Patents

Literature

331 results about "Pre washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-spinning cashmere and its processing method

A semi fine spinning cashmere process, which is blended from cashmere and other fibers, wherein the cashmere is 5-95 %, the other fibers are 95-5 %, and the yarn counter is 28Nm-120Nm. Said process pre-washing cashmere in water at normal temperature, respectively dyeing washed cashmere and other blended fibers, yarn mixing preserving the dyed cashmere, making yarn mixing by yarn mixer, carding by carding machine, first drawing and second drawing, spinning into rove and spun yarn, coning and twisting then to obtain products. Said invention solves fuzzing and pilling.

Owner:山东恒泰纺织有限公司

Method for removing various pollutants in fume by combining discharge plasmas and absorption

ActiveCN101716451ACombined removalLow investment costDispersed particle separationAir quality improvementElectricityMulti pollutant

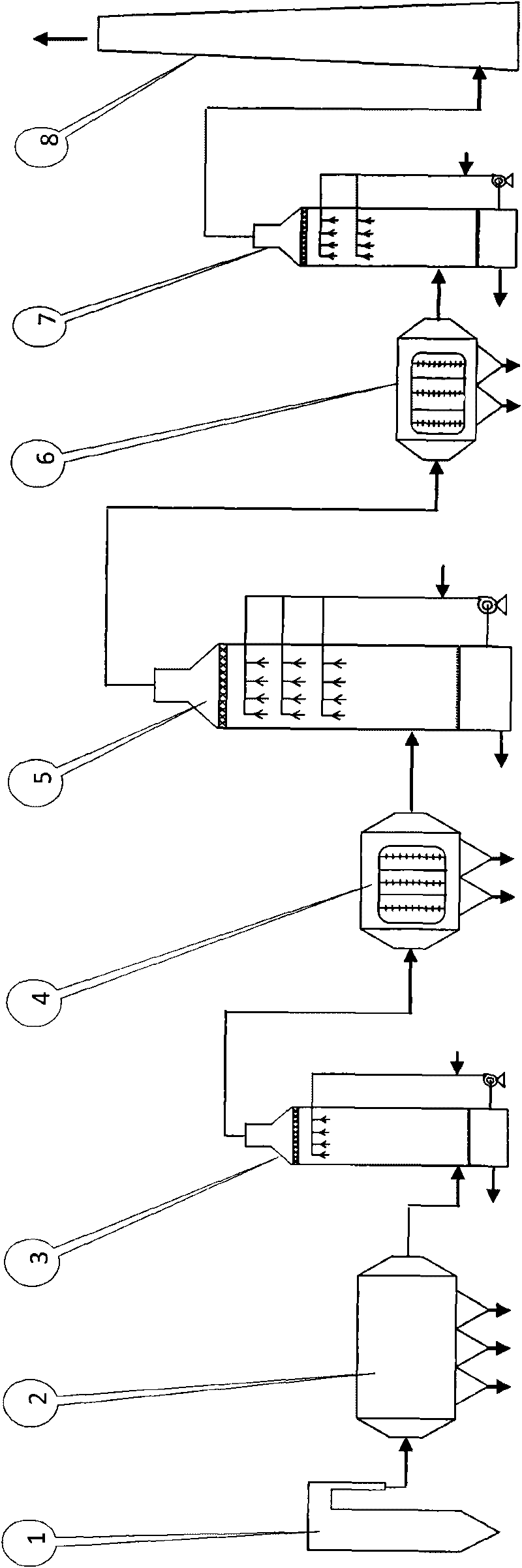

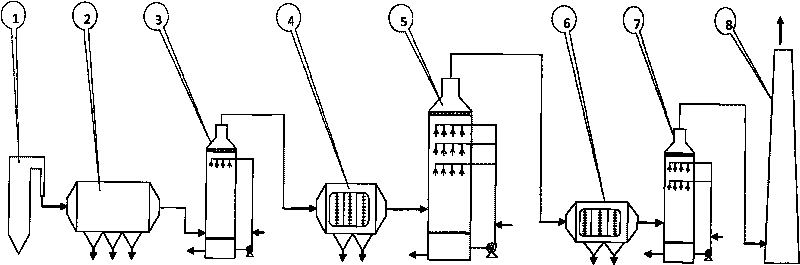

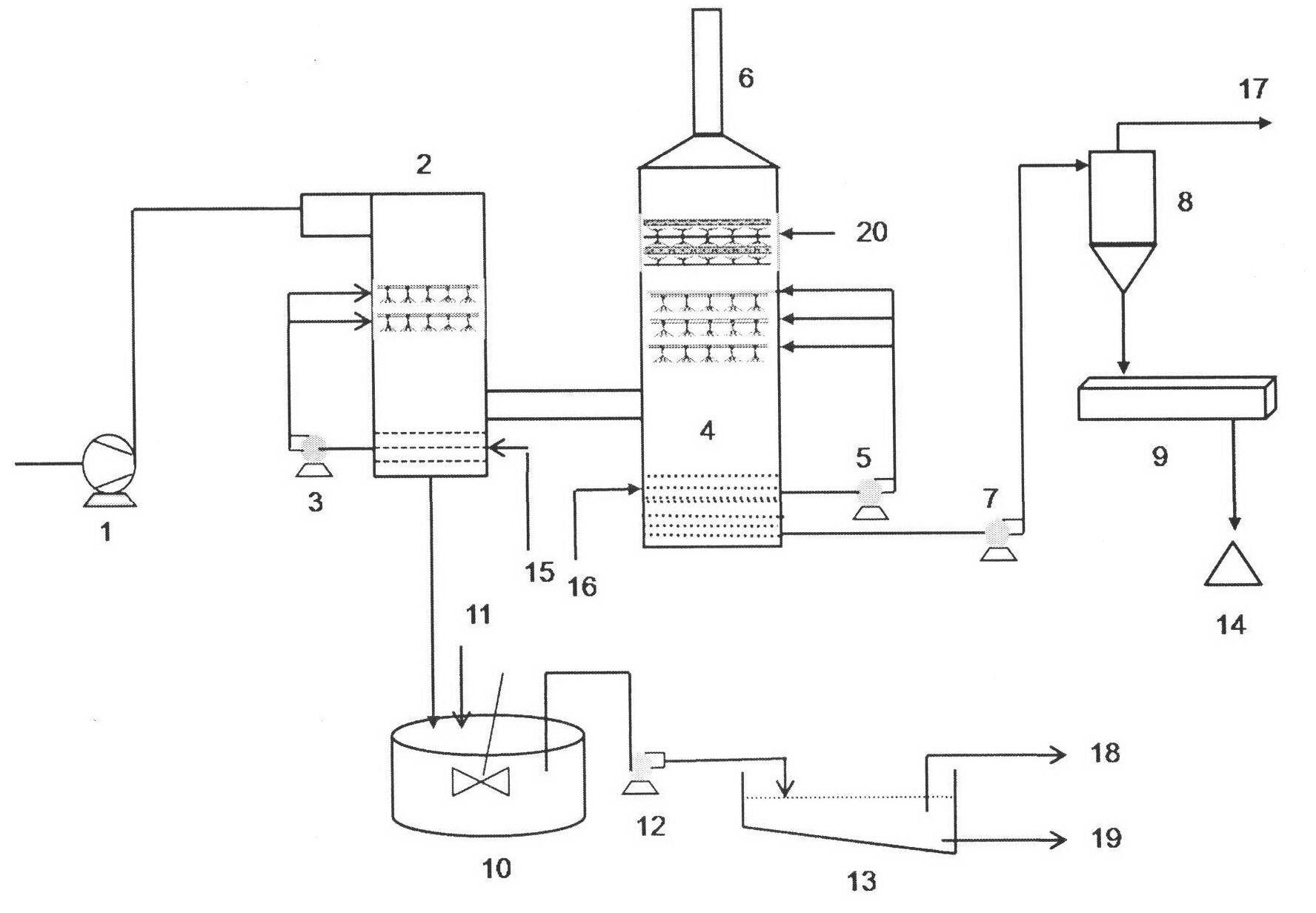

The invention discloses a method for removing various pollutants in fume by combining discharge plasmas and absorption. The method comprises the following steps: electrically dedusting or dedusting fire coal or burning fume by a cloth bag; and sequentially pumping the fume through a pre-washing tower, a primary discharge plasma reactor, a primary absorption tower, a secondary discharge plasma reactor and a secondary absorption tower, wherein the pre-washing tower is used for pre-cleaning the fume, lowering the temperature and condensing the absorption liquid; the primary discharge plasma reactor is used for oxidizing NO, charging thin particulate matter, trapping and removing; the primary absorption tower is used for washing and removing SO2, NOx and charged thin particulate matter; the secondary discharge plasma reactor is used for oxidizing an element Hg, charging acid mist and ammonium mist, trapping and removing; and the secondary absorption tower is used for washing and removing oxidized Hg and other pollutants. By the treatment, the removal rates of the SO2, the NOx, the Hg and the thin particulate matter respectively reach above 95%, 75%, 75% and 80%; and the leakage amountof ammonia is below 5mg / m<3>.

Owner:BEIHANG UNIV

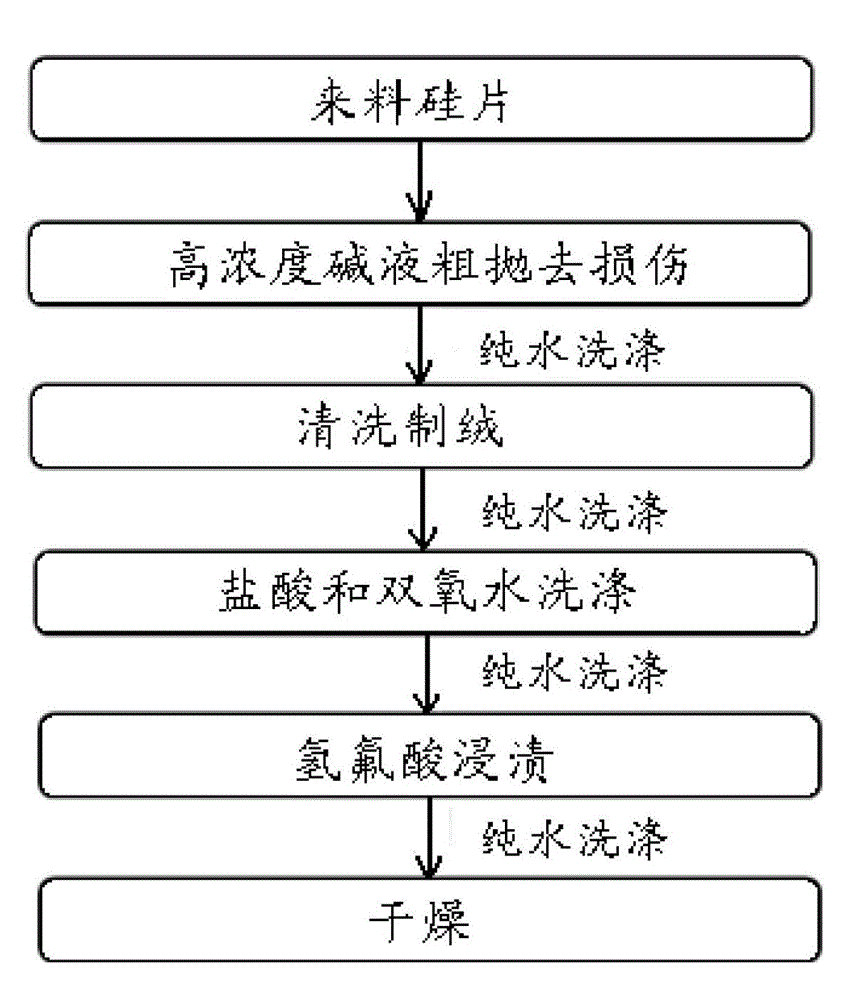

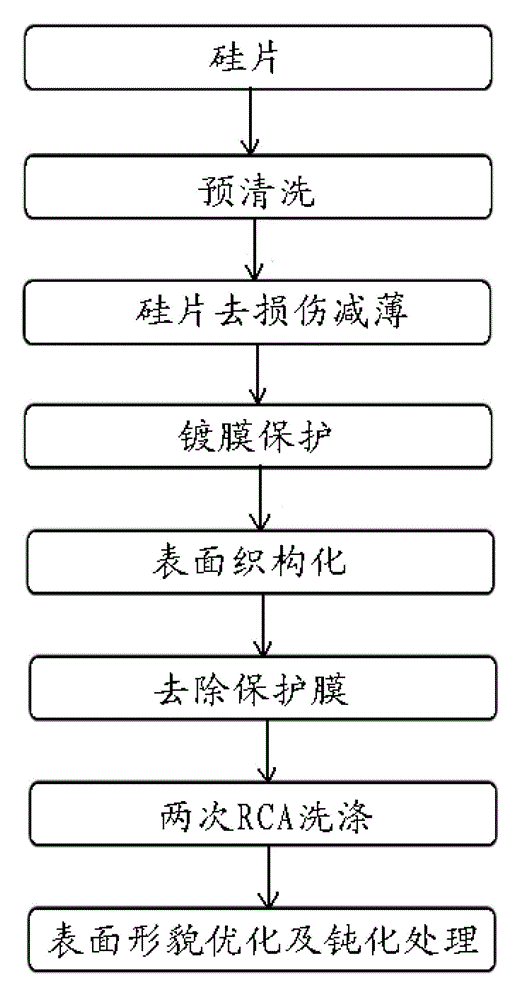

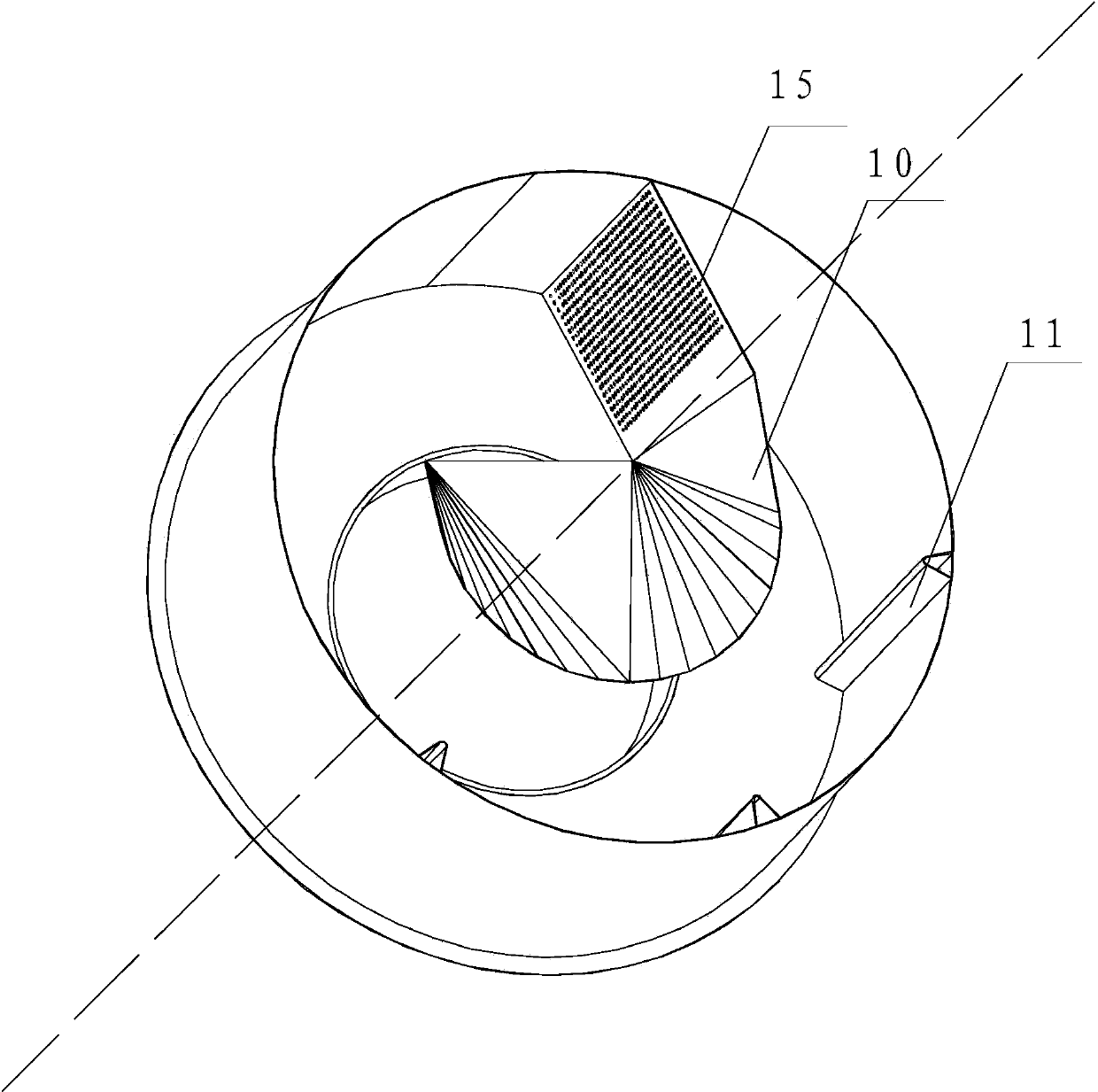

Wet surface processing technique used for manufacturing high efficiency crystalline silicon solar cells

ActiveCN102751377AMeet the requirements of one-side cleaning and making woolImprove the quality of surface chemical passivationAfter-treatment detailsFinal product manufactureTectorial membraneProcess quality

The invention relates to a wet surface processing technique used for manufacturing high efficiency crystalline silicon solar cells. The surface wet processing technique comprises the following steps of (1) pre-washing a silicon chip; (2) removing damage and thinning the silicon chip, wherein the upper and lower surfaces of the silicon chip are in a polishing shape; (3) coating protection: depositing a protective film on a single surface of the silicon chip; (4) surface structuralizing: obtaining a pyramid suede structure with a depth of 4-10 microns for the surface of the silicon chip which has no protective film, and meanwhile keeping a plane state for the surface of the other side of the silicon chip which has the protective film; (5) removing the protective film; (6) performing RCA washing, and (7) enhancing and optimizing for the surface appearance and forming a wet passivated surface. With the adoption of the wet surface processing method provided by the invention, the requirement on single-sided cleaning and texturing of the substrate of the thin silicon chip in the manufacturing process of high efficiency solar cells can be simply satisfied; the cleaning process quality and the battery efficiency and yield can be effectively improved; and moreover, no additional relevant cleaning equipment is required, and thus, the process cost is saved.

Owner:TRINASOLAR CO LTD

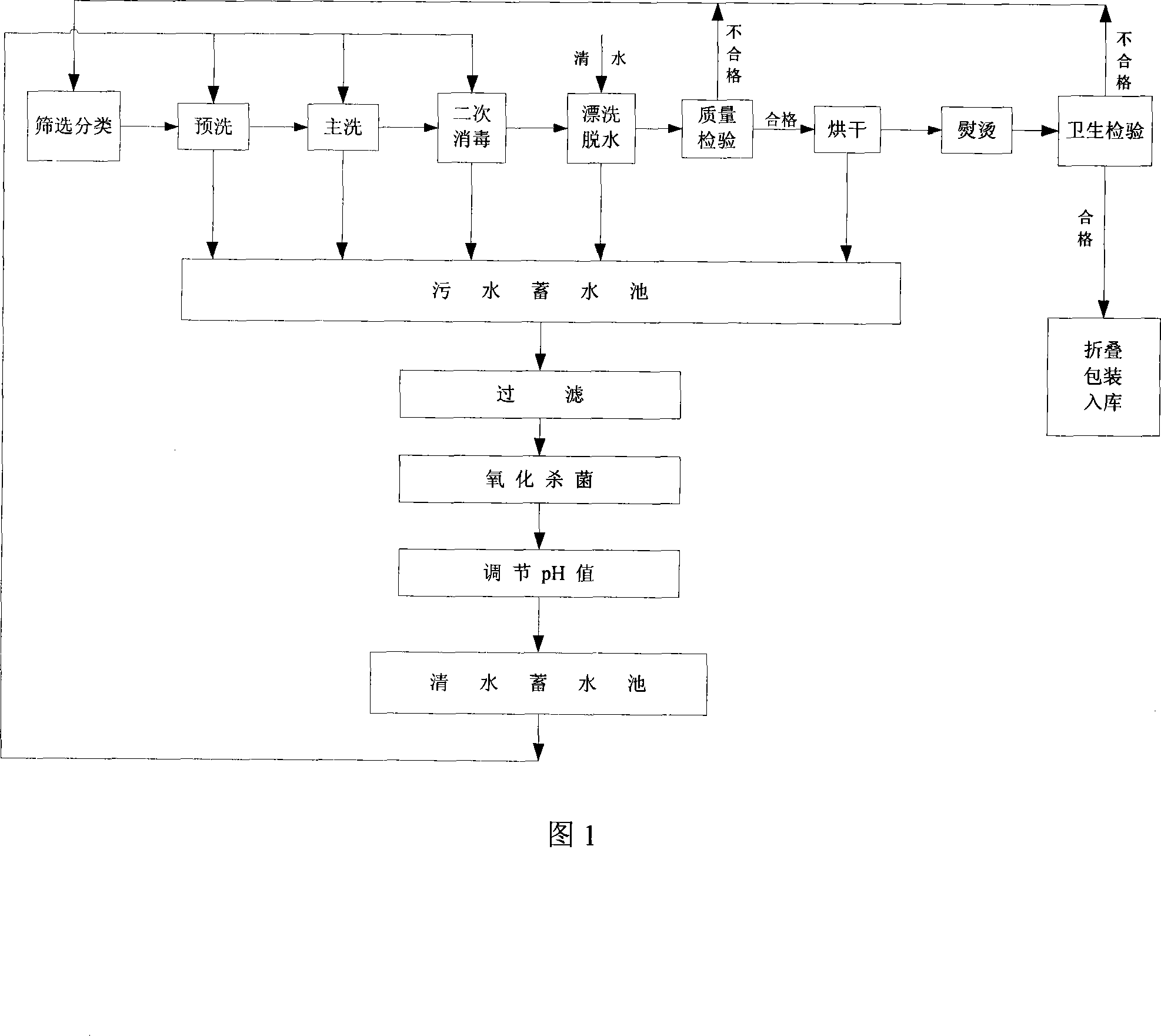

Cloth grass washing process

InactiveCN101086110AReduce pollutionSave waterOther washing machinesWashing machine with receptaclesWater resourcesSewage

The invention discloses a cloth straw washing process, it includes screening and sorting, pre-washing, washing, second sterilizing, rinsing and dewatering, quality testing, drying, ironing, sanitary testing, folding and packaging , storing, sewage processing and washing. The invention circulates and uses the sewage after the washing sewage is purified and processed through advanced technology flow process, it saves water resources as much as possible, reduces the environmental pollution from washing sewage; at the same time, it can monitor and control the quality and sanitary index of washing materials in the washing technology, ensure the washed cloth straw in the technology flow process meet various testing index all over state.

Owner:BEIJING NIUSHIDAN WHITE WASHING TECH

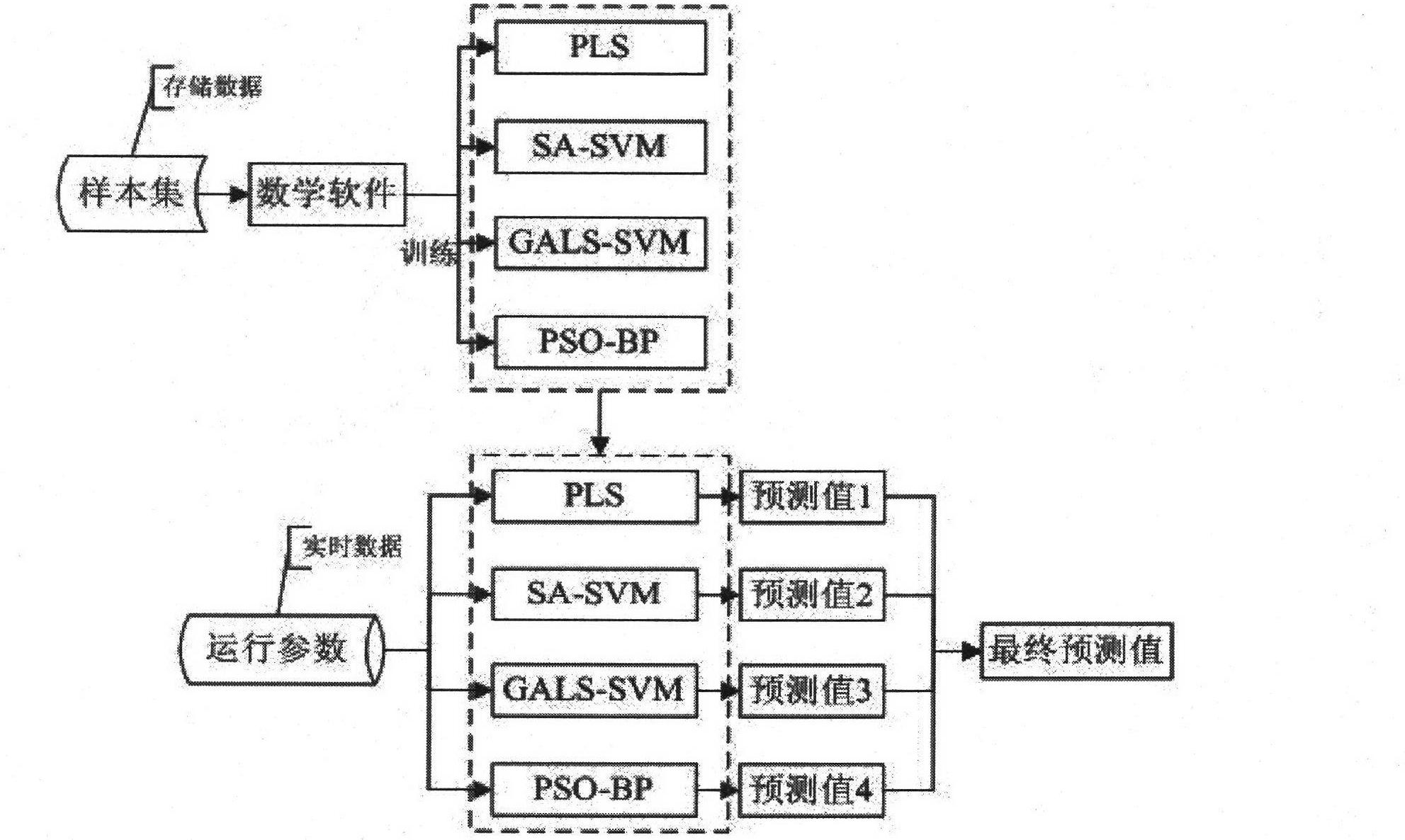

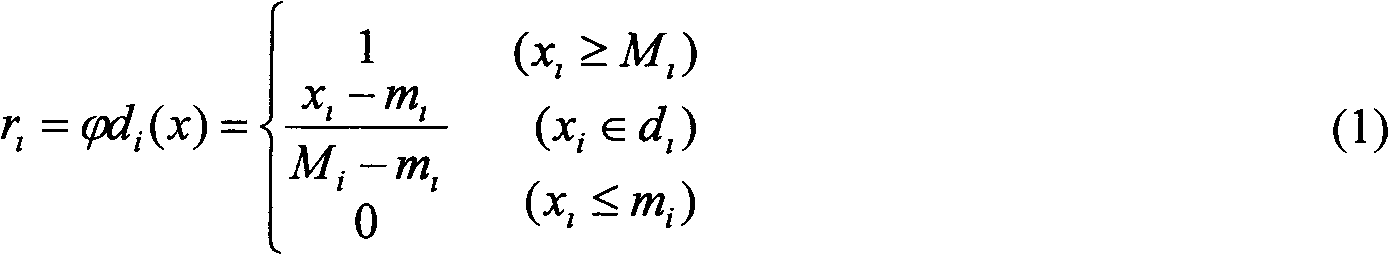

Method for predicting ammonia process flue gas desulphurization efficiency based on multiple parameters

InactiveCN102693451AReal-time monitoring of desulfurization efficiencyThe method is scientific and reasonableDispersed particle separationBiological neural network modelsPredictive methodsSlurry

The invention relates to a method for predicting ammonia process flue gas desulphurization efficiency based on multiple parameters. The method is characterized by comprising the following steps of: selecting four different artificial intelligent computation models and taking parameters acquired in an ammonia process desulphurization system operational process such as multiple groups of flue gas amounts, flow of a circulating pump, the flow of a concentration pump, the ammonia concentration, the concentration of absorption liquid, the liquid-gas ratio, the inlet flue gas temperature, the ammonia consumption, the density of spraying slurry, the pH value of slurry of a spraying tower and the pH value of the slurry of a pre-washing tower as input variables of the four models; respectively training each model, and establishing a non-linear function relationship between four desulphurization parameters and the desulphurization efficiency; then respectively transmitting parameters monitored in real time into the trained artificial intelligent model, and predicting the desulphurization efficiency; and taking the average value of two predicted values in the middle as a final predicted value... The method disclosed by the invention can be used for better predicting the ammonia process desulphurization efficiency and has the characteristics of higher stability and stronger prediction capability compared with single model prediction.

Owner:NORTHEAST DIANLI UNIVERSITY

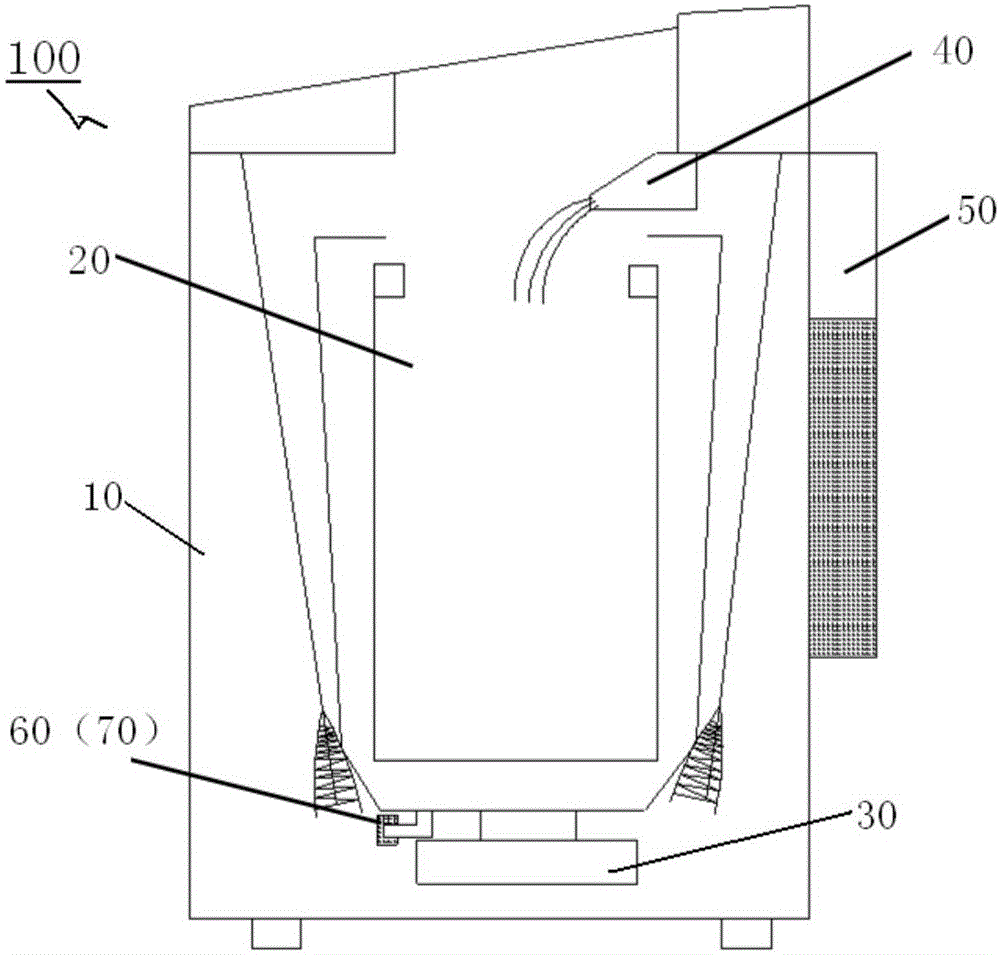

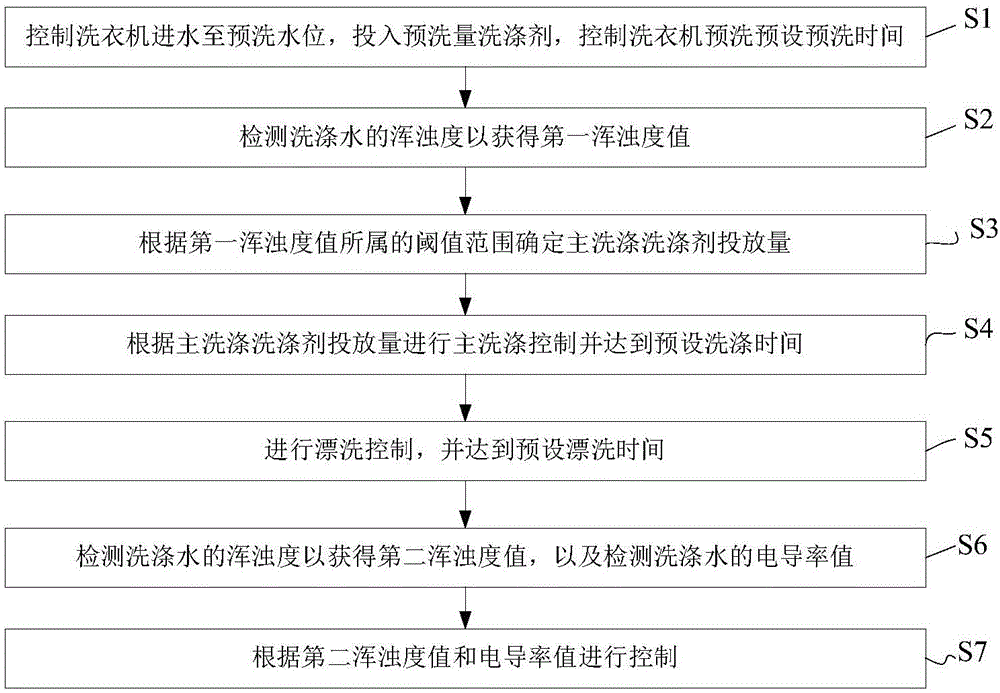

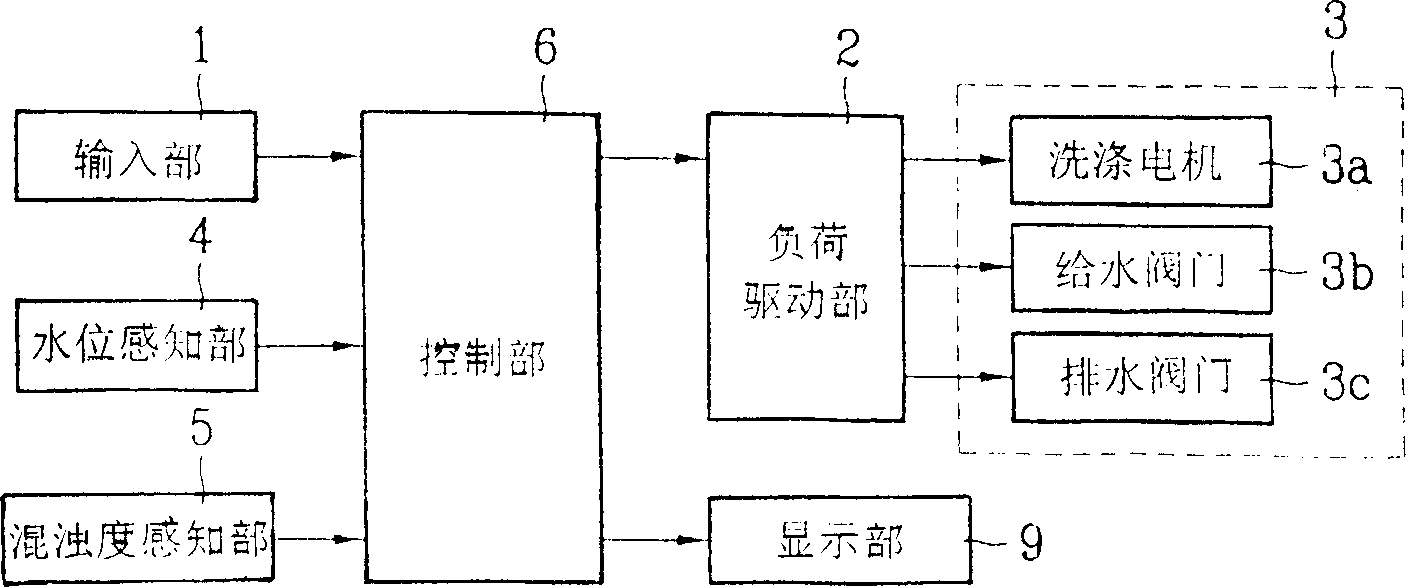

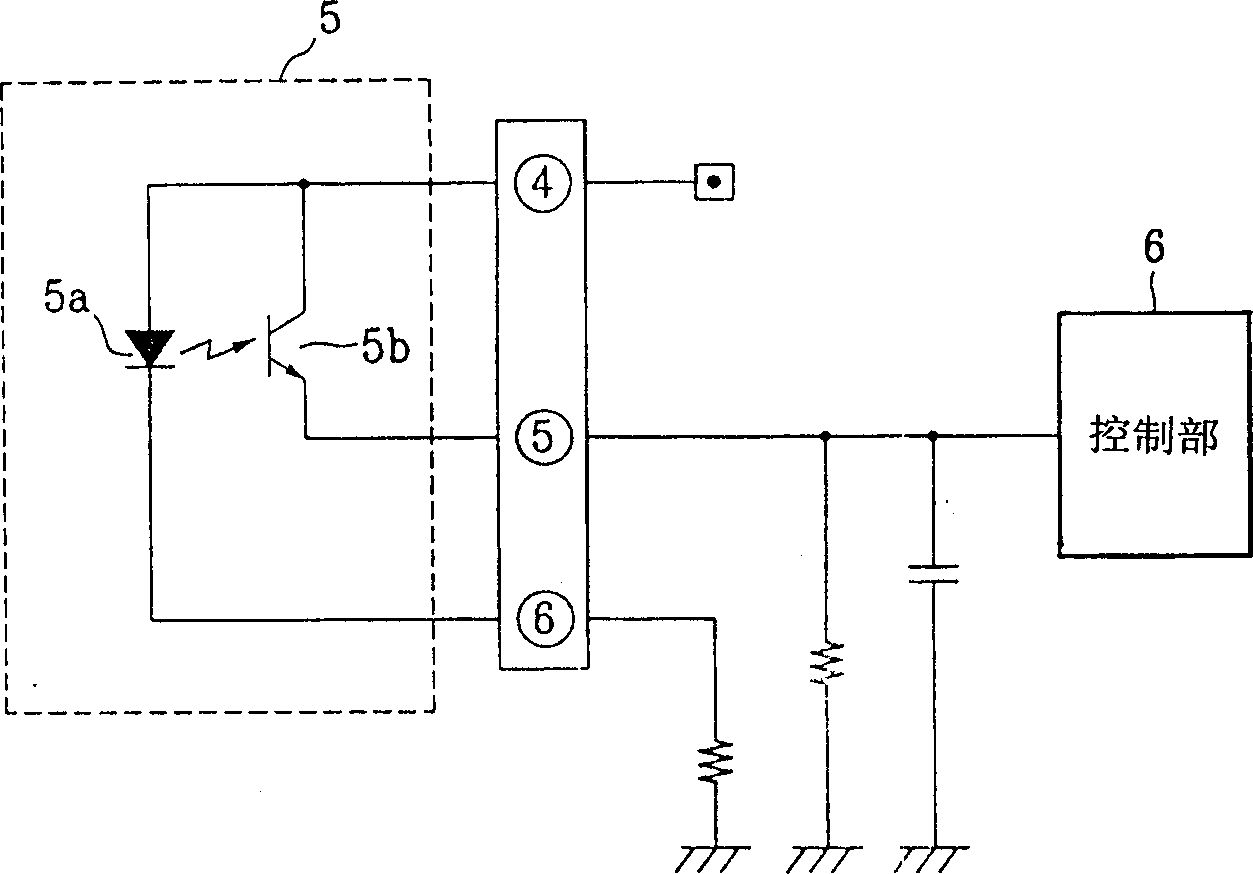

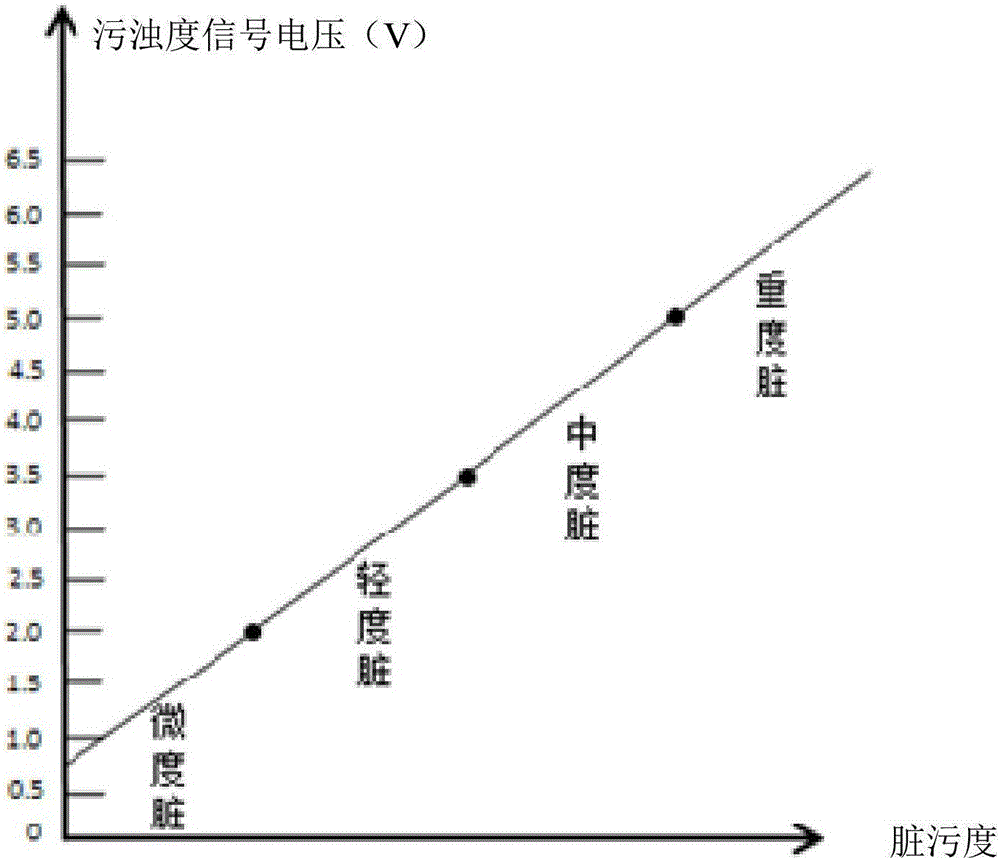

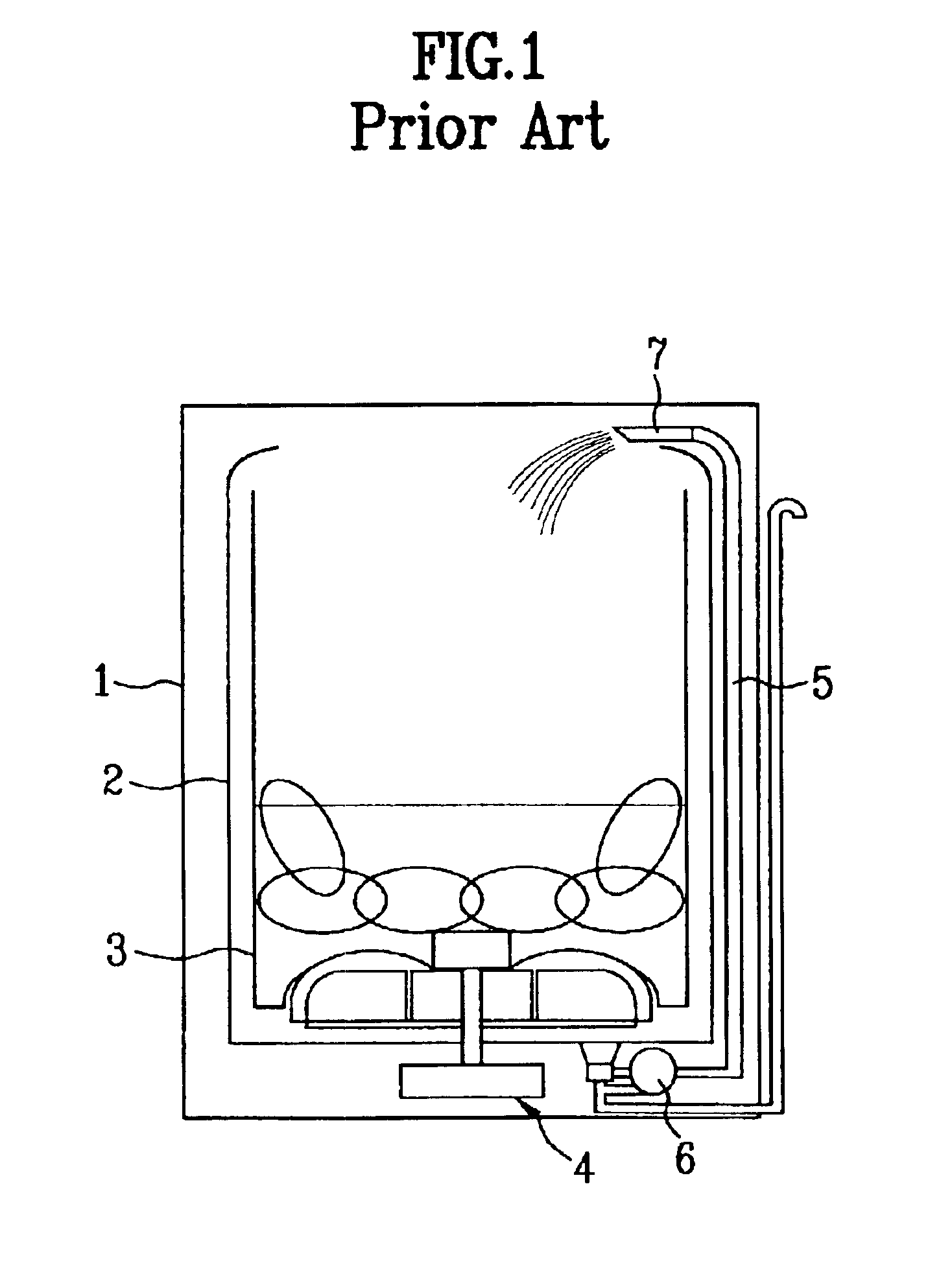

Washing machine and control method thereof

ActiveCN105088651AGuaranteed to wash cleanAvoid harmOther washing machinesControl devices for washing apparatusTurbidityElectro conductivity

The invention discloses a washing machine which comprises a tank, a washing tub, a motor, a detergent storage tank, a detergent put-in device, a turbidity sensor, a conductivity sensor and a controller. The detergent put-in device is used for putting detergent agent in the detergent storage tank into the washing tub according to detergent put-in amount signals. The turbidity sensor is used for detecting the after-pre-washing turbidity of washing water in the washing tub to obtain a first turbidity value and detecting the after-rinsing-suspension turbidity of washing water to obtain a second turbidity value. The conductivity sensor is used for detecting an after-rinsing-suspension conductivity value of washing water. The controller is used for controlling pre-washing, generating the detergent put-in amount signals according to the first turbidity value and controlling rinsing according to the second turbidity value and the conductivity value. By means of the washing machine, stains on clothes can be reduced, and clothes can be cleaner after being washed and rinsed. The invention further discloses a control method of the washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

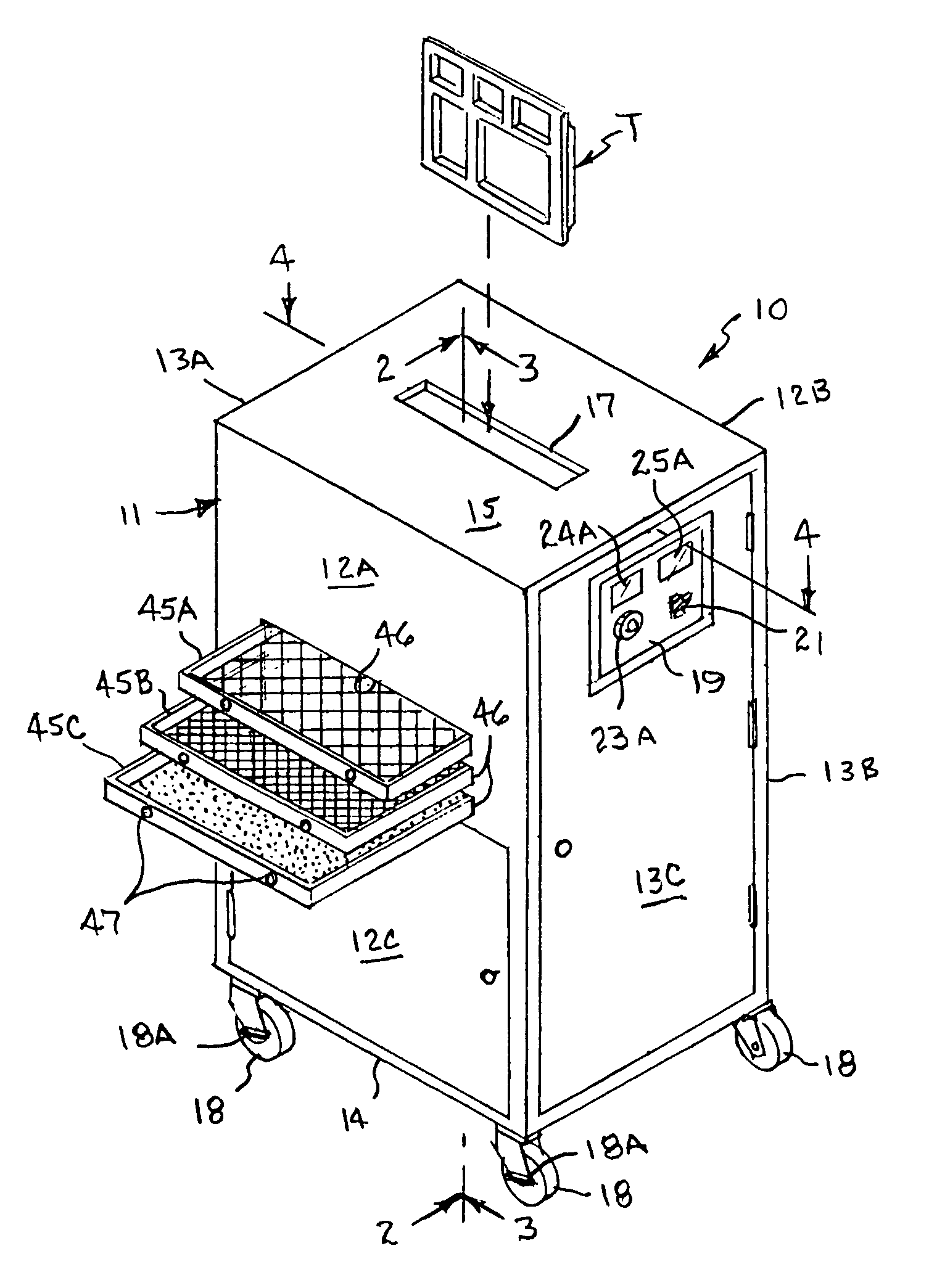

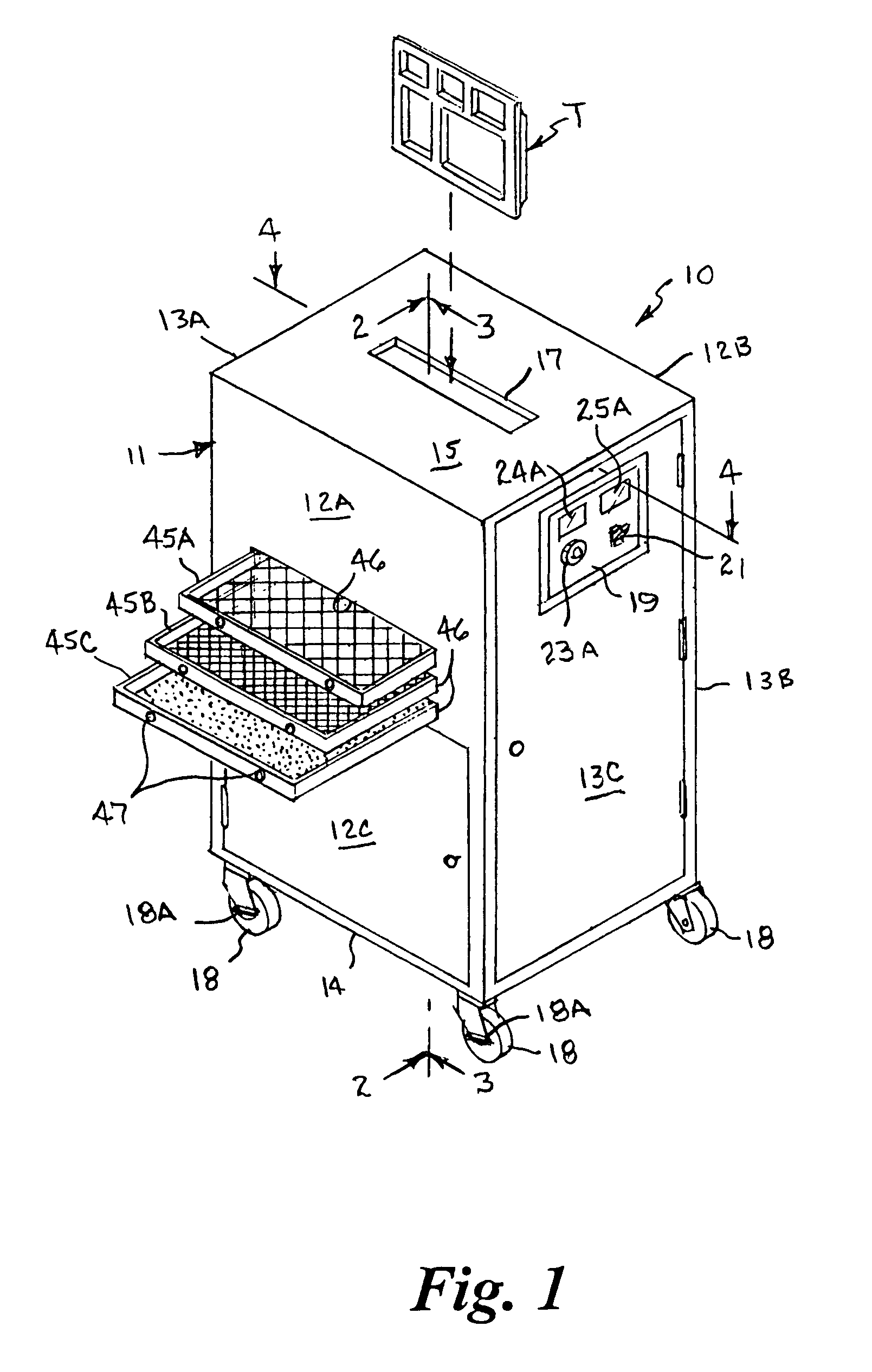

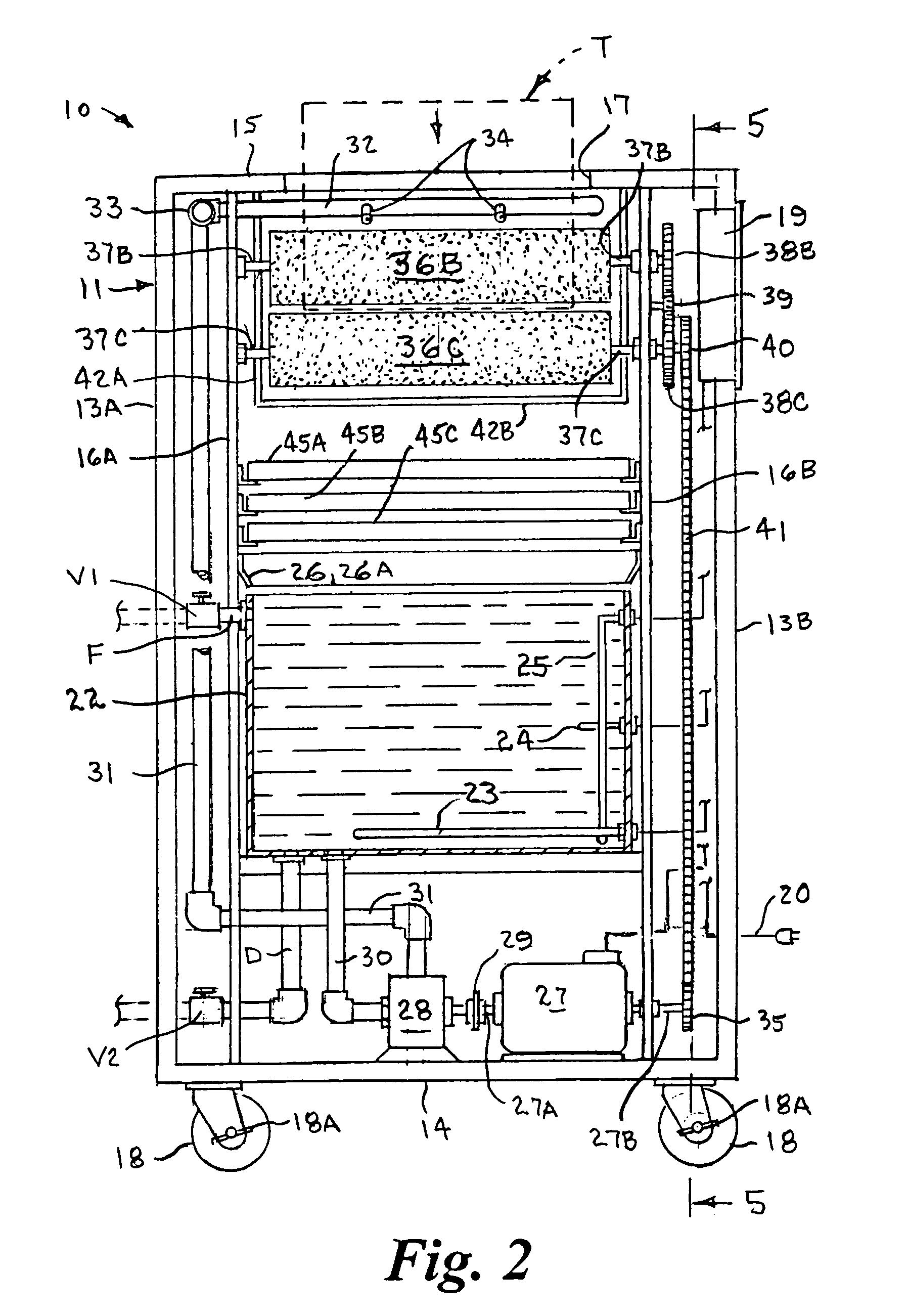

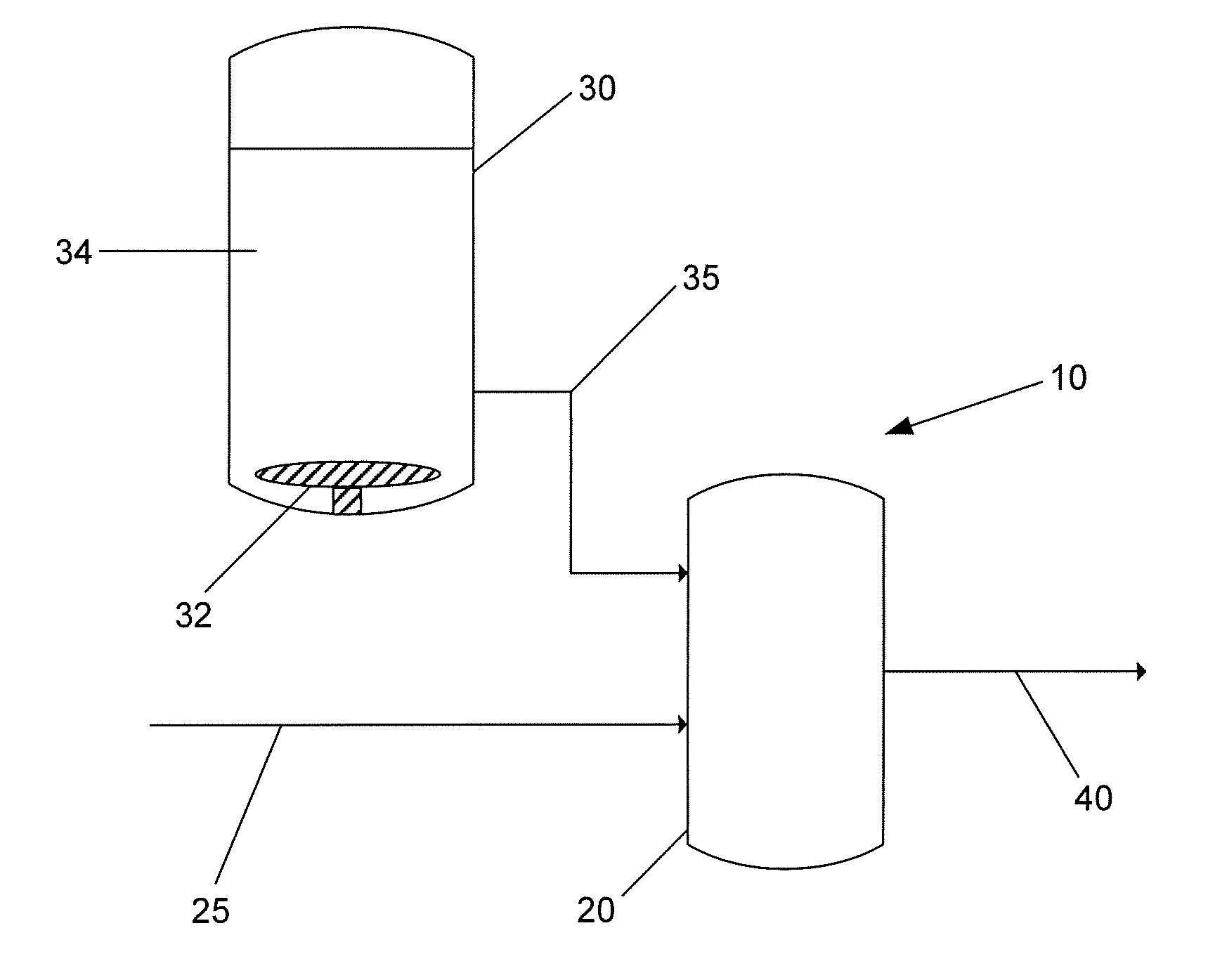

Portable food tray pre-wash and water recycling apparatus

InactiveUS7455067B1Reduce water wasteEasily accessible and removable for installation and cleaningBowling gamesCarpet cleanersPre washingThermal water

A portable food tray pre-wash and water recycling apparatus and method for pre-washing reusable food trays prior to placement in a separate cleaning and sanitizing unit that significantly reduces water wasted in kitchen and scullery areas. The apparatus includes a portable cabinet having a slot in a top end for inserting a food tray, laterally opposed spray nozzles beneath the slot that spray both sides of the tray, laterally opposed rotating brushes beneath the nozzles that scrub the tray, a tray support and brush comb member that supports the tray in a vertical position and removes particles from the brushes, a series of removable incrementally smaller gauge filters vertically spaced beneath the brushes that slide in from one side to filter the water, a water reservoir beneath the filters, a heating unit to heat and disinfect the filtered water, and a pump that recycles heated water back to the nozzles.

Owner:COTTON RANDALL D

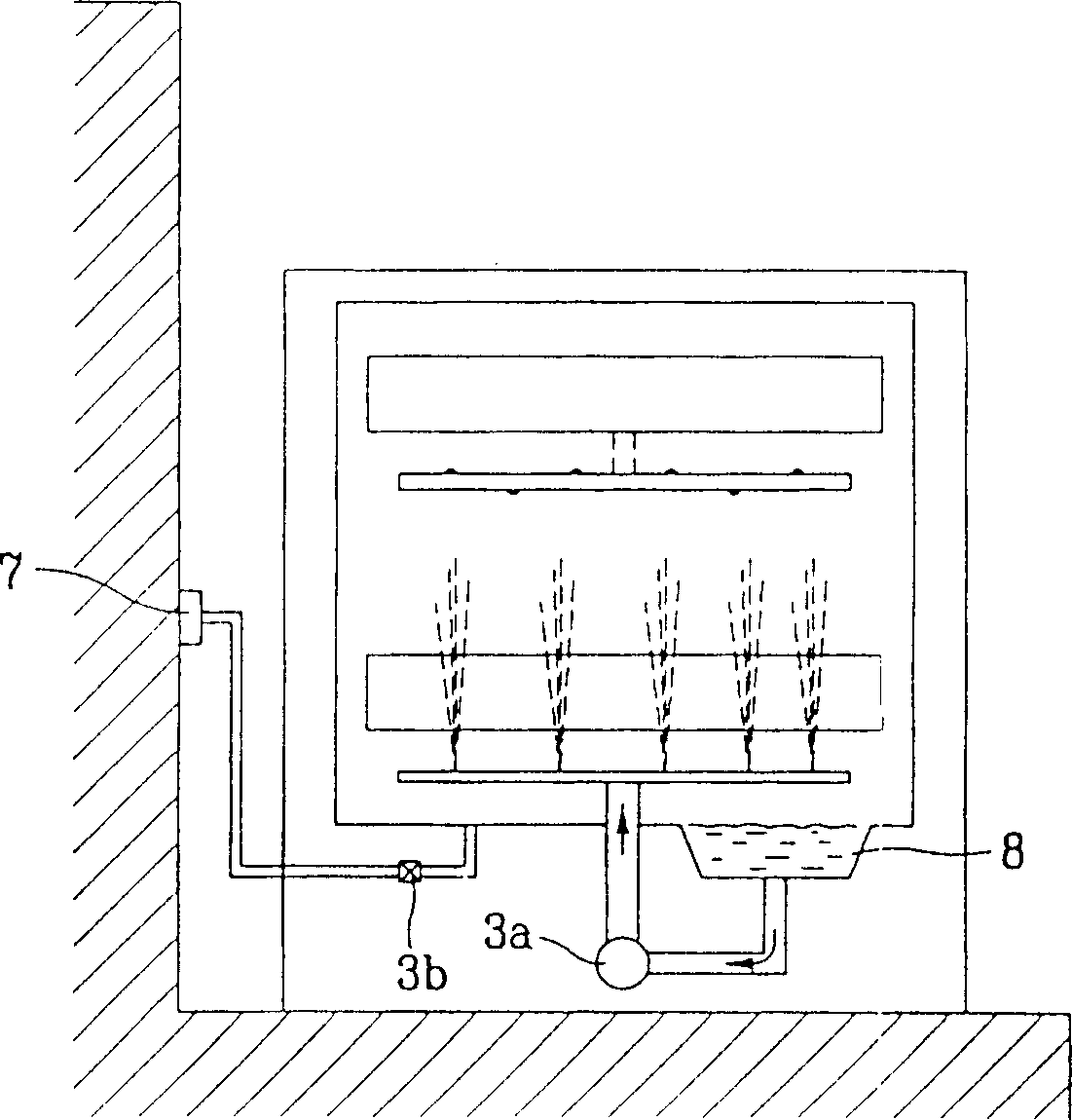

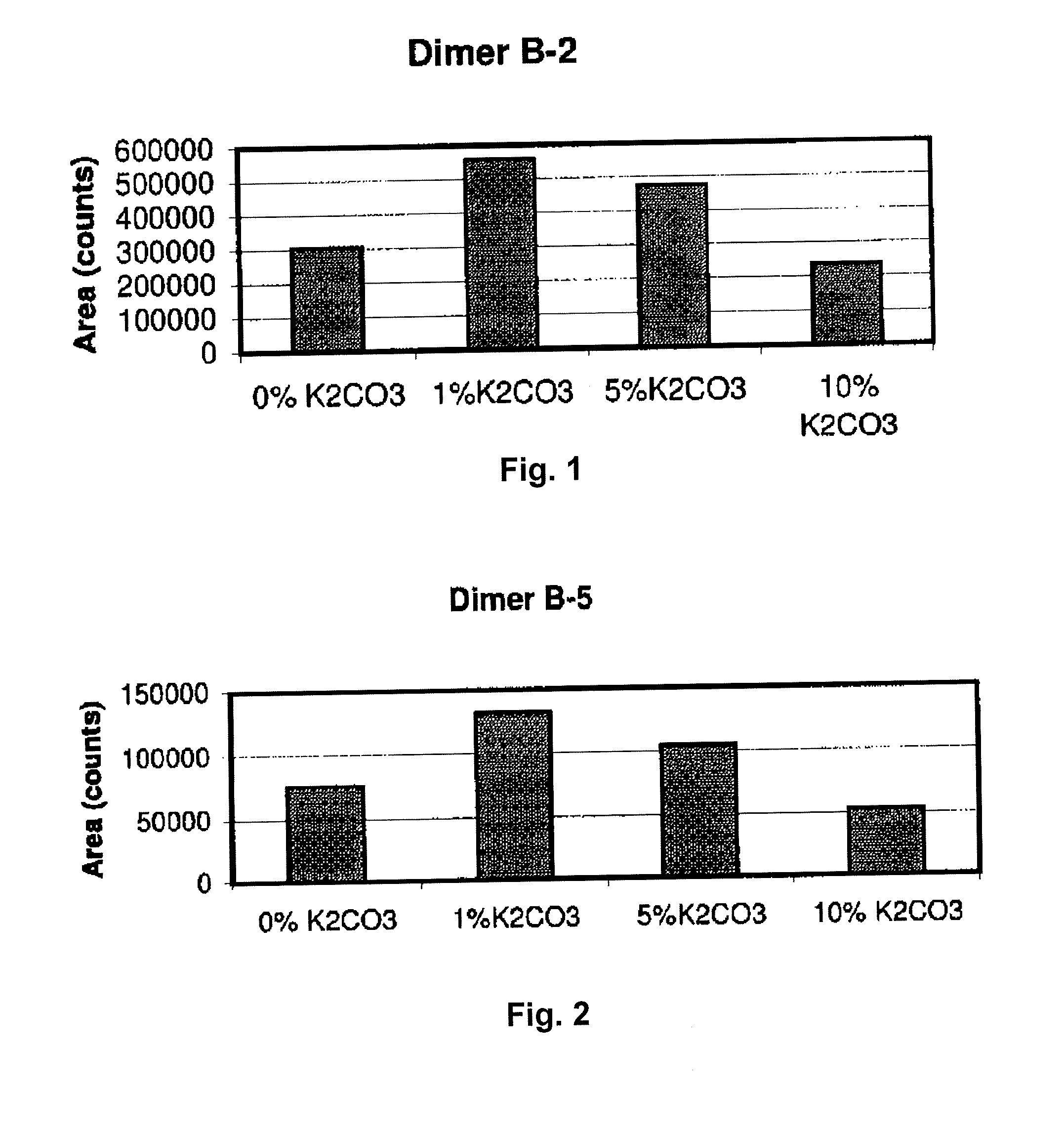

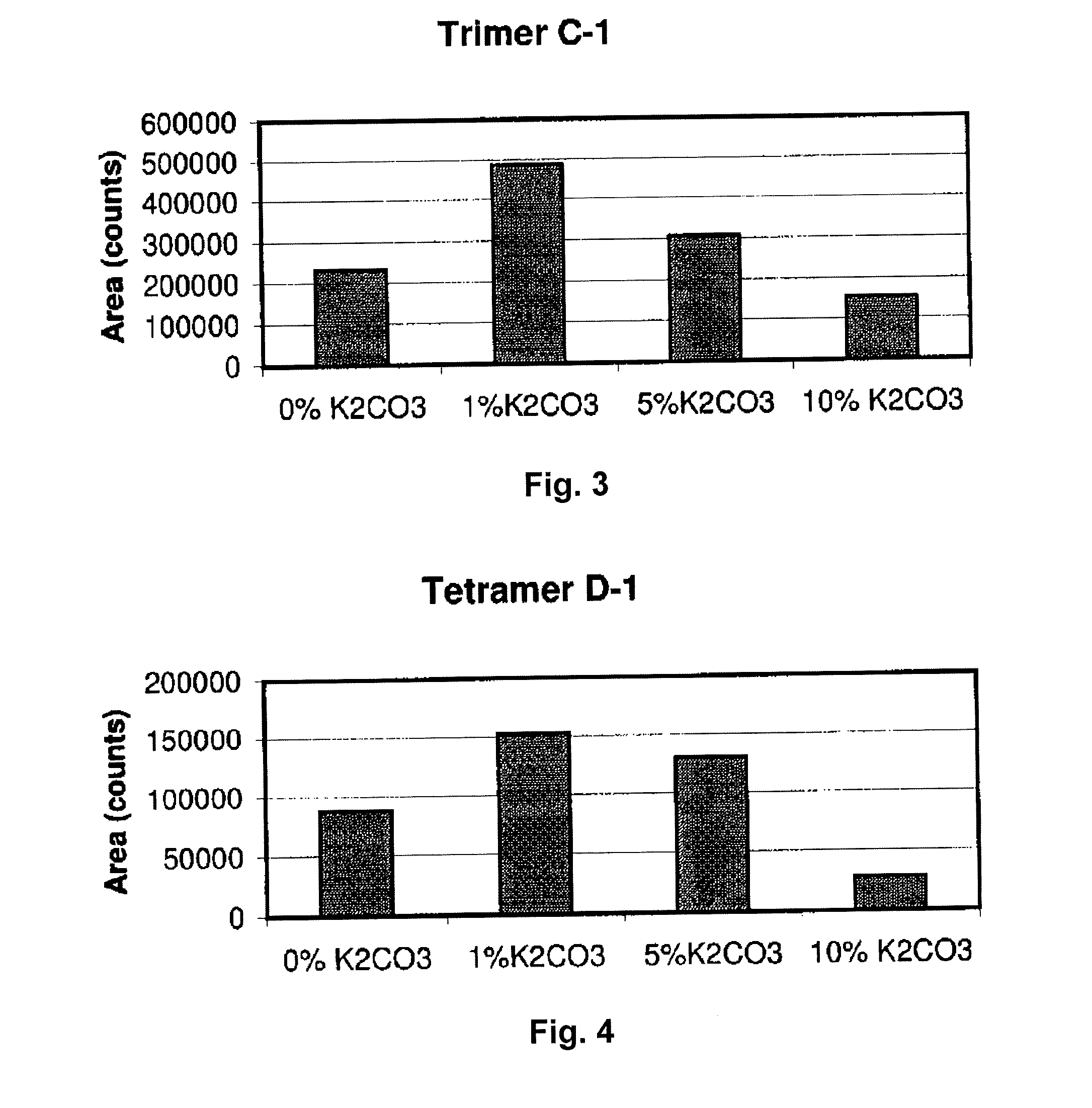

Method for controlling operation of disch washing machine according to turbidity of washing water

InactiveCN1682639AAccurate detectionImprove washing effectTableware washing/rinsing machine detailsScattering properties measurementsTurbidityProcess engineering

The present invention is method of controlling operation of dish washing machine according to the turbidity of washing water, and has compensation function on the turbidity detecting error caused by the error of the turbidity detecting sensor. The method includes the stage of supplying washing water to the set level based on the washing command of the operator; the stage of detecting the first turbidity of the washing water; the stage of the second turbidity of circular washing water during pre-washing; and the stage of controlling the washing operation based on the detected first turbidity and the second turbidity. Compensating the turbidity detecting error can raise the washing performance of dish washing machine and the system reliability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Process for preparing super activated carbon from nut shell carbon and waste liquid activation treatment method of process

The invention discloses a process for preparing super activated carbon from nut shell carbon and a waste liquid activation treatment method of the process, belonging to the field of biochemical engineering and energy materials. The process comprises the following steps: soaking nut shell carbon which is subjected to pre-washing and thermal treatment A into an oxidization substance in a vacuum reaction kettle; performing thermal treatment B on the nut shell carbon soaked into the oxidization substance, and soaking into an alkali aquo-complex activating agent in the vacuum reaction kettle; in inert gas or reductive atmosphere, heating the nut shell carbon to perform thermal treatment C so as to obtain activated nut shell carbon; adding water to leach and separate the activated nut shell carbon so as to obtain alkali activated mother liquor A and a solid; adding water into the solid for leaching again so as to obtain carbonate mother liquor B and activated carbon slurry; performing multi-stage washing and acidization treatment on the activated carbon slurry, washing with water, and separating so as to obtain a crude activated carbon product; and performing thermal treatment D of different stages on the crude activated carbon product, thereby obtaining an activated carbon product. The super activated carbon with high yield and good properties can be prepared, and meanwhile useful byproducts such as bicarbonate and hydrated silica can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

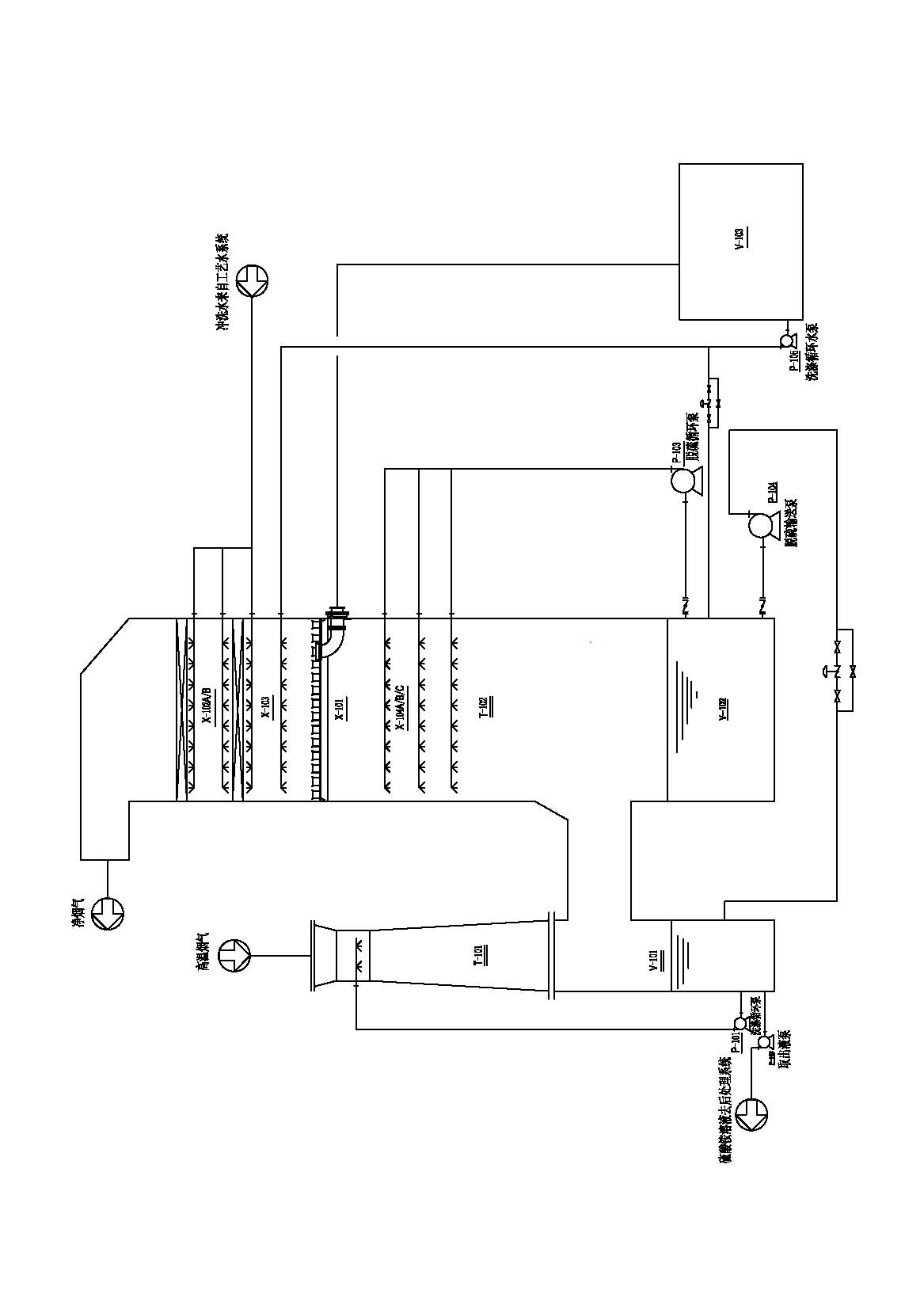

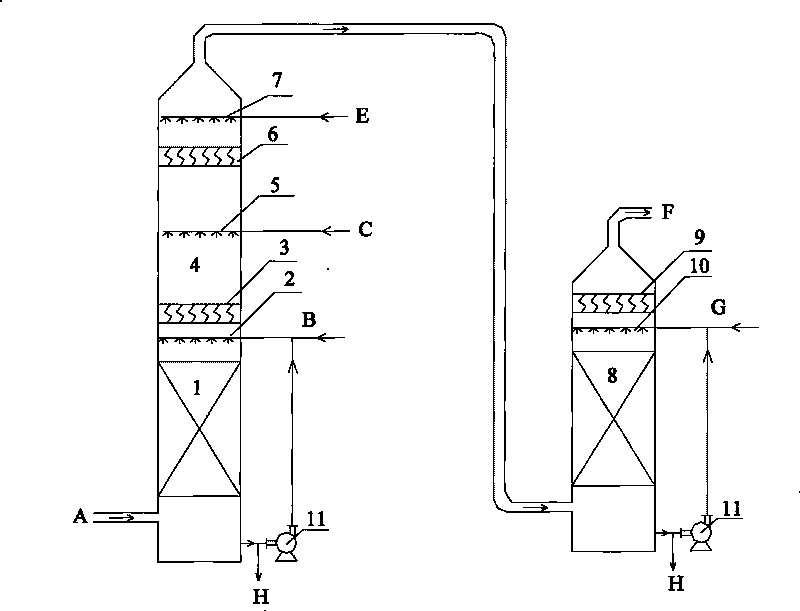

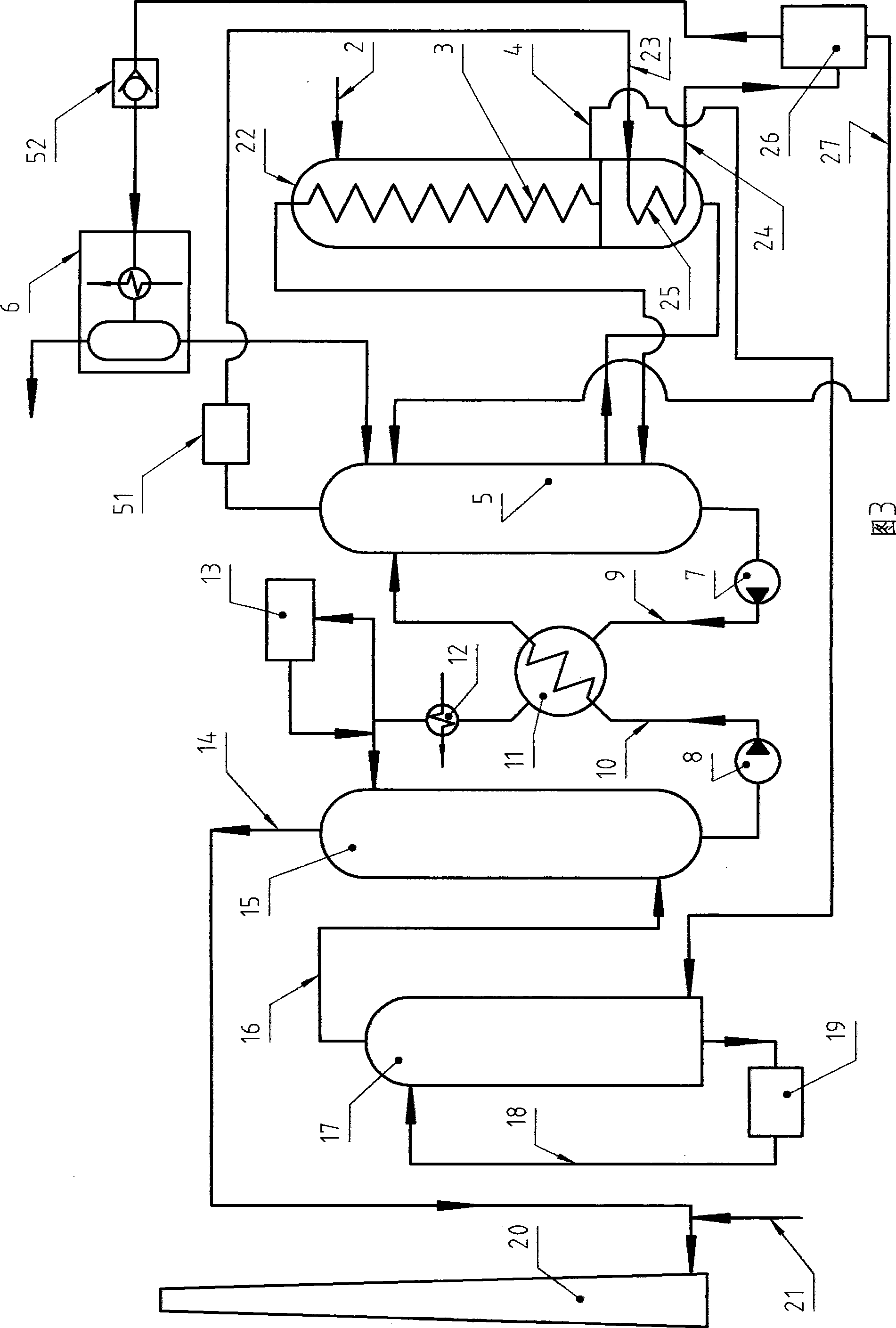

Double-tower ammonia-method desulfurization process

InactiveCN101934192AHigh recovery rateSimple and fast operationDispersed particle separationFlue gasSlurry

The invention relates to a double-tower ammonia-method desulfurization process which is characterized in that the desulfurization process of flue gas is carried out in a twin tower formed by combining a pre-washing tower and a desulfurizing tower, because slurry in the pre-washing tower and the desulfurizing tower keeps a certain concentration gradient, the twin towers are stable in operation and running, simultaneously reduce the abrasion of the slurry for the desulfurizing tower and members in the desulfurizing tower and prolong the service life of equipment. The pre-washing tower comprises a dust-removing section, a cooling section and a concentration section; and the lower part of the desulfurizing tower is provided with an oxidization section, the middle of the desulfurizing tower is provided with a main absorption section, and the upper part of the desulfurizing tower is provided with a water washing section. The pre-washing tower and the desulfurizing tower are both provided with sprinklers. The process has the advantages of simple and convenient operation, less aerosol in purified flue gas and high recovery rate of ammonium sulfate products.

Owner:JIANGSU HEYICHANG ENVIRONMENTAL PROTECTION ENG & TECH

Method of washing cocoa beans to improve the quality of the cocoa products obtained from such beans

ActiveUS20110229616A1Reduce the amount of metalReducing free fatty acidsFruit stoningCocoaButter cocoaPre washing

Owner:OLAM INT

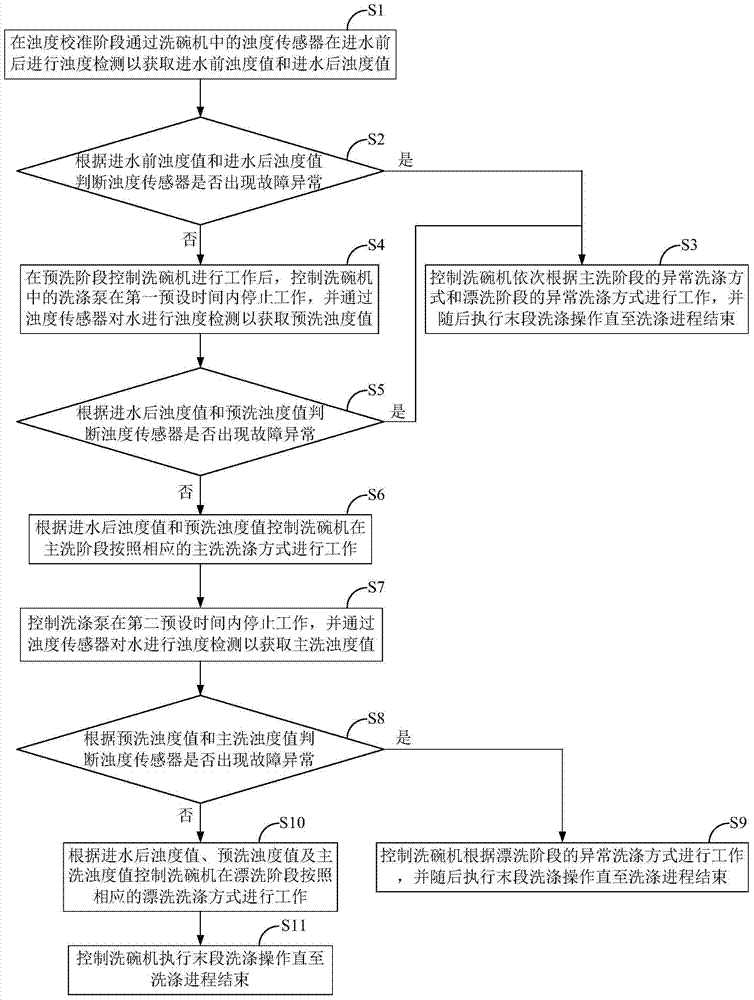

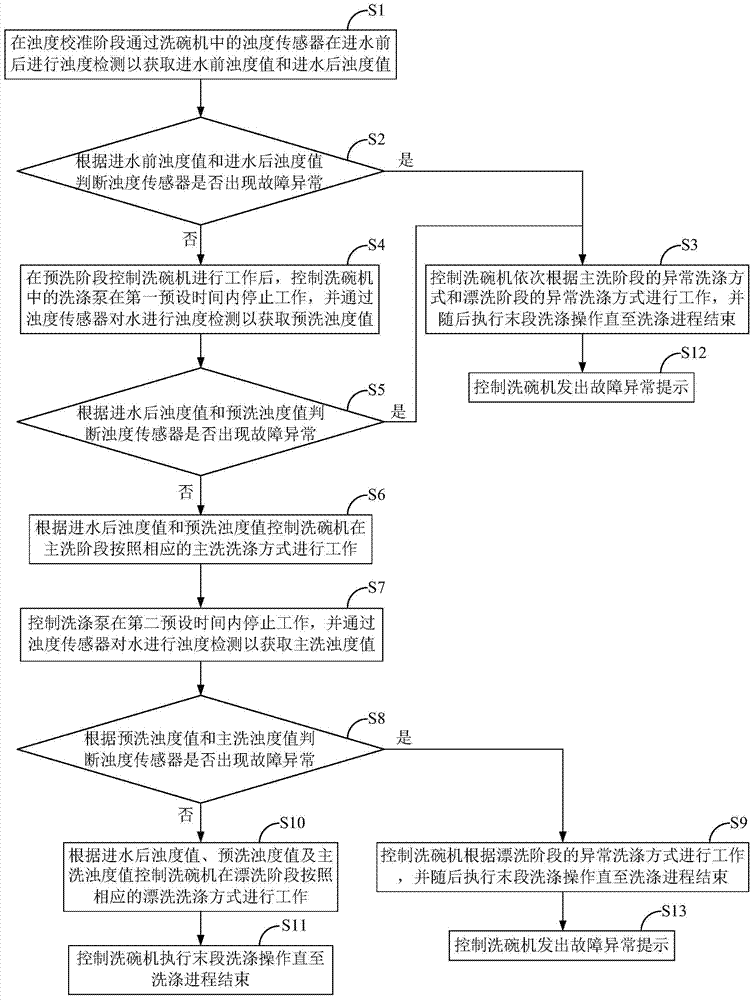

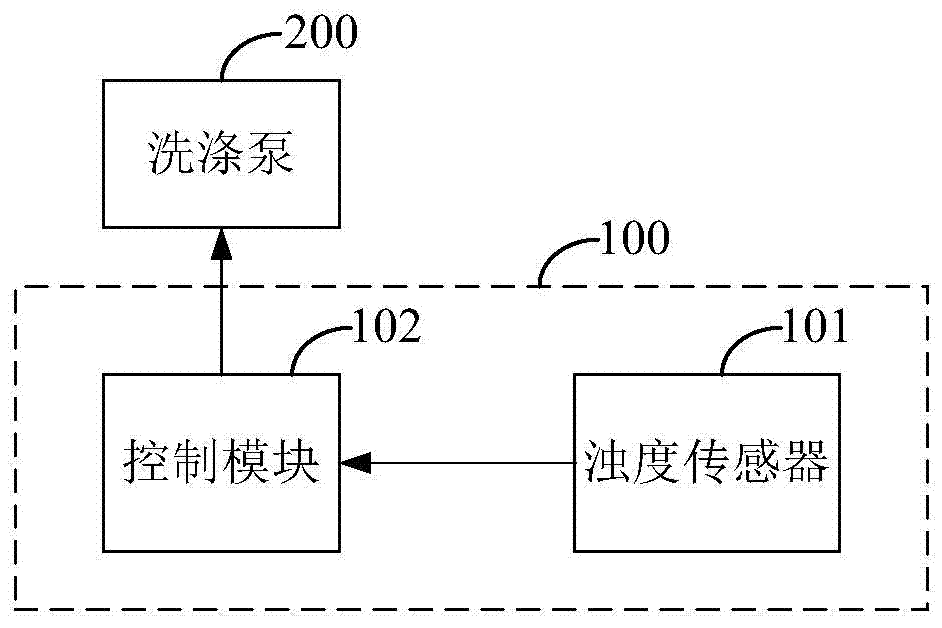

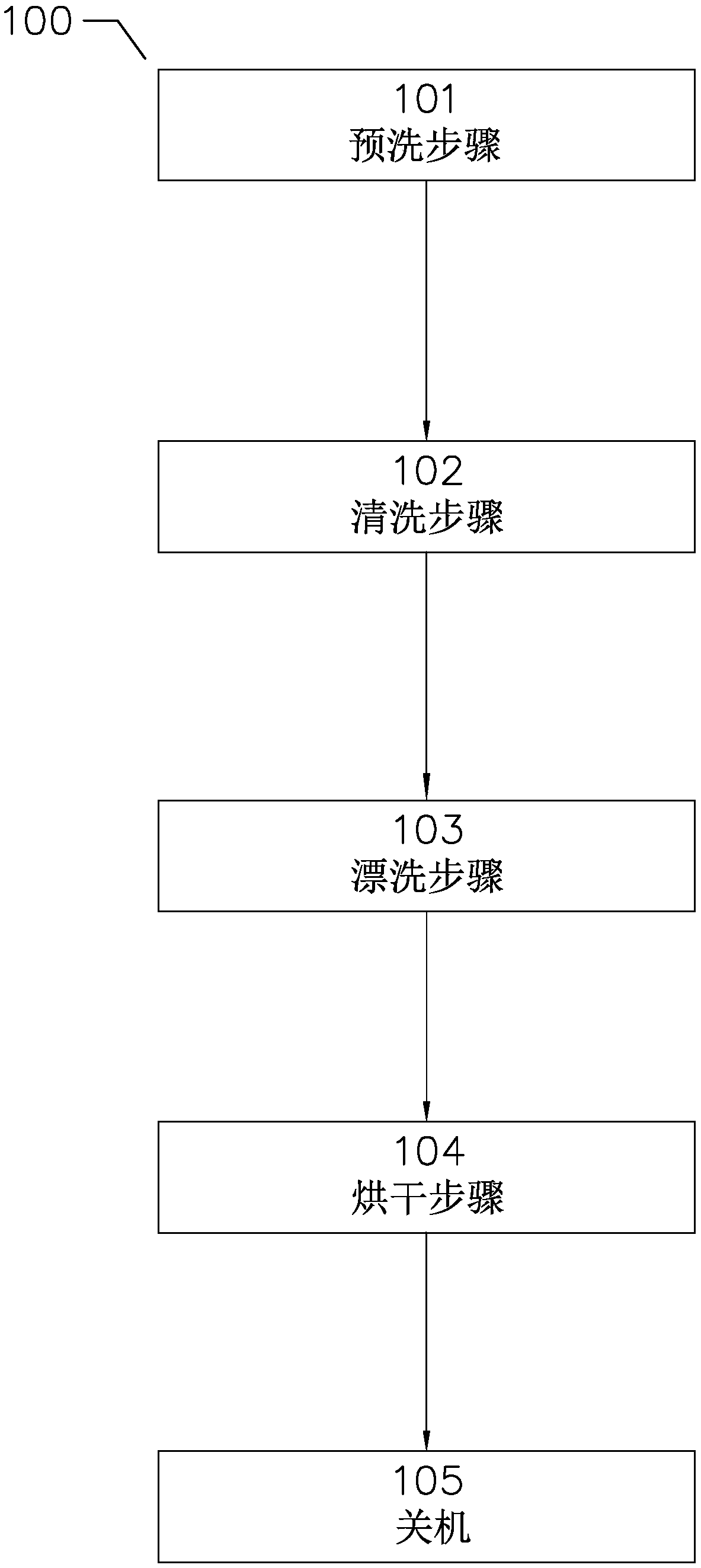

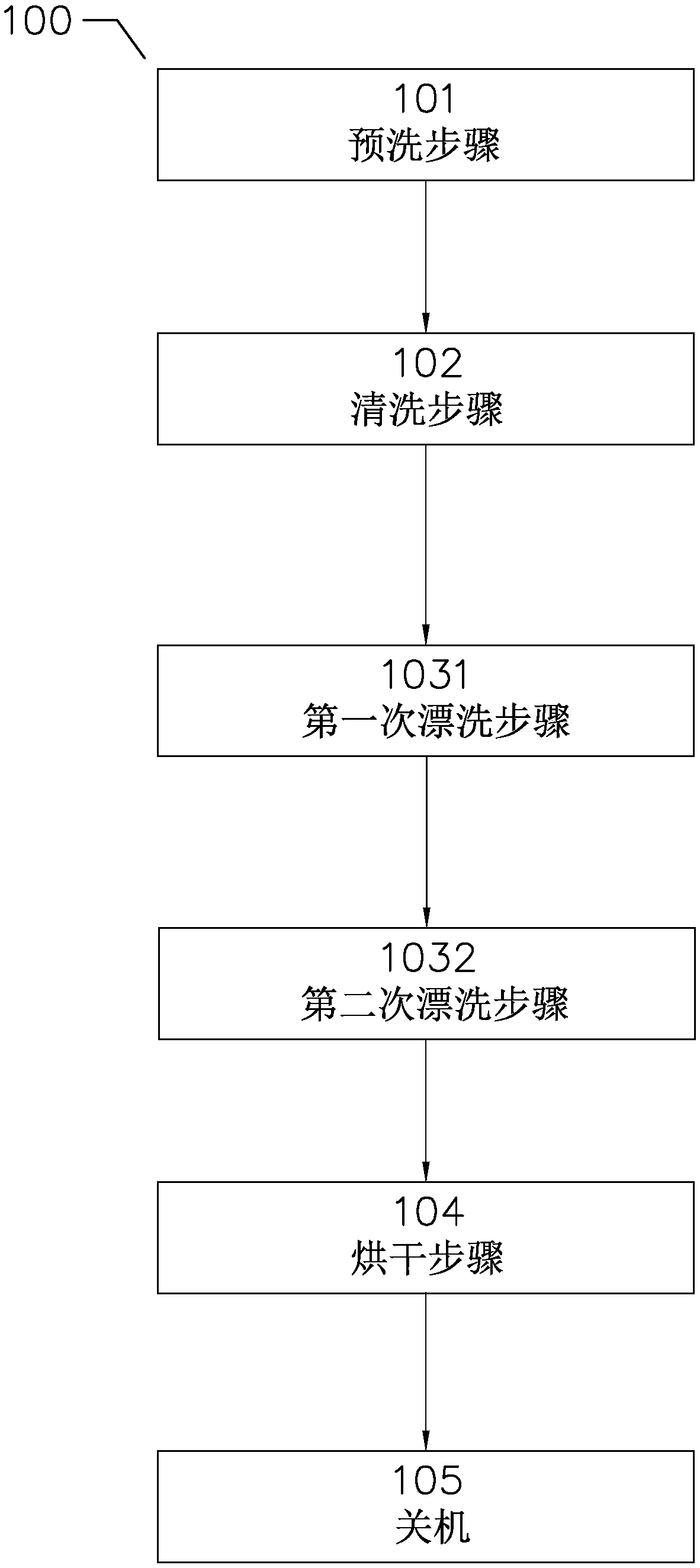

Dish washing machine and washing control method and device thereof

ActiveCN104490356ASolve the problem of not being able to complete the washing process by itselfTableware washing/rinsing machine detailsProgramme control in sequence/logic controllersTurbidityProcess engineering

The invention belongs to the technical field of control of tableware washing, and provides a dish washing machine and washing control method and device of the dish washing machine. The method is that the subsequent washing modes are accurately selected in the turbidity calibration stage, the pre-washing stage and the main washing stage of the dish washing machine according to the detected turbidity value; the fault and abnormality of a turbidity sensor is determined at the turbidity calibration and the pre-washing stage according to the detected turbidity value; in case of fault and abnormality in the turbidity sensor, the dish washing machine is controlled to work by an abnormal washing mode in the main washing stage and the abnormal washing mode at a rinsing stage; the fault and abnormality of the turbidity sensor are determined at the main washing stage according to the detected turbidity value. According to the method, the dish washing machine is controlled to automatically work by the abnormal washing mode in the rinsing stage in case of fault and abnormality in the turbidity sensor, so that the problems that the turbidity is easily inaccurately determined to cause that dish washing machine cannot adaptively wash tableware, and the dish washing machine is failed to wash in case of fault and abnormality in the turbidity sensor, can be solved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Washing method for improving washing efficiency of dish washing machine and dish washing machine used by washing method

InactiveCN109744971APrecise control of prewash timeTableware washing/rinsing machine detailsPre washingComputer science

The invention discloses a washing method for improving the washing efficiency of a dish washing machine. The method comprises the following steps that S1, after the gate of the dish washing machine isclosed, a detection module extracts a tableware surface image and feeds back the image to an image processor, and the image processor processes image information to generate a tableware surface smudge factor c1, and S2, the image processor transmits the surface smudge factor c1 to a controller; the controller prejudges the smudge degree of the tableware surface and conducts pre-washing for t1 minutes by adjusting the water pressure, water temperature and water amount of the dish washing machine water inlet. The image processor generates the tableware surface smudge factor after processing theimage, the tableware surface smudge factor is transmitted to the controller, thus the controller can know the smudge degree of the current tableware, and thereby controlling the water pressure, watertemperature and water amount of the dish washing machine, the pre-washing time of the dish washing machine can be accurately controlled, the dish washing machine can control different washing situations according to cleanness degree of the tableware and accurately controls washing, and thus the washing time is saved.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

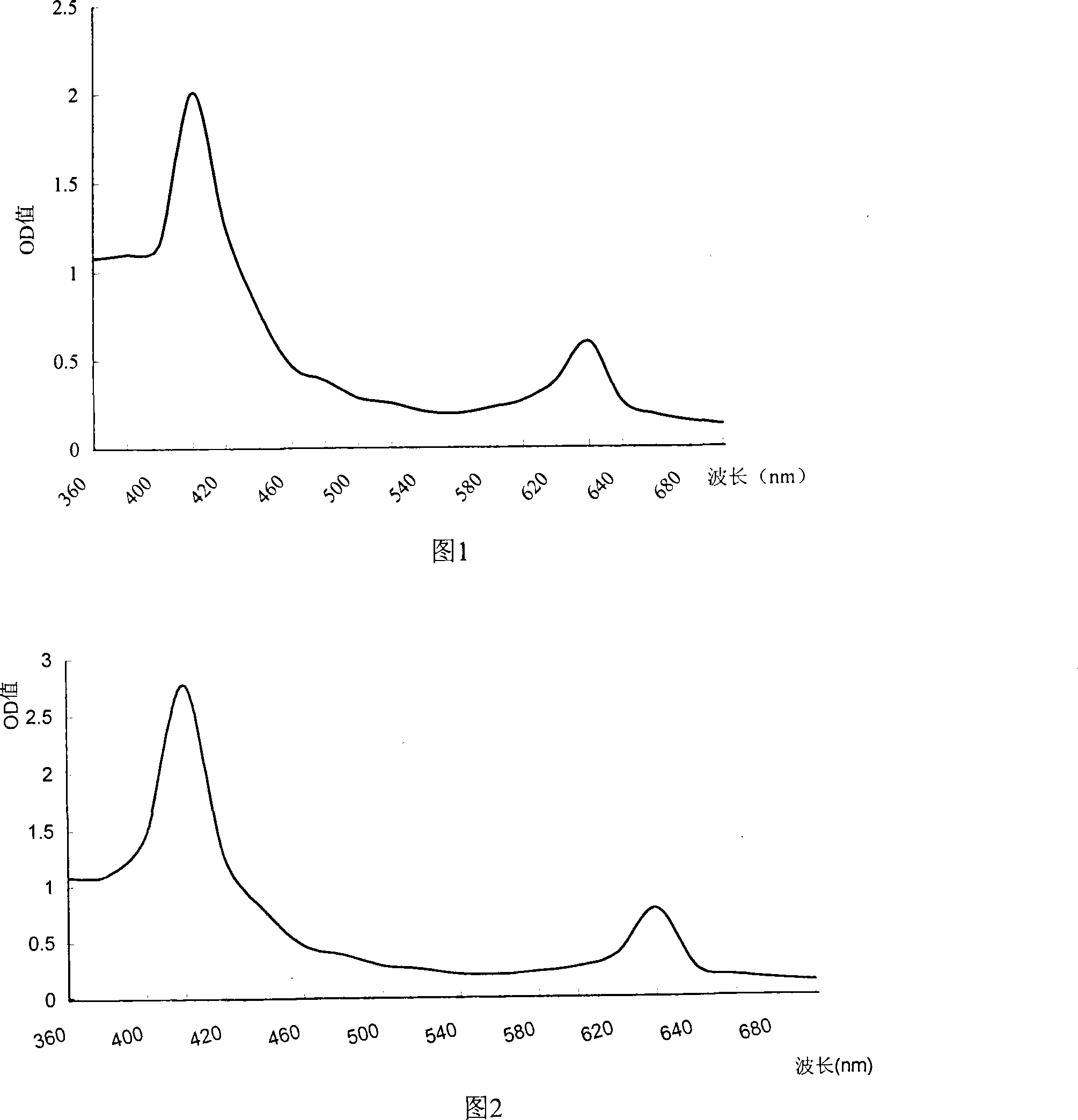

Production process of water soluble ginkgo leaf extractive

InactiveCN101254220ARetain and optimize the content of active ingredientsSimple production processGinkgophyta medical ingredientsCardiovascular disorderAlcohol freeGinkgo biloba

A production process of a water soluble ginkgo leaf extract comprises the following steps of pulverizing ginkgo leaf, and extracting with ethanol for 2-4 times to obtain concentrated solution I; diluting with purified water, filtering to obtain medicinal liquid II, washing the residue with purified water for several times, filtering the supernatant to obtain medicinal liquid III, mixing with the medicinal liquid II, diluting with water, and filtering to obtain clear medicinal liquid IV; adsorbing with macroporous adsorptive resin, pre-washing with purified water or ethanol, and eluting with ethanol to obtain medicinal liquid V; concentrating the medicinal liquid V to obtain alcohol-free concentrated extract VI; extracting the concentrated extract VI with ethanol for 2-4 times, filtering, and concentrating the filtrate to obtain concentrated extract VII; or alternatively completely dissolving conventional ginkgo leaf extract in ethanol, recovering ethanol to obtain concentrated extract, extracting with ethanol for 2-4 times, filtering, and concentrating the filtrate to obtain concentrated extract VII; and extracting the concentrated extract VII with purified water for 2-4 times, cooling the extractive solution, filtering, concentrating, and drying to obtain the water soluble ginkgo leaf extract. The inventive production process has the advantages of simple process, stable product quality, and good economic benefit.

Owner:ZHEJIANG CONBA PHARMA

A Dishwasher Washing Method and a Dishwasher

InactiveCN108968861AImprove intelligenceGuaranteed washing effectWashing processesTurbidityProcess engineering

The invention provides a dishwasher washing method and a dishwasher, comprising a washing step, a rinsing step and a drying step. The dishwasher sets a pre-washing step before the washing step by adding water of capacity C1 to the sink and heating the water until the temperature reaches temperature T1. The washing pump works for time t1 and then suspends for time t2; the dishwasher determines thewashing mode according to the turbidity of the water detected by the turbidity sensor. The dishwasher determines the washing mode by adding a certain capacity of water, heating the water to a certaintemperature, washing for a period of time and then suspending for a period of time, and finally detecting the turbidity of the water through the turbidity sensor. This method adds a fast, accurate andefficient pre-washing process, and then determines the washing mode according to the detection of the turbidity sensor. Compared with the existing method of continuously detecting the turbidity of the water during the cleaning process, the method is more efficient for ensuring the washing effect by prolonging the cleaning time.

Owner:杭州小月亮科技有限公司

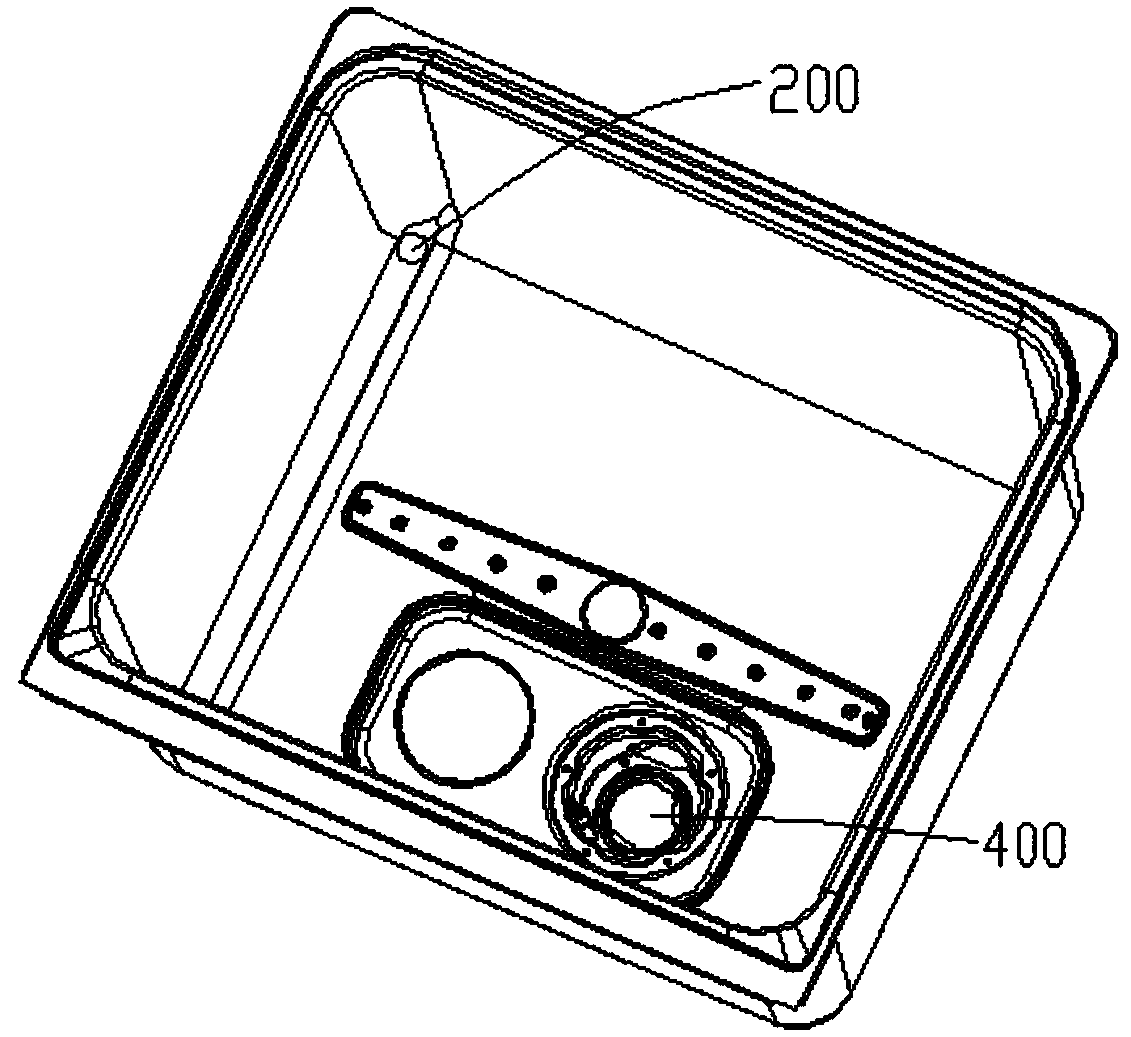

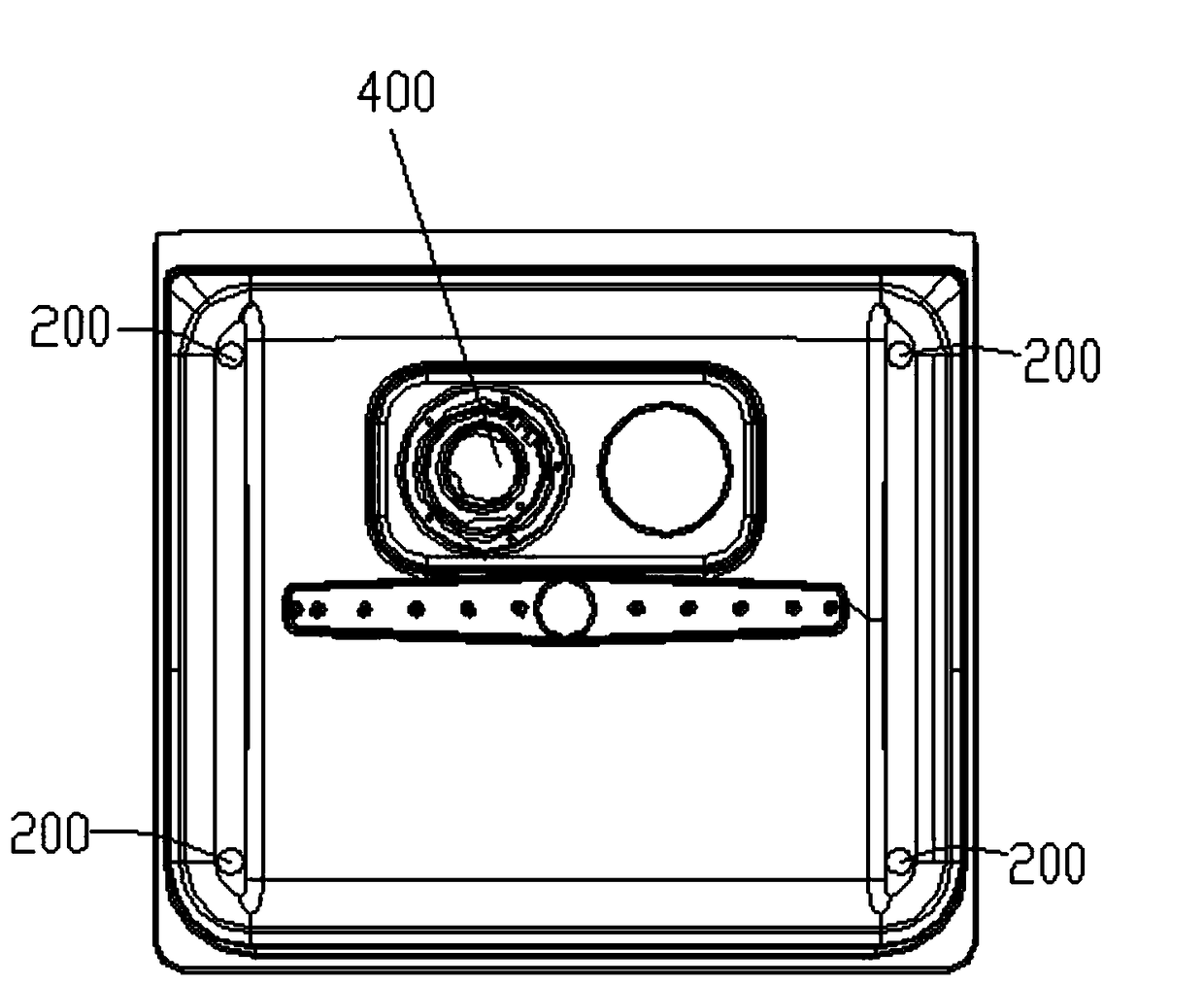

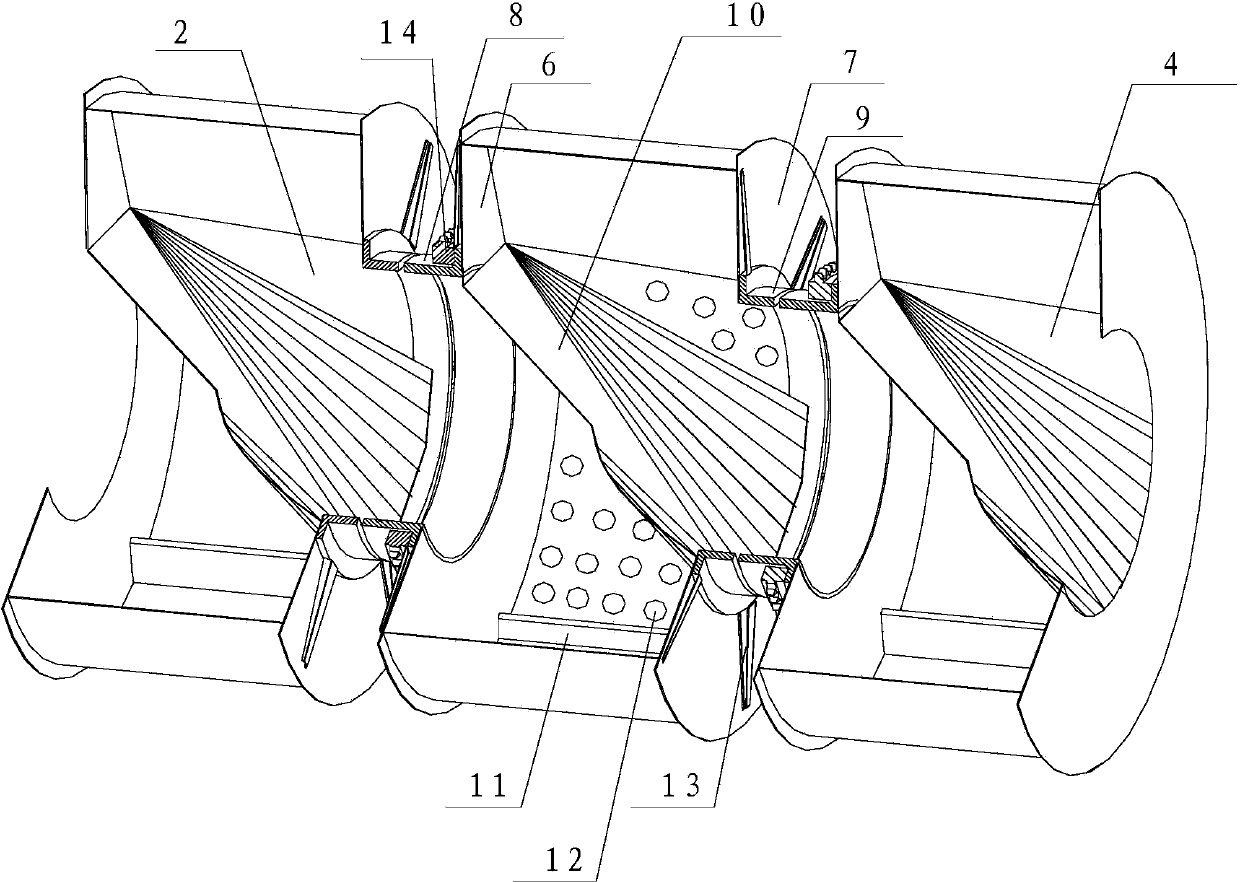

Pre-washing method of water sink type dishwasher

ActiveCN104997477AAvoid collisionIncrease flushing powerTableware washing/rinsing machine detailsElectricityWater flow

The invention discloses a pre-washing method of a water sink type dishwasher. The method includes the following steps that: 1) water flows in, and when water inflow achieves a predetermined water quantity, heating begins; 2) a circulating water pump starts operating with rated power of 50 to 60%, and vortex stirring can be formed through fines arranged at the upper surface of a rotating spraying arm; 3) when the temperature of washing water reaches a set temperature, a heating device is turned off; 4) when the water inflow reaches a predetermined water quantity submerging dishes, the water stops flowing in; and 5) when a set time is up, the circulating water pump is stopped, and a water drainage channel is opened, and a pre-washing stage is terminated. With the pre-washing method of the water sink type dishwasher of the invention adopted, various problems in washing Chinese dishes can be solved, and washing efficiency can be effectively improved, and more water and electricity can be saved.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

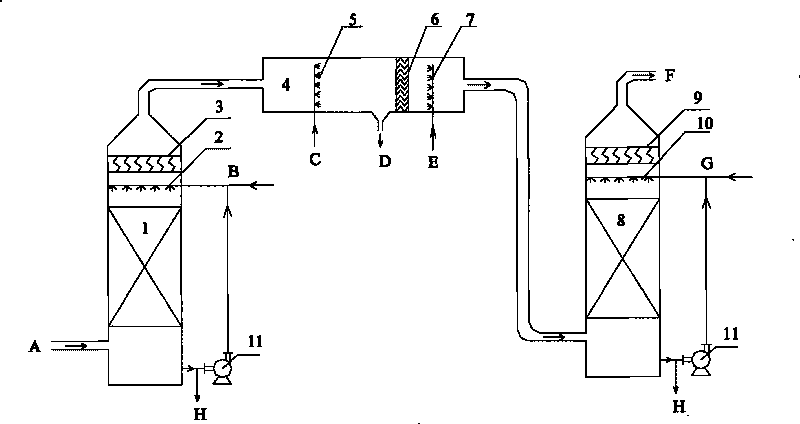

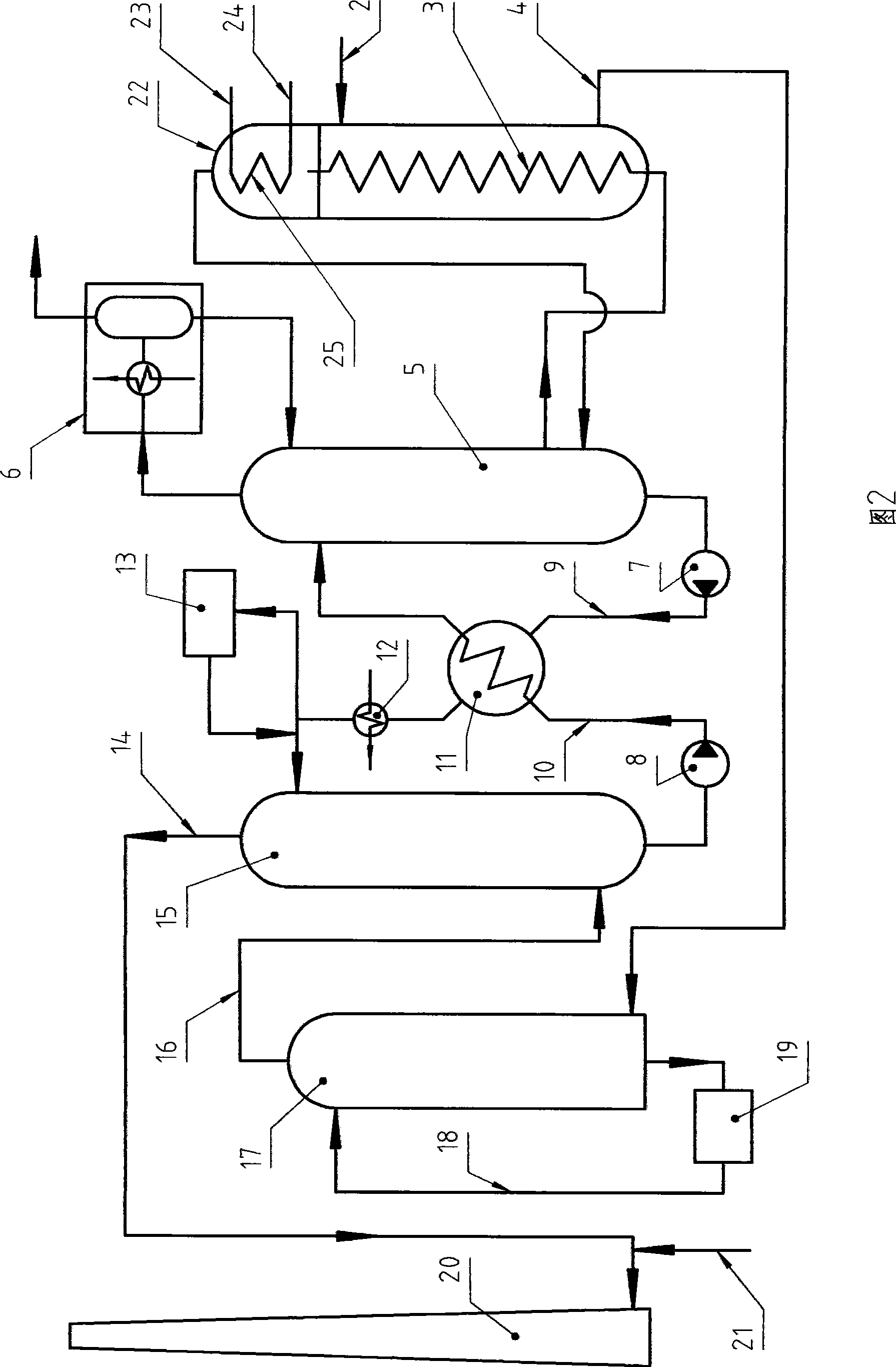

Desulfuration and mercury-removing combined smoke purifying process and system based on magnesium oxide method desulfuration process

InactiveCN102205203AWith resource utilizationRealize resource utilizationDispersed particle separationMagnesium/calcium/strontium/barium sulfides/polysulfidesGas phaseSulfide

The invention discloses a desulfuration and mercury-removing combined smoke purifying process and system based on a magnesium oxide method desulfuration process. The desulfuration and mercury-removing combined smoke purifying process comprises the steps of: improving a pre-washing tower in the magnesium oxide method desulfuration process, circularly spraying original smoke by adopting a halogen oxidant solution to realize full oxidization of elementary substance mercury Hg0 in smoke; transforming oxidized gas-phase bivalent mercury ions into liquid-phase bivalent mercury ions through an improved wet-type magnesium oxide method desulfuration process; and transforming the liquid-phase bivalent mercury ions in a wastewater treatment system into a stable mercuric sulfide precipitate through adding a mercury stabilizing agent. The system mainly comprises the pre-washing tower, a desulfuration tower, a cyclone separator, a vacuum belt fulter, a wastewater basin and a sedimentation basin, wherein the pre-washing tower is used for preparing a mercury oxidant and a magnesium oxide solution and oxidizing mercury; the desulfuration tower is used for carrying out desulfuration and mercury removal on smoke; the cyclone separator and the vacuum belt fulter are used for treating side products; and the wastewater basin and the sedimentation basin are respectively used for treating wastewater and the mercuric sulfide precipitate. The process can be used for effectively removing divalent mercury and elementary substance mercury in the smoke on the premise of ensuring the advantages of the magnesium oxide method desulfuration process, and is suitable for reconstructing the traditional magnesium oxide method desulfuration process.

Owner:CECEP L&T ENVIRONMENTAL TECH

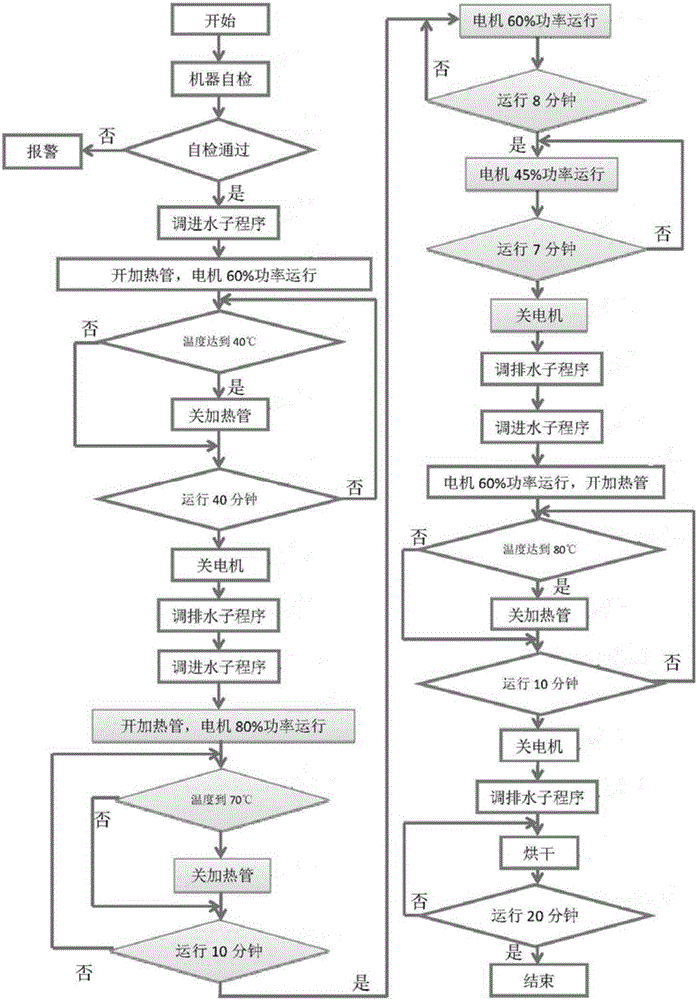

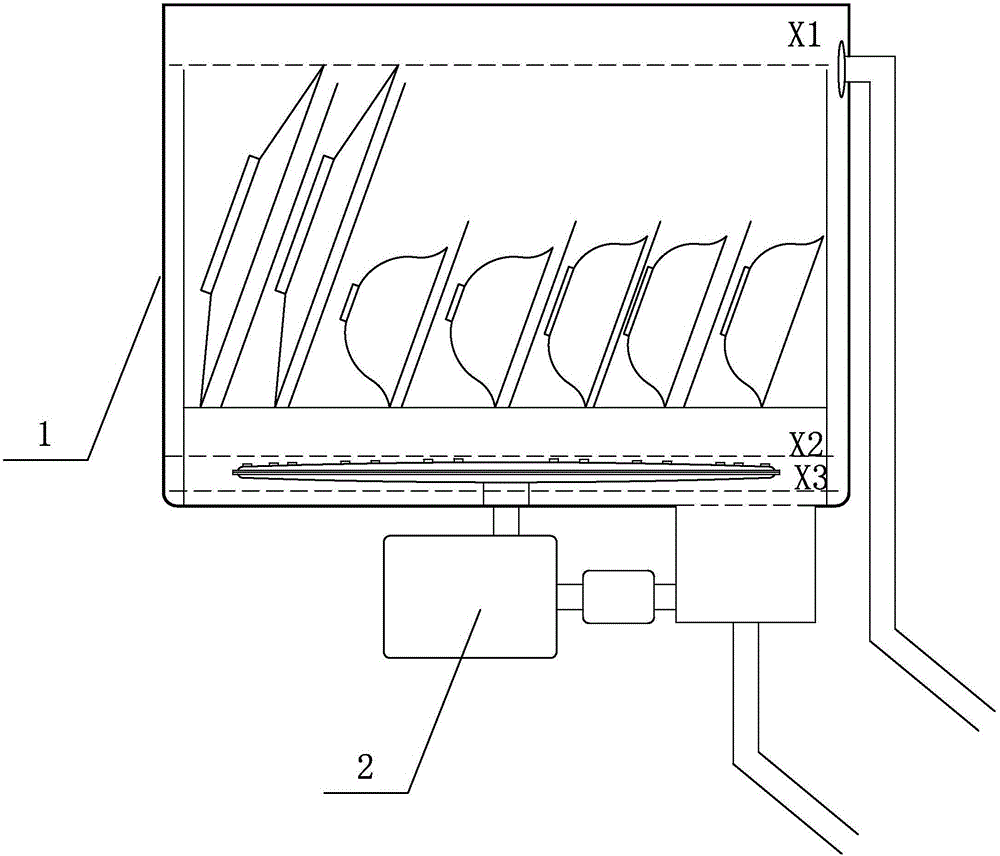

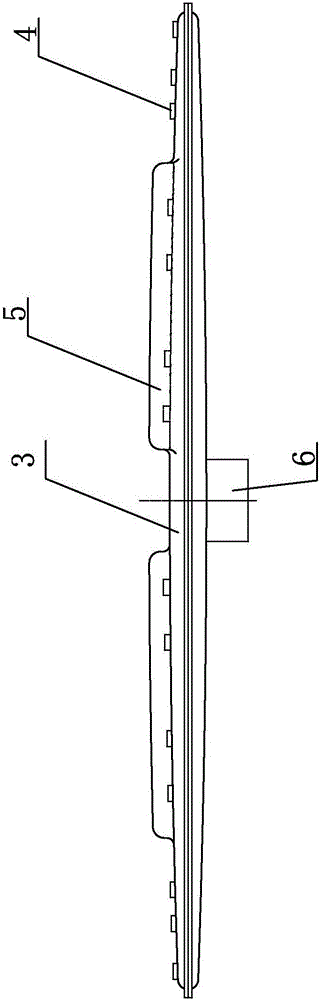

Domestic full-automatic dish-washing machine and its cleaning method

InactiveCN1836623AKeep healthyEasy to cleanTableware washing/rinsing machinesPhysical well beingEngineering

The washing method for automatic household dish washer includes taking dishes one by one from the pre-washing area, washing dishes one by one rotarily with the washing head in the washing area, and rising, soaking and draining dishes one by one in the draining area. The automatic household dish washer includes a pre-washing area, a washing area and a draining area. The pre-washing area and the draining area are connected separately to the two ends of the washing area. The washing area has washing head capable of being elevated vertically, and the washing head is connected to a horizontal conveying mechanism to take dish from the pre-washing area to the draining area. The automatic household dish washer has compact structure, low cost, low water and power consumption, ideal washing effect and other advantages, and is suitable for use in household.

Owner:云琛

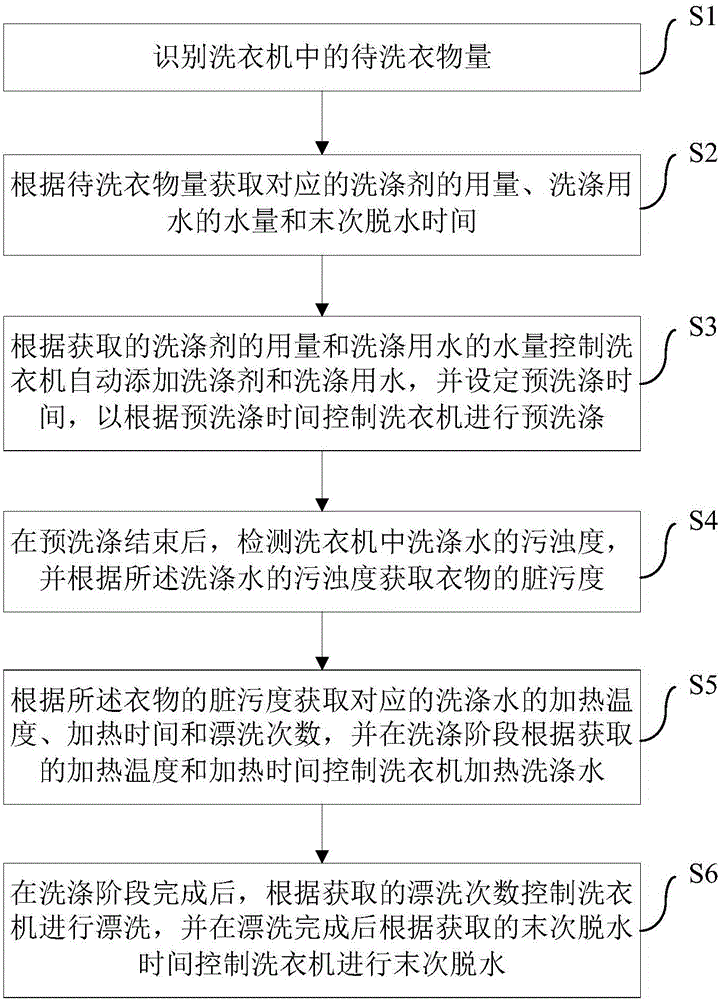

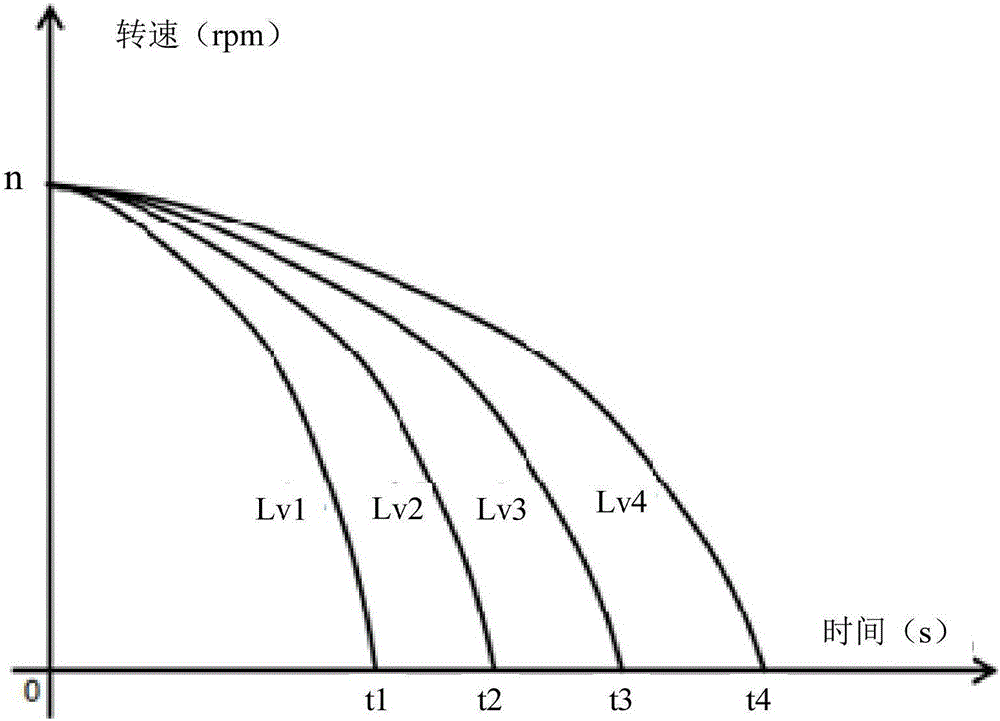

Washing control method and washing control device of washing machine and washing machine

InactiveCN106012415AImprove experienceSave power resourcesOther washing machinesControl devices for washing apparatusHeating timeBleach

The invention discloses a washing control method and a washing control device of a washing machine, and the washing machine. The washing control method comprises the following steps: recognizing the amount of to-be-washed clothes in the washing machine; obtaining the using amount of corresponding detergent, the water quantity of washing water and the last dewatering time according to the amount of the to-be-washed clothes; controlling the washing machine to automatically add the detergent and the washing water according to the obtained using amount of the detergent and the water quantity of the washing water, and setting pre-washing time, thus carrying out pre-washing; after the pre-washing is ended, detecting the dirty degree of the corresponding washing water in the washing machine, and obtaining the dirty degree of the clothes according to the dirty degree of the washing water; obtaining heating temperature, heating time and bleaching frequency of the corresponding washing water according to the dirty degree of the clothes, and controlling the washing machine to heat the washing water according to the obtained heating temperature and the obtained heating time in a washing stage; after the washing stage is completed, controlling the washing machine to bleach according to the obtained bleaching frequency, and controlling the washing machine to carry out the last dewatering according to the last dewatering time obtained after the bleaching is completed.

Owner:WUXI LITTLE SWAN CO LTD

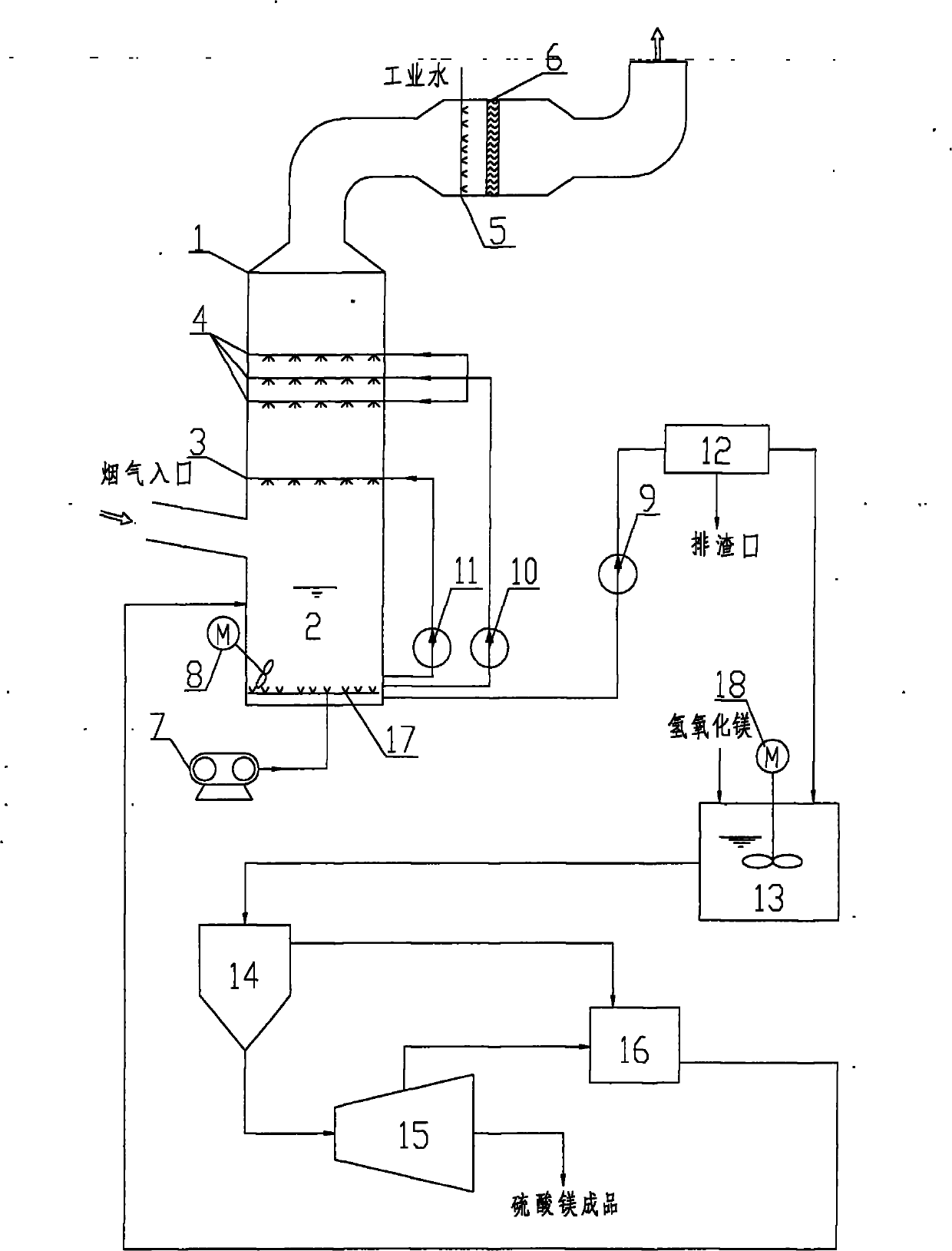

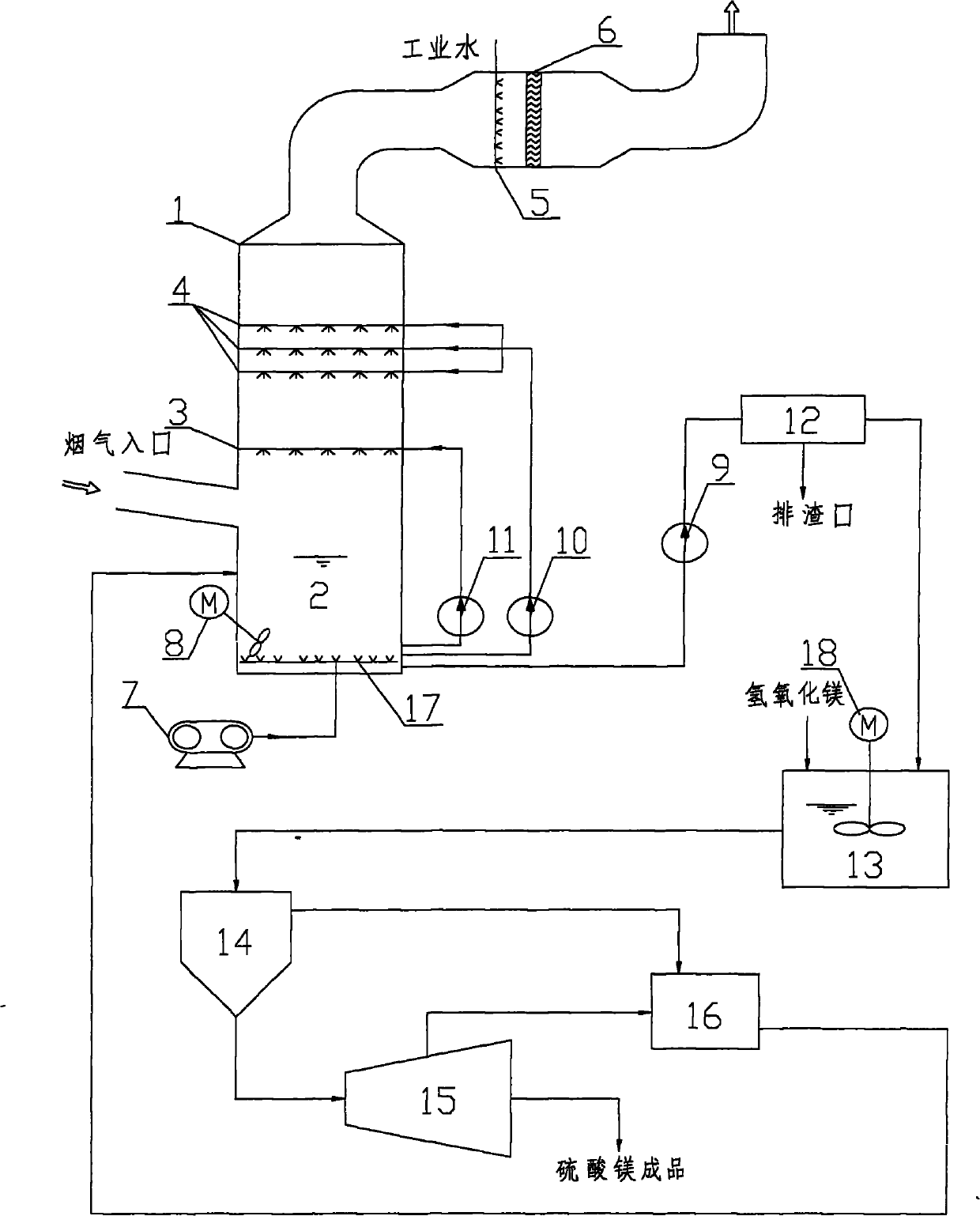

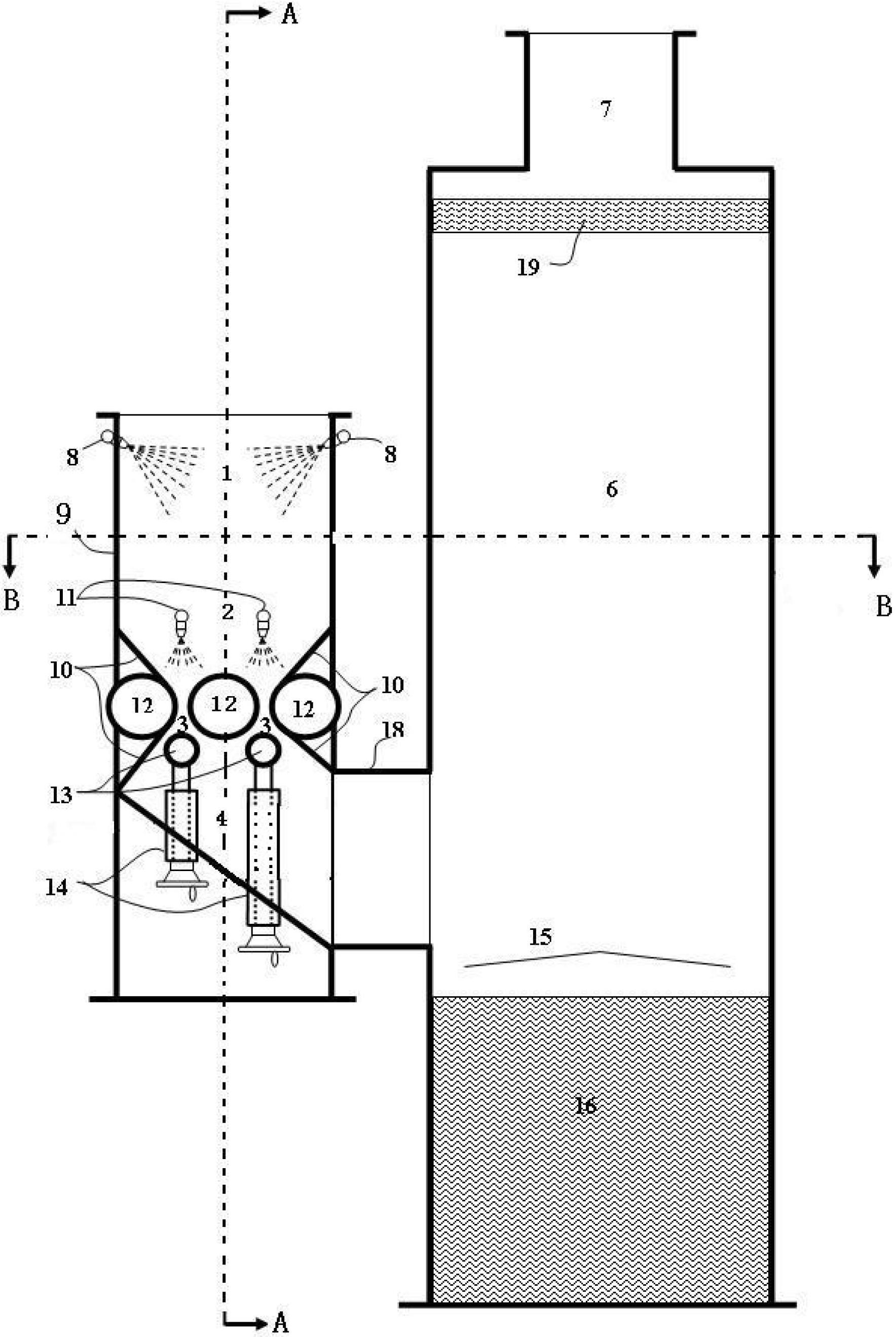

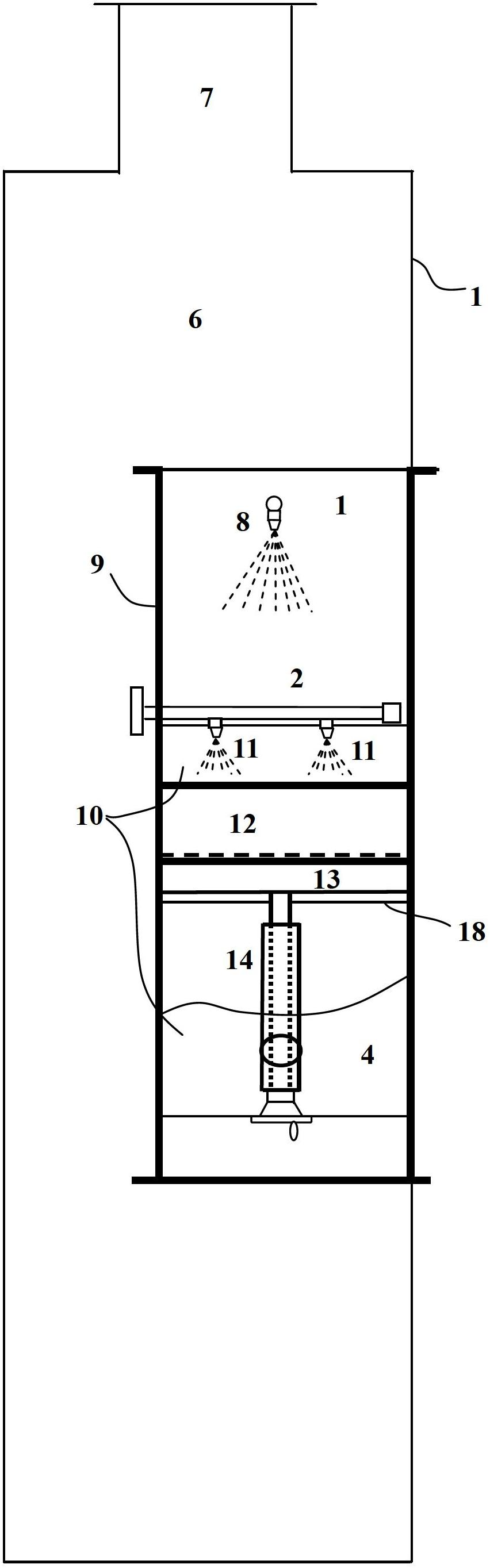

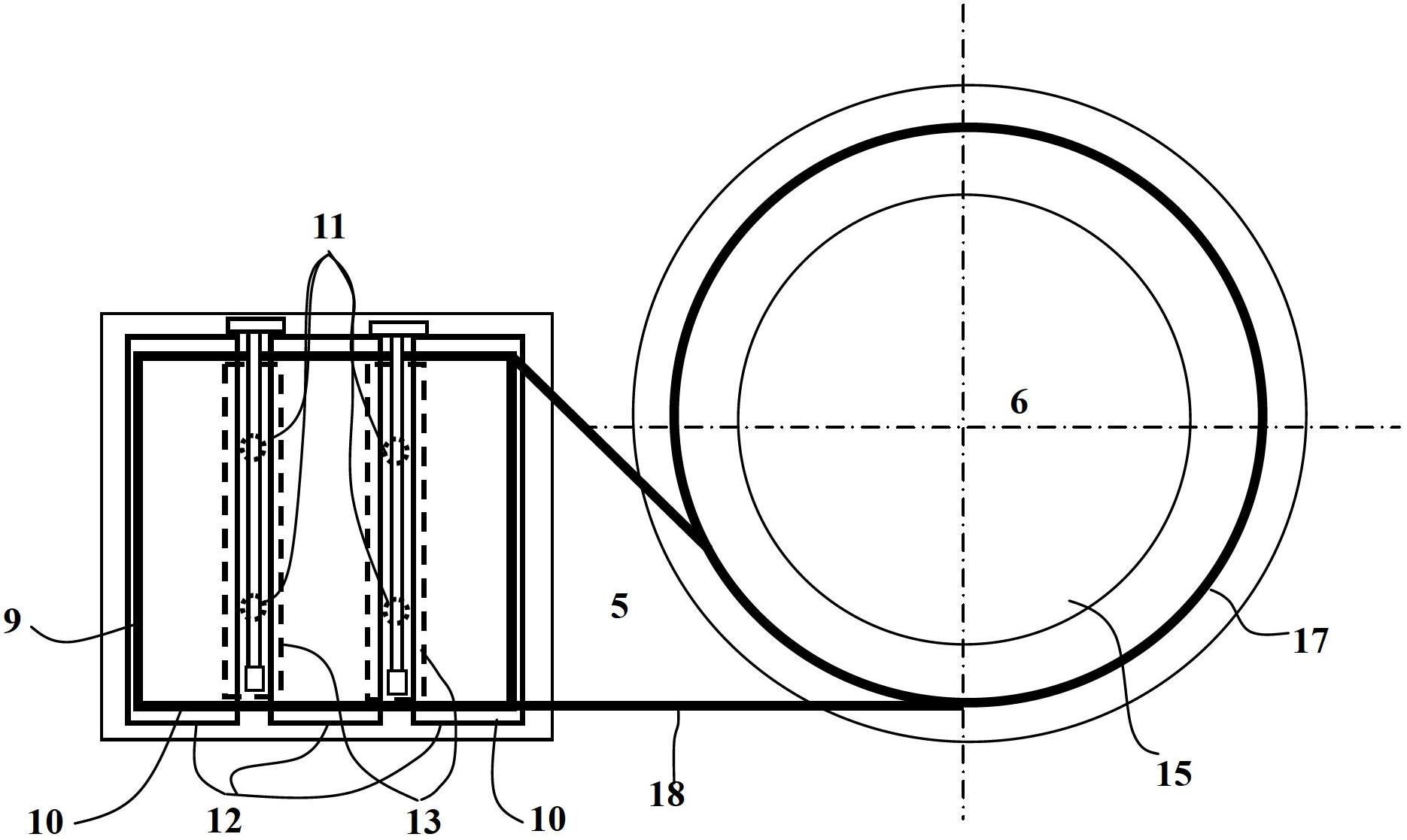

Energy-saving and consumption-reducing magnesium oxide flue gas desulfurization process and device

InactiveCN101947406ASmall footprintReduce energy consumptionChemical industryDispersed particle separationSlagSmall footprint

The invention discloses an energy-saving and consumption-reducing magnesium oxide flue gas desulfurization process and an energy-saving and consumption-reducing magnesium oxide flue gas desulfurization device. The device consists of an absorbing tower, a neutralizing tank, a concentration and sedimentation tank, a centrifugal separator and a middle tank, and is characterized in that flue gas directly enters the absorbing tower without passing through a pre-washing tower; a cooling spray layer is arranged in the absorbing tower to cool down the entered flue gas, so that area occupied is reduced; a filtering and slag removing device is arranged behind an extraction pump, so that purity of magnesium sulfide serving as a byproduct is improved; the neutralizing tank is provided with a magnesium hydroxide feed port; and supernatant of the concentration and sedimentation tank and dilute solution separated by the centrifugal separator are used as absorption liquid to newly enter the absorbing tower after passing through the middle tank. The entire desulfurization system has the advantages of simple process, no secondary pollution, low energy consumption and small occupied area and is particularly suitable for enterprises with magnesium oxide resources and small reserved lands.

Owner:山西晋丰节能环保工程设计有限公司 +1

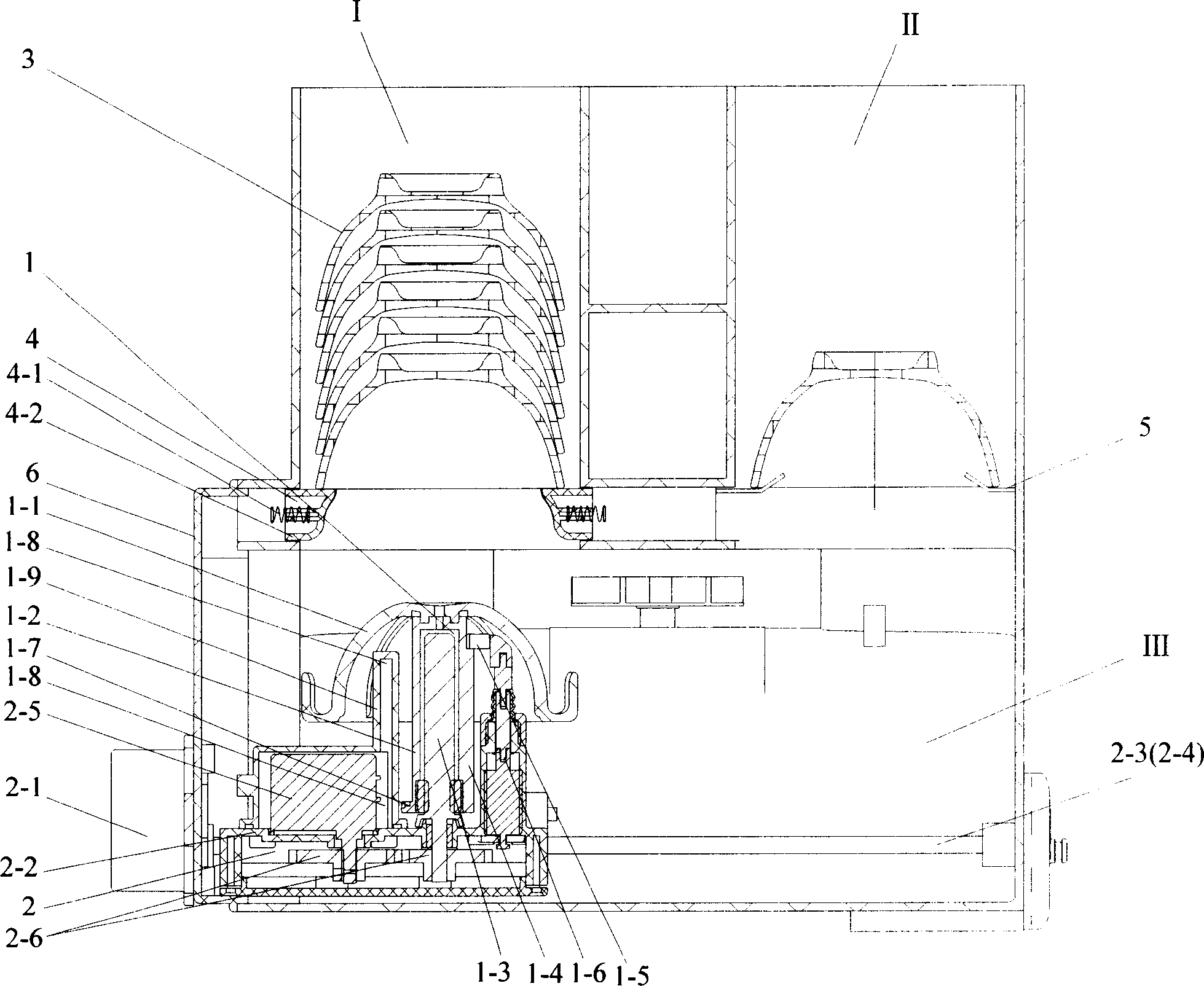

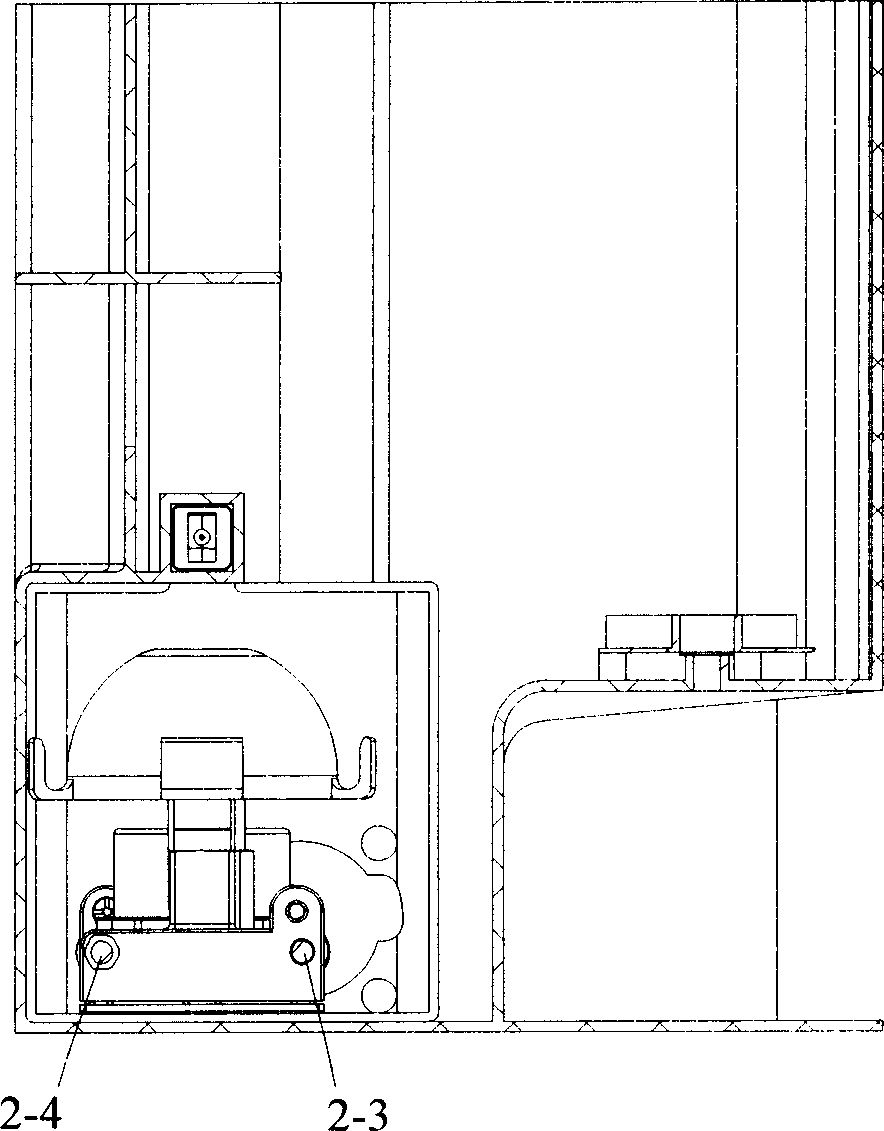

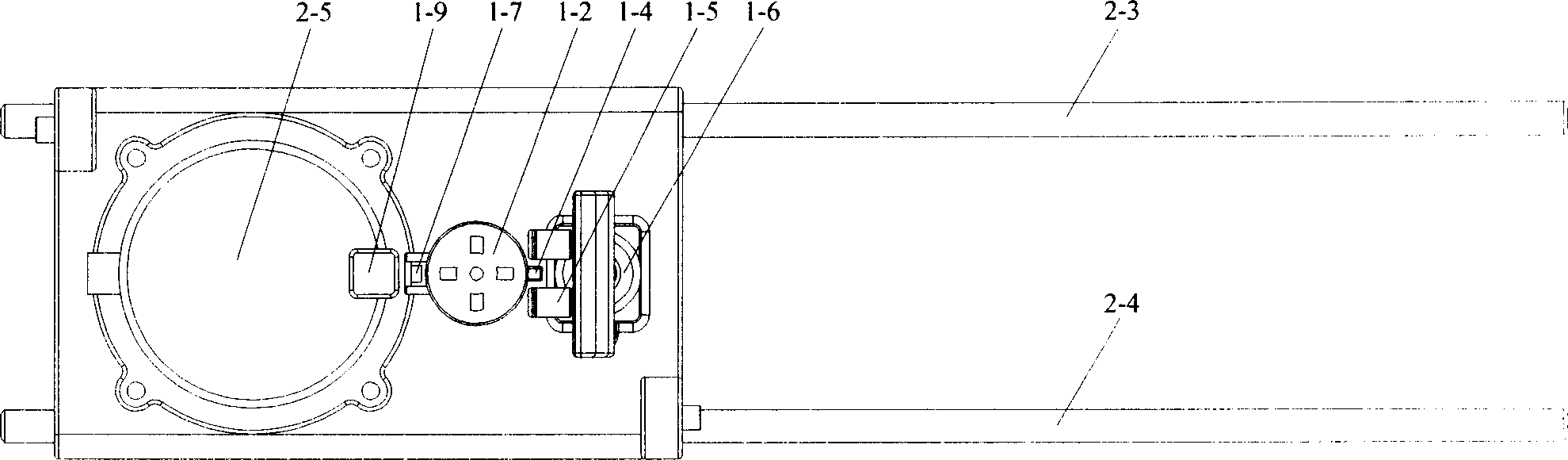

Integrated Venturi air washing device

InactiveCN102657991ARealize automatic adjustmentEasy to adjustHuman health protectionCombination devicesCyclonic separationFlue gas

The invention discloses an integrated Venturi air washing device. The device comprises two communicated barrels, wherein one barrel is a washing tower in which waste gas can be subjected to pre-washing treatment such as cooling and humidifying, and washing liquid can be injected and fully mixed with flue gas; the other barrel is a separation tower which mainly finishes gas-liquid separation; and the two barrels are connected into a whole through a communicating pipe. After being pretreated, the waste gas is washed and separated by using a Venturi effect and the cyclone separation principle. The Venturi air washing device is small in size, can be flexibly arranged, is easy to manufacture, is flexibly regulated, and can be suitable for large flue gas treatment, small workshop air purification and the like.

Owner:CESTOIL ENVIRO CO LTD

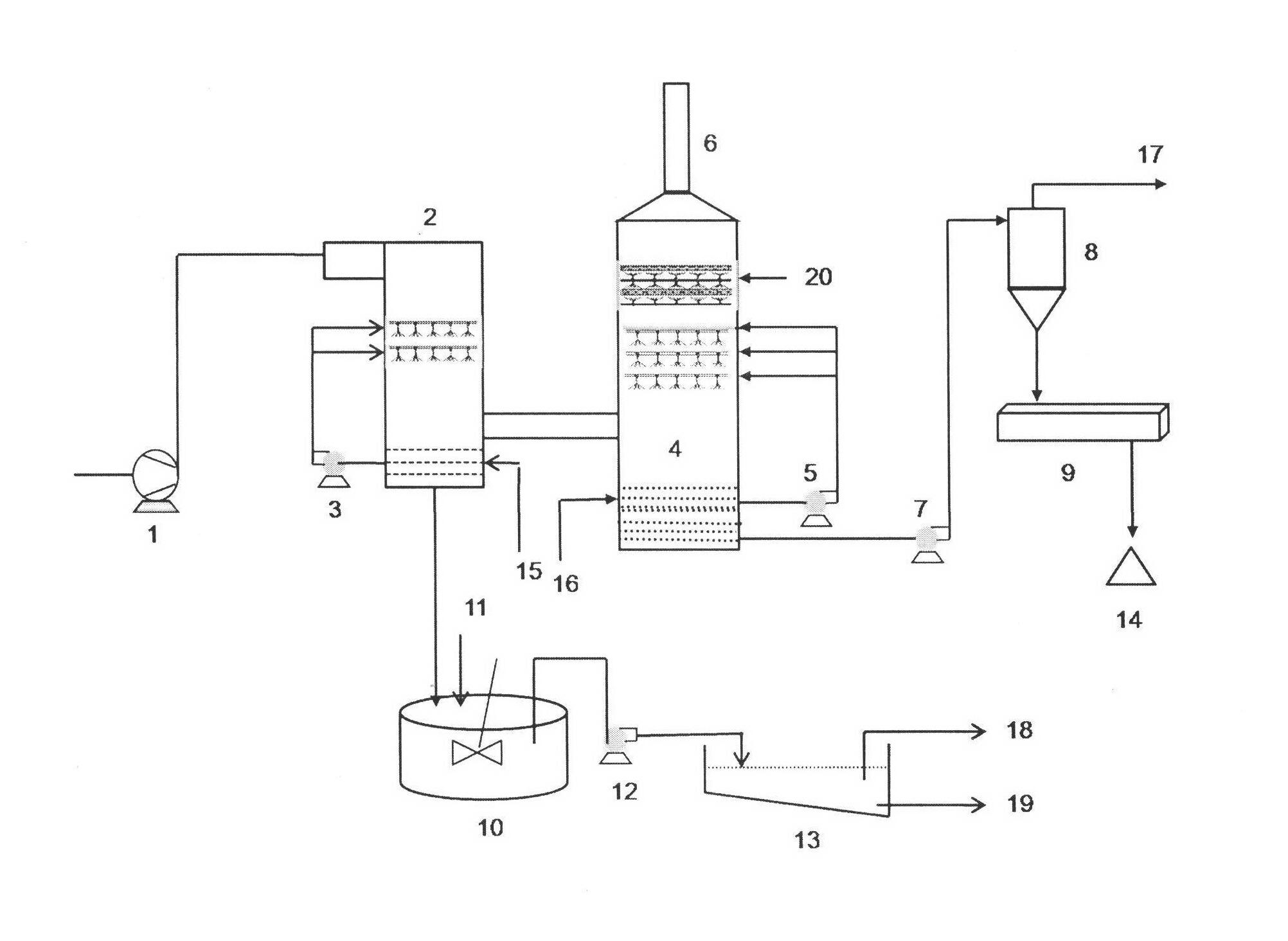

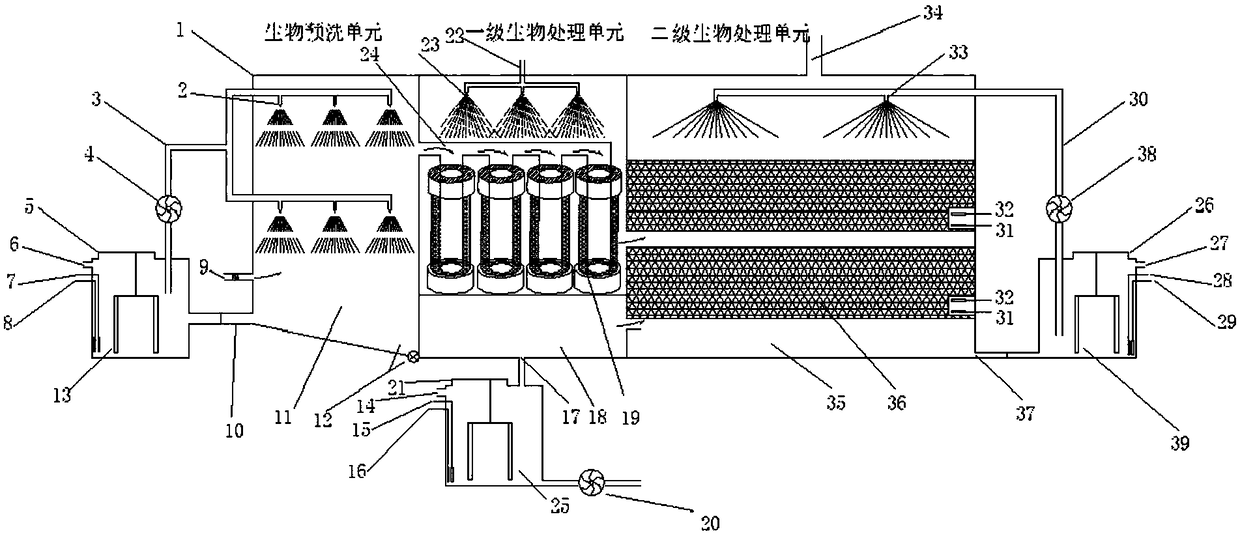

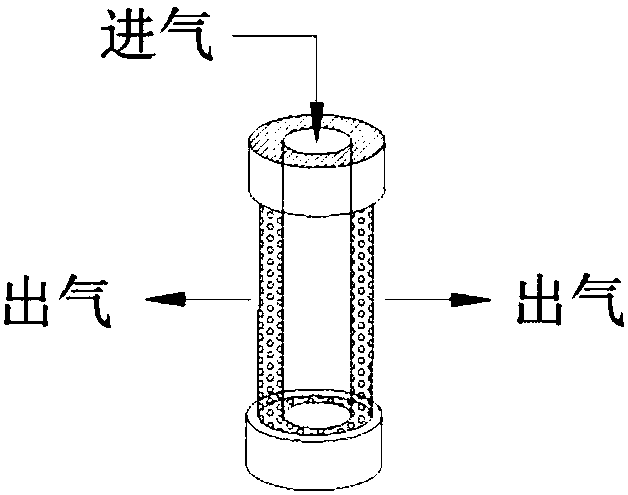

Multi-stage tandem type bio-integrated deodorization method and device

ActiveCN108211773AReduce pollutionReduce energy consumptionDispersed particle separationAir quality improvementEnvironmental engineeringProduct gas

The invention provides a multi-stage tandem type bio-integrated deodorization method and device. The device comprises a biological pre-washing unit, a primary biological treatment unit, and a secondary biological treatment unit which are connected in series; the biological pre-washing unit receives a malodorous gas; the malodorous gas is mixed with atomized biological pre-washing bacterial liquid;liquid absorbing and decomposing the malodorous gas falls into a bottom pool; the first biological treatment unit is filled with polyhedral hollow ball fillers; the secondary biological treatment unit is filled with secondary foamed polyurethane particle sponge fillers; the malodorous gas is respectively absorbed, adsorbed and degraded by microorganisms attached to the fillers when passing through the fillers in the primary biological treatment unit and the secondary biological treatment unit. The multi-stage tandem type bio-integrated deodorization method and device provided by the inventionrealize up-to-standard treatment of the malodorous gas while operating at low energy consumption and low cost so as to reduce pollution of the malodorous gas on atmosphere.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

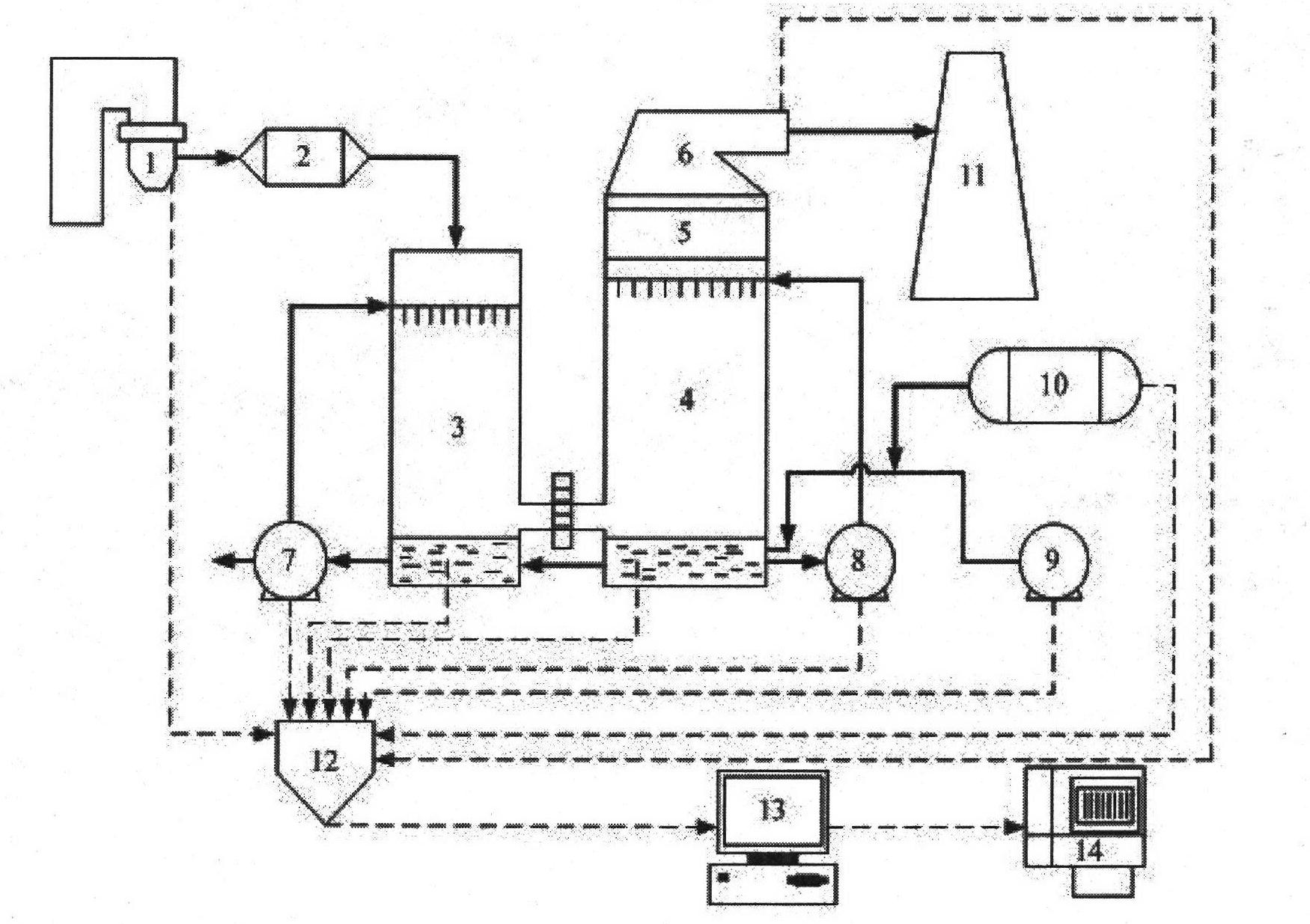

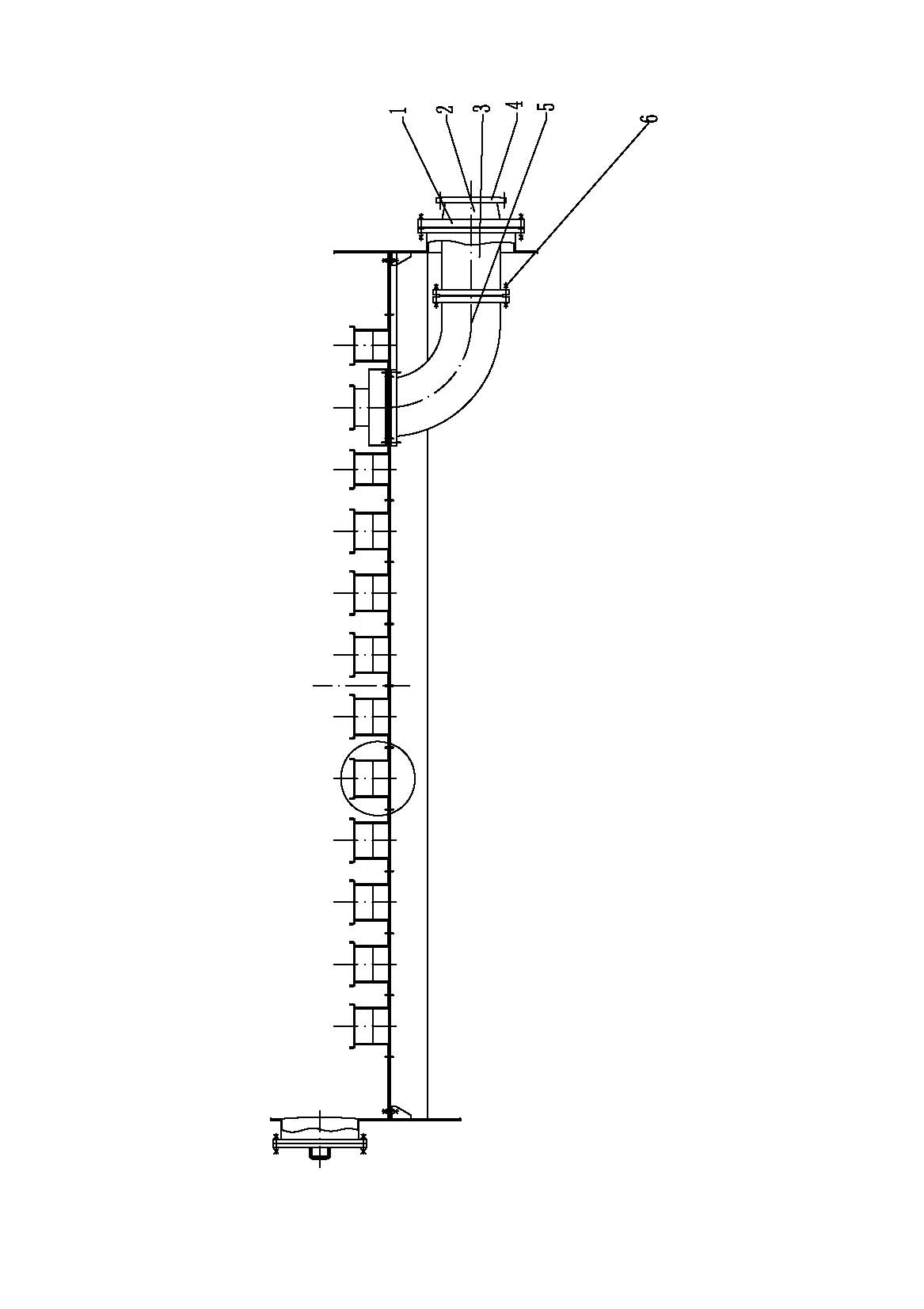

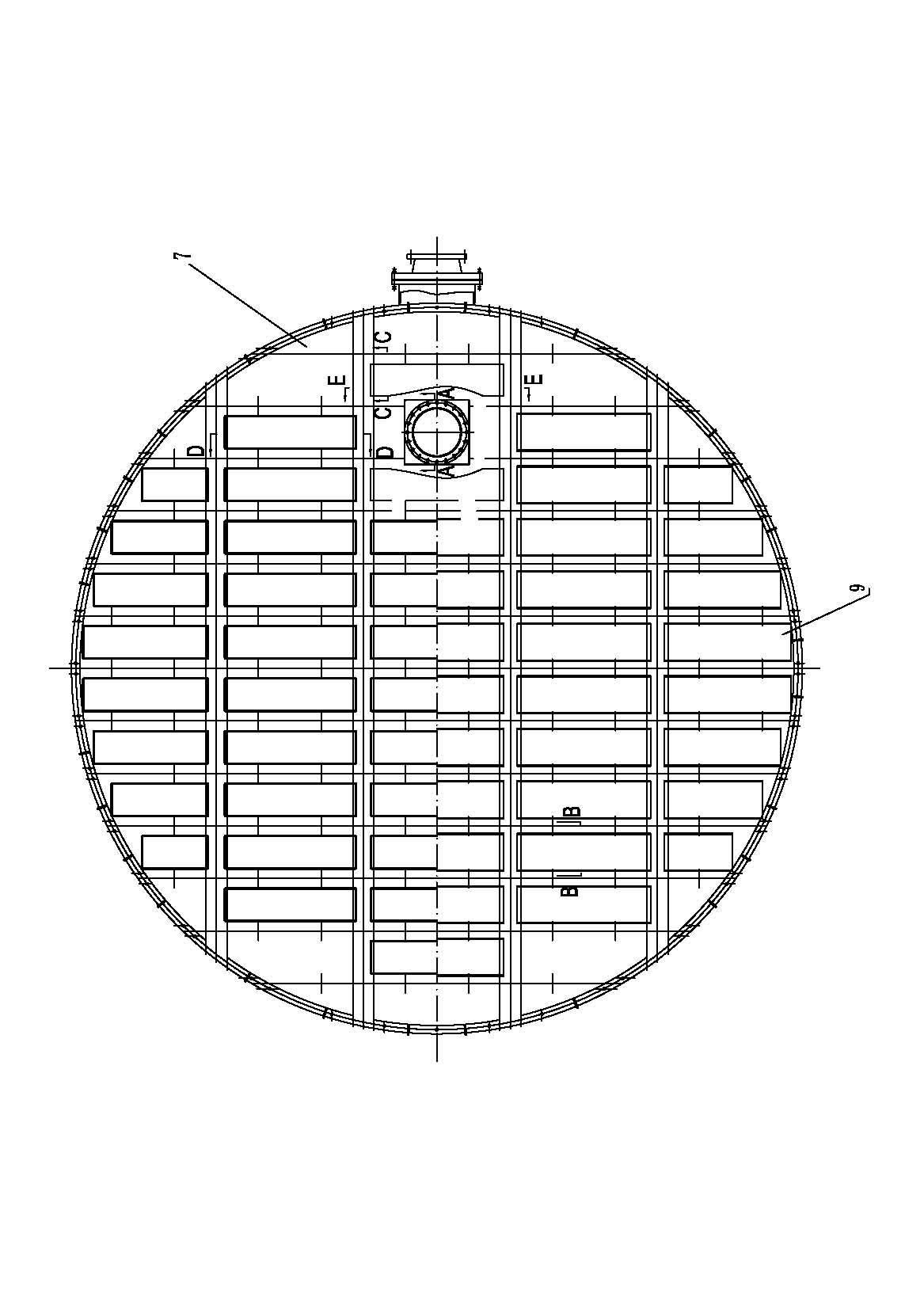

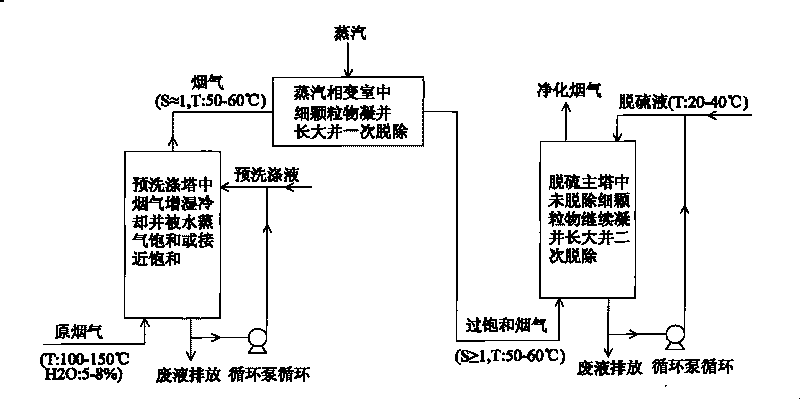

Device and method for promoting fine particle matters to be removed in coal-burning wet flue gas desulfuration process

InactiveCN101732970AReduce consumptionEfficient removalUsing liquid separation agentLiquid wasteWater vapor

The invention provides a device and a method for promoting fine particle matters to be removed by applying a steam phase-change principle, aiming at the character of high flue gas and water vapor content in a coal-burning WFGD process with a pre-washing tower. The device for promoting the fine particle matters to be removed in the coal-burning wet flue gas desulfuration process comprises the pre-washing tower, a steam phase-change chamber and a main desulfurizing tower; the steam phase-change chamber is provided with a waste liquor washing outlet, a flue gas inlet and a flue gas outlet; the flue gas inlet is connected with a flue gas outlet of the pre-washing tower; the flue gas outlet is connected with a flue gas inlet of the main desulfurizing tower; and a steam nozzle, a demister and a washing water nozzle are sequentially arranged between the flue gas inlet and the flue gas outlet of the steam phase-change chamber.

Owner:SOUTHEAST UNIV

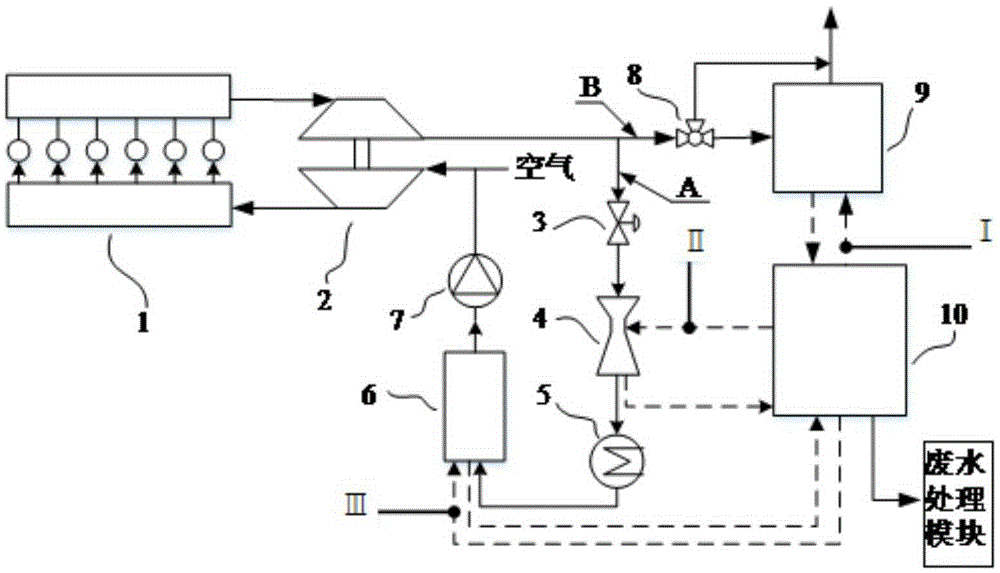

Combined desulphurization and denitration device and method of marine diesel engine

InactiveCN105289241AEfficient removalAvoid high pressureUsing liquid separation agentAtmospheric airFresh air

The invention discloses a combined desulphurization and denitration device and method of a marine diesel engine. The exhaust gas of the diesel engine is divided into two paths, wherein one path enters a denitration channel A and is recirculated to an air cylinder to participate in burning so as to lower the NOx emission of an engine; the other path enters a desulphurization channel B and is discharged to ambient atmosphere after being subjected to desulphurization processing. In the denitration channel A, the exhaust gas flows through components including a one-way stop valve, a Venturi scrubber, a cooler, a cleaning device, a blower and the like, particles and SO2 in the exhaust gas are removed through processing processes including pre-washing, cooling, washing, pressurizing and the like, and finally, the exhaust gas is mixed with fresh air from the intake channel of the diesel engine to enter the air cylinder and participate in burning; in the desulphurization channel B, the exhaust gas is discharged into the environment atmosphere after being subjected to particle removal by washing tower desulphurization. The Tier III requirement of IMO (International Maritime Organization) on marine fuel sulphur content and NOx emission in the exhaust gas can be met, and meanwhile, the corrosion and the abrasion on an engine compressor, a cylinder liner and the like by the exhaust gas can be lowered.

Owner:HARBIN ENG UNIV

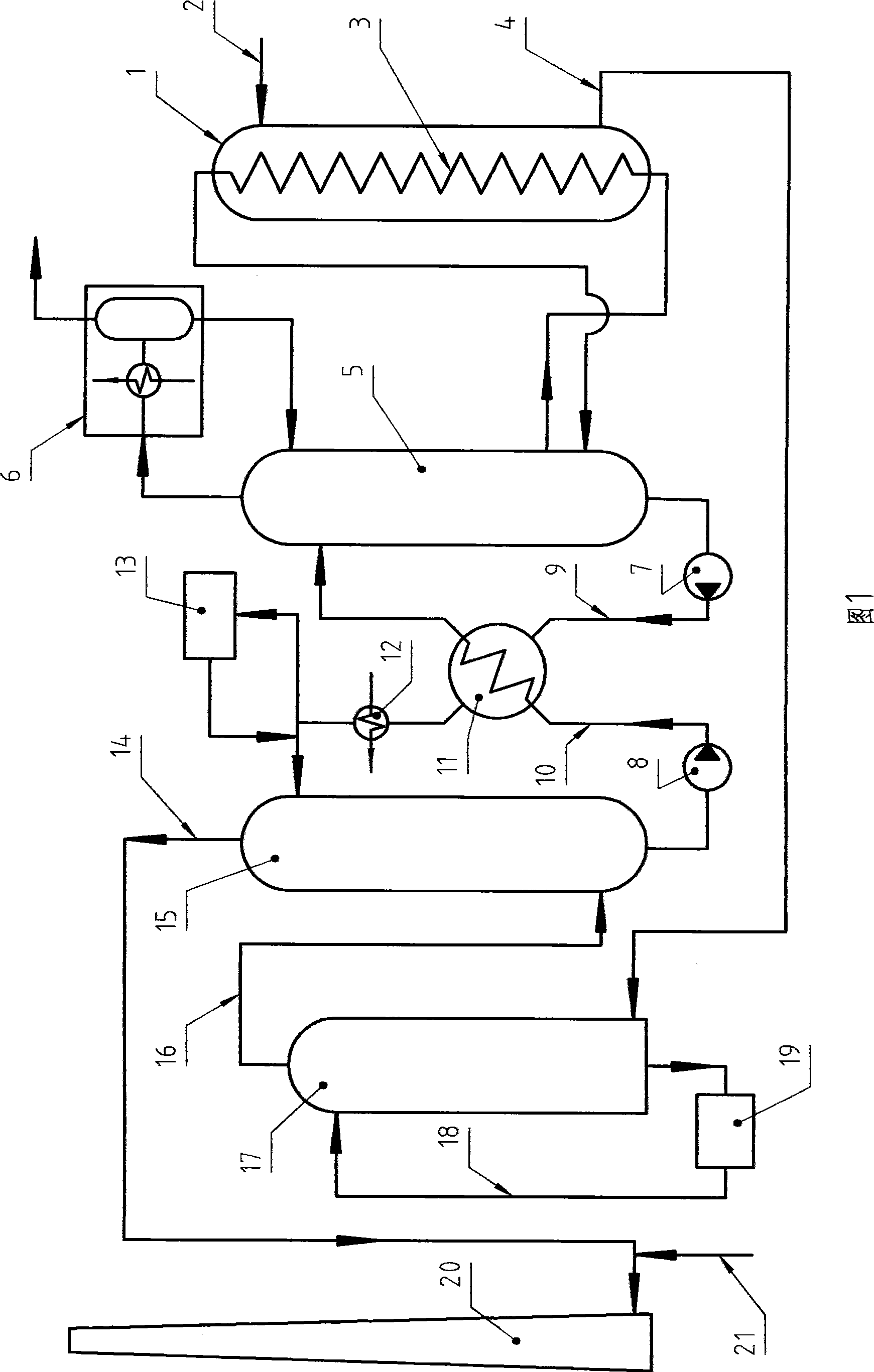

Renewable devulcanization technological process and use thereof

ActiveCN101362047AReduce energy consumptionLower your temperatureChemical industryDispersed particle separationThermal energyDesorption

The invention relates to a technique of renewable desulfurization, and the application thereof. The technique comprises the steps of the washing and cooling of desulfurated flue gas, the absorption and desorption of SO2 and heat energy supply during a desorption process and is characterized in that: at least part of heat energy required during the desorption process is supplied by the physical sensible heat carried by the flue gas to be desulfurated so as to solve the problems that during the desulfurization process, on the one hand, a great amount of steam is consumed for heating, and on the other hand flue gas needs to be cooled quickly at very low temperature in a pre-washing tower, thus leading to dual energy consumption. The invention also relates to the application of the technique of the renewable desulfurization, for example, flue gas desulfurization applicable to a sintering system of a steel plant, the flue gas desulfurization applicable to ironmaking blast furnace gas and the like. The technique and the application have the advantages of saving energy and water as much as possible and reducing heat pollution to the environment while saving energy.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

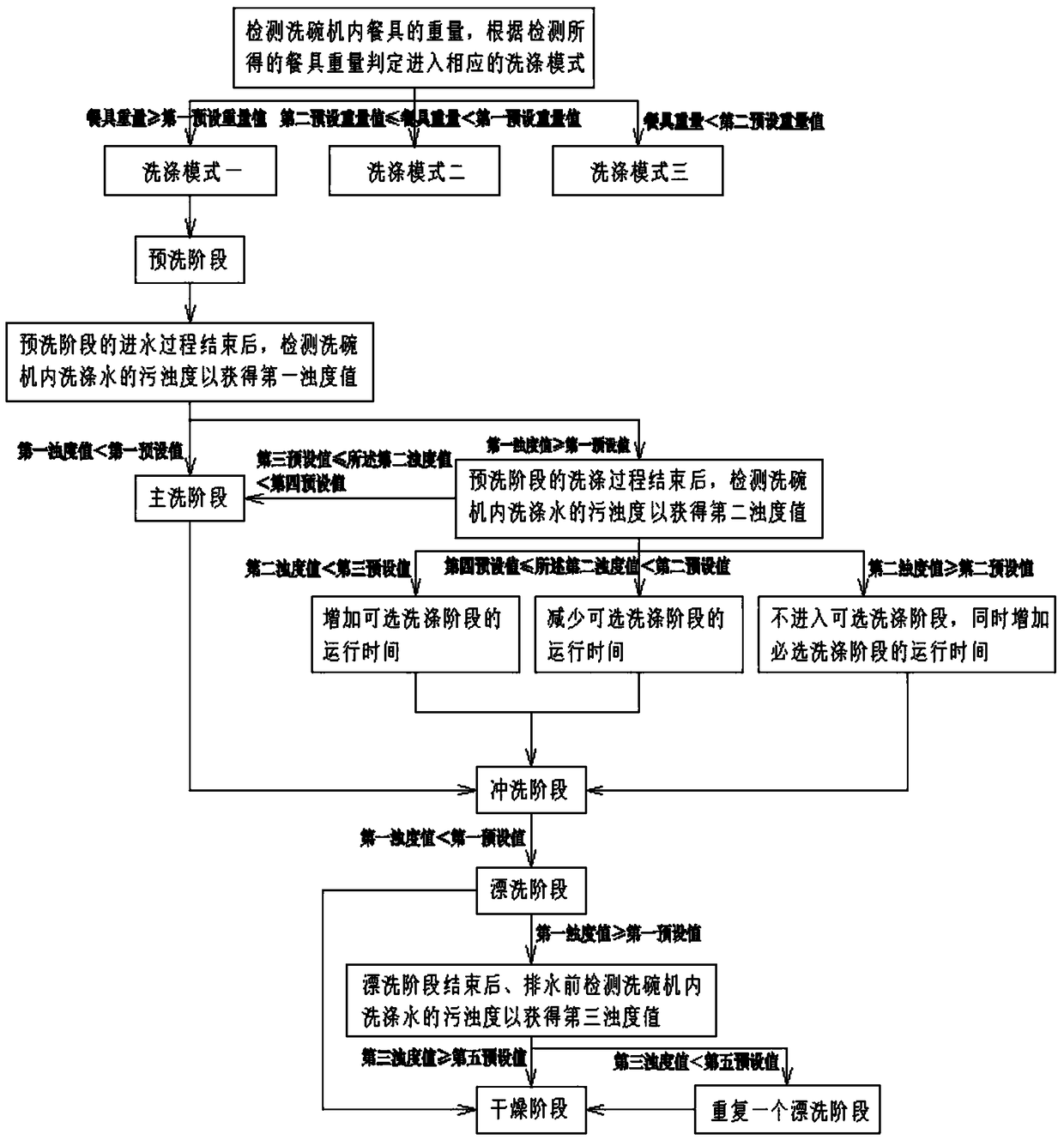

Automatic washing control method and automatic washing control device for dish washing machine

PendingCN108720772AHigh accuracy of dirt recognitionSimple designWashing controlling processesTurbidityEngineering

The invention discloses an automatic washing control method and an automatic washing control device for a dish washing machine. The automatic washing control method includes detecting the weight of tableware in the dish washing machine and determining corresponding washing modes, which the dish washing machine is about to enter, according to the detected weight of the tableware; enabling the dishwashing machine to enter required washing phases, detecting the turbidity of washing water in the dish washing machine in the required washing phases to obtain turbidity values, determining whether the dish washing machine needs to enter optional washing phases or not according to the turbidity values, and adjusting the running time of the required washing phases and the optional washing phases according to the turbidity values. The washing modes include the required washing phases, the optional washing phases, rinsing phases and drying phases which are sequentially operated; the required washing phases include pre-washing phases, and the optional washing phases include main washing phases and flushing phases. The automatic washing control method and the automatic washing control device have the advantages of high tableware dirt identification accuracy and capability of effectively saving water and power.

Owner:VATTI CORP LTD

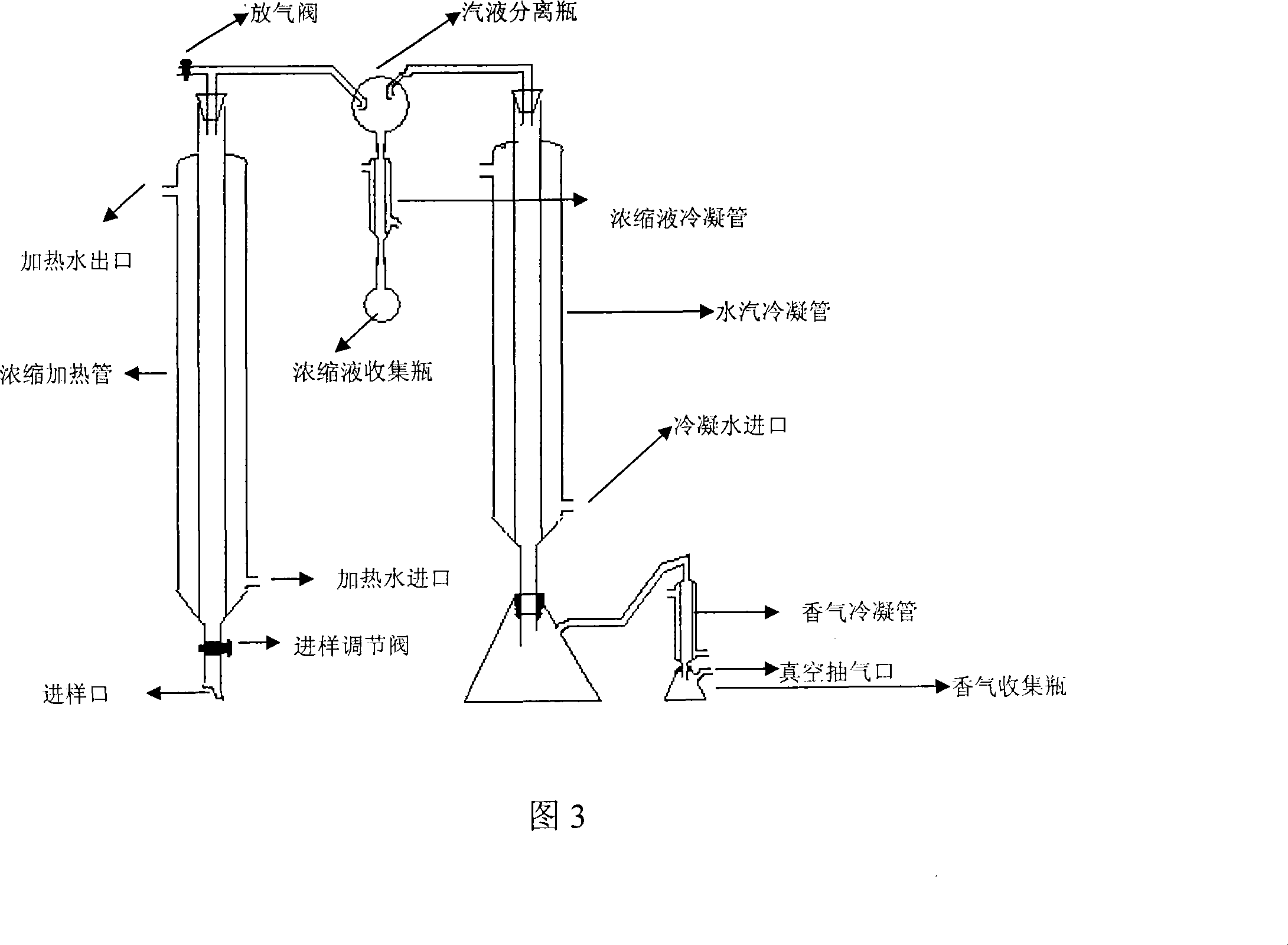

Vegetable condensed juice prepared using vegetable leaf and preparation method thereof

The invention discloses a vegetable concentrated juice prepared from vegetable leaves and a preparation method thereof. The concentrated juice is prepared by pre-washing raw materials, freezing, thawing, making juice, settling and concentrating clean fluid. The invention further discloses a method for extracting chlorophyll and preparing sodium copper chlorophyllin or sodium zinc chlorophyllin from the wastes left after preparing the vegetable concentrated juice. The vegetable concentrated juice provided by the invention has good taste, special vegetable flavor and good stability with little loss in nutrition components or active substances. The main technical indexes of the sodium copper chlorophyllin and sodium zinc chlorophyllin prepared by the method of the invention basically comply with the national GB3262-82 standard, thereby having the effects of cost saving and environment protection.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV

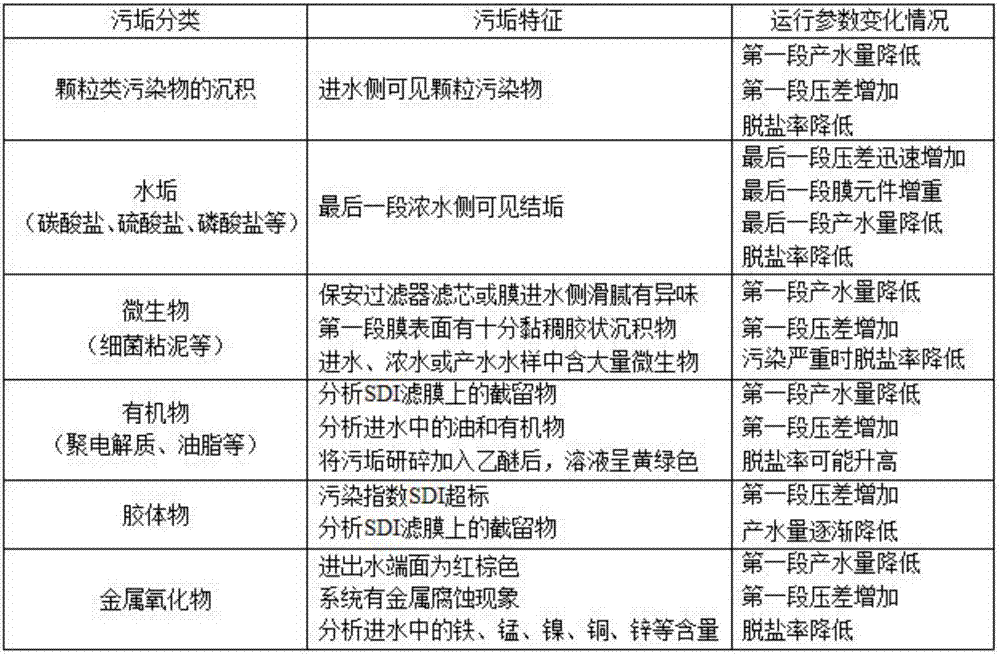

Washing method of film used in leachate treatment process

ActiveCN107261854AWater production recoveryHigh energySemi-permeable membranesSpecific water treatment objectivesIsothiazolinoneAcetic acid

A washing method of a film used in a leachate treatment process includes following steps: preparing a washing agent: (1), mixing NaOH, fatty alcohol polyoxyethylene ether and reverse osmosis generated water to obtain pre-washing alkaline washing liquid; (2), mixing sodium tripolyphosphate, sodium polyacrylate, NaOH, fatty alcohol polyoxyethylene ether, EDTA tetrasodium salt and reverse osmosis generated water to obtain alkaline washing liquid; (3), mixing sodium tripolyphosphate, sodium polyacrylate, sodium hypochlorite and reverse osmosis generated water to obtain washing-assistant alkaline washing liquid; (4), mixing sodium diethylhexyl sulfosuccinate, hydrochloric acid, citric acid, isothiazolinone and reverse osmosis generated water to obtain acidic washing liquid; judging type of the film: selecting at least two of the above washing liquids for permutation and combination, and washing the film sequentially according to a permutation and recombination sequence. The washing method realizes optimization grouping of different washing liquids and is convenient, simple, more thorough in washing, long in washing period and wider in application range.

Owner:GUANGZHOU HUANTOU ENVIRONMENTAL SERVICES CO LTD

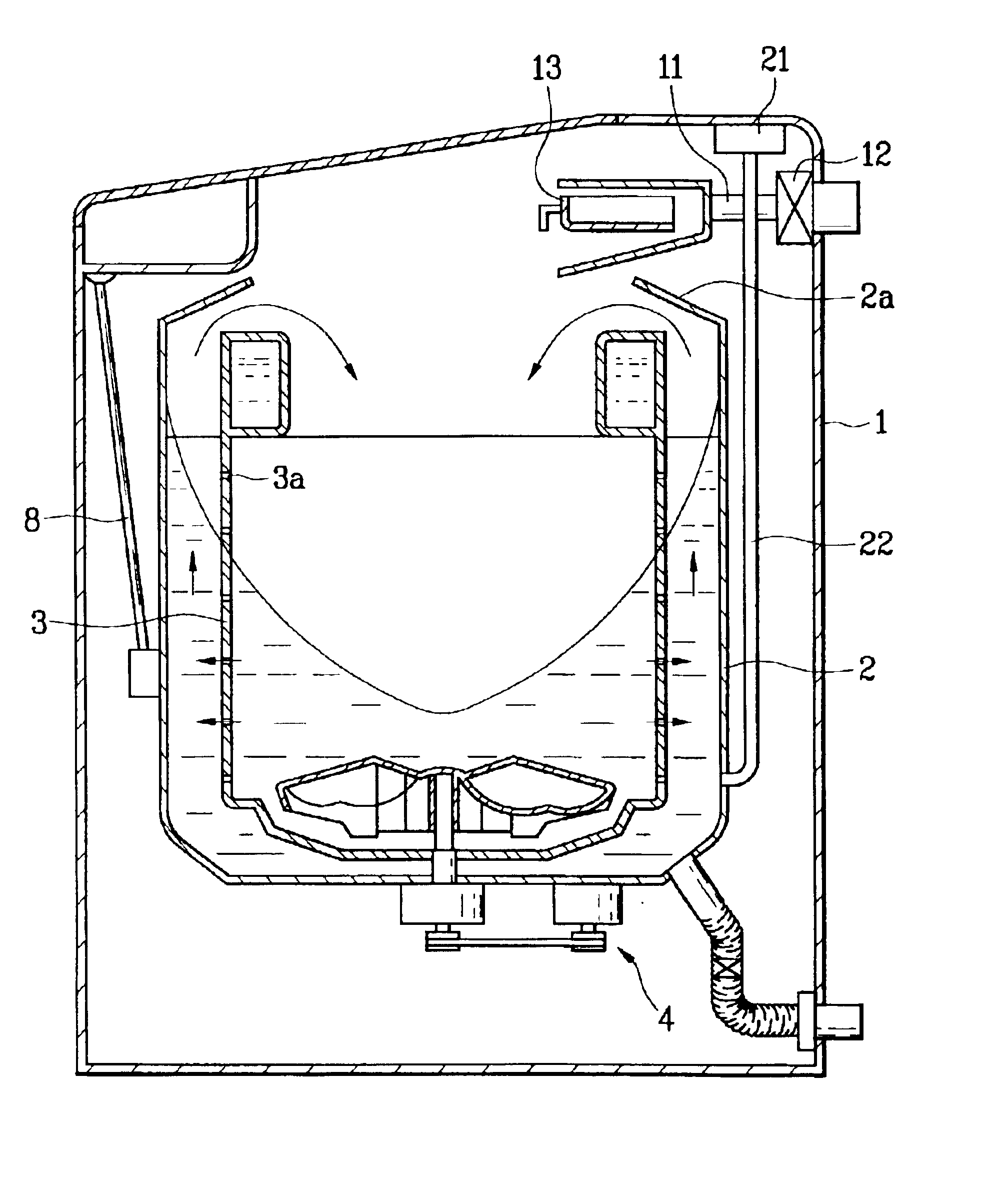

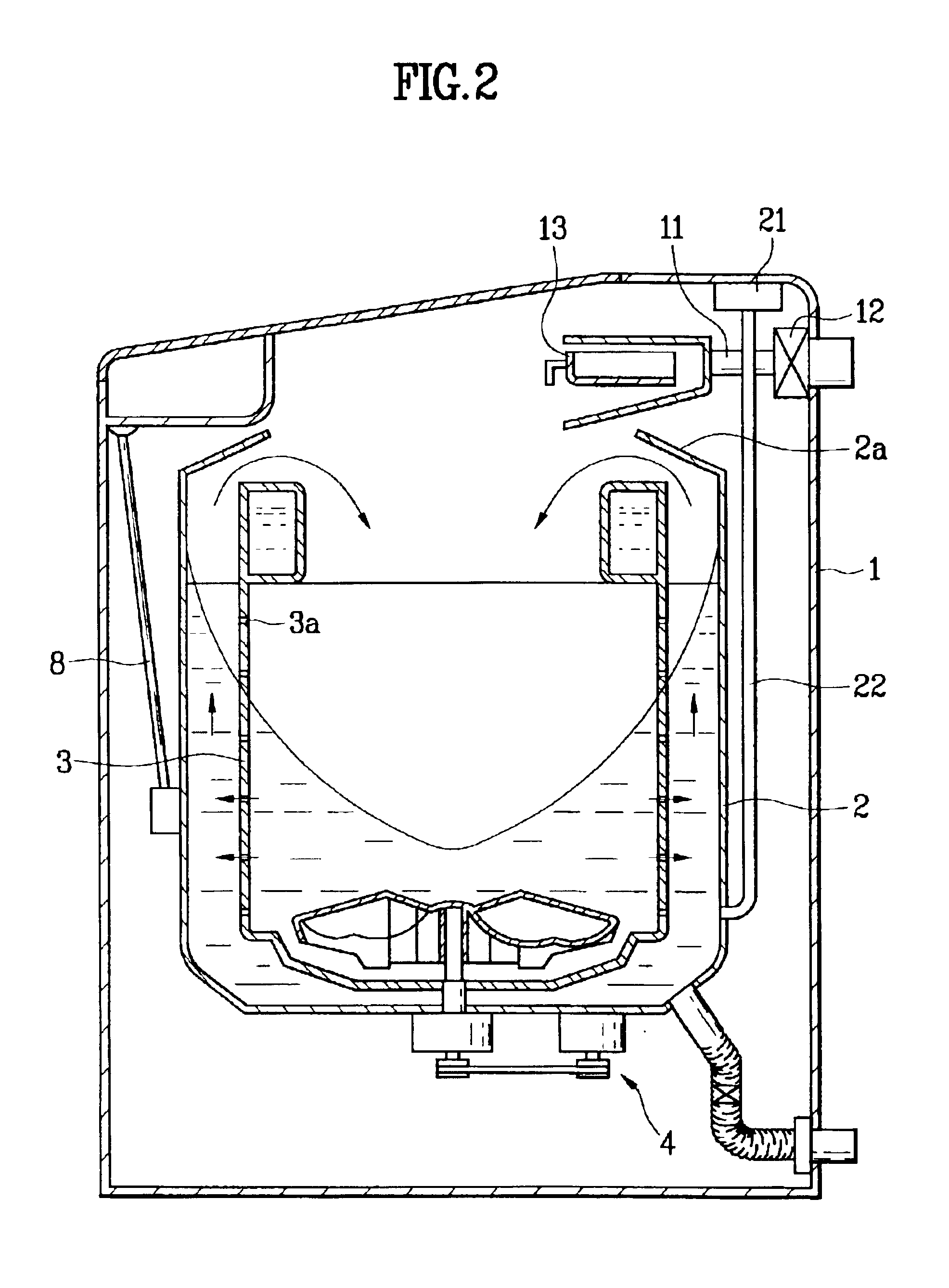

Method for controlling washing in washing machine

InactiveUS6871370B2Reduce speedPrevent splashOther washing machinesControl devices for washing apparatusEngineeringCentrifugal force

Method for controlling washing in a washing machine including the steps of (a) sensing an amount of laundry in an inner tub and determining a washing water level proper to the amount of laundry, (b) introducing washing water into the inner tub according to the washing water level, and (c) rotating the inner tub in one direction so that the washing water rises along a space between the inner tub and an outer tub and is sprayed into the inner tub again by a centrifugal force during the step (b), whereby carrying out a pre-washing during water supply even if no separate water re-circulating device is provided.

Owner:LG ELECTRONICS INC

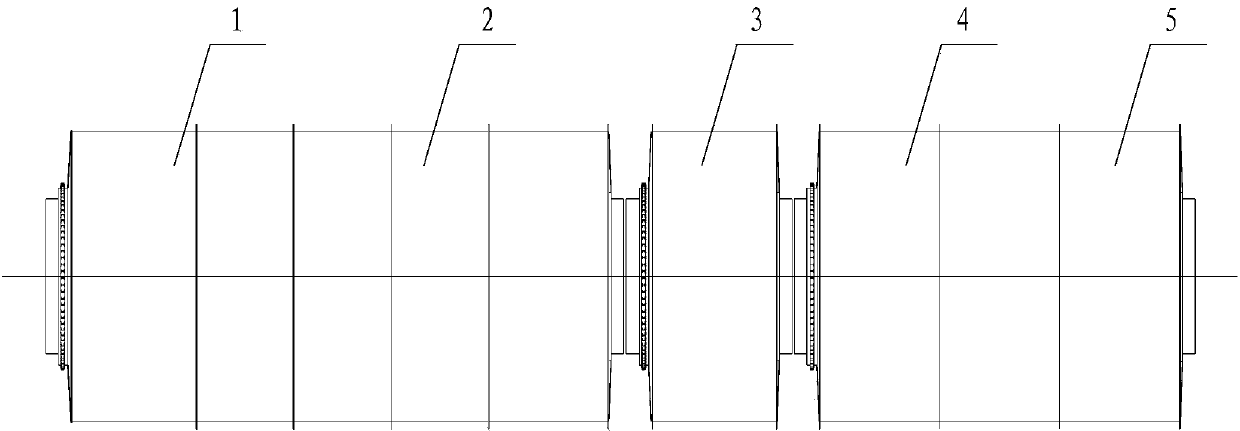

Tunnel type continuous washing machine

InactiveCN103726256AReduce the amount of sewageImprove washing effectOther washing machinesTextiles and paperAfter treatmentEngineering

The invention relates to a tunnel type continuous washing machine, and belongs to the field of washing equipment. The tunnel type continuous washing machine comprises a pre-washing area, a main washing area, a rinsing area and an after-treatment area, wherein a dewatering area is inserted between the main washing area and the rinsing area and comprises an inner barrel and an outer barrel; two panels are respectively fixed at an inlet and an outlet of the inner barrel; an inlet supporting steel ring and an outlet supporting steel ring are respectively fixed on surfaces, which are not fixed on the inner barrel, of the inlet panel and the outlet panel; the inlet supporting steel ring, the outlet supporting steel ring and the inner barrel are integrated; an optional one of the inlet supporting steel ring and the outlet supporting steel ring is connected with an external driving device; a conveying screw plate is fixed in the inner barrel; a through hole is formed in the inner wall of the inner barrel; and the inner barrel of the dewatering area is driven by an independent motor to rotate. By using the tunnel type continuous washing machine, the rinsing efficiency can be effectively improved; water consumed during rinsing is reduced; resources are saved; dewatered cloth grasses are easily rinsed cleanly; and a washing effect is obviously improved.

Owner:SHANGHAI WEISHI MACHINERY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com