Automatic pipe outlet equipment and method for ceramic roller rod pipe billet

A technology for ceramic rollers and blank tubes, applied in the field of machinery and equipment, can solve the problems of large error in the length of the blank tube, high labor intensity, and many people, so as to reduce the length error, reduce the influence of human factors, and improve products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

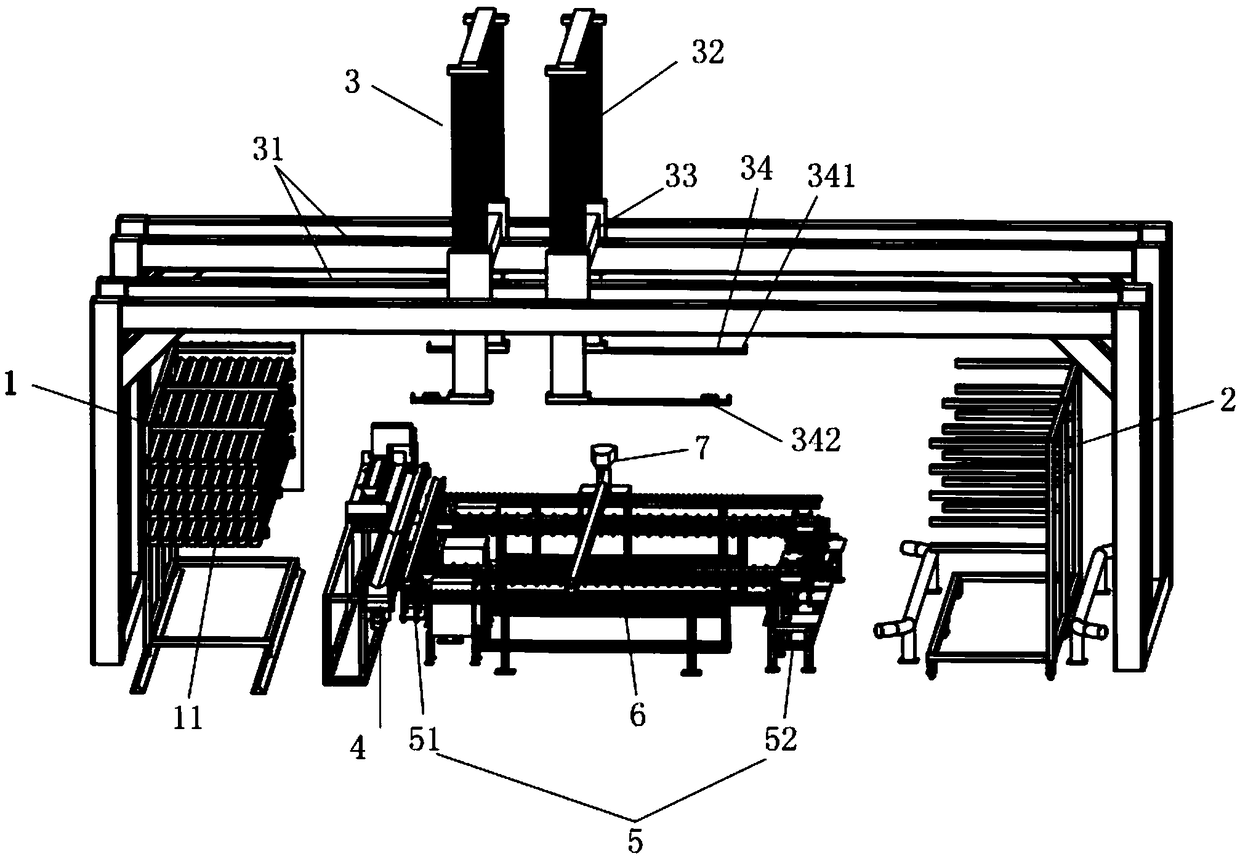

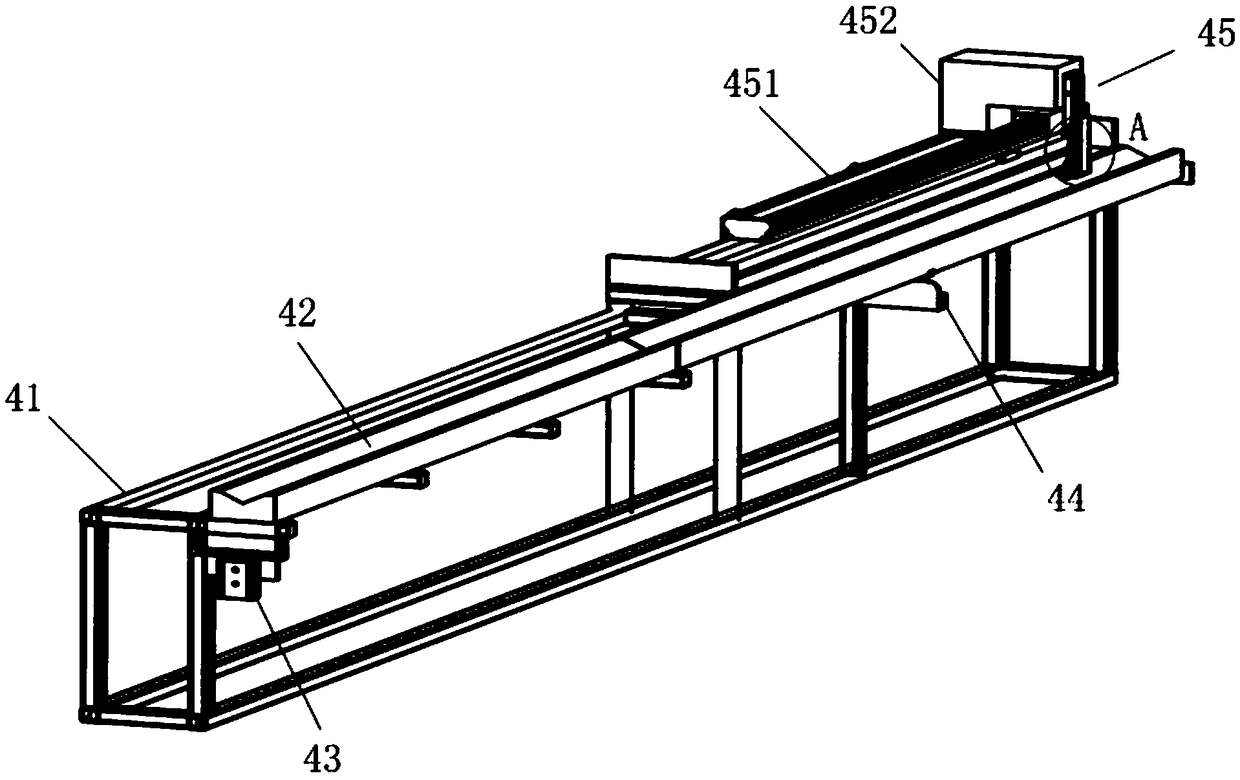

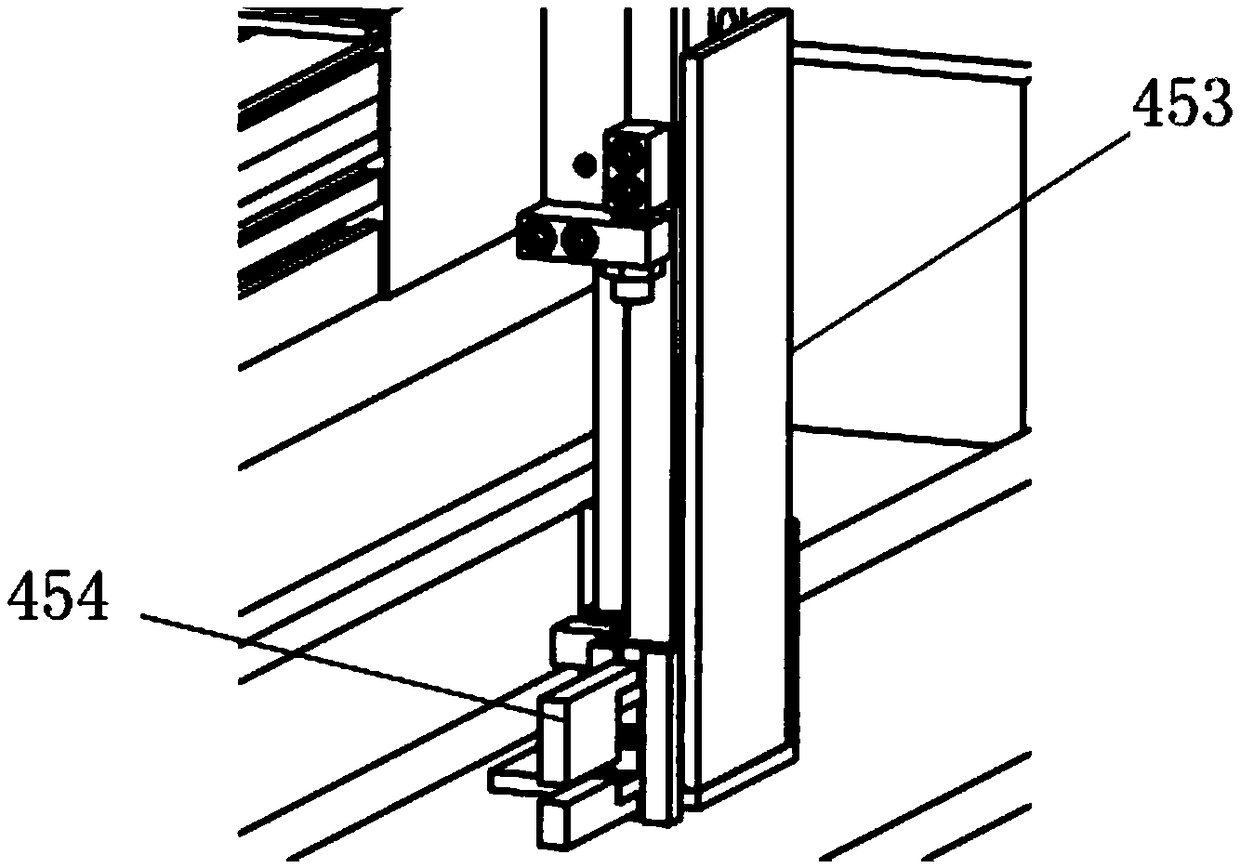

[0037] see figure 1 , an automatic pipe discharge device for ceramic roller billet tubes provided by the present invention, comprising a blank tube tooling storage rack 1, a blank tube storage rack 2, a pick-and-place mechanism 3, a pipe cutting and dumping mechanism 4, a lifting mechanism 5, and a conveying mechanism 6 and drilling mechanism7.

[0038] The billet tube tooling storage rack 1 of the present invention is used for storing the billet tube tooling 11, and the billet tube tooling 11 is used for loading the billet tube, so as to prevent the billet tube from being damaged or deformed during transportation. The blank tube storage rack 2 is used for storing the blank tube, specifically, the blank tube is stored on the blank tube storage rack 2 together wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com