Electric nibbler

a technology of electric nibbler and electric ring, which is applied in the field of electric hand tools, can solve the problems of inability to control the conventional electric nibbler, material waste and working space, and the momentum of the punch pin, etc., and achieve the effect of safe use, convenient and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

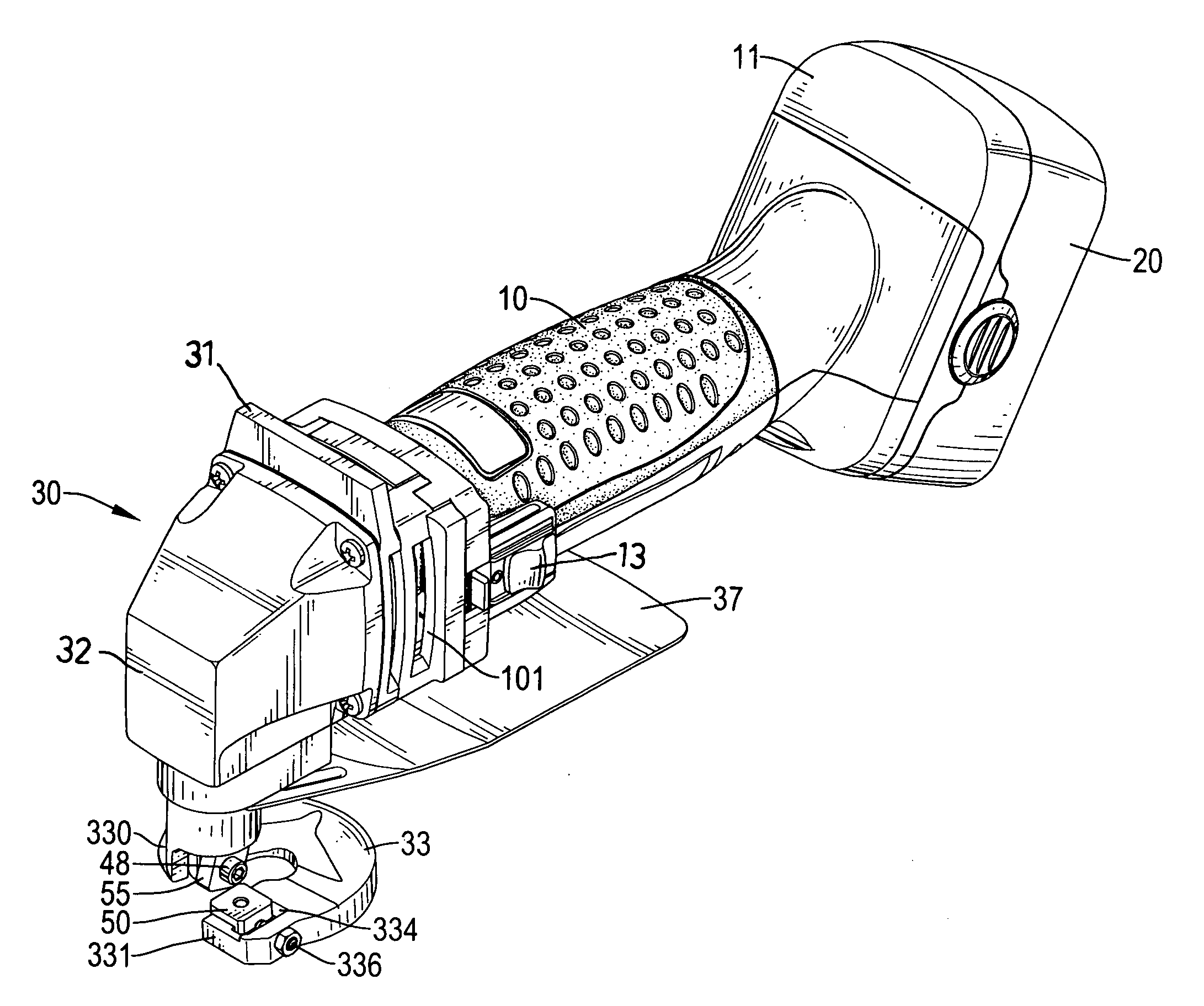

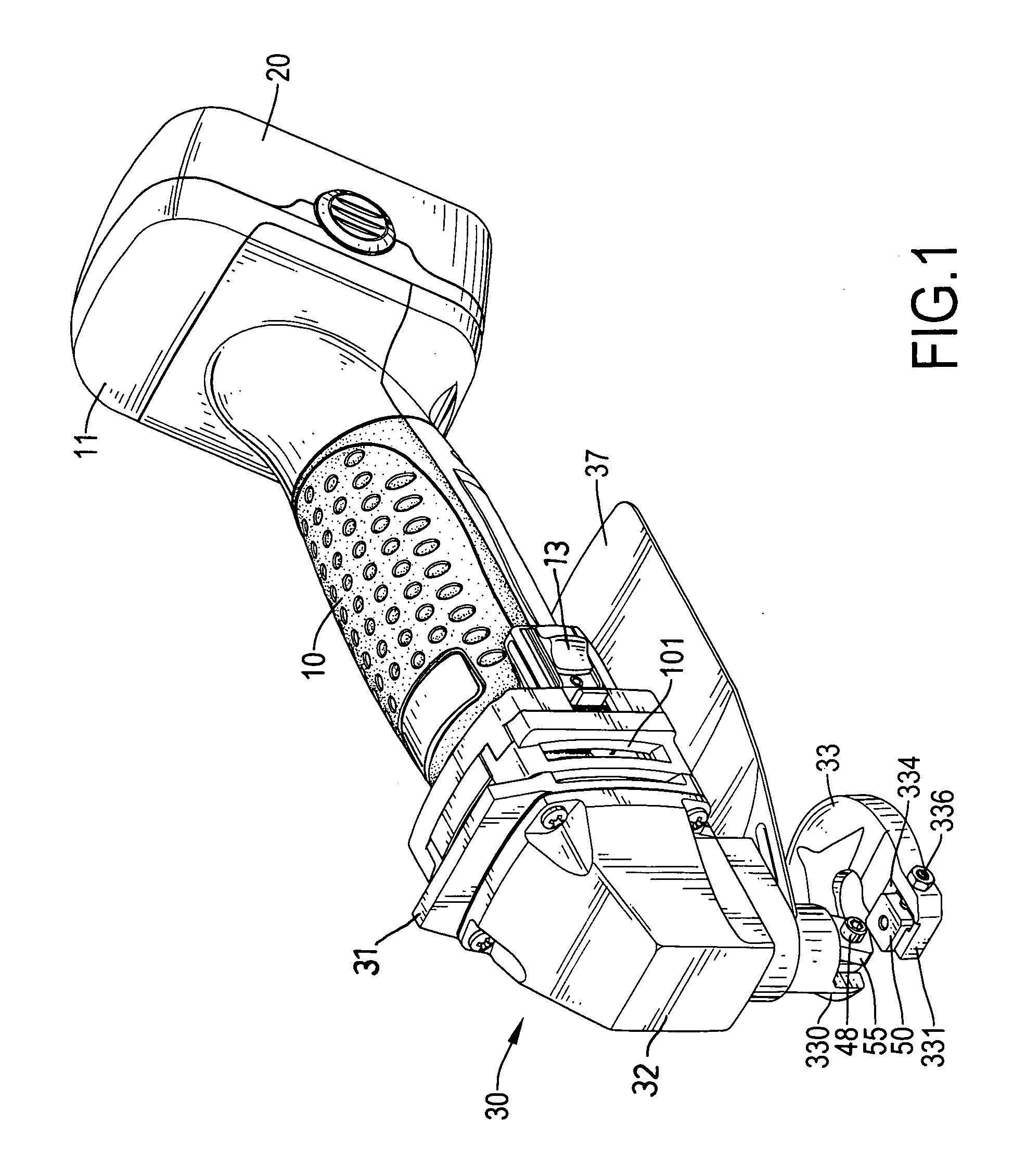

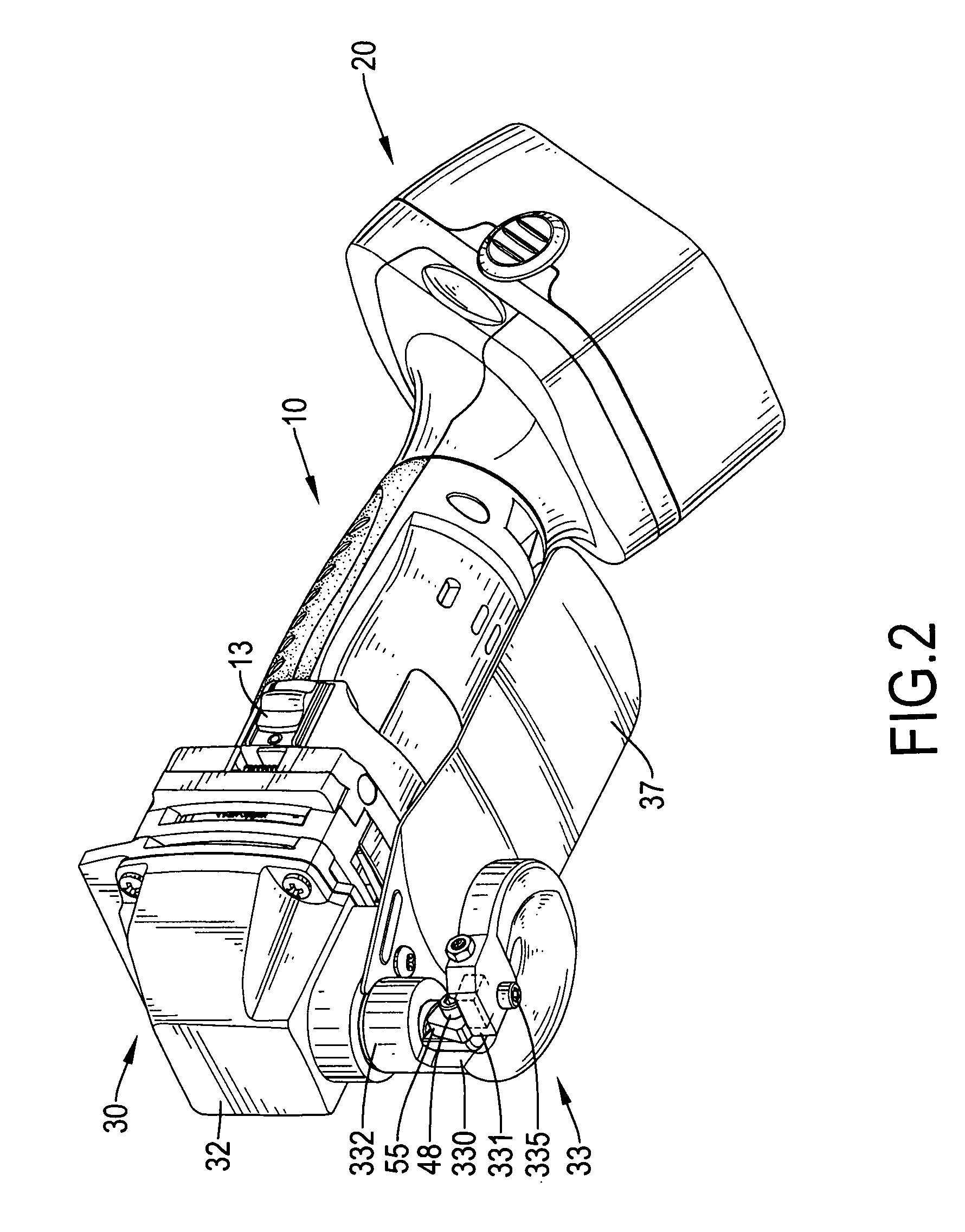

[0024]With reference to FIGS. 1 to 3, an electric nibbler in accordance with the present invention comprises a handle (10), a battery package (20), a front cover (30), a base (33), a lower blade (50), an optional safety plate (37), a drive device (15), a transmitting device (40) and an upper blade (55).

[0025]The handle (10) is hollow, is implemented with two half-casings and has a front end, a rear end, an interior, an outer surface, a battery seat (11), multiple ventilating holes (101) and a switch (13). The battery seat (11) is formed on the rear end of the handle (10). The ventilating holes (101) are formed through the outer surface of the handle (10) between the front end and the rear end and are communicated with the interior of the handle (10). The switch (13) is mounted on the outer surface of the handle (10) near the front end.

[0026]The battery package (20) is detachably attached to the battery seat (11) of the handle (10), is electrically connected to the switch (13) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com