Non-woven fabric slitting equipment

A technology of non-woven fabrics and equipment, applied in the field of non-woven fabric cutting equipment, can solve the problems of reducing the service life of the equipment, increasing the occurrence of accidents, and low degree of automation, so as to reduce the length error, increase the friction force, and improve the automation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

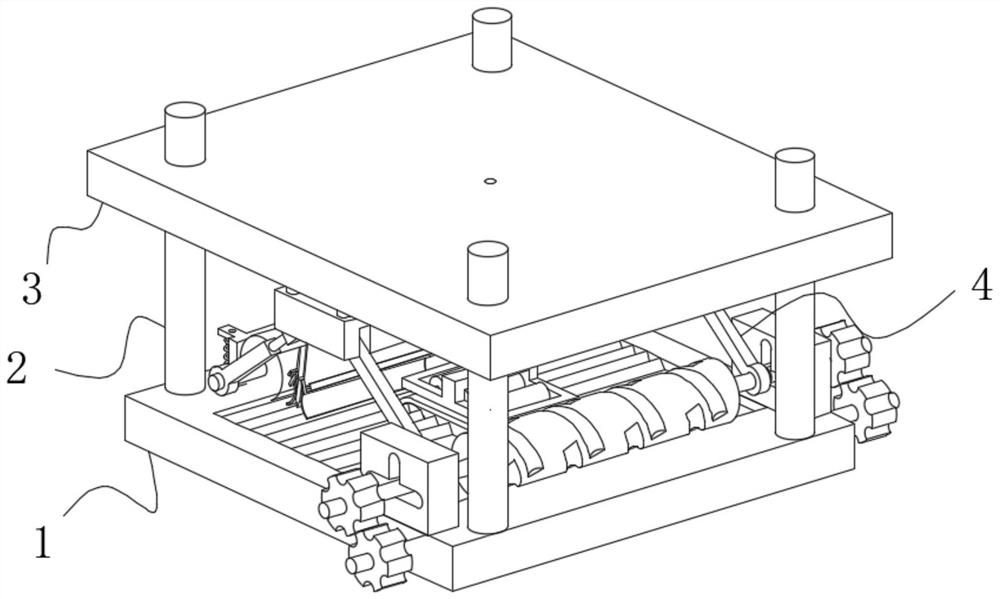

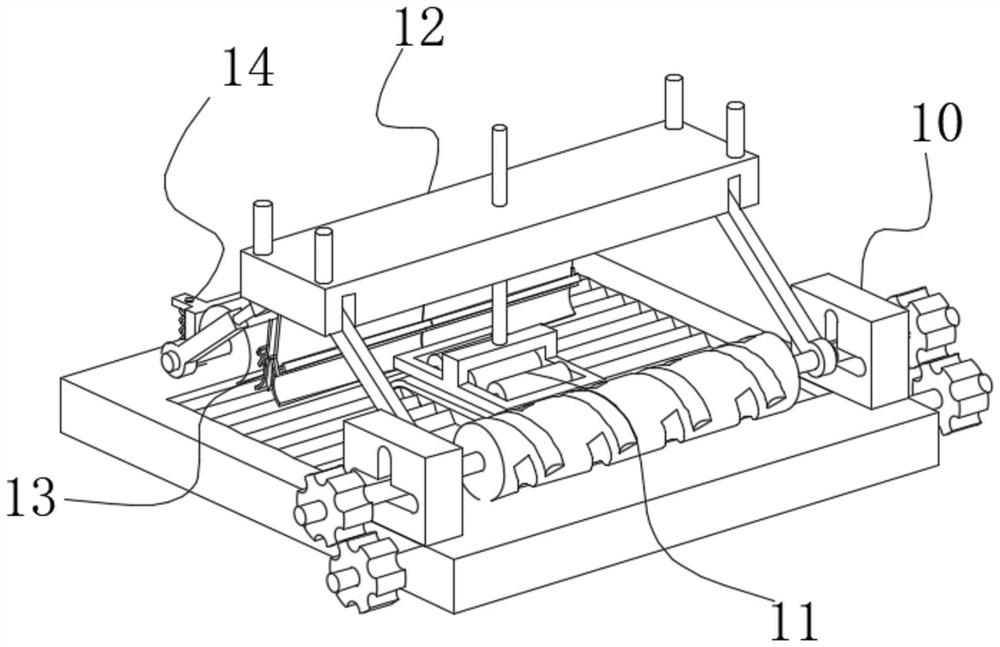

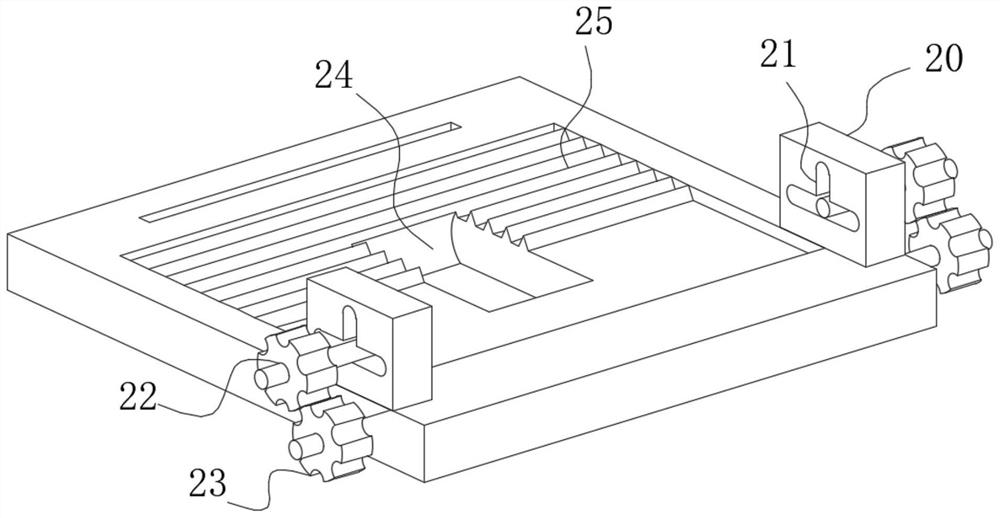

[0023] use Figure 1-Figure 7 A non-woven fabric slitting device according to an embodiment of the present invention is described as follows.

[0024] Such as Figure 1-Figure 7 As shown, a kind of non-woven fabric cutting equipment of the present invention comprises a bottom plate 1;: the upper surface of the bottom plate 1 is fixedly connected with a guide rod 2, and the outer surface of the top end of the guide rod 2 is slidably connected with a top plate 3, and the bottom of the top plate 3 is arranged Cutting mechanism 4 is arranged, and cutting mechanism 4 is positioned at the top of bottom plate 1, and cutting mechanism 4 comprises material receiving mechanism 10, and the left side of material receiving mechanism 10 is provided with feeding mechanism 11, and the top of feeding mechanism 11 is provided with tiling mechanism 12, tiling A cutter 13 is movably connected to the bottom left of the mechanism 12, and a movable plate 14 is arranged on the left side of the cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com