Plane prototyping photo-curing three-dimensional printing method capable of controlling workpiece strength

A three-dimensional printing and light curing technology, applied in the directions of additive manufacturing, manufacturing tools, manufacturing auxiliary devices, etc., can solve the problems of difficult to remove the support structure, damage the contact part, rough deformation of the surface of the parts, etc., to improve the surface quality, reduce damage, The effect of changing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

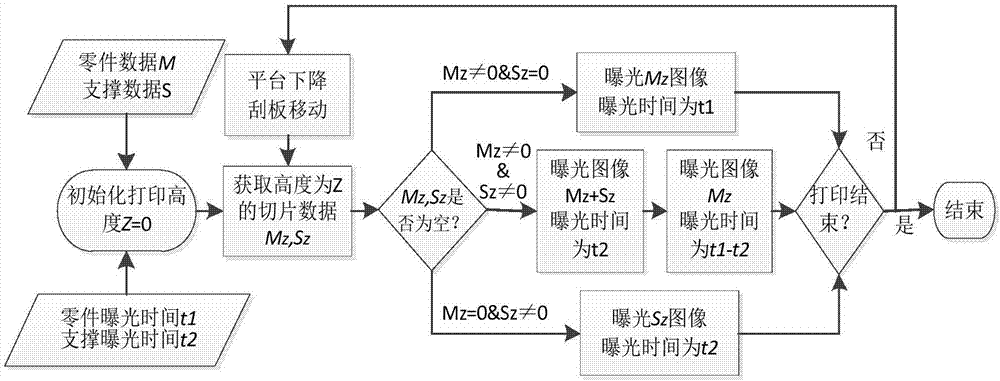

[0030] In this embodiment, a surface-molding light-curing three-dimensional printing method with controllable part strength, such as figure 1 As shown, perform the following steps:

[0031] 1) Initialization, using CAD modeling, 3D scanning or other existing digital model generation technologies to generate a digital model of the part, the digital model of the part includes the digital model of the part and the supporting digital model of the part;

[0032] Input the three-dimensional discrete data (such as STL file) of the part model and the support model respectively, and take the absolute coordinate Z=0 as the base, slice the part model according to the layer thickness h to generate a picture sequence M={M0,M1,M2,... }, part of the supporting model is sliced to generate a picture sequence S={S0, S1, S2,...}.

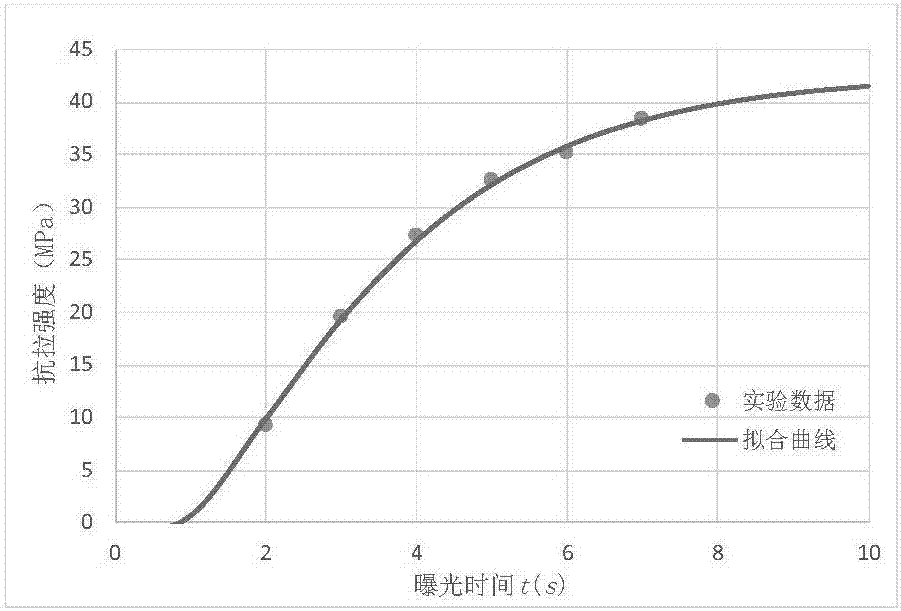

[0033] 2) Determine the exposure time t according to the relational equation;

[0034] The relationship equation is

[0035] It can be seen from the formula tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com