Fast and safe lithium ion battery dismantling and analyzing device

A lithium-ion battery and analysis device technology, applied in the direction of shearing device, nibbling cutting device, other manufacturing equipment/tools, etc., can solve the problem of not being able to observe the surface of the pole piece at close range for a long time, and take pictures and collect evidence during the disassembly process Troublesome, dismantling environment and other problems, to achieve the effect of saving manpower, protecting safety, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the technical solution of the present invention will be described in detail through specific examples.

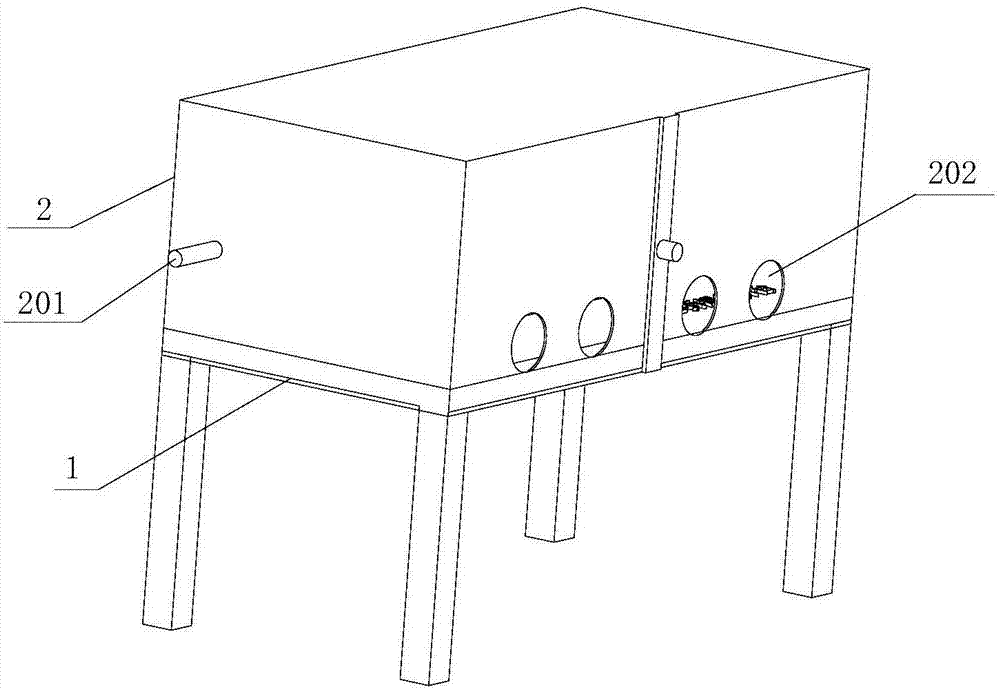

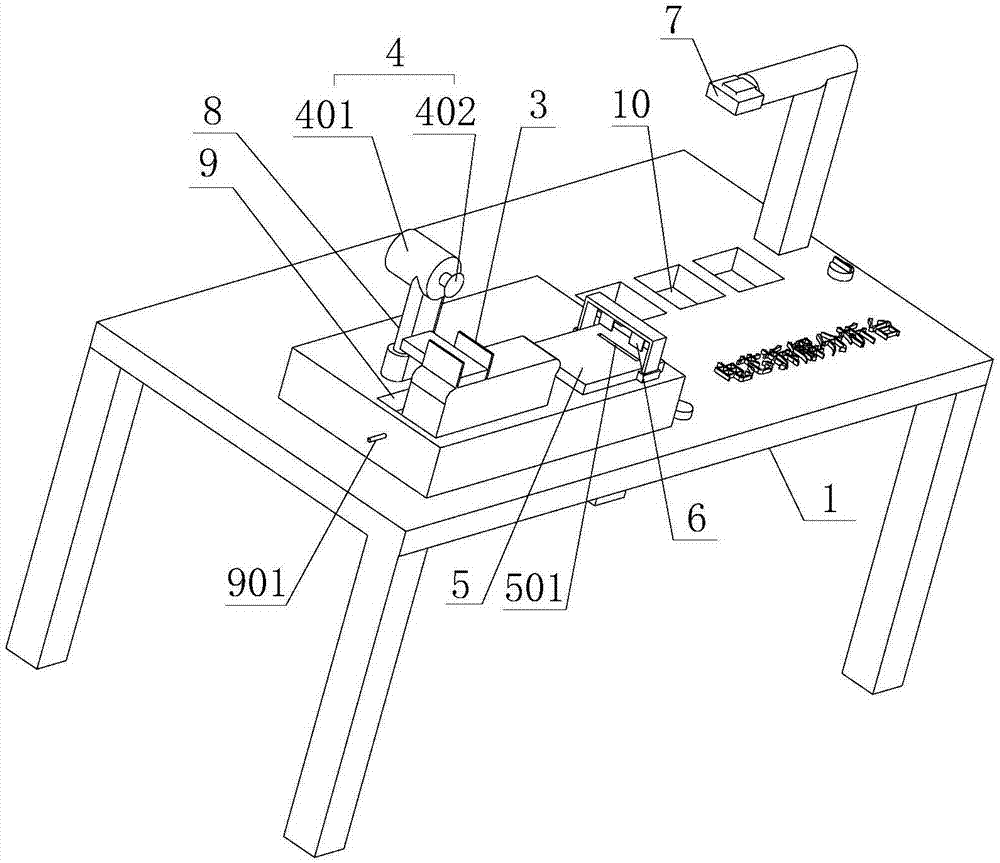

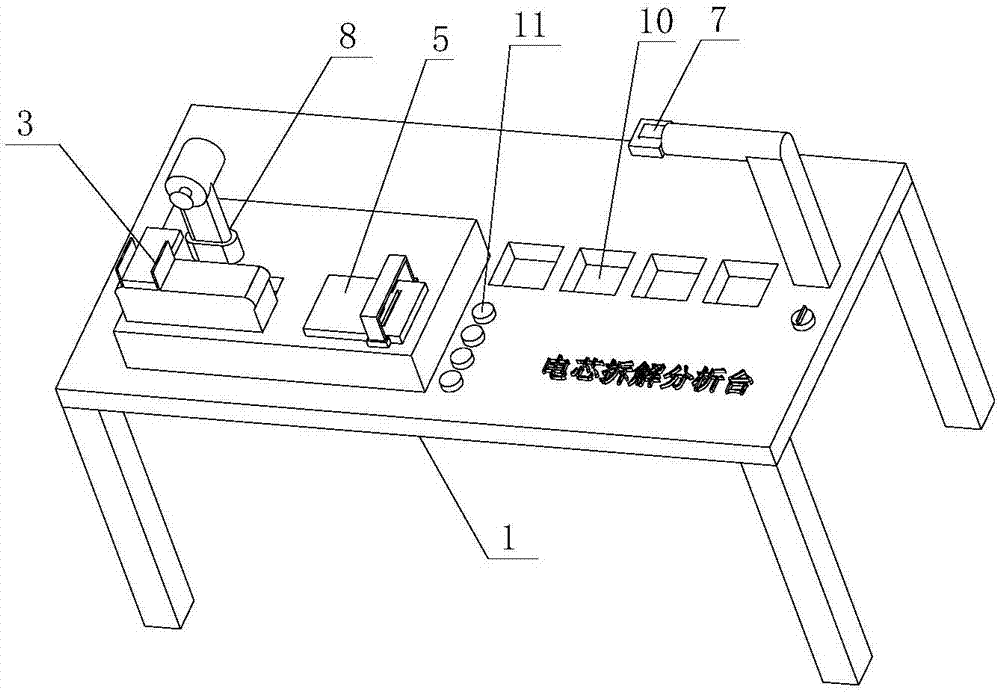

[0031] Such as Figure 1-3 as shown, figure 1 It is a schematic structural diagram of a lithium-ion battery rapid and safe disassembly analysis device proposed by the present invention; figure 2 Schematic diagram of the structure of the operating platform in a fast and safe disassembly and analysis device for lithium-ion batteries proposed by the present invention Figure 1 ; image 3 Schematic diagram of the structure of the operating platform in a fast and safe disassembly and analysis device for lithium-ion batteries proposed by the present invention Figure II .

[0032] refer to figure 1 , a lithium-ion battery rapid and safe disassembly and analysis device proposed by the embodiment of the present invention, comprising: an operating platform 1 and a box body 2 arranged above the operating platform 1 and cooperating with the operating platform 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com