Patents

Literature

380results about How to "Guaranteed shape accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

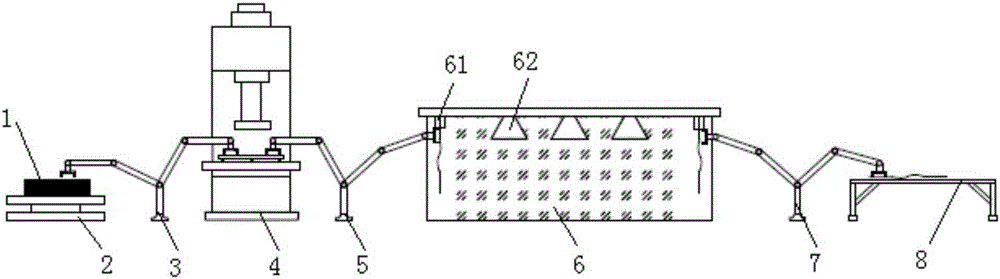

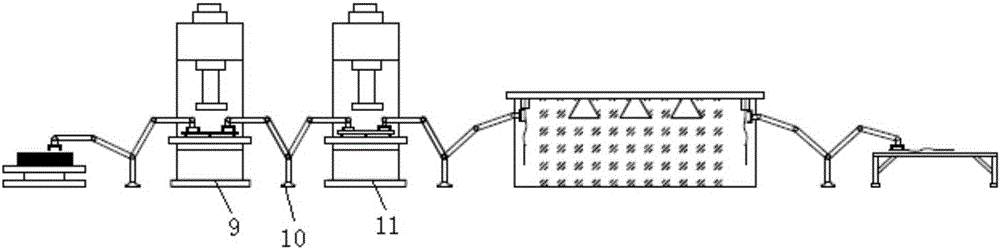

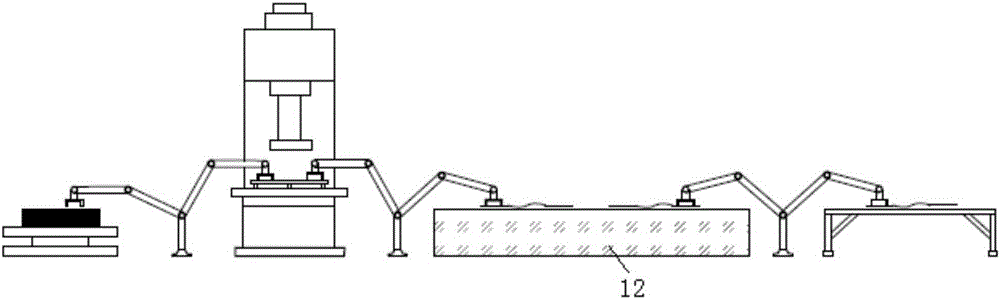

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

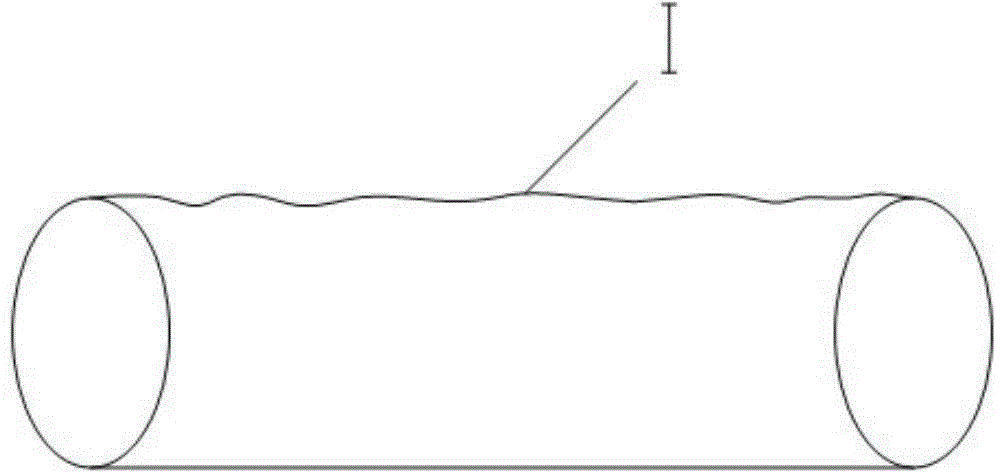

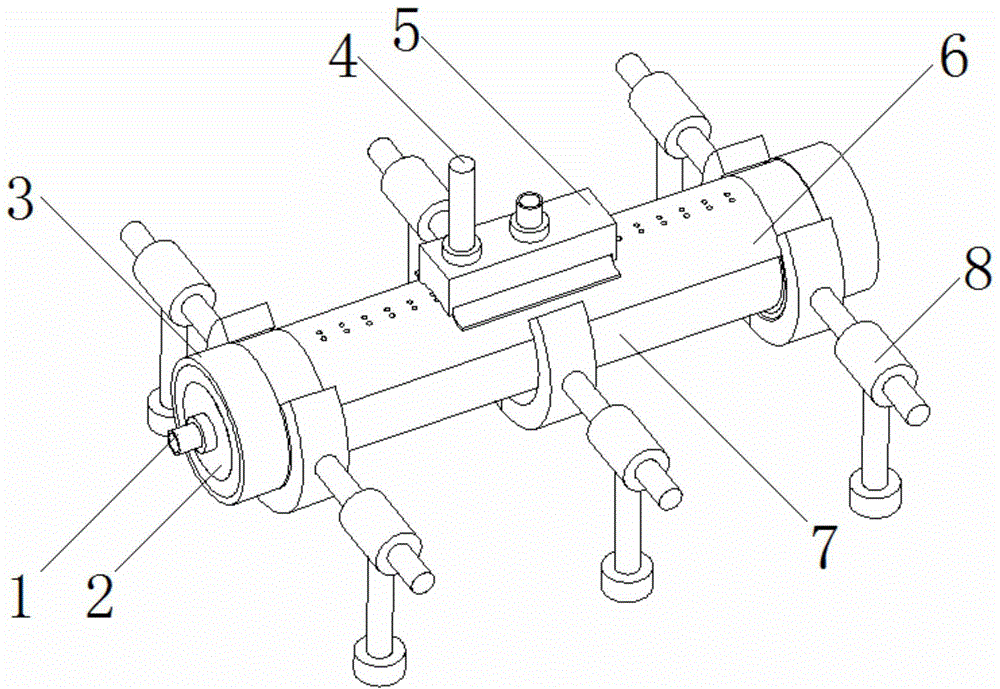

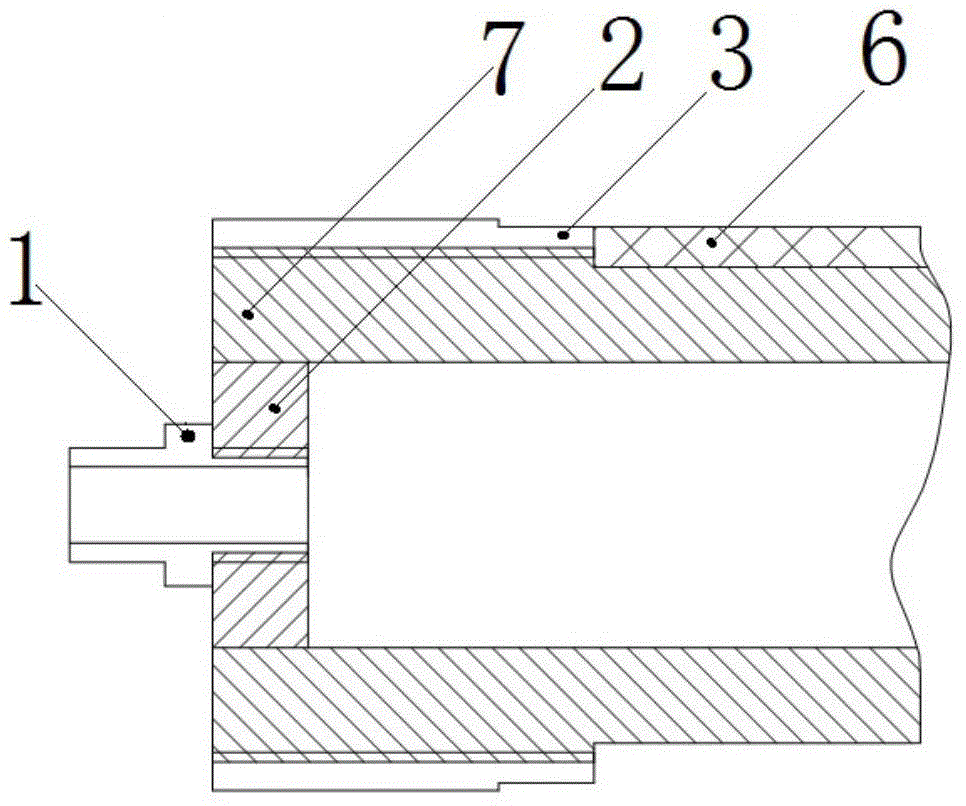

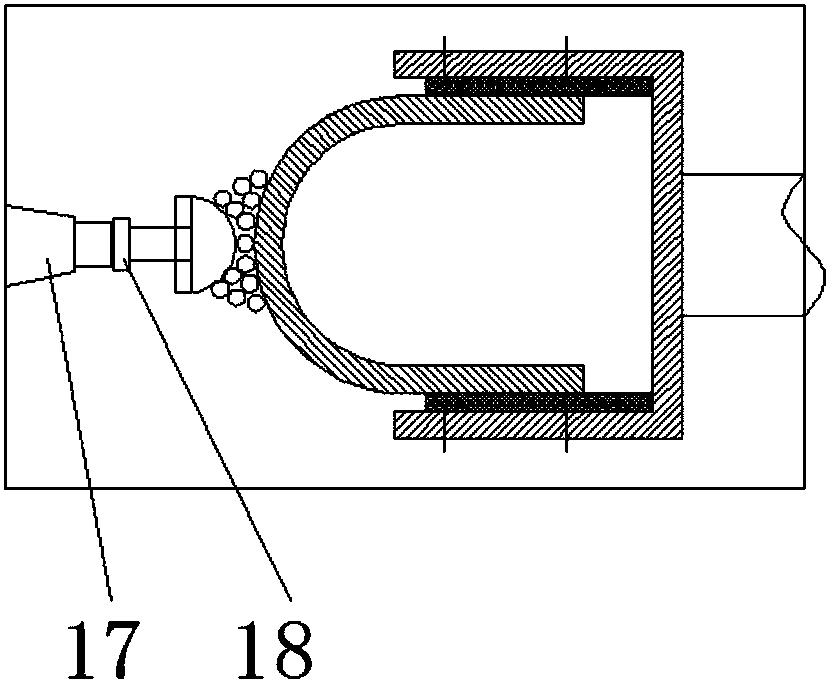

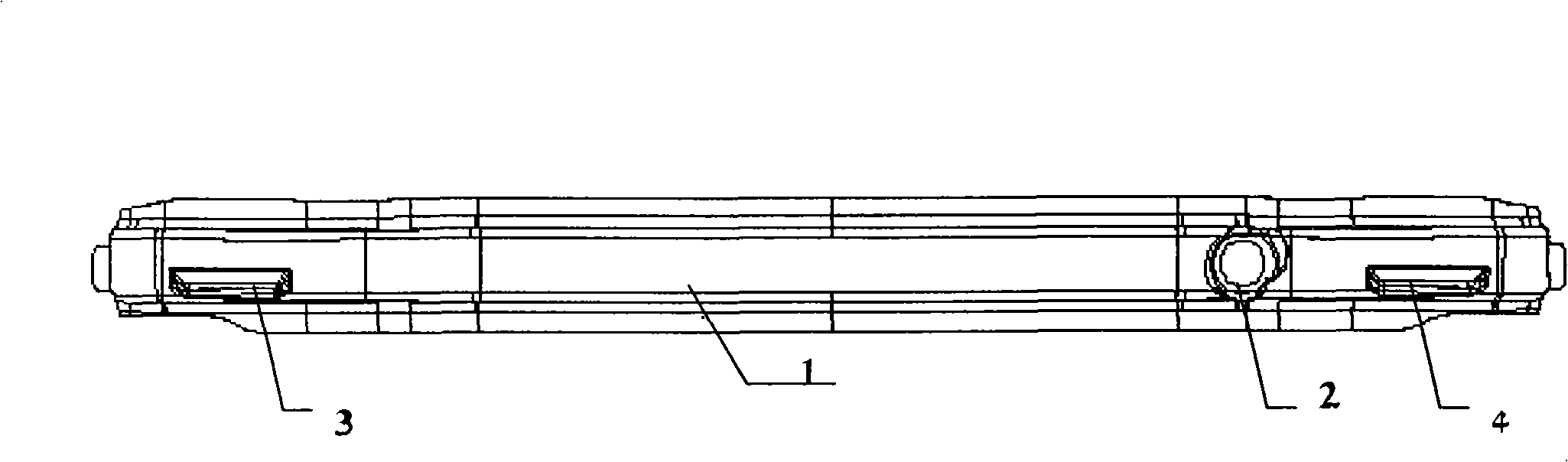

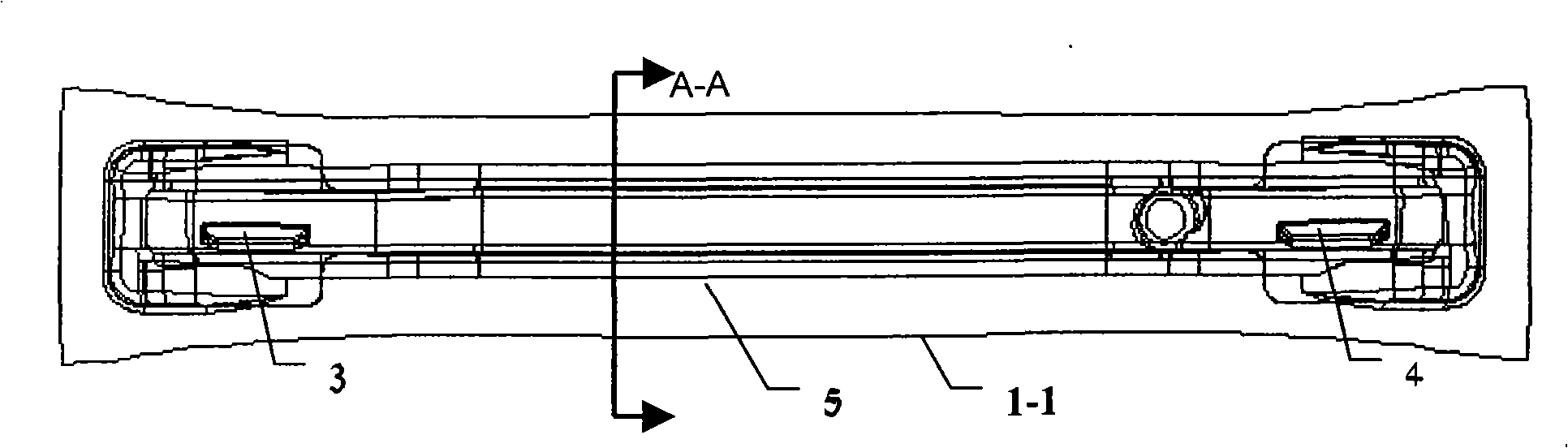

Joint welding clamp of titanium alloy straight pipe and joint welding method

InactiveCN103978290AAvoid partial collapseEliminate influence of welding qualityWelding/cutting auxillary devicesAuxillary welding devicesCopperTitanium alloy

The invention discloses a joint welding clamp of a titanium alloy straight pipe and a joint welding method. The joint welding quality and precision of the titanium alloy straight pipe can be guaranteed by adopting auxiliary supporting and clamping inside the titanium alloy straight pipe and protecting a welding influenced region by inert gas. The method comprises the steps of sealing places where copper sleeves are matched with the titanium alloy straight pipe by sealing tapes at the two ends of a gas feeding pipe, feeding protective gas to a weld joint by two exhaust holes in the feeding pipe, and forming an integral part for supporting a welding region in an auxiliary way by fixedly connecting an arc-shaped copper block, with two exhaust holes, on the gas feeding pipe through super glue; taking out the gas feeding pipe and the arc-shaped copper block from the titanium alloy straight pipe after the completion of welding due to the fact that the radian of the arc-shaped copper block is smaller than a semicircle, performing gas protection on the welding joint outside the titanium alloy straight pipe by a protective cover, fixing a welding gun on the protective cover by a clamp ring, and driving the welding gun to move by moving the protective cover; clamping the titanium alloy straight pipe by adopting an arc-shaped clamp, in order to guarantee the welding continuity..

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

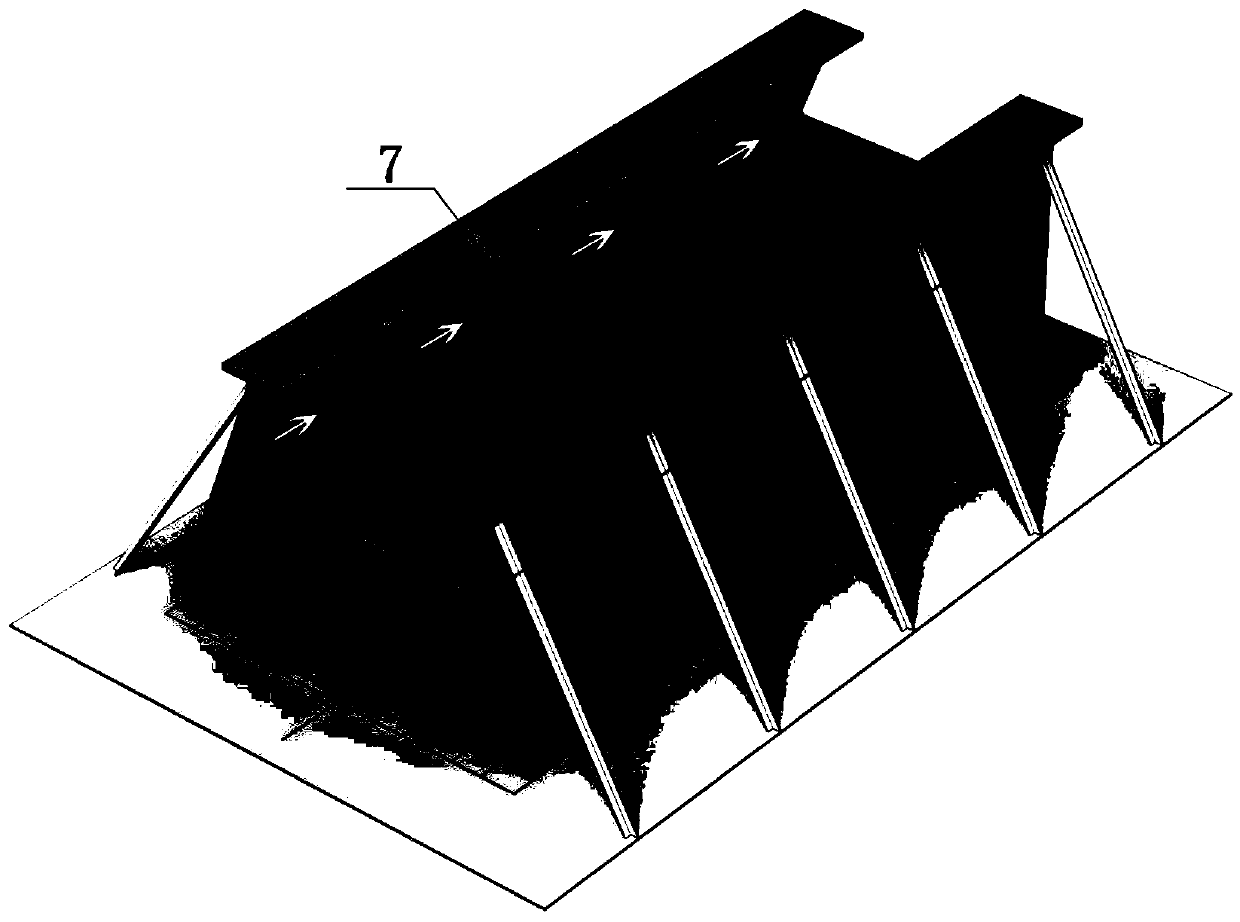

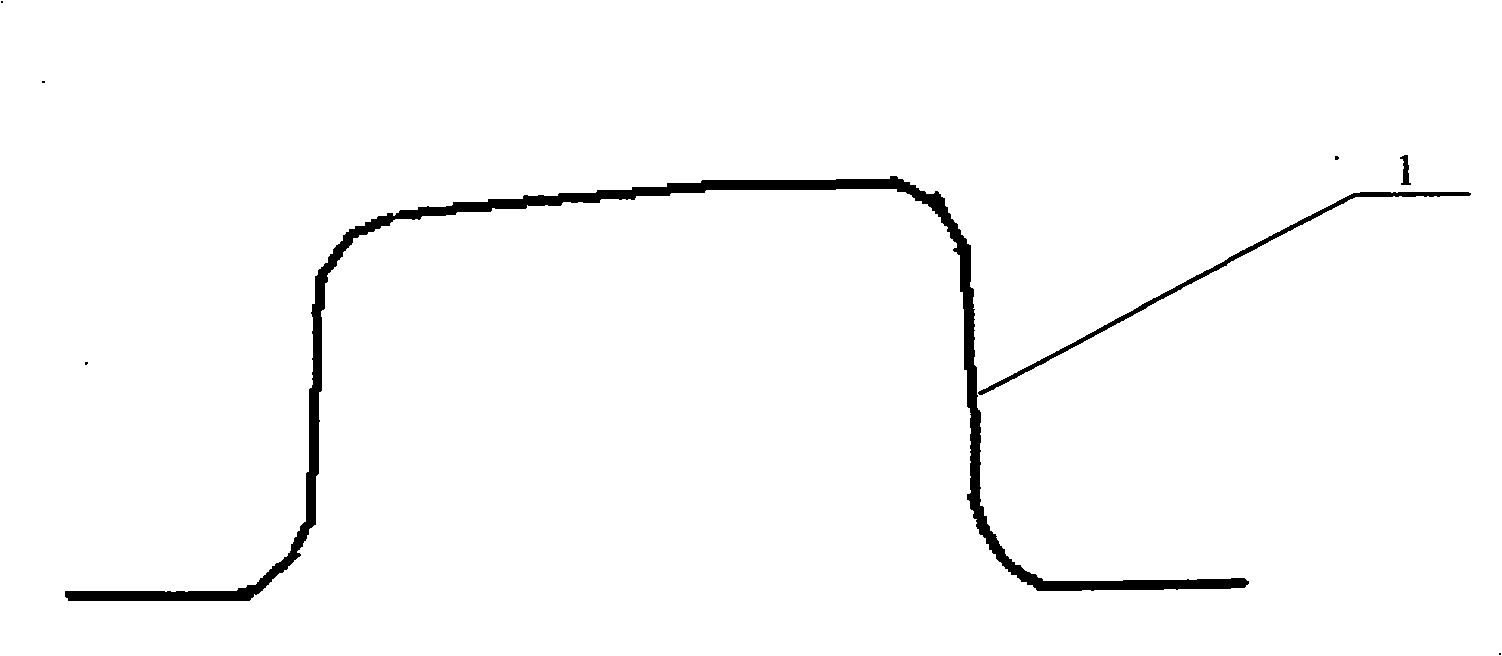

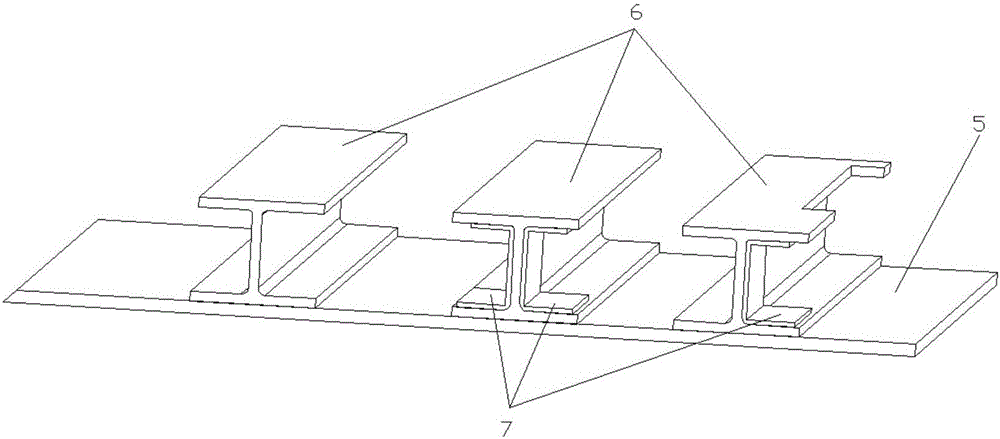

Ultra-large type combined H-section steel column and manufacturing method thereof

ActiveCN104196166AGuaranteed bearing capacityNovel structural designStrutsPillarsManufactured materialStructural engineering

The invention discloses an ultra-large type combined H-section steel column. The ultra-large type combined H-section steel column comprises two I-section steels and a connecting web; the two I-section steels are respectively arranged at two sides of the connecting web, and the section is of an H shape after installation; the upper end face of the connecting web and the I-section steels at two sides form a concave structure, a stiffening plate is arranged along the concave structure, and a reinforcing rod is arranged on the stiffening plate. Meanwhile, the invention further provides a manufacturing method of the steel column. According to the steel column and the manufacturing method thereof disclosed by the invention, when the bearing capacity of the post is ensured, the structure of the column is maximally simplified, raw materials are saved, the cost is saved, the manufacturing process is simple, the installation precision can be ensured, the effective usable area of a building is increased, the gravity of the structure is reduced, and the seismic response of the structure is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

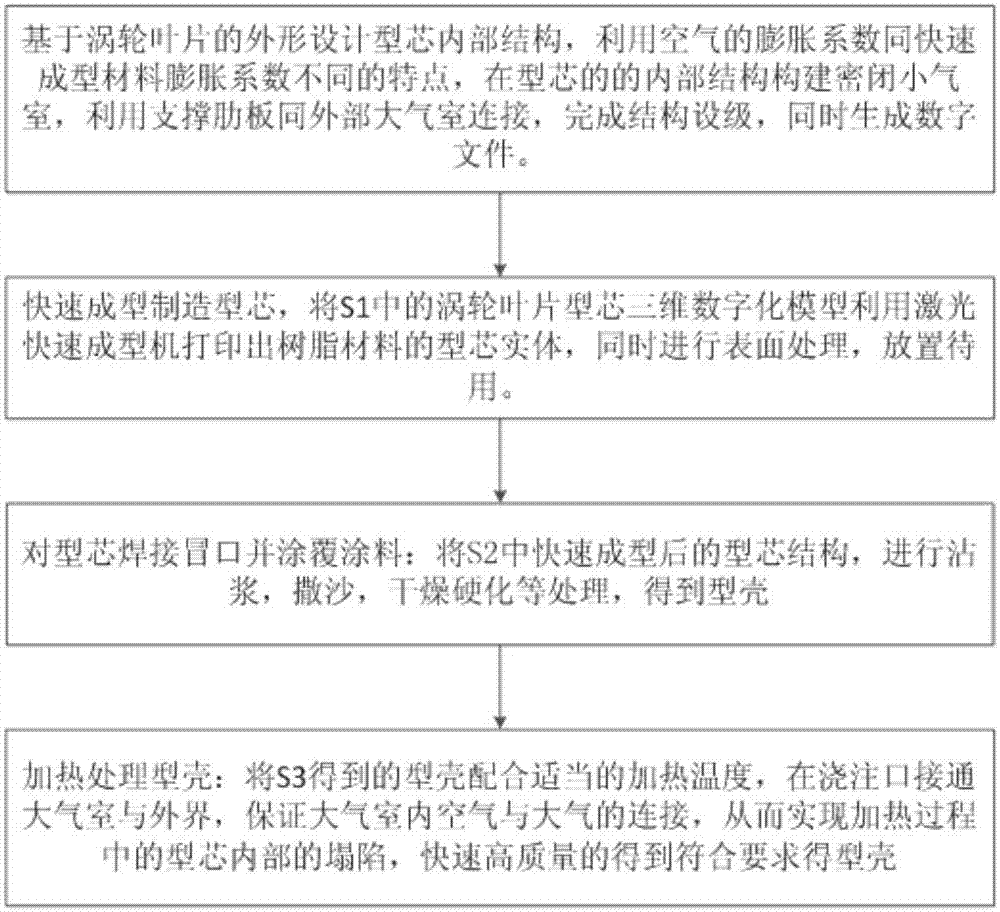

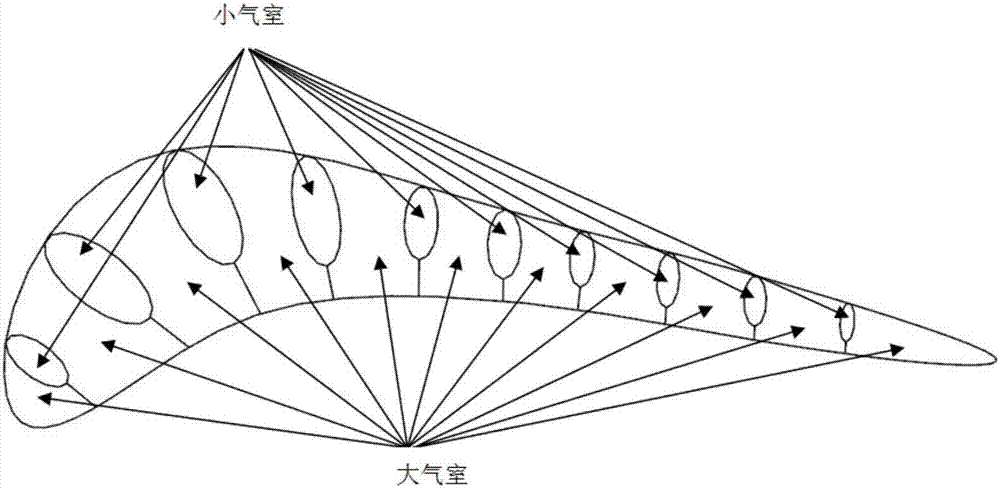

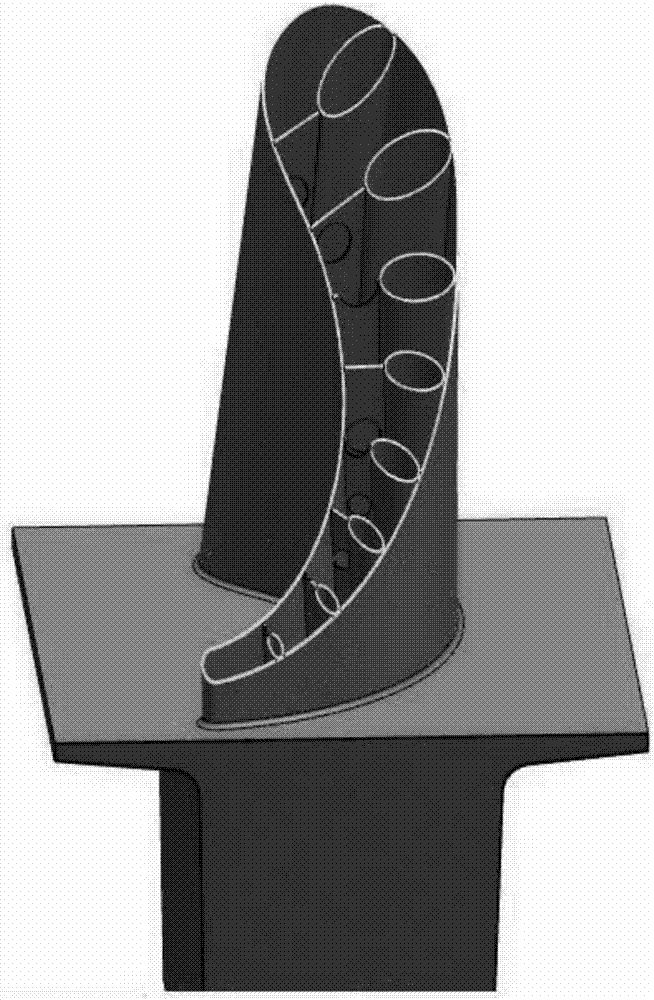

Rapid prototyping and investment casting combined dewaxing method facing turbine blade

InactiveCN107199311ASolve the problem of high burst rateRaise the possibilityAdditive manufacturing apparatusFoundry mouldsEngineeringSlurry

The invention relates to a rapid prototyping and investment casting combined dewaxing method facing a turbine blade. The method includes the steps that an internal structure of a mould core is designed according to the appearance of the turbine blade, closed small gas chambers are established in the internal structure of the mould core through the characteristic that the expansion coefficient of air is different from the expansion coefficient of a rapid prototyping material, the small gas chambers are connected with external large gas chambers through supporting rib plates, the structure design is completed, and a digital file is generated at the same time; operation is conducted on a three-dimensional model of the mould core of the turbine blade, a mould core entity of a resin material is printed through a laser rapid prototyping machine, and surface treatment is conducted at the same time for standby application; slurry dipping, sand spreading and drying hardening treatment are conducted on the mould core structure subjected to rapid prototyping, and a mould shell is obtained; and the obtained mould shell is heated, the large gas chambers communicate with the outside world at a sprue gate, and the mould shell meeting the requirement is rapidly obtained with high quality. By means of the scheme mentioned above, the problem that the ceramic mould shell expansion breakage rate in dewaxing is too high when an additive manufacturing material is used as a wax mould is effectively solved.

Owner:XIAN TECHNOLOGICAL UNIV

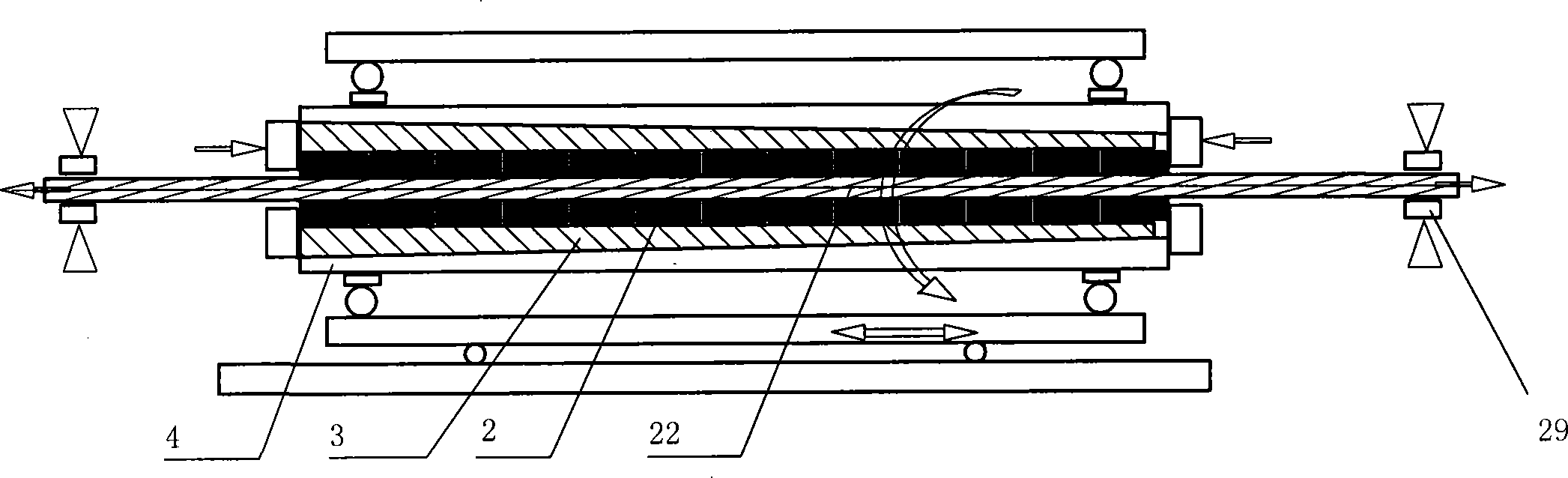

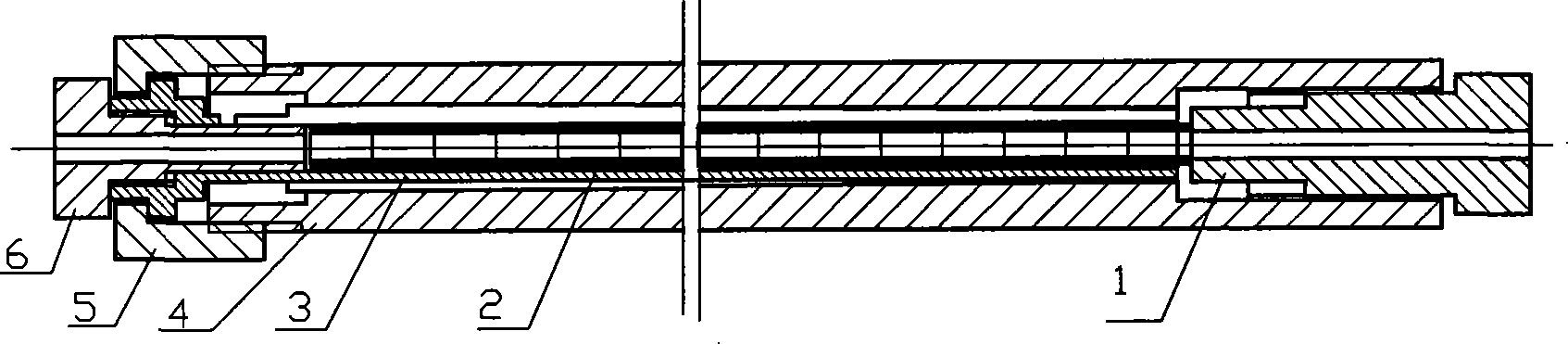

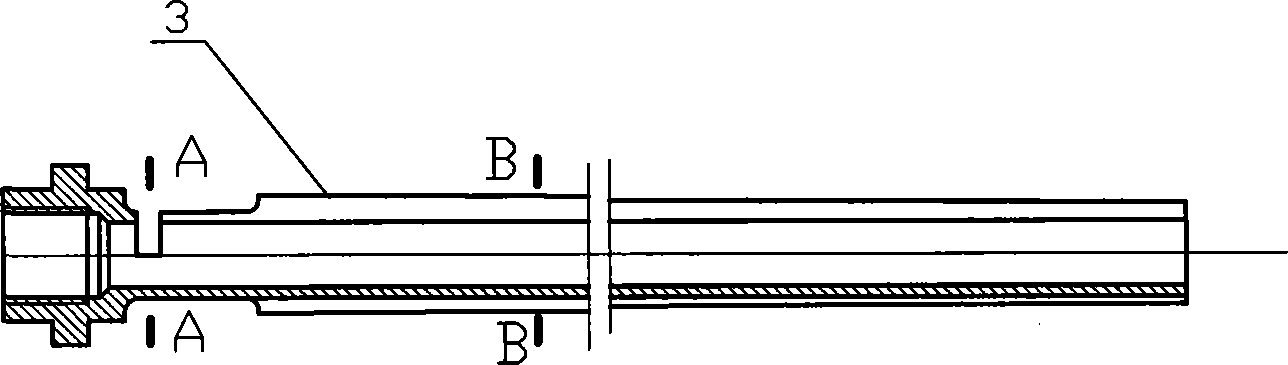

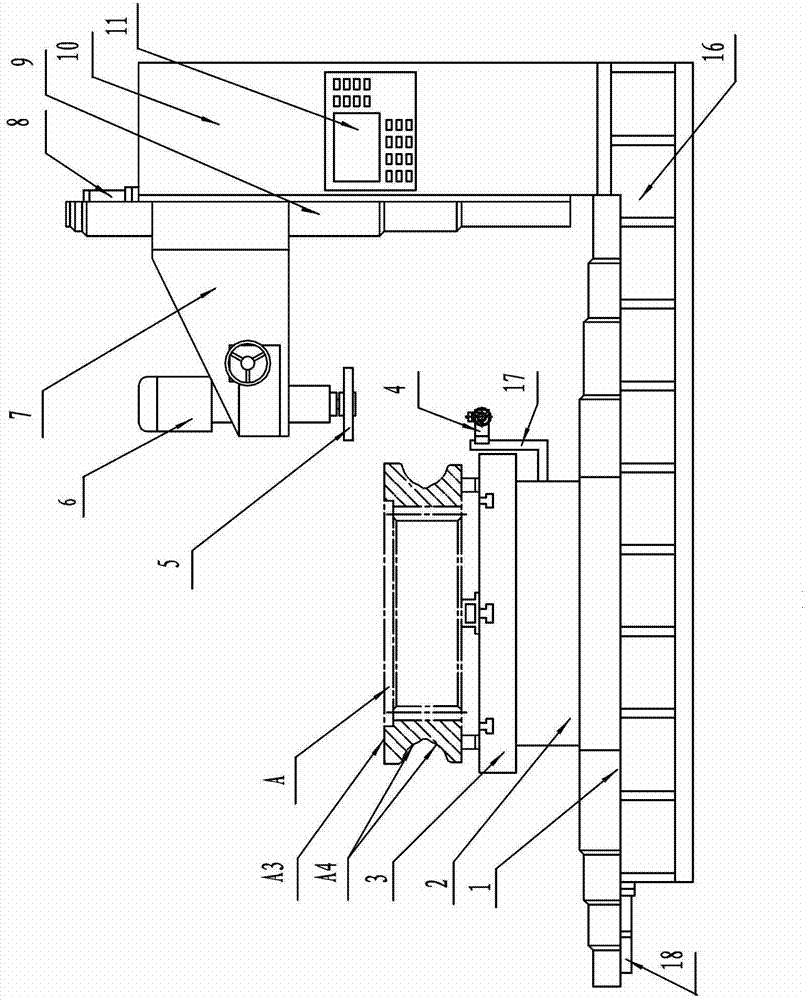

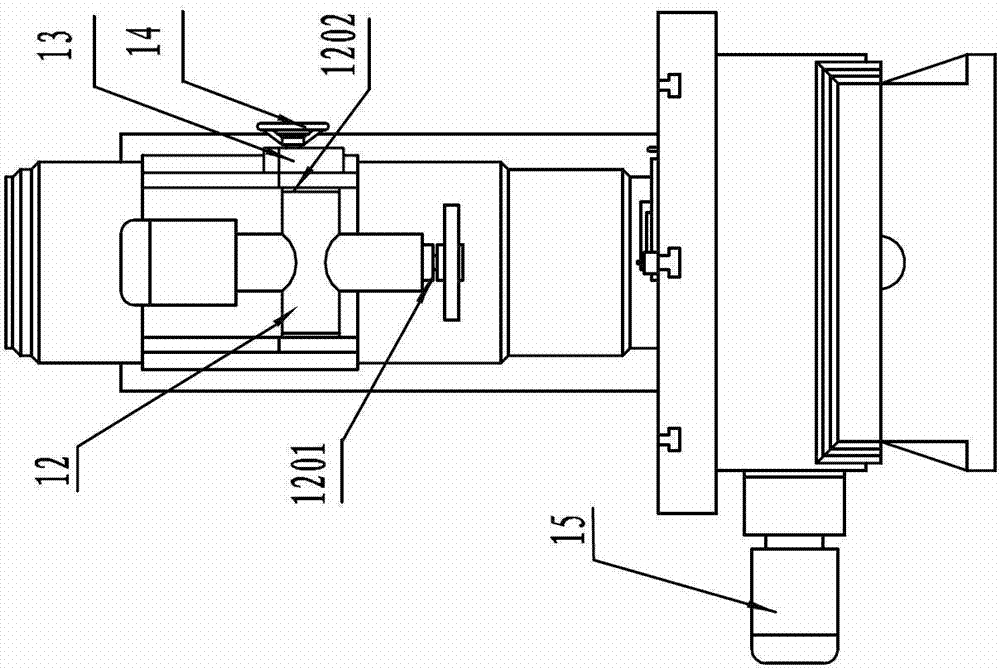

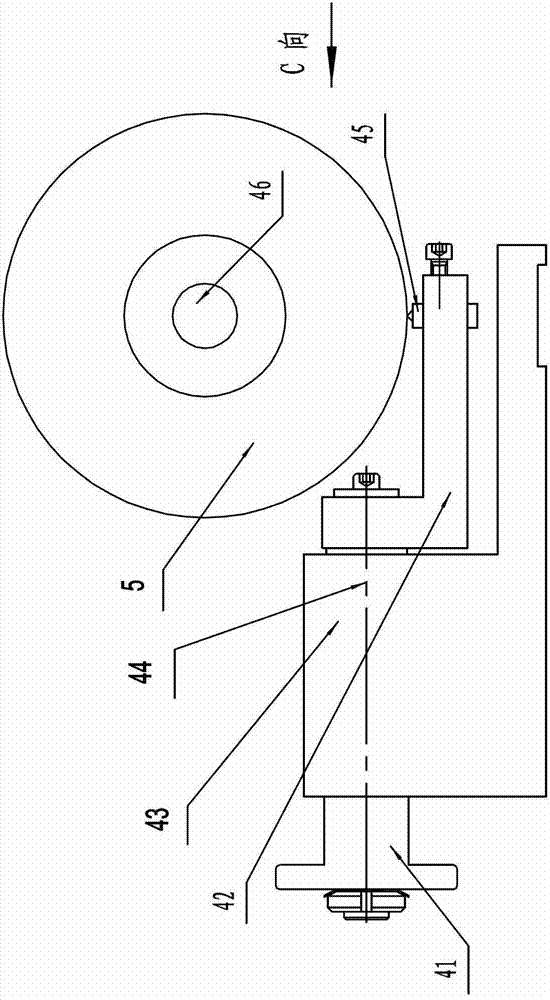

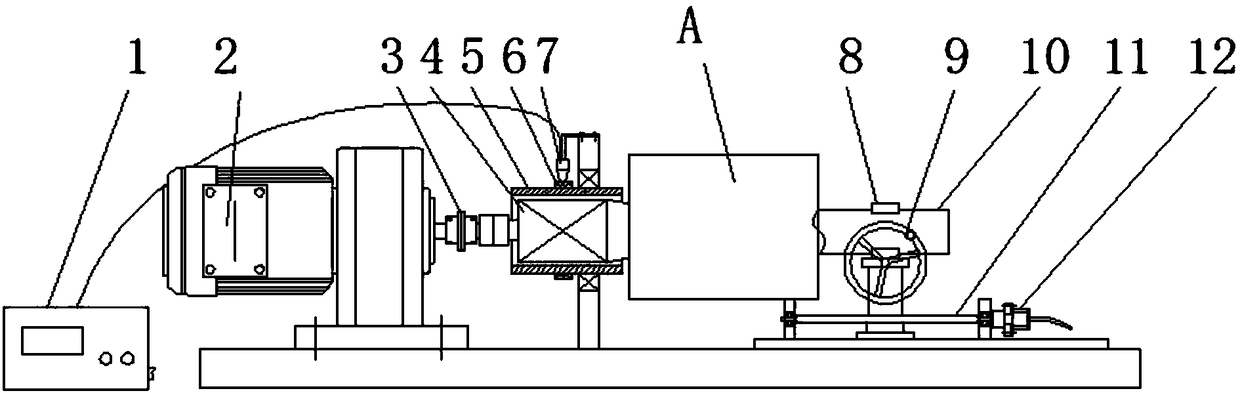

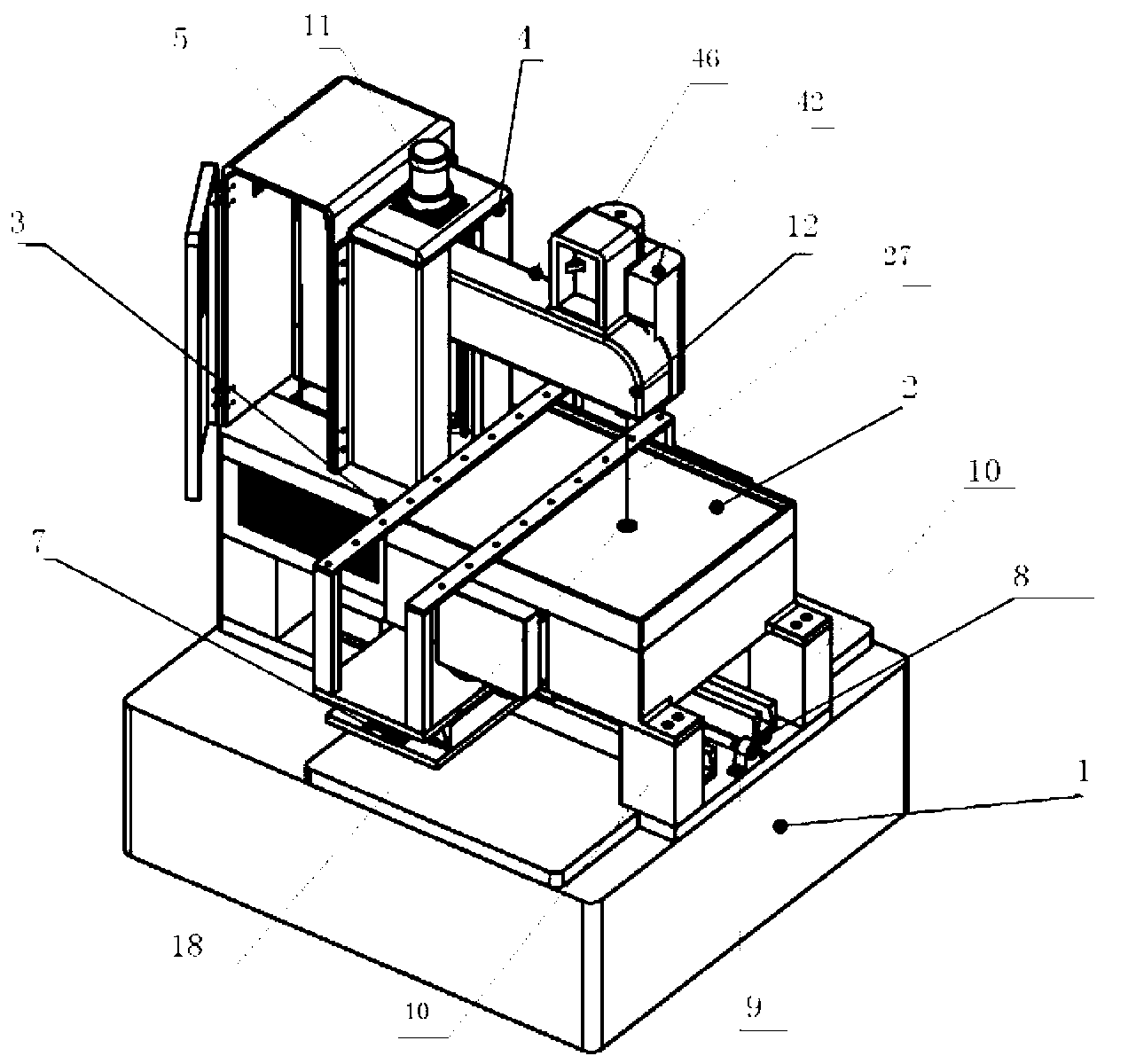

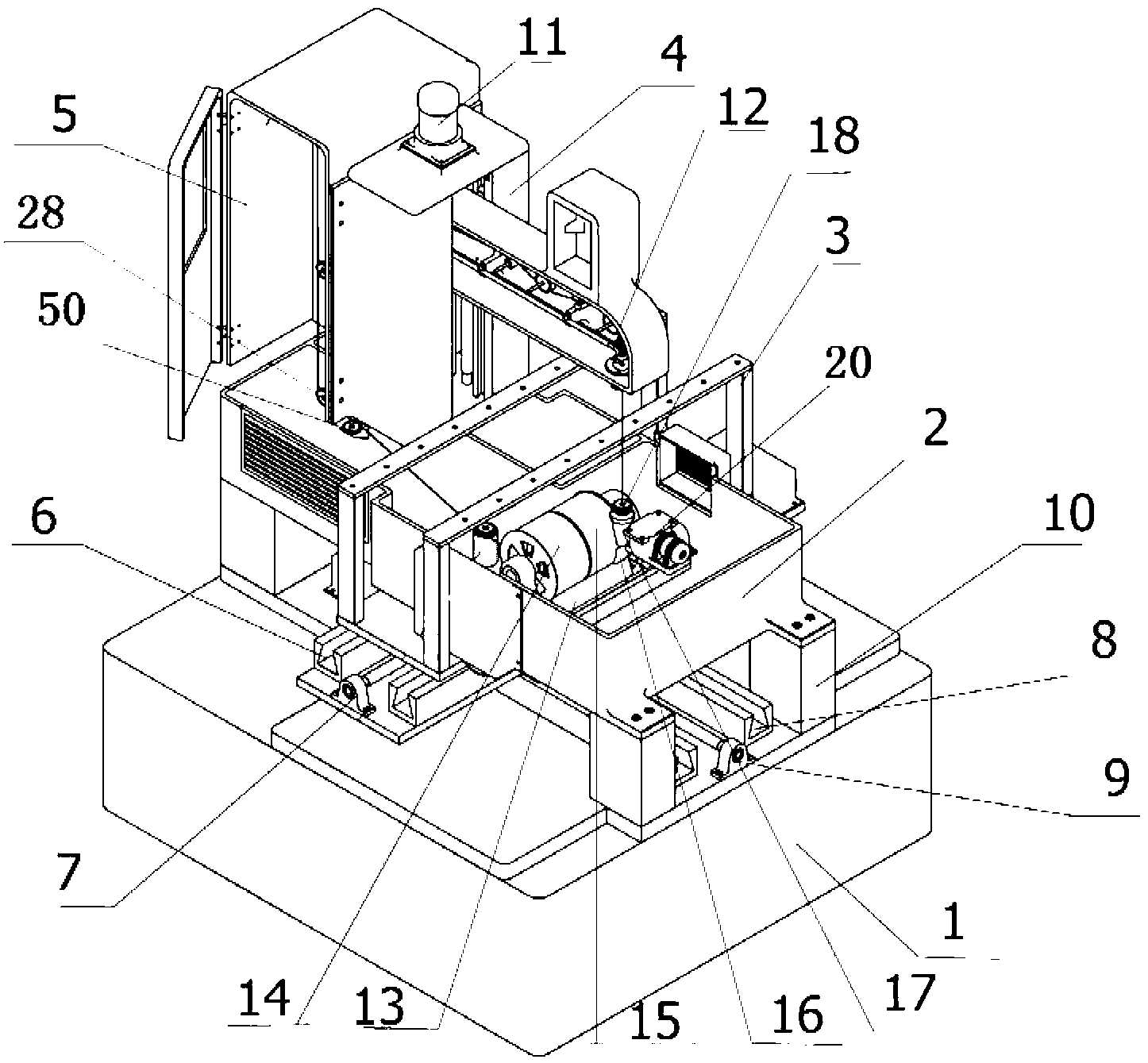

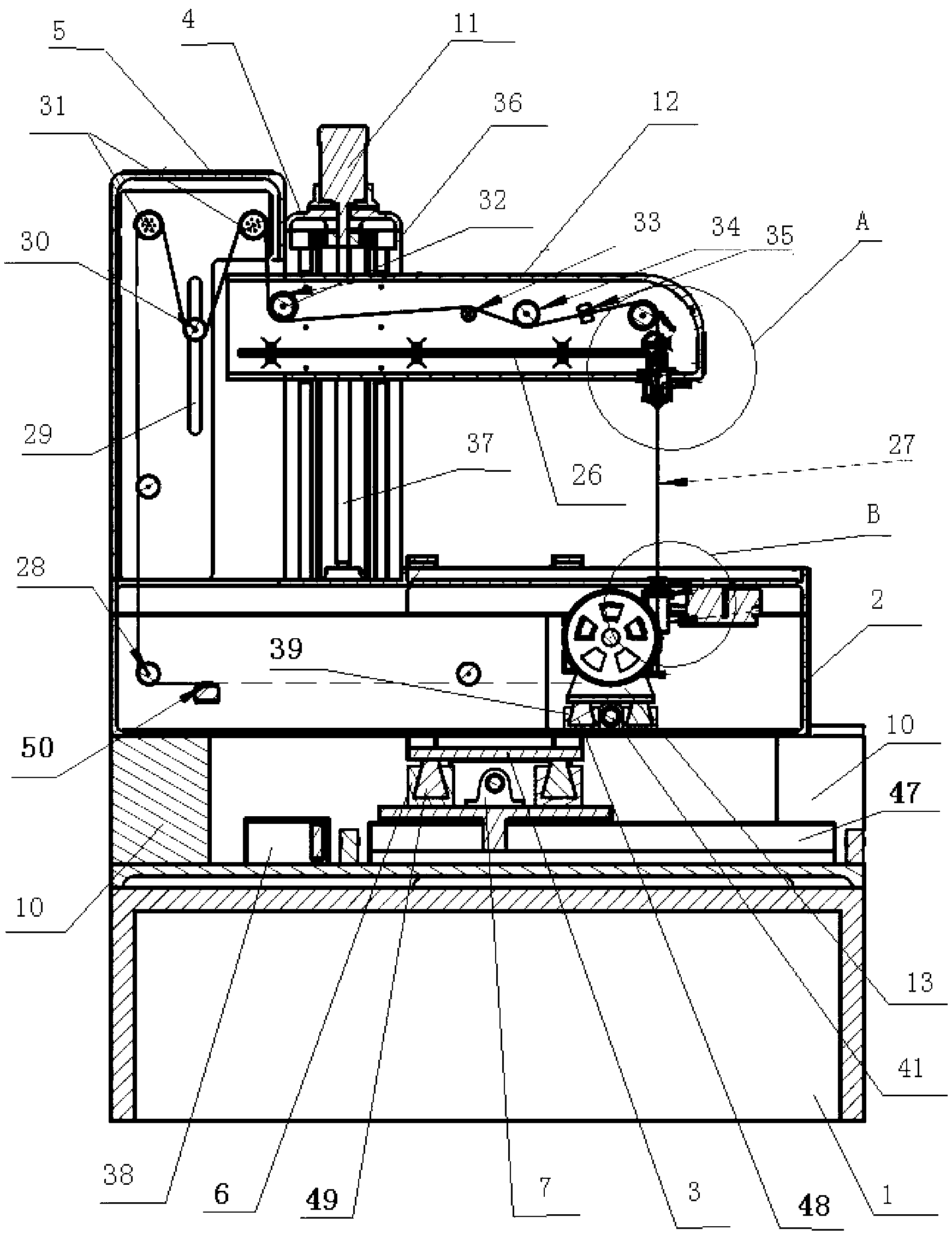

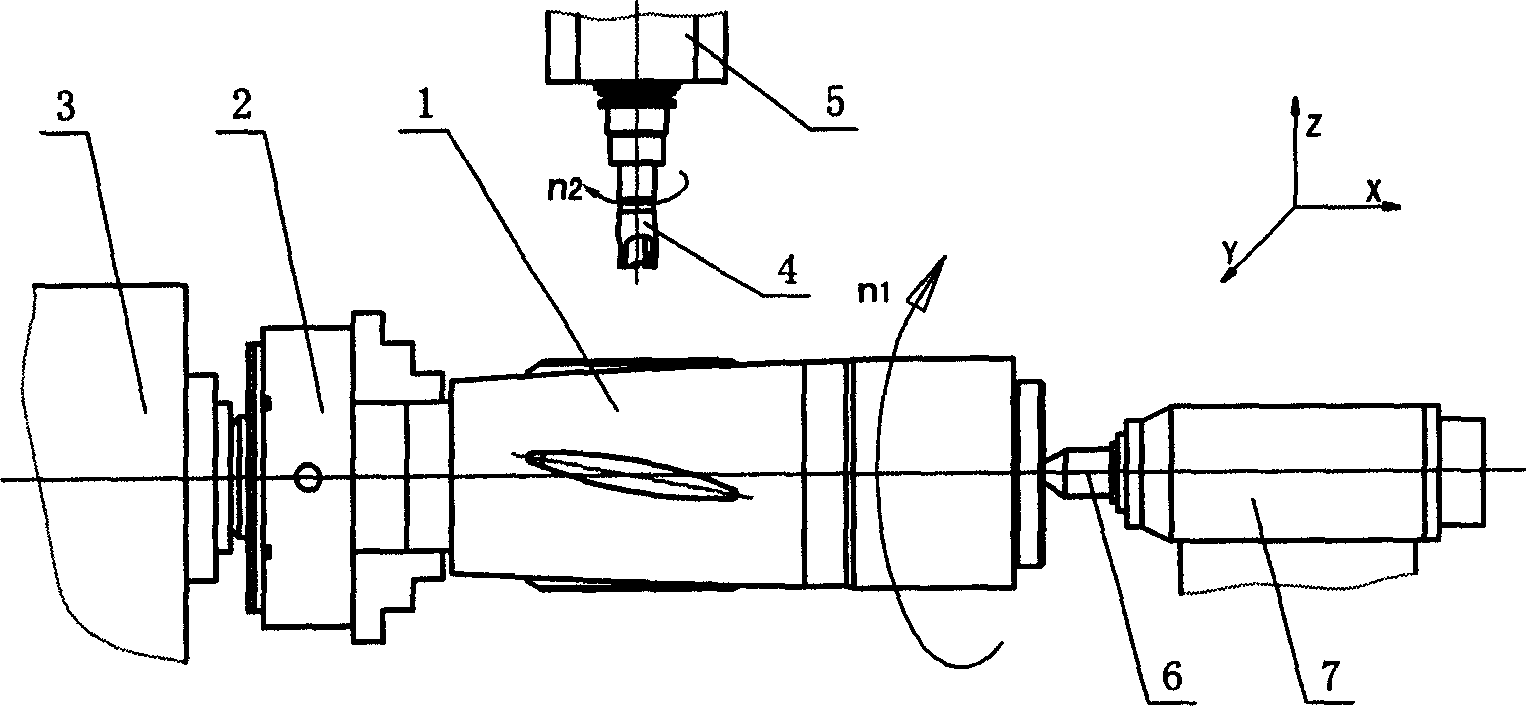

Miniature ceramic bearing hole abrading machine

InactiveCN101249622AImprove grinding precisionReduce labor intensityRevolution surface grinding machinesReciprocating motionEngineering

The invention discloses an inner-hole grinding machine with micro-ceramic bearing. A centering sleeve (3), which has an external surface with a taper and a shrinkable inner-hole diameter, is arranged in a rotary shaft(4) with an internal cone. A workpiece (2) can be mounted in the inner hole of the centering sleeve. A clamping device which clamps the centering sleeve (3) and the workpiece in the rotary shaft (4) is arranged on the two ends of the rotary shaft. An grinding steel wire rope (22) axially passes through the centering sleeve (3) and the inner hole of the workpiece (2), and the two ends of the grinding steel wire rope are fixed on a tension and clamping mechanism (29). The rotary shaft (4) is arranged on a rotary support which allows the rotary shaft to rotate around the axis line of the rotary shaft under high speed. The rotary support is arranged on a linear supporting seat which allows the rotary support to move back and forth along the axial line of the rotary shaft. The relative friction motion combined by reciprocating and rotating is produced between the wall of the inner hole of the workpiece and the convex site of the grinding steel wire rope, so the grinding of the inner hole of the ceramic bearing is achieved. Through controlling the parameters such as grinding time, tension force of grinding steel wire rope, the grinding machine can ensure that the grinding precision of the inner hole of the ceramics bearing is increased by one order of magnitude as compared with traditional grinding, and the efficiency is increased by 10 times.

Owner:CENT SOUTH UNIV

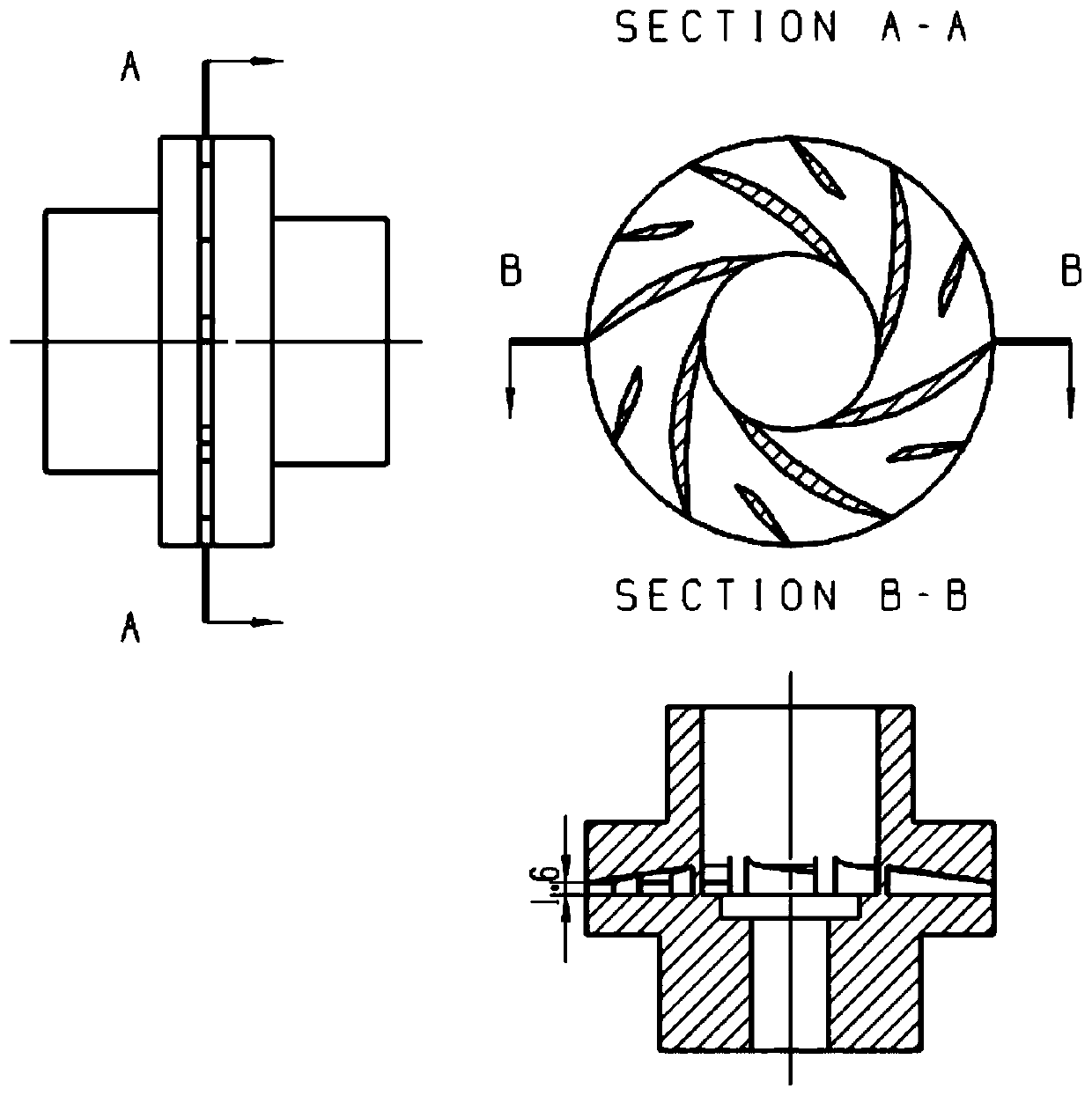

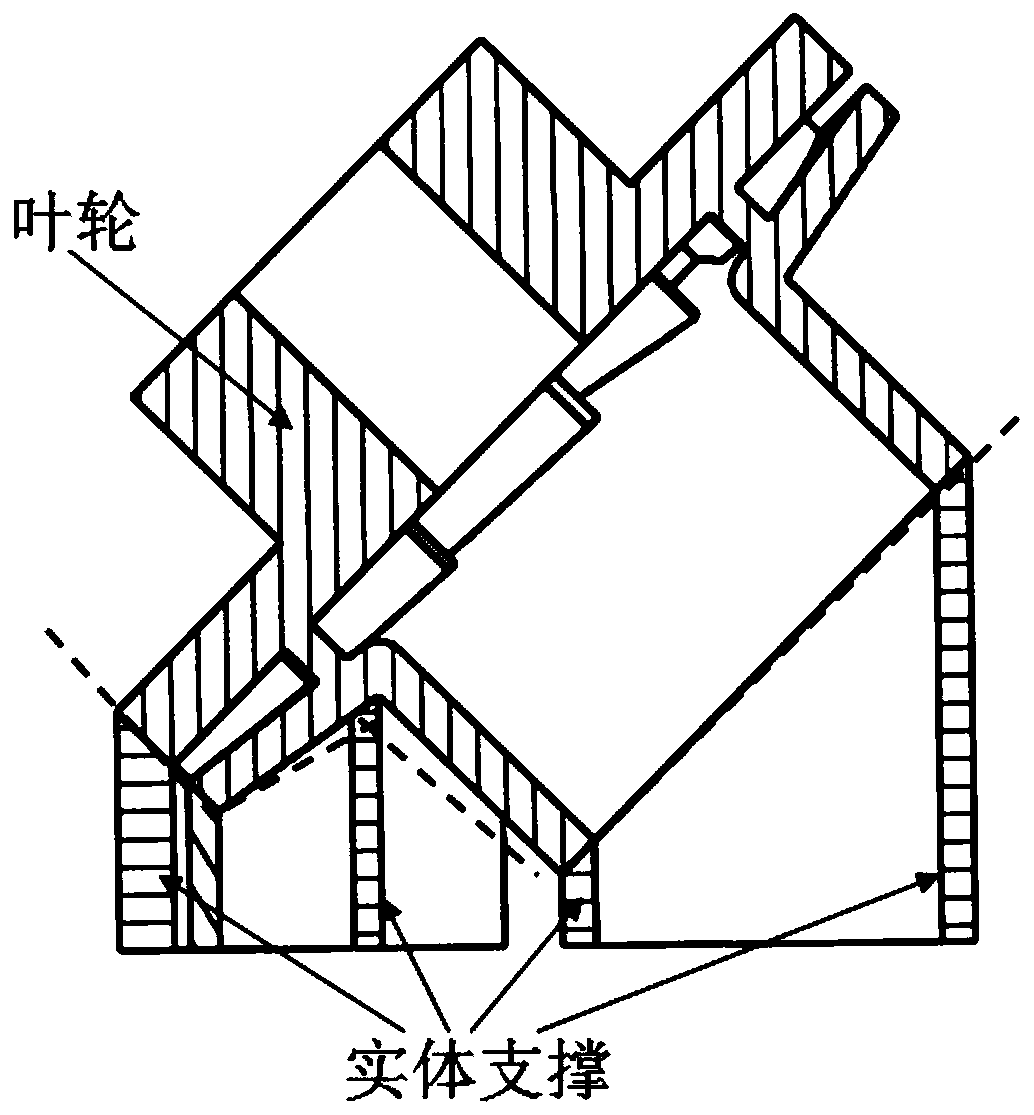

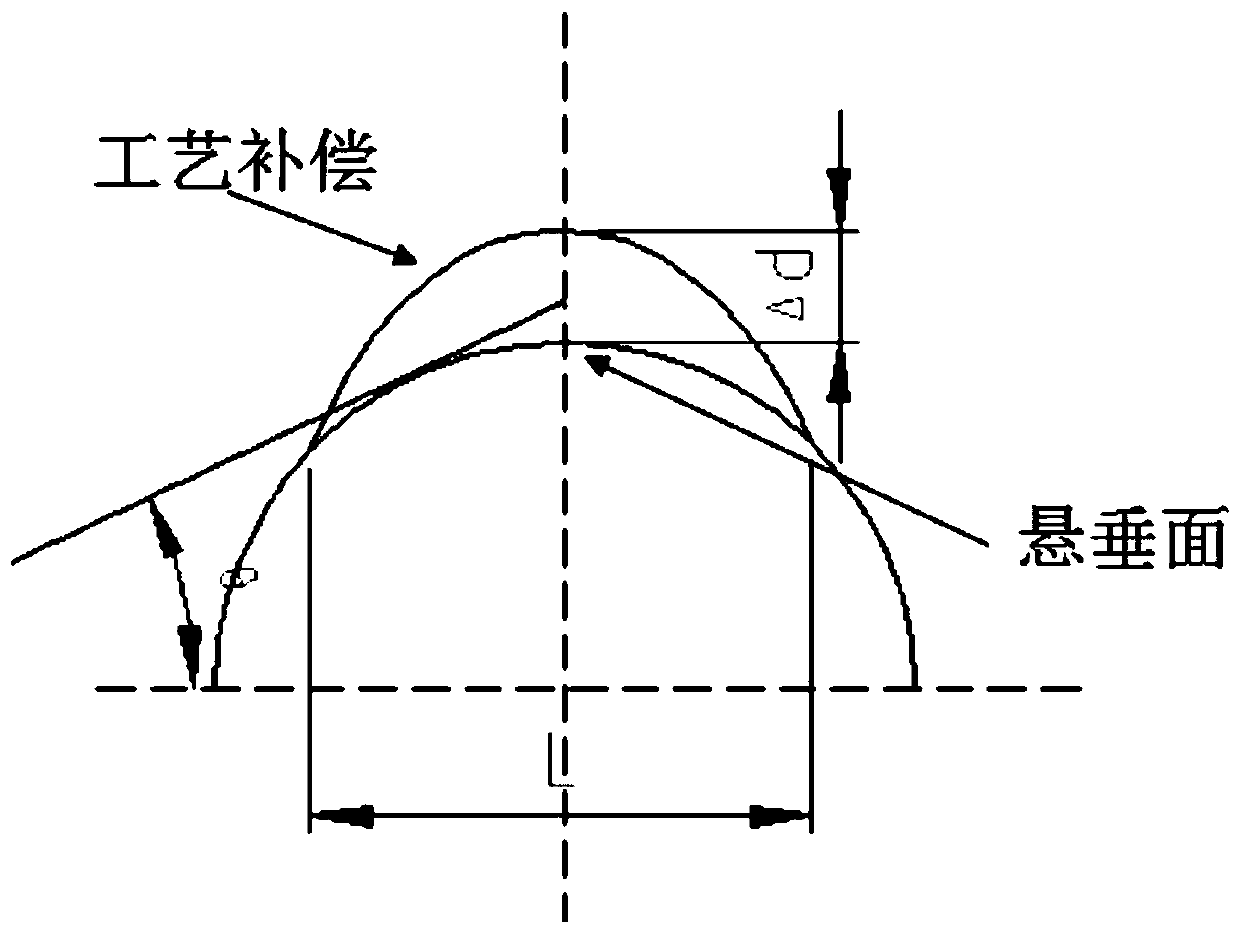

Selective laser melting forming method for small-gap closed aluminum alloy impeller

ActiveCN110153425AGuaranteed dimensional accuracyGuaranteed shape accuracyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingImpeller

The invention relates to a selective laser melting forming method for a small-gap closed aluminum alloy impeller, and belongs to the technical field of metal additive manufacturing. The small gap refers to that an outlet gap between a front cover plate and a rear cover plate in the impeller is not more than 3 mm. Process pre-compensation is adopted, and a columnar support convenient to remove is additionally arranged, so that the size precision, the shape precision and the surface roughness of an inner runner are ensured, wherein the precision can reach + / -0.1 mm, the surface roughness of theinner runner subjected to surface finishing can reach Ra of 1.6 microns, so that overall additive manufacturing of the small-gap closed aluminum alloy impeller becomes possible.

Owner:XIAN SPACE ENGINE CO LTD

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

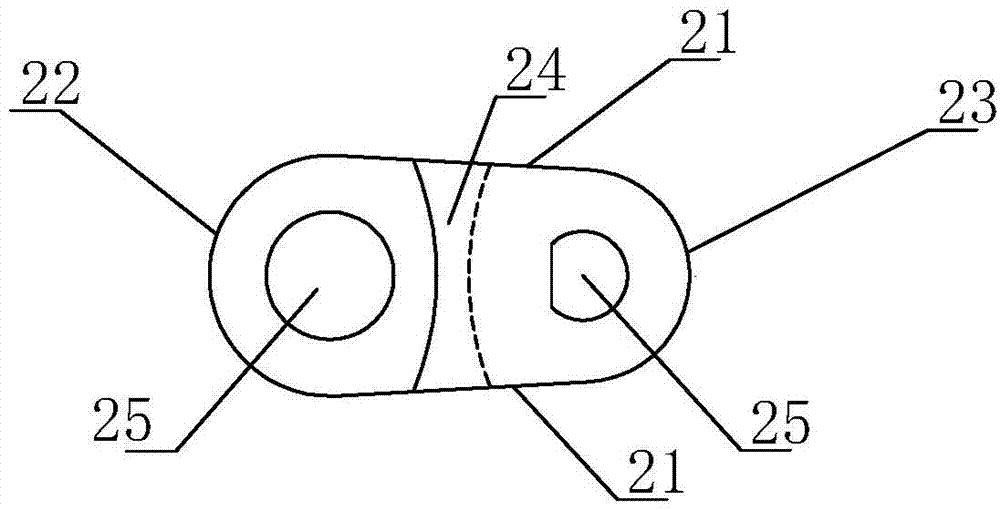

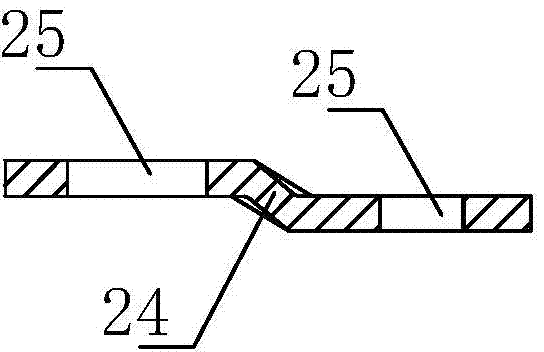

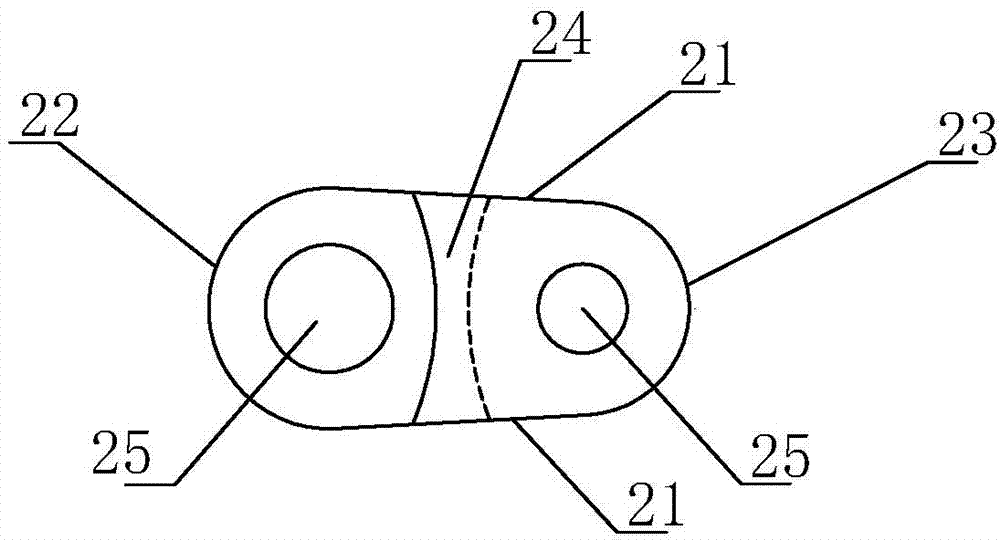

Chain, chain transition chain plate and automatic chain transition chain plate integration punch forming technology

ActiveCN104259377AShorten processing timeImprove efficiencyChain linksMetal chainsEngineeringSteel belt

The invention discloses an automatic chain transition chain plate integration punch forming technology and a chain and a chain transition chain plate manufactured by same. The automatic chain transition chain plate integration punch forming technology comprises automatically achieving positioning hole punching and trimming of a transition chain plate, trimming, primary bending, bending and finishing, pre-punching, fine punching, blanking and the like through a progressive die on a punching machine during an advancing process of a steel belt. According to the automatic chain transition chain plate integration punch forming technology, automatic machine operation replaces traditional manual operation, production efficiency of products is improved, the forming process is achieved through primary bending and bending and finishing, cracks caused at the bending positions can be reduced, and accordingly the smoothness of the transition chain plate is guaranteed; the hole size accuracy and shape accuracy and the hoe diameter euphotic belt quality are guaranteed due to the pre-punching and the fine punching; machining is performed based on the same positioning reference, the product size accuracy and the product identity are guaranteed, the product quality is improved, and the unaccepted product rate is reduced.

Owner:HANGZHOU DONGHUA CHAIN GRP

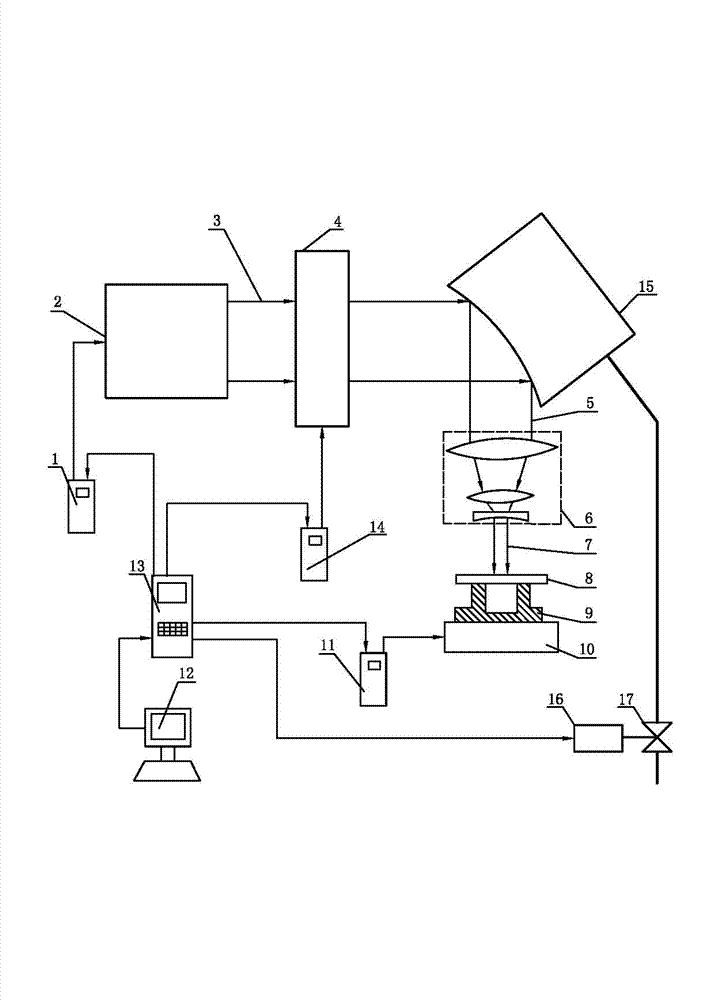

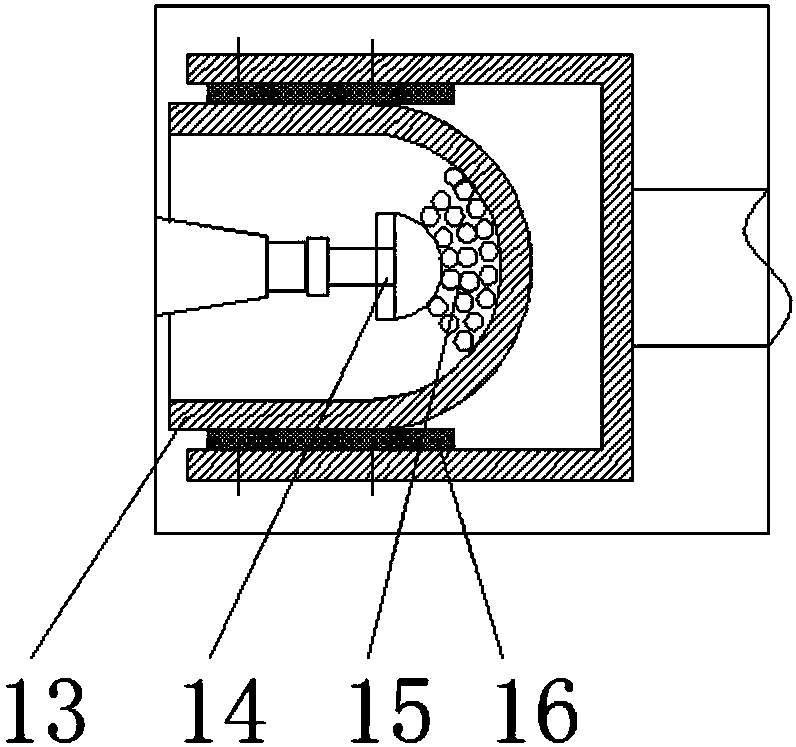

Pulse laser drilling device and drilling method thereof

ActiveCN102962589AEliminate the problem of excessive sprayingNo taper phenomenonLaser beam welding apparatusNumerical controlOptoelectronics

The invention discloses a pulse laser drilling device in the field of laser drilling devices and a drilling method thereof. The device comprises a laser generator, wherein an ultra pulse convertor, a plus lens group and a clamp are sequentially arranged on the light path of the laser generator; the signal input terminal of the laser generator is connected with the signal output terminal of a numerical control box through a laser generator control device; the signal input terminal of the ultra pulse convertor is connected with the signal output terminal of the numerical control box through an ultra pulse convertor control device; the numerical control box is connected with a computer; and the drilling method comprises the steps that a plurality of short pulse laser beams, with power density values being steadily increased, are focalized to be a laser focal point through the plus lens group, and the laser focal point irradiates the surface of a workpiece, so as to perform drilling. The pulse laser drilling device and the drilling method thereof improve the shape precision during hole machining, guarantee the machining quality of holes, and can be applied to laser drilling.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

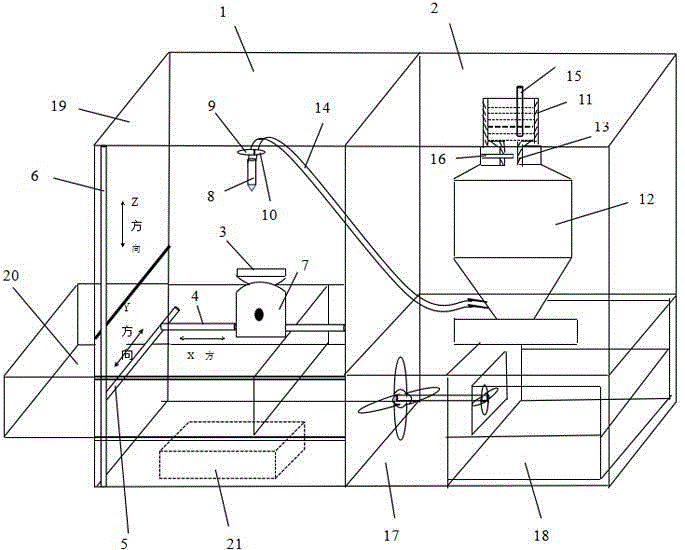

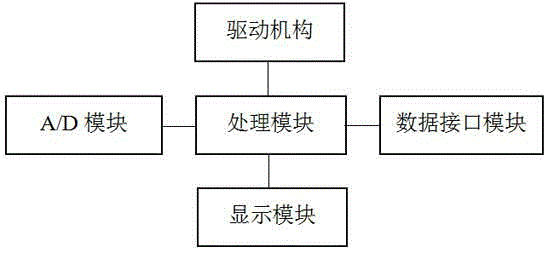

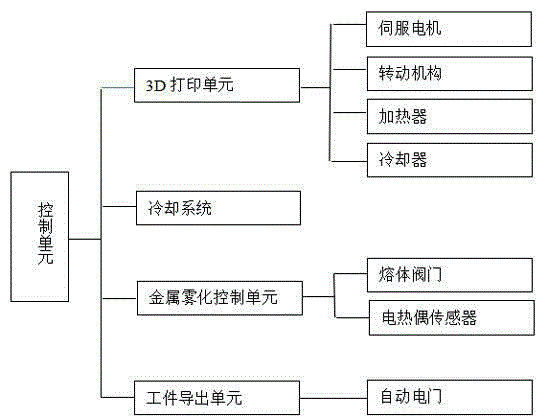

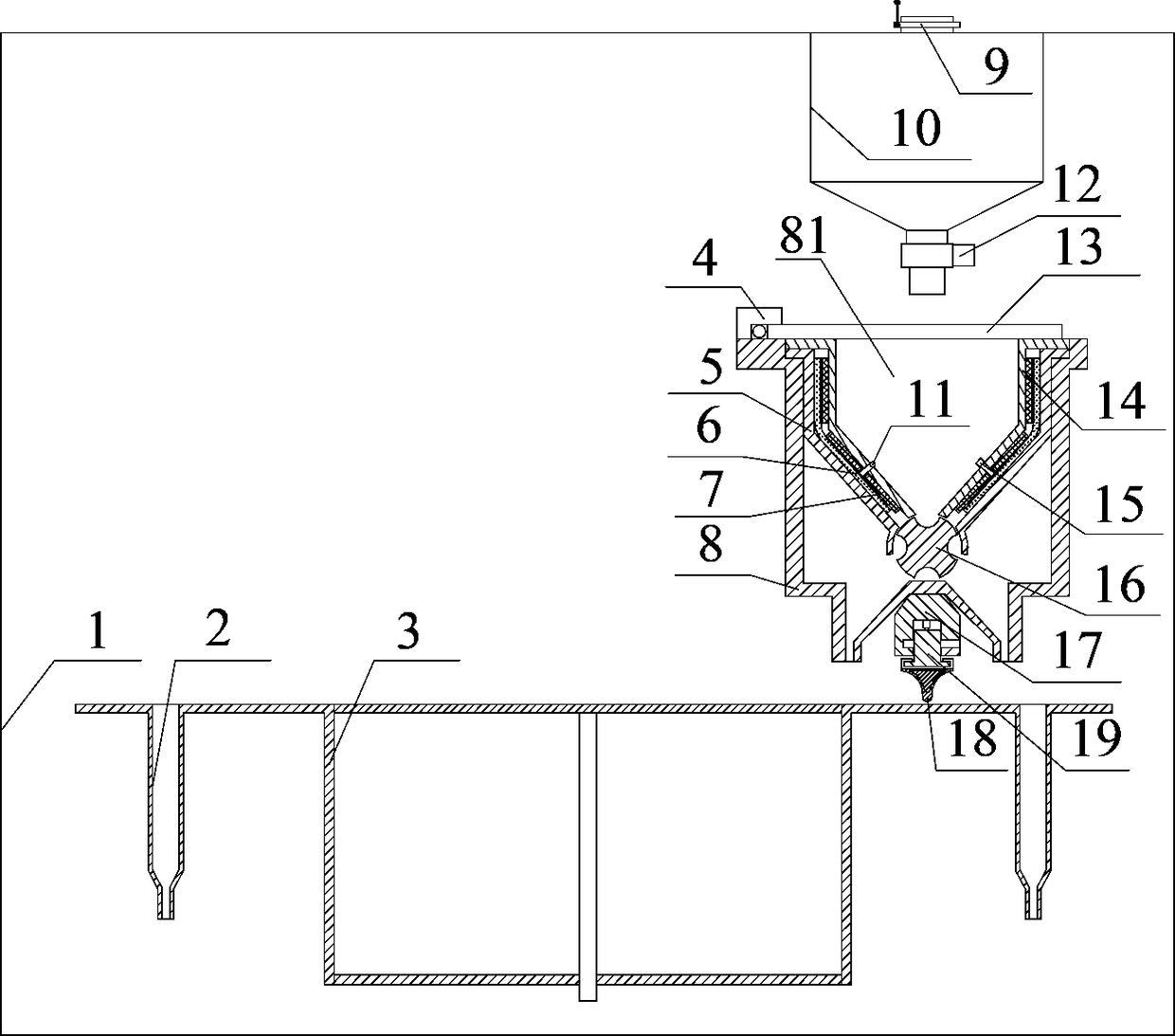

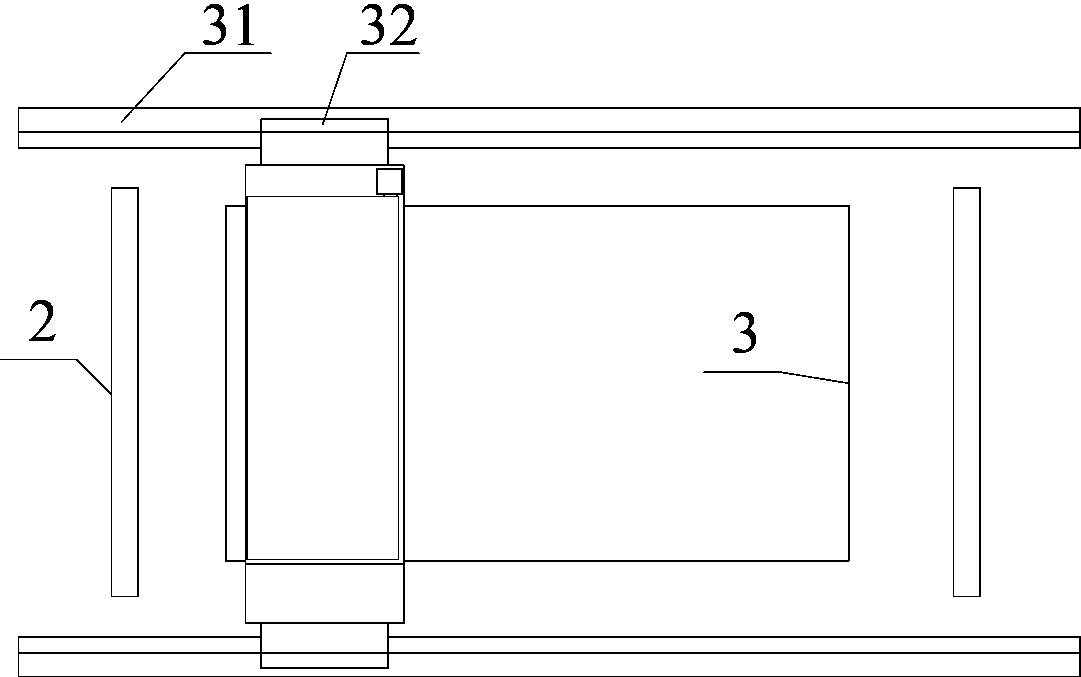

Metal 3D printer using atomized metal as consumable

The invention discloses a metal 3D printer using atomized metal as a printing material. The metal 3D printer comprises a 3D printing unit, a metal atomization control unit, a control unit, a cooling system, a mist extractor, and a finished workpiece automatic-discharging unit. The 3D printing unit comprises a workbench, a servo motor, a rotational structure, an atomized metal spray nozzle, a liquid conveying pipe, a heater and a cooler, wherein the atomized metal spray nozzle is connected with an atomizing chamber through the liquid conveying pipe. The metal atomization control unit comprises a smelting furnace, an atomizing furnace, a thermocouple sensor, a liquid conveying tube and a melt valve, wherein the smelting furnace is connected with the atomizing chamber through the liquid conveying tube. The finished workpiece automatic-discharging unit comprises an electric automatic door and a workpiece finished product box and is used for automatically discharging finished workpieces. According to the invention, ultra-micro metal powder is not required, the kinds of selectable metal are multiple, appearance accuracy of printed metal devices is guaranteed, and the purpose that multiple metal materials which are randomly distributed are printed simultaneously can be achieved through simple improvement; in addition, due to the fact that a workpiece automatic-discharging structure is used, the function that the printer in a no-man control state can continuously print multiple models is achieved.

Owner:FUZHOU UNIVERSITY

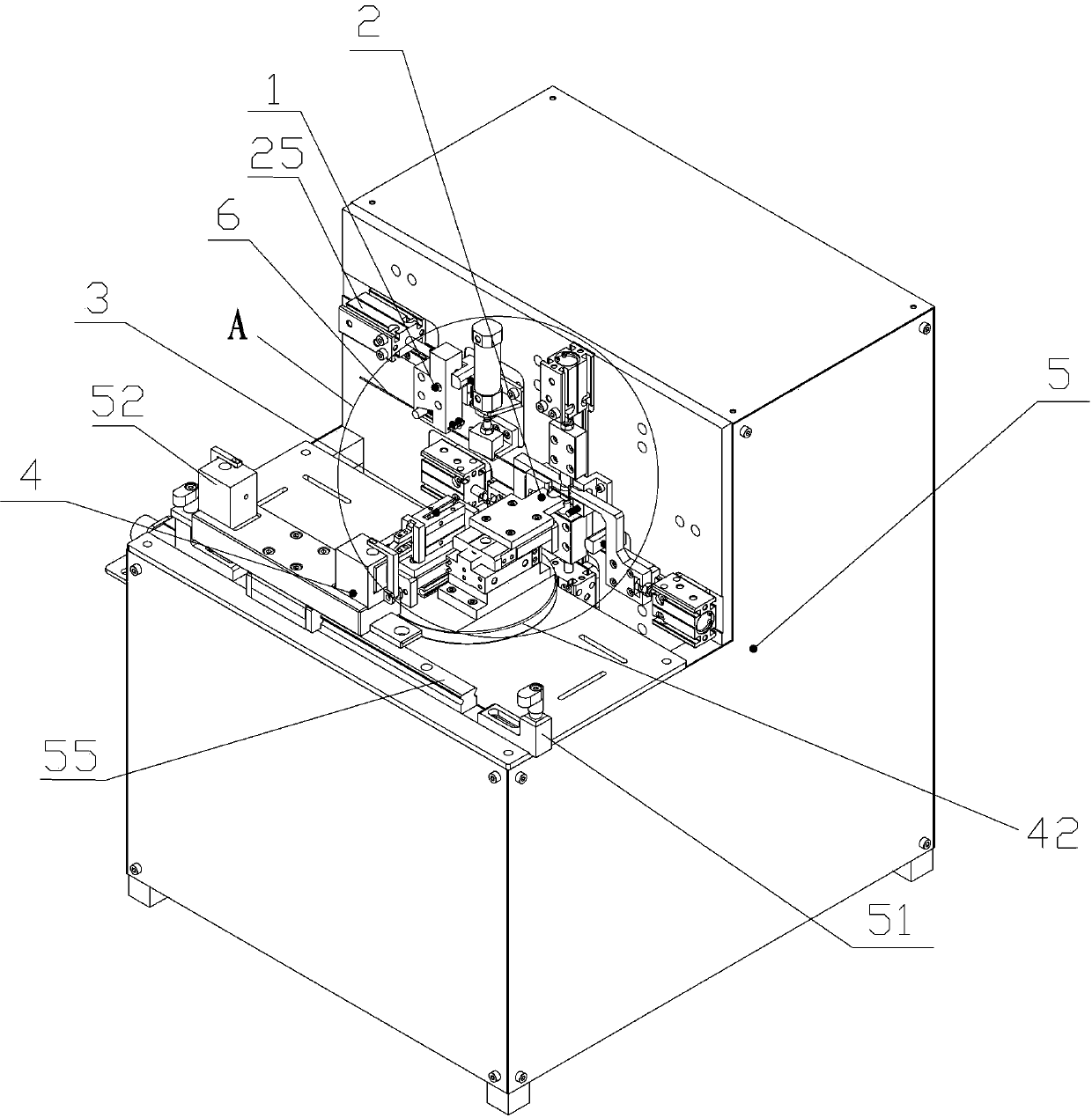

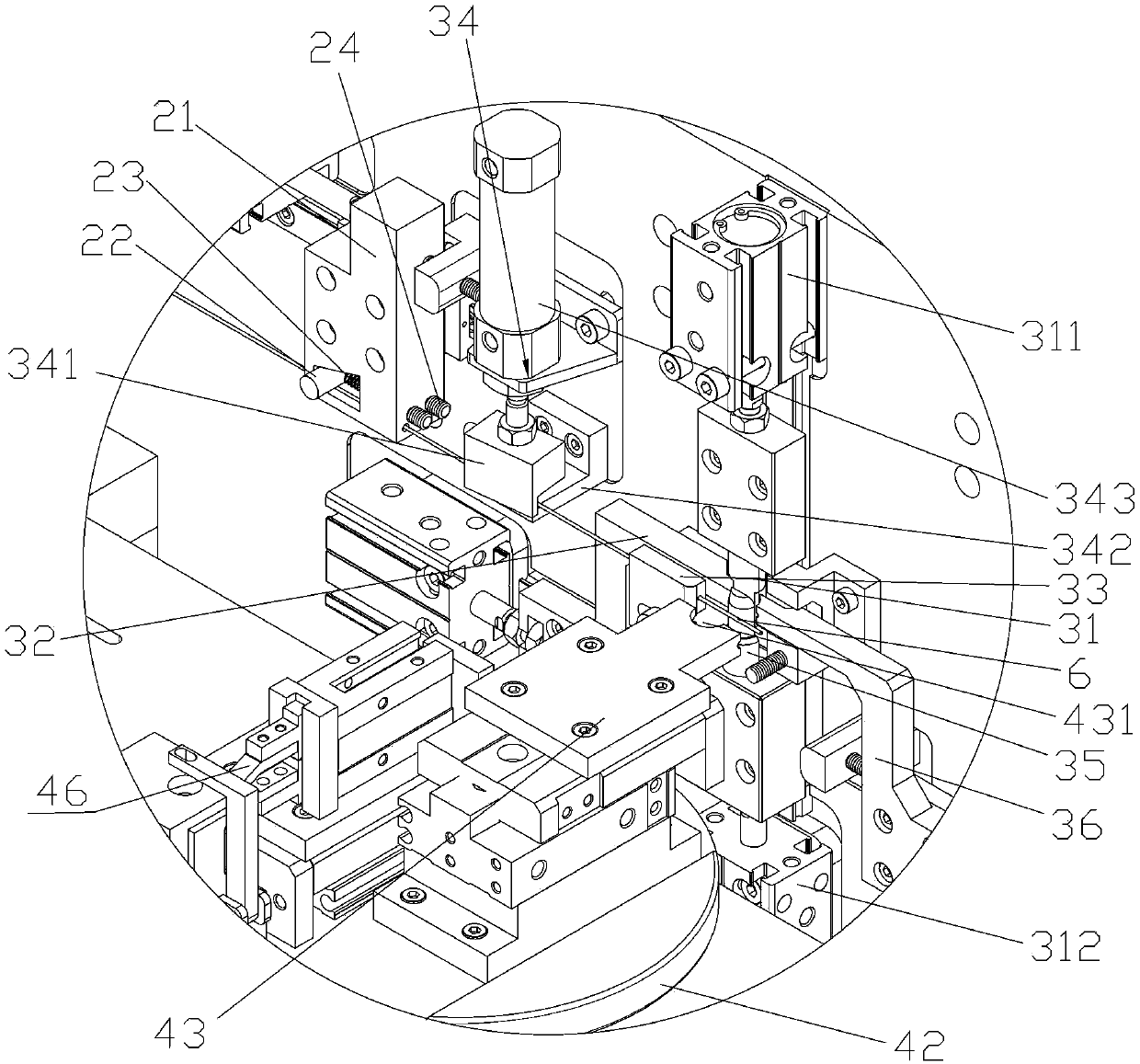

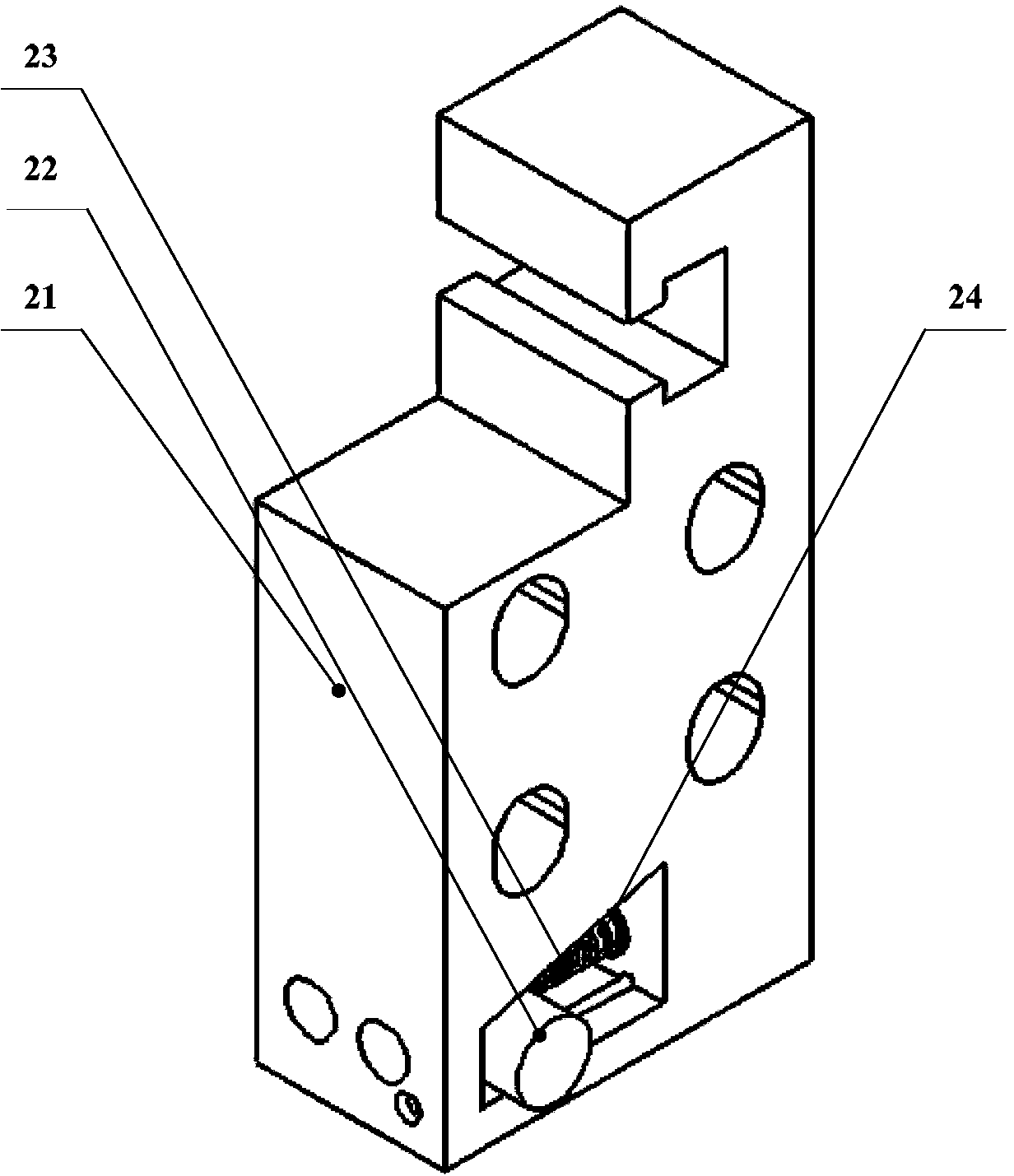

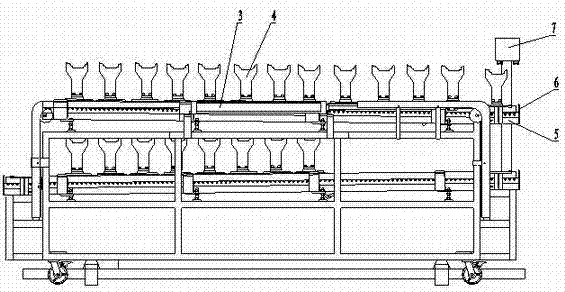

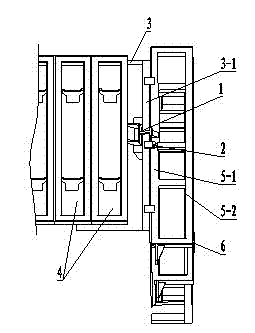

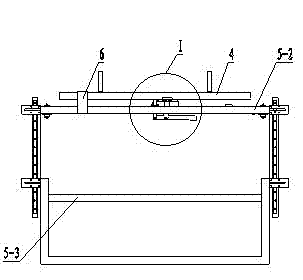

Forming and assembling equipment for decorative chain fastening members

ActiveCN103394923AQuality assuranceQuality improvementOther manufacturing equipments/toolsEngineeringSoldering

The invention belongs to the technical field of decoration processing equipment, and discloses forming and assembling equipment for decorative chain fastening members. The forming and assembling equipment for the decorative chain fastening members comprises a rack, a feeding device, a forming device, an assembling member clamping device and a fastening member clamping and transferring device, wherein the feeding device is used for feeding gold threads, the forming device is used for compressing the gold threads to form the fastening members, the assembling member clamping device is used for clamping assembling members, and the fastening member clamping and transferring device is used for clamping the fastening members and transferring the fastening members to the positions of the assembling members. The feeding device, the forming device, the assembling member clamping device and the fastening member clamping and transferring device are all arranged on the rack. The forming and assembling equipment for the decorative chain fastening members ensures the quality of decorative chains, the forming consistency of the fastening members is good, and assembling and soldering of the assembling members and the fastening members are easier to achieve. The degree of automation is high, and the complex degree of working of workers is reduced greatly. Further, time and labor are saved in a processing process, processing efficiency is high, a processing cycle is shortened, cost is lowered, and the forming and assembling equipment for the decorative chain fastening members can adapt to the modern production and manufacturing requirements of low cost, short cycles and high quality.

Owner:SHENZHEN INST OF ADVANCED TECH +1

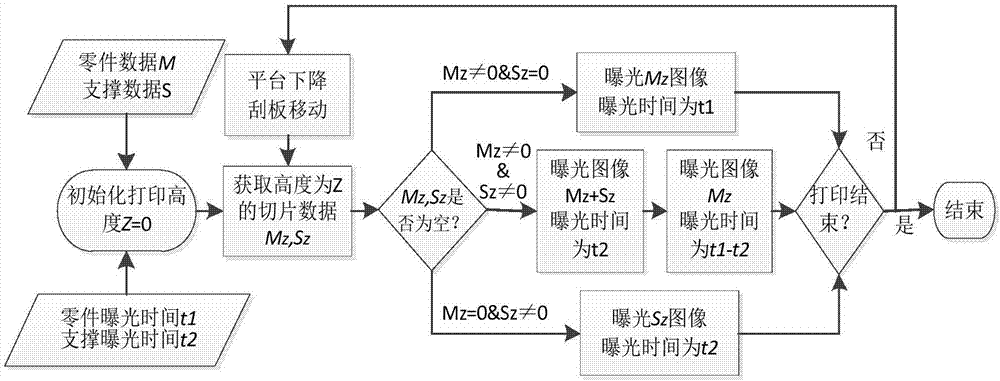

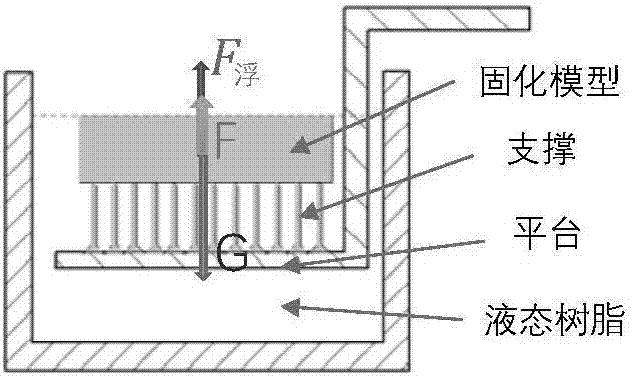

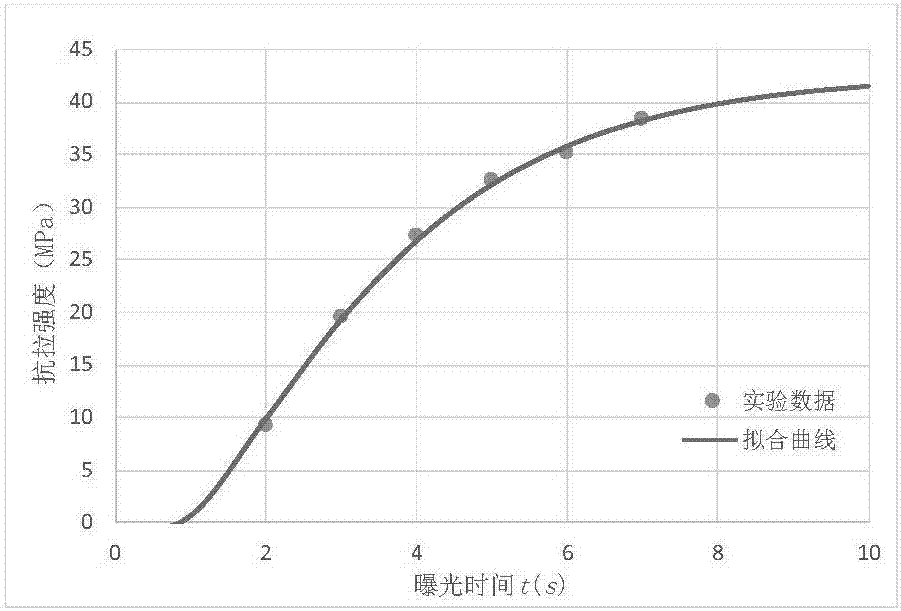

Plane prototyping photo-curing three-dimensional printing method capable of controlling workpiece strength

InactiveCN107263862AImprove surface qualityChange intensityAdditive manufacturing apparatus3D object support structuresSerializationUltimate tensile strength

The invention relates to a plane prototyping photo-curing three-dimensional printing method capable of controlling workpiece strength, and belongs to the technical field of plastic processing. The method includes the following implementation steps that (1) initialization is conducted, and a digital model generation technology is used for generating a workpiece digital model; (2) the strength of the part digital model and the strength of a supporting digital model are set, and exposure time of the workpiece digital model is determined; (3) the workpiece digital model in the step (1) is subjected to slicing operation; (4) a z-layer two-dimensional slice of the workpiece digital model is judged, and the exposure time is subjected to difference control according to the z-layer two-dimensional slice; and (5) the slicing layer z value of a two-dimensional image in the step (4) is judged so as to determine whether printing needs to be completed or not. By the adoption of the method, in the plane prototyping photo-curing three-dimensional printing process, the exposure time difference can be controlled through software differences according to the curing characteristic of a photosensitive resin material, and the workpiece strength can achieve gradient distribution and serialization only through one material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Laser selective laser melting rapid preheating and powder spreading device

PendingCN108080639AReduce energy consumptionReduce residual stressAdditive manufacturing apparatusIncreasing energy efficiencyClosed cavityForming processes

The invention discloses a laser selective laser melting rapid preheating and powder spreading device. The laser selective laser melting rapid preheating and powder spreading device comprises a closedcavity, wherein a forming cavity and a recycling cavity are arranged in the closed cavity; an automatic powder adding mechanism is arranged on the upper portion of the forming cavity; and a scraper powder spreading mechanism with an adjusting assembly is arranged on the automatic powder adding mechanism in a matched manner. A metal powder preheating unit is directly integrated in a powder storagecabin, powder which is about to participate in printing only needs to be rapidly preheated to a set temperature, residual stress generated in a forming process of the metal powder is reduced, the shape accuracy and the dimensional accuracy of a forming piece are ensured, quantitative powder feeding can be realized by a scarper portion, bidirectional powder spreading is implemented, and online leveling of a scraper can be implemented.

Owner:NINGBO RUNYES MEDICAL INSTR

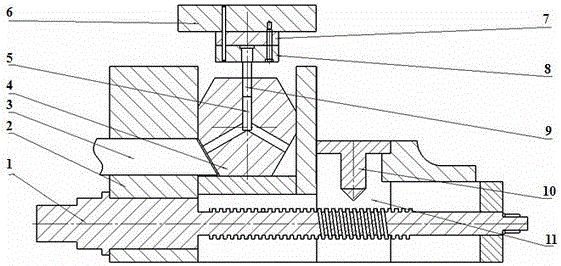

Numerically controlled grinder special for slewing bearing processing

InactiveCN103203677AHigh dimensional accuracyIncrease roughnessGrinding drivesAbrasive surface conditioning devicesBall screwSlewing bearing

A numerically controlled grinder special for slewing bearing processing comprising a grinder body and a workbench, a column and a grind head assembly, a grinding wheel dresser, a numerical control system and a cooling system. The grinder body and the workbench comprise working turntable components including a working turntable seat, a working turntable and a turntable motor. The working turntable components are mounted on an X-axis rail of the grinder body and moves on the X-axis left to right driven by an X-axis servo motor and a ball screw mounted inside the grinder body to complete grind feed processing of the X-axis. A workpiece mounted on the working turntable is driven by the turntable motor to rotate with the turntable to complete rotate feed processing. The grind head assembly comprises a grind head motor, a grind head component is composed of a rotary grind head seat and a grind head grinding wheel; and the grind head motor is mounted on the rotary grind head seat, and the grind head grinding wheel is driven by a main shaft of the rotary grind head seat to rotate so as to complete grind processing. The surface of the grinding wheel can be trimmed to be in a shape of slewing bearing rolling grooves by the grinding wheel dresser. By the aid of the numerically controlled grinder, the inner and outer cycle faces, the rolling grooves and a mounting plane of the slewing bearing can be clamped and grind processed in one step synchronously.

Owner:柳州市冉达机械有限公司

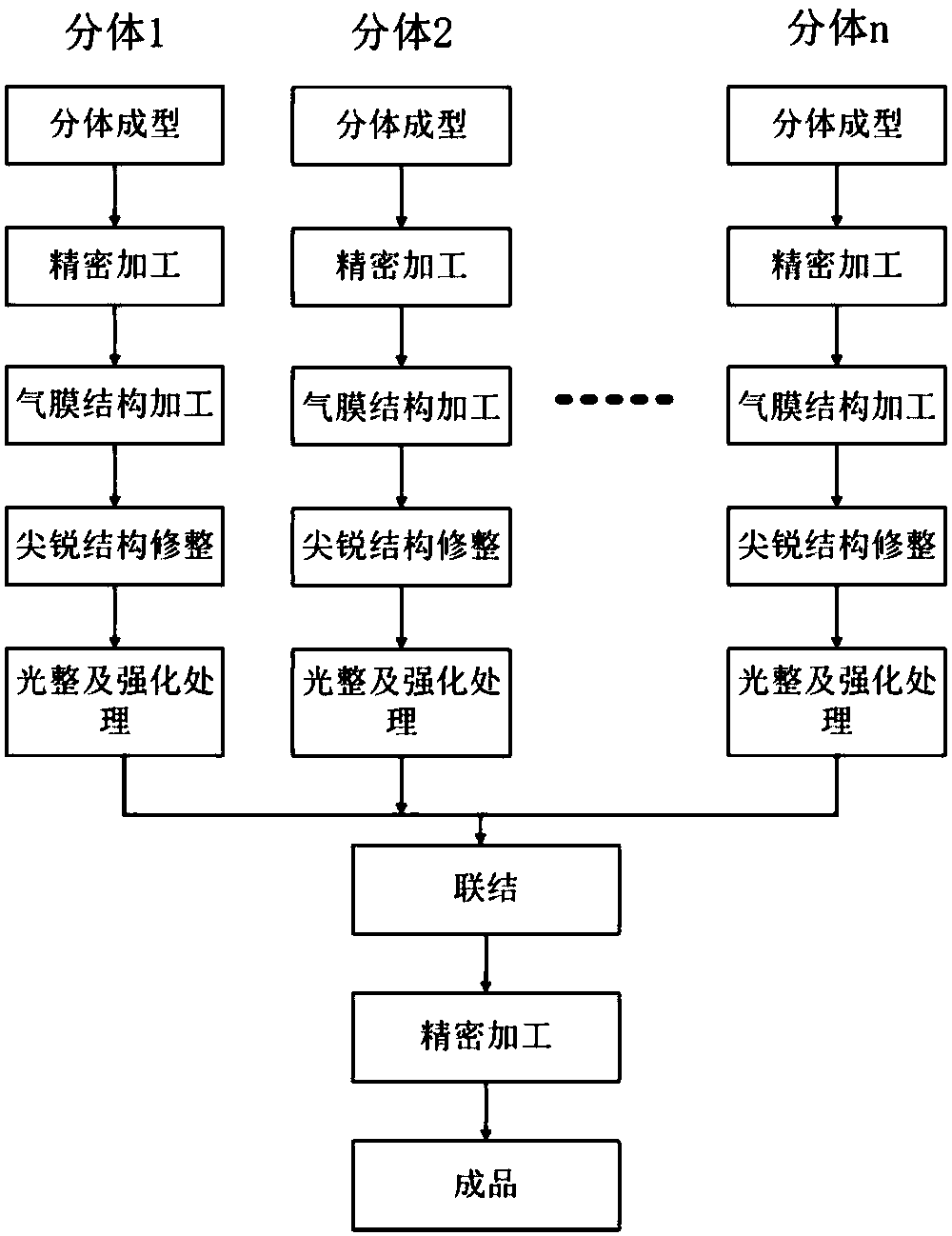

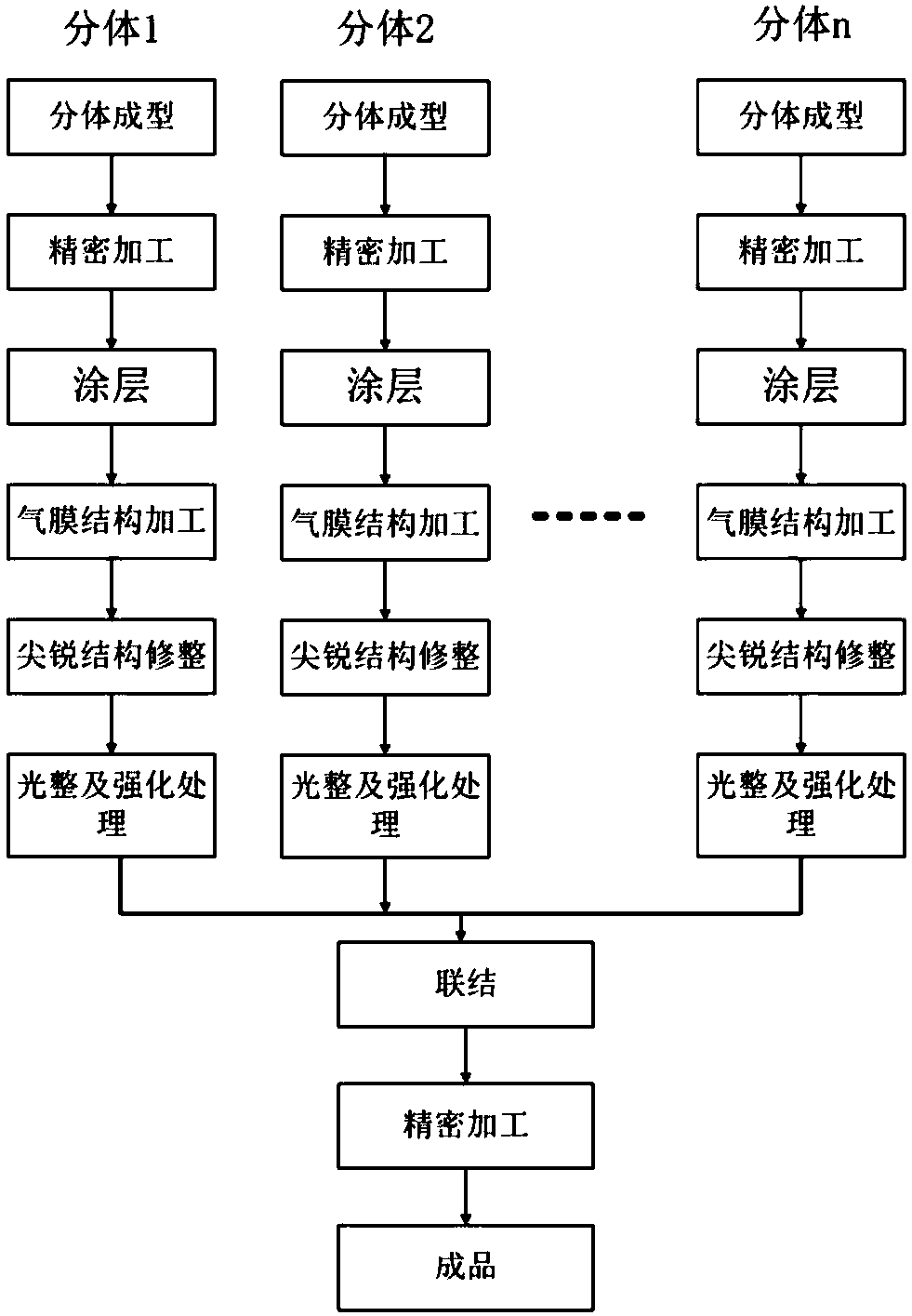

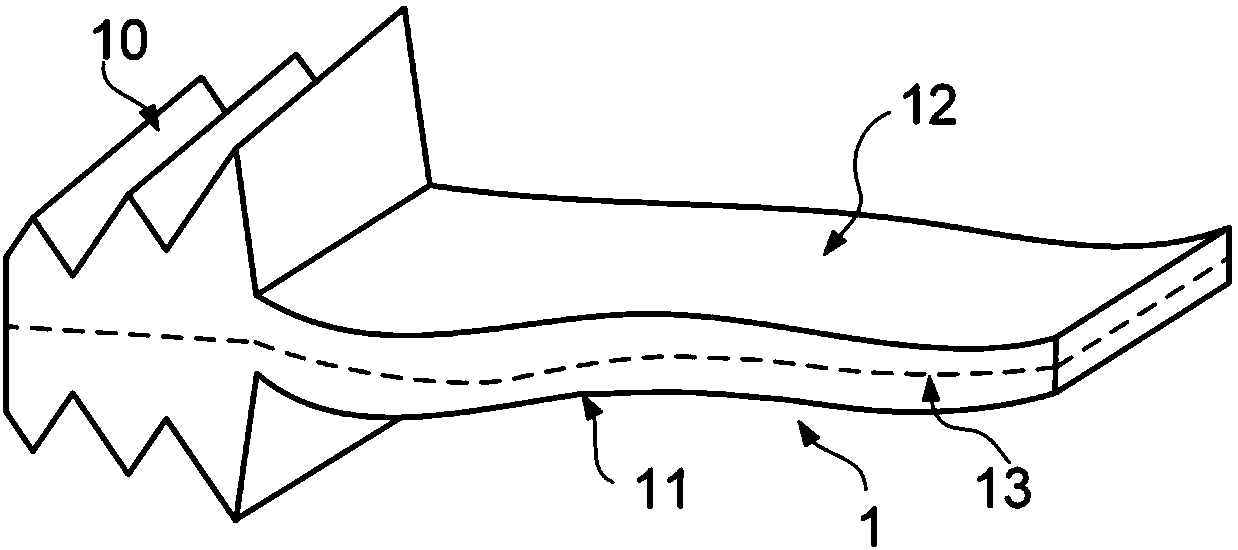

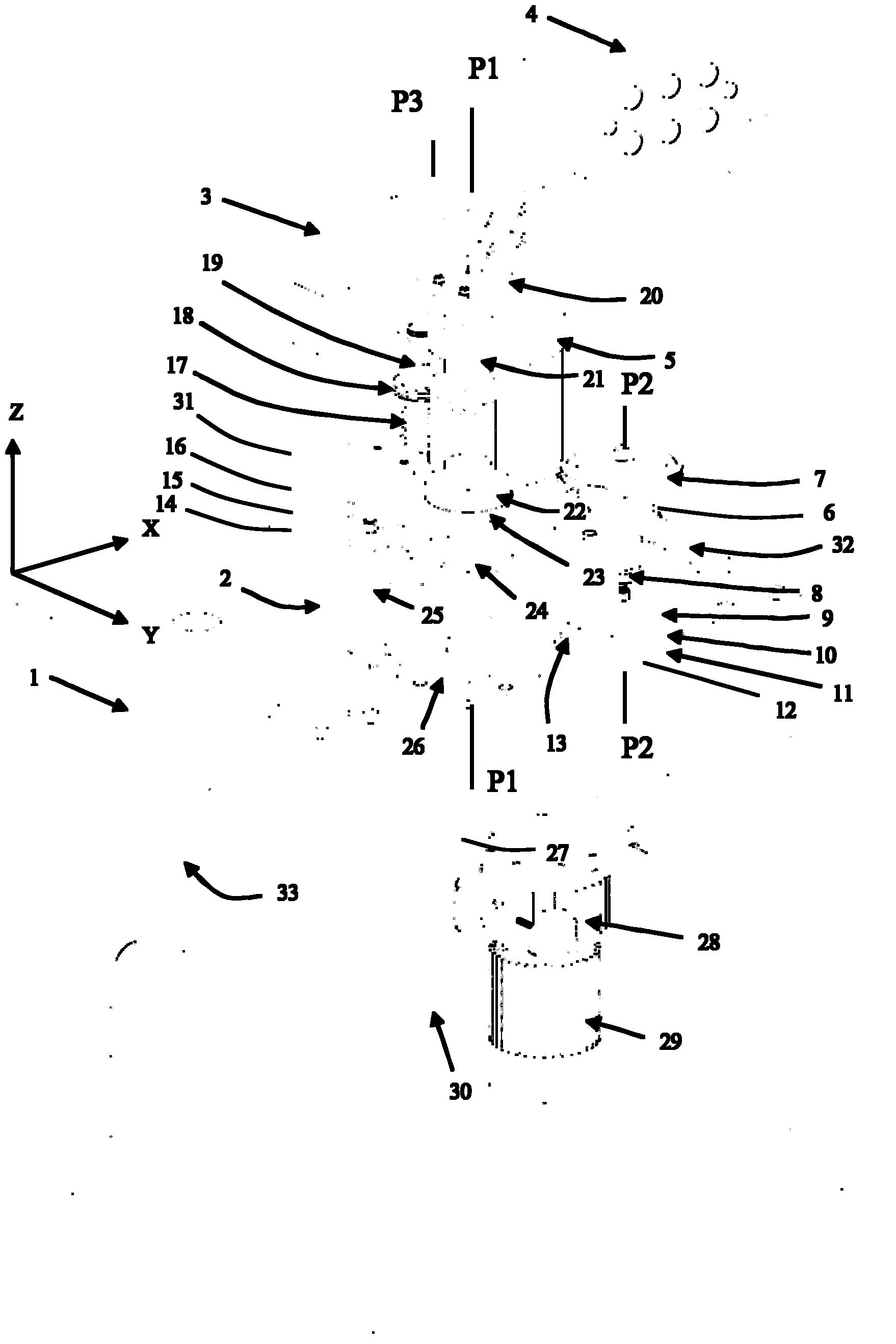

Hollow blade as well as manufacturing method and application thereof

InactiveCN108223019AQuality assuranceGuaranteed reliabilityBlade accessoriesMachines/enginesEngineeringMachining

The invention discloses a hollow blade as well as a manufacturing method and application thereof. The hollow blade comprises a cooling structure, an inner cavity and a transition structure, wherein the transition structure is located at the junction of the cooling structure and the wall surface of the inner cavity. Compared with the prior art, the blade avoids a sharp structure of the air film cooling structure of the inner cavity, the machining method can guarantee shape precision and consistency of the blade and the air film cooling structure, and occurrence of the back damage problems is thoroughly avoided from a process route layer, so that the quality and reliability of the blade are guaranteed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Automobile rear-view mirror three-dimension profiling edge grinding machine and method used for edging automobile rear-view mirror

InactiveCN103264336AGuaranteed shape accuracyGuaranteed dimensional accuracyEdge grinding machinesEngineeringReducer

An automobile rear-view mirror three-dimension profiling edge grinding machine comprises a machine tool, a pneumatic transmission control part, a fixed-axis rotation part, a rotation part and a cooling liquid addition part. The fixed-axis rotation part comprises a motor II, a cycloid needle wheel type reducer, a profiling, a locating profiling, an upper rubber base and a lower rubber base, wherein the motor II is connected with the cycloid needle wheel type reducer, drives the profiling, the locating profiling and the lower rubber base to rotate around a fixed shaft through a gear, and drives a workpiece which is clamped between the upper rubber base and the lower rubber base to rotate around the fixed shaft. The rotation part comprises a motor I, a rocker arm, a grinding wheel, a guide wheel mechanism, a cam-type mechanism and an elastic air cylinder, wherein the cam-type mechanism is circular-arc-shaped cylinders with different heights, and the circular-arc central axis of the circular-arc-shaped cylinders and the rotation center of the rocker arm coincide when the circular-arc-shaped cylinders are installed. When the profiling rotates by a circle, the rocker arm swings one time back and forth at the left-right limit position, the included angle theta between the rocker arm and the AO direction finishes a periodic change, the rotating workpiece G is wrapped for one circle by the grinding wheel, and the three-dimension grinding machining of an automobile rear-view mirror is finished.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

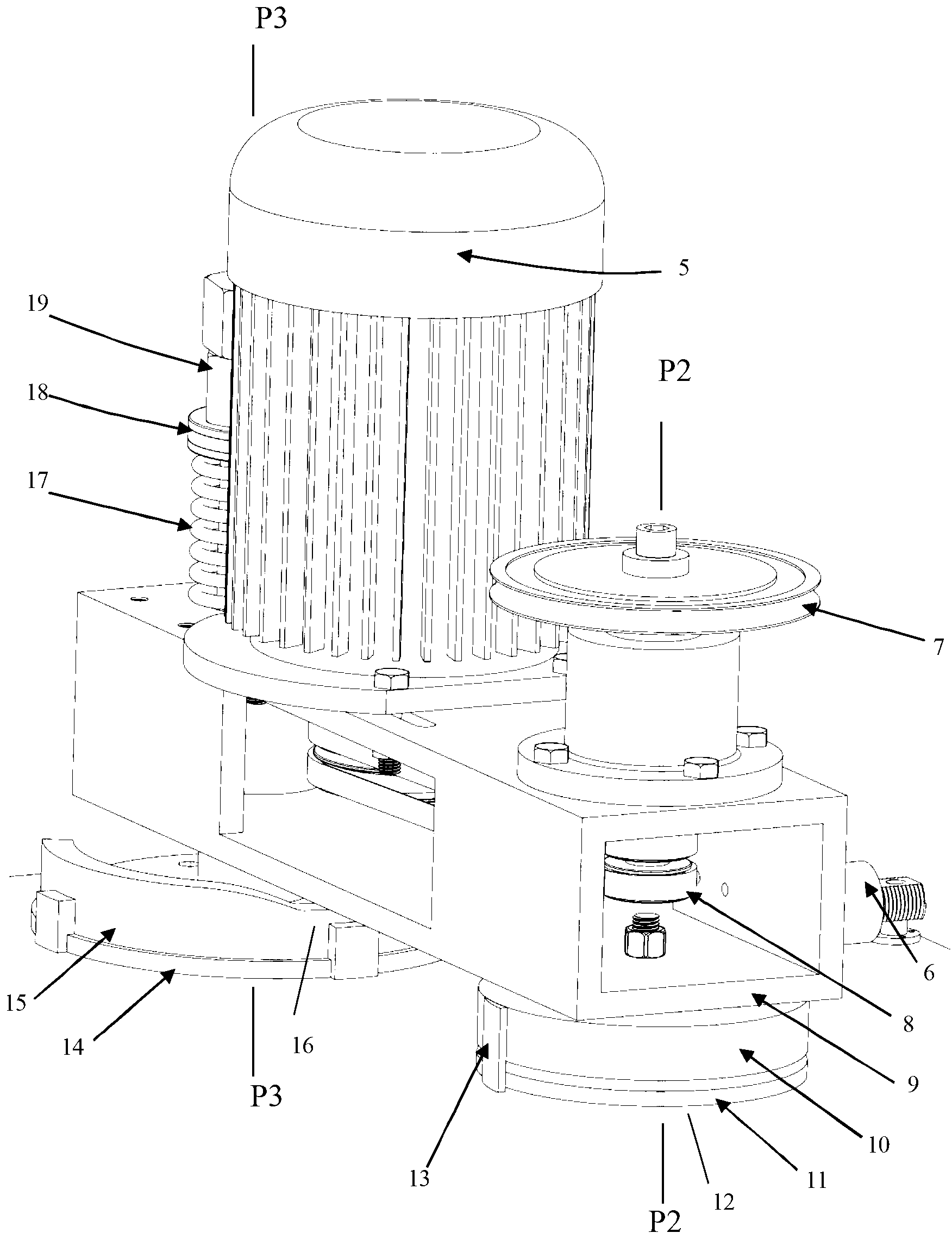

Device and method for processing surface of hemispherical-surface workpiece by rotary ultrasonic magnetic grinding

InactiveCN108581648AGuaranteed shape accuracyGuarantee processing qualityEdge grinding machinesPolishing machinesMotor driveMagnetic poles

The invention relates to a device and a method for processing the surface of a hemispherical-surface workpiece by rotary ultrasonic magnetic grinding. The device comprises a rotary drive device, an ultrasonic magnetic grinding device and a workpiece feeding device, wherein the ultrasonic magnetic grinding device consists of an ultrasonic generator, a collector ring, a carbon brush, an amplitude-change pole, a transducer, a collet chuck and a magnetic pole head, wherein the magnetic pole head is a cylindrical magnetic pole with a hemispherical end surface; the workpiece feeding device consistsof a step motor, a feeding lead screw, a workbench, a hand-operated lead screw and a clamp; when the step motor drives the feeding lead screw to rotate, the workbench can drive a workpiece to longitudinally move back and forth along the magnetic pole head; the hand-operated lead screw drives the workpiece to transversely move back and forth; and during processing, a processing gap is formed between the processed surface of the workpiece and the magnetic pole head, and the processing gap is filled with a magnetic abrasive. Through the processing device with the reasonable design and the processscheme, reasonable process parameters are set, so that precision finishing processing of a hemispherical part is realized, and grinding and processing efficiency can be remarkably improved.

Owner:UNIV OF SCI & TECH LIAONING

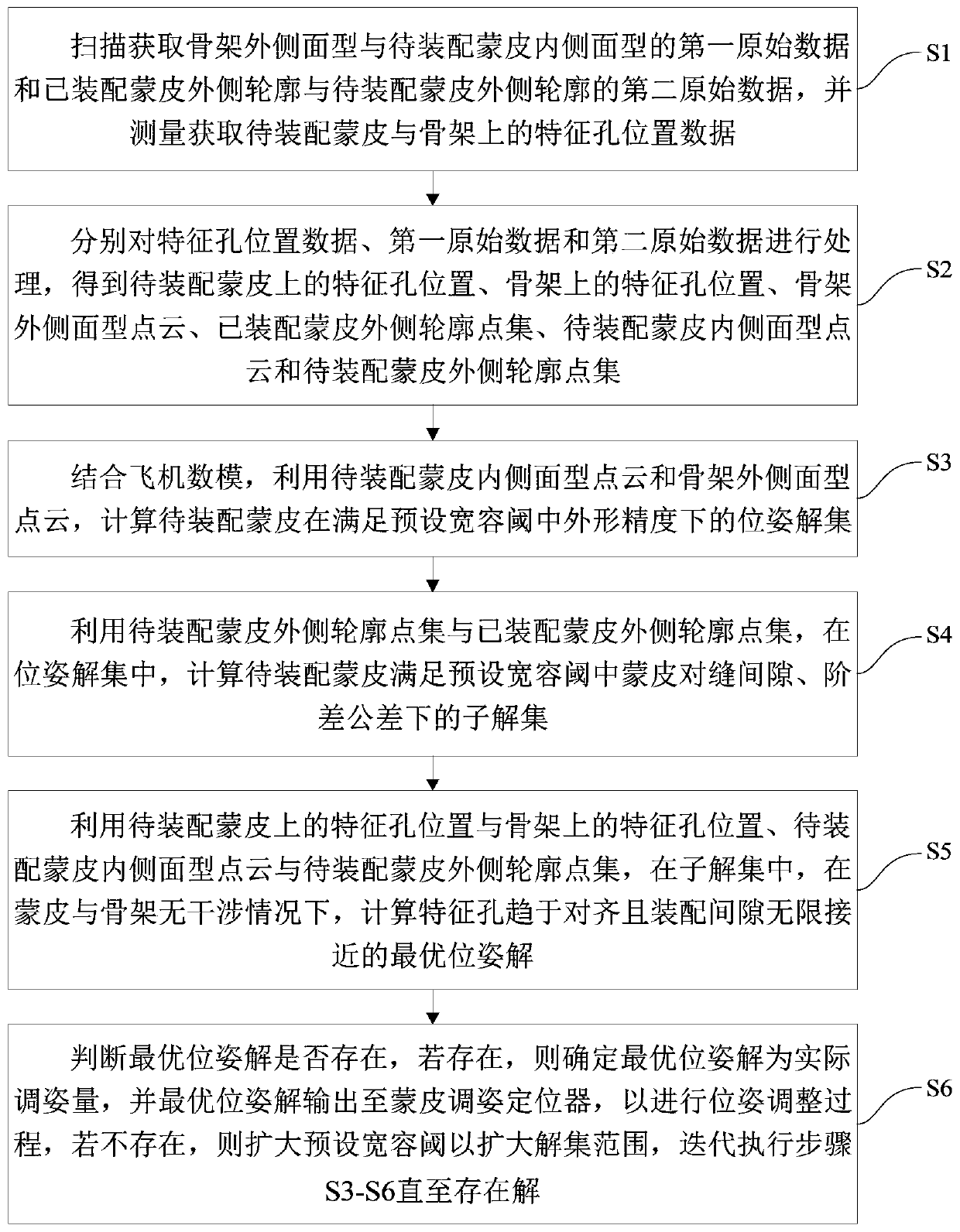

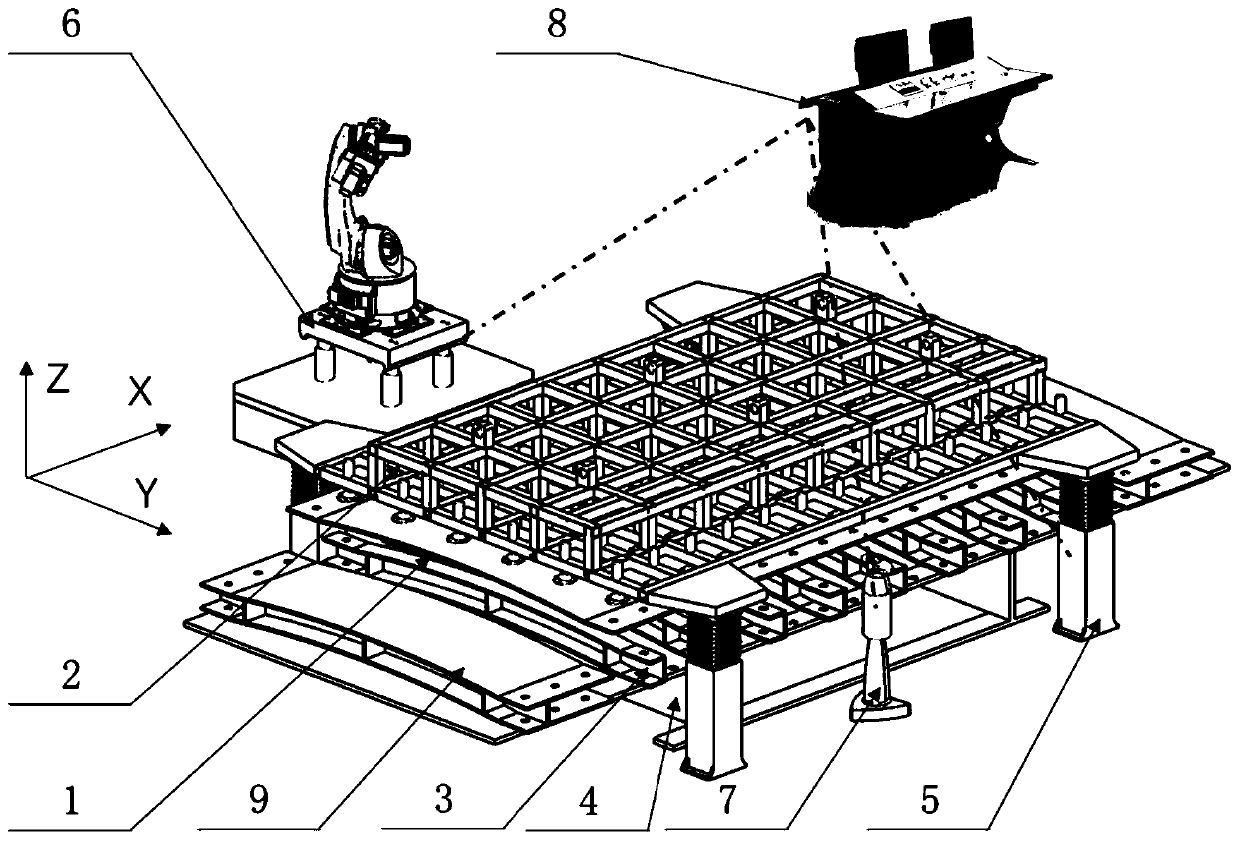

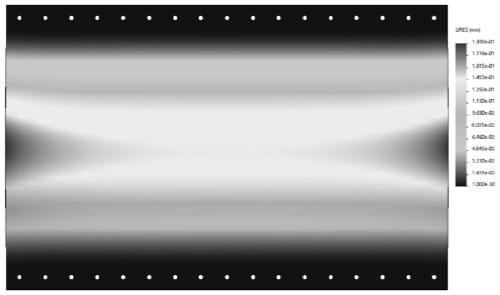

Multi-constraint-condition aircraft skin attitude adjustment method and system

ActiveCN111137468AGuaranteed shape accuracyReduce assembly clearanceAircraft assemblyEngineeringComputer vision

The invention discloses a multi-constraint-condition aircraft skin attitude adjustment method and system. The method comprises the steps: acquiring related position data of a skeleton and inner and outer sides of an assembled skin / a to-be-assembled skin; processing the data to obtain a feature hole position on the to-be-assembled skin, a feature hole position on the skeleton, an outer side surfacetype of the skeleton, an inner side surface type point cloud of the to-be-assembled skin and an outer side contour point set of the to-be-assembled skin; calculating a pose solution set of the to-be-assembled skin under the condition of meeting a tolerance threshold by using the point cloud; enabling the point set to be in the pose solution set, and calculating a sub-solution set, under the condition of meeting a tolerance threshold, of the to-be-assembled skin; calculating an optimal pose solution with an infinitely small assembly gap in the sub-solution set by utilizing the positions of thefeature holes, the inner side point cloud and the point sets of the outer side contour of the to-be-assembled skin; and judging whether the optimal pose solution exists or not, if so, carrying out apose adjustment process according to the solution, otherwise, expanding a tolerance threshold, and iterating the process until the solution exists. With the method, the docking task requirement can bemet on the premise of multi-tolerance constraint.

Owner:TSINGHUA UNIV

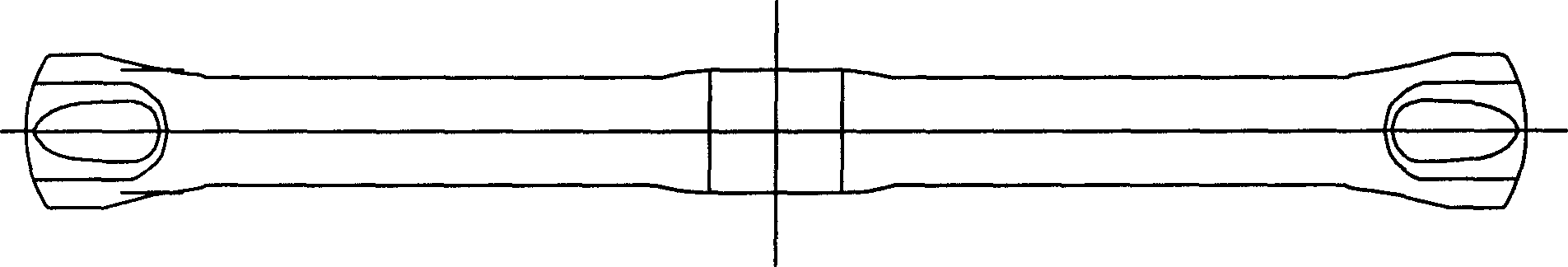

New process method for manufacturing mold capable of ensuring size accuracy of cast blade for large-scale water turbine

ActiveCN101716654AUnique material selectionEasy to implementFoundry mouldsFoundry coresWater turbineCasting mold

The invention relates to a new process method for manufacturing a mold capable of ensuring the size accuracy of a cast blade for a large-scale water turbine. The method is characterized by comprising the following steps of: selecting materials; designing a technical scheme for manufacturing the mold; establishing a three-dimensional model for manufacturing the mold; manufacturing a mold blank; processing the mold; and detecting the mold. The process method of the invention is unique and solves the problem that a distorted-surface blade casting mold has low manufacturing efficiency and that the kind of casting mold manufactured by the traditional manual method cannot achieve the accuracy of a design size. The method solves the deformation problem of the mold per se and ensures the size accuracy of a blade-type mold through the research and application of a new material and a new method in a mold manufacturing process.

Owner:KOCEL EQUIP

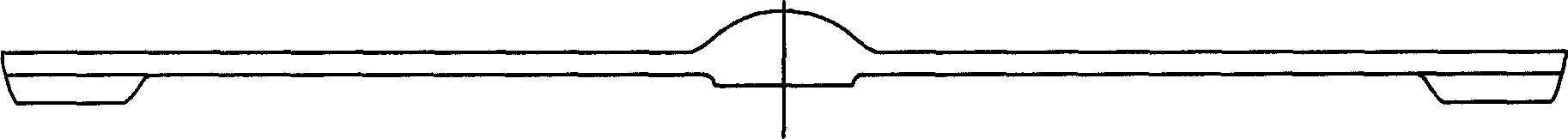

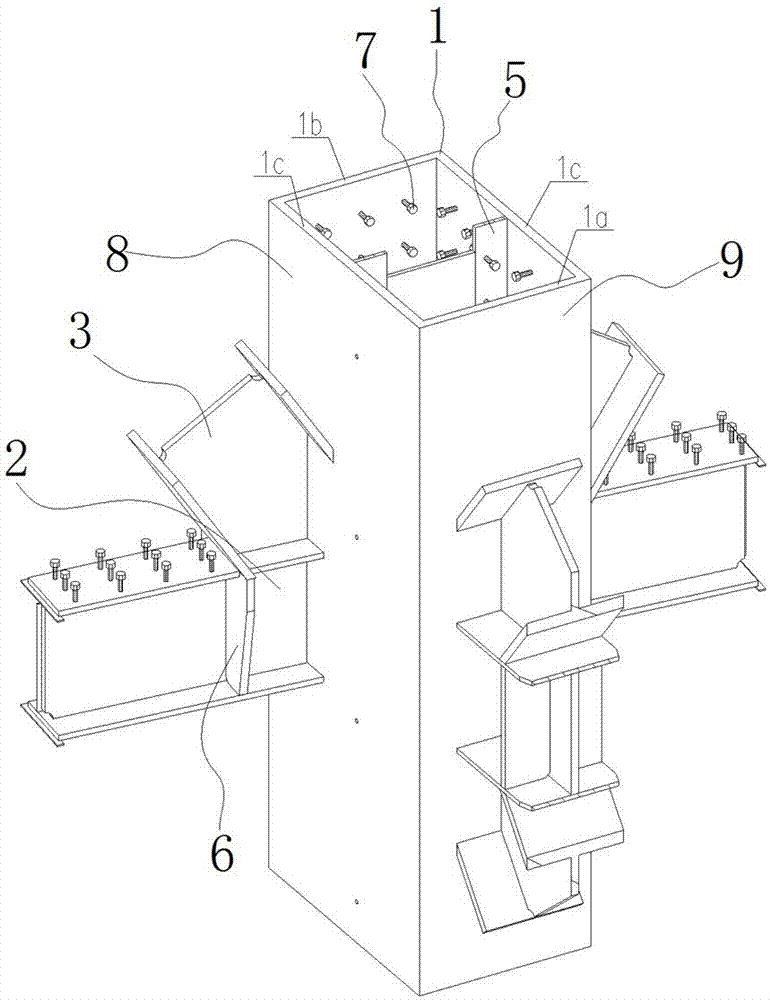

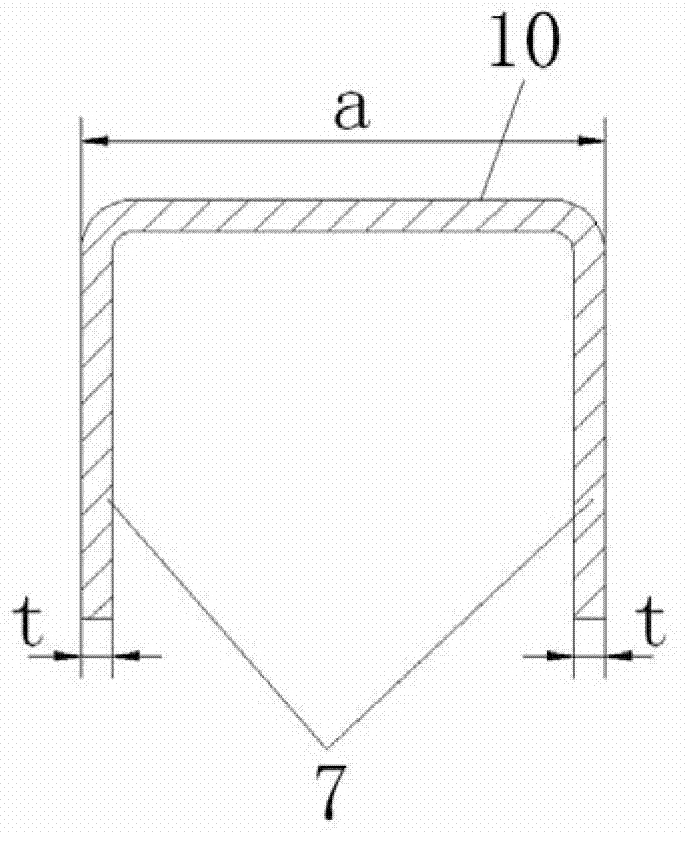

Low-alloy high-strength steel automobile rear bumper beam and manufacturing method thereof

The invention relates to a back bumper beam of a low-alloy high-intensity steel vehicle; the body of the beam is an integral component for steel plate shaping with a 'U'-shaped transverse section; the mounting hole and the reinforcing ribs of the sleeve of a tow hook are arranged on the body of the beam. The invention is characterized in that the material of the body of the beam is the low-alloy high-intensity steel, the components of which includes that the content of C is less than or equal to 0.2 percent, the content of Mn is less than or equal to 2 percent, the content of P is less than or equal to 0.03 percent, the content of S is less than or equal to 0.03 percent, the content of Alt is more than or equal to 0.02 percent and the content of Nb is less than or equal to 0.9 percent; besides, the anti-tension intensity of the steel is larger than 590 MPa. The manufacture method of the beam includes the following steps of: extending and shaping to obtain the blank of the body of the beam, the left and right ends of which are provided with the reinforcing ribs and the transverse section of which is 'U'-shaped; cutting the edge and punching: punching the mounting hole of the sleeve of the tow hook in the blank of the body of the beam and cutting off the redundant plate materials; rolling and shaping: shaping the blank of the body of the beam into the size of a finished product. The invention organically combines extending and shaping and ensures the precision after being shaped by a shaping tool; the product not only can completely meet the intensity requirement of the back bumper beam of the vehicle, but also can realize batch manufacture as well as reduce cost.

Owner:CHANGAN FORD AUTOMOBILE CO LTD

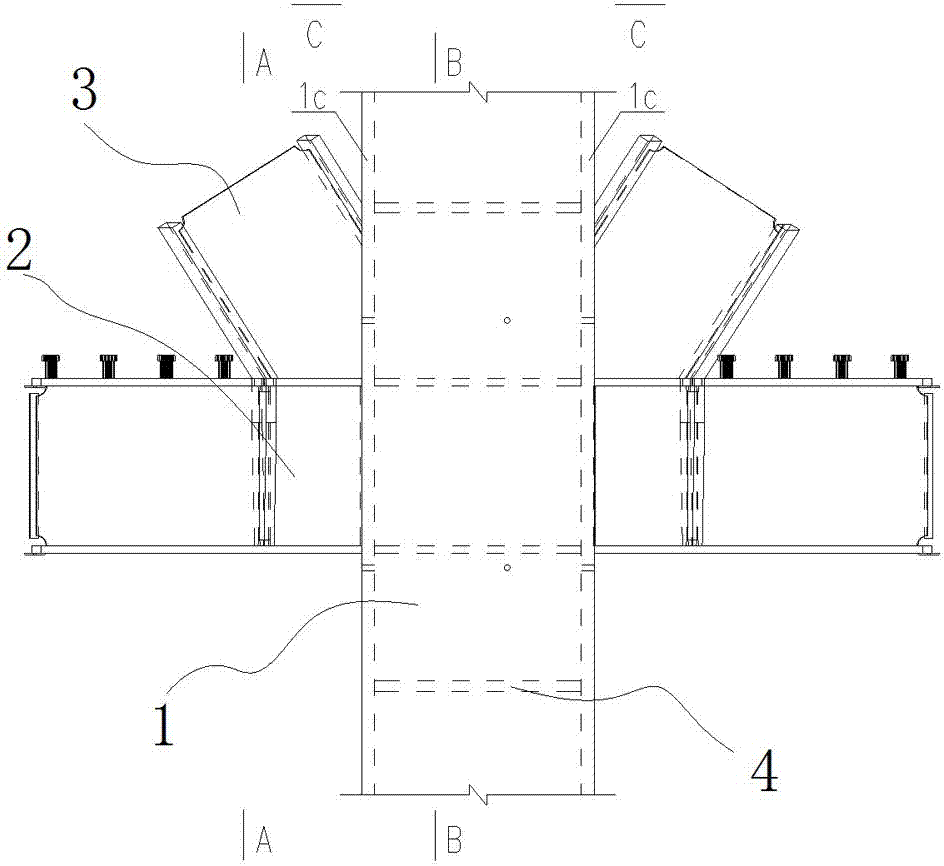

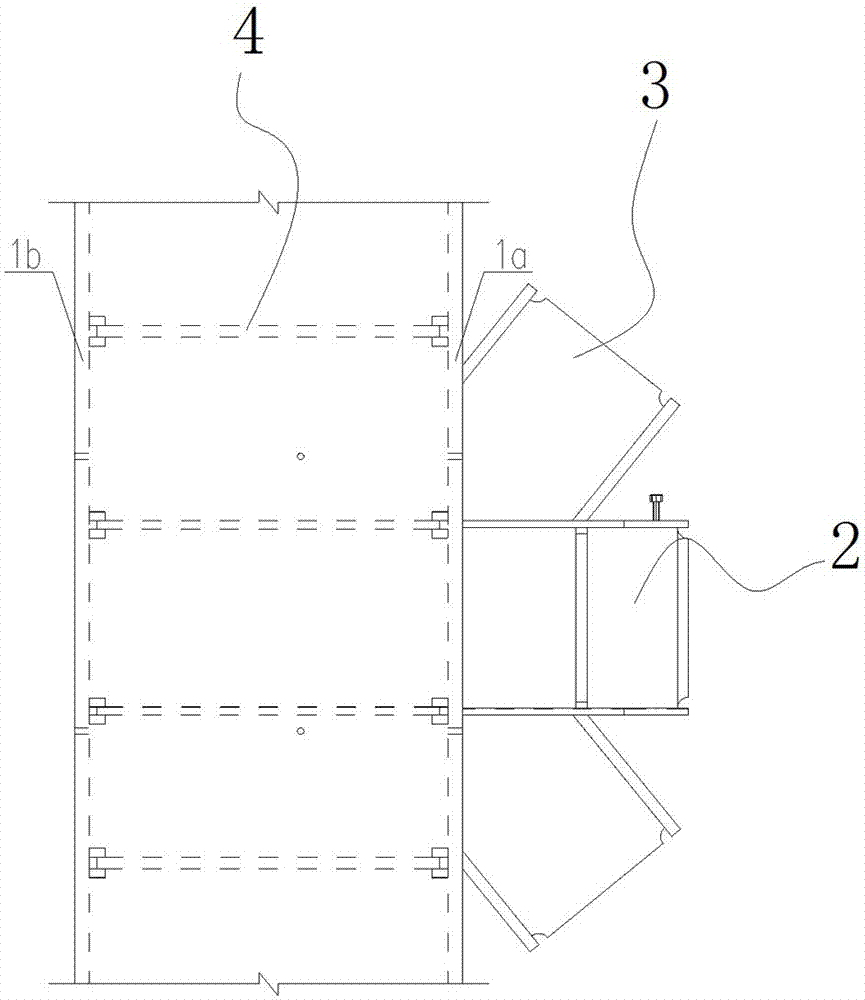

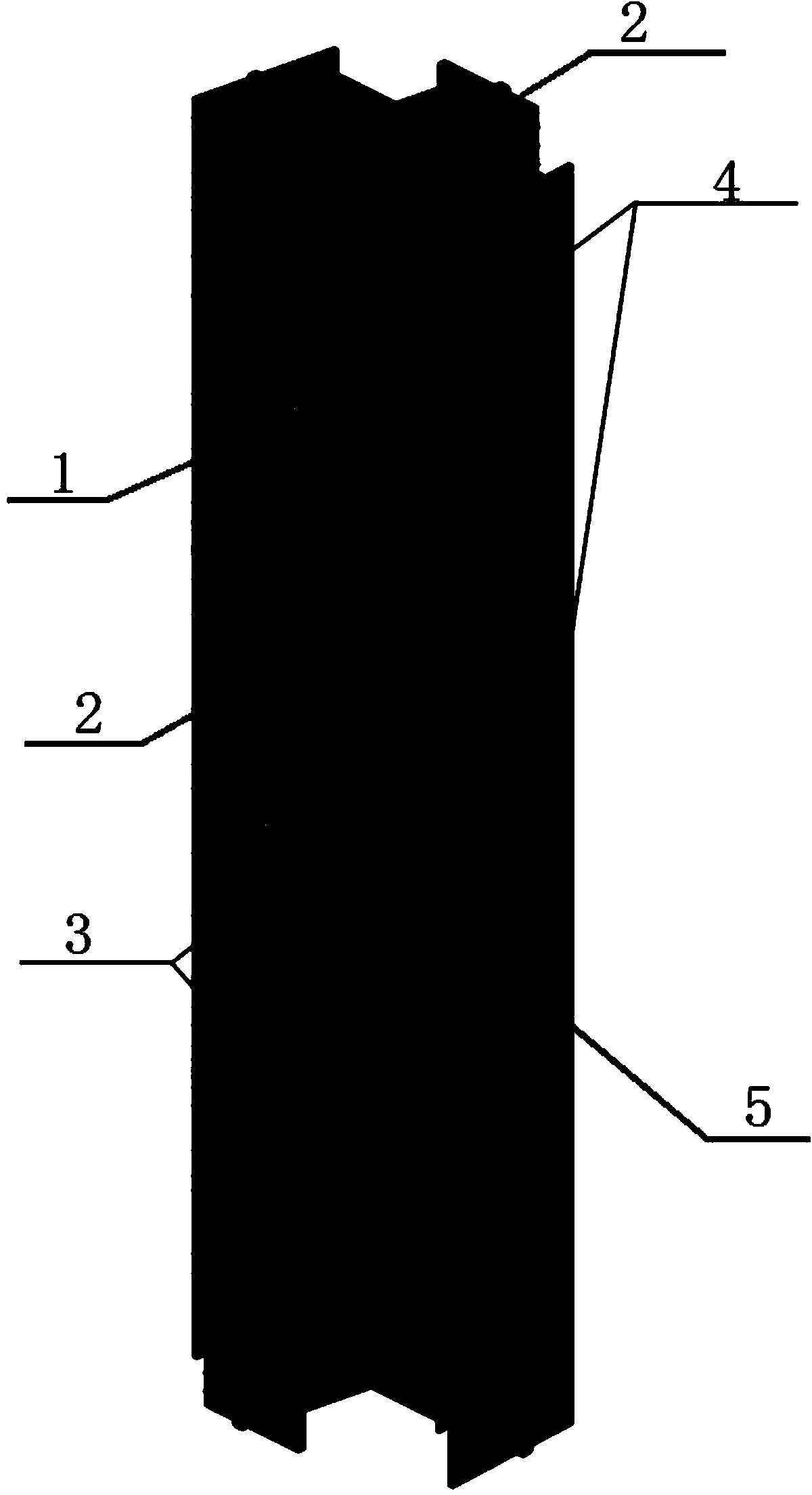

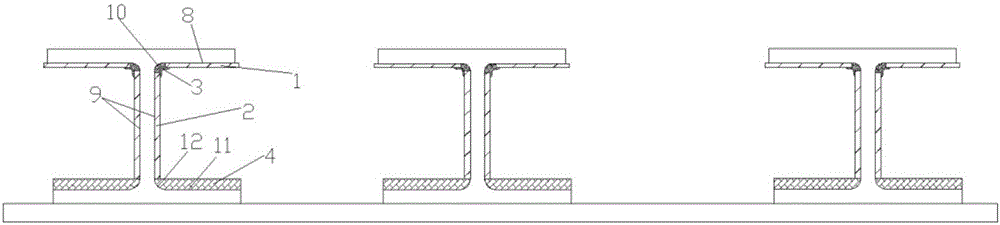

Large-section thick-wall welding box-type member and manufacturing method thereof

InactiveCN107035060AQuality assuranceGuaranteed shape accuracyBuilding componentsThick wallMechanical engineering

The invention relates to a welding box-type member, in particular to a large-section thick-wall welding box-type member and a manufacturing method thereof and belongs to the field of steel structures. The large-section thick-wall welding box-type member comprises box-type parts, bracket components are arranged on side walls of the box-type parts, and the box-type parts are positioned through reinforced components. According to the large-section thick-wall welding box-type member and the manufacturing method thereof, the structure is compact, the manufacturing process is further improved and the product grade is improved.

Owner:浙江东南网架股份有限公司

Electrospark wire-electrode cutting and punching combined machine tool

The invention relates to an electrospark wire-electrode cutting and punching combined machine tool which comprises a base, a guide frame, a vertical column, a transverse guiderail, a longitudinal guiderail, a motor cabinet, a cantilever and a workpiece clamping holder; a wire outlet nozzle, a high-pressure water nozzle, a high-pressure water pipe, a broken-wire prevention detection clamping mechanism, a compression wheel, an elastic compression wheel, a compression wheel, a tension detection sensor, a deviation correction wheel, an upper guide wheel, a lower guide wheel, a high-pressure water nozzle, a wire outlet nozzle, a single type electromagnetic clutch, a main wire storage tube and an auxiliary wire storage tube; a punching motor, a pulse electric-cutting fluid mechanism, a punching needle tightening component, a belt transmission mechanism, a double-reduction mechanism, and the like. The electrospark wire-electrode cutting and punching combined machine tool has the characteristics that an automatic wire threading function can ensure automation of a workpiece in the process from punching to wire cutting, be free from expending time for manually carrying threading wires and trying to cut, and ensure the precision of the machining position and machining shape of the workpiece, as well as automatic and precise machining. The combined machine tool has an automation function that other machine tools do not have. The efficiency and precision are improved, and the machining cost is lowered.

Owner:UNIV OF SCI & TECH BEIJING

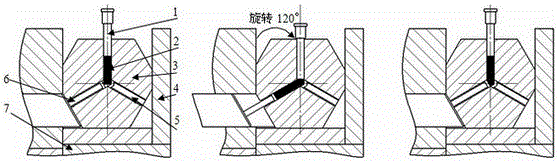

Method for preparing titanium alloy nano materials through warm extrusion of herringbone channel mold

The invention discloses a method for preparing titanium alloy nano materials through warm extrusion of a herringbone channel mold. The method is characterized in that through the herringbone central axis, the herringbone channel mold is rotated by 120 degrees, and then subsequent-pass extrusion is carried out; repeated plastic deformation of the titanium alloy nano materials can be achieved, and finally, large deformation is accumulated; the nano titanium alloy materials are obtained; in each pass extrusion process, the rotating direction of the herringbone mold is changed, and uniform severe plastic deformation of the titanium alloy can be achieved; and the grain size is uniform, and refined nano grains are equiaxed grains with large grain boundary angles, and the mechanical property of the blocky nano titanium alloy is further improved, and on the premise that the high density is ensured, the high strength and the good toughness are high.

Owner:福建省诺希科技园发展有限公司

Giant cruciform combination column and manufacturing method thereof

ActiveCN104196164AGuaranteed bearing capacityNovel structural designStrutsMilling equipment detailsCruciformMechanical engineering

The invention discloses a giant cruciform combination column which comprises two pieces of T-shaped steel and a pieces of I-shaped steel, wherein the T-shaped steel is mounted at two sides of the I-shaped steel so as to form a cruciform column body structure with side plates; the upper part, the middle and the lower part of the column body structure are respectively provided with two layers of stiffening plates; studs are arranged on the side plates of the column body structure; corbels are arranged at the parts, connected with the stiffening plates, of the I-shaped steel. The invention further discloses a manufacturing method of the giant cruciform combination column. Based on the giant cruciform combination column and the manufacturing method thereof, the structure of the column is simplified to a maximum extent while the load-bearing capacity of the column is ensured, the raw materials and the cost are saved, and the effective usable area of a building is increased; the self-weight of the structure is reduced, and thus the structural seismic response is reduced.

Owner:JIANGSU HUNING STEEL MECHANISM

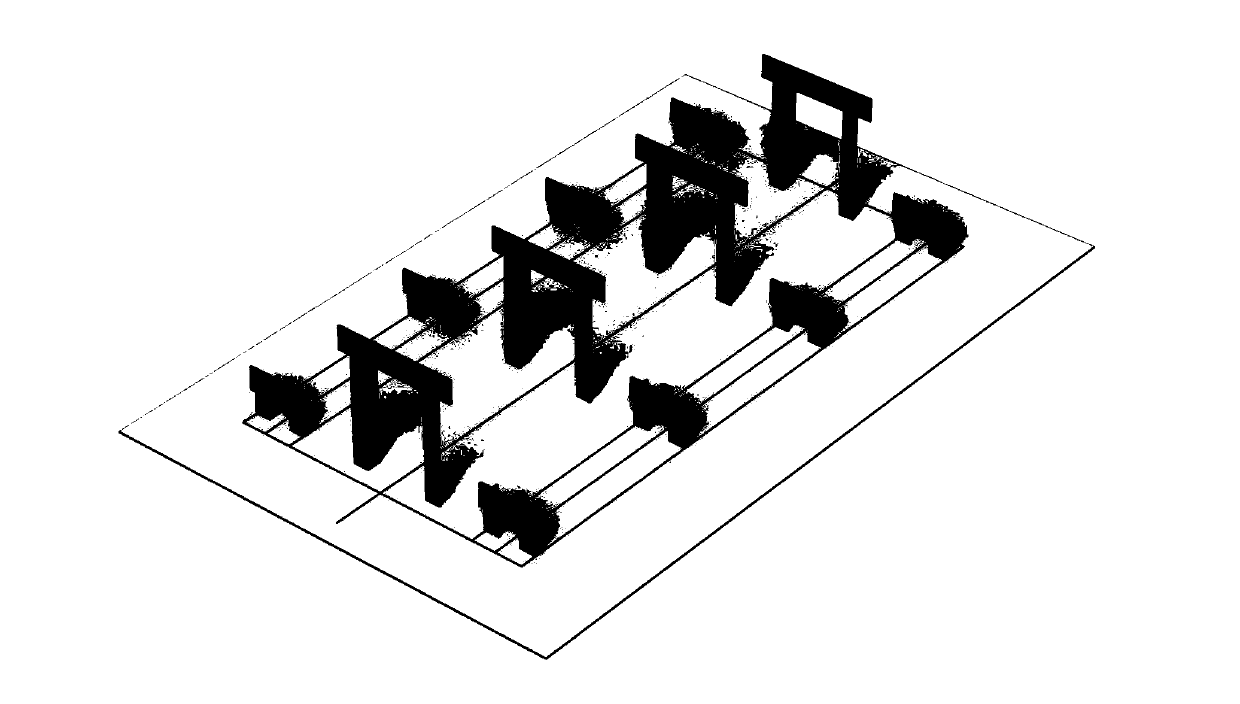

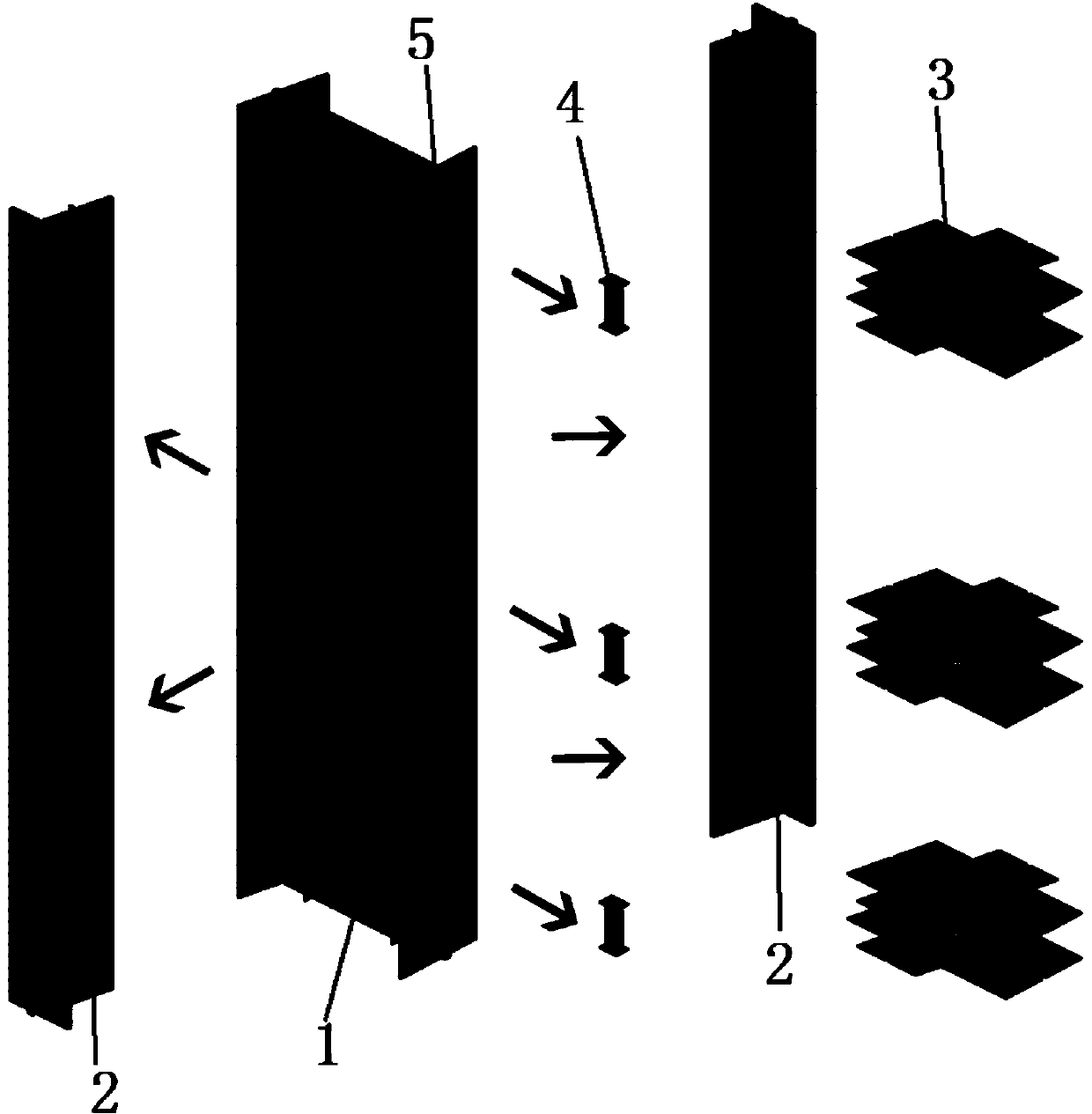

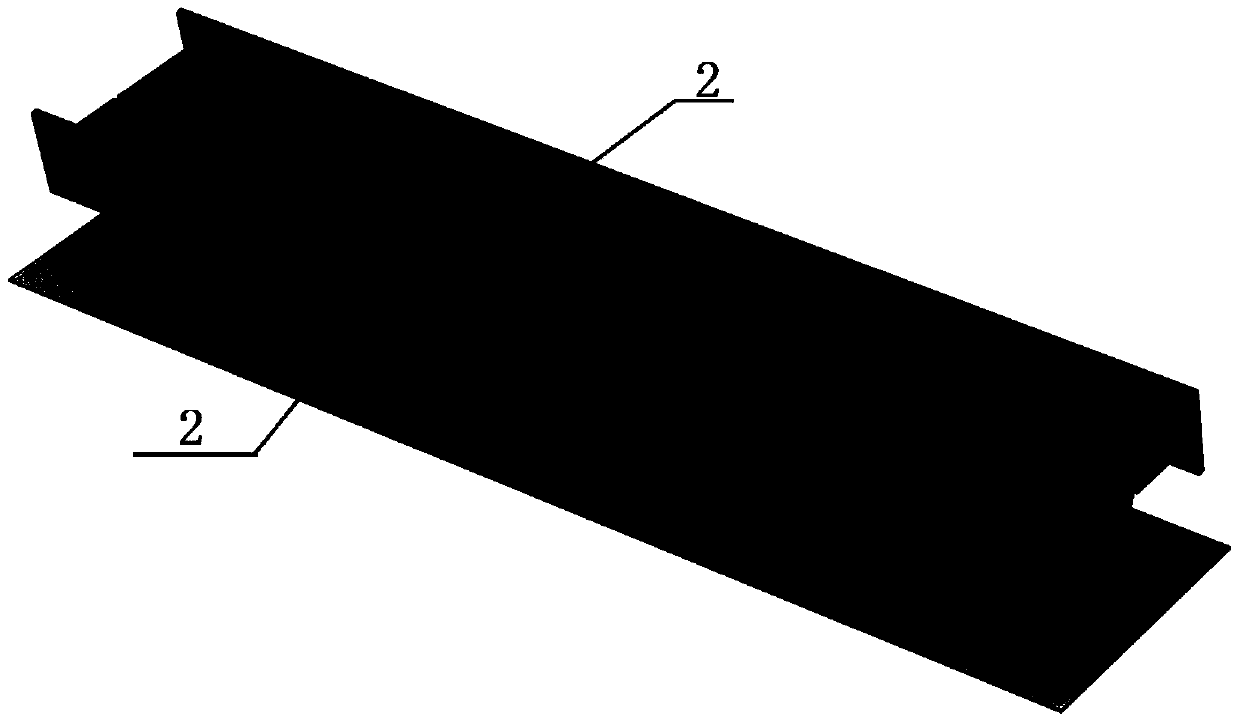

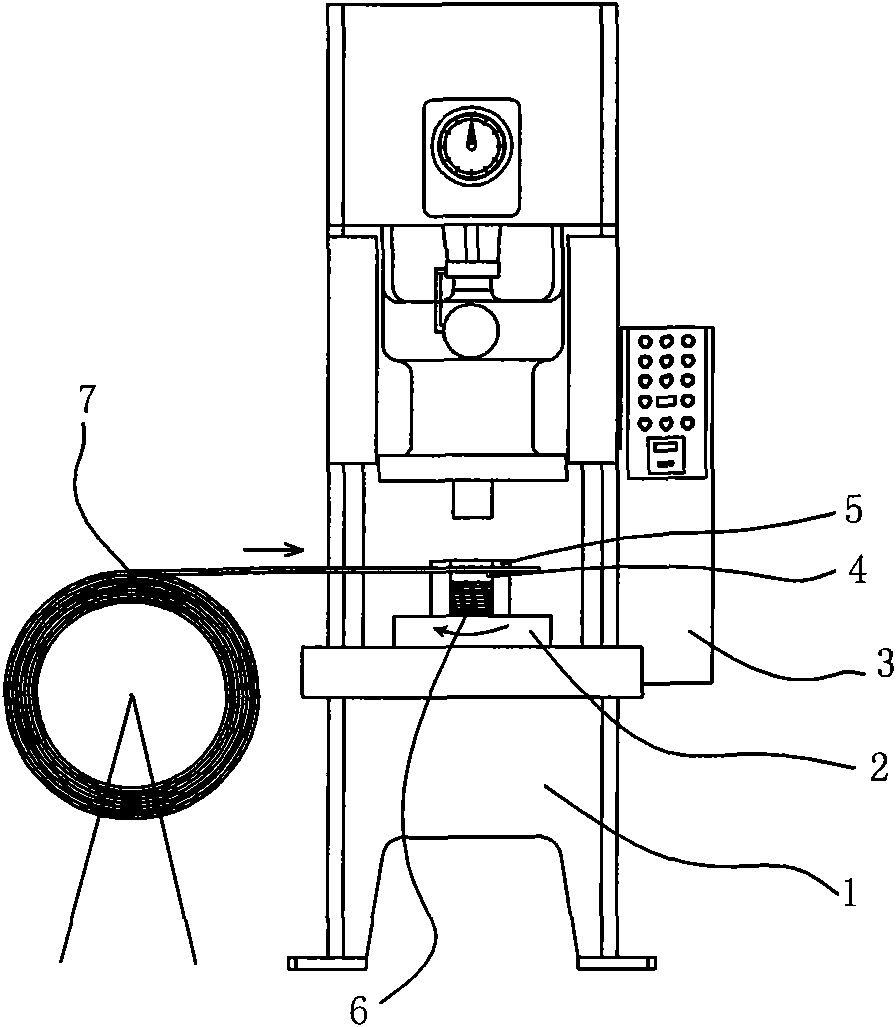

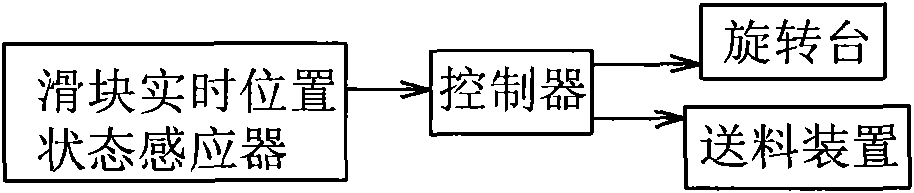

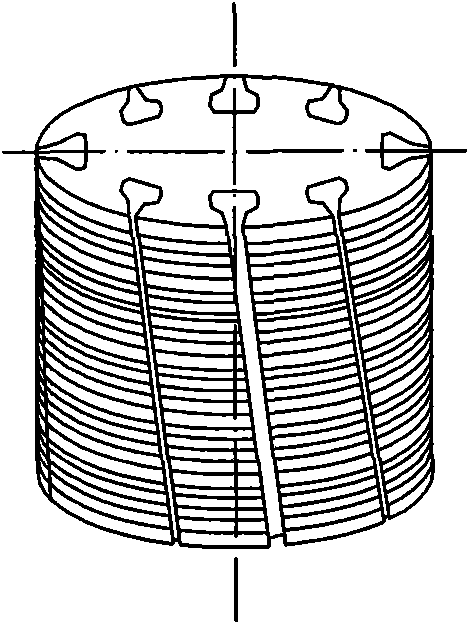

Method for manufacturing laminated rotor and stator

InactiveCN101931288AGuaranteed shape accuracyHigh precisionManufacturing stator/rotor bodiesSocial benefitsPunch press

The invention relates to a method for manufacturing laminated rotor and stator. In the method, strip steel is used as a raw material, and is punched and riveted by adopting a punch and a punch molding and rivet mould arranged on the punch to manufacture the stator and rotor; a lower mould of the punch molding and rivet mould is provided with a rivet bin; the rivet bin is provided with a rotating device; the punch is provided with a controller and a slide real-time position state inductor; the slide real-time position state inductor and the rotating device are connected with the controller; the controller indicates the rotating device to rotate at an angle alpha before the next stator and rotor is contacted with last stator and rotor in the rivet bin, so that the rotating device can deflect between two laminated adjacent stator and rotor. By combining high-speed automatic production line implementation of motor stator and rotor punching, the product accuracy can be greatly improved, the materials can be saved, the consumption is reduced, and the social benefit is remarkable.

Owner:YANGZHOU FORGING MACHINE TOOL

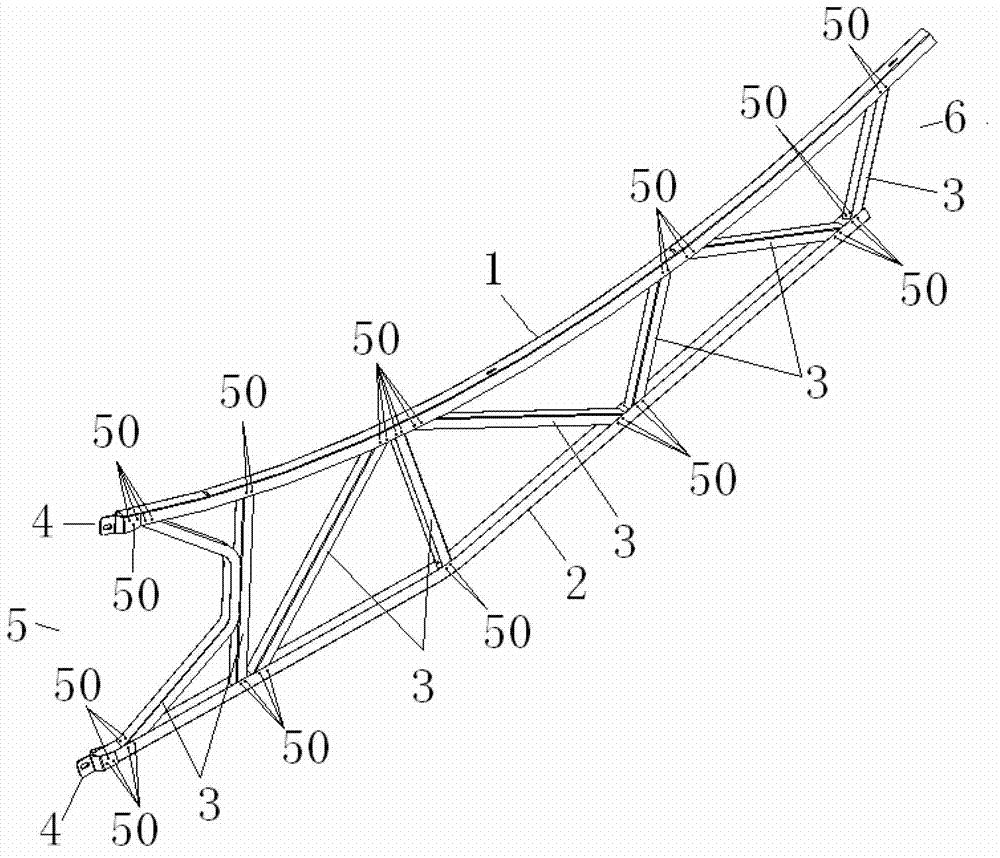

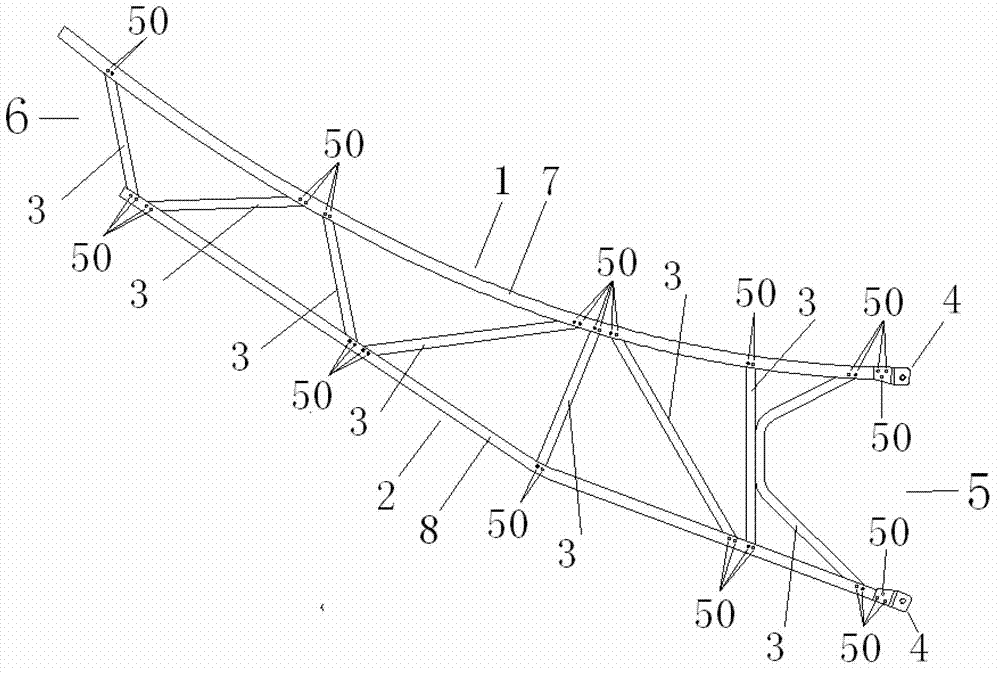

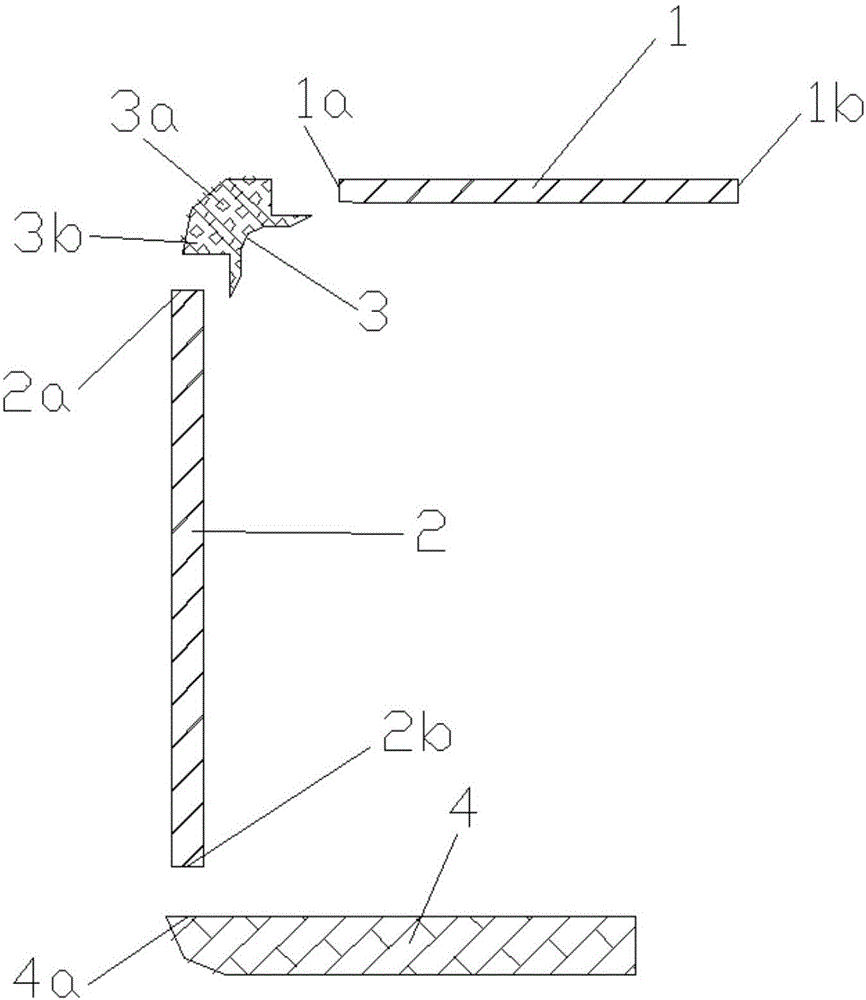

Support arm for reflector of paraboloid trough condenser

InactiveCN102788443AHigh shape accuracyHigh dimensional accuracySolar heat devicesSolar thermal energy generationCurve shapeUltimate tensile strength

The invention discloses a support arm for a reflector of a paraboloid trough condenser. The support arm for the reflector of the paraboloid trough condenser comprises a top boom (1), a lower boom (2), web members (3) and connecting pieces (4). The top boom (1), the lower boom (2) and the web members (3) are metal thin-wall parts of which the cross sections are non-closed. The top boom (1) of which the surface is treated is bent into a curve shape or a broken line shape; the top boom (1) is suitable for installing at least one parabolic cylinder reflector sub-mirror (20) in shape; the web members (3) of which the surfaces are treated are located between the top boom (1) and the lower boom (2) of which the surface is treated and are connected with the top boom (1) and the lower boom (2) in the manner of riveting without rivets to form the certain-strength and certain-rigidity support arm of a plane girder structure; the connecting pieces (4) are connected with the end parts of the top boom (1) and the lower boom (2) at the first end (5) of the support arm in the manner of riveting without rivets; and the support arm is connected with a central girder (60) through the connecting pieces (4).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Automatic device and method for machining curve surface of external spiral space

InactiveCN1712163AMeet the technical requirements of high-speed turning and millingSimple structureMilling equipment detailsMilling cutterEngineering

An automatic lathe or miller for machining the spirally curved surface is composed of mainshaft box, mainshaft, chuck, machine frame, tailstock, center on the axle of tailstock, and milling tool driving unit consisting of X,Y and Z slide benches and electric mainshaft. Its machining technology includes such steps as milling reference surface, milling for shaping, refining and tempering.

Owner:SHENYANG LIGONG UNIV

Composite mold for integrally molding inner profile of ribbed composite wall panel

The invention belongs to the polymer matrix composite molding technology, and relates to a composite mold for integrally molding an inner profile of a ribbed composite wall panel. The molding mold comprises an upper flange molding soft mold body, a web molding soft mold body, an upper R corner molding soft mold body and a lower flange and R corner molding soft mold body. The upper R corner molding soft mold body of the composite mold is made of a rigid and flexible blended and cured material, and therefore the rigidity of a soft mold upper R corner area is increased, the pressure in a tank is better transmitted to an upper R corner area of the ribbed composite wall panel, and the defects of upper R corner area hole concentration, layering, appearance deviation and the like can be effectively avoided. The lower flange and R corner molding soft mold body is utilized for guaranteeing the inner quality and appearance accuracy of a lower flange and a lower R corner area, especially a side profile of the lower flange and R corner molding soft mold body is chamfered according to the theoretical appearance of an inner profile of a lower R corner of each rib, the procedure of preparing a lower R corner molding soft mold body by entering the tank is omitted, the mold manufacturing cost is reduced, and the appearance accuracy of the lower R corner area is improved.

Owner:AVIC COMPOSITES

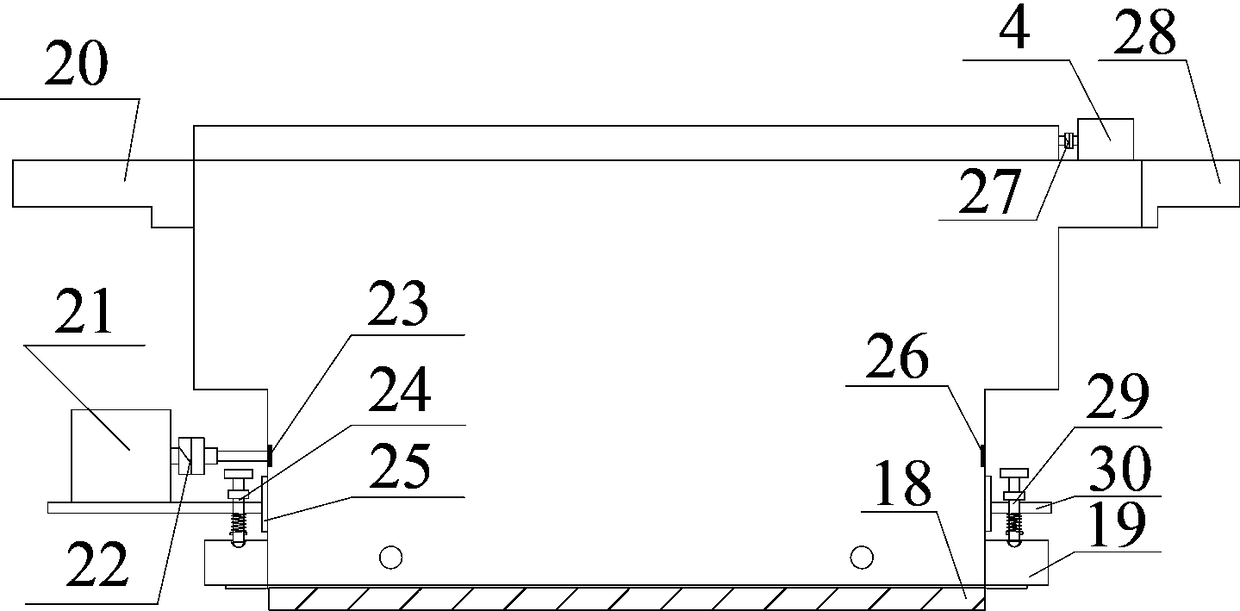

Spacing device of equipment for delivering welding workpieces in circulating manner

ActiveCN102785792AImprove delivery efficiencyGuaranteed shape accuracyPackagingConveyor partsAutomatic controlEngineering

A spacing device of equipment for delivering welding workpieces in a circulating manner is used for solving the spacing problem of a slipping bracket during the operation of the equipment, is mounted on the equipment provided with a slipping workbench rack and a lifting workbench rack, and comprises a slipping spacing mechanism, a lifting spacing mechanism and a spacing stop block, wherein the slipping spacing mechanism comprises a spacing component and an unlocking piece; the spacing component is hinged to the slipping workbench rack of the equipment, and is matched with the unlocking block to control a slipping bracket; and the unlocking block is fixed on the lifting workbench rack of the equipment. The spacing device has the advantages that the structure is simple; the conception is ingenious; the performance is stable; the investment cost is low; the welding workpieces can be positioned reliably during a delivering process; automatic control of spacing and releasing is realized; the workpiece delivering efficiency is improved; and the shape precision and the position precision of the workpieces during follow-up processing are guaranteed.

Owner:长城汽车股份有限公司平湖分公司

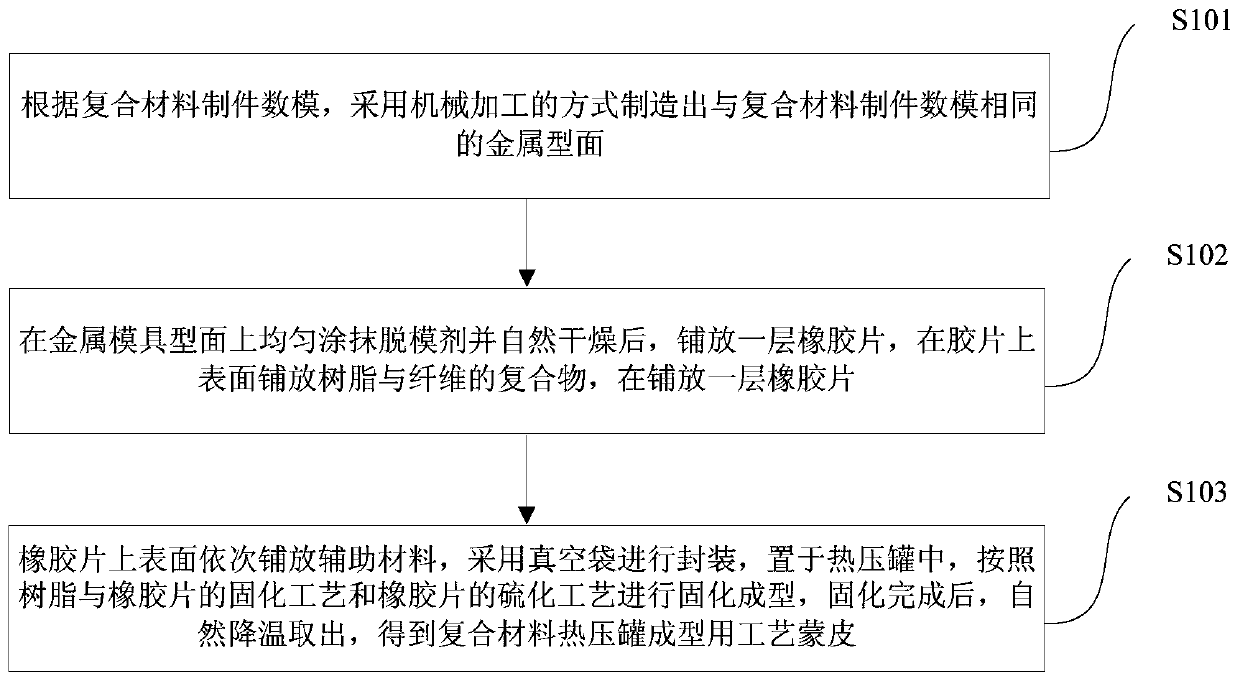

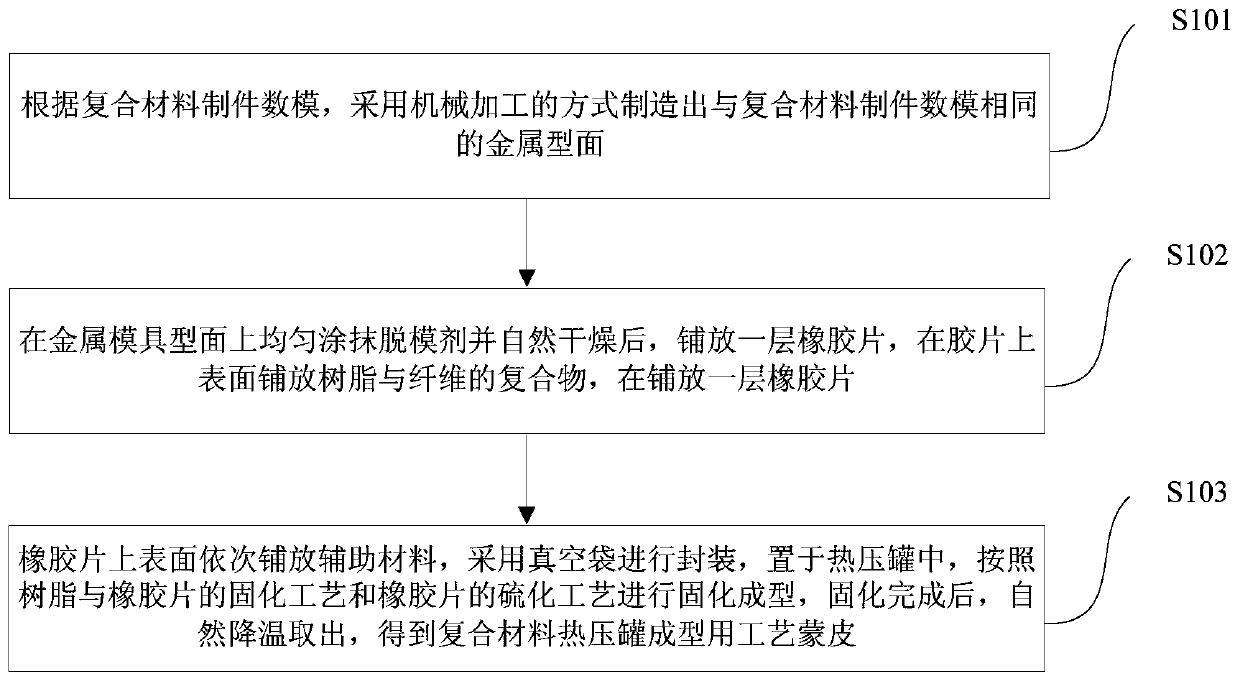

Process skin for autoclave forming of composite product and preparation method of process skin

The embodiment of the invention discloses a process skin for autoclave forming of a composite product and a preparation method of the process skin. In the autoclave forming process, the process skin is put on the upper surface of the composite product, an auxiliary material is put on the upper surface of the process skin, under the pressure applied by an autoclave, a prepreg preform is overall pressed downwards, the internal quality is improved, and wrinkles, caused by the weak deformation capacity of the auxiliary material, generated on the surface of the composite product are avoided. Meanwhile, a molded surface consistent with the upper surface of the composite product is arranged on the process skin, so that the appearance precision of the composite product is well guaranteed. The process skin can be widely applied to autoclave forming of composite products with complex shapes, and the appearance precision and the internal quality of the products are greatly improved.

Owner:AVIC BASIC TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com