Automatic shearing device of aluminum profile

A technology of shearing device and aluminum profile, applied in the direction of shearing device, accessory device of shearing machine, device for cutting by nibbling, etc., can solve the problems of large length error and low work efficiency, and achieve length error small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

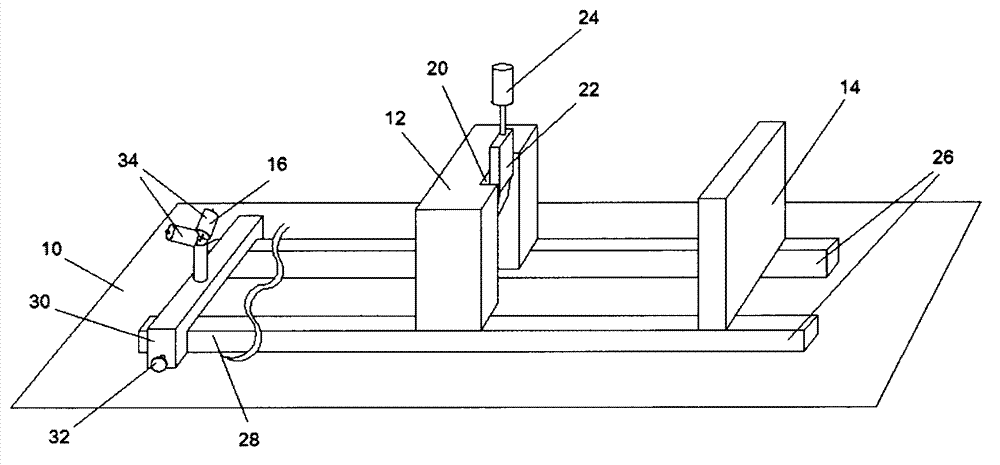

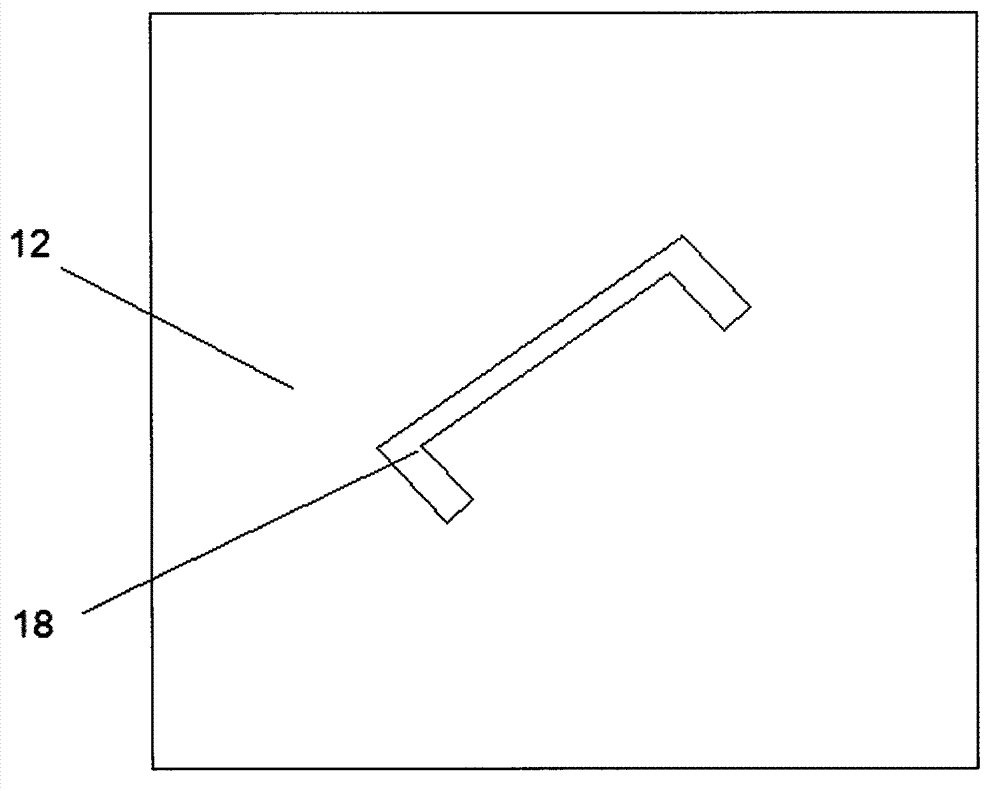

[0014] Such as figure 1 As shown, an automatic aluminum profile shearing device of the present invention includes a frame 10 on which a cutter seat 12 , a length-limiting baffle 14 and a support frame 16 are arranged. Wherein, cutter seat 12 is provided with such as figure 2 As shown in the profile hole 18 , the cross section of the profile hole 18 is the same as the cross section of the aluminum profile (not shown), which is convenient for the aluminum profile to pass therethrough. A vertical chute 20 is arranged on one side of the cutter seat 12 , and a cutter 22 is movably arranged in the chute 20 , and the outlet of the profile hole 18 is located in the chute 20 . The cutter 22 is driven by the oil cylinder 24 to move up and down to cut off the aluminum profile. The length-limiting baffle 14 is provided with a touch switch (not shown) at the position facing the profile hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com