Heat insulation waterproof waterborne coating

A technology of water-based coatings, pigments and fillers, which can be used in coatings and other directions to solve the problems of unsatisfactory waterproofing and heat resistance of coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

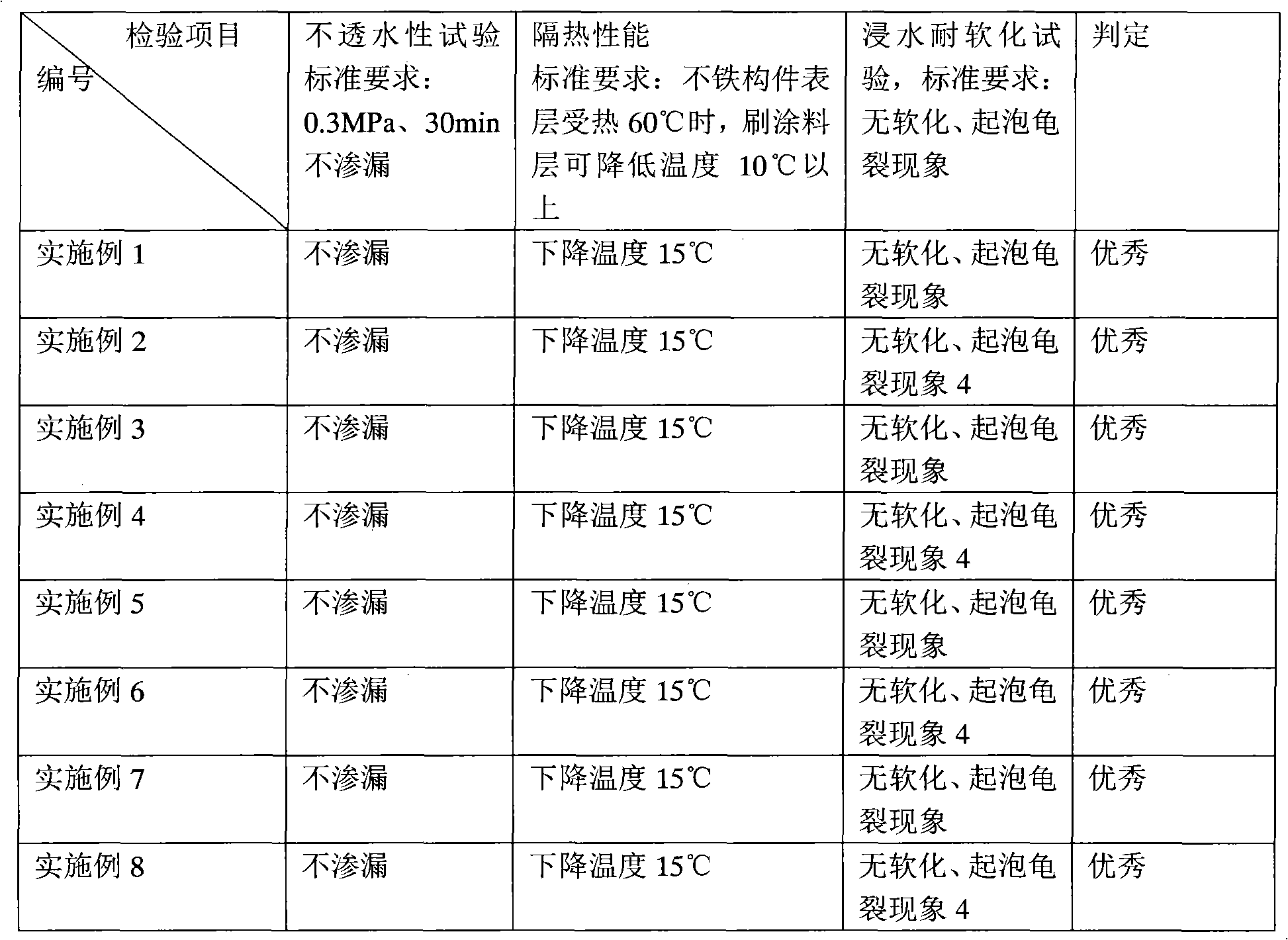

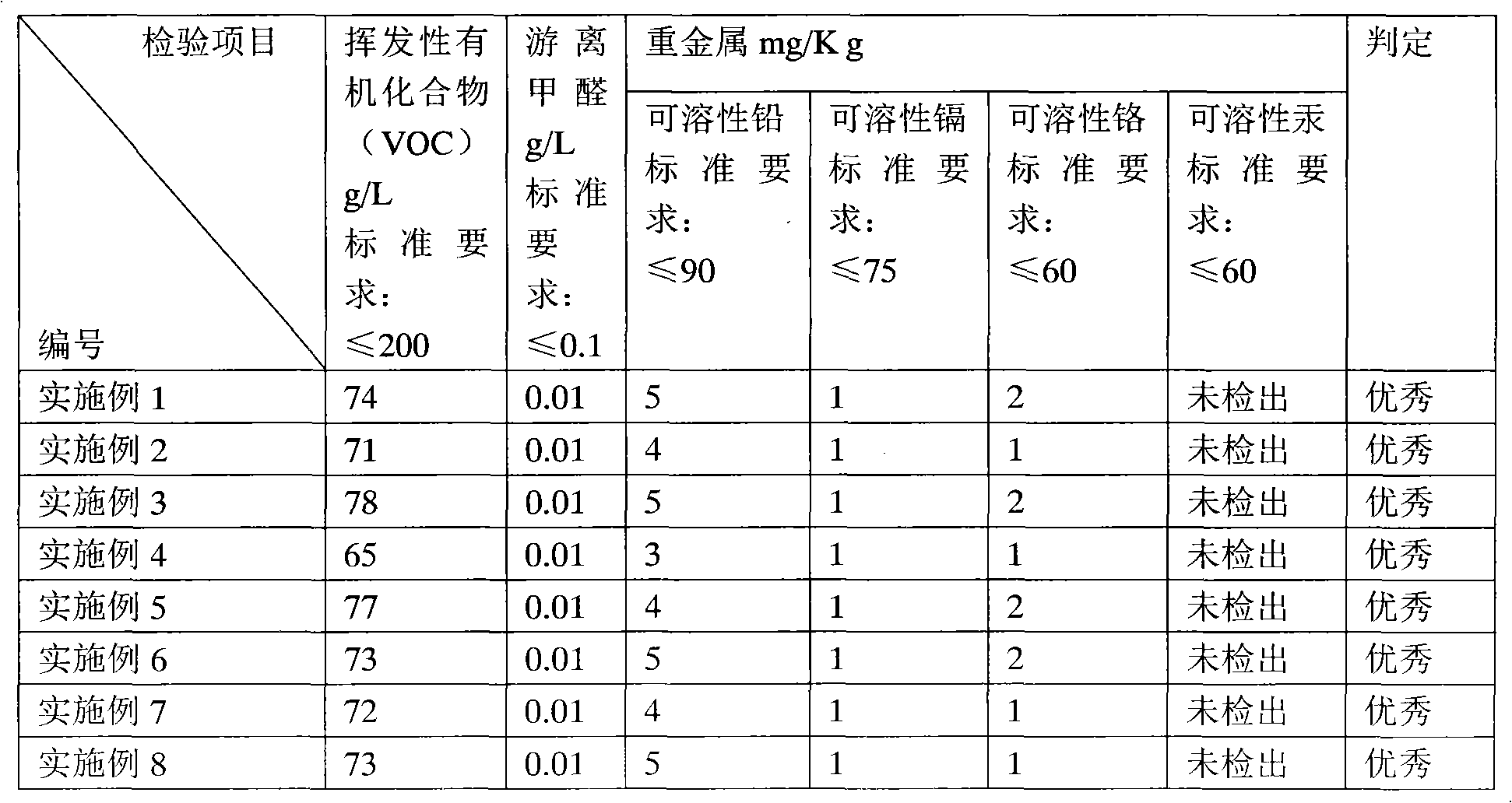

[0011] A heat-insulating and waterproof water-based coating is composed of 41wt% of film-forming emulsion, 53wt% of pigment and filler, 2.77-8wt% of additives, and clear water as the balance. The weight percent of pigments and fillers in the entire water-based paint is composed of titanium dioxide 8-11wt%, mica powder 8.8-9wt%, heavy calcium powder 3-4wt%, light calcium powder 7-8wt%, talc powder 5-7wt%, kaolin 2.2-3wt%, phosphorus powder 2-4wt%, hollow glass microsphere powder 5-8wt%. The weight percentage of preferred additives in the whole water-based paint is composed of 0.1~0.2wt% dispersant, 0.08~0.1wt% lubricant, 0.1~1.2wt% leveling agent, 0.7~1wt% defoamer, 1.0% plasticizer ~3.2wt%, antifreeze 0.7~1.3wt%, preservative 0.09~1.0wt%. According to the inspection standard Q / HZGC01-2006 "Organic Polymer Waterproof Coatings", the coatings prepared with this ratio have excellent properties. As shown in Table 1, the coatings have excellent waterproof and heat insulation proper...

Embodiment 2

[0013] A heat-insulating and waterproof water-based coating is composed of 42wt% of film-forming emulsion, 50wt% of pigments and fillers, 2.77-8wt% of additives, and clear water as the balance. The weight percent of pigments and fillers in the entire water-based paint is composed of titanium dioxide 8-11wt%, mica powder 8.8-9wt%, heavy calcium powder 3-4wt%, light calcium powder 7-8wt%, talc powder 5-7wt%, kaolin 2.2-3wt%, phosphorus powder 2-4wt%, hollow glass microsphere powder 5-8wt%. The weight percentage of preferred additives in the whole water-based paint is composed of 0.1~0.2wt% dispersant, 0.08~0.1wt% lubricant, 0.1~1.2wt% leveling agent, 0.7~1wt% defoamer, 1.0% plasticizer ~3.2wt%, antifreeze 0.7~1.3wt%, preservative 0.09~1.0wt%. According to the inspection standard Q / HZGC01-2006 "Organic Polymer Waterproof Coatings", the coatings prepared with this ratio have excellent properties. As shown in Table 1, the coatings have excellent waterproof and heat insulation prop...

Embodiment 3

[0015] A heat-insulating and waterproof water-based coating is composed of 43% by weight of film-forming emulsion, 44% by weight of pigment and filler, 2.77-8% by weight of additives, and the balance is clear water. The weight percent of pigments and fillers in the entire water-based paint is composed of titanium dioxide 8-11wt%, mica powder 8.8-9wt%, heavy calcium powder 3-4wt%, light calcium powder 7-8wt%, talc powder 5-7wt%, kaolin 2.2-3wt%, phosphorus powder 2-4wt%, hollow glass microsphere powder 5-8wt%. The weight percentage of preferred additives in the whole water-based paint is composed of 0.1~0.2wt% dispersant, 0.08~0.1wt% lubricant, 0.1~1.2wt% leveling agent, 0.7~1wt% defoamer, 1.0% plasticizer ~3.2wt%, antifreeze 0.7~1.3wt%, preservative 0.09~1.0wt%. According to the inspection standard Q / HZGC01-2006 "Organic Polymer Waterproof Coatings", the coatings prepared with this ratio have excellent properties. As shown in Table 1, the coatings have excellent waterproof an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com