Automobile rear-view mirror three-dimension profiling edge grinding machine and method used for edging automobile rear-view mirror

An automotive rearview mirror and edger technology, which is applied to machine tools, grinders, and grinding/polishing equipment suitable for grinding workpiece edges, can solve the problems of high equipment manufacturing costs, use costs and maintenance costs, and achieve product The effect of improving quality and production efficiency, reducing labor intensity, and improving operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

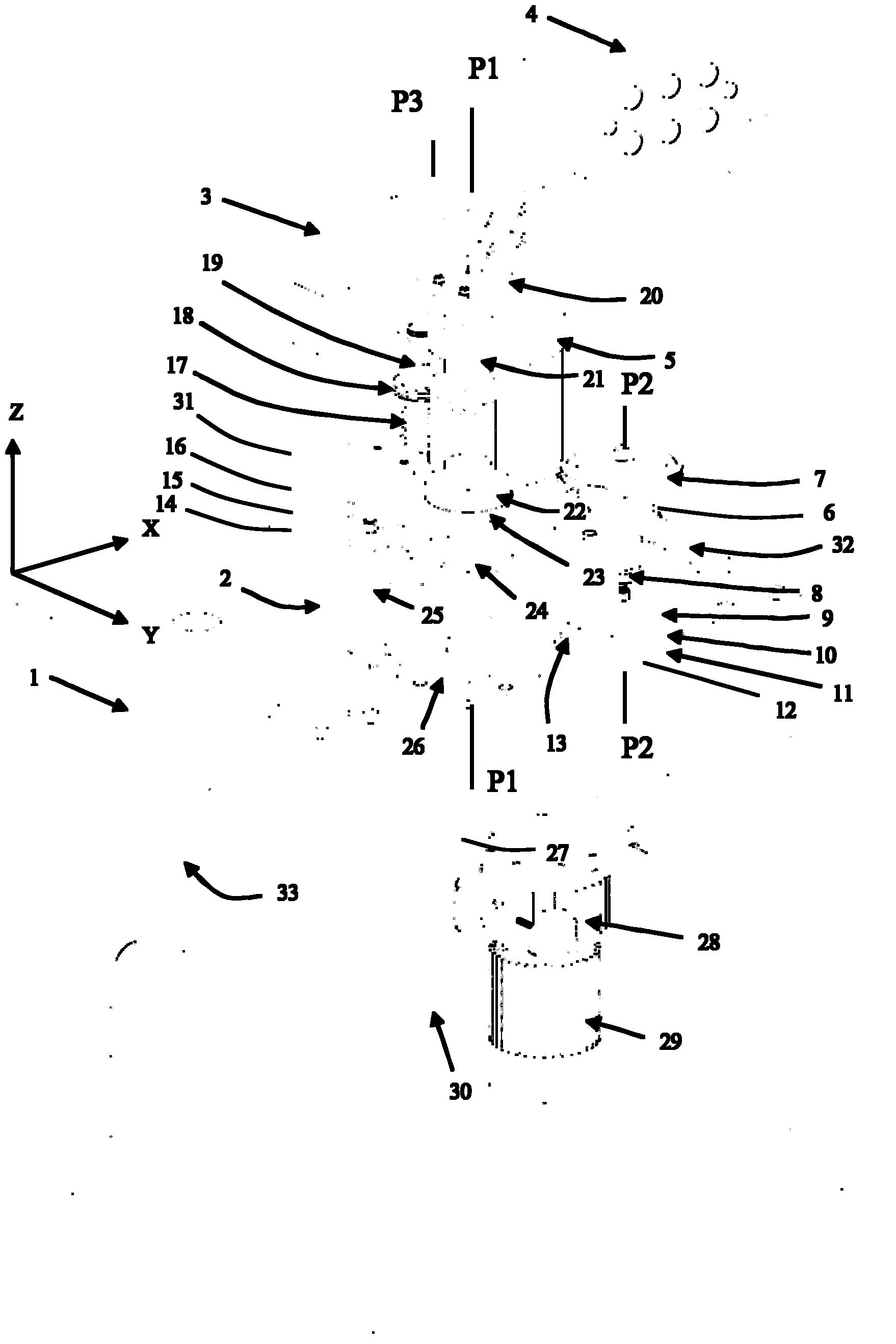

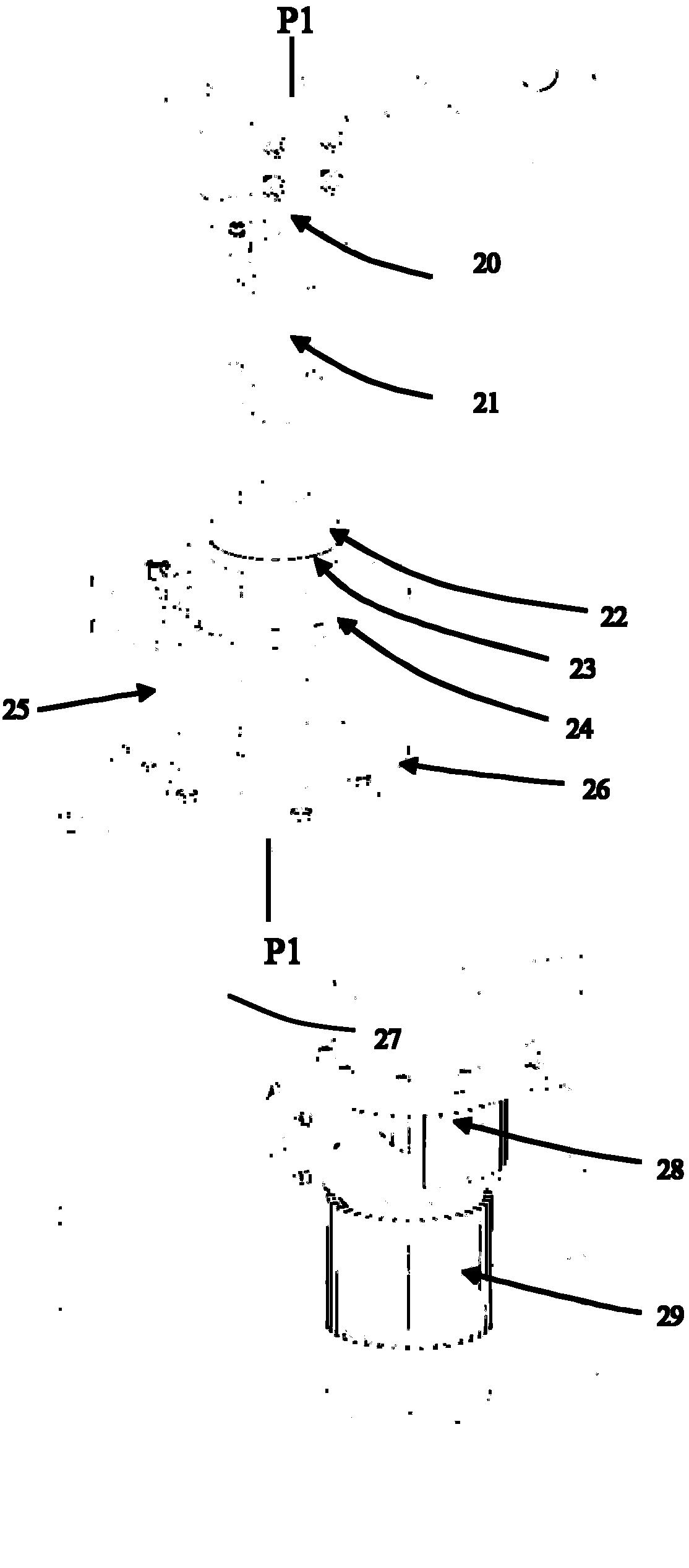

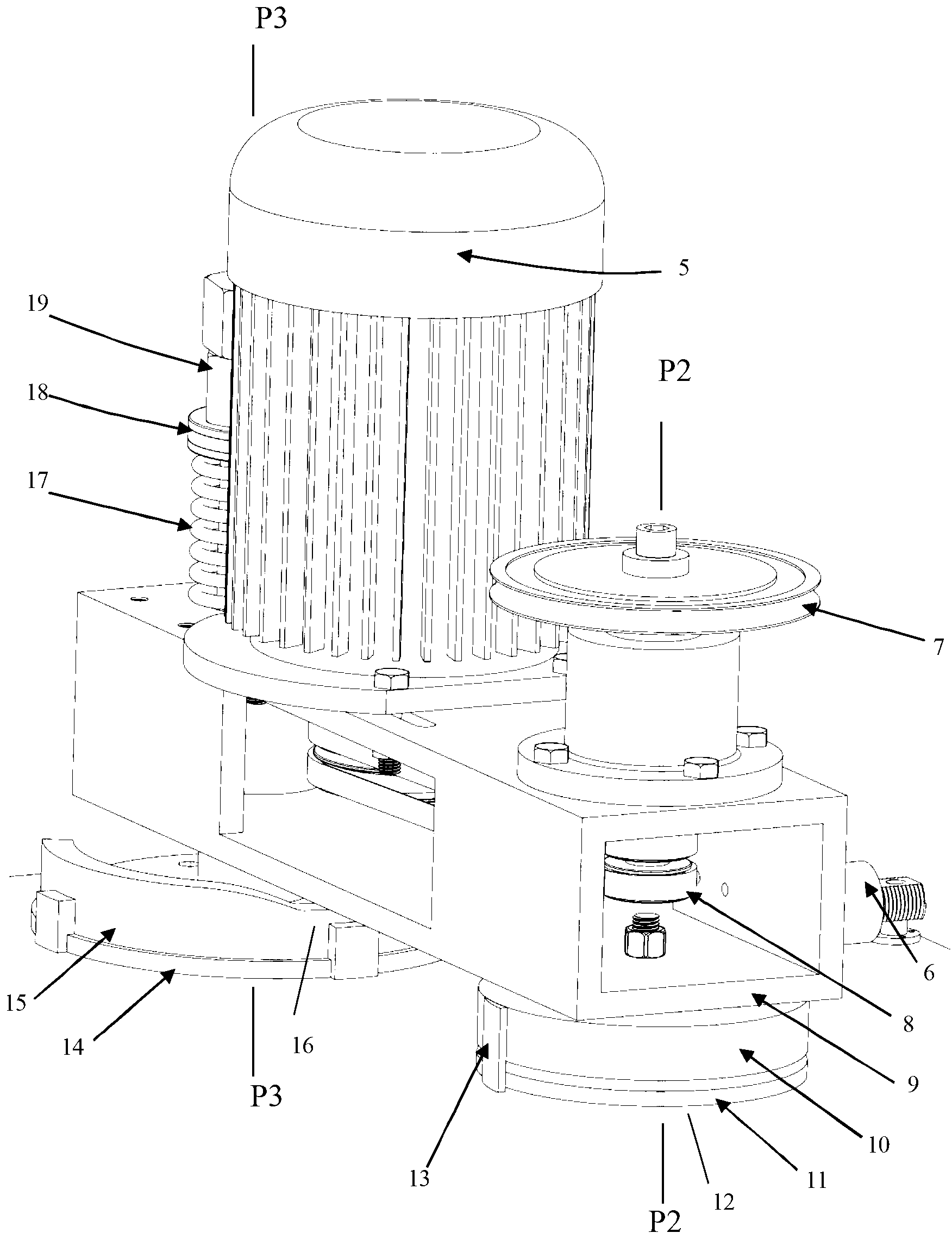

[0066] Example 1: A three-dimensional profiling and edging machine for automobile rearview mirrors

[0067] Such as Figure 1-1 to Figure 1-3 As shown, the three-dimensional profiling and edging machine for automobile rearview mirror includes a machine tool part, a pneumatic transmission control part, a fixed-axis rotating part, a rotating part and a cooling liquid adding part;

[0068] Among the above 5 components, the pneumatic transmission control part is a mature technology and need not be repeated. The coolant addition part is mainly to cool the workpiece during the grinding process, including the water pump 31 (not shown in the figure), the nozzle 32, and the sewage pipe 33- and the coolant water tray installed under the workbench are also mature technologies, which are not shown in the figure and will not be repeated here.

[0069] Combine below Figure 1-1 to Figure 1-3 The difference in structure between the three-dimensional profiling and edging machine for automobil...

Embodiment 2

[0081] Embodiment 2: A method for three-dimensional edging of automobile rearview mirrors.

[0082] The method adopts the three-dimensional profiling and edging machine for automobile rearview mirror described in Embodiment 1, and uses a cam-like mechanism composed of a similar cam 15, a fixed support 14 and a sliding part 16 to achieve simultaneous completion of the automobile rearview mirror at one time. The three-dimensional edging method, the cam-like 15 is an arc-shaped cylinder with different heights, the bottom of the arc-shaped cylinder is flat, and the top is the integral contour part I1501, the working part 1502, the transition part 1503 and the contour part II 1504, the contour part I 1501 and the contour part II 1504 are planes, the working part 1502 and the transition part 1503 are arc surfaces; Rotation center axis P3 coincides, and slide piece 16 is fixed on the bottom of swing arm 9, and quasi-cam 15 is fixed on machine tool bed 1 with the fixed center axis P3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com