Patents

Literature

532results about "Washing processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

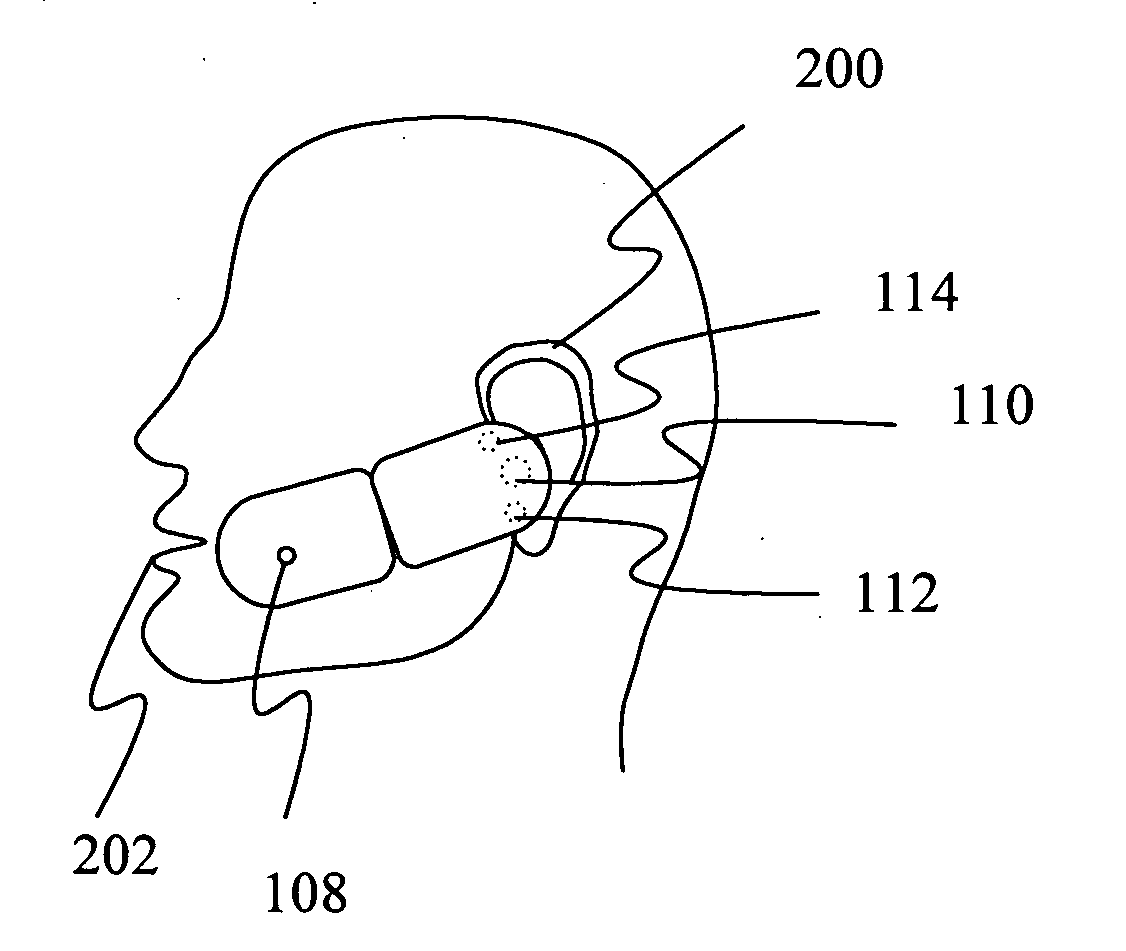

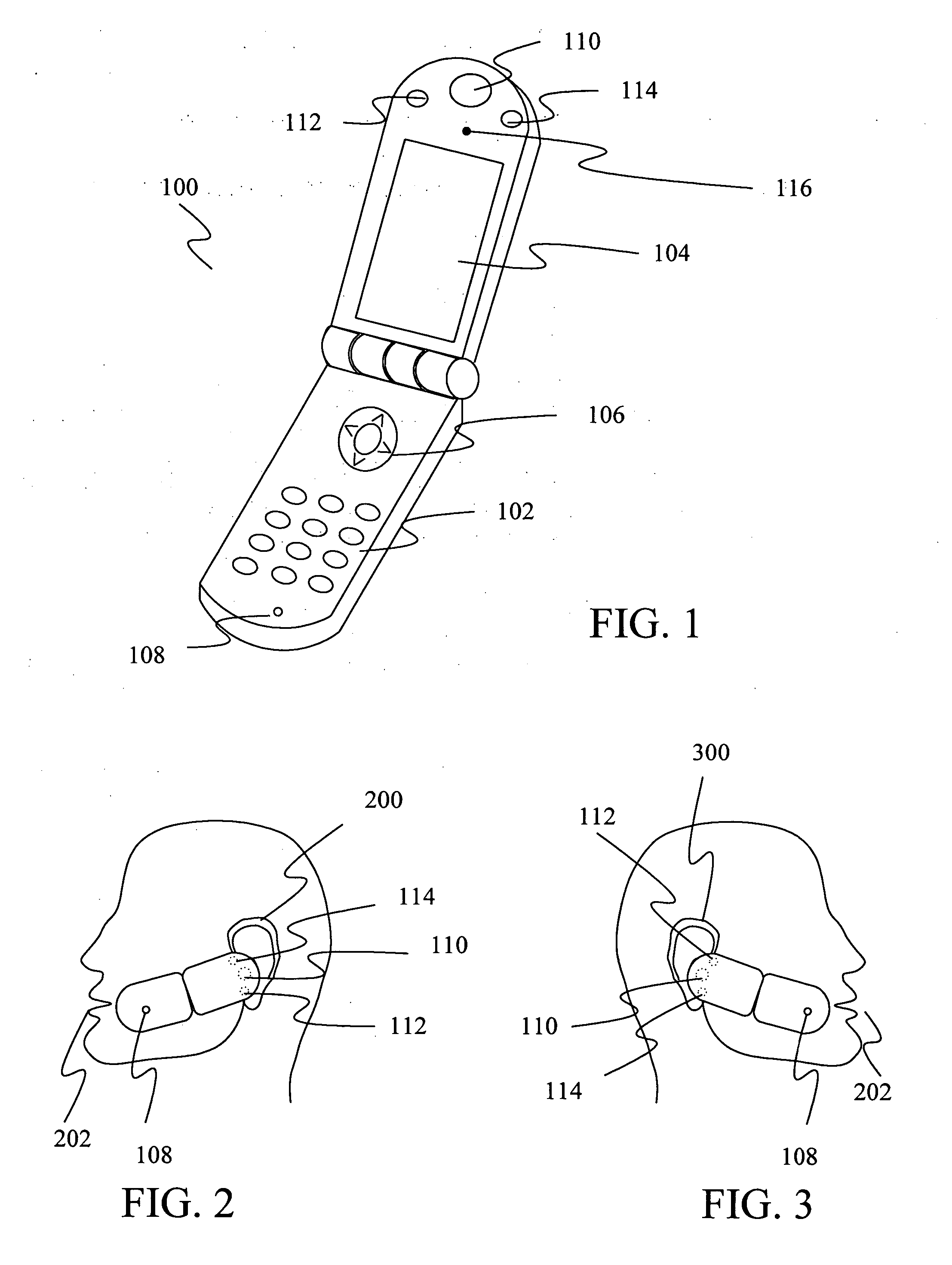

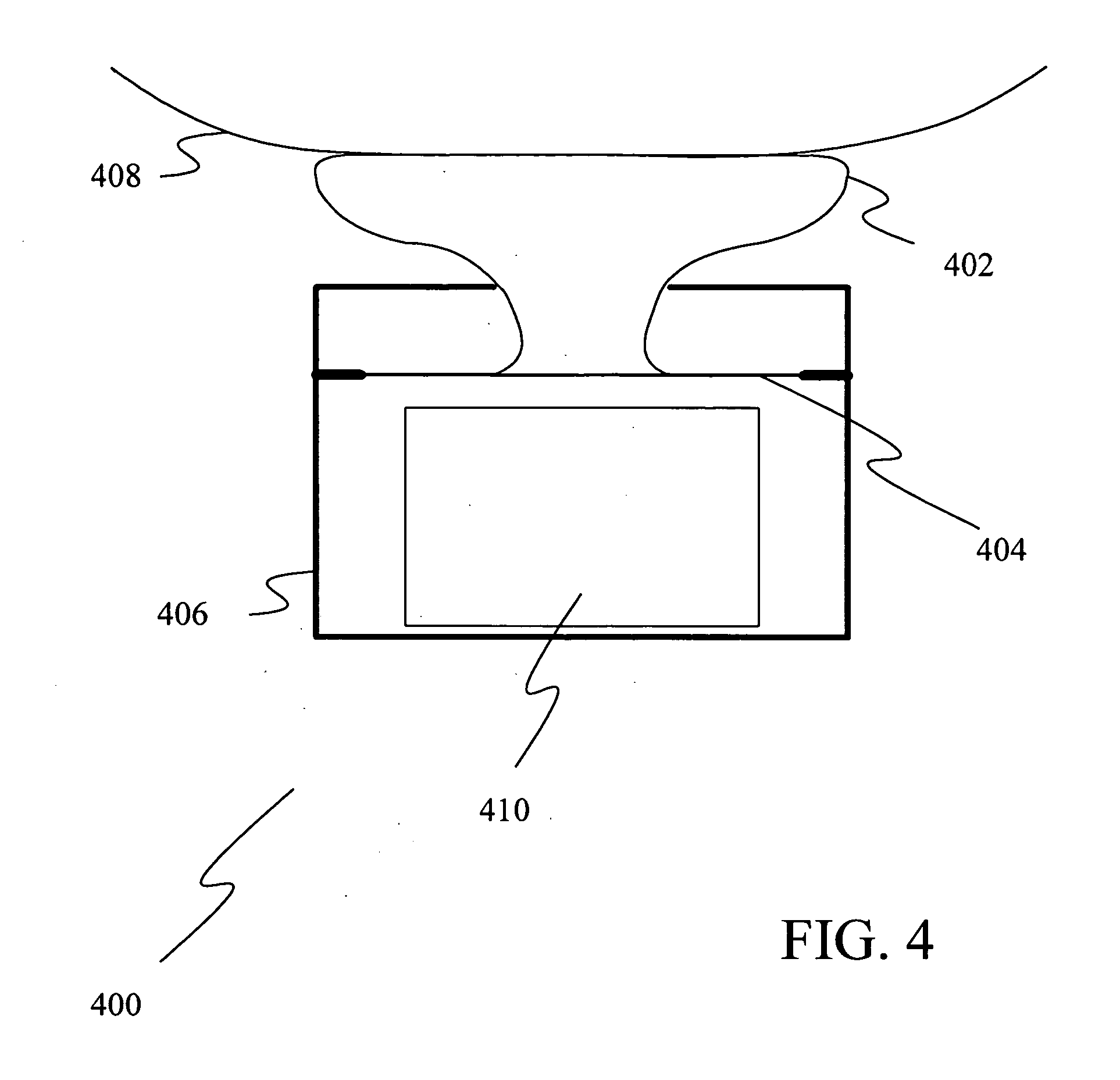

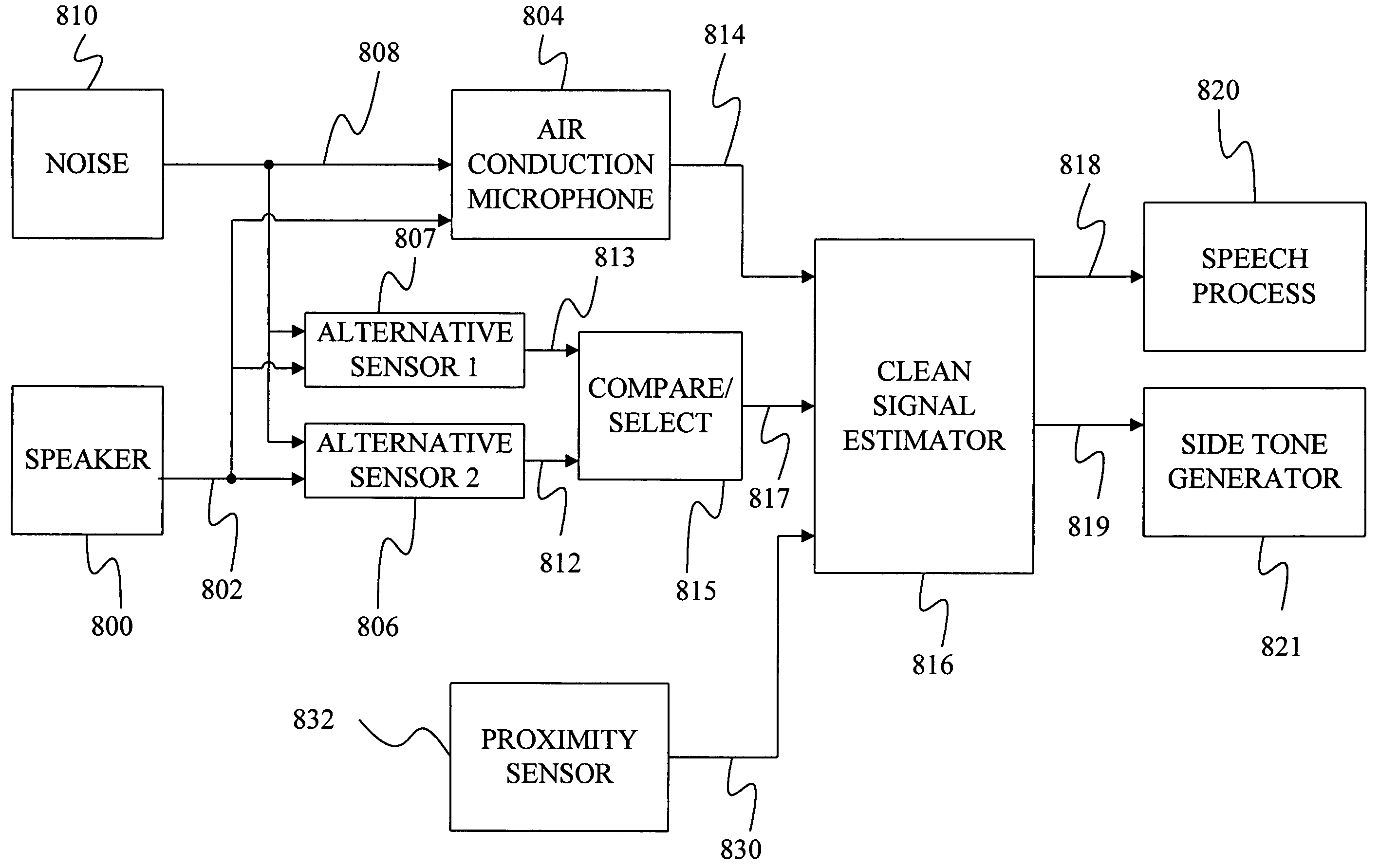

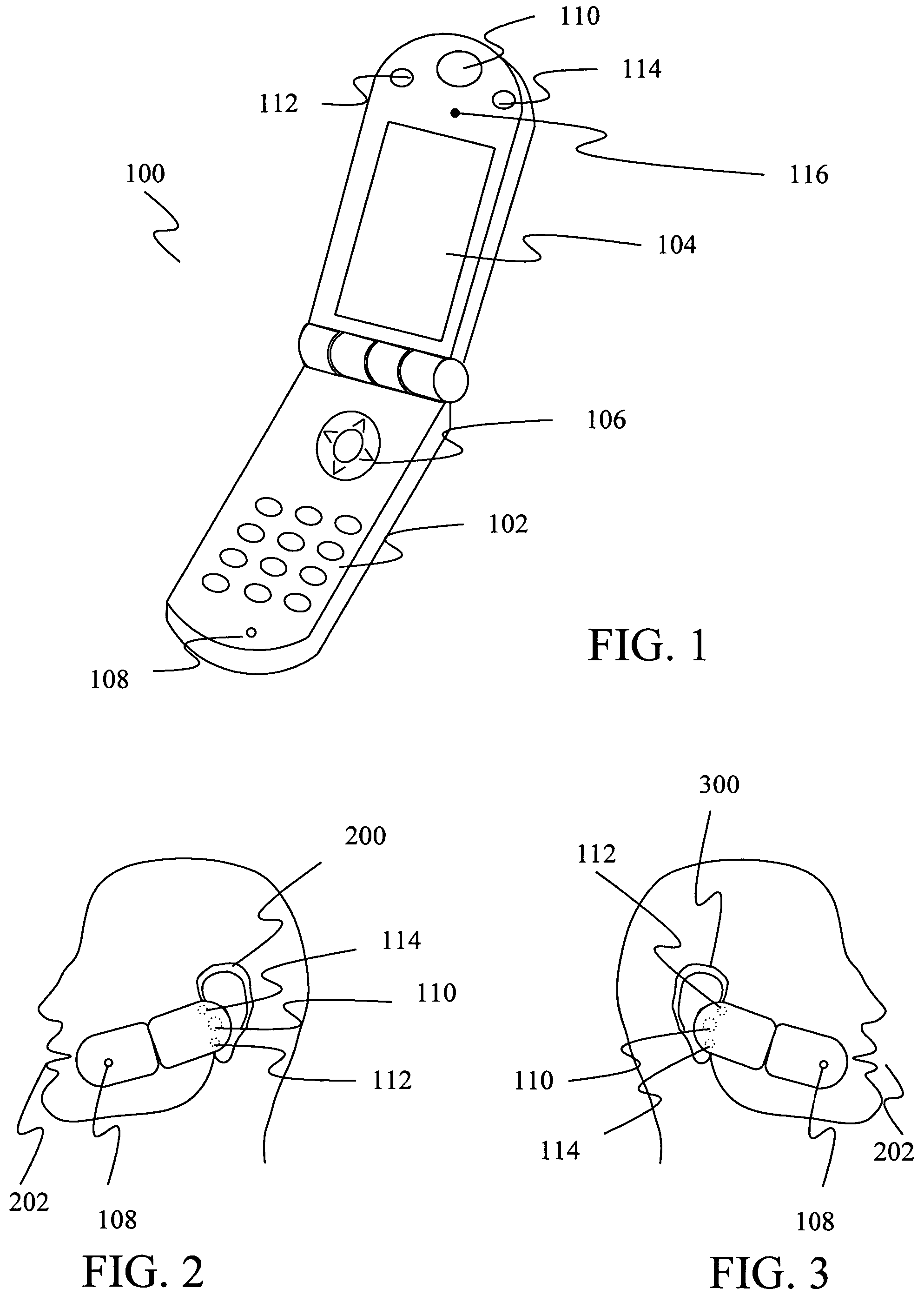

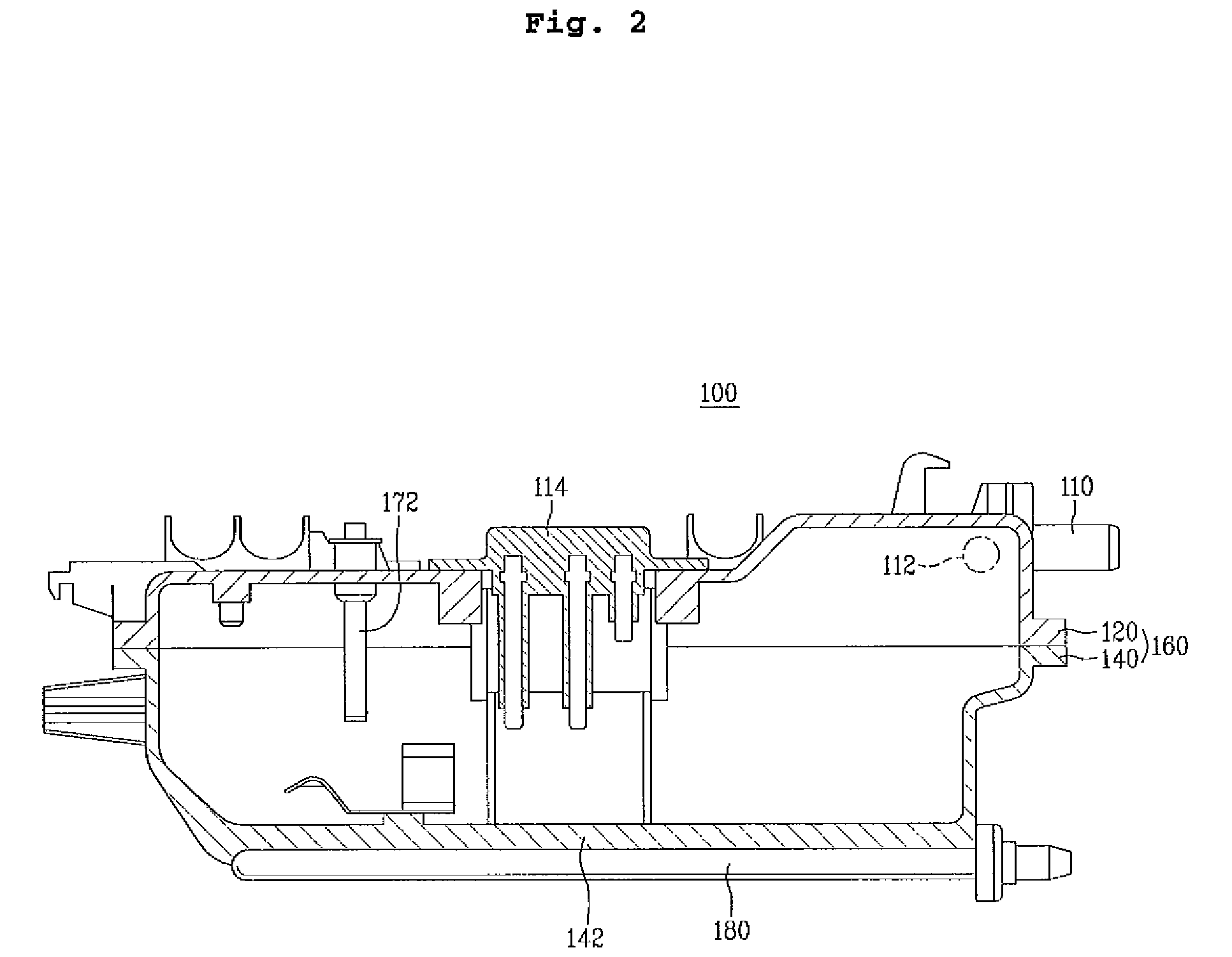

Method and apparatus for multi-sensory speech enhancement on a mobile device

A mobile device is provided that includes a digit input that can be manipulated by a user's fingers or thumb, an air conduction microphone and an alternative sensor that provides an alternative sensor signal indicative of speech. Under some embodiments, the mobile device also includes a proximity sensor that provides a proximity signal indicative of the distance from the mobile device to an object. Under some embodiments, the signal from the air conduction microphone, the alternative sensor signal, and the proximity signal are used to form an estimate of a clean speech value. In further embodiments, a sound is produced through a speaker in the mobile device based on the amount of noise in the clean speech value. In other embodiments, the sound produced through the speaker is based on the proximity sensor signal.

Owner:ZHIGU HLDG

Automatic dishwashing compositions containing a halogen dioxide salt and methods for use with electrochemical cells and/or electrolytic devices

InactiveUS6921743B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsElectrolysed waterPhosphate

The present invention relates to automatic dishwashing detergent compositions and methods of using compositions comprising halogenated salts, phosphate and / or silicate in conjunction with electrolyzed water in automatic dishwashing appliances comprising an electrochemical cell and / or electrolytic device for treating tableware to improve cleaning, sanitizing and stain removal by controlling hardness, corrosion and dispersancy.

Owner:PROCTER & GAMBLE CO

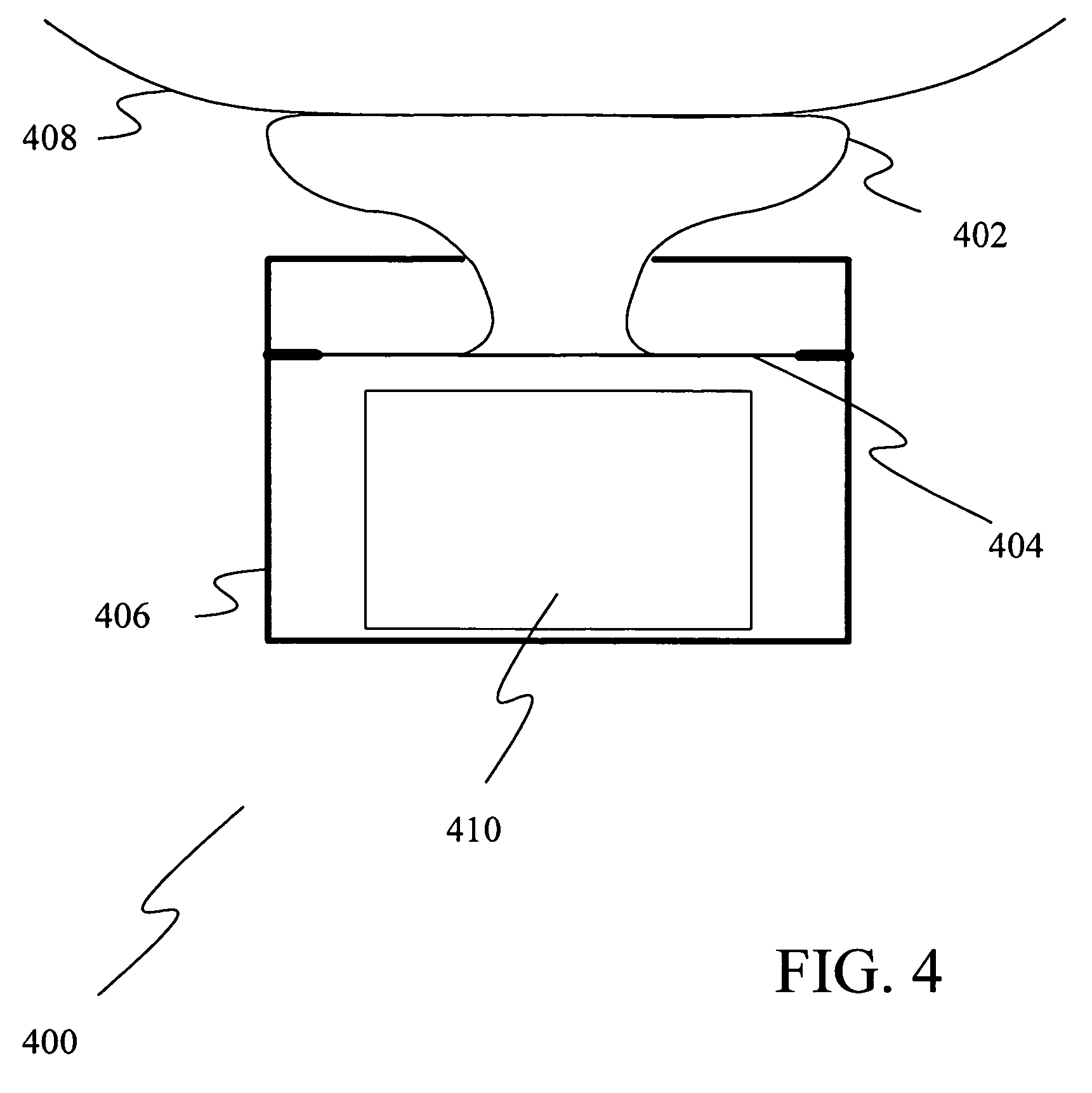

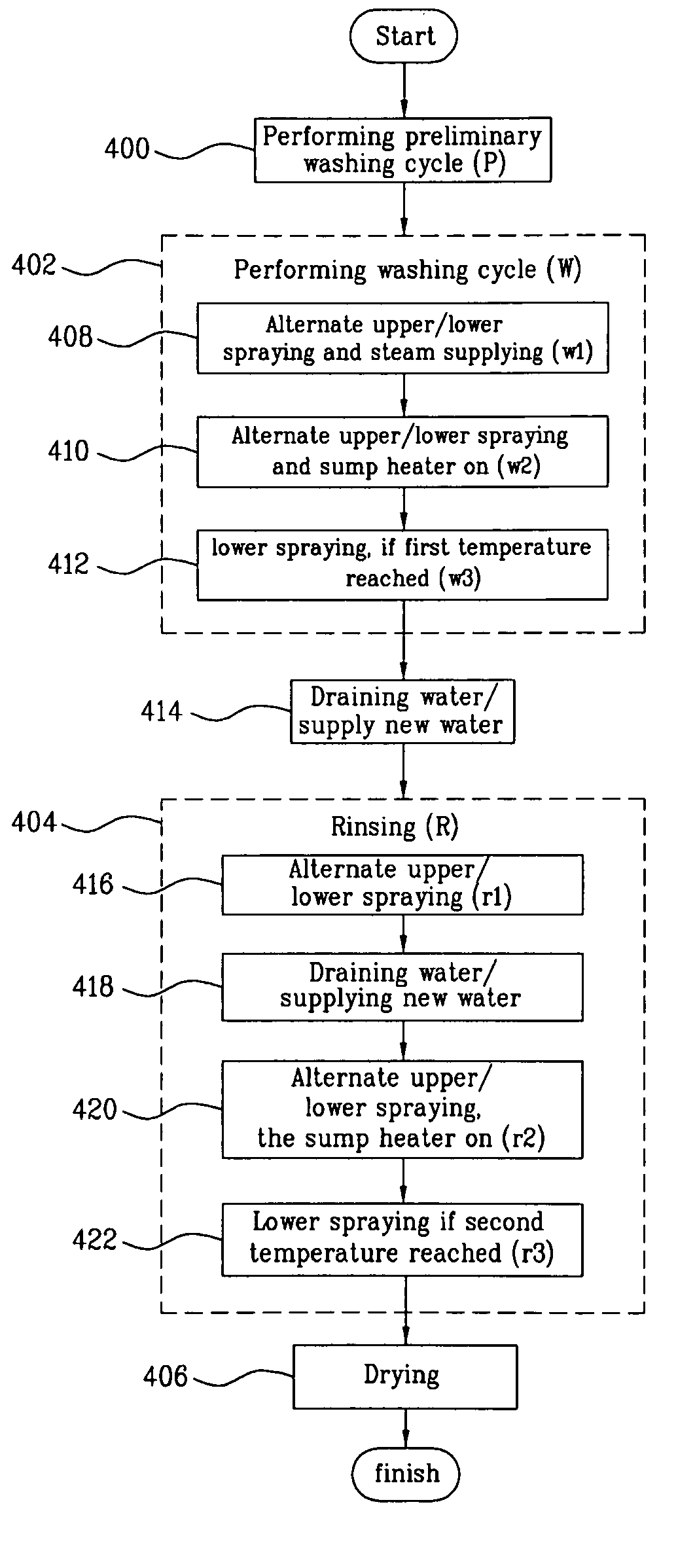

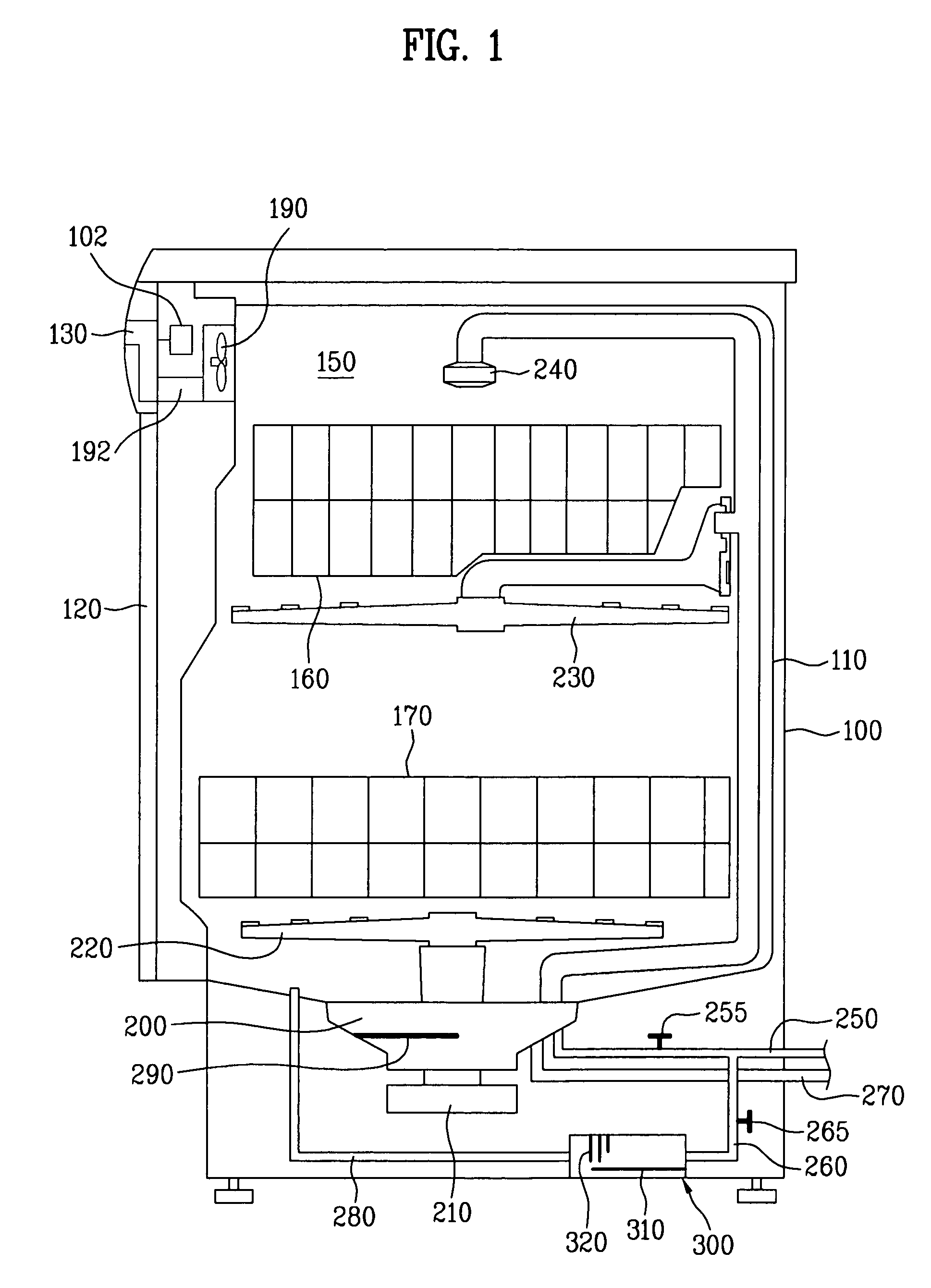

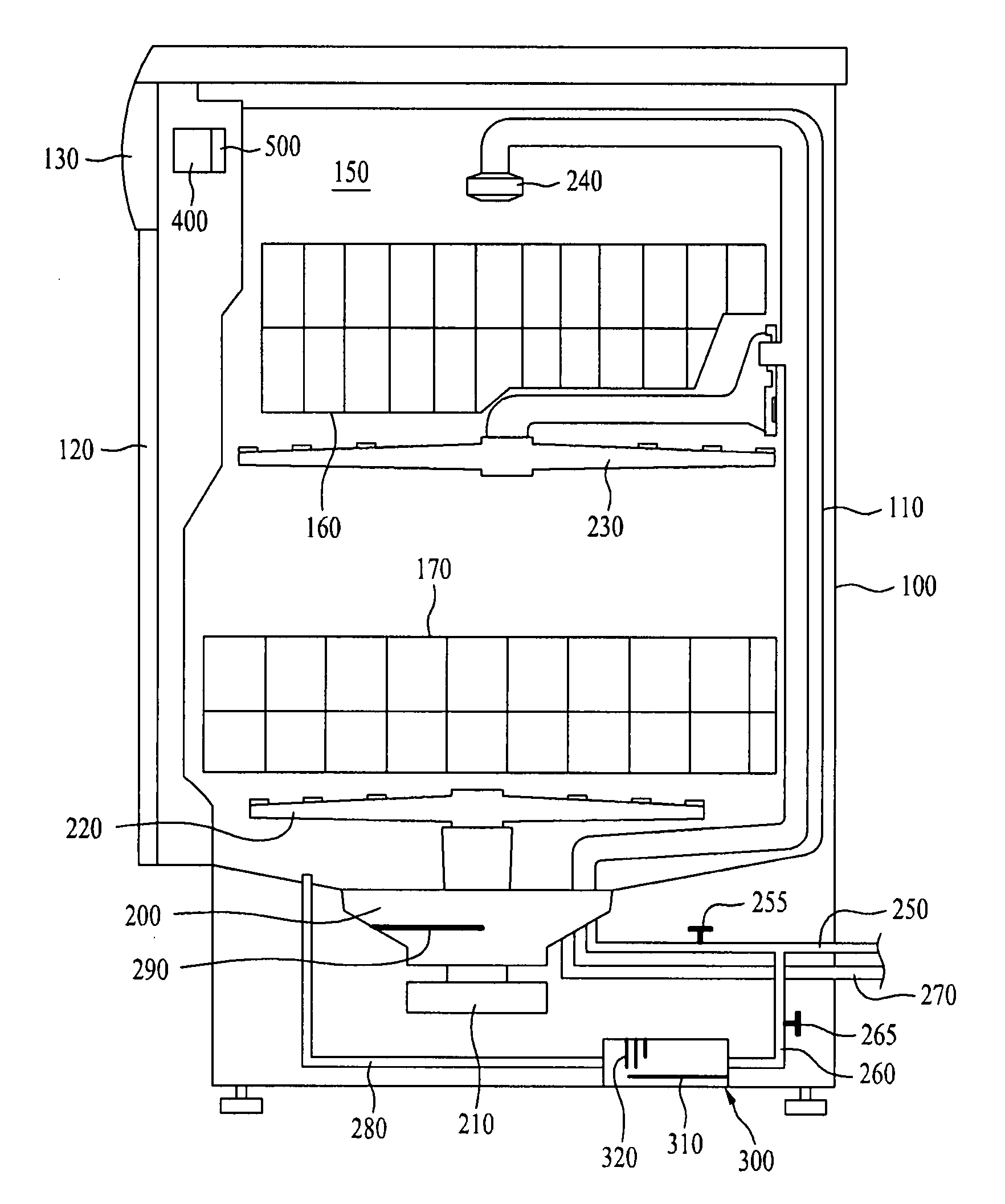

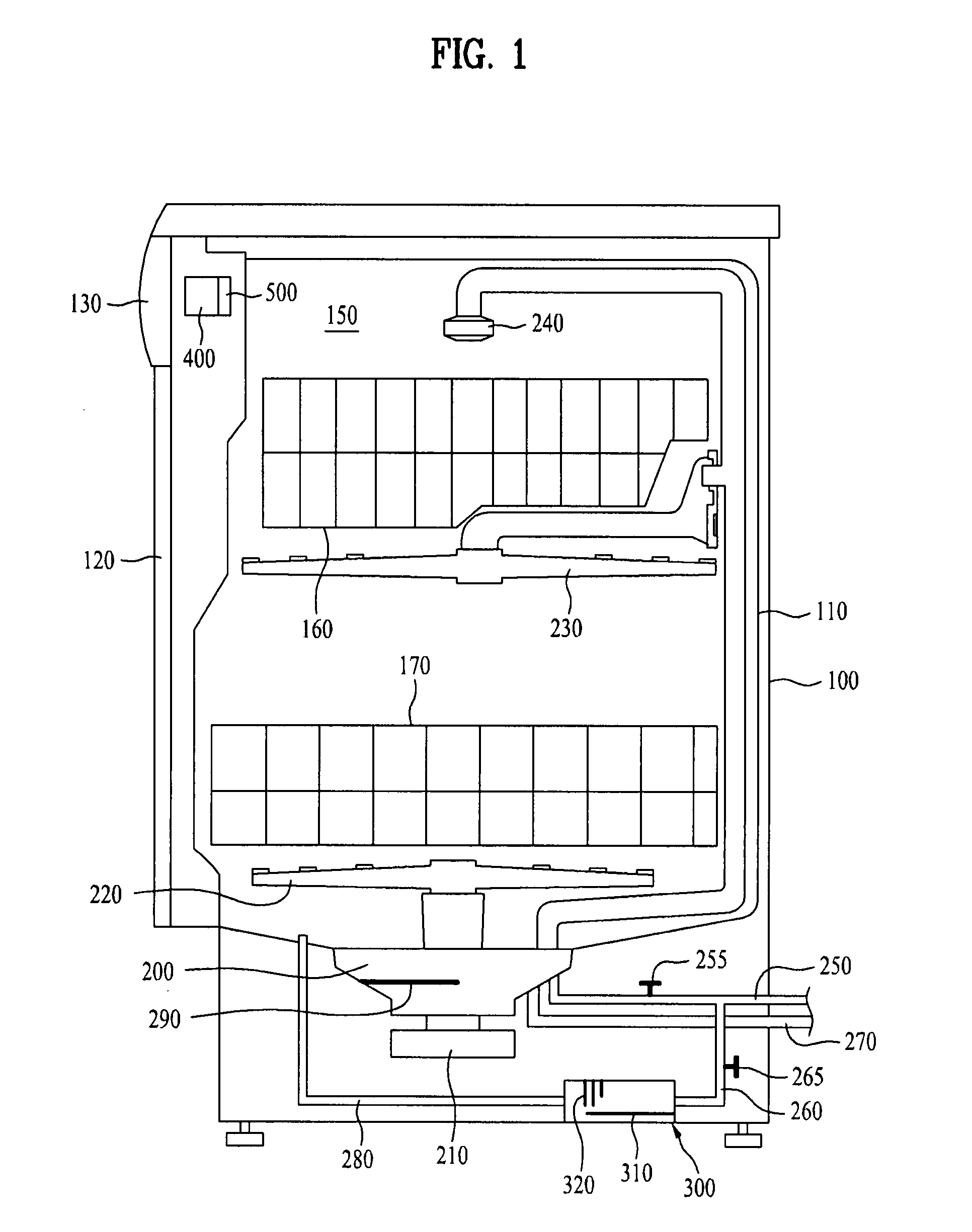

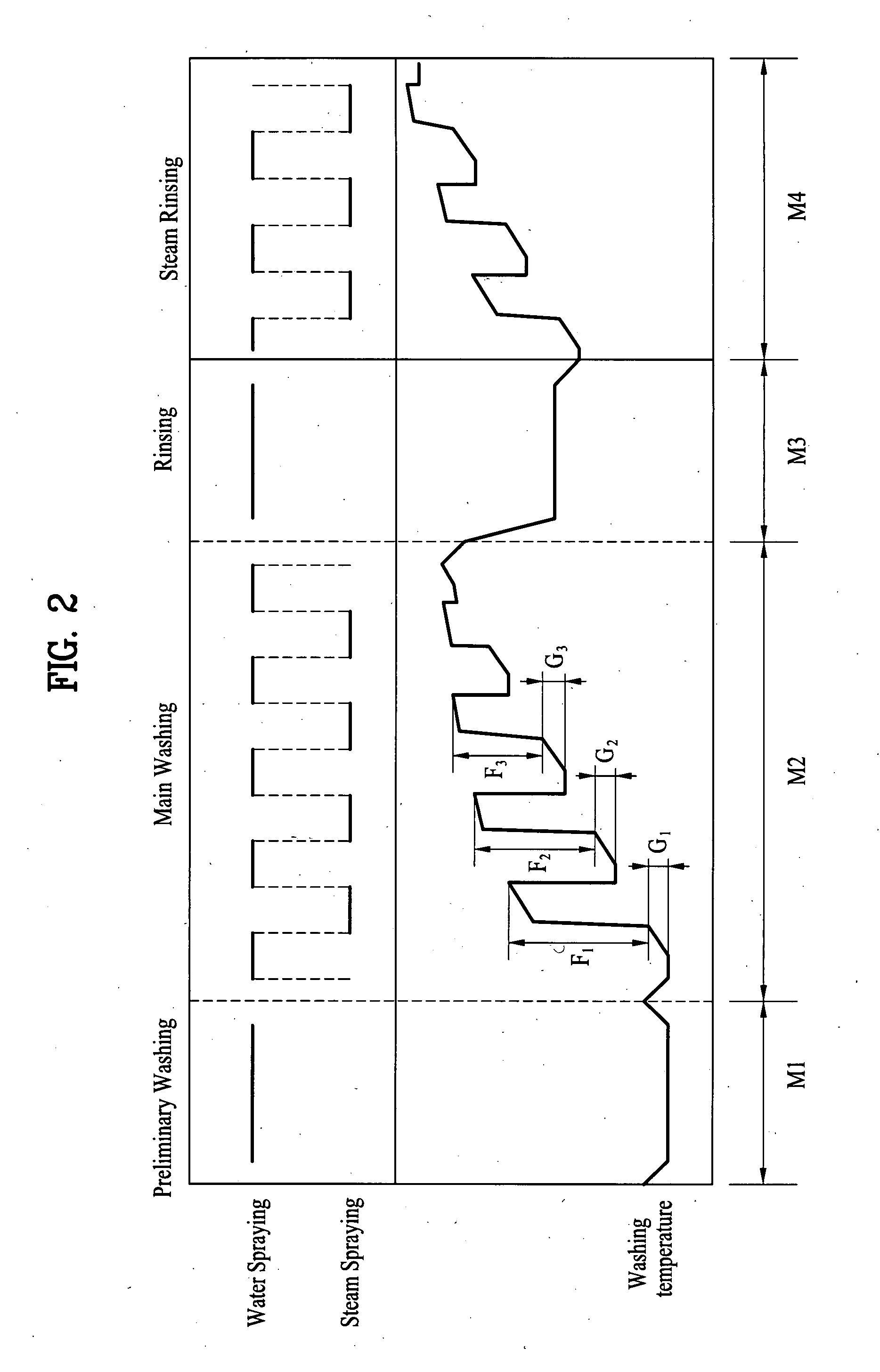

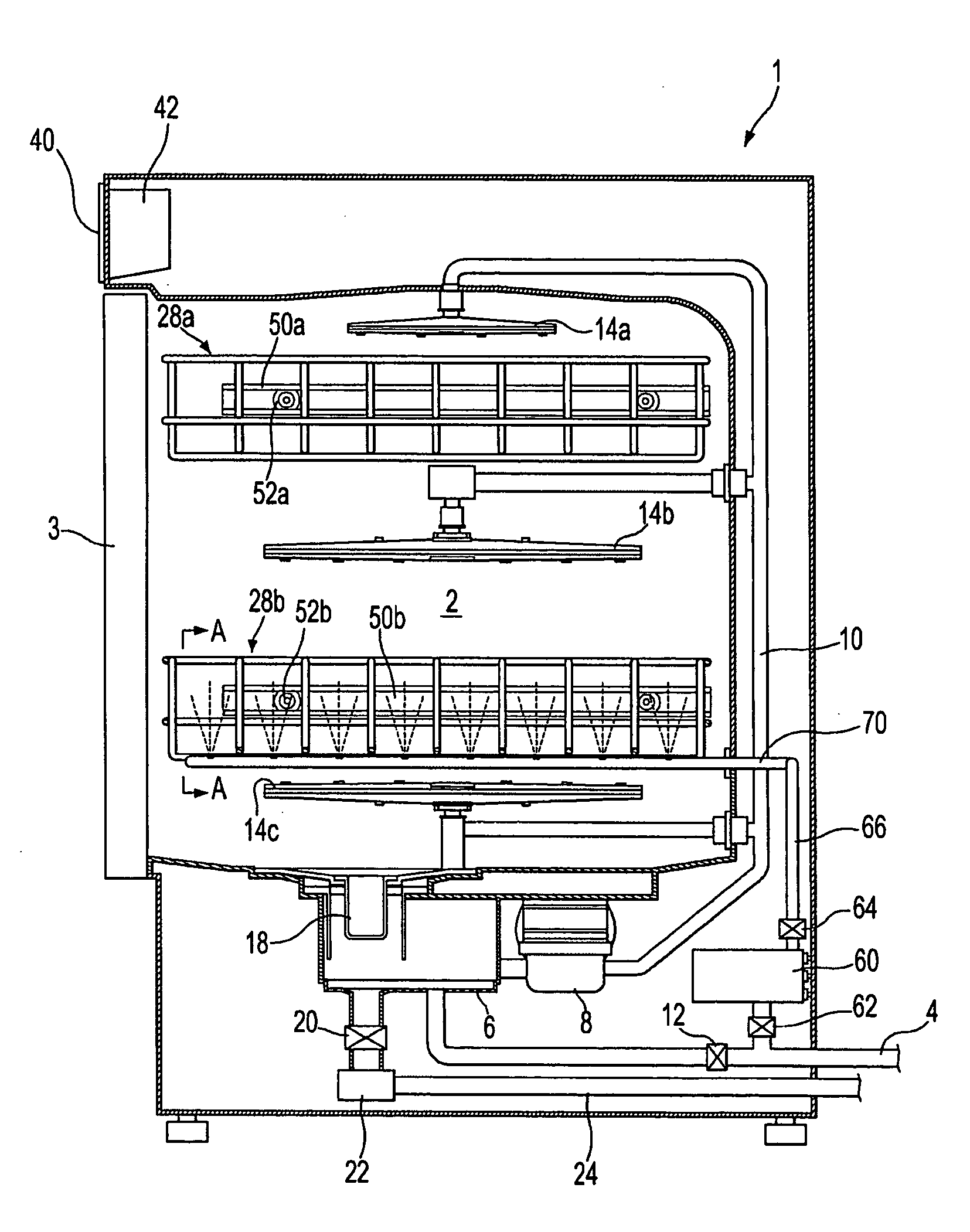

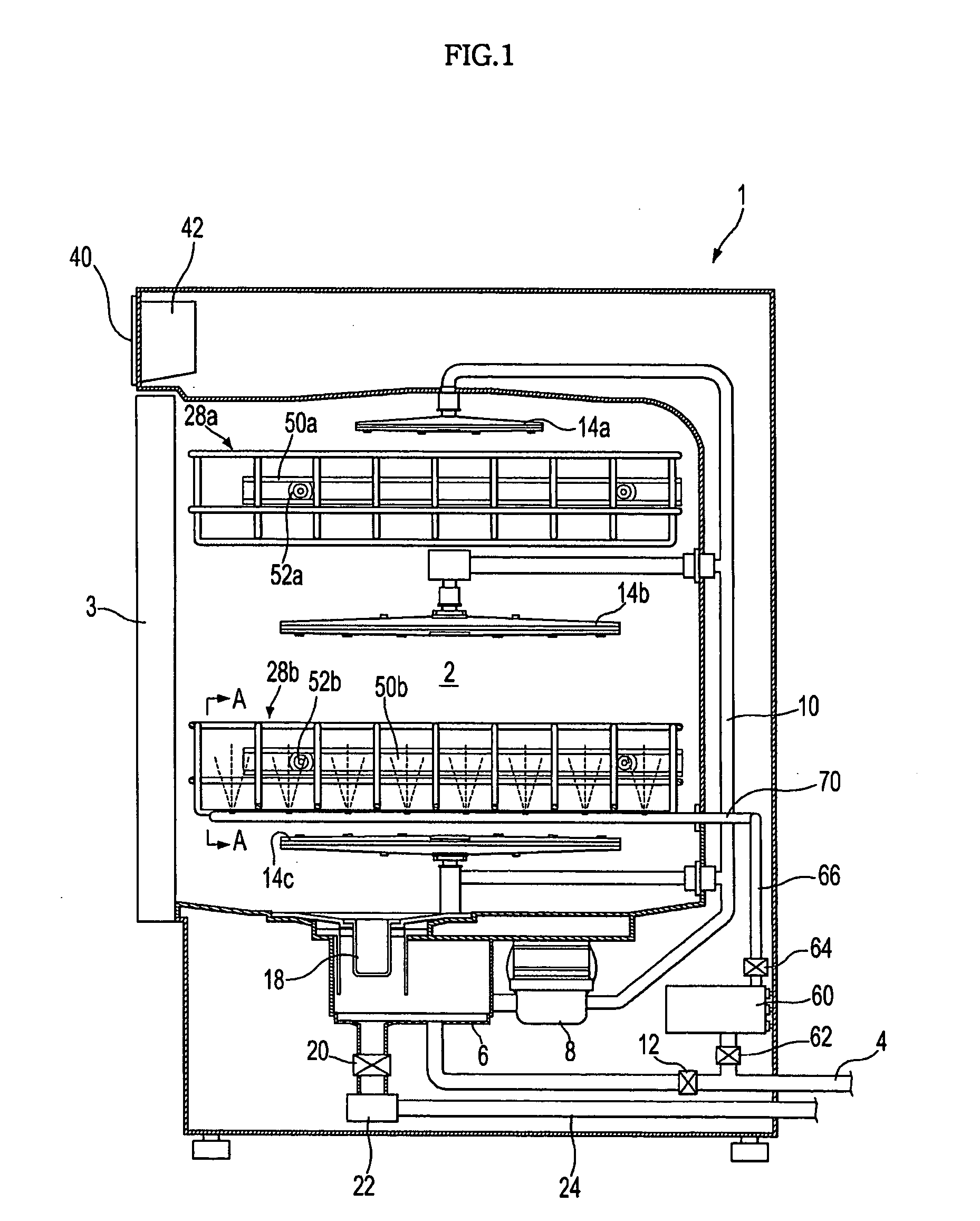

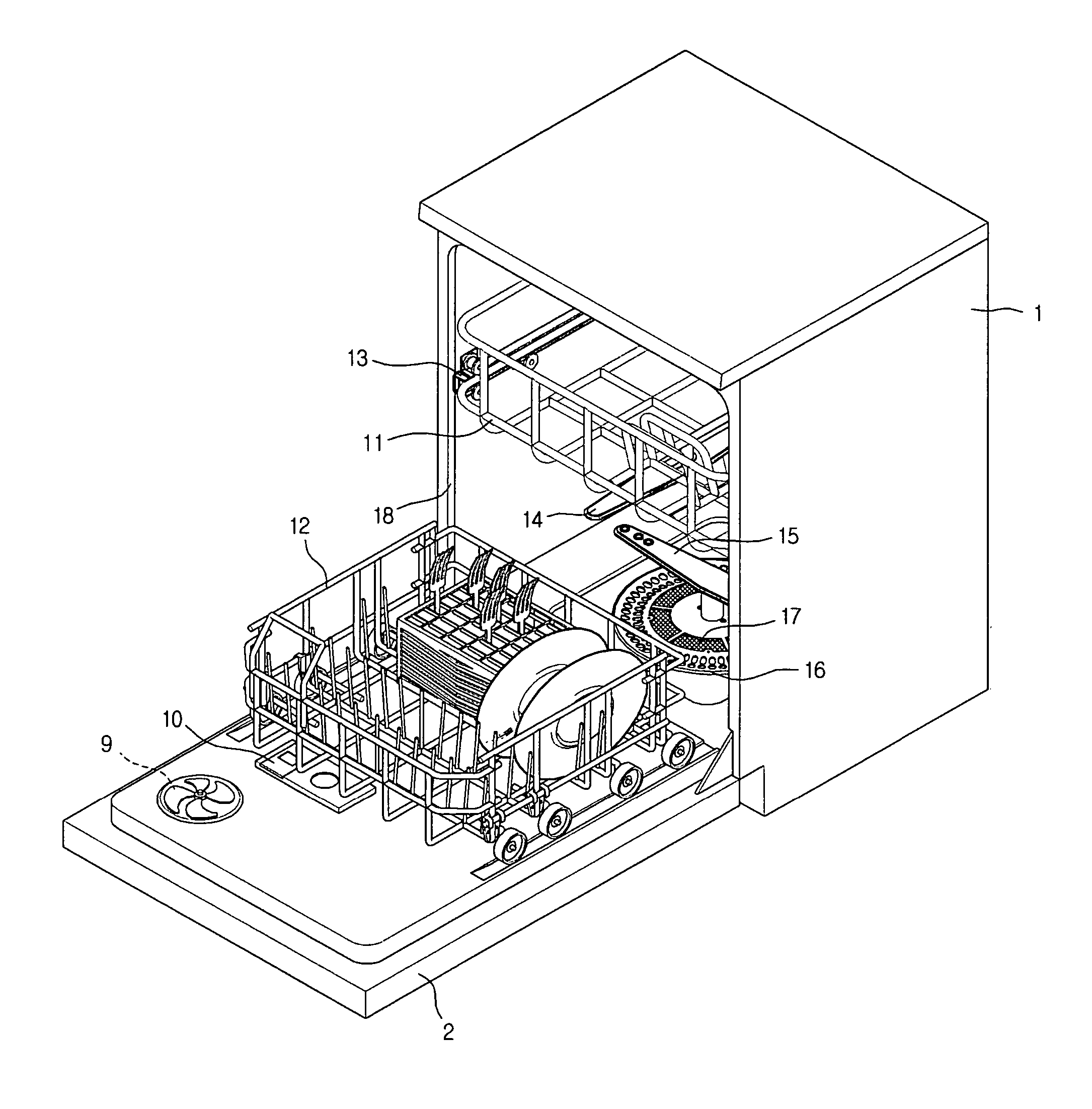

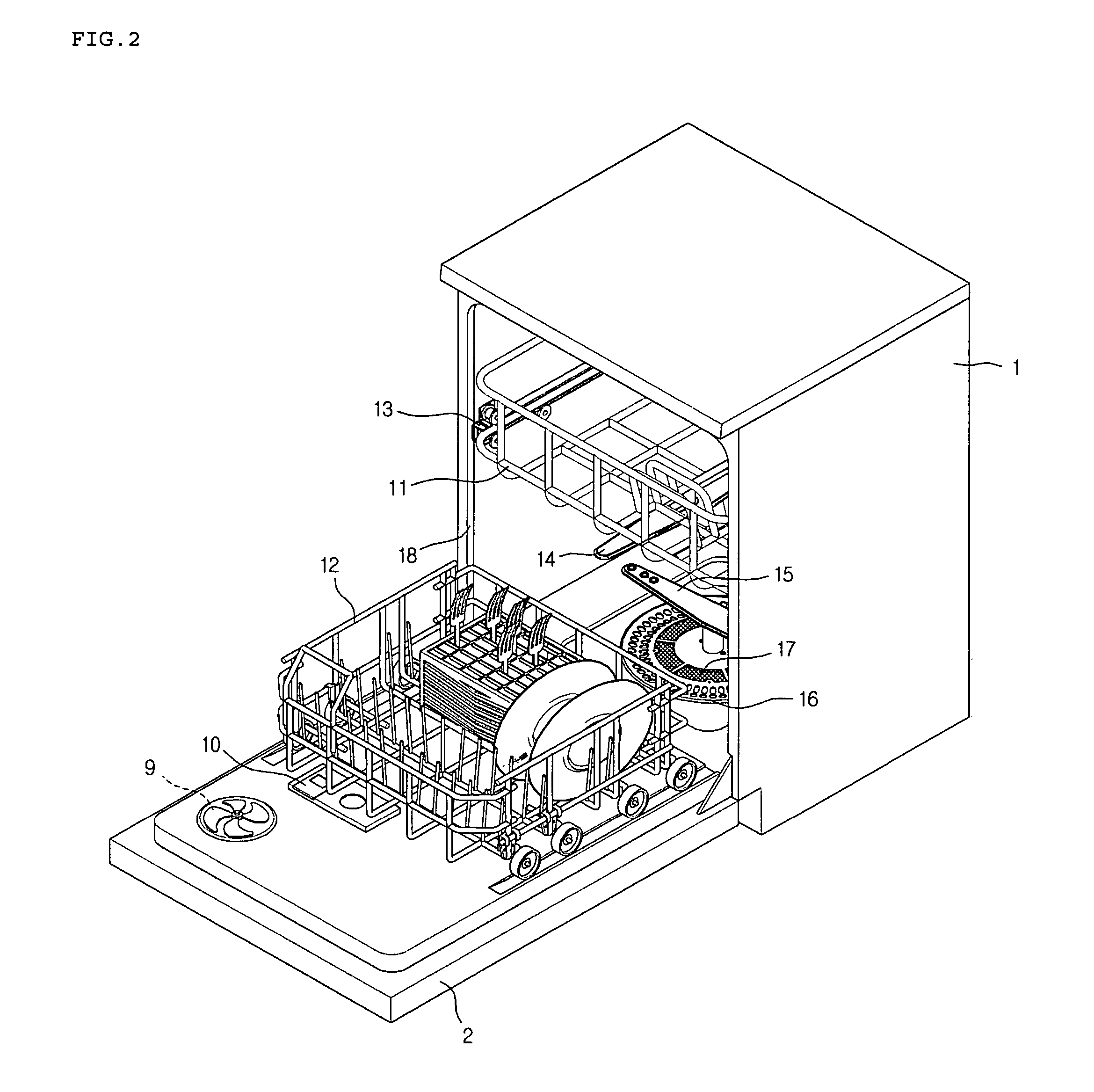

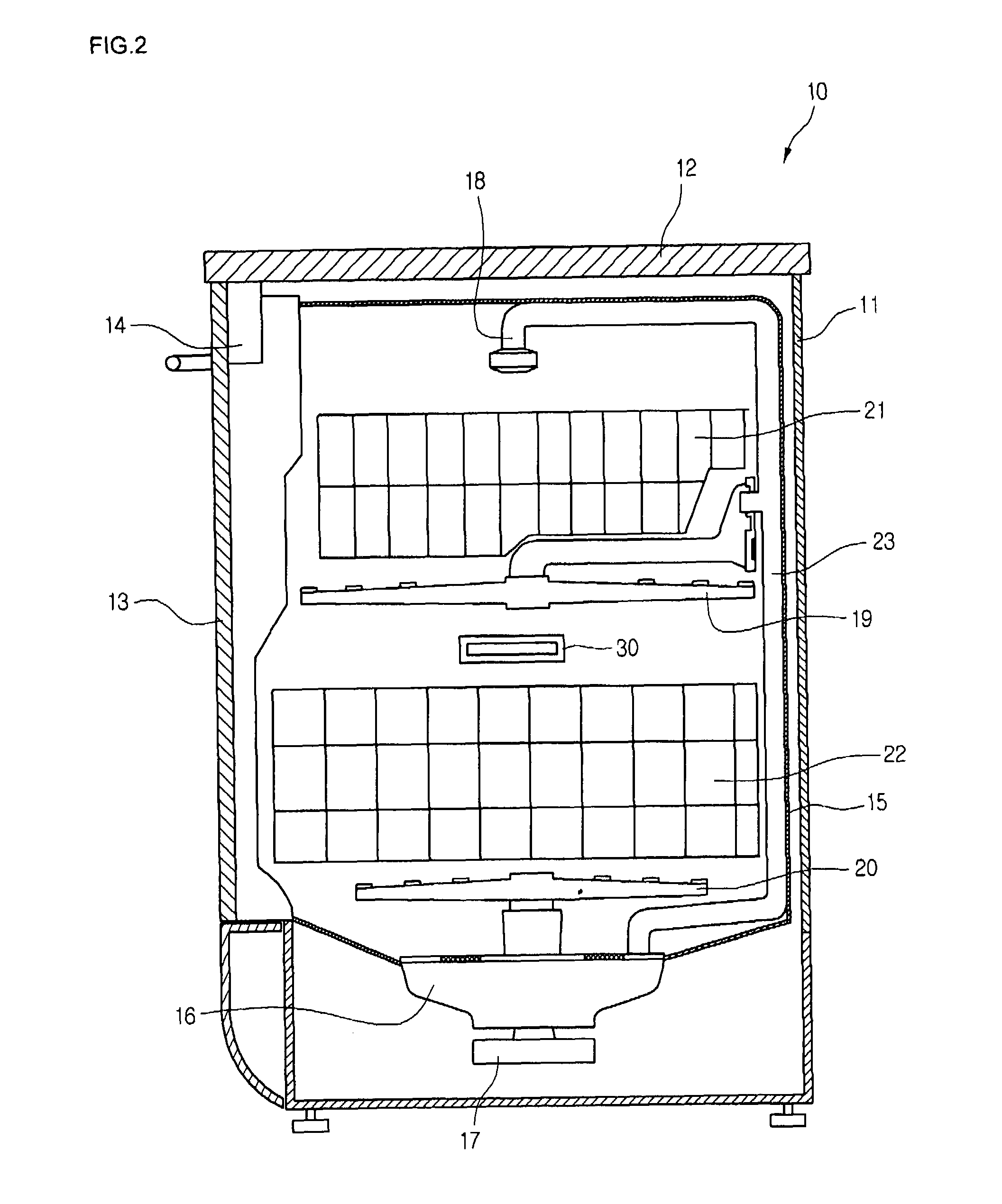

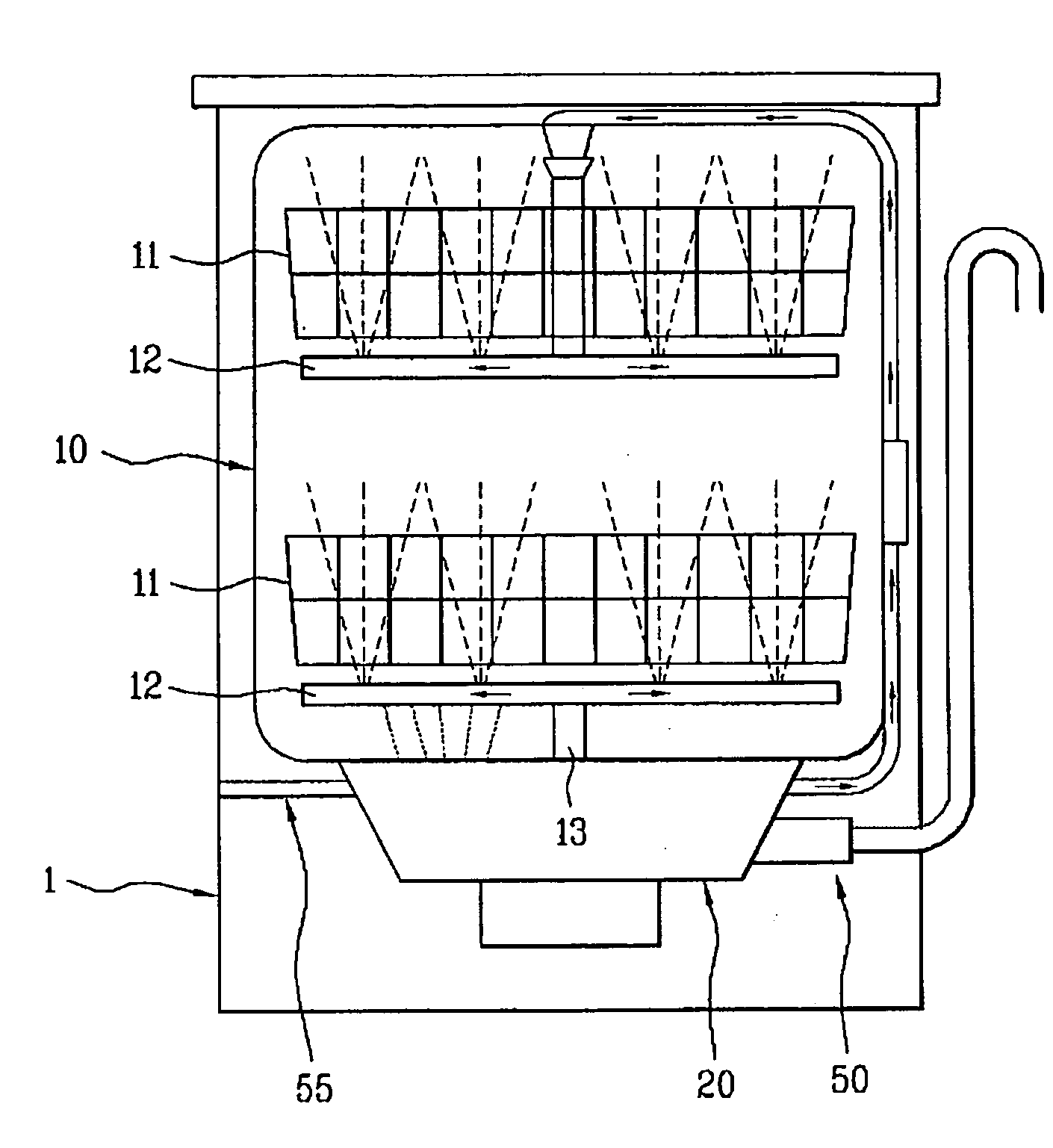

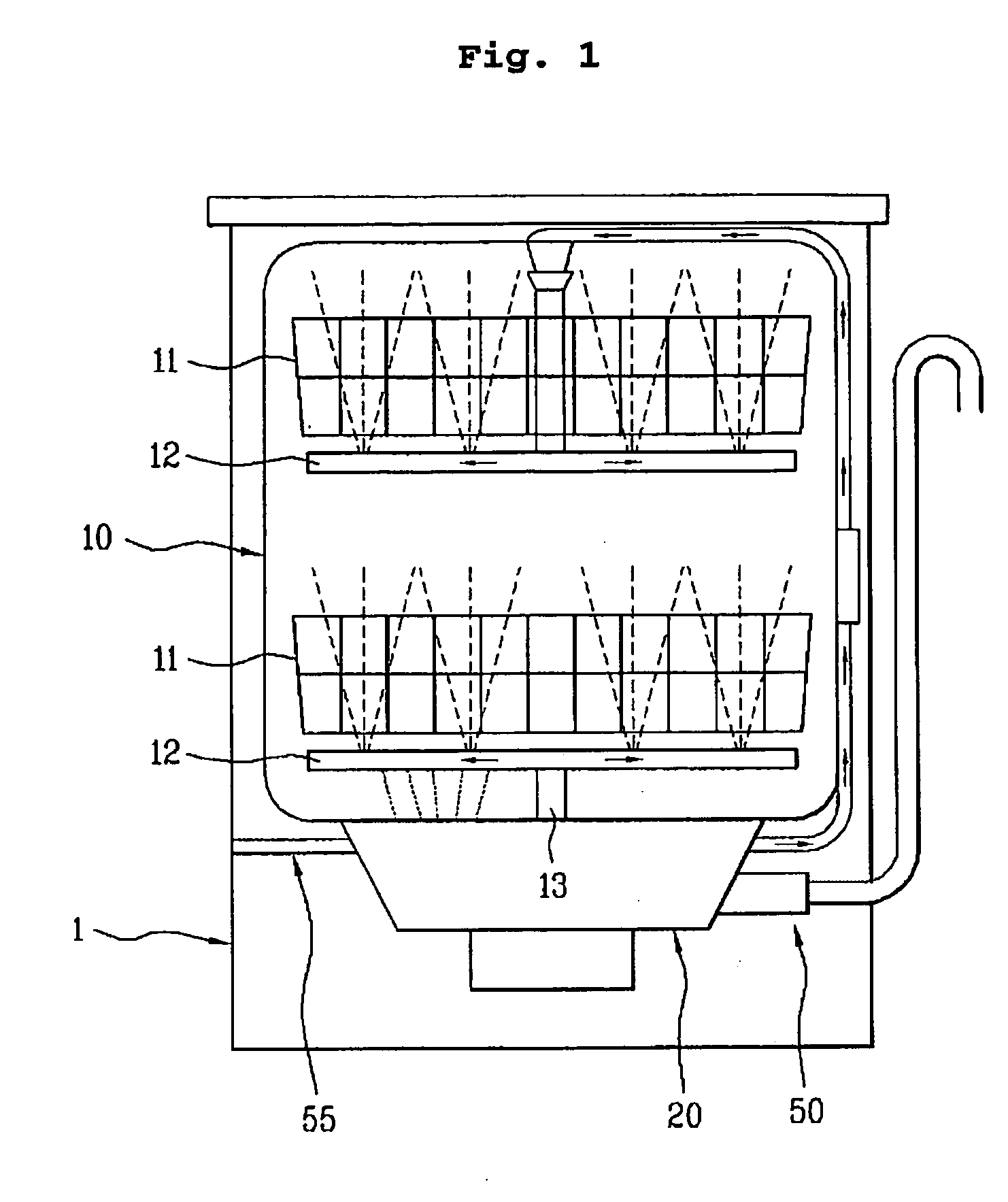

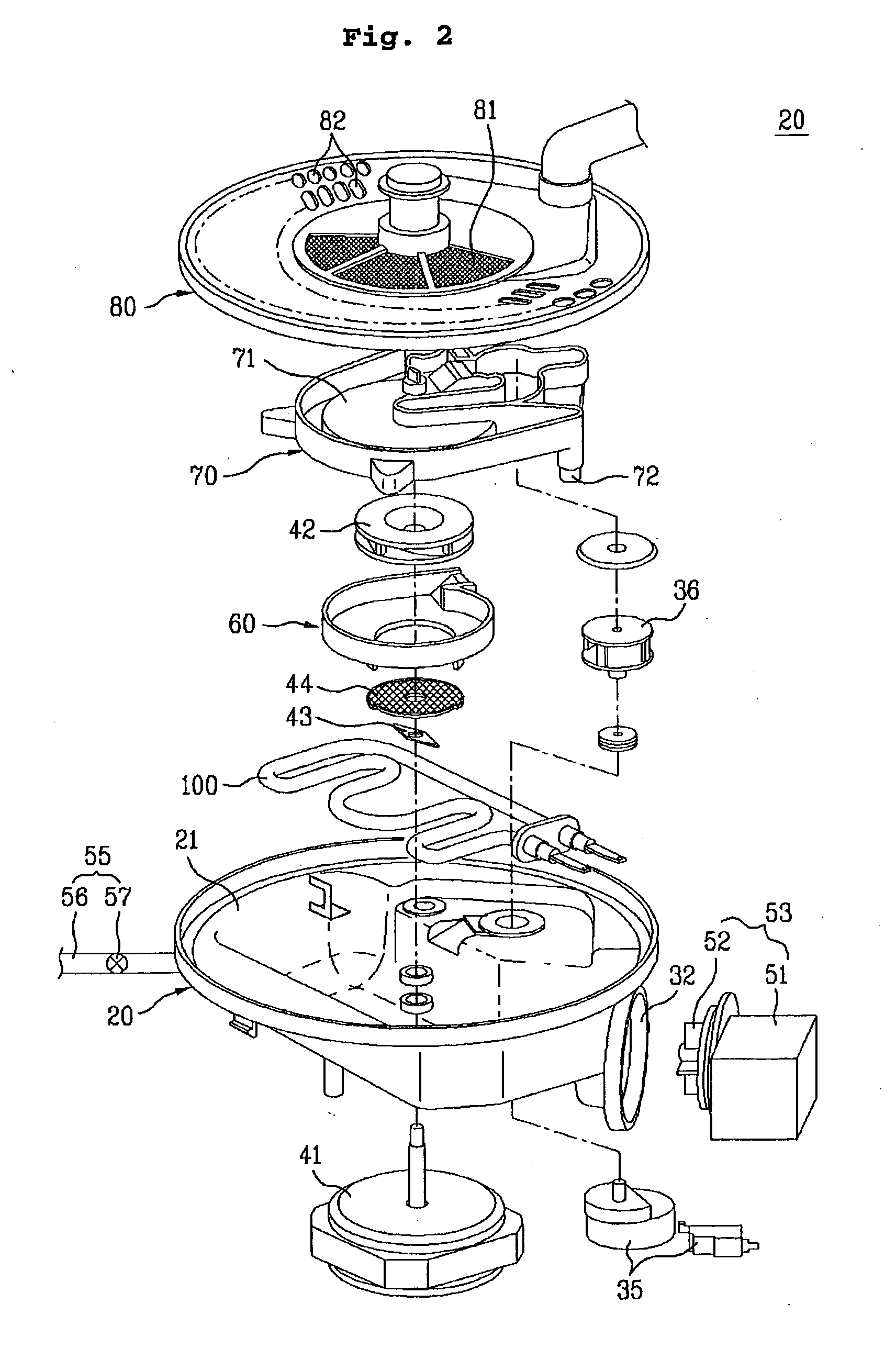

Diswasher and controlling method of the same

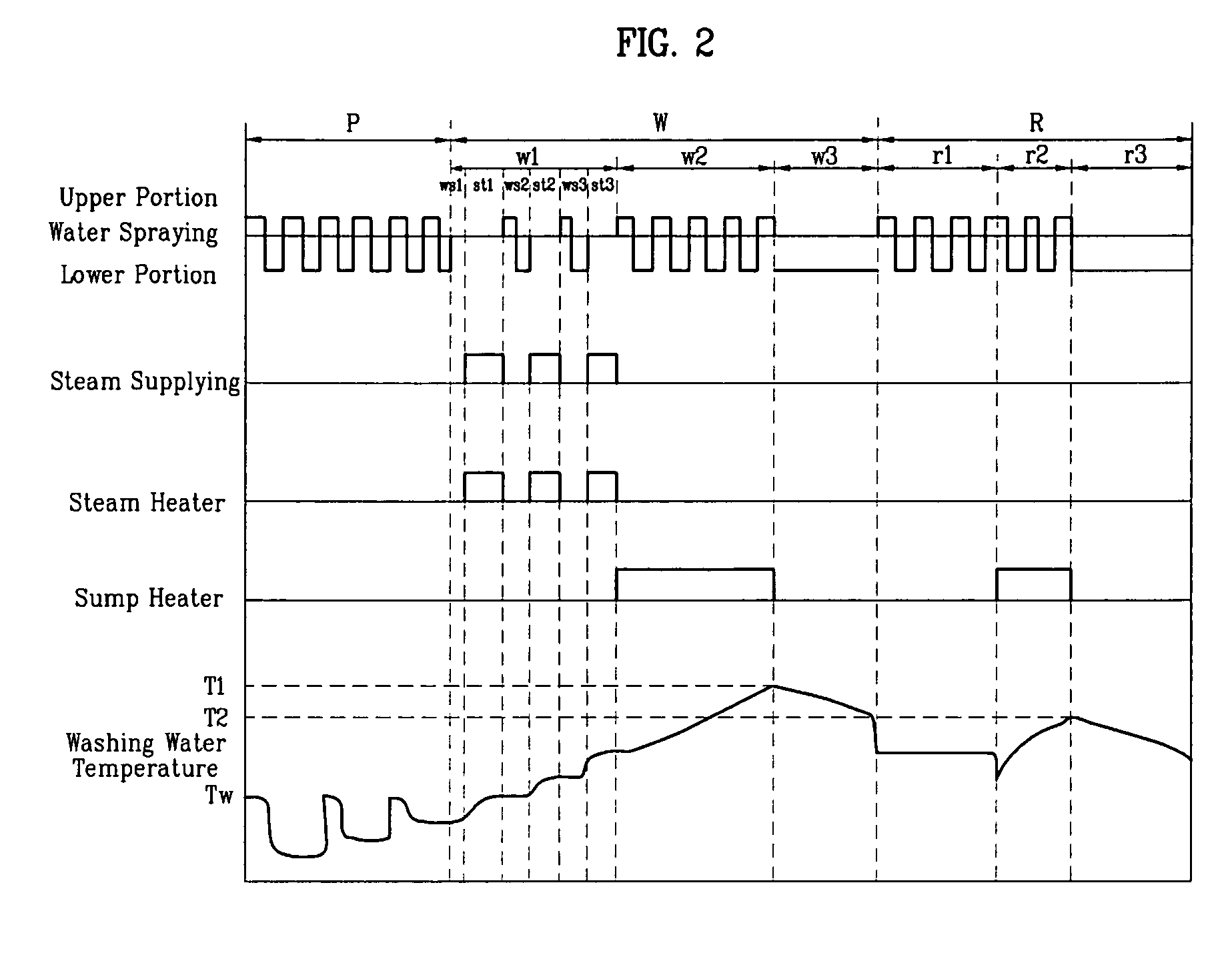

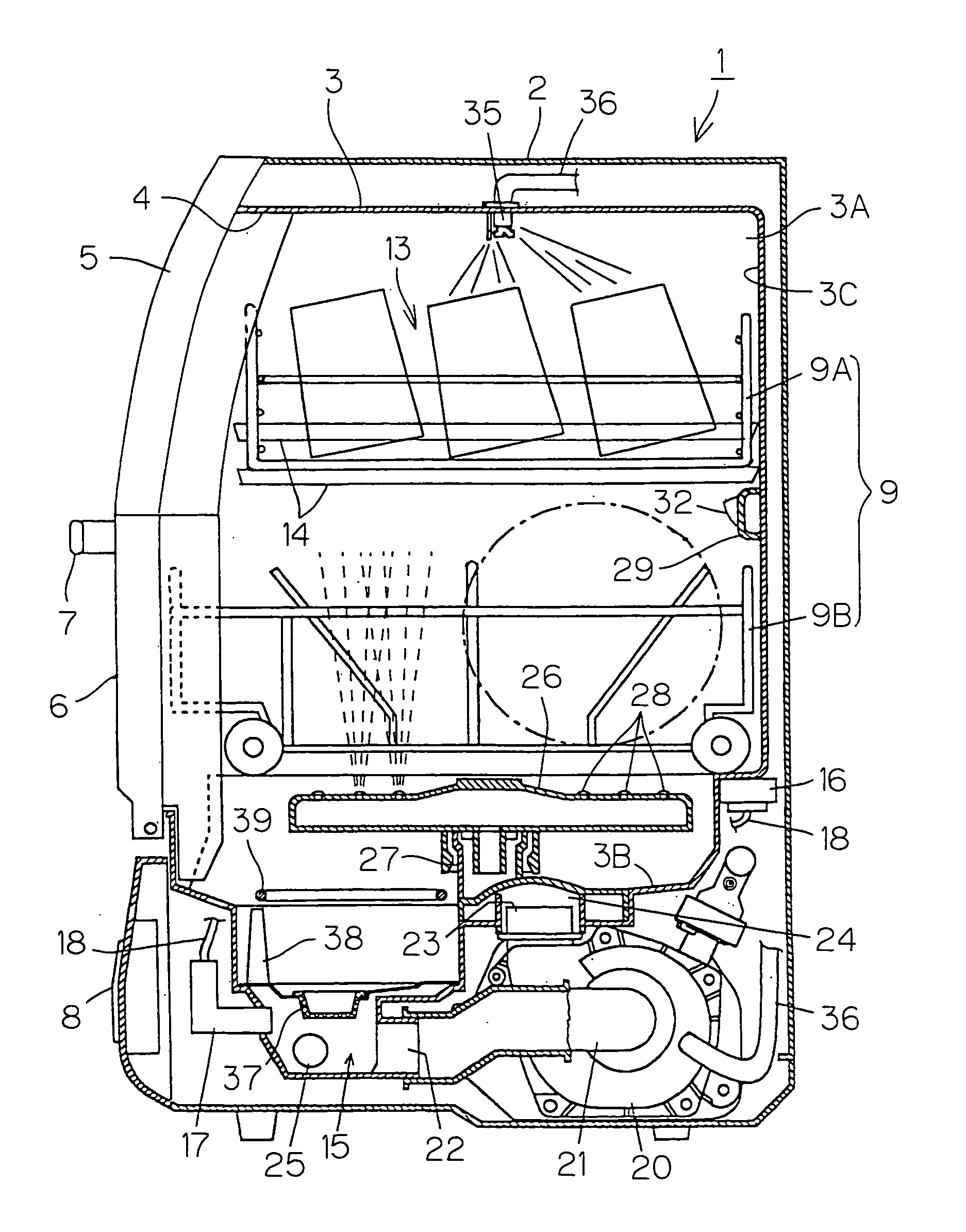

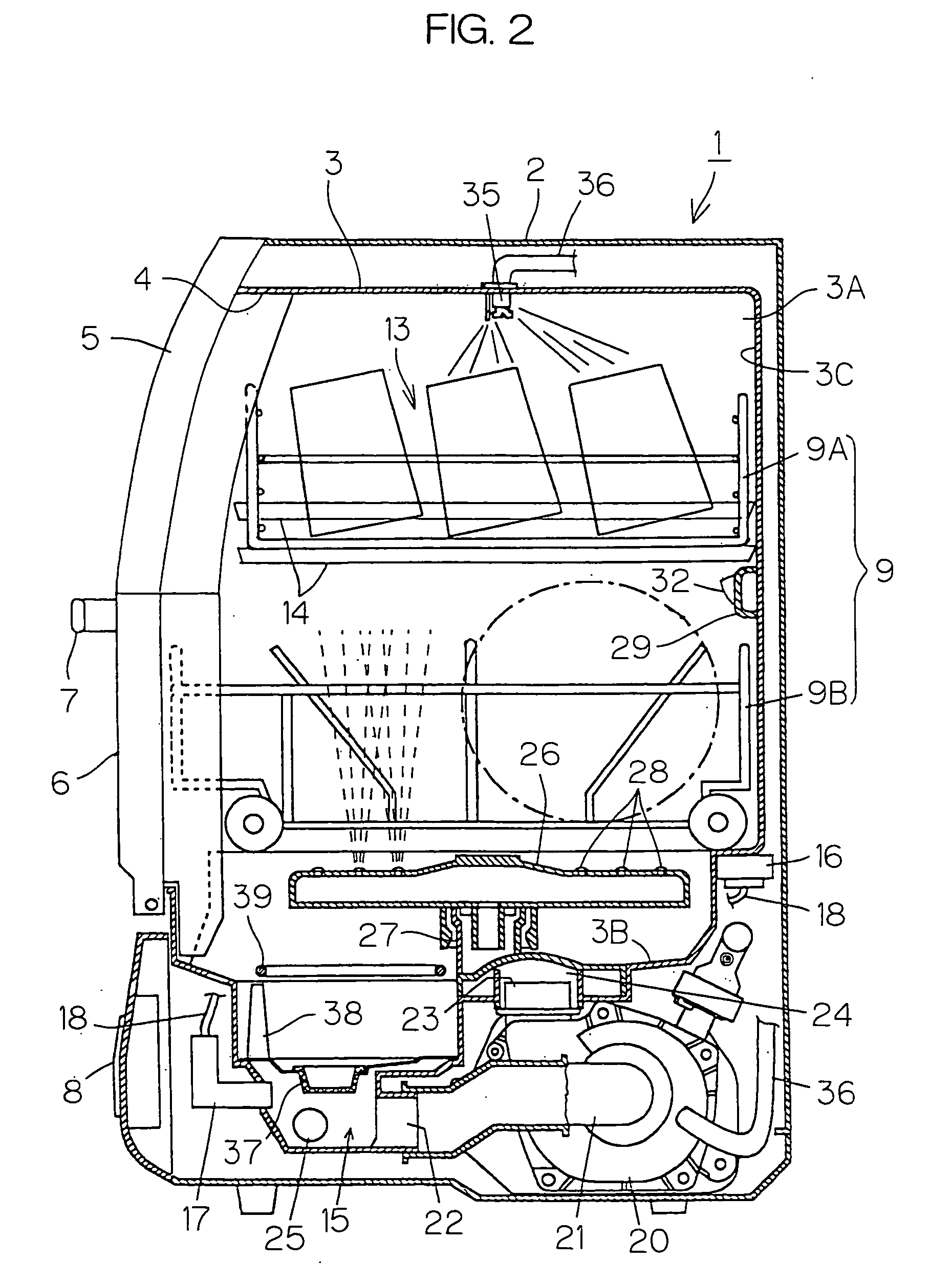

ActiveUS20100043828A1Improve washing efficiencyImprove operationTableware washing/rinsing machine detailsWashing processesProcess engineeringRunning time

Dishwashers and methods of control for operation of dishwashers are disclosed. The dishwasher may include an upper rack in an upper portion of a washing compartment configured to receive small dishes, such as a cup having a small washing load, and a lower rack in a lower portion of the washing compartment for placing large dishes, such as a dinner bowl having a large washing load. The operation of the dishwasher can include wash and rinse cycles having a plurality of sub-cycles. During the sub-cycles, the upper and lower racks can be selectively sprayed with water and steam can be supplied to the washing compartment based on configured conditions, such as a water temperature or operation time being reached. The operation of the dishwasher can reduce excessive washing of dishes having small washing loads and reduce power consumption of the dishwasher.

Owner:LG ELECTRONICS INC

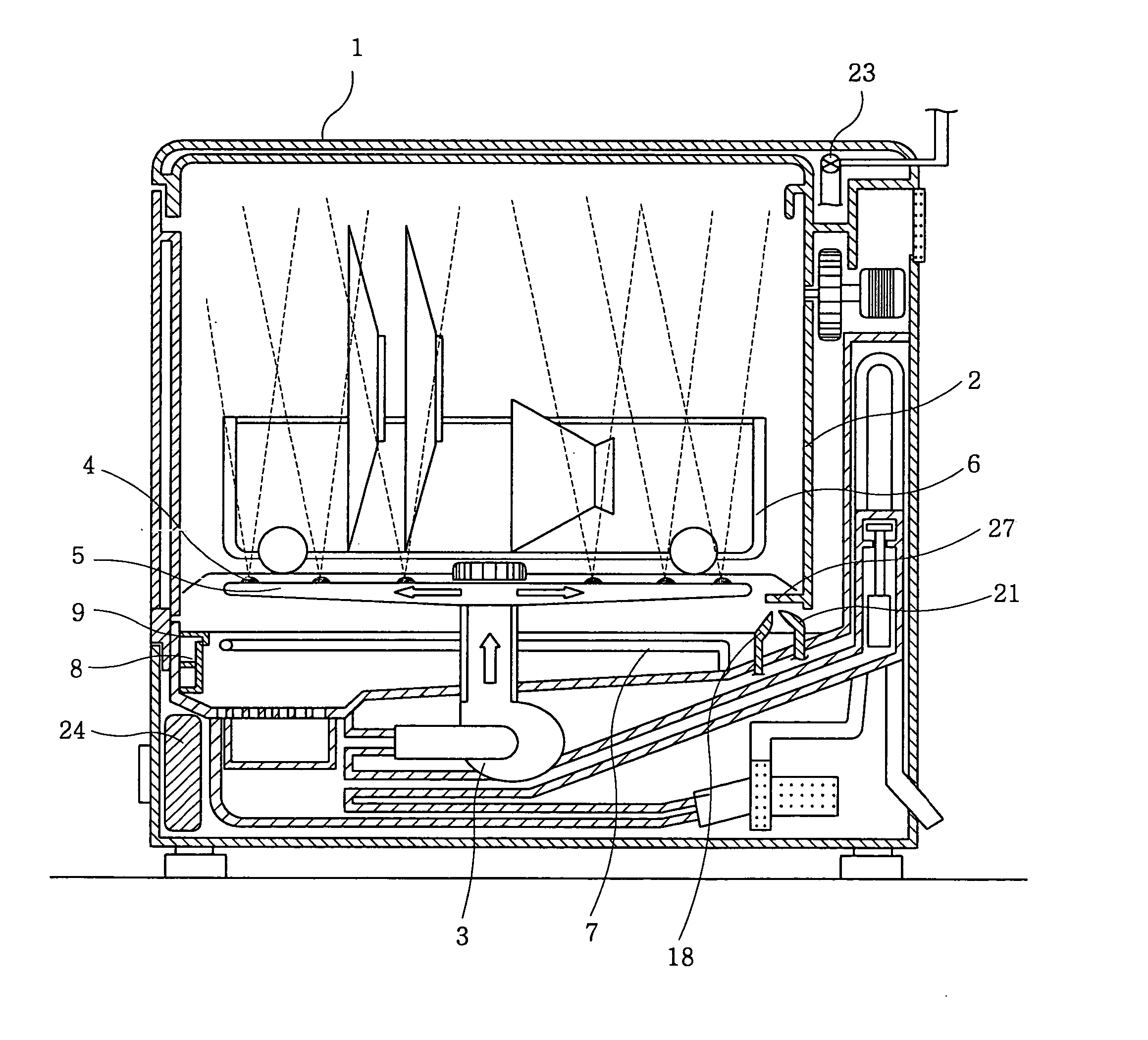

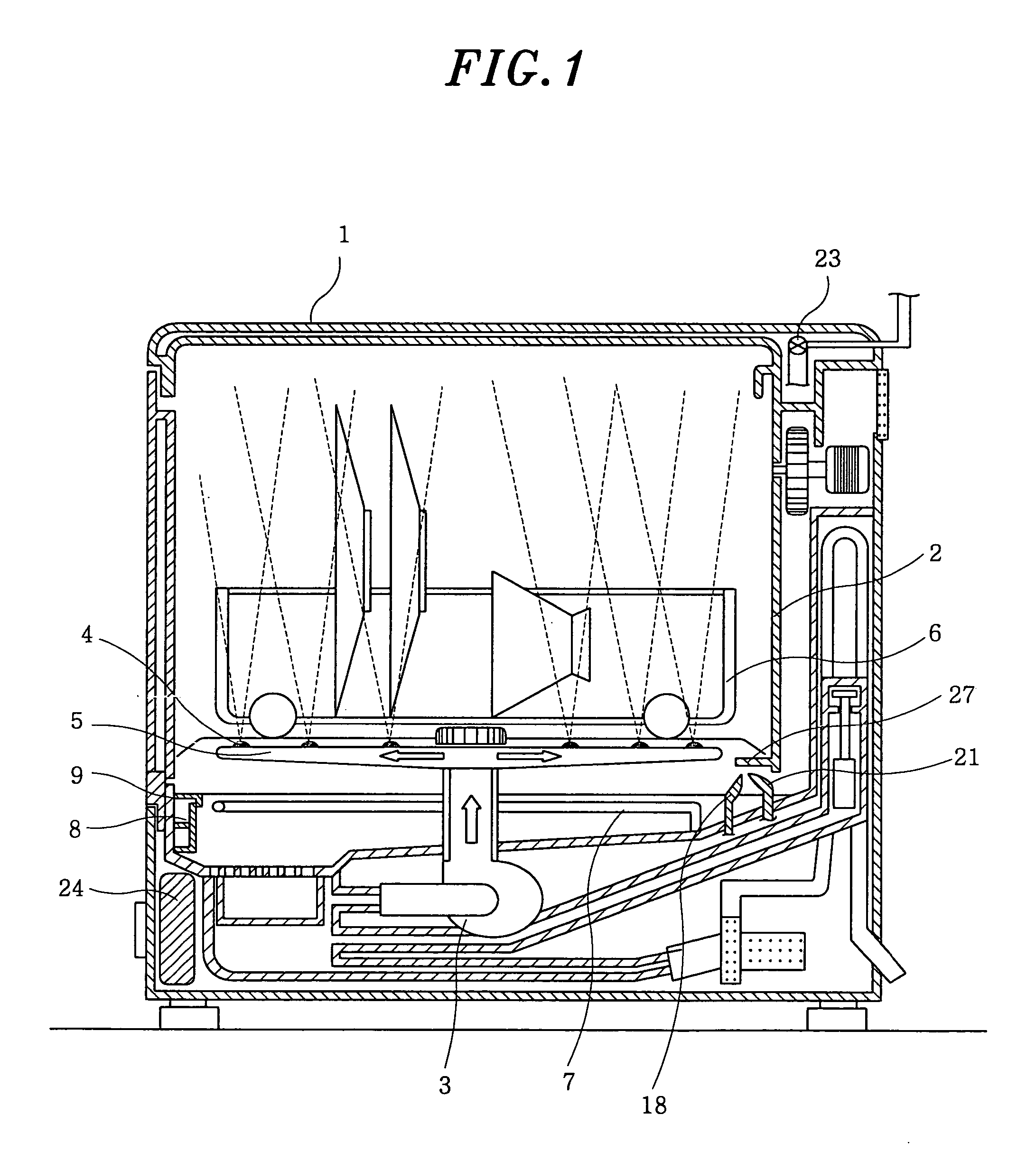

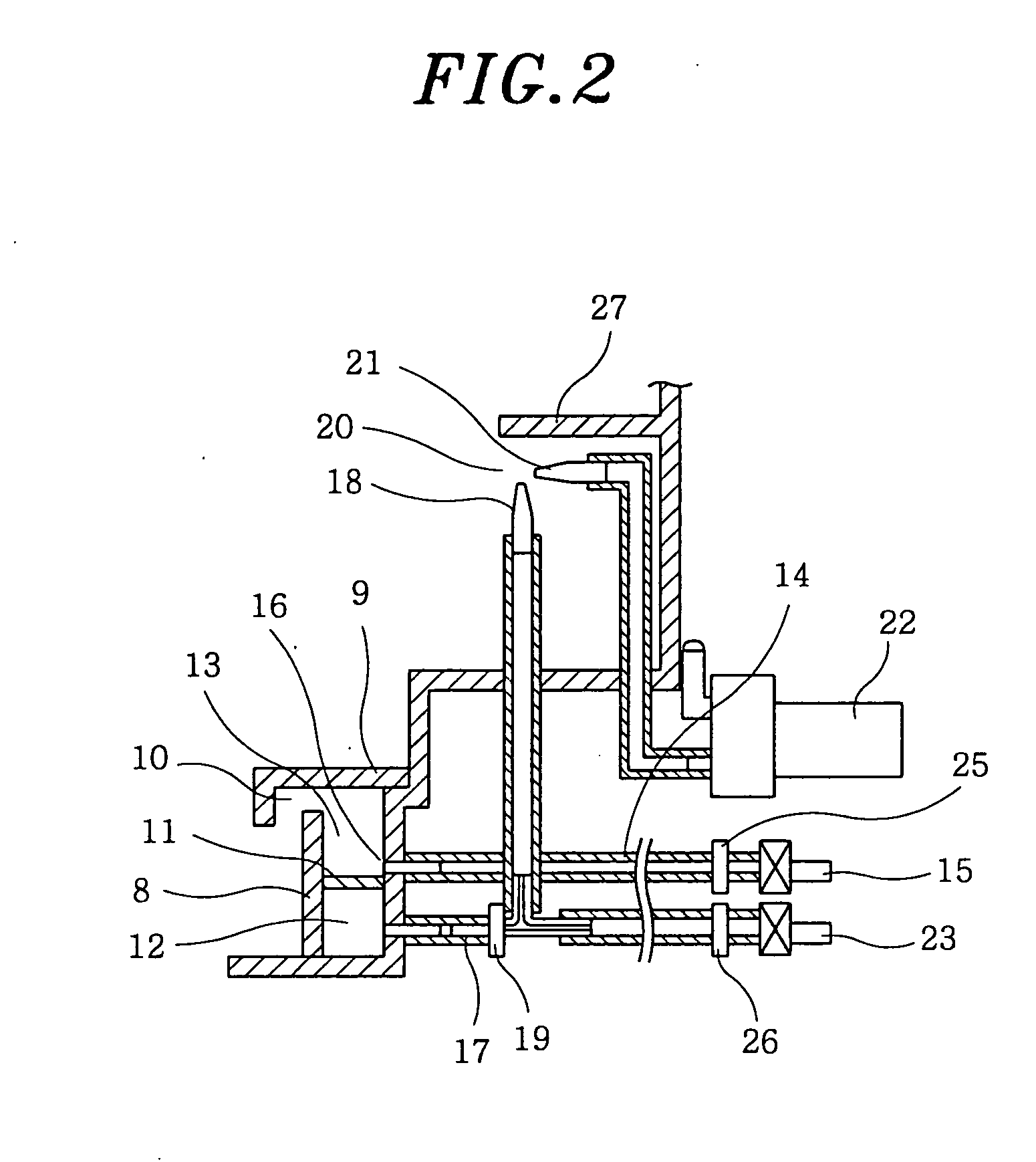

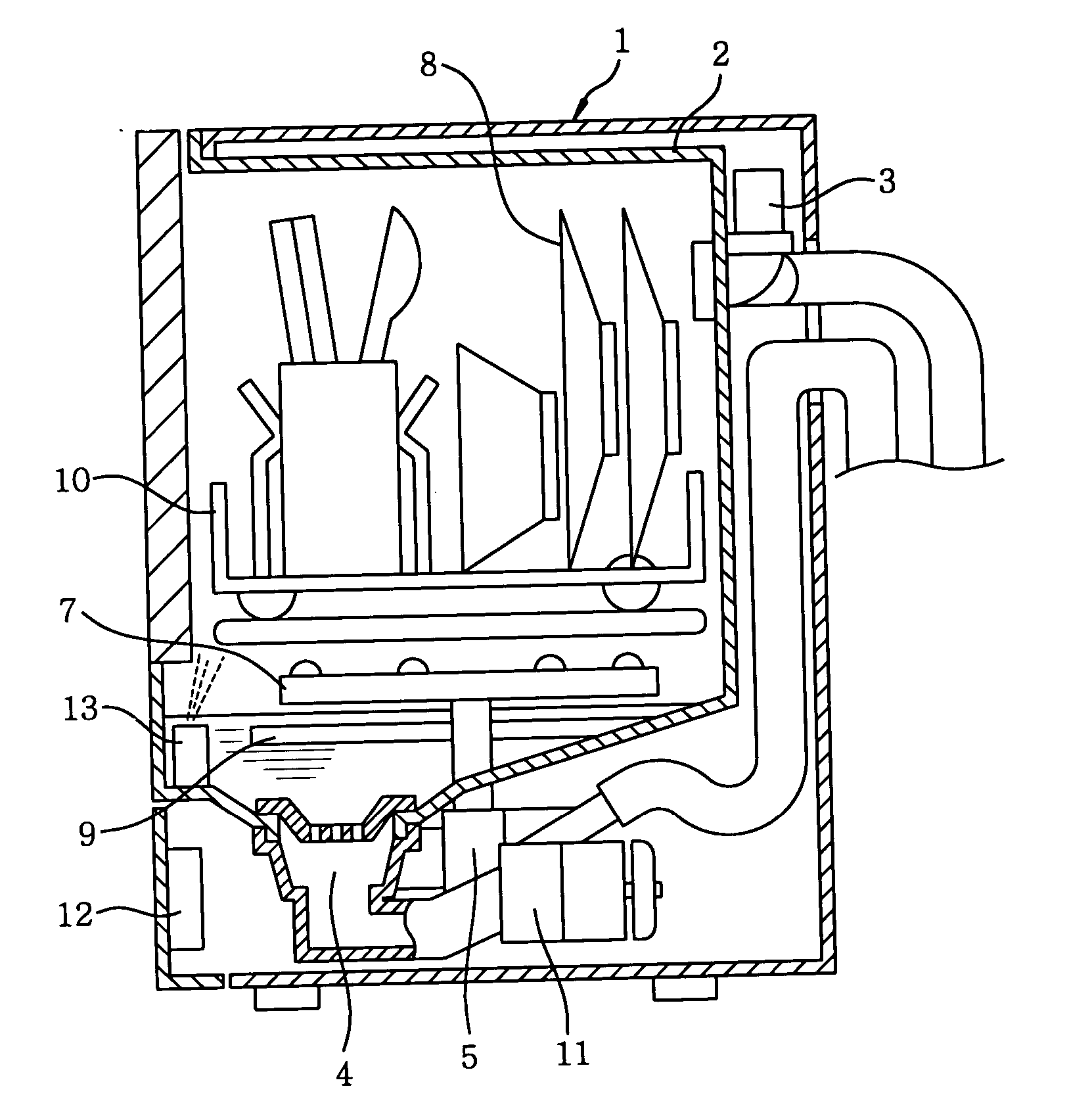

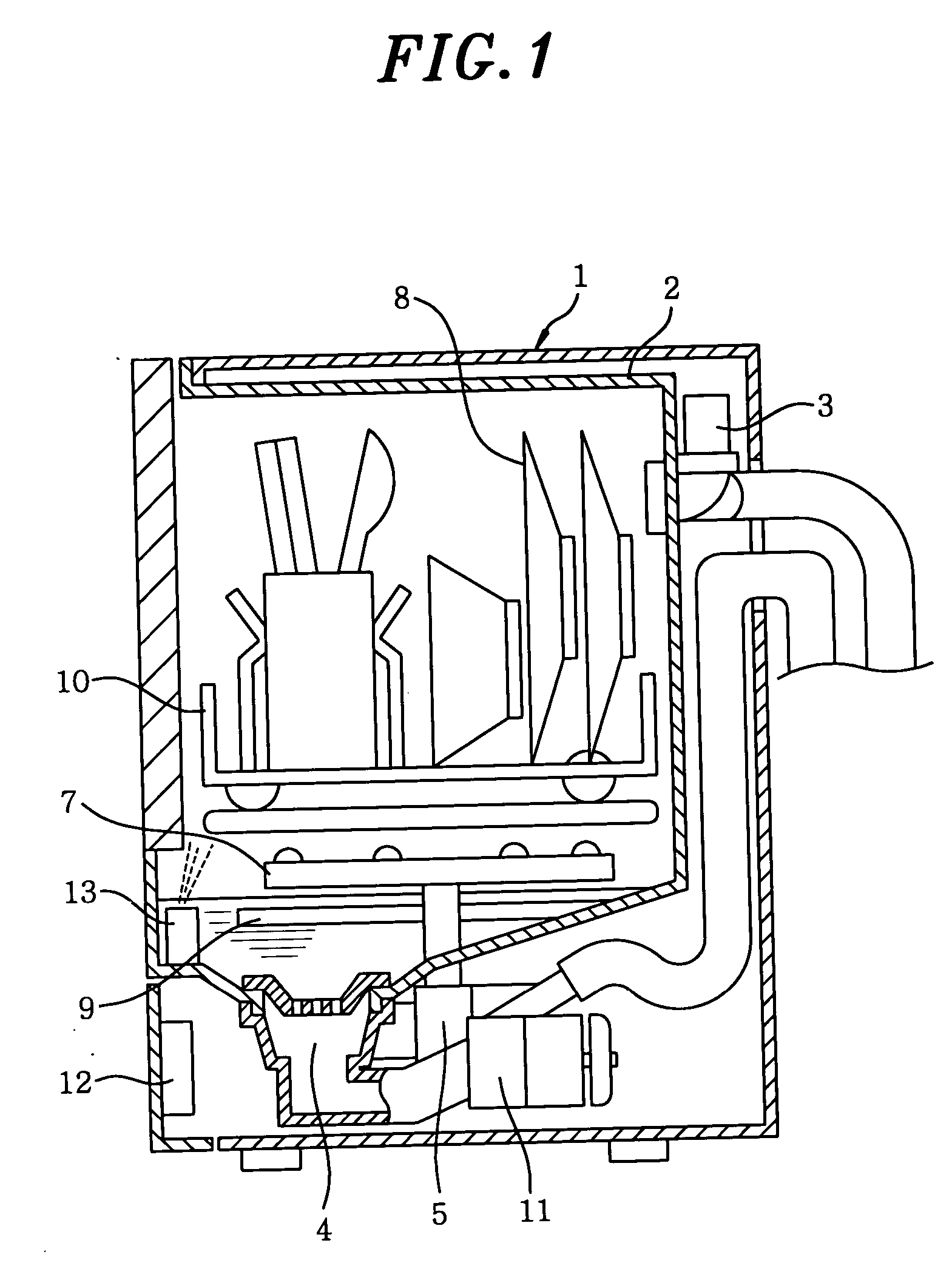

Dish washing machine

InactiveUS20050022847A1Avoid a lotEasy to washTableware washing/rinsing machine detailsWashing processesWash waterHigh heat

A dish washing machine according to the present invention carries out, in a kitchen detergent course, a soaking step for spraying a wash water stored in a containing tank toward dishes and leaving the dishes for a predetermined time precedent to a washing step. In the soaking step, a low temperature soaking is carried out in which the wash water in a washing tank is kept at about 30° C. (temperature appropriate for removing soils containing protein ingredients with a kitchen detergent, especially a neutral detergent), and thereafter a high temperature soaking is carried out in which the wash water in the washing tank is kept at about 50° C. Thereby, the soils containing protein ingredients attached to the dishes can be well removed away with the kitchen detergent.

Owner:SANYO ELECTRIC CO LTD

Cleaning method and dishwasher using same

InactiveUS20050224098A1Easy to cleanEasy to disassembleTableware washing/rinsing machine detailsWashing processesProcess engineeringCleaning methods

Owner:PANASONIC CORP

Dish washing machine and control method of the same

InactiveUS20080289654A1Safely and efficiently cleanReduce the amount requiredTableware washing/rinsing machine detailsWashing processesWash waterProcess engineering

A dish washing machine and a control method of the same are disclosed. The dish washing machine may include a first heater for heating wash water to wash items in a dishwasher. The dishwasher may also include a second heater for generating steam to be supplied to the dishes. A controller is configured to control the first and second heaters to operate alternately.

Owner:LG ELECTRONICS INC

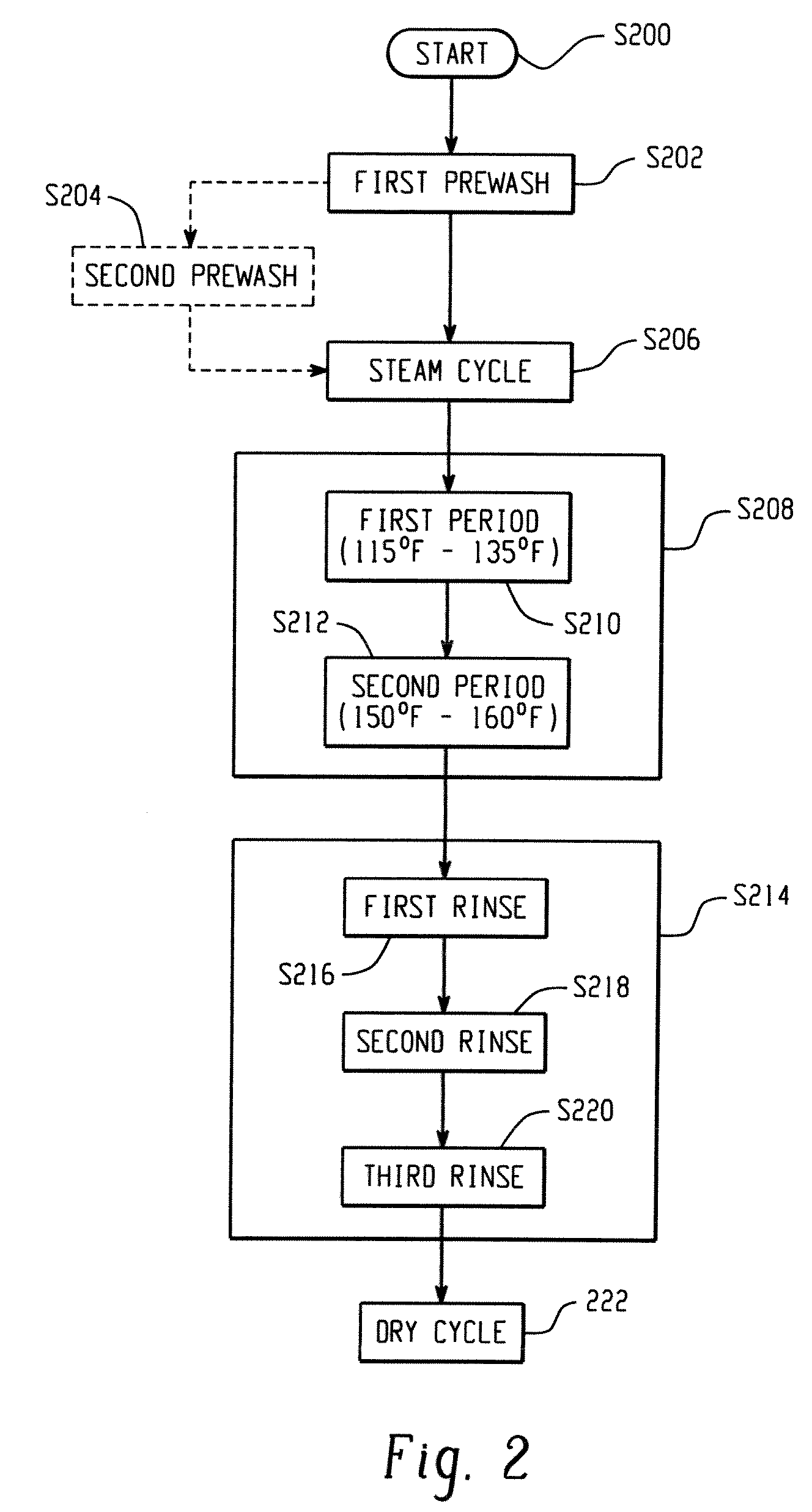

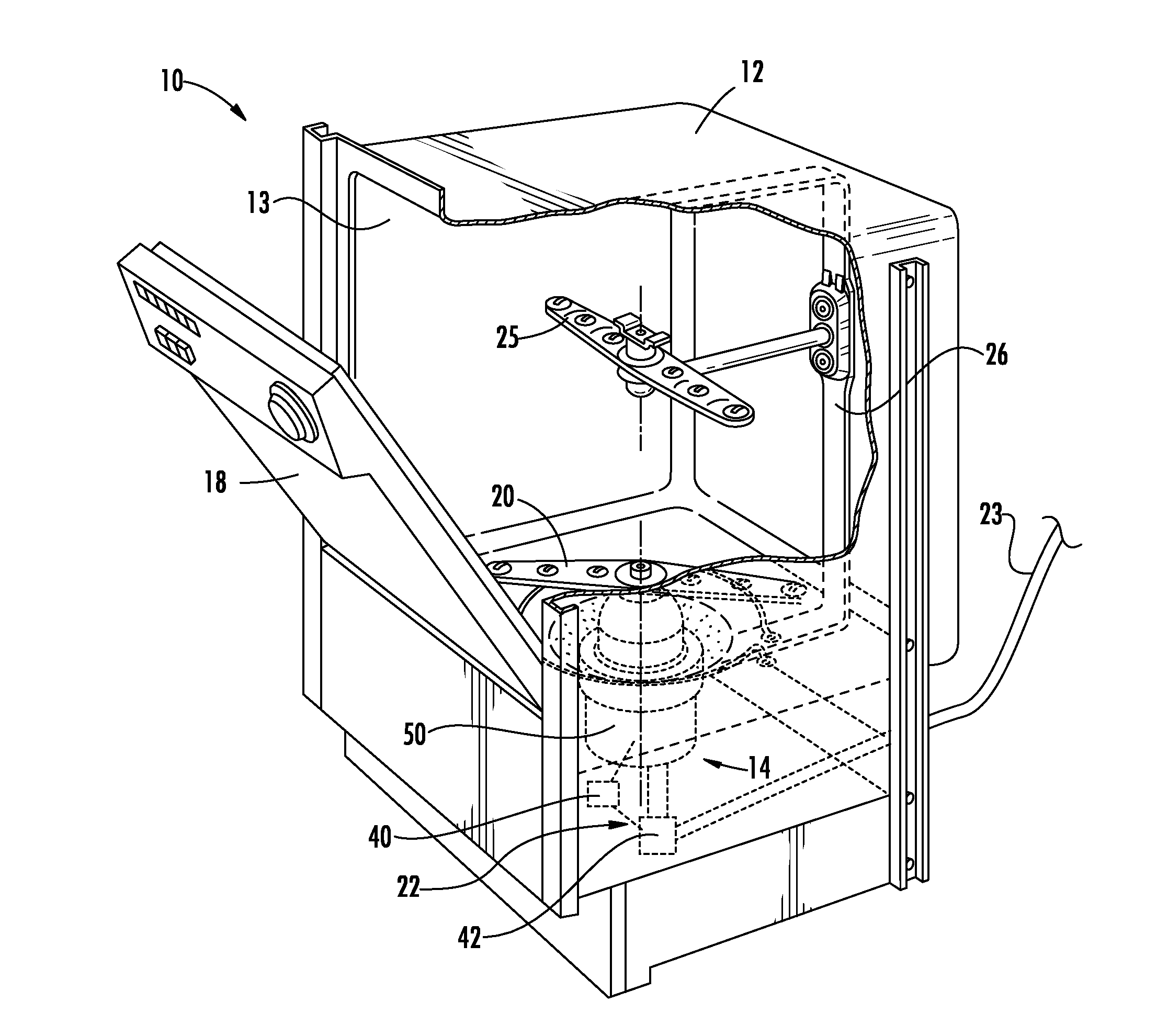

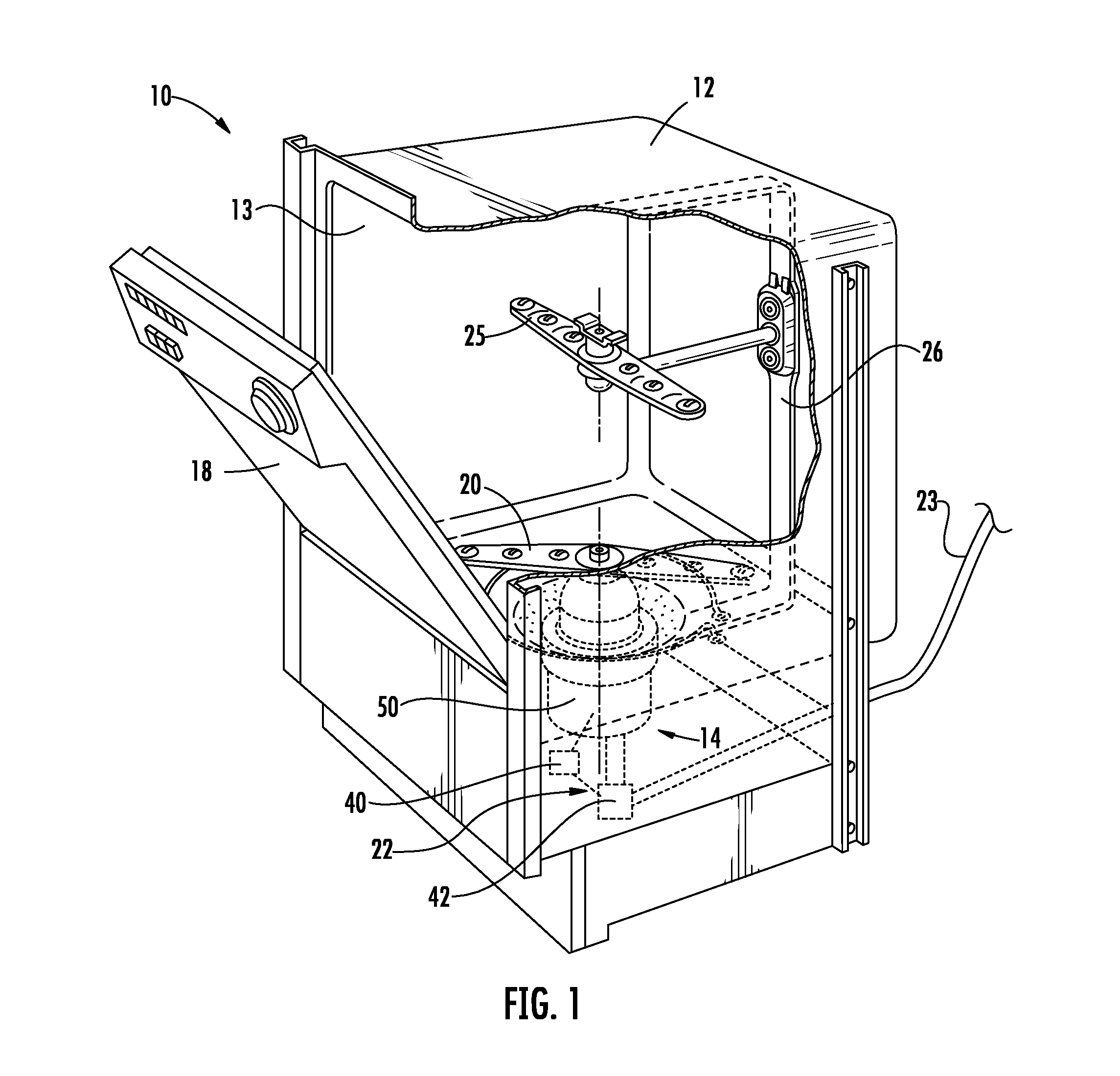

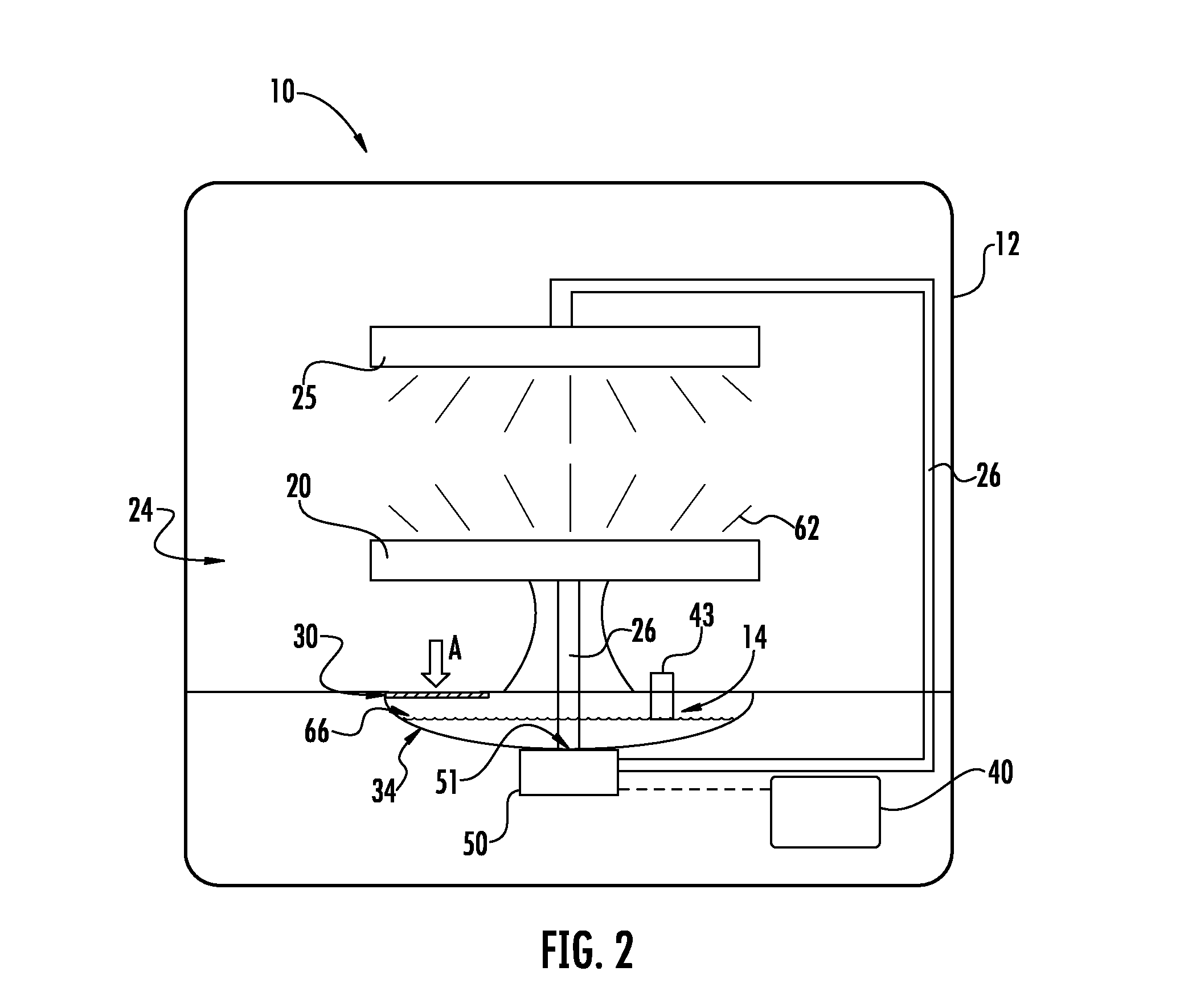

Deep clean cycle

InactiveUS20110000511A1Improve performanceSelectively energizing the heaterWashing processesAutomatic washing/rinsing machine detectionEngineeringEnzyme

A dishwasher includes a housing, a wash chamber in the housing that receives kitchenware therein, a detergent dispenser for introducing a detergent into the wash chamber, and a heater for raising temperature in the wash chamber. The dishwasher further includes a controller for selectively controlling water supply to and from the dish chamber. The controller establishes a temperature of the wash fluid circulating in the wash chamber during the first period in a range from about 115° F. (46° C.) to about 135° F. (58° C.) to enhance the wash performance of enzyme-based detergents and establishes a temperature of the wash fluid during a second period in the range from about 150° F. (65° C.) to about 160° F. (72° C.) to enhance wash performance of a chlorine-based detergent. A method of washing kitchenware contained in the dishwasher comprises (i) removing loose soil on the kitchenware in at least one pre-wash cycle, (ii) washing the kitchenware in a main wash cycle, and (iii) rinsing the kitchenware in at least one rinse cycle. The main wash cycle comprises the actions of (i) washing the kitchenware in a first temperature range for enzyme-based detergent for a first period and (ii) washing the kitchenware in a second temperature range for chlorine-based detergent for a second period.

Owner:GENERAL ELECTRIC CO

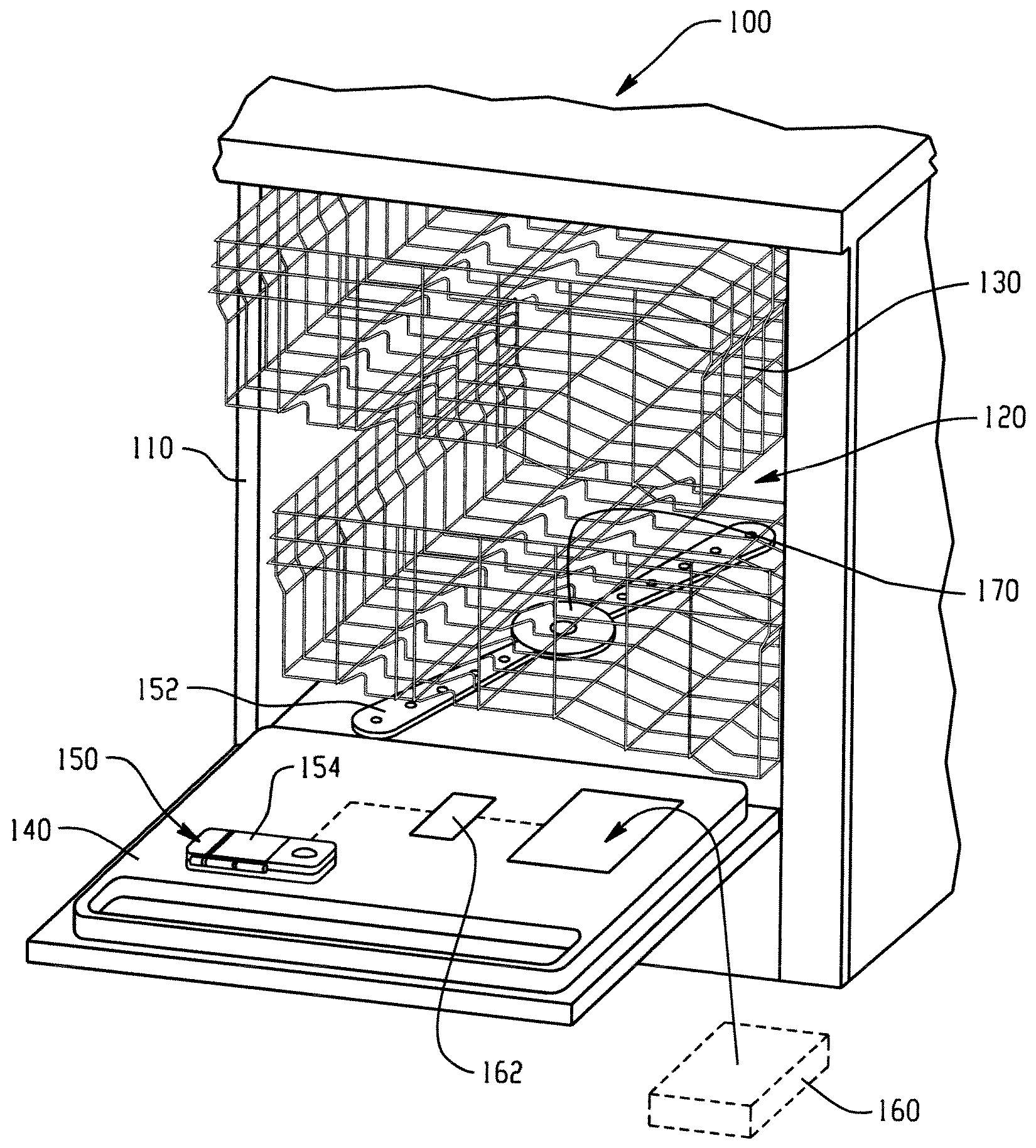

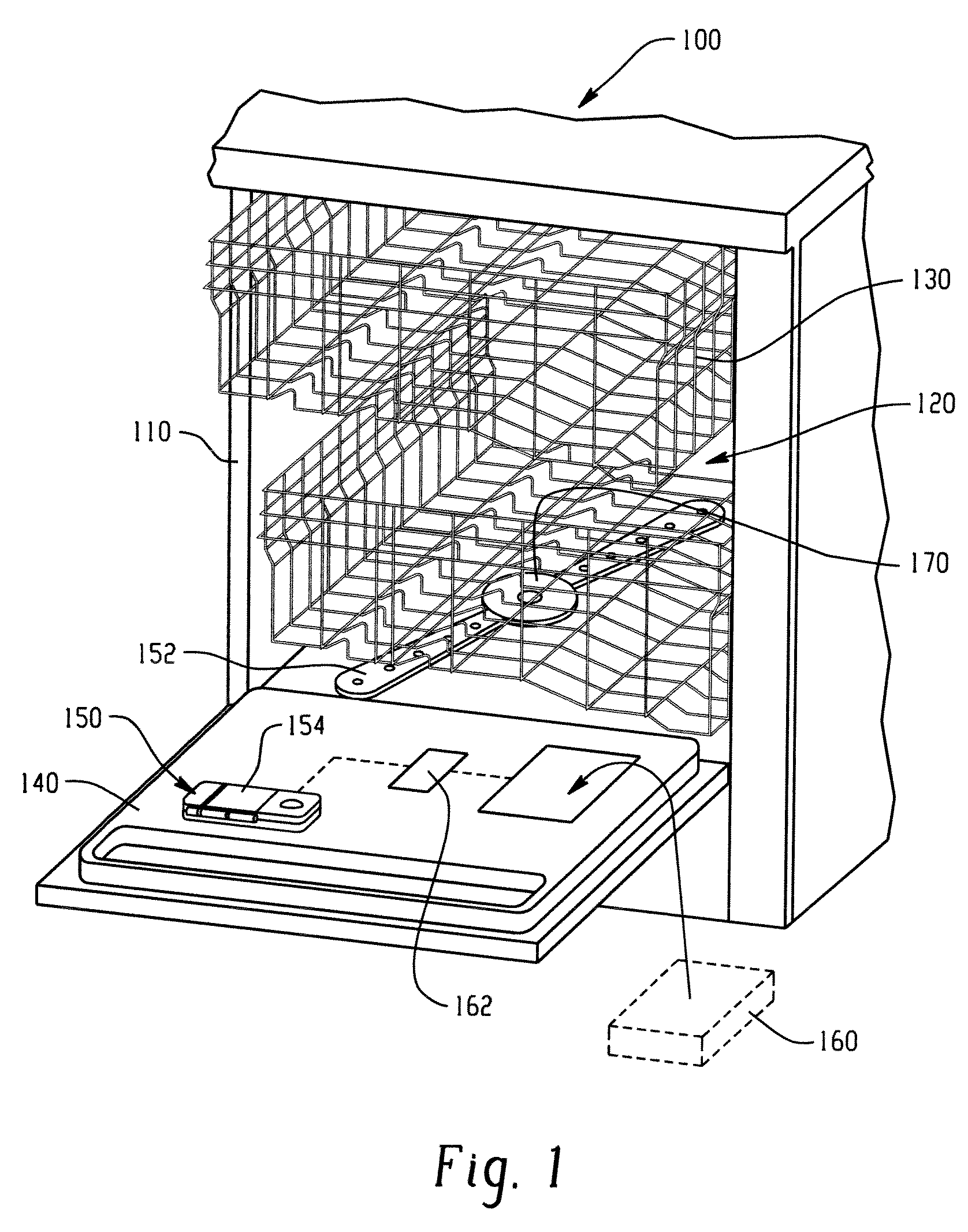

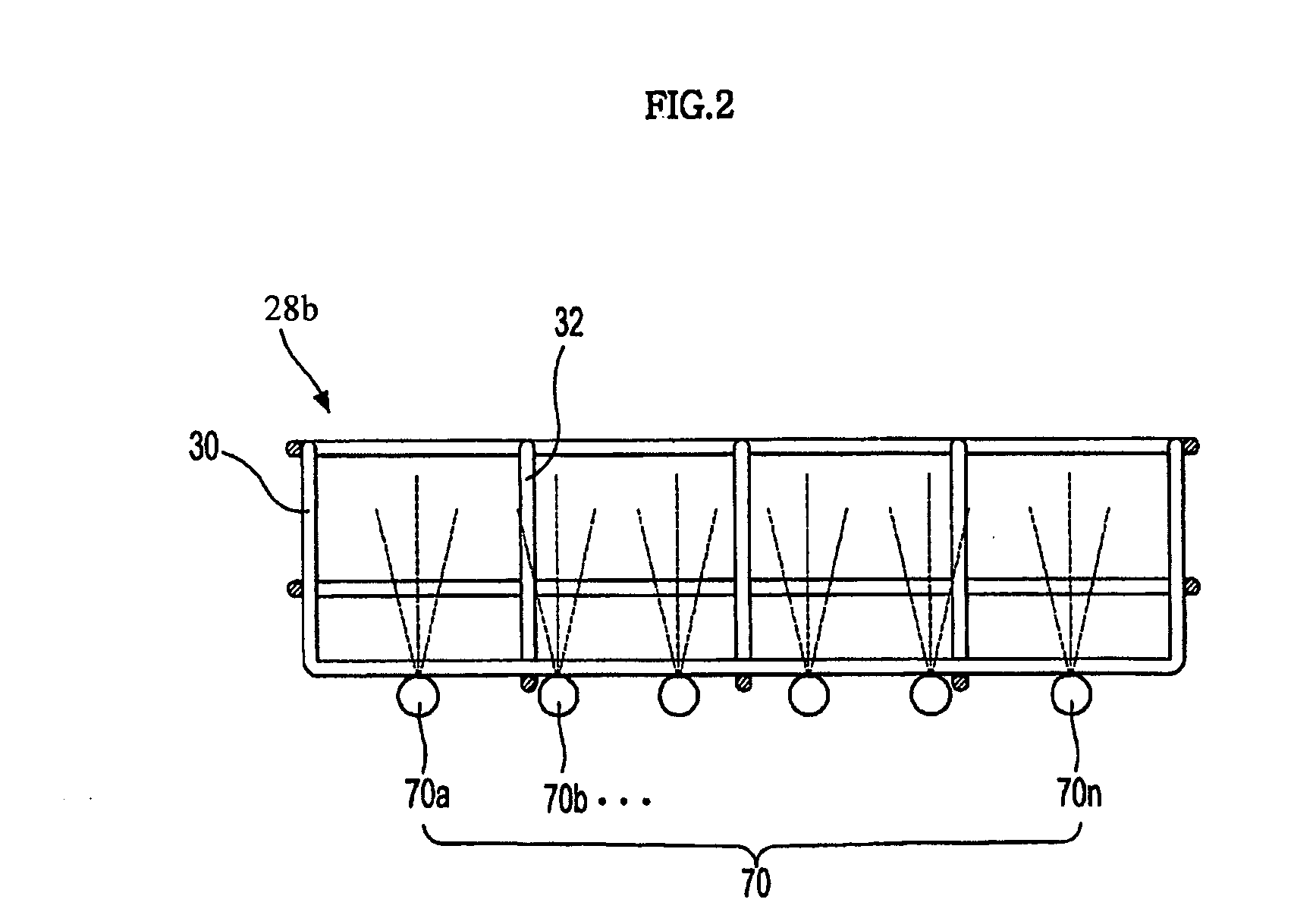

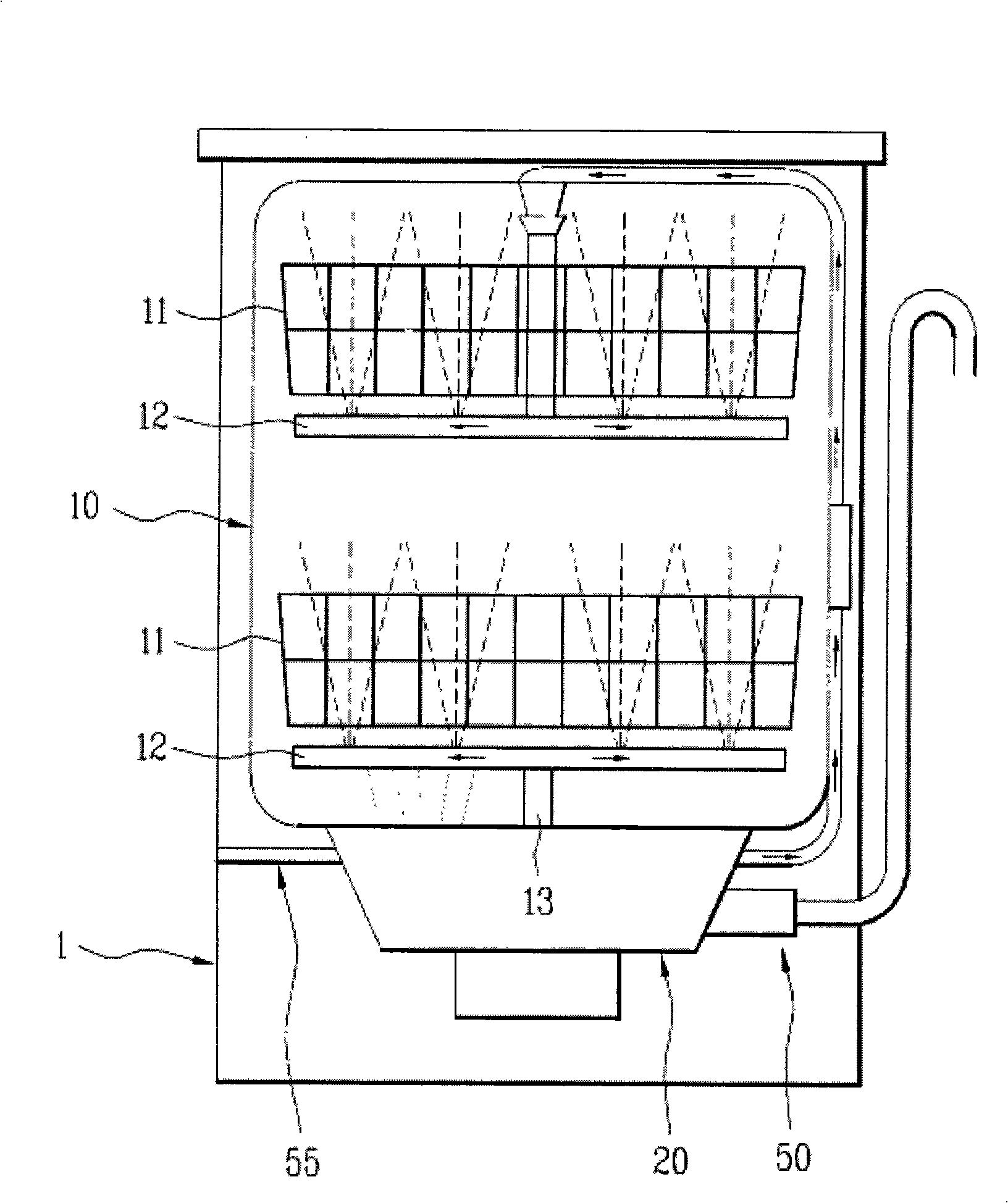

Dishwasher having steam washing function and dishwashing method

InactiveUS20070235063A1Prevent leakageImprove performanceTableware washing/rinsing machine detailsWashing processesInjection pressureWash water

A steam / water mixed dishwasher using steam and water together, and, more particularly, a dishwasher and dishwashing method of achieving improvement in washing performance and efficiency via direct steam injection to dishes. The dishwasher includes a body containing a dishwashing tub, at least one dish basket disposed in the dishwashing tub and adapted to receive dishes therein, a steam generator to generate steam by heating wash water, and steam injection nozzles to inject the steam generated from the steam generator. The steam injection nozzles are disposed at the same height as a lower surface of the dish basket. The dishwashing method includes injecting steam from a number of the plurality of steam injection nozzles by opening a number of the plurality of control valves, to thereby maintain an injection pressure of the steam generated from the steam generator.

Owner:SAMSUNG ELECTRONICS CO LTD

Automatic dishwashing compositions and methods for use with electrochemical cells and/or electrolytic devices

InactiveUS20050075257A1Improved tableware cleaningImproved sanitizingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsElectrolysisPhosphate

The present invention relates to automatic dishwashing detergent compositions and methods of using compositions comprising halogenated salts, phosphate and / or silicate in conjunction with electrolyzed water in automatic dishwashing appliances comprising an electrochemical cell and / or electrolytic device for treating tableware to improve cleaning, sanitizing and stain removal by controlling hardness, corrosion and dispersancy.

Owner:THE PROCTER & GAMBLE COMPANY

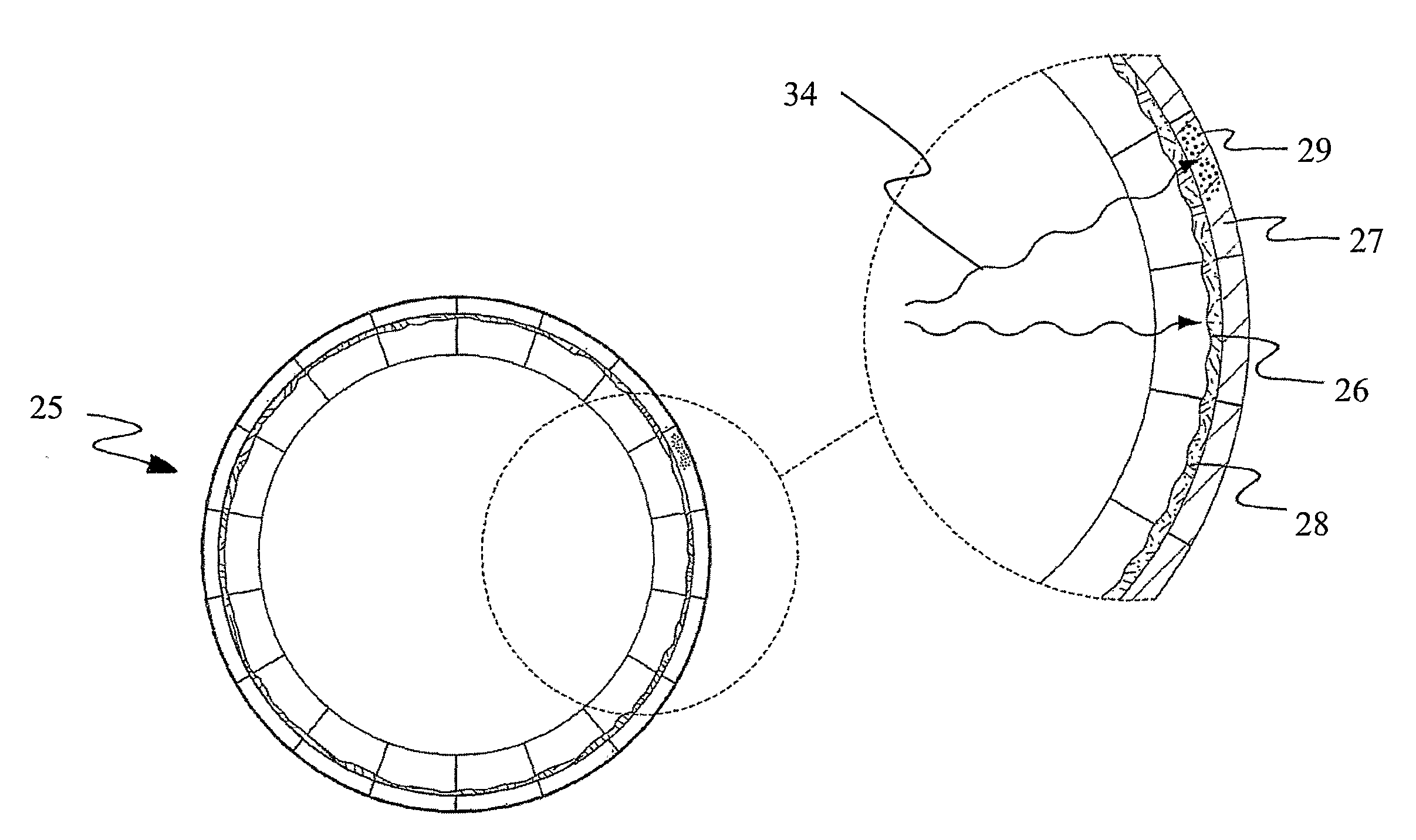

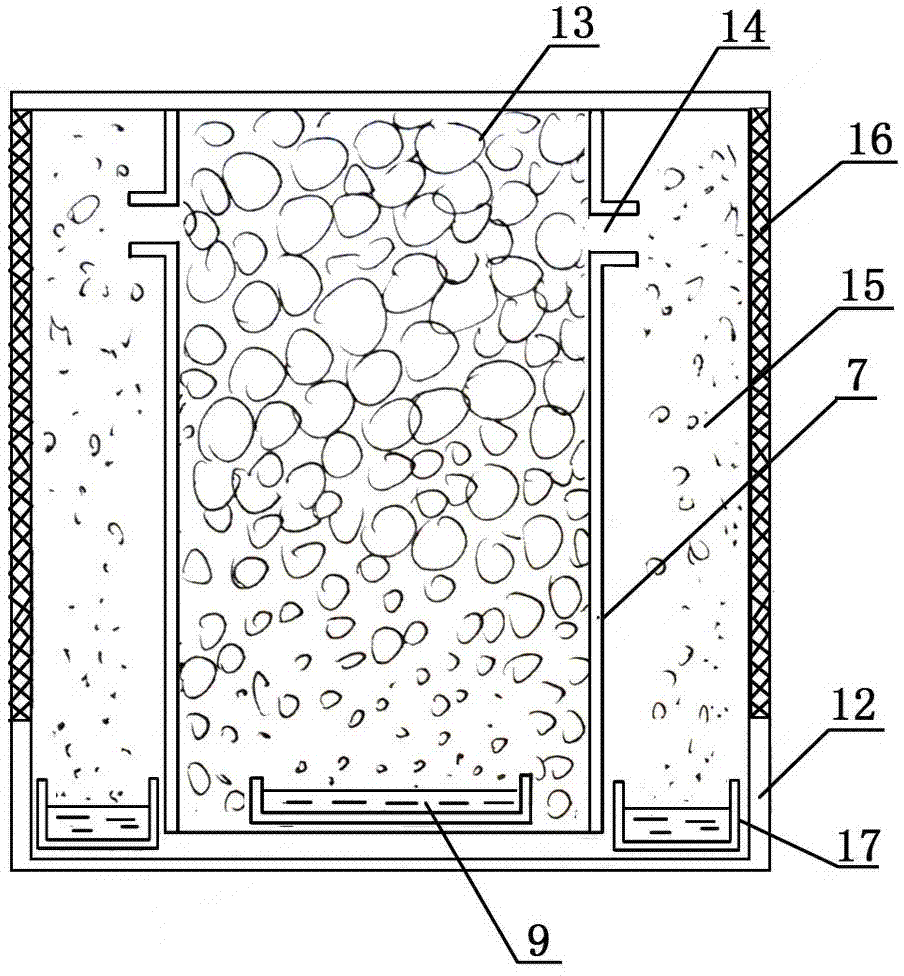

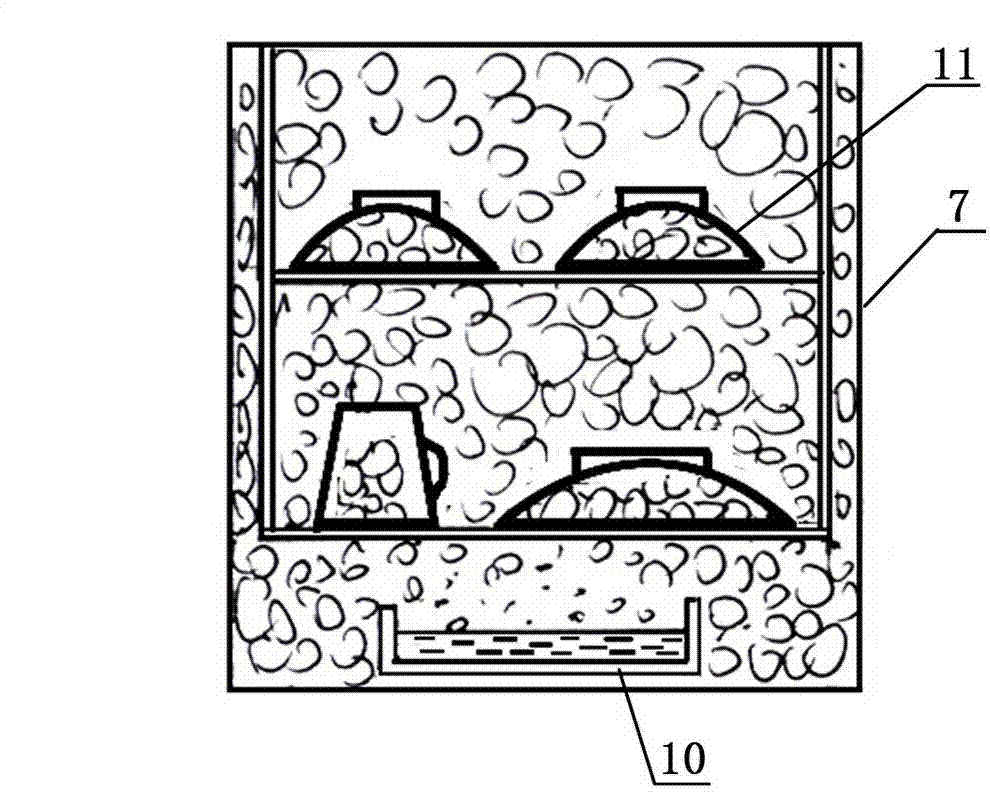

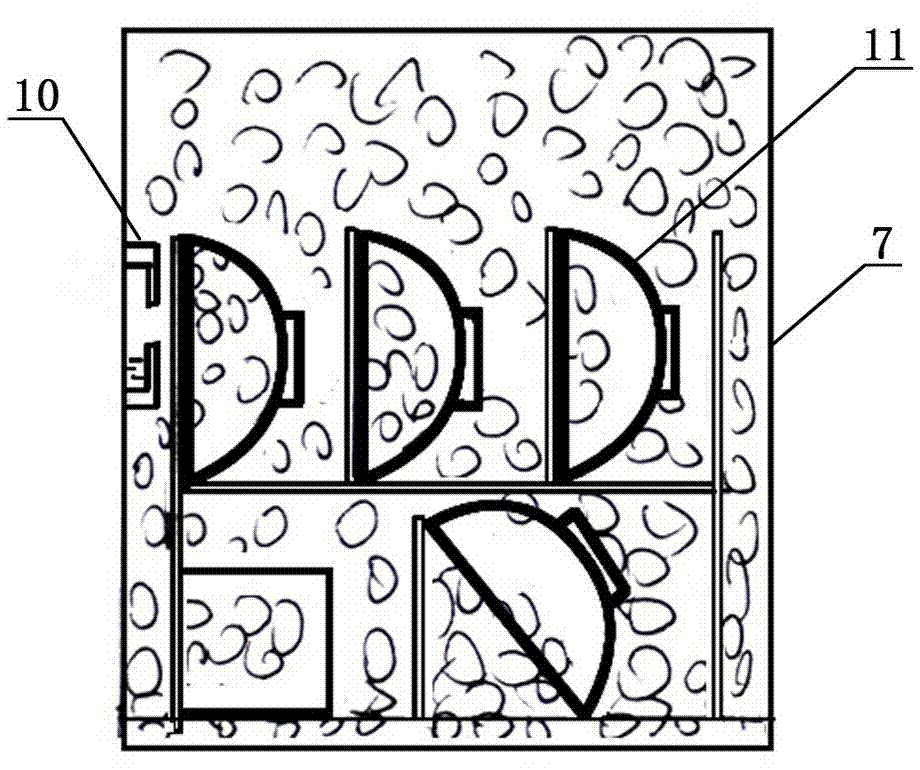

Cleaning Method

InactiveUS20130276242A1Easy to cleanLower Level RequirementsOrganic detergent compounding agentsWashing processesWash waterCleaning methods

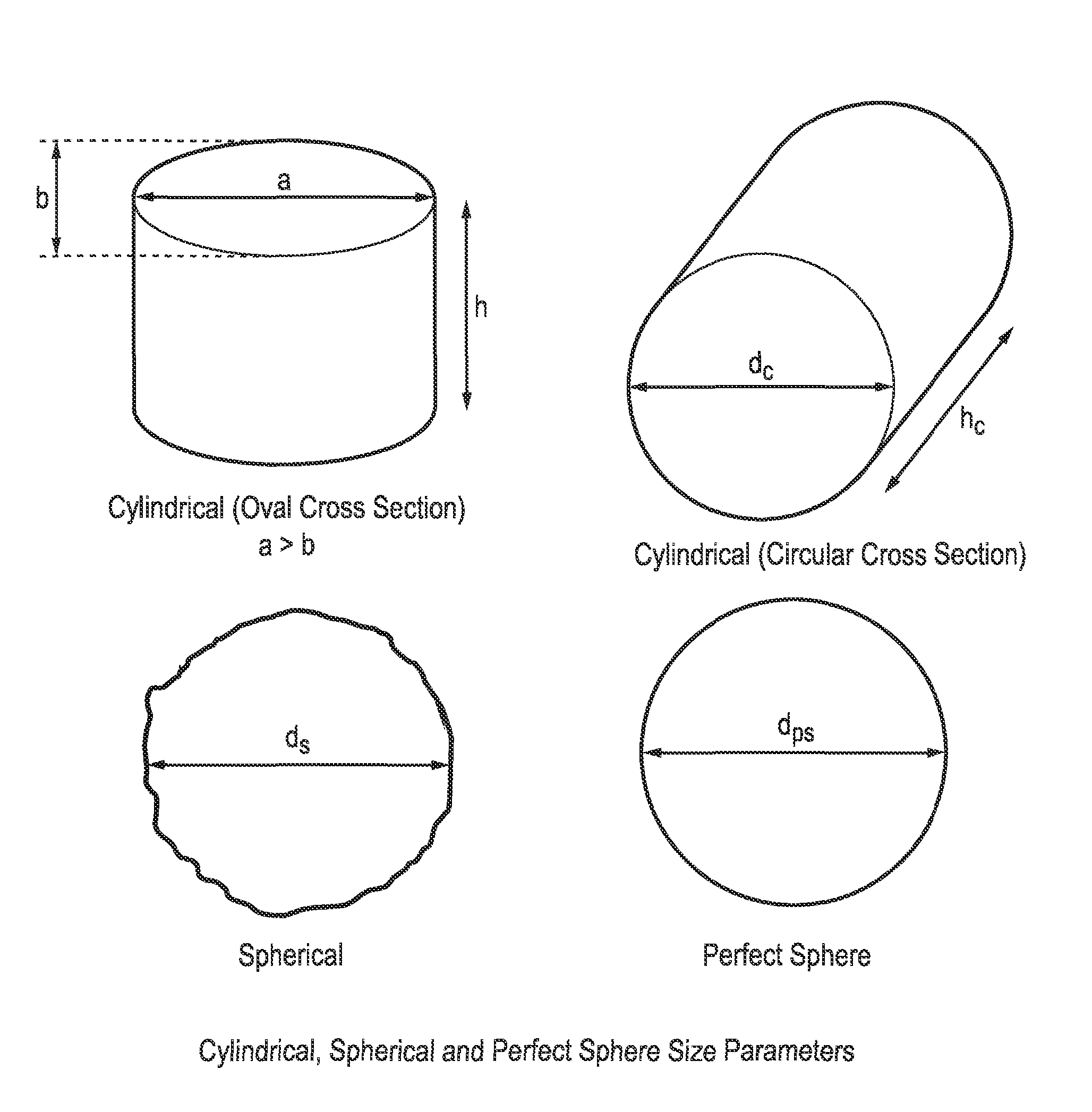

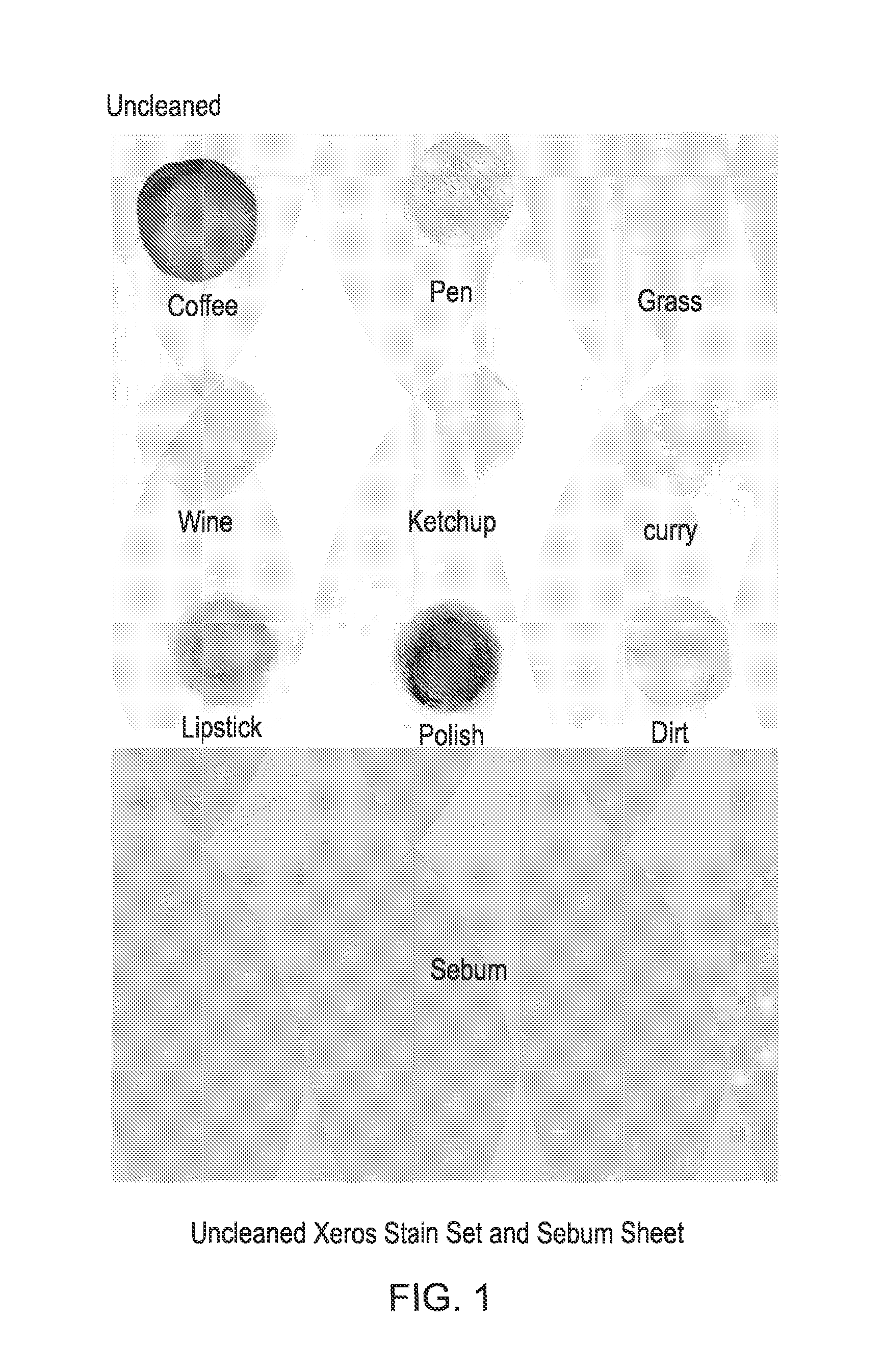

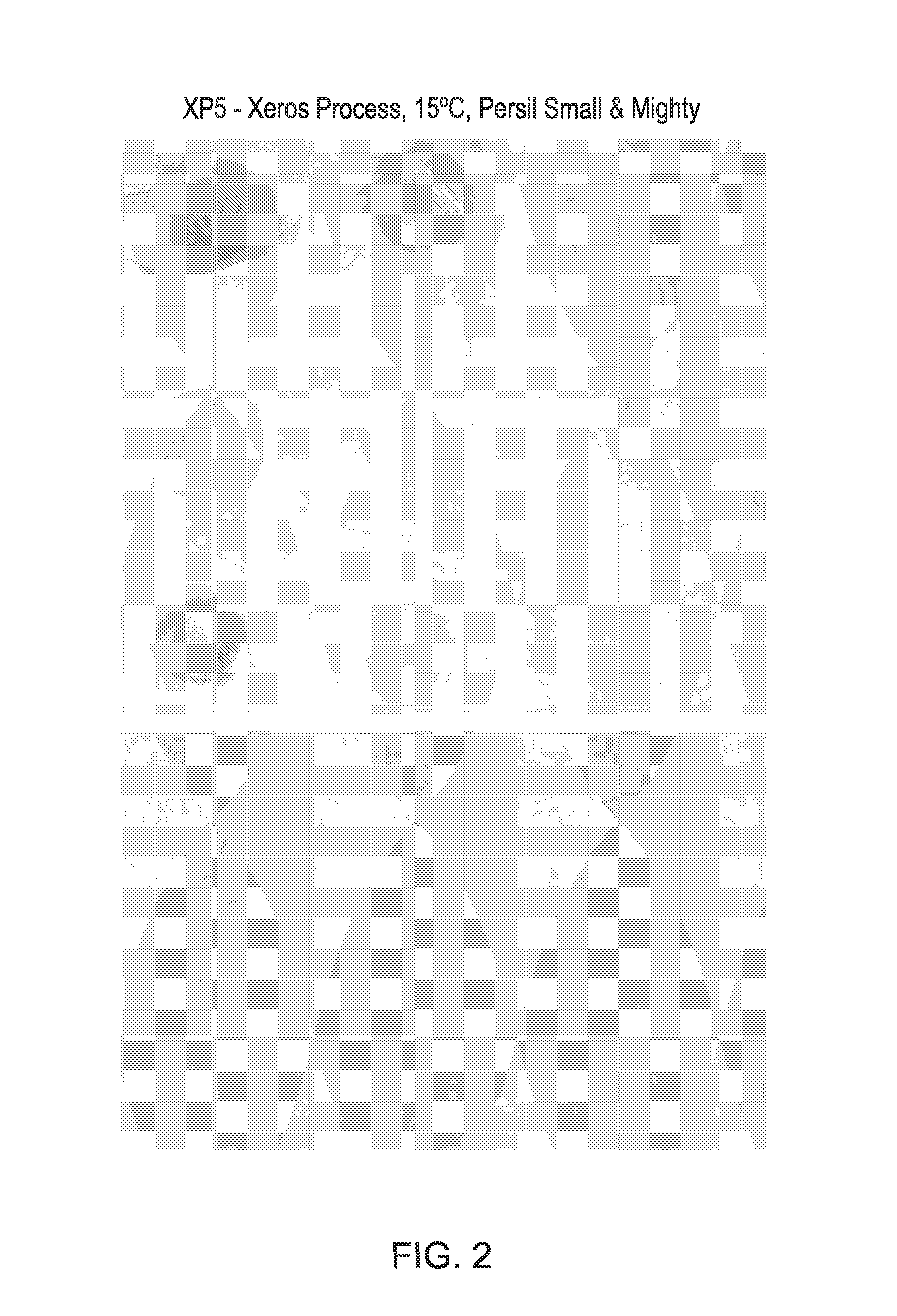

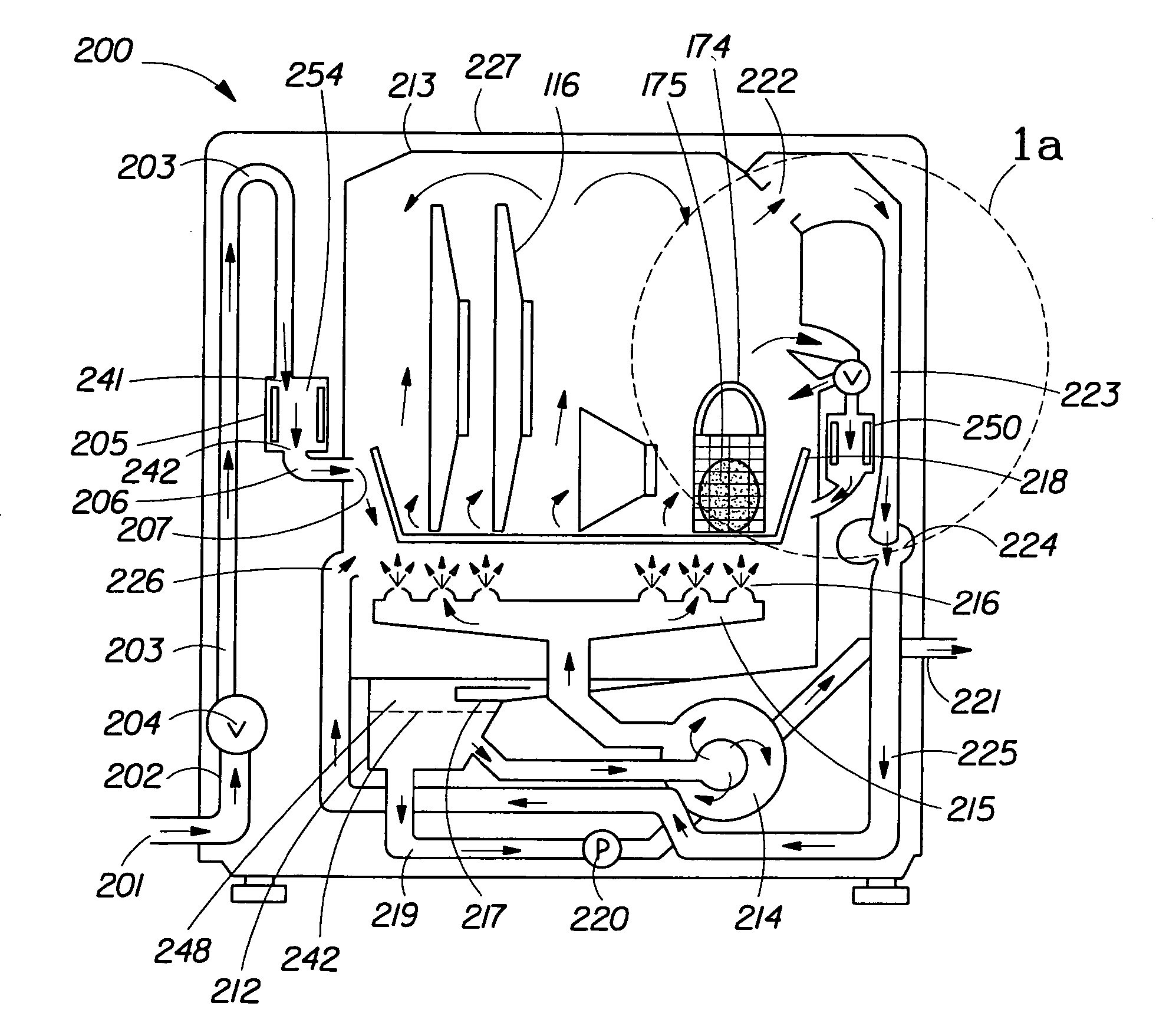

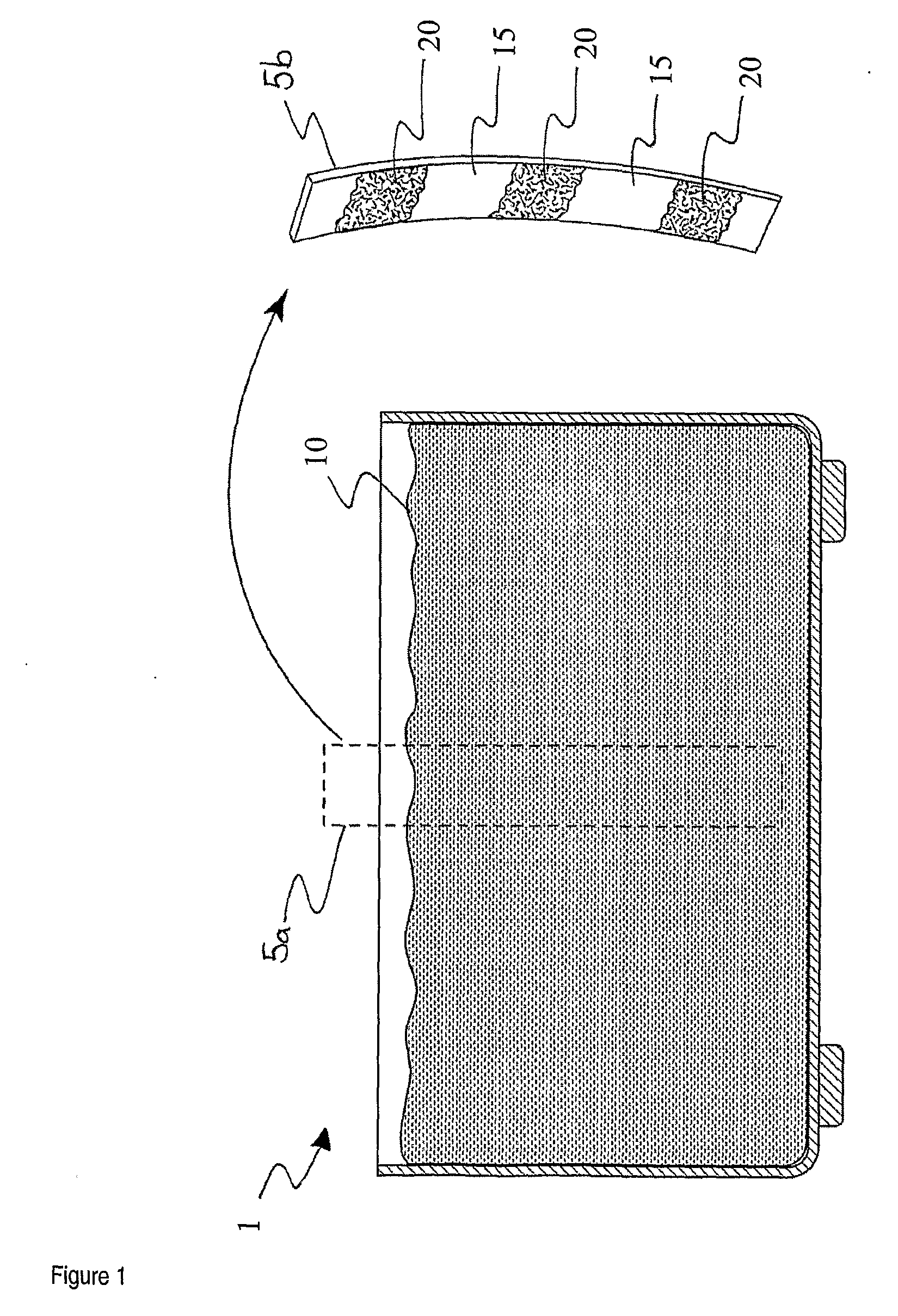

The invention provides a method for the cleaning of a soiled substrate, the method comprising treating the substrate with a solid particulate cleaning material and wash water, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls and having a capacity of between 5 and 50 litres for each kg of fabric in the washload, wherein said solid particulate cleaning material comprises a multiplicity of polymeric particles at a particle to fabric addition level of 0.1:1-10:1 by mass, each particle being substantially cylindrical or spherical in shape and having an average density in the range of 0.5-2.5 g / cm3 and an average volume in the range of 5-275 mm3, and wherein said drum comprising perforated side walls is rotated at a speed which generates G forces in the range of from 0.05 to 900 G. The polymeric particles may comprise foamed or unfoamed polymeric materials which may comprise either linear or crosslinked polymers. Preferably, at least one detergent is employed in the cleaning process. The invention provides optimum cleaning performance as a result of improved mechanical interaction between substrate and cleaning media and is preferably used for the cleaning of textile fabrics. The method allows for significant reductions in the consumption of detergents, water and energy when compared with the conventional wet cleaning of textile fabrics, and also facilitates reduced washing-related textile fabric damage. The invention also envisages a cleaning composition comprising a solid particulate cleaning composition and at least one additional cleaning agent. In particular embodiments of the invention, the solid particulate cleaning material is separated and recovered and then re-used in subsequent cleaning processes. Typically, the solid particulate cleaning material is itself cleaned intermittently in order to maintain its efficacy.

Owner:XEROS LTD

Signal-based electrochemical methods for automatic dishwashing

InactiveUS20060096618A1Improve cleanlinessImproved sanitizingInorganic/elemental detergent compounding agentsTableware washing/rinsing machine detailsSpecific timeElectrochemical cell

Methods of improving tableware cleaning, sanitizing and stain removal using an automatic dishwashing appliance containing an electrochemical cell and / or electrolytic device. The methods comprise steps for generating electrolyzed water by intermittently activating and / or intermittently deactivating the cell so as to sequentially provide a bleaching species at specific times during the wash and / or rinse cycle. Said methods include a signal-sensing system capable of detecting a composition comprising a signal-providing agent, methods of using said compositions, and articles of manufacture.

Owner:PRICE KENNETH NATHAN +3

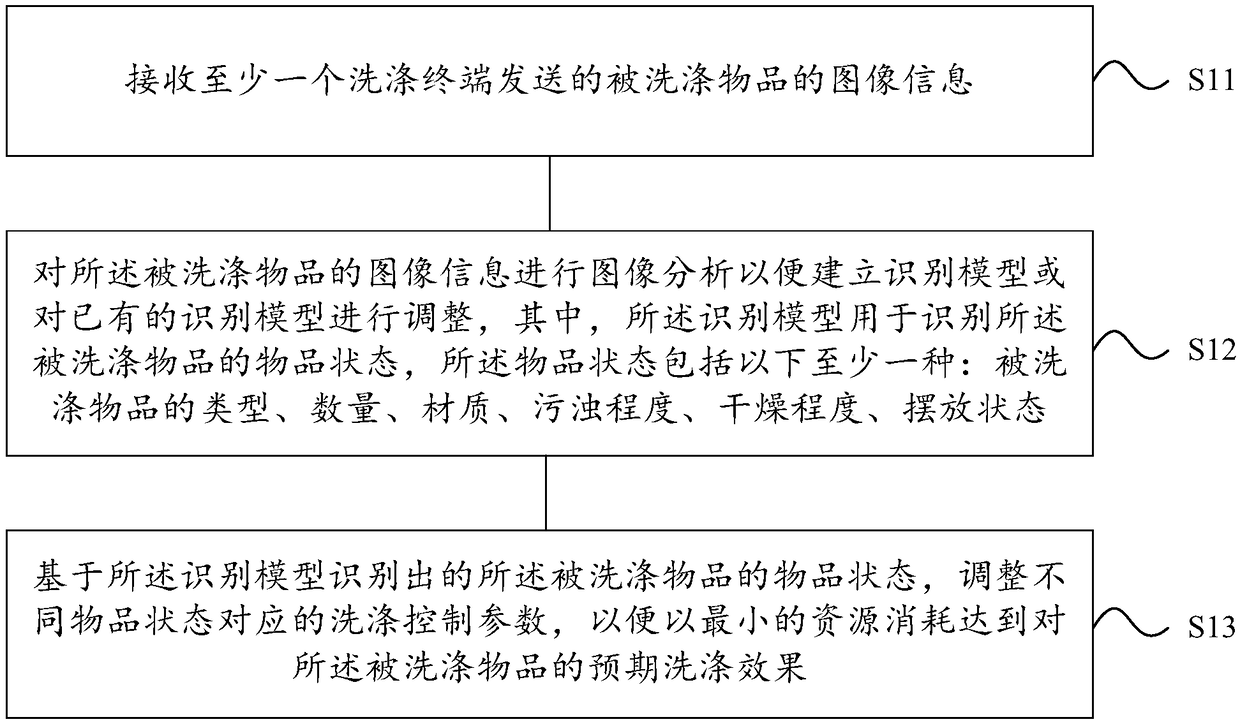

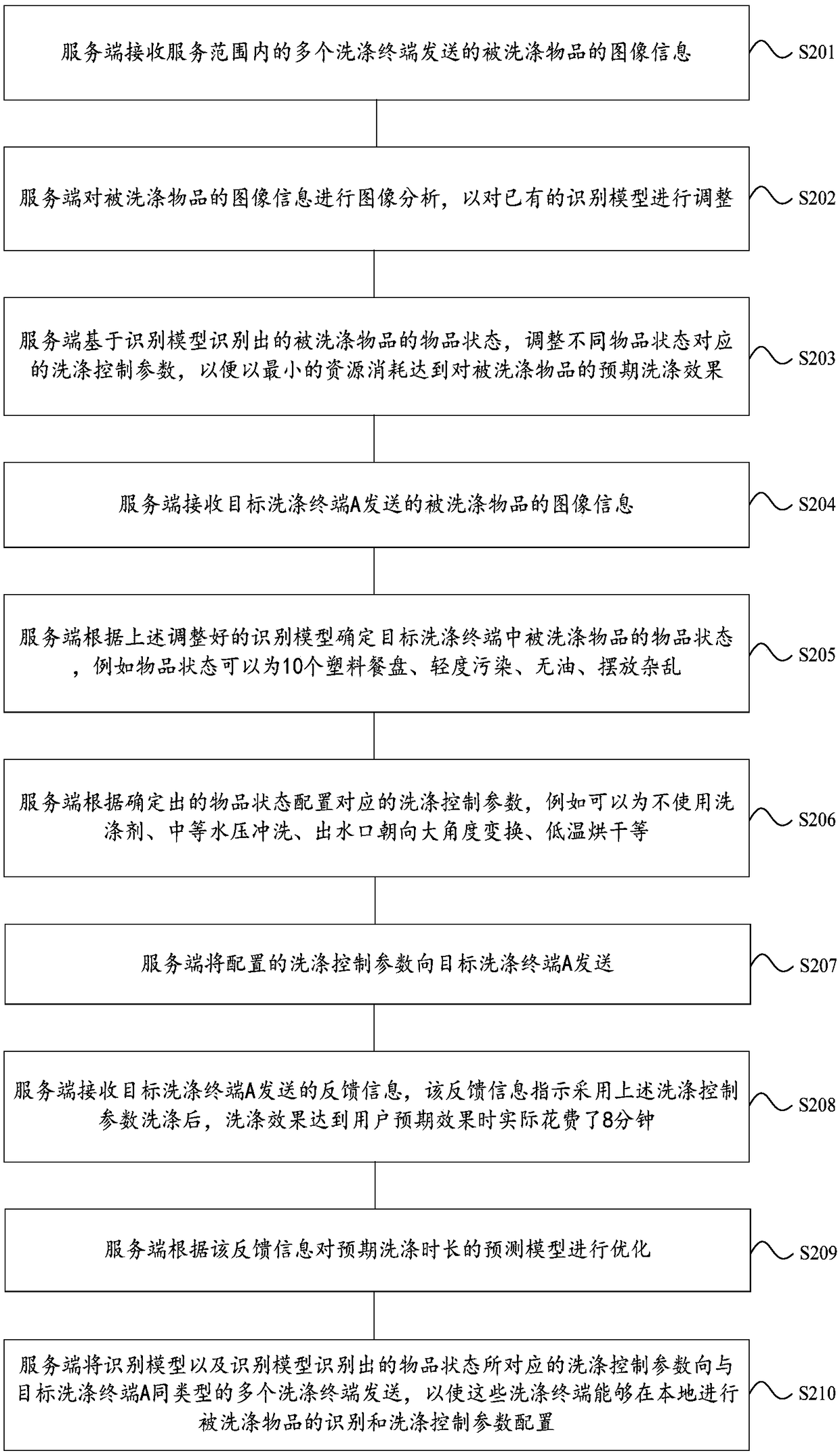

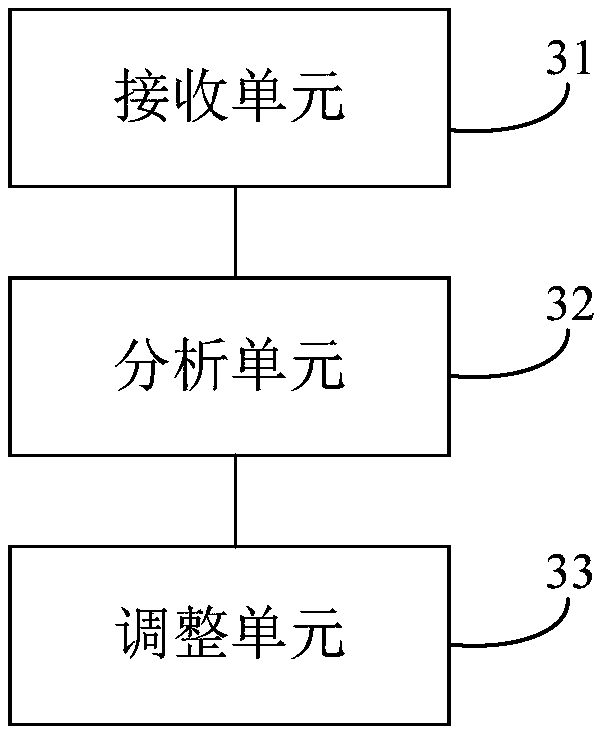

Washing control optimizing method, device, electronic device and storage medium

ActiveCN108814501AAvoid repetitionImprove efficiencyTableware washing/rinsing machine detailsWashing processesImaging analysisElectric equipment

The embodiment of the invention discloses a washing control optimizing method, device, electronic device and storage medium and relates to the technical field of smart home. The washing control optimizing method, device, electronic device and storage medium can effectively improve the optimizing efficiency and effects of washing control programs. The washing control optimizing method comprises receiving image information of objects to be washed, which is transmitted by at least one washing terminal, performing image analysis on the image information of the objects to be washed to establish identification models or adjusting existing identification models, wherein the identification models are used for identifying the object states of the objects to be washed, and the object states compriseat least one of following parameters including type, number, texture, dirty degree, drying degree and placing state of the objects to be washed; based on the identification models, identifying the object states of the objects to be washed, and adjusting washing control parameters corresponding different object states so as to achieve expected washing effects on the objects to be washed at the minimal consumption of resources. The washing control optimizing method, device, electronic device and storage medium can be applied to washing program optimization of washing equipment.

Owner:KINGSOFT

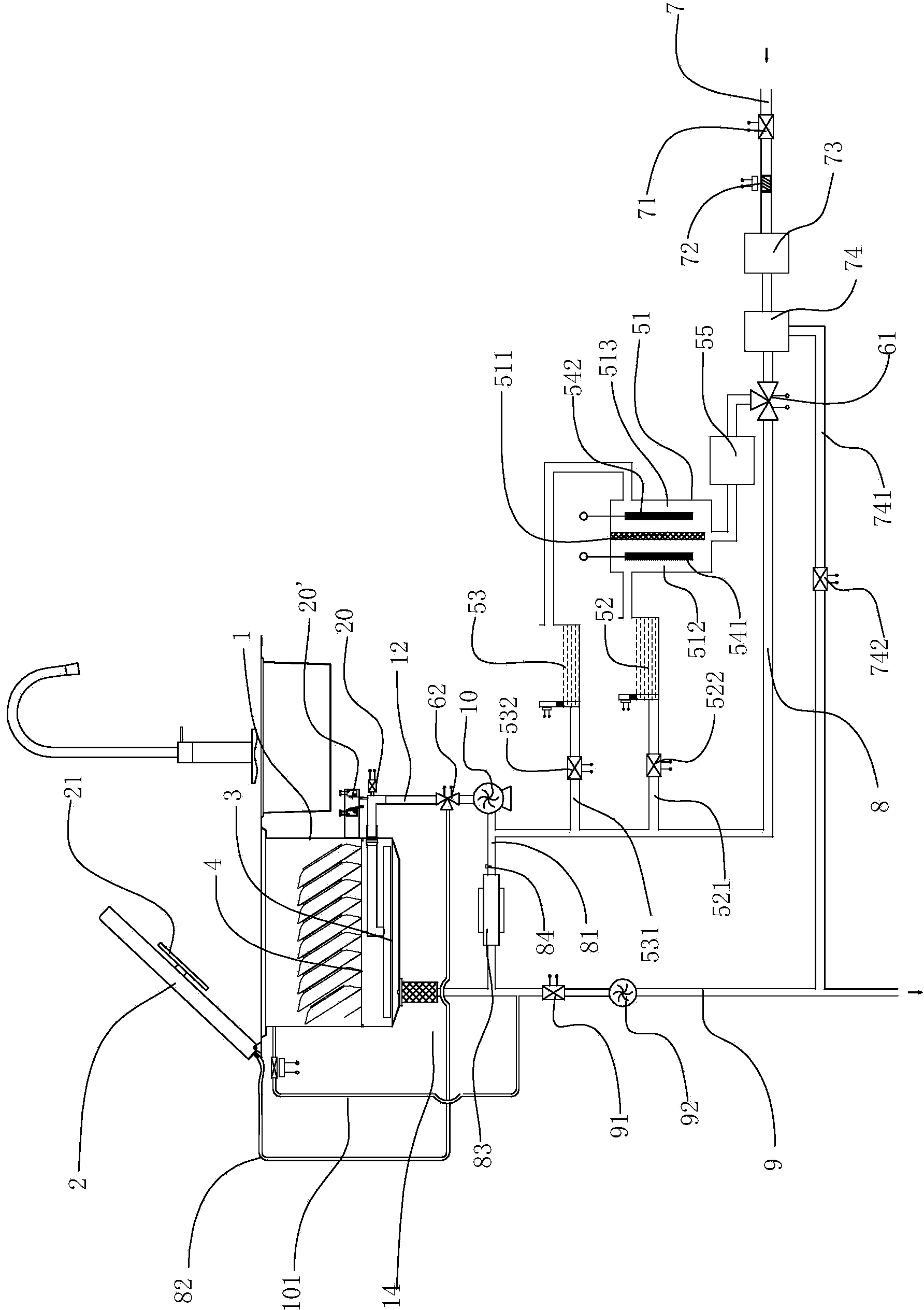

Cleaning machine with brine electrolysis device and cleaning method thereof

ActiveCN103801530AEasy to cleanImprove antivirusWashing processesSpecific water treatment objectivesAlkaline waterElectricity

The invention discloses a cleaning machine with a brine electrolysis device and a cleaning method thereof. The cleaning machine comprises a container. A water inlet is formed in the circumferential face of the container, a rotary gushing arm is arranged above the bottom face of the container, and the outer side of the water inlet is provided with a movable water inlet pipe which can be inserted in or stretch out of the water inlet and is communicated with the rotary gushing arm. The cleaning machine further comprises the brine electrolysis device. The water inlet pipe of the outside enters a first three-way electromagnetic valve, the other two ends of the first three-way electromagnetic valve are connected with a water channel and a circulating water pump of the brine electrolysis device respectively, and a water outlet of the circulating water pump is connected to a second three-way electromagnetic valve. A water outlet pipe of an acidic water tank and a water outlet pipe of an alkaline water tank are both communicated with the circulating water pump. The second end of the second three-way electromagnetic valve is connected to a movable water inlet pipe. According to the cleaning machine with the brine electrolysis device and the cleaning method thereof, electrolyzed alkaline water and acidic water are used for conducting circulation cleaning and sterilizing, and thus pollution of waste water to the environment is reduced; moreover, the design process is reasonable and compact, cleaning time is short, the quantity of electricity is greatly saved, and the efficiency of labor is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

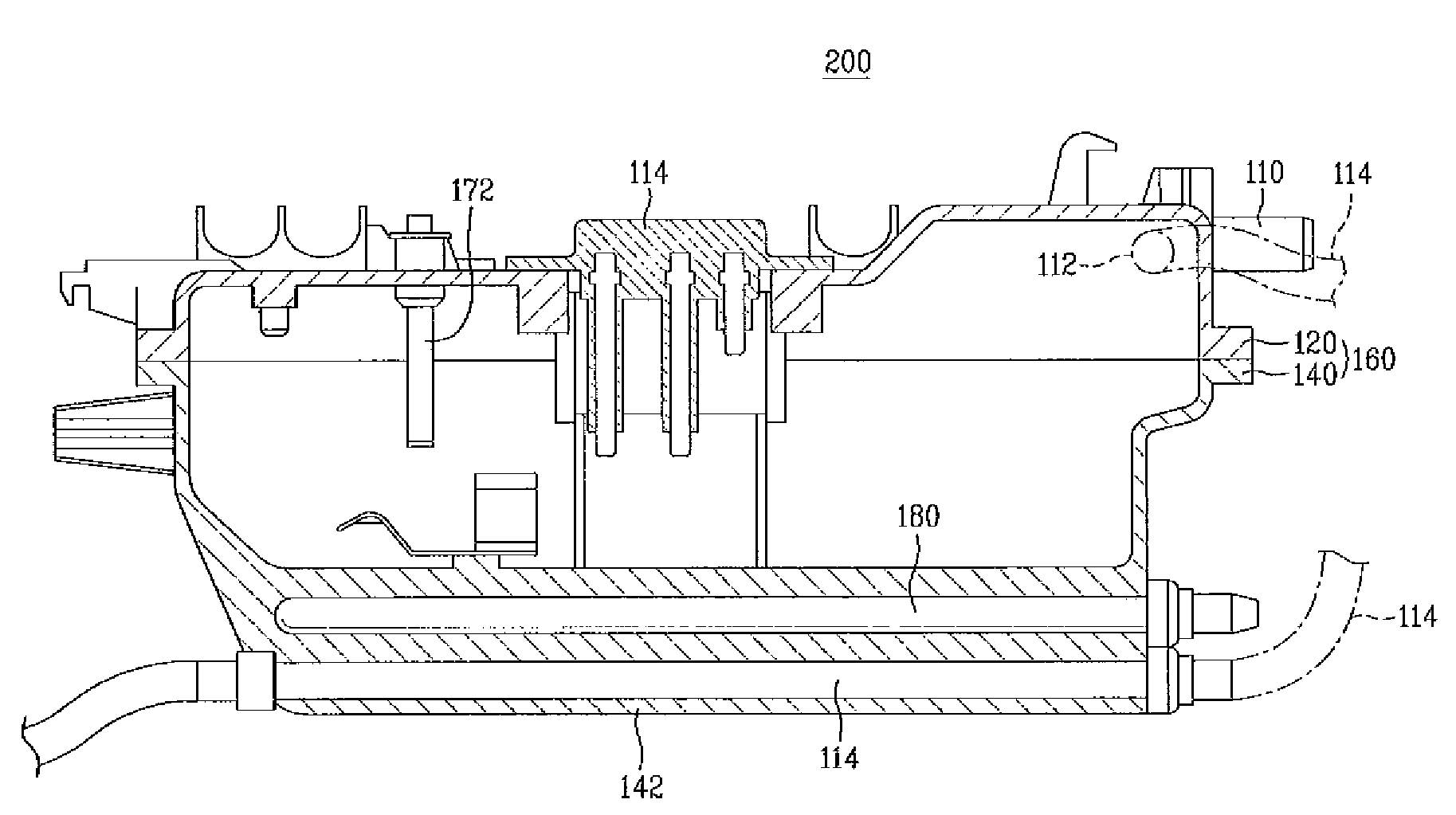

Dishwasher and controlling method thereof

ActiveUS20070102025A1Easy to useSatisfy cleanlinessWashing processesHollow article cleaningEngineeringHolding room

A dishwasher and a controlling method thereof are provided. The dishwasher includes a tub, a door, a steam generator, and a dish storage. The tub holds dishes and is opened at one end. The door selectively seals the opened end of the tub. The steam generator is provided outside the tub to generate steam. The steam discharger discharges the steam generated by the steam generator into the tub. The dish storage stores dishes to be sterilized by the steam discharged from the steam discharger.

Owner:LG ELECTRONICS INC

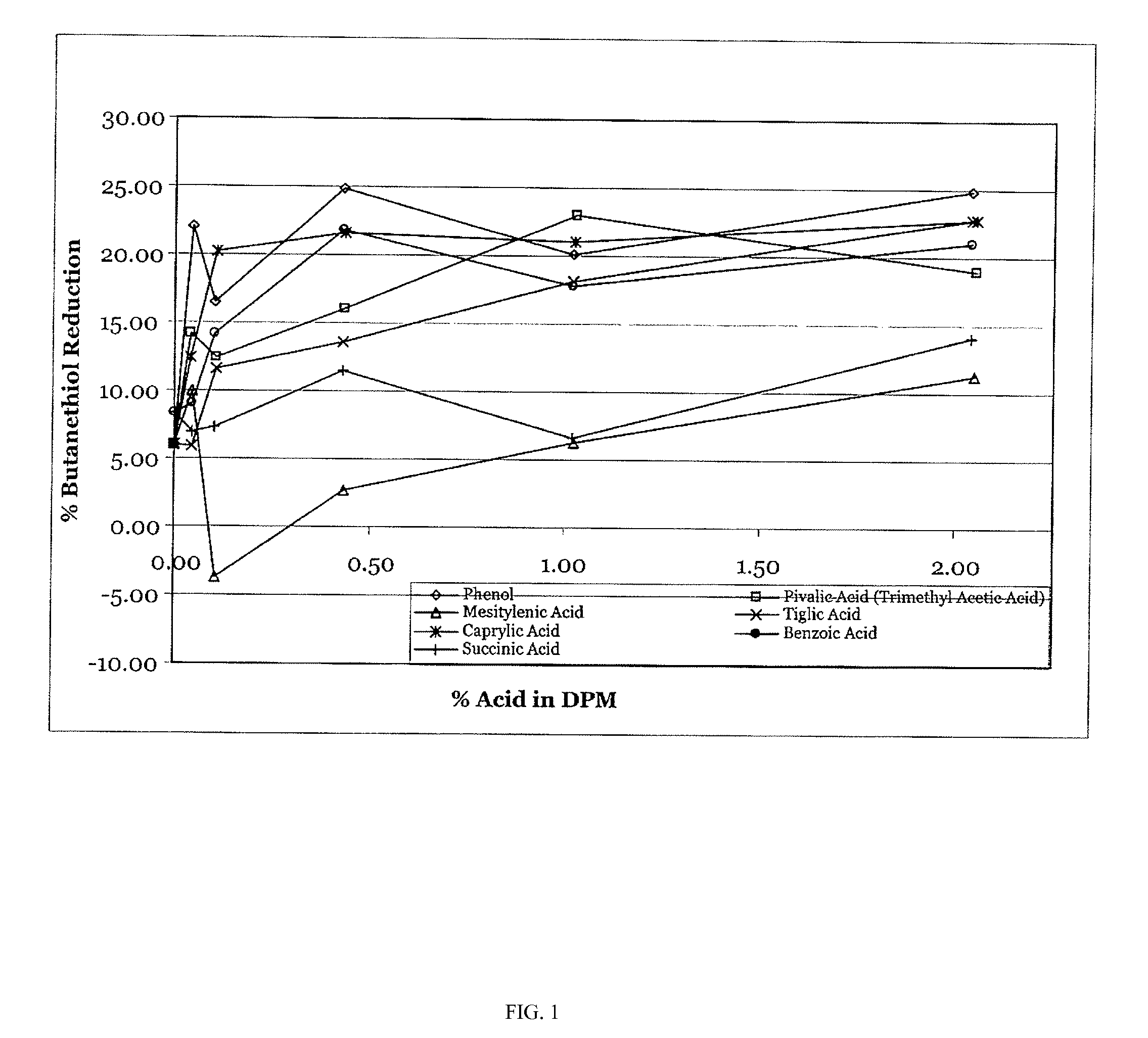

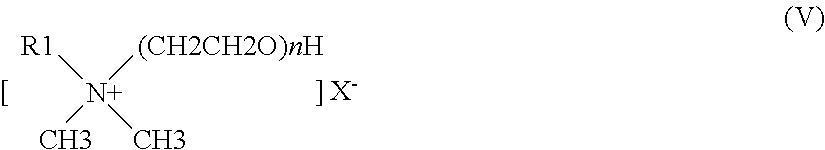

Dishwashing Detergent Composition Having A Malodor Control Component And Methods Of Cleaning Dishware

A dishwashing detergent composition comprising a malodor control component, and methods of cleaning dishware are provided. In some embodiments, the dishwashing detergent composition comprises at least one volatile aldehyde and an acid catalyst.

Owner:THE PROCTER & GAMBLE COMPANY

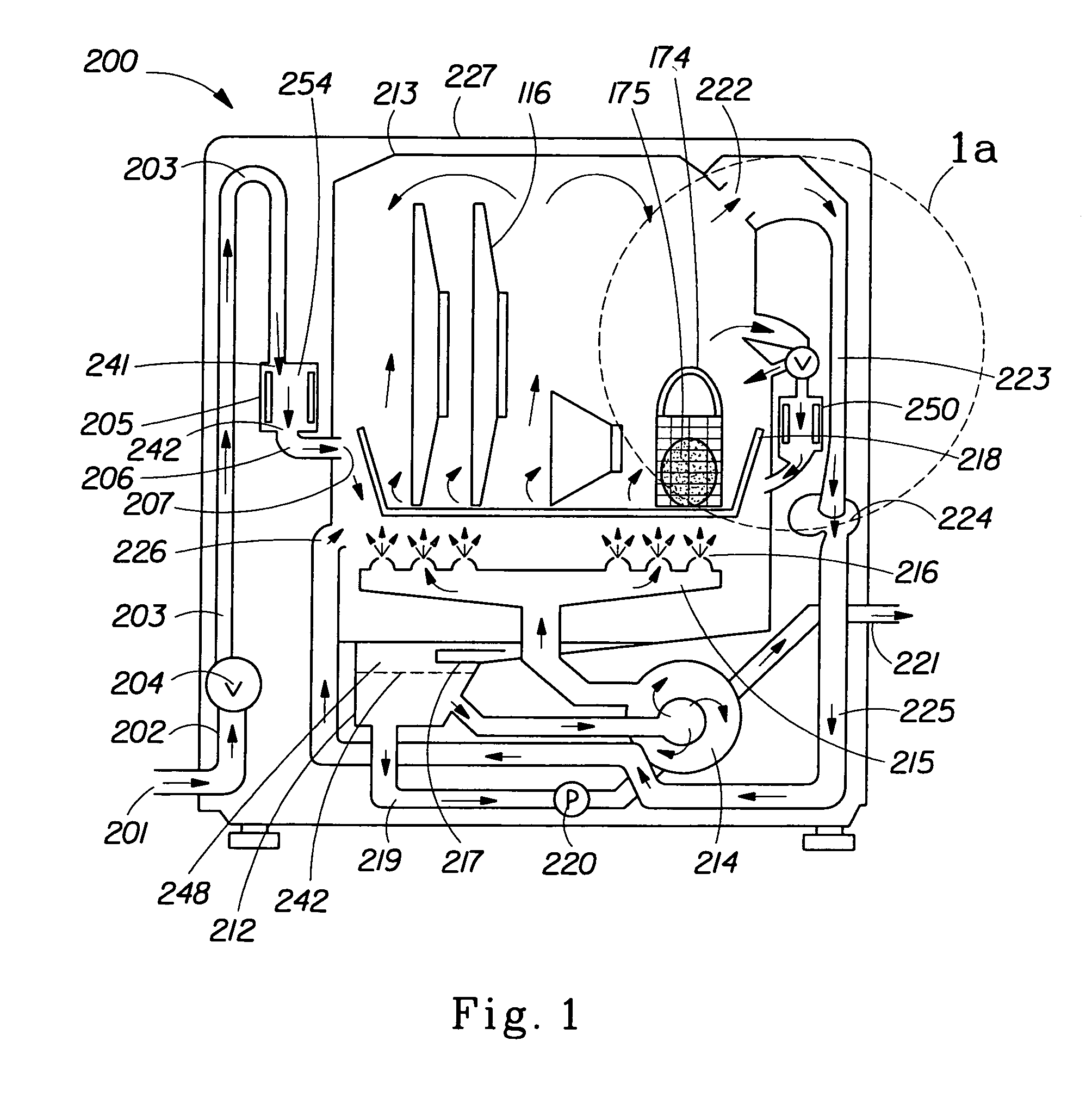

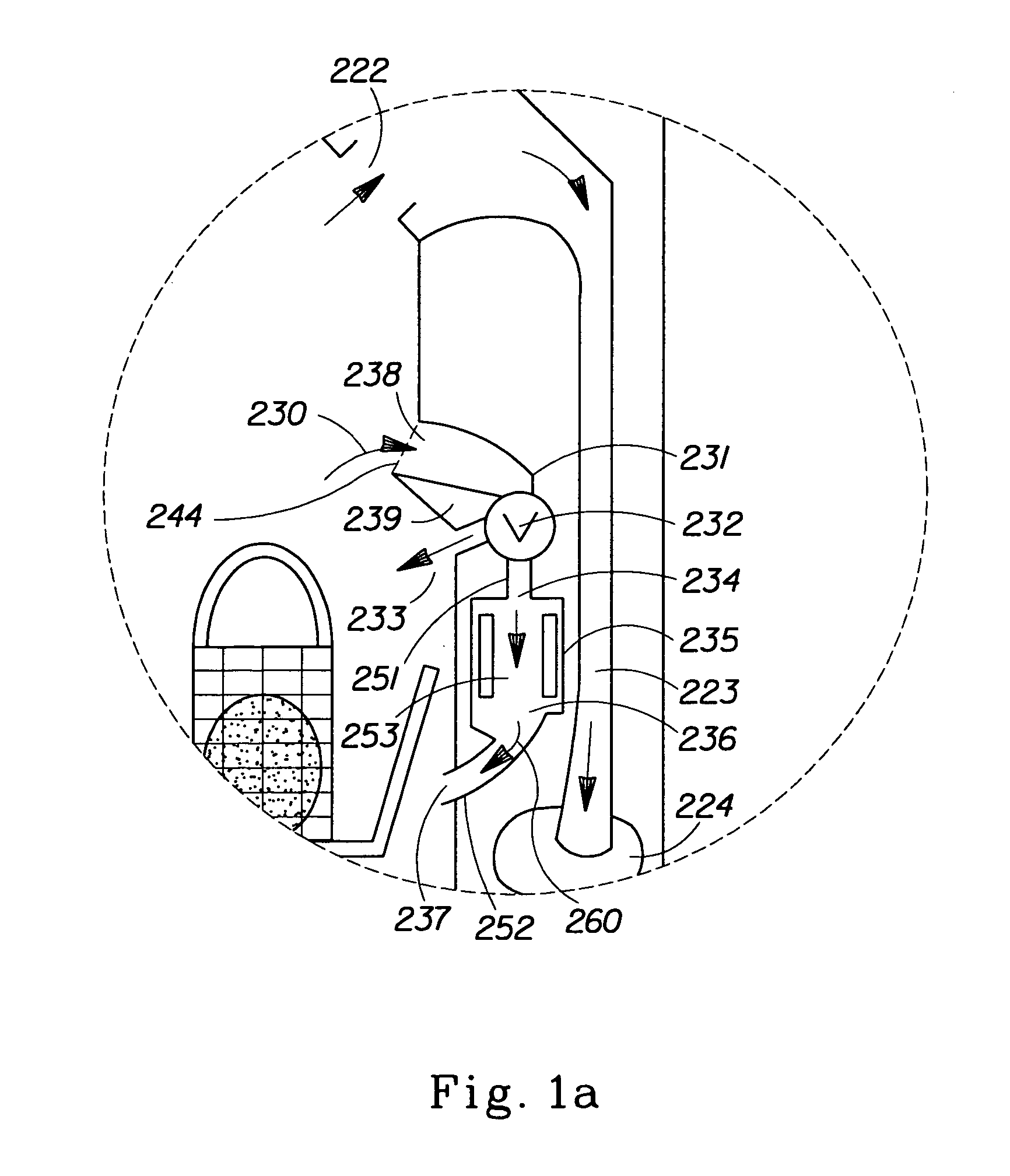

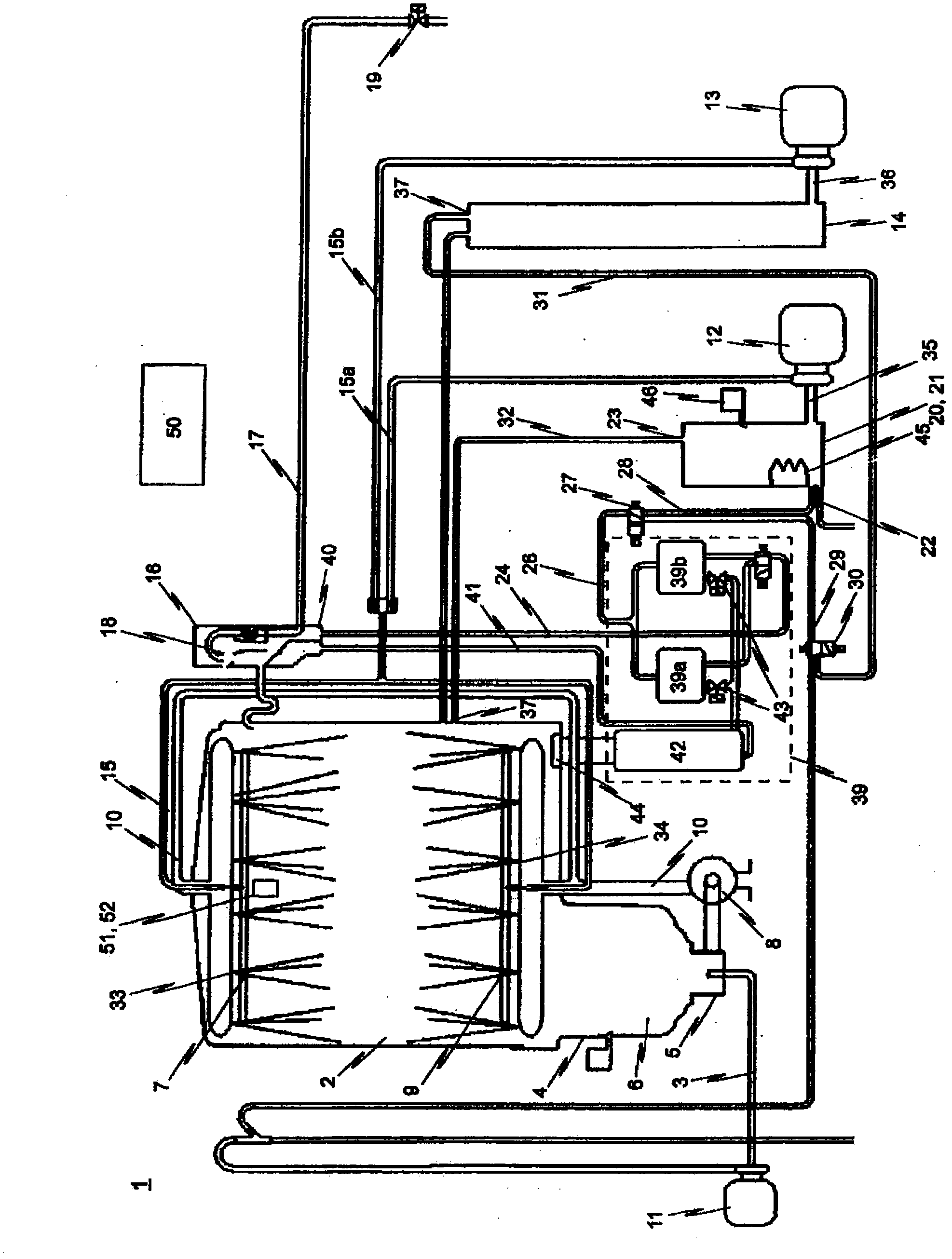

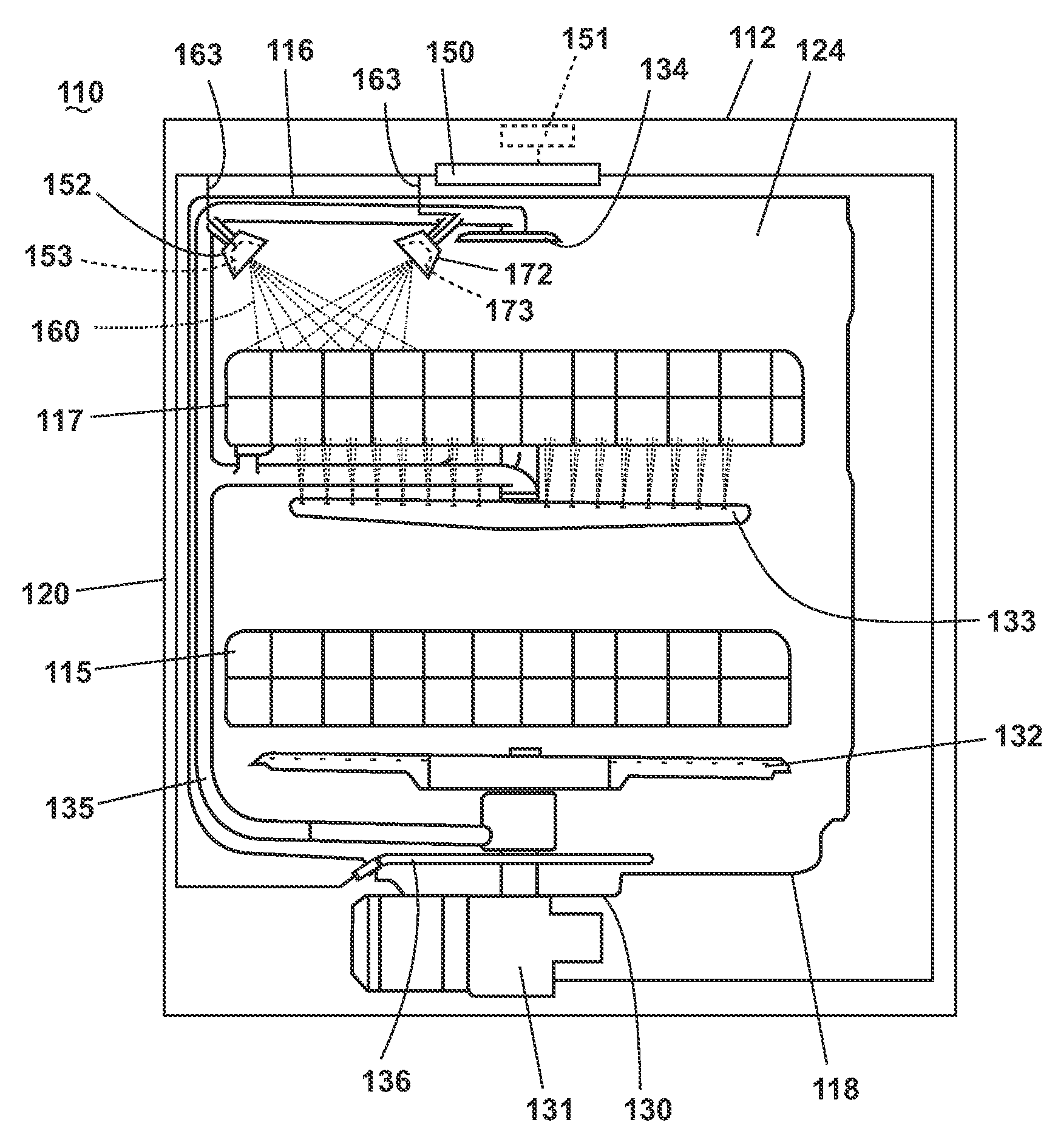

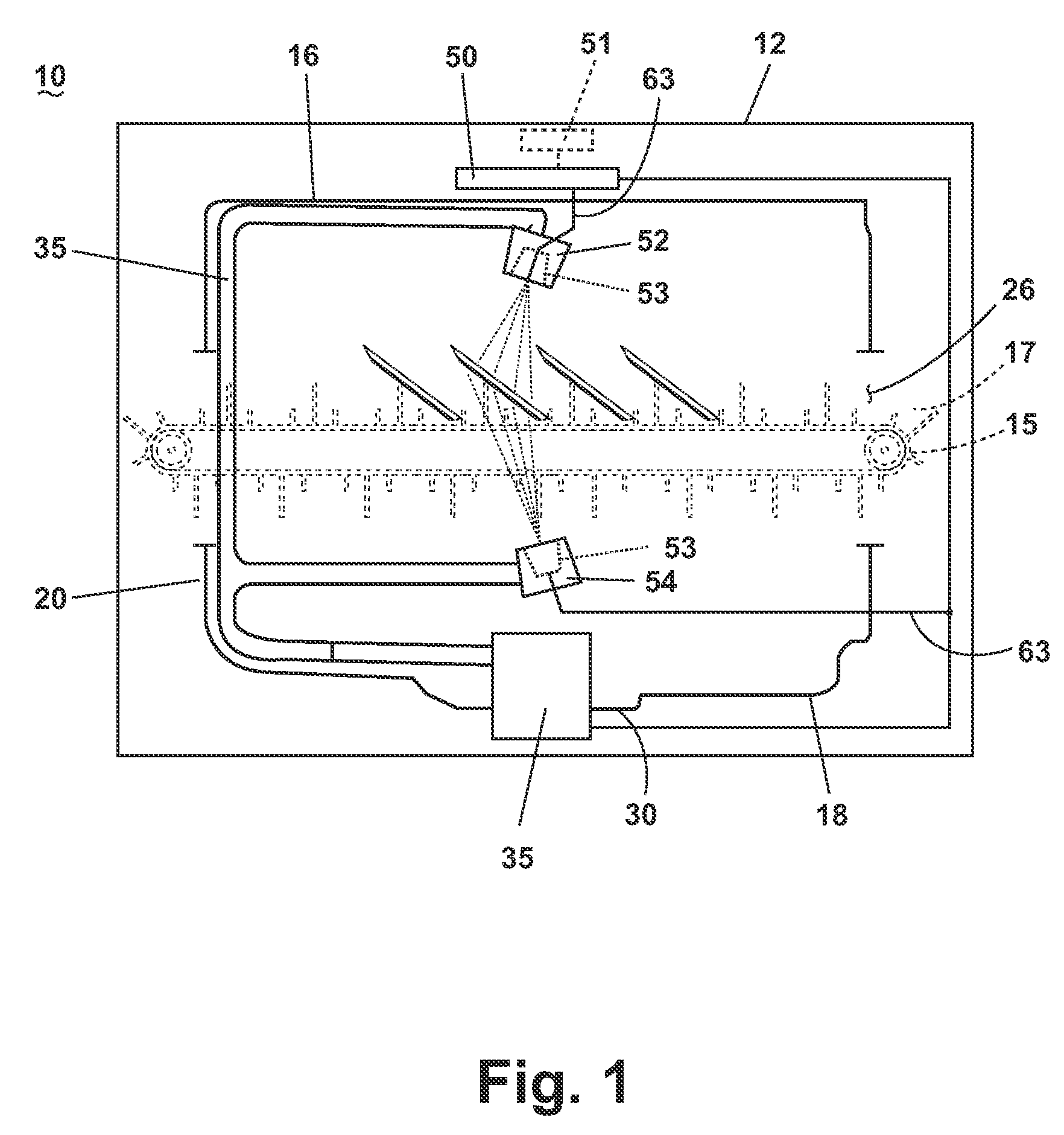

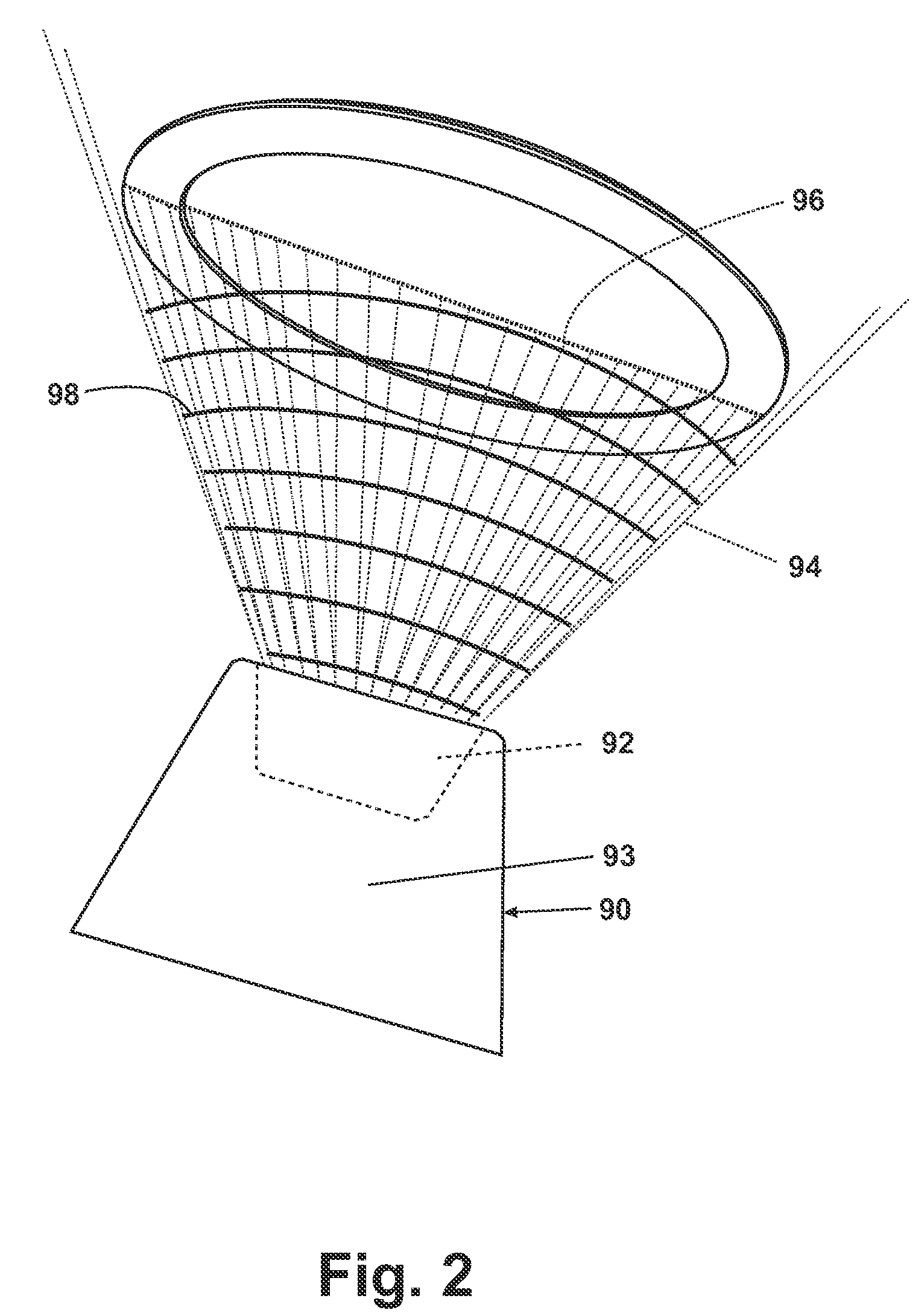

Dishwasher and method for cleaning wash ware

InactiveCN101998839AAutomatic optimization and adjustment of processing parametersFull cleaning effectTableware washing/rinsing machine detailsWashing processesProgrammable automationProcedural approach

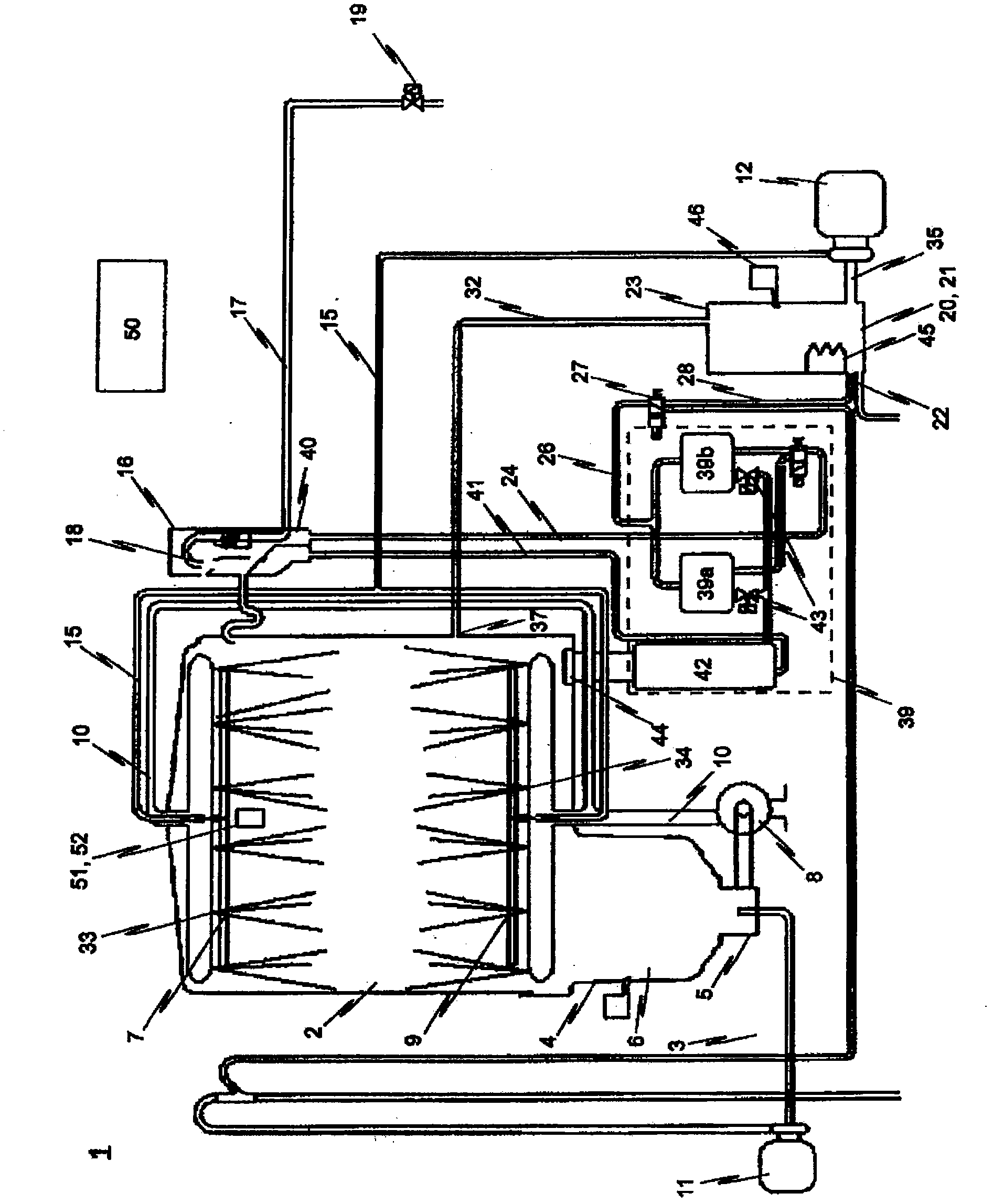

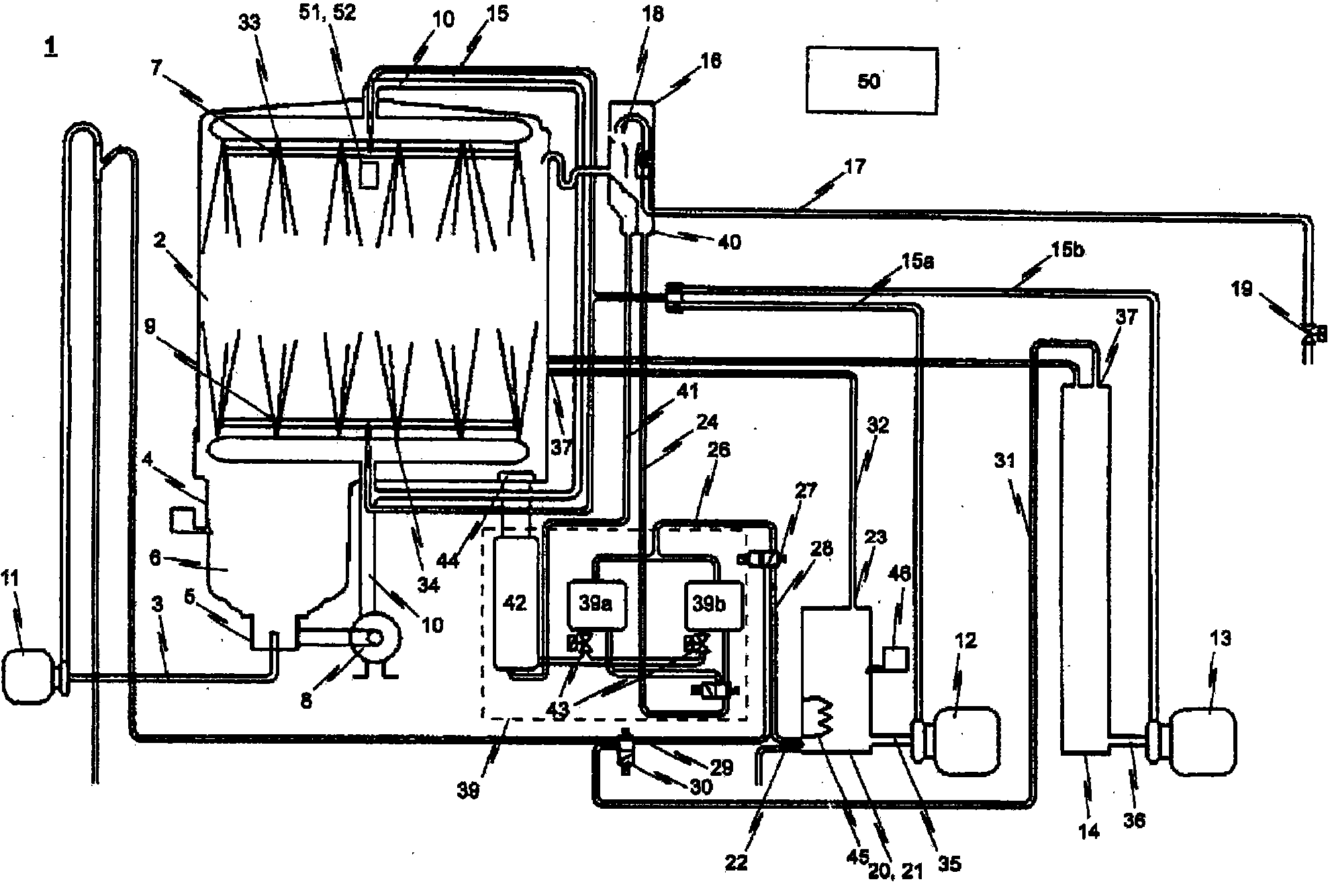

The invention relates to a dishwasher (1) in the form of a programmable automatic machine, which has a programme control device (50) for carrying out at least one treatment programme, a treatment chamber (2) into which and from which wash ware can be manually inserted and removed, a tank (4) into which fluid from the treatment chamber (2) can flow off by gravity, and a washing system (33, 8, 34, 10) with a washing pump (8) and with a washing line system (10) for conveying washing fluid (6) during a washing phase out of the tank (4) through washing nozzles (33, 34) into the treatment chamber (2). In order to achieve an efficient treatment (cleaning and drying) of the wash ware, along with as low a consumption as possible of resources in terms of water, chemicals and, in particular, energy, there is provision, according to the invention, for the dishwasher (1) to have, furthermore, a wash-ware detector device (51) which is designed for detecting the type of wash ware to be treated, furthermore the programme control device (50) being designed to select a predetermined or determinable treatment programme for at least the washing phase automatically as a function of the detected type of wash ware to be treated and to set the process parameters associated with the selected treatment programme.

Owner:PREMARK FEG L L C

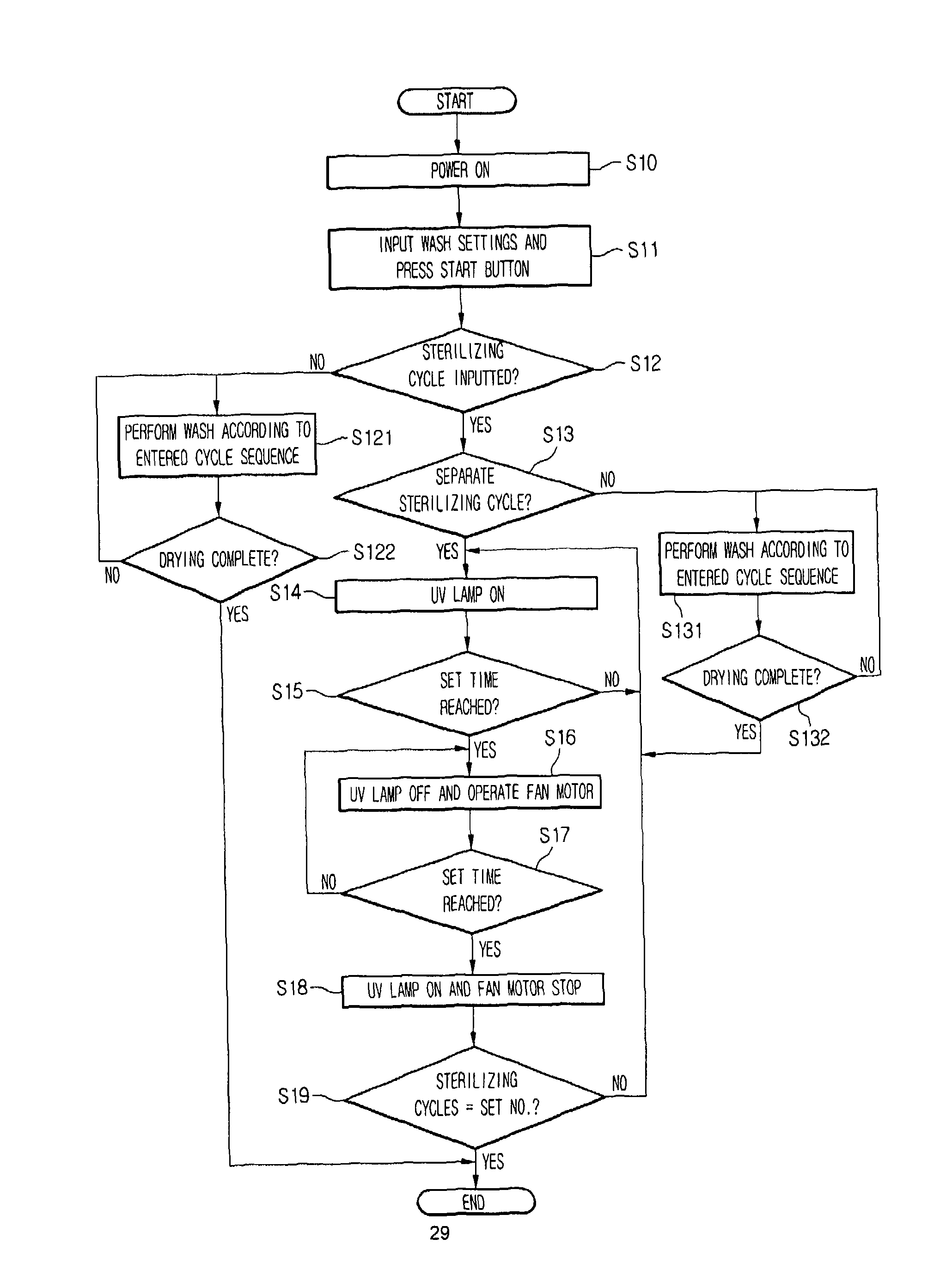

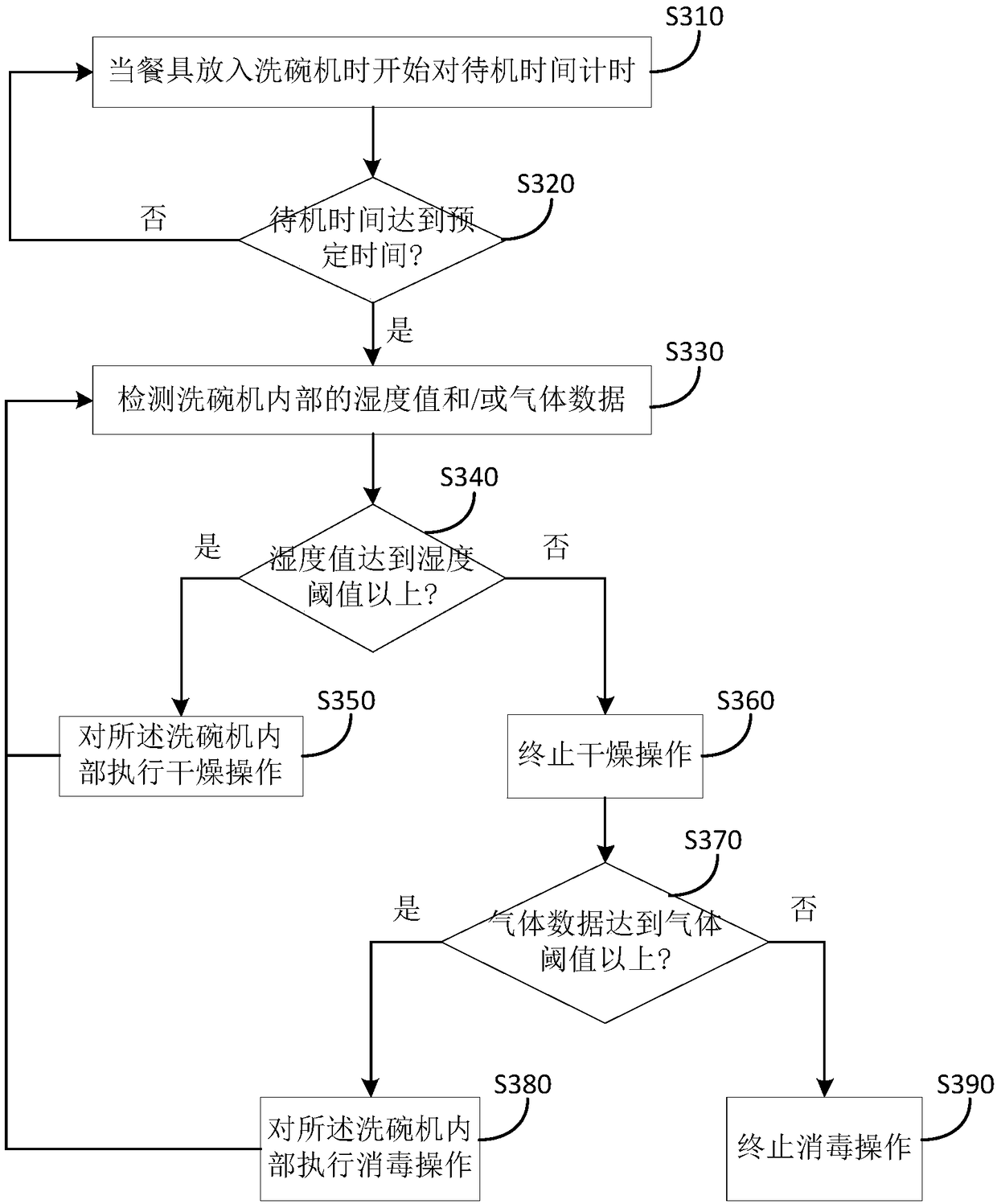

Sterilizing control method for dishwasher

ActiveUS7897104B2Hinders its propagationTableware washing/rinsing machine detailsWashing processesEmbedded system

Owner:LG ELECTRONICS INC

Dish washer and its control method

InactiveCN101336821AGood removal effectAchieve sterilizationLevel controlTableware washing/rinsing machine detailsWash waterWater tanks

The present invention discloses a dish washer which comprises the following parts: a dish washing cylinder which is used for washing the dish; a water tank which is used for accommodating the wash water supplied for the dish washing cylinder; and a heater which is used for heating the wash water contained in the water tank and supplies vapor to the dish washing cylinder. According to the invention mentioned above, the vapor is supplied to the dish washing cylinder accommodating the dish thereby easily eliminating the food residue stuck on the dish and simultaneously realizing the germicidal treatment to the dish and the dish washing cylinder. Besides, additional heater, water feeding device or nozzle for supplying the vapor is not required to be installed thereby the dish washer can be easily manufactured and the expense can be greatly reduced.

Owner:NANJING LG PANDA APPLIANCES

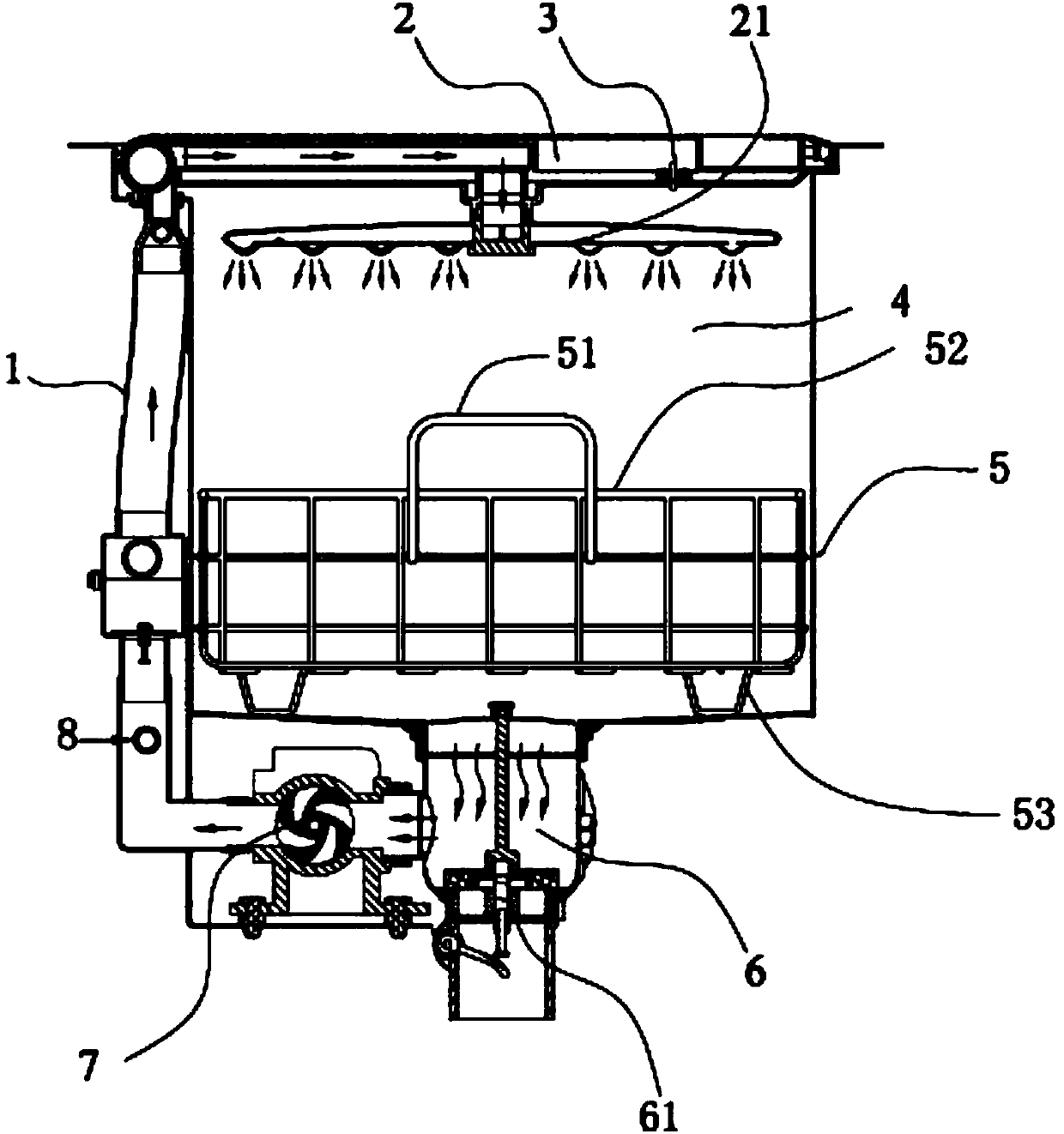

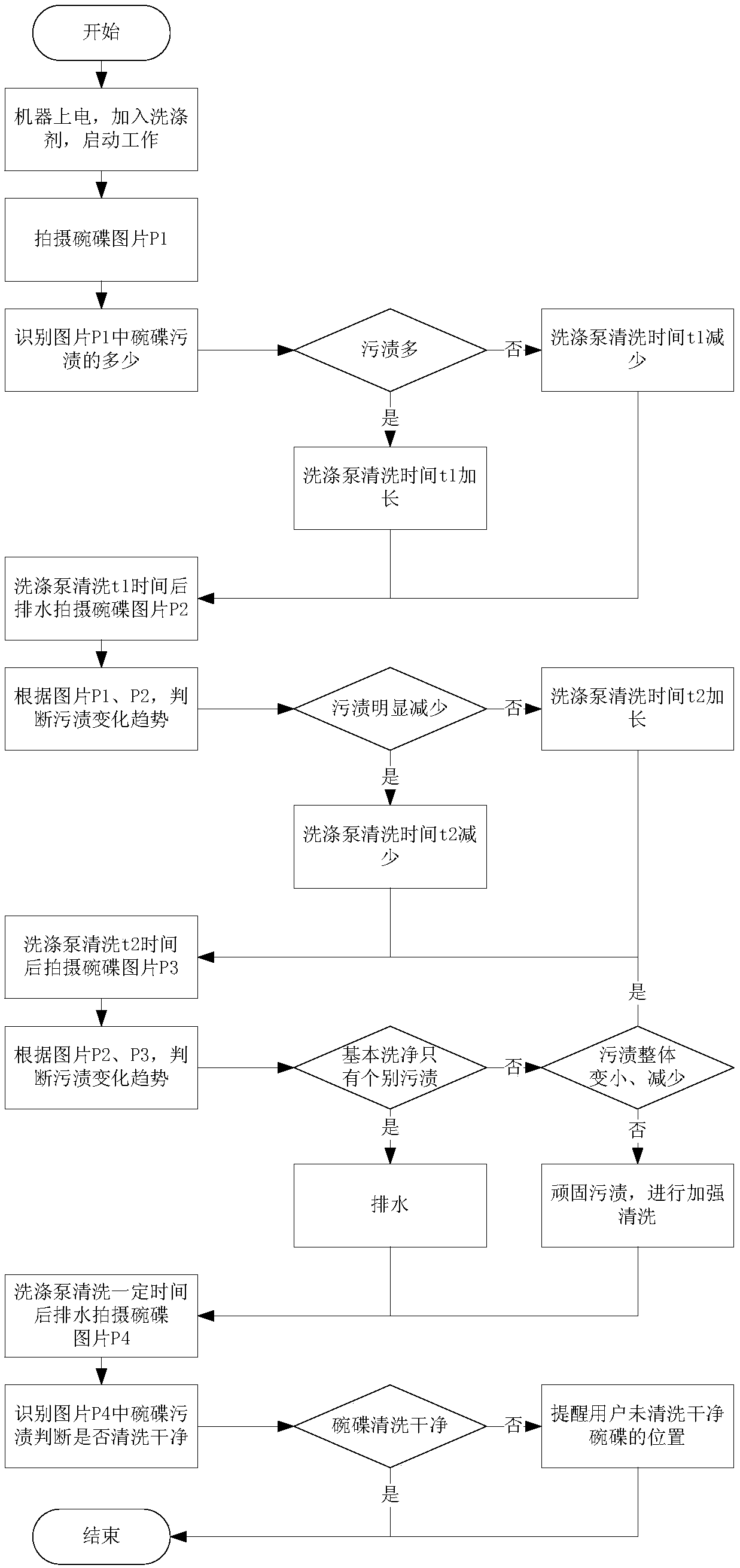

Intelligent water tank cleaning method

InactiveCN107837054AHigh intelligenceTableware washing/rinsing machine detailsWashing processesEngineeringWater tanks

The invention provides an intelligent water tank cleaning method, and relates to the field of kitchens. The method comprises the steps that the stain condition of to-be-cleaned objects in a water tankcontaining cavity is detected; the water tank is controlled to be cleaned according to the stain condition of the to-be-cleaned objects, and cleaning parameters such as the cleaning times and time can be dynamically adjusted according to the variation tendency of stains on bowls and dishes. The intelligence level of a machine is greatly improved, water and energy are saved.

Owner:JOYOUNG CO LTD

Methods and apparatus for ultrasonic cleaning

InactiveUS20110135534A1Increase entryFurther cavitationBacterial antigen ingredientsWashing processesCavitationMegasonic cleaning

The present invention relates to a method of cleaning a surface by applying highly propagating ultrasonic energy to said surface, the method comprises immersing at least a portion of the surface into a fluid, wherein said fluid is in contact with an highly propagating ultrasonic energy emitting assembly; and emitting highly propagating ultrasonic energy from the assembly into the fluid to generate cavitation at the surface thereby cleaning said surface.

Owner:CAVITUS PTY LTD

Method and system for washing

InactiveUS20050252532A1Tableware washing/rinsing machine detailsWashing processesWater softeningProcess engineering

Owner:THE PROCTER & GAMBLE COMPANY

Steam generator

Owner:LG ELECTRONICS INC

Method and device for controllable foam cleaning for washing, disinfection and sterilization

ActiveCN103191880AImprove efficiencyControl penetrationWashing processesOther washing machinesMode of actionInternal pressure

The invention relates to a method and a device for controllable foam cleaning for washing, disinfection and sterilization. A heating component is used for heating a working solution to generate foams, and a lot of foams are directly formed in a cleaning room or introduced to the cleaning room from the outside; through the effective control of foam cleaning, the dirt, harmful substances and microorganisms which are attached to cleaning objects in the cleaning room are in sufficient contact with effective ingredients on the foam surface in the cleaning room, separated, destroyed or killed by various modes of action, separated from the surface of a cleaned object together with foams along with the decrease of internal pressure and temperature of the cleaning room, and then discharged out from the cleaning room. Compared with the traditional product, the cleaning device designed according to the technology is higher in efficiency, shorter in washing time, lower in energy consumption, less in water consumption and lower in noise and product cost. The method and the device are suitable for cleaning, disinfection or sterilization of various cleaning objects such as tableware, medical appliances, clothes, industrial parts, antiques and antiquities, pets, animals and human skin.

Owner:河北合盛科技有限公司

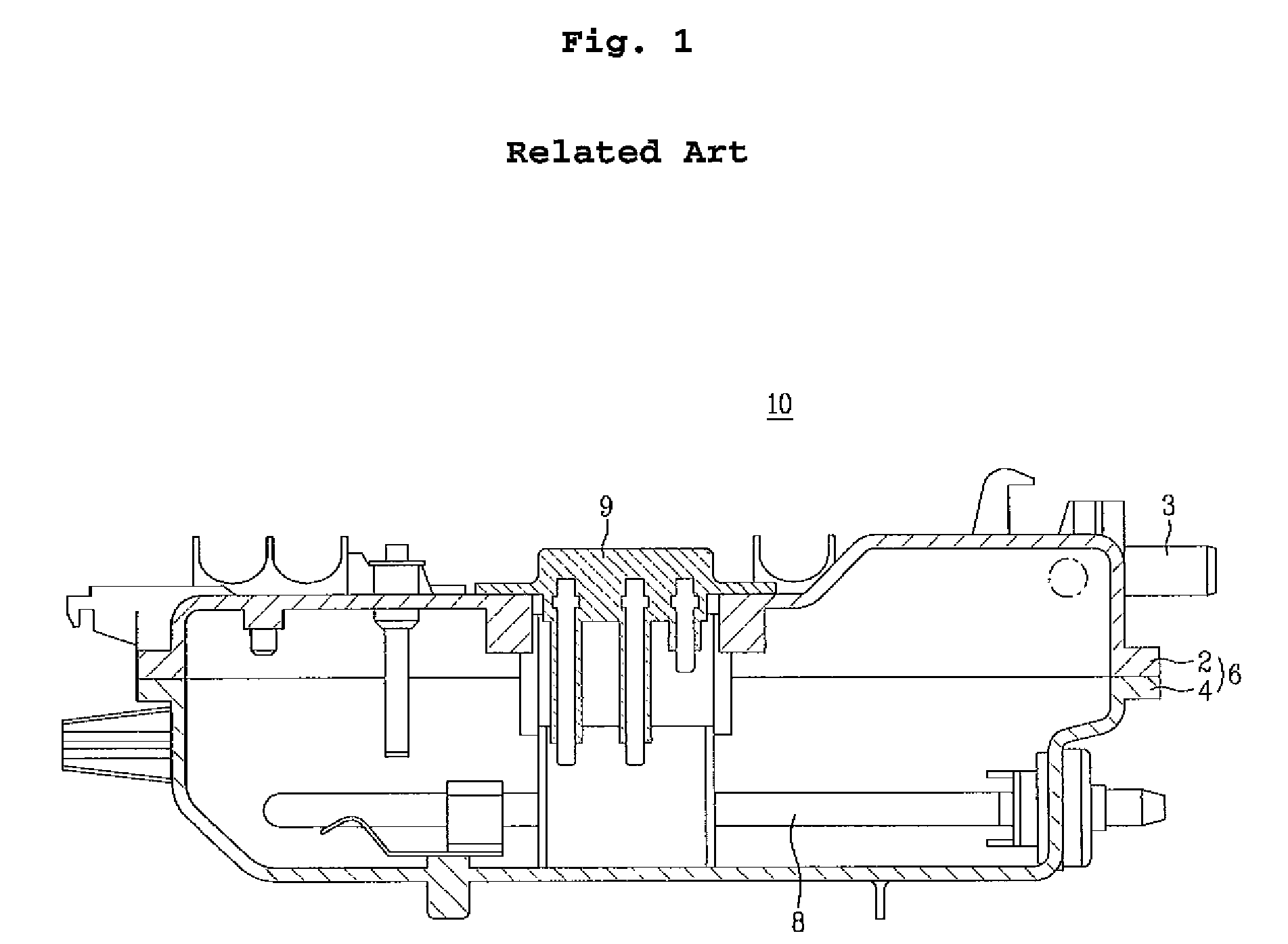

Method for controlling dishwasher

InactiveUS20090235957A1Eliminate the problemTableware washing/rinsing machine detailsWashing processesWash waterSpray nozzle

A method for controlling a dishwasher is disclosed. The control method basically includes a preliminary washing operation for spraying wash water required to hydrate waste adhered to dishes, a main washing operation implemented plural times for washing the dishes contaminated by the waste, a rinsing operation implemented after the preliminary washing operation and also, after the main washing operation for rinsing the dishes from which the waste is removed, and a drying operation for drying the dishes after completion of the washing and rinsing operations. The control method further comprises a steam supply operation implemented at least once before, after, or during the main washing operation for supplying steam to the dishes. With the control method, steam is supplied to a tub in which dishes are received, to enable not only easy removal of food waste adhered to the dishes, but also sterilization of the dishes and tub. The supply of steam is accomplished without requiring an additional steam supply heater, water supply device and nozzle, resulting in easy fabrication and reduced costs.

Owner:LG ELECTRONICS INC

Automatic detergent dishwashing composition

InactiveUS20090233830A1Prevent grit formationAvoid performanceSurface-active detergent compositionsWashing processesGramEnzyme

Owner:THE PROCTER & GAMBLE COMPANY

Method and system for detecting and removing a clogging condition of a filter in a dishwasher

ActiveUS20140158163A1High degreeReduce the risk of failureWashing controlling processesWashing processesNormal rateWater level

Embodiments of the present invention relate to methods and systems for detecting and removing a clogging condition of a filter in a dishwasher. According to one embodiment, the method includes determining a normal water level or a normal rate of water level change for a wash cycle of the dishwasher and monitoring a water level or a rate of water level change during execution of the wash cycle. The method further includes detecting the clogging condition of the filter by detecting a deviation thereof. A current position of the wash cycle being executed may then be determined. The method further includes executing a remedial operation to facilitate removal of the clogging condition and determining if the clogging condition has been removed. Finally, the method includes resuming operation of the dishwasher at a wash cycle position based on the current position if the clogging condition has been removed.

Owner:ELECTROLUX HOME PROD CORP NV

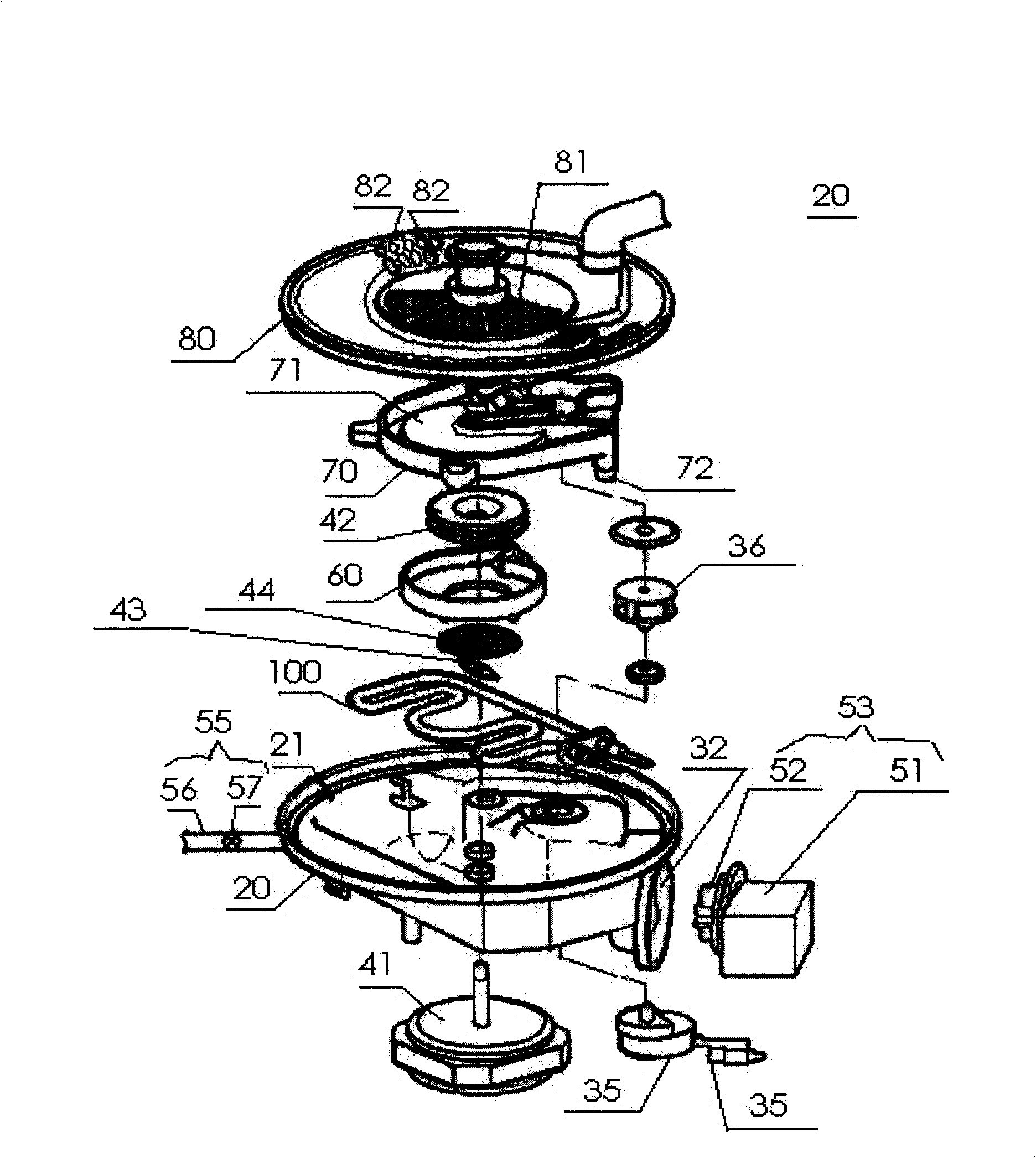

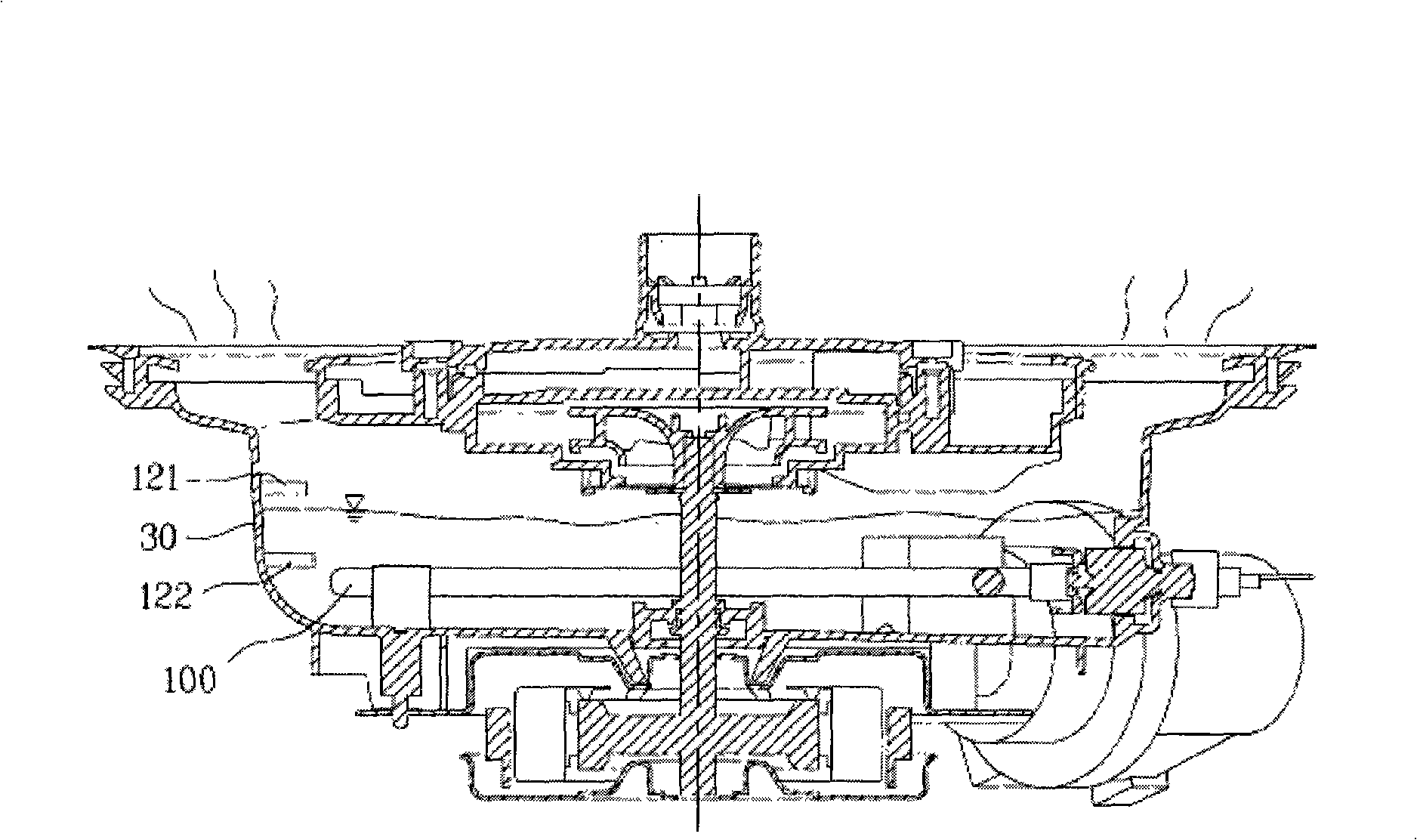

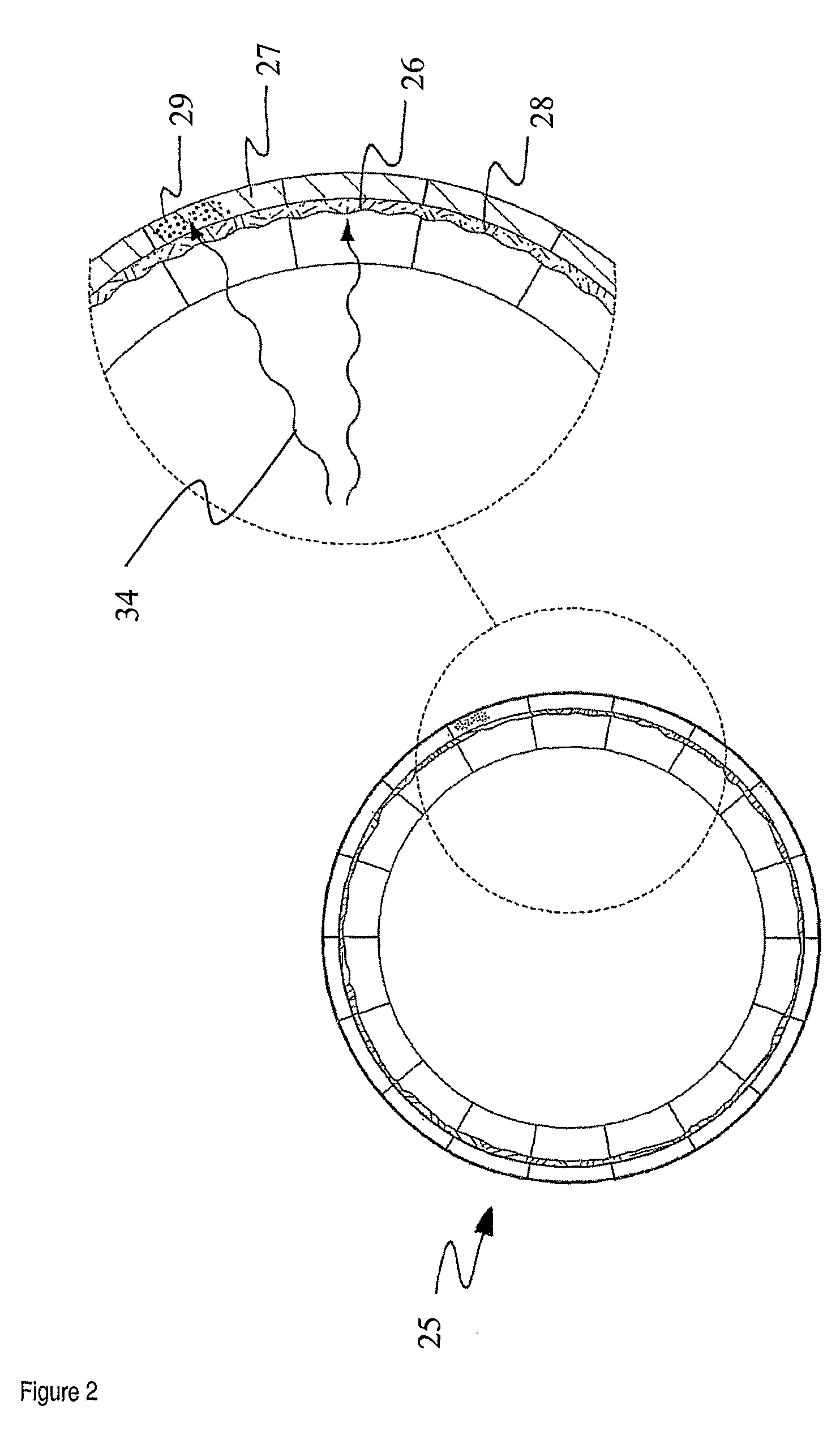

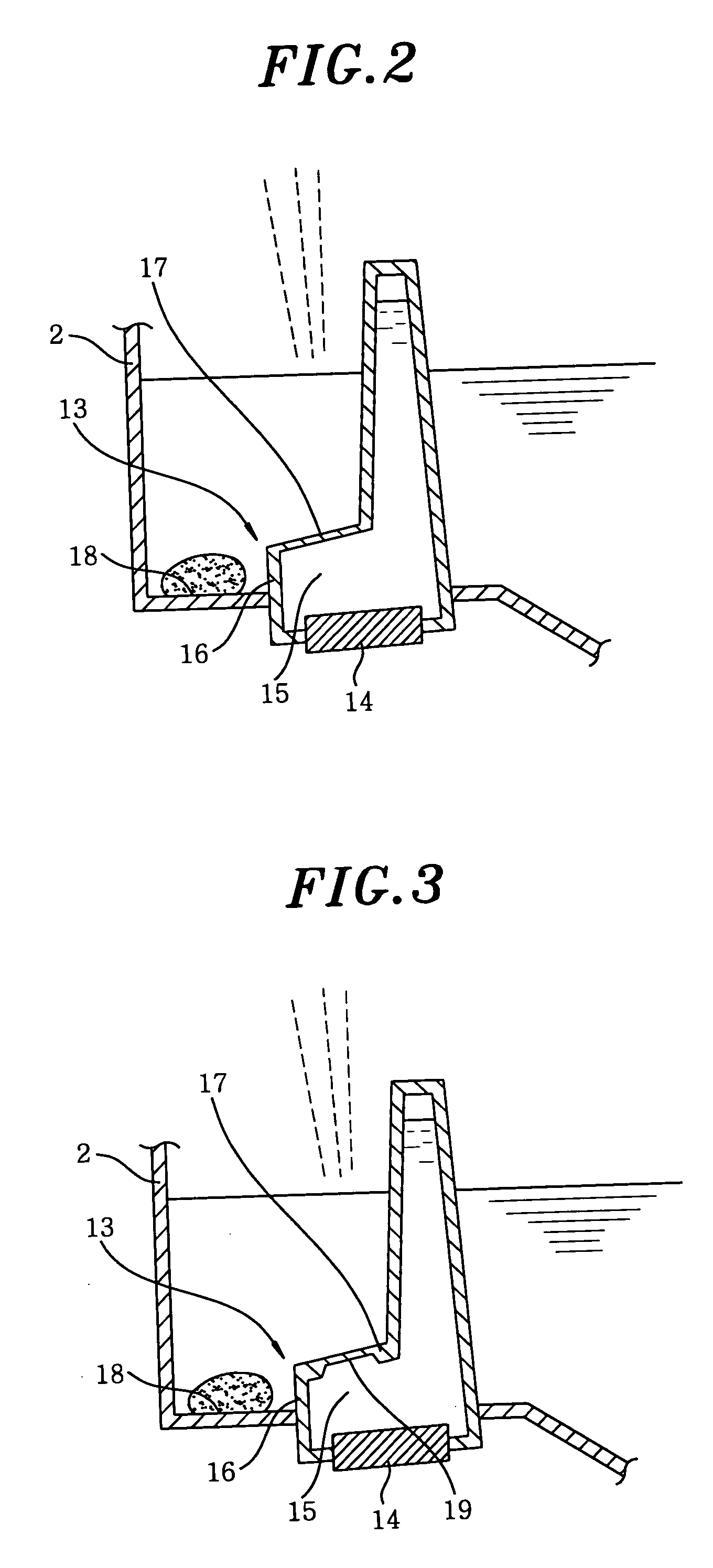

Mist generating device, and dishwasher and washing machine using same

InactiveUS20050268668A1Tableware washing/rinsing machine detailsWashing processesEngineeringUltrasonic vibration

A mist generating device includes a mist generation vibrator, and a sealed vessel accommodating therein a fluid and provided at a side of a vibrating surface of the mist generation vibrator. A wall portion which constitutes a part of the sealed vessel and faces the mist generation vibrator has a thin film membrane and a mist of liquid outside the sealed vessel is generated by ultrasonic vibration transmitted from the mist generation vibrator via the fluid in the sealed vessel and the thin film membrane.

Owner:PANASONIC CORP

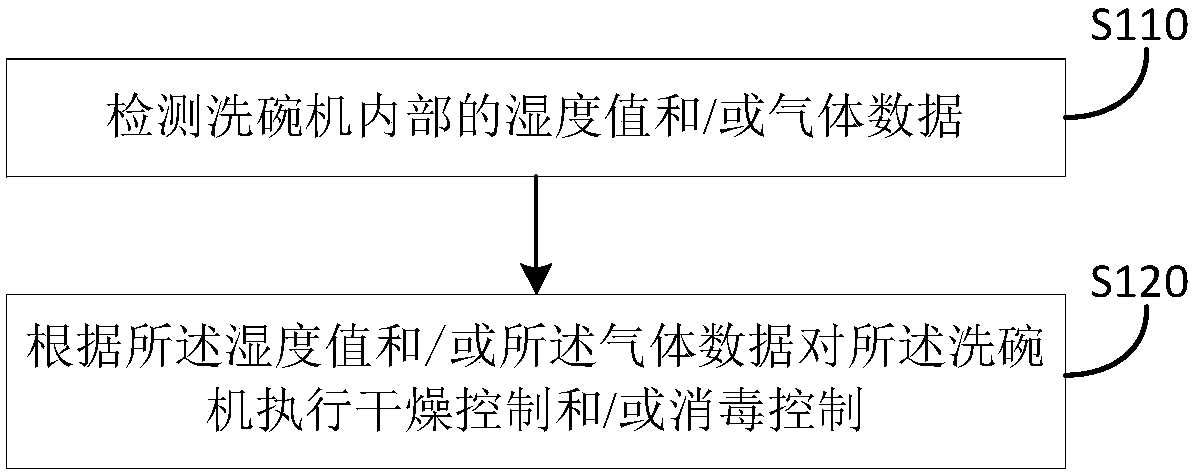

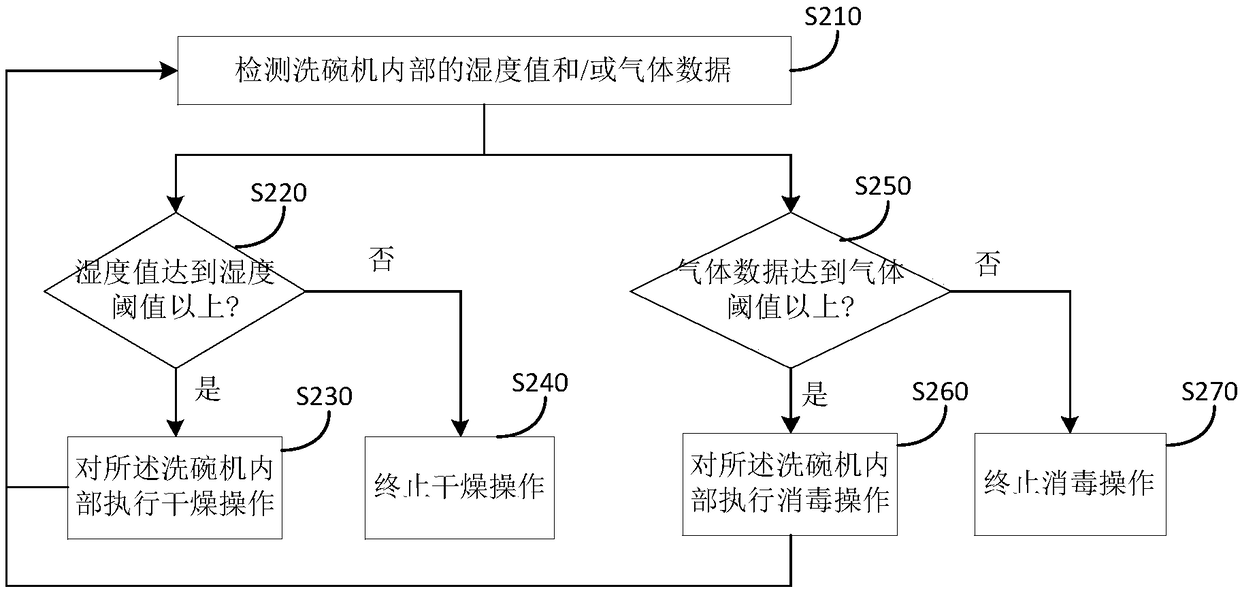

Method and device for controlling dish-washing machine

ActiveCN108095651AEnsure hygieneAvoid breedingTableware washing/rinsing machine detailsWashing processesEngineeringHumidity

According to the embodiment, the invention provides a method and a device for controlling a dish-washing machine, and belongs to the field of household appliances. The method for controlling the dish-washing machine comprises the following steps: detecting a humidity value and / or gas data in the dish-washing machine; and in accordance with the humidity value and / or the gas data, implementing drying control and / or disinfecting control on the dish-washing machine. According to the method and the device for controlling the dish-washing machine, when tableware, which is to be cleaned, is accumulated in the dish-washing machine, the interior of the dish-washing machine is dried and disinfected, so that a resource is saved, and meanwhile, bacterium breeding is avoided.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com