Spray valve control system of spray tower

A control system, spray tower technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problem of unable to change the ratio of water pressure to air pressure, spray tower bottom corrosion, spray tower wall corrosion and other problems, to achieve the best atomization effect, avoid long-term electrification, and avoid excessive corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

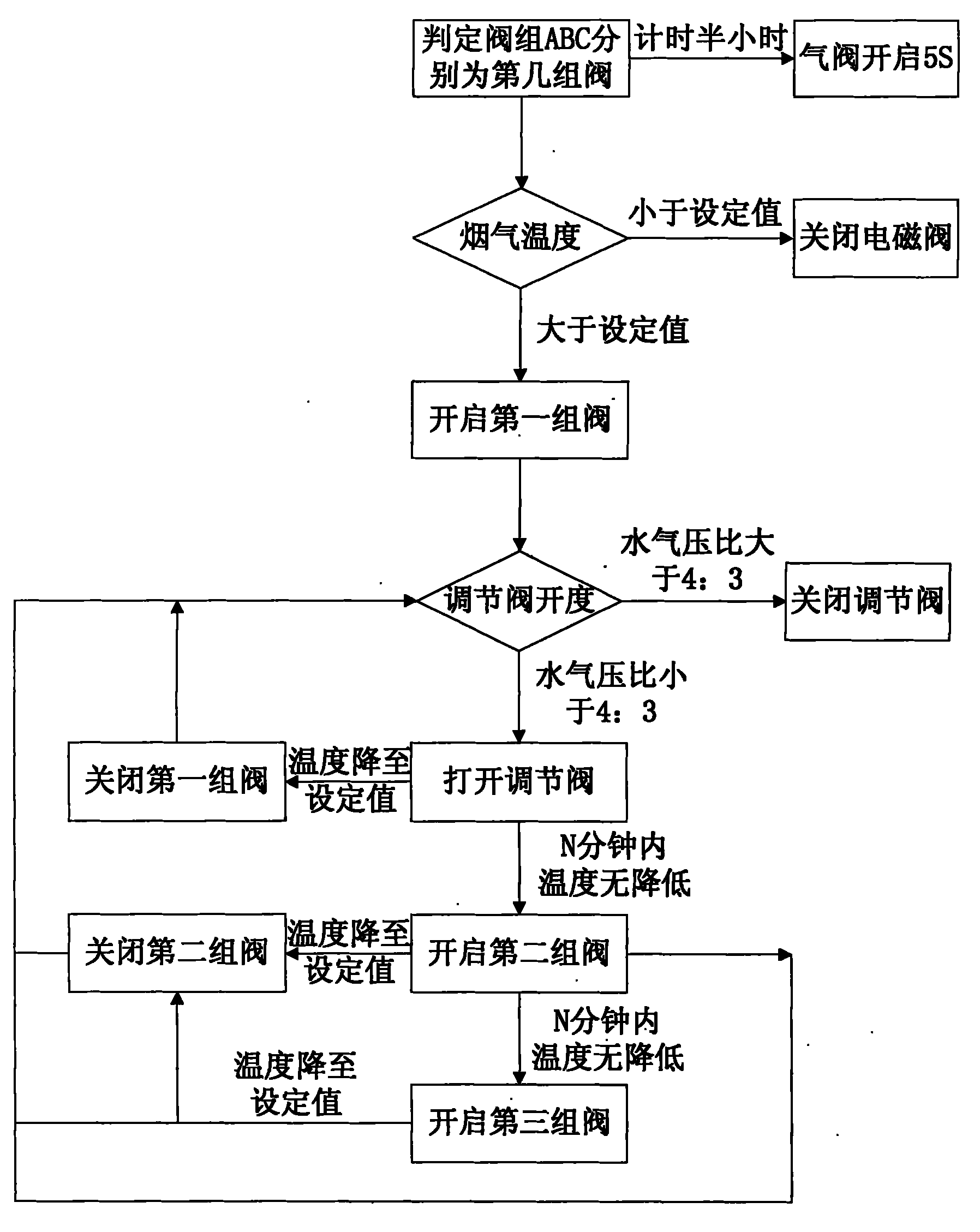

[0045] A spray valve control system for a spray tower, including a water spray solenoid valve, an air spray solenoid valve, a booster pump, a pressure gauge, a flow meter, an automatic regulating valve and a PLC controller, and the PLC controller controls two groups of solenoid valves 11 , 12 controls water spray and air spray, and a cycle control module is designed in the PLC controller to realize two sets of solenoid valves 11 and 12 to be controlled in sequence: when the spray tower starts to work, the solenoid valve 11 is the first group of solenoid valves, and the solenoid valve 12 It is the second group of solenoid valves; after four hours of the preset time, the PLC controller sends an adjustment command, the solenoid valve 12 is the first group of solenoid valves, and the solenoid valve 11 is the second group of solenoid valves; after eight hours of the preset time, Each group of solenoid valves returns to the original state, that is, the solenoid valve 11 is the first ...

Embodiment 2

[0049] A spray valve control system for a spray tower, including a water spray solenoid valve, an air spray solenoid valve, a booster pump, a pressure gauge, a flow meter, an automatic regulating valve and a PLC controller, and the PLC controller controls two groups of solenoid valves 11 , 12 controls water spray and air spray, and a cycle control module is designed in the PLC controller to realize two sets of solenoid valves 11 and 12 to be controlled in sequence: when the spray tower starts to work, the solenoid valve 11 is the first group of solenoid valves, and the solenoid valve 12 It is the second group of solenoid valves; after six hours of the preset time, the PLC controller sends an adjustment command, the solenoid valve 12 is the first group of solenoid valves, and the solenoid valve 11 is the second group of solenoid valves; after twelve hours of the preset time , each group of solenoid valves returns to the original state, that is, the solenoid valve 11 is the first...

Embodiment 3

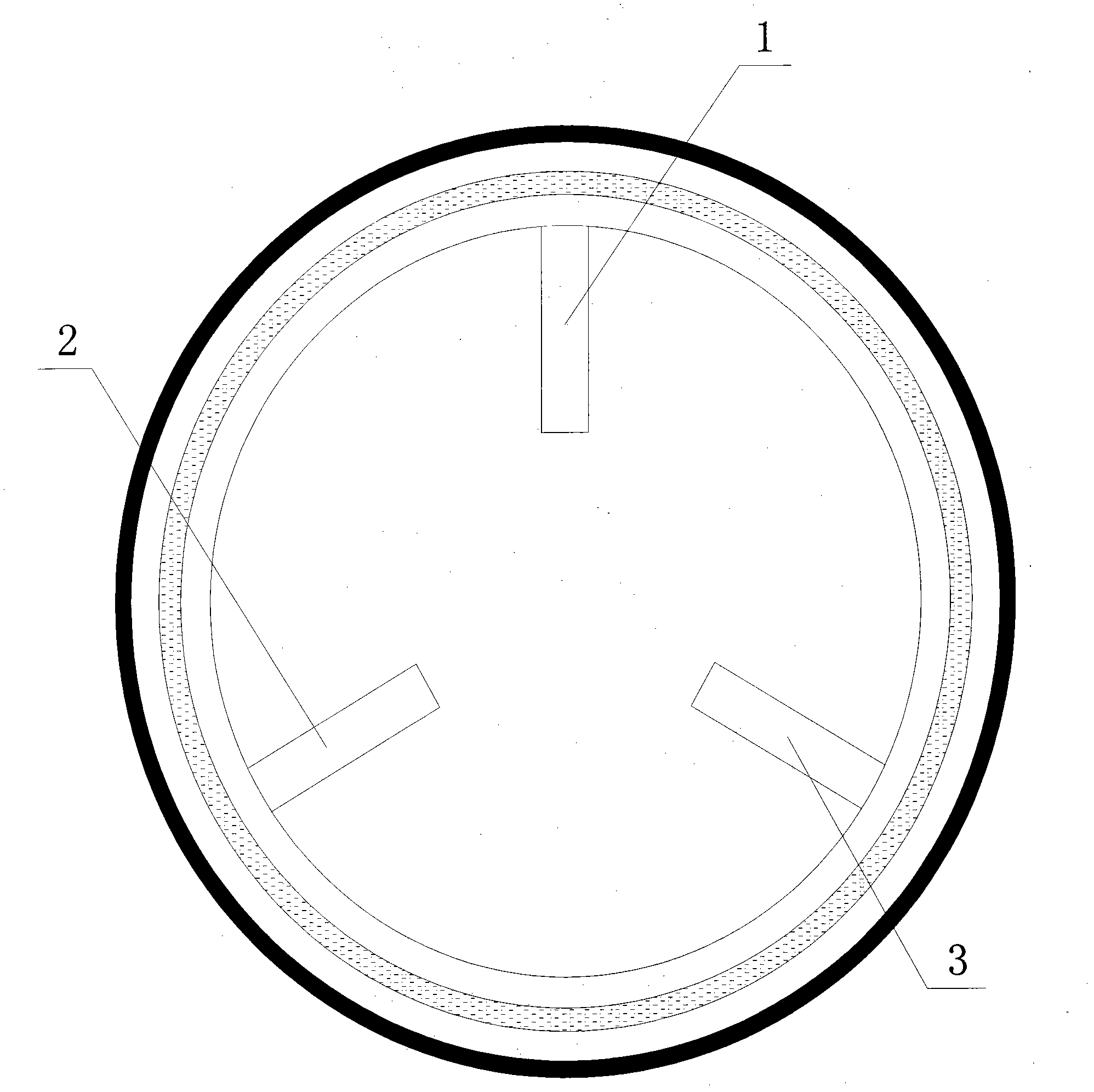

[0053] Such as figure 1 As shown, a spray valve control system of a spray tower, the spray tower includes three sets of solenoid valves 11, 12, 13 controlled by a PLC controller, and three sets of solenoid valves 11, 12, 13 control the water spray valve and air spray For the opening and closing of the valve, a cycle control module is designed in the PLC controller to realize the sequential control of three sets of solenoid valves 11, 12, and 13: when the spray tower starts to work, the solenoid valve 11 is the first set of solenoid valves, and the solenoid valve 12 is the second group of solenoid valves, and solenoid valve 13 is the third group of solenoid valves; after four hours, the PLC controller sends an adjustment command, solenoid valve 12 is the first group of solenoid valves, solenoid valve 13 is the second group of solenoid valves, and the solenoid valve 13 is the second group of solenoid valves. Valve 11 is the third group of solenoid valves; after eight hours, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com