A Dishwasher Washing Method and a Dishwasher

A dishwashing machine and dishwashing technology, which is applied in the direction of tableware washing machine/rinsing machine, washing process, cleaning equipment, etc., can solve the problems of long washing time, insufficient washing time, waste water, etc., so as to ensure the washing effect and save Washing time, the effect of guaranteeing the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

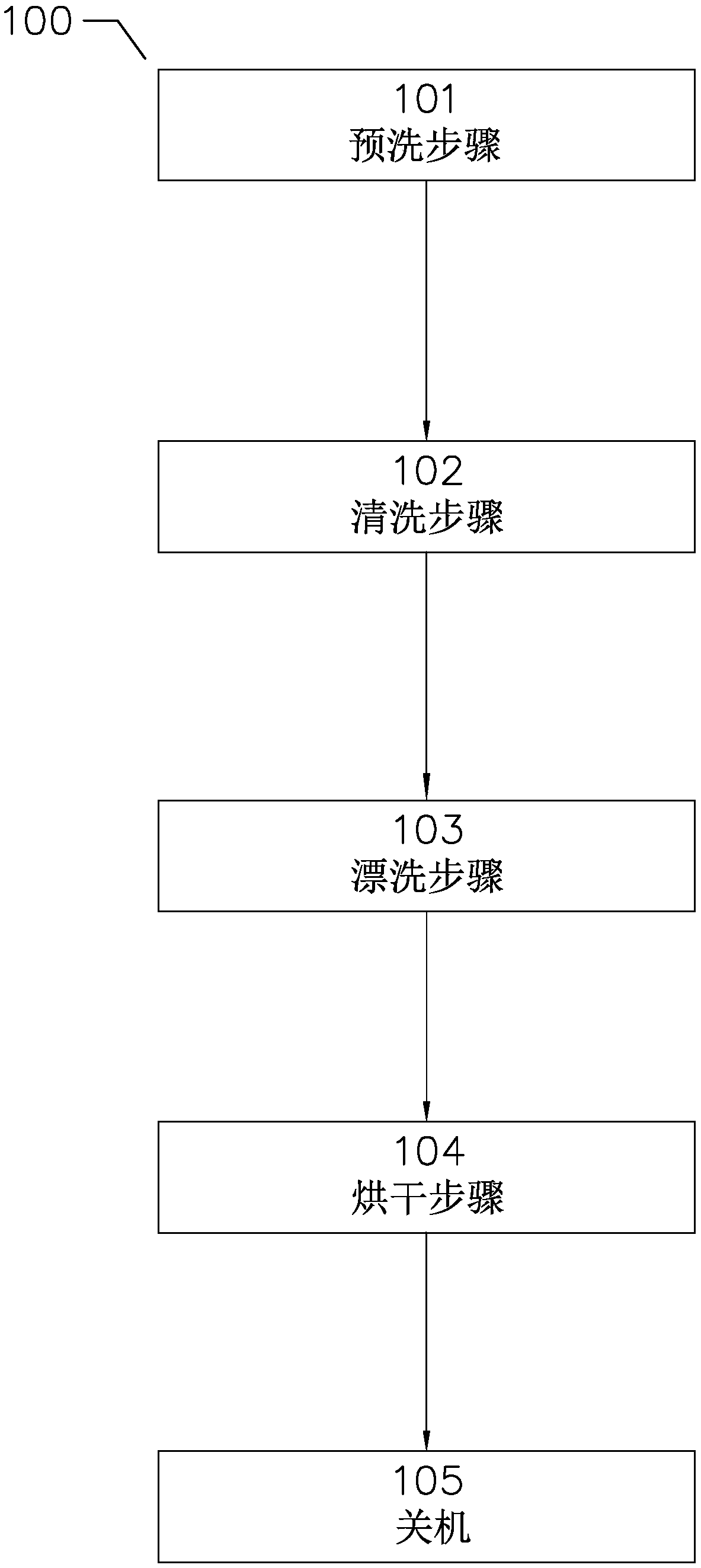

[0038] Such as figure 1 As shown, the present invention provides a dishwashing method 100 for a dishwasher. The dishwasher includes a casing, a control panel, a respirator connected to a water source, an inner container for placing tableware, and a spray arm disposed in the inner container. , Drying device, the inner tank includes a water tank with a heating element, the bottom of the inner tank is provided with a washing pump and a drain pump connected to the water tank, a turbidity sensor is installed between the washing pump and the water tank, and the dishwasher is equipped with multi-level washing dishes The multi-level dishwashing mode includes quick washing mode, standard washing mode and enhanced washing mode. The total washing time of the enhanced washing mode is longer than that of the standard washing mode, and the total washing time of the standard washing mode is longer than that of the quick washing mode. Time, specifically, the total washing time of the fast was...

Embodiment 2

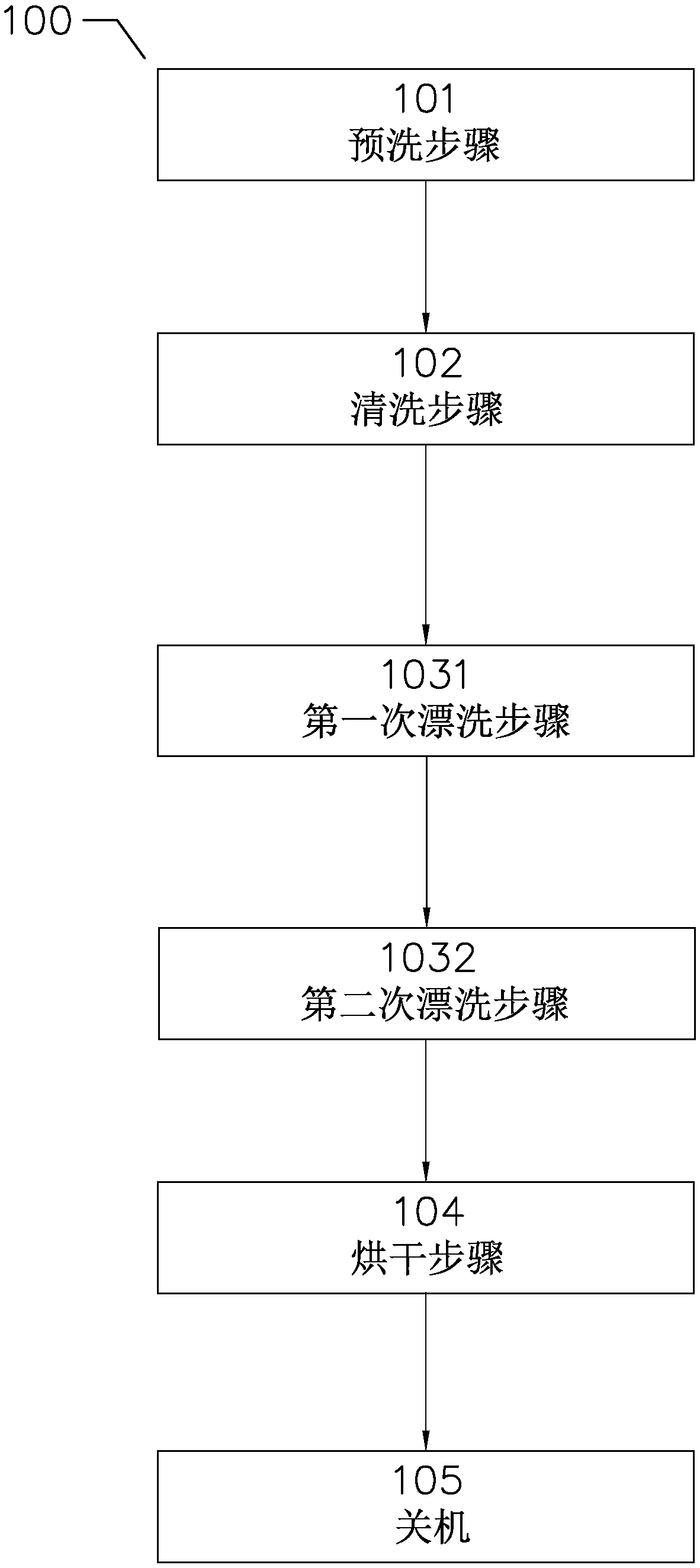

[0068] The difference between this embodiment and the first embodiment is that the rinsing step includes a first rinsing step and a second rinsing step.

[0069] In this example, if figure 2 As shown, the dishwashing method 100 of the dishwasher includes:

[0070] Pre-washing step 101: add water with a capacity of C1 to the tank and heat the water to T1 temperature, then stop heating, the washing pump works for t1 and pauses for t2, the turbidity sensor obtains the turbidity of the water, and the dishwasher uses the turbidity sensor to The turbidity of the water obtained to determine the dishwashing pattern;

[0071] Cleaning step 102: continue to add water to the water tank to the set capacity and heat the water to the set temperature, the washing pump works and supplies water to the spray arm so that the spray arm can clean the tableware in the inner container, and drain the pump after cleaning work to drain the water;

[0072] The first rinsing step 1031: add water to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com