Non-corrosive steel pickle acid catalyst and process for preparing the same

A technology for pickling liquid and catalyst, applied in the field of stainless steel pickling liquid catalyst and its preparation, can solve the problems of affecting the quality of stainless steel surface pickling, endangering the health of operators, equipment corrosion, etc., so as to avoid over-corrosion phenomenon and improve utilization rate, the effect of accelerated removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

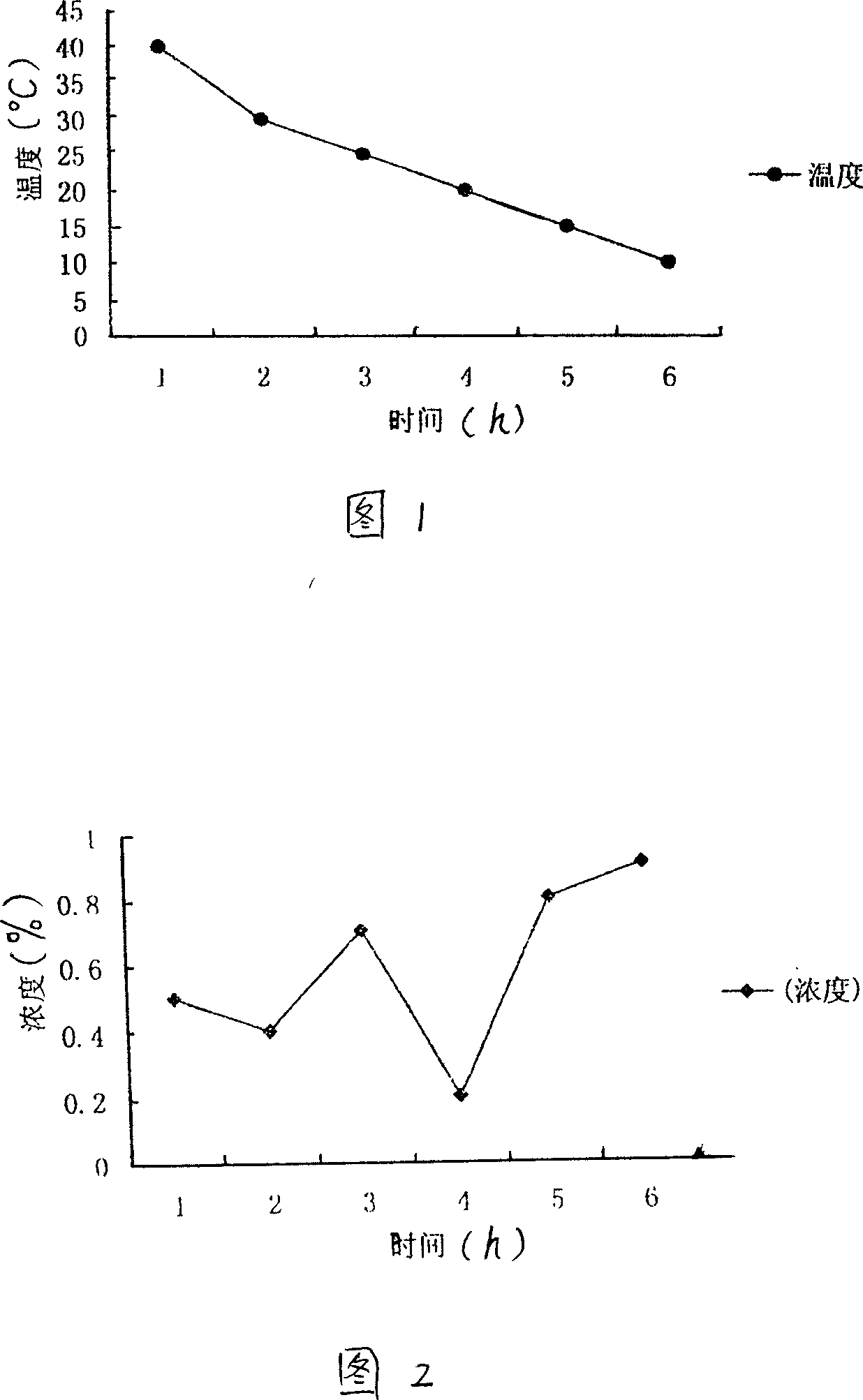

Image

Examples

Embodiment 1

[0012] The stainless steel pickling solution catalyst of the present invention is composed of the following raw materials (the following percentages are percentages by weight): 80‰ of fatty alcohol polyoxyethylene ether, 60‰ of alkyl alcohol amide phosphoric acid ester, 10‰ of sodium benzoate, and ethylenediaminetetraacetic acid Disodium 2‰, the rest is water.

[0013] After mixing the above raw materials, heat to 50°C and stir evenly.

Embodiment 2

[0015] The stainless steel pickling solution catalyst of the present invention is composed of the following raw materials (the following percentages are percentages by weight): 220‰ of fatty alcohol polyoxyethylene ether, 180‰ of alkyl alcohol amide phosphoric acid ester, 60‰ of sodium benzoate, and ethylenediaminetetraacetic acid Disodium 30‰, the rest is water.

[0016] After mixing the above raw materials, heat to 65°C and stir evenly.

Embodiment 3

[0018] The stainless steel pickling solution catalyst of the present invention is composed of the following raw materials (the following percentages are percentages by weight): 180‰ of fatty alcohol polyoxyethylene ether, 120‰ of alkyl alcohol amide phosphoric acid ester, 40‰ of sodium benzoate, and ethylenediaminetetraacetic acid Disodium 15‰, the rest is water.

[0019] After mixing the above raw materials, heat to 80°C and stir evenly.

[0020] The above-mentioned fatty alcohol polyoxyethylene ether can be replaced by alkylphenol polyoxyethylene ether, such as nonylphenol polyoxyethylene ether.

[0021] The chemical formula of fatty alcohol polyoxyethylene ether is:

[0022] R-O-(CH 2 CH 2 O) 7 h

[0023] Fatty alcohol polyoxyethylene ether can be a common surfactant, such as lauryl alcohol polyoxyethylene ether and tridecyl alcohol polyoxyethylene ether.

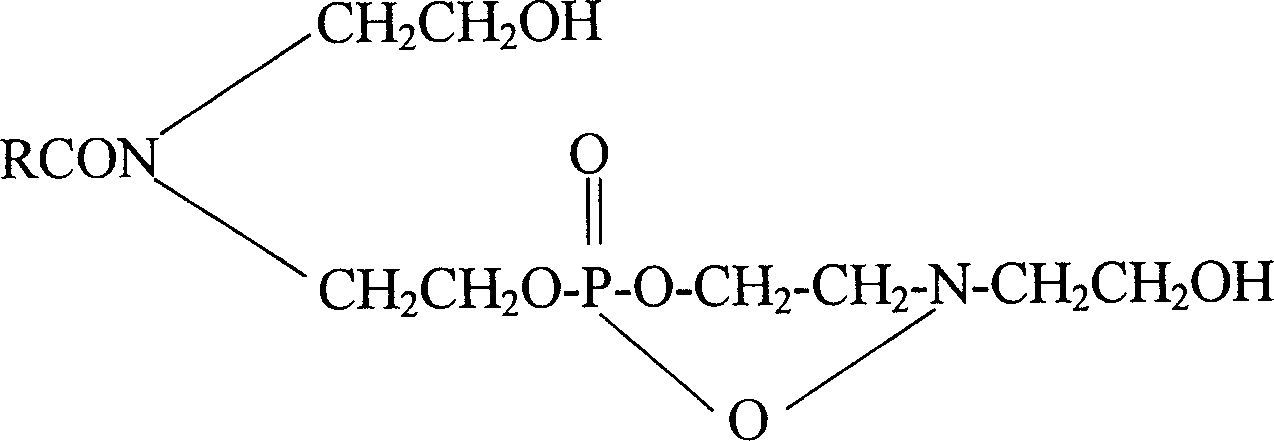

[0024] The structural formula of alkylolamide phosphate is:

[0025]

[0026] The above-mentioned alkylolami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com