Wiring board punching marking tool for power grid

A terminal board and power grid technology, applied in manufacturing tools, workshop equipment, etc., can solve the problems of wasting metal materials, affecting the probability of passing, and slowing down the progress of secondary construction, so as to improve construction efficiency, reduce waste, and improve marking. The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] To facilitate a further understanding of the technical solution of the present invention, the technical content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The orientation descriptions of left, right, front, back, up and down mentioned in the text all indicate relative positions and cannot be considered as a limitation to the technical content of the present invention.

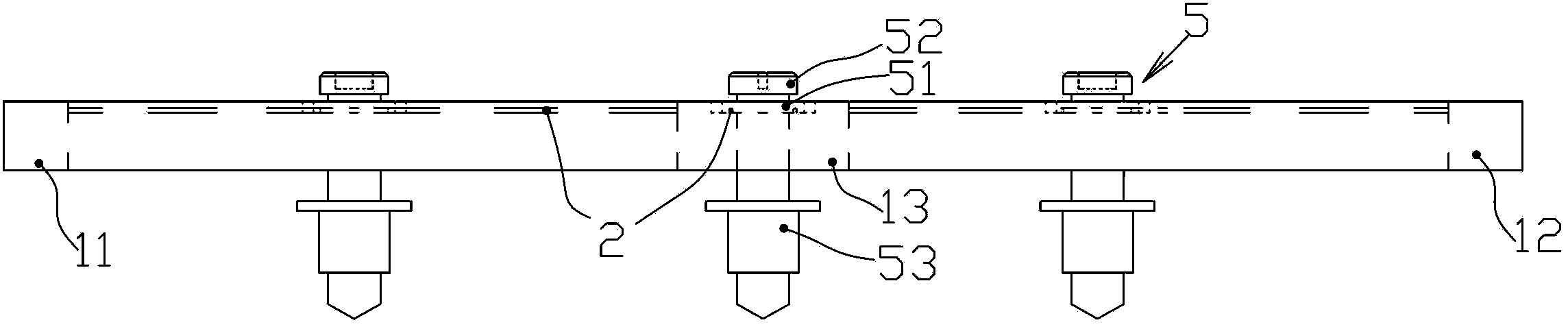

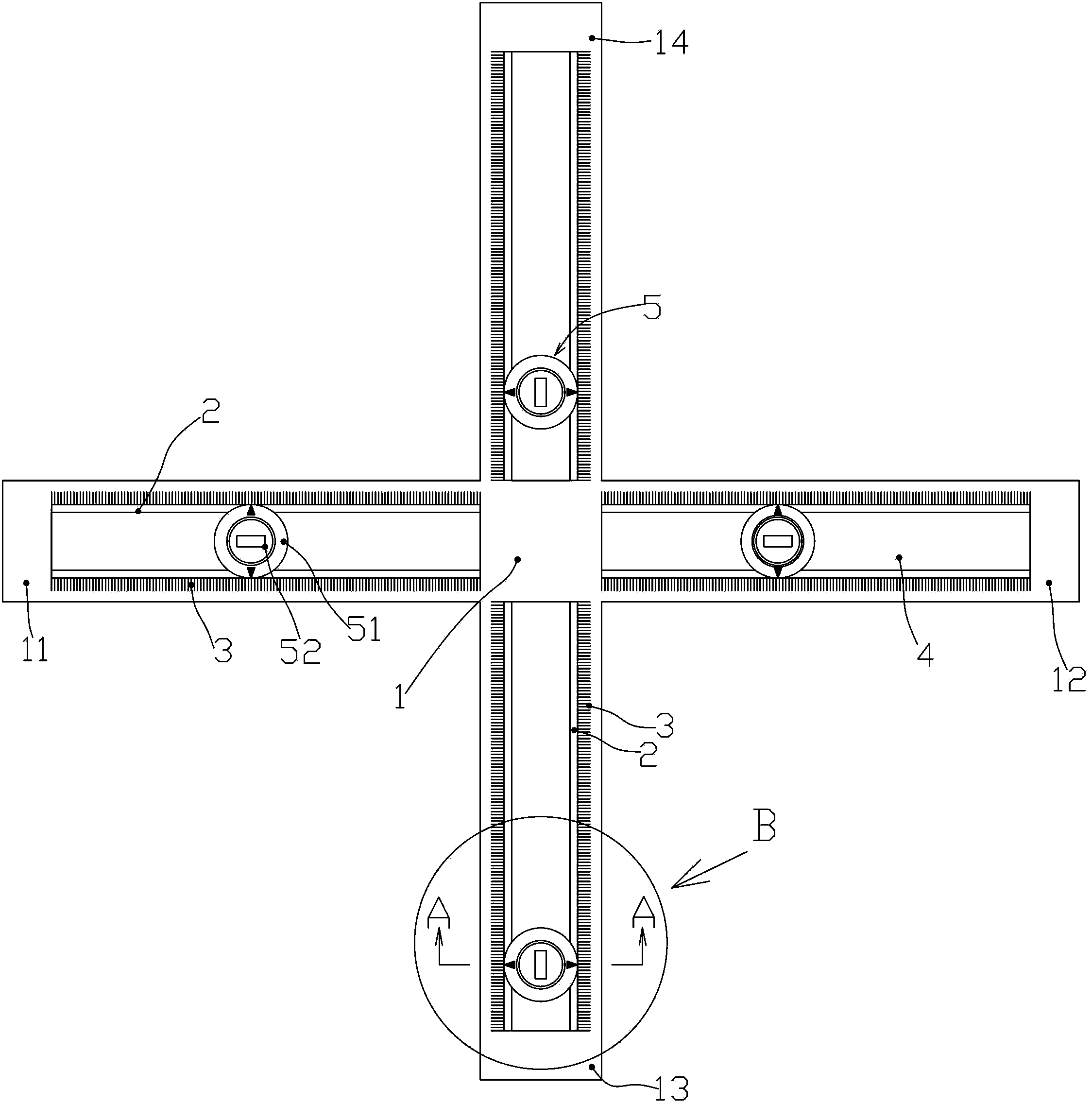

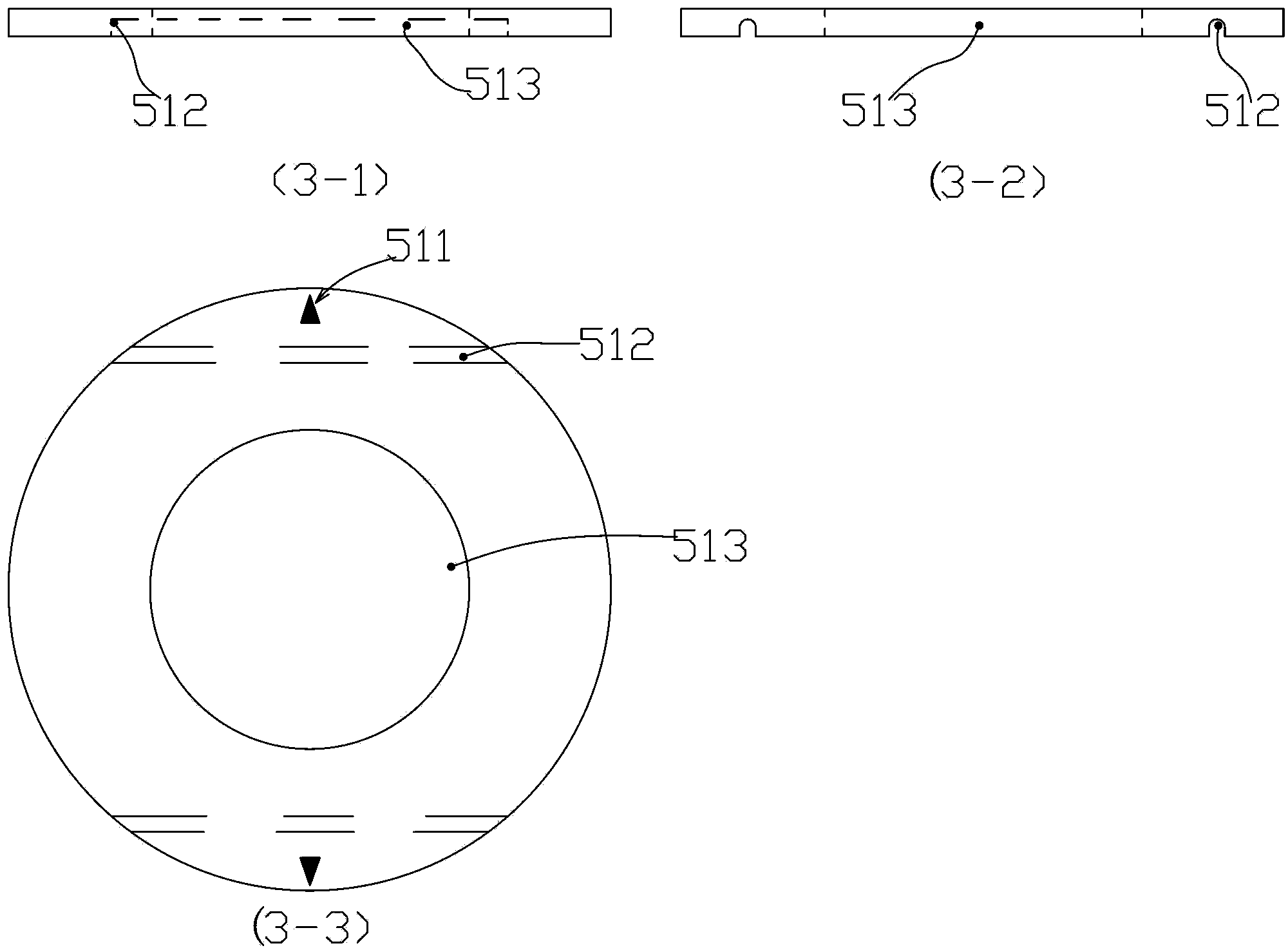

[0030] Such as figure 1 with figure 2 with image 3 [(3-1) Schematic diagram of the front view structure, (3-2) is the schematic diagram of the left view structure of the pointer plate, (3-3) is the schematic diagram of the top view structure of the pointer plate] As shown in the figure, a hole-punched wiring board for power grid The marking tool includes a cross frame 1 and four positioning marking components 5. The cross frame 1 includes a left arm 11, a right arm 12, a forearm 13, and a rear wall 14 arms. The four posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com