Support arm for reflector of paraboloid trough condenser

A technology of a condenser and a mirror, which is applied to the field of a condenser mirror support arm, can solve the problems that the size and shape accuracy of the support arm cannot be satisfied, the weight of the support arm is reduced, and the investment in the mold is large, etc., and achieves high shape and dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

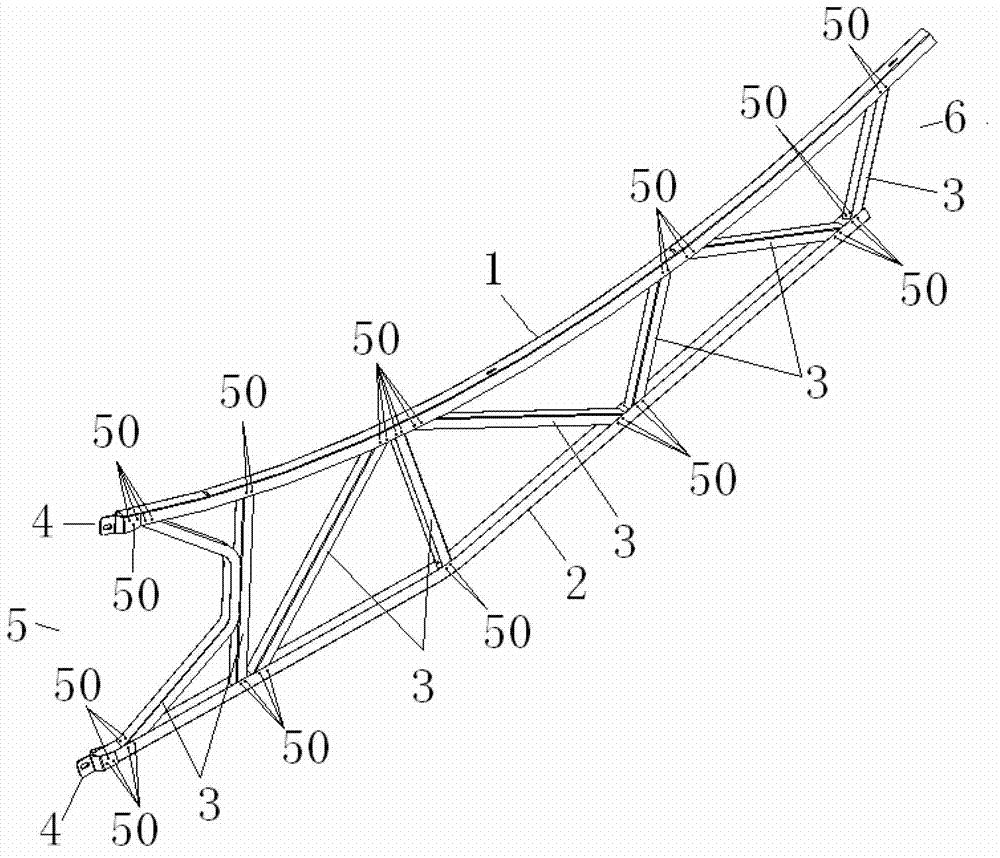

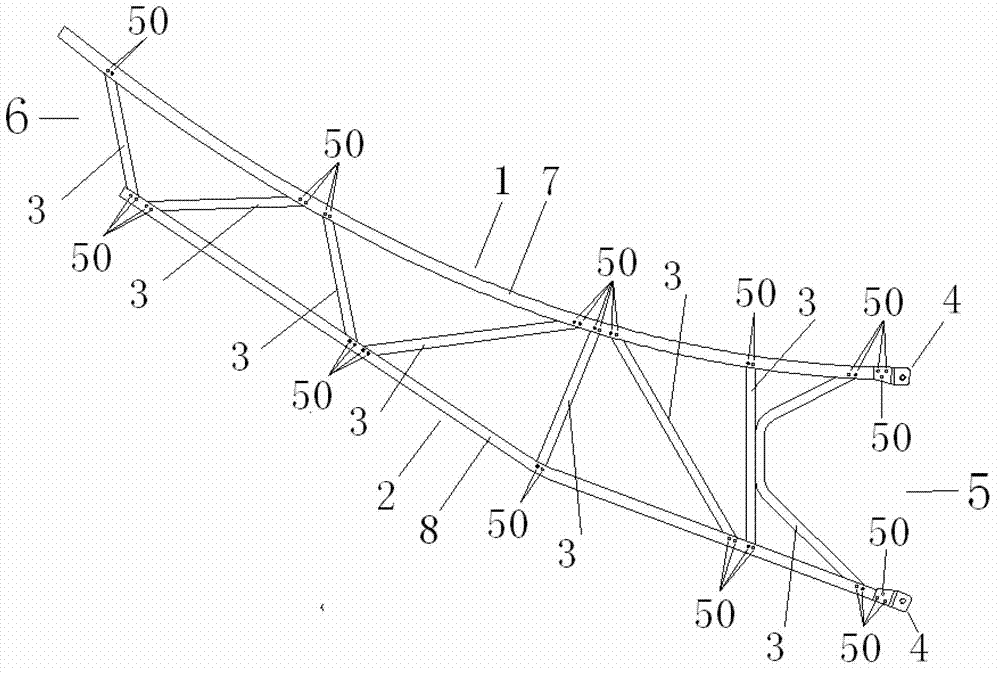

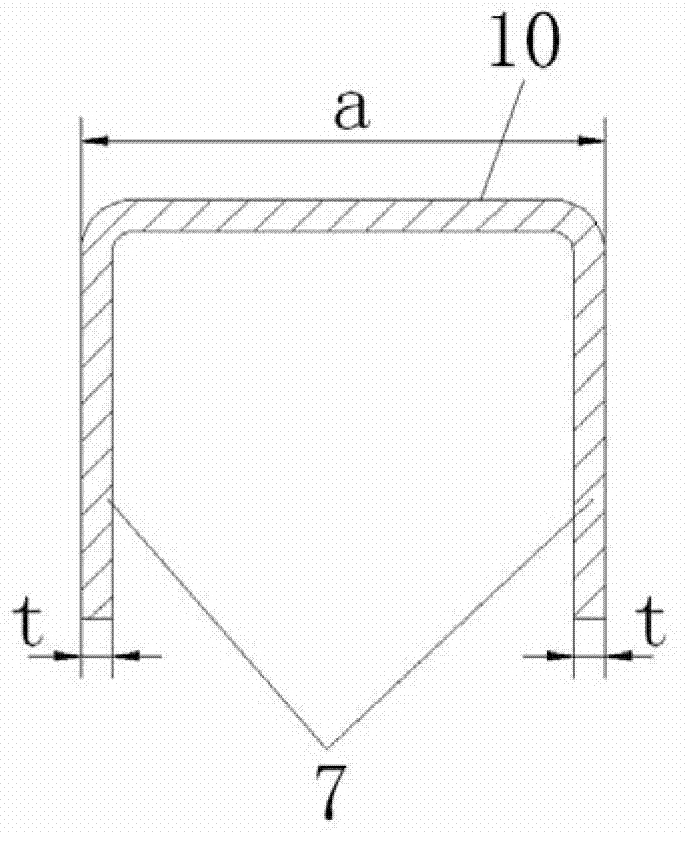

[0036] Such as figure 1 As shown, the reflector arm of the parabolic trough concentrator is composed of an upper chord 1 , a lower chord 2 , a web 3 and a connecting piece 4 . The upper chord 1, the lower chord 2, and the web 3 are metal thin-walled parts with a U-shaped cross-section processed from cold-rolled thin steel plates. The upper chord 1 is located at the top of the arm, and the section of the upper chord 1 is as follows: image 3 shown. The lower chord 2 is located at the bottom of the arm, and the section of the lower chord 2 is as follows: Figure 4 As shown, the cross-sectional size of the lower chord 2 is the same as that of the upper chord 1. The section of the web bar 3 is as Figure 5 As shown, the section width of the web 3 is c=a-2t=b-2t, so that the web 3 can be inserted into the U-shaped grooves of the upper chord 1 and the lower chord 2 . Eight webs 3 are located between the upper chord and the lower chord, and are arranged along the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com