Plate shearer capable of positioning plates accurately

A technology of accurate positioning and shearing machine, applied in the field of sheet metal blanking and cutting, can solve the problems of low production output, complicated operation process, errors in manual marking and marking, etc., and achieves a high degree of automation, high dimensional accuracy and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

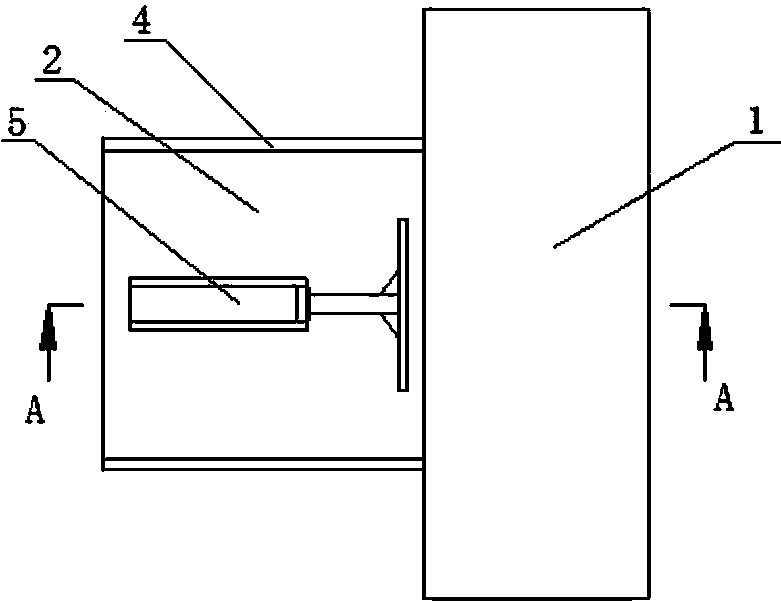

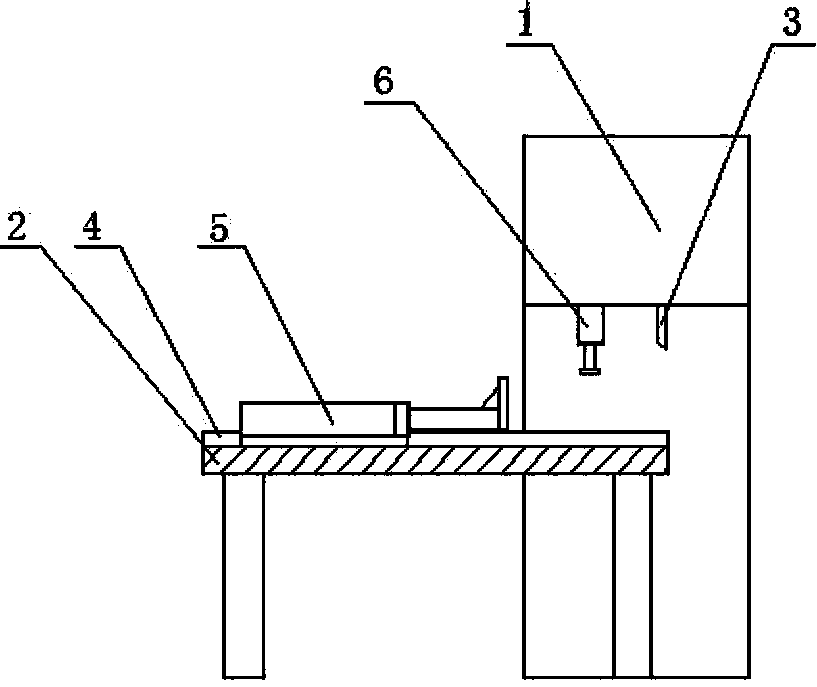

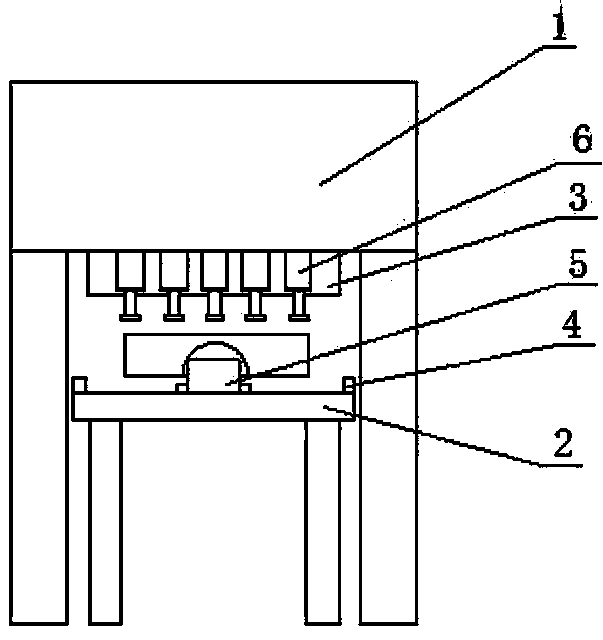

[0014] Such as Figure 1-3 As shown in the figure, a shearing machine with accurate sheet positioning includes a body 1, a workbench 2 and a shearing blade 3 that can move up and down along the body 1, and the moving direction of the shearing blade 3 is perpendicular to the workbench 2. The table top is characterized in that: the shearing blade 3 and the edge of the workbench 2 form a shear structure, the workbench 2 is provided with a boss 4 perpendicular to the table of the workbench 2, the boss 4 is perpendicular to the shear blade 3, and the workbench 2 A cylinder I5 parallel to the boss 4 is installed on the table, a solenoid valve is installed on the cylinder I5, and a displacement sensor is installed on the piston rod of the cylinder I5. It also includes a PLC controller, and the solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com