Double airflow supersonic plasma spray gun

A supersonic plasma and dual air flow technology, applied in the direction of plasma, electrical components, etc., can solve the problems of increased production cost and downtime loss, low arc starting effect and service life, poor stability of equipment and process, etc., to achieve optimal coating Performance quality, flow uniformity, effect of protecting tungsten cathode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

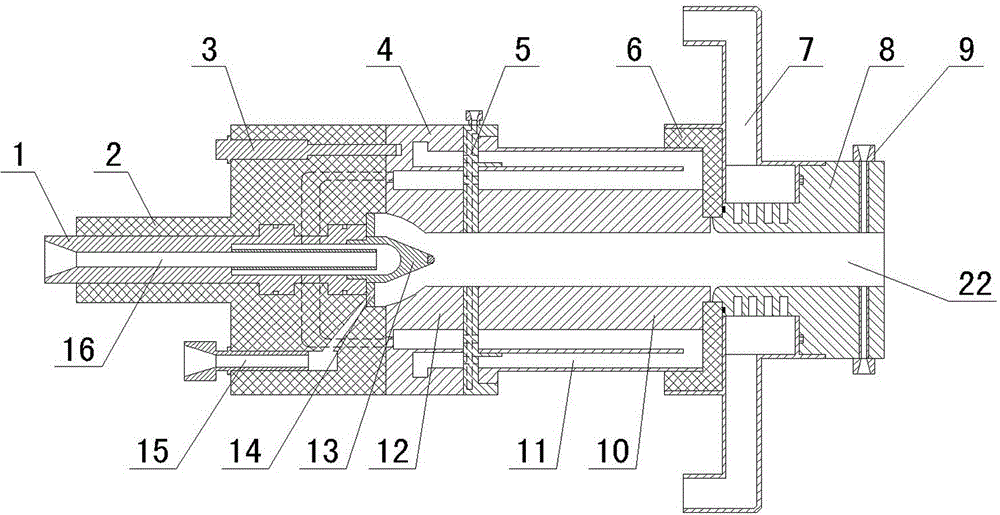

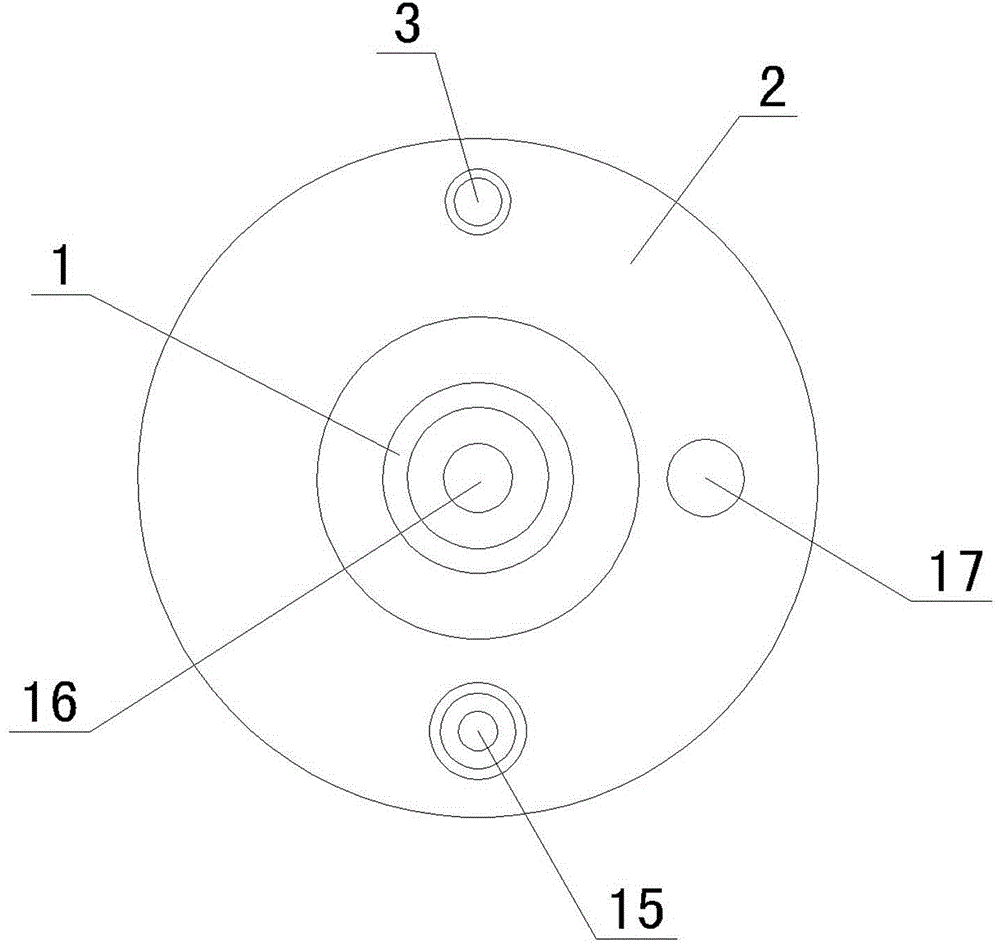

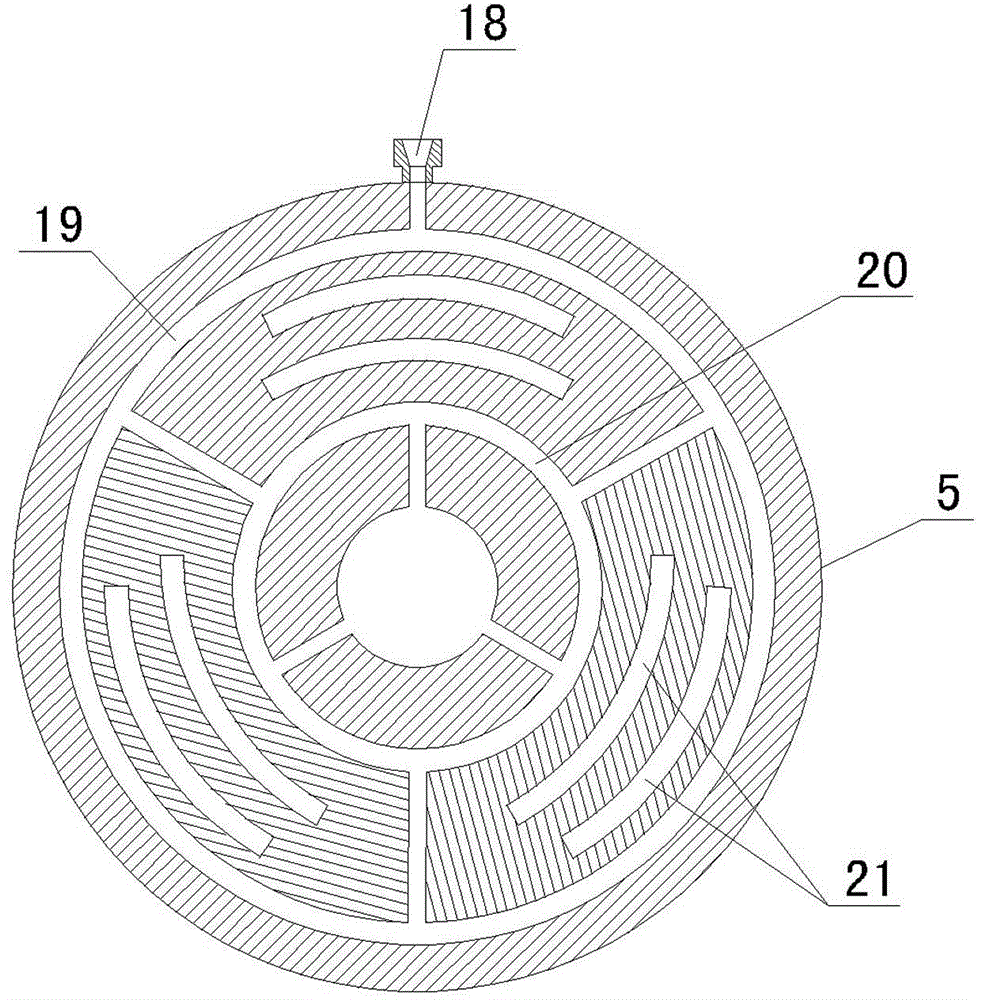

[0029] The double-flow supersonic plasma spray gun of the present invention presses figure 1 The schematic diagram of the structure is assembled. The insulating back seat 2 is made of Teflon plastic, the high-frequency generator joint 3, the cathode rod 1 and the water outlet channel 17 are all made of red copper, the diameter of the high-frequency generator joint 3 is 6 mm, and the outer diameter of the cathode rod 1 is 13 mm, The inner diameter is 9mm, the outer diameter of the water outlet channel 17 is 12mm, and the inner diameter is 8mm. The front end of the cathode rod 1 is threaded to install a tungsten cathode 13 with a diameter of 10mm. The intermediate pole seat 4 is made of steel; the arcing intermediate pole 12 and the accelerating intermediate pole 10 are made of chrome-zirconium copper alloy, and the inner diameter is 10mm. The air gas distribution ring 5 is made of red copper. The volume ratio of propane and air is about 1 / 19. The pressure of argon is 0.9MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com