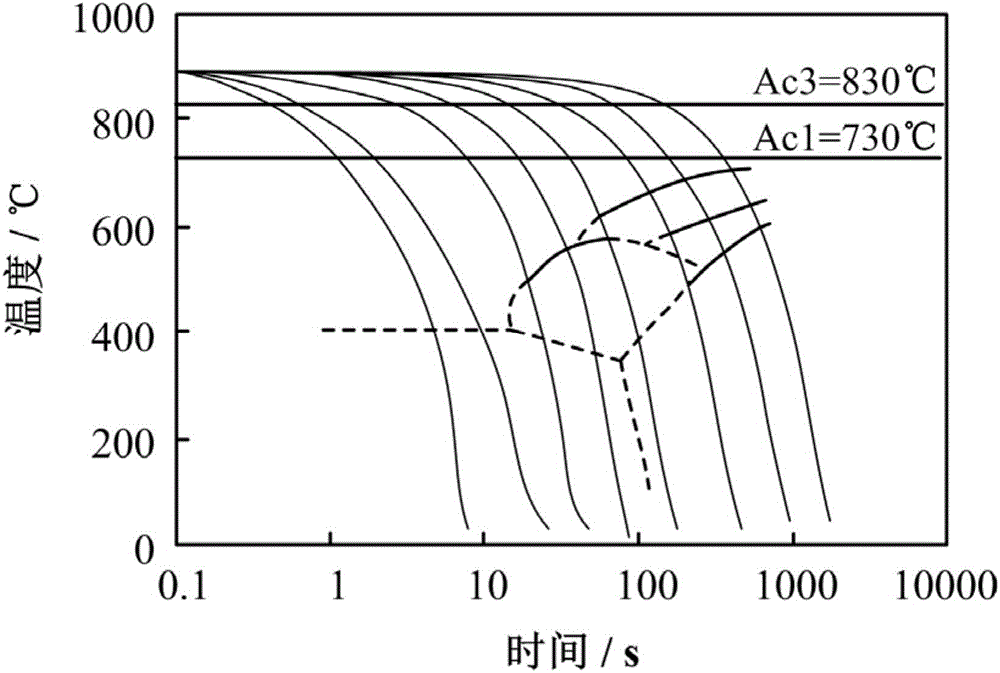

Heat insulation waterproof waterborne coating

InactiveCN101831219AImprove performance qualityImprove film qualityCoatingsCarvacryl acetateDefoamer

The invention discloses a heat insulation waterproof waterborne coating which comprises the following compositions in percentage by weight: 40-48wt% of film forming emulsion, 41-54 wt% of pigment filler, 2.77-8 wt%of additive and the balance of clear water, wherein the film forming emulsion is ethylene-vinyl acetate copolymer EVA and acrylic copolymer emulsion, the pigment filler is one or multiple kinds of titanium dioxide, mica powder, heavy calcium powder, light calcium powder, talcum powder, kaolin, phosphatic powder and hollow tiny glass powder or all of the substances, and the additive is one or multiple kinds of dispersant, lubricant, flow agent, defoamer, plasticizer, antifreeze and preservative or all of the substances which are usually used by technicians of the field. The coating has the advantages of excellent heat insulation and waterproof performance, favorable environmental protection, difficult pulverization, fast drying and simple and convenient construction.

Owner:HUIZHOU GUCHENG TECH

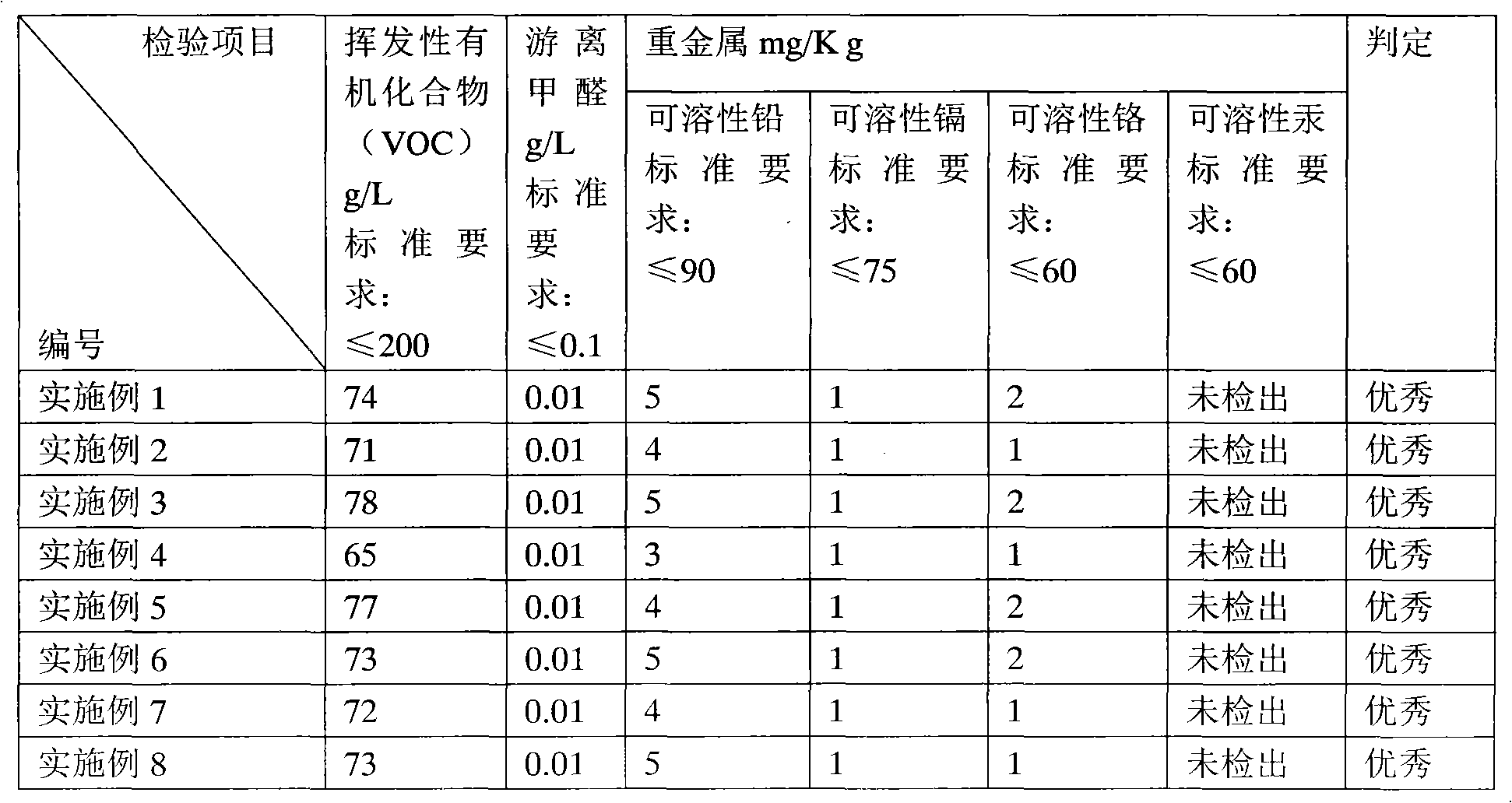

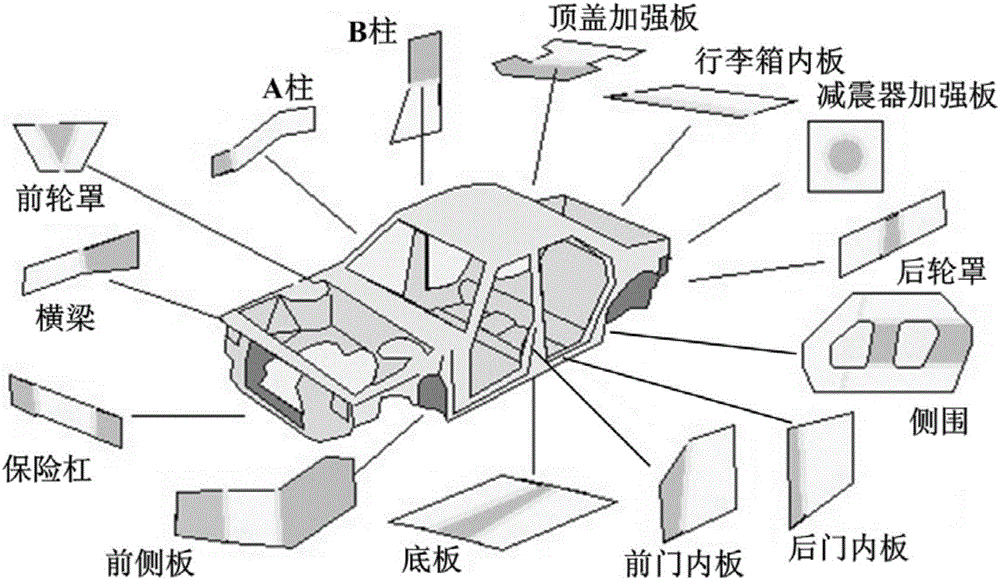

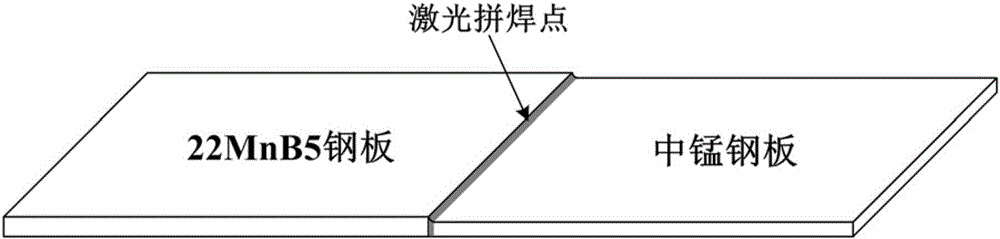

Laser tailor-welded high-strength steel warm forming preparation method

InactiveCN106350741AReduce manufacturing costLow quenching rateLaser beam welding apparatusThree-phaseQuenching

The invention discloses a laser tailor-welded high-strength steel warm forming preparation method. The laser tailor-welded high-strength steel warm forming preparation method is characterized by comprising the following steps: manufacturing a 22MnB5 steel plate and a medium manganese steel plate into a steel part for later use; carrying out laser tailor-welded connection treatment; carrying out heating treatment on the steel part for later use, which is subjected to laser tailor-welding; transferring the steel part onto a stamping mold to carry out stamping forming and quenching; finally obtaining a two-phase or three-phase microstructure formed by lots of ferrite, martensite or bainite in the 22MnB5 steel area of the tailor-welded steel part; and obtaining a martensite organization structure in the medium manganese steel area, thereby forming a warm forming technology of the laser tailor-welded high-strength steel, which has no need for coating treatment in advance and has gradient distributed mechanical property. The laser tailor-welded high-strength steel warm forming preparation method has the beneficial effects that the process combination of laser tailor-welding and the warm forming technology is realized; the warming forming technology is used for enabling 22MnB5 steel to form the two-phase or three-phase microstructure; the two-phase or three-phase microstructure is matched with medium manganese steel having martensitic structure in the end to obtain a custom-made warm forming part with gradient distributed performances; the technological process is simplified; and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

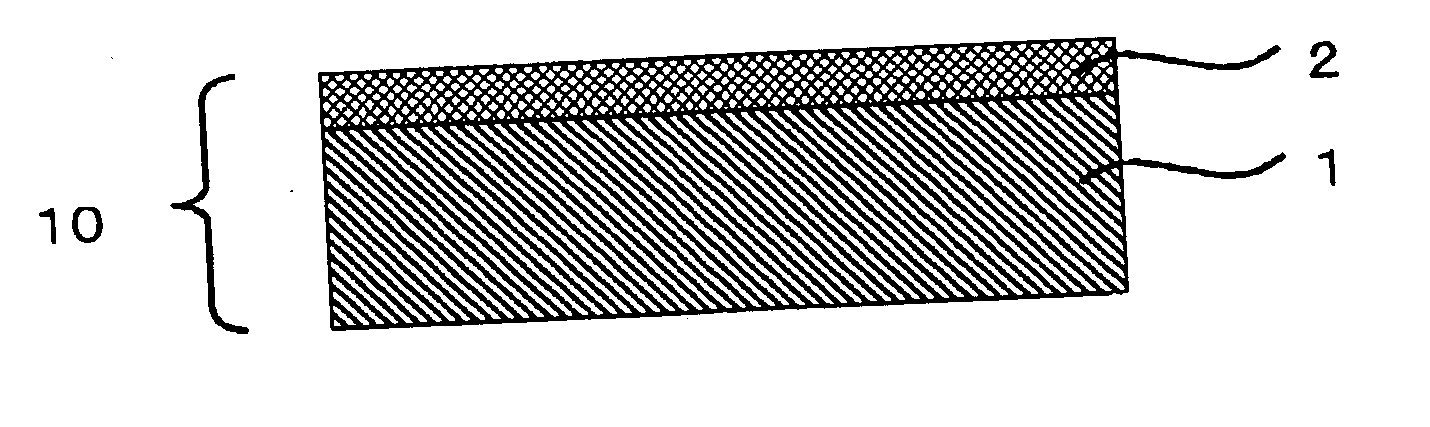

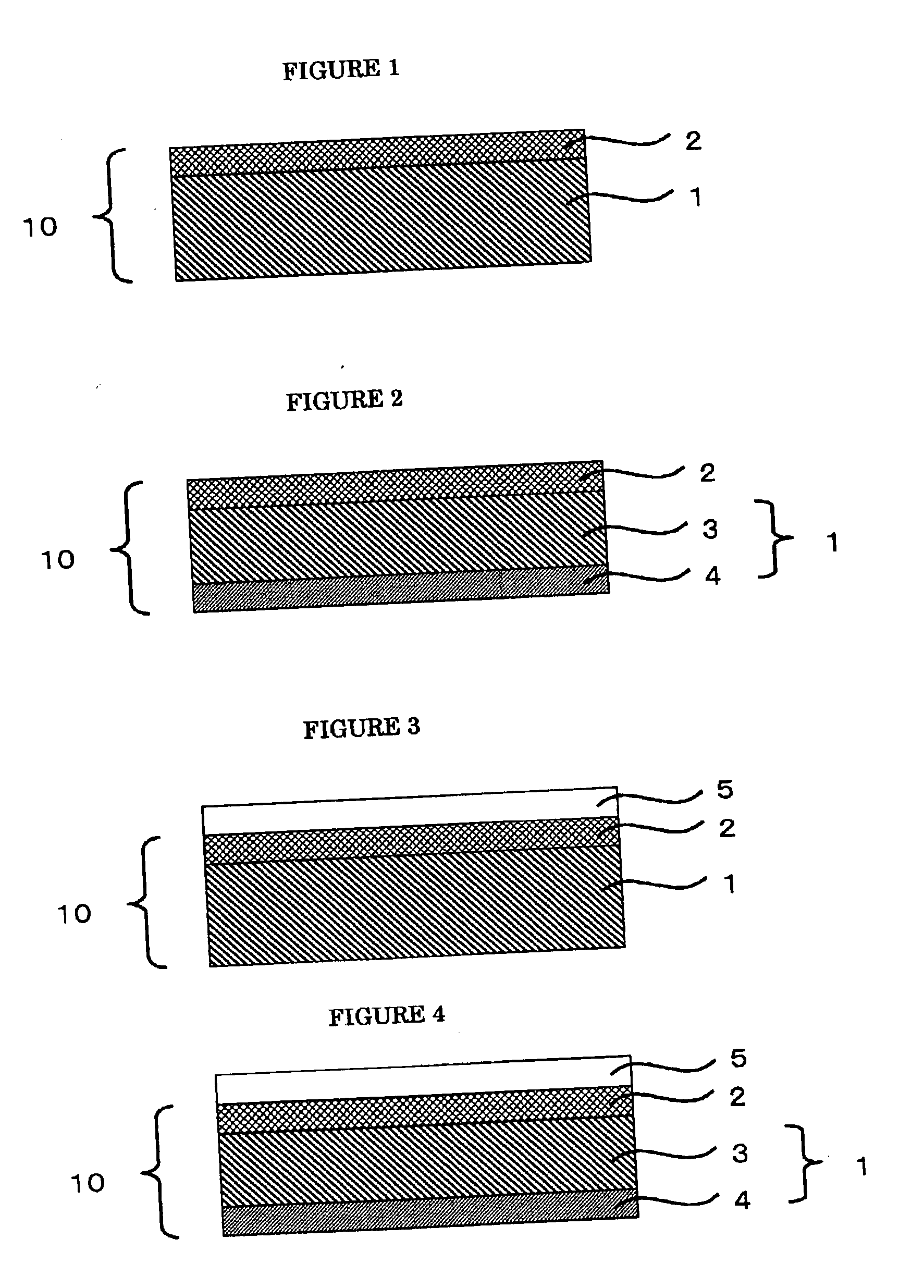

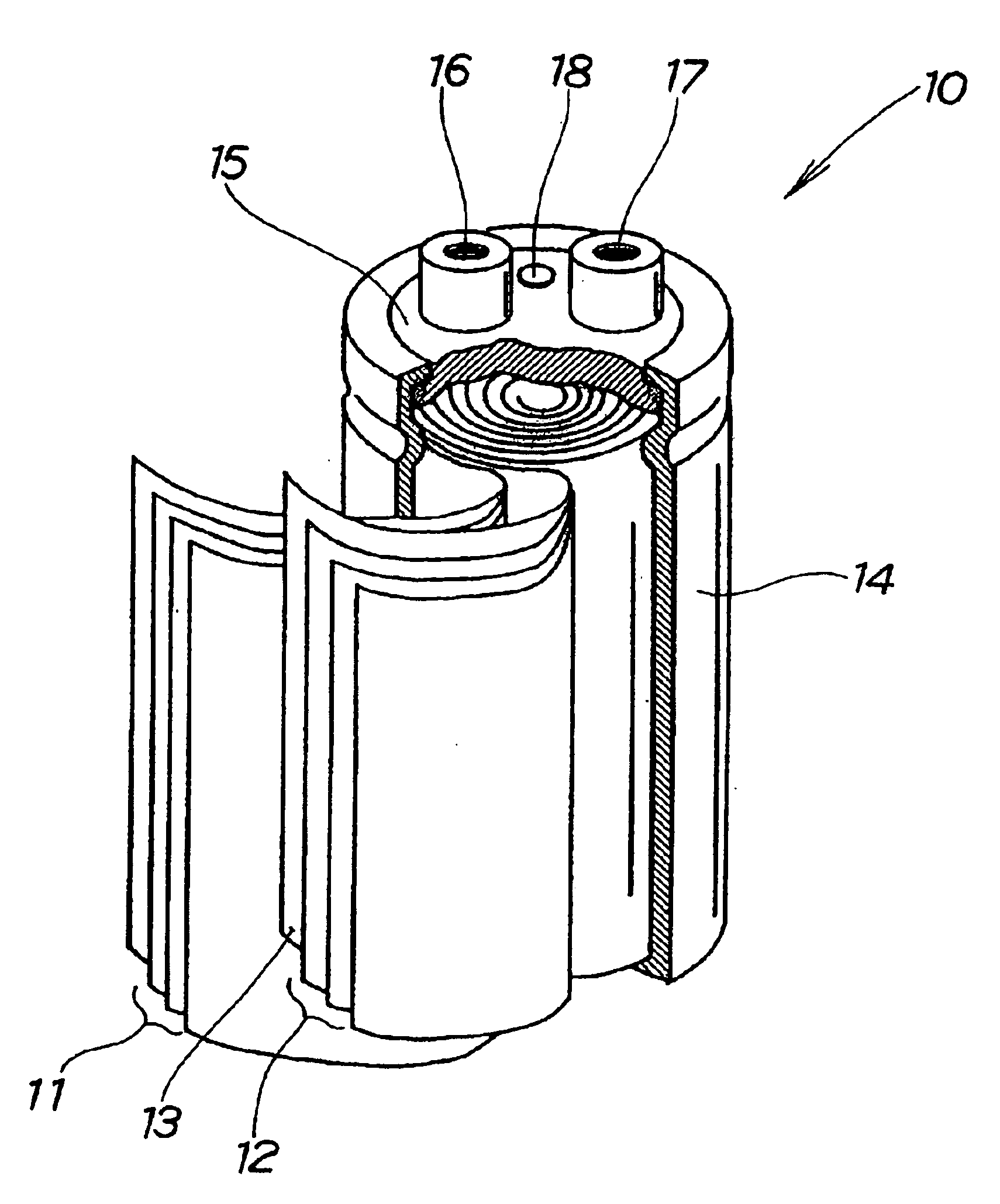

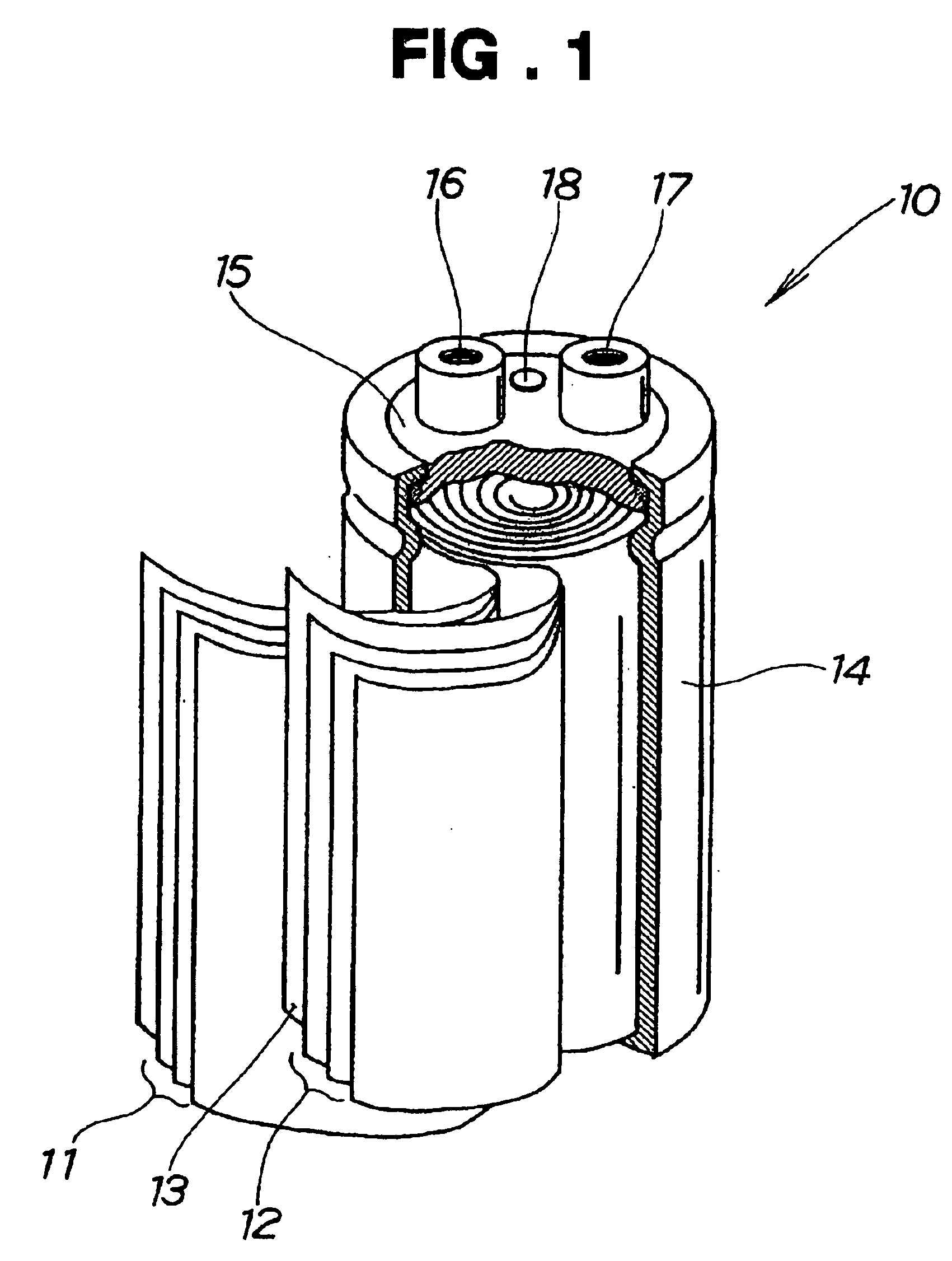

Adhesive sheet

InactiveUS20050031822A1Improve performance qualityImprove machinabilityLamination ancillary operationsFilm/foil adhesivesElectronic circuitEngineering

The object of the invention is to provide an adhesive sheet suitable for applications to surface protection involving cutting processing, and in particular an adhesive sheet suitable for applications to surface protection requiring excellent cutting processability, chemical solution treatment and dicing, particularly in the fields of electronic circuit material, semiconductor material and optical material demanding high performance and qualities, are not detrimental to the environment. An adhesive sheet 10 having an adhesive layer 2 laminated on at least one side of a substrate layer 1, wherein the substrate layer 1 contains an olefin polymer, and has a tensile modulus of elasticity and tear strength in a specific range.

Owner:MITSUI CHEM INC

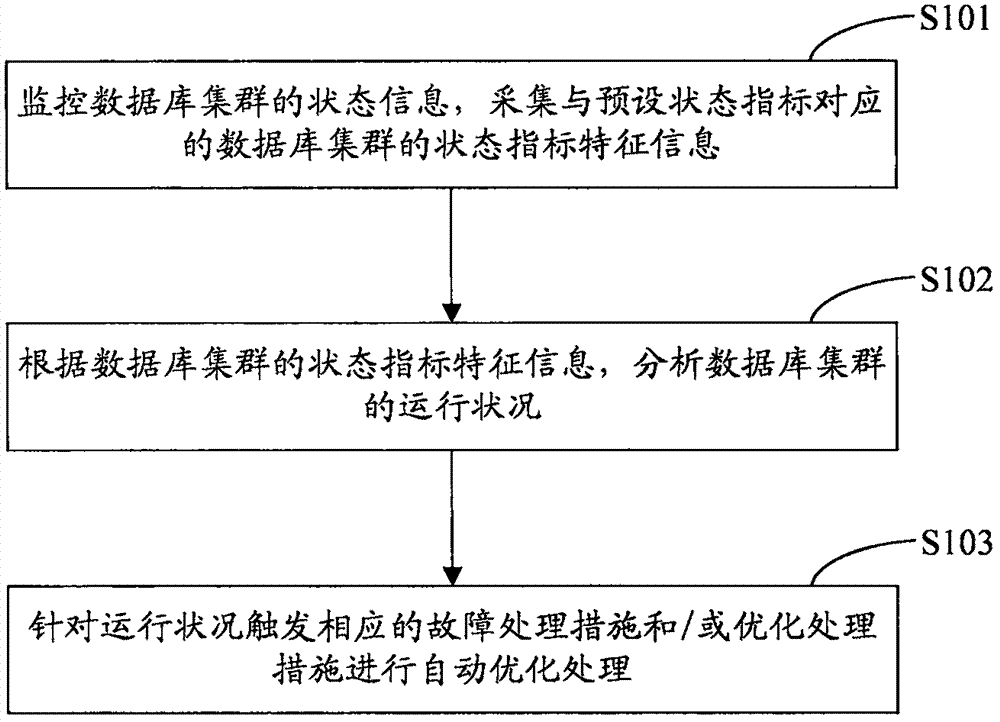

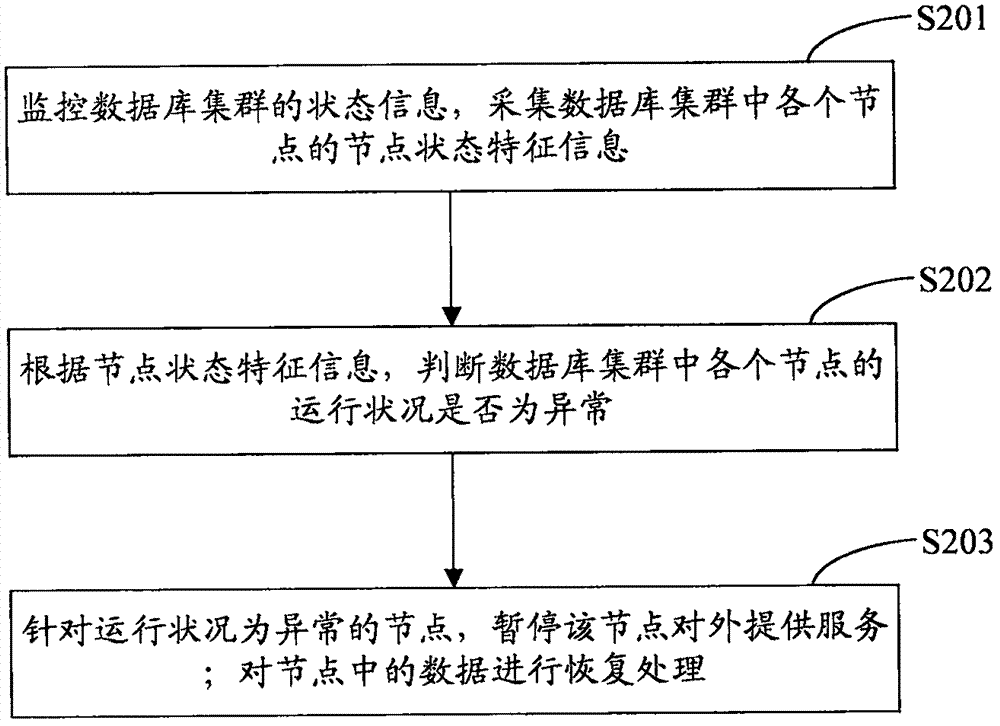

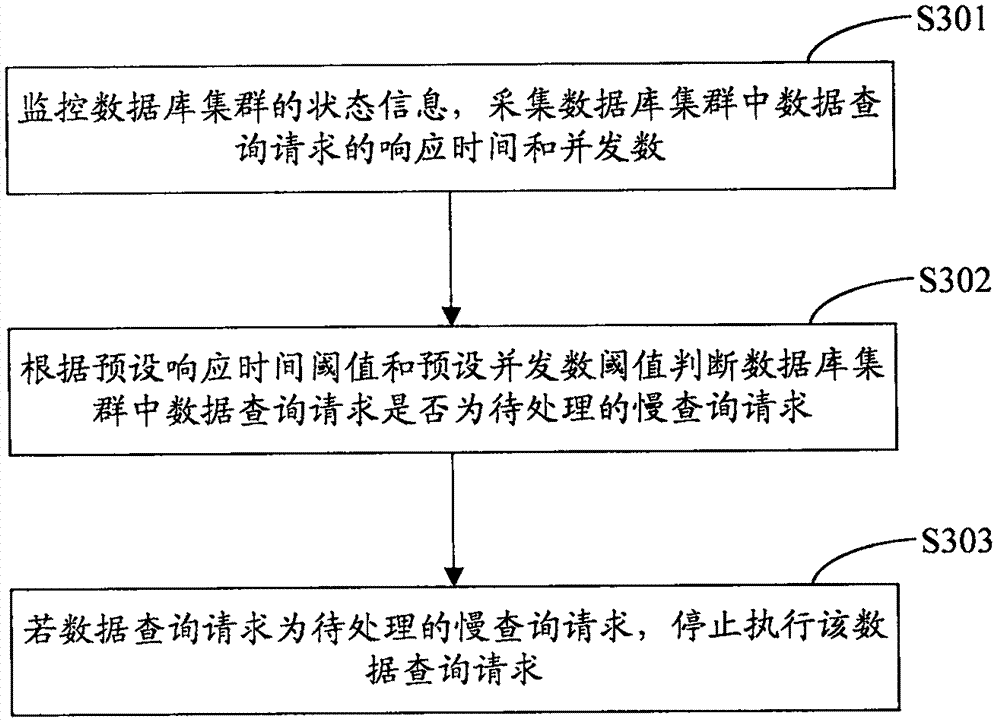

Method, device and server for processing database cluster automatically and optimally

InactiveCN107391633AImprove performance qualityImprove service qualityHardware monitoringSpecial data processing applicationsQuality of serviceAnalysis data

The invention discloses a method, device, server and computer storage medium for processing a database cluster automatically and optimally. The method includes the steps of monitoring state information of the database cluster, and collecting the state index characteristic information, corresponding to a preset state index, of the database cluster; according to the state index characteristic information of the database cluster, analyzing operation status of the database cluster; for the operation status, triggering a corresponding fault handling measure and / or an optimization measure for automatic and optimal processing. According to the technical scheme, for different operation status of the database cluster, the corresponding fault handling measure and / or the optimization measure can be triggered for automatic and optimal processing, and compared with the prior art, no investment of excessive human resources is needed, so that the human cost is reduced; besides, various failures and to-be-optimized problems in a database can be discovered in time, and the problems can be automatically processed, so that the performance and the service quality of the database are improved.

Owner:BEIJING QIHOO TECH CO LTD

Design and manufacturing method of porous grid structure material

InactiveCN105499575AManufacturing flexibilityImprove performance qualityAdditive manufacturing apparatusTissue regenerationLaser scanningSize ratio

The invention discloses a design and manufacturing method of a porous grid structure material and aims to solve the problems of blindness and uncertainty in traditional manufacturing of a porous material and apply an effective design concept for the porous material to practical manufacturing. The design and manufacturing method comprises the following steps: obtaining a data image based on topological optimization simulation; performing three-dimensional rebuilding on the data image on Solid Works; importing to magics software as a unit grid structure; filling into various three-dimensional models of specific parts which need to adopt the grid structure at any size ratio; afterwards manufacturing the parts. According to the design and manufacturing method, firstly, the three-dimensional model of each part is imported to a computer on a worktable; the printing angle and the printing position are set according to the three-dimensional graph structure; a powder layer is sintered into a corresponding two-dimensional shape on the layer; powder with the same thickness is repeatedly laid on the worktable on which one layer of graph is sintered; laser scanning is still performed according to the scanning route of the layer until the overall three-dimensional graph is completed. The design and manufacturing method disclosed by the invention has the advantages of reducing the elasticity modulus of the part and realizing good mechanical properties.

Owner:BEIJING UNIV OF TECH

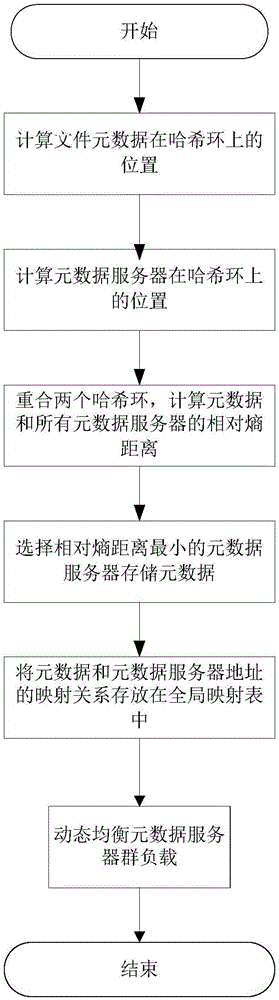

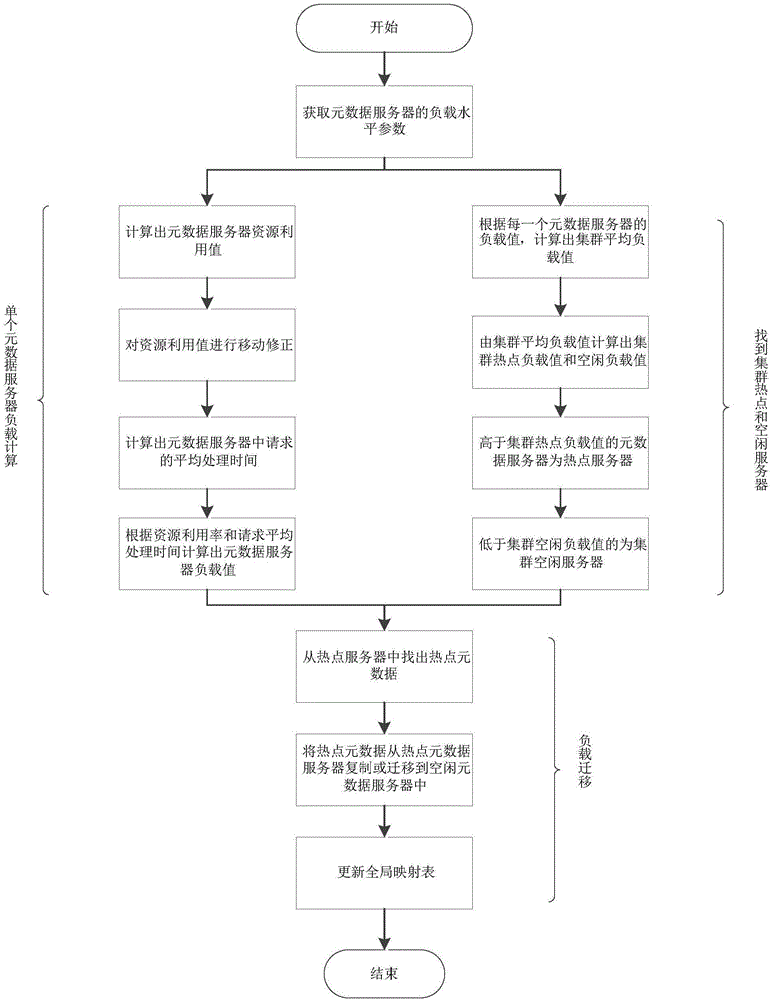

Distributed-type metadata management method with dynamic equilibrium load

ActiveCN106161120ALoad balancingImprove performance qualityData switching networksHash functionShortest distance

The invention relates to a distributed-type metadata management method with dynamic equilibrium load. The distributed-type metadata management method includes a), determination of weight of related load parameters, namely determining degree of importance among the related load parameters to acquire a judgment matrix, and judging the matrix to perform calculation to acquire optimal solution of the load parameters; b), dividing of metadata, namely calculating distance between the metadata and metadata servers on a hash ring through hash function with consistency of the weight and according to current calculation capability of the metadata servers, and storing the metadata in the metadata servers with the shortest distance corresponding to the metadata. With the method, the metadata can be uniformly distributed in a cluster of the metadata servers according to the current state of the metadata servers, dynamic equilibrium load of the cluster of the metadata servers can be performed when load is in dynamic change, and performance and storage quality of the cluster of the metadata servers are greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

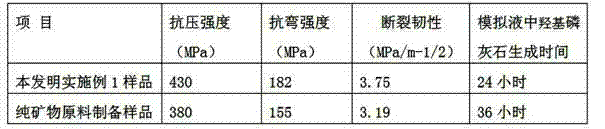

Biological microcrystalline glass prepared by utilizing phosphate tailings and preparation method thereof

The invention relates to biological microcrystalline glass prepared by utilizing phosphate tailings and a preparation method thereof. The biological microcrystalline glass comprises the following raw materials in parts by weight: 30 to 35 parts of the phosphate tailings, 15 to 25 parts of quartz sand, 10 to 16 parts of aluminium hydroxide, 20 to 28 parts of calcium hydrophosphate, 9 to 13 parts of calcium fluoride, 0 to 5 parts of magnesium oxide, 0 to 5 parts of zinc oxide and 0.5 part of sodium borate, wherein the utilization rate of the tailings reaches more than 30%. Compared with a product produced by utilizing conventional chemical raw materials, the biological microcrystalline glass has better physical and chemical properties and realizes reduction in the raw material cost by more than 30%. Based on the SiO2-Al2O3-P2O5-CaO-CaF2 system, the magnesium and the zinc are utilized to replace the partial calcium, so that a new magnesium-series wagnerite phase and a zinc-series zinc pointed crystal phase are generated, and therefore, the brittleness of the biological microcrystalline glass is improved while the mechanical strength is improved. In addition, the biocompatibility, the bioactivity and the chemical stability of the biological microcrystalline glass are improved.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

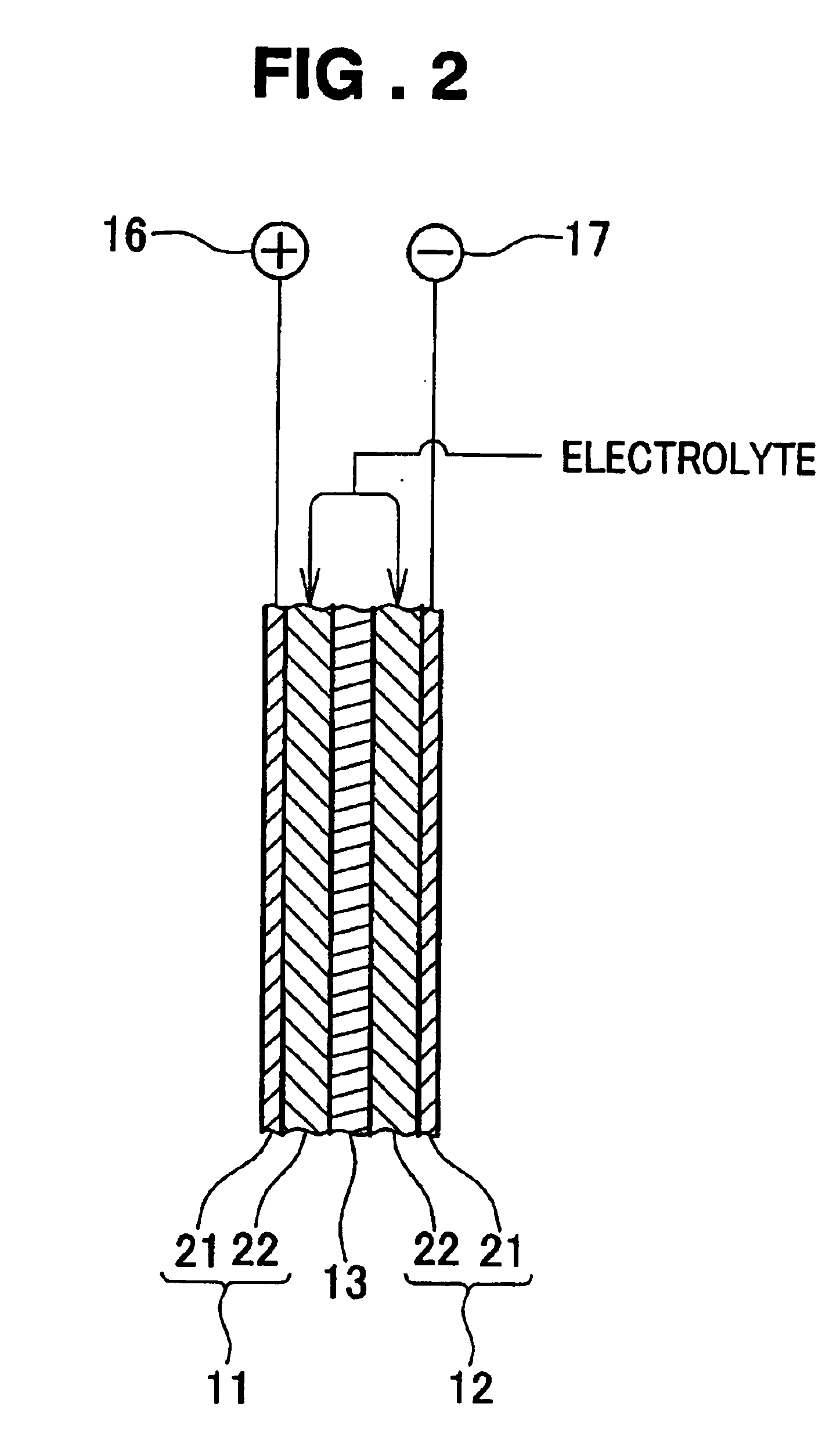

Metal collector foil for electric double layer capacitor, method of producing the metal collector foil, and electric double layer capacitor using the metal collector foil

ActiveUS6845003B2Effectively suppress the age-related deterioration of an electric double layer capacitorEasy to operateLiquid electrolytic capacitorsDouble layer capacitorsCapacitanceDielectric layer

A metal collector foil for an electric double layer capacitor is an etched metal collector foil having an oxide film in an amount of not greater than 300 mg / m2, and a capacitance per unit surface area of not less than 150 μF / cm2. The etched metal collector foil is free from a dielectric layer formed by an anodic formation process on a surface of the etched metal collector foil. A method of producing the metal collector foil and an electric double layer capacitor incorporating therein the metal collector foil are also disclosed.

Owner:HONDA MOTOR CO LTD +1

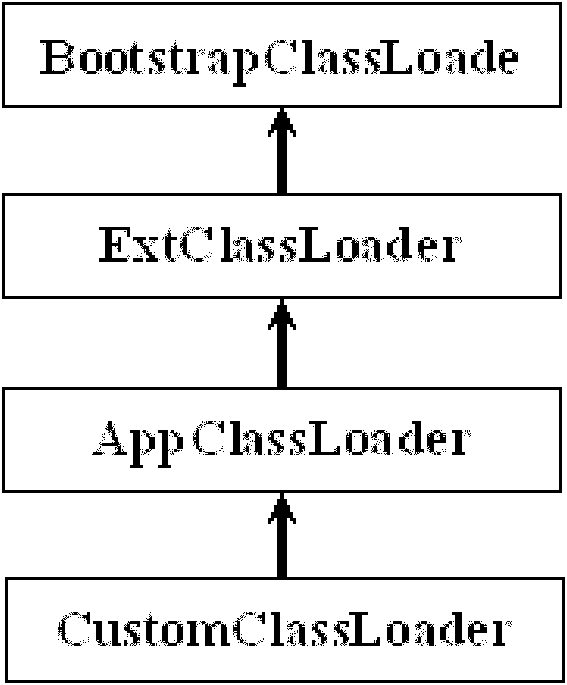

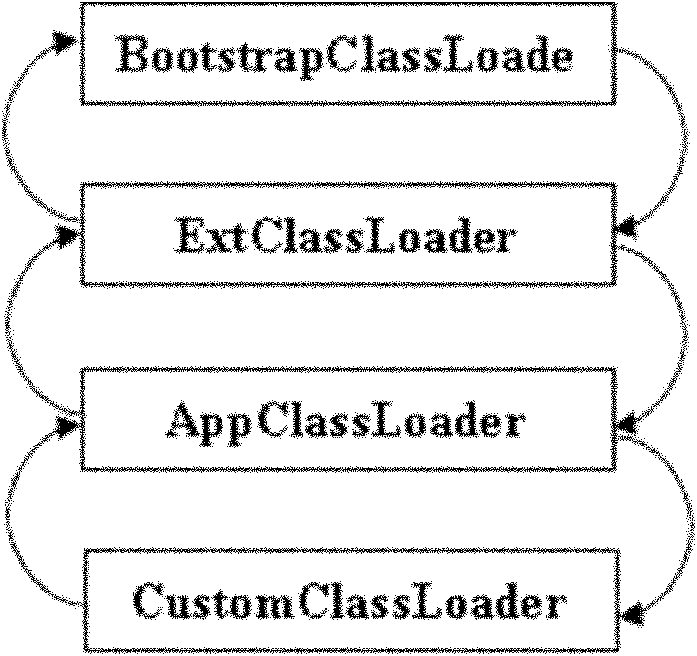

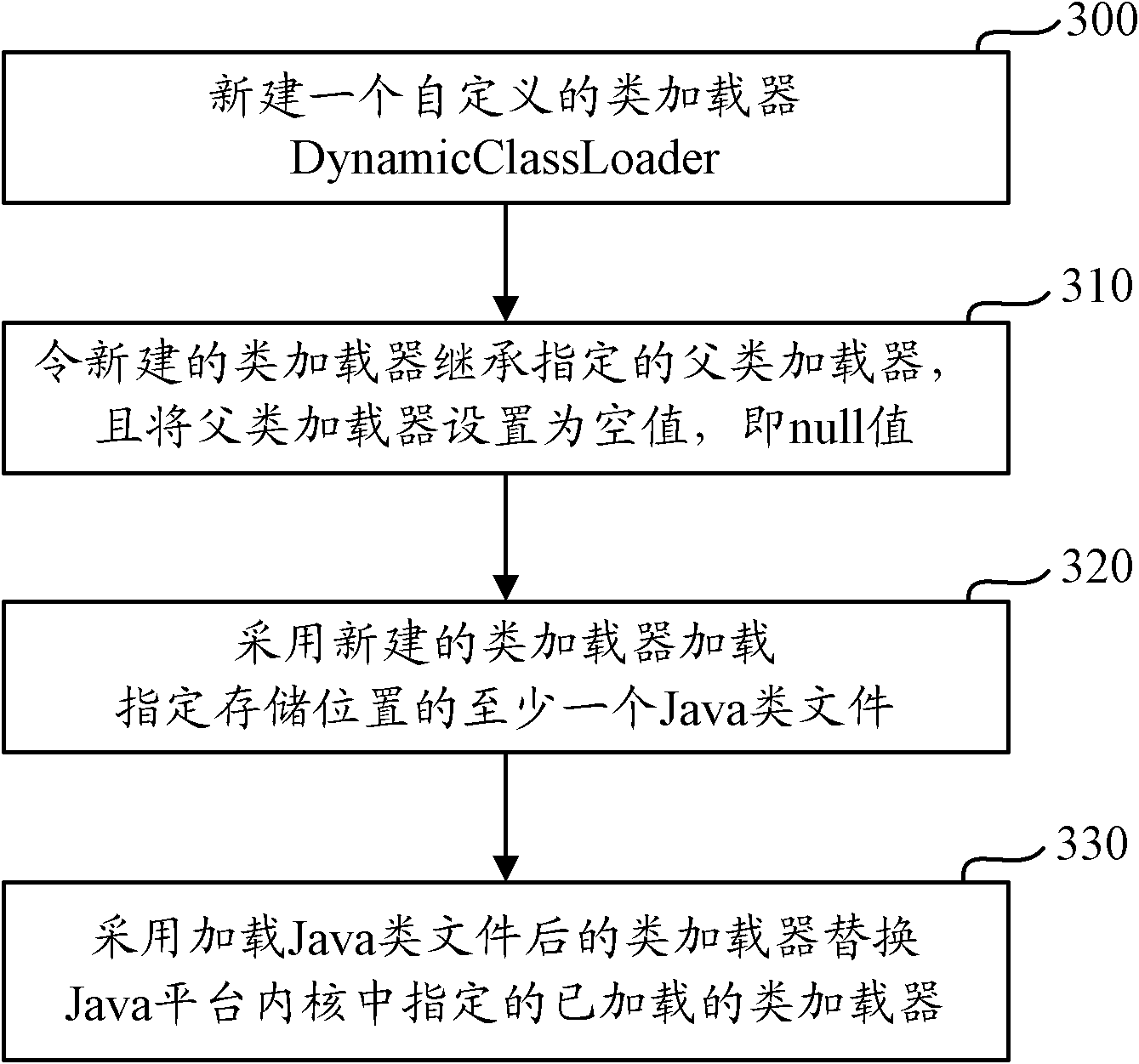

Method and device for dynamically upgrading Web service system based on Java platform

ActiveCN102073525AGuaranteed continuityImprove performance and quality of serviceProgram loading/initiatingWeb serverService quality

The invention relates to the field of computers, and discloses a method and a device for dynamically upgrading a Web service system based on a Java platform, which are used for realizing dynamic upgrading of the Web service system on the premise of not interrupting a Web service. The method comprises the following steps of: loading a Java-class file at an appointed position by adopting a self-defined class loader; and replacing an appointed class loader in a Java platform core by adopting the class loader in which the Java-class file is loaded. Thus, an original Java-class file can be directly replaced by adopting an upgraded Java-class file to realize the dynamic upgrading of the Web service system without restarting a Web server or interrupting the Web service. Therefore, the continuity of the Web service is ensured, the performance and the service quality of the Web service system are improved.

Owner:ZTE CORP

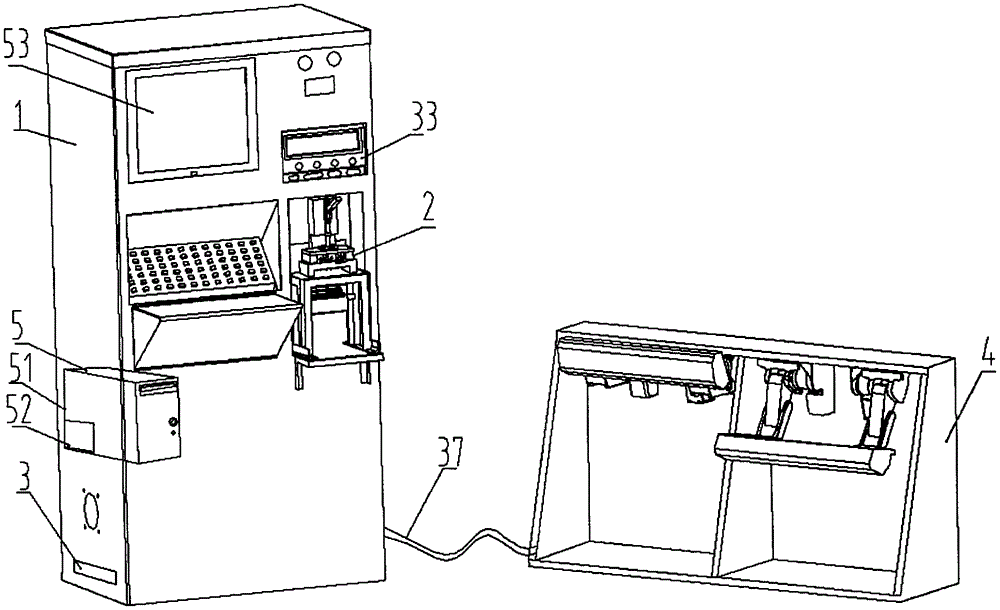

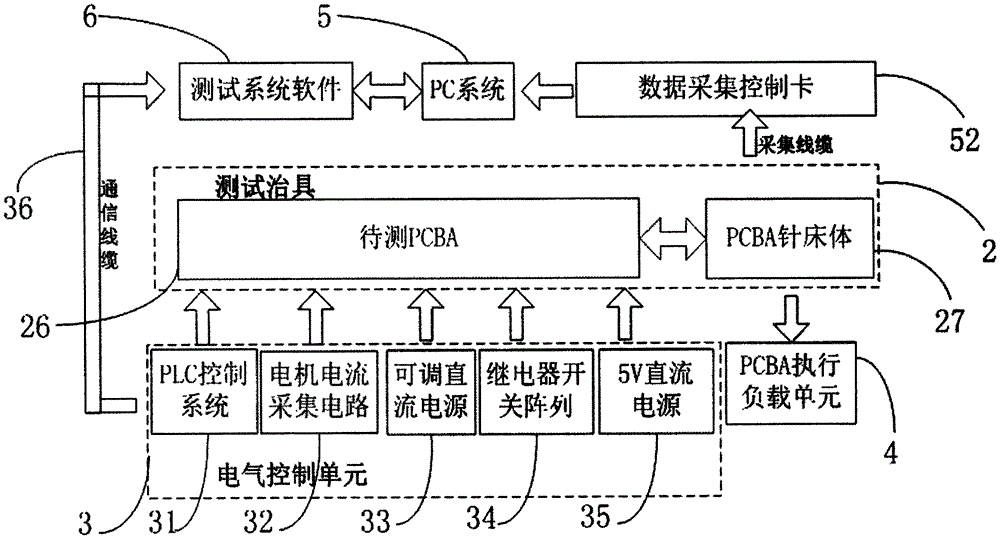

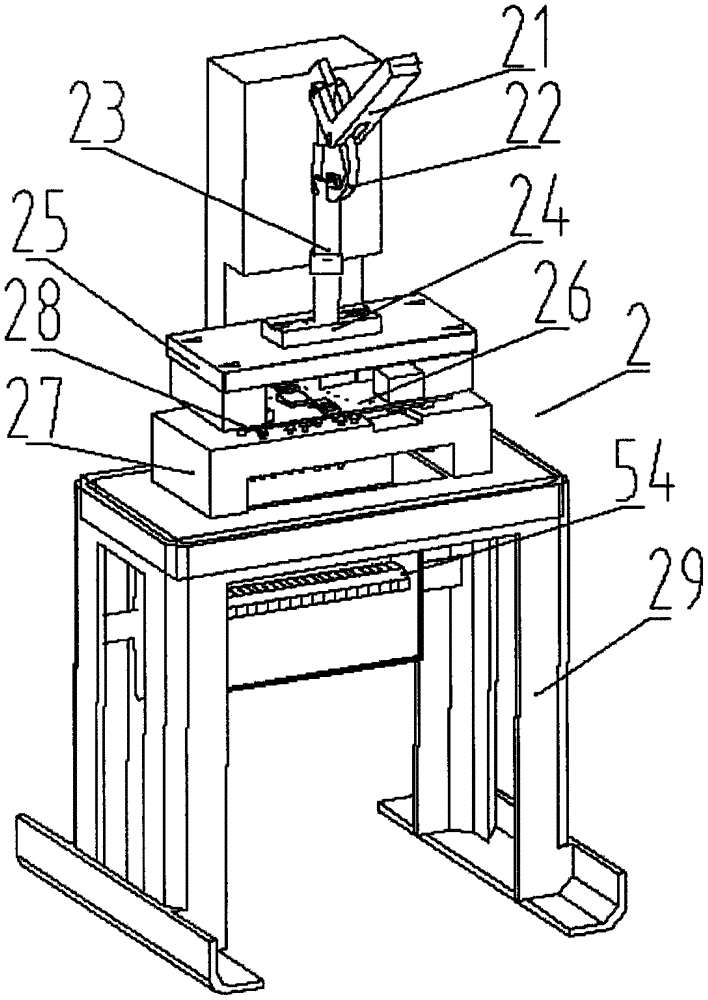

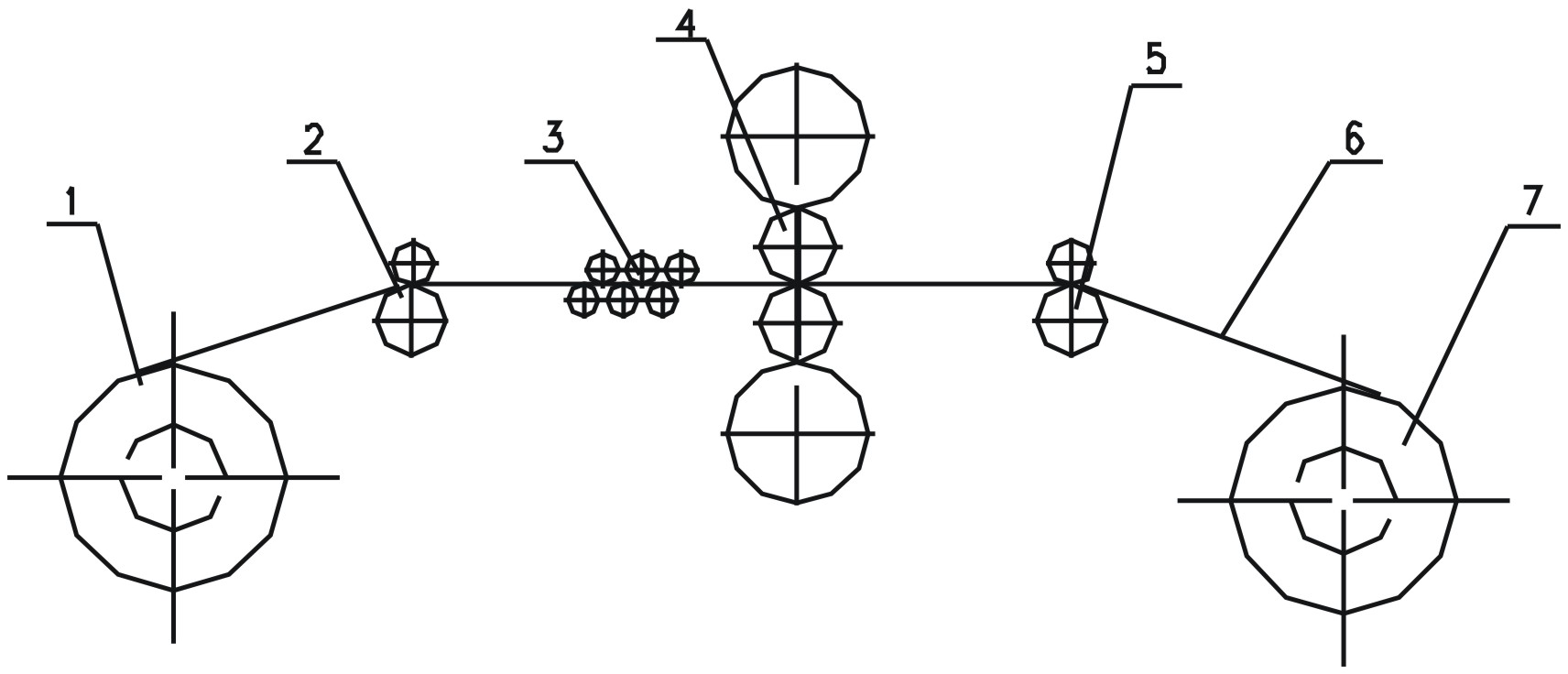

Vehicle-mounted PCBA on-line testing system and testing method

PendingCN104155593ARapid positioningImprove the efficiency of research and developmentElectronic circuit testingReal-time dataSystem stability

The invention discloses a vehicle-mounted electric pedal PCBA on-line testing system and a testing method. The testing system comprises a testing cabinet, a testing fixture, an electric control unit, a PCBA executing load unit, a PC system and testing system software. The testing fixture, the electric control unit and the PC system are fixed into the testing cabinet. The testing system sends out controlling and testing information through the testing system software, the PCBA executing load unit is driven by a to-be-tested PCBA plate to move, a current Hall sensor collects real-time data of a direct current motor in the moving process, the data information of tested points of the to-be-tested PCBA plate in the working process is electrically transmitted through a testing probe, the collected real-time data are transmitted to a PC system through a data collection control card and are processed by the testing system software, and the testing function of the to-be-tested PCBA plate is achieved. The vehicle-mounted PCBA on-line testing system and the testing method have the advantages that the stability of the system is good, the precision is high, the testing speed is high, operation is convenient and data can be stored, and the vehicle-mounted PCBA on-line testing system and the testing method can be applied to the technical field of PCBA testing.

Owner:CHINA JILIANG UNIV

Straightening and leveling process for hot-rolled high-strength steel

ActiveCN102626726AReduce residual stress levelsResidual Stress Level GuaranteeMetal rolling arrangementsUltimate tensile strengthMechanical engineering

The invention relates to a straightening and leveling process for hot-rolled high-strength steel. The straightening and leveling process is characterized in that: hot-rolled high-strength band steel is fed into a straitening machine and a leveling machine in sequence. The process comprises the following specific steps of: firstly, setting the total elongation rate of a unit according to yield strength needed by a band steel product on the tail of a process section; secondly, distributing a total elongation rate set value to the straitening machine and the leveling machine for presetting the straightening and leveling process; thirdly, detecting the total elongation of detected and processed band steel in real time; and lastly, comparing the total elongation of the detected and processed band steel with the total elongation rate set value, dynamically adjusting the rolling force of the leveling machine in real time to ensure that the total elongation rate of a band steel product on the tail of the process section is constant, lowering the residual stress level of the band steel by using the straightening machine, and ensuring the performance quality of the band steel product on the tail of the process section. Due to the adoption of the process, the internal residual stress level of the hot-rolled band steel can be lowered fully, and the performance quality of a hot-rolled high-strength steel product is improved effectively.

Owner:WISDRI ENG & RES INC LTD

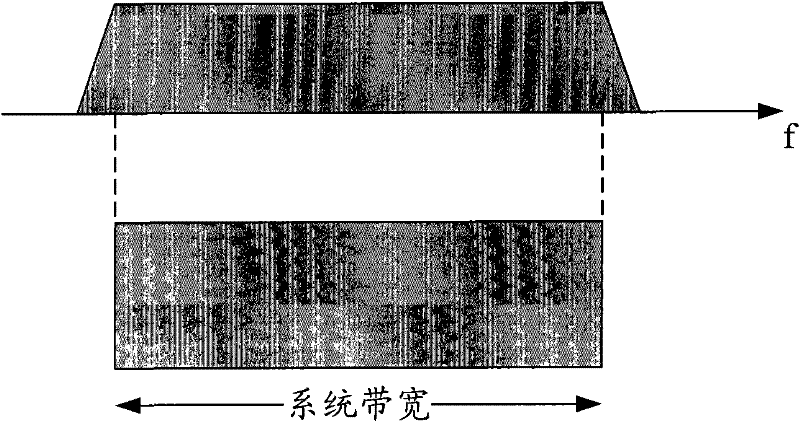

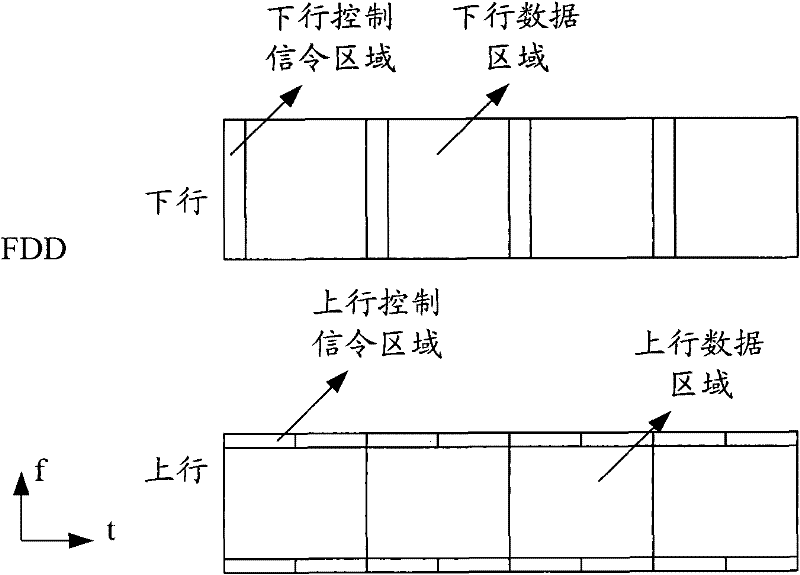

Merging feedback and instruction method, device and system for answer information

ActiveCN102347823AImprove fault toleranceImprove performance qualityError prevention/detection by using return channelNetwork traffic/resource managementQuality of serviceFault tolerance

The invention discloses a merging feedback and instruction method, a device and a system for answer information, which are used for merging and feeding back the answer information on the basis of a feedback window in a long term evolution-advanced (LTE-A) system. The merging feedback method comprises the following steps that: user equipment (UE) merges and feeds back data receiving conditions in the feedback window to a base station side in a mode of not feeding back answer information but feeding back ACK / NACK information according to the preset configuration information so that the base station side can obtain the data receiving state of the UE in time, in addition, when the data receiving is abnormal, the corresponding processing is carried out through adopting the accurate strategy in time, so the fault tolerance capability of the system is improved, and the performance and the service quality of the system are also improved. The invention simultaneously provides a merging feedback device and a system for the answer information and provides a merging feedback and instruction method of the answer information, and a corresponding device and a system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

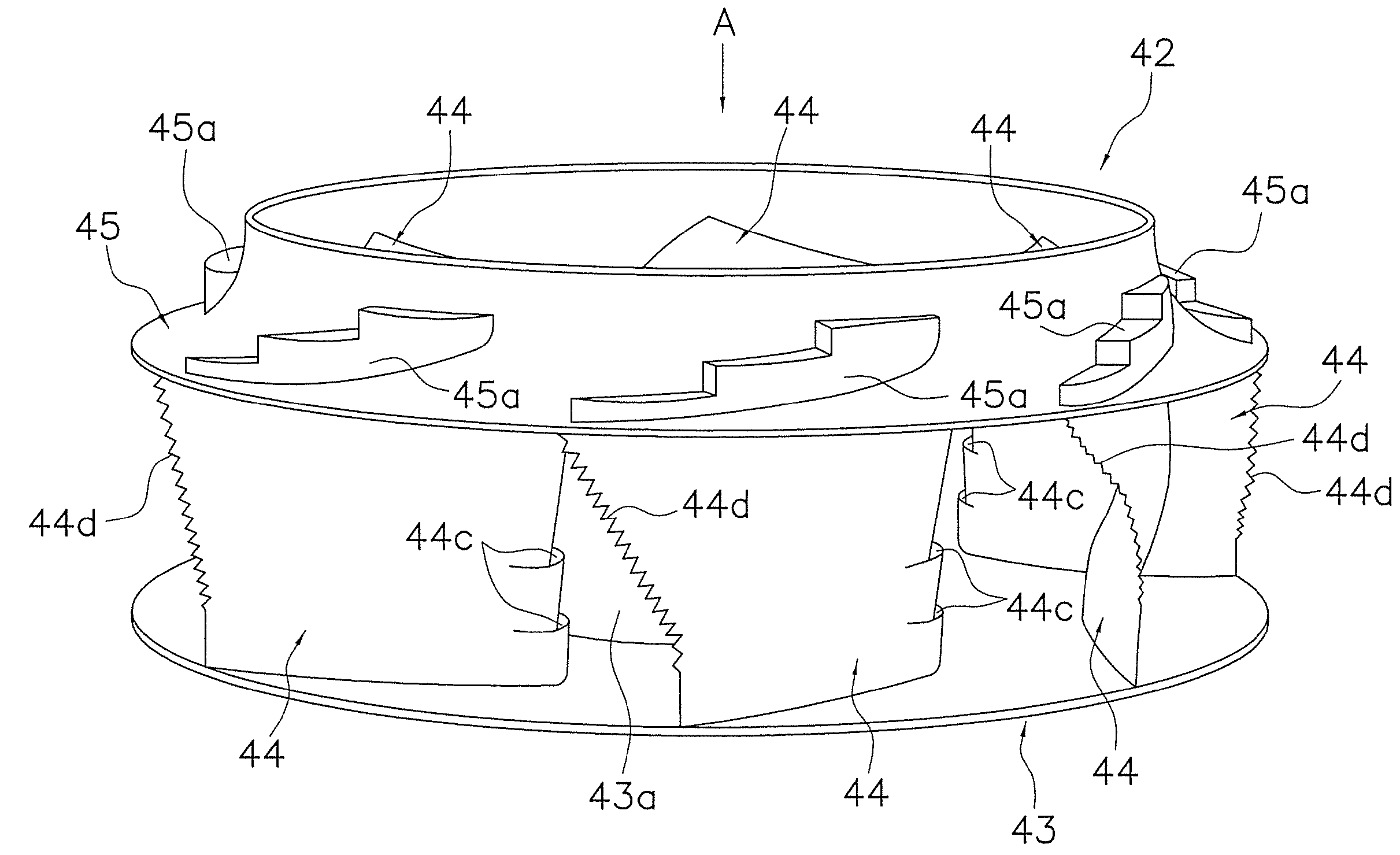

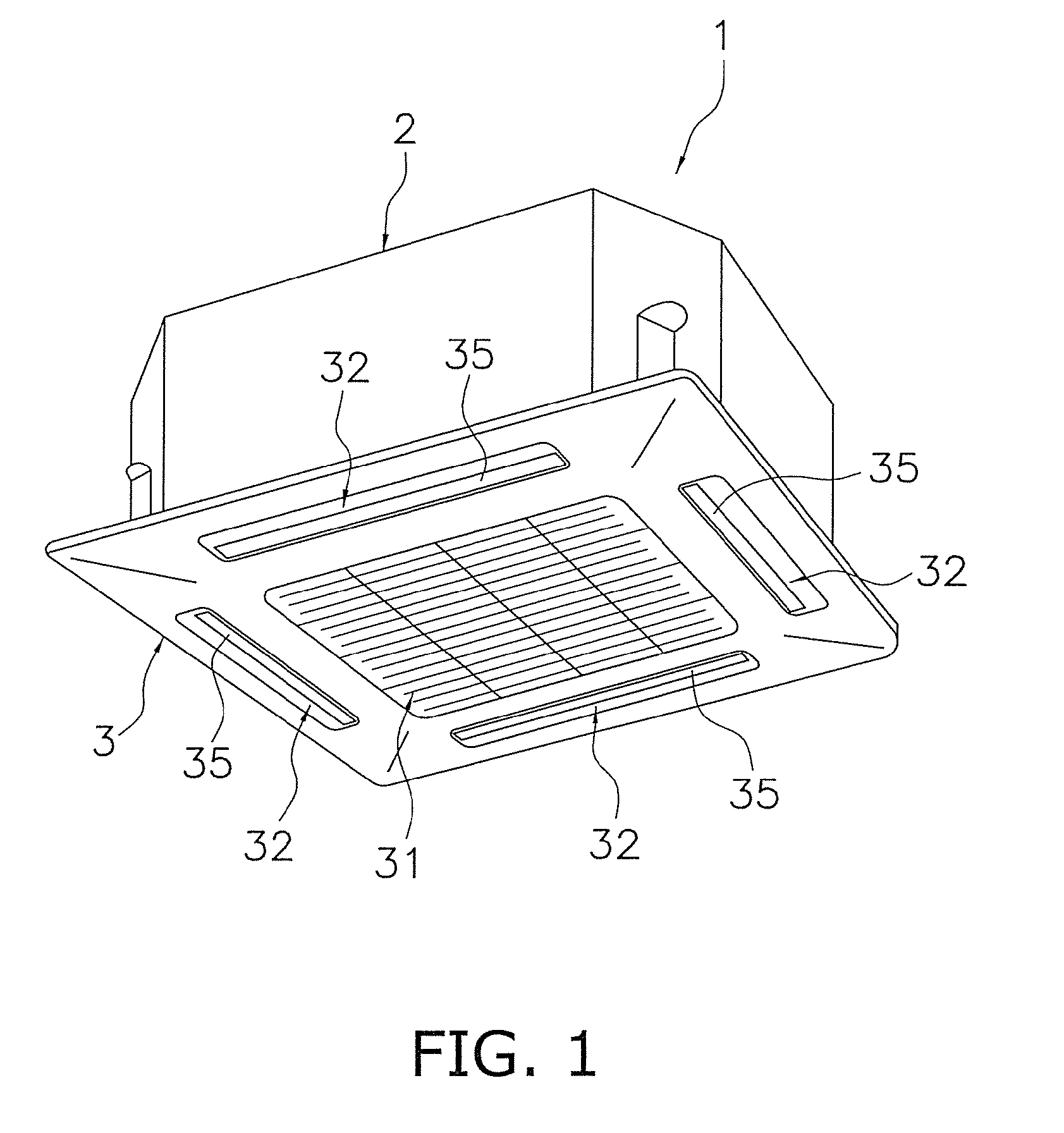

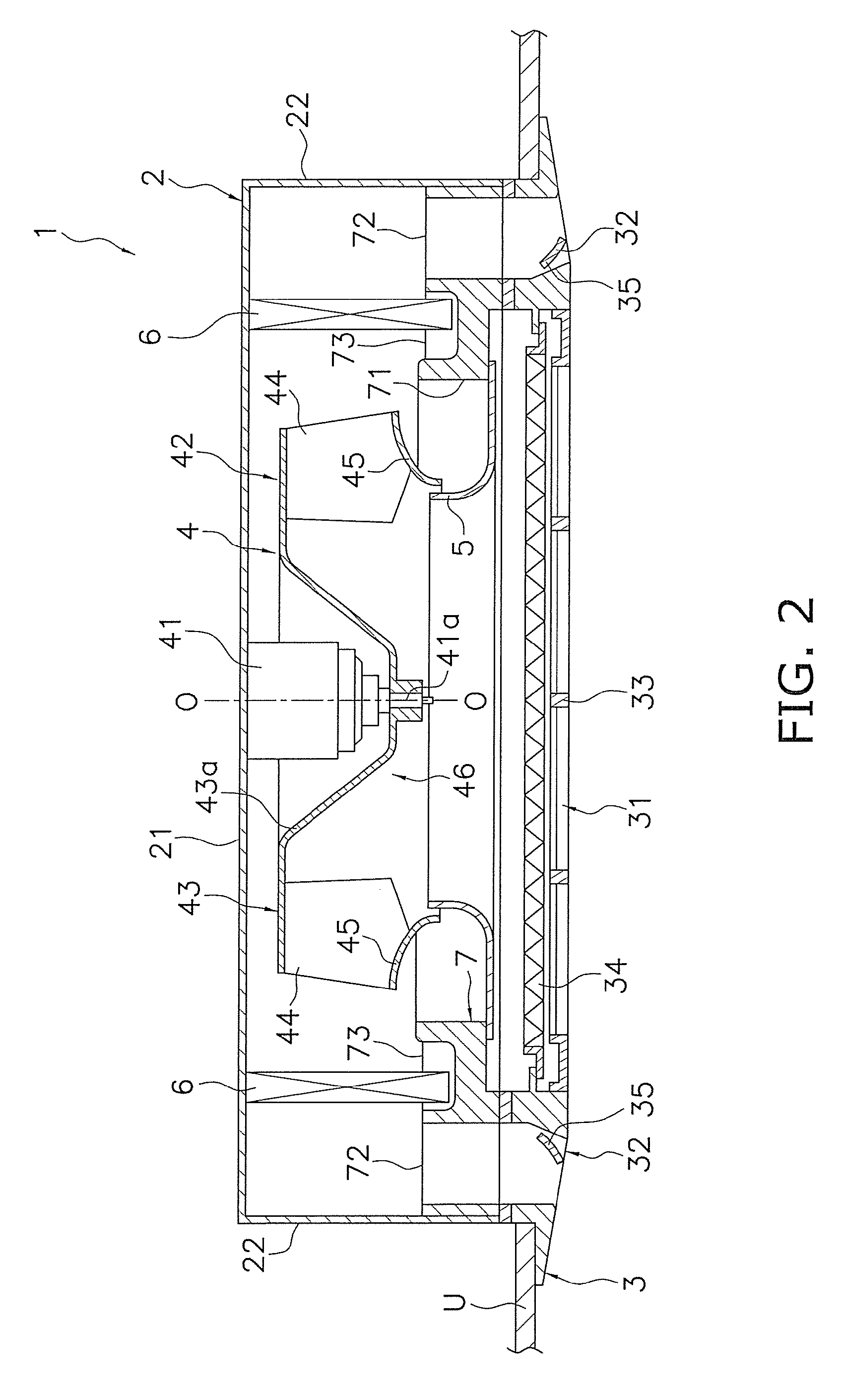

Impeller blade for centrifugal blower, blade-supporting rotator, impeller for centrifugal blower, and method for manufacturing impeller for centrifugal blower

InactiveUS20090047133A1Improve welding strengthImprove blowing performancePropellersRotary propellersImpeller

Blades of an impeller for a centrifugal blower are resinous hollow blades having hollow spaces formed in the blade interiors, and having first blade weld parts welded to plate weld surfaces of an end plate, wherein first blade weld surfaces inclined with respect to the plate weld surfaces are formed on the first blade weld parts in a state in which the first blade weld parts are disposed to face the plate weld surfaces in the axial direction.

Owner:DAIKIN IND LTD

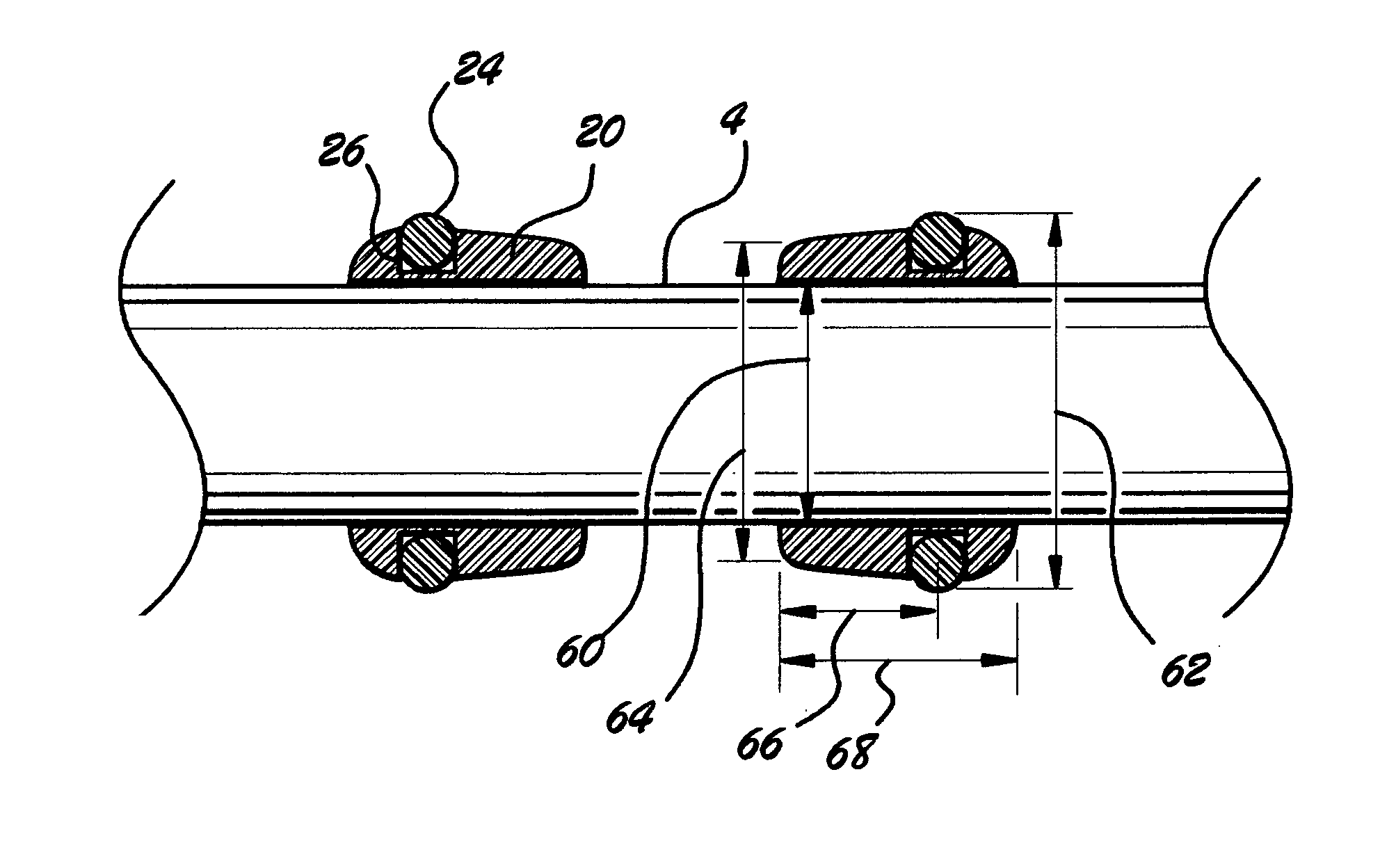

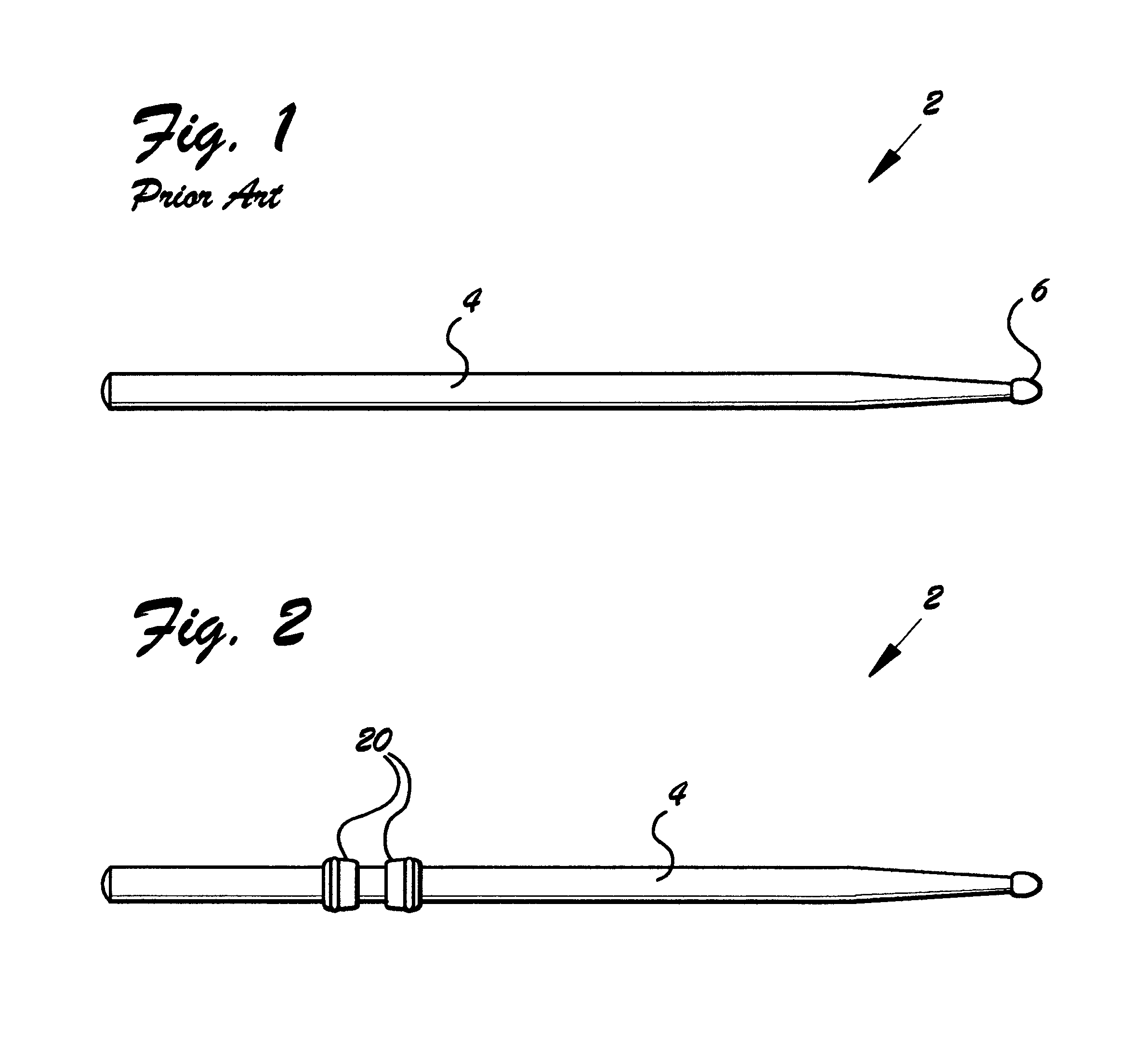

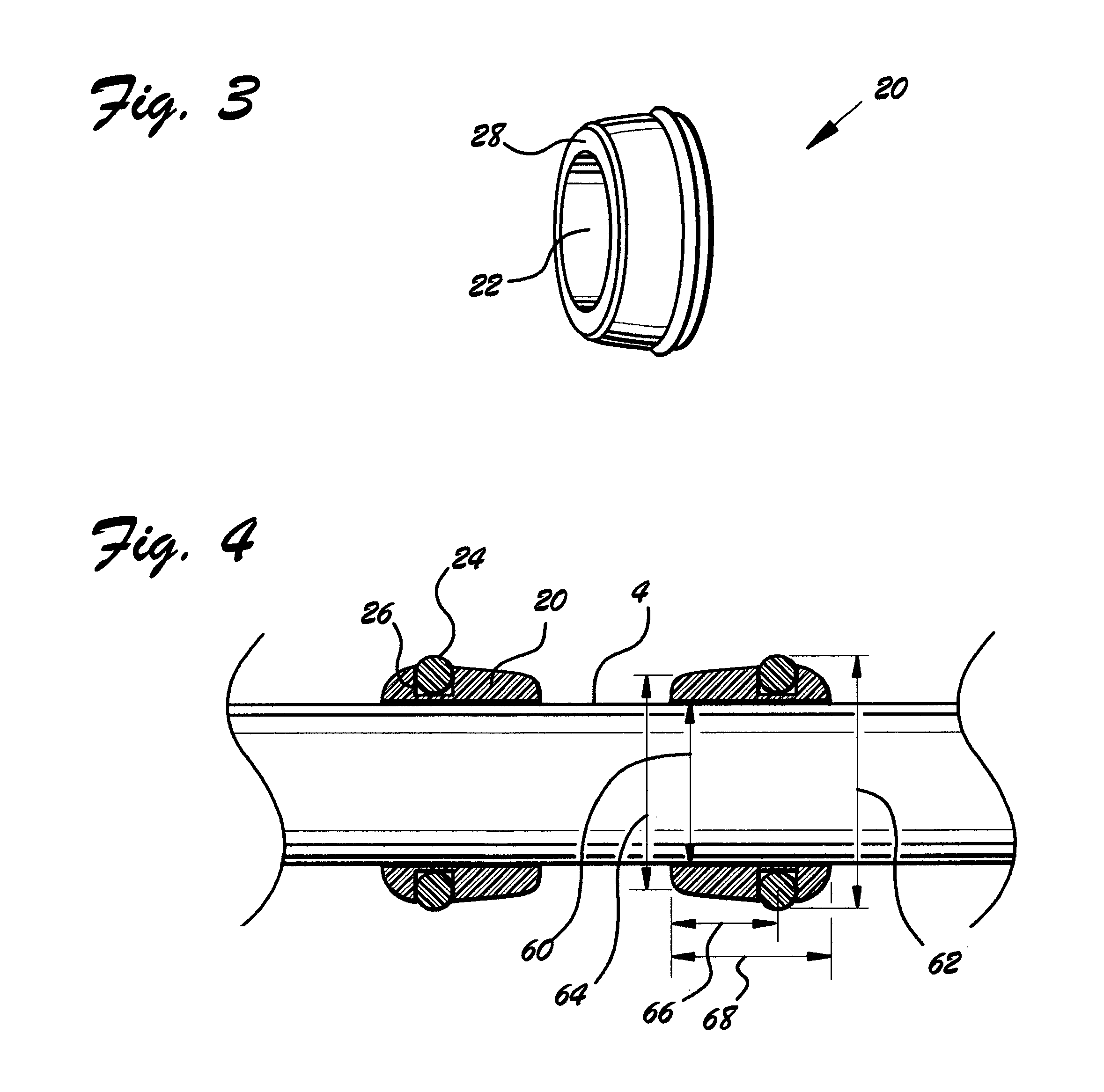

Ergonomic rings for drum sticks, method of installation, and method of use

InactiveUS7176369B1Precise positioningLow costPercussion musical instrumentsEngineeringMiddle finger

Ergonomic rings for drum stick, method of installation, and method of use. A pair of resilient rings is installed on a drum stick spaced apart substantially by a distance equal to the width of a drummer's middle finger. The ergonomic rings have the effect of increasing drum stick radius, thereby substantially reducing the amount of force the drummer must expend to play the drum stick, reducing drummer fatigue, and increasing drummer speed. In addition, the rings aid in ensuring that the drummer's hand is disposed in the correct location along the length of the drum stick, and in preventing the drum stick from slipping out of the drummer's hand during play. Methods of installation and use are also disclosed.

Owner:BROOKS ROBERT C

Pure inorganic acid formation process for positive electrode foil for high-voltage bolt type aluminium electrolytic capacitor

ActiveCN105405658AExtended service lifeImprove electricity qualityAnodisationElectrolytic capacitor manufactureAluminium foilAluminium

The invention discloses a pure inorganic acid formation process for a positive electrode foil for a high-voltage bolt type aluminium electrolytic capacitor. The pure inorganic acid formation process is characterized by comprising the steps of dipping an etched foil into water for performing a dipping treatment to generate a hydrate film on the surface of the etched aluminium foil, then putting the etched aluminum foil, after the aluminum foil is subjected to the dipping treatment, into a dicarboxylic acid solution for further performing the dipping treatment, next putting the aluminum foil into a phosphate solution for performing a first time of formation to generate a dielectric oxide film on the surface of the aluminium foil; and then performing a second time of boric acid formation, and performing a roasting treatment and a phosphoric acid treatment to obtain the final positive electrode aluminium foil. According to the pure inorganic acid formation process for the positive electrode foil for the high-voltage bolt type aluminium electrolytic capacitor, the produced positive electrode foil is better in of electric property, low in current leakage, and high in hydration resistance, so that the formation process can particularly satisfy the high-quality demand of the high-voltage bolt type aluminium electrolytic capacitor; the service life of the high-voltage bolt type aluminium electrolytic capacitor can be prolonged, and the market competitiveness of the product is further enhanced; and in addition, experiments prove that the current leakage can be reduced by more than 28% by the formation process, and the service life of the aluminium electrolytic capacitor is improved by more than 1700 hours proved by an accelerated life test.

Owner:XINJIANG XIBU HONGYUAN ELECTRONICS CO LTD

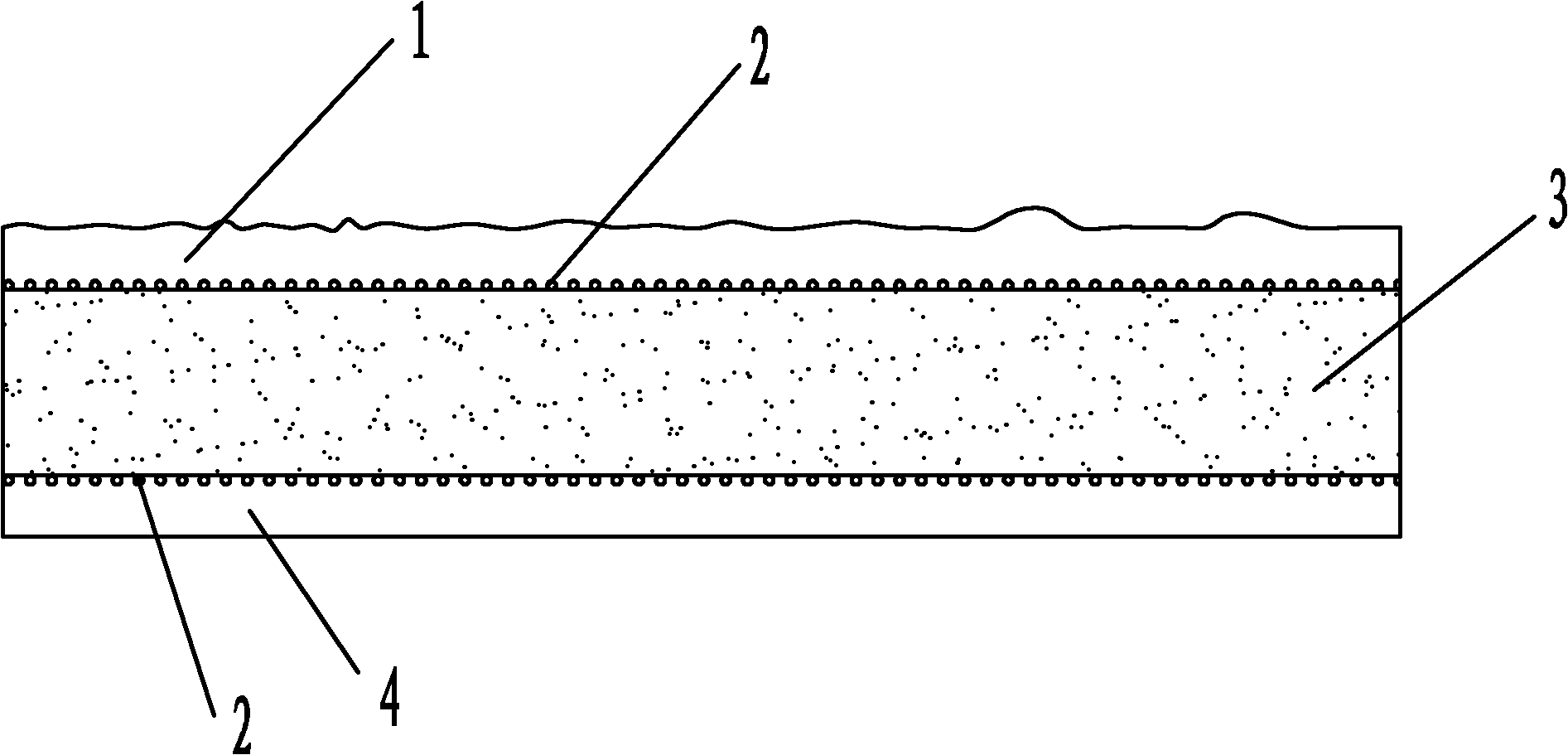

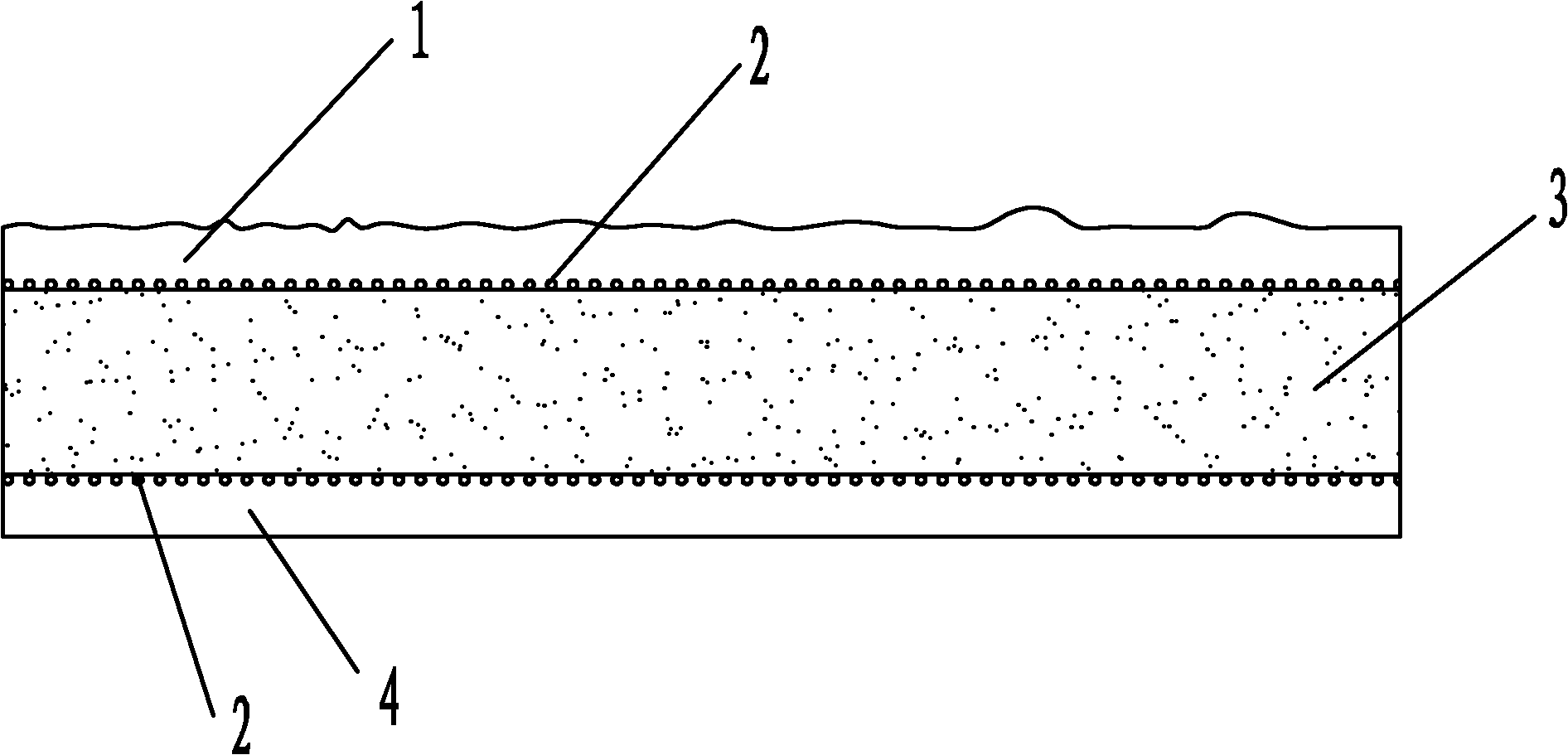

Baseplate of integral heat-preservation and energy-saving plate and preparation method thereof

InactiveCN102152501AImprove performance qualityAchieve heat preservation and energy saving functionCovering/liningsWallsFiberPlastics industry

The invention relates to a baseplate of an integral heat-preservation and energy-saving plate and a preparation method thereof, and the baseplate is characterized by mainly comprising a surface layer, a structure reinforced fibermesh, a middle layer, a structure reinforced fibermesh and a bottom layer which are sequentially connected, wherein the surface layer mainly comprises the following materials in parts by weight:. The preparation method comprises the following steps: preparing liquid raw materials and dry powder; respectively uniformly blending the dry powder, reinforcing glass fibers,poly-propylene fibers and pulps by using a uniform agitator so as to form a spare base stock; paving the surface layer, the middle layer and the bottom layer; paving the structure reinforced fibermesh between every two layers; and carrying out rolling and maintenance forming. The baseplate and preparation method thereof provided by the invention have the advantages that the natural raw materials such as tailings in the mining industry and the stone processing industry and the like and the debris puffed particles in the plastics industry are fully used, and various inorganic modified materialsare added, by carrying out low-temperature mould pressing on the materials in a certain proportion and utilizing the condensation reaction of the materials and the natural texture performance of a special mould, the baseplate of an ecological light-weight and low-carbon integral heat-preservation and energy-saving plate with natural stone or other material mechanisms can be processed by using a specially-designed processing device.

Owner:易科美德(天津)环保建材有限公司

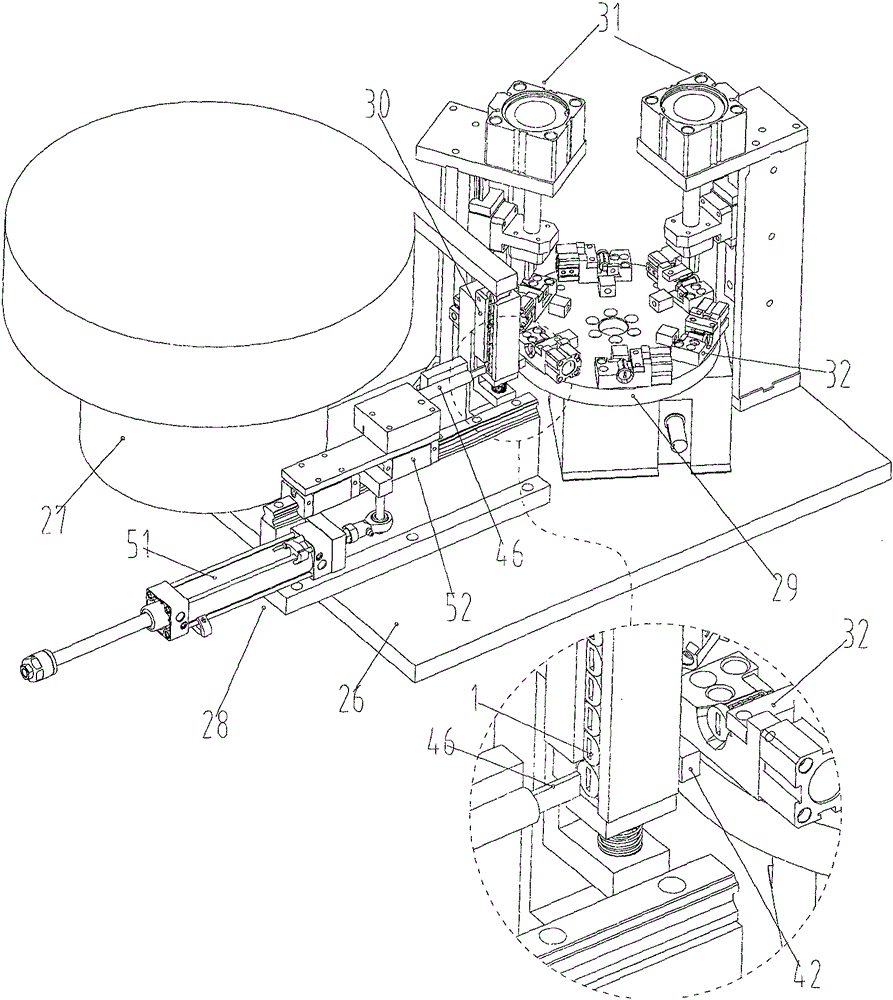

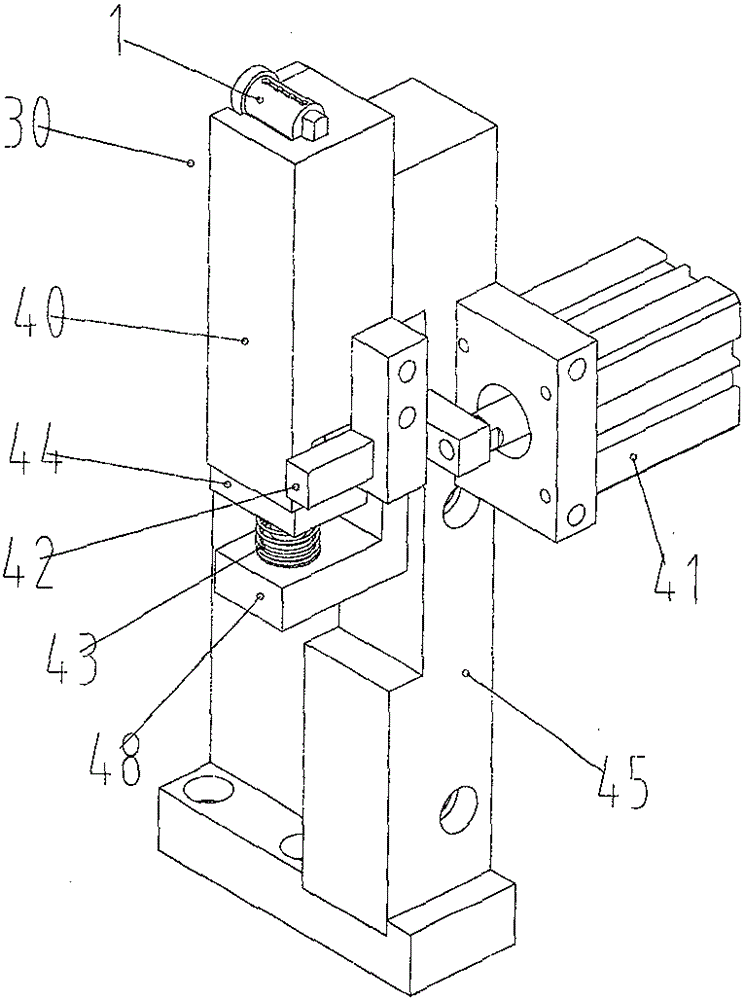

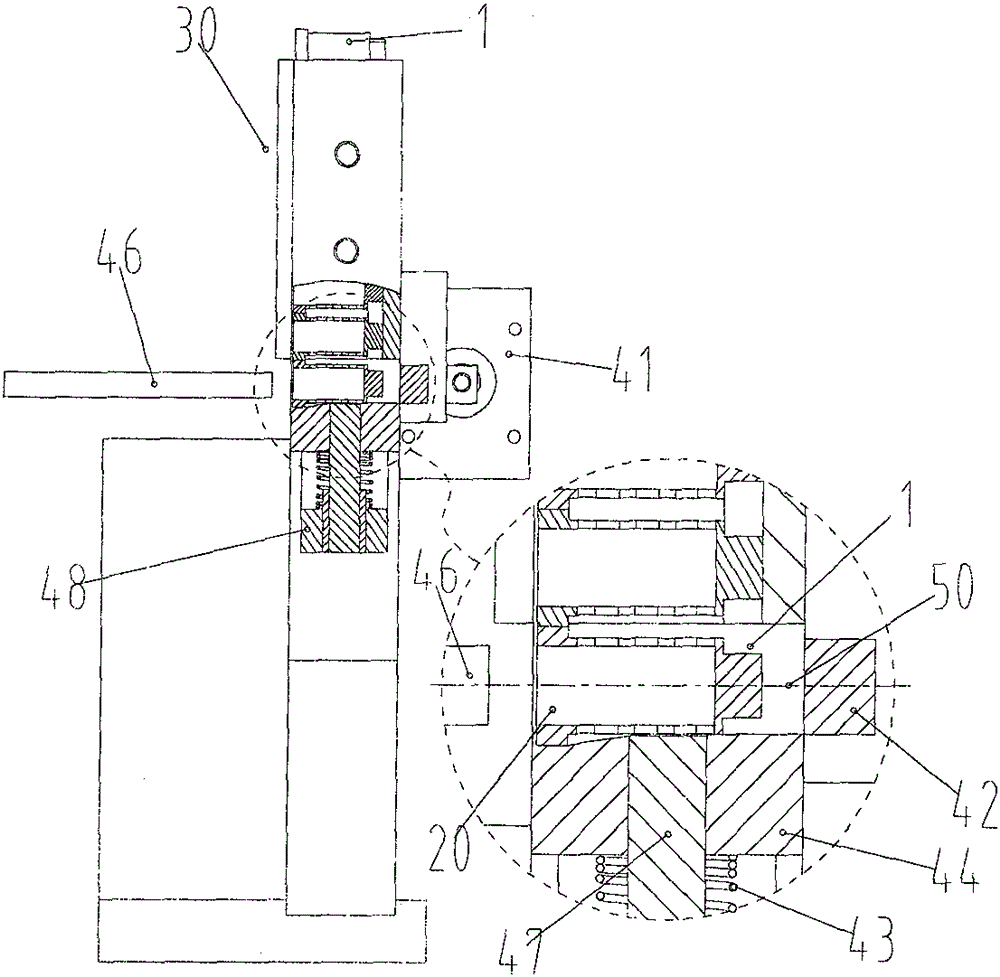

Full-automatic lock cylinder deburring equipment and deburring technique

ActiveCN105215771AEasy to moveImprove work efficiencyWork clamping meansNibbling shearing machinesEngineeringCam

The invention relates to the field of machine manufacturing, in particular to a tool mechanism used for machining lock cylinders. Full-automatic lock cylinder drburring equipment comprises a vibrating disc, a propelling mechanism, a rotary table, a feeding mechanism, deburring mechanisms and tool clamps. The vibrating disc is placed on a workbench. The feeding mechanism is arranged at the position of a discharge outlet of the vibrating disc. The propelling mechanism is arranged on one side of the feeding mechanism. The tool clamps are arranged on the rotary table at equal intervals. The rotary table is driven by a cam indexer to rotate in an equal angle mode. The deburring mechanisms are further arranged above the tool clamps. According to the full-automatic lock cylinder deburring equipment, rapid feeding, clamping, positioning, three-time deburring and discharging of lock cylinders are achieved, the high-efficiency action takt is utilized for deburring the lock cylinders three times, and high-quality machined surfaces are obtained.

Owner:滁州辉煌无纺科技有限公司

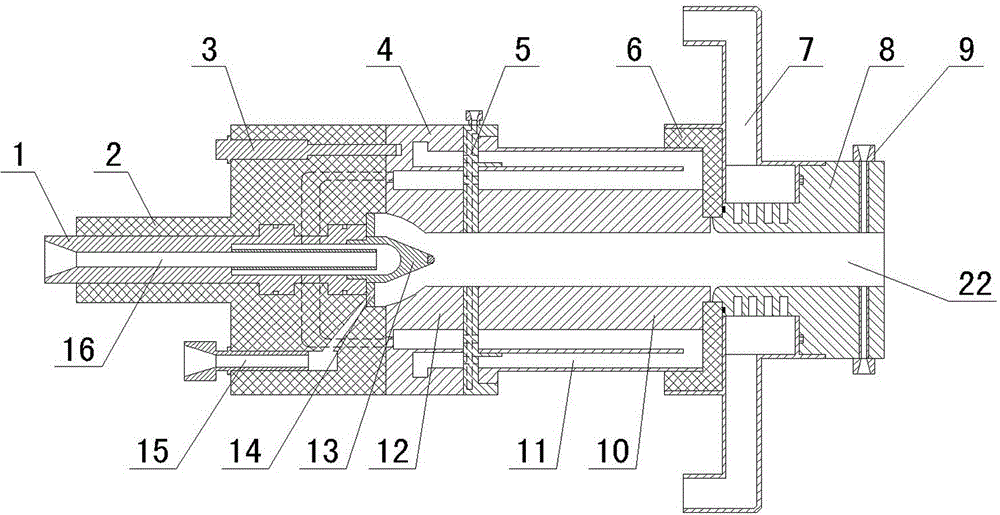

Double airflow supersonic plasma spray gun

The invention provides a double airflow supersonic plasma spray gun comprising a cathode rod, an arcing intermediate pole, an acceleration intermediate pole and an anode. Theanode is provided with a powder feeding mouth. The arcing intermediate pole, the acceleration intermediate pole and the anode are internally and coaxially provided with cavity channels which are communicated with each other and used for penetration of plasma airflow. The cathode rod is arranged in an insulated rear base. One end, which is close to the arcing intermediate pole, of the cathode rod is provided with a tungsten cathode and an argon gas distribution ring which is used for piping of argon. The insulated rear base is internally provided with a high frequency generator connector and an argon input channel which is communicated with the argon gas distribution ring. The arcing intermediate pole and the acceleration intermediate pole are arranged on an intermediate pole base, and an air gas distribution ring used for piping of mixed gas formed by air and combustible gas is arranged between the arcing intermediate pole and the acceleration intermediate pole. A problem of short service life of the cathode of pure air supersonic plasma equipment is solved, and production cost is greatly reduced in comparison with that of pure argon supersonic plasma equipment. Besides, plasma temperature and speed can be adjusted through ratio of air to combustible gas so that technology performance is high.

Owner:GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com