Patents

Literature

404results about "Nibbling shearing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

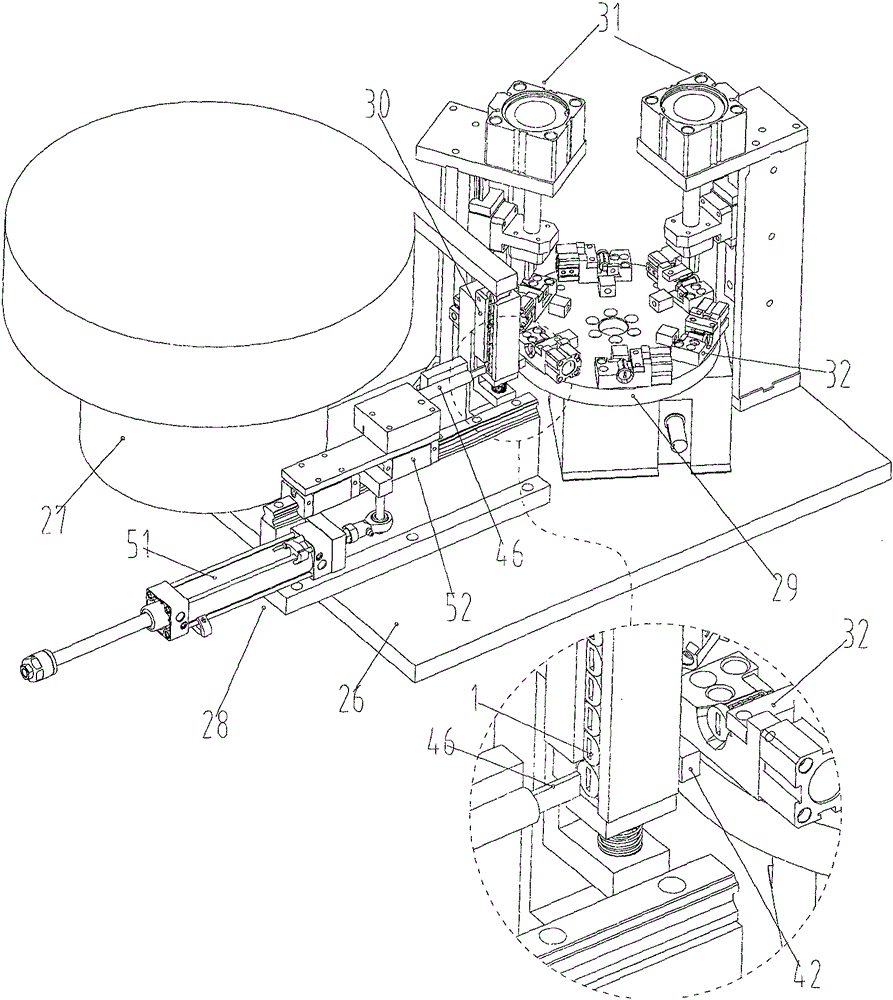

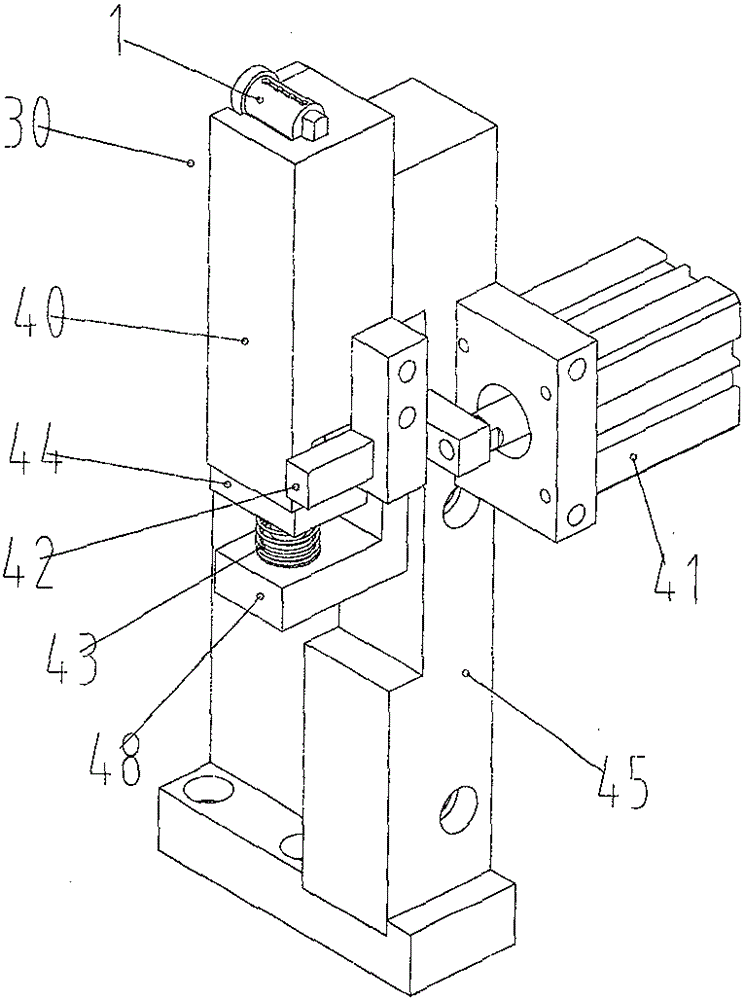

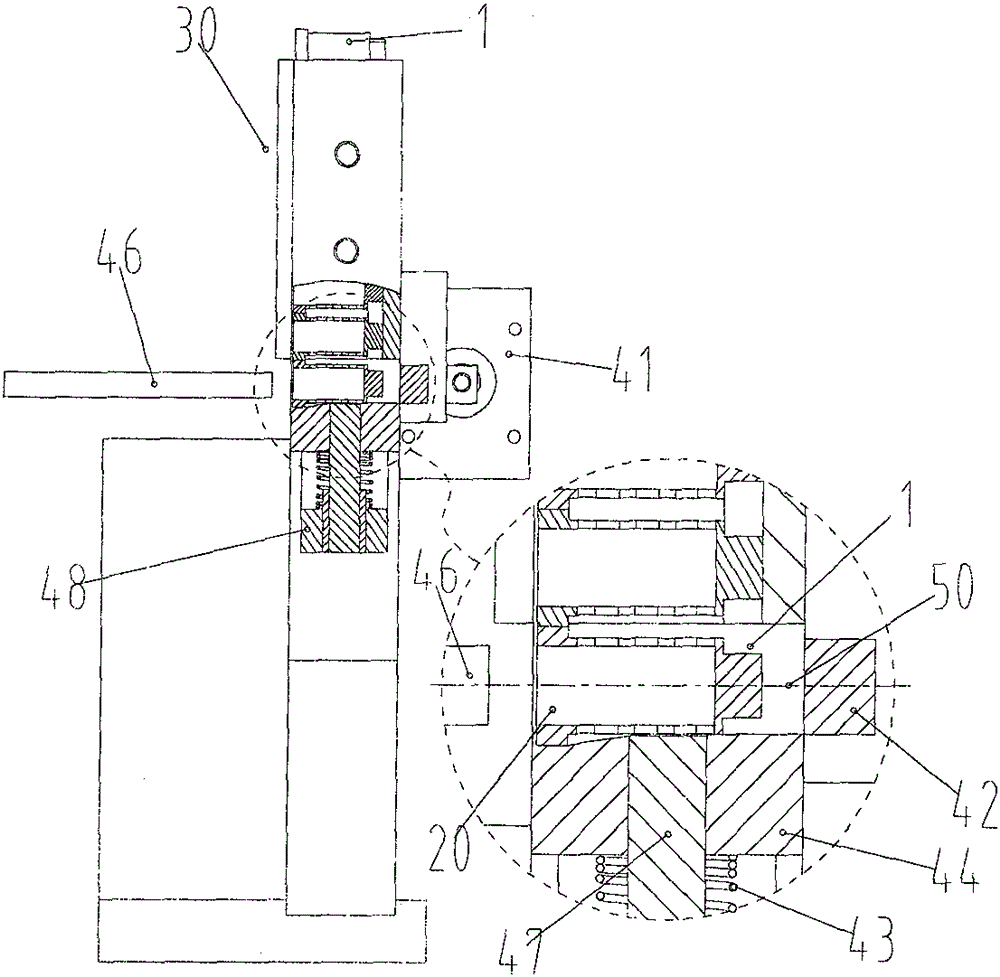

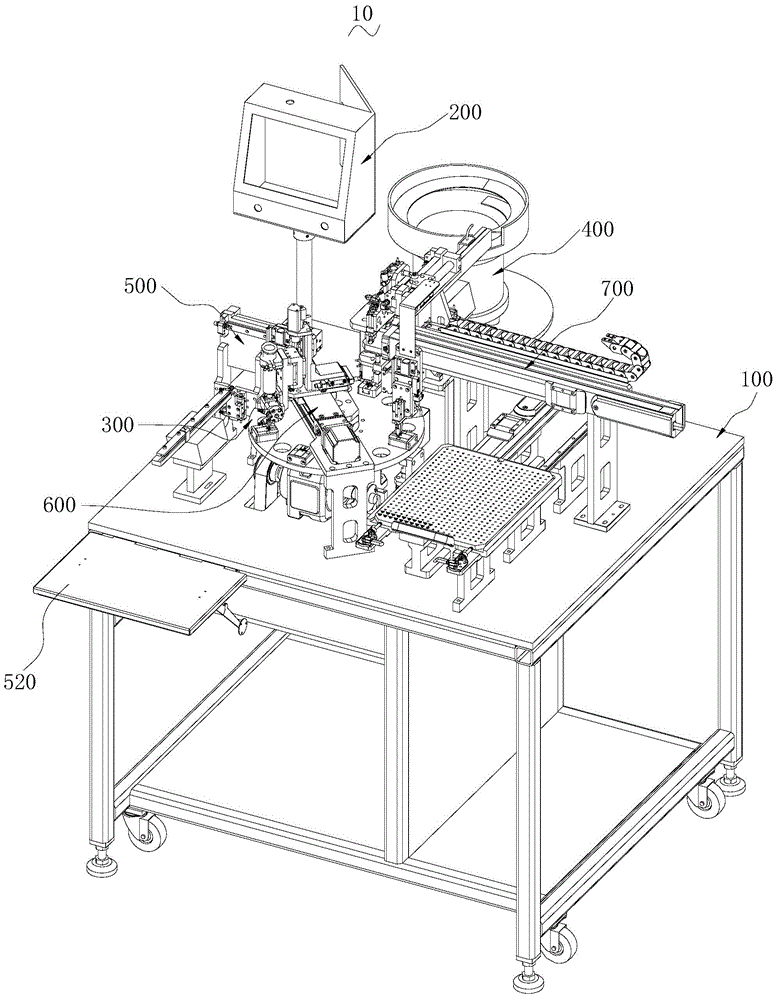

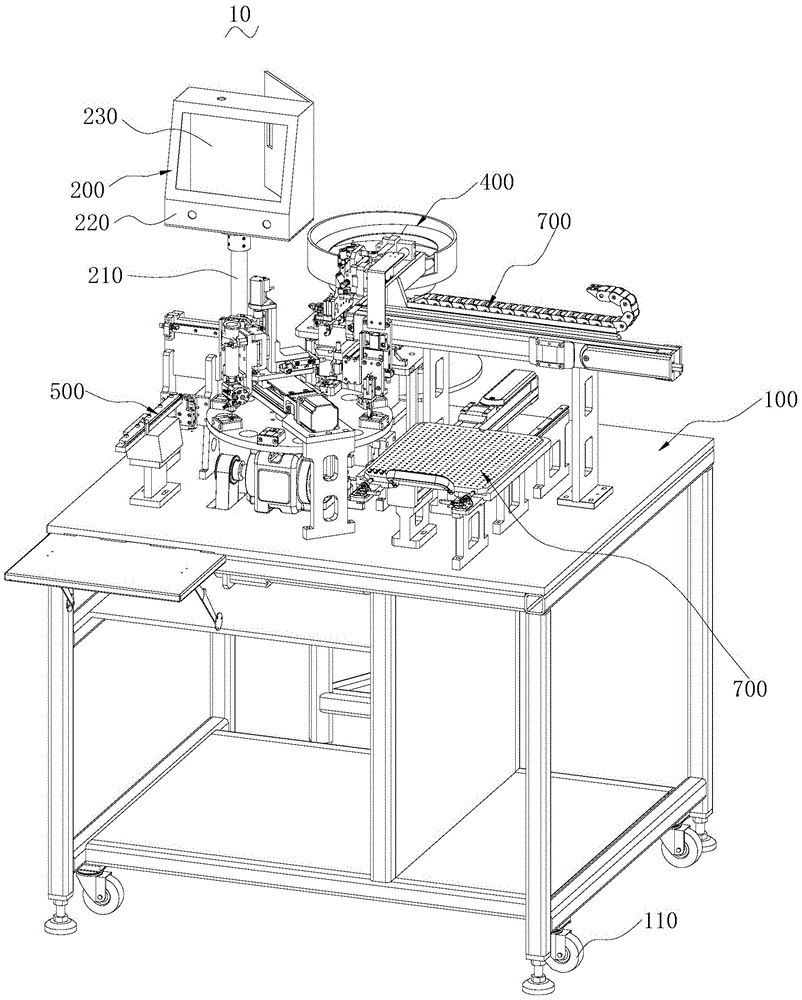

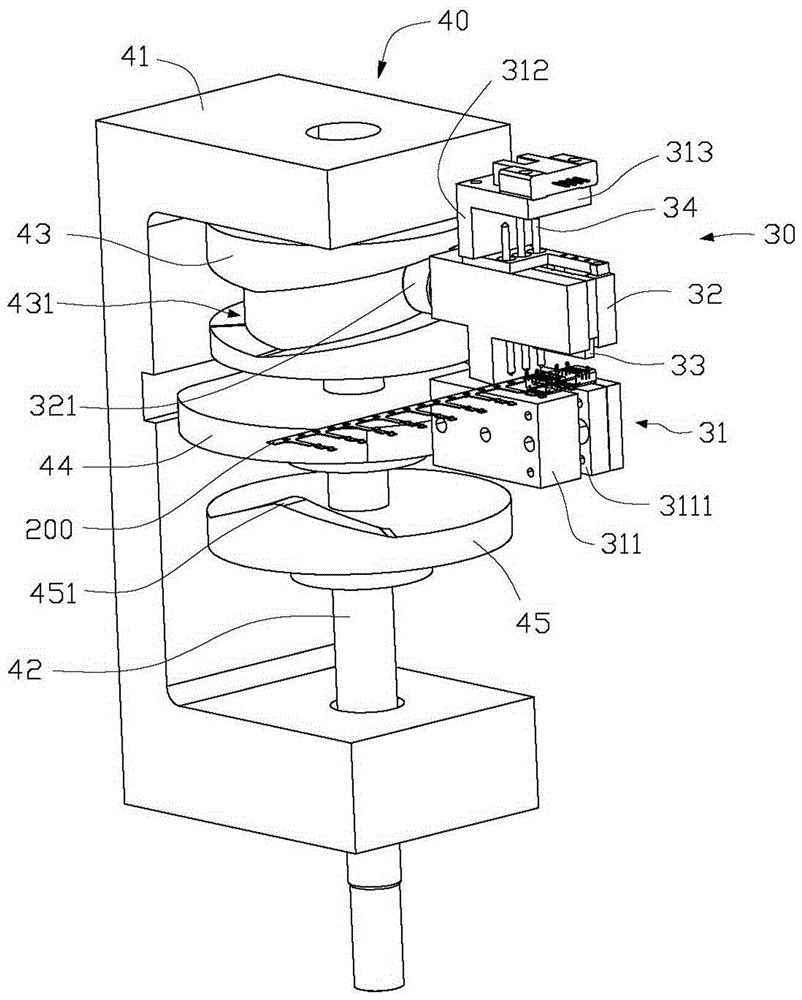

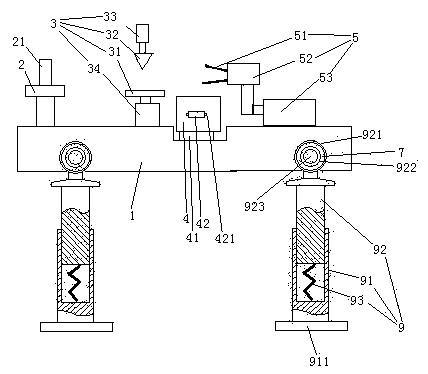

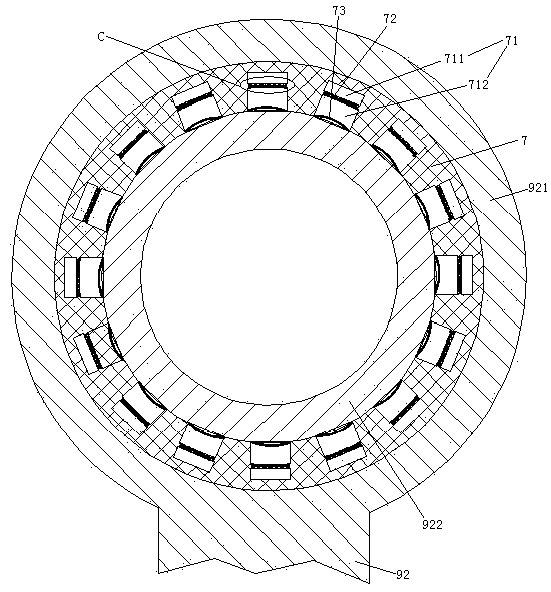

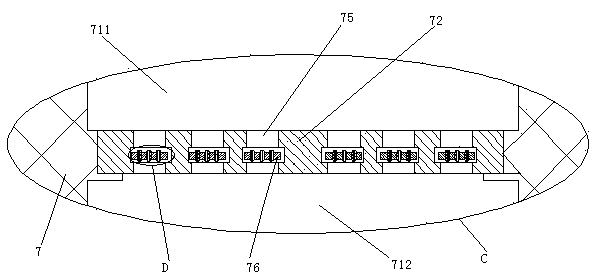

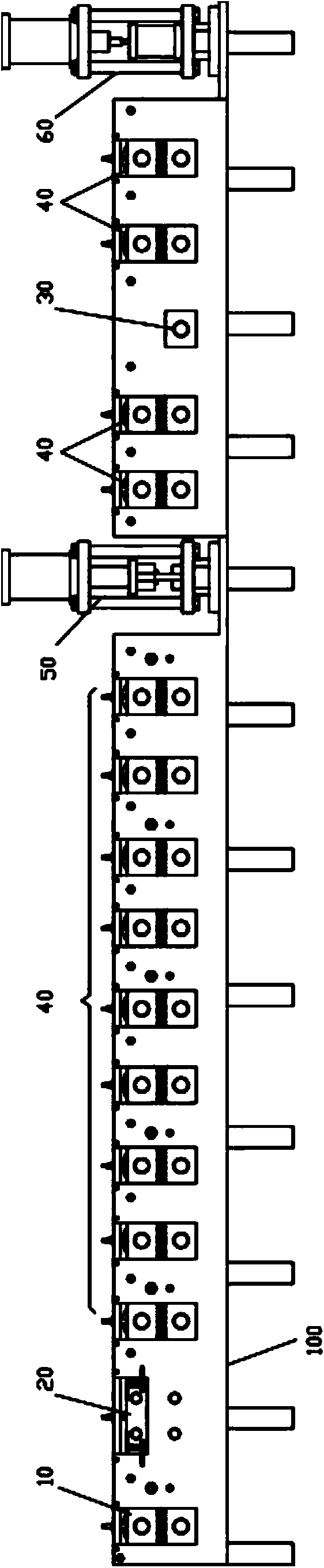

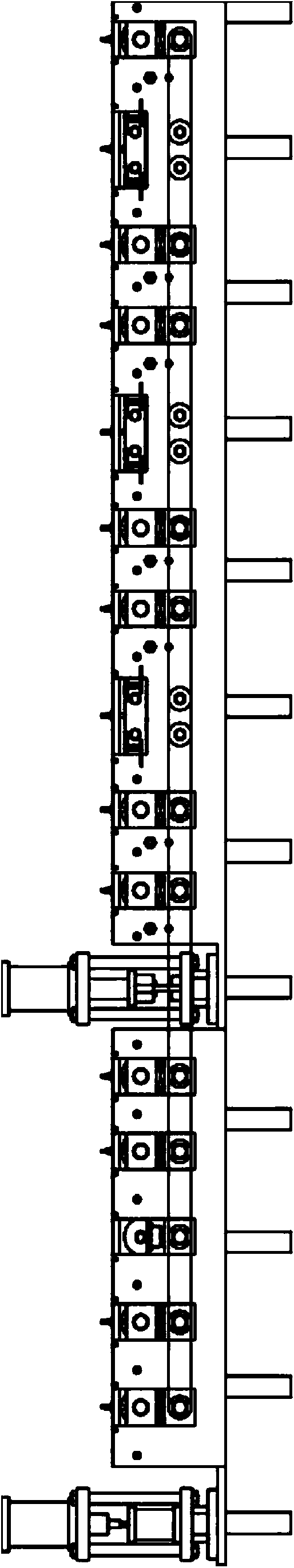

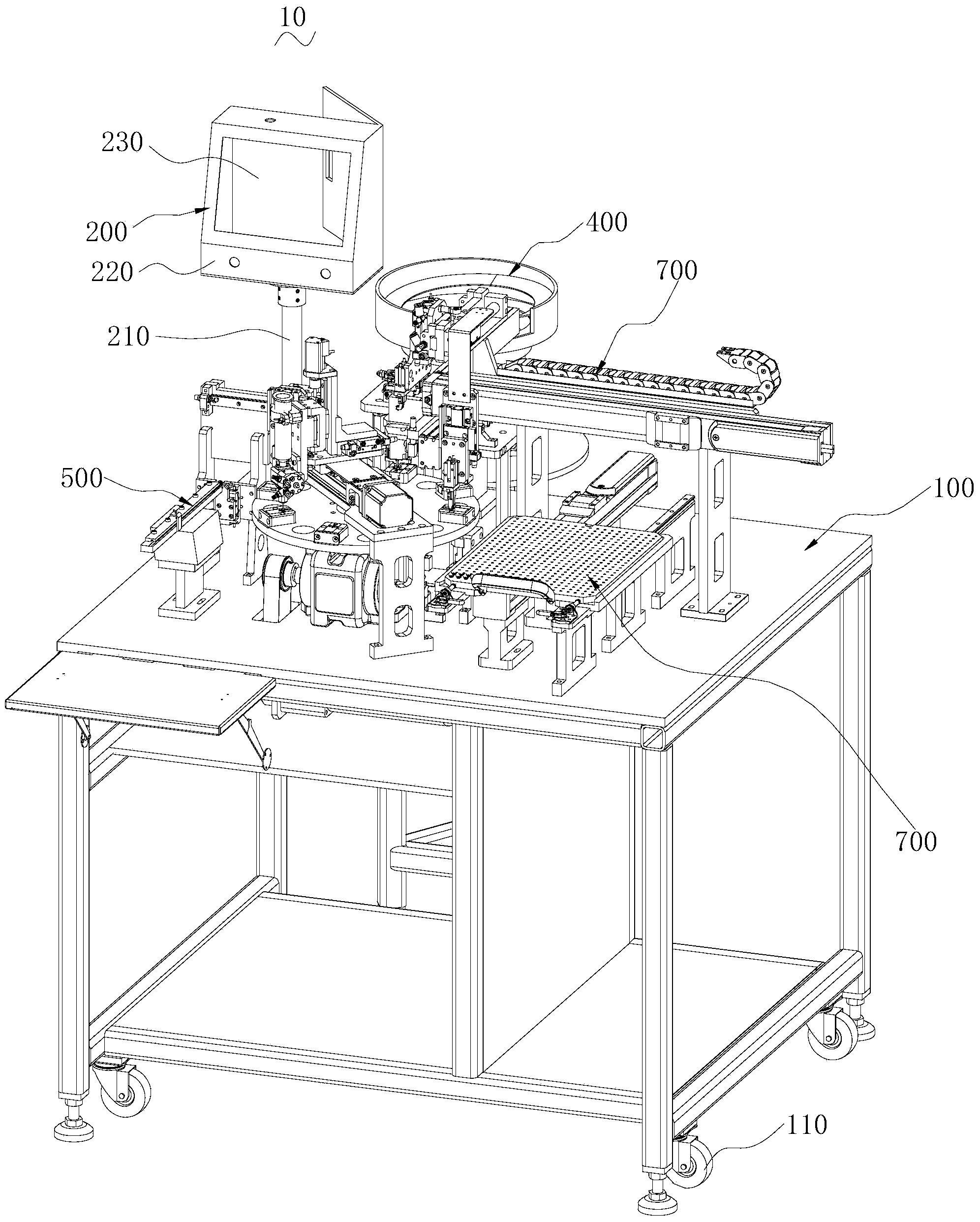

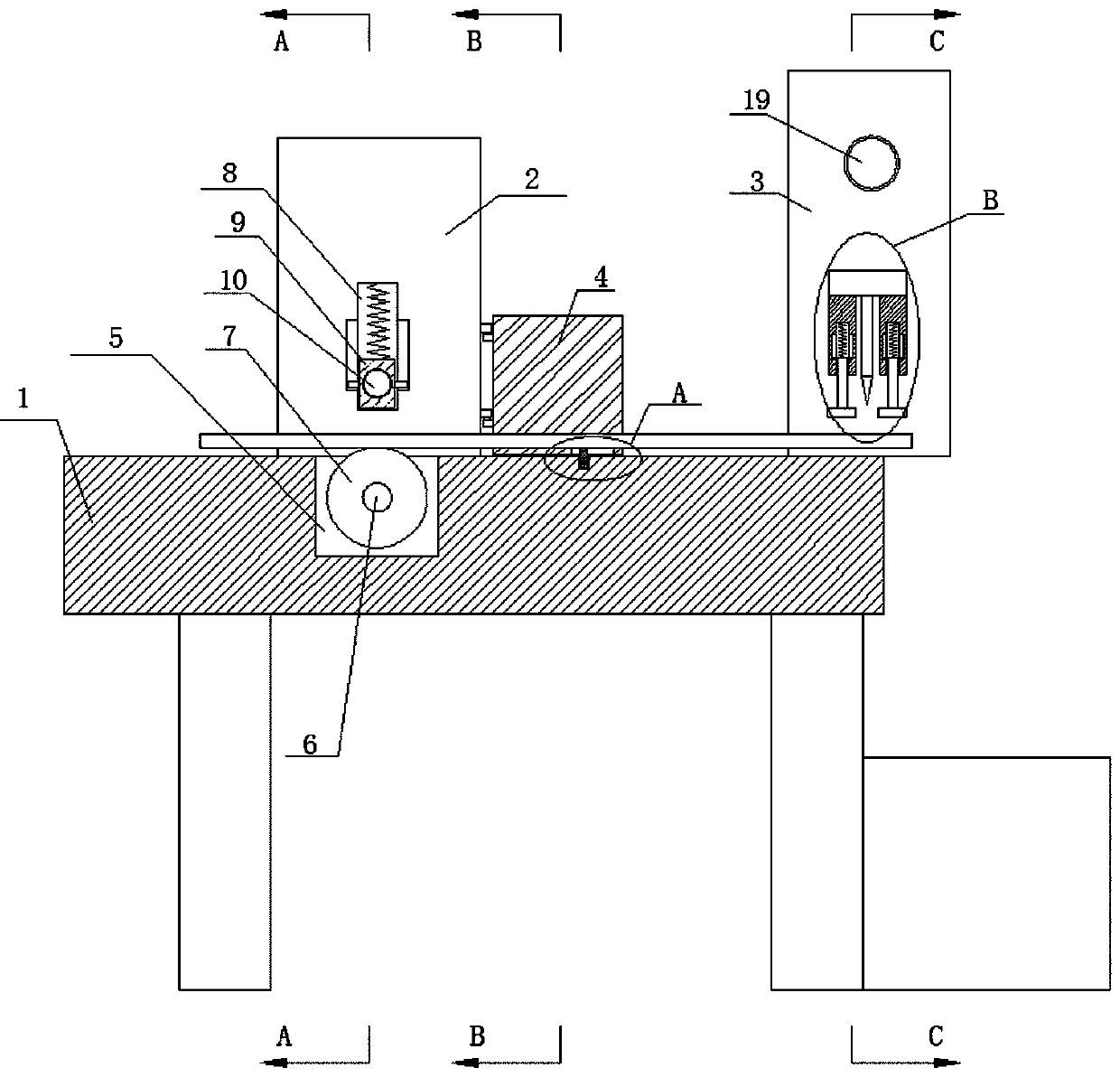

Full-automatic lock cylinder deburring equipment and deburring technique

ActiveCN105215771AEasy to moveImprove work efficiencyWork clamping meansNibbling shearing machinesEngineeringCam

The invention relates to the field of machine manufacturing, in particular to a tool mechanism used for machining lock cylinders. Full-automatic lock cylinder drburring equipment comprises a vibrating disc, a propelling mechanism, a rotary table, a feeding mechanism, deburring mechanisms and tool clamps. The vibrating disc is placed on a workbench. The feeding mechanism is arranged at the position of a discharge outlet of the vibrating disc. The propelling mechanism is arranged on one side of the feeding mechanism. The tool clamps are arranged on the rotary table at equal intervals. The rotary table is driven by a cam indexer to rotate in an equal angle mode. The deburring mechanisms are further arranged above the tool clamps. According to the full-automatic lock cylinder deburring equipment, rapid feeding, clamping, positioning, three-time deburring and discharging of lock cylinders are achieved, the high-efficiency action takt is utilized for deburring the lock cylinders three times, and high-quality machined surfaces are obtained.

Owner:滁州辉煌无纺科技有限公司

Fiber cement shear

InactiveUS20060112566A1Easy to manufactureLess prone to failurePortable power-driven toolsNibbling shearing machinesFiberReciprocating motion

A hand tool for shearing a fiber cement workpiece and attachable to a drill having a drill chuck has a shearing head having a blade to contact and shear the workpiece; and a coupler connected to the shearing head and imparting reciprocating motion to the blade. The shearing head has a skid plate to contact the workpiece and an enclosed aperture through which the blade reciprocates.

Owner:MALCO PRODS

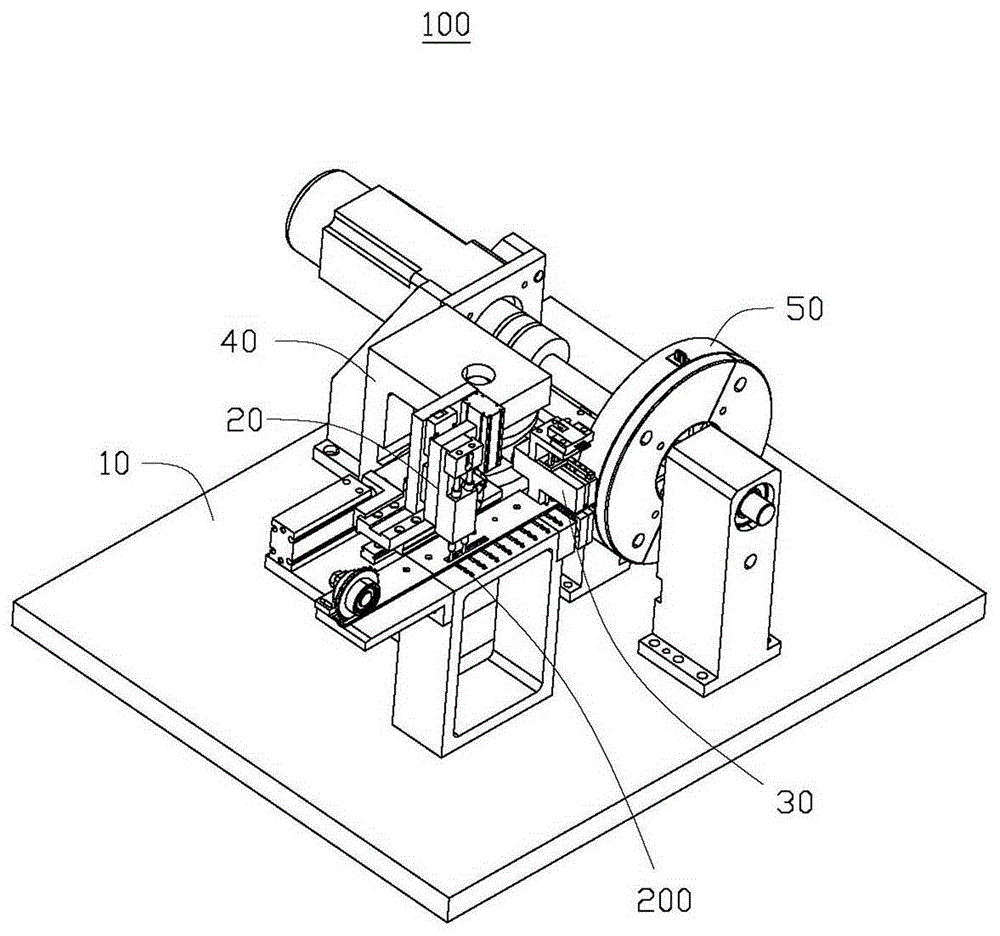

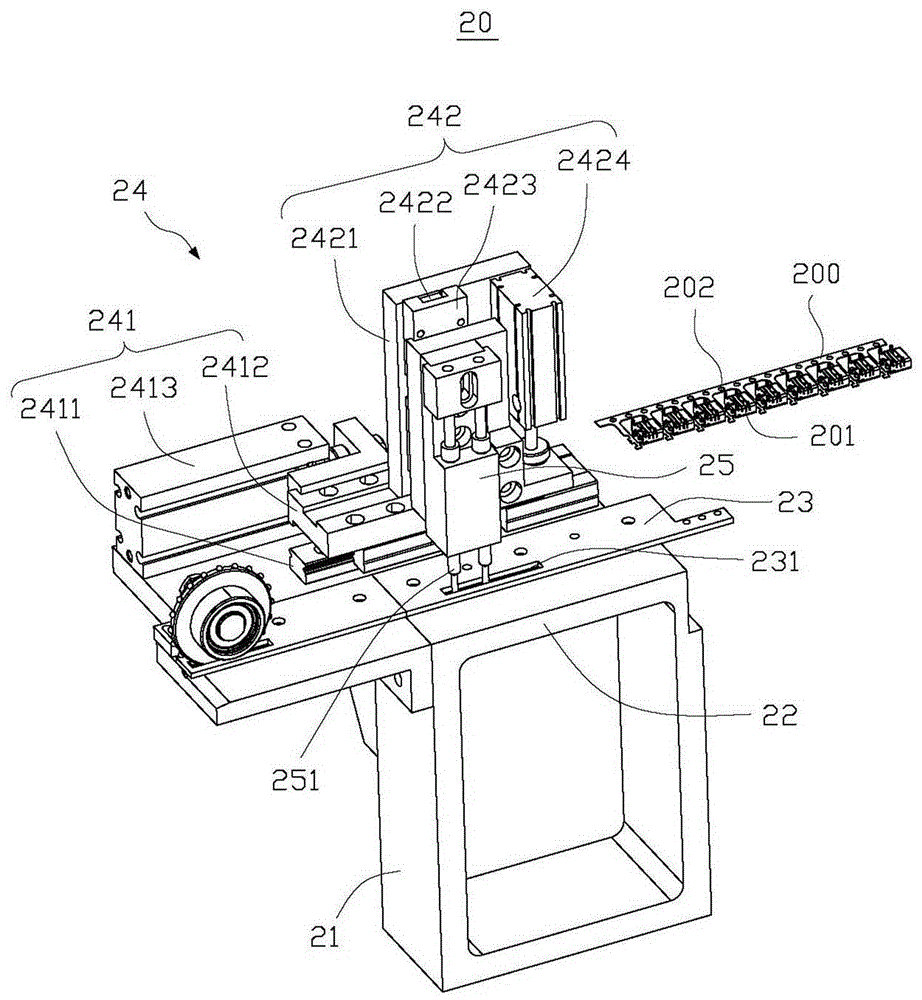

Cutting device for manufacturing of LED (light emitting diode) kits and LED kit automatic assembly machine

ActiveCN104314938AIncrease productivityImprove product qualityLiquid surface applicatorsCoatingsEngineeringLED lamp

The invention relates to a cutting device for manufacturing of LED (light emitting diode) kits and an LED kit automatic assembly machine. The cutting device comprises a bracket, a material vibration mechanism, a material shifting mechanism, a cutting mechanism, a material fetching mechanism and a waste box, wherein the bracket is arranged on a worktable, the material vibration mechanism is arranged on the bracket, the material shifting mechanism is arranged at one side, near the material vibration mechanism, of the bracket, the cutting mechanism is arranged on the bracket and is arranged near the material vibration mechanism, the material fetching mechanism is arranged on the bracket and is arranged near the cutting mechanism, and an opening of the waste box faces the cutting mechanism. The cutting device for manufacturing of the LED kits has the advantages that only an LED lamp is arranged in a material vibration cylinder by an operator, then the LED lamp in the material vibration cylinder is arranged on a material vibration plate, and one part of pins of the LED lamp can be cut off; compared with the traditional manual operation method, the production efficiency is higher, and the product quality is also higher.

Owner:NINGBO SUNPU OPTO SEMICON

Automatic cutting device

ActiveCN106541297ASimple structureIncrease productivityFeeding apparatusNibbling shearing machinesCamMechanical engineering

The invention discloses an automatic cutting device. The automatic cutting device comprises a feeding mechanism, a cutting mechanism, a cam mechanism and a discharging mechanism. The feeding mechanism is used for feeding materials to the cutting mechanism. The cutting mechanism comprises a mounting rack, a sliding block which is mounted on the mounting rack in a sliding mode and a tool which is mounted on the sliding block. The cam mechanism comprises a first cam, a second cam and a third cam. The first cam is provided with an annular groove, the second cam is an eccentric wheel, and the surface of the third cam is provided with protrusions. The first cam is used for driving the sliding block to move. The discharging mechanism comprises a discharging plate and a shifting assembly. The discharging plate comprises a plurality of feeding blocks and a plurality of discharging blocks. The shifting assembly comprises a shifting support, a feeding shifting rod and a discharging lever. The second cam is used for driving the feeding shifting rod to move. The feeding shifting rod is used for shifting the feeding blocks. The discharging lever abuts against the surface of the third cam. The protrusions are used for lifting the discharging lever. The discharging lever is used for pressing the discharging blocks.

Owner:FU DING ELECTRONICSAL TECH JIASHAN

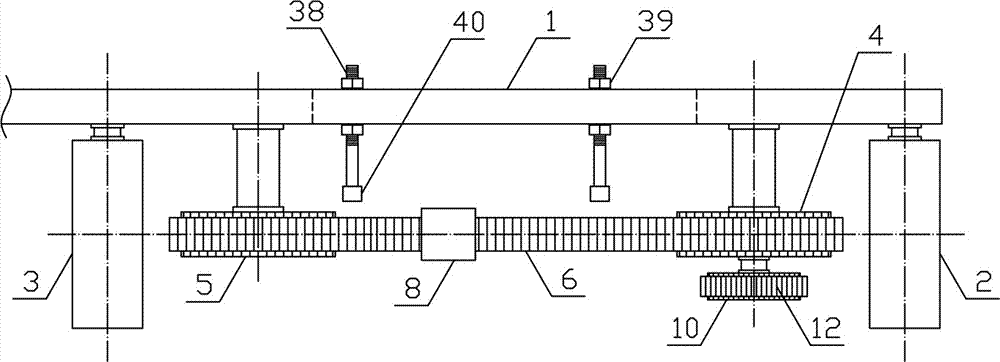

Aluminum pipe equal cutting device

InactiveCN106513828ARealize intermittent cuttingRealize the effect of automatic equal cuttingNibbling shearing machinesShearing machine accessoriesOptical axisArchitectural engineering

The invention relates to an aluminum pipe equal cutting device. The aluminum pipe equal cutting device comprises a baseplate, a worktable and a guide frame; a C-shaped frame is horizontally and slidingly mounted on the worktable; a fastening bolt is mounted on the C-shaped frame; a cushion plate is arranged on the left side of the worktable; a cutter is arranged rightly above the cushion plate; the upper end of the cutter is welded with a shank with a U-shaped groove; a convex block is slidingly mounted in the U-shaped groove in the horizontal direction; a turntable is arranged on the back side of the shank; the convex block is eccentrically welded on the left end surface of the turntable; the turntable is connected with a polish shaft; the right end of the polish shaft is welded with a thread rod; the thread rod is connected with a motor; and the thread rod is in threaded connection with an extension plate. The aluminum pipe equal cutting device is high in automation degree; and through thread transmission and rotation of the convex block, the aluminum pipe equal cutting device not only can realize driving of aluminum pipes to perform constant-speed sliding, but also can realize intermittent cutting of the aluminum pipes, so that the automatic equal cutting effect of the aluminum pipes can be realized, and the control and the use are simple.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

Automatic shearing device of aluminum profile

InactiveCN102756164AWith automationSmall length errorNibbling shearing machinesShearing machine accessoriesEngineeringTouch switch

The invention discloses an automatic shearing device of aluminum profile. The automatic shearing device comprises a frame and is characterized in that a cutter base is arranged on the frame, profile holes communicated horizontally are arranged on the cutter base, the cross sections of the profile holes are matched with that of aluminum profile to be machined, the cutter base is provided with a cutter driven by an oil cylinder and capable of moving along the cutter base vertically on the lateral side close to the rear end of the profile, the rear end of the cutter is further provided with a length-limiting retaining plate parallel to and right opposite to the cutter base, a touch switch is arranged on the length-limiting retaining plate at the position right opposite to the profile hole, and the touch switch is electrically connected with the oil cylinder. The automatic shearing device of the aluminum profile first determines the length of the aluminum profile to be cut through the length-limiting retaining plate, and the oil cylinder is controlled through the touch switch to cut the aluminum profile automatically. The automatic shearing device of the aluminum profile has the advantages of being automatic, efficient and small in length errors and the like.

Owner:苏州禾源机电工程技术有限公司

Shock insulation type copper rod cutting machine

InactiveCN105499696AEasy to cutImprove efficiencyNibbling shearing machinesMaintainance and safety accessoriesRubber ringEngineering

The invention relates to cutting equipment. A shock insulation type copper rod cutting machine comprises a tray, a shearing device and a line drawing device which are sequentially arranged on a rack; the tray is connected to the rack in a rotational manner, and an insertion rod is arranged on the tray; the shearing device comprises a cutting board, a cutting knife located above the cutting board and a cutting air cylinder for driving the cutting knife to ascend and descend; the line drawing device comprises a line clamp, a finger clamping air cylinder for driving the line lamp to open and close and a line drawing oil cylinder for driving the finger clamping air cylinder to open and close relative to the shearing device; an installation pin is arranged on the rack and comprises an upper section and a lower section, the lower end of the upper section is sleeved with the upper end of the lower section, an installation base is arranged at the lower end of the lower section, a damping spring for supporting the upper section is arranged in the lower section, and a connecting ring is arranged at the upper end of the upper section; and an inner ring is arranged in the connecting ring in a penetrating manner and connected with the connecting ring together through a rubber ring, and a connecting pin connected to the rack is arranged on the inner ring in a penetrating manner. According to the shock insulation type copper rod cutting machine, the problems that when a waste copper rod is manually cut, time and labor are wasted, and the efficiency is low are solved.

Owner:XINXING PIPES ZHEJIANG COPPER

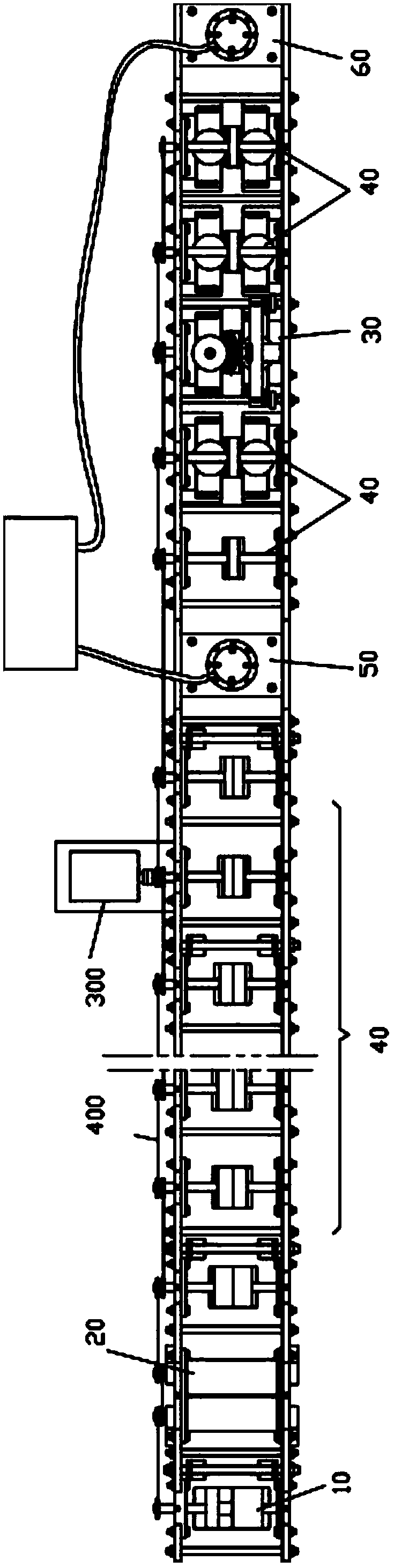

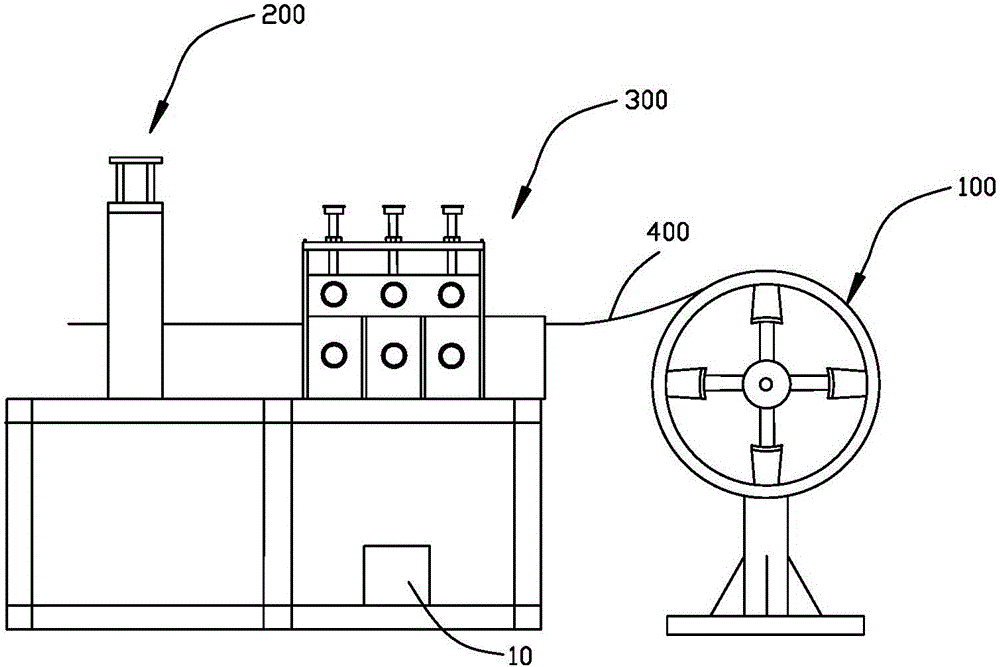

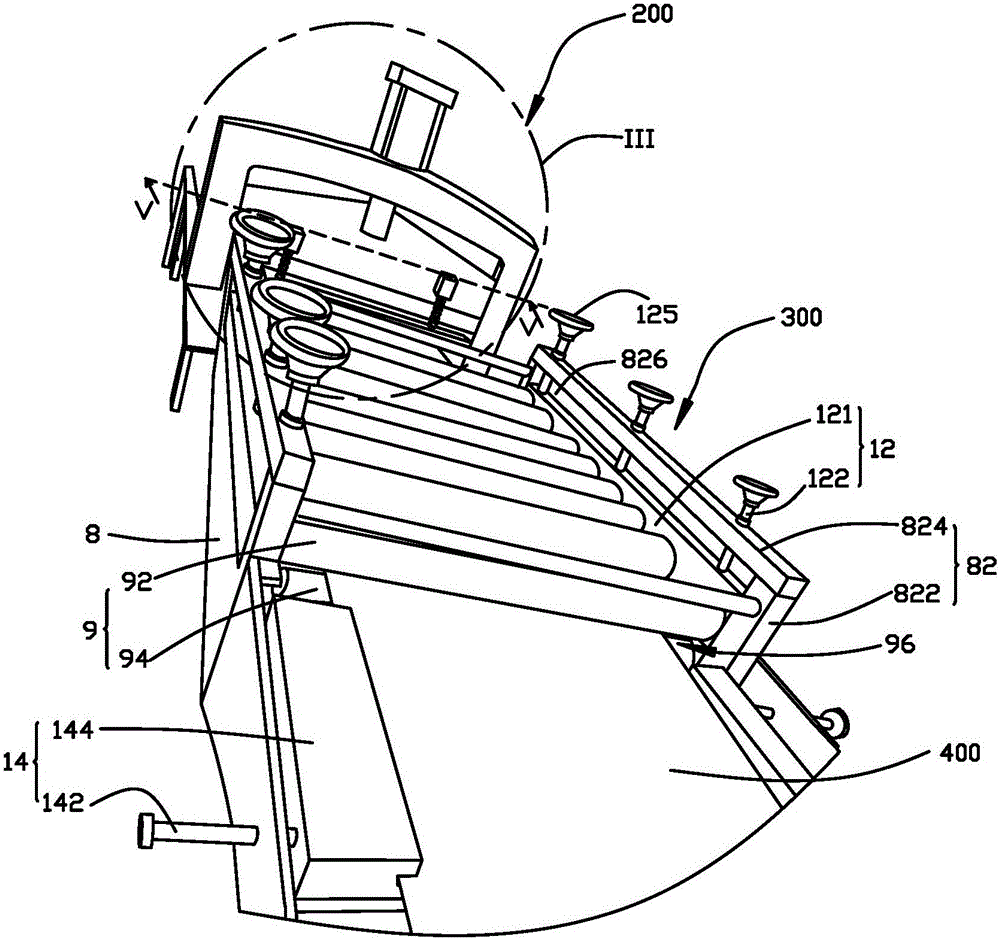

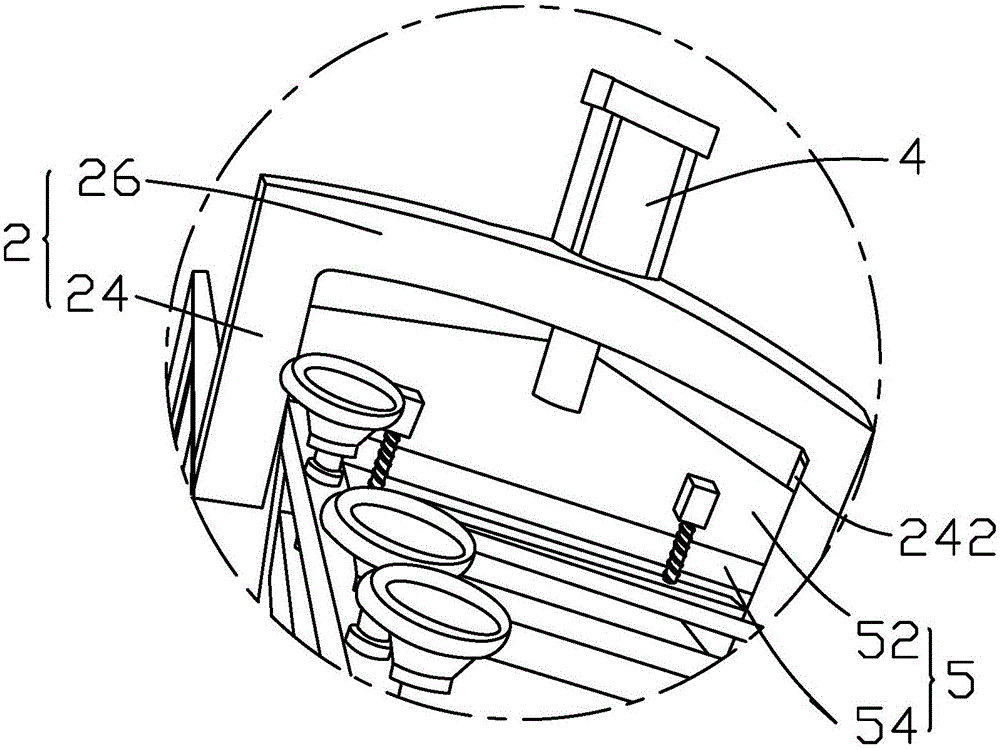

Air inlet frame forming machine of tank type ventilator

InactiveCN103447822ANo manual bendingIncrease productivityOther manufacturing equipments/toolsNibbling shearing machinesDrive motorEngineering

The invention provides an air inlet frame forming machine of a tank type ventilator. The air inlet frame forming machine comprises a rack and a driving motor, wherein the rack is provided with a feed roll group, an adjusting roll group, a shaping roll group and multiple forming roll groups, which are arranged linearly; the middle of the rack is provided with a punching machine; the front part of the rack is provided with a cutting punching mechanism; the feed roll group is positioned at the tail end of the rack; the adjusting roll group is positioned at the front part of the feed roll group; the shaping roll group is positioned at the part, adjacent to the cutting punching mechanism, of the rack; a left plate or a right plate is fixedly connected with a connecting bracket; a bent plate which is bent upward is formed at the top end of the connecting bracket; an included angle between the bent plate and the connecting bracket is 120-135 degrees; a rectifying tray is hinged to the bent plate. The air inlet frame forming machine can be used for realizing automatic once forming and punching of a steel band, cutting off the steel band without manual bending, and improving the production efficiency; the back surface of the rectifying tray props against the inner side wall of the lateral bent part of the bent steel band which is subjected to bending processing, so that a certain included angle is formed between the lateral bent part of the steel band and the middle bottom surface of the steel band, and design demands are ensured.

Owner:绍兴上虞通风机有限公司

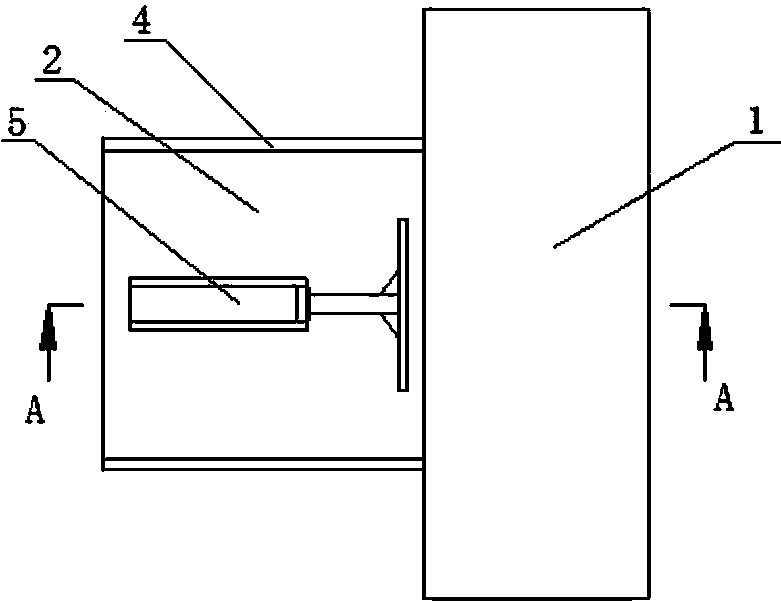

Plate shearer capable of positioning plates accurately

InactiveCN103639524AHigh dimensional accuracyEasy to operateNibbling shearing machinesShearing control devicesReciprocating motionEngineering

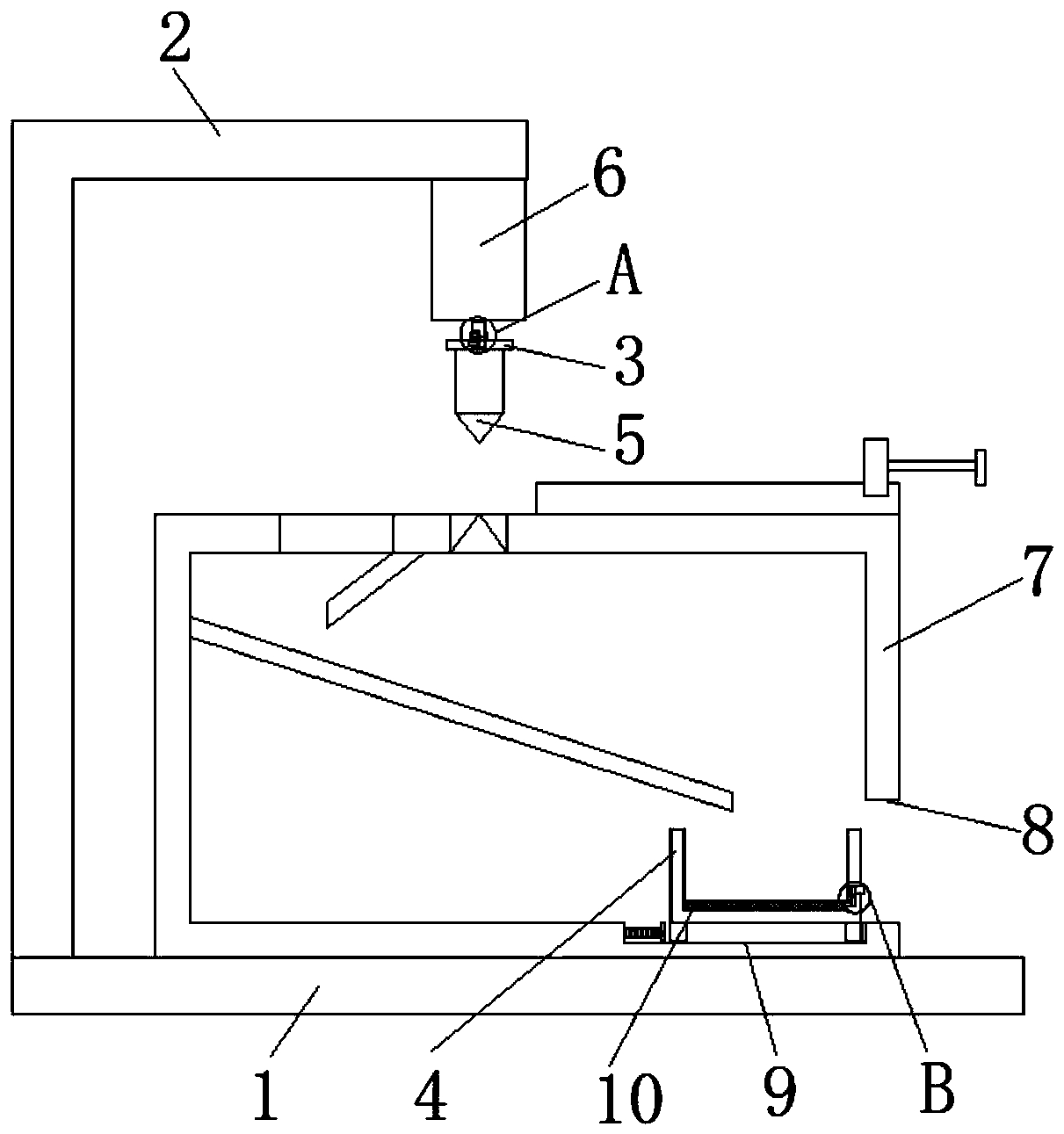

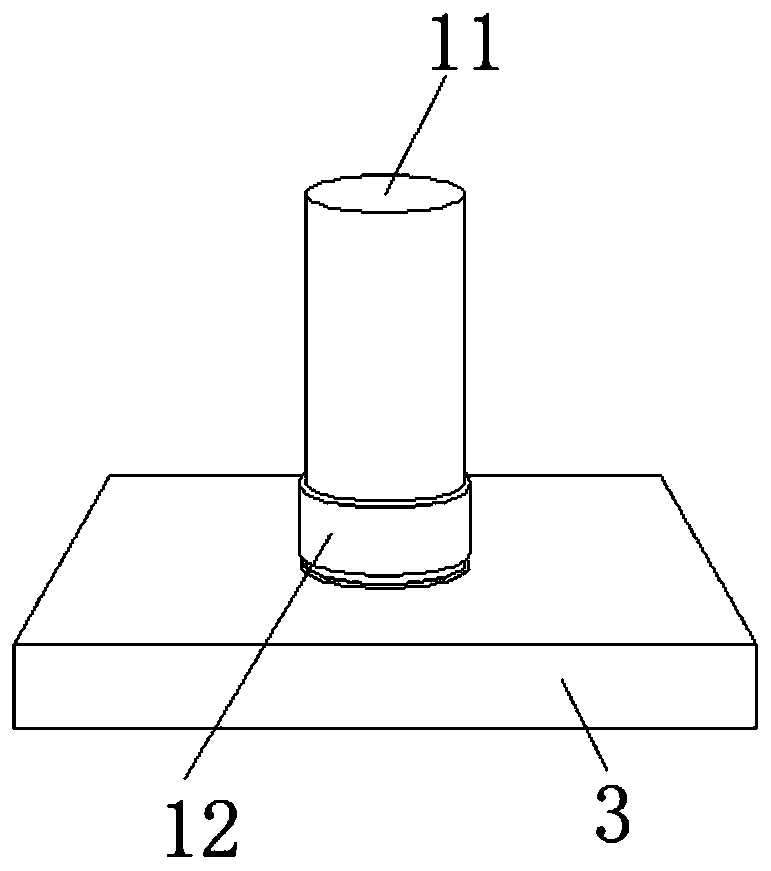

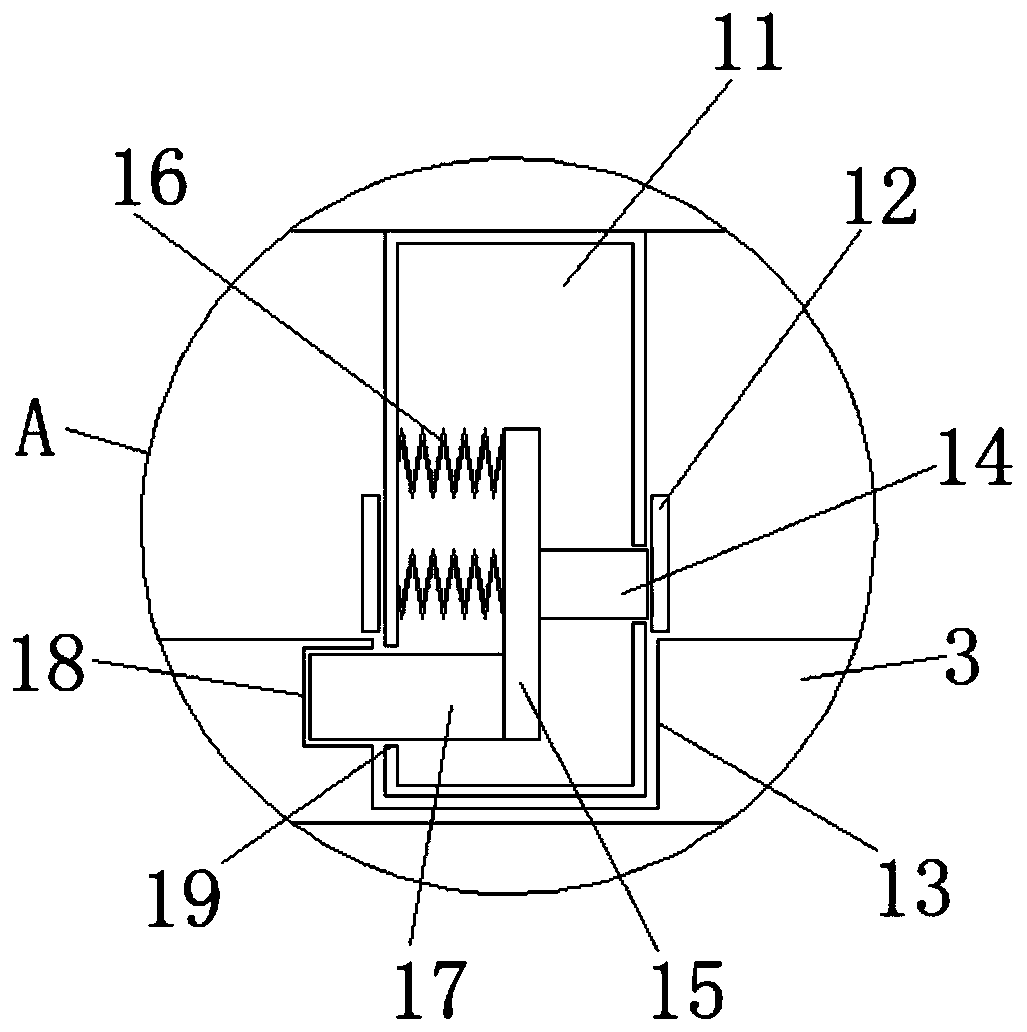

The invention discloses a plate shearer capable of positioning plates accurately. The plate shearer comprises a machine body (1), a working table (2) and a plate shearing blade (3) capable of making reciprocating motions vertically along the machine body (1), wherein the moving direction of the plate shearing blade (3) is perpendicular to a table board of the working table (2), a shearing structure is formed by the plate shearing blade (3) and the edge of the working table (2), a boss (4) perpendicular to the table board of the working table (2) is arranged on the working table (2), the boss (4) is perpendicular to the plate shearing blade (3), a cylinder I (5) parallel to the boss (4) is mounted on the table board of the working table (2), an electromagnetic valve is mounted on the cylinder I (5), and a displacement sensor is mounted on a piston rod of the cylinder I (5). The plate shearer further comprises a PLC, and the electromagnetic valve and the displacement sensor are both connected with the PLC. The plate shearer has the advantages that line marking is not needed, the automation degree is high, operation is easy, and the plates can be positioned accurately.

Owner:SICHUAN GALAXY STEEL STRUCTURE ENG

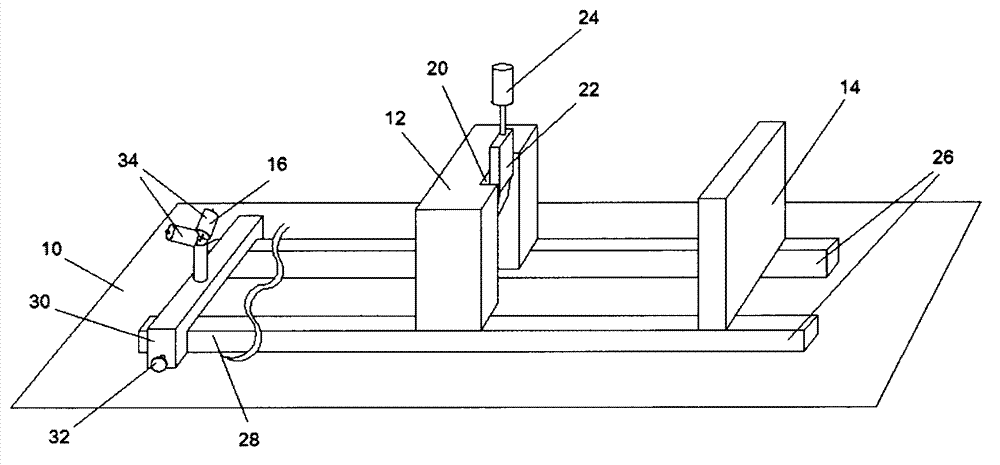

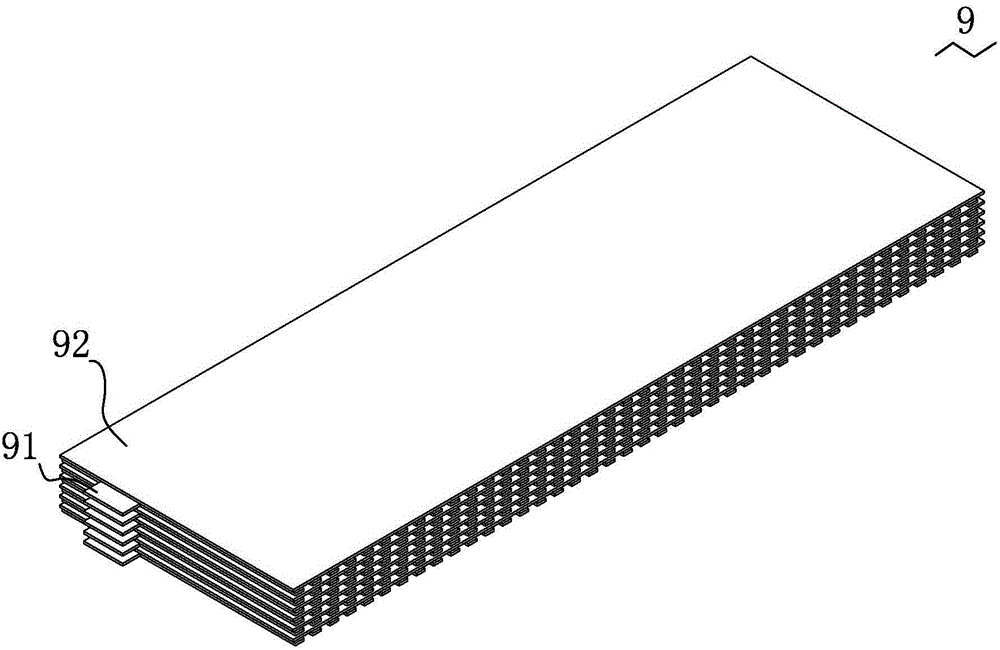

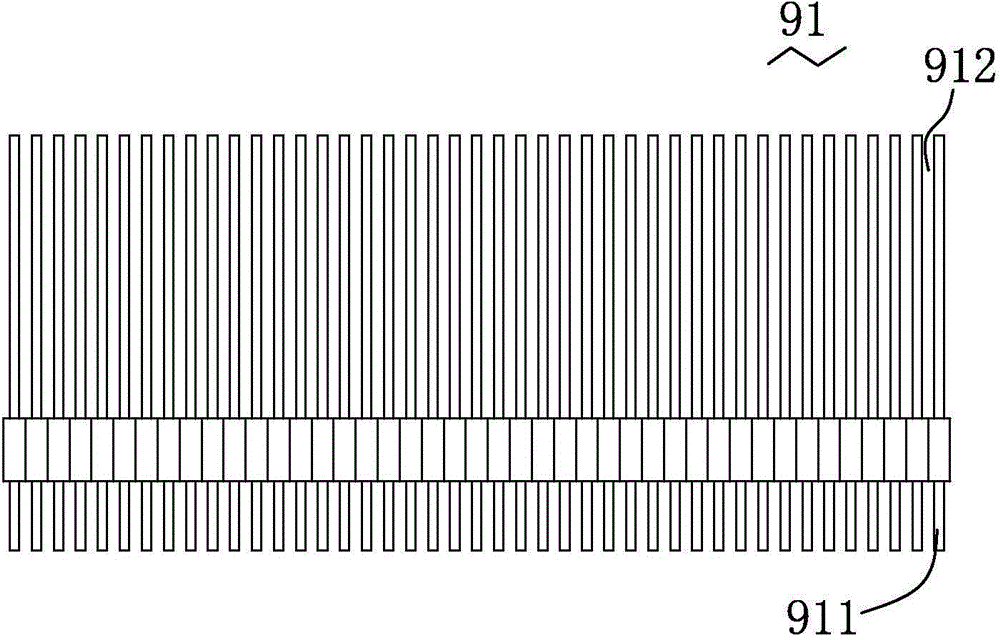

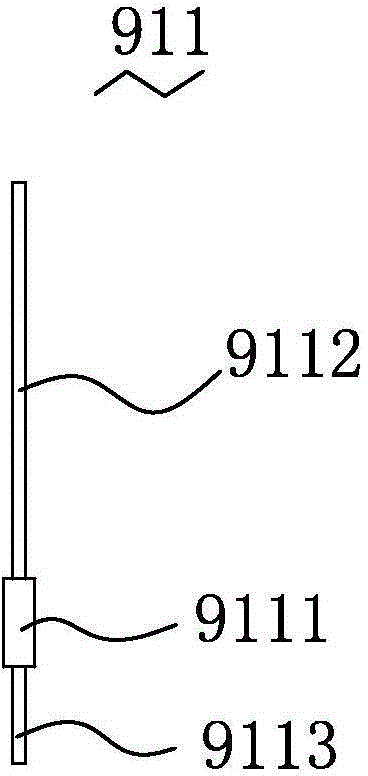

Sheet type tab processing device

ActiveCN105618835AImprove stabilityHigh precisionFinal product manufactureSecondary cells manufactureEngineeringTransfer mechanism

The invention discloses a sheet type tab processing device. The processing device comprises a machine frame, a lifting mechanism, a transferring mechanism, a restoration material cutting mechanism and a feeding mechanism, wherein the lifting mechanism, the transferring mechanism, the restoration material cutting mechanism and the feeding mechanism are installed on the machine frame. The restoration material cutting mechanism comprises a restoration unit, a material cutting unit and a driving unit, wherein the restoration unit is used for conducting restoration processing on a plate of tabs, the material cutting unit is used for segmenting a sheet type tab from the plate of tabs in a third set position, and the driving unit is used for driving the material cutting unit to move longitudinally. The material cutting unit comprises a hook, a cutting knife and a pressing block, wherein the hook is capable of downwards extending into a clearance between two sheet type tabs at the most front end of the plate of tabs so as to hook the tabs to move forwards, so that the sheet type tabs at the most front end of the plate of tabs are located at the third set position; the cutting knife can move downwards for cutting apart the joint of the two sheet type tabs at the most front end of the plate of tabs; the pressing block is capable of tightly pressing the plate of tabs downwards when the cutting knife does cutting action downwards. The sheet type tab processing device is compact in structure, the sheet type tabs are high in segmentation stability and precision, and the device can be well suitable for segmentation processing of plate type pole pieces.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

Steel bar punching and blanking machine with automatic feeding function

InactiveCN105215465AWith automatic feeding functionSimple structureNibbling shearing machinesShearing machine accessoriesPunchingSteel bar

The invention discloses a steel bar punching and blanking machine with the automatic feeding function. The steel bar punching and blanking machine comprises a base, a locating device, a cutter device and a feeding device. The cutter device comprises a cutter holder and a return spring. The feeding device comprises a pressure sensor, vertical clamping rollers and horizontal clamping rollers. In work, a steel bar manually penetrates a locating hole of a locating sleeve through the vertical clamping rollers and the horizontal clamping rollers, and the steel bar is pushed by the feeding device to move forwards; after the front end of the steel bar abuts against the pressure sensor, a controller controls a press head of a hydraulic machine to move downwards to push a cutter to move downwards, and the steel bar is then punched at the stipulated length; and after the steel bar is punched, the cutter returns to the original position upwards under the effect of the return spring, and meanwhile short-section materials generated after punching operation fall into a collecting device through a discharging groove and a discharging hole. The steel bar punching and blanking machine with the automatic feeding function is simple in structure, punching operation is easy and convenient, the automatic feeding function is achieved, and production efficiency is high.

Owner:CHONGQING CHANGZHAN MACHINERY

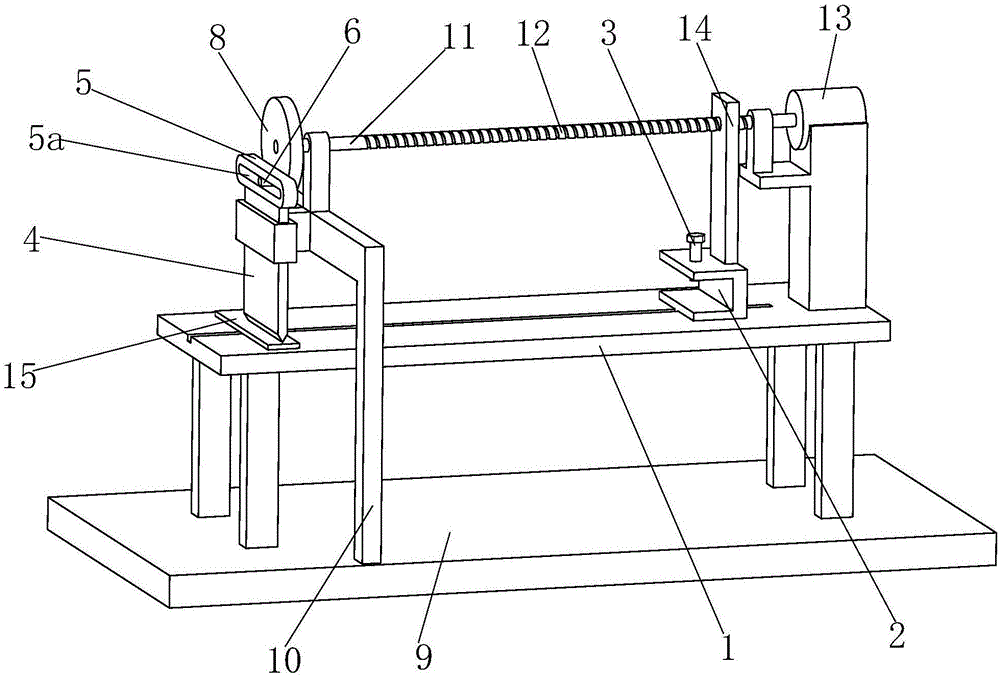

lead ingot slicer

InactiveCN102275007AWon't warpWon't snapNibbling shearing machinesShearing machine accessoriesHydraulic cylinderEngineering

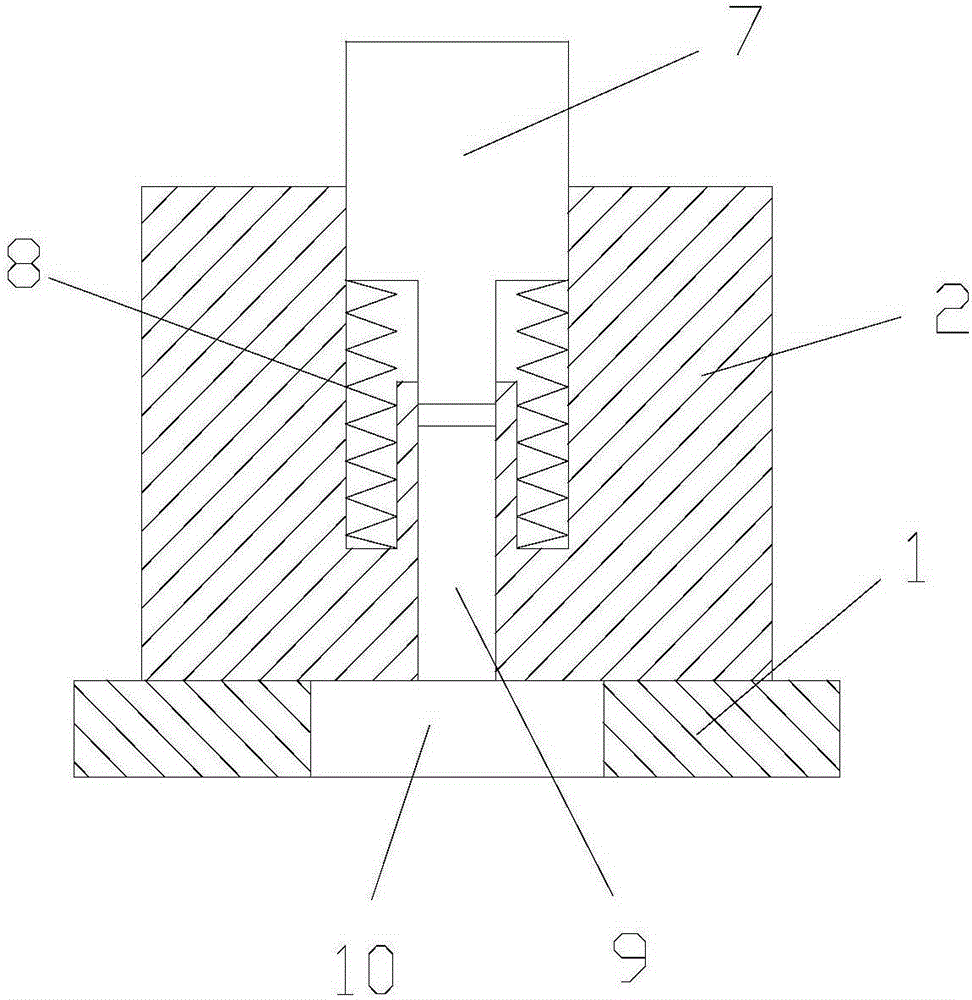

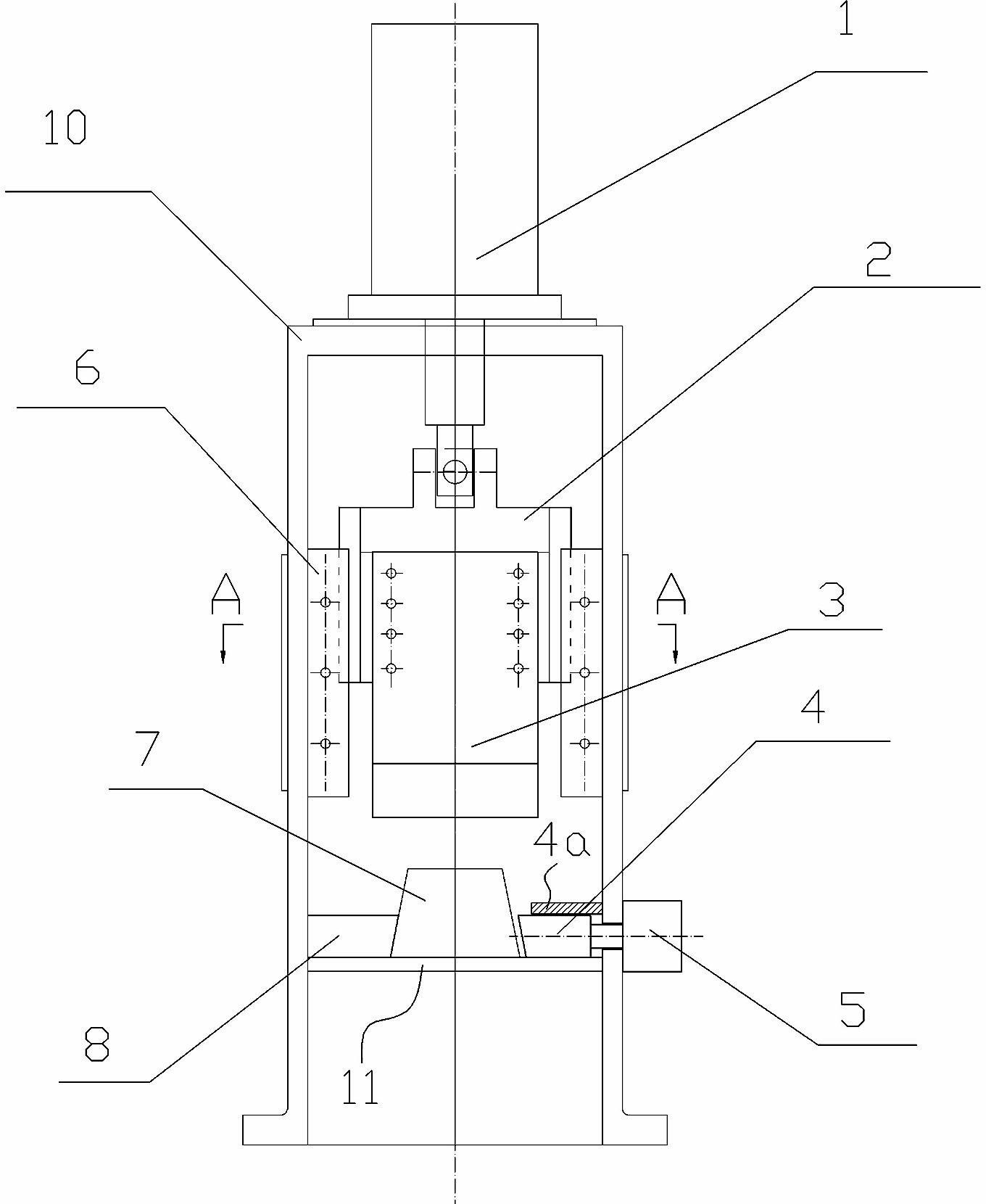

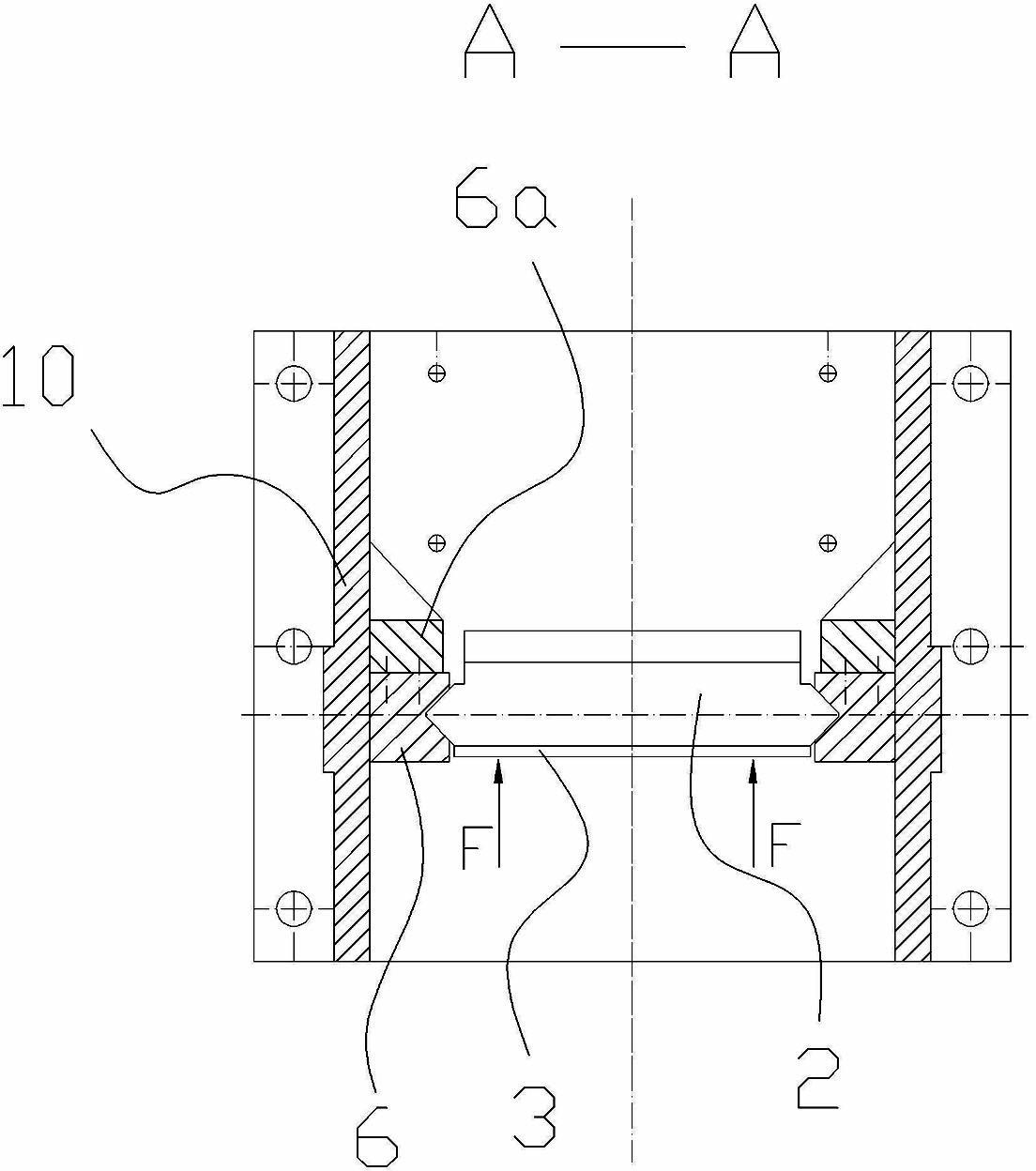

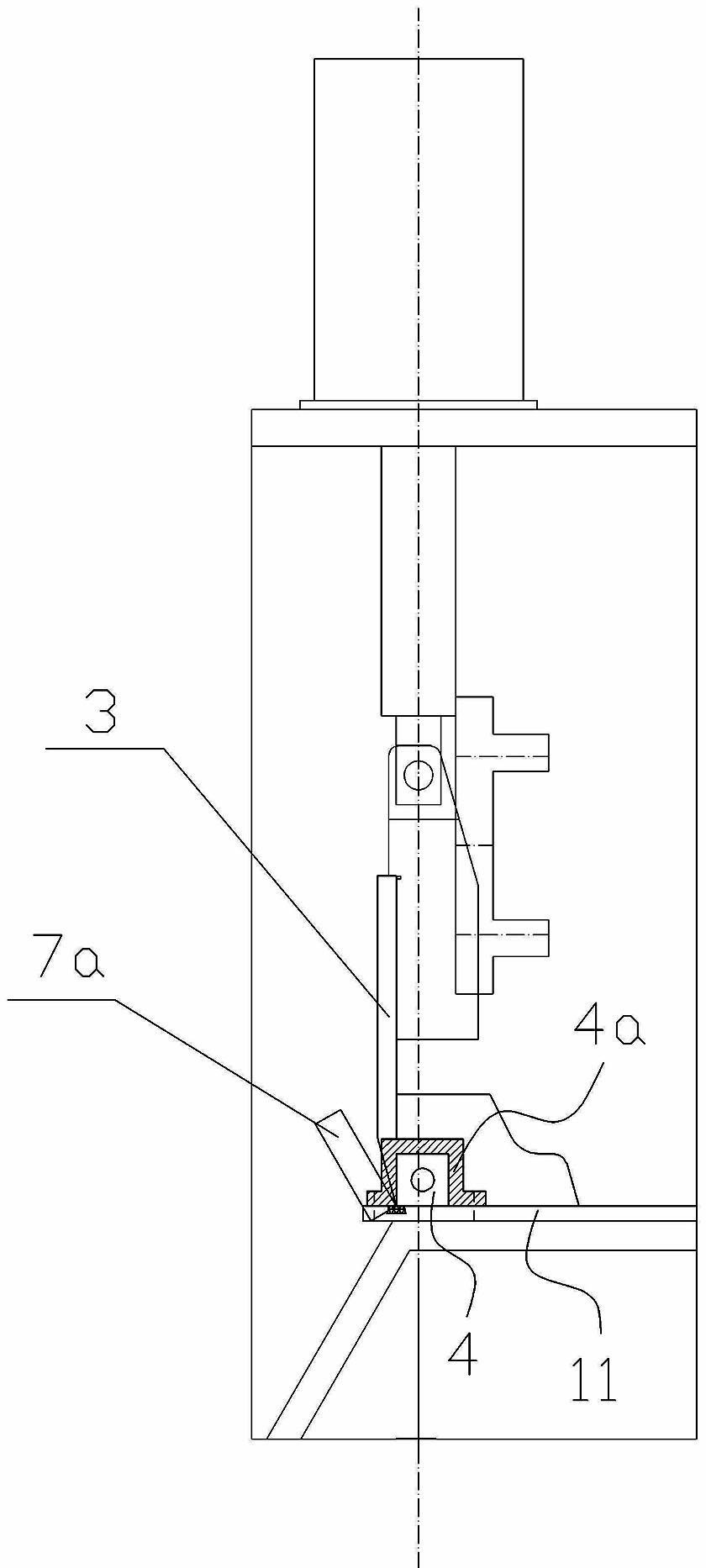

The invention relates to a lead ingot slicing machine. A guide rail (6) is arranged on both sides of a frame (10). A sliding block (2) is arranged in the guide rail (6). The upper end of the slider (2) is connected to the set The hydraulic cylinder (1) at the upper end of the frame is connected, and a cutter (3) is connected to the slider. The lead ingot conveying platform (11) is arranged on the frame below the cutter (3), and the conveying platform on one side of the frame A fixed positioning block (8) is arranged on (11), and a cylinder (5) is arranged on the other side of the frame to connect with a movable positioning block (4), which slides and fits with the guide sleeve (4a). The advantages of the present invention: when the lead ingot is transported to the shearing position, the cylinder pushes the movable positioning block to move laterally to clamp the lead ingot, and the lead ingot will not warp during the shearing process, and the lead ingot can be cut completely. There is less waste and the cutter will not snap. Therefore, the present invention has the advantages of high efficiency, high material utilization rate, long service life and the like.

Owner:乔欣

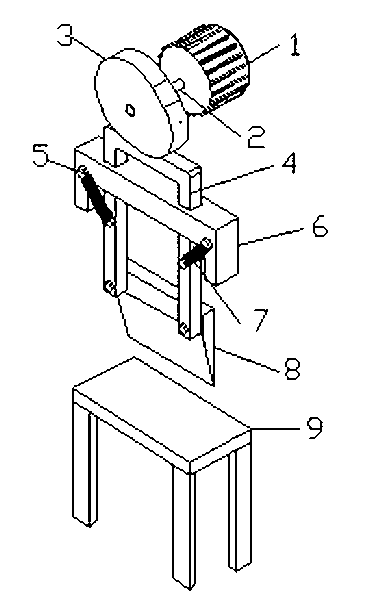

Scrap cutter

InactiveCN103264314AAchieve reductionConvenient collection workNibbling shearing machinesMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses a scrap cutter. The scrap cutter comprises a motor (1), wherein the motor (1) is connected with a cam (3) through a rotary shaft (2); a driven rod (4) is positioned below the cam (3) and is arranged in a sliding groove of a rack (6); reset springs (7) are arranged on the rack (6) and are connected with the driven rod (4); a cutting knife (8) is connected to the lower end of the driven rod (4); and a cutting board (9) is arranged below the cutting knife (8). According to the scrap cutter, the motor is used as a driver, and the cam (3) rotates to drive the driven rod (4) so as to further drive the cutting knife (8) to reciprocate vertically to cut scraps off. The scrap cutter is reasonable in structural design and high in efficiency, the problem that overlong scraps are taken into a scrap remover through an outlet of the scrap remover can be effectively solved, and the scrap remover is prevented from being damaged.

Owner:GUIZHOU UNIV

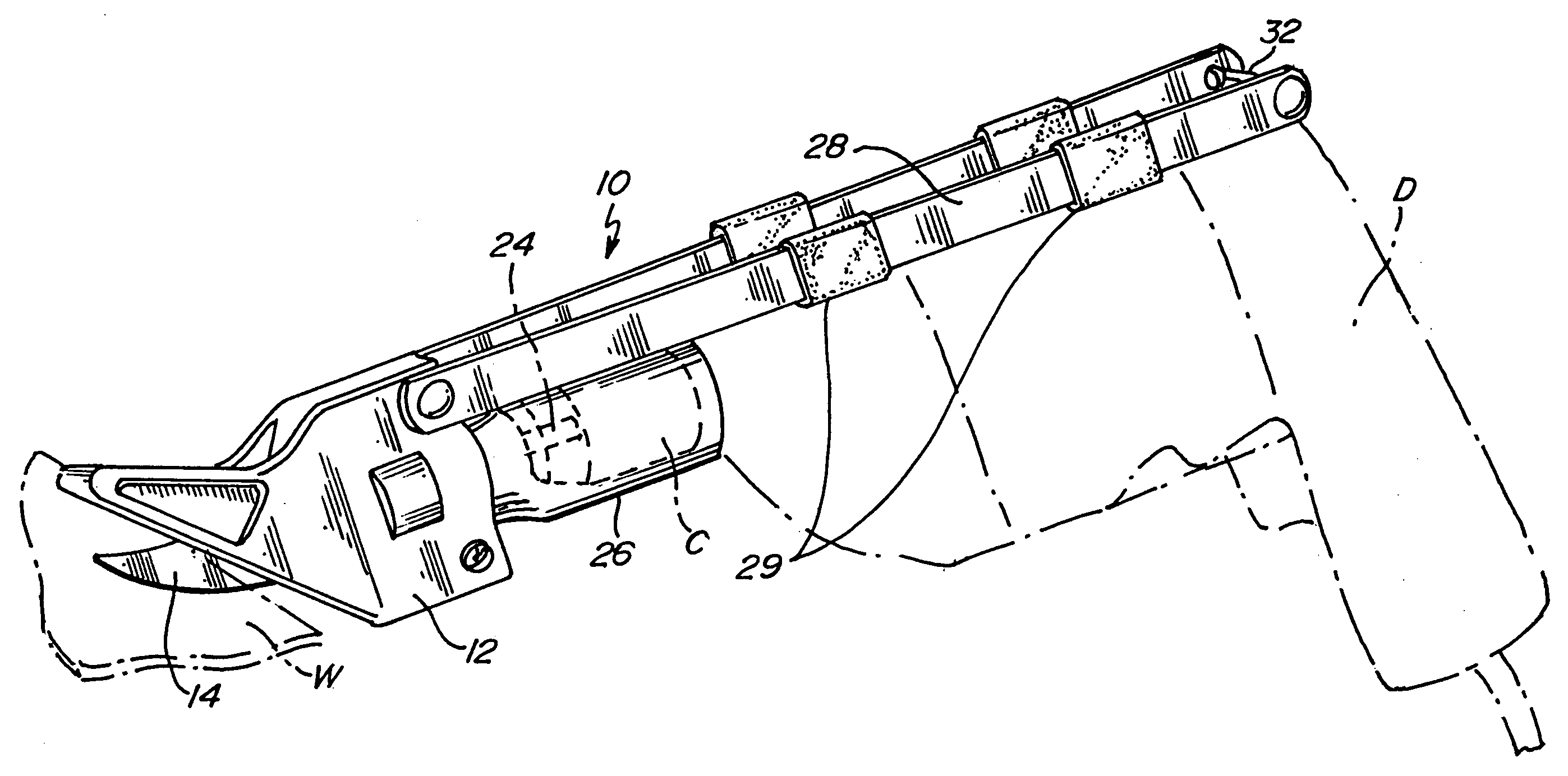

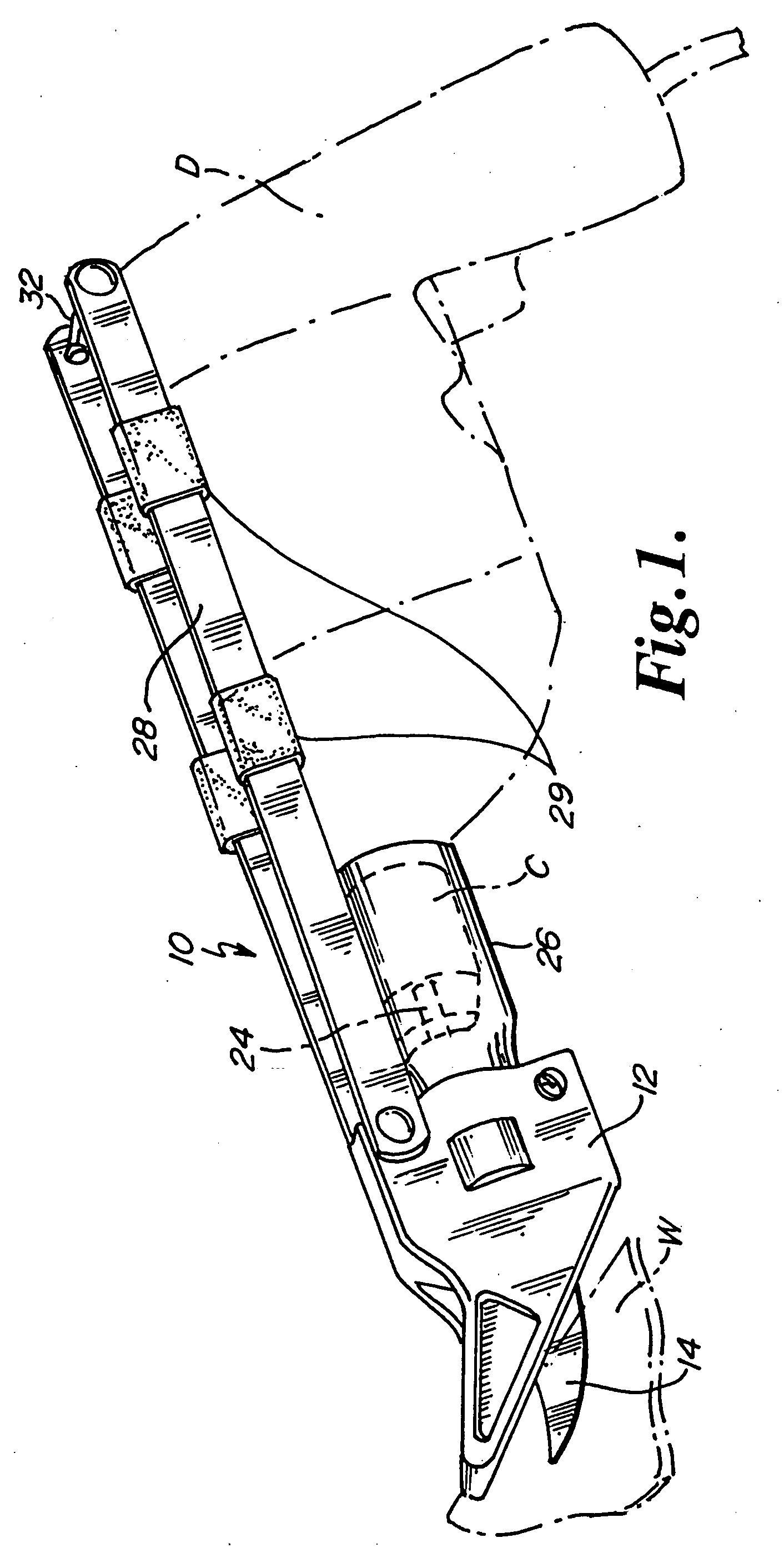

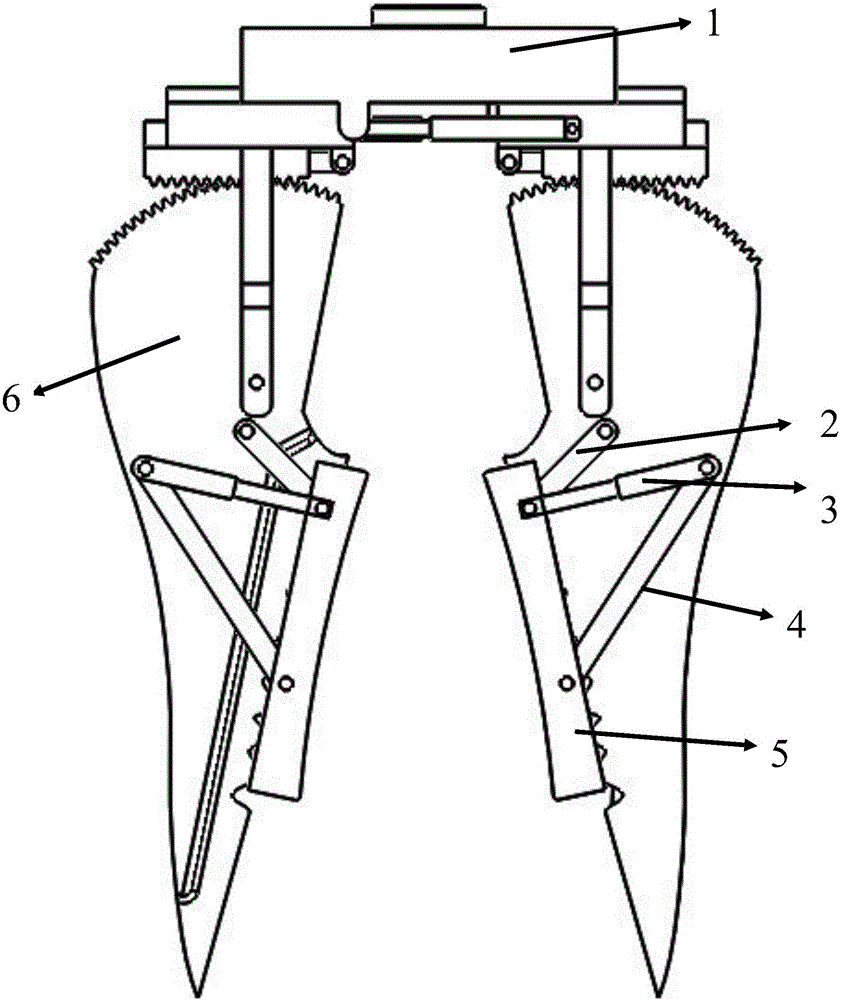

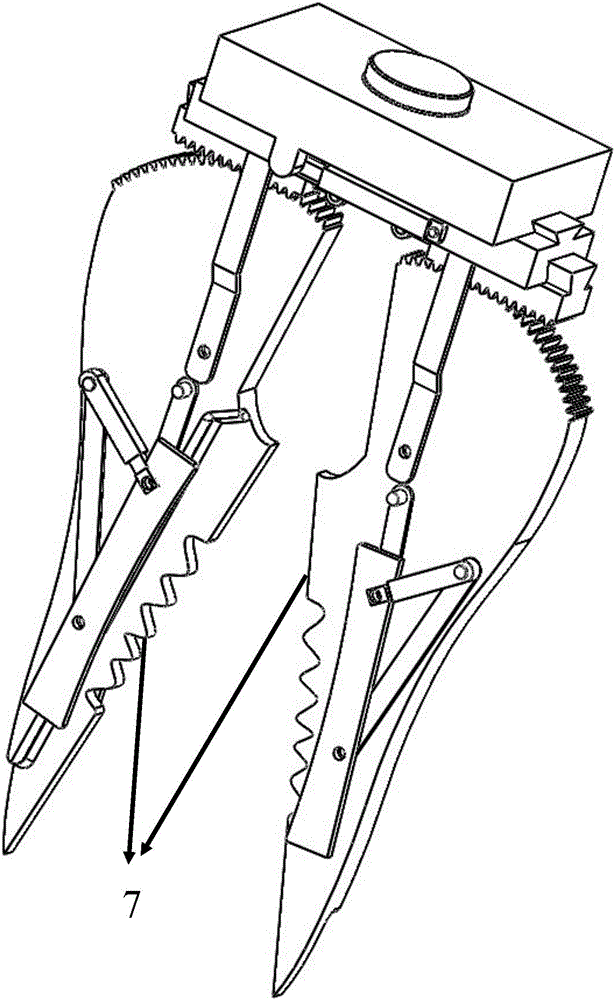

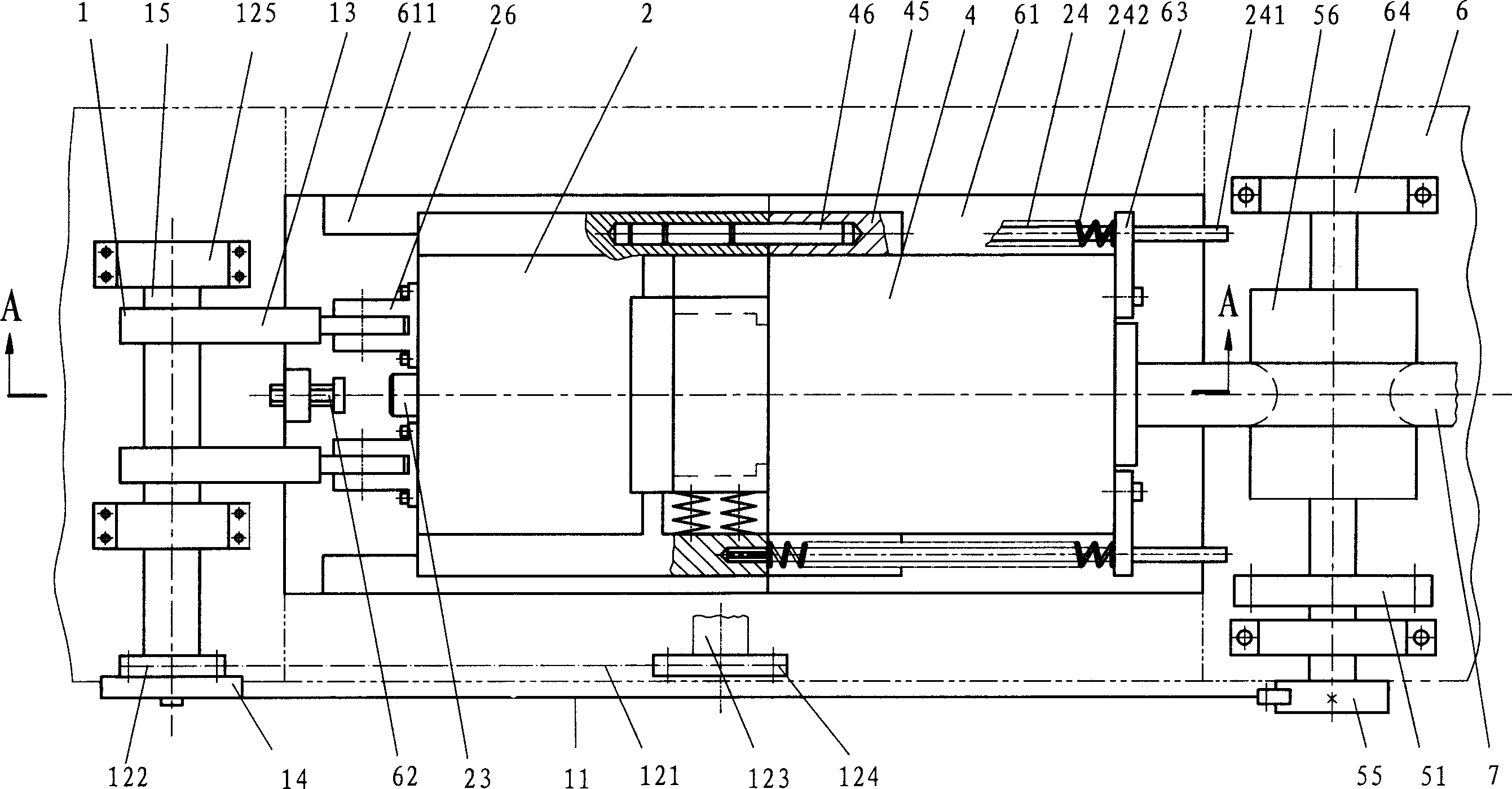

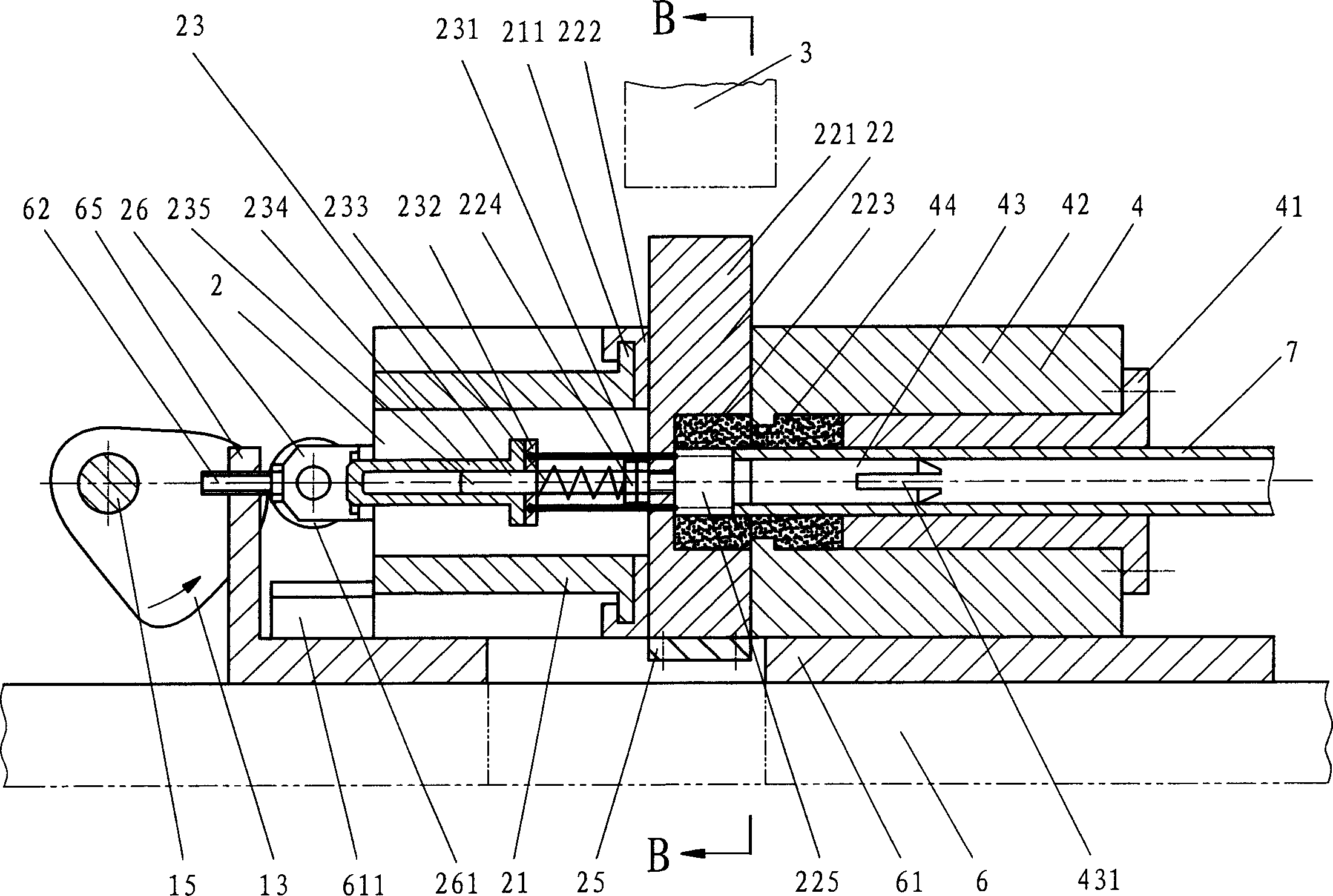

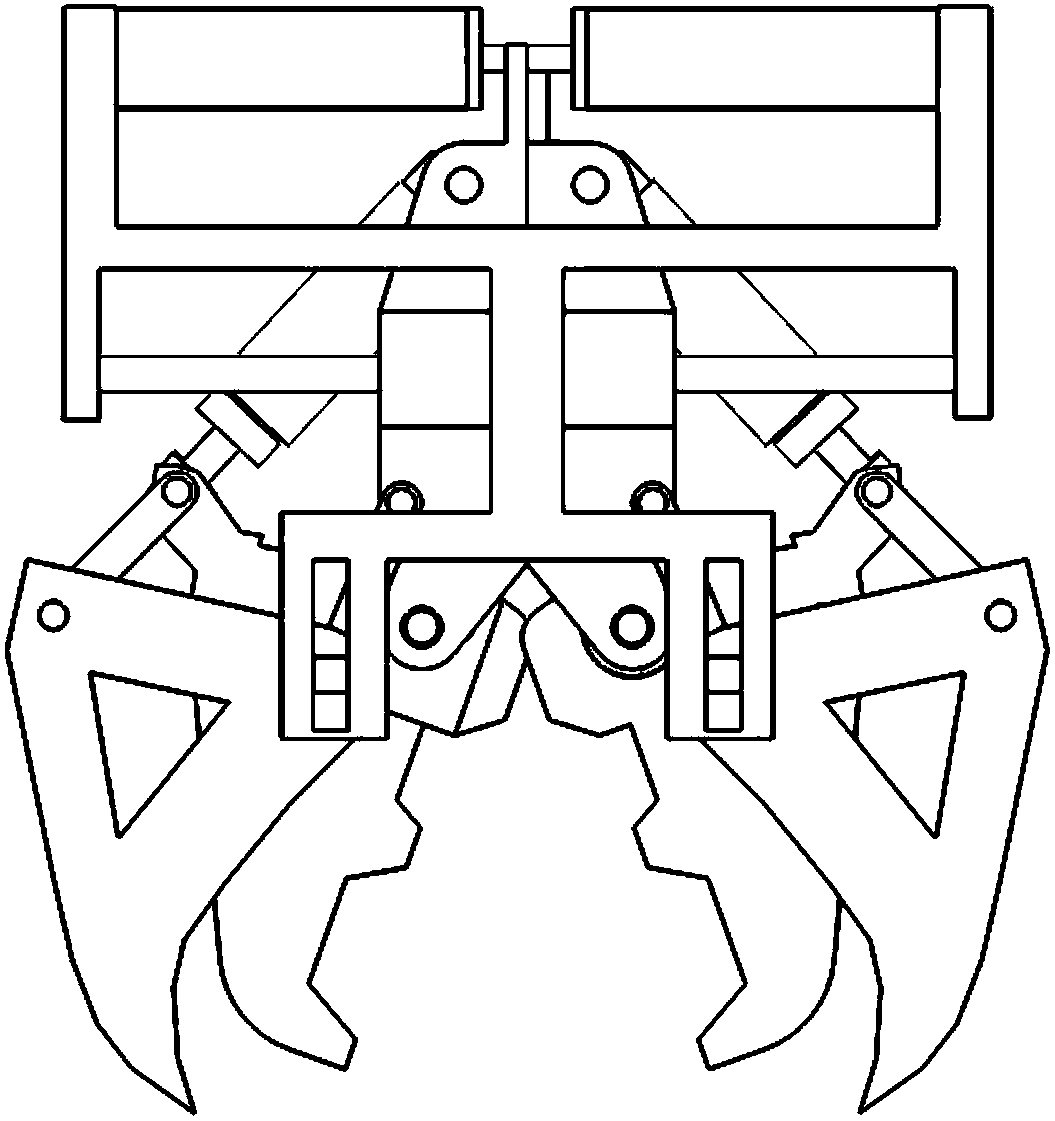

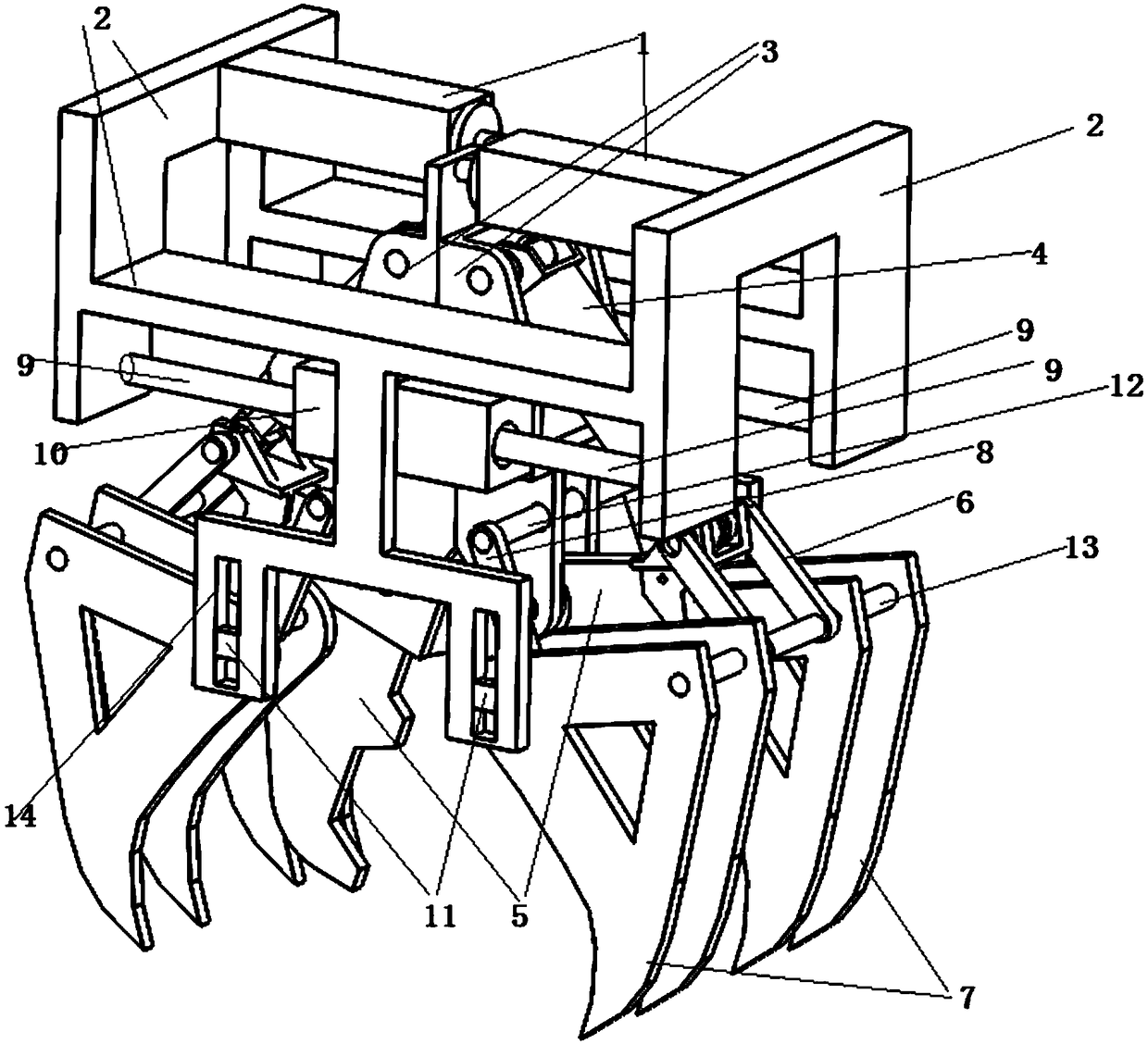

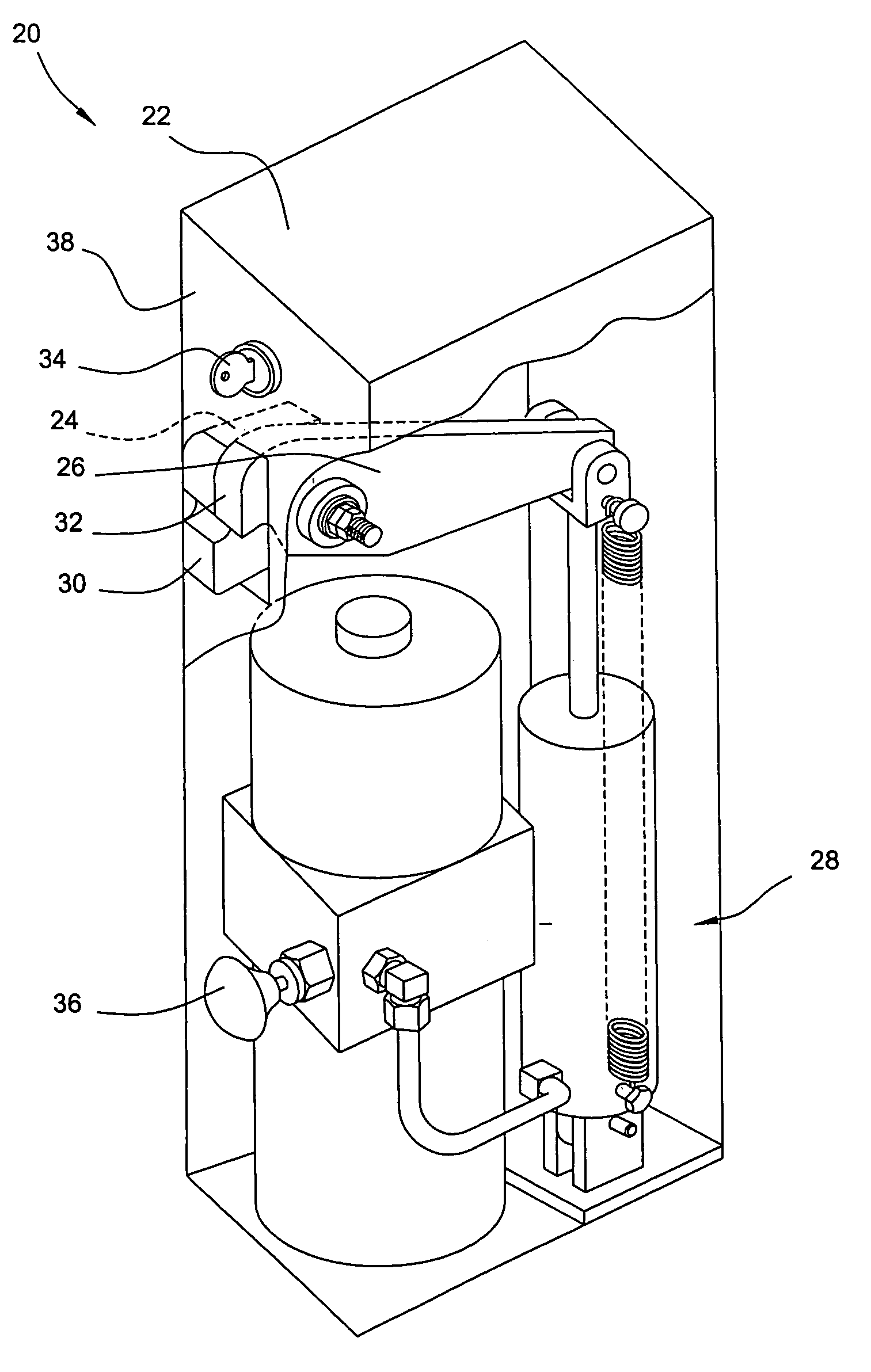

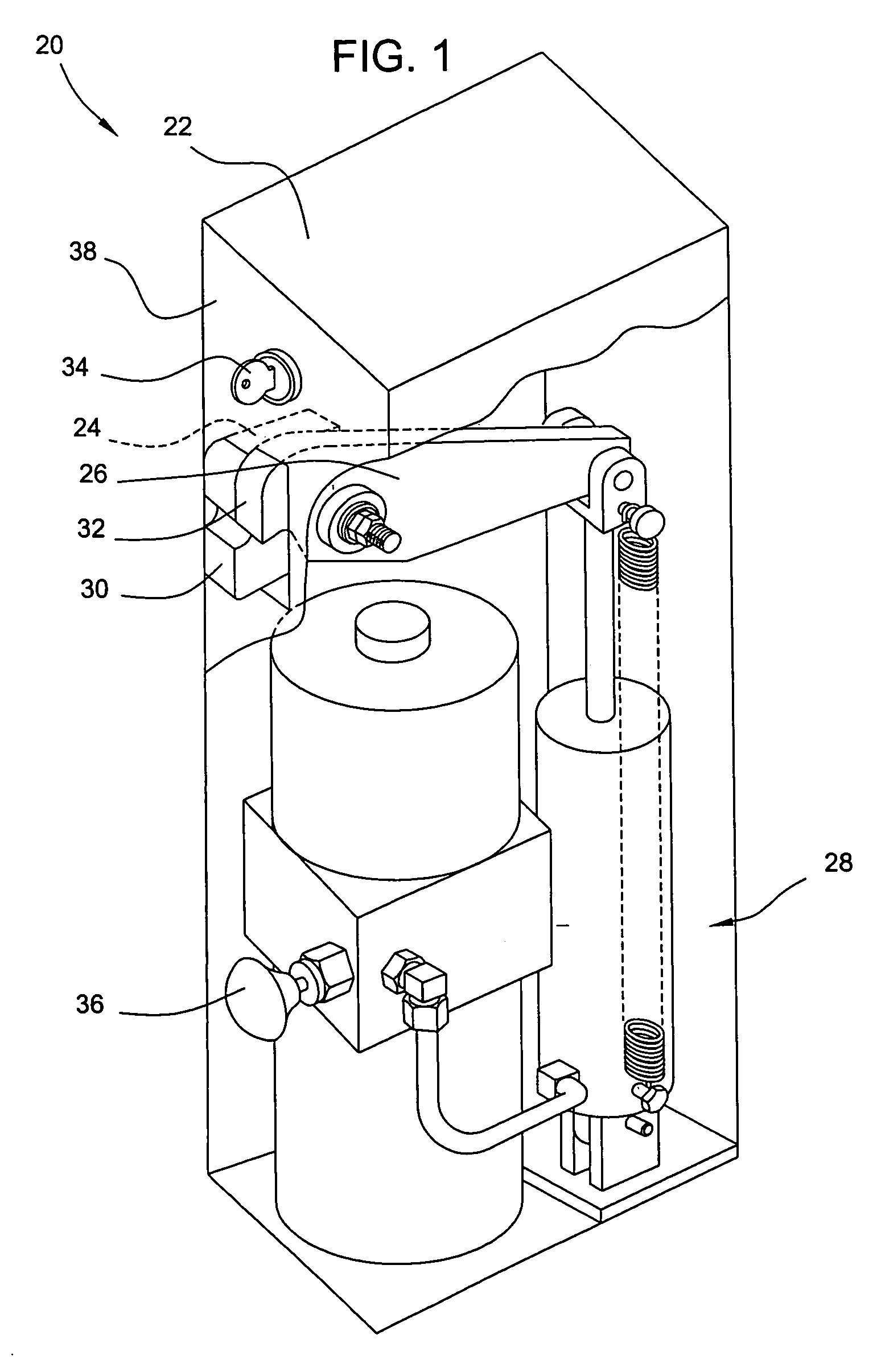

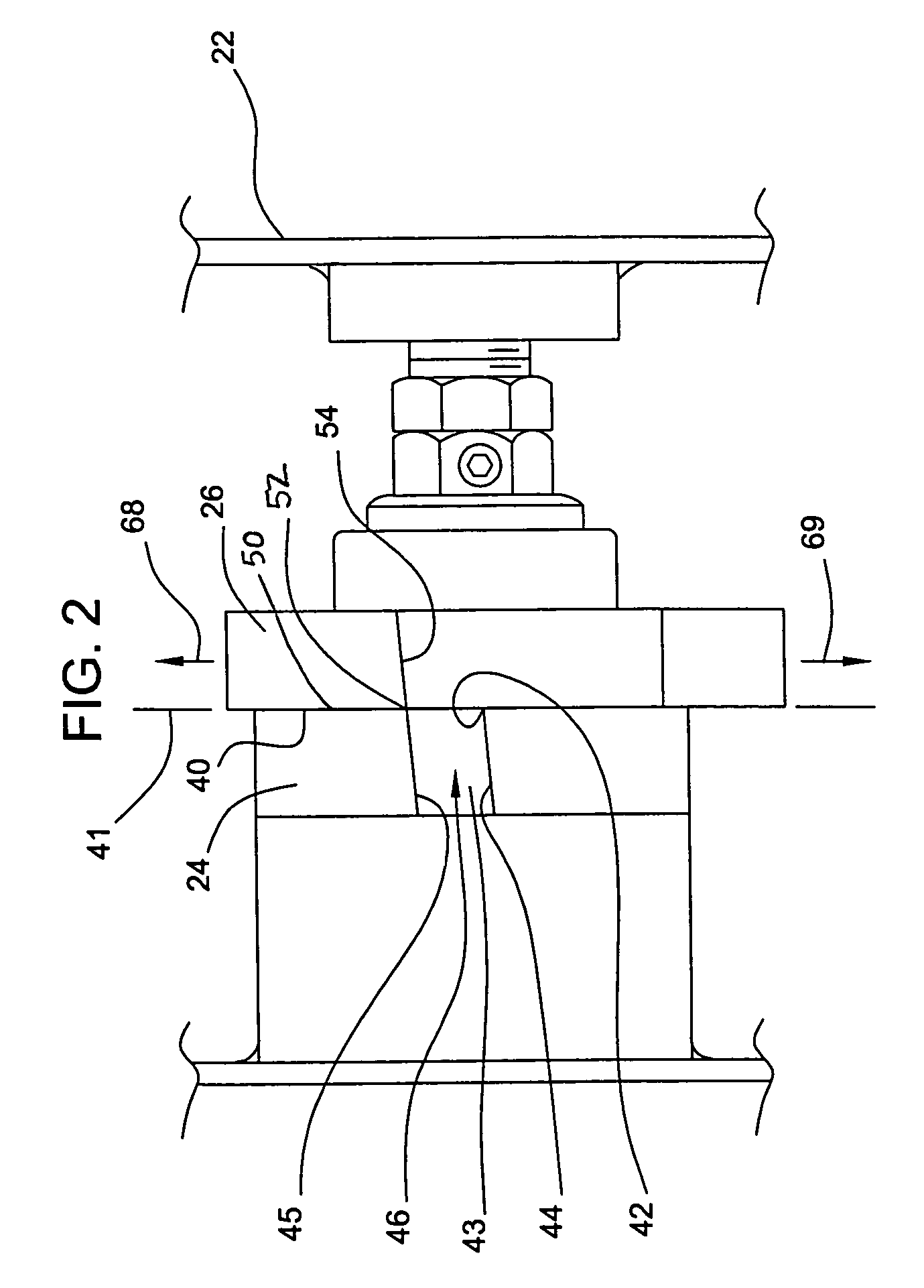

Clamping shearing snatching and seam expanding integral rescue tool

ActiveCN105750627AAdd grab functionSimple structureFire rescueNibbling shearing machinesHydraulic cylinderEngineering

The invention discloses a clamping shearing snatching and seam expanding integral rescue tool, which comprises a clamping shearing holding snatching and seam expanding conversion device, a constant shearing force device, holding and snatching mechanisms of four pairs of four-connecting-rod mechanisms and a seam expanding device, wherein a deformation hydraulic cylinder of the clamping shearing holding snatching and seam expanding form conversion device and a slide block realize the mutual switching among the clamping shearing, holding snatching and seam expanding forms; the constant shearing force device provides uniform shearing force for the clamping and shearing process; the secondary collapse in the rescue process is prevented; a holding snatching hydraulic cylinder of the four-connecting-rod holding snatching mechanism controls the position of holding snatching claws to realize the shielding and the work of clamp shear blades, and is matched with the clamping shearing holding snatching and seam expanding conversion device to complete the holding and snatching operation. The four functions including the clamping, shearing, holding snatching and seam expanding are integrated into one tool; the structure is reasonable and creative; the operation is simple and convenient; the dealing with complicated rescue environment can be realized; the complicated residue operation can be fast completed; the rescue efficiency is improved.

Owner:江阴智产汇知识产权运营有限公司

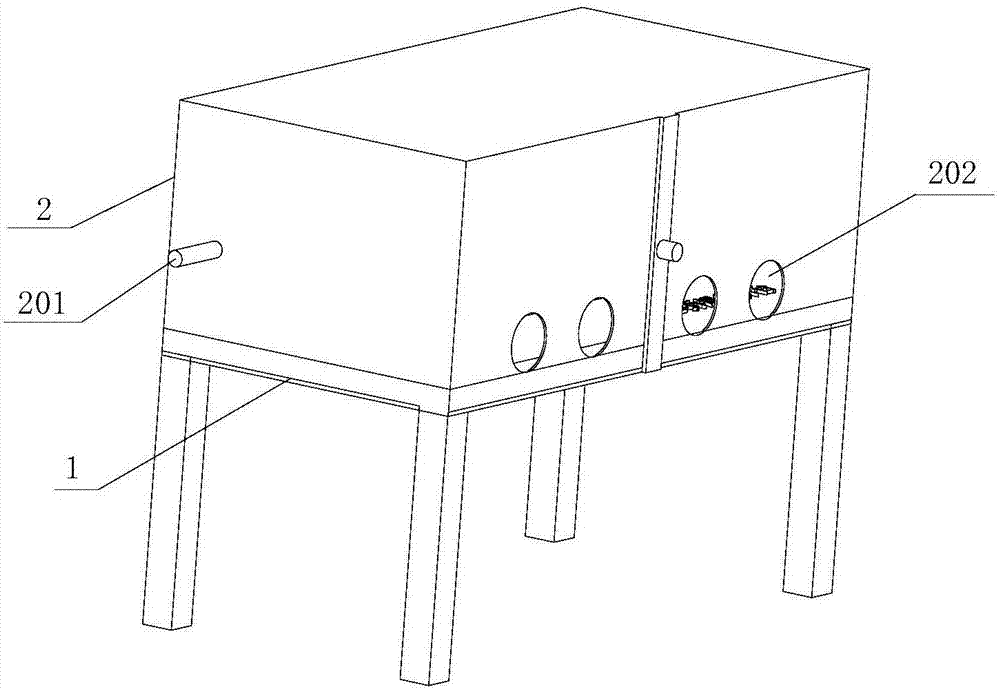

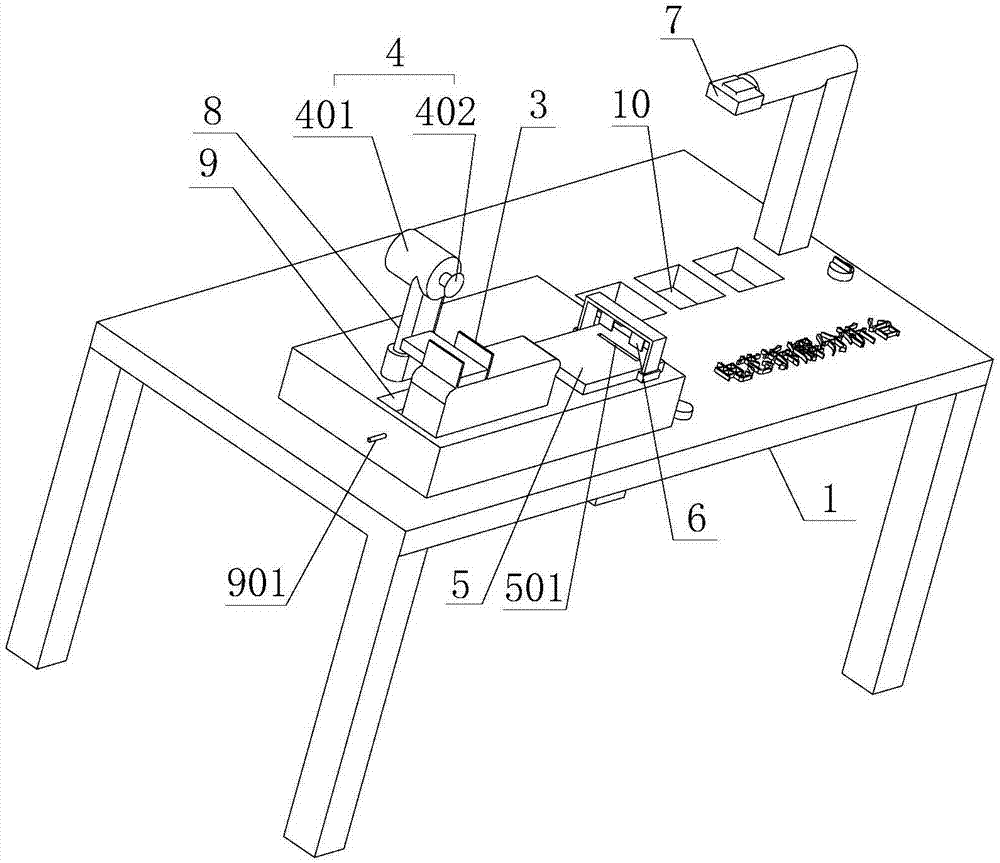

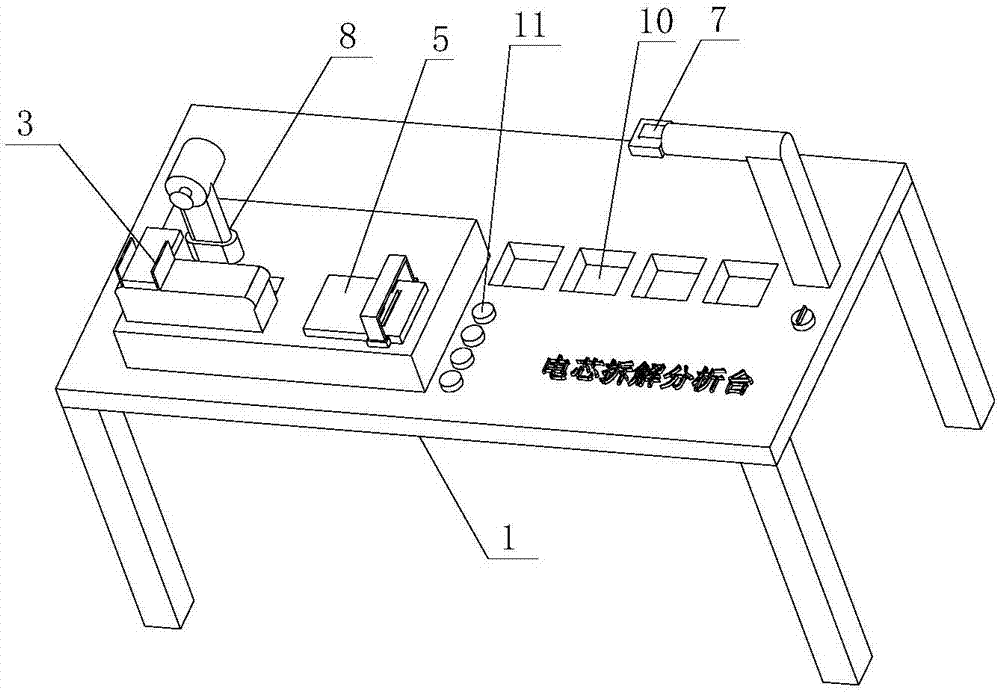

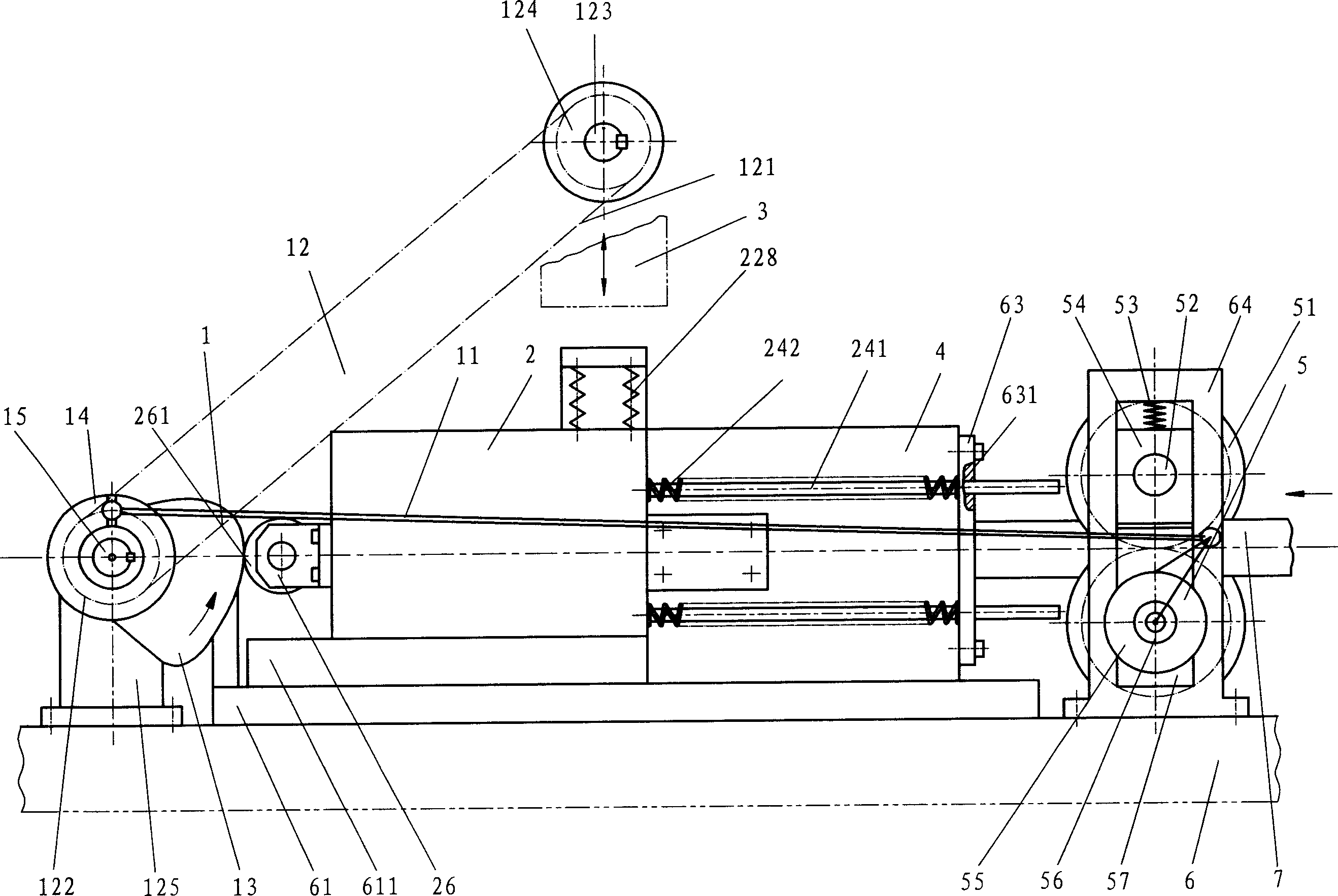

Fast and safe lithium ion battery dismantling and analyzing device

InactiveCN107344291AAvoid contactProtection securityOther manufacturing equipments/toolsGrinding machinesElectrical batteryLithium-ion battery

The invention discloses a lithium-ion battery rapid and safe disassembly analysis device, comprising: an operation platform and a box body arranged above the operation platform and cooperating with the operation platform to form a closed space above the operation platform, wherein: the operation platform includes a disassembly area and an analysis area located on one side of the dismantling area; the dismantling area is equipped with a battery case cutting mechanism for cutting the battery case and a battery tab cutting mechanism for cutting the battery tab; the analysis area A camera is installed at the place; the box body is made of transparent material, and the box body is provided with a vacuum interface for external vacuum equipment and an operation port for manual passage. The structure of the invention is simple and compact, and can effectively save manpower and improve work efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Automatic steel tube feeding unit

InactiveCN1806981AImprove flatnessIncrease productivityTube shearing machinesNibbling shearing machinesSteel tubePlunger

The invention relates steel tube automatic baiting unit. The unit comprises moving mould, plunger tip, static model, feeding, transmitting part and operating board. The static model is fixed on the operating board, moving mould is on the guide rail of operating board, the plunger tip is above moving mould, and feeding part is on the end of operating board. The transmitting element of transmitting part is connected with the end of the bent axle of sources of power presser, and the output shaft of transmitting part is connected with feeding part. The static model comprises static model body, static molding, and floating core. The moving mould comprises moving mould body, movable mould part, moving molding, moving core, moving chock, static chock and elastic body. Using the unit, the product can't deform, the cross-section planeness is high, and the productivity is improved. The unit is used to product many kinds of steel tubes whose wall thickness is 2-15mm.

Owner:邬龙达

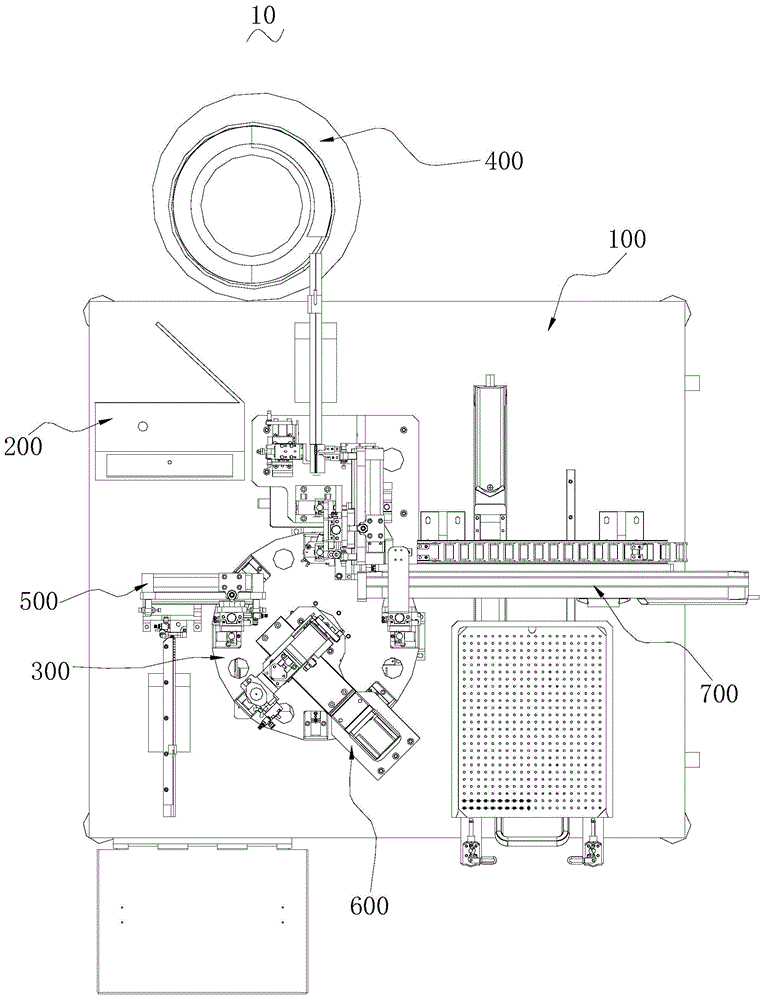

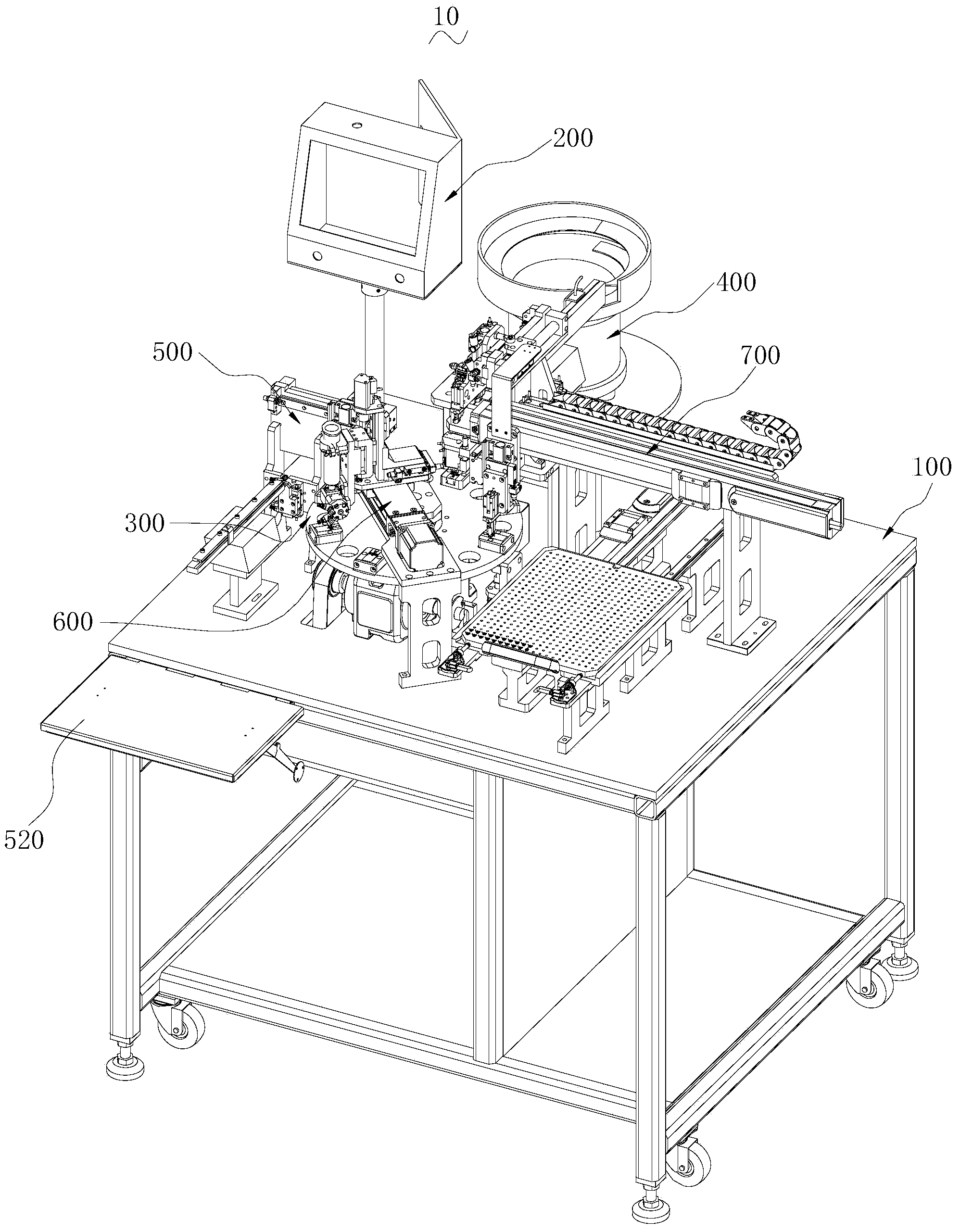

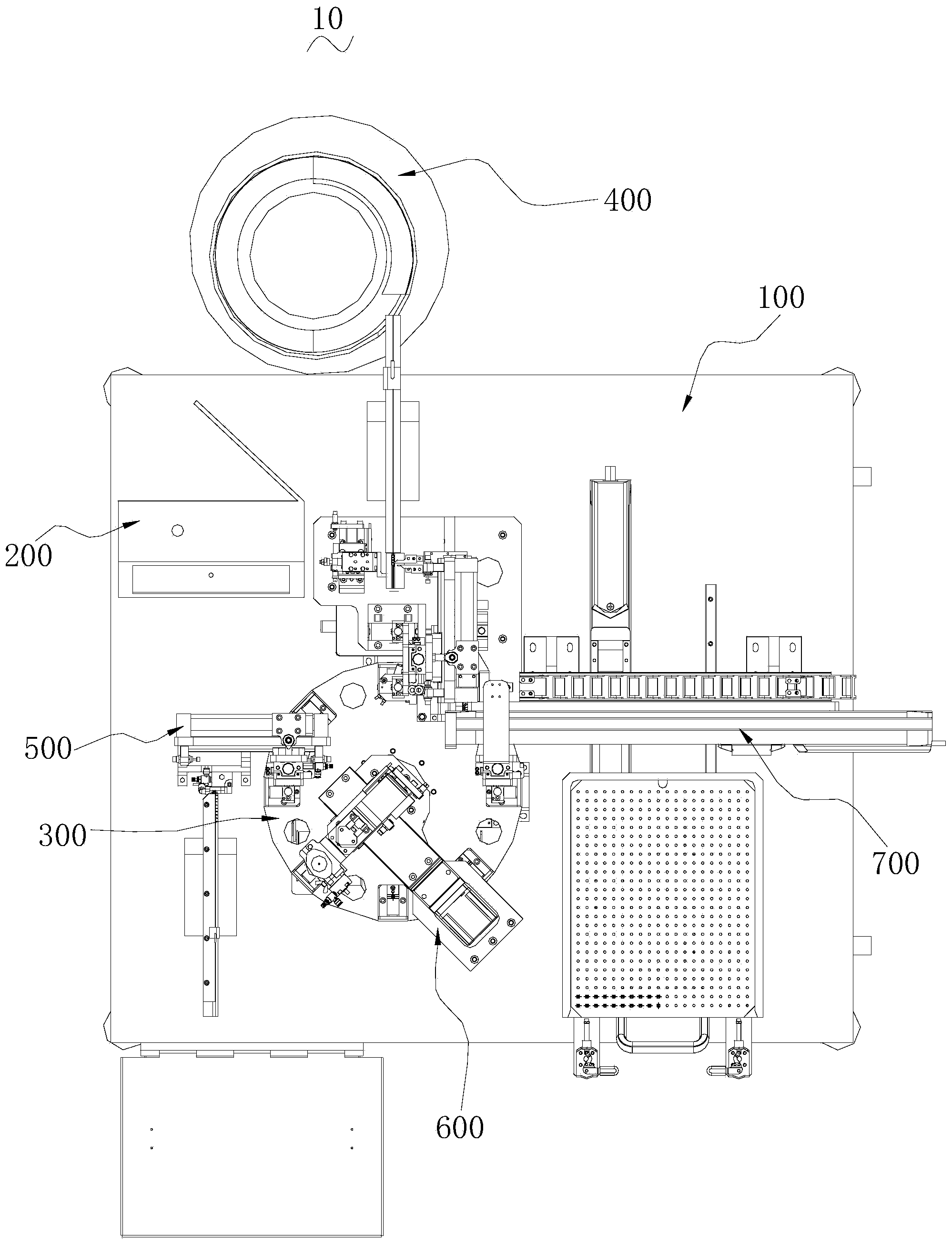

Automatic assembling machine for manufacturing LED (Light Emitting Diode) connection kit

ActiveCN104295577AIncrease productivityImprove product qualityNibbling shearing machinesFastening meansEngineeringLED lamp

The utility model discloses an automatic assembling machine for manufacturing an LED (Light Emitting Diode) connection kit. The automatic assembling machine comprises an operating platform, a rotary plate device, a cutting device, a feeding device, a dispensing device and a collection device, wherein the rotary plate device is arranged on the operating platform, the cutting device, the feeding device, the dispensing device and the collection device are arranged on the operating platform and are sequentially arranged around the rotary plate device. According to the automatic assembling machine for manufacturing the LED connection kit, an operator places an LED lamp on the cutting device only and places a plastic member on the feeding device, so as to automatically complete a preparation technology of the whole LED connection kit; furthermore, compared with a traditional manual way, the automatic assembling machine is higher in production efficiency and higher in product quality.

Owner:济南泰禾雕塑有限公司

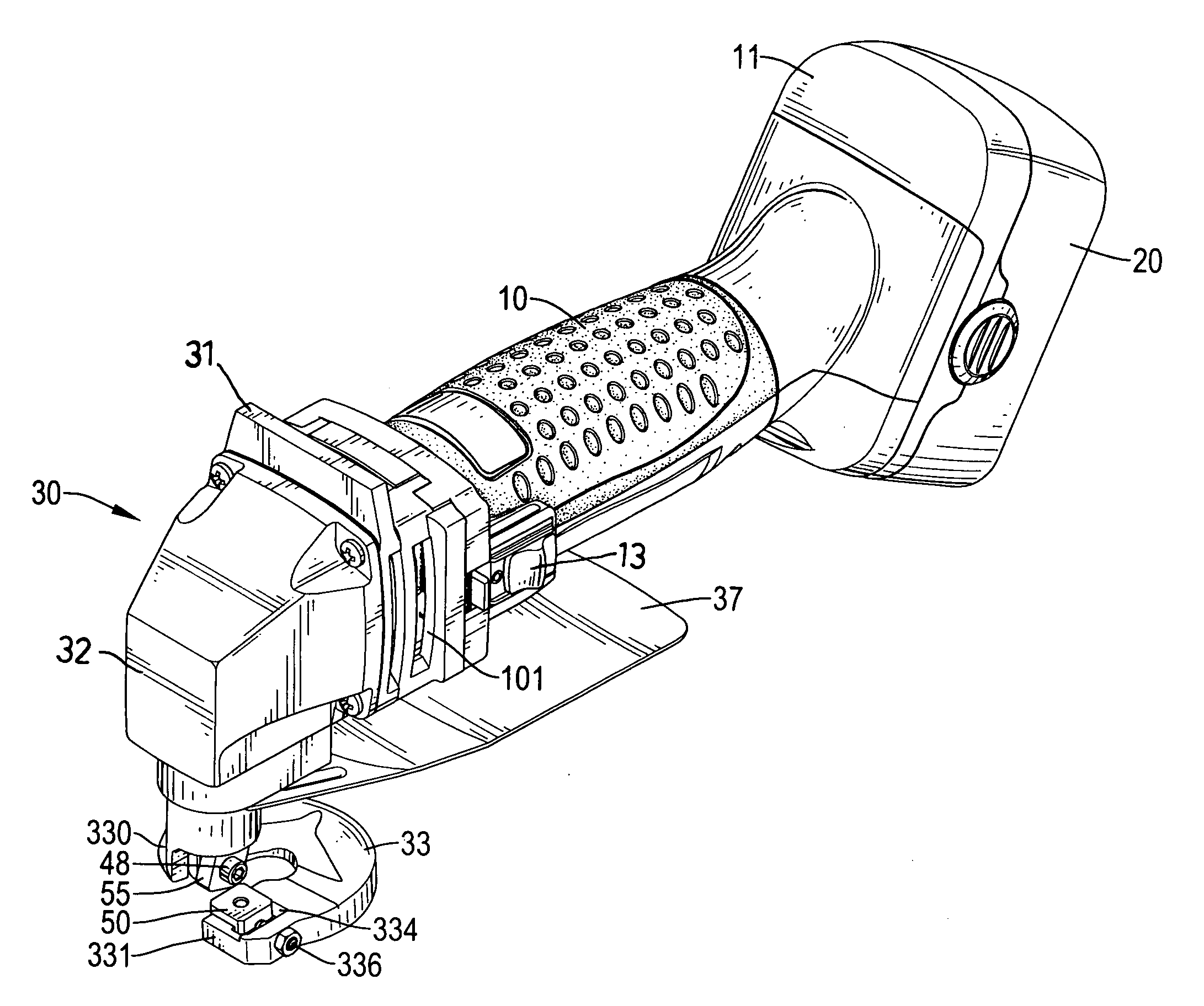

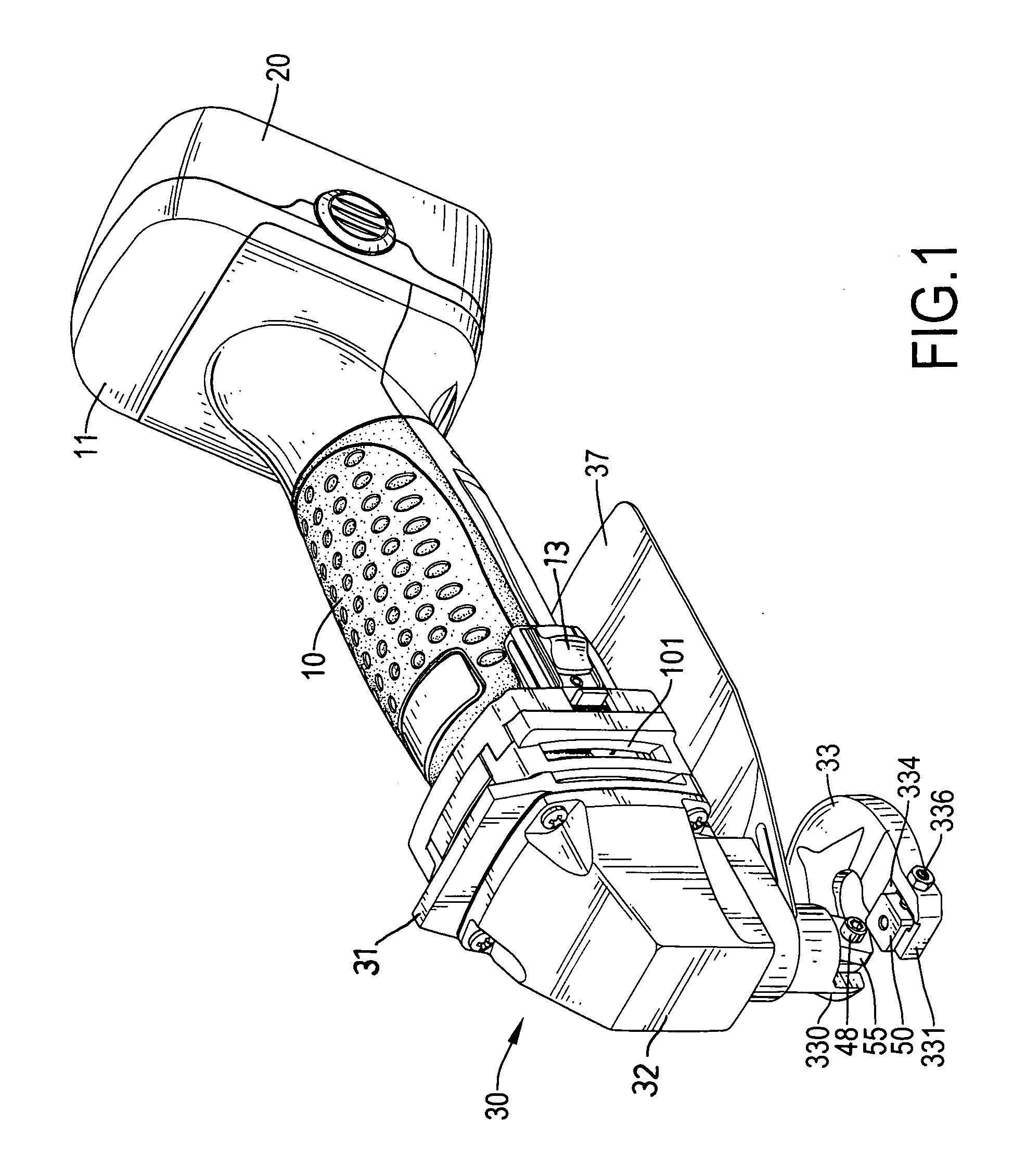

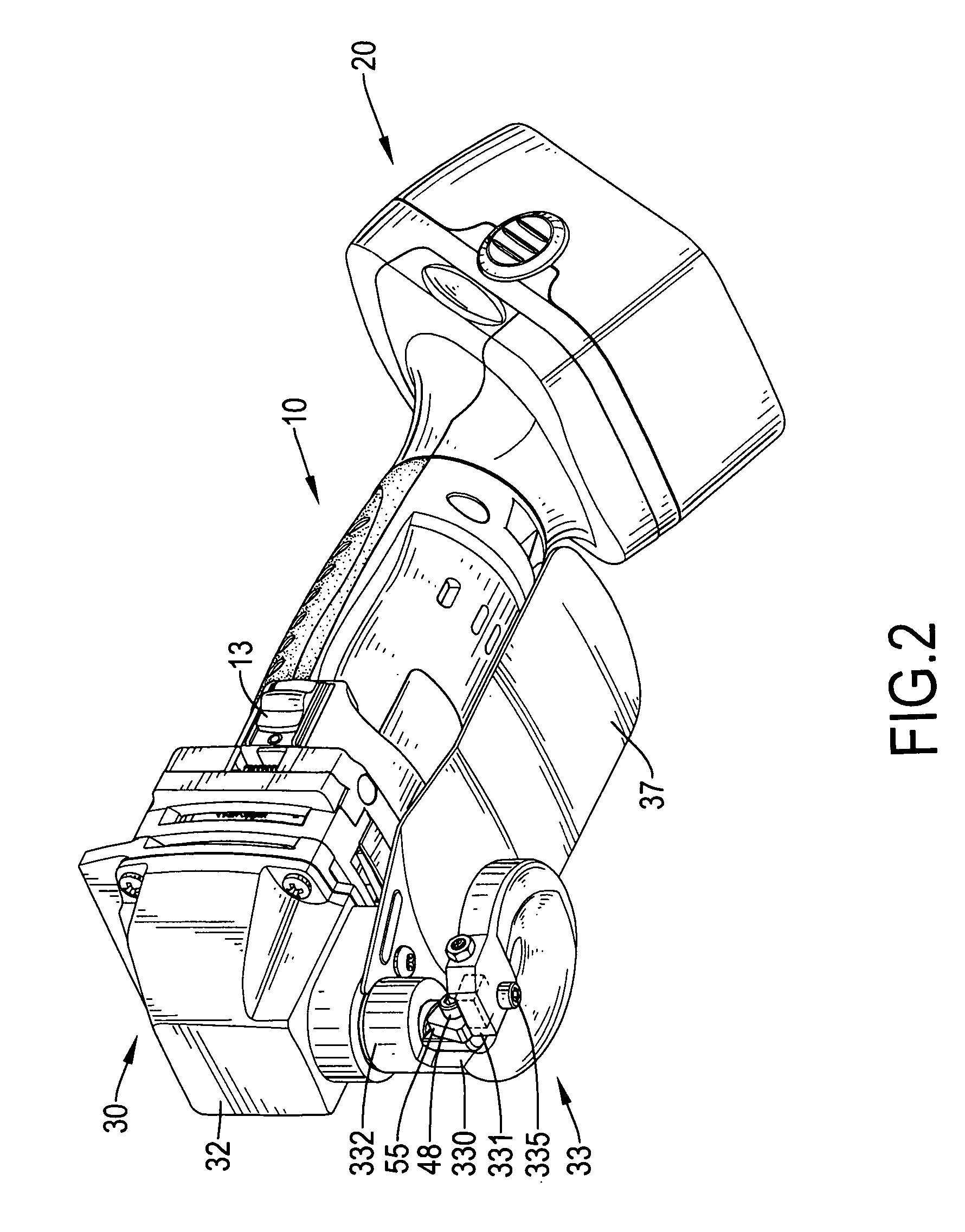

Electric nibbler

InactiveUS20080201961A1Used safely and conveniently and quicklyNibbling shearing machinesMetal working apparatusGear wheelDrive shaft

An electric nibbler has a handle, a battery package, a front cover, a base, a lower blade, a drive device, a transmitting device and an upper blade. The battery package is detachably attached to the battery seat of the handle. The front cover is mounted securely to the handle and has a mounting bracket and a housing. The base is connected securely to the housing and has an upper segment and a lower segment. The lower blade is connected securely to the lower segment. The drive device is mounted in the handle and a drive shaft. The transmitting device is connected to the drive device and has a connecting tube, a transmitting shaft, a drive axle, a gear wheel, a crank and a piston rod. The upper blade is connected securely to the bottom end of the piston rod.

Owner:TECHWAY INDAL

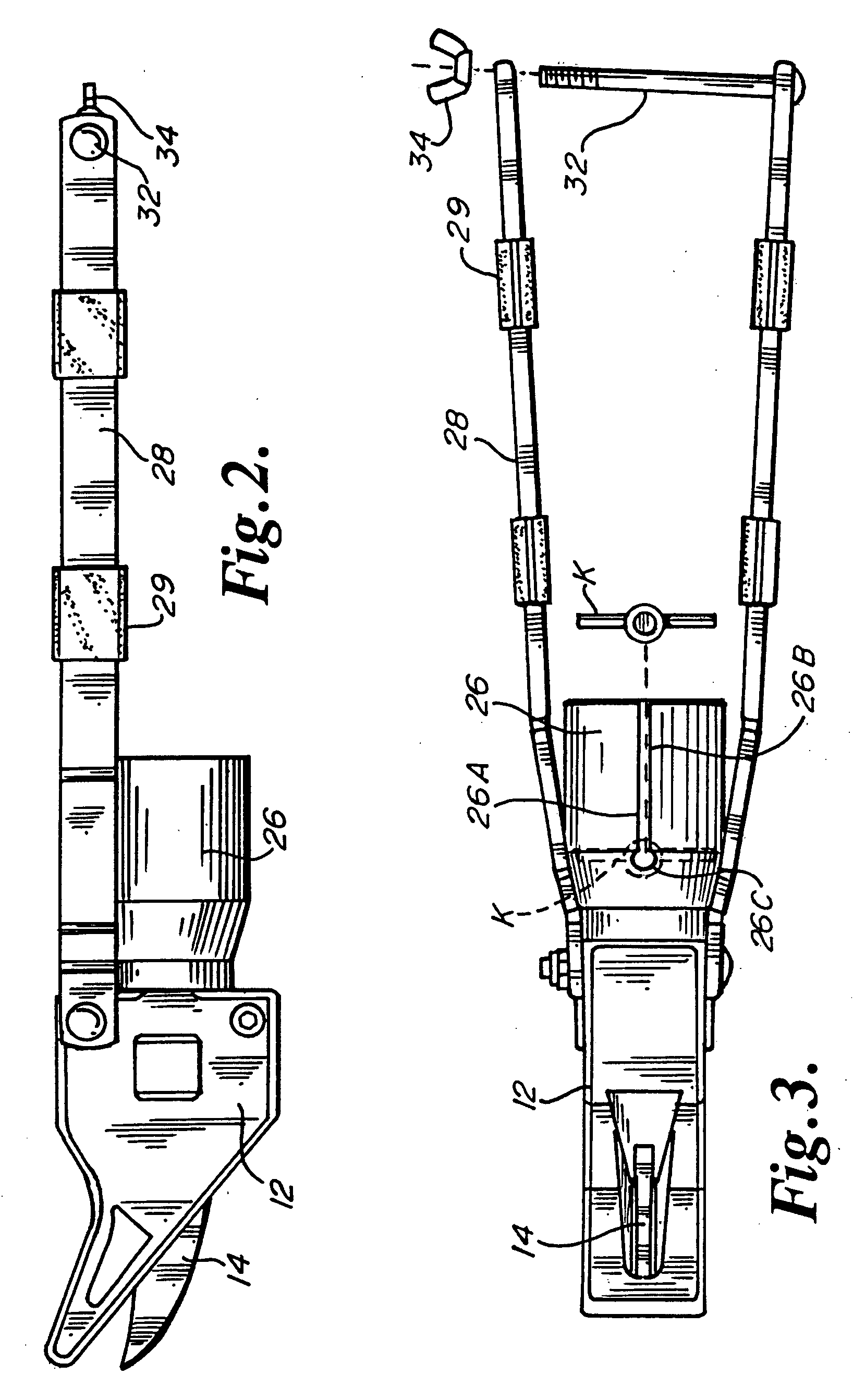

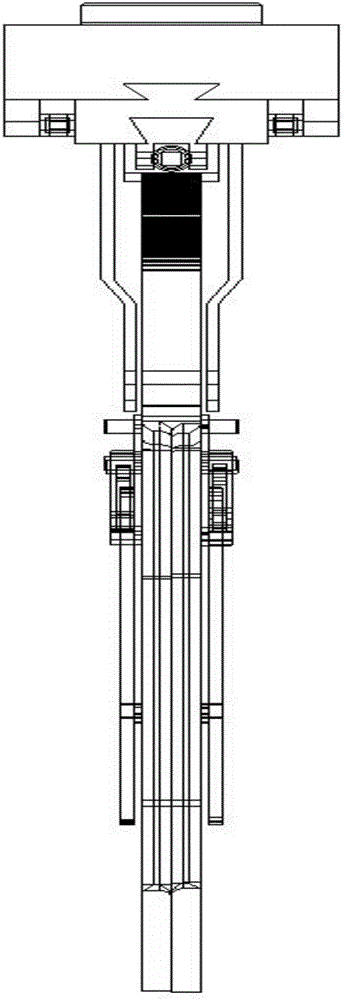

Gripping-shearing-grabbing multi-functional engineering accessory applying single-degree-of-freedom deformation mechanism

ActiveCN108356345AStructure labor savingQuick conversionGripping headsBuilding repairsHydraulic cylinderSingle degree of freedom

The invention provides a gripping-shearing-grabbing multi-functional engineering accessory applying a single-degree-of-freedom deformation mechanism. The gripping-shearing-grabbing multi-functional engineering accessory is of a symmetric structure, and comprises a gripping-shearing device, a holding-grabbing device and a separation-deformation device, and further comprises two hydraulic cylinders,a base, two separation bases, a driving hydraulic cylinder, hydraulic scissors, holding-grabbing connecting rods, holding-grabbing claws, separation connecting rods, base guiding rods, base sliding blocks, separation sliding blocks, first connecting rods, second connecting rods and separation sliding block rail grooves. The gripping-shearing-grabbing multi-functional engineering accessory provided by the invention has the beneficial effects that by utilization of a double-sliding-block mechanism, the relative movement between the holding-grabbing device and the gripping-shearing device is achieved; the switchover from the gripping-shearing device to holding-grabbing device is quickly completed; furthermore, the working requirements are met in all the working states; and no motion interference is caused.

Owner:BEIJING UNIV OF TECH

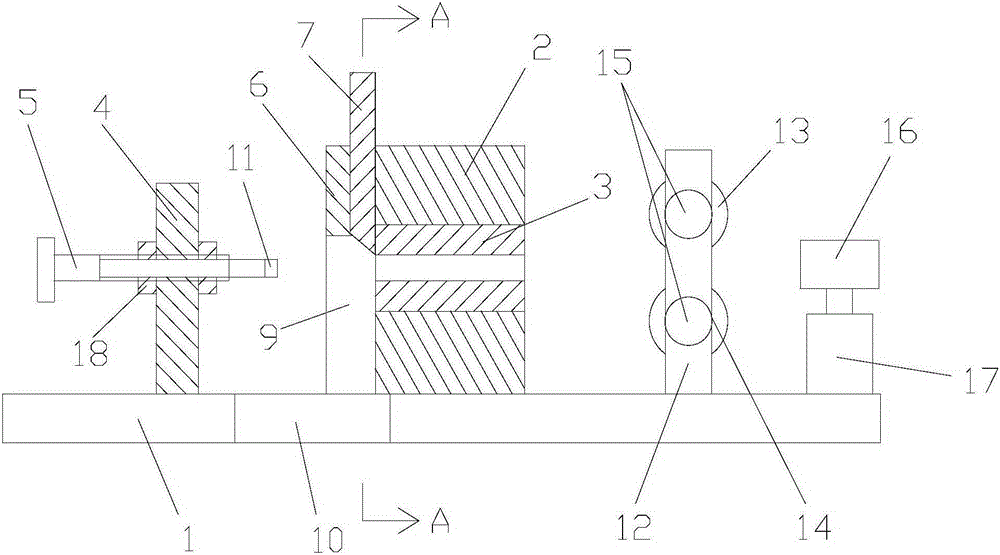

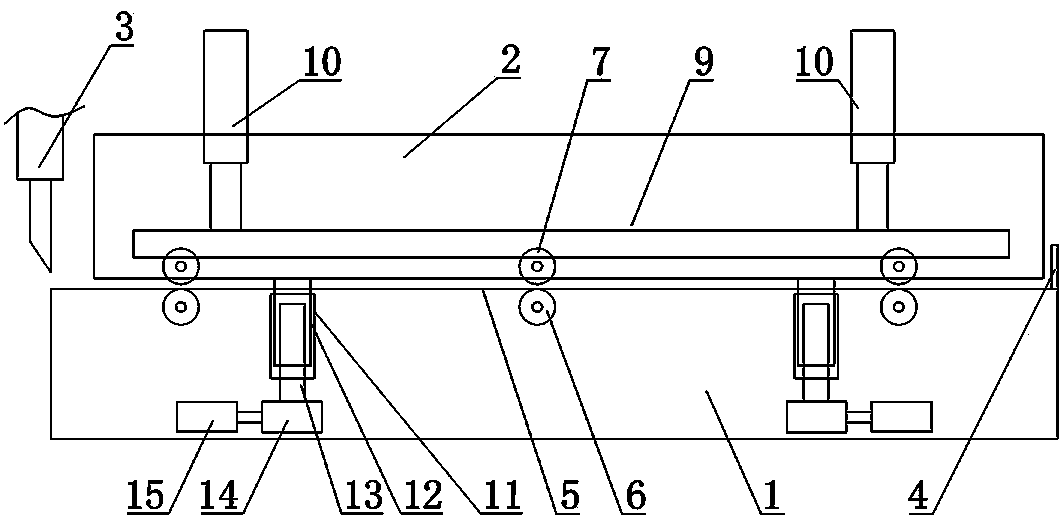

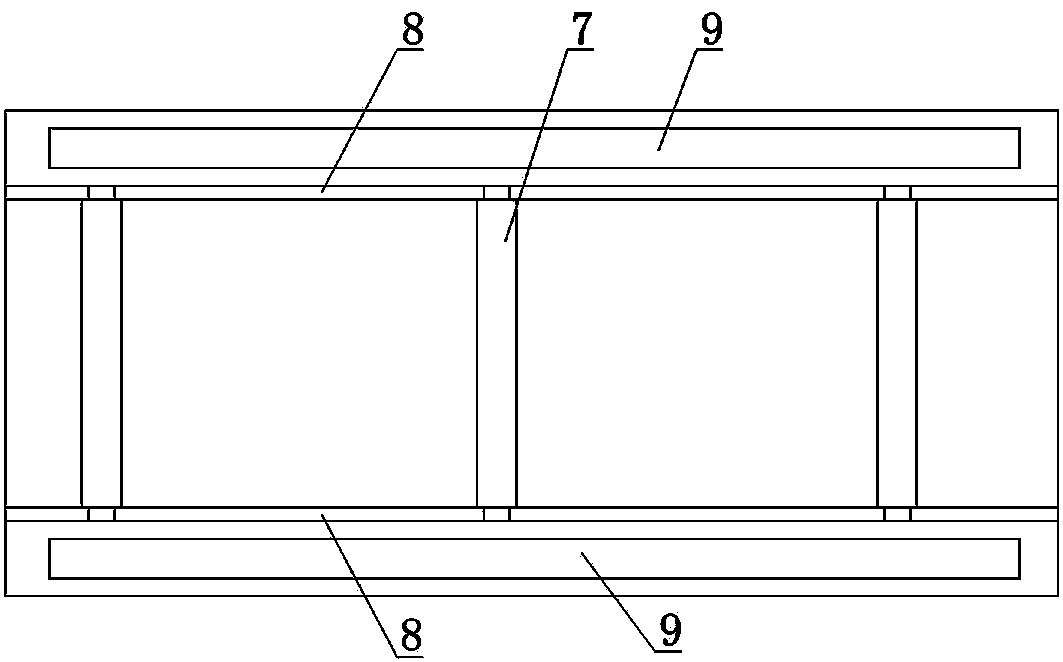

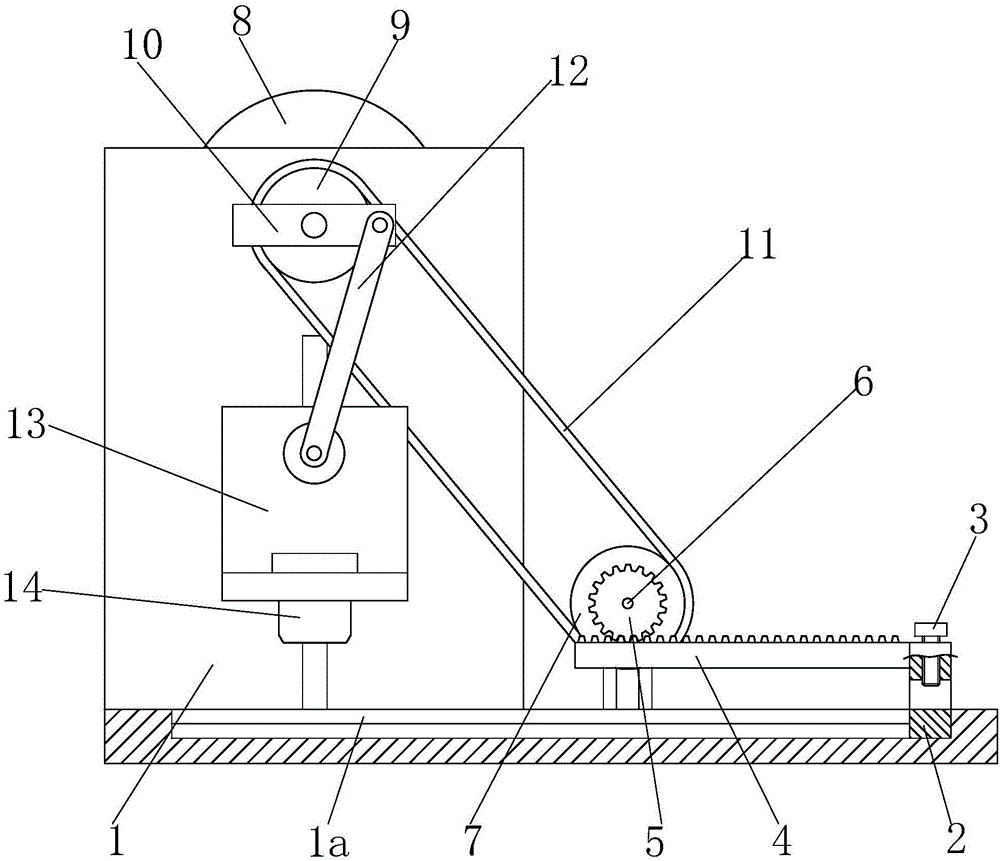

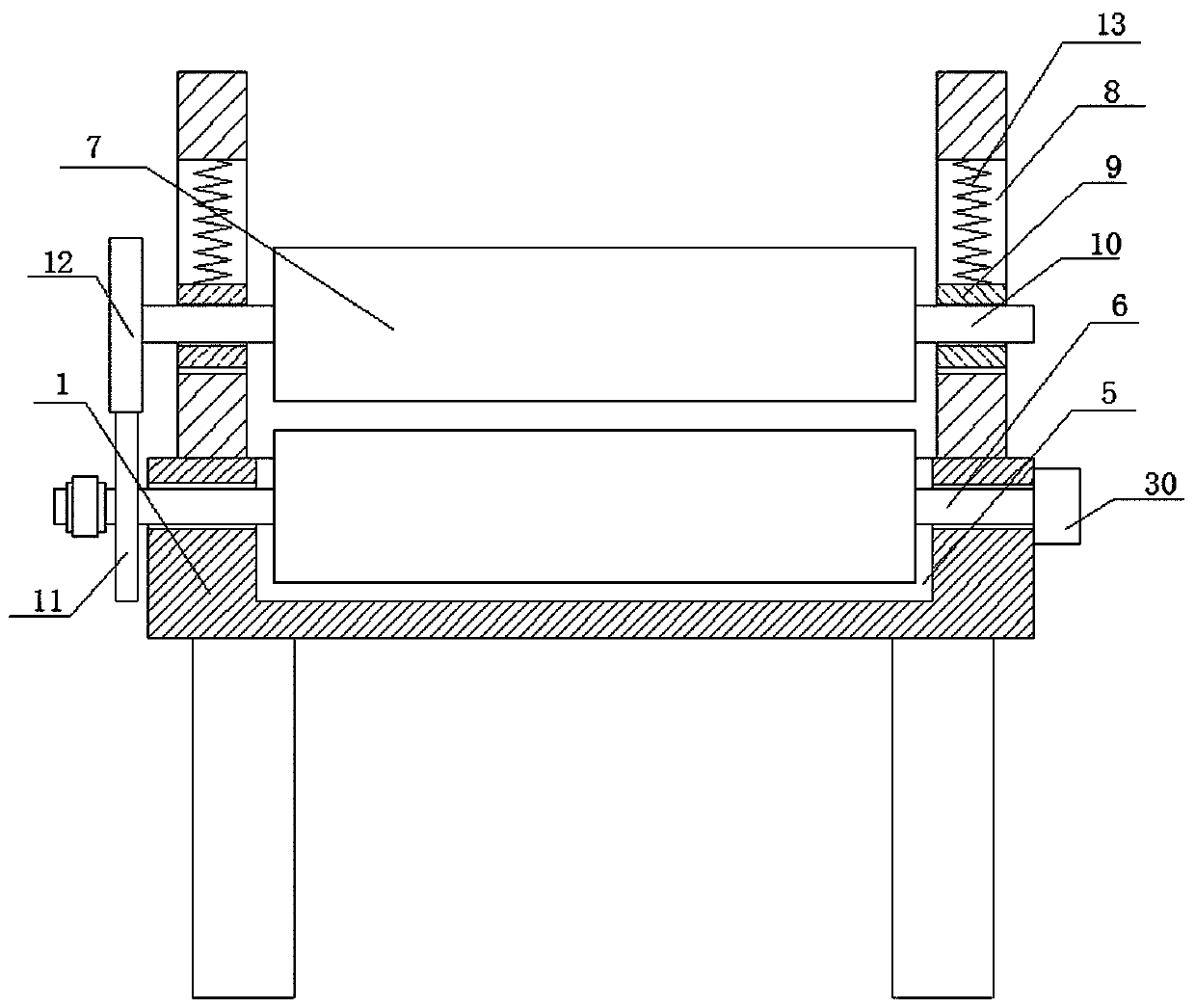

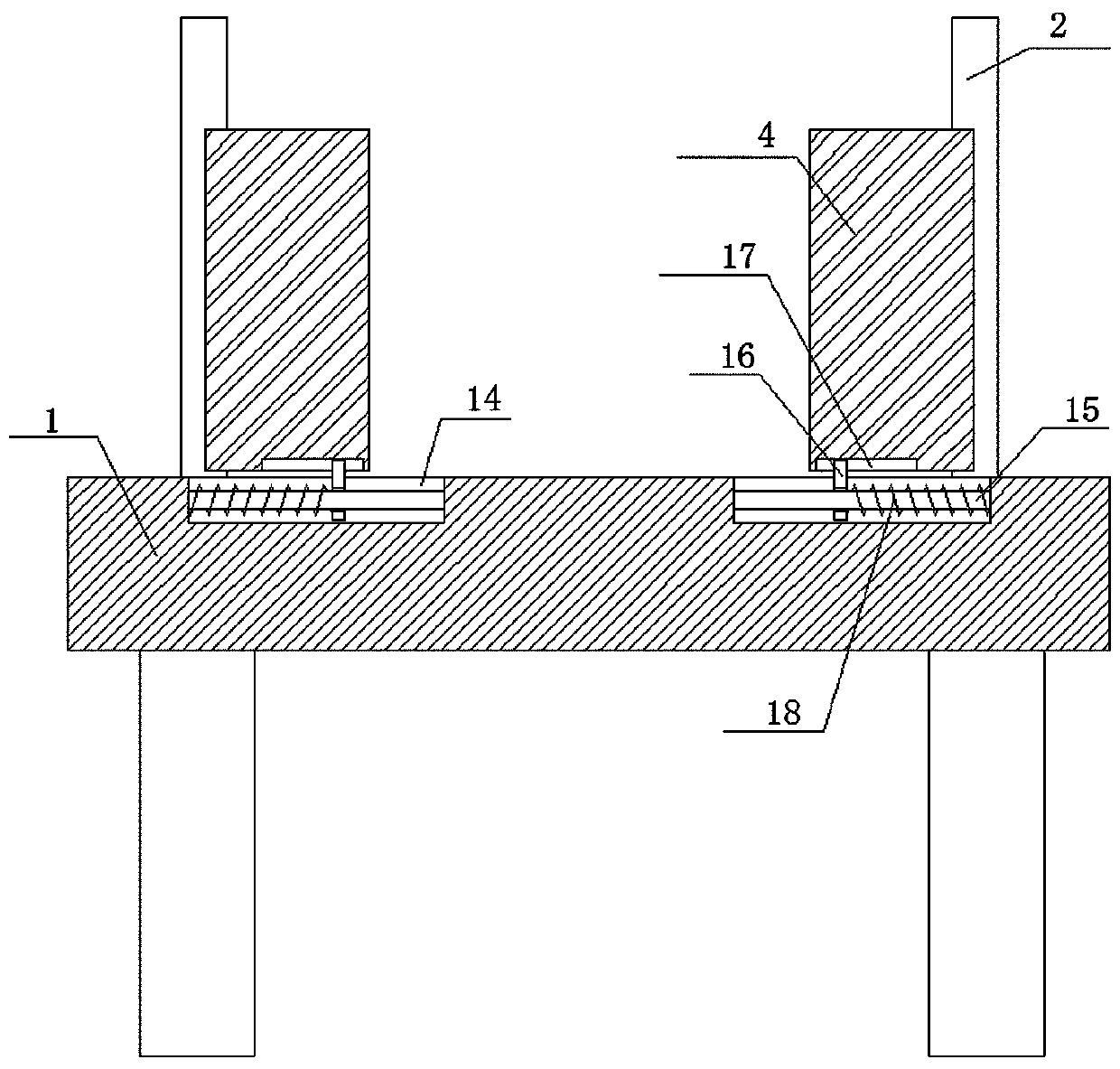

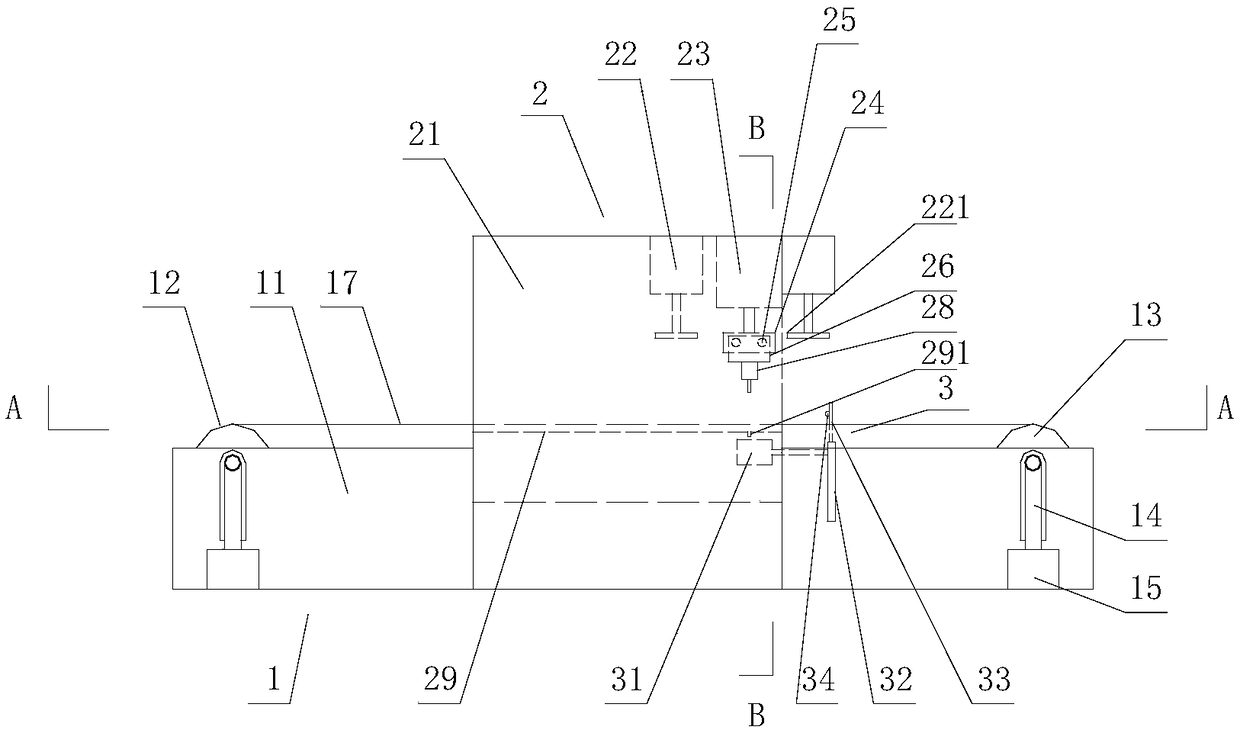

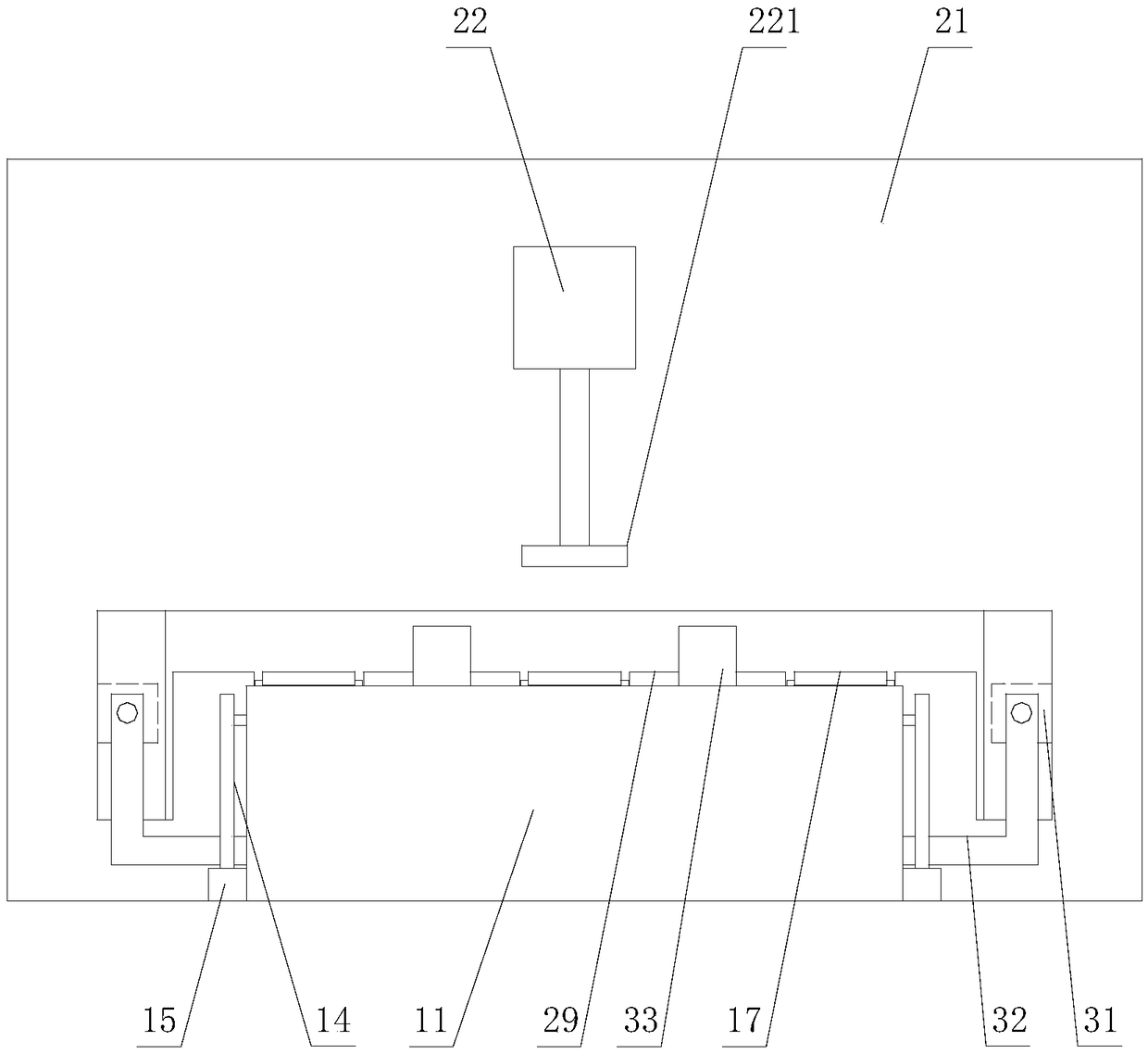

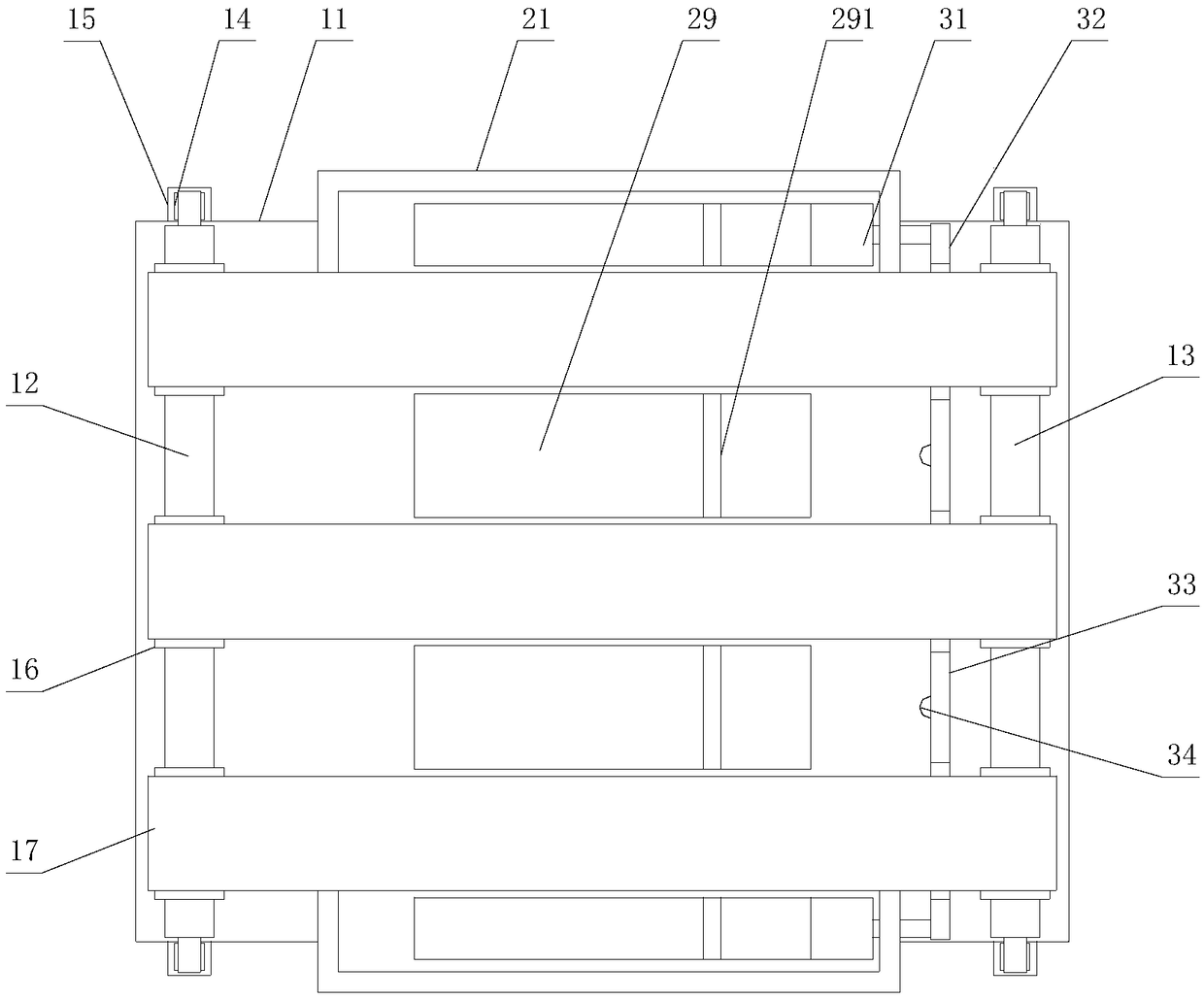

Fixed length plate shearing machine applicable to plates of different thicknesses

InactiveCN103639522AGuaranteed flatnessHigh dimensional accuracyMetal-working feeding devicesNibbling shearing machinesEngineeringVertical cylinder

The invention discloses a fixed length plate shearing machine applicable to plates of different thicknesses. The fixed length plate shearing machine comprises a machine base (1) and a machine cover (2). Supporting plates (8) are arranged on the machine cover (2), upper shaft rollers (7) are mounted between the two supporting plates (8), pressing plates (9) are arranged on the outer sides of the two supporting plates (8), and the pressing plates (9) are connected with piston rods of vertical cylinders (10). Two lifting devices are respectively and symmetrically arranged on the two sides of the machine base (1) and the two sides of the machine cover (2). The two lifting devices on each side are arranged at the two ends of the machine base (1) respectively. The fixed length plate shearing machine has the advantages that due to the arrangement of the pressing plates, the smoothness in the plate shearing process is guaranteed, the dimensional precision of sheared metal plates is high, and material waste is avoided; due to the arrangement of the lifting devices, the metal plates of different thicknesses and specifications can be sheared by the plate shearing machine, the applied range of the machine is widened, equipment cost is lowered, and the utilization rate of equipment is improved.

Owner:SICHUAN GALAXY STEEL STRUCTURE ENG

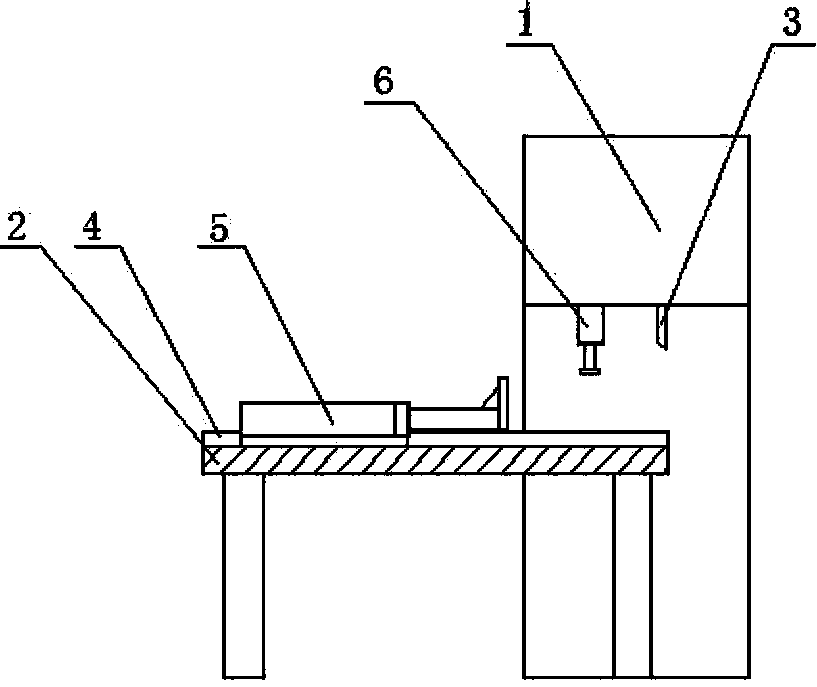

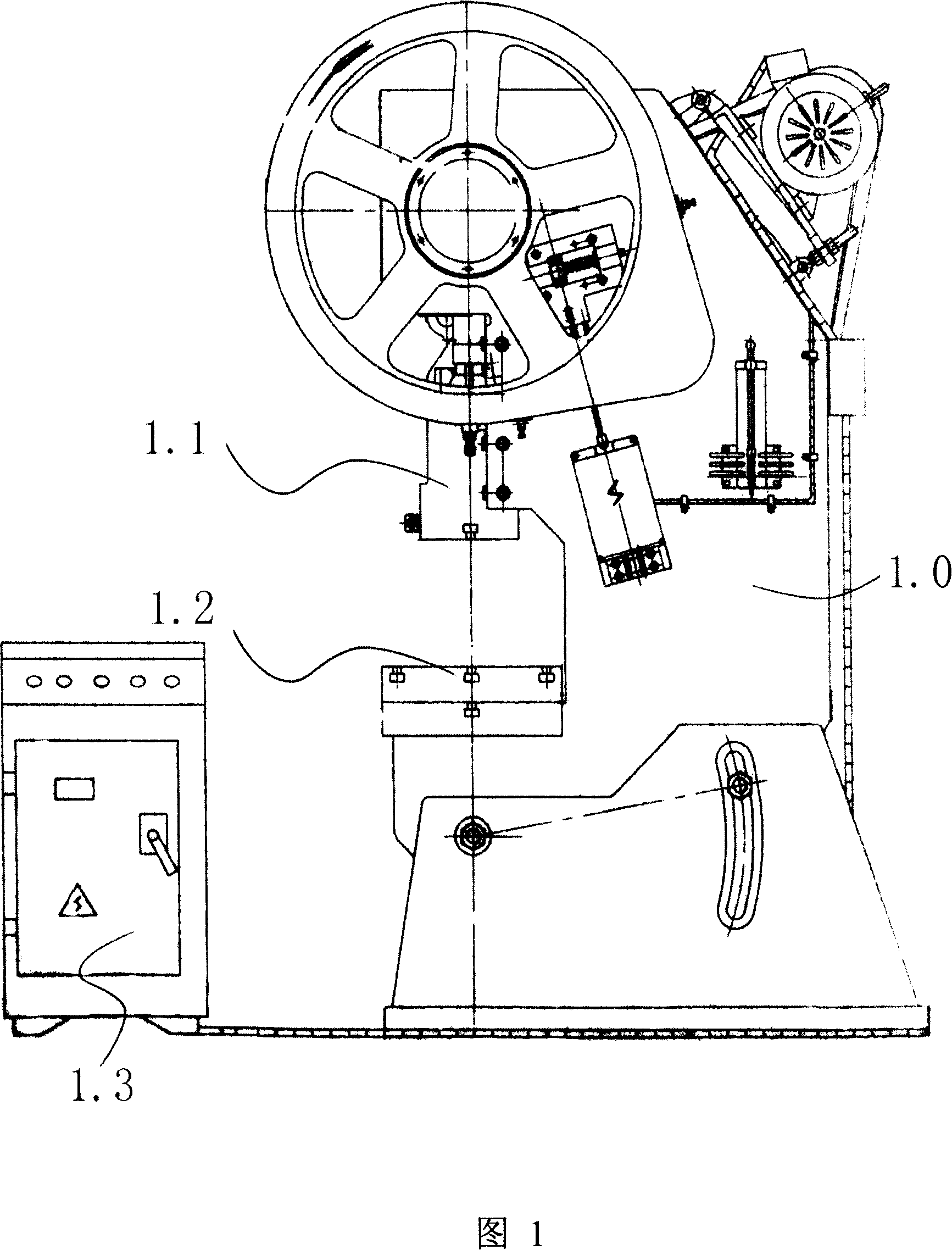

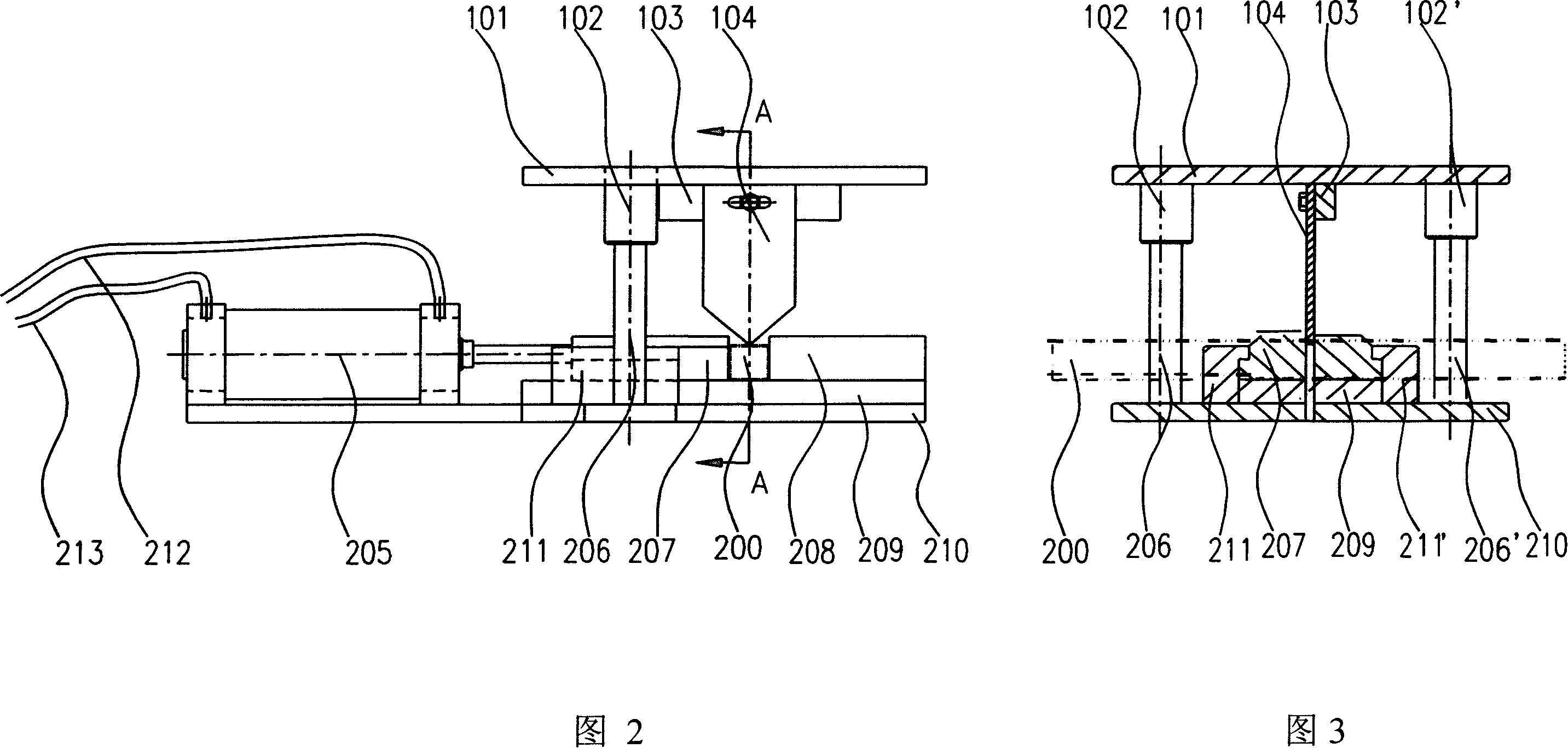

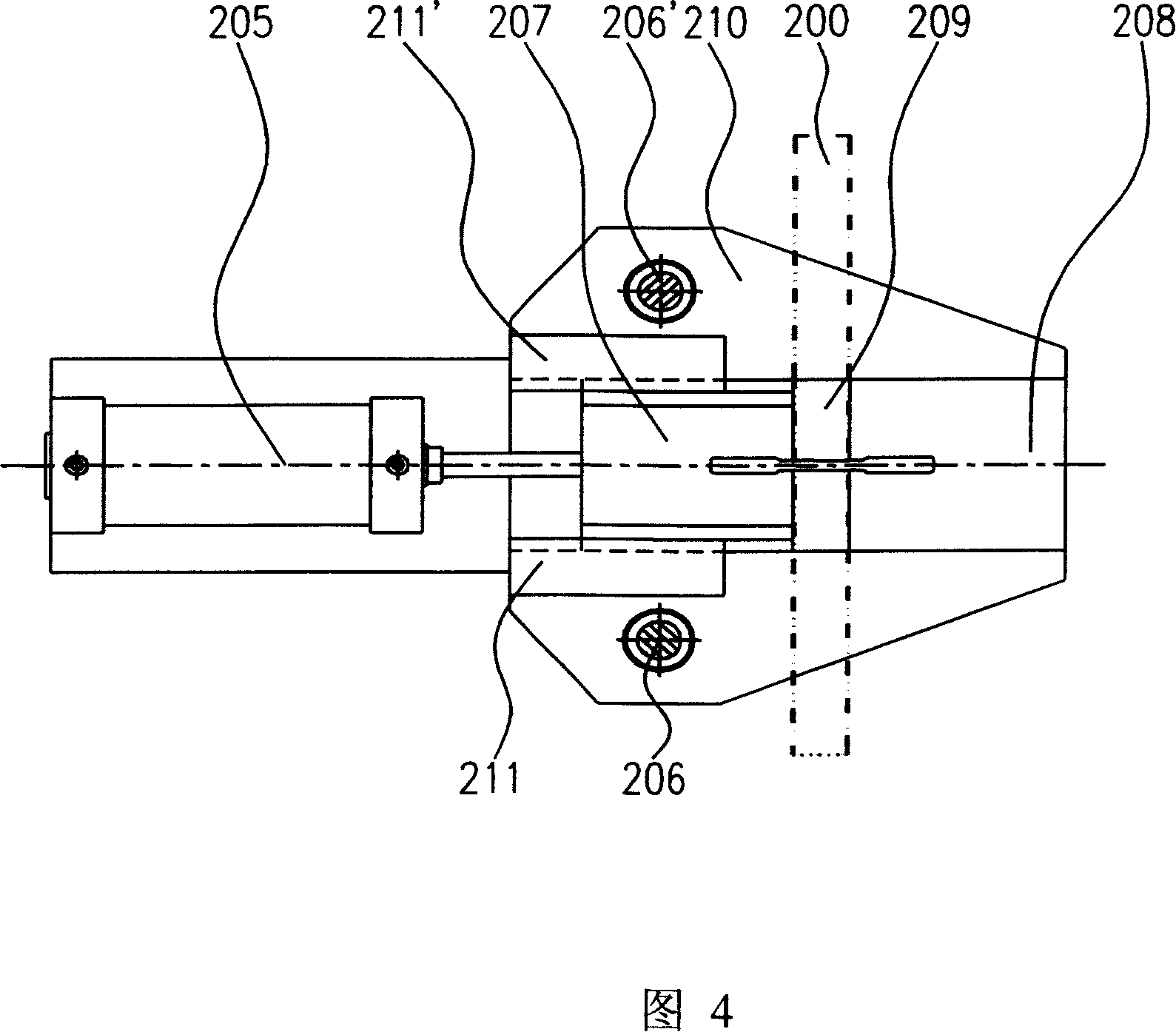

Tube baiting device used for stamper

InactiveCN101130212AEasy to installEasy to carryTube shearing machinesNibbling shearing machinesWorking environmentEngineering

The invention discloses a tubular blanking device on the stamper, which comprises the following parts: blanking mechanism, tube clamping mechanism, cylinder to mate tube clamping mechanism and air compressor to supply gas resource to interconnect cylinder, wherein the blanking mechanism lies on the slider of stamper, which contains knife on the slider; the tube clamping mechanism lies on the working table of stamper, which includes a fixing female die, a sliding female mold with back end of the sliding female mold in connection with the piston rod of the cylinder and the front end corresponding to the front end of the fixing female mold; the front end is opened with knife groove toward knife direction. The invention modifies the working environment greatly to adapt the entire manufacturing procedure, which improves the manufacturing efficiency.

Owner:ZHONGTONG BUS HLDG

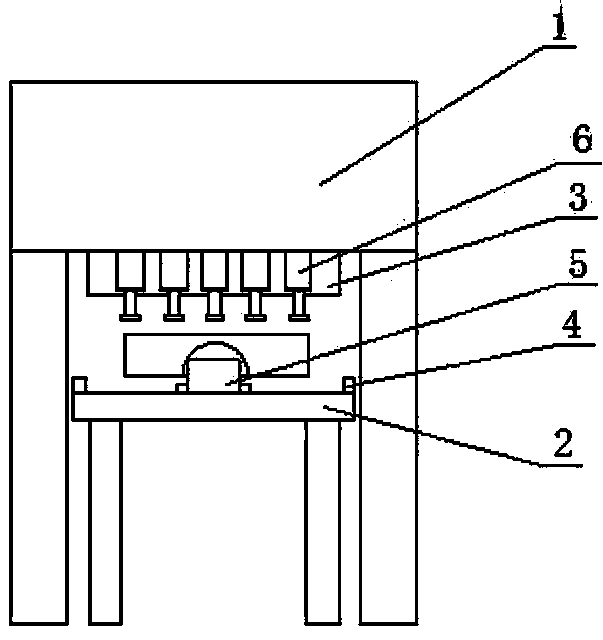

Plate cutting equipment and cutting device thereof

InactiveCN106041194APrevent movementHigh precisionNibbling shearing machinesShearing machine accessoriesEngineeringEquipment use

The invention provides a cutting device. The cutting device comprises a mounting rack, a cutting driving part and a cutting part. The cutting driving part is mounted on the mounting rack. The cutting part is connected with the cutting driving part so as to be driven by the cutting driving part to move in the vertical direction to cut workpieces. The cutting device further comprises material pressing mechanisms. Each material pressing mechanism comprises a mounting block, a sliding rod and a material pressing head; the mounting block is mounted on the cutting part and internally provided with a slideway, one end of the sliding rod is slidably mounted in the slideway, and the other end of the sliding rod is connected with the material pressing head; and the side, away from the sliding rod, of the material pressing head forms an abutting face which is located below the cutting part. The invention further provides plate cutting equipment using the cutting device. When the cutting device cuts the workpieces, the material pressing heads can make contact with the workpieces at first and abut against the workpieces in a pressing mode in the cutting process of the workpieces, and the workpieces are prevented from moving in the cutting process, so that the cutting precision of the workpieces is improved.

Owner:广西田阳至恒门业有限公司

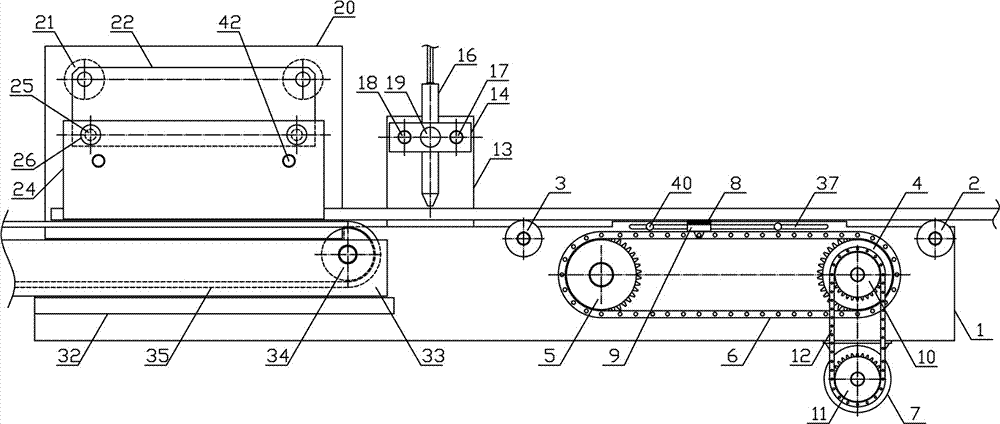

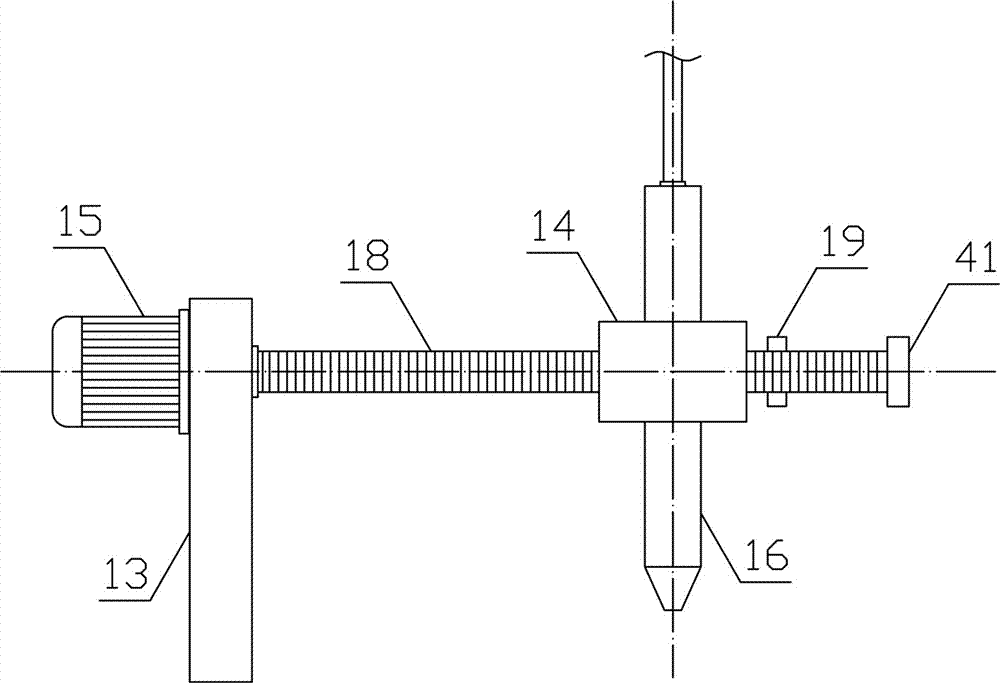

Automatic segmenting cutting machine for aluminum pipe

ActiveCN106363230AGuarantee the effect of equidistant cuttingAchieve the effect of automatic segmentation and equidistant cuttingNibbling shearing machinesShearing machine accessoriesControl mannerGear wheel

The invention relates to an automatic segmenting cutting machine for an aluminum pipe. The automatic segmenting cutting machine for the aluminum pipe comprises a machine base frame. A horizontal sliding chute is arranged on the lower portion of the machine base frame. A fixing sleeve is installed on the horizontal sliding chute in a sliding manner. A fastening bolt is installed on the fixing sleeve. A rack is welded to the fixing sleeve. The rack is meshed with a gear. The gear is connected with a transmission shaft. A first belt wheel is installed on the back portion of the transmission shaft. A motor is installed on the left side portion of the machine base frame. The motor is connected with a second belt wheel and a rectangular rotating plate. A belt is arranged between the second belt wheel and the first belt wheel. A long connection transmission rod is hinged to the rectangular rotating plate. A sliding frame is hinged to the lower end of the long connection transmission rod and provided with a cutter. The automatic segmenting cutting machine for the aluminum pipe is high in automation degree and can synchronously drive the long aluminum pipe to slide and control the cutter to conduct reciprocating up-and-down sliding just through one control element, and then the effect that the aluminum pipe is automatically segmented and cut at equal intervals can be achieved through the easy and convenient control manner.

Owner:WUHU HENGHAO MACHINERY MFG

Chain cutter

InactiveUS6880378B1Minimize timeMinimizing energyNibbling shearing machinesMetal working apparatusEngineeringBending force

A compact chain cutting apparatus for automatically shearing and opening a chain link of a selected thickness in one operation is disclosed. The apparatus includes a housing, a first shearing member, a second shearing member, and an electro-hydraulic actuator system. The first shearing member is mounted to the housing. The second shearing member is pivotally mounted to the housing for movement to exert, in cooperation with the first shearing member, shearing and bending forces upon the chain link. The electro-hydraulic actuator system cooperates with the second shearing member to move automatically the second shearing member to shear and to bend the chain link, thereby defining an opening in the chain link greater than the thickness of the link.

Owner:VINDEE INDS

Iron bar automatic segmenting mechanism

ActiveCN107971558AEasy to sendSmooth and precise transmissionNibbling shearing machinesShearing machine accessoriesMetallic materialsMechanical equipment

The invention discloses an iron bar automatic segmenting mechanism, and belongs to the field of metal material processing mechanical equipment. The iron bar automatic segmenting mechanism includes a material-carrying mechanism, a material-cutting mechanism and a fixing material-pushing mechanism which are sequentially and fixedly arranged at one side of a fixing support in the horizontal direction, and a material-carrying chain which is winded is horizontally arranged between a main material-carrying chain and a secondary material-carrying chain; a material-carrying electromagnet is fixedly arranged at the outer side of the material-carrying guiding plate, a reciprocating material-cutting plate is slidably arranged at a material-cutting guiding rod in the horizontal direction, and a cutting handpiece is slidably arranged at the reciprocating material-cutting plate in the vertical direction; and a horizontal-pushing guiding rod is separately and horizontally fixed to two sides below a horizontal-pushing connecting plate, a fixing guiding plate and a moving guiding plate are separately and vertically arranged at two sides of the horizontal-pushing guiding rod, and the material-transporting mechanism is horizontally and fixedly arranged at the upper side of a material-transporting supporting plate. According to the iron bar automatic segmenting mechanism, the structural design isreasonable, iron bars can be transferred horizontally, stably, accurately and intermittently according to needed length, the iron bars can be clamped and cut and automatic feeding can be realized, andthe need for machining using can be met.

Owner:ZHEJIANG ZHUOYI TEXTILE

Intelligent lithium battery pole piece cutting device

InactiveCN110788391AFast and stable cuttingSimple structureMetal-working feeding devicesNibbling shearing machinesEngineeringPole piece

The invention belongs to the field of lithium battery processing equipment, particularly relates to an intelligent lithium battery pole piece cutting device, and aims to solve the following problems in the prior art: a cutter shaft is adopted for cutting, during the operating process of the cutter shaft, a pole piece is likely to be stressed nonuniformly, as a result, the cut pole piece is likelyto have a crumple, or the pole piece is extremely wide to cause that the rejection rate is large, the working strength of a worker is high, and the potential safety hazard exists. According to the technical scheme, the intelligent lithium battery pole piece cutting device comprises a base, wherein two symmetrical first support plates and two symmetrical second support plates are fixedly mounted onthe top of the base; a rotating groove is formed in the bottom of the base; a first rotary rod and a second rotary rod are rotatably connected onto the rotating groove and the two first support plates separately; and rollers are fixedly arranged on the external sides of the first rotary rod and the second rotary rod in a sleeving manner. The intelligent lithium battery pole piece cutting device is simple in structure and convenient to use, can rapidly and stably cut a lithium battery pole piece and facilitates application by a user.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Automatic feeding and cutting device for metal plates

ActiveCN106808011AHigh precisionAccurate shapeNibbling shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses an automatic feeding and cutting device for metal plates. The automatic feeding and cutting device comprises a positioning device and a power dragging box, wherein the positioning device comprises a group of lathe bed supporting rods, a longitudinal positioning clamping frame and a clamping air cylinder; a positioning lathe bed bracket is arranged below the lathe bed supporting rods; one side, in the width direction, of the lathe bed which consists of the lathe bed supporting rods, is equipped with a transverse positioning stop pin; the other side of the lathe bed is equipped with a transverse positioning clamping air cylinder; the longitudinal positioning clamping frame is arranged above one end of the lathe bed; a top plate of the transverse positioning clamping air cylinder is matched with the transverse positioning stop pin for realizing transverse positioning of plates; the clamping air cylinder is arranged on the longitudinal positioning clamping frame; the power dragging box is arranged on a pair of guide rails, and a guide rod is arranged above the guide rails; one end of the guide rod is connected with one side of the longitudinal positioning clamping frame, and the other end of the guide rod is arranged on a guide rod base; a longitudinal positioning clamping air cylinder and a pushing plate are further arranged above the power dragging box; and the pushing plate is matched with the clamping air cylinder to realize longitudinal positioning of plates. Plates are more accurate in shape and dimension while sheared; and the automatic feeding and cutting device is simple in structure, is safe to use, is convenient to operate, and is high in efficiency.

Owner:CHANGSHU KAIBO STAINLESS EQUIP

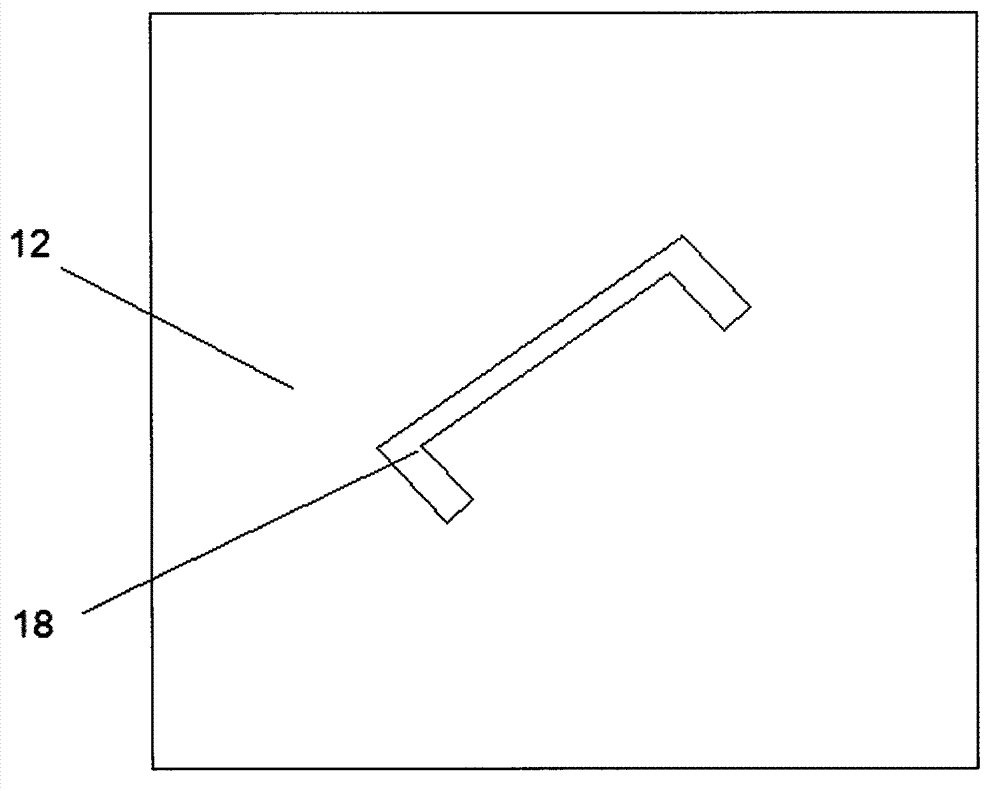

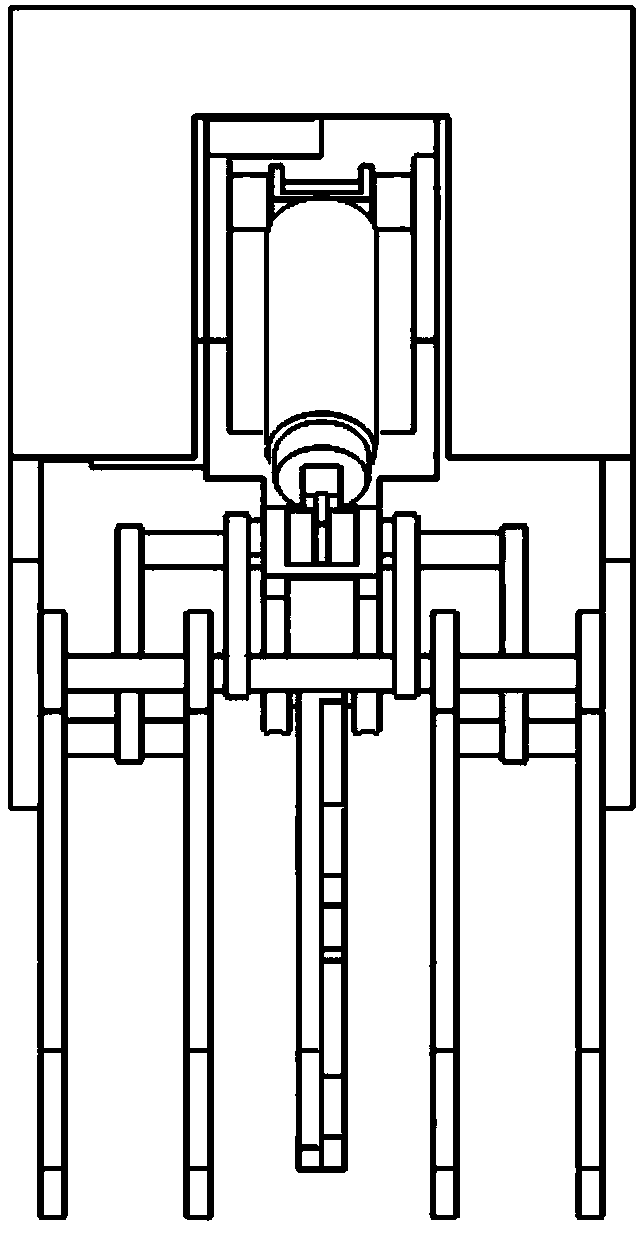

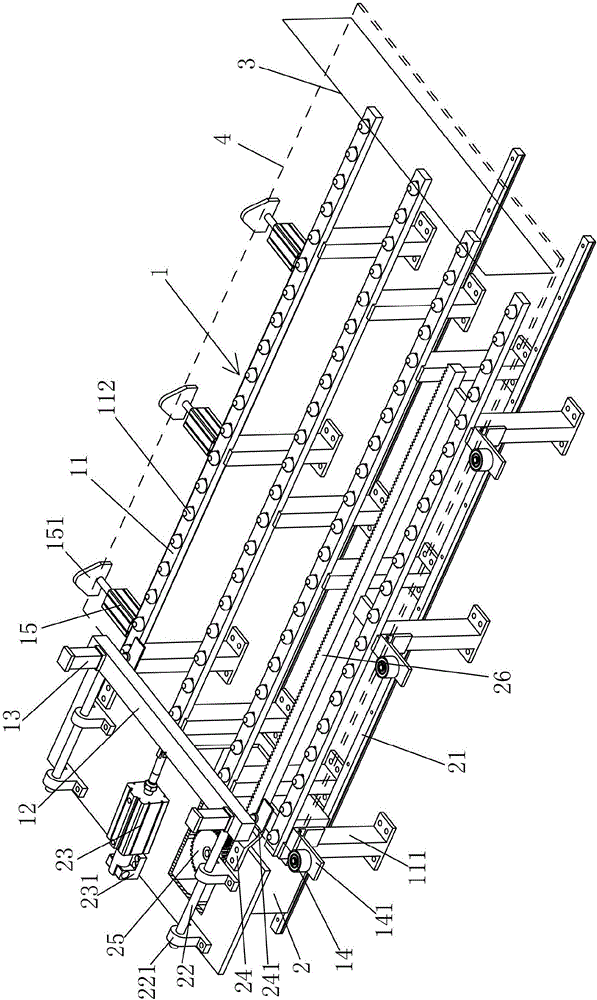

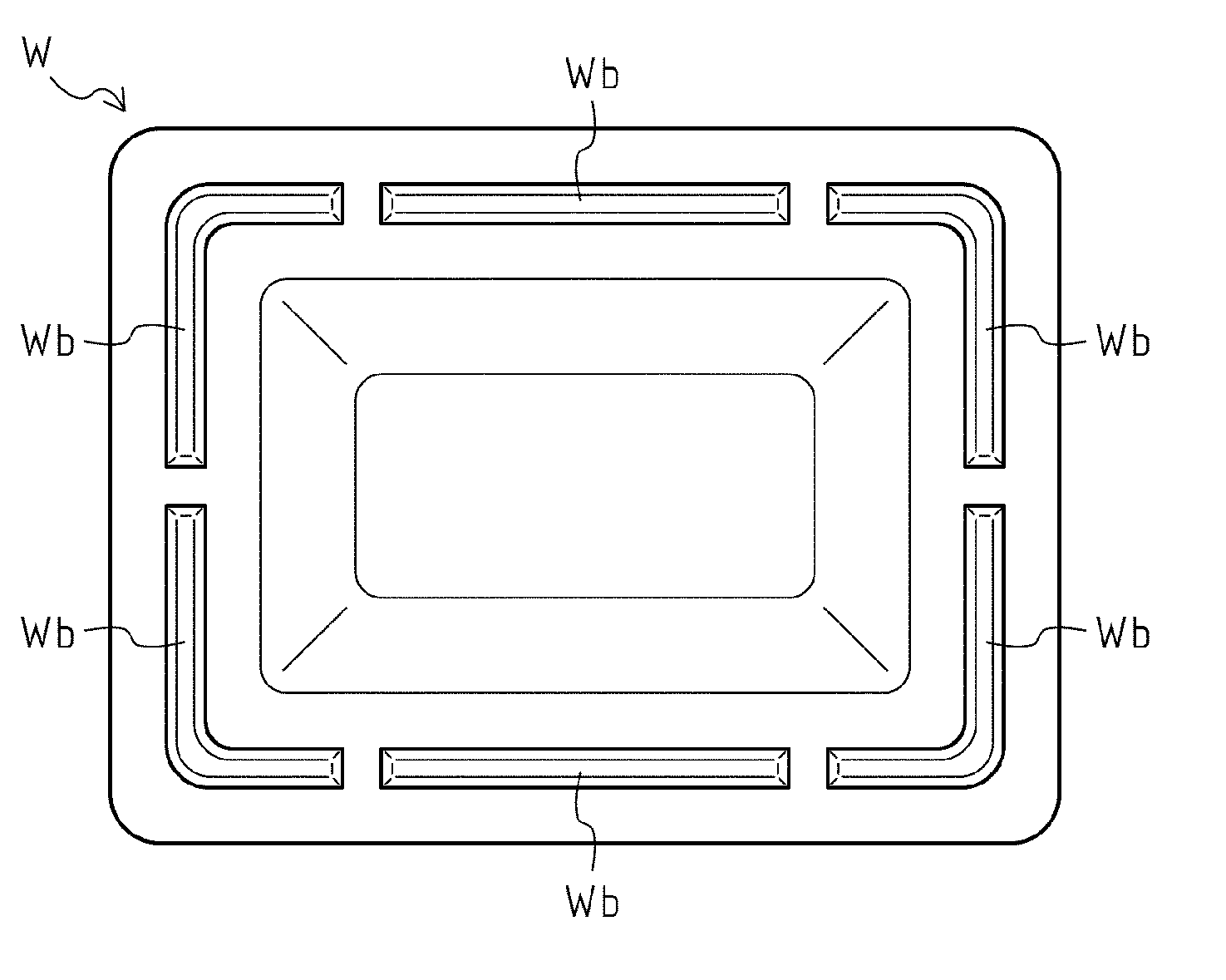

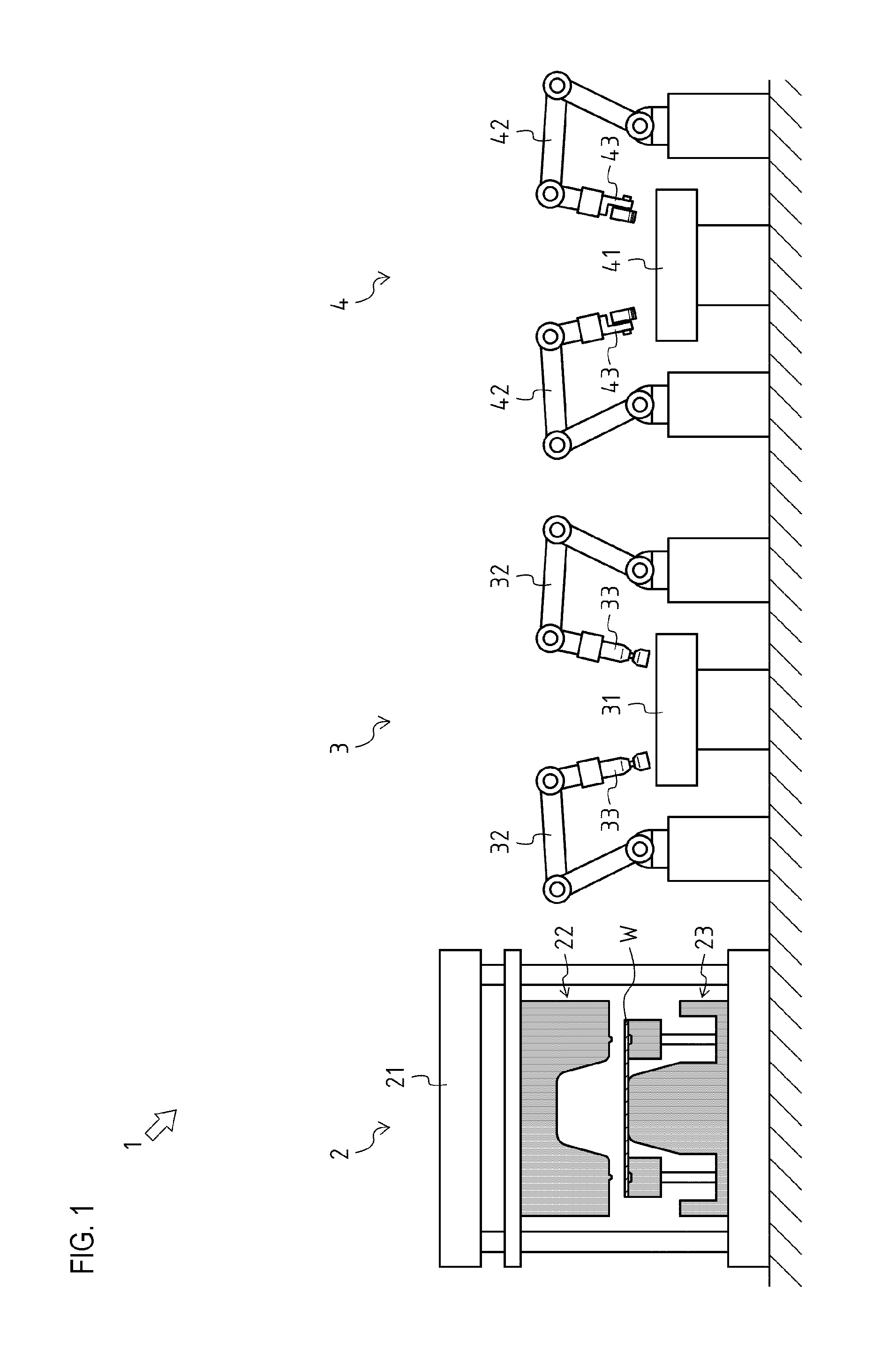

Method for working steel sheet, and apparatus for working steel sheet

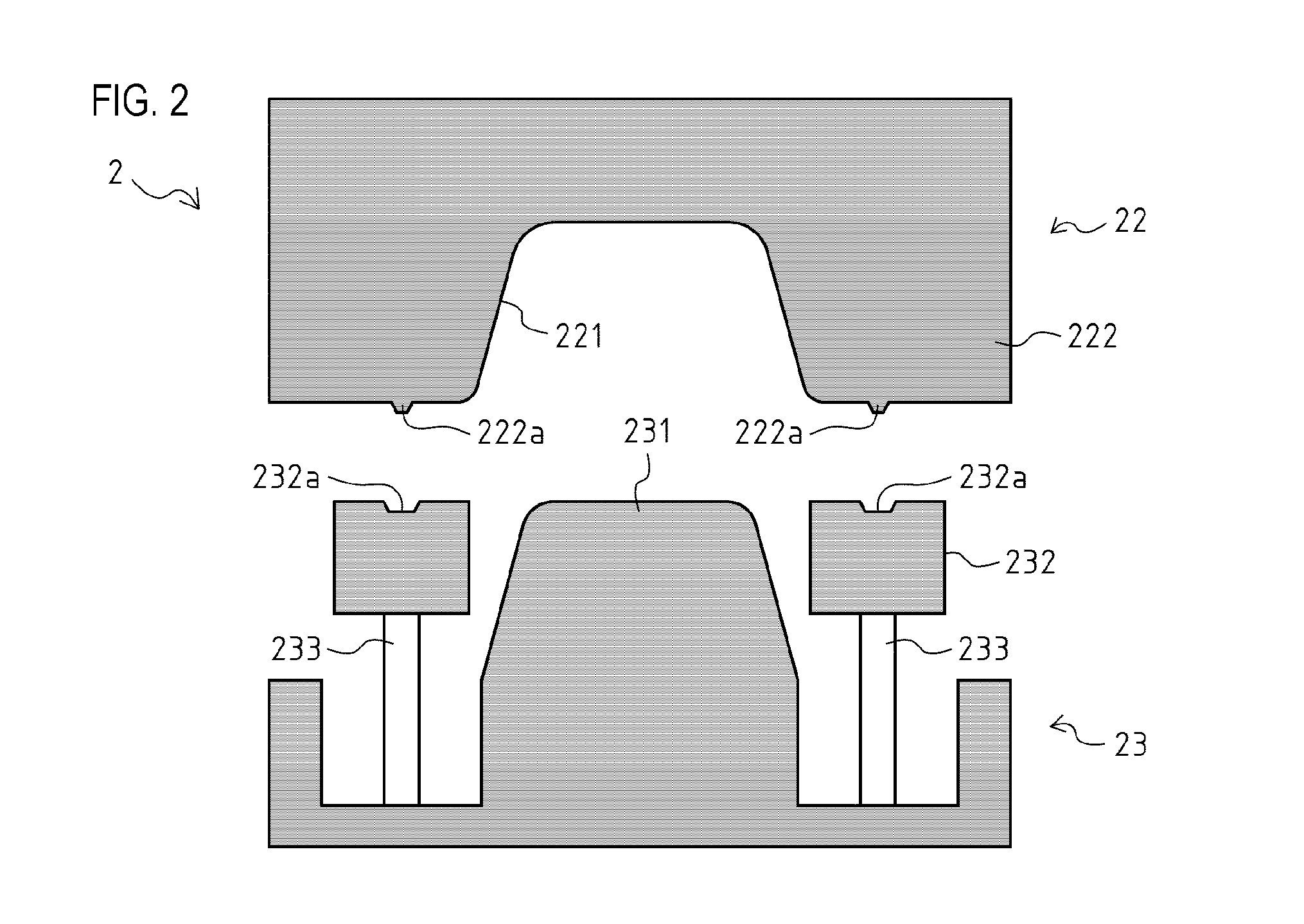

Provided is a technique capable of inexpensively working a steel sheet. A method for working a workpiece with an apparatus for working a workpiece, includes: a drawing step for performing drawing with a drawing device having an upper die and a lower die; and a cutting step for cutting the drawn workpiece with a cutting device having nibblers. The nibbler has a cylindrical case, a punch housed in the case, which reciprocates in a top-bottom direction to punch the workpiece, and a die arranged below the case, the die having a die hole into which the punch enters, and an ejecting hole communicating with the die hole, through which a scrap is ejected. The nibbler trims the workpiece fed between the case and the die.

Owner:TOYOTA JIDOSHA KK

Plate shearing equipment for producing new energy automobile parts

ActiveCN110919073AEasy to moveCannot be disassembled easilyMetal-working feeding devicesNibbling shearing machinesNew energyStructural engineering

The invention discloses plate shearing equipment for producing new energy automobile parts. The plate shearing equipment comprises a base, a dismounting mechanism, a fixing mechanism and a protectionmechanism. A plate shearing equipment body is arranged on the top end surface of the base, and an air cylinder is arranged on the top end surface of the inner side of the plate shearing equipment body. A connecting rod is arranged on the surface of one side of the bottom end of the air cylinder, and a mounting plate is arranged on the surface of one side of the connecting rod. By means of a rubbersleeve, when the rubber sleeve is moved to one side, an extrusion column is elastically moved to one side under the acting force of a first spring, and a clamping column connected to one side of a first connecting plate is driven to move to one side under the acting force of the first spring, so that one end of the clamping column is separated from the interior of a first connecting hole, and thefixed state between the connecting rod and a mounting groove is opened. By means of an installation groove, the connecting rod conveniently slides to one side inside the installation groove.

Owner:友信宏科新能源(徐州)有限公司

Steel plate cutting device and steel plate cutting method

InactiveCN109047896ARealize fully automatic transportationAchieve reductionNibbling shearing machinesShearing machine accessoriesSheet steelEngineering

The invention relates to a steel plate cutting device and a steel plate cutting method. The steel plate cutting device comprises a steel plate conveying mechanism, a steel plate cutting mechanism anda length control mechanism. The steel plate conveying mechanism used for conveying a steel plate. The steel plate conveying mechanism achieves height adjustment through cooperation between vertical movement supports and support drive devices. Conveying belts of the steel plate conveying mechanism are arranged in a spaced manner. Cutting platforms for steel plate cutting are arranged in the gaps between the adjacent conveying belts. When the steel plate is conveyed, the conveying belts are higher than the cutting platforms, and the cutting position of the steel plate is controlled through the length control mechanism in the steel plate conveying process. After the steel plate is conveyed in place, the height of the steel plate conveying mechanism is lowered and smaller than that of the cutting platform, and then cutting of the steel plate is completed through the steel plate cutting mechanism. The steel plate cutting device achieves full automation of steel plate conveyance and cutting,and fixed-length cutting of the steel plate is achieved through the length control mechanism; the height of the conveying belt and height of the cutting platforms alternately change, it is avoided that when the steel plate is cut, the belts are cut and damaged, and the service life of the steel plate conveying mechanism is prolonged.

Owner:潘景玮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com