Aluminum alloy brazing material, brazing member, brazed article and brazinh method therefor using said material, brazing heat exchanging tube, heat exchanger and manufacturing method thereof using sai

A technology of heat exchange tubes and brazing materials, applied in heat exchange equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of unsuitable thin tubes, prevent excessive corrosion, reduce corrosion depth, and resist corrosion. Good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

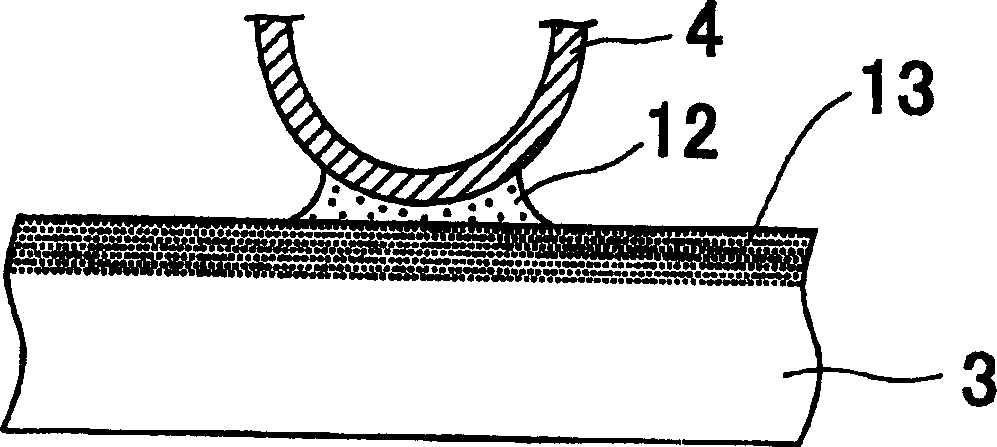

[0090] The aluminum alloy brazing material according to the present invention is used to manufacture various brazing parts or brazing products, so as to finally improve the corrosion resistance of the brazing products. Therefore, an aluminum alloy brazing material and a brazing product according to the present invention will be described below.

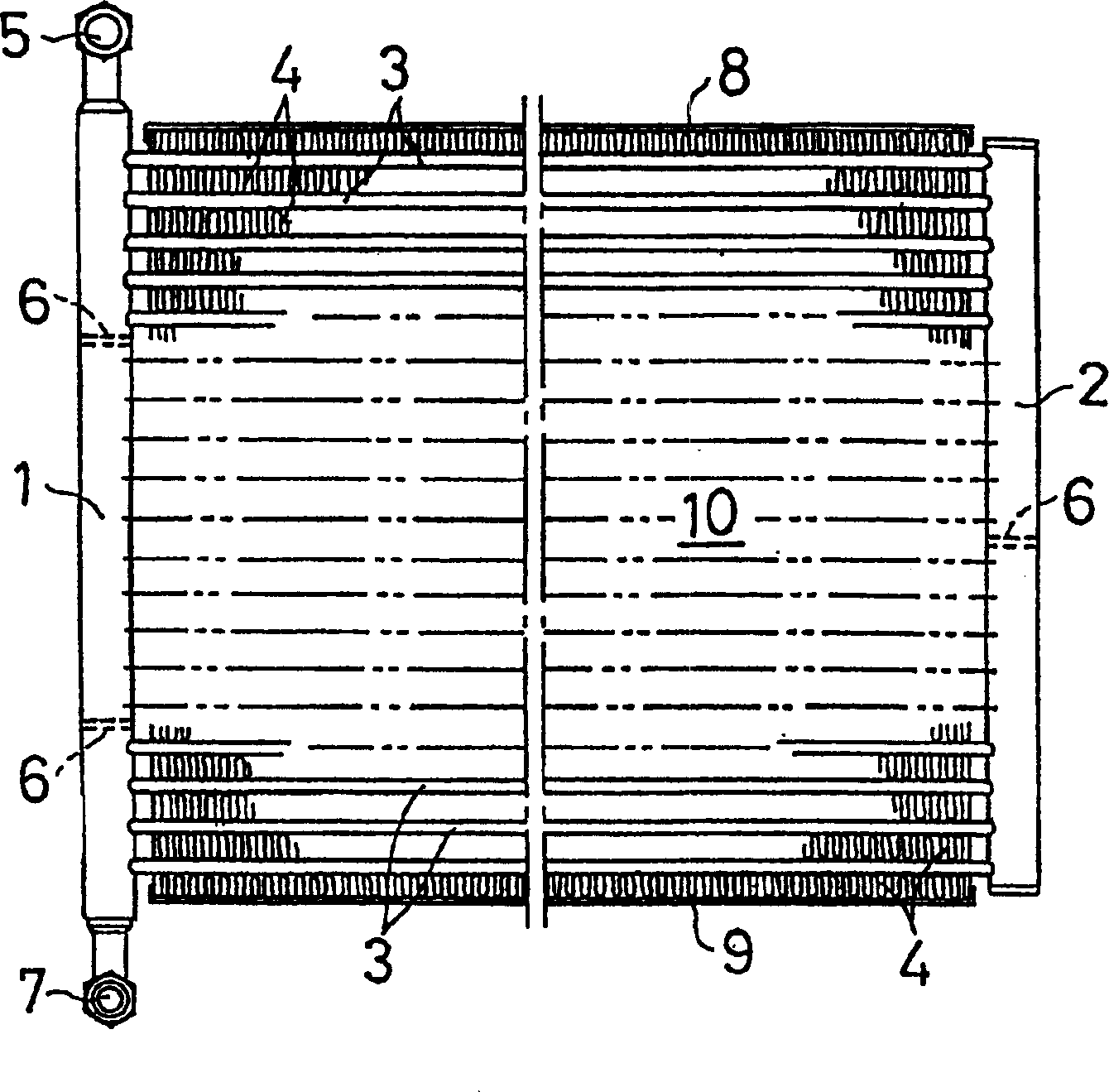

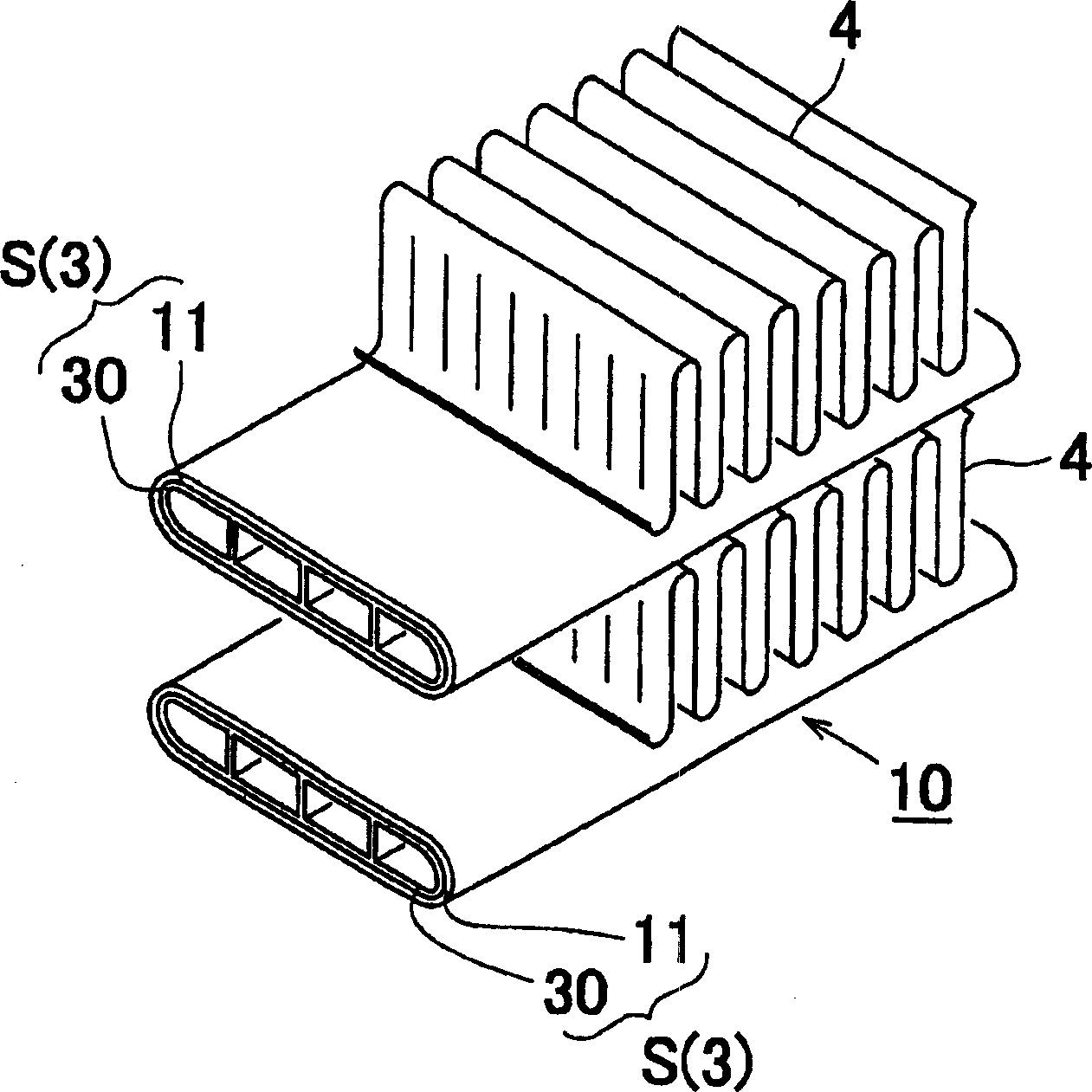

[0091] To be brazed with fins for use in aluminum or aluminum alloy heat exchangers such as condensers or evaporators in automobiles, domestic or commercial air-conditioning units, or heat exchange tubes for radiators can be used as the above-mentioned brazing parts example. In the following description, "brazing parts or brazed heat exchange tubes", "substrates or heat exchange tube base materials", and "brazed products or heat exchangers" will be abbreviated as "brazing parts, etc.", respectively, "Substrates, etc.", "Brazing products, etc." The following description is mainly for the case where the brazed part is a brazed heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com