Spacing device of equipment for delivering welding workpieces in circulating manner

A technology of circulating conveying and limiting device, which is applied to the limit of welding workpieces when conveying between different processes, and the field of workpiece limiting device, which can solve the problems of cumbersome control process, high investment cost, difficult maintenance, etc., so as to improve the transportation Efficiency, low input costs, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

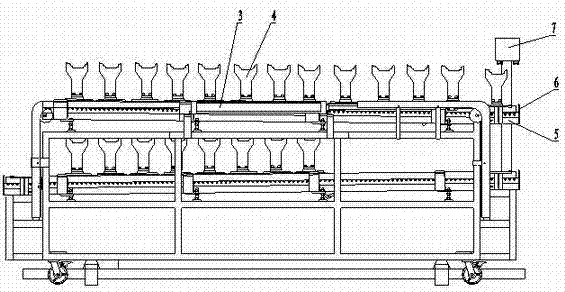

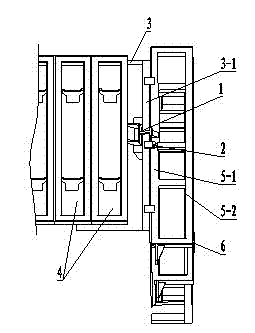

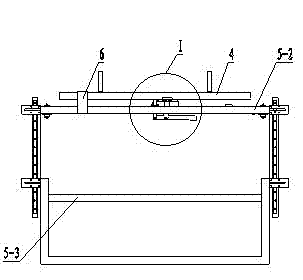

[0023] See Figure 2, image 3 , Figure 4 , Figure 5 , the present invention is installed on the welding workpiece circular transportation equipment provided with the sliding workbench 3 and the lifting workbench 5, which includes the sliding limit mechanism 1, the lifting limit mechanism 2 and the limit stopper 6, so The sliding limit mechanism 1 is composed of a limit assembly and an unlocking block 1-2. The limit assembly is hinged on the sliding workbench 3 of the circulation transport equipment. The limit assembly includes a T-shaped control block 1-1, Slip control block 1-3 and connection bracket 1-5, described T-shaped control block 1-1 is fixed on the front part of connection support 1-5, and described slip control block 1-3 comprises left and right symmetrical arrangement Two parts, they are installed on the rear of the connecting bracket 1-5, the connecting bracket 1-5 is hinged with the sliding workbench 3 of the circulating transport equipment through the hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com