Joint welding clamp of titanium alloy straight pipe and joint welding method

A seam welding and titanium alloy technology, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve the problems of long residence time, local collapse welding stress, material softening, etc., and avoid the increase of welding stress , Save shielding gas, eliminate the effect of welding oxidation hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is a seam welding jig and a seam welding method for a titanium alloy straight pipe.

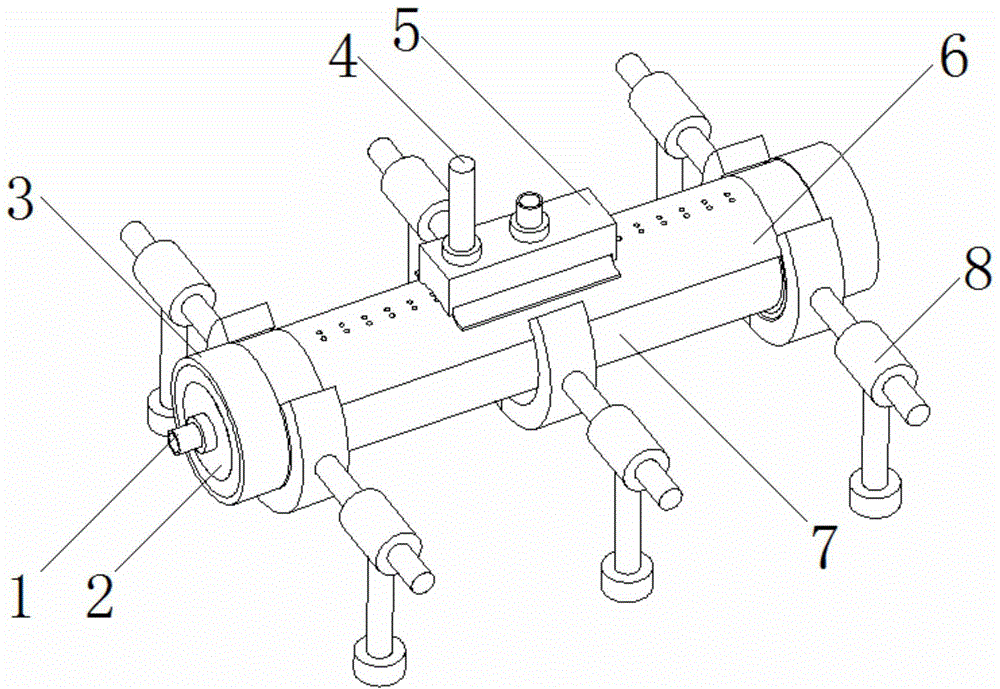

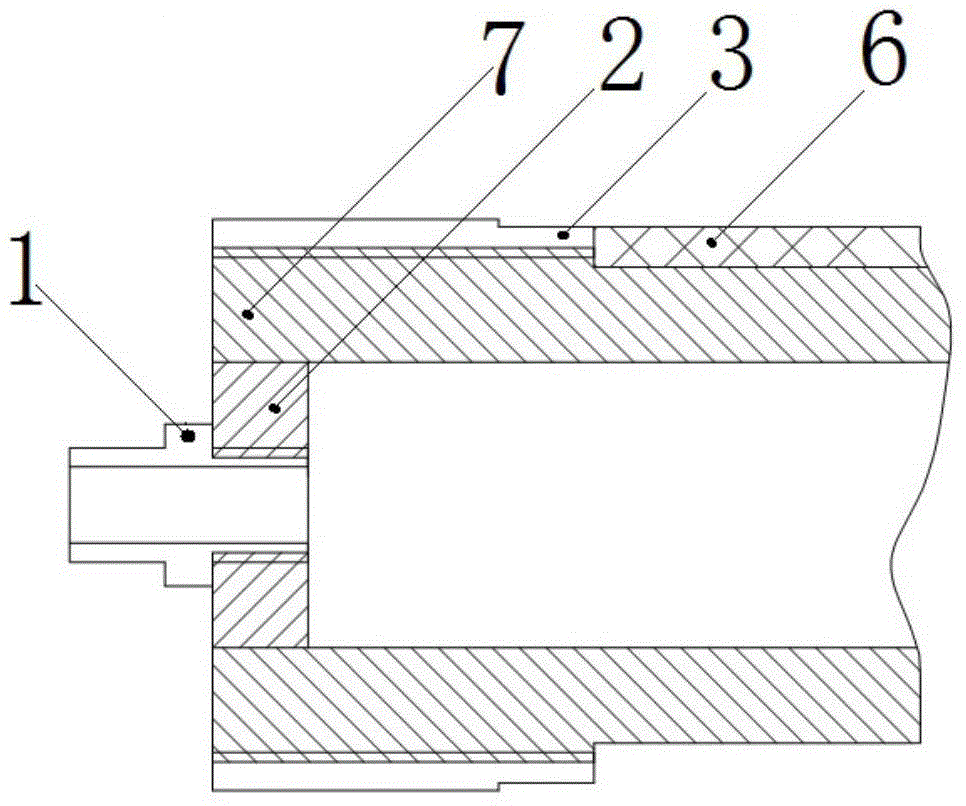

[0026] refer to Figure 1 to Figure 5, the seam welding fixture of the titanium alloy straight pipe of the present embodiment consists of a vent nozzle 1, a blocking plate 2, a copper sleeve 3, a welding torch 4, a protective cover 5, an arc-shaped copper block 6, a first vent pipe 7, and an arc-shaped clamp With 8 components. The first ventilation pipe 7 is a cylindrical structure with external threads at both ends. There are two rows of circular holes with the same diameter at equal intervals on the wall of the first ventilation pipe 7 along the axial direction. The blocking plate 2 is installed on the first ventilation pipe 7. At both ends inside, the outer diameter of the blocking plate 2 is the same as the inner diameter of the first ventilation pipe 7, the blocking plate 2 and the first ventilation pipe 7 are an interference fit, and the end faces are sealed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com