Patents

Literature

56results about How to "Small length error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

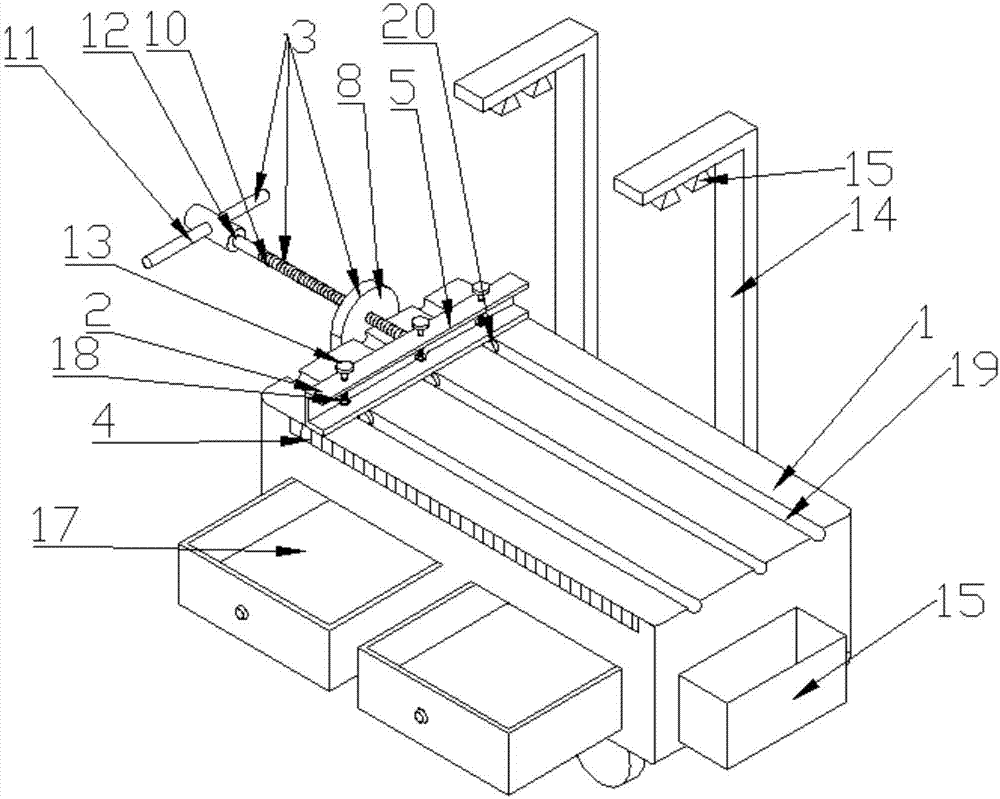

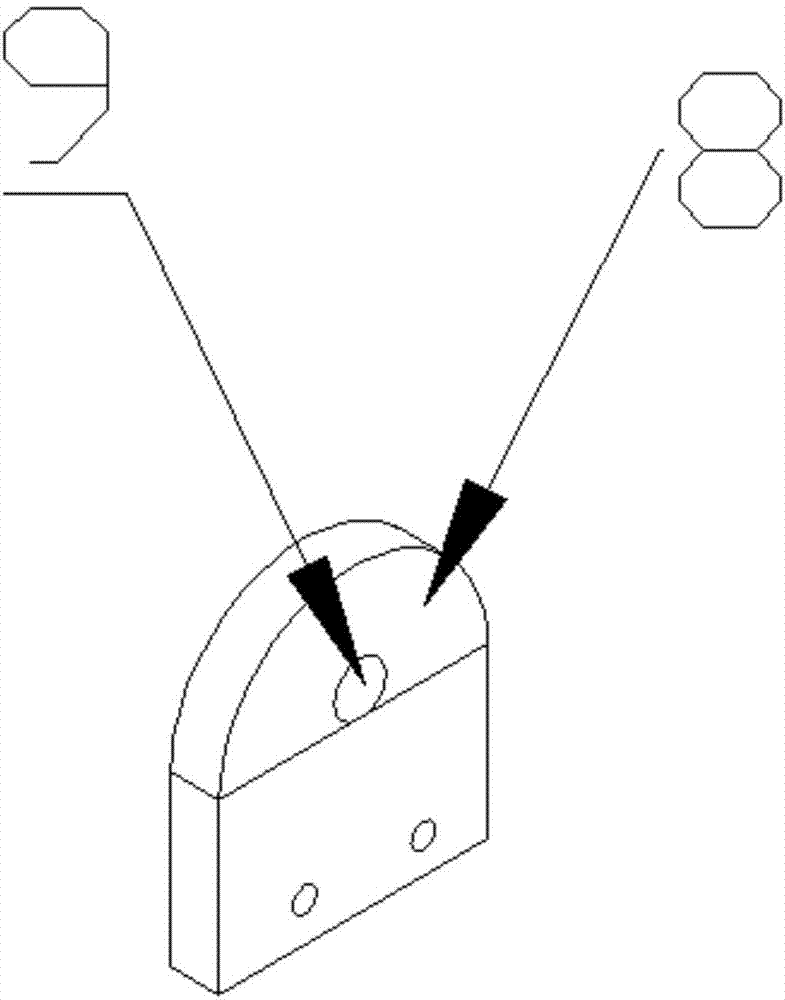

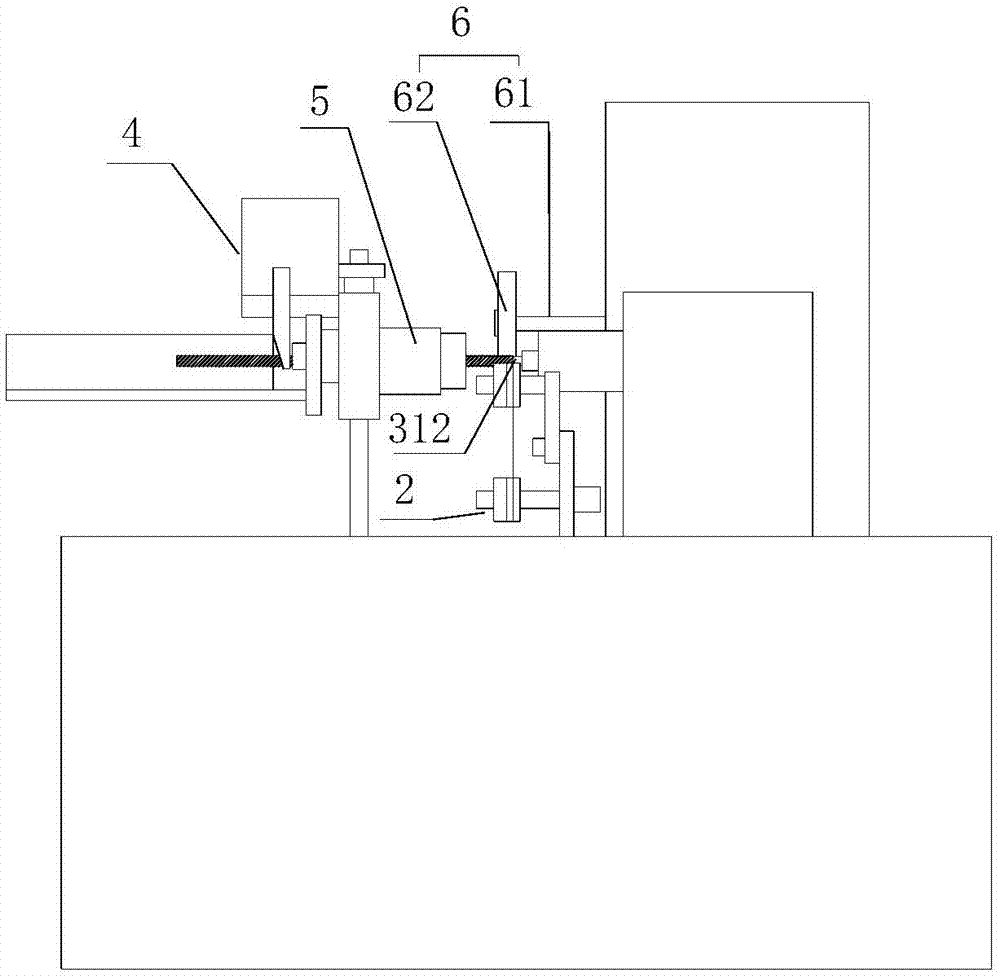

Automatic shearing device of aluminum profile

InactiveCN102756164AWith automationSmall length errorNibbling shearing machinesShearing machine accessoriesEngineeringTouch switch

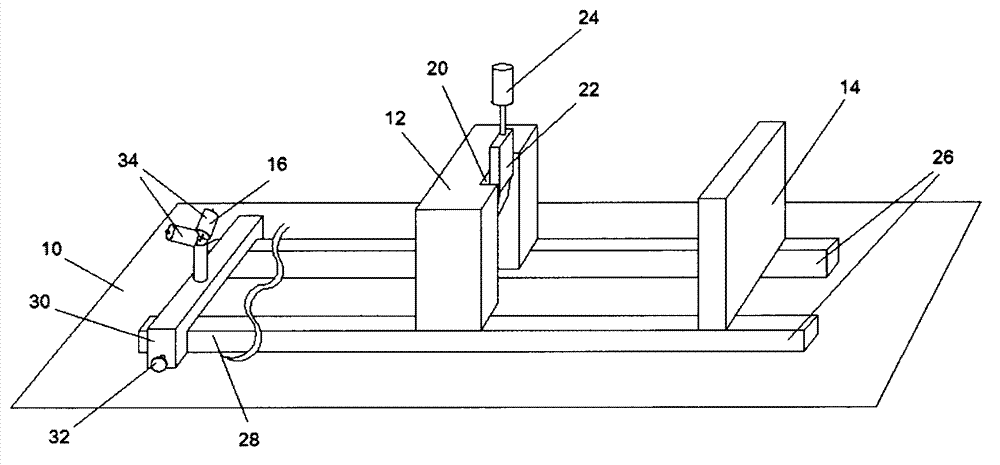

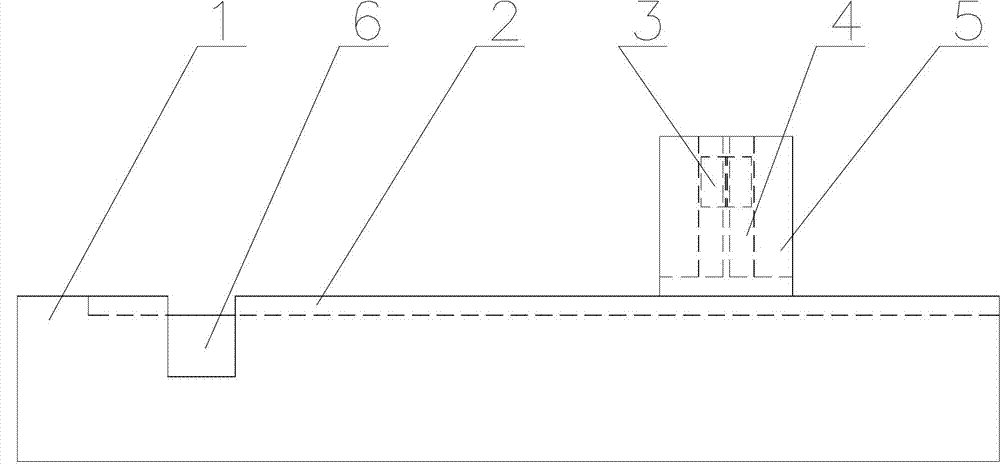

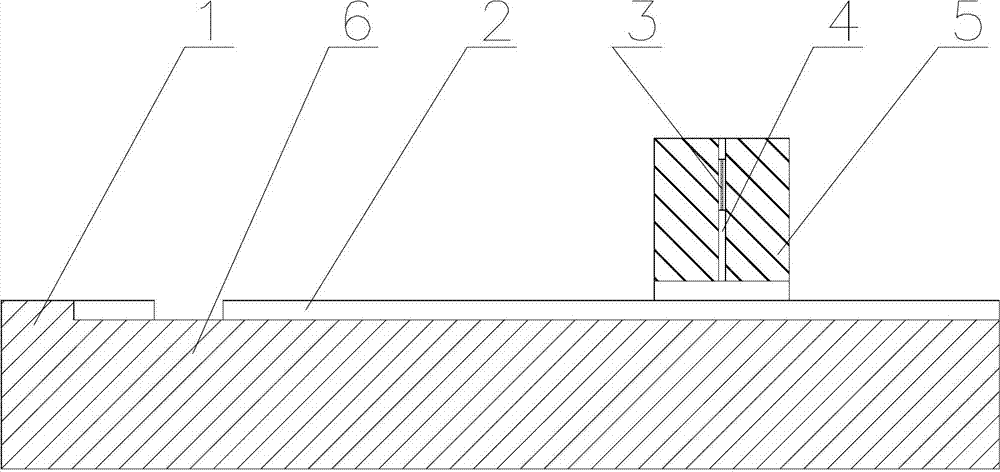

The invention discloses an automatic shearing device of aluminum profile. The automatic shearing device comprises a frame and is characterized in that a cutter base is arranged on the frame, profile holes communicated horizontally are arranged on the cutter base, the cross sections of the profile holes are matched with that of aluminum profile to be machined, the cutter base is provided with a cutter driven by an oil cylinder and capable of moving along the cutter base vertically on the lateral side close to the rear end of the profile, the rear end of the cutter is further provided with a length-limiting retaining plate parallel to and right opposite to the cutter base, a touch switch is arranged on the length-limiting retaining plate at the position right opposite to the profile hole, and the touch switch is electrically connected with the oil cylinder. The automatic shearing device of the aluminum profile first determines the length of the aluminum profile to be cut through the length-limiting retaining plate, and the oil cylinder is controlled through the touch switch to cut the aluminum profile automatically. The automatic shearing device of the aluminum profile has the advantages of being automatic, efficient and small in length errors and the like.

Owner:苏州禾源机电工程技术有限公司

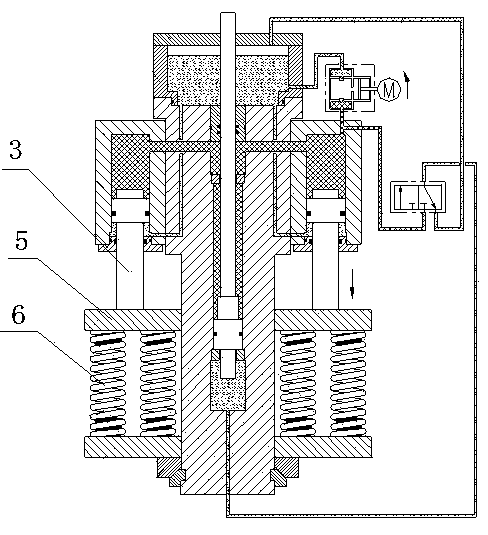

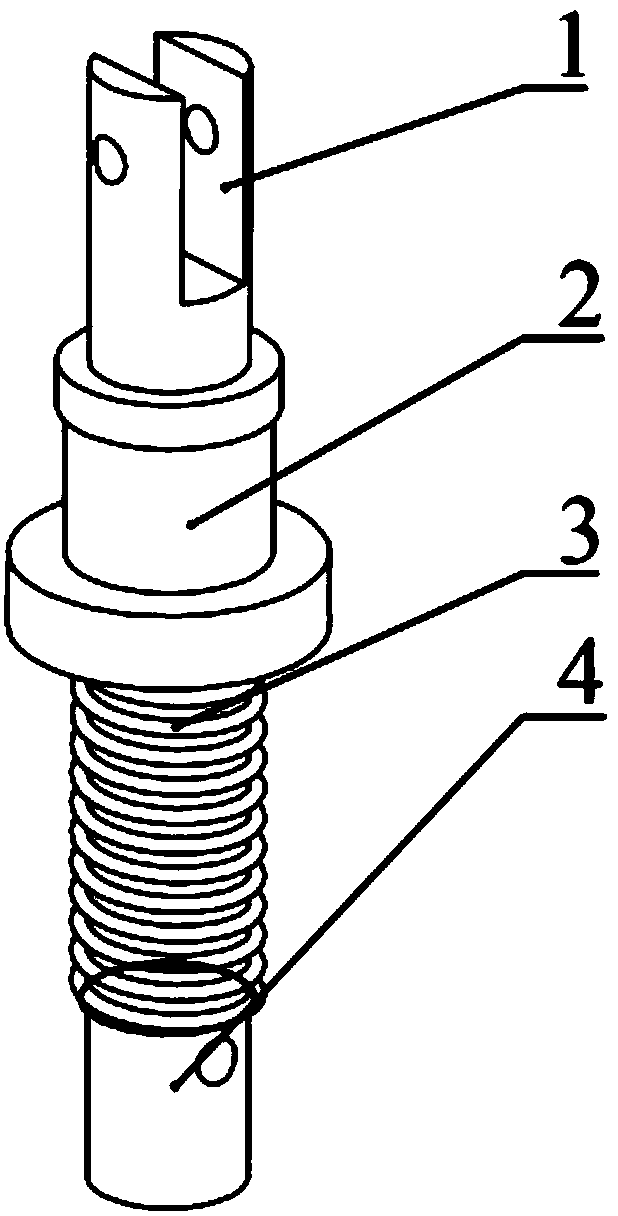

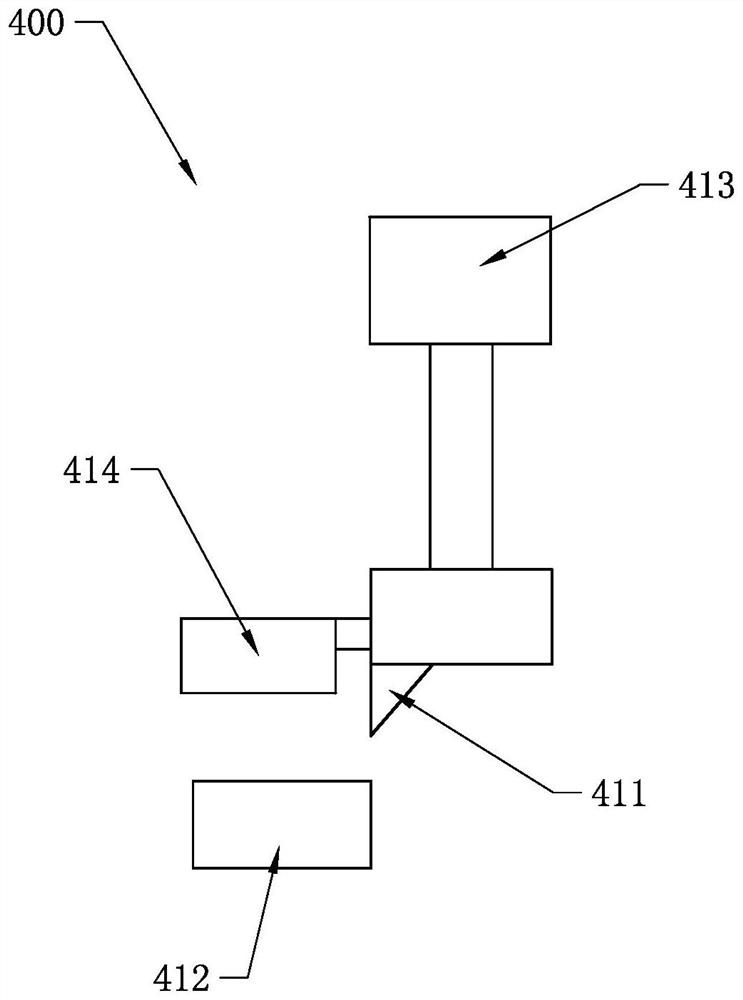

Spring energy storage hydraulic operation mechanism and energy storage spring unit

InactiveCN104143468ASmall length errorReduce slopeHigh-tension/heavy-dress switchesAir-break switchesLinear relationshipCylinder block

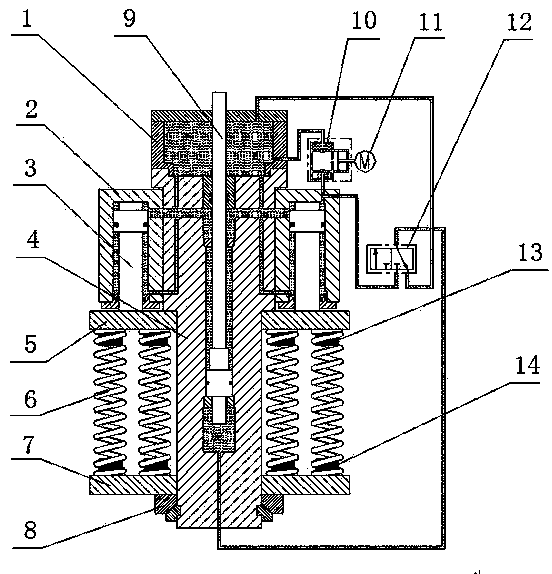

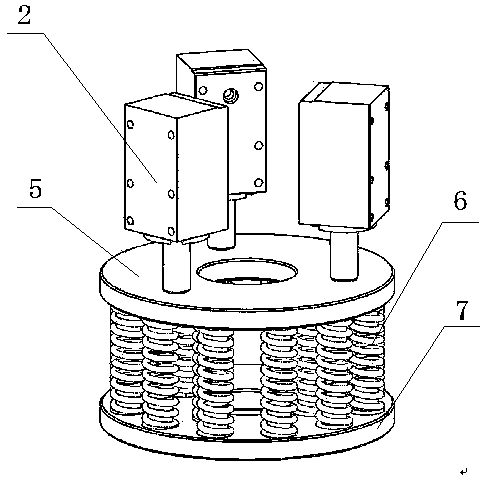

The invention discloses a spring energy storage hydraulic operation mechanism and an energy storage spring unit. The energy storage spring unit comprises an upper press plate, a lower press plate, and an energy storage spring installed between the upper press plate and the lower press plate in an abutting mode, wherein the upper press plate and the lower press plate are arranged on a cylinder block of a working cylinder in a sleeved mode, the energy storage spring is formed by spiral compression springs which are arranged into an array between the upper press plate and the lower press plate in an abutting mode, and the center line of the spiral compression spring array coincides with the axis of the cylinder block of the working cylinder. On one hand, the machining error of a single spiral compression spring is small, a linear relationship is formed between output force and displacement, performance is stable, the influence of environment temperature is avoided in normal use, and therefore the energy storage spring unit is an ideal energy storage element; on the other hand, the multiple spiral compression springs are arranged in parallel, the slope of the characteristic curve of a single spiral compression spring can be reduced exponentially, ideal output characteristics can be obtained through reasonable design, the effect that large output force is obtained through small displacement is achieved, and the more the springs are, the smaller the length error of the spring assembly is and the higher the output precision is.

Owner:STATE GRID CORP OF CHINA +2

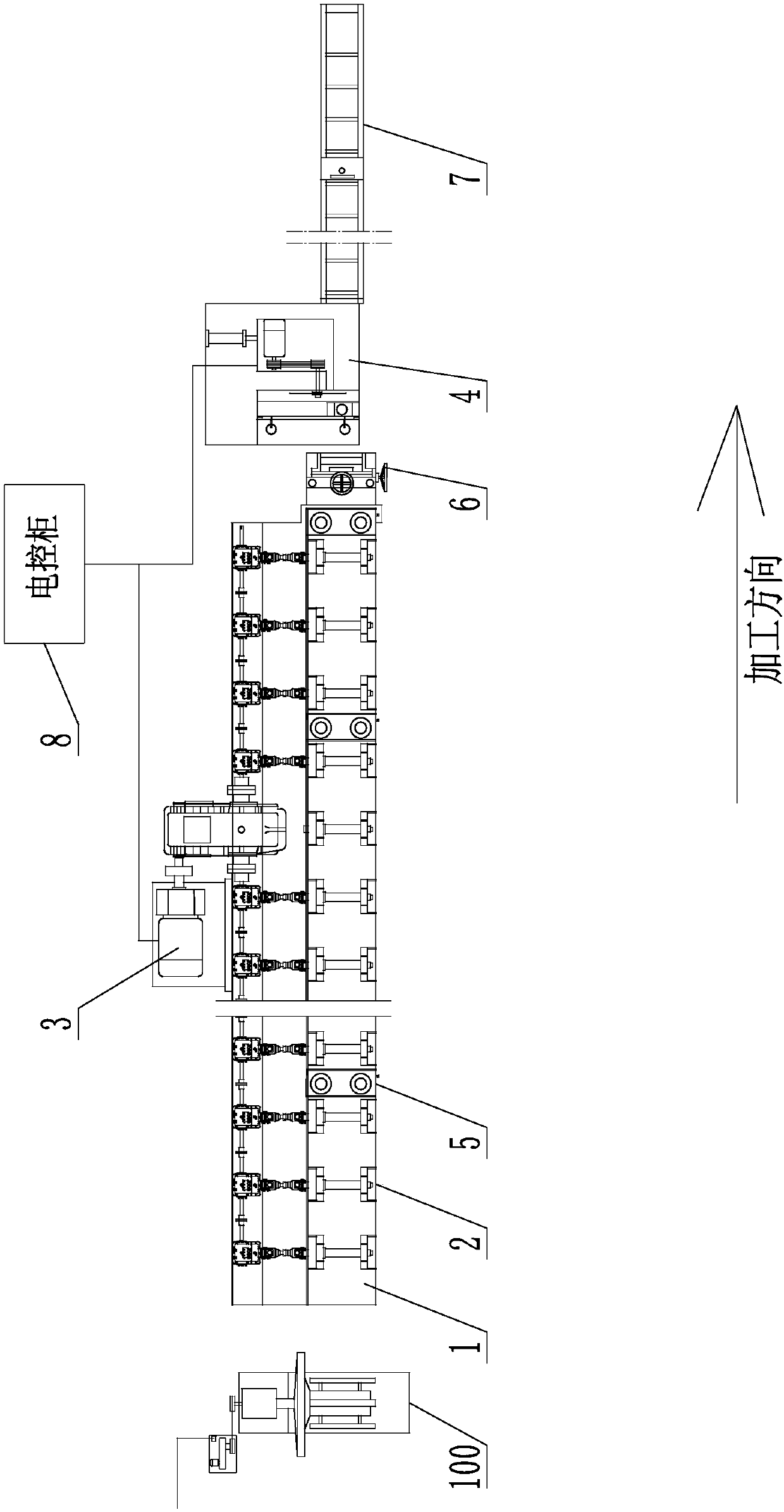

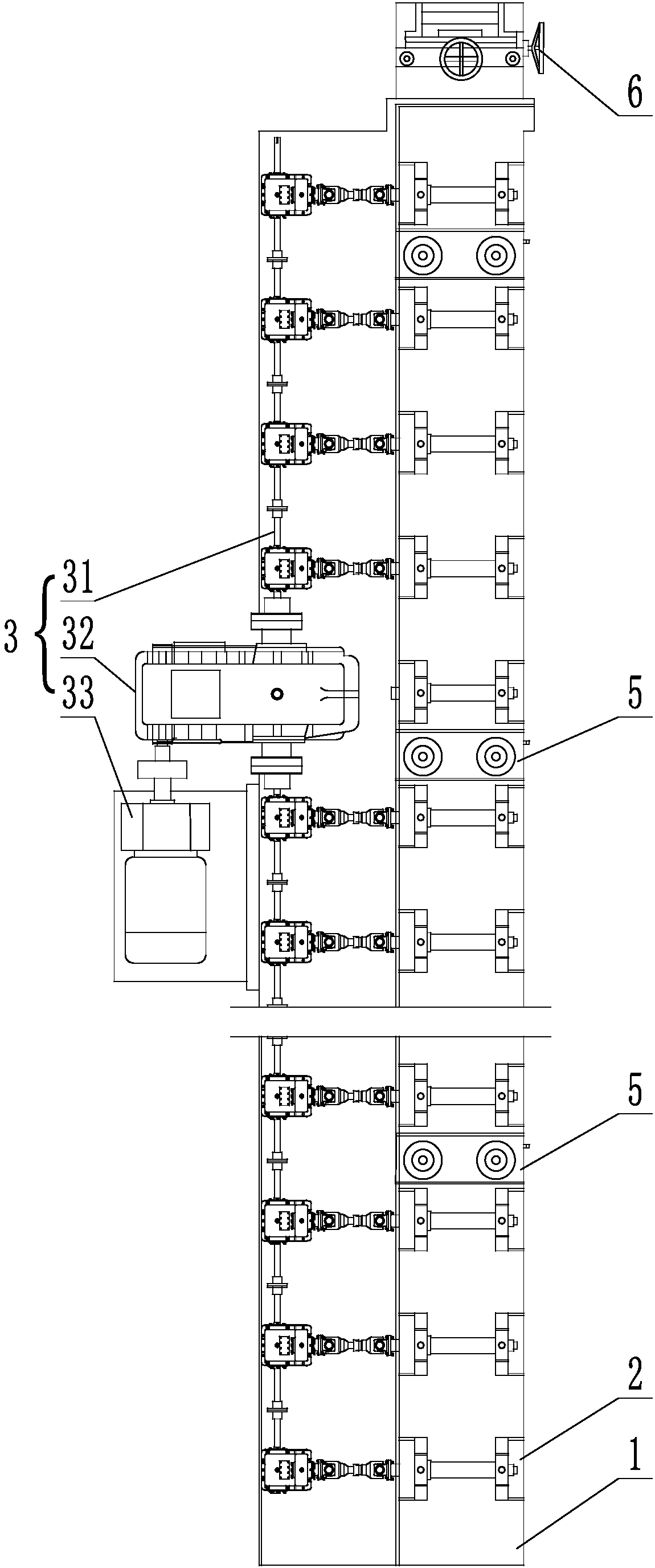

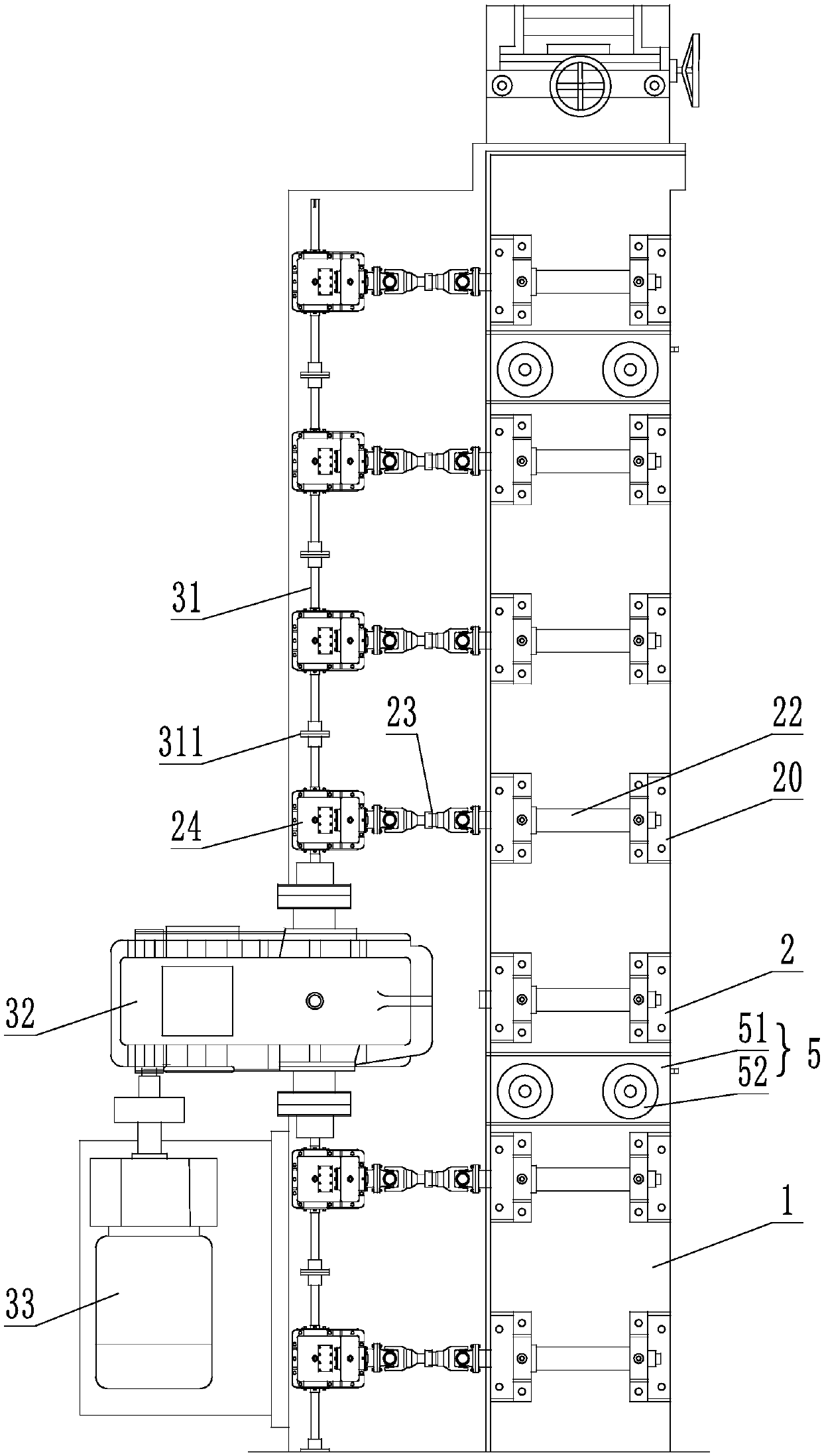

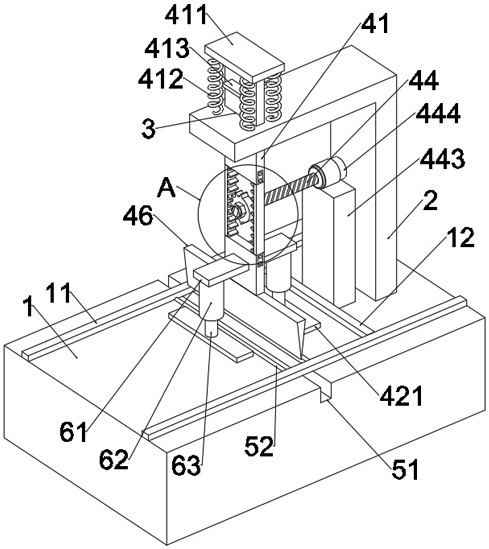

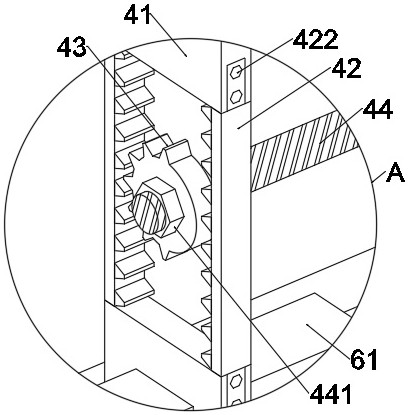

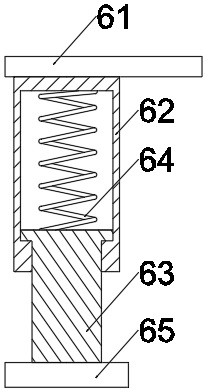

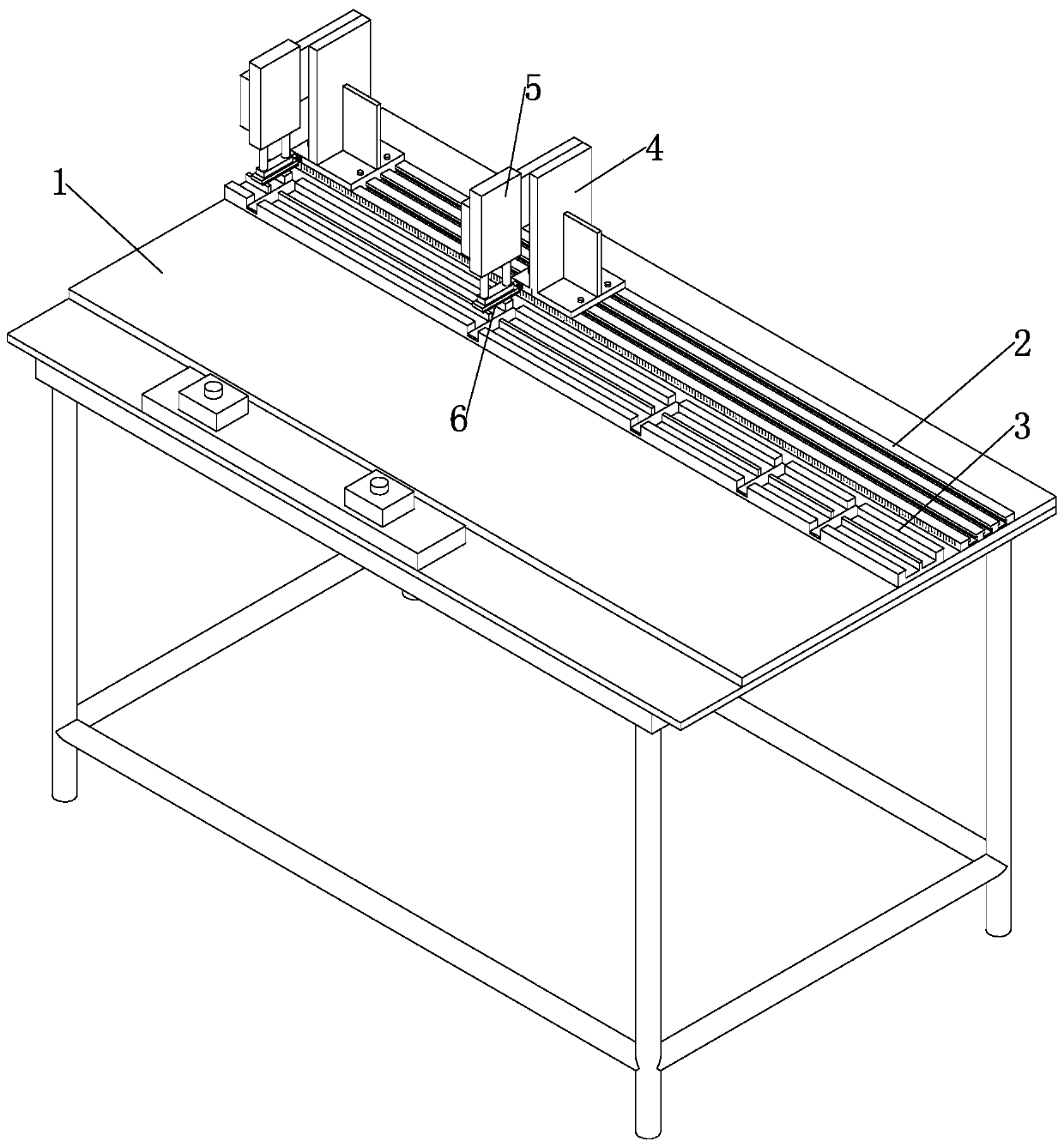

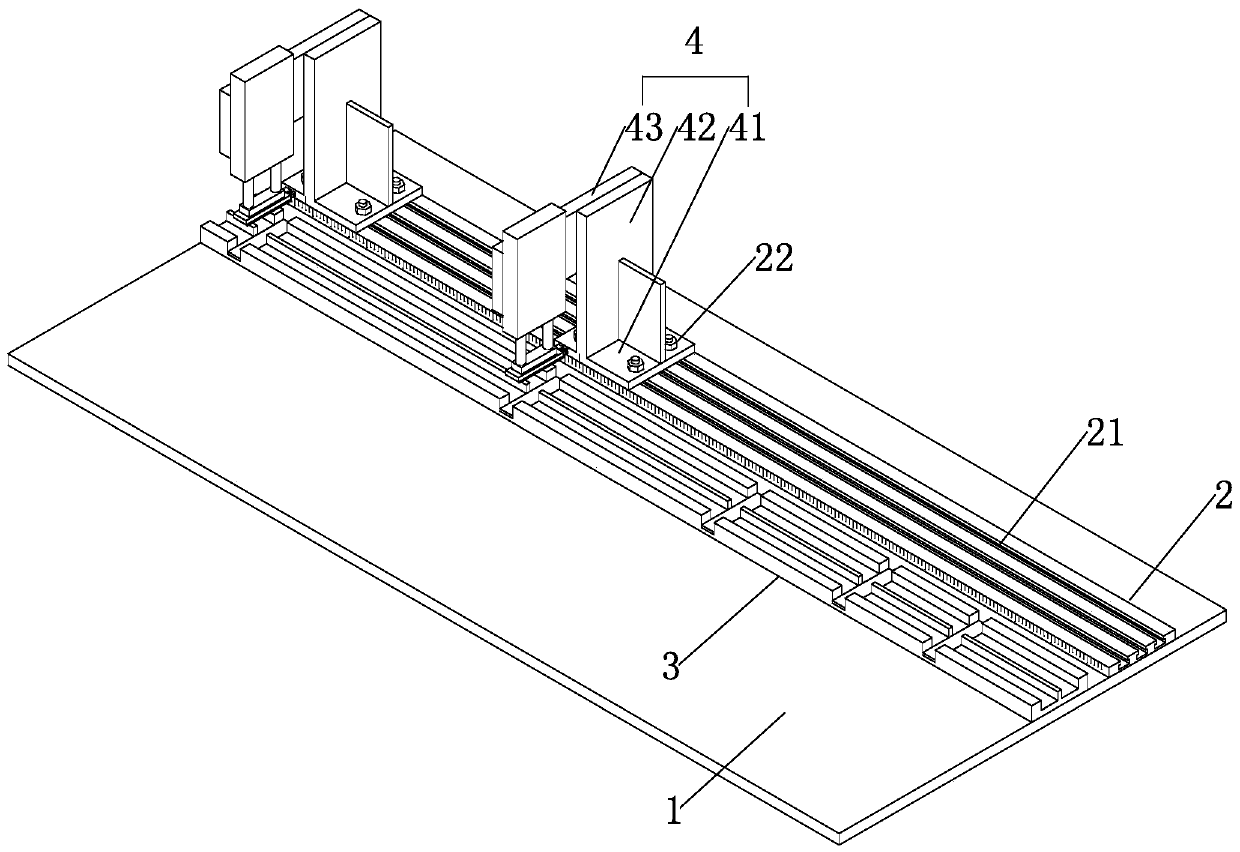

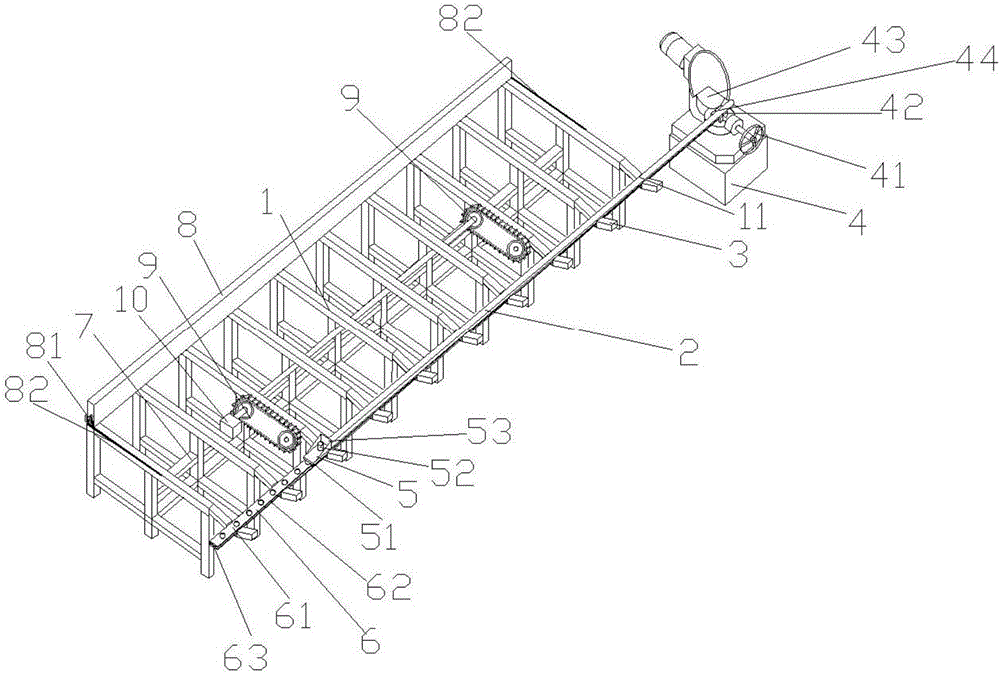

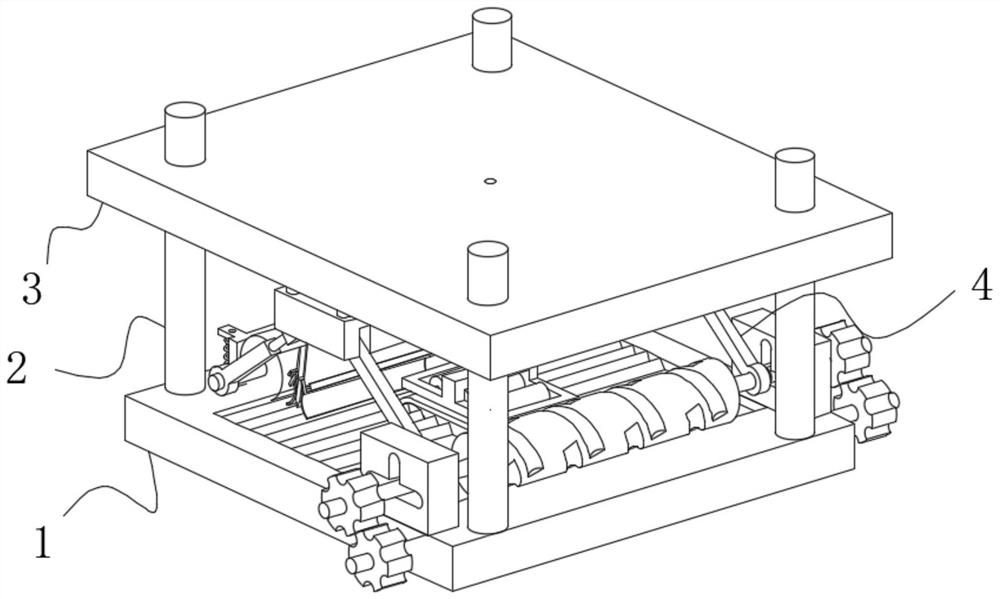

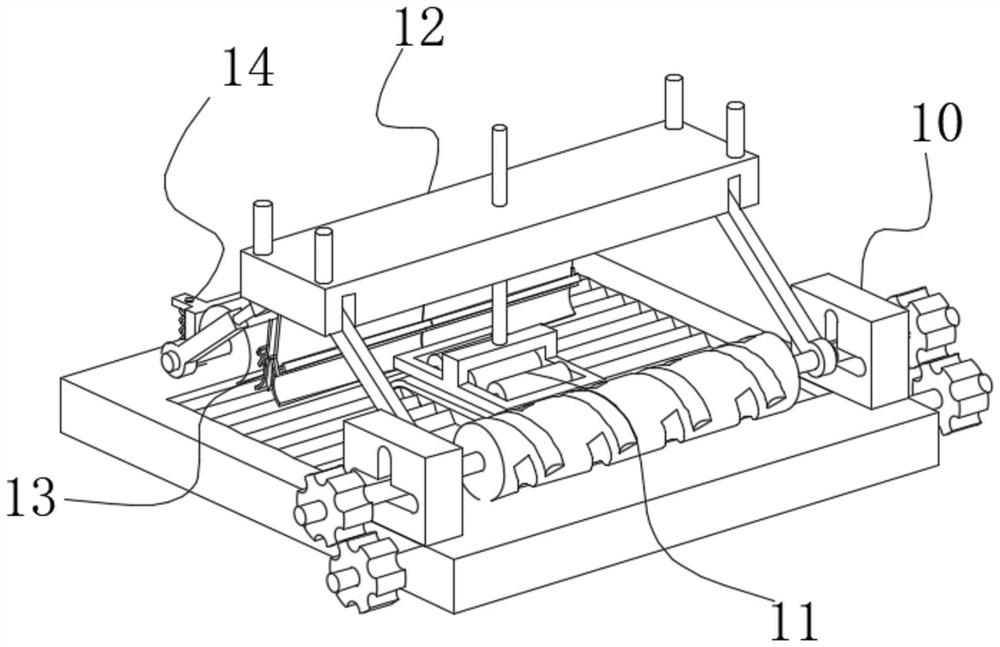

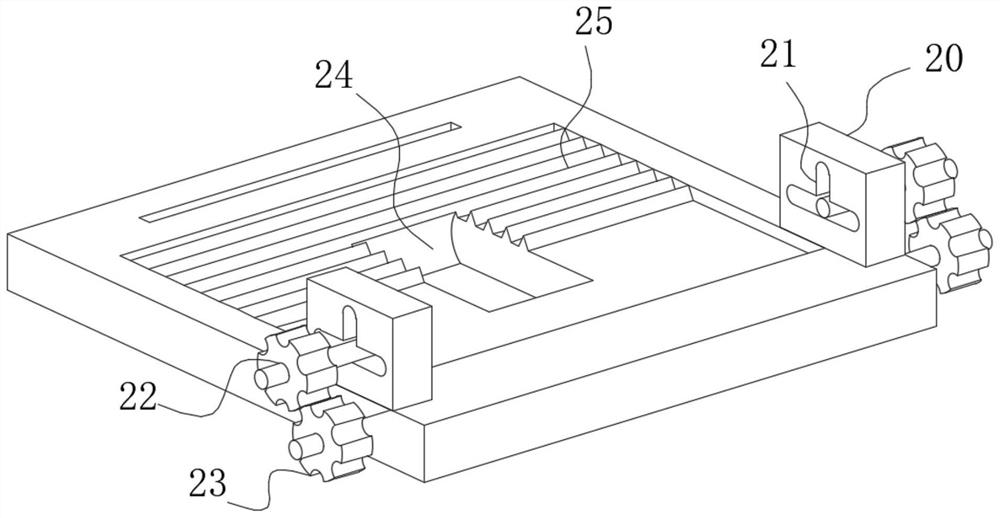

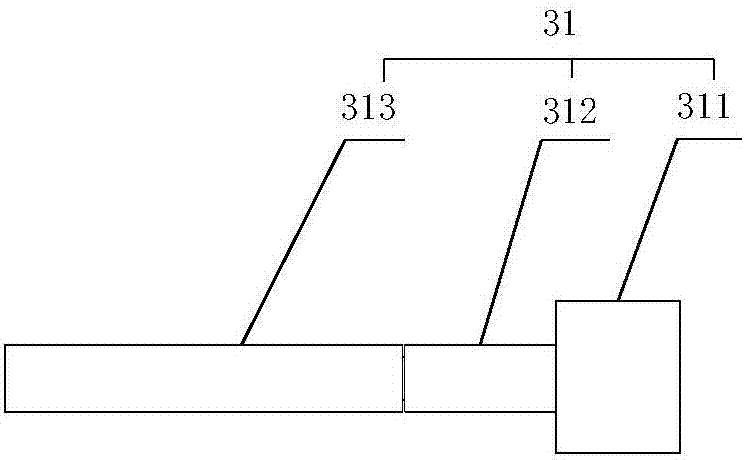

Cold roll forming machine

InactiveCN107584280AShorten the timeSmall size errorMetal-working feeding devicesOther manufacturing equipments/toolsCouplingRoll forming

The invention relates to a cold roll forming machine. The cold roll forming machine comprises a base. A plurality of forming main machines arranged in the same direction are arranged on the base in the length direction, a containing frame for containing steel plates is arranged at one end of the base, and a sectional-material cutting platform is arranged at the other end of the base; upper pressing rollers and lower pressing rollers for bending the steel plates are rotatably arranged on the forming main machines, input shafts of the lower pressing rollers are connected with gear cases throughfirst couplers, the multiple gear cases are located on a same straight line and connected through a shared rotating shaft, a speed reducer is connected to the middle of the rotating shaft, and a mainmotor is connected to the input end o the speed reducer. The steel plates can be uniformly bent and formed, then the bent sectional materials are cut as required, used time of steel plate bending is shortened, and the processing efficiency is improved.

Owner:BEIJING CHENGDONG INT MODULAR HOUSING

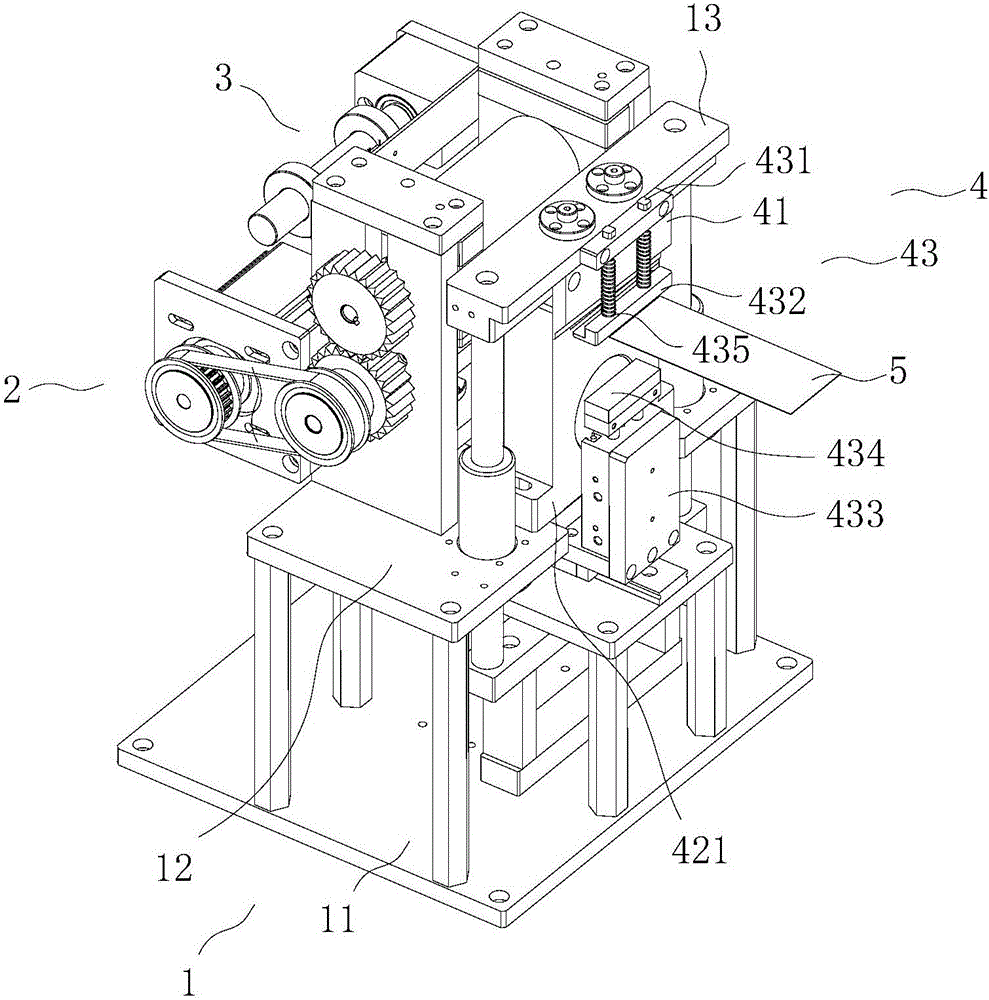

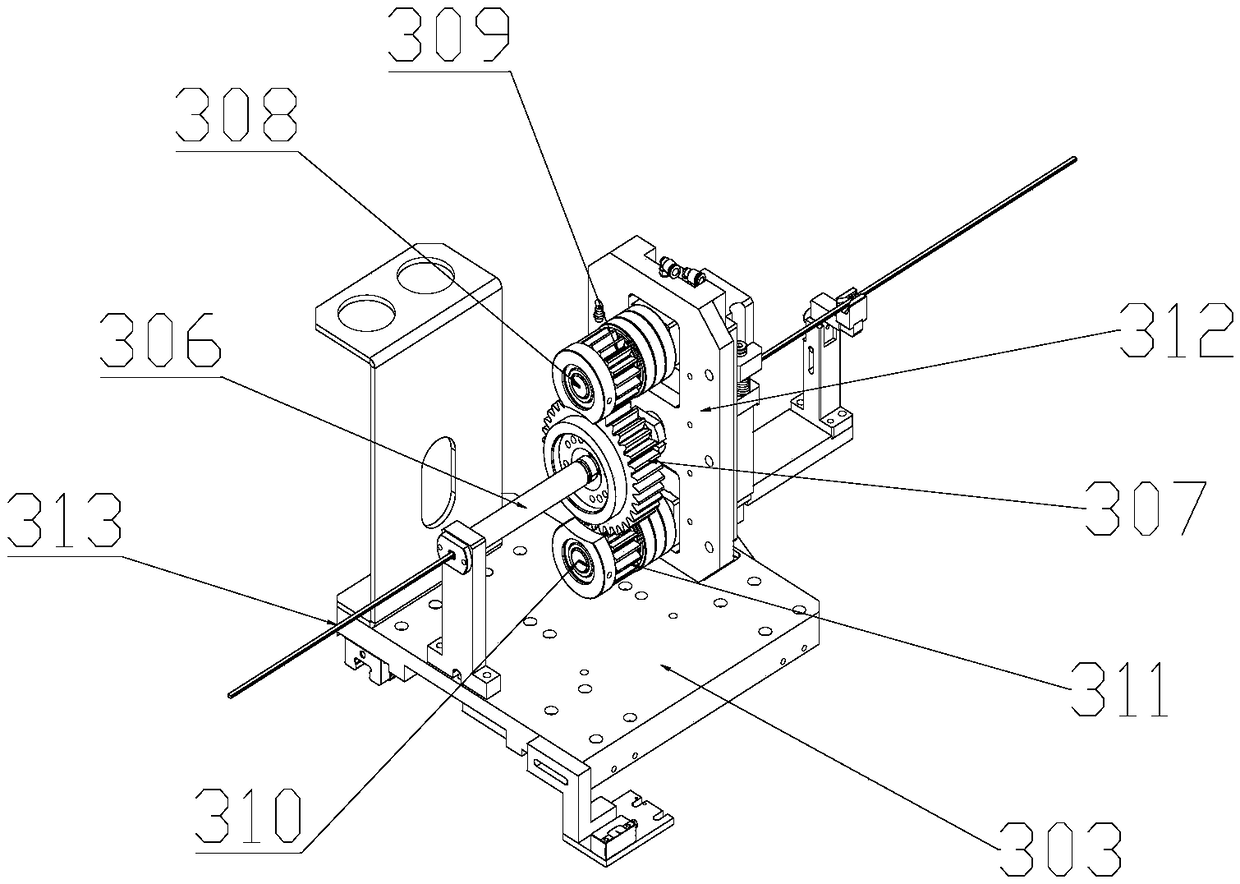

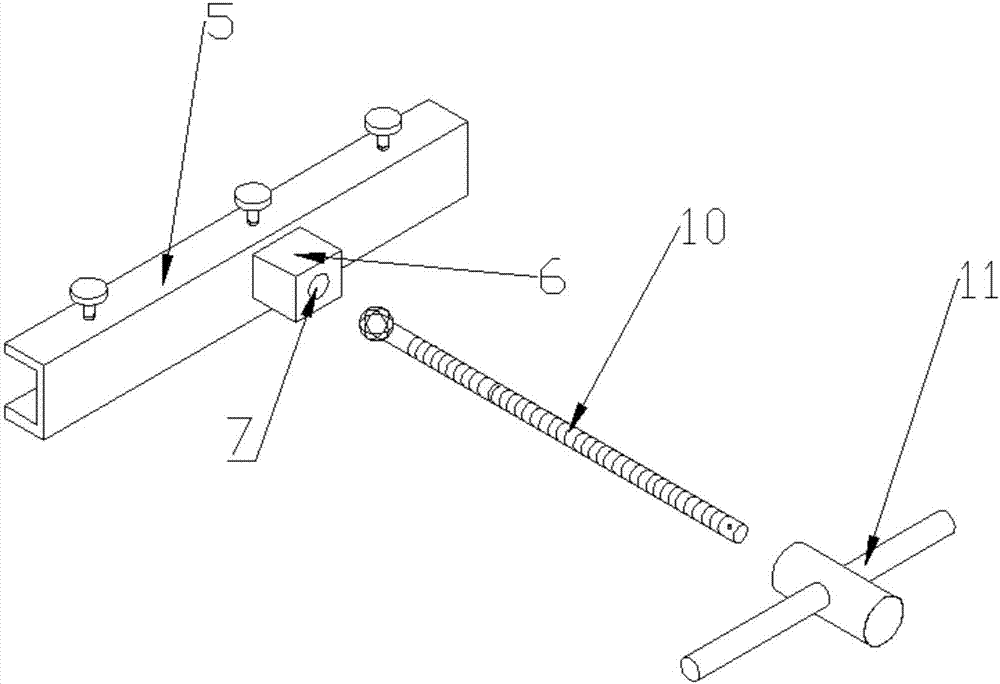

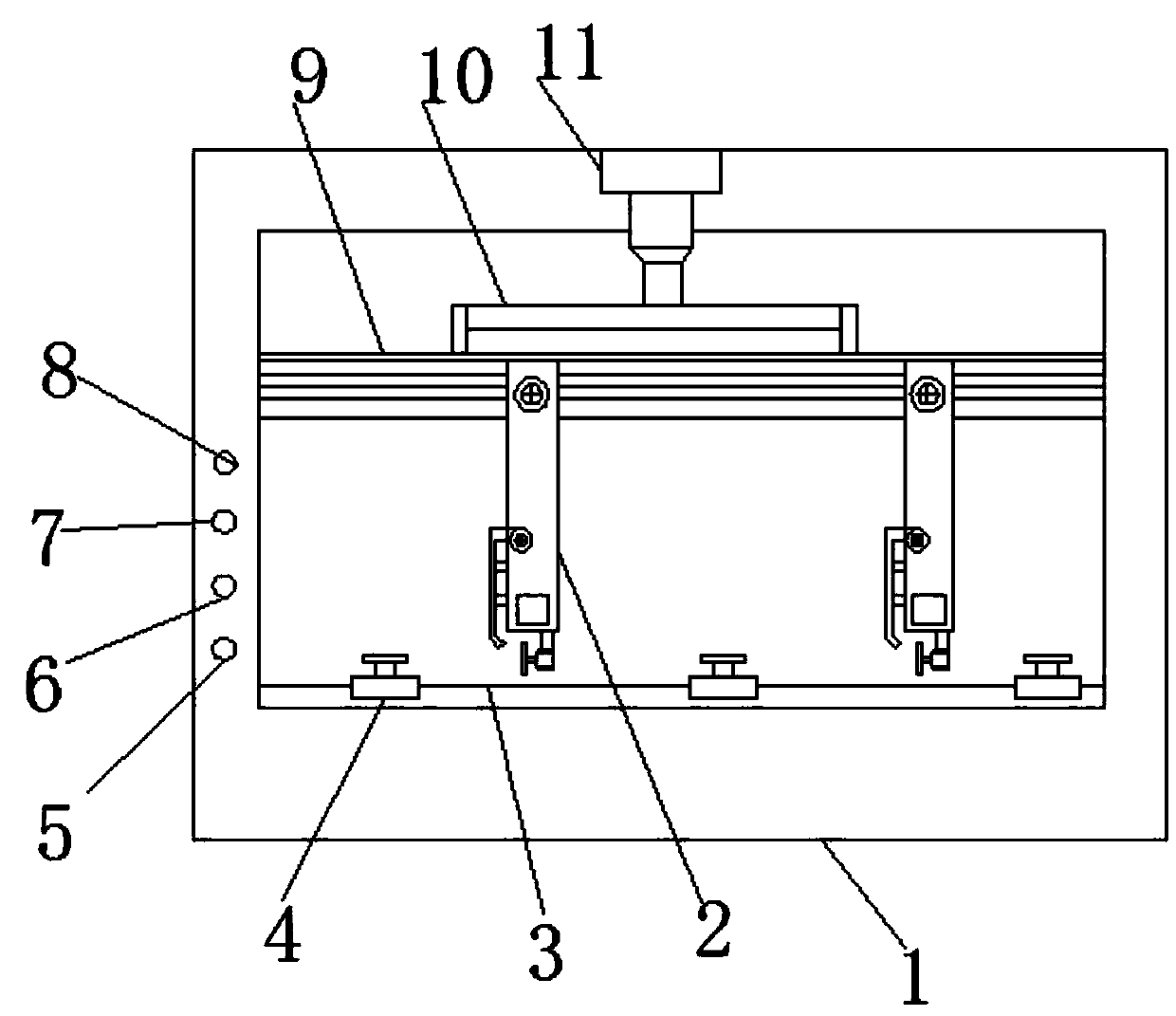

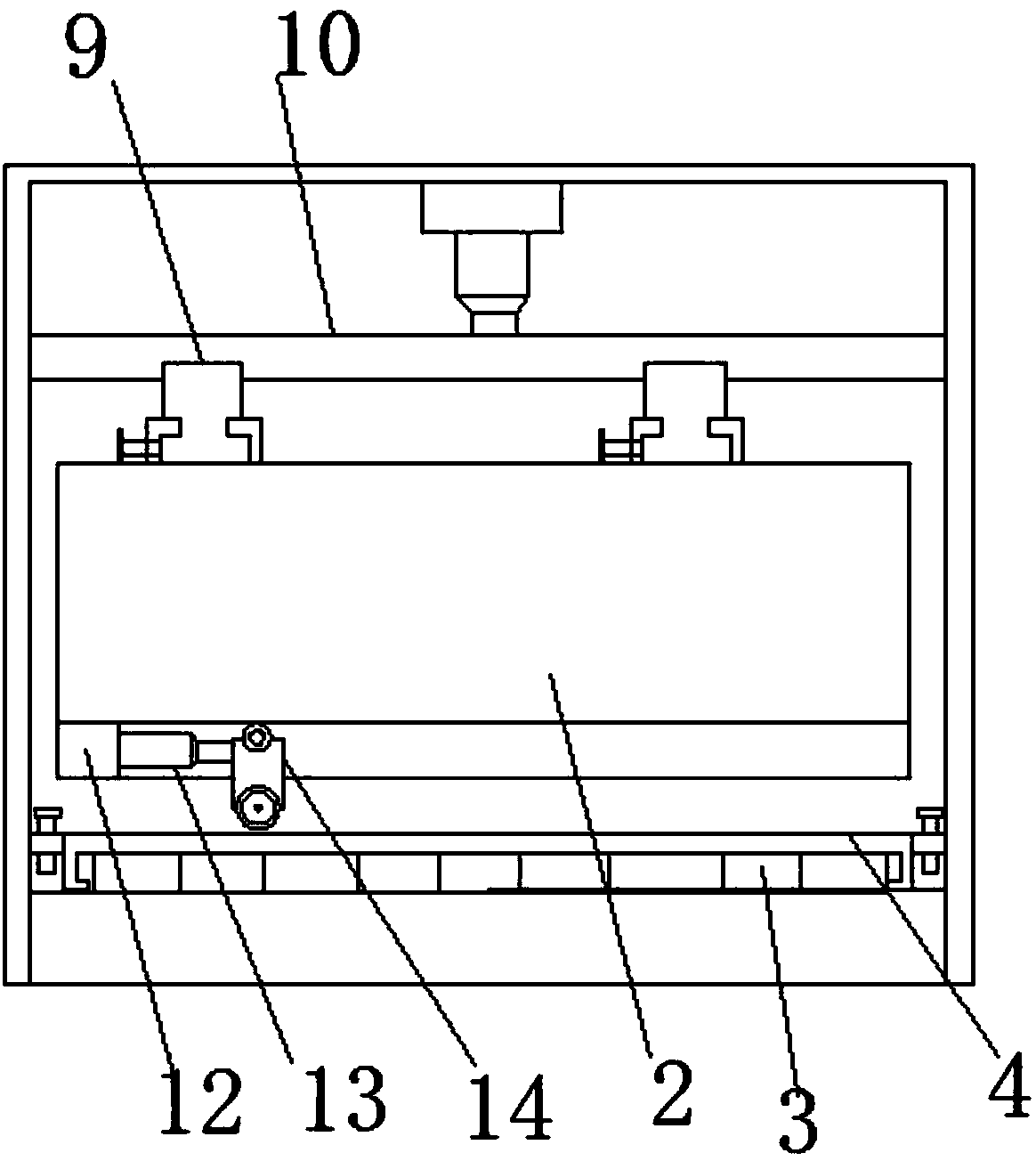

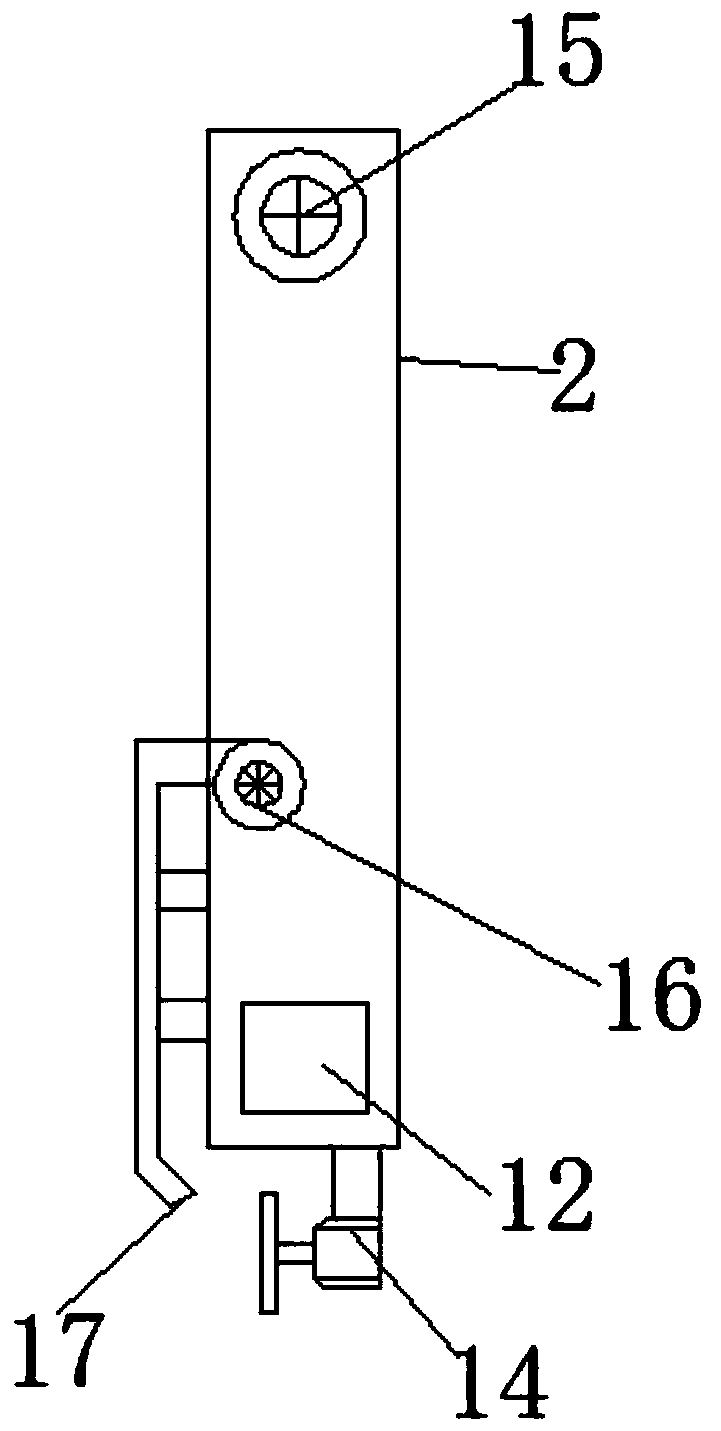

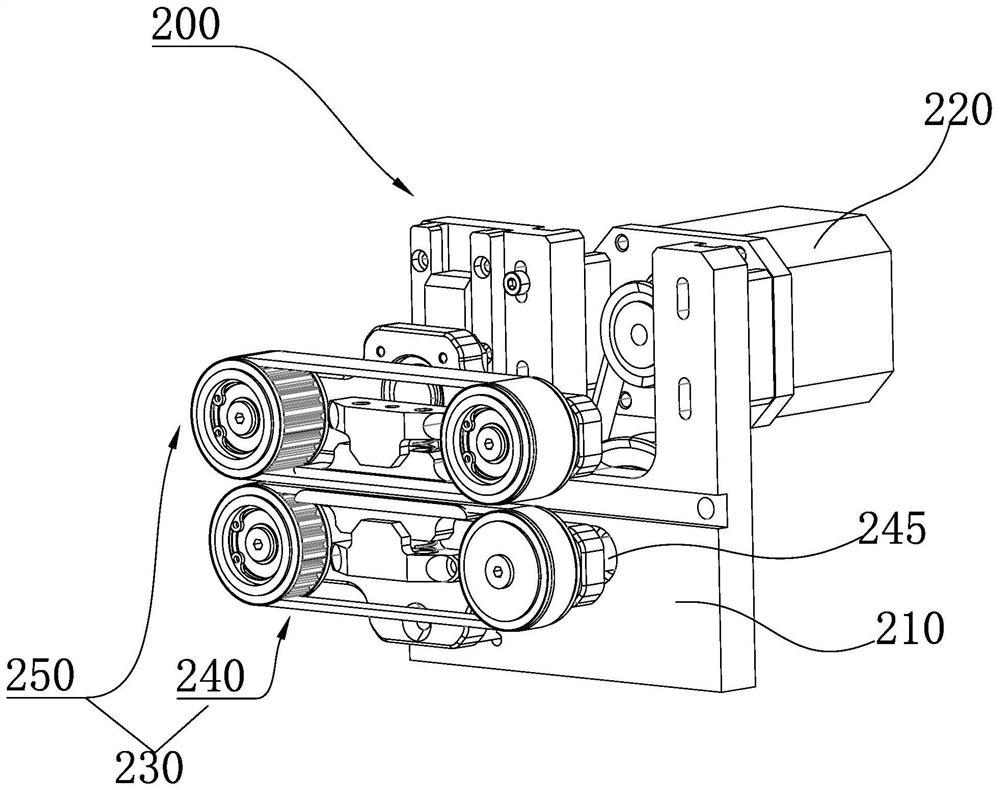

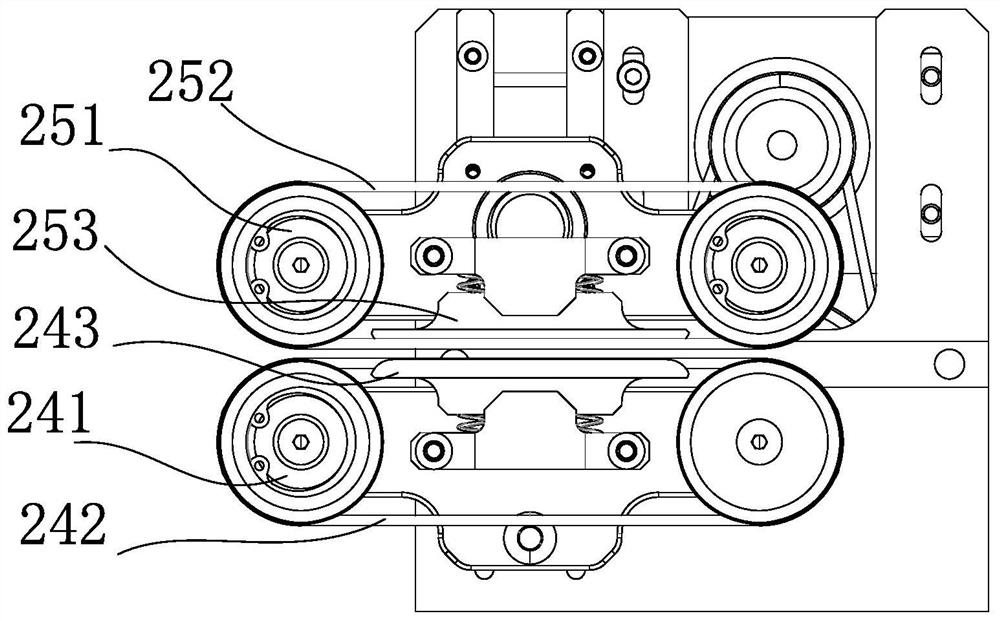

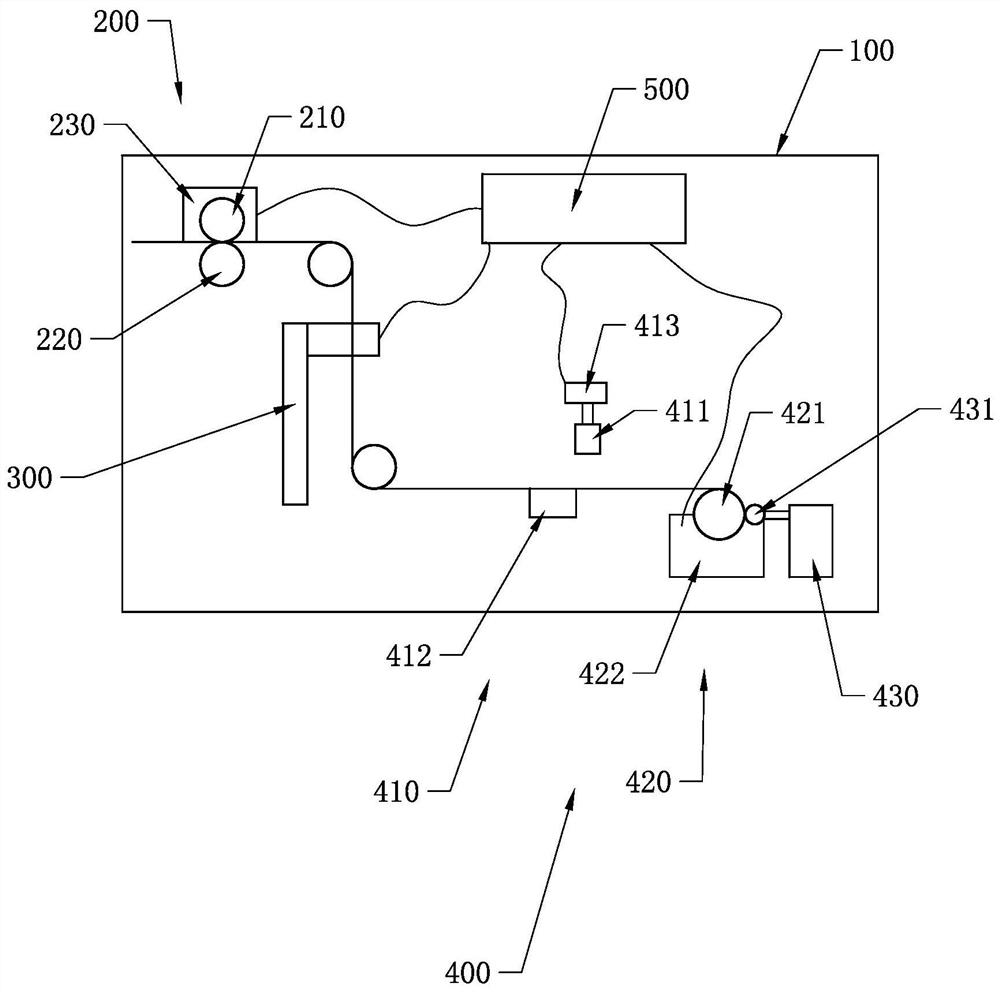

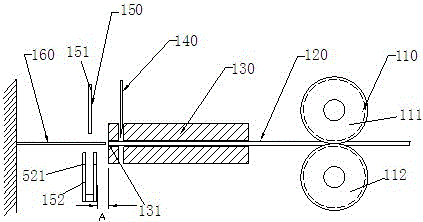

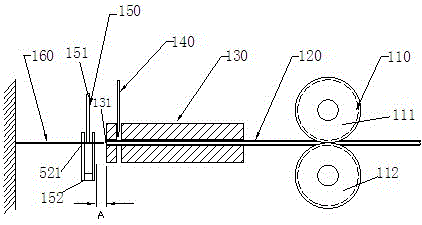

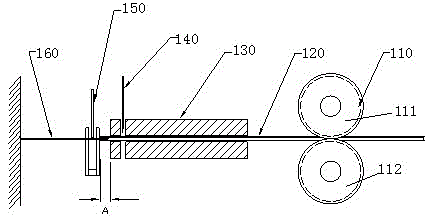

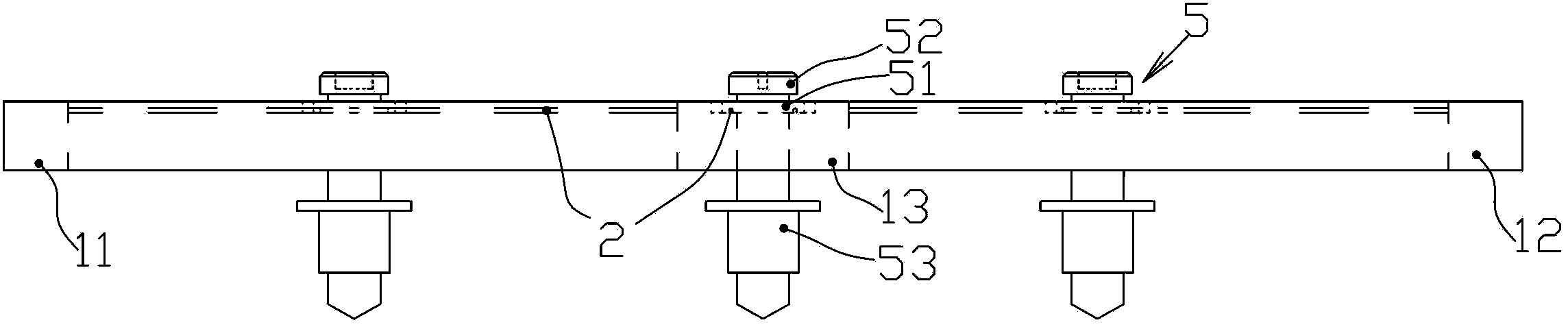

Equidistant cutting device

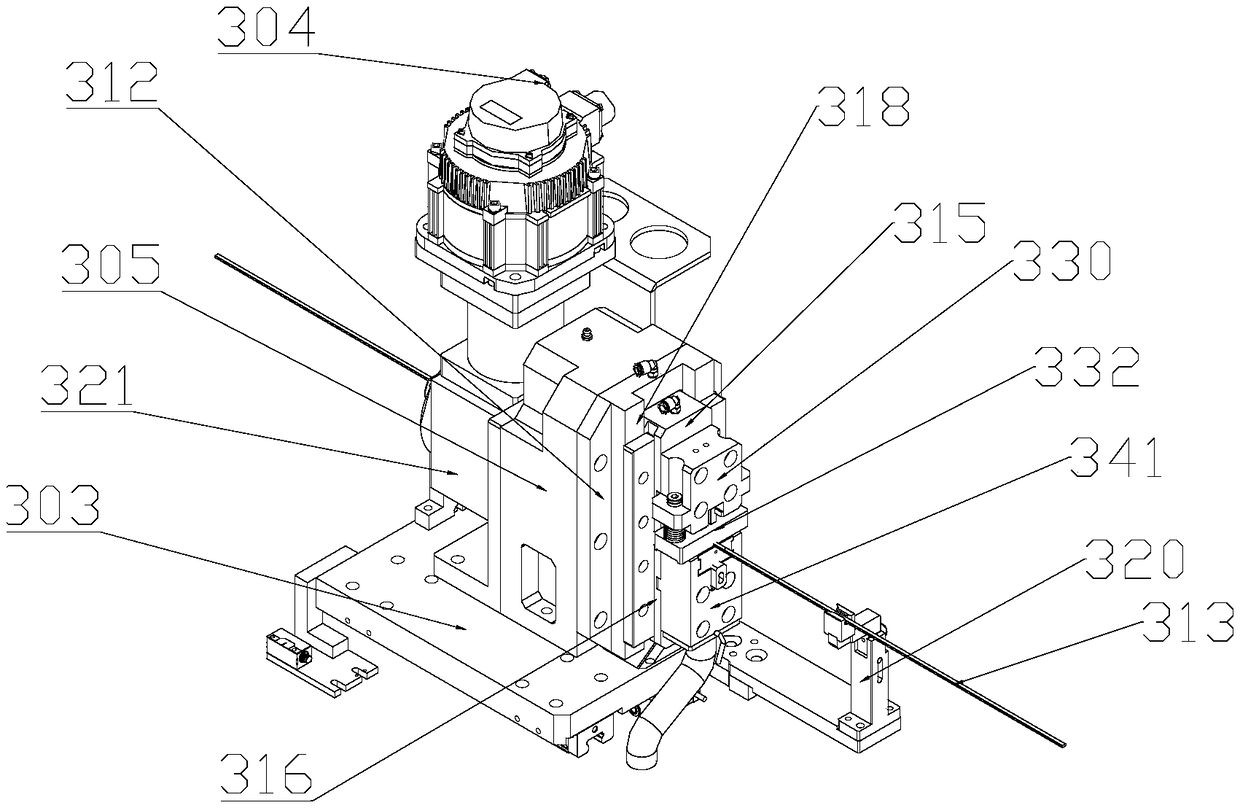

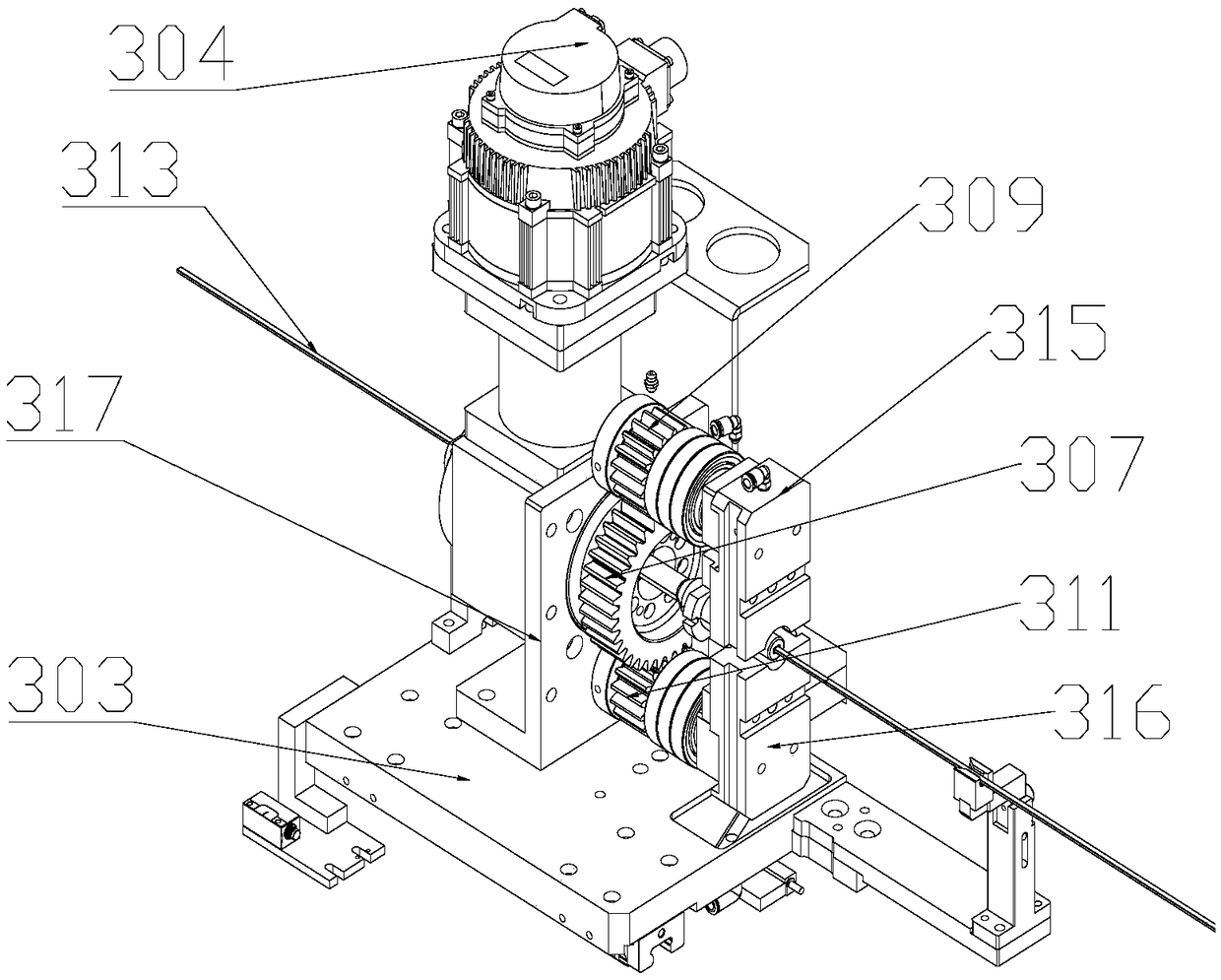

The invention discloses an equidistant cutting device. The equidistant cutting device comprises a work support, a conveying assembly arranged on the work support, a supply assembly arranged on the feed side of the conveying assembly and a cutting assembly arranged on the discharge side of the conveying assembly; the conveying assembly comprises a stepping motor fixedly arranged on the work support, an upper conveying roller, a lower conveying roller and a transmission structure, wherein the upper conveying roller and the lower conveying roller are arranged in the vertical direction, and the transmission structure enables the stepping motor to drive the upper conveying roller and the lower conveying roller to rotate; the cutting assembly comprises a cutter fixedly arranged on the work support, a first clamping mechanism clamping material is arranged on the feed side of the cutter, and a second clamping mechanism driving the material to move towards the cutter is arranged on the discharge side of the cutter; the stepping motor and the second clamping mechanism are connected to a control assembly. Through mutual rotation of the upper conveying roller and the lower conveying roller, the material is driven to penetrate through the part between the upper conveying roller and the lower conveying roller, the control assembly accurately controls the rotation angle of the stepping motor, the speed of conveying the material by the upper conveying roller and the lower conveying roller is adjusted, and the length error of the material cut each time is reduced.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

New energy automobile motor copper wire automatic molding equipment

PendingCN108889884APrevent fallingImprove securityWire articlesElectric machinesNew energyCopper wire

The invention discloses a new energy automobile motor copper wire automatic molding integrated equipment, comprises an assembly slide rail, wherein one end of the assembly slide rail is provided witha copper wire coiling and uncoiling device and the other end is provided with a copper wire molding device, and a copper wire stripping device, a copper wire traction device, a copper wire cutting device and an automatic copper wire clamping device are sequentially arranged from left to right between the copper wire coiling and uncoiling device and the copper wire molding device. The device automatically unwinds the copper wire, and uninterrupted conveying is realized by the traction device, in this convey process, As that paint strip device travels with the cop wire, and finish stripping thecopper wire in the course of traveling, A thread cutting device is also arranged after the paint stripping operation, The copper wire cutting is completed, and the copper wire is conveyed to the copper wire molding device by an automatic clamping device to complete the molding operation, and in the operation, the paint stripping device, the wire cutting device and the automatic clamping device alltravel together with the copper wire, so that the paint stripping, the cutting and the molding are automatically completed when the copper wire is uninterruptedly conveyed.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

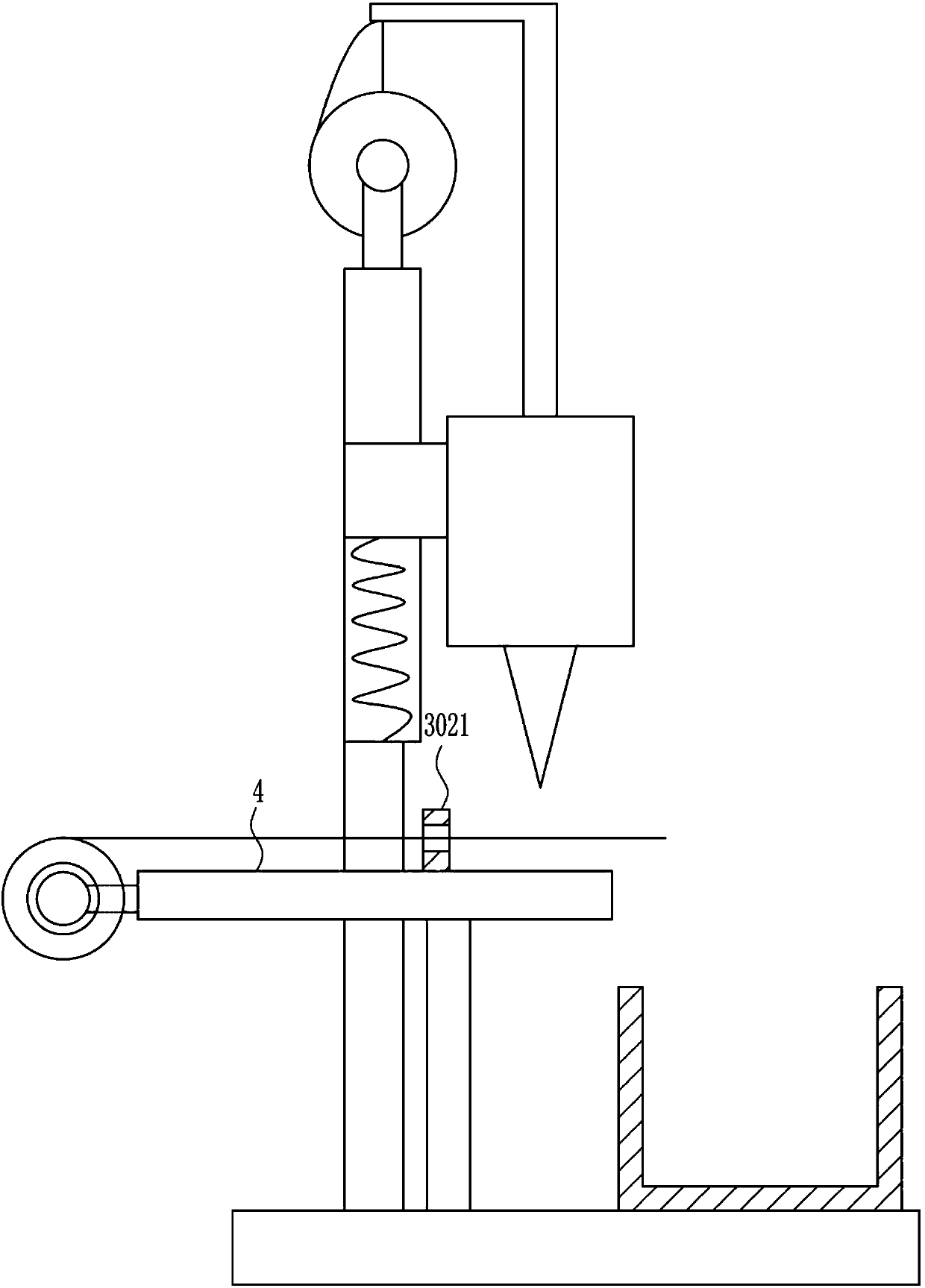

Industrial cutting equipment for performing fixed-length cutting on different cables

ActiveCN108023299AImprove cutting efficiencyAvoid damageApparatus for cutting/splicing cablesFixed lengthCivil engineering

The invention relates to cable cutting equipment, particularly relates to industrial cutting equipment for performing fixed-length cutting on different cables, and aims to provide the industrial cutting equipment for performing fixed-length cutting on different cables with low fixed-length cutting length error, capability of performing continuous cable cutting and high cutting efficiency by solving the technical problems. For solving the technical problems, the invention provides the industrial cutting equipment for performing fixed-length cutting on different cables; the industrial cutting equipment comprises a bottom plate, a collection box, a supporting rod, a placement plate, a first connecting block, a first rotary shaft, a supporting plate, a sliding rail, a sliding block, a first spring, a weight balancing block, a cutter and the like; and the collection box is placed on the right side on the bottom plate. The industrial cutting equipment achieves the effects of low fixed-lengthcutting length error, capability of performing continuous cable cutting and high cutting efficiency.

Owner:浙江湖州德镭激光科技有限公司

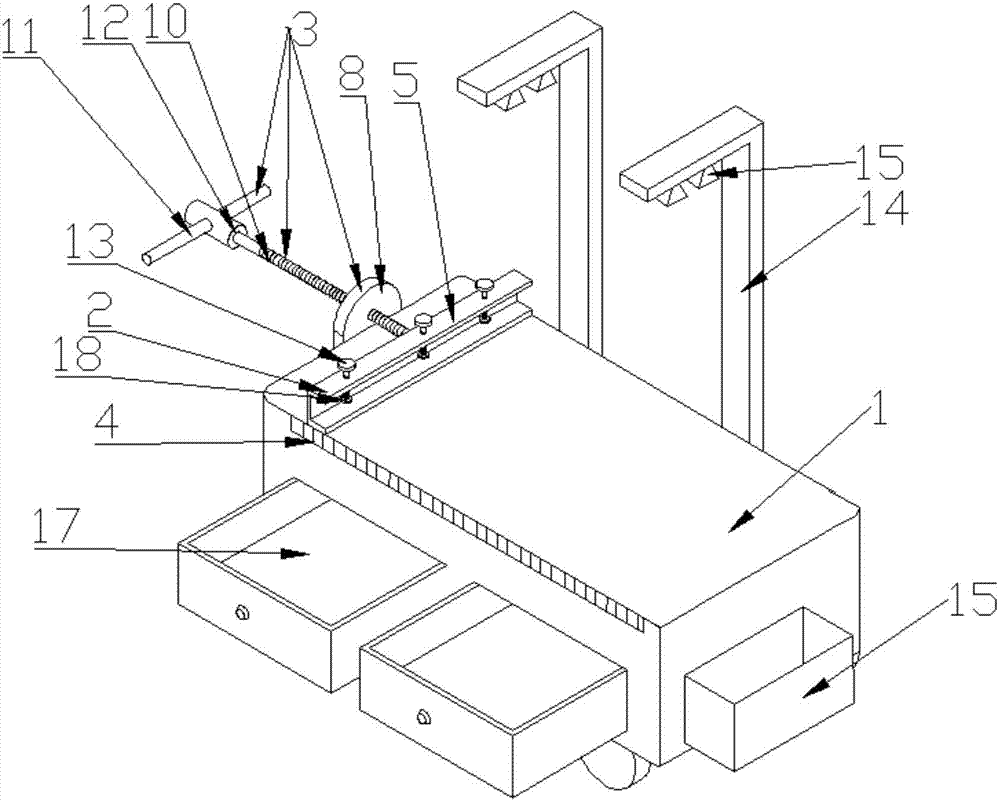

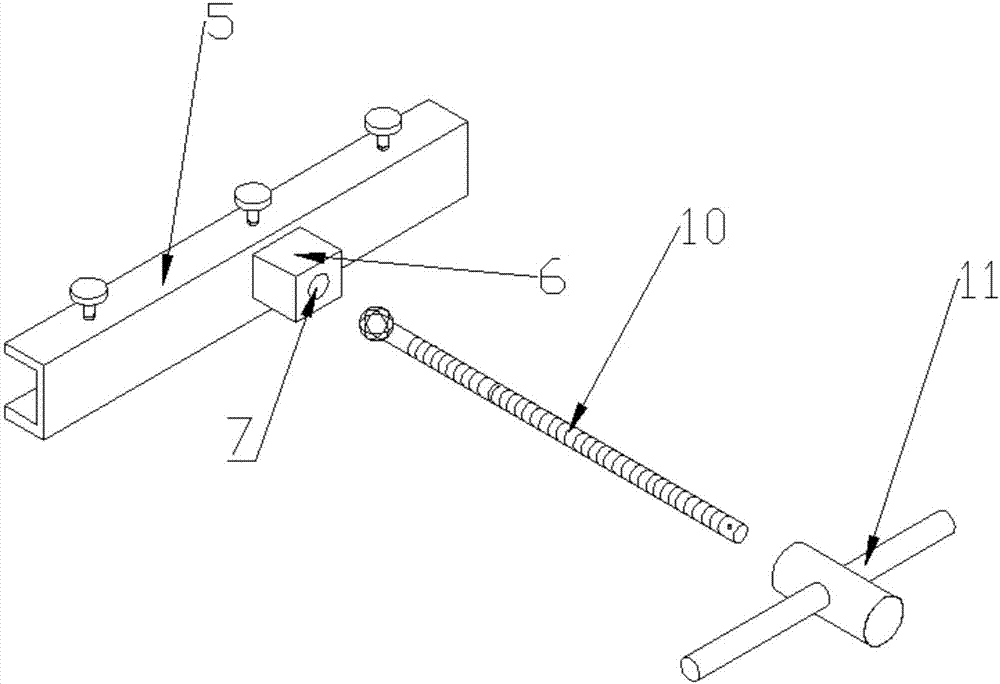

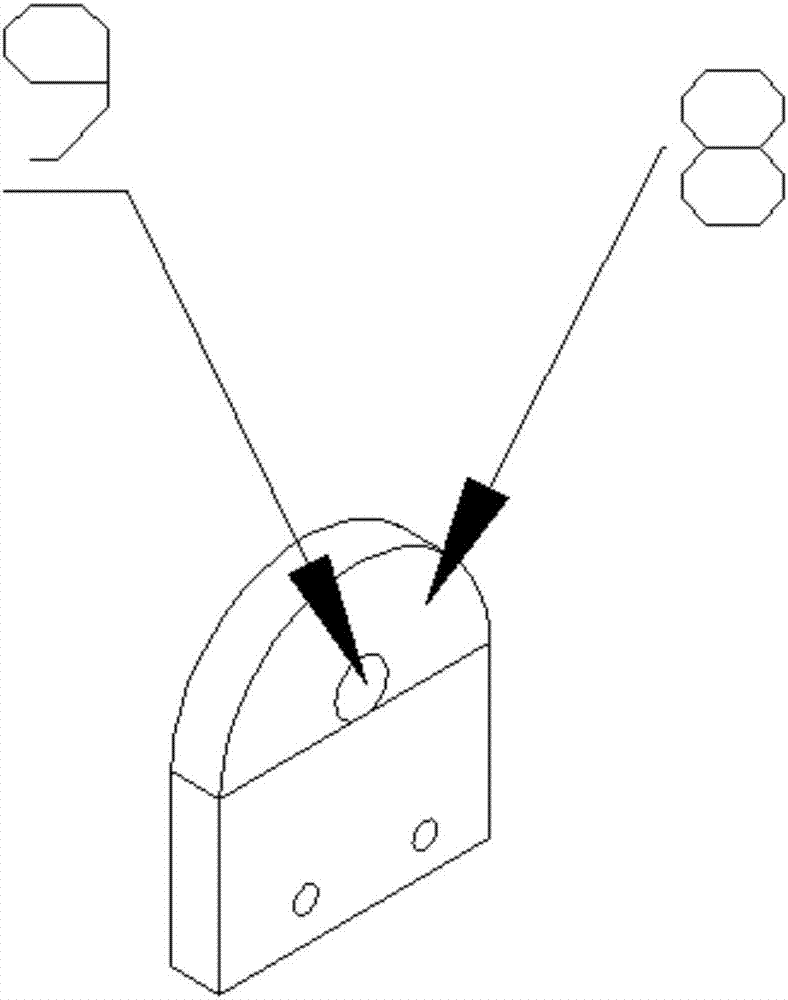

Equal-length cutting device for steel plate

InactiveCN107457448ANot easy to get tiredImprove efficiencyMetal working apparatusMaintainance and safety accessoriesSheet steelRebar

The invention discloses an equal-length cutting device for a steel plate, and relates to the field of building material processing. The equal-length cutting device comprises a horizontal workbench, a clamping part arranged on the horizontal workbench and capable of moving left and right, and a drive part used for driving the clamping part to move left and right on the horizontal workbench, wherein a graduated scale is arranged at one end close to the top of the horizontal workbench, of the side surface of the horizontal workbench. The equal-length cutting device disclosed by the invention solves the following three problems: (1) the positions of steel bars are gradually moved in a cutting process, so that cutting accuracy is low; (2) flexible scale measurement has a large error and costs much time in the case of each measurement; and (3) operating personnel are extremely easily fatigued in the case of direct estimation without measurement, so that the cutting error is increased.

Owner:成都捷科菲友信息技术有限公司

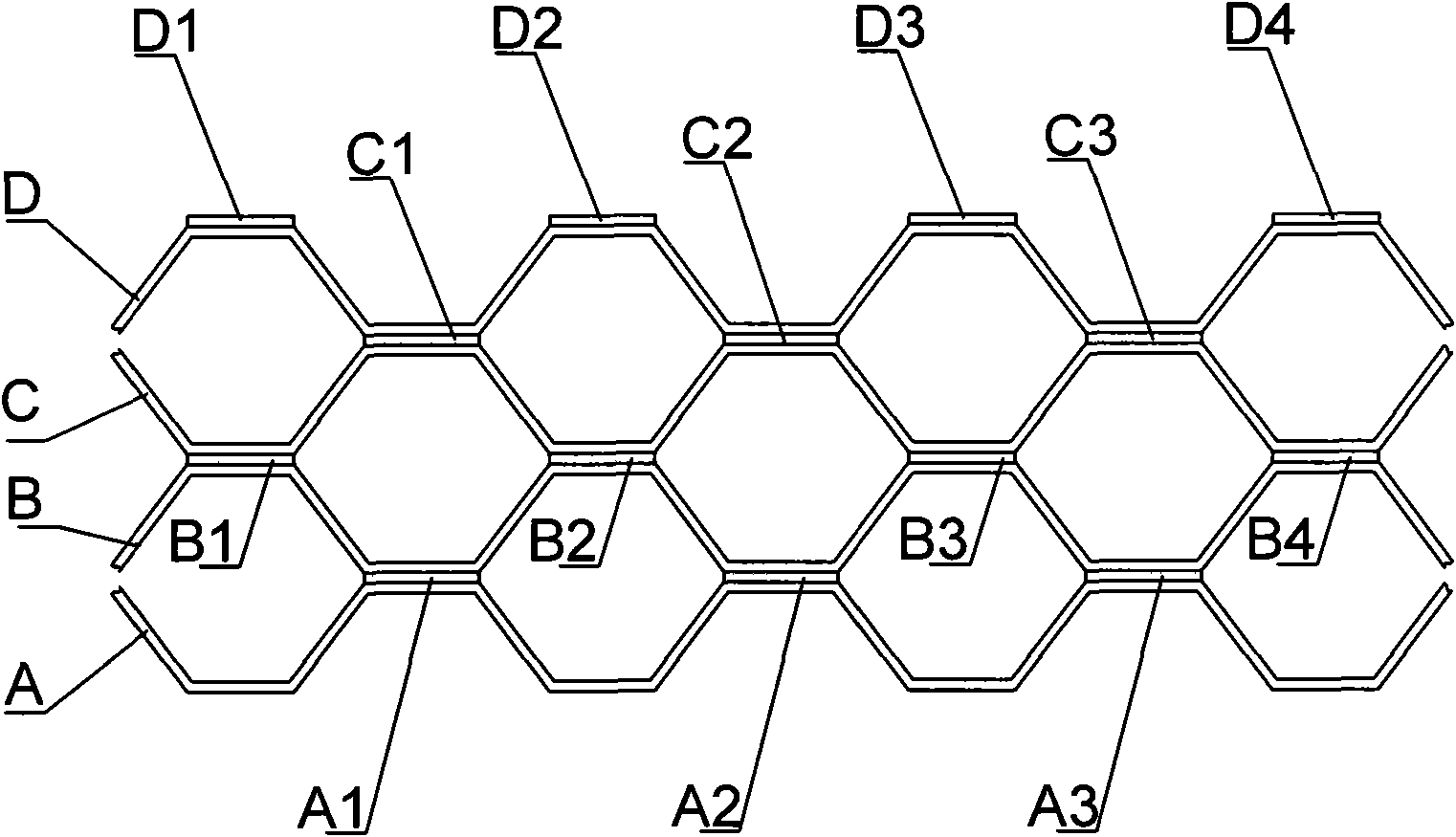

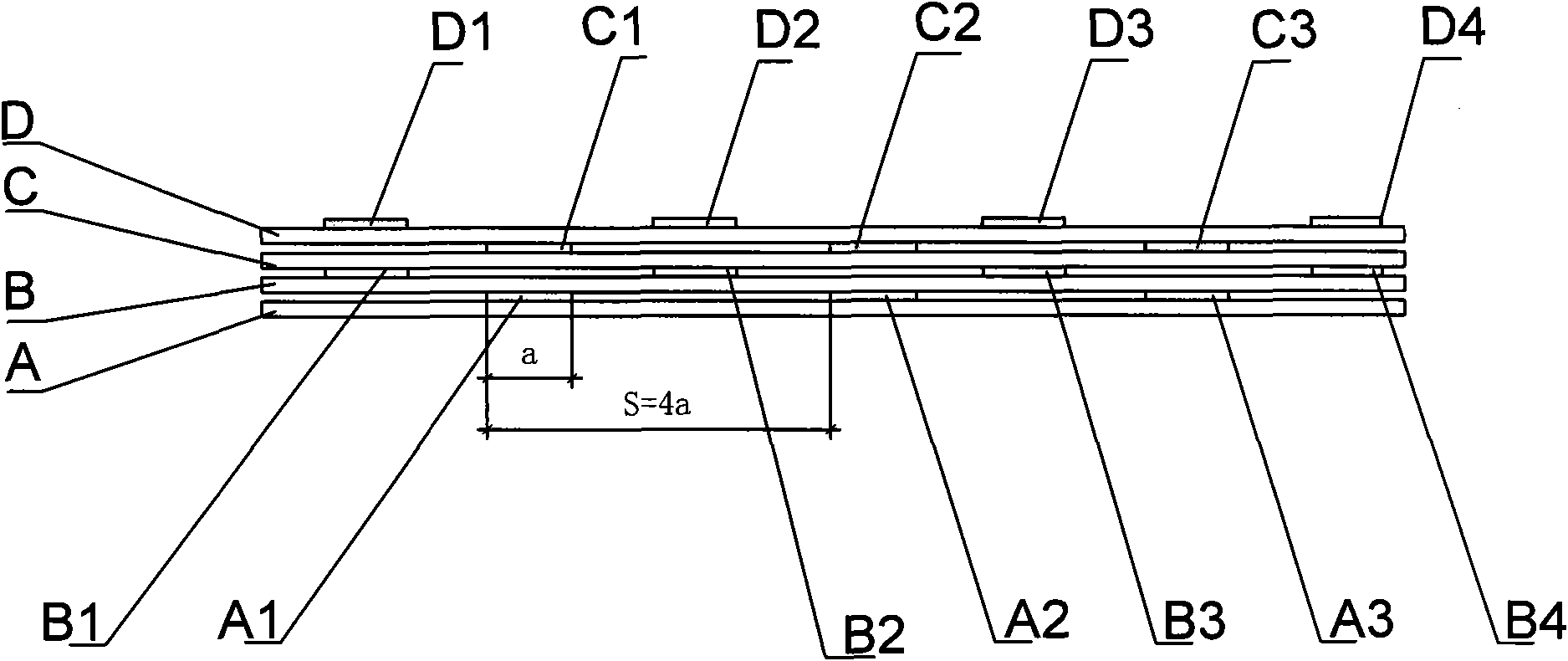

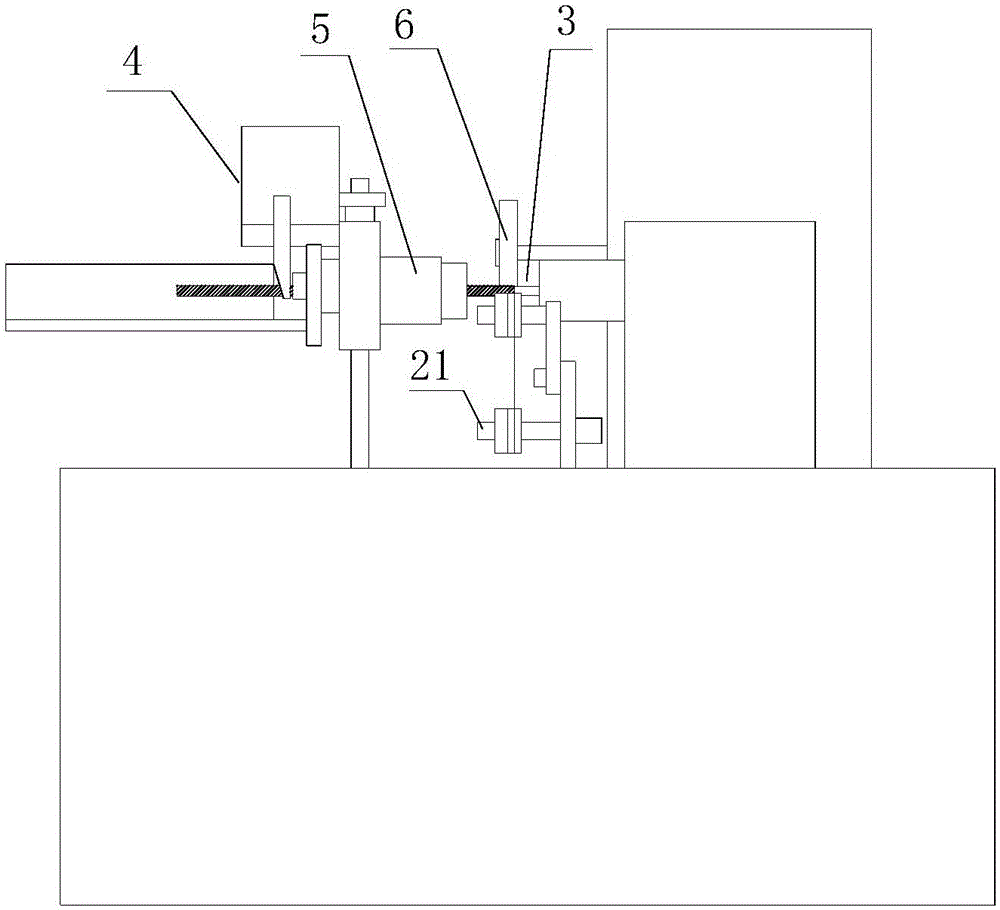

Shearing control device for foils for manufacturing microporous aluminum honeycomb material

ActiveCN101870119ASmall length errorImprove tidinessMetal working apparatusEngineeringAluminium alloy

The invention discloses a shearing control device for foils for manufacturing a microporous aluminum honeycomb material. The shearing control device comprises a feeding mechanism, a shearing mechanism and a control system, wherein in the feeding mechanism, a feeding roller is driven to run by a first drive part; in the shearing mechanism, a shearing machine is driven to shear an aluminum alloy foil by a second drive part; the control system comprises a length control unit and an adhesive tape identifying unit; the adhesive tape identifying unit is used for identifying an adhesive tape; the length control unit controls the shearing length of the aluminum alloy foil; and the shearing mechanism is driven to shear the aluminum alloy foil in a preset length by the control system according to the identified information and the length information. The shearing control device for the foils for manufacturing the microporous aluminum honeycomb material can precisely performing cut-to-length to ensure high regularity of stretched hexagonal honeycomb grids, and the performance requirements of the aluminum honeycomb material are basically met.

Owner:佛山市利铭蜂窝复合材料有限公司

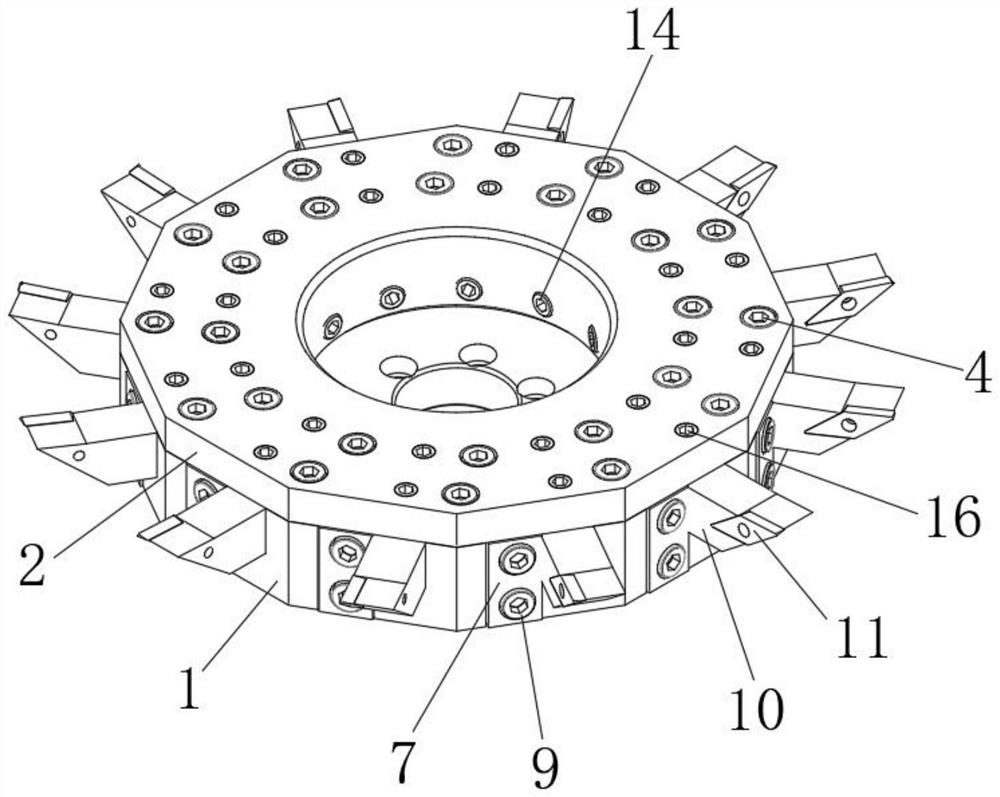

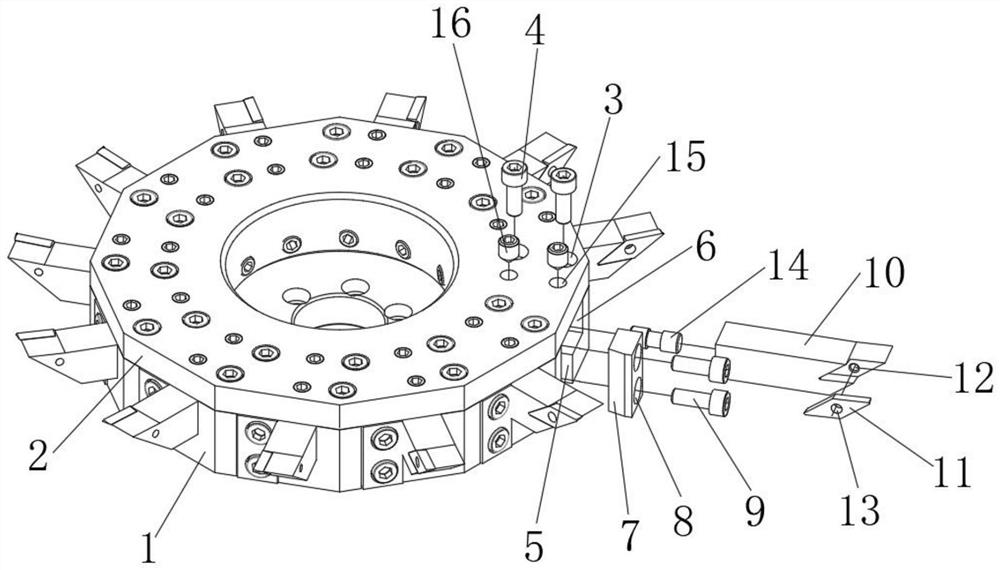

12-station adjustable fly-cutter head structure for lathe

PendingCN112355334AEasy to adjustImprove machining accuracyTool holdersPositioning apparatusStructural engineeringCentrifugal force

The invention discloses a 12-station adjustable fly-cutter head structure for a lathe. The 12-station adjustable fly-cutter head structure comprises a fly-cutter head body, a fly-cutter head cover isconnected to the top of the fly-cutter head body through screws, fixing grooves are formed in the outer side of the fly-cutter head body at equal intervals, and cutter grooves are formed in the positions, located on one sides of the fixing grooves, of the outer side of the fly-cutter head body. The 12-station adjustable fly-cutter head structure is compact in structure, easy and convenient to operate and high in practicability, a tool can be rapidly and accurately adjusted by arranging forward and reverse screws, the tool can extend outwards or be stored inwards in a tool groove, and comparedwith traditional manual beating adjustment, the length error of the tool extending out of or stored in the tool groove is greatly reduced, so that the machining precision of the lathe is greatly improved. Meanwhile, the fly-cutter head made of a 7074 aviation aluminum material is arranged, so that the overall weight of the equipment is reduced, the centrifugal force is reduced, the machining efficiency is improved, the product is more attractive in appearance in the using process, the machining cost is low, and the market requirement is met.

Owner:中山市宇洋数控机械有限公司

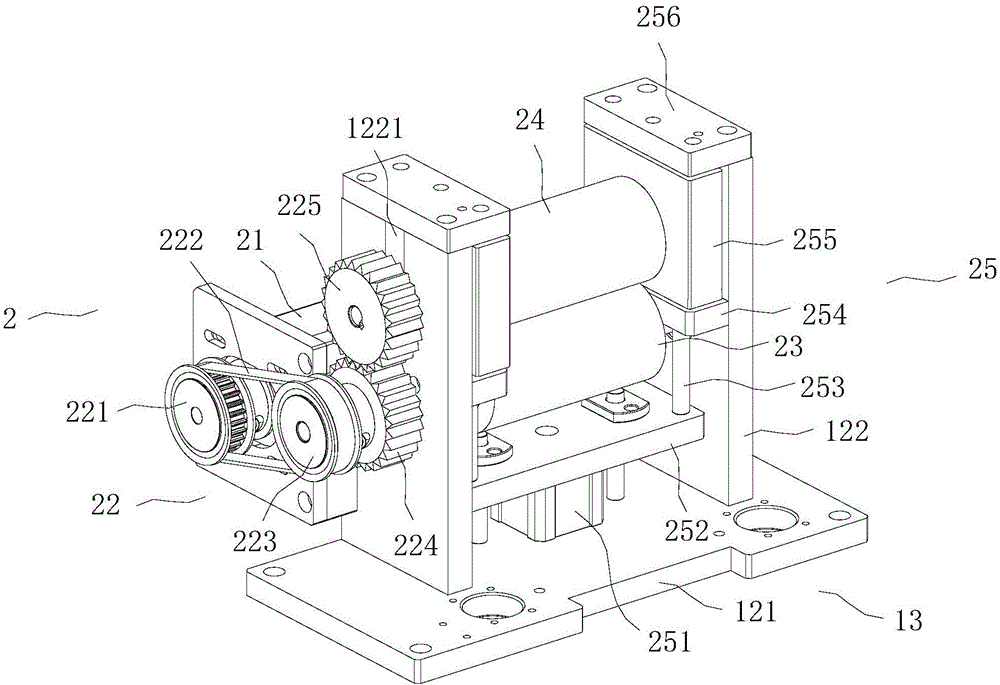

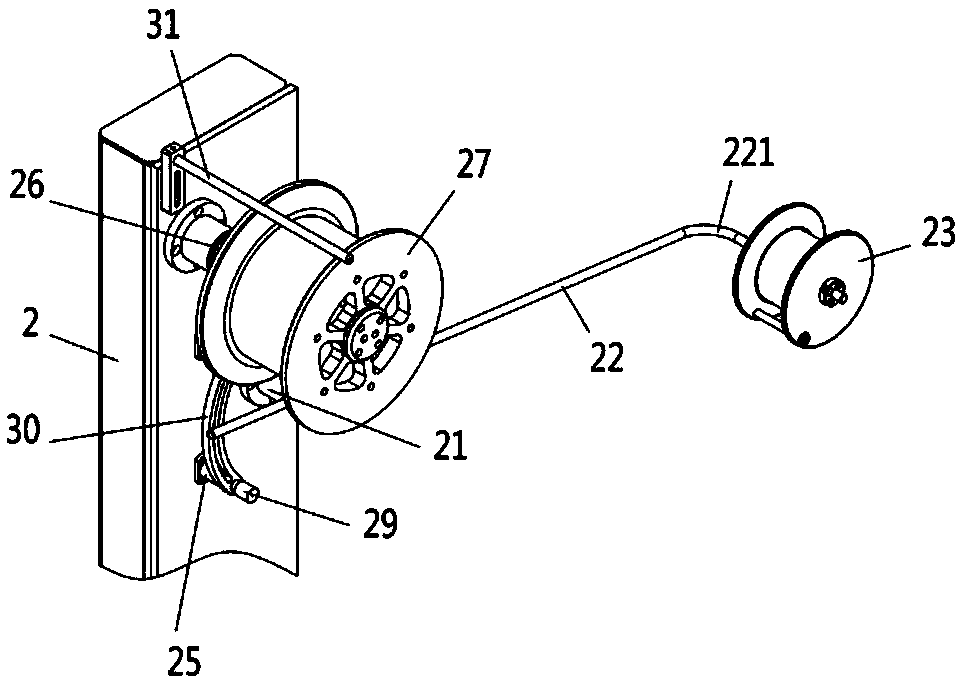

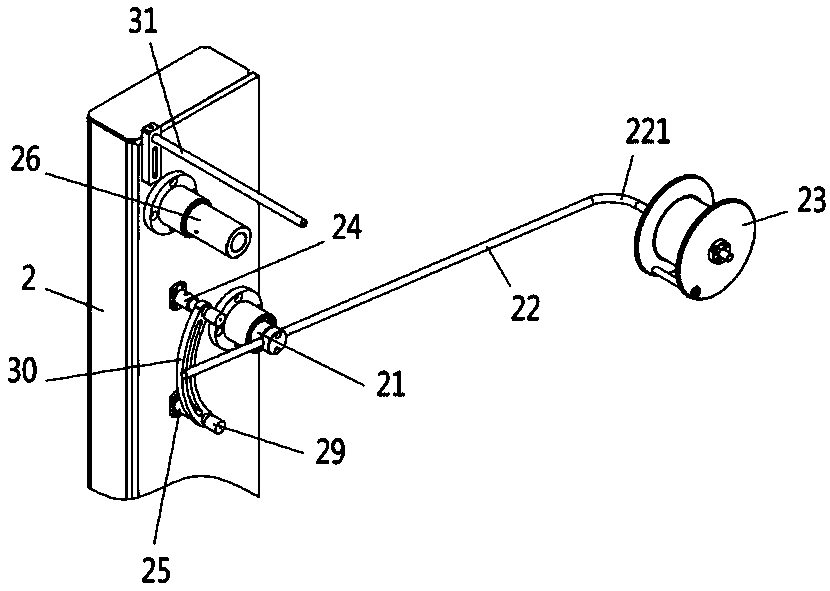

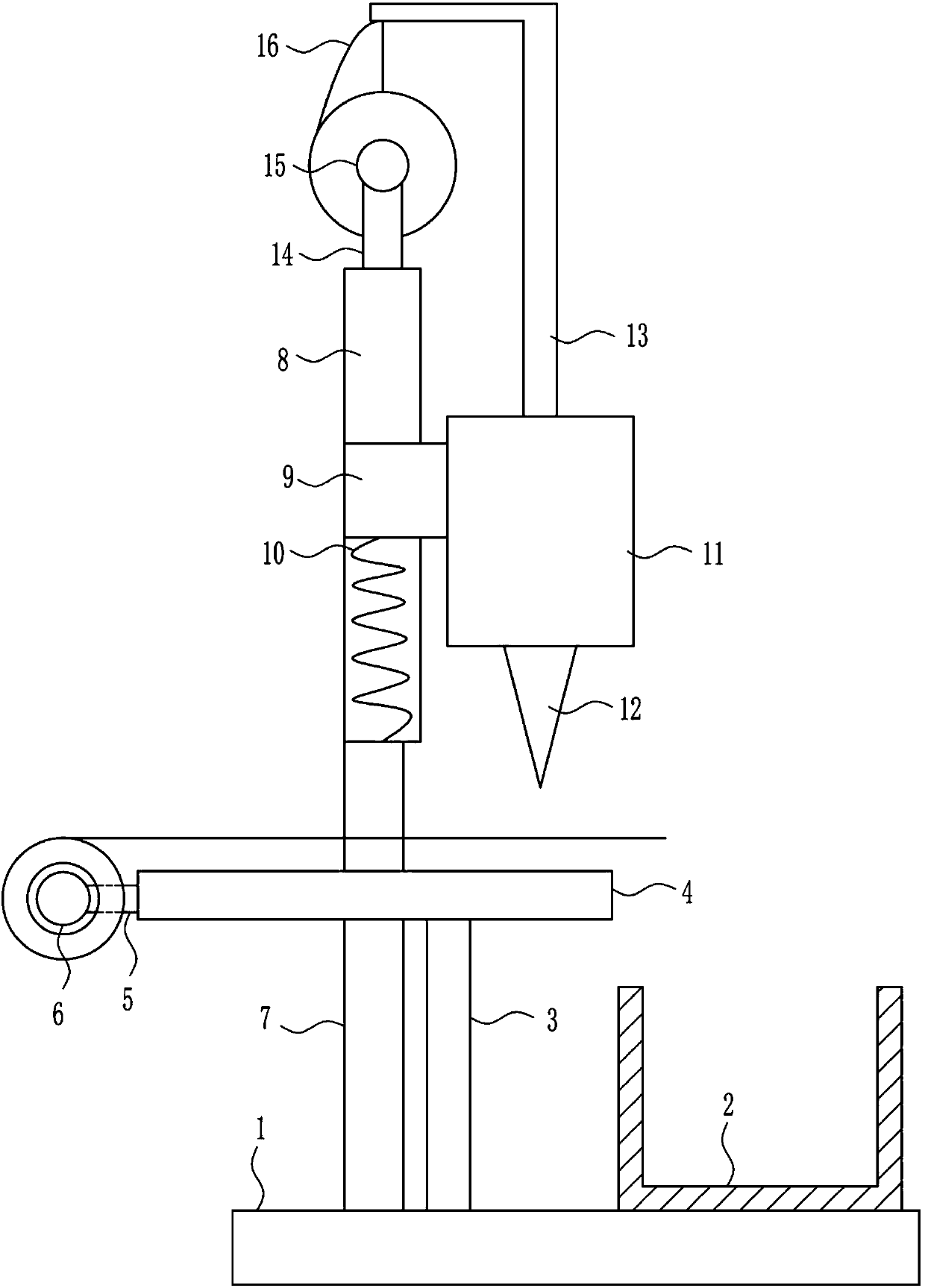

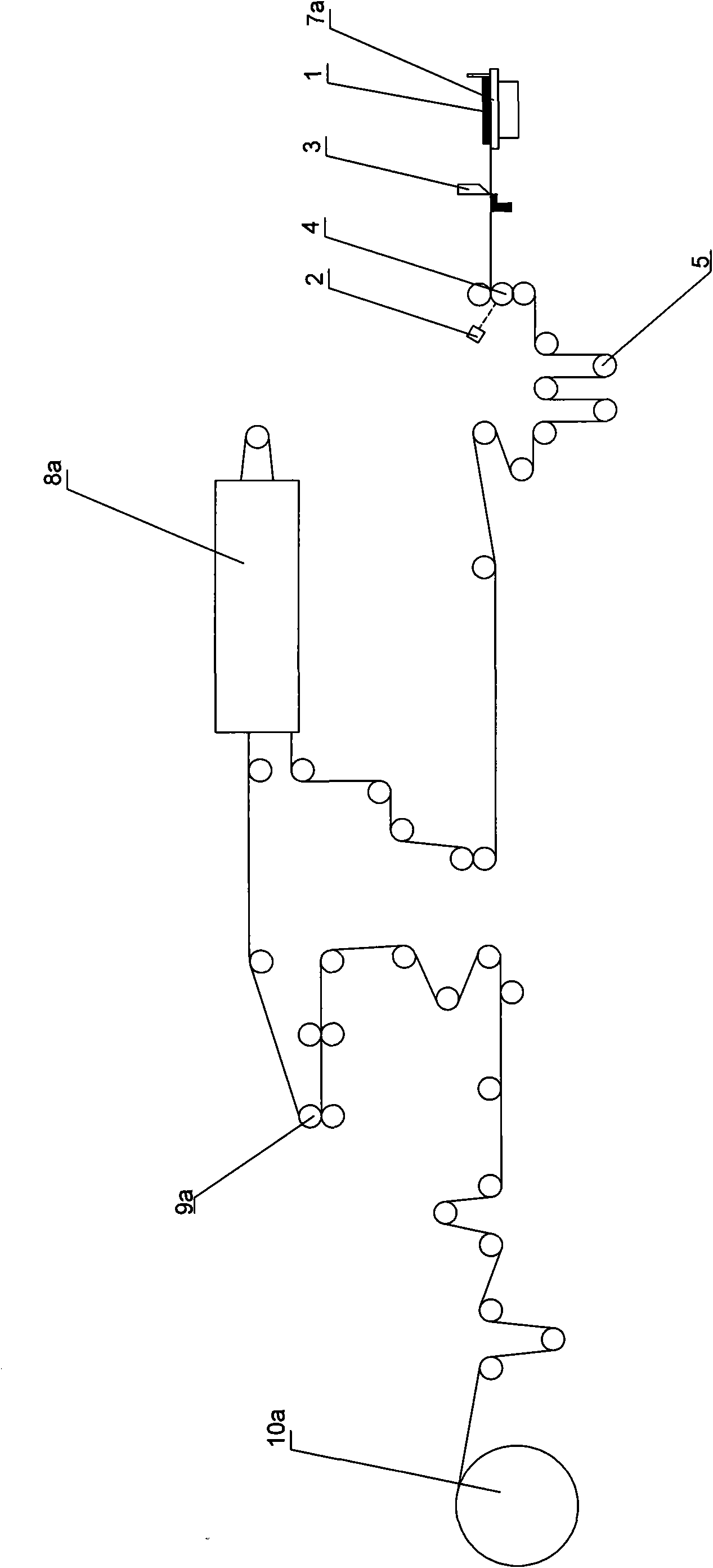

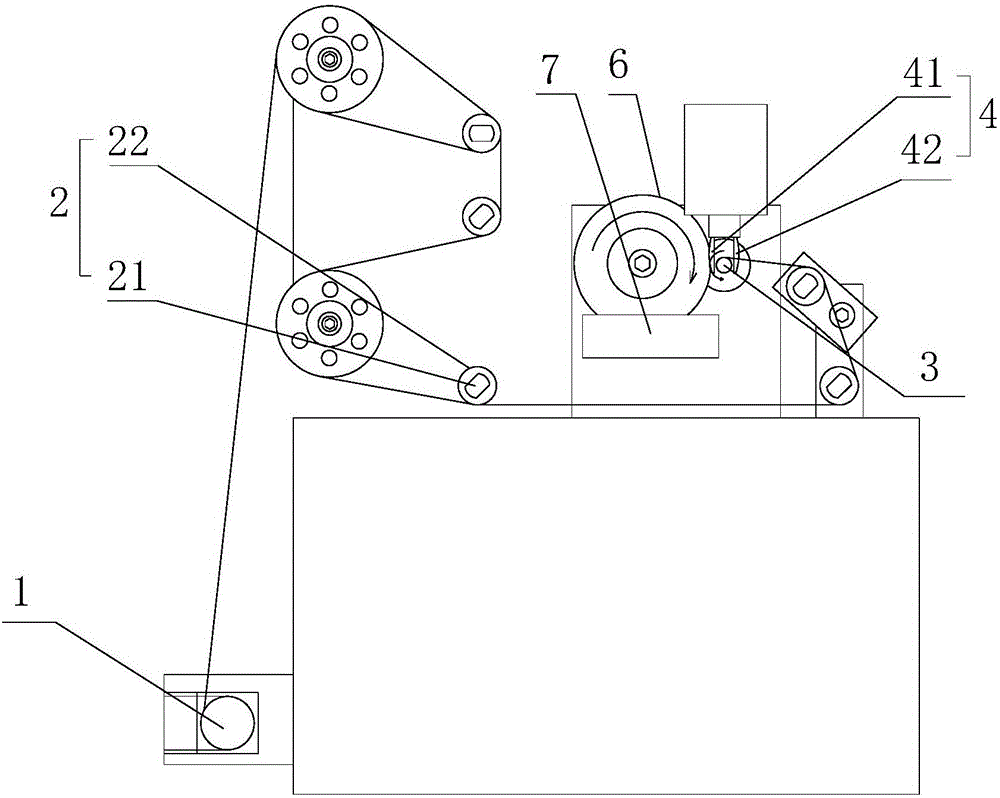

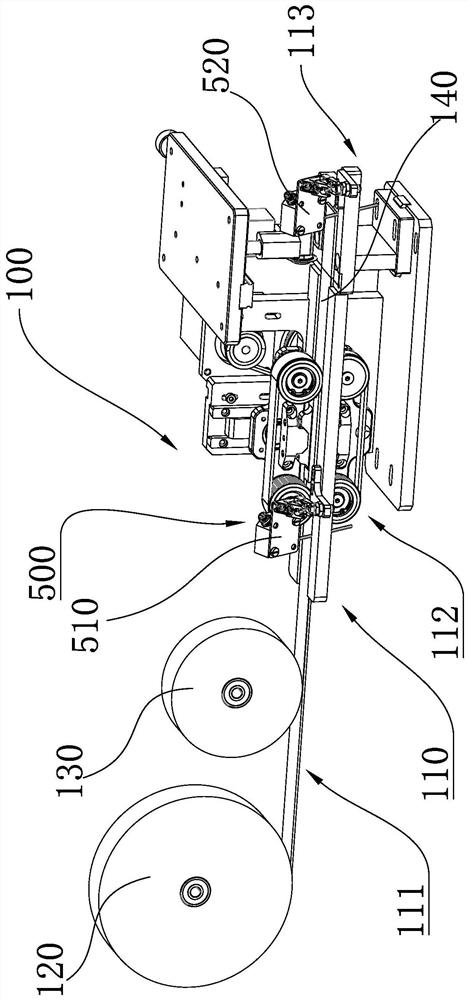

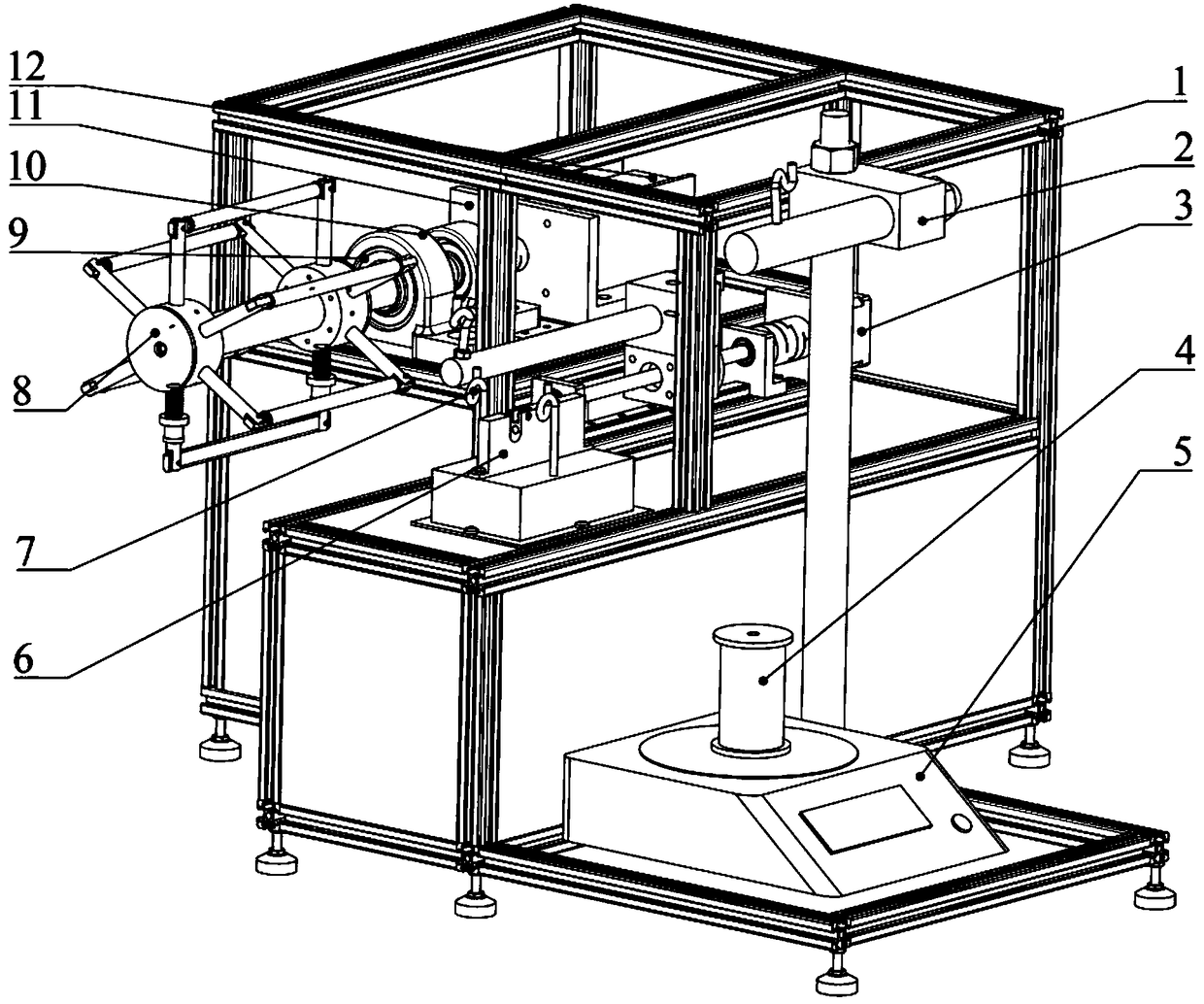

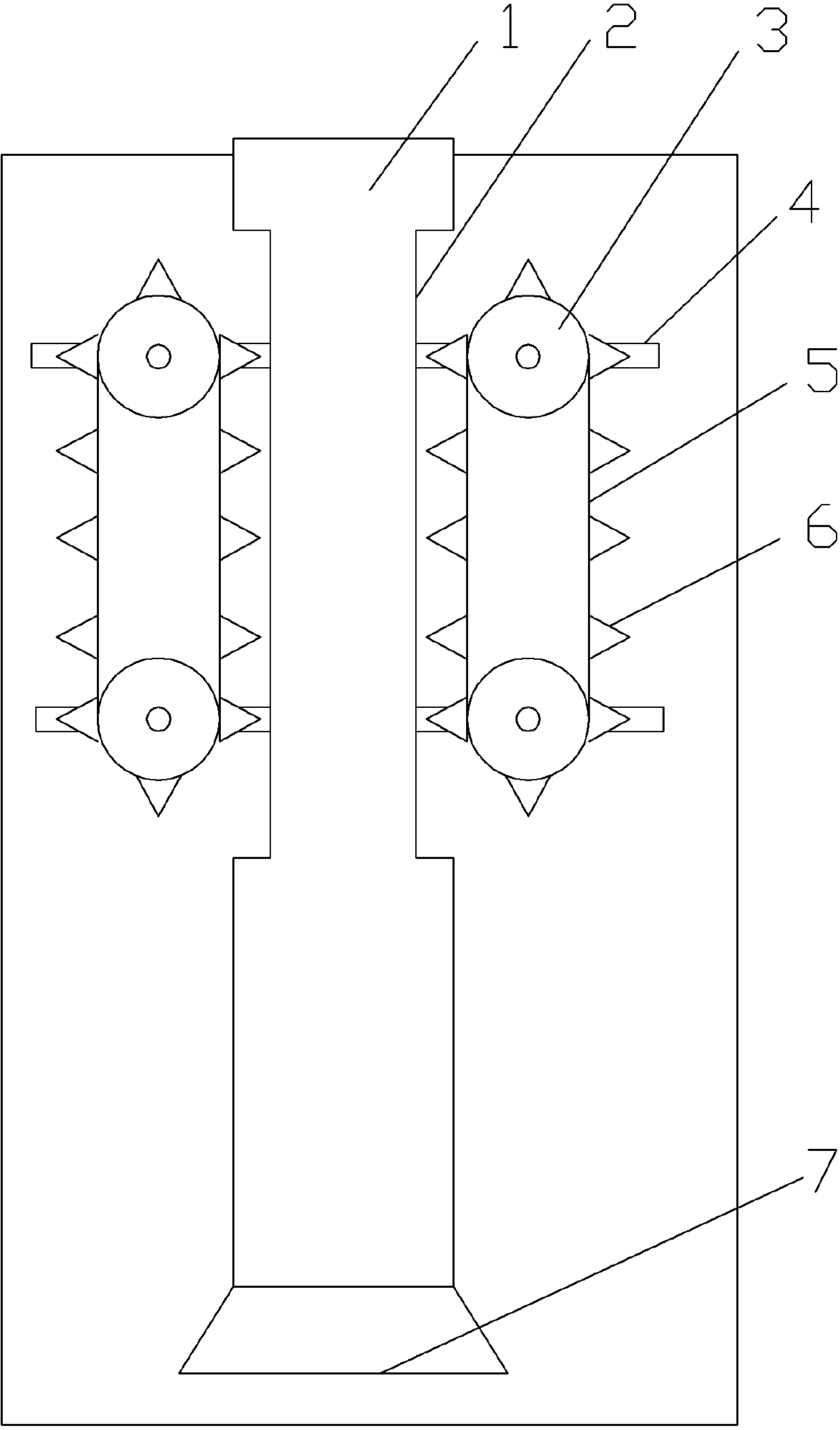

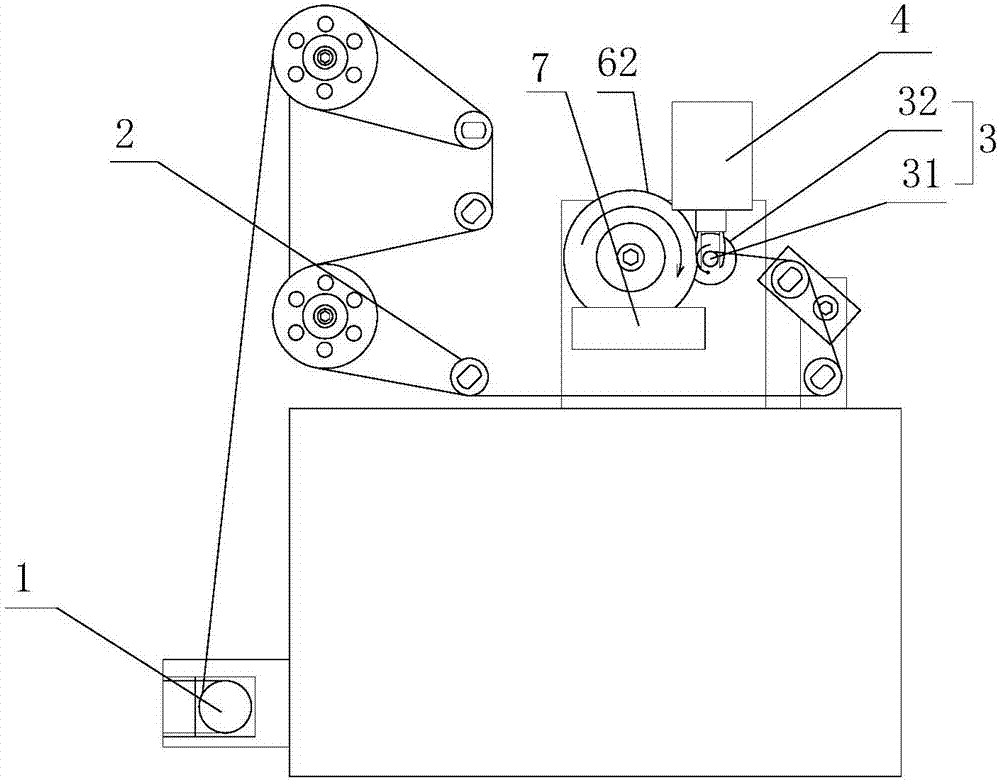

Shearing and cutting-off type winding machine

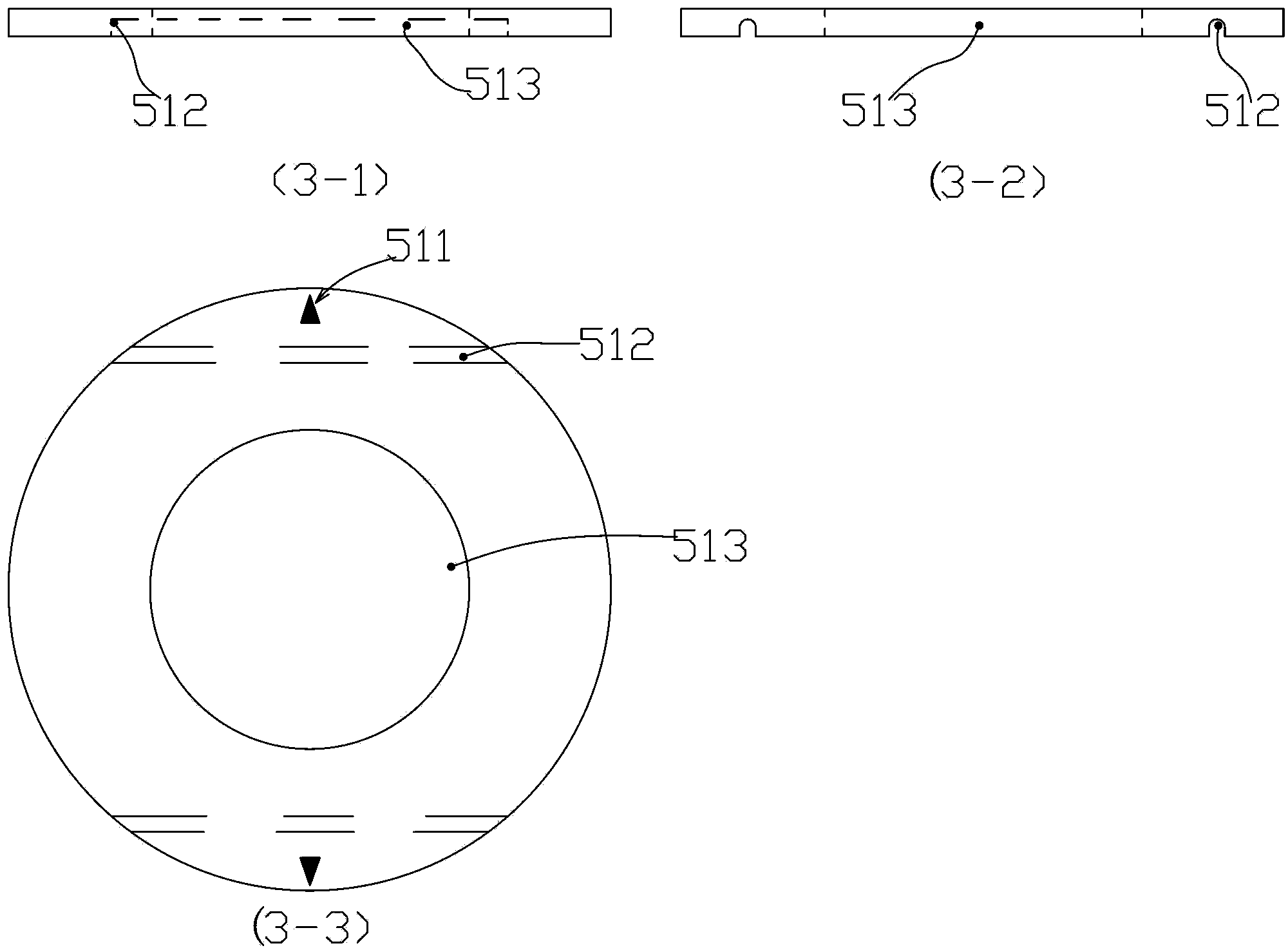

InactiveCN106311934ASmall length errorReduce generationMetal working apparatusWinding machineConductor Coil

The invention discloses a shearing and cutting-off type winding machine. The shearing and cutting-off type winding machine comprises a paying-off device, a wire-guiding device, a wire-winding device and a cutting-off device, wherein the paying-off device is used for paying-off action; the wire-guiding device which is located at the output end of the paying-off device comprises rotary shafts which are rotatably mounted and wire-guiding wheels which are fixedly mounted on the rotary shafts, and coders are mounted on the rotary shafts; the wire-winding device which is located at the output end of the wire-guiding device for wire-winding action comprises a mandrel and a first driving mechanism for driving the mandrel to rotate; the cutting-off device which is located at the output end of the wire-winding device for cutting-off action comprises a first slicer, a second slicer and a second driving mechanism, both the first slicer and the second slicer are located at one end of the mandrel, and are located on two sides of the extending direction of the mandrel, respectively, and are arranged opposite to each other; the second driving mechanism is used for driving the first slicer and the second slicer to be matched with each other so as to cut off a workpiece therebetween. According to the shearing and cutting-off type winding machine disclosed by the invention, a finished piece is small in error in length and high in product percent of pass.

Owner:安徽省宁国市天成电气有限公司

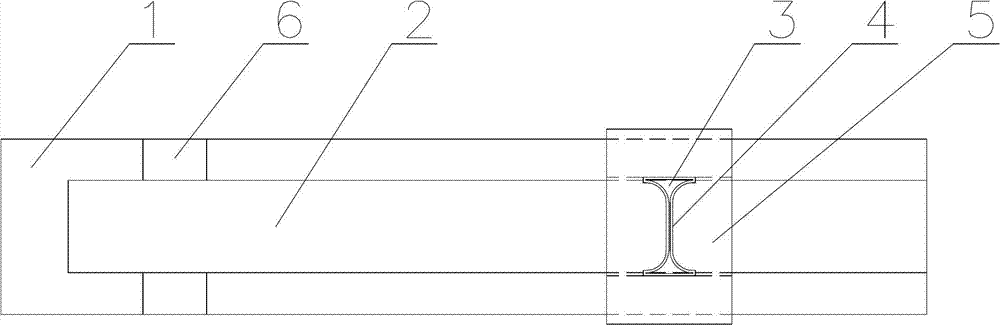

Copper foil cutting machine

The invention discloses a copper foil cutting machine which comprises a base and an I-shaped cutter; wherein, a groove for placing the copper foil is arranged on the base in the transverse direction, and a left copper foil limiting baffle is arranged at the left end of the groove; the cutter is arranged on a longitudinal pneumatic telescopic rod through a fixture and is located right above the right side of the groove, and the width of the cutter is greater than that of the copper foil. The copper foil cutting machine is simple in structure and convenient in use, can cut out copper foil segments with little error in length in batches and simultaneously finish fillet technology in the cutting process so as to improve the production efficiency.

Owner:昆山市达功电子厂

Copper wire shearing device

PendingCN108714666AImprove thread cutting efficiencySmall length errorElectronic waste recyclingCopper wireEngineering

The invention discloses a copper wire shearing device. The copper wire shearing device comprises a power mechanism and a scissor mechanism. The copper wire shearing device is characterized in that a power motor drives two eccentric shafts to achieve revolution through a hollow shaft, the two eccentric shafts cooperate with elliptical holes correspondingly, an upper sliding guide block and a lowersliding guide block are driven to move on a vertical sliding rail, so that downward moving of the upper sliding guide block is achieved, and upward moving of the lower sliding guide block is achieved;and a copper wire penetrates through the part between a guide block and a lower die and is located between two guide plates at the same time. According to the copper wire shearing device, an upper shearing body is pressed downwards and a lower shearing body is ejected upwards correspondingly under the drive of the upper sliding guide block and the lower sliding guide block, a pressing head mutually cooperates with a lower pointed edge in a second square hole, the copper wire is sheared into a tip shape, an upwarp part on an upper pointed edge cooperates with an upwarp part in the lower pointed edge, and a pointed part is flattened; and the copper wire with a certain length can be sheared according to needs, the wire shearing efficiency of the copper wire is improved, the length error of the copper wire is small, meanwhile, the two ends of the copper wire are sheared into the required pointed shapes, the pointed ends of the copper wire are flattened, later welding is facilitated, and the occupied space of welding joints is reduced.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

Tool gauge for precisely drawing hyperbolic curve

ActiveCN108248255ASimple stepsEasy to operateNon-circular curve drawing instrumentsEngineeringRuling pen

The invention discloses a tool gauge for precisely drawing a hyperbolic curve, and relates to the technical field of tool gauges. The tool gauge comprises a ruling pen and a limiting device; the ruling pen comprises line lump devices, a center column and a pen sleeve device; the line lump devices comprise the upper line lump device and the lower line lump device; the peripheral side face of the center column is matched with the upper line lump device and the lower line lump device; the lower end face of the lower line lump device is rotationally connected with a first round limiting groove; the limiting device comprises a handle, an origin fixing column and focus fixing columns; one side face of the handle is provided with a first rectangular through hole and a second rectangular through hole; the first rectangular through hole is in slide fit with the peripheral side face of the first focus fixing column of the focus fixing columns; and the second rectangular through hole is in slidefit with the peripheral side face of the second focus fixing column of the focus fixing columns. According to the tool gauge, through action of the ruling pen and the limiting device, the problems that when a hyperbolic curve is drawn during study and work, large errors exist, and the required hyperbolic curve cannot be comprehensively drawn out are solved.

Owner:TAIZHOU SUMING VALVES CO LTD

Equal-length cutting device for construction industry

InactiveCN107486599ANot easy to get tiredImprove efficiencyMetal working apparatusPositioning apparatusArchitectural engineeringRebar

The invention discloses an equal-length cutting device for the construction industry, and relates to the field of construction material machining. The equal-length cutting device comprises a horizontal workbench, a position clamping part and a driving part; the position clamping part is arranged on the horizontal workbench and can move leftwards and rightwards; the driving part is used for driving the position clamping part to move leftwards and rightwards on the horizontal workbench; a graduation ruler is arranged at one end of the side surface, close to the top of the horizontal workbench, of the horizontal workbench; and a plurality of semicircular grooves are formed in the horizontal workbench. The following four problems that (1) the cutting precision is not sufficient due to the fact that a steel bar may gradually move in the cutting process, (2) if measurement is required every time, a tape has a great error and more time is consumed due to the measurement when the tape is used for the measurement, (3) if estimation is carried out directly without the measurement, operating personnel are prone to fatigue easily so that the cutting error is increased, and (4) different devices are required usually due to the fact that the steel bar and a steel plate have different areas and the fixing modes of the steel bar and the steel plate are different are solved.

Owner:成都捷科菲友信息技术有限公司

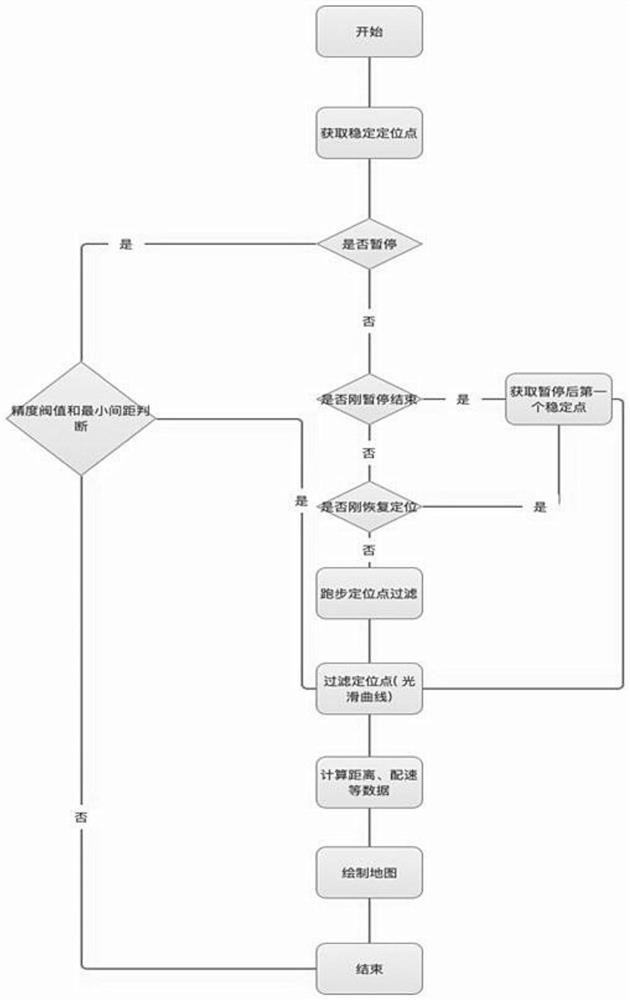

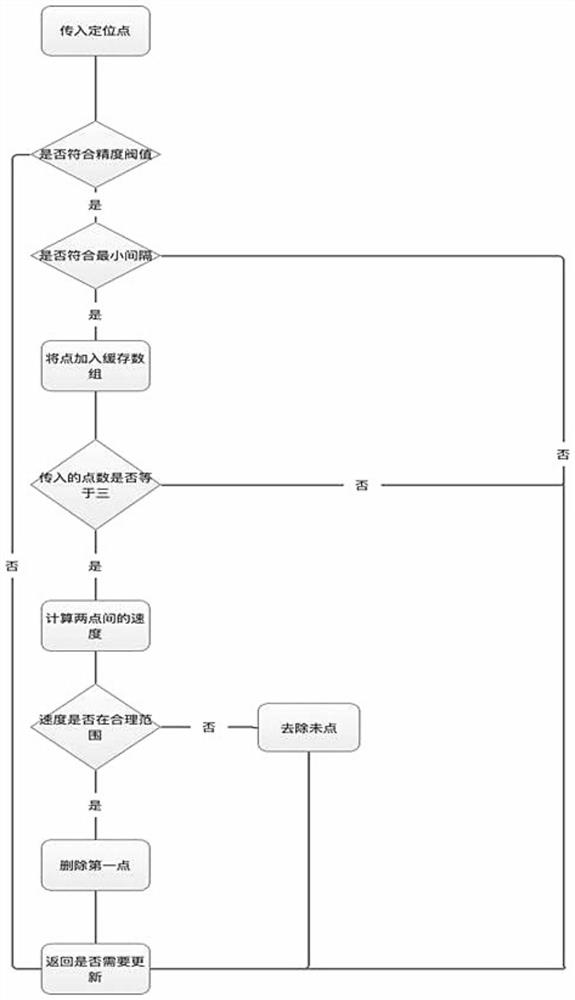

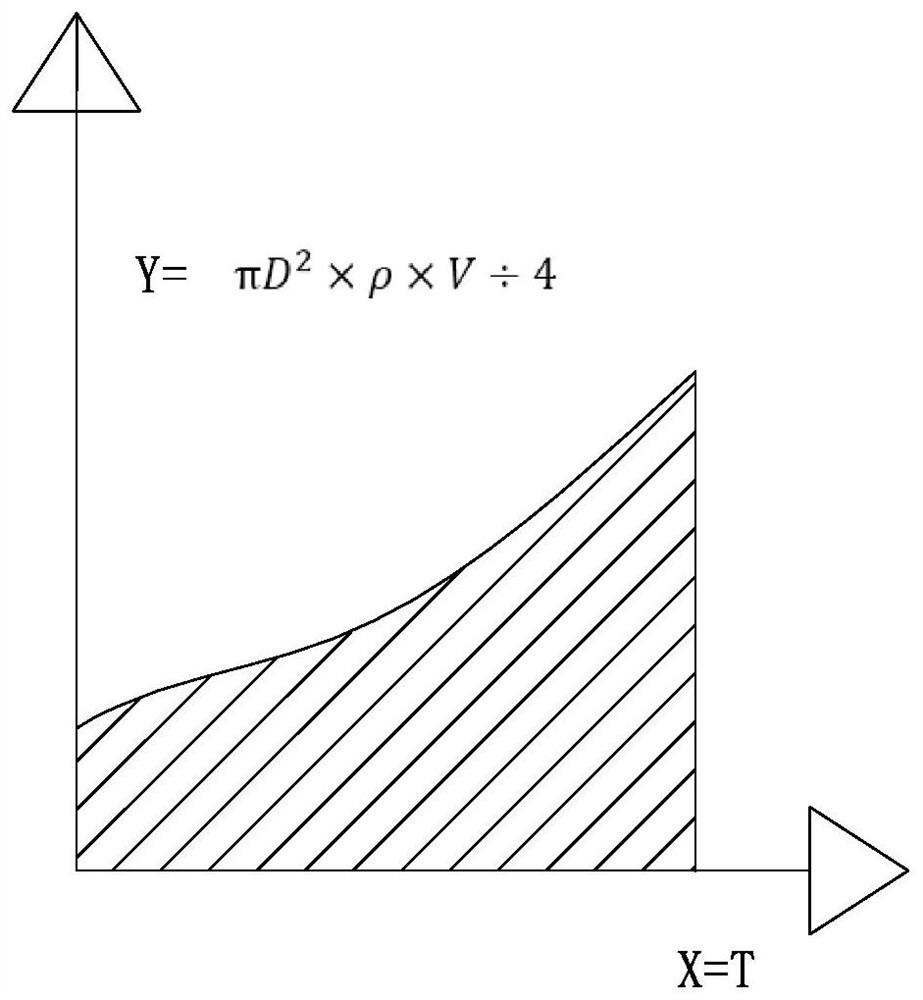

Running track algorithm based on satellite positioning

ActiveCN112511694AImprove accuracySmall length errorSubstation equipmentSatellite radio beaconingTechnical supportPoint location

The invention discloses a running track algorithm based on satellite positioning. Calculation comprises the following steps: A, obtaining stable positioning points through a GPS; B, calculating whether positioning is temporary or not; C, calculating whether positioning is just suspended or not; D, calculating whether the positioning point is just recovered or not; E, calculating and filtering running positioning points; F, calculating a filtering positioning point to realize a smooth curve; G, calculating corresponding data such as matching speed, distance and the like; H, drawing a map. According to the method, the first point appears at the position close to the real position, the accuracy of the first point is improved, and the running track length error is reduced. Large-amplitude track distortion is avoided; and if no positioning exists for a period of time, the obtained stable point is subjected to smooth calculation again, and the position of the positioning point is changed within a certain range, so that the running track displayed on the APP interface is smoother and more attractive when being observed by naked eyes, and is closer to a real value in total mileage, and a powerful technical support is provided for ensuring effective application of the running APP.

Owner:厦门家康天下科技股份有限公司

Silica gel sealing gasket production cutting device and using method thereof

PendingCN114131672AReduce labor intensityAvoid manual cuttingMetal working apparatusGear wheelSilica gel

The silica gel sealing gasket production cutting device comprises an operation table, one side of the top of the operation table is connected with an L-shaped plate, a sliding groove is formed in the top of the L-shaped plate, and a cutting mechanism is arranged in the sliding groove. Through continuous rotation of the incomplete gear, under the interaction of the front rack and the rear rack, automatic cutting and resetting of the cutter are achieved, manual cutting is avoided, the cutting efficiency is high, the clamping plate and the racks are integrally formed, installation and positioning of the incomplete gear are completed through the locking nut, and the cutting efficiency is high. The two racks are connected with the upper plate body and the lower plate body through the inner hexagon bolts, parts of the whole mechanism are fully exposed, observation is convenient, replacement is easy, the actual length of the silica gel on the left side is larger than the length of the silica gel when the silica gel is laid flatly through the arrangement of the protrusions, and therefore the length of the silica gel shrunk in the demolding process is compensated to a certain degree, and the service life of the silica gel is prolonged. And the length error after cutting is reduced.

Owner:镇江润众新能源科技有限公司

Automatic cutout device for mattress connection spring production

The invention discloses an automatic cutout device for mattress connection spring production. The automatic cutout device comprises a frame and an operation box, a spring containing groove is formed in the bottom of the frame, a switch A is arranged on the left side of the frame, a switch B is arranged above the switch A, an air blower switch is arranged above the switch B, a control switch is arranged above the air blower switch, and a hydraulic pump is installed at the middle portion of the top end of the frame. According to the automatic cutout device, a fixed rod is arranged on the springcontaining groove, fastening screws are arranged at the left and right ends of the top of the fixed rod, and therefore when a connection spring is cut, the spring can be better fixed without positionchanging and swing, and the automatic cutout device is relatively practical and suitable for wide use and popularization.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

Double-cutter sealing strip cutting-off machine

The invention discloses a double-cutter sealing strip cutting-off machine. The double-cutter sealing strip cutting-off machine comprises a workbench which is provided with a cutter adjusting rail anda sealing strip placement plate in the length direction of the workbench in parallel; the cutter adjusting rail is slidably provided with two cutter frames, and the same sides of the two cutter framesare connected with air cylinders located above the sealing strip placement plate correspondingly; and piston rods of the two air cylinders are downward in the vertical direction and stretch out synchronously, and cutters transversely perpendicular to the length direction of the sealing strip placement plate are detachably fixed to the lower ends of the piston rods. According to the double-cuttersealing strip cutting-off machine, through the two cutters, the two ends of the sealing strip can be cut at the same time in the natural state, the cutting length of the sealing strip meets the requirement, the machining precision of the sealing strip is improved, and the product quality is improved.

Owner:北京华通橡塑制品有限公司

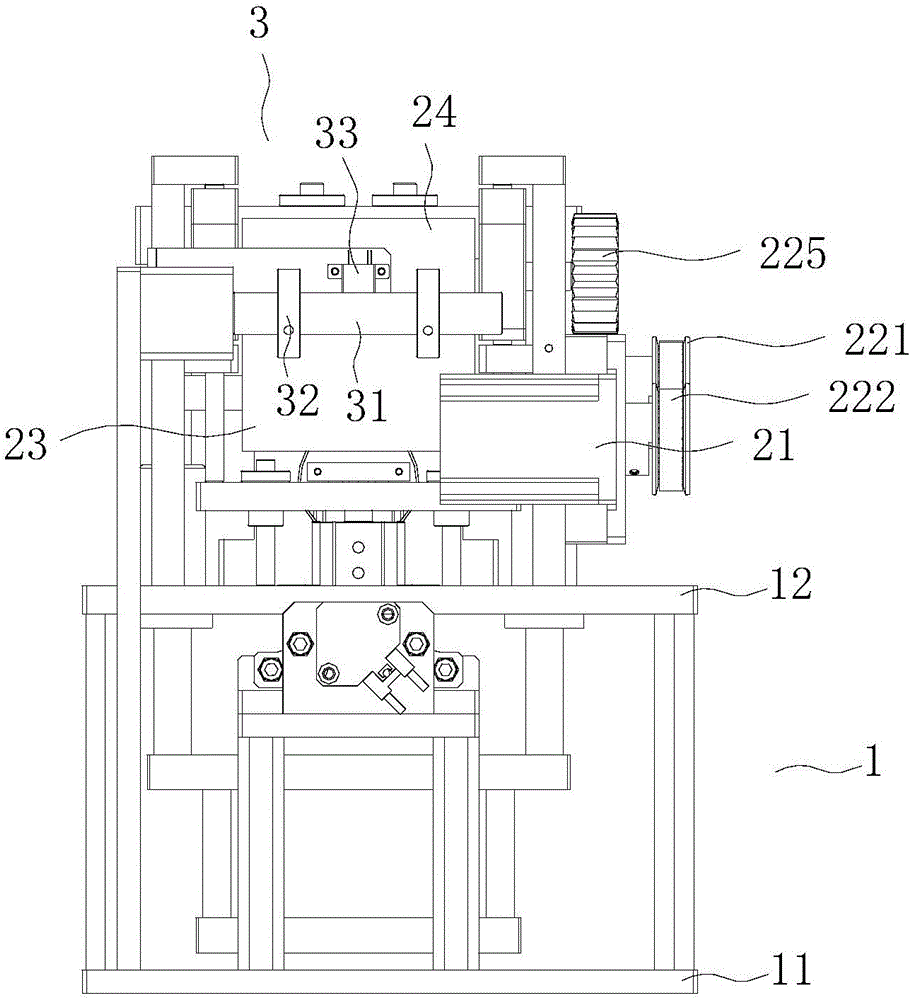

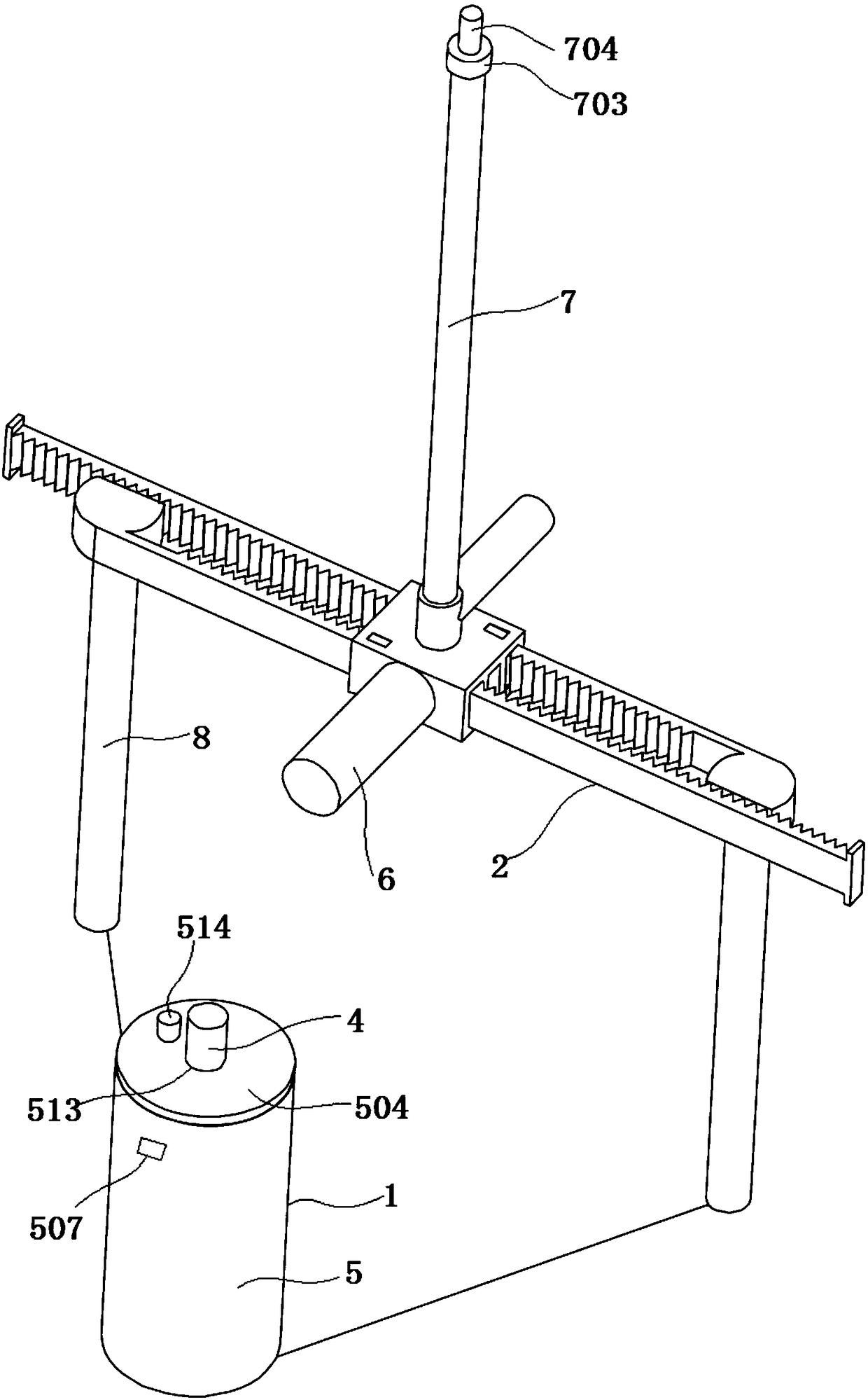

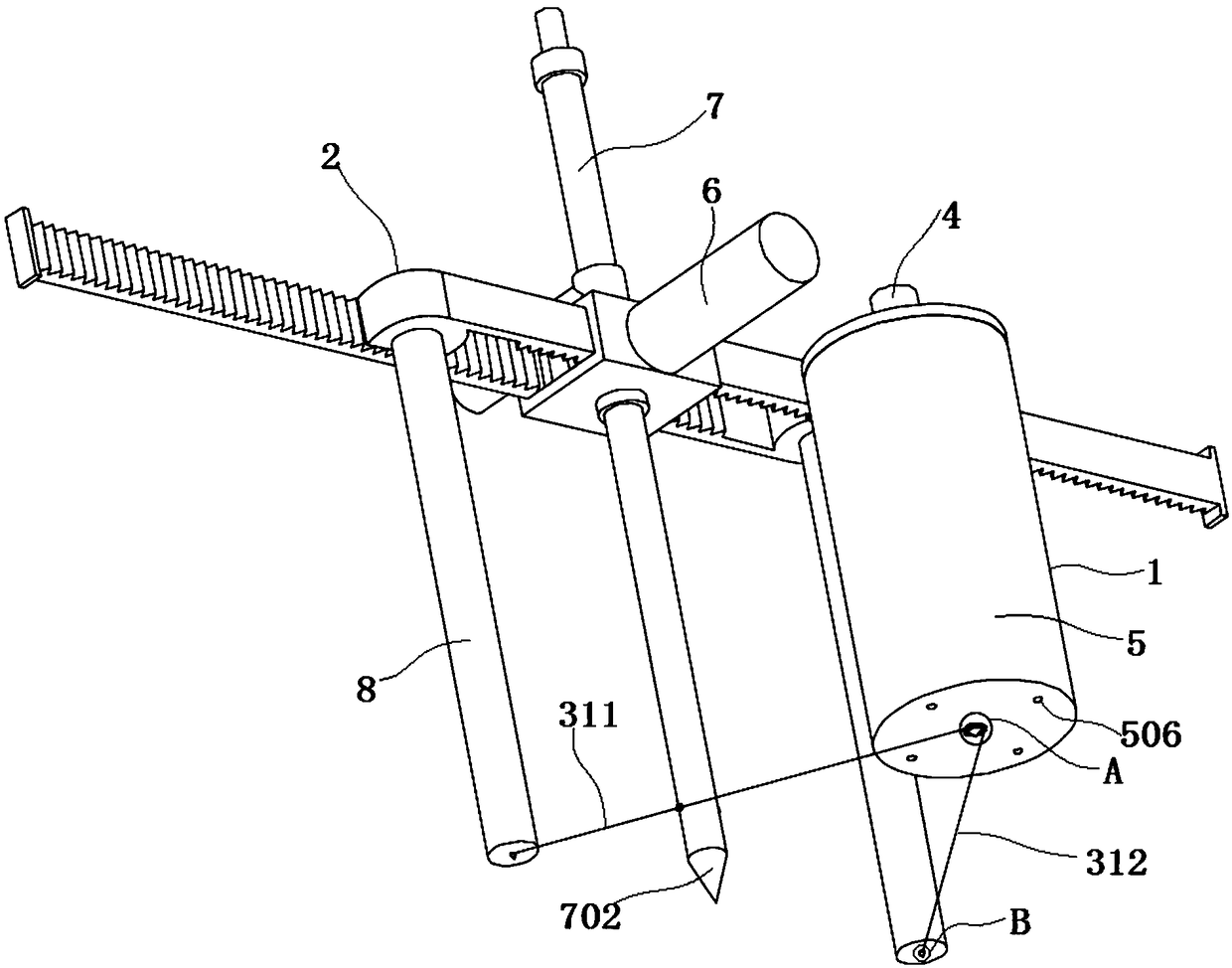

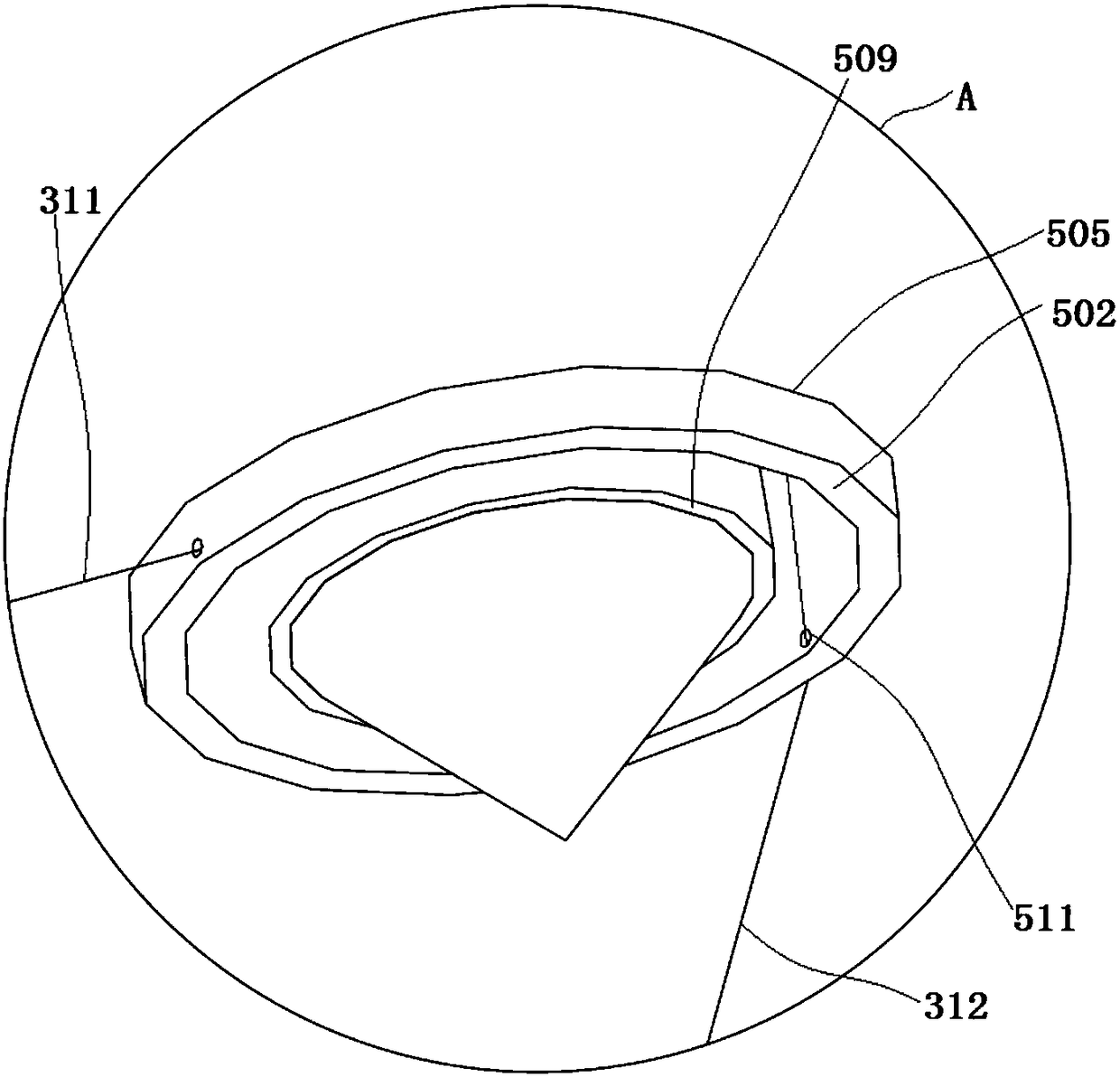

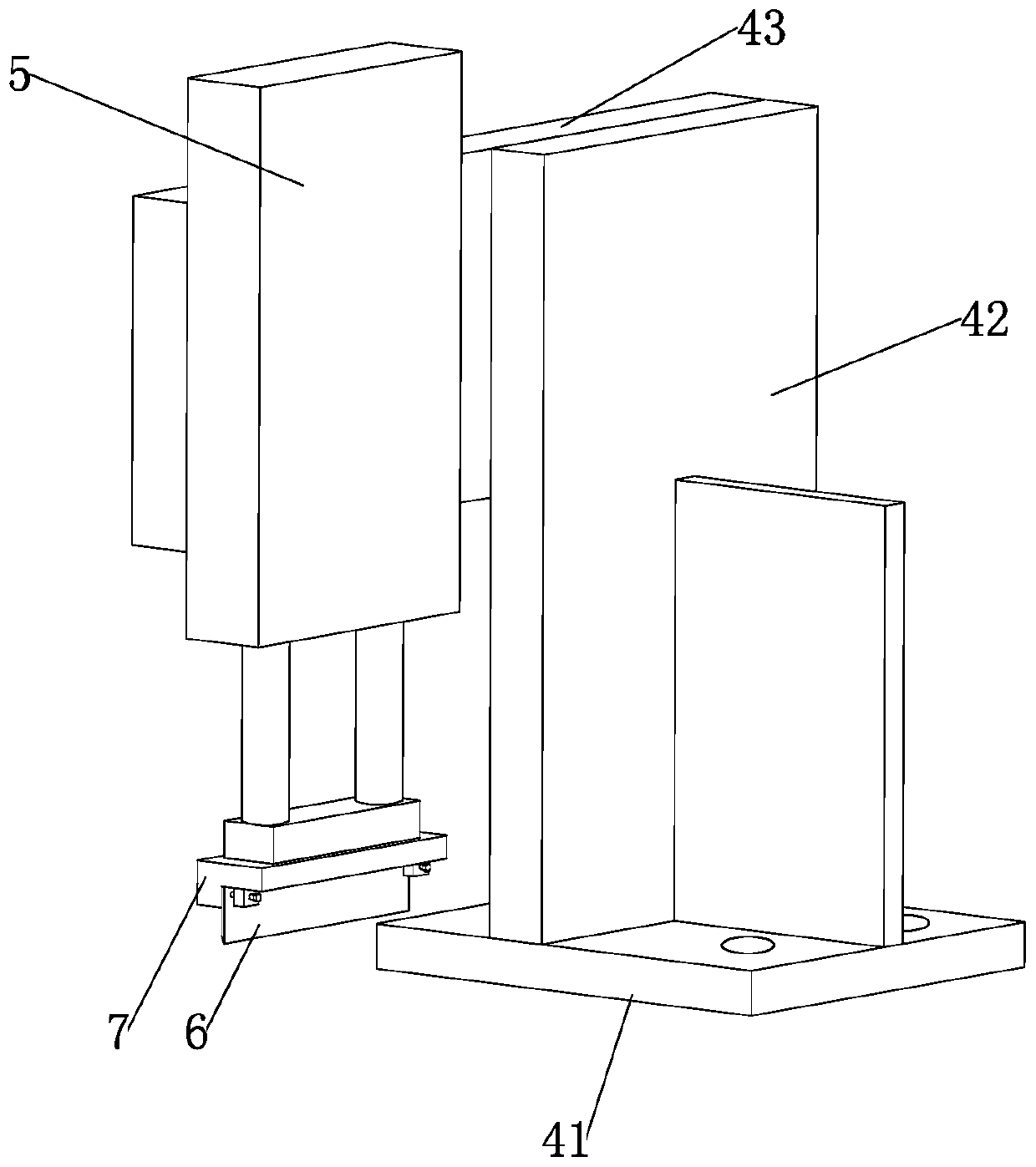

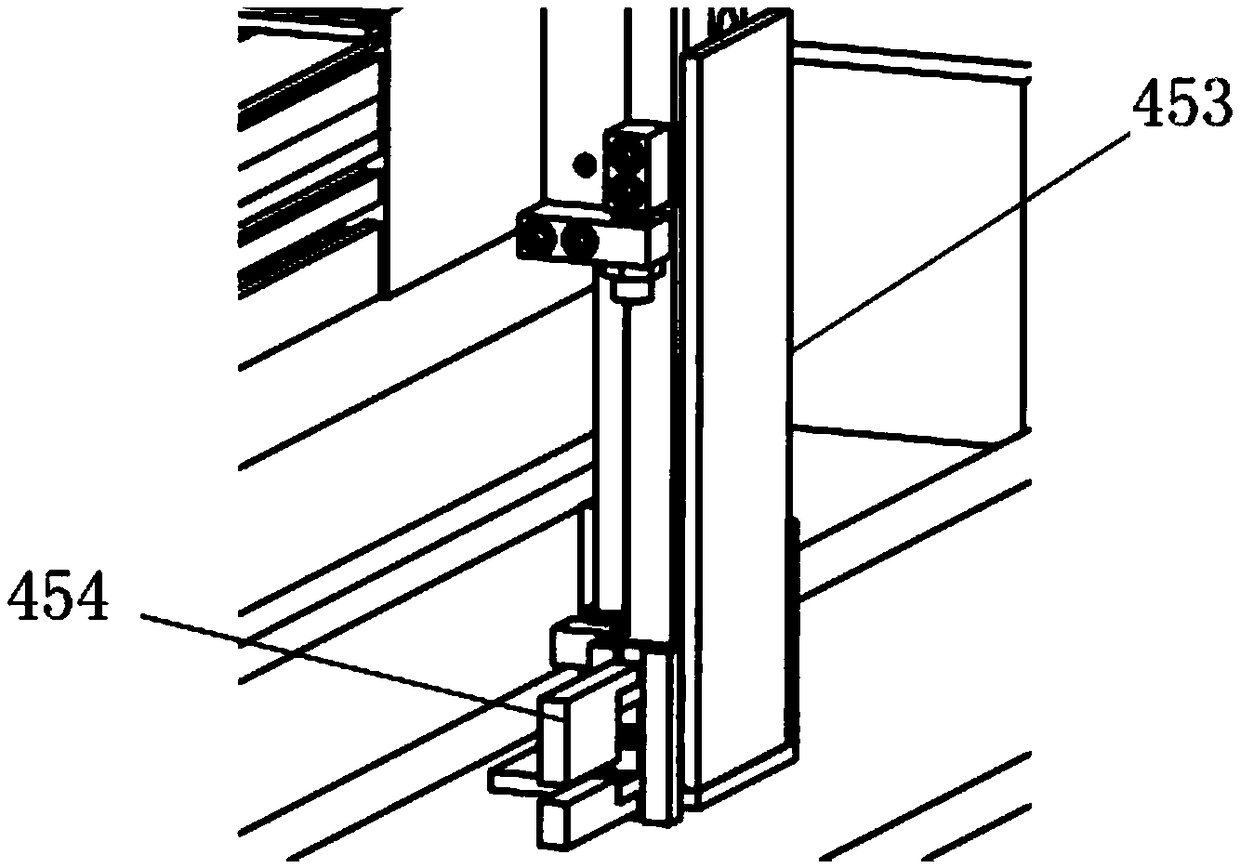

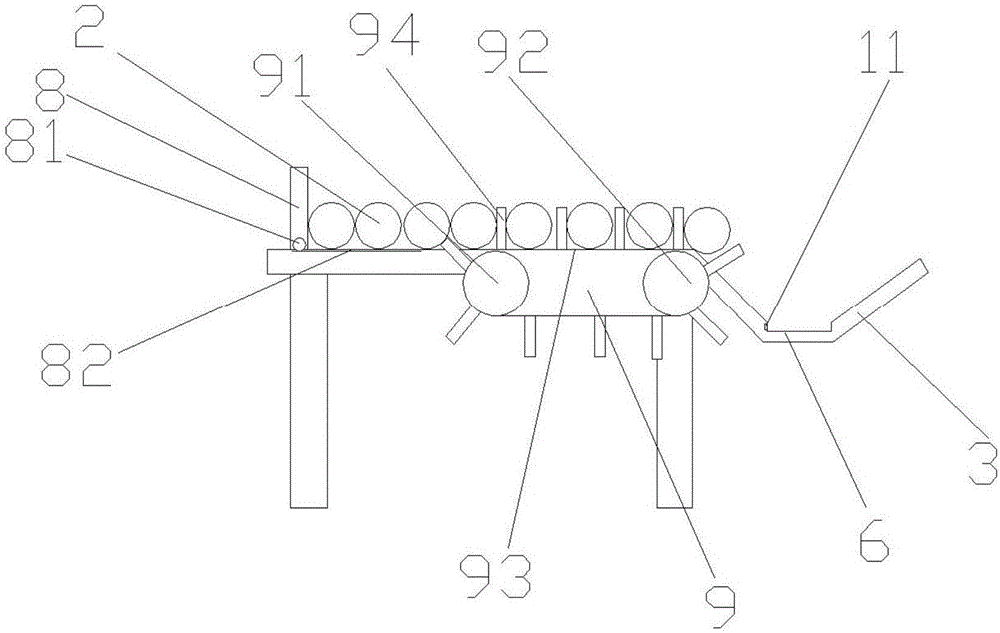

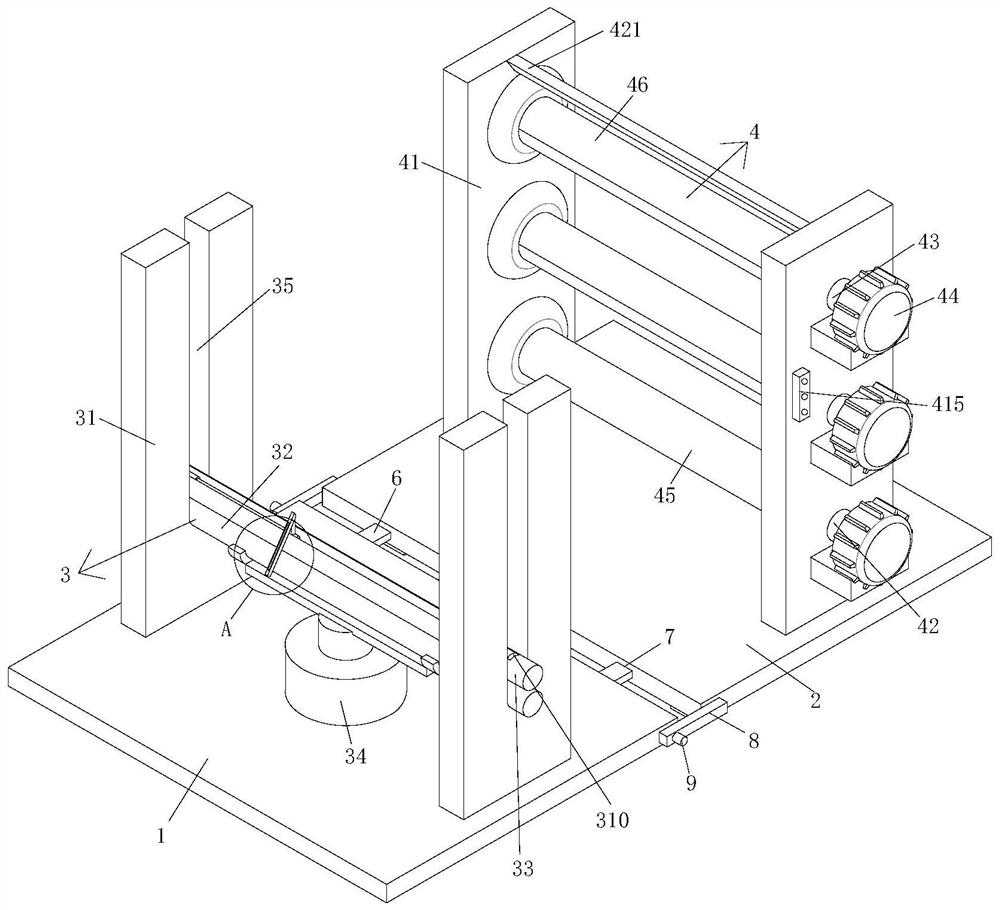

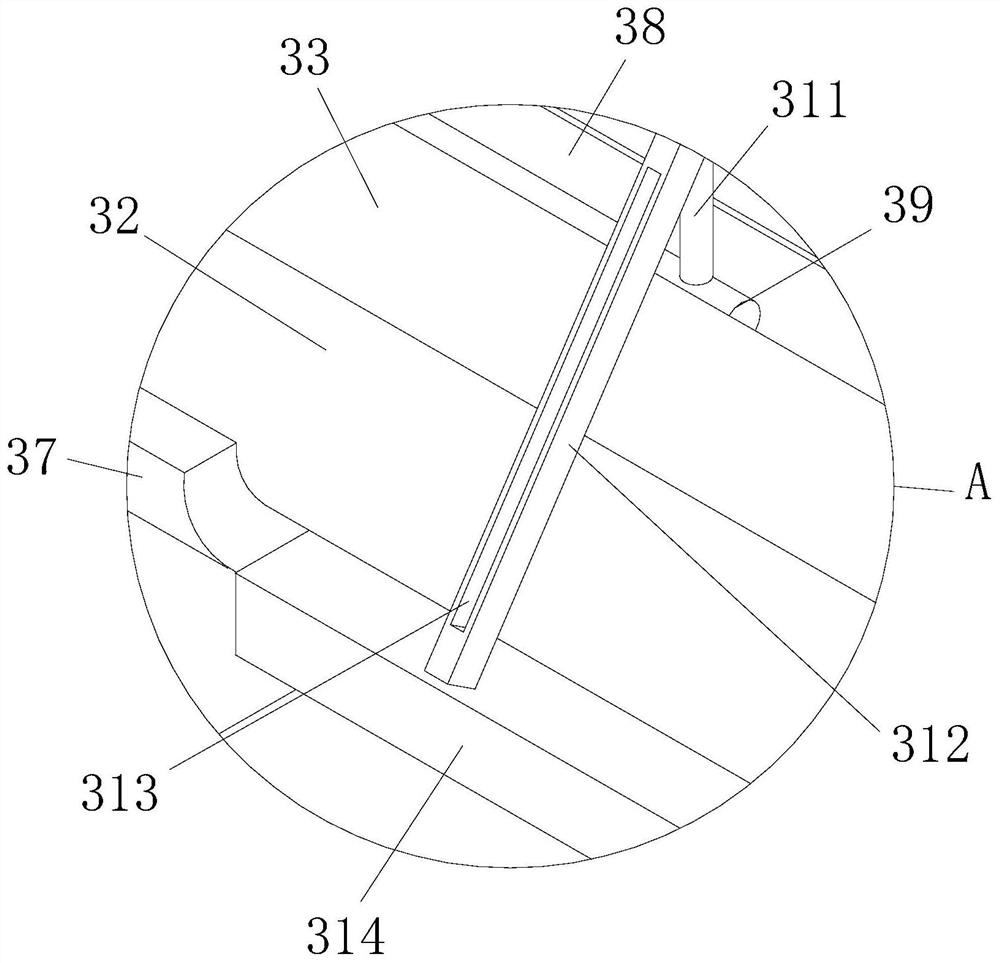

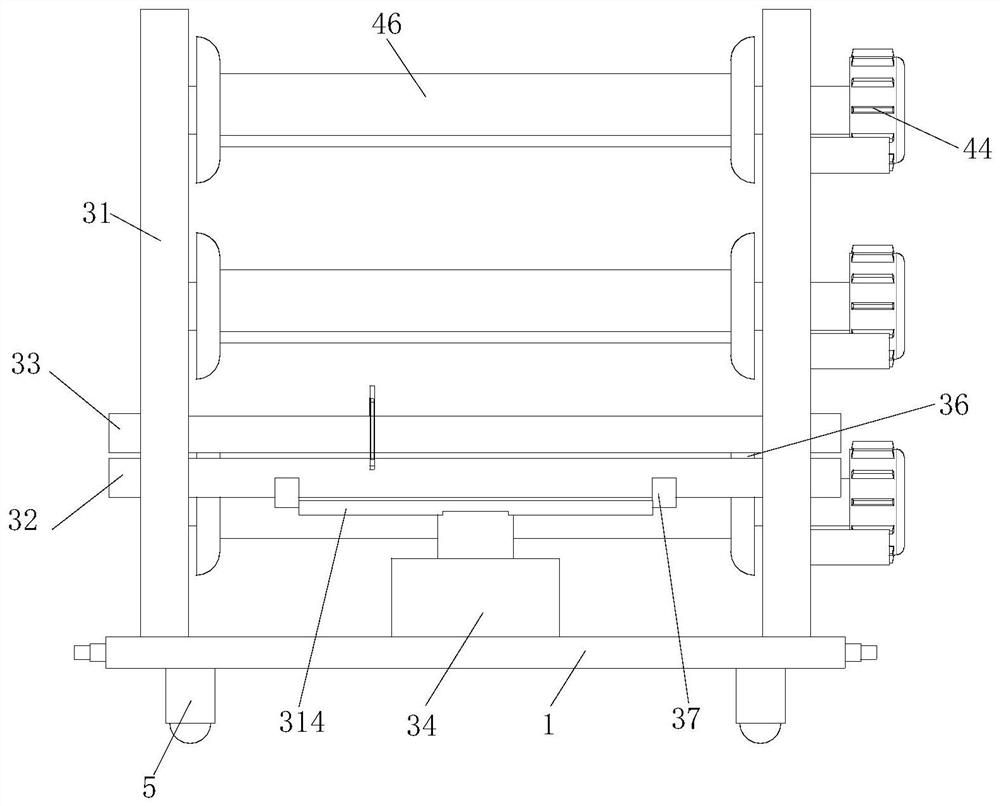

Automatic pipe outlet equipment and method for ceramic roller rod pipe billet

ActiveCN109176857ASmall length errorReduce the influence of human factorsDischarging arrangementAuxillary shaping apparatusEngineeringFront and back ends

The invention discloses automatic pipe outlet equipment for a ceramic roller rod pipe billet and further provides an automatic pipe outlet method for the ceramic roller rod pipe billet accordingly. The automatic pipe outlet equipment comprises a pipe billet tool storage frame, a pipe billet storage frame, a taking-placing mechanism, a pipe cutting and dumping mechanism, a lifting mechanism, a conveying mechanism and a drilling mechanism; the pipe cutting and dumping mechanism comprises a rack, an air bed arranged on the rack, a cutting assembly, an inclining assembly used for inclining the airbed, and a clamping assembly used for clamping the pipe billet; the air bed comprises a front end and a rear end; and the front end of the air bed is arranged at a discharging outlet of a forming machine, the pipe billet is automatically transferred from the discharging outlet of the forming machine to the air bed, and the cutting assembly is arranged on the lower portion of the front end of theair bed and used for cutting the pipe billet. According to the automatic pipe outlet equipment, cutting, drilling and carrying of the ceramic roller rod pipe billet are completed, automation is achieved, personnel equipping is reduced, and the production efficiency is improved.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD

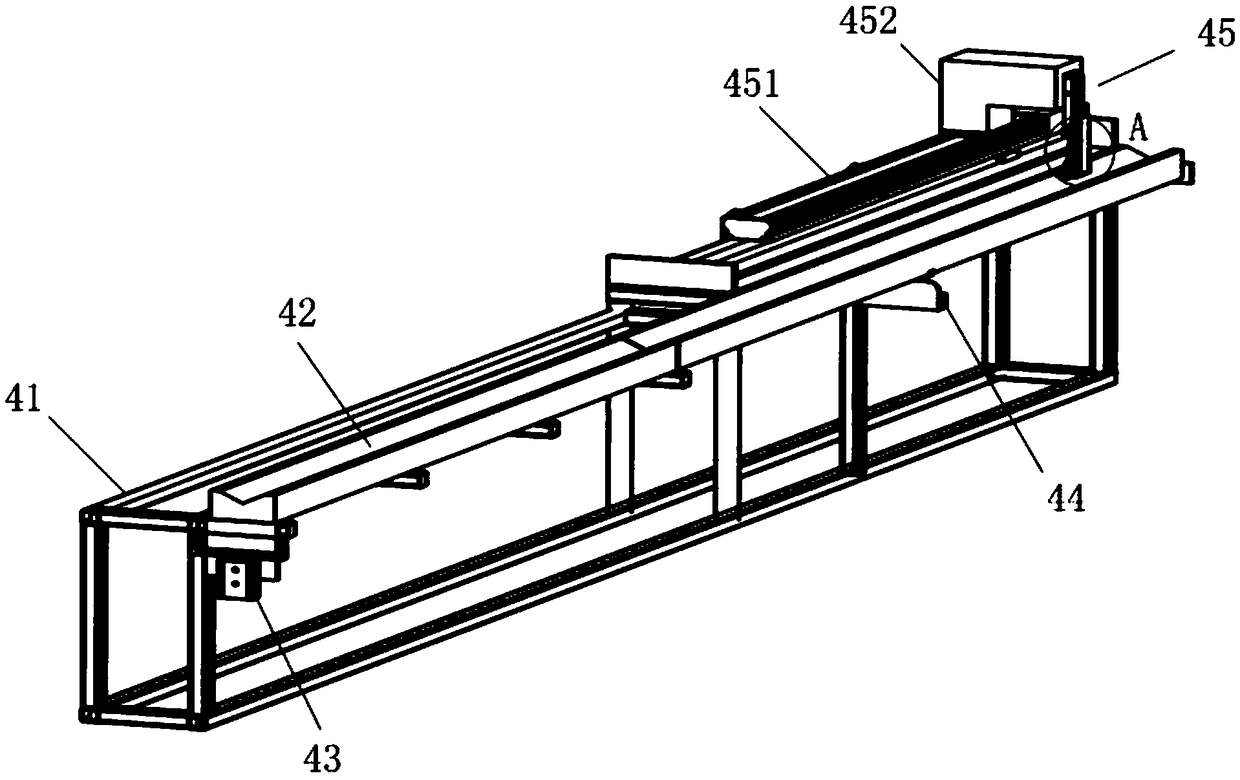

Full-automatic fixed-length cutting device of adhesive tapes and method thereof

InactiveCN113371523AImprove the efficiency of cut-to-lengthNo manual operationArticle deliveryWebs handlingAdhesive beltMechanical engineering

The invention provides a full-automatic fixed-length cutting device of adhesive tapes and a method thereof and belongs to the technical field of processing of adhesive tapes. The full-automatic fixed-length cutting device comprises a machine body, a driving mechanism and a cutting mechanism, wherein a channel for conveying adhesive tapes and release paper is formed in the machine body; the channel comprises a feeding part, a pressing part and a discharging part; the driving mechanism is mounted on the machine body and is used for driving the adhesive tapes and the release paper to be conveyed from the feeding part to the discharging part and pressing the adhesive tapes and the release paper; the cutting mechanism is mounted on the machine body and is located at a position close to the discharging part; and the cutting mechanism is used for carrying out fixed-length cutting on the pressed and formed adhesive tapes. According to the full-automatic fixed-length cutting device of adhesive tapes and the method thereof, the driving mechanism is used for conveying the adhesive tapes and the release paper; after the adhesive tapes and the release paper are pressed, the cutting mechanism is used for carrying out automatic fixed-length cutting on the the adhesive tapes and the release paper; full-automatic pressing and cutting are achieved; manual operation is not needed; the working efficiency is high; the cutting precision is high; and the fixed-length cutting efficiency of the adhesive tapes is greatly improved.

Owner:NINGBO POLYTECHNIC

Steel tube fixed-length cutting device

InactiveCN106475628AEffectively fixedSmall length errorMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a steel tube fixed-length cutting device. The steel tube fixed-length cutting device comprises a frame and a cutting machine. A rack platform and a conveyor are arranged on the frame. One side of the rack platform is provided with V-shaped brackets. The other side of the rack platform is provided with a movable baffle. A movable ruler and ruler grooves are arranged on the V-shaped brackets. The steel tube fixed-length cutting device provide by the invention realizes fixed-length cutting, saves time and labor and is small in steel tube length error, applicable to different lengths of steel tubes and wide in fixed-length range.

Owner:ZHANGJIAGANG CITY SHENGDINGYUAN PIPE MAKING

Small raw silk fineness inspection device for silk reeling enterprises

The invention relates to a small raw silk fineness inspection device for silk reeling enterprises. The device comprises a fixed length silk picking module, a silk guide module, an STM32 single-chip microcomputer controller, a high precision electronic scale, a silk ingot, a rack and a computer, wherein the fixed length silk picking module comprises a winding mechanism, two bearing seats and corresponding bearings, an alternating current (AC) servo motor, a servo driver and a servo motor support; a transmission shaft of the winding mechanism is fixed by means of a cantilever beam, a fixed length raw silk can be wound onto the winding mechanism from the sink ingot, and a silk picking operation can be performed at the non-fixed side; the silk guide module comprises a ball screw slide table, asilk guide hook position adjusting device, a silk guide hook, a broken silk detecting sensor and an adjustable bracket; the ball screw slide table translates the silk guide hook so as to translate the winding position, so that a stacking error is eliminated; the broken silk is detected at the same time. The small raw silk fineness inspection device is small in overall size, and the length of theraw silk to be detected is flexible to obtain; the demand of small-scale and diversified raw silk fineness self-testing of the silk reeling enterprises can be met.

Owner:CHINA JILIANG UNIV

Cutting device for drainage pipe of air conditioner

InactiveCN104002325APrecise length controlGuaranteed lengthMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for a drainage pipe of an air conditioner and relates to a feeding device, in particular to a feeding device for the drainage pipe of the air conditioner. The feeding device for the drainage pipe of the air conditioner comprises a working table, a feeding pipeline and rotary shafts, wherein the rotary shafts are connected with the working table in a rotary mode in the radial direction, the feeding pipeline is cylindrical and is fixed to the working table, the rotary shafts are located on the two sides of the feeding pipeline and are symmetrically distributed, a feeding wheel is detachably and fixedly connected to the end, located above the working table, of each rotary shaft, the end, located below the working table, of each rotary shaft is driven by a motor to rotate, feeding ports which are matched with the feeding wheels are formed in the two sides of the feeding pipeline, and feeding teeth which are matched with a corrugated drainage pipe are arranged on the circumference of each feeding wheel. By the adoption of the feeding device for the drainage pipe of the air conditioner, the error of the length of the corrugated pipe obtaining after cutting can be reduced.

Owner:重庆锦利塑业有限公司

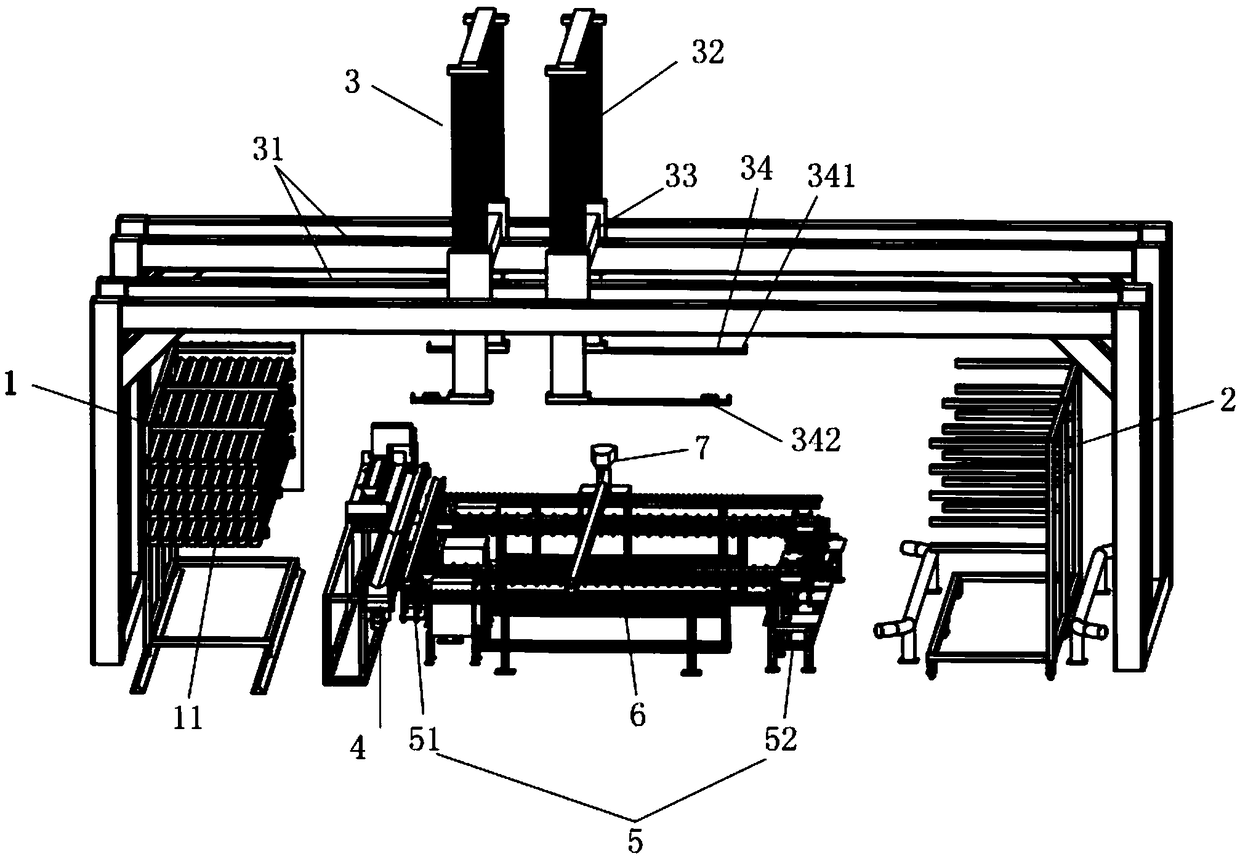

An automatic winding system

ActiveCN110902492BObtain diameter data in real timeGuaranteed qualifiedFilament handlingWinding machineControl engineering

The invention discloses an automatic winding system, which comprises a frame. The frame is provided with a guide mechanism, a detection mechanism, a winding mechanism, and a controller electrically connected to the detection mechanism and the winding mechanism. To guide the enameled wire to move, the detection mechanism is used to detect the diameter of the enameled wire, the winding mechanism is used to wind the enameled wire on the drum, the winding mechanism has a cutting assembly for intermittently cutting the enameled wire, and the controller has data A storage module, a data processing module and a logic control module, the data storage module is used to store the real-time diameter and real-time winding data of the enameled wire, the data processing module is used to obtain the real-time remaining winding time required for the enameled wire, the The logic control module is used to control the action of the cutting assembly according to the real-time remaining winding time. The automatic winding system of the present invention can accurately control the diameter, length and weight of the enameled wire wound on the drum to meet the requirements of customers.

Owner:鹤山市江磁线缆有限公司

A casing machine device

Owner:吴根佑

Non-woven fabric slitting equipment

InactiveCN114000340AHigh degree of automationSolve the problem that the production accuracy is greatly affectedSevering textilesStructural engineeringNonwoven fabric

The invention belongs to the field of non-woven fabric cutting, and particularly relates to non-woven fabric slitting equipment. The equipment comprises a bottom plate; a guide rod is fixedly connected to the upper surface of the bottom plate, a top plate is slidably connected to the outer surface of the top end of the guide rod, and a cutting mechanism is arranged at the bottom of the top plate and located at the top of the bottom plate. According to the non-woven fabric slitting equipment, the cutting mechanism is arranged, when non-woven fabric enters the equipment from the left side of a movable plate, a feeding mechanism conveys the non-woven fabric to the right side of a tiling mechanism, the top plate downwards extrudes the tiling mechanism, the tiling mechanism tensions the non-woven fabric to be cut, a cutter downwards cuts the non-woven fabric under the effect of gravity and pressure, the non-woven fabric is broken under extrusion of the cutter and a rack, the cut non-woven fabric is rolled out through a material collecting mechanism, the automation degree of non-woven fabric cutting is improved, the influence of manual intervention on the cutting precision is reduced, and the problem that when traditional cutting equipment cuts the non-woven fabric, due to low automation, manual intervention greatly influences the production precision is solved.

Owner:韦向乐

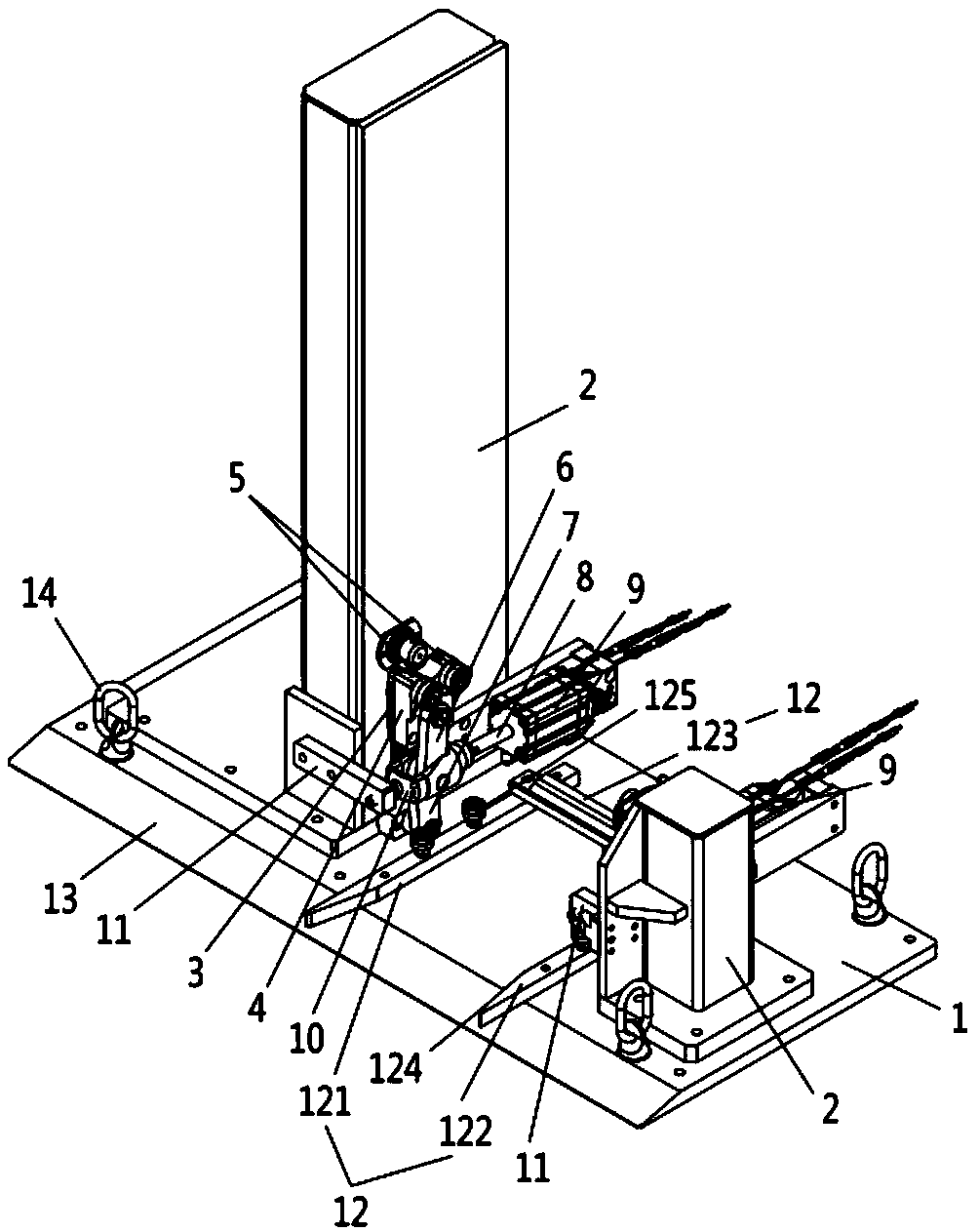

A method for inserting insulating paper into a motor stator embedding groove

InactiveCN107370316BImprove plasticityGuaranteed stabilityApplying solid insulationSlot insulationPulp and paper industry

The invention provides an insertion method for motor stator line inserting slot insulation paper. In the method, a one-step forming process of insulation paper is divided into multistage forming, forming internal stress of the insulation paper is released in each forming process, and in repeated heating and forming processes, plasticity of the insulation paper is improved, and stability after forming is ensured. The method solves problems that thermal formed insulation paper easily deforms in a cooling process, fit accuracy of the insulation paper and a stator slot is poor, the insulation paper may be reworked, and working efficiency is influenced. A servo motor is used for fixed length transmission, length of insulation paper feeding can be accurately controlled, and when height of a motor line inserting slot changes, just paper feeding length needs adjusting. The servo motor reduces length error of insulation paper feeding, reduces errors of insulation paper length and motor line inserting slot after the insulation paper is inserted, so as to improve integrated performance of a motor.

Owner:常州航空工模具有限公司

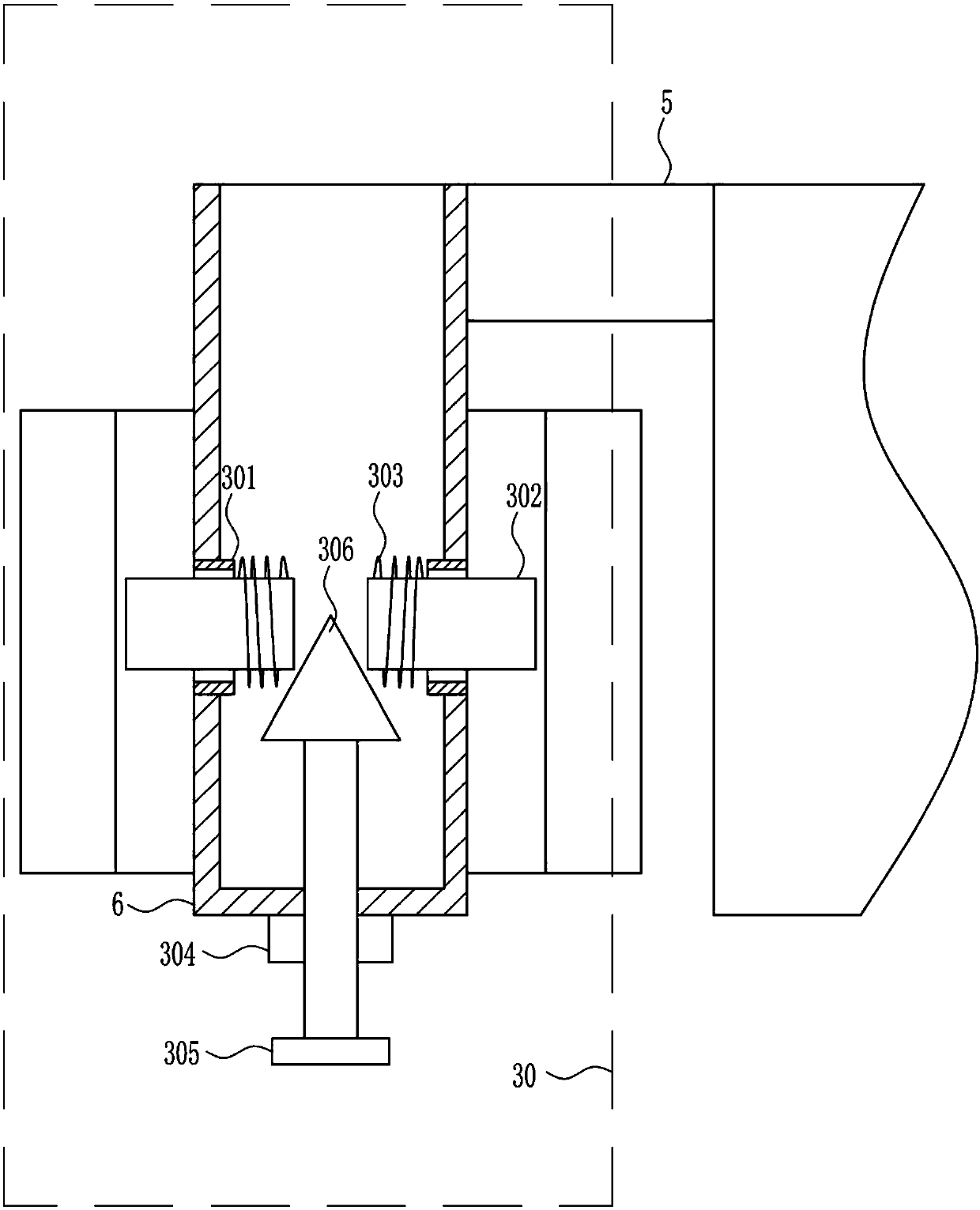

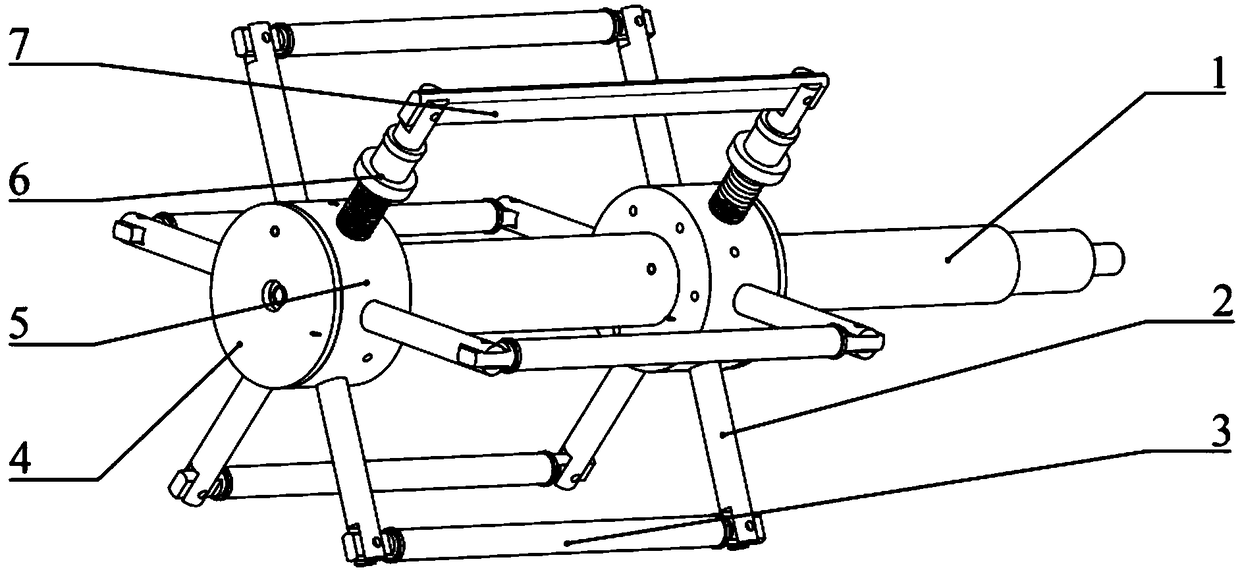

An anti-jamming wire winding device

ActiveCN106311933BMeet production requirementsAvoid stuck linesMetal working apparatusEngineeringConductor Coil

The invention discloses wire-jamming-preventing wire-winding equipment. The wire-jamming-preventing wire-winding equipment comprises a paying-off device, a wire-guiding device, a wire-winding device and a cutting-off device, wherein the paying-off device is used for paying-off action; the wire-guiding device comprises rotary shafts which are rotatably mounted and wire-guiding wheels which are fixedly mounted on the rotary shafts, and coders are mounted on the rotary shafts; the wire-winding device comprises a mandrel and a driving mechanism, wherein the mandrel comprises a limiting part, a rotating part and a swinging part which are coaxially arranged, the limiting part is fixedly connected to the rotating part, and the outer diameter of the limiting part is greater than that of the rotating part; the swinging part is located at one end, far from the limiting part, of the rotating part, and one end of the swinging part is movably connected to the rotating part while the other end of the swinging part is a free end, and the outer diameter of the swinging part is equal to that of the rotating part; the driving mechanism is located at one end, far from the rotating shaft, of the limiting part, and is connected to the limiting part for driving the limiting part to rotate; and the cutting-off device is located at the output end of the wire-winding device for cutting off wires. The equipment disclosed by the invention can avoid the wire-jamming problem, and a finished piece is small in length error and high in product percent of pass.

Owner:安徽省宁国市天成电气有限公司

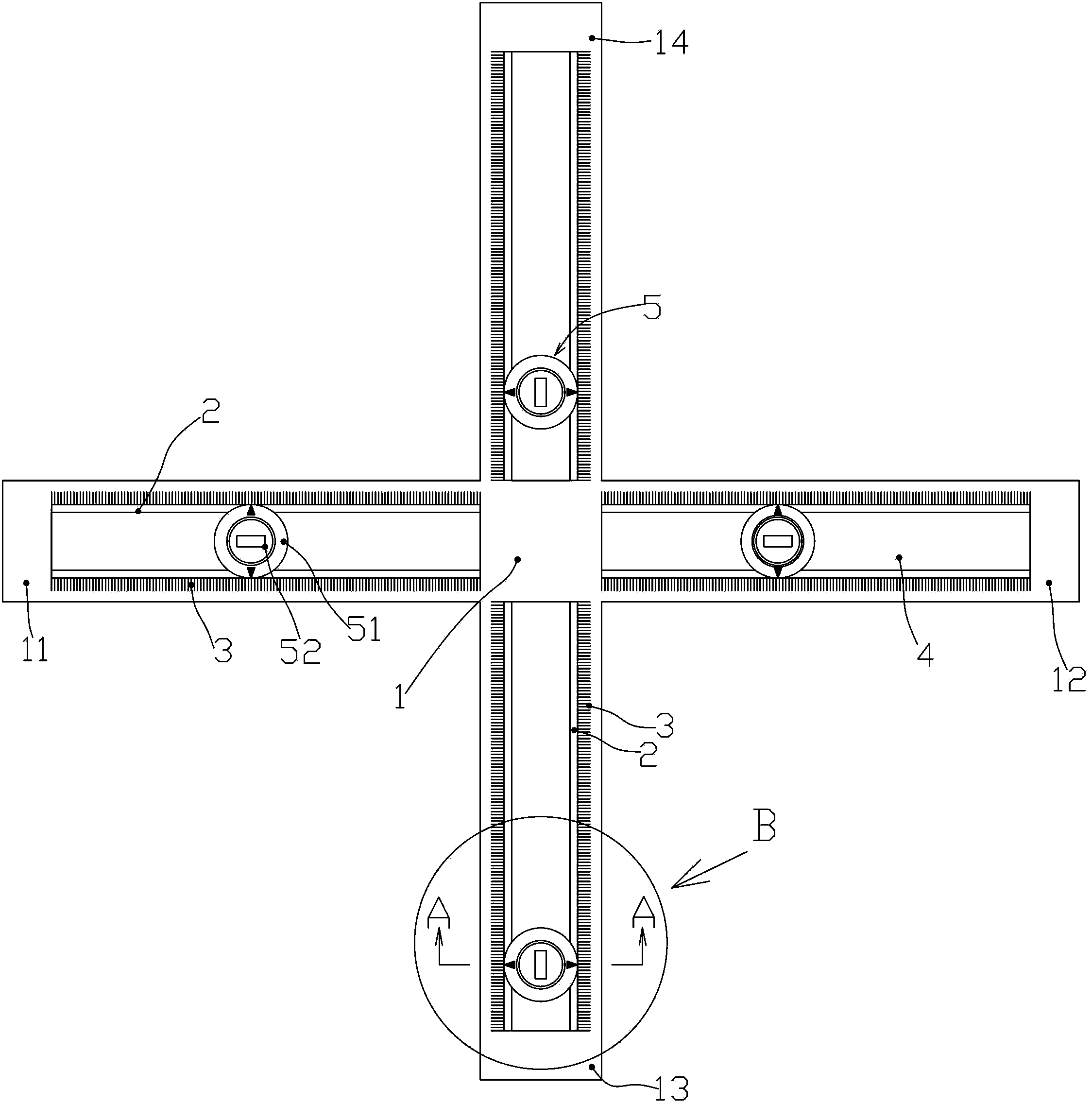

Wiring board punching marking tool for power grid

ActiveCN103302655BSmall length errorGuaranteed shape accuracyOther workshop equipmentPunchingPower grid

A wiring board punching marking tool for a power grid includes a cross framework and four positioning marking components, wherein the cross framework includes a left arm, a right arm, a front arm and a rear arm; the four positioning marking components are mounted on the four arms respectively. The tool has the benefits that the centers of all mounting holes can be confirmed as per positions of the mounting holes in equipment, then the positioning marking components of the punching marking tool are fixed on all the arms of the cross framework, then the punching marking tool is placed on a wiring board, the positioning marking components are beat through a rawhide hammer, so that the center position of a punched hole in the wiring board can be obtained, and position reference points of four holes forming a square when the four hole centers are connected can be obtained through one-time positioned fixing and marking, obtained shapes and position precision of the four holes can be finally guaranteed, the probability of one-time qualified marking for the hole distance of the wiring board can be improved, waste of metal materials can be reduced, and the construction efficiency of secondary construction can be improved.

Owner:STATE GRID CORP OF CHINA +1

A textile thread equal volume winding device based on textile processing

The invention provides a textile thread equivalent winding device based on textile processing, comprising a first support plate, a second support plate, a spinning thread angle control mechanism for controlling the angle of the spinning thread, and a spinning thread angle control mechanism for spinning the thread The self-adaptive winding mechanism for winding, the bottom of the first support plate and the bottom of the second support plate are equipped with moving wheels, and the spinning angle control mechanism is arranged on the first support plate, which relates to the textile field. Based on the textile thread equivalence winding device for textile processing, according to the problems existing in the existing spinning thread winding process, which are easy to repeatedly fix the thread head and the length of the thread is not easy to control, it is designed to freely control the length of the winding line. The special structure of rewinding the spun yarn in the same amount as the multi-roller effectively solves the difficulty of controlling the winding length of the reeling rod when the general reeling device rewinds the spun yarn. The length and thickness of the winding wire are prone to large errors.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com