Patents

Literature

50 results about "Programmable automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Programmable automation is a form of automation for producing products in batches. The products are made in batch quantities ranging from several dozen to several thousand units at a time. For each new batch, the production equipment must be reprogrammed and changed over to accommodate….

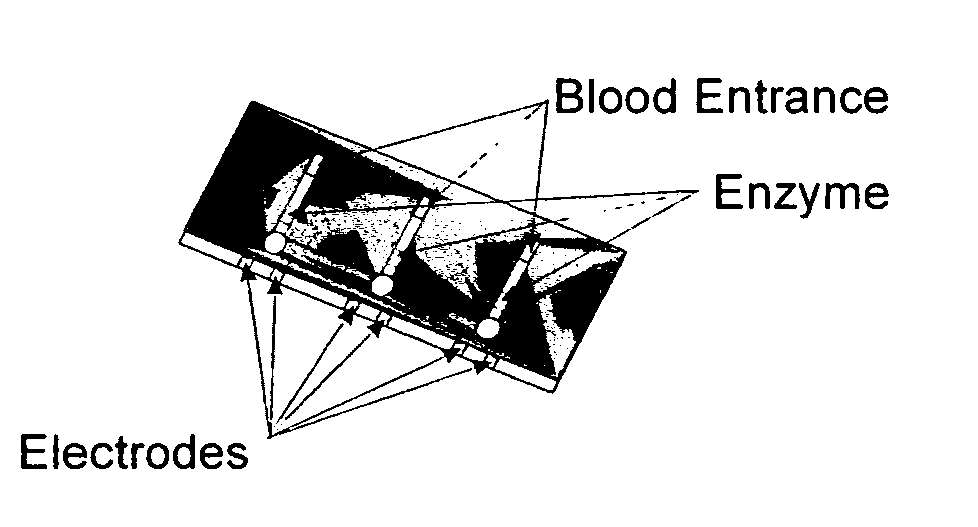

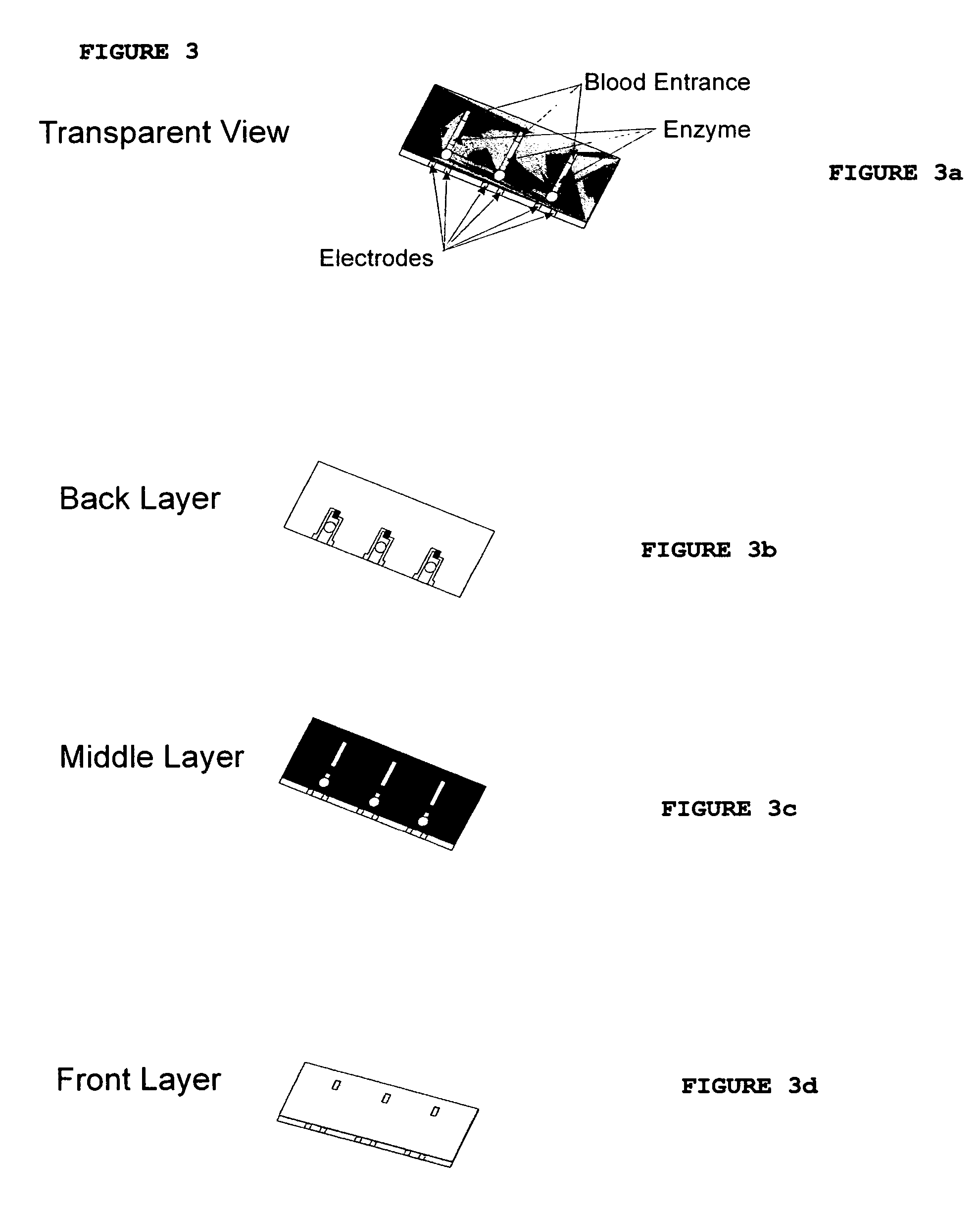

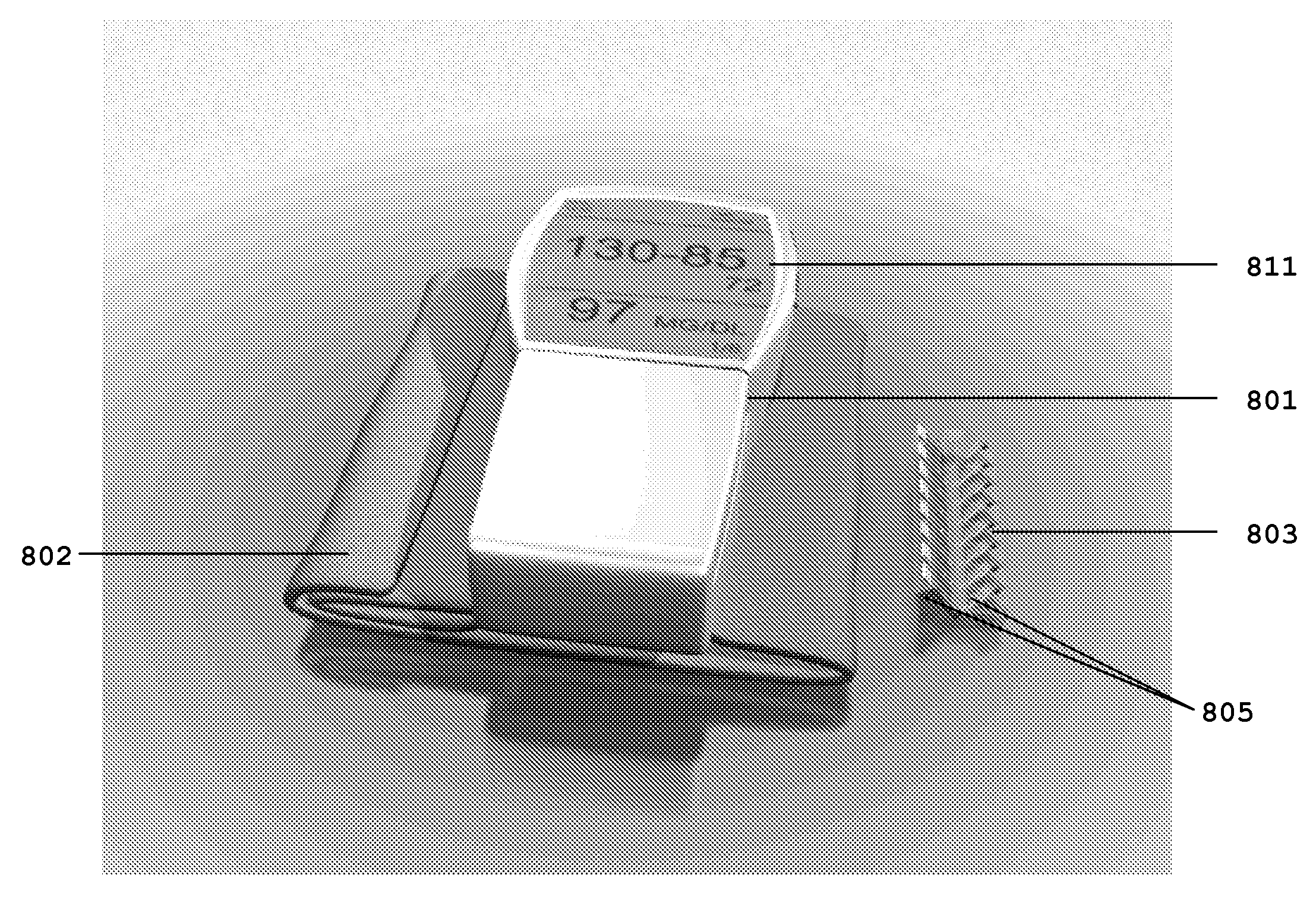

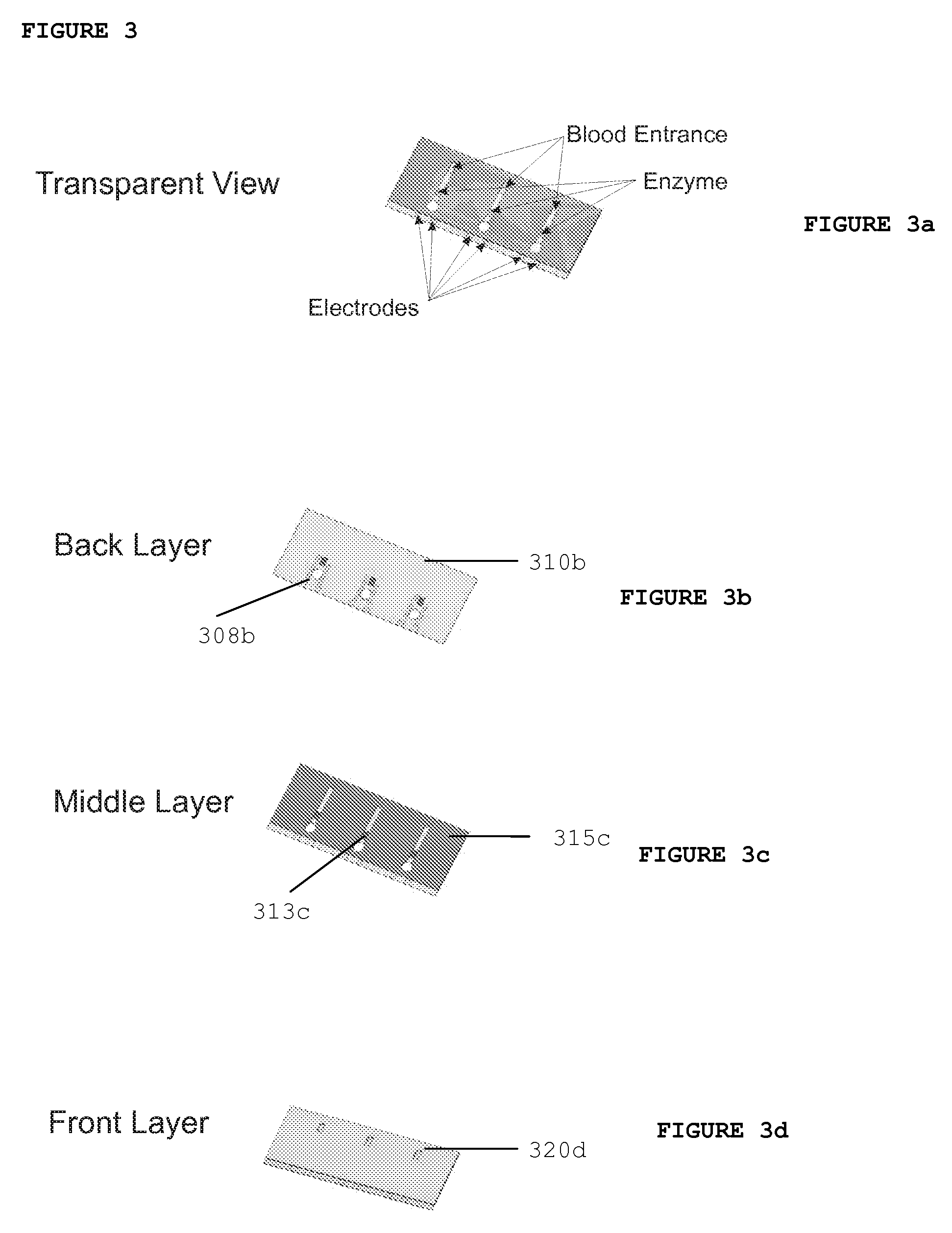

Wearable, programmable automated blood testing system

InactiveUS20070123801A1Enabling measurement of levelAutomatic measurementMicrobiological testing/measurementCatheterAnalyteProgrammable automation

The present invention is a programmable, automated device for the measurement and analysis of blood analytes and blood parameters. The device components are combined in a single apparatus and either programmed to initiate automatic, periodic blood sampling or initiate automatic blood sampling via operator input. The device operates automatically to draw blood samples at suitable, programmable frequencies to analyze the drawn blood samples and obtain the desired blood readings.

Owner:GLUCON

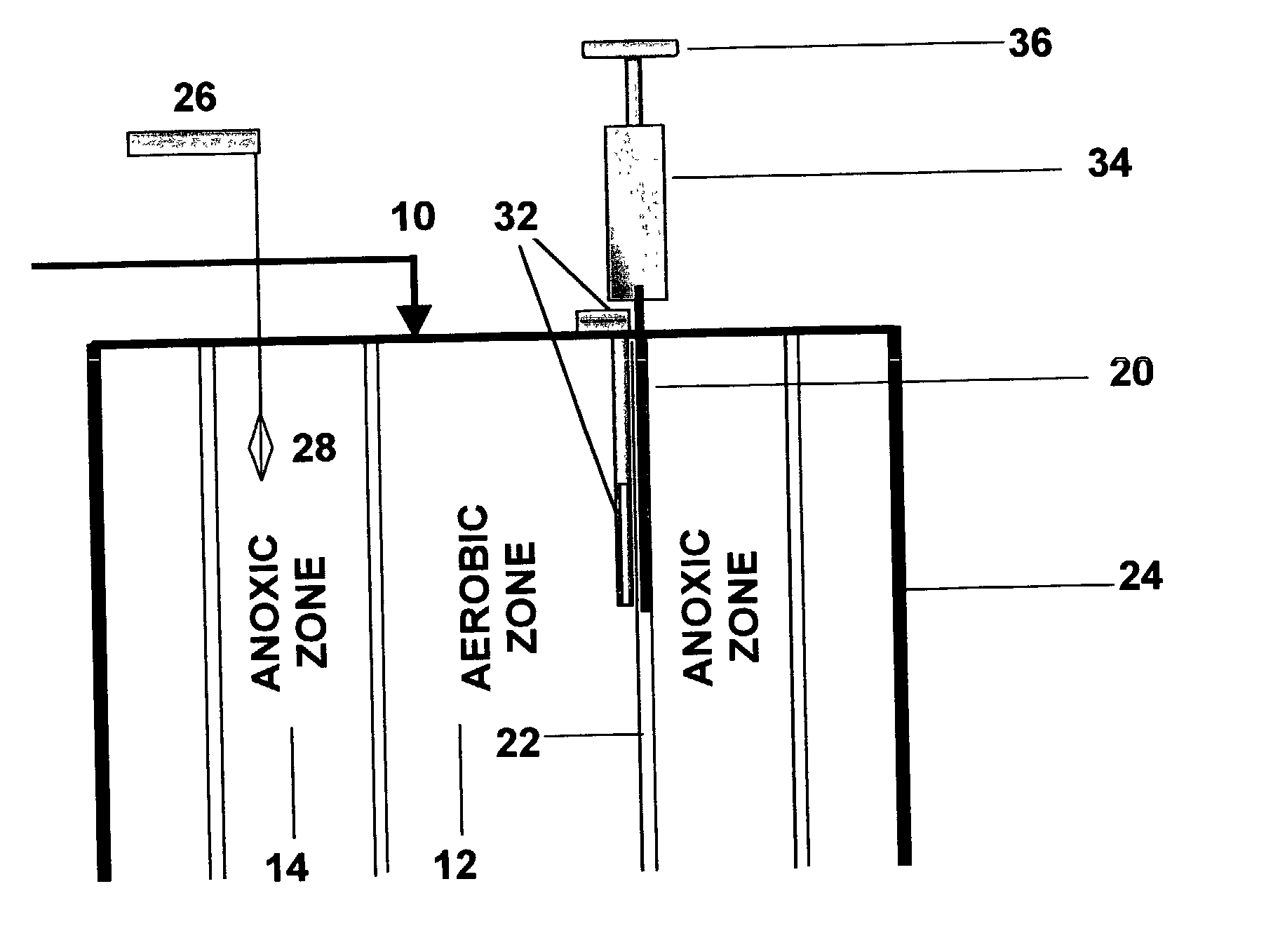

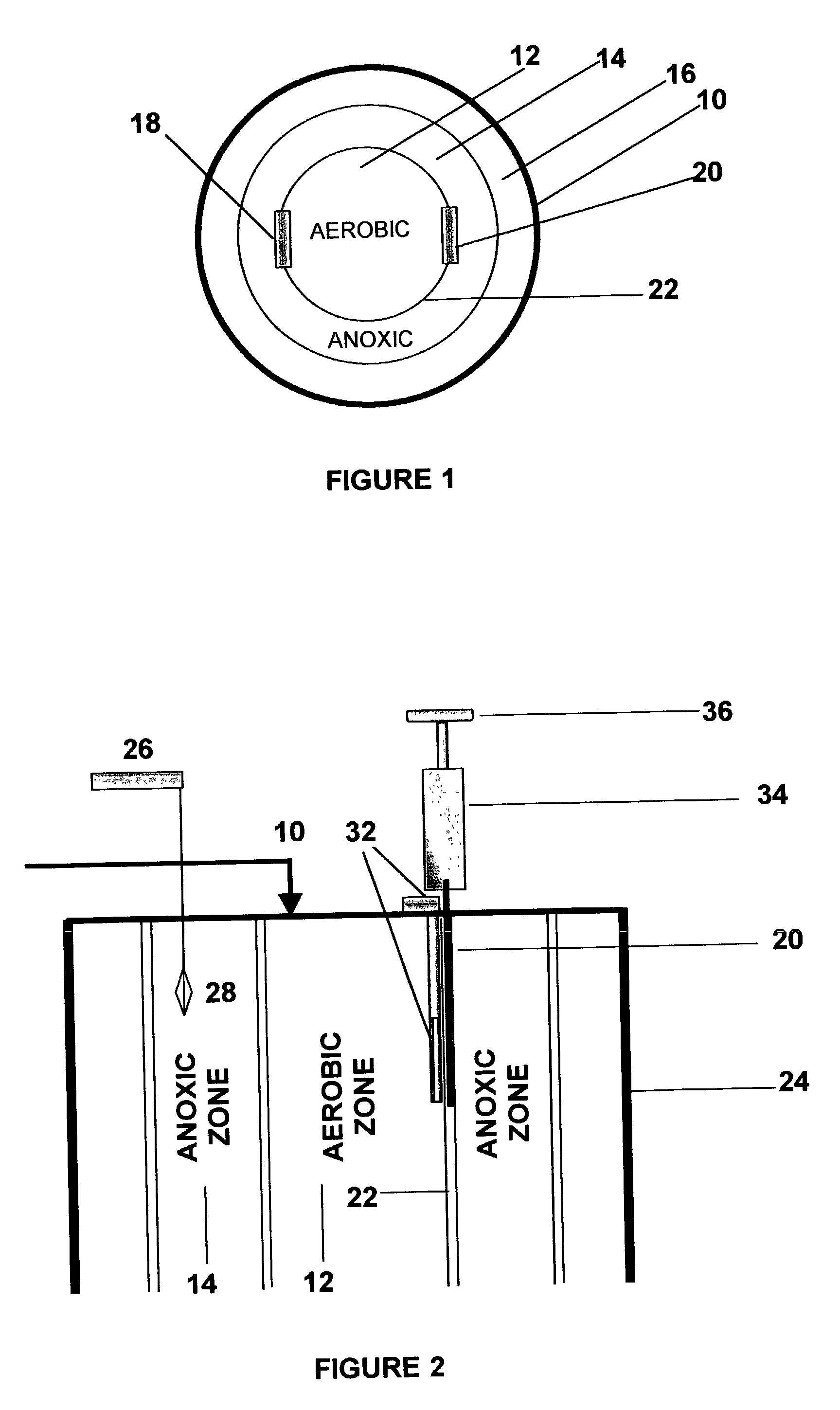

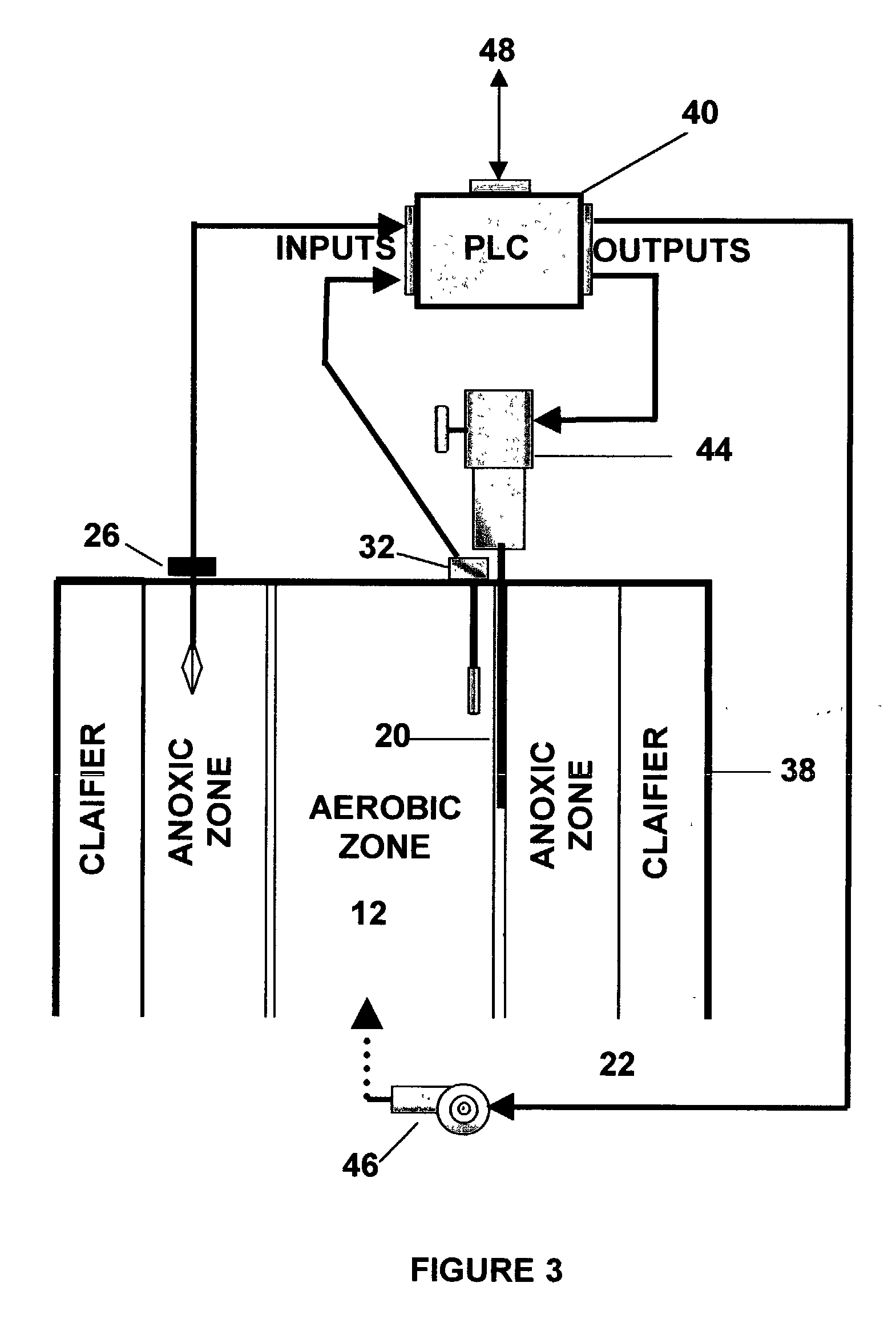

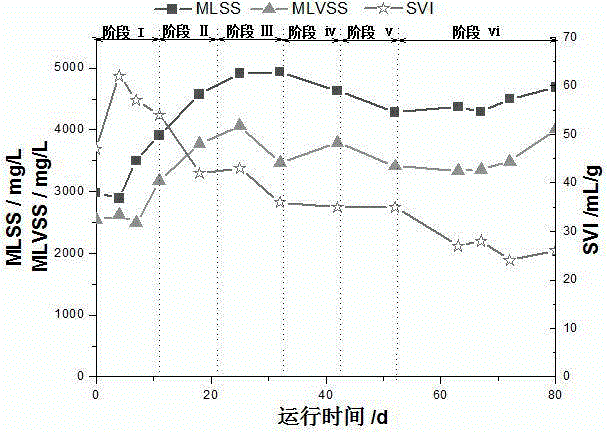

Dynamically responsive aerobic to anoxic inter-zone flow control system for single vessel multi-zone bioreactor wastewater treatment plants

InactiveUS20040035770A1Improve adaptabilityStable and fastLiquid separation auxillary apparatusWater treatment parameter controlProgram instructionProgrammable logic controller

An inter-zone aerobic to anoxic zone flow rate control system for single vessel multi-zone bioreactor plants for wastewater treatment is described herein. The system of the invention provides control of the relative treatment times of the mixed liquor in the horizontally disposed and adjacent aerobic and anoxic treatment zones of the bioreactor by providing one or more flow rate adjusting gates located between the aerobic and anoxic zones of the bioreactor. The opening of the gates is adjustable in accordance with sensed conditions in the treatment zones. An automated embodiment of the invention includes a programmable logic controller that provides control scripts for adjusting the opening of one or more flow control gates according to inputs from sensors and per programmed instructions. An automated and supervised embodiment of the invention includes a computer interfaced with a programmable automating controller. The computer provides status reports, commands to the programmable automating controller, storage and analysis of data, as well as a means of communicating to remote monitoring centers and networks.

Owner:ATARA ENVIRONMENTAL

Wearable, programmable automated blood testing system

The present invention is a programmable, automated device for measurement and analysis of blood analytes and blood parameters. The device components are preferably combined in a single housing and either programmed to initiate automatic, periodic blood sampling or initiate automatic blood sampling via operator input or in response to a predefined event or in response to a signal from another instrument. The device operates automatically to draw blood samples and analyze the drawn blood samples to obtain the desired blood readings.

Owner:GLUCON

Process control system and method for configuring a process control system

InactiveUS20070073419A1Computer controlSimulator controlControl communicationsProgrammable automation

A process control system comprising: a programmable automation controller; and at least one process control peripheral. Each process control peripheral is in data and control communication with the programmable automation controller. Upon configuration of the process control system, the programmable automation controller executes a single software program to assist a user to (i) define prescribed information in respect of the process control peripheral, including configuration information; (ii) define trigger conditions, if any, associated with the process control peripheral; and (iii) define alarm conditions, if any, associated with the process control peripheral. Once configured, the software program is operable to provide information in respect of the process control system to the user.

Owner:EMBEDDED TECH

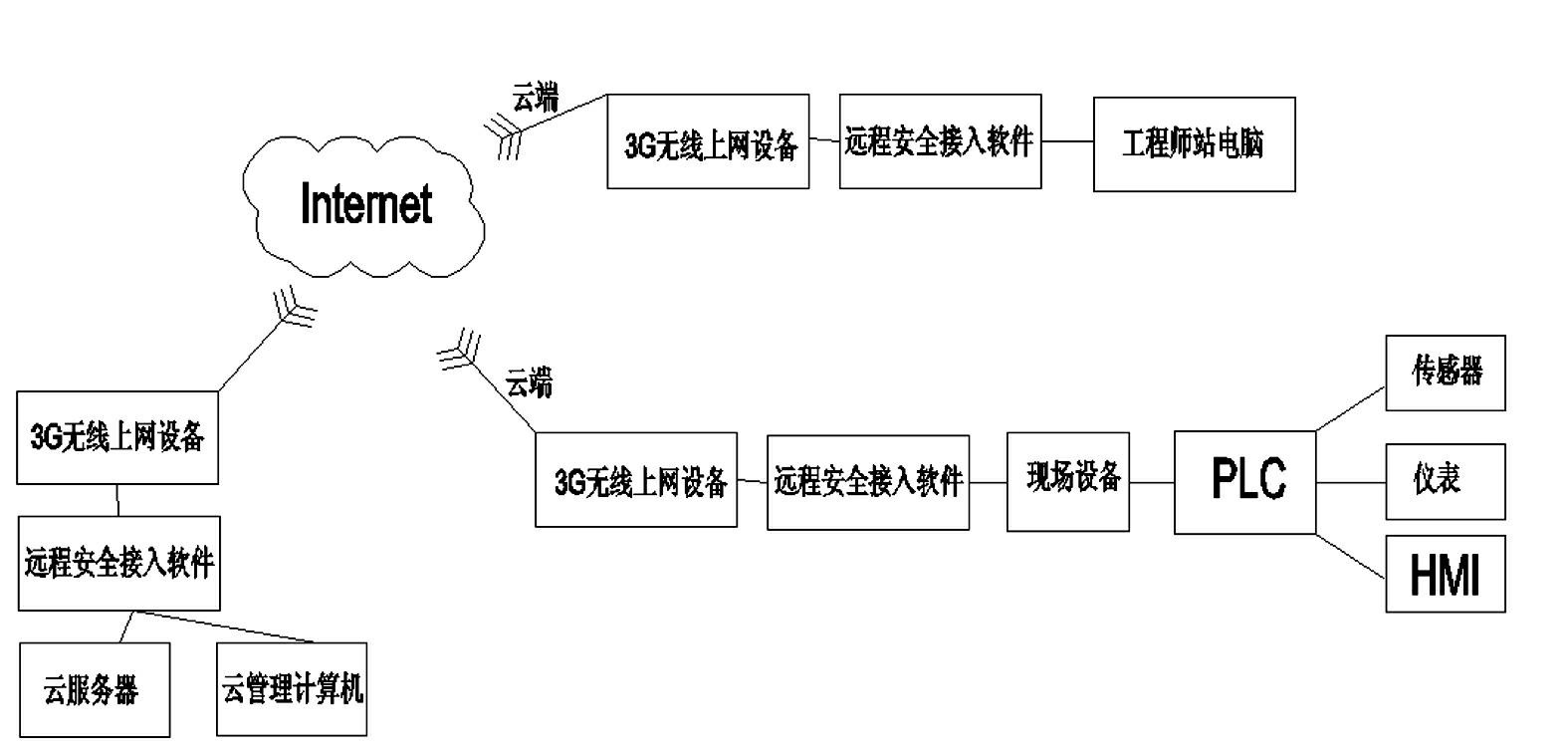

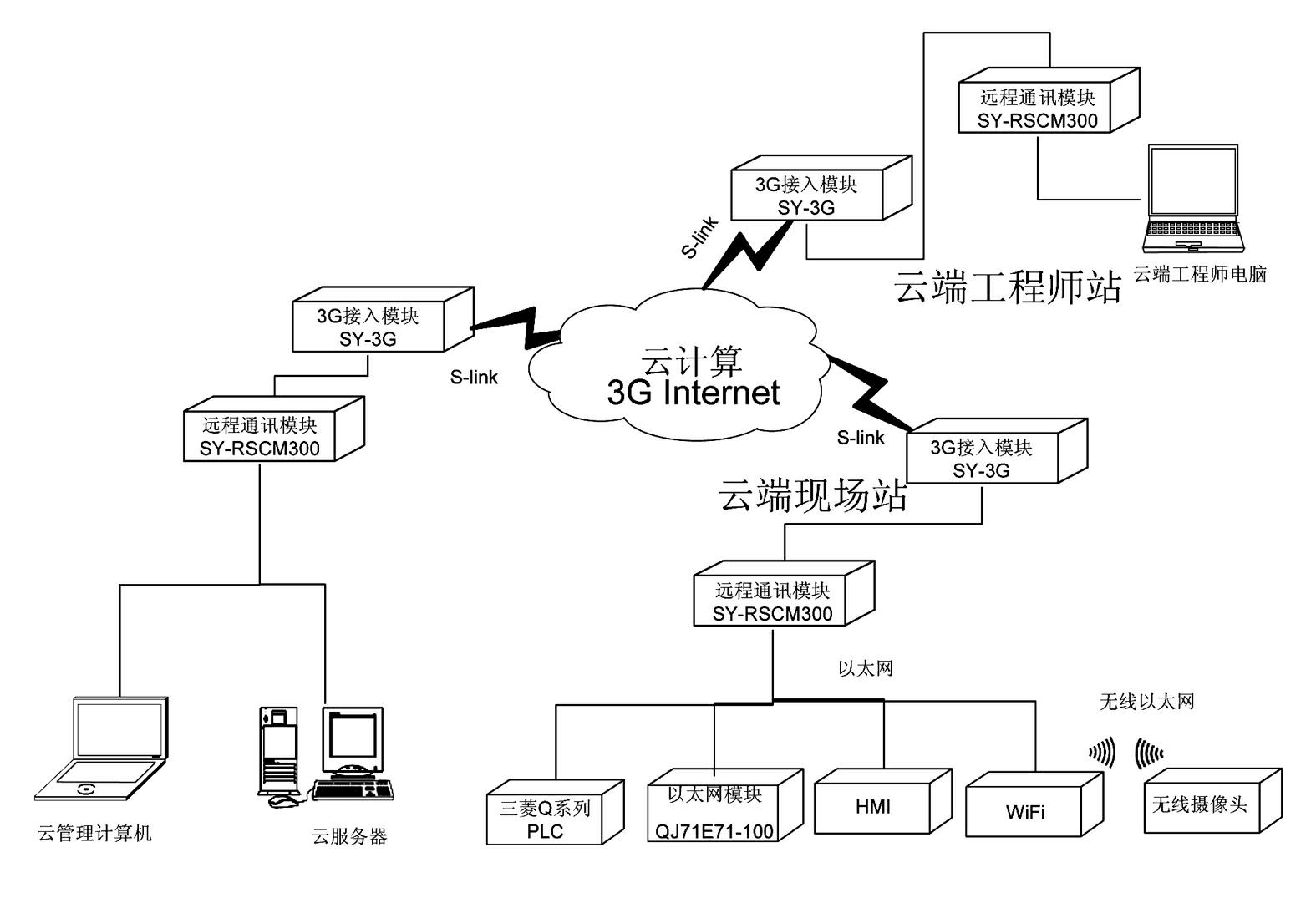

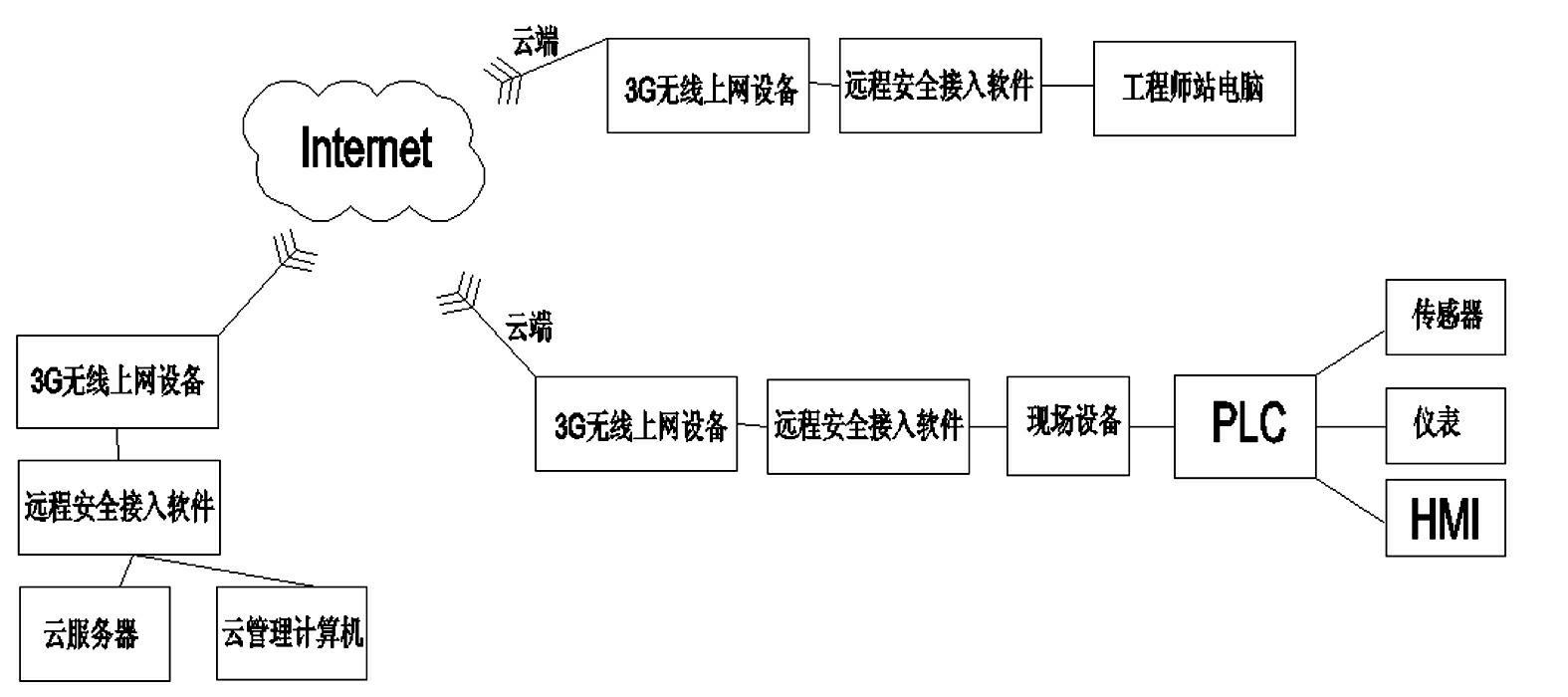

Remote monitored maintenance method and system based on 3G and cloud computing technology

InactiveCN102130947AReal-time online diagnosisLive debuggingPublic key for secure communicationHuman–machine interfaceInternet network

The invention discloses a remote monitored maintenance method and system based on 3G and a cloud computing technology, which belong to 3GInternet network remote monitored maintenance in the industrial automation industry. Field data and video signals of control systems such as a programmable logic controller (PLC), a programmable automation controller (PAC), a human-machine interface (HMI), a frequency converter, a host computer and the like of a remote cloud field station are acquired in real time by using a 3G Internet network and a cloud server platform, so that practical difficulties in remote online diagnosis, debugging, online program modification and program uploading and downloading in an enterprise are eliminated, wireless monitored maintenance of the remote cloud field station is realized, and field attention of a field operating engineer is not required. The remote monitored maintenance system can be applied to any place covered by the 3G network, is operated very conveniently and flexibly, is easy for remote management, debugging and maintenance, and has the characteristics of online instantaneity, safety, high speed, easiness in operation and introduction and the like.

Owner:SHENZHEN FUTURELOOKS AUTOMATION SYST

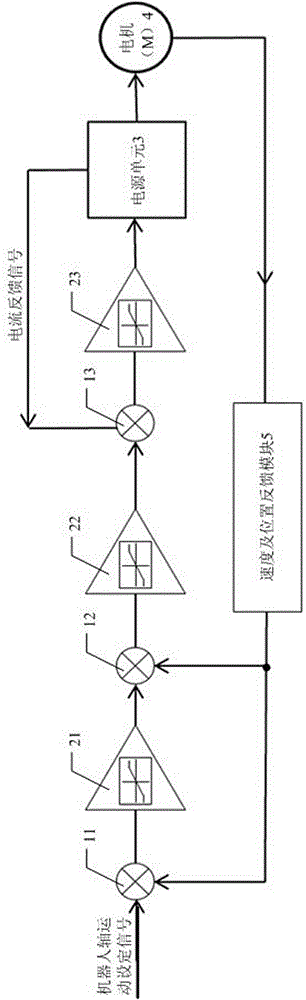

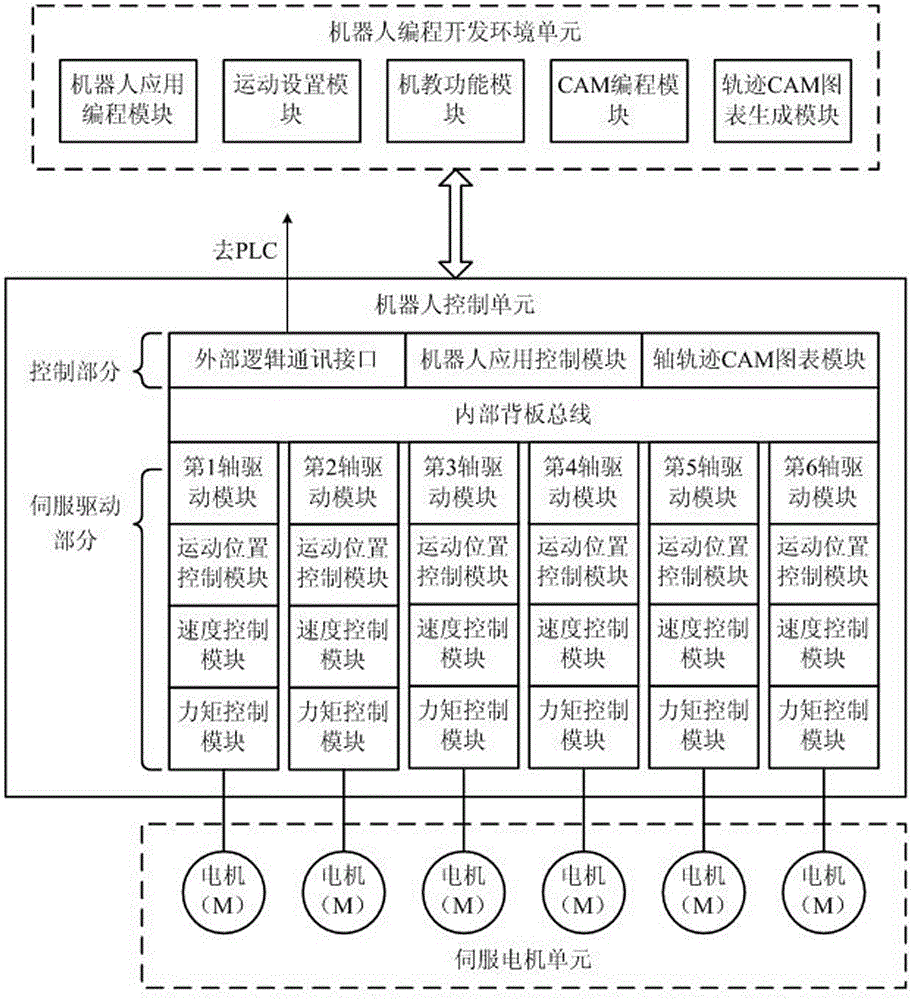

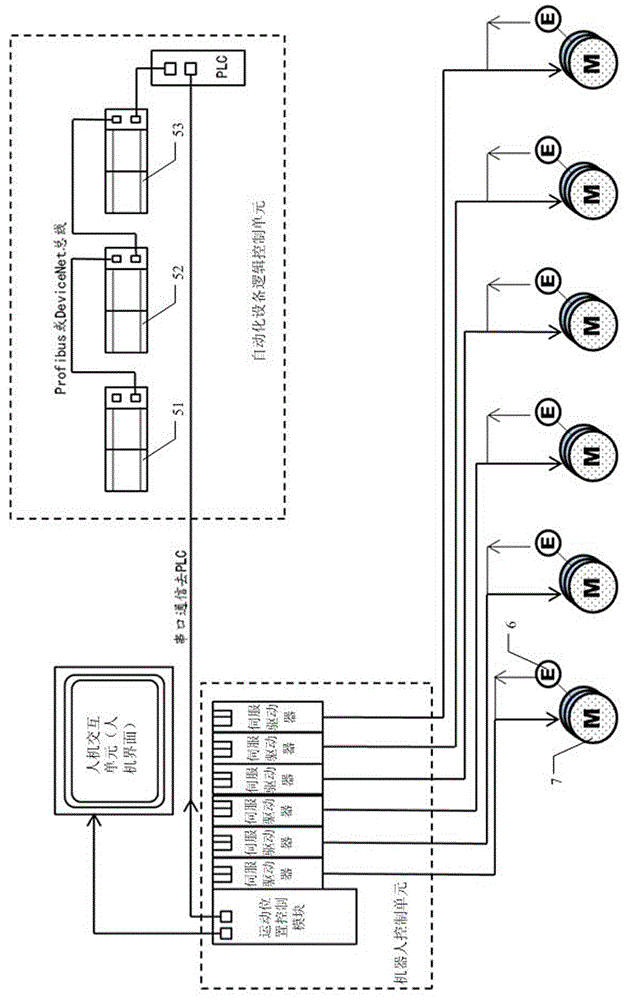

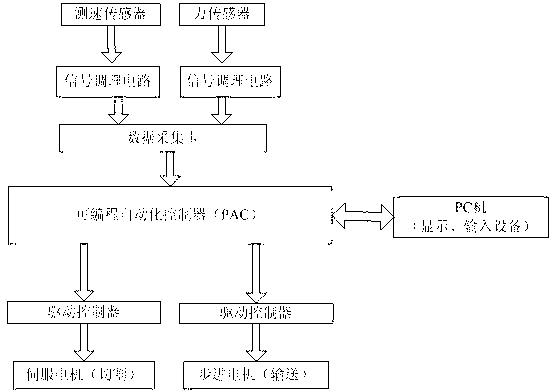

Field bus-based PAC (Programmable Automation Controller) industrial robot control system

ActiveCN102862161AEasy to controlOvercome costsProgramme-controlled manipulatorExtensibilityComputer module

The invention discloses a field bus-based PAC (Programmable Automation Controller) industrial robot control system which comprises a robot axis servo control unit, a high-speed real-time Ethernet field bus, a man-machine interaction, a PAC, and a plurality of input-output modules, wherein the robot axis servo control unit is used for controlling and driving axle joints of manipulators of an industrial robot, the PAC is used for controlling the robot axis servo control unit and the man-machine interaction unit respectively and are respectively connected with the robot axis servo control unit and the man-machine interaction unit, and the plurality of input-output modules are extensibly arranged and are respectively connected with the robot axis servo control unit through the high-speed real-time Ethernet field bus. The system can be used for overcoming the defects of being unreasonable in structure, inconvenient to install and maintain, low in reliability, poor in precision, high in cost, poor in extensibility and the like in the prior art, so as to realize the disadvantages of being reasonable in structure, convenient to install and maintain, high in reliability, good in precision, low in cost and good in extensibility.

Owner:苏州东控自动化科技有限公司

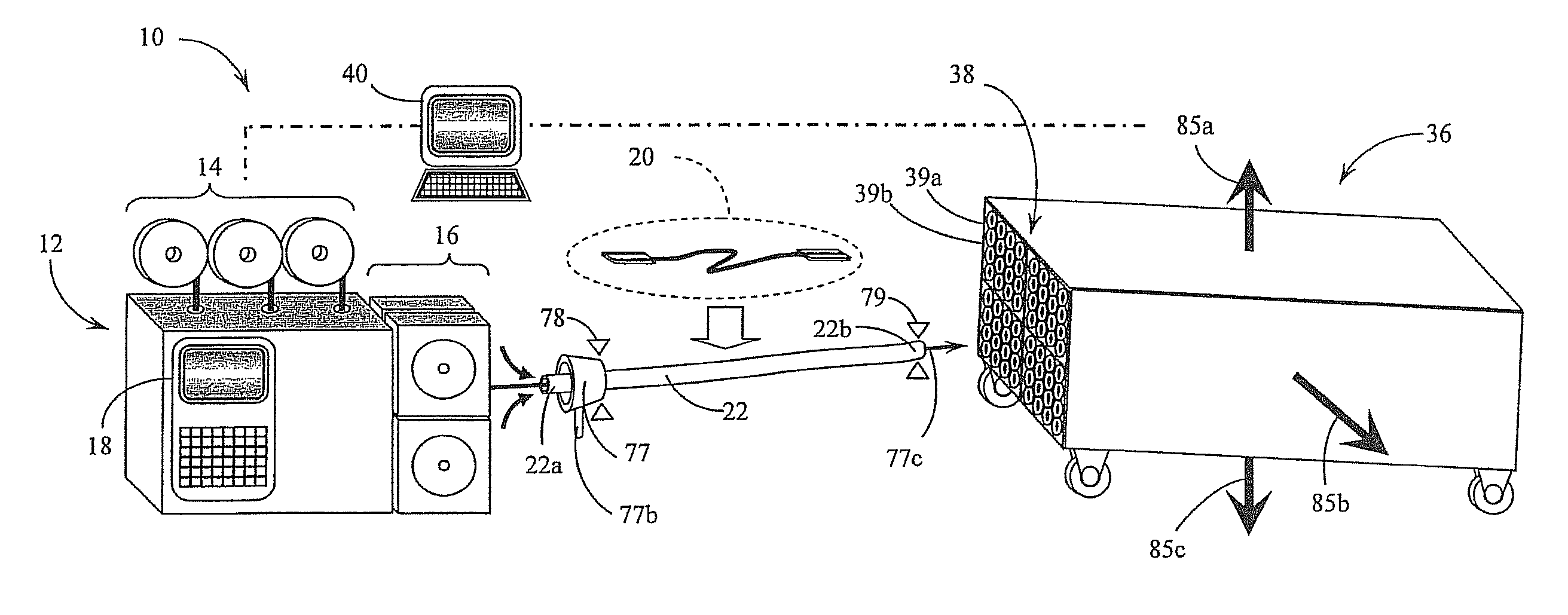

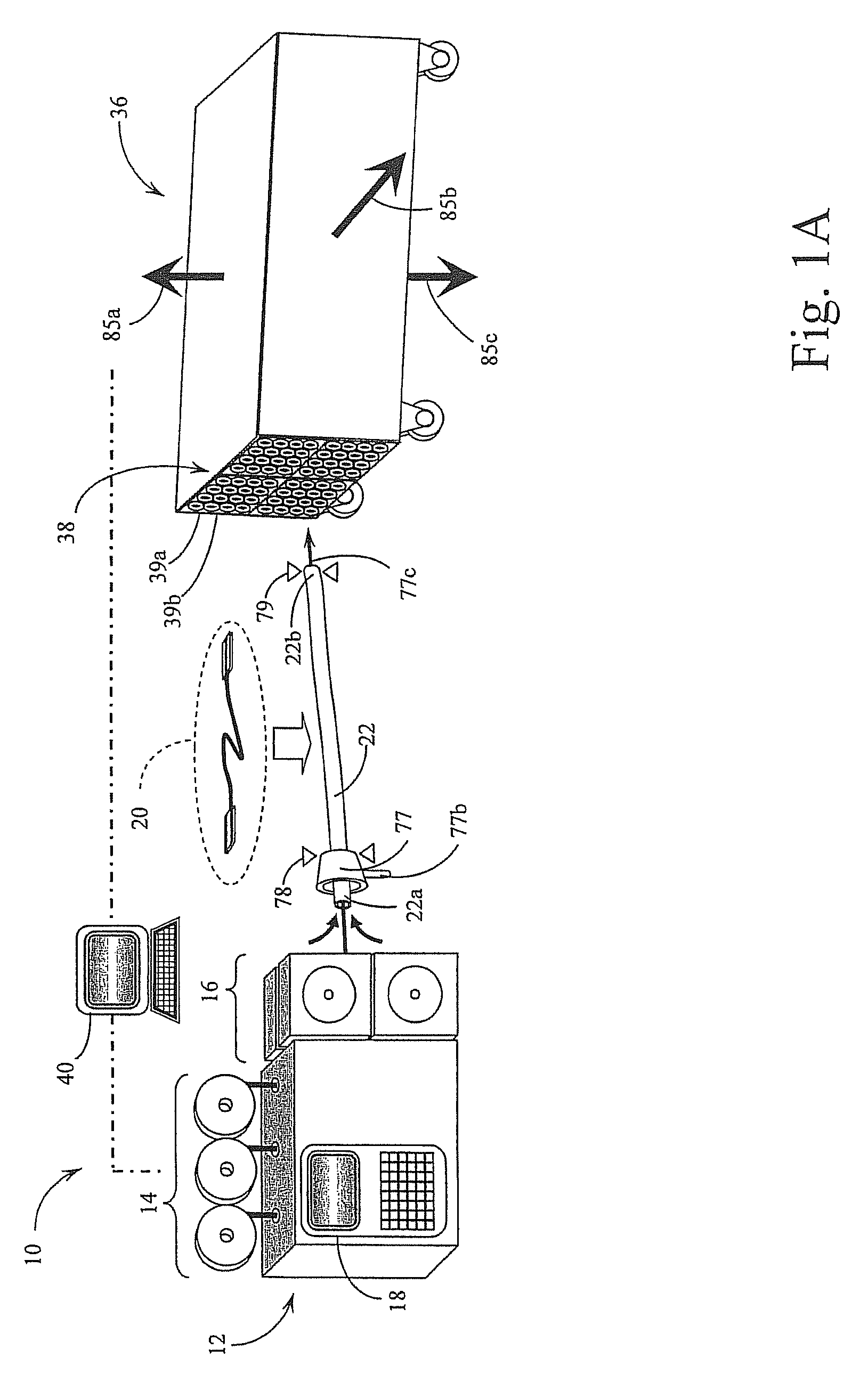

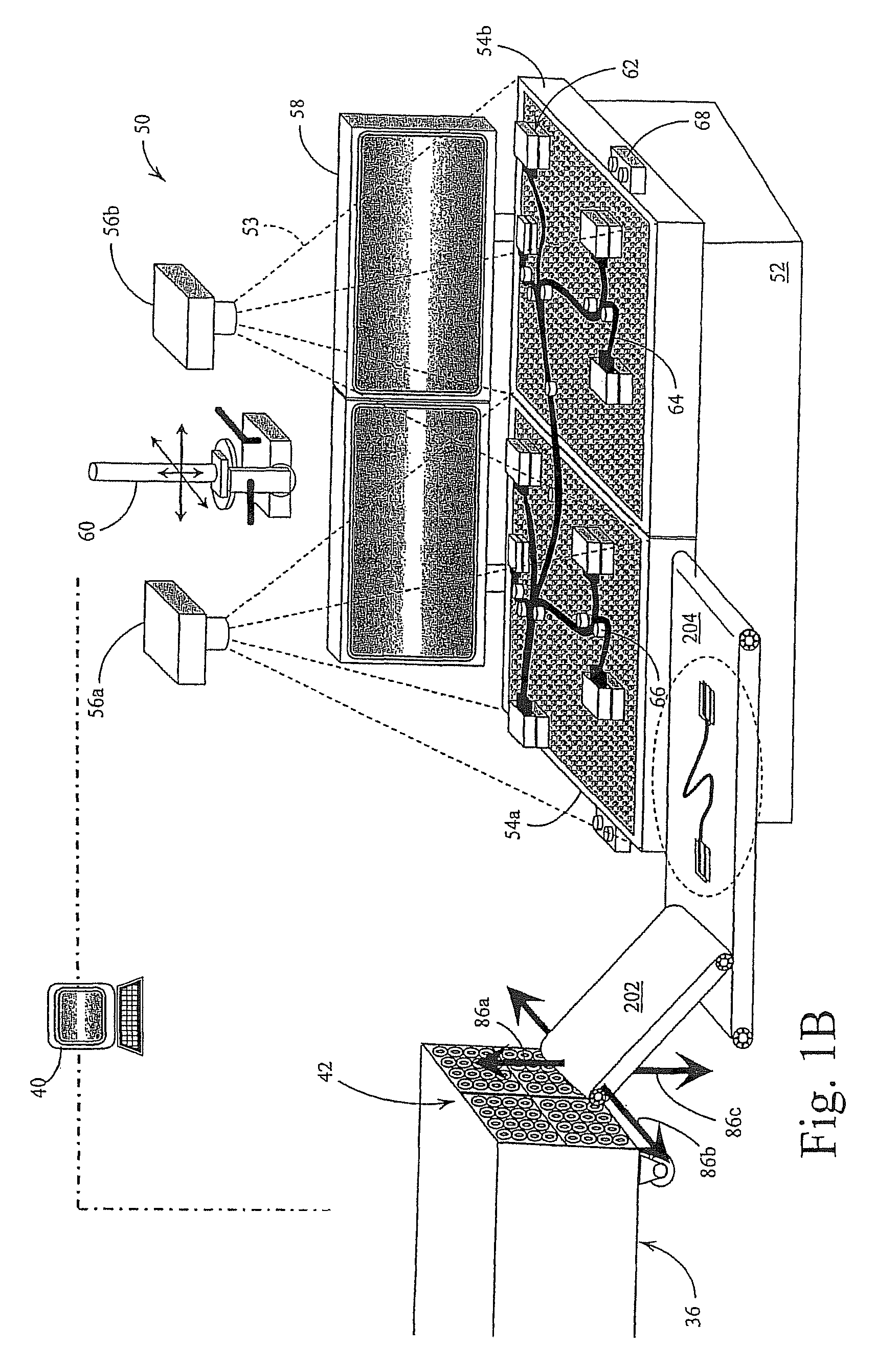

Integrated wire harness batch production with double buffer assembly systems and methods

ActiveUS9257808B1Improve storage densityMaterial minimizationContact member assembly/disassemblyManufacturing wire harnessesDelivery systemAssemblers

Automated wire harness production systems and methods that rapidly present individual circuits to an assembler operating a wire harness layout board. Automatic wire indexing, sorting, and delivery systems transfer circuits into, and retrieve circuits from, a transportable programmable, automated, indexed storage system equipped with an array of individual circuit tubes, and a script-controlled assembly system sends visual, aural, and other cues to help an assembler populate and configure a wire harness layout board with connector blocks and turn posts, and guides the assembler in building, testing, reworking, and delivering the corresponding batch of wire harnesses.

Owner:AUTOMATED WIRING SYST

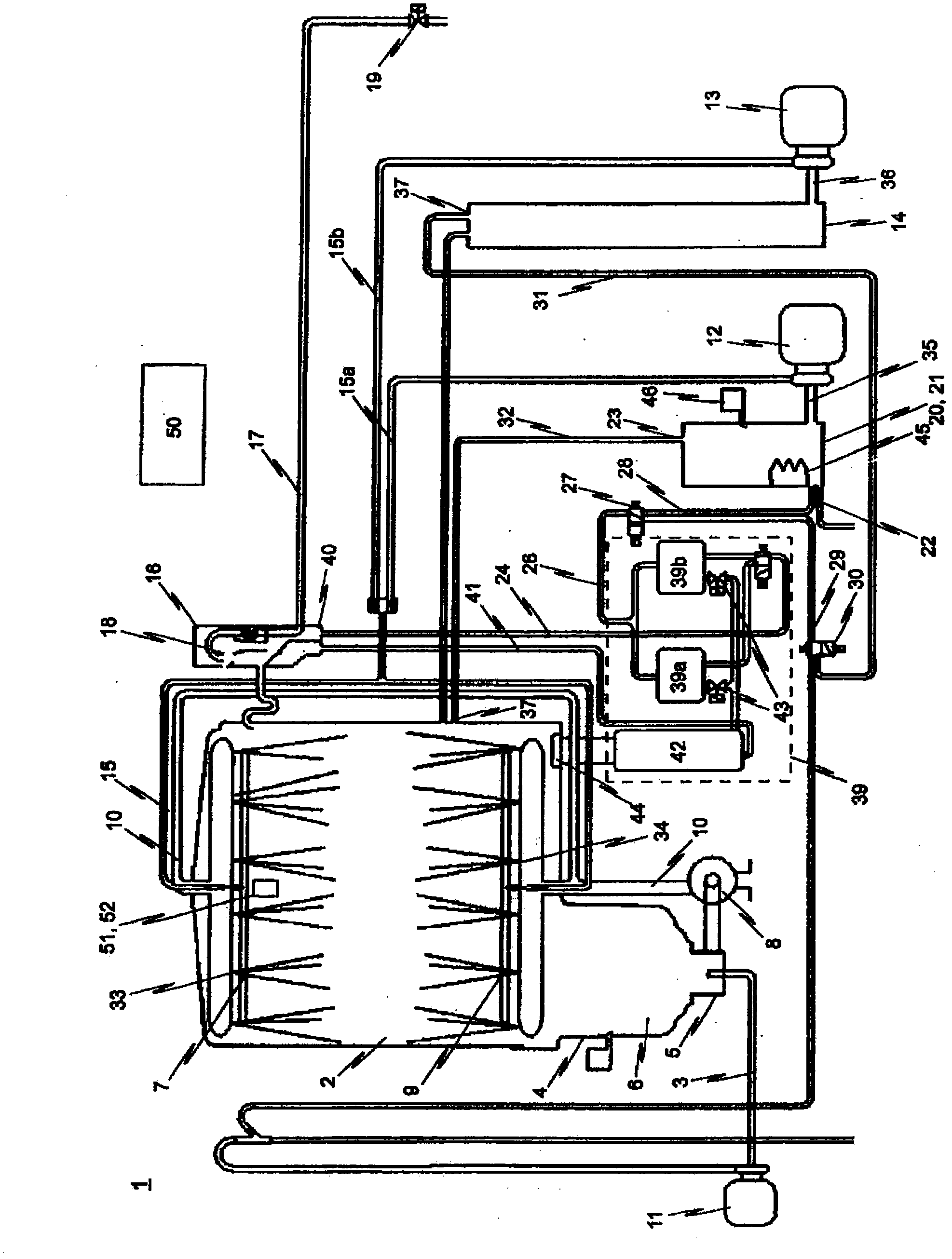

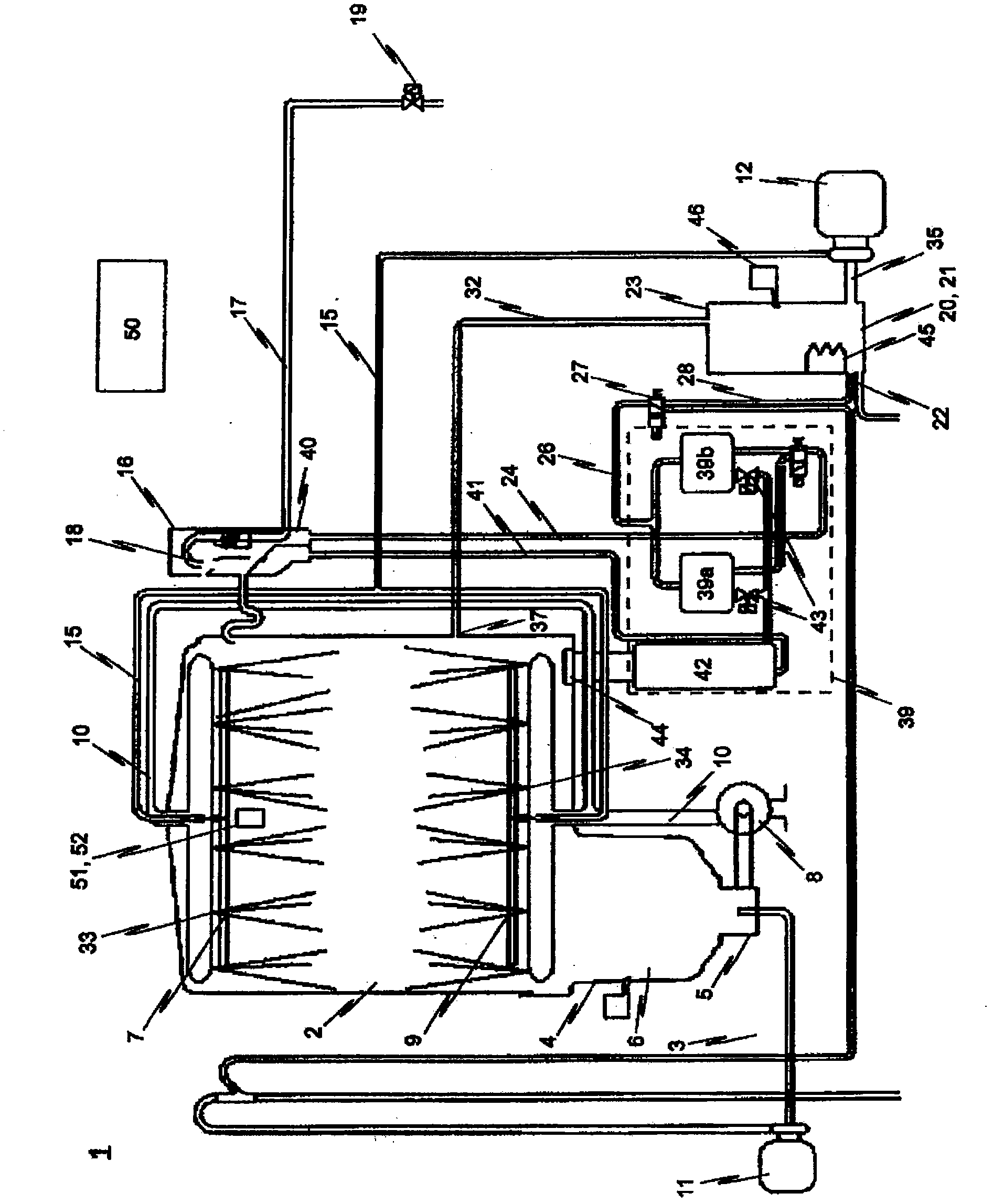

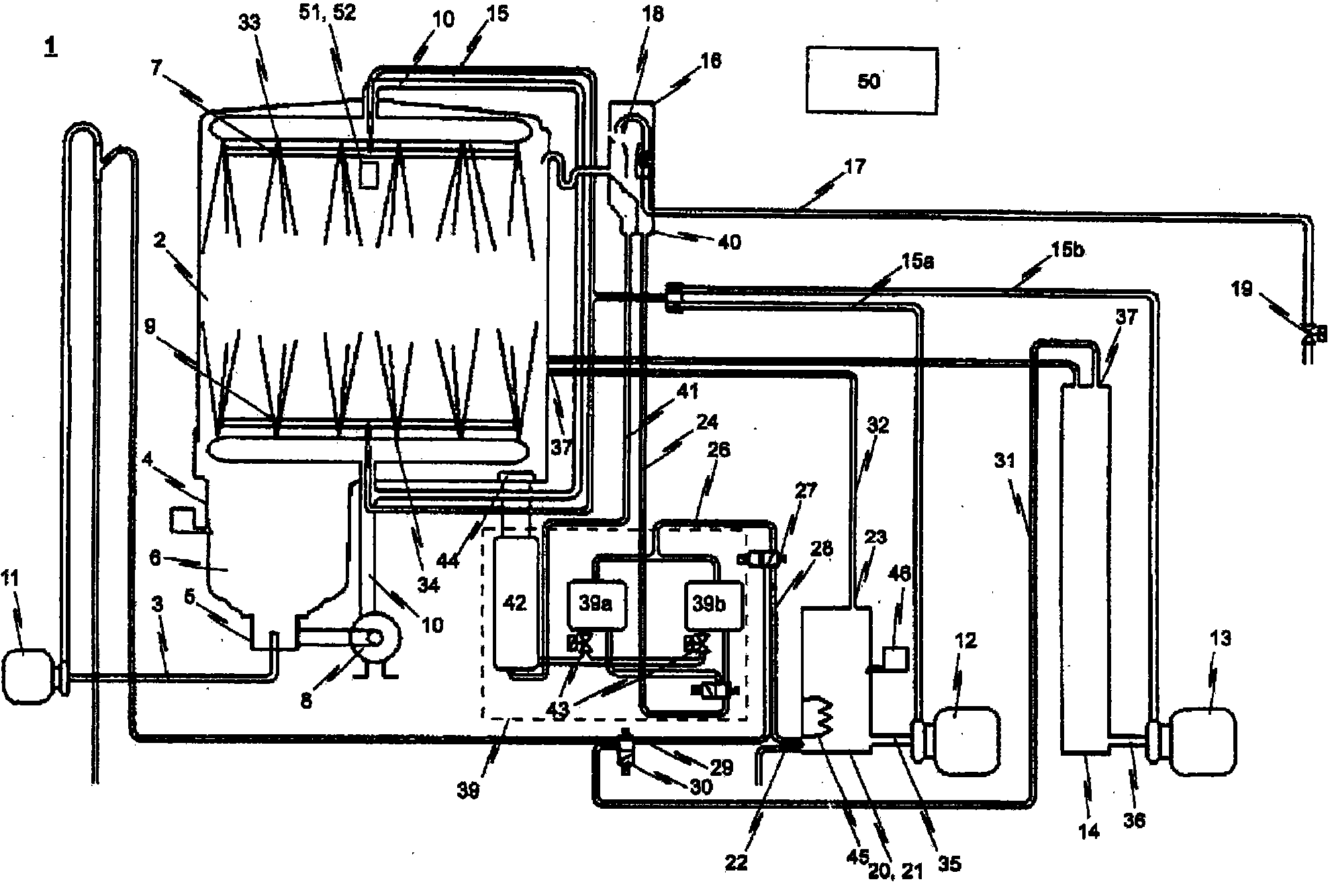

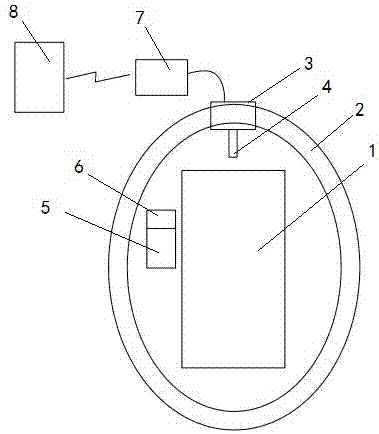

Dishwasher and method for cleaning wash ware

InactiveCN101998839AAutomatic optimization and adjustment of processing parametersFull cleaning effectTableware washing/rinsing machine detailsWashing processesProgrammable automationProcedural approach

The invention relates to a dishwasher (1) in the form of a programmable automatic machine, which has a programme control device (50) for carrying out at least one treatment programme, a treatment chamber (2) into which and from which wash ware can be manually inserted and removed, a tank (4) into which fluid from the treatment chamber (2) can flow off by gravity, and a washing system (33, 8, 34, 10) with a washing pump (8) and with a washing line system (10) for conveying washing fluid (6) during a washing phase out of the tank (4) through washing nozzles (33, 34) into the treatment chamber (2). In order to achieve an efficient treatment (cleaning and drying) of the wash ware, along with as low a consumption as possible of resources in terms of water, chemicals and, in particular, energy, there is provision, according to the invention, for the dishwasher (1) to have, furthermore, a wash-ware detector device (51) which is designed for detecting the type of wash ware to be treated, furthermore the programme control device (50) being designed to select a predetermined or determinable treatment programme for at least the washing phase automatically as a function of the detected type of wash ware to be treated and to set the process parameters associated with the selected treatment programme.

Owner:PREMARK FEG L L C

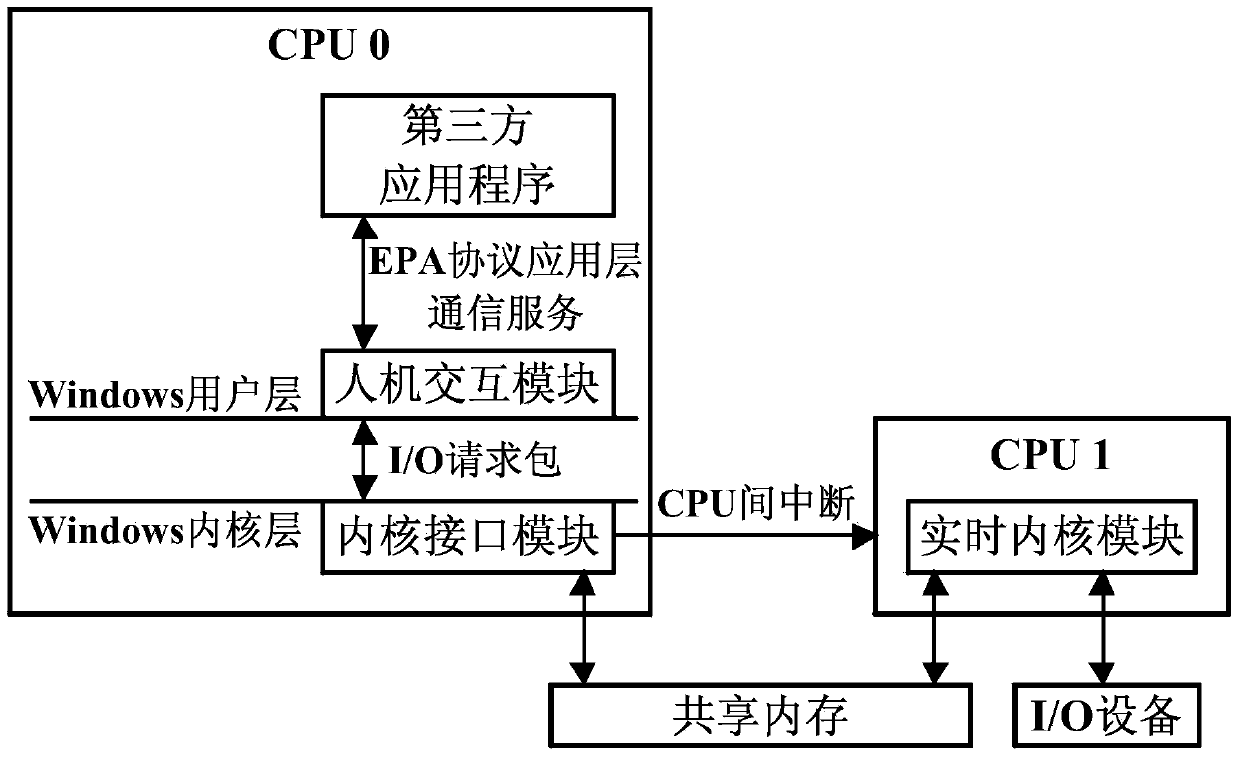

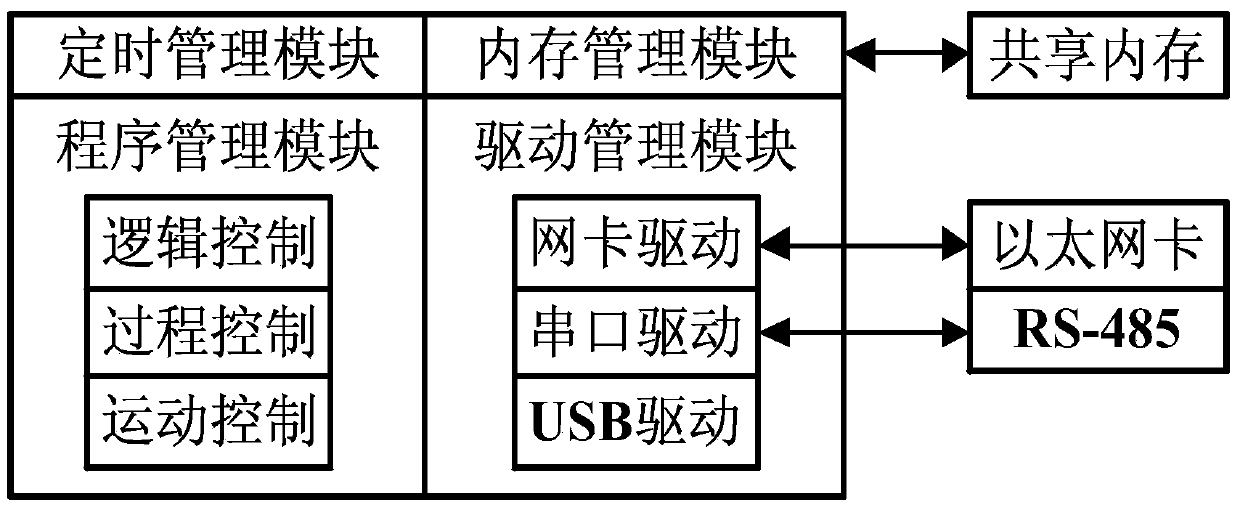

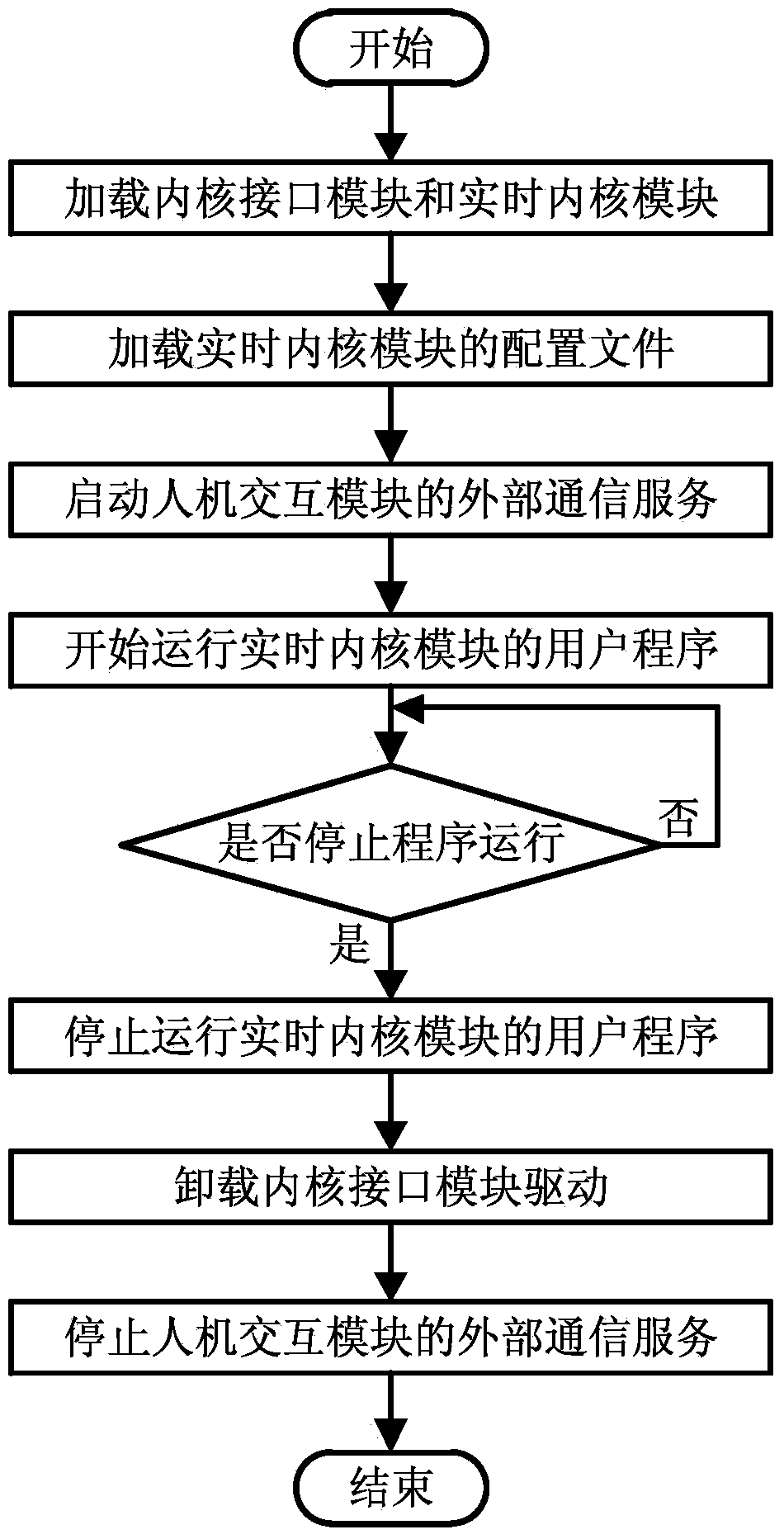

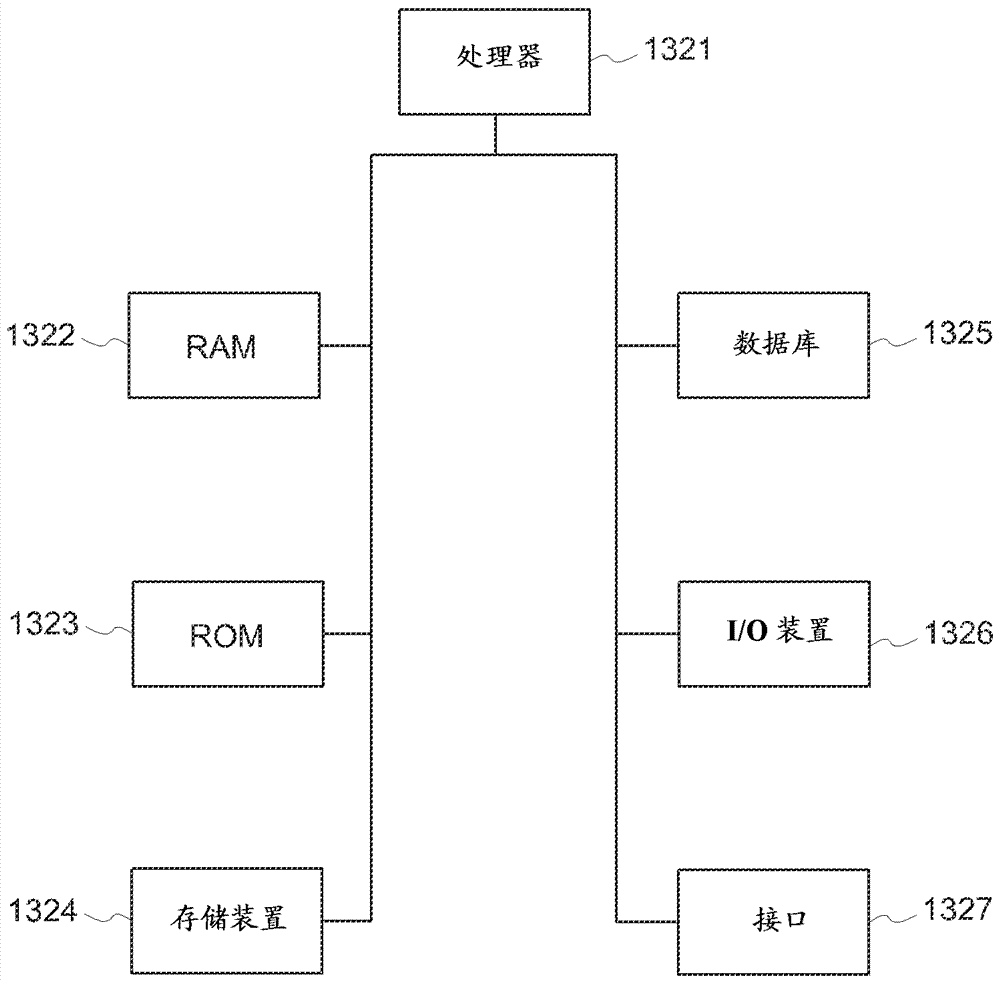

PAC (programmable automatic controller) real-time control system based on dual-core processor

ActiveCN103744342AGuarantee opennessGuaranteed stabilityProgramme control in sequence/logic controllersReal-time Control SystemDual core

The invention relates to the technical field of PAC (programmable automatic controller) systems, in particular to a PAC real-time control system based on a dual-core processor. The PAC real-time control system comprises the dual-core processor based on an industrial PC (personal computer), a shared memory and I / O (input / output) equipment, wherein the dual-core processor comprises processor cores CPU0 and CPU1, a third-party application program in the CPU0 is connected with a human-machine interaction module, the human-machine interaction module in the CPU0 is connected with an inner core interface module, the inner core interface module in the CPU0 is respectively connected with a real-time inner core module and the shared memory, a real-time inner core module in the CPU1 is respectively connected with the shared memory and the I / O equipment, the CPU0 operates a Windows operating system and is in charge of human-machine interaction and network communication, and the CPU1 is enabled to operate PAC real-time inner core codes and be in charge of execution of user programs and control over the I / O equipment. The two cores of the dual-core processor are separated, and the two mutually independent CPU0 and CPU1 operate different system inner cores due to undertaking different tasks, so that the openness, the stability and the real-timeness of the system are ensured.

Owner:大连爱智控制系统有限公司

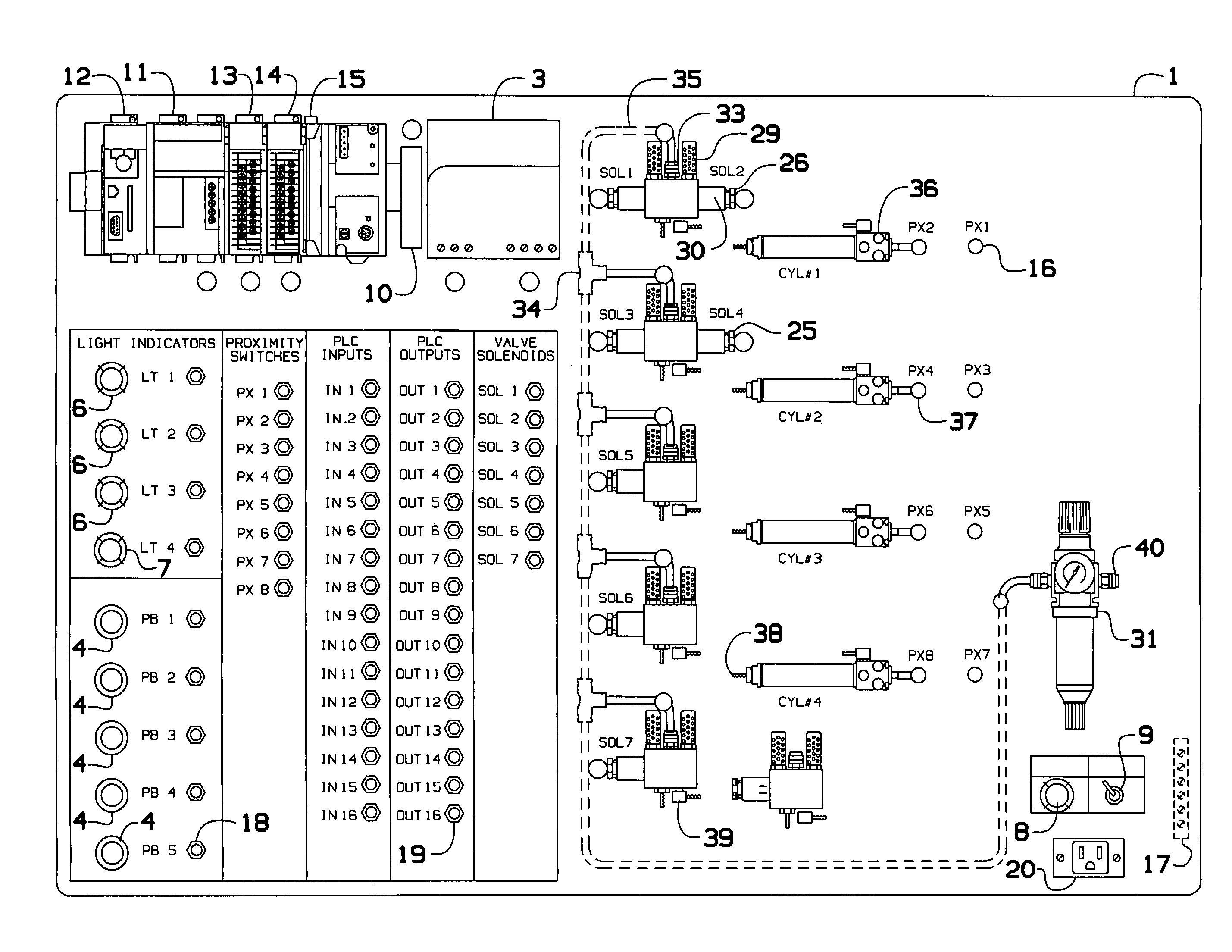

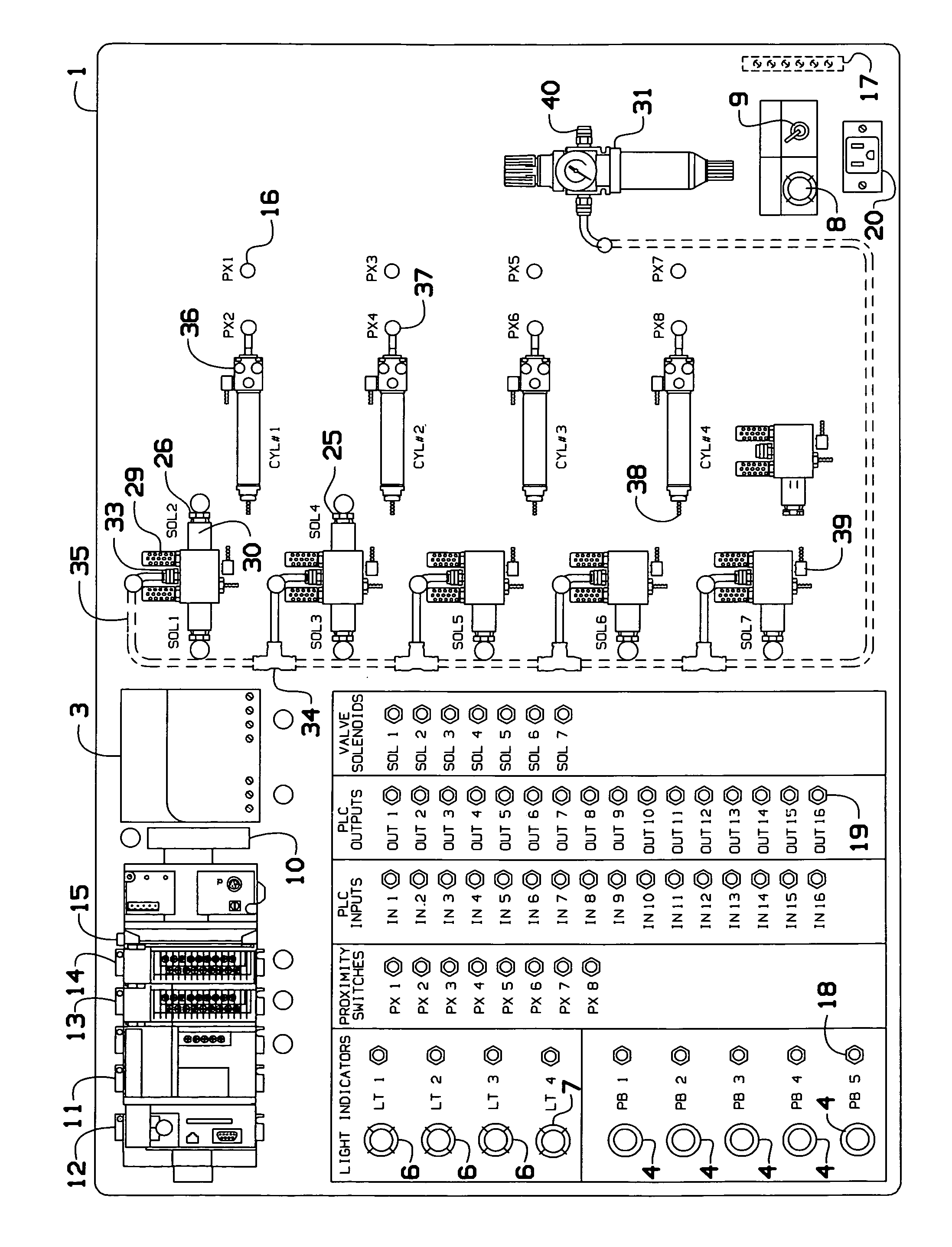

Automation trainer for training technician, engineers and tradesmen to program a programmable automation controller

An automation trainer is useful for students to develop programs then download to a programmable automation controller (PAC) or a programmable logic controller (PLC). The programs can be used to sequence cylinders that are controlled by valves and sensors. The automation trainer, along with lab experiments, simulate real world problem solving and programming. The automation trainer simulates real world machines and is easily expandable and flexible.

Owner:SIEDLIK MARK

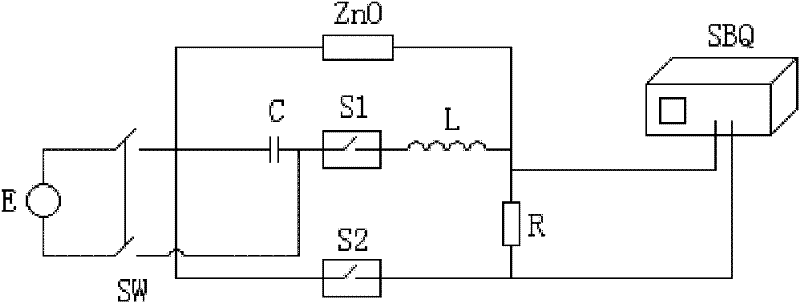

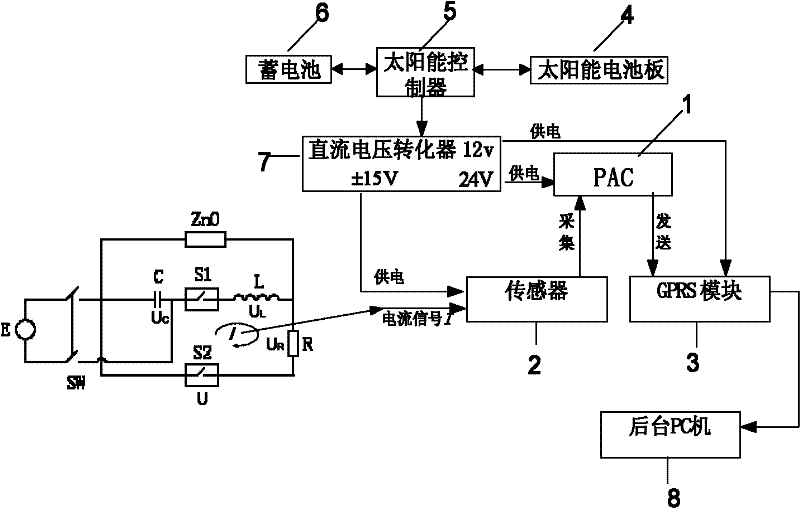

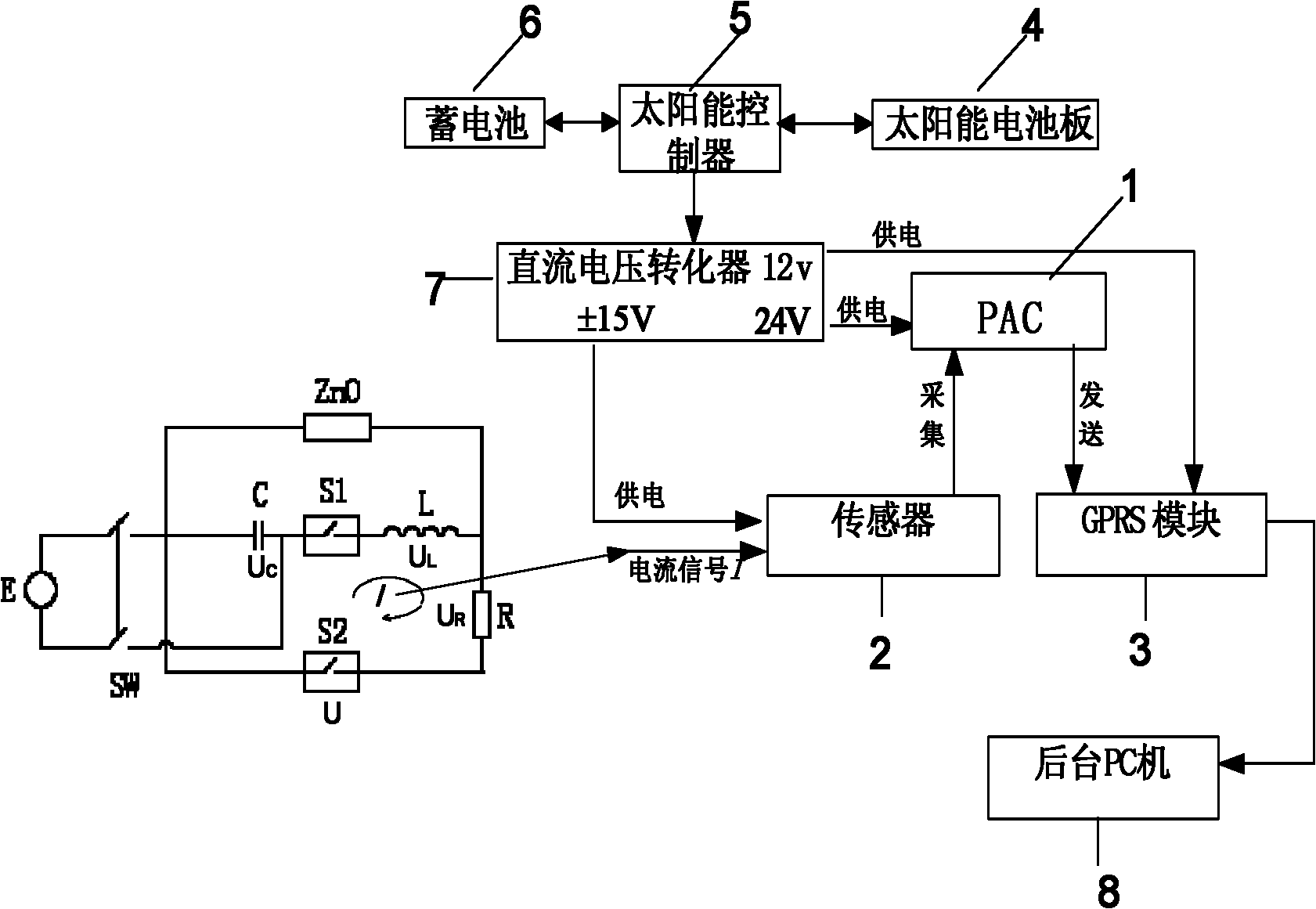

Active high voltage direct current switch oscillation loop parameter on-line measuring system and method thereof

ActiveCN102230948ARealize online detectionGuaranteed uptimeResistance/reactance/impedenceWireless transmissionHigh-voltage direct current

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +1

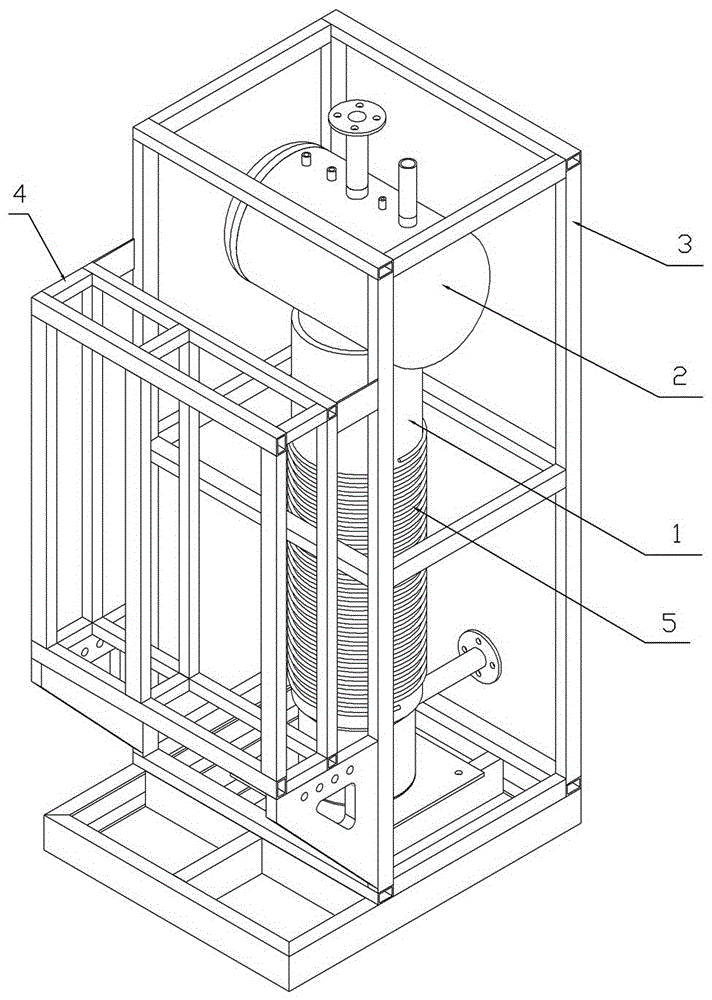

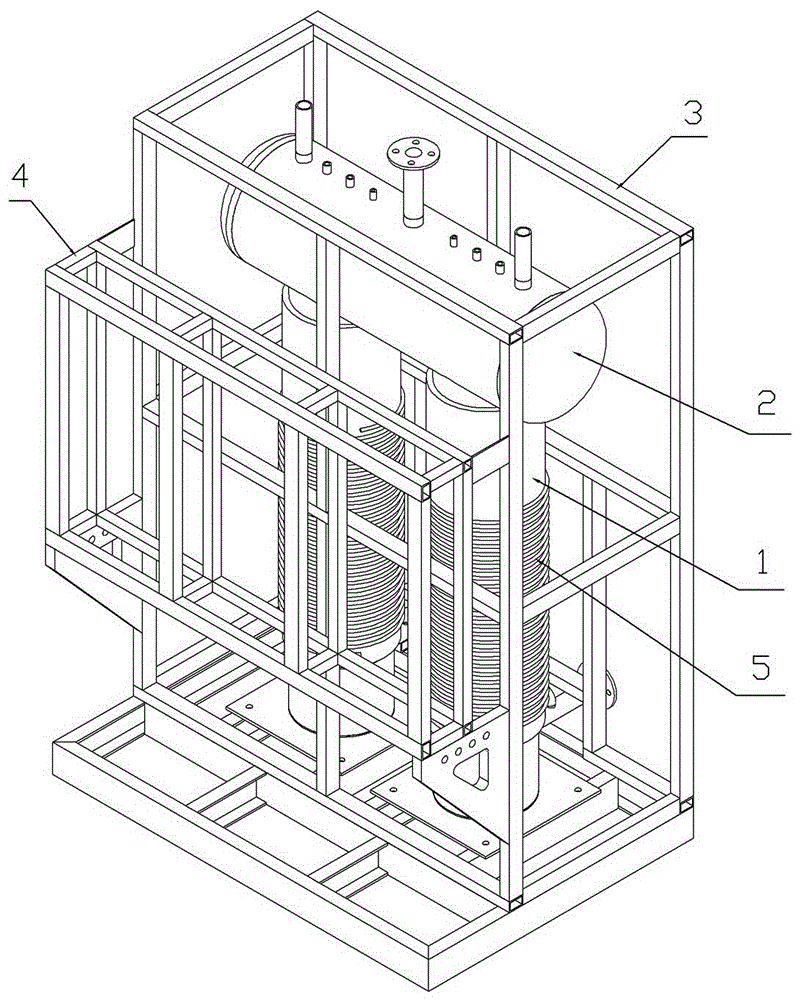

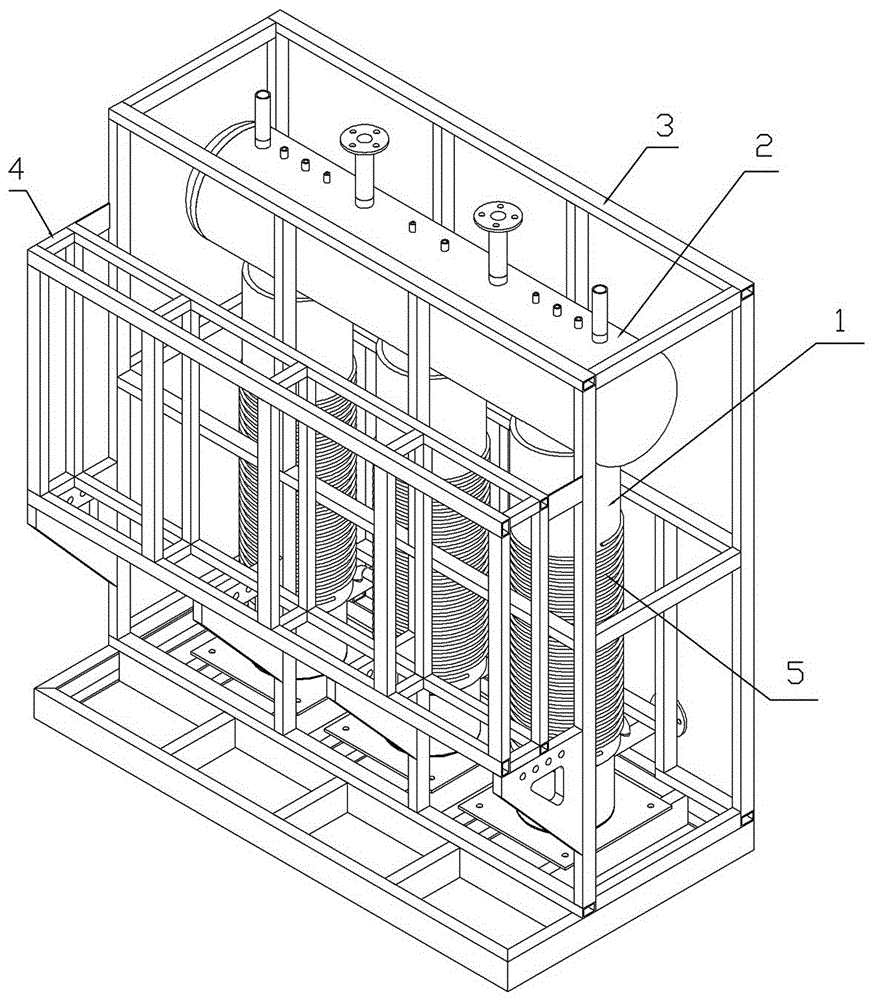

Electromagnetic steam boiler

ActiveCN105716063AAvoid unsafe hazardsIncrease the level of automationSteam generation heating methodsBoiler controlAutomatic controlProgrammable automation

The invention relates to a steam boiler. The electromagnetic steam boiler comprises a boiler body formed by heating pipes (1) and a steam chamber (2) and an electric control part, wherein the boiler body is arranged in a box-type structure body (3); heating coils (5) are arranged around the heating pipes (1); the front part of the box-type structure body (3) is provided with a control box (4); the electric control part is arranged in the control box (4); according to an electromagnetic heating principle, by adopting an electromagnetic heating mode, an electromagnetic heating electronic part is organically combined with the boiler body; and by utilizing the characteristics of high frequency and high power of a field effect tube, the working frequency of the heating coils is between 20 to 50 KHZ by adopting a trigger circuit. According to the electromagnetic steam boiler, a modern electronic technology is organically combined with traditional boiler functions; a single-chip microcomputer technology and a programmable automatic control technology are integrated in the production process of the boiler, so that energy is saved, and the environment is protected; the heat efficiency reaches above 95%; and the automation degree of the operation of the boiler is greatly improved.

Owner:郑州亚飞凌电子产品有限公司

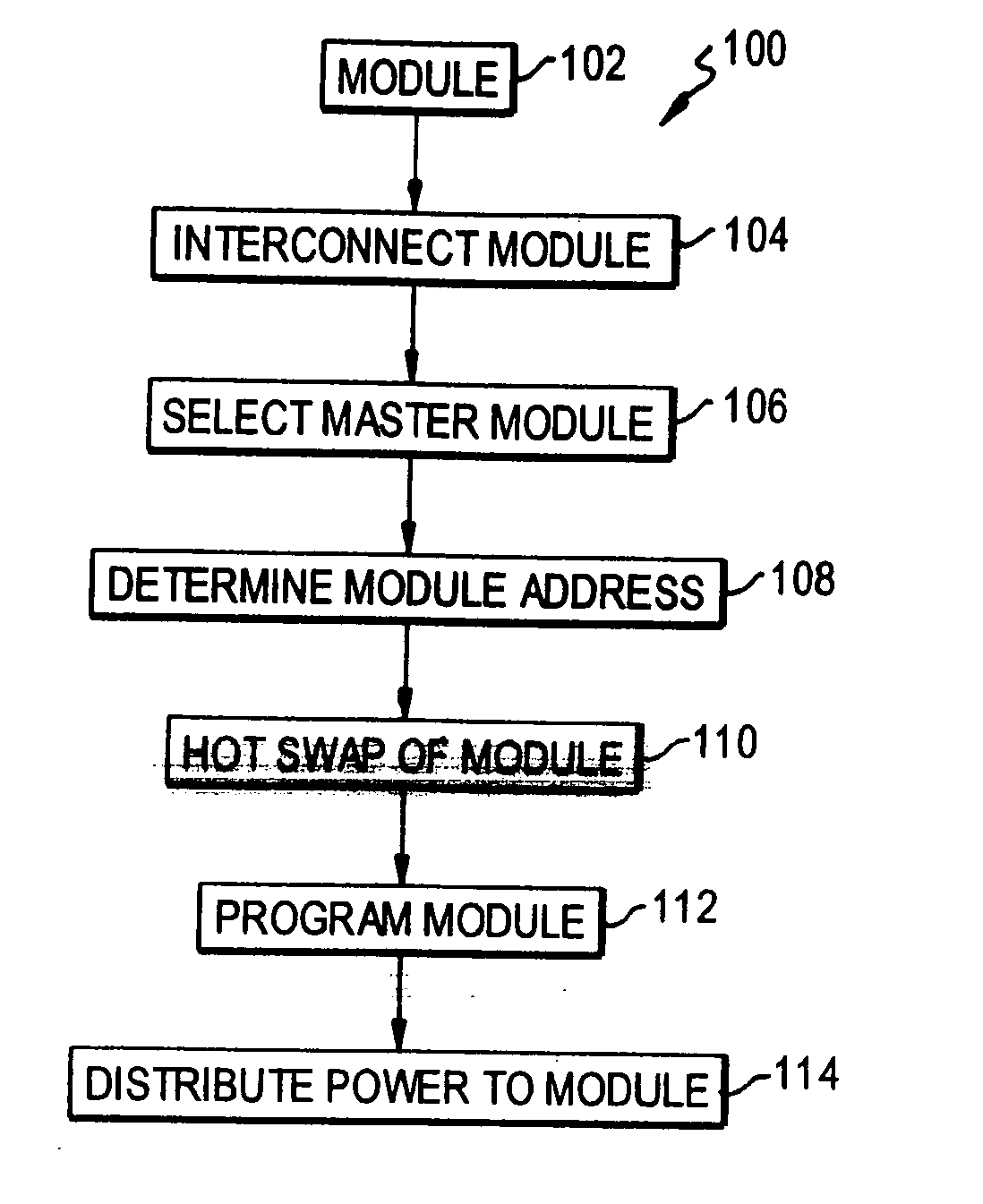

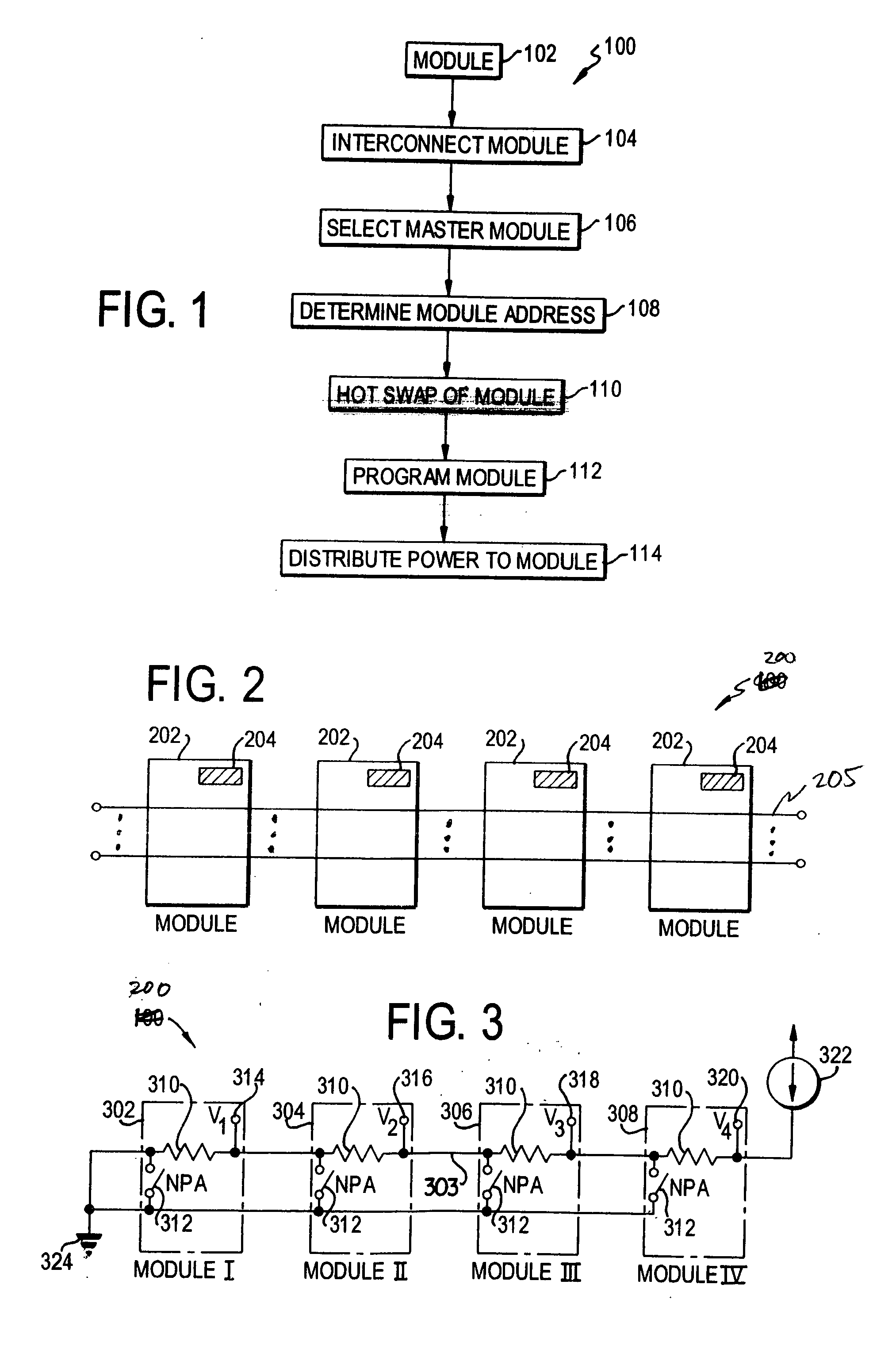

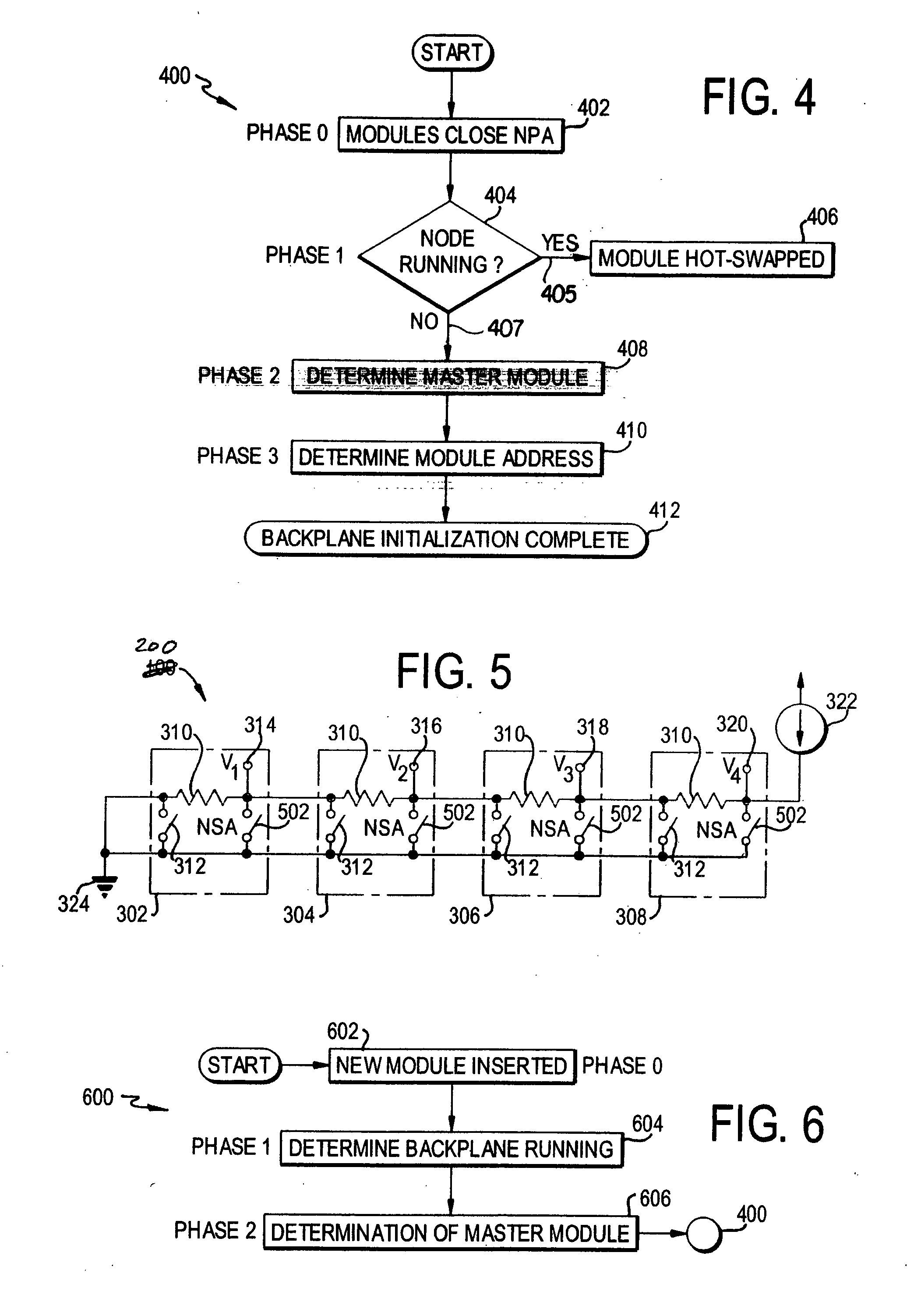

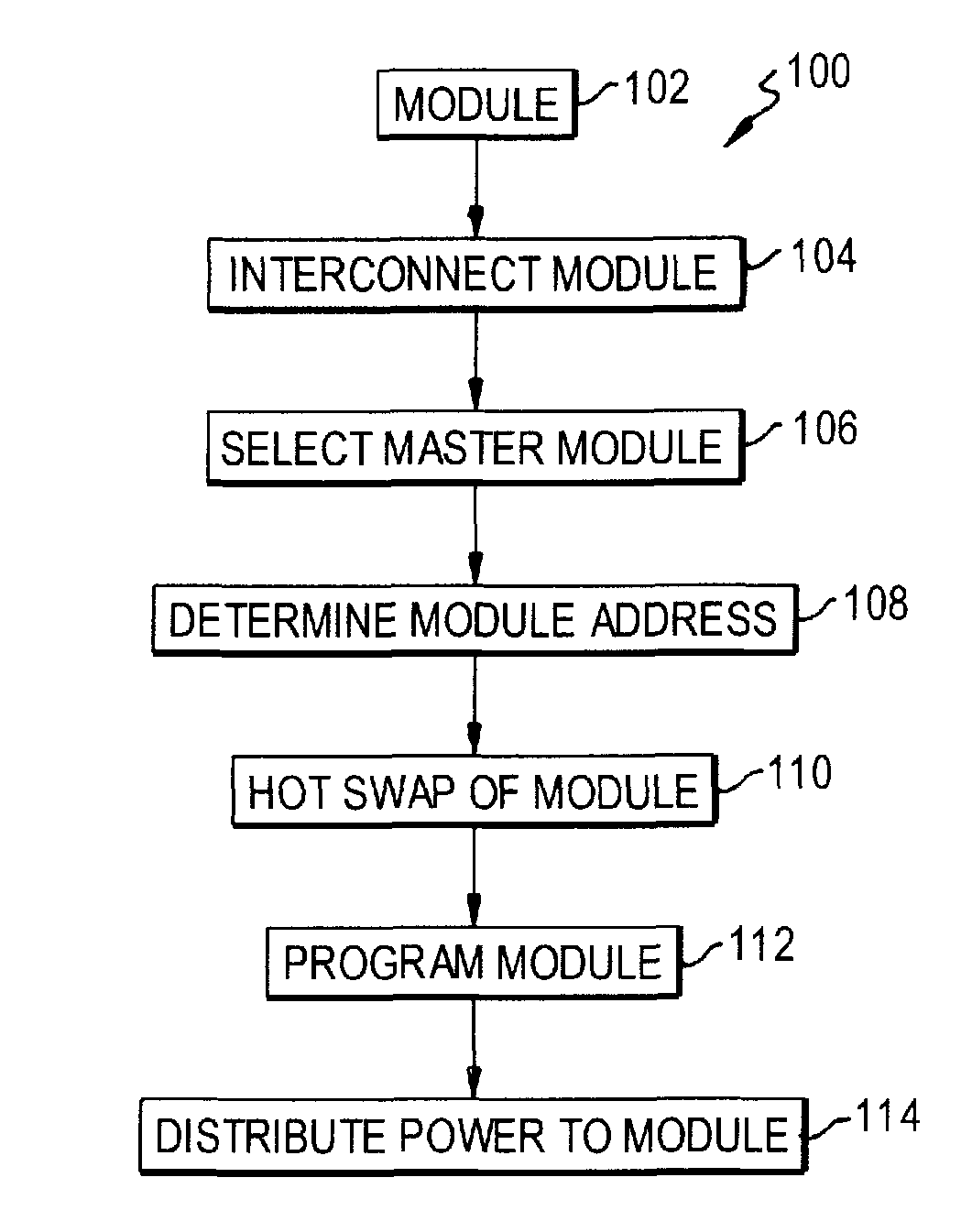

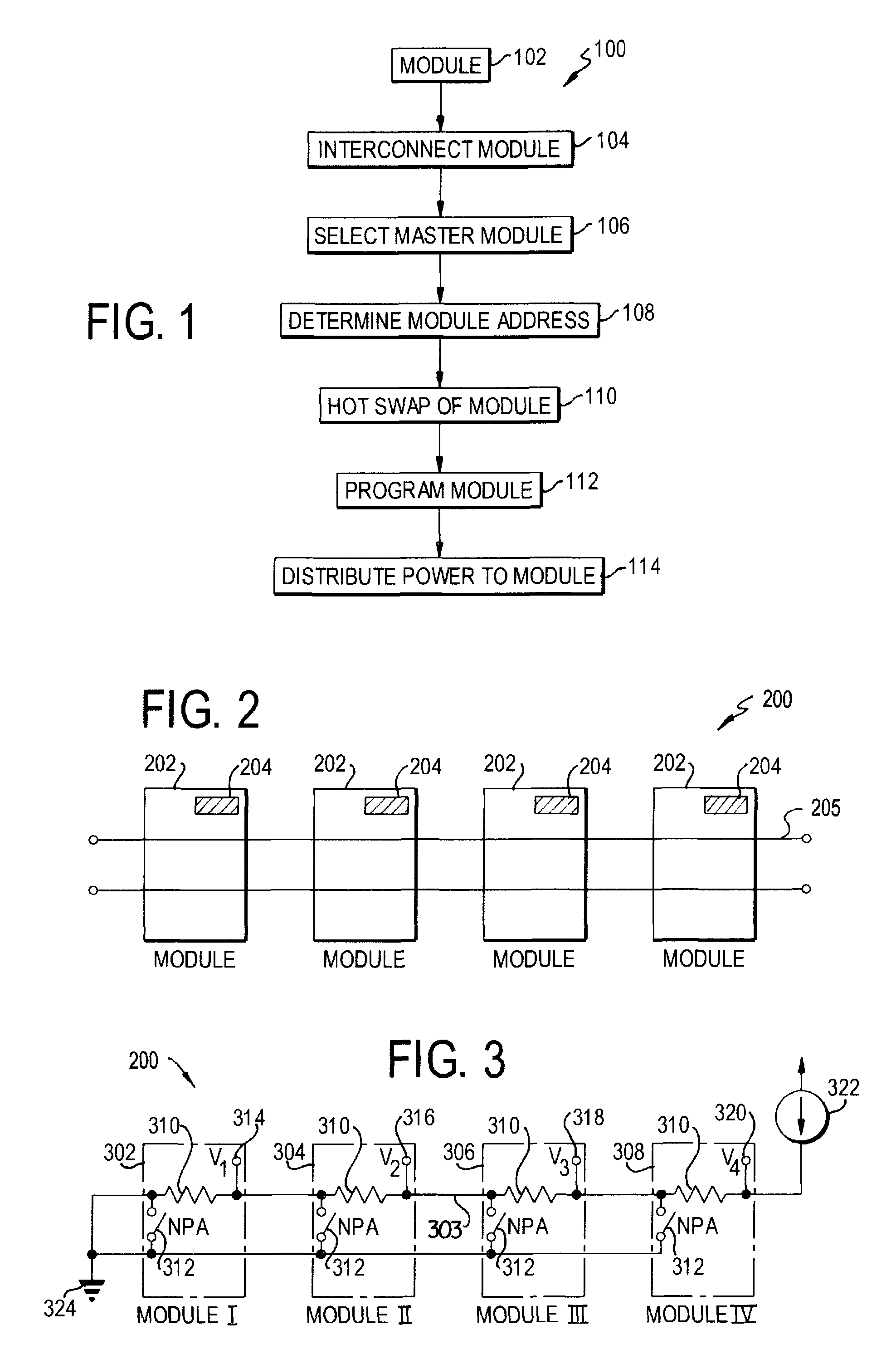

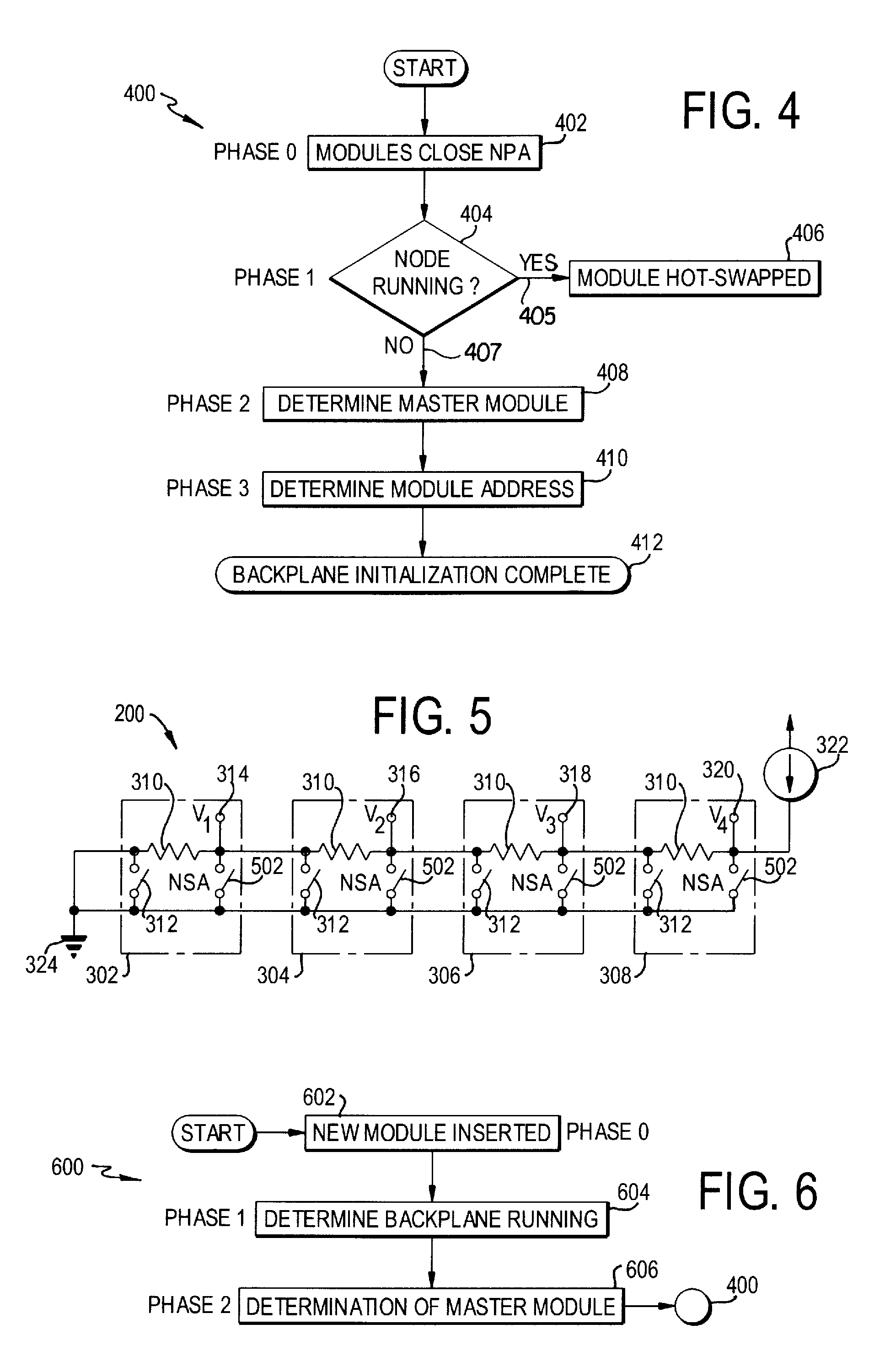

Modular programmable automation controller with multi-processor architecture

An apparatus and method for forming a control node in a programmable architecture, is disclosed. The node includes a plurality of user-programmable, microprocessor-based modules connected together. The modules are connected to create a parallel-processing environment with a selected functionality. Hot-swapping of the modules can be determined in the node. Power is distributed throughout the modules in the node. The modules may be automatically programmed to accommodate a target independent device.

Owner:FAIRMONT AUTOMATION

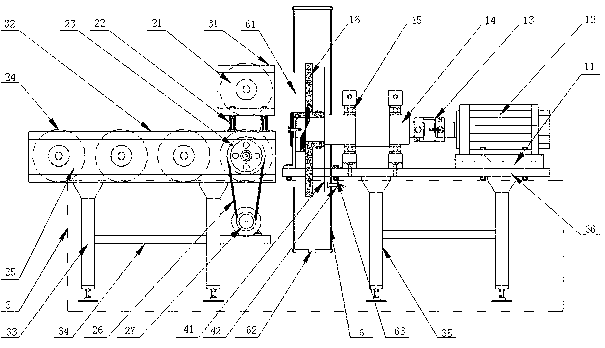

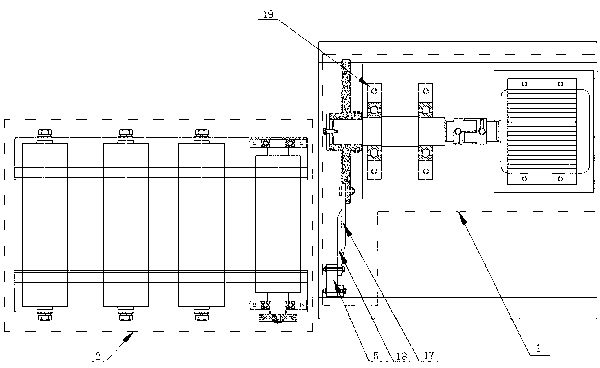

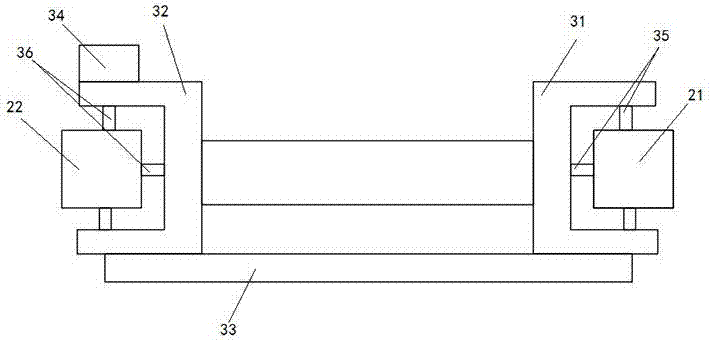

Testing apparatus for straw cutting performance and testing method thereof

InactiveCN103063568AVersatileSimple structureForce measurementWork measurementData acquisitionProgrammable automation

The invention relates to a testing apparatus for straw cutting performance. The testing apparatus is composed of a mechanical system and a measurement and control system, wherein the mechanical systems comprises a rack, a cutting device and a conveyer device; the measurement system comprises a force sensor, a speed sensor, a data acquisition card, a programmable automation controller (PAC) and a personal computer (PC). The testing apparatus for the straw cutting performance and the method are simple and compact in structure, can perform continuous cutting and data acquisition on different portions of one or more straws in one test, increase efficiency of a cutting test and save time. The testing apparatus can perform related tests for different cutting conditions such as cutting ways, cutting tools, cutting speed, cutting angles and the like, thereby allowing the functions of a testing bench to be more comprehensive and providing experimental data and evidence for the research and development of cutting machines.

Owner:JIANGSU UNIV

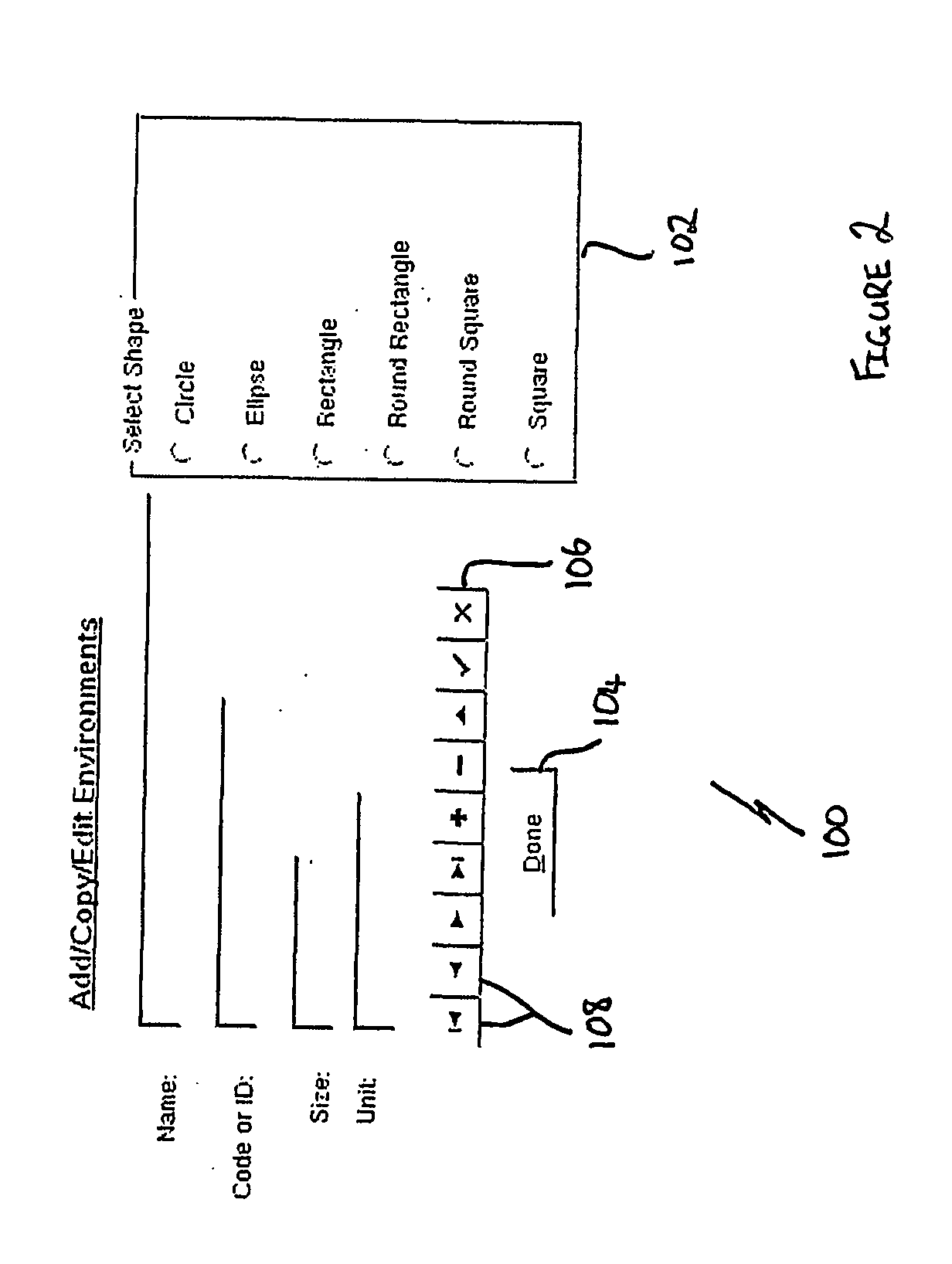

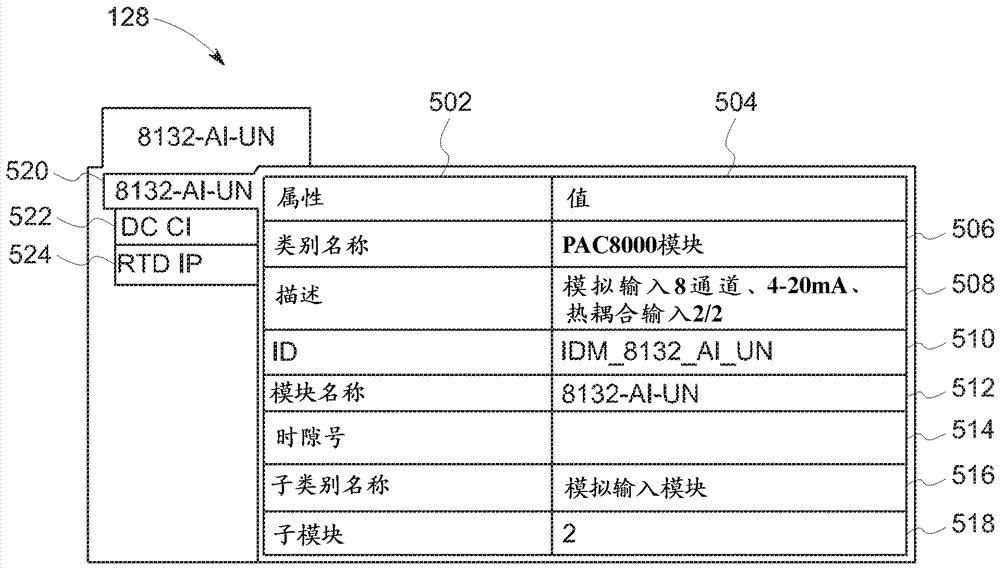

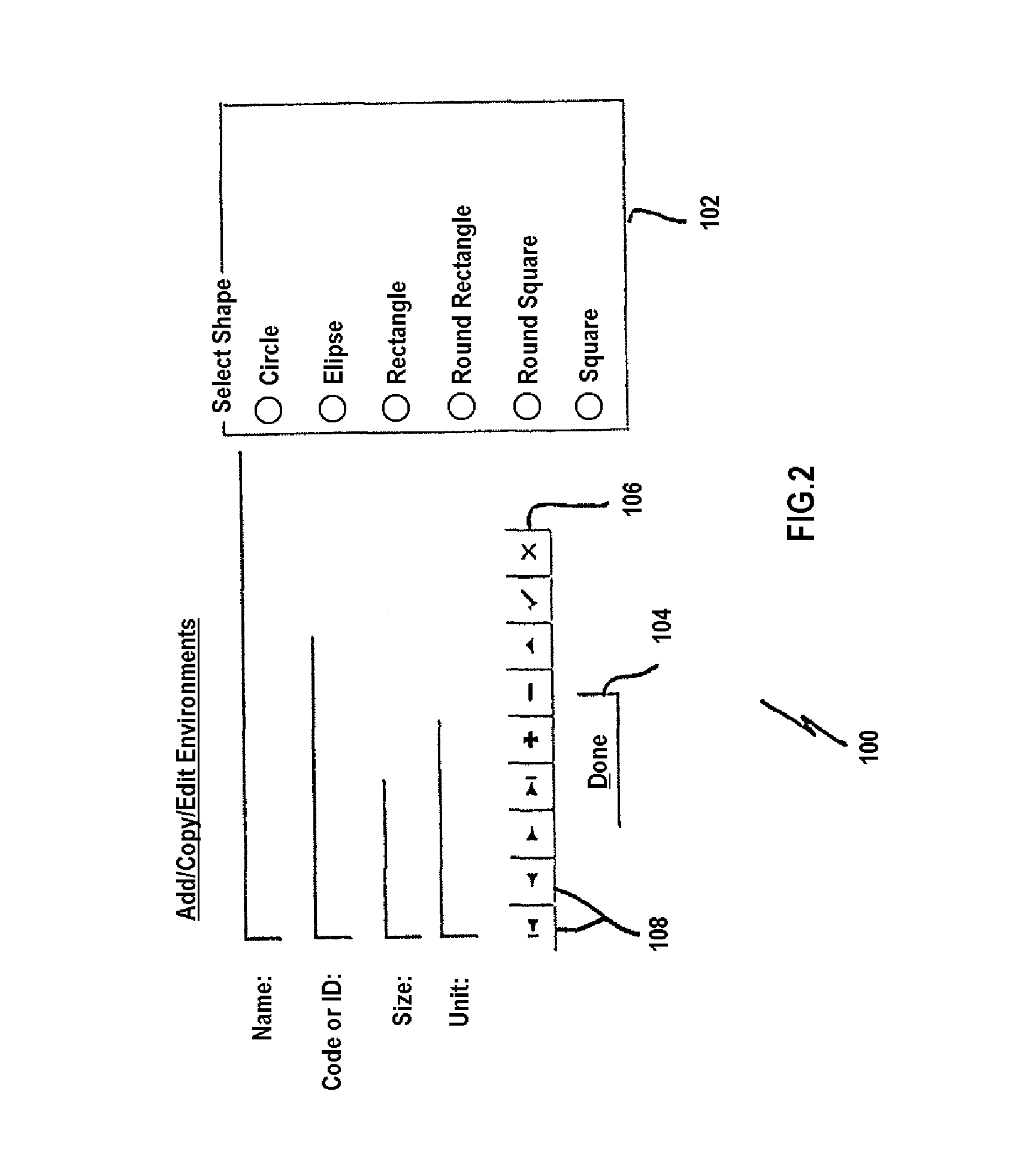

Graphical interface for configuration of industrial automation systems

ActiveCN107066252AExecution for user interfacesProgramme control in sequence/logic controllersGraphicsGraphical user interface

Exemplified herein is a graphical user interface for an industrial automation system that provides, in a single aggregated and eloquent view, a configuration workspace to discover and present configuration details of control components within an industrial automation system. These components may include industrial controllers, programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, programmable automation controllers (PACs), and the like, which have modules (as well as submodules) connected thereto. Among other things, the configuration workspace enables a holistic view of identified hardware configuration and the modular reconciliation and troubleshoot of the network device and module configurations.

Owner:INTELLIGENT PLATFORMS LLC

Modular programmable automation controller with multi-processor architecture

An apparatus and method for forming a control node in a programmable architecture, is disclosed. The node includes a plurality of user-programmable, microprocessor-based modules connected together. The modules are connected to create a parallel-processing environment with a selected functionality. Hot-swapping of the modules can be determined in the node. Power is distributed throughout the modules in the node. The modules may be automatically programmed to accommodate a target independent device.

Owner:FAIRMONT AUTOMATION

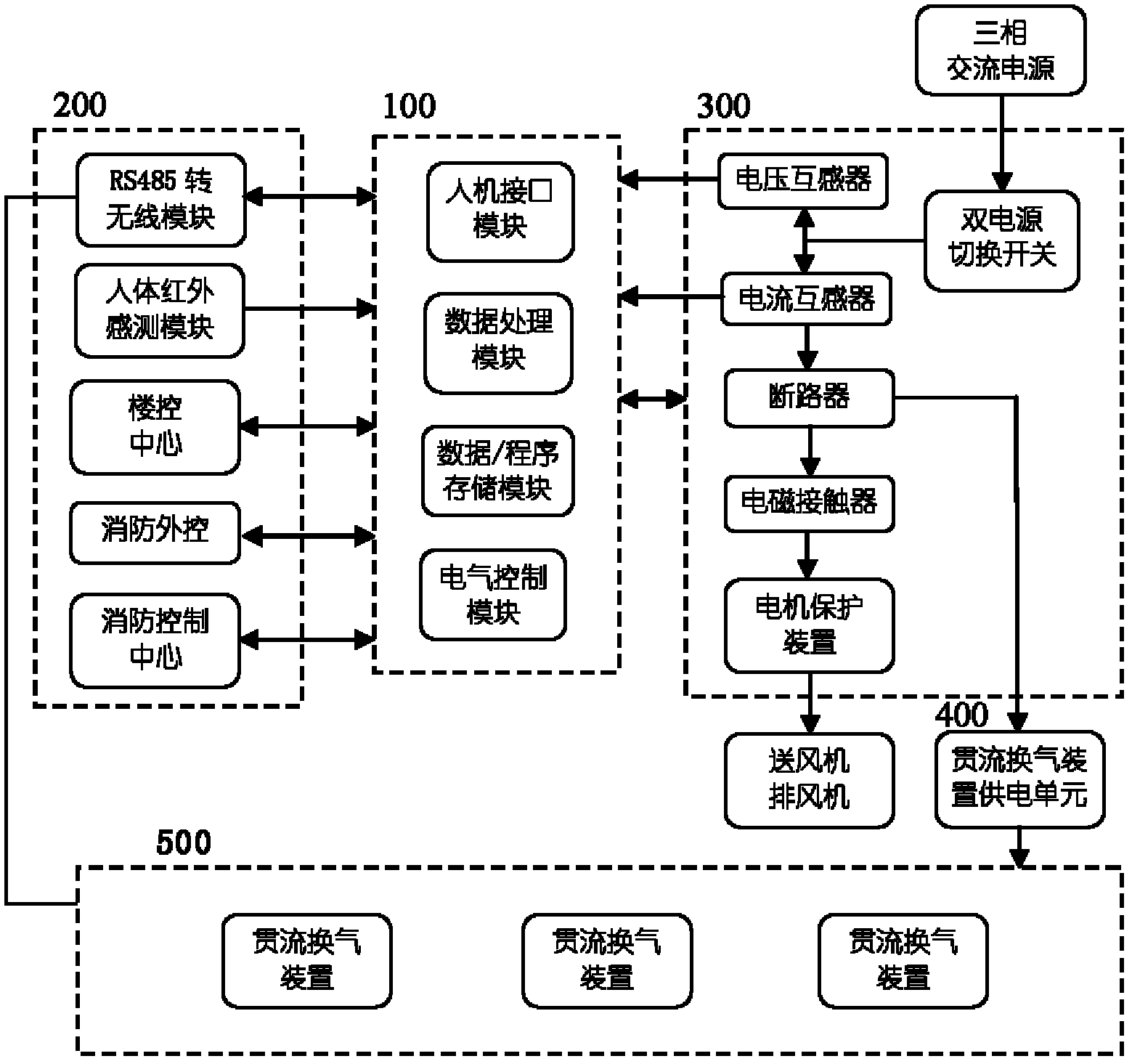

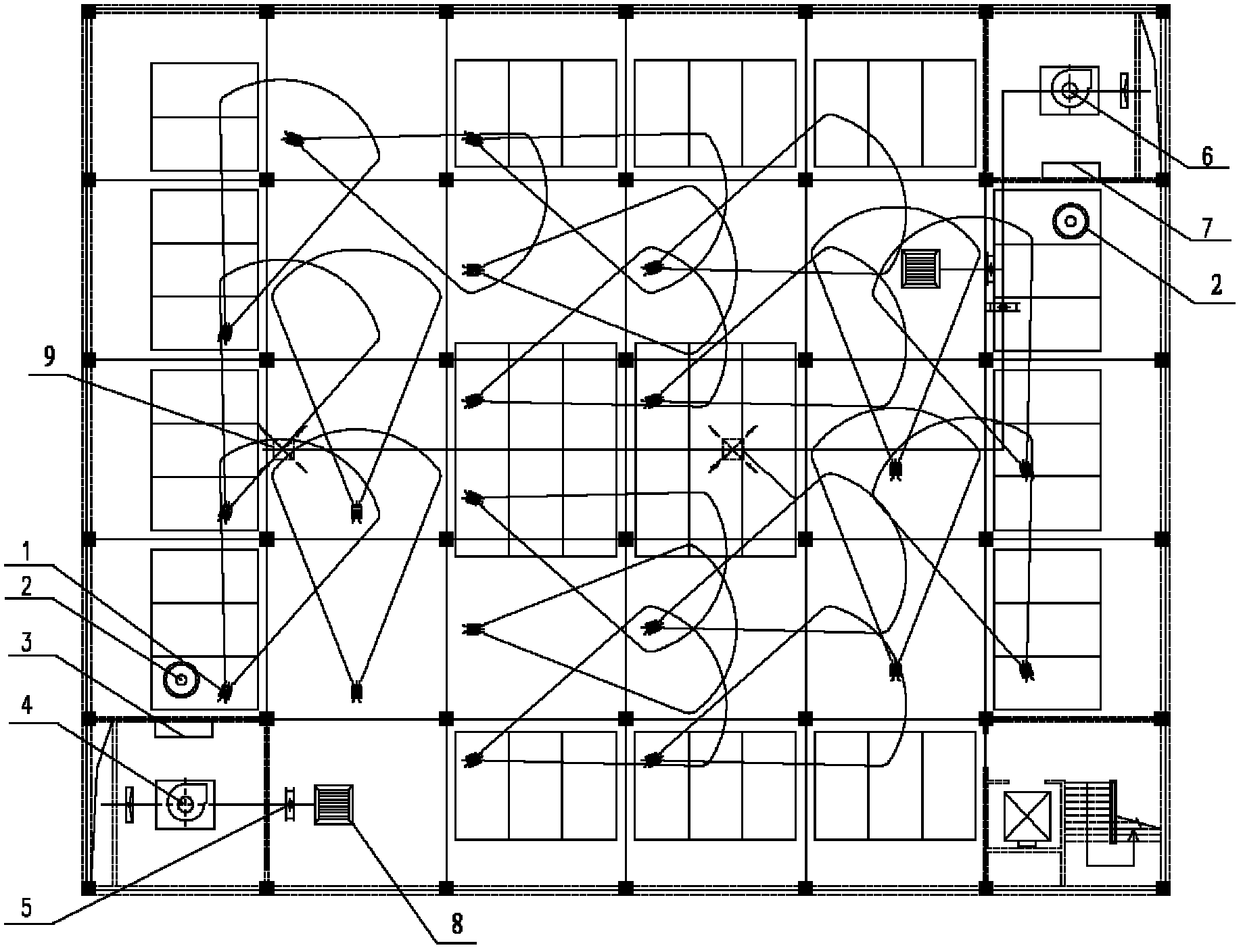

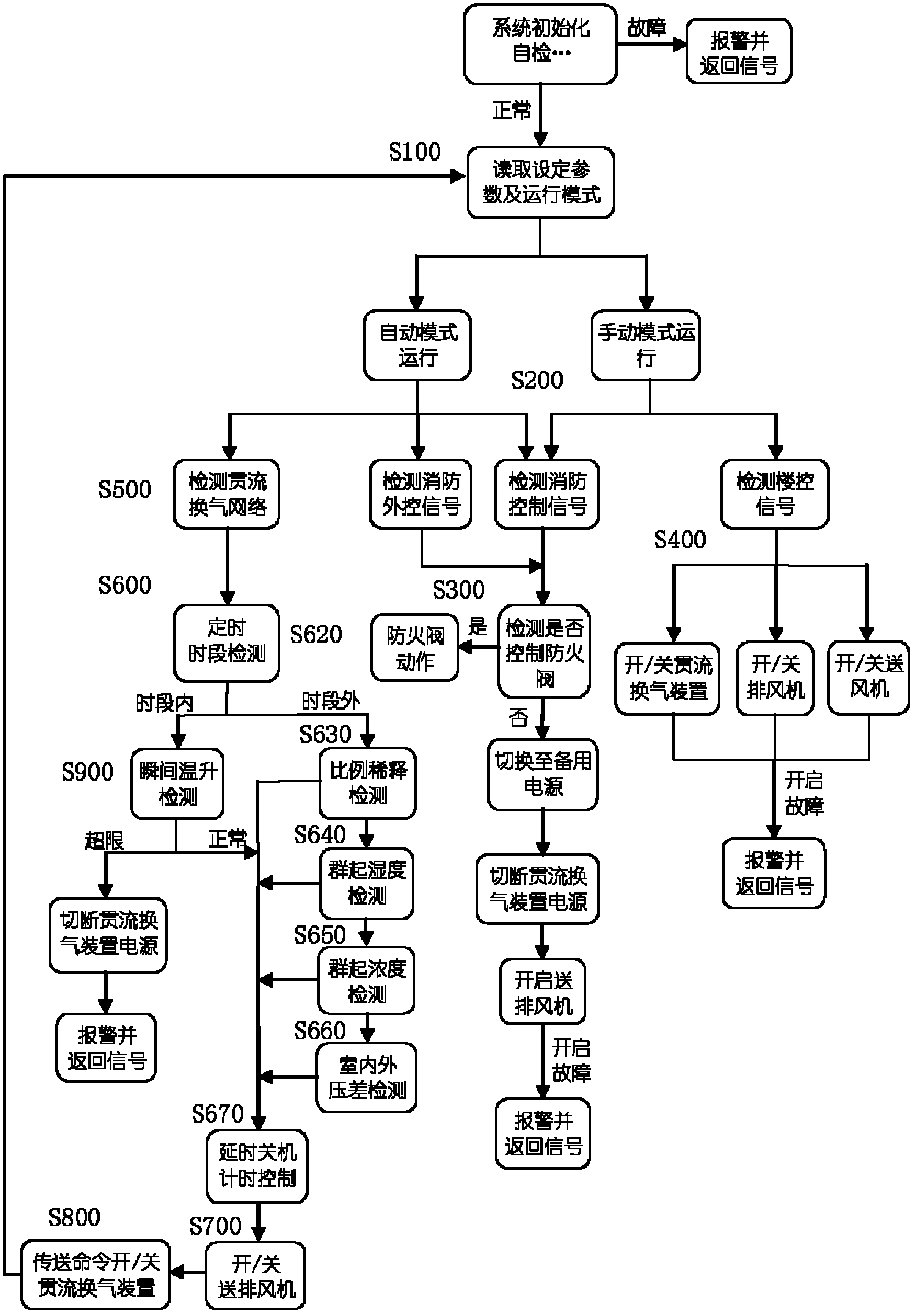

Intelligent through-flow air-interchange ventilation control system and control device and method thereof

InactiveCN102305455AReal-time monitoring of running statusGuarantee air qualitySpace heating and ventilation safety systemsLighting and heating apparatusStart timeProgrammable automation

The invention relates to an intelligent through-flow air-interchange and ventilation control system controlled by a ventilation system suitable for use in large premises. The intelligent through-flow air-interchange and ventilation control system comprises a programmable automation controller (PAC) control unit, a external interface unit, a power-supply control unit and a through-flow air-interchange device power-supply unit, wherein the PAC control unit is bidirectionally connected with a wireless communication module, a building control center, a fire-fighting external control center and a fire-fighting control center by the external interface unit, and is connected with a plurality of through-flow air interchange devices arranged in distribution by the wireless communication module in a bidirectional network mode; the PAC controller uses computer programs to realize air-interchange ventilation system control; and in combination with the wireless communication module network control, flexible programming can be carried out according to the configuration of site equipment, so as to achieve communication and remote centralized control between ventilation control devices in different ventilation subareas; and pollutant concentration in the environment of large-space buildings and the operation condition of air-interchange devices can be monitored in real time; and thus under the condition of ensuring air quality in the environment, starting time of air delivery and ventilation devices are reduced, thereby achieving the effects of environment protection and energy conservation.

Owner:上海风翼空调设备有限公司

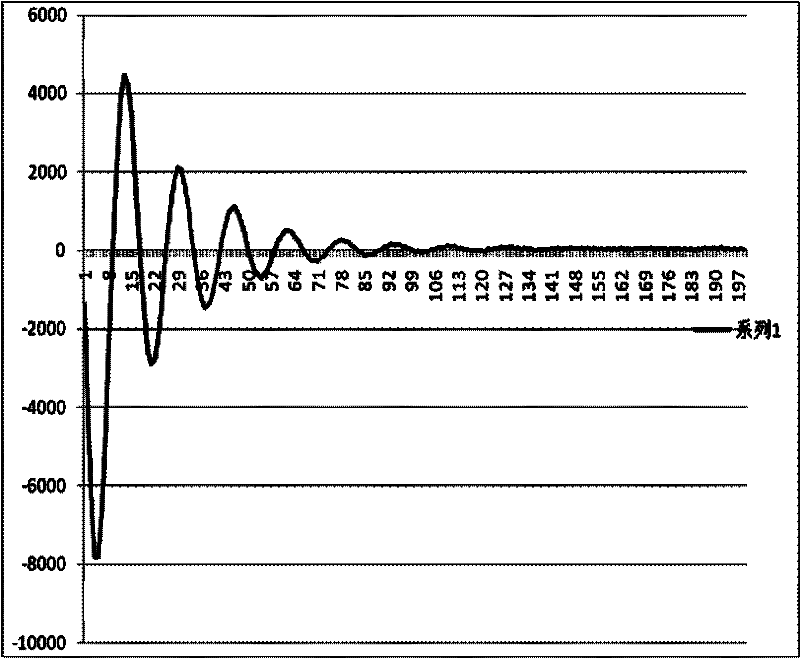

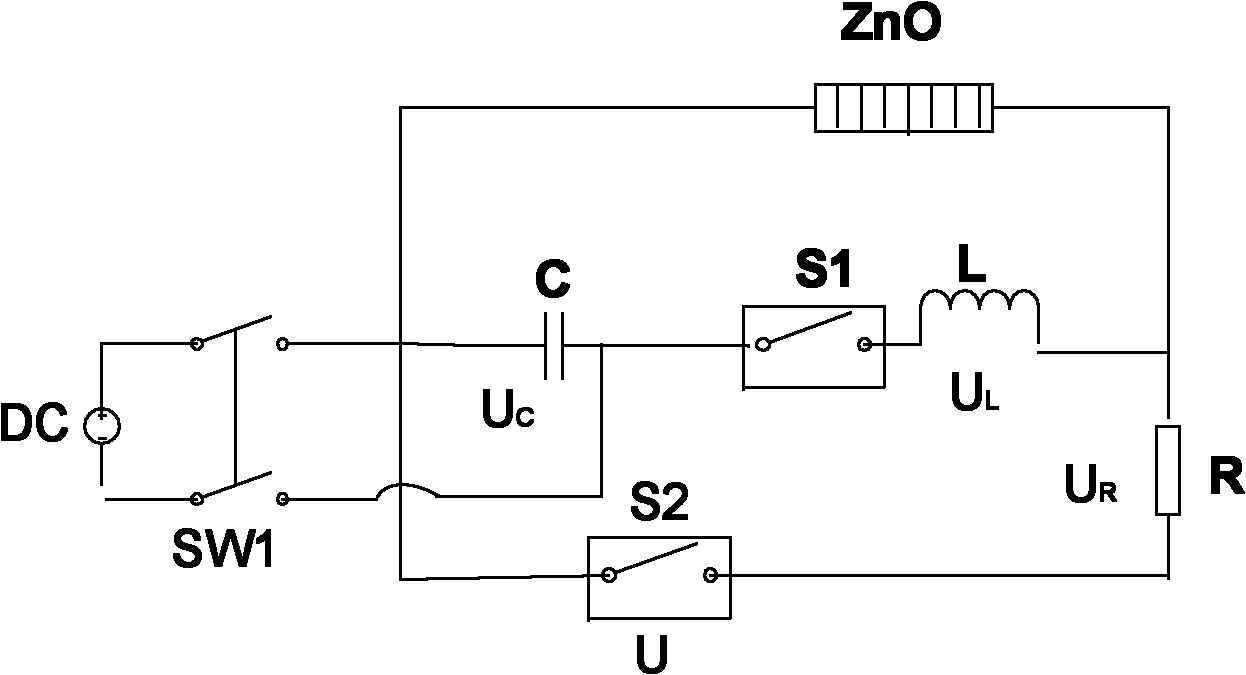

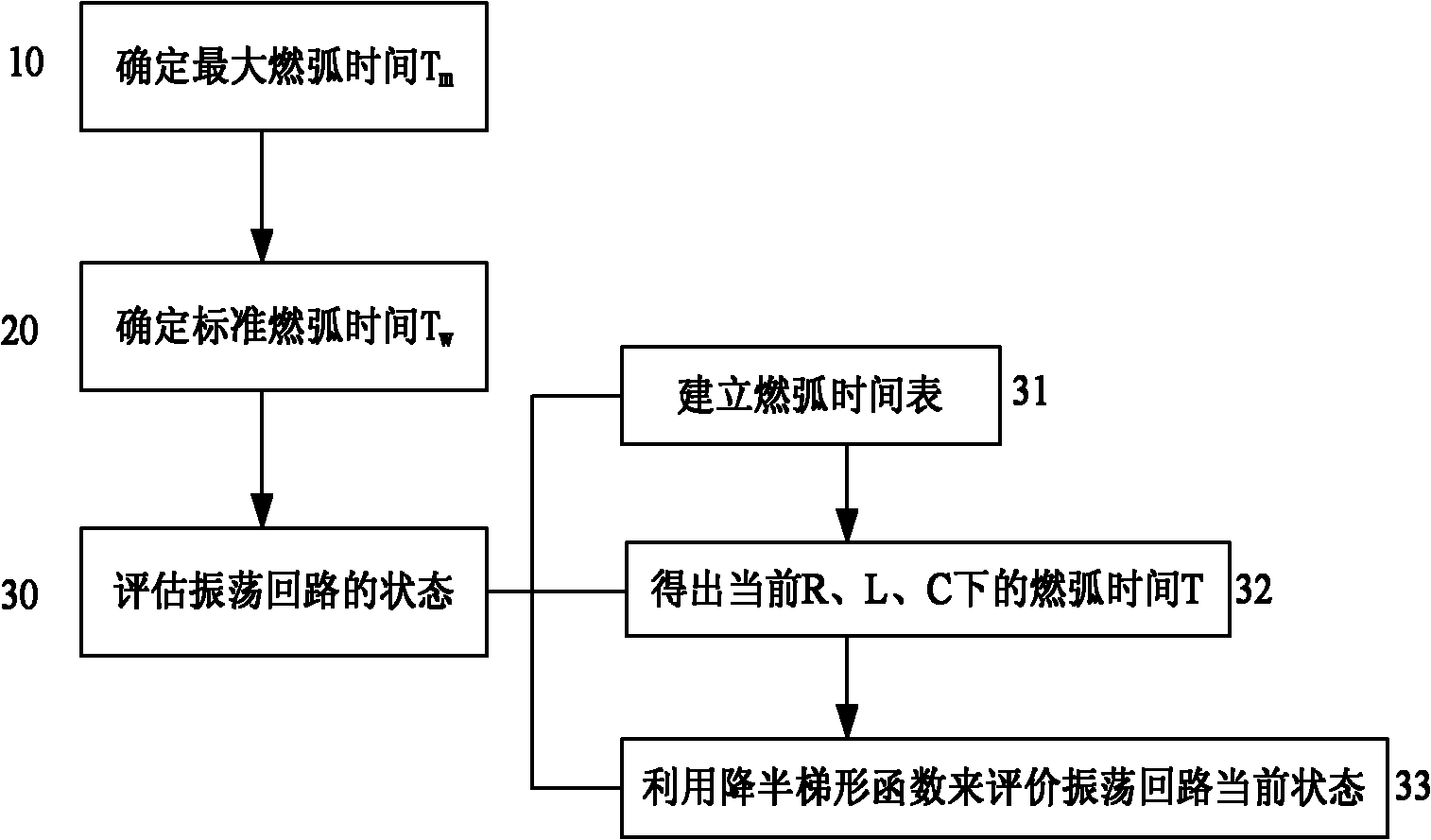

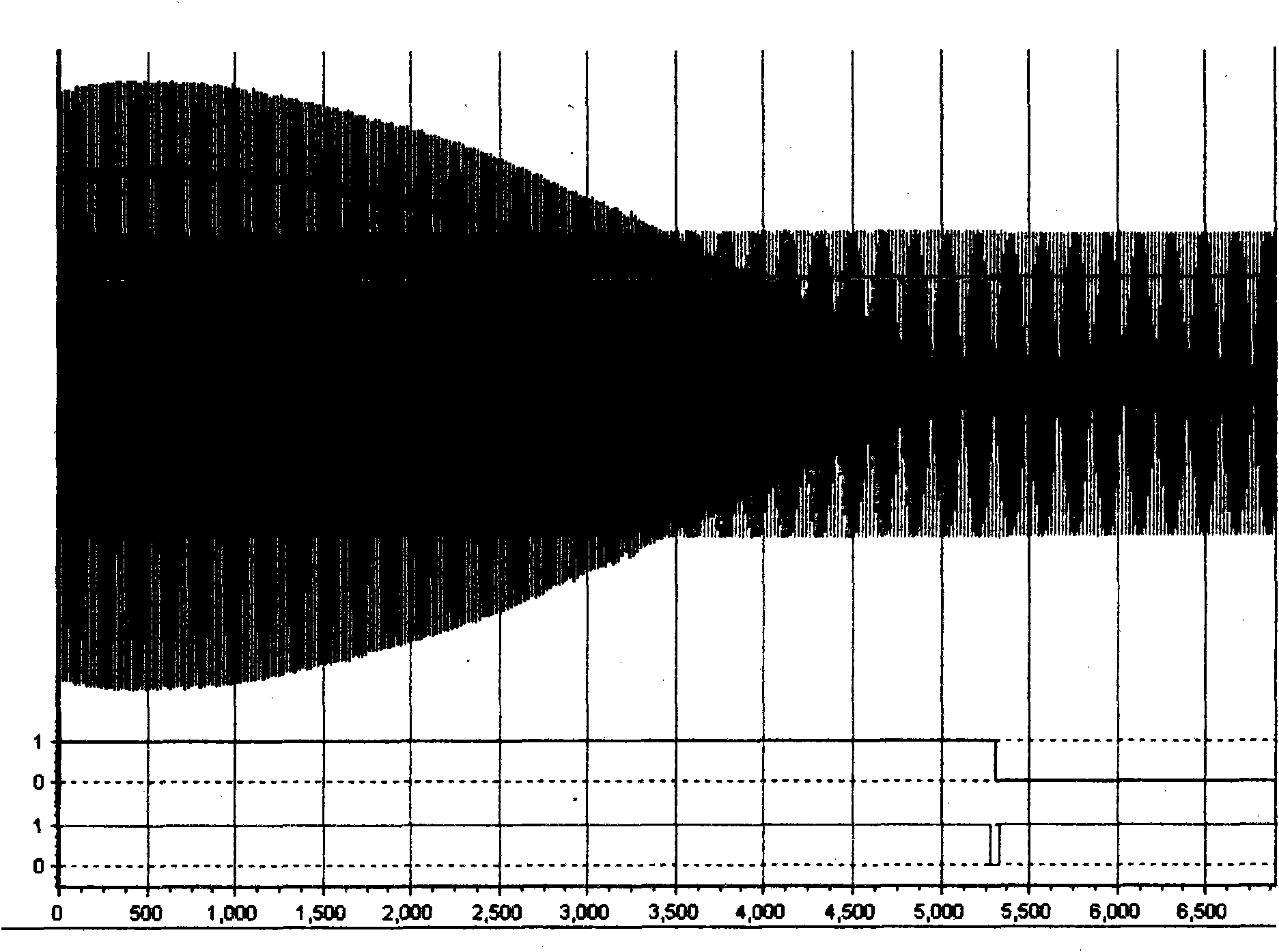

System and method for evaluating status of oscillation circuit of active high-voltage direct-current switch

ActiveCN102156260AGuaranteed uptimeStable current waveformCircuit interrupters testingGeneral Packet Radio ServiceWireless transmission

The invention discloses a system and a method for evaluating a status of an oscillation circuit of an active high-voltage direct-current switch, and relates to a technology for evaluating the status of the oscillation circuit of the high-voltage direct-current switch. In the method, the current of the oscillation circuit is acquired by a programmable automation controller (PAC) and a hall current sensor, and the acquired current signal is transmitted to a background personal computer (PC) via a general packet radio service (GPRS) wireless transmission module, so on-line detection on the current of the oscillation circuit of the high-voltage direct-current switch is realized; and the status of the oscillation circuit is evaluated by programming by taking the background PC as a working platform. The method comprises the following steps of: (1) determining the maximum arc time Tm of the oscillation circuit; (2) determining standard arc time Tw of the oscillation circuit; and (3) evaluating the status of the oscillation circuit. By the invention, the status of the oscillation circuit of the direct-current switch can be evaluated at any time; the waveform of the current generated by the oscillation circuit is kept stable; and the long-term reliable operation of a direct-current power transmission system and the safety and stability of the overall system are guaranteed.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +1

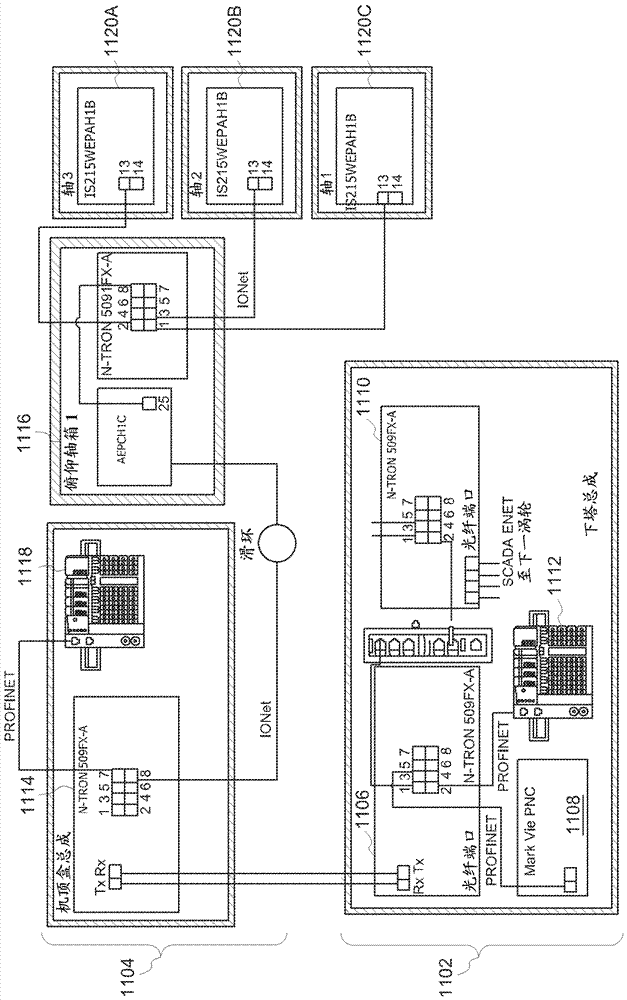

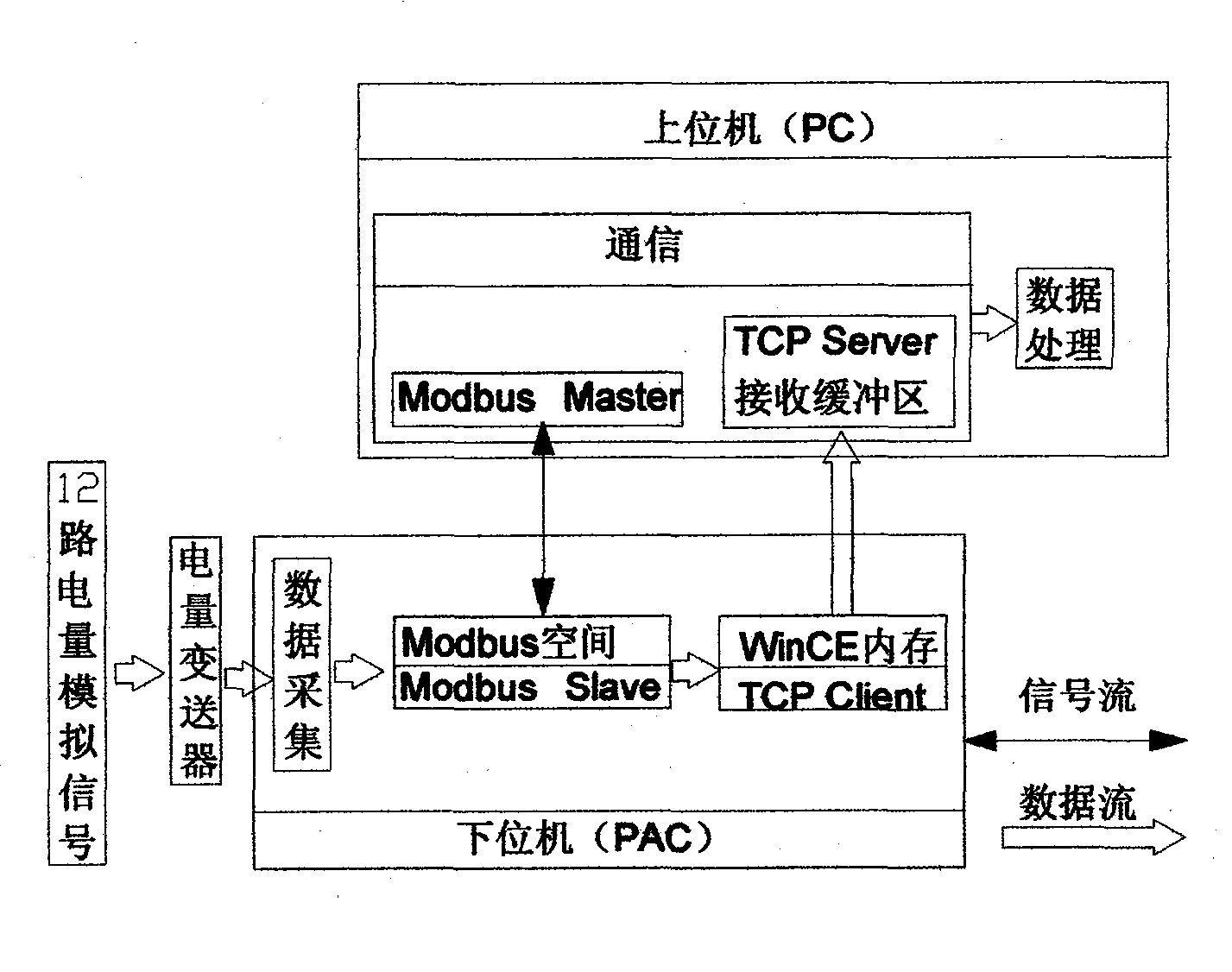

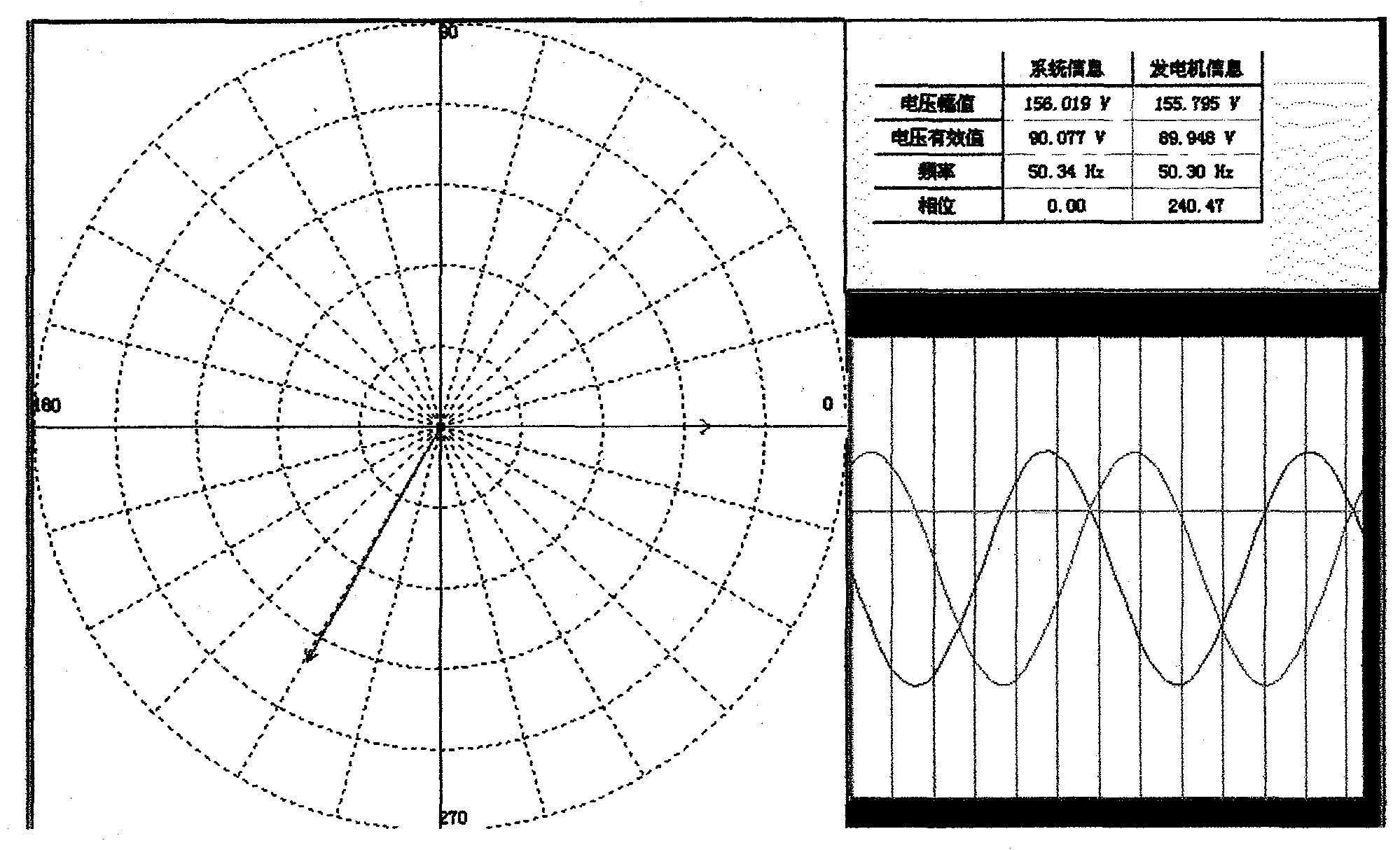

Generator contemporary process monitoring and analyzing system

ActiveCN101876690AEasy to useSupport playbackDynamo-electric machine testingData synchronizationField experiment

The invention relates to a generator contemporary process monitoring and analyzing system which comprises an electric quantity collecting and uploading module, a data calculating and analyzing module and a result output module. In the system, a PAC (Programmable Automation Controller) is used as a lower computer, and the storage and the real-time transmission of mass data of 12 channels are realized by utilizing the characteristic of multiple CPUs of the PAC. A concrete method for utilizing the PAC of the system comprises the following steps of: cutting continuously collected data into small pieces by utilizing double systems of the PAC; and realizing real-time uploading through a TCP / IP (Transmission Control Protocol / Internet Protocol) in an interval between two data samplings of a sampling module so that an upper computer can receive data from the lower computer in the process of a field experiment for analyzing. The system can realize data synchronous uploading, supports the recovery of a contemporary process and has the function of automatic analysis on the contemporary process of the generator.

Owner:CHANGSHA VICTORY ELECTRICITY TECH

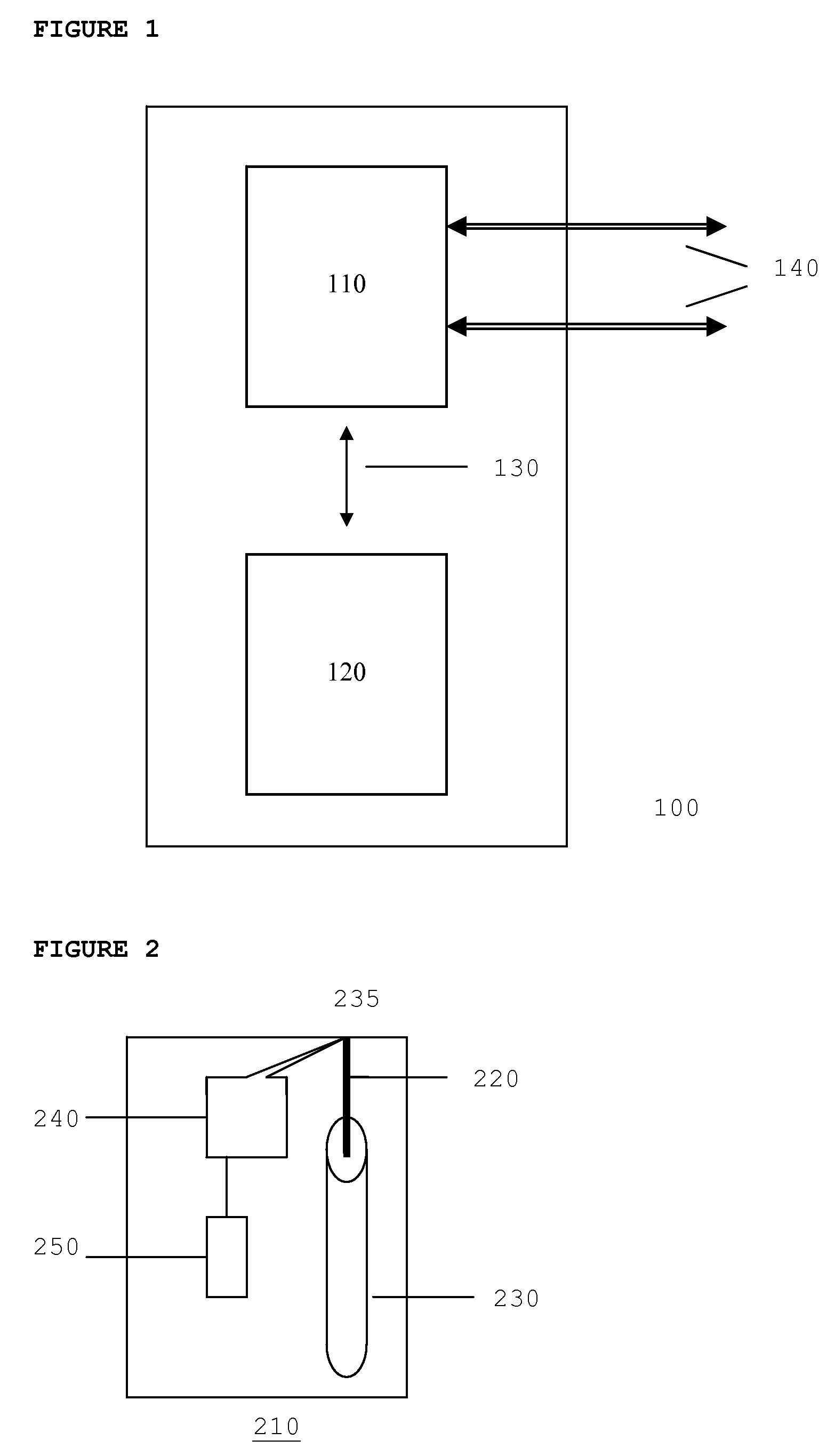

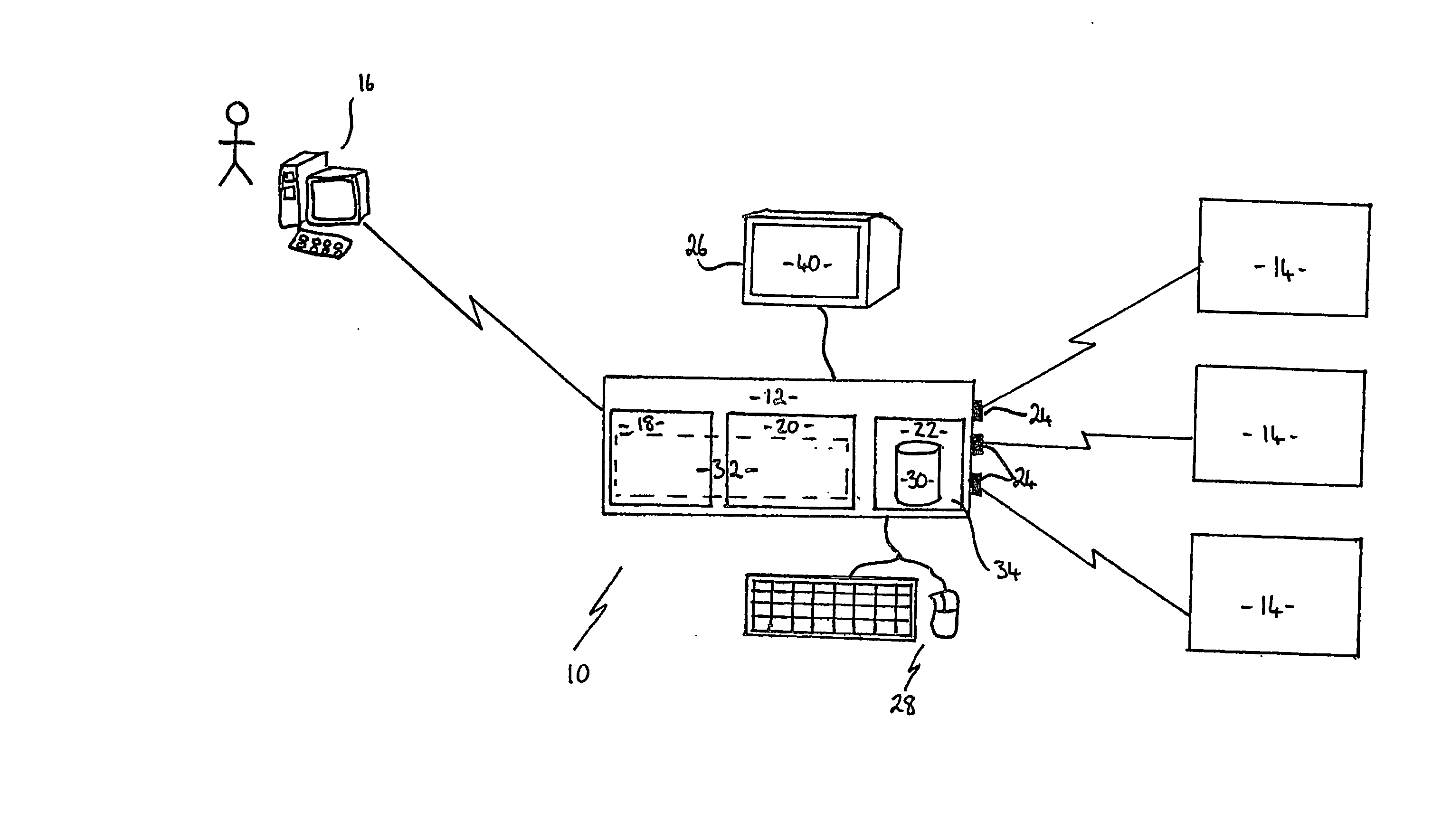

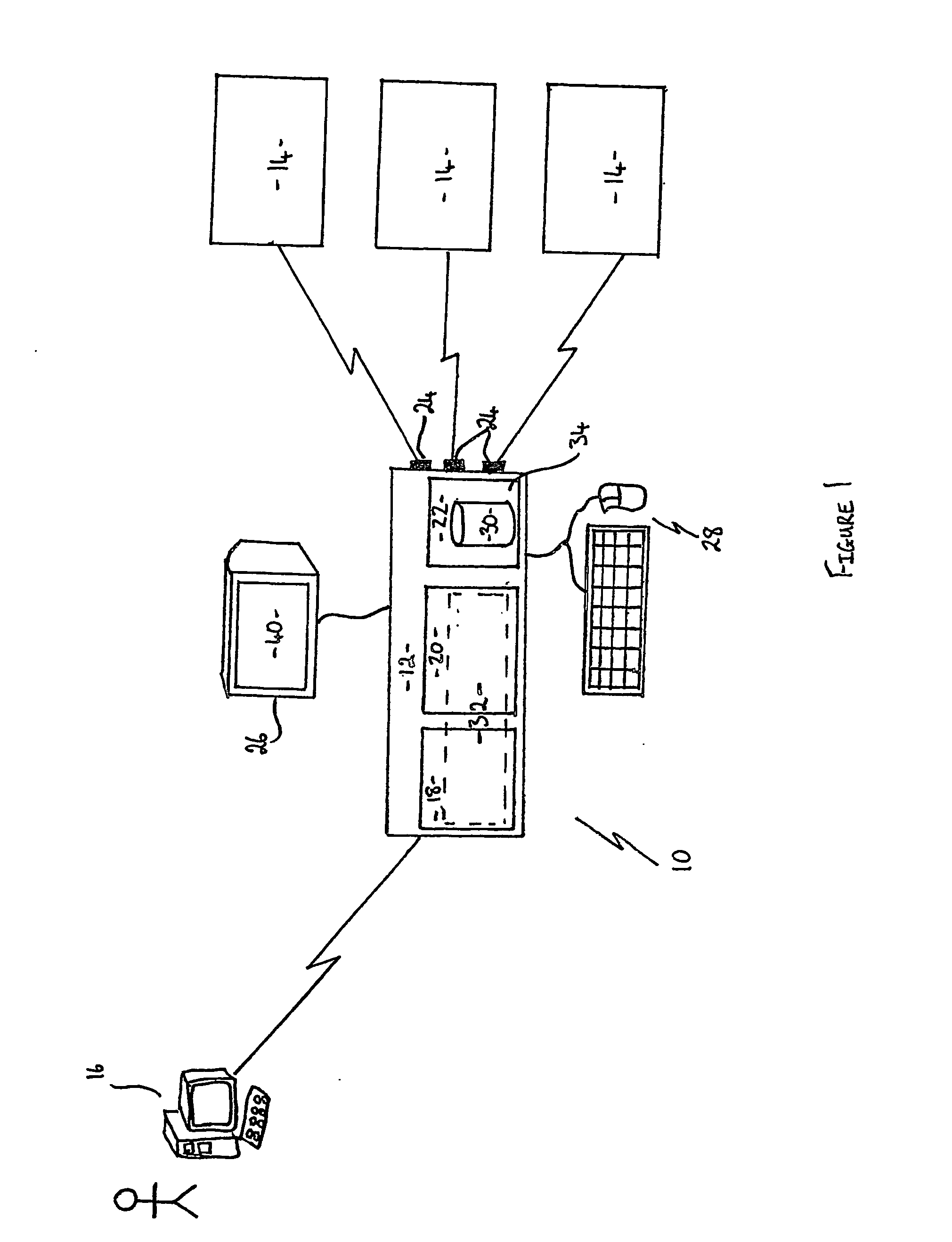

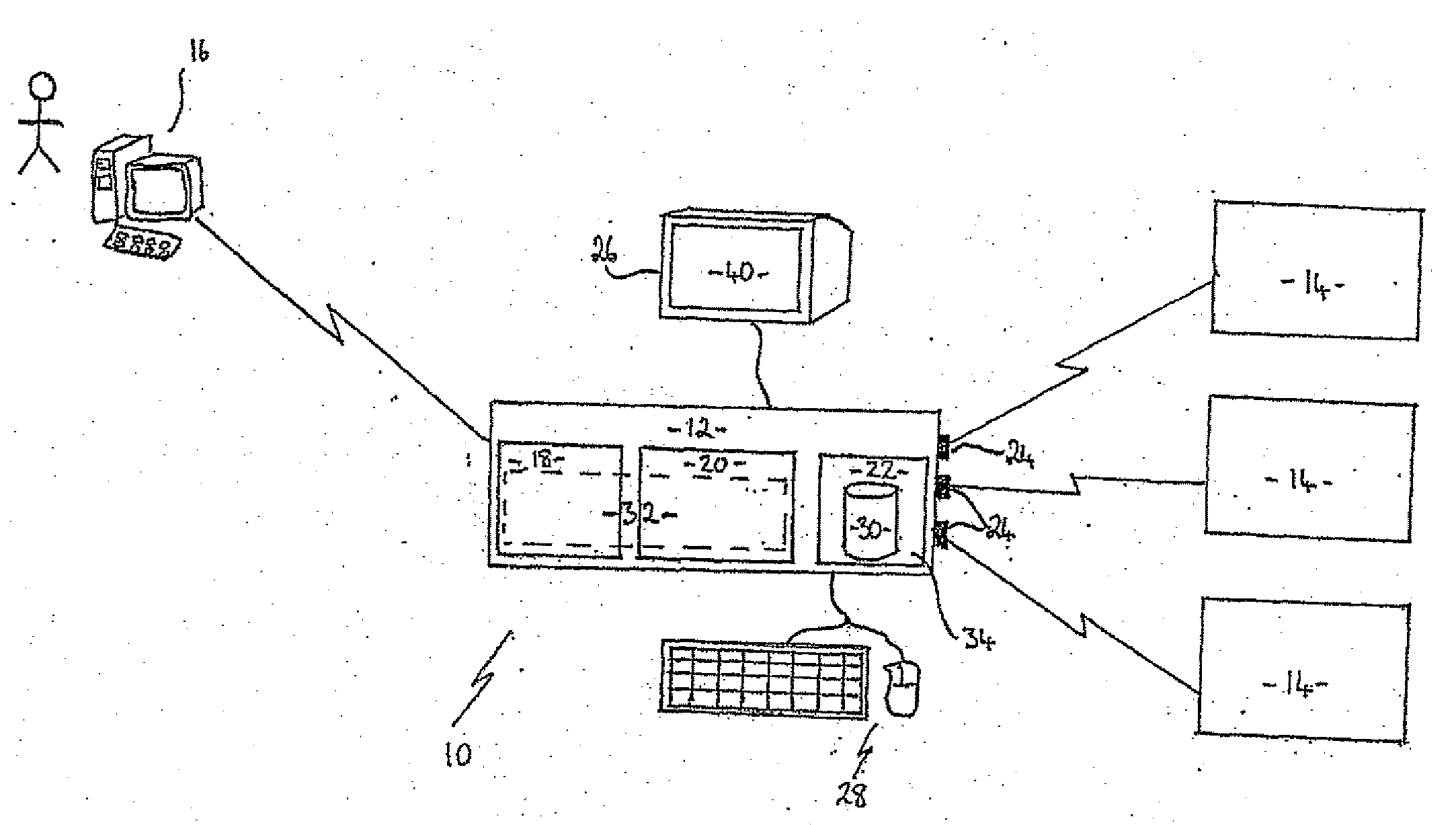

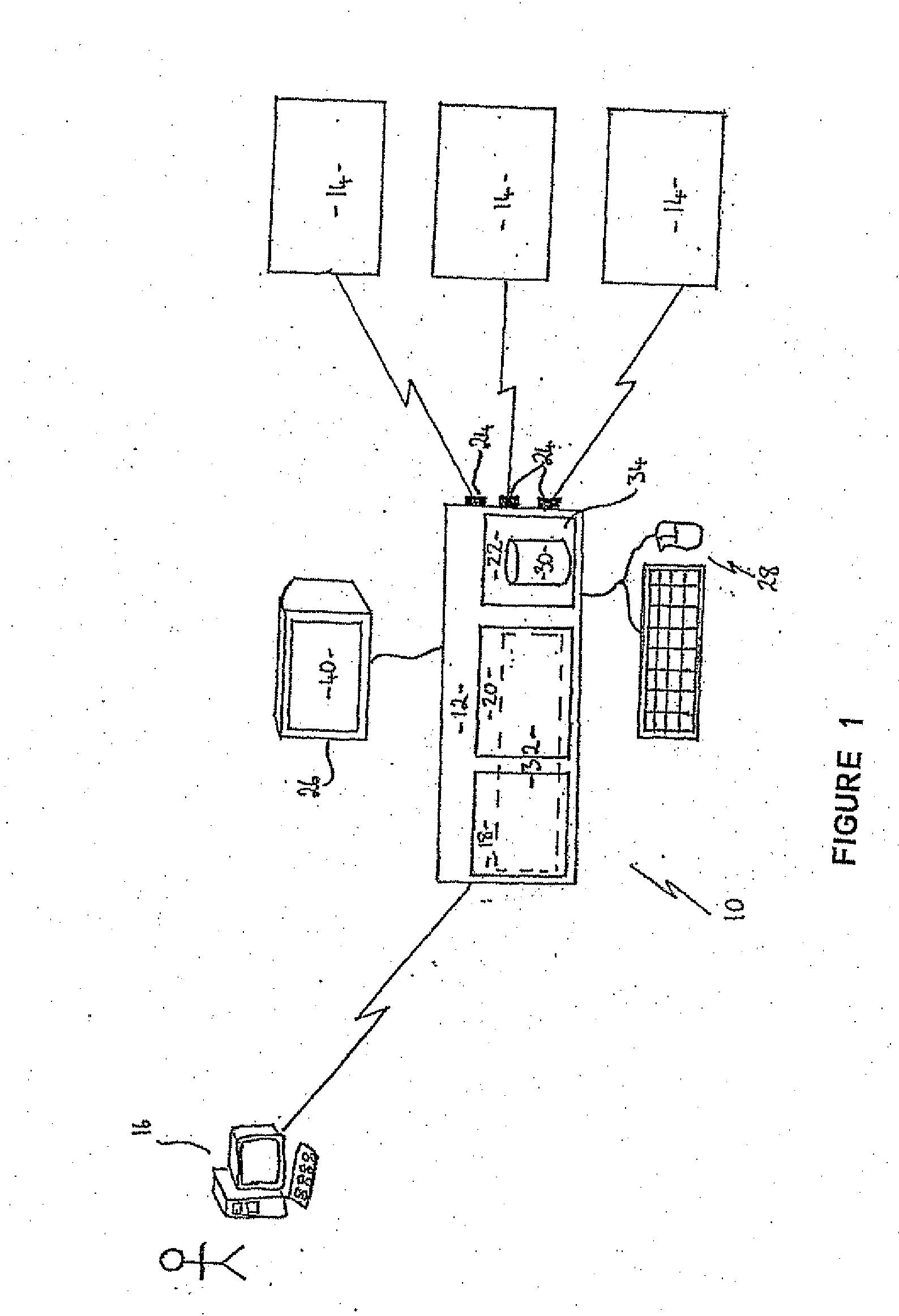

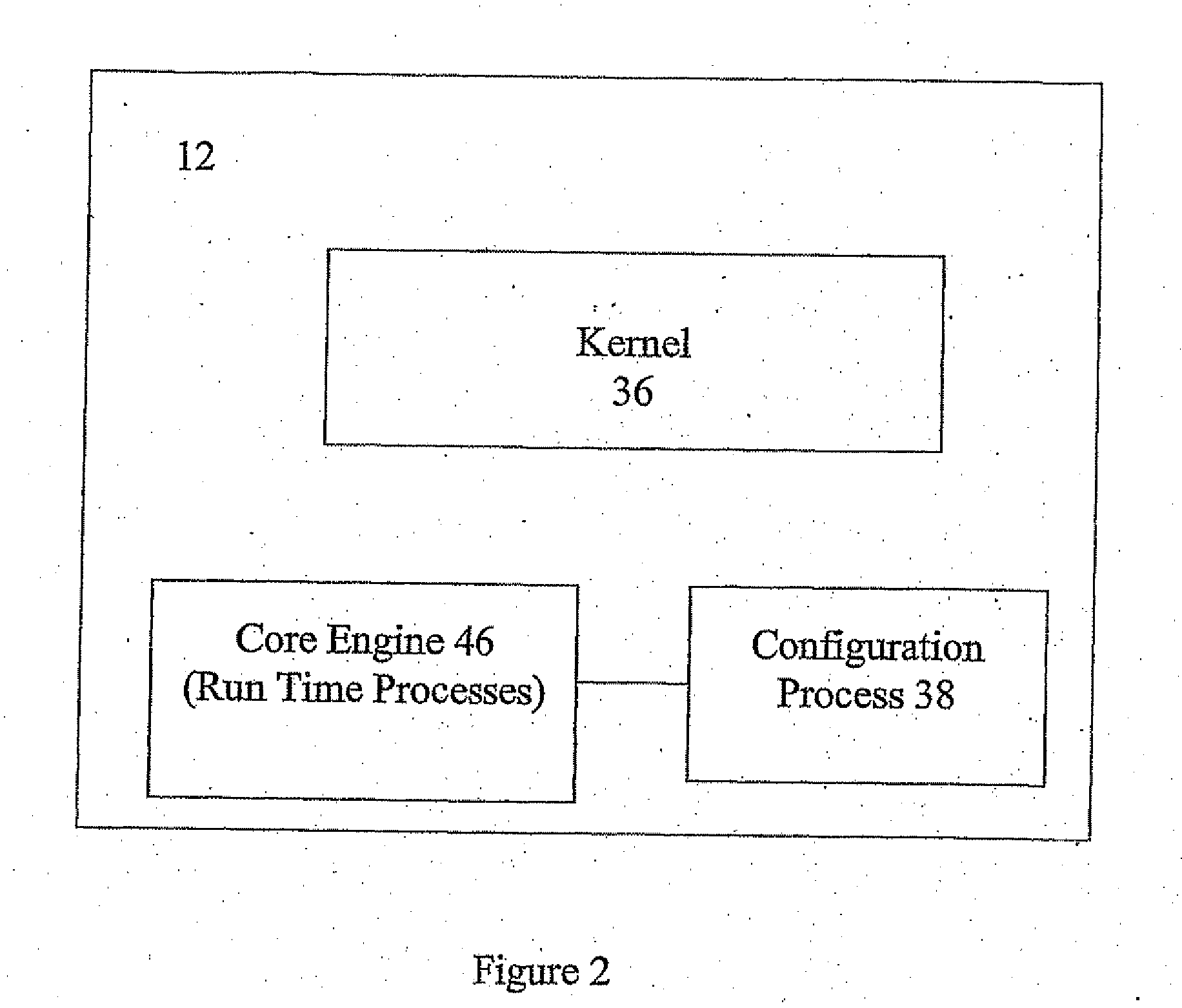

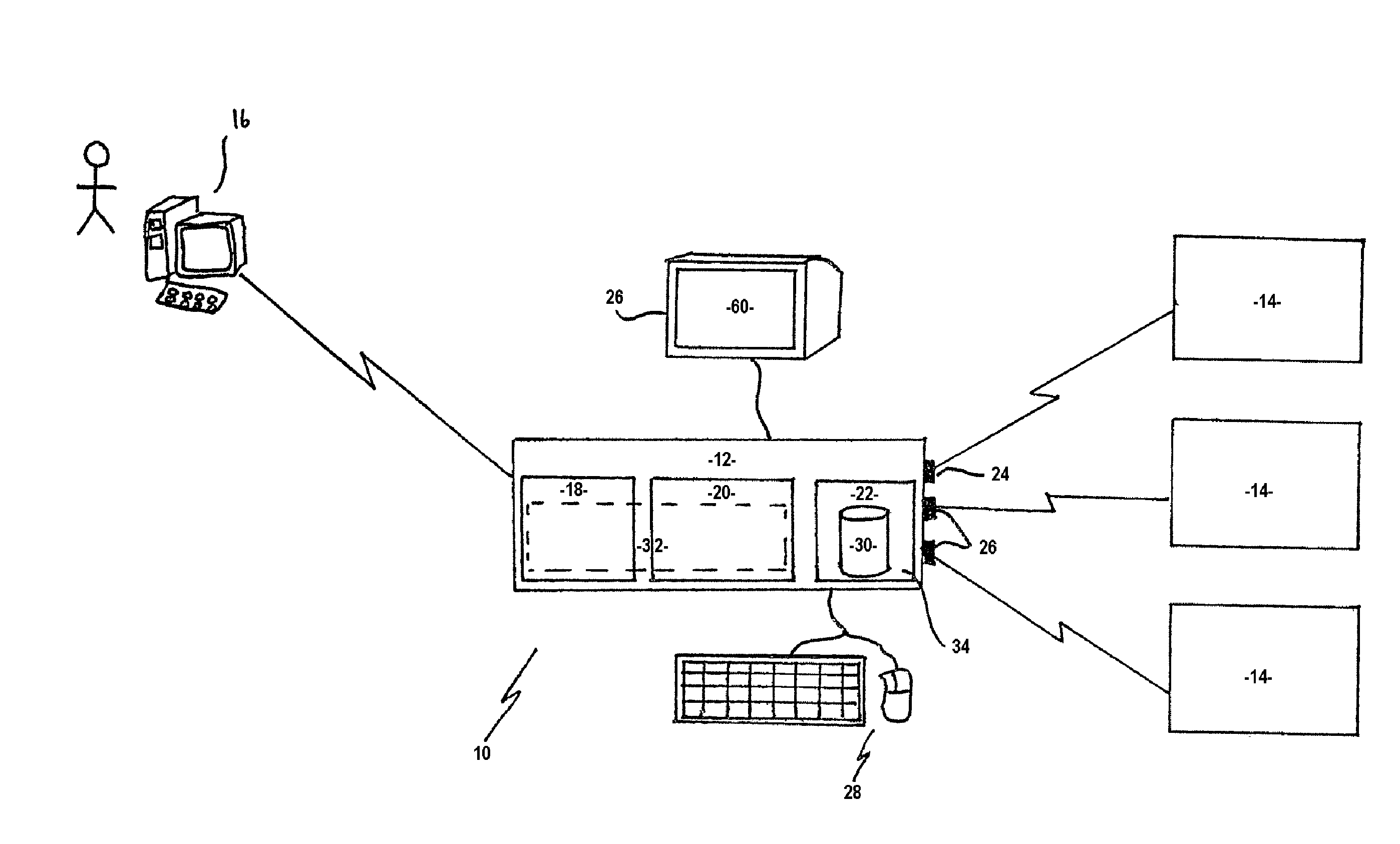

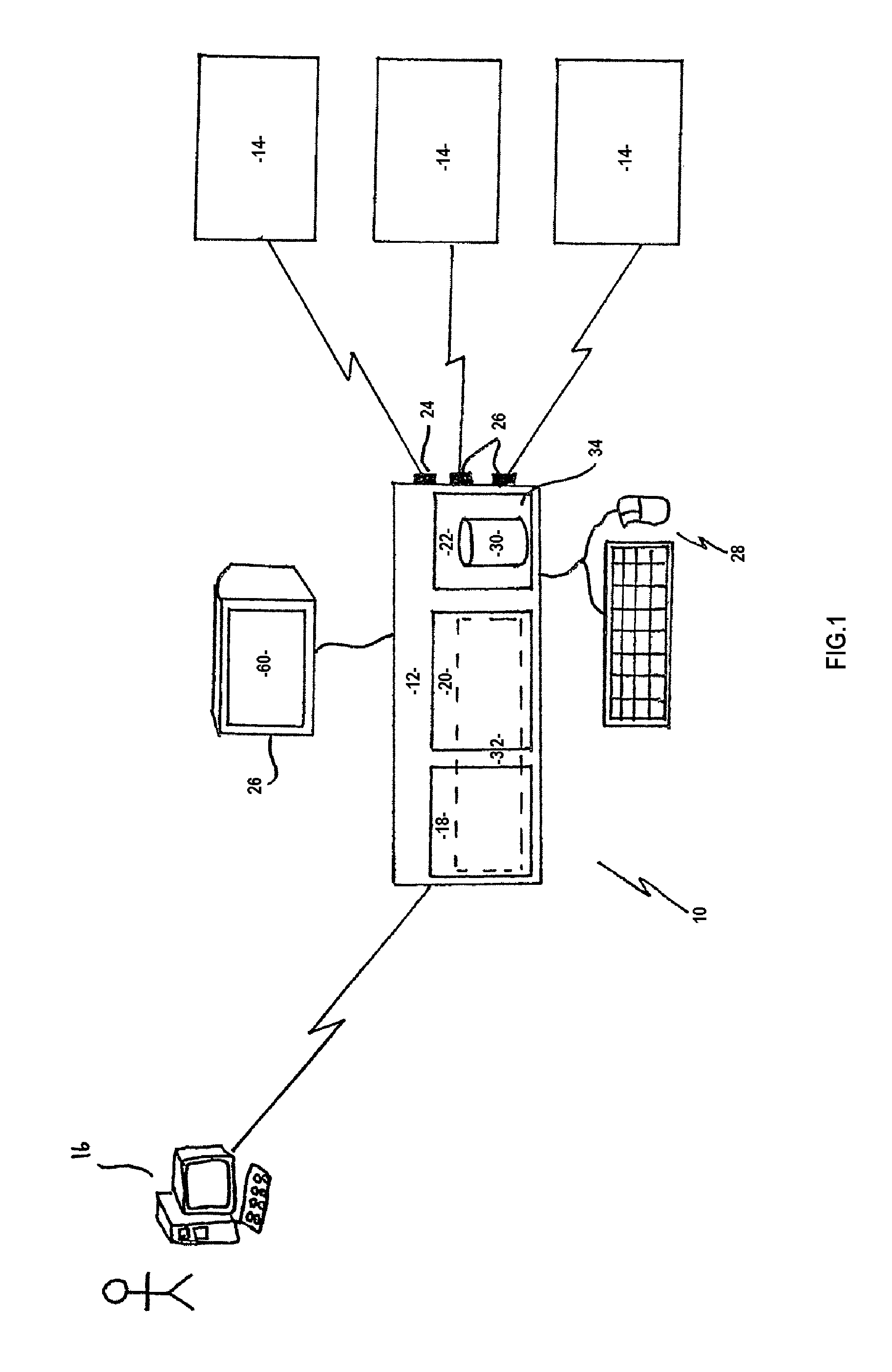

Process Control System and Method for Operating a Process Control System

InactiveUS20090018675A1Small operationLow costProgramme controlComputer controlOperational systemProgrammable automation

A process control system comprising: a programmable automation controller (“PAC”) (12); and at least one process control peripheral device (14). The peripheral devices are controlled by the PAC depending upon user-configured settings. The PAC uses an operating system which comprises a kernel, a configuration process and run-time processes. The run-time processes comprises a number of sub-processes that allow the PAC to monitor and log the peripheral devices and / or environment and control the peripheral devices in accordance with the configurations and any changes to the environment in which the peripheral devices are located.

Owner:EMBEDDED TECH

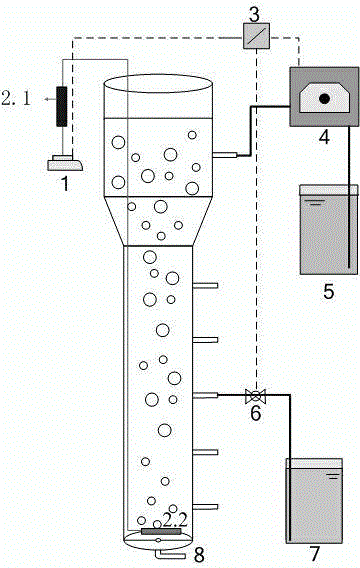

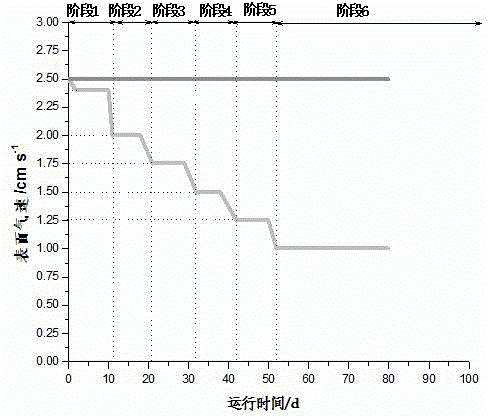

Energy-saving and consumption-reduction stable operation device and method for enhancing aerobic granule sludge

InactiveCN104803478AImprove removal efficiencyOvercoming VulnerabilityEnergy based wastewater treatmentSustainable biological treatmentChemical oxygen demandMixed liquor suspended solids

The invention discloses an energy-saving and consumption-reduction stable operation device and a method for enhancing aerobic granule sludge. The device comprises a water inlet unit, a reactor main body, an aeration unit, a water outlet unit and a time control unit, wherein the time control unit is a programmable automatic time controller, and comprises a time control switch and a liquid level meter probe; the time control switch controls a cyclic process of reactor operation; and water inflow is controlled by the liquid level meter probe via electrical signal conduction. An operation cycle is divided into water inlet, standing, aeration, settling and water outlet stages; sludge is inoculated; MLSS (mixed liquor suspended solid) is inoculated as 4-6g / L; an inlet water matrix is town sewage; COD (chemical oxygen demand) concentration of inlet water is 300-800mg / L; a height-diameter ratio of 4-8 and a drainage ratio of 30-70% are adopted; the operation cycle is 4-6h; the settling time is 5-15min; and the aeration time is 3-5h. According to the device and the method, the aerobic granule sludge which is large in granule size, high in settling velocity, stable in structure and rich in flora can be formed, and the problems of high aeration energy consumption, easy sludge bulking in an operation process, unstable long-time operation of a system and the like in the prior art are solved.

Owner:ZHEJIANG UNIV

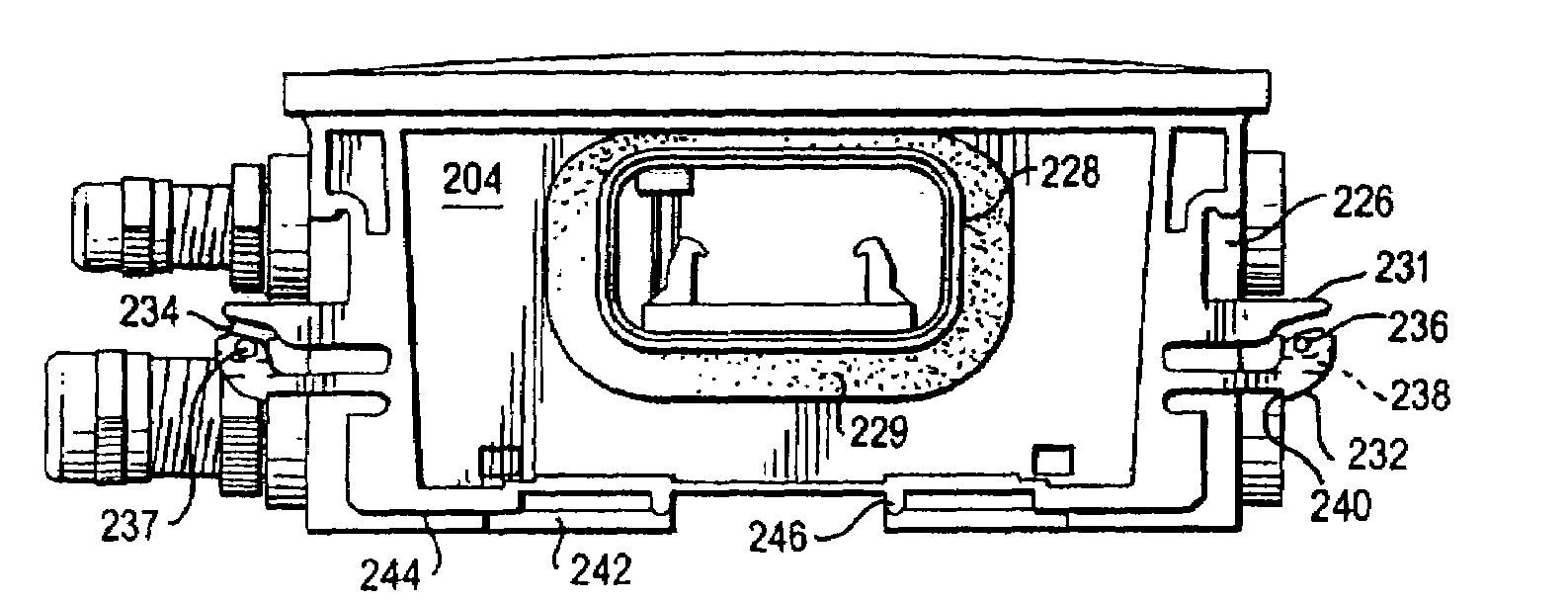

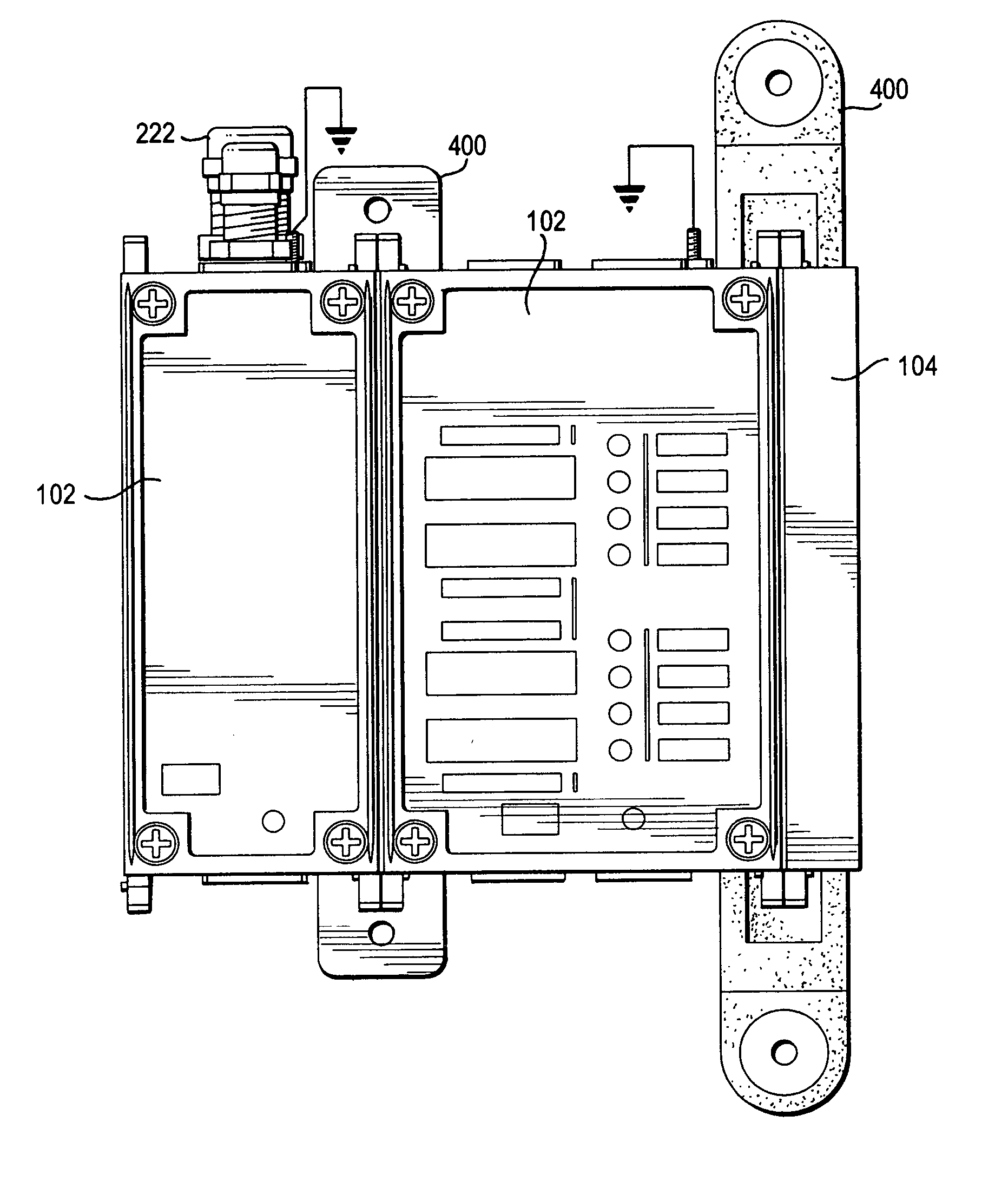

Programmable automation controller assembly

ActiveUS7476802B2Reduce disruptionMinimizes system downtimePLC for automation/industrial process controlInstallation of lighting conductorsProgrammable logic controllerProgrammable automation

A programmable logic controller or programmable automation controller assembly that can be used in harsh environments. A plurality of user-configurable housings are used to accommodate a customer's desired functionality design. A two-board design is featured to enable electronics in the controller assembly. The two-board design includes an active board that houses a majority of electrical components in the controller assembly, and a wiring hub that is used for wiring terminations. A mechanism is provided for a field-removable labeling system that withstands harsh environmental conditions.

Owner:FAIRMONT AUTOMATION

Process Control System and Method for Configuring a Process Control System

InactiveUS20110301721A1Electric controllersIgnition automatic controlProgrammable automationComputer science

A process control system includes a programmable automation controller and at least one process control peripheral, each process control peripheral in data and control communication with the programmable automation controller such that, upon configuration of the process control system, the programmable automation controller executes a single software program to assist a user to define prescribed information in respect of the process control peripheral, including configuration information, define trigger conditions, if any, associated with the process control peripheral, and define alarm conditions, if any, associated with the process control peripheral. The software program thereafter is operable to provide information in respect of the process control system to the user.

Owner:EMBEDDED TECH

Programmable automation controller assembly

ActiveUS20050248925A1Reduce disruptionMinimizes system downtimePLC for automation/industrial process controlInstallation of lighting conductorsProgrammable logic controllerProgrammable automation

A programmable logic controller or programmable automation controller assembly that can be used in harsh environments. A plurality of user-configurable housings are used to accommodate a customer's desired functionality design. A two-board design is featured to enable electronics in the controller assembly. The two-board design includes an active board that houses a majority of electrical components in the controller assembly, and a wiring hub that is used for wiring terminations. A mechanism is provided for a field-removable labeling system that withstands harsh environmental conditions.

Owner:FAIRMONT AUTOMATION

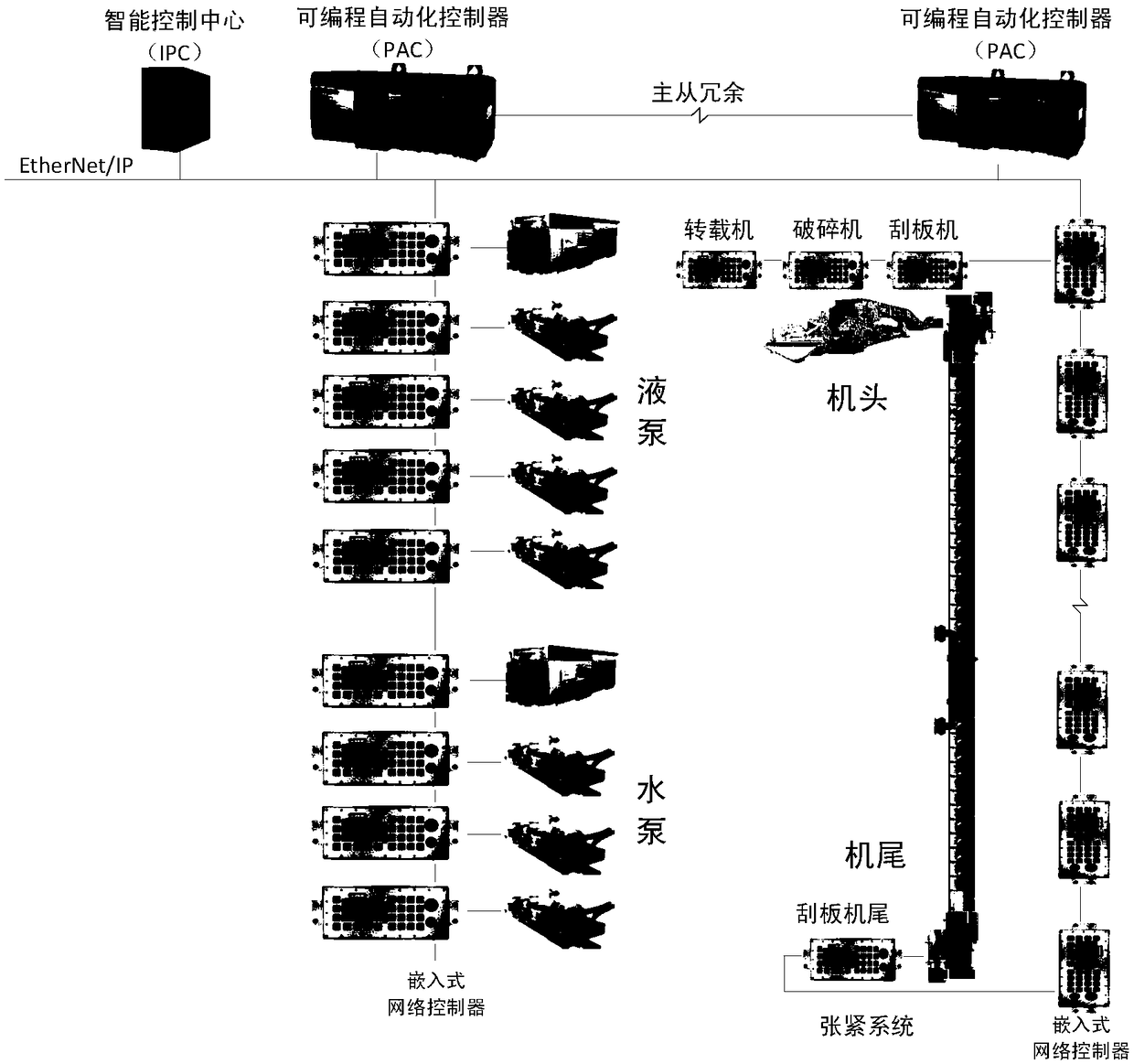

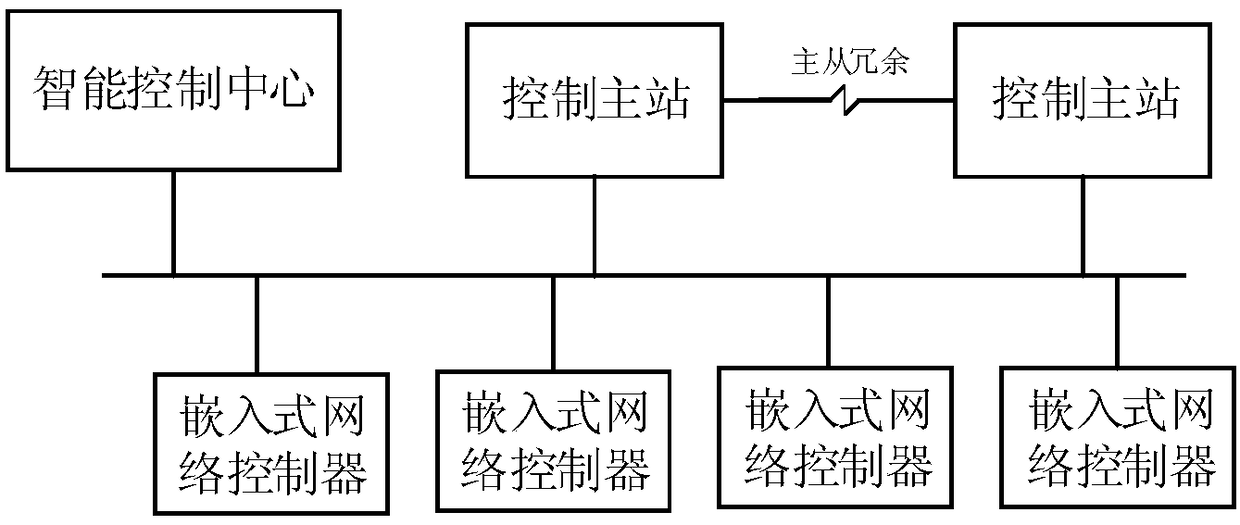

Automatic control system of fully mechanized mining face

InactiveCN108490897ASimplify the data collection processSimplify the control problemTotal factory controlProgramme total factory controlAutomatic controlPrimary station

The present invention provides an automatic control system of a fully mechanized mining face based on an Ethernet / IP industrial Ethernet protocol and by taking an IPC (Industrial Personal Computer) asan intelligent control center, PAC (Programmable Automation Controller) as a control main station and an embedded network controller as a substation. The intelligent control center achieves parameteroptimization of the control main station and regulates operation speeds and intelligent control of mining and transport branches of the working face; the control main station is high in timeliness and high in reliability, and can be configured to achieve full working face device automatic control; and the embedded network controller can achieve control of an emulsification pump, an atomizing pump, a filtration station and three transportation machines and can uniformly receive dispatching of the control main station.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

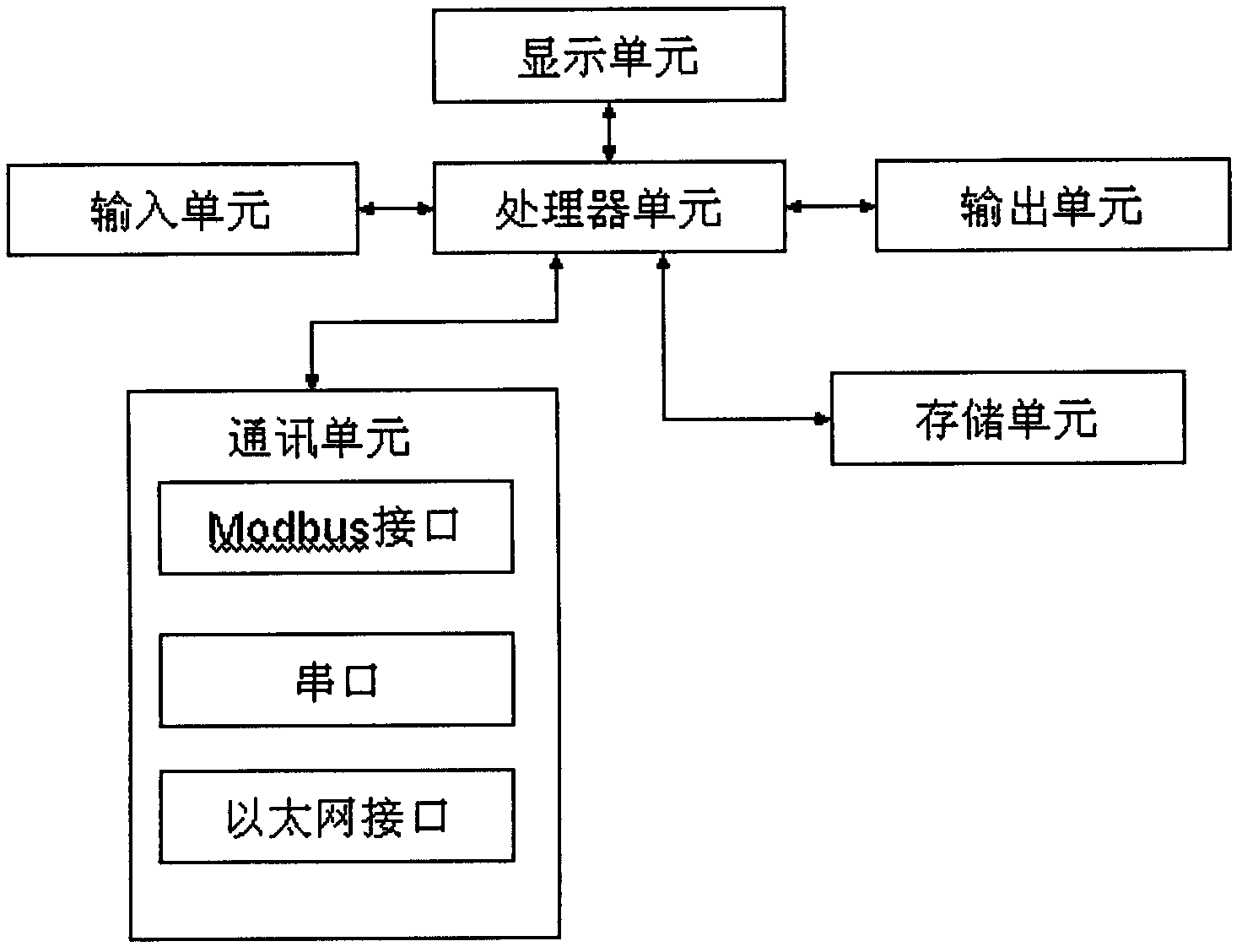

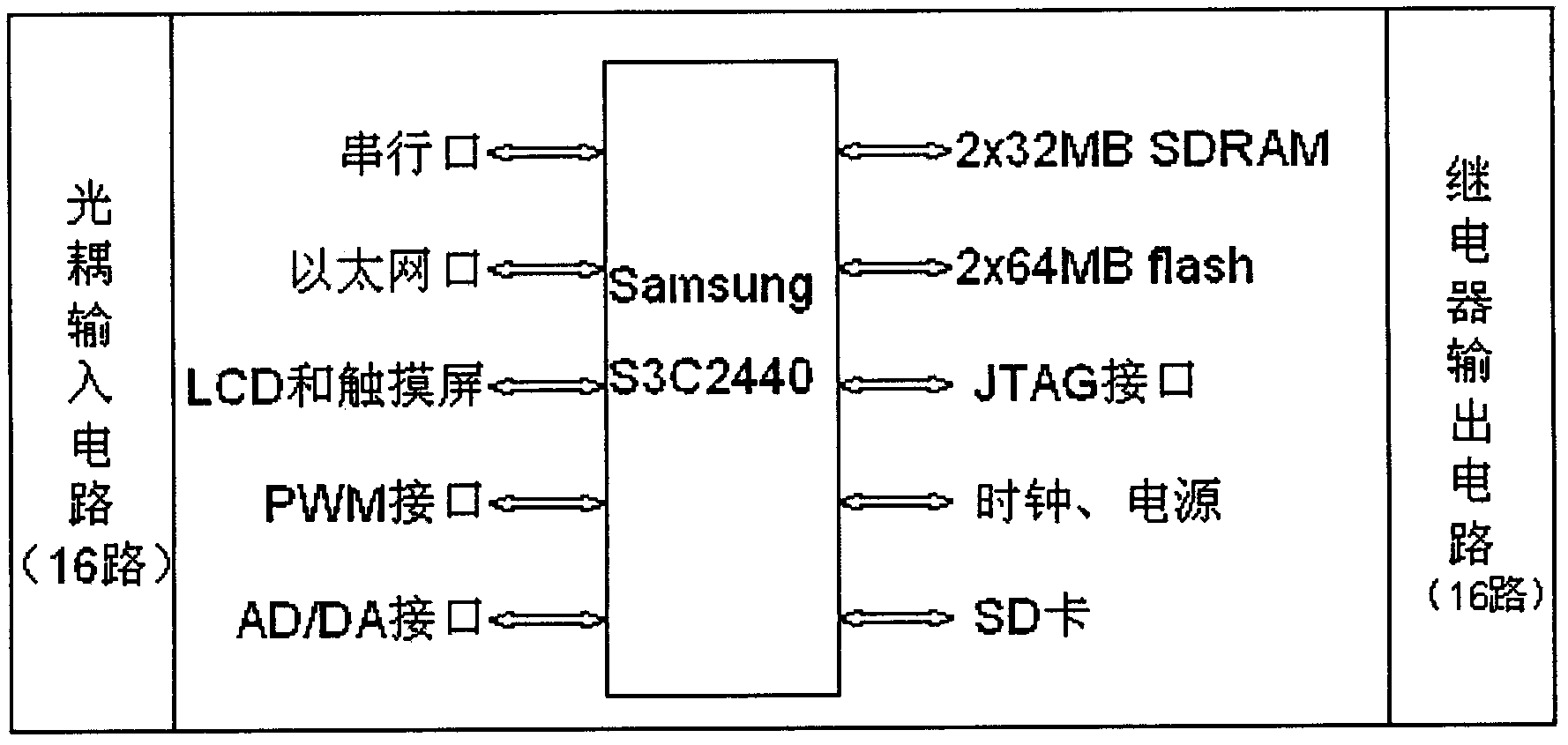

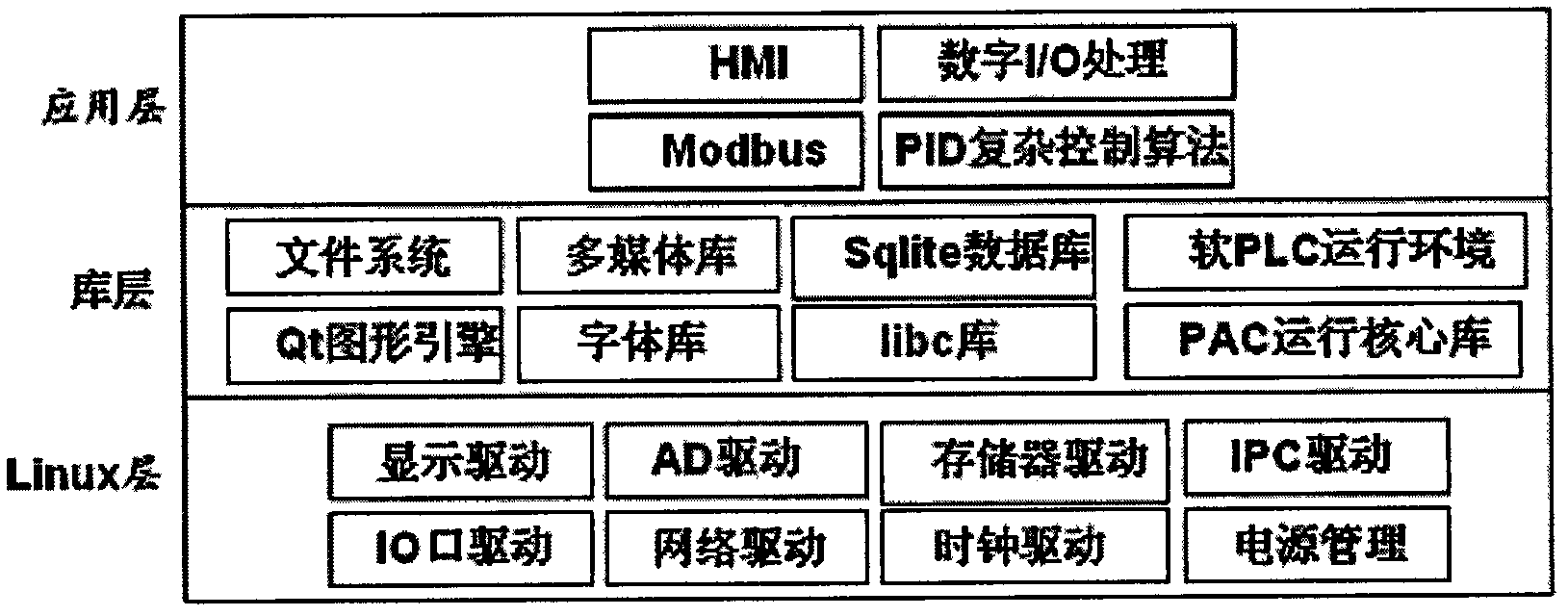

Advanced RISC machine-Linux (ARM-Linux)-based compiled programmable automation control (PAC)

InactiveCN102621960ASatisfy logicFulfil requirementsTotal factory controlProgramme total factory controlExtensibilityHuman–machine interface

The invention relates to a programmable automation control (PAC), in particular to a novel integrated advanced RISC machine-Linux (ARM-Linux)-based compiled PAC integrating the functions of a programmable logic controller (PLC), a touch screen, a database SQLite, ModBus communication and the like. Hardware comprises a processor unit, a display touch screen unit, an input unit, an output unit, a storage unit and a communication unit, and software comprises a Linux operating system, a PAC running system, a Qt interface, the database SQLite, communication and the like. The communication unit comprises an RJ45 network interface and a field bus ModBus, and has high extensibility. The running of a touch monitoring interface and the running of the PLC can be independent from each other, the hybrid programming of a ladder diagram, an instruction list and a C language is supported, and a hybrid program of the ladder diagram, the instruction list and the C language can be directly compiled into an ARM-executable file, so that the running speed of the compiled PAC is increased by 5 to 10 times compared with that of an interpreted PLC. The development efficiency and cost of the compiled PAC are more competitive than those of the conventional development mode integrating the PLC, a human machine interface and configuration software, and a broad application space can be provided for a user.

Owner:李斌 +2

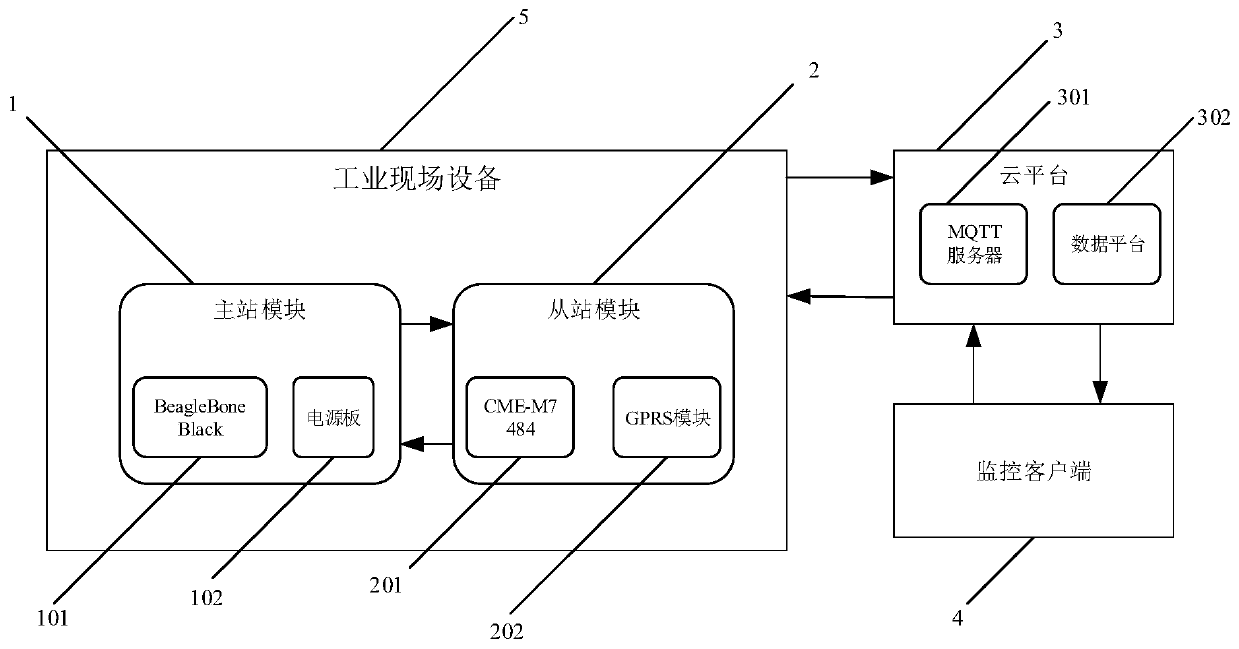

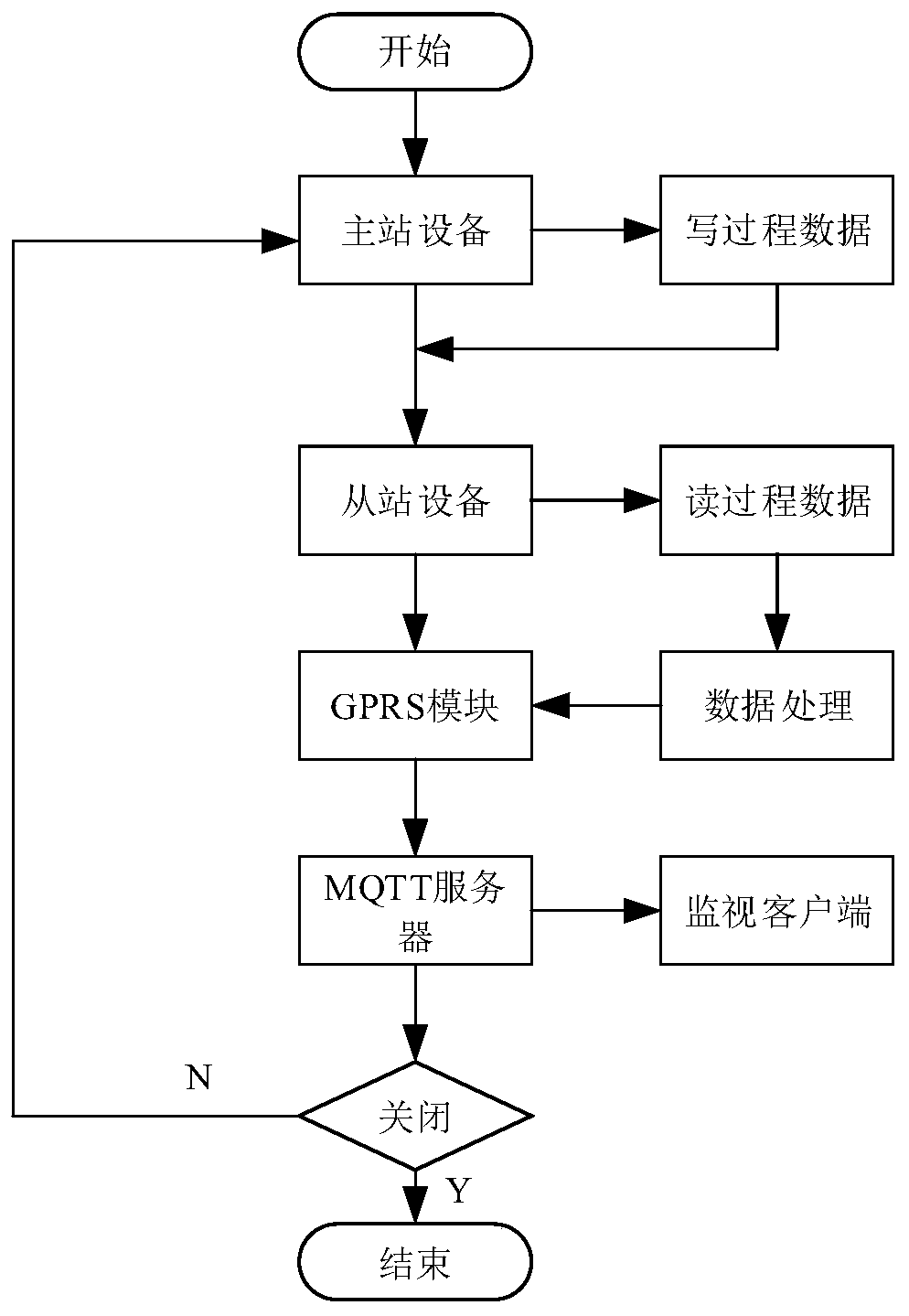

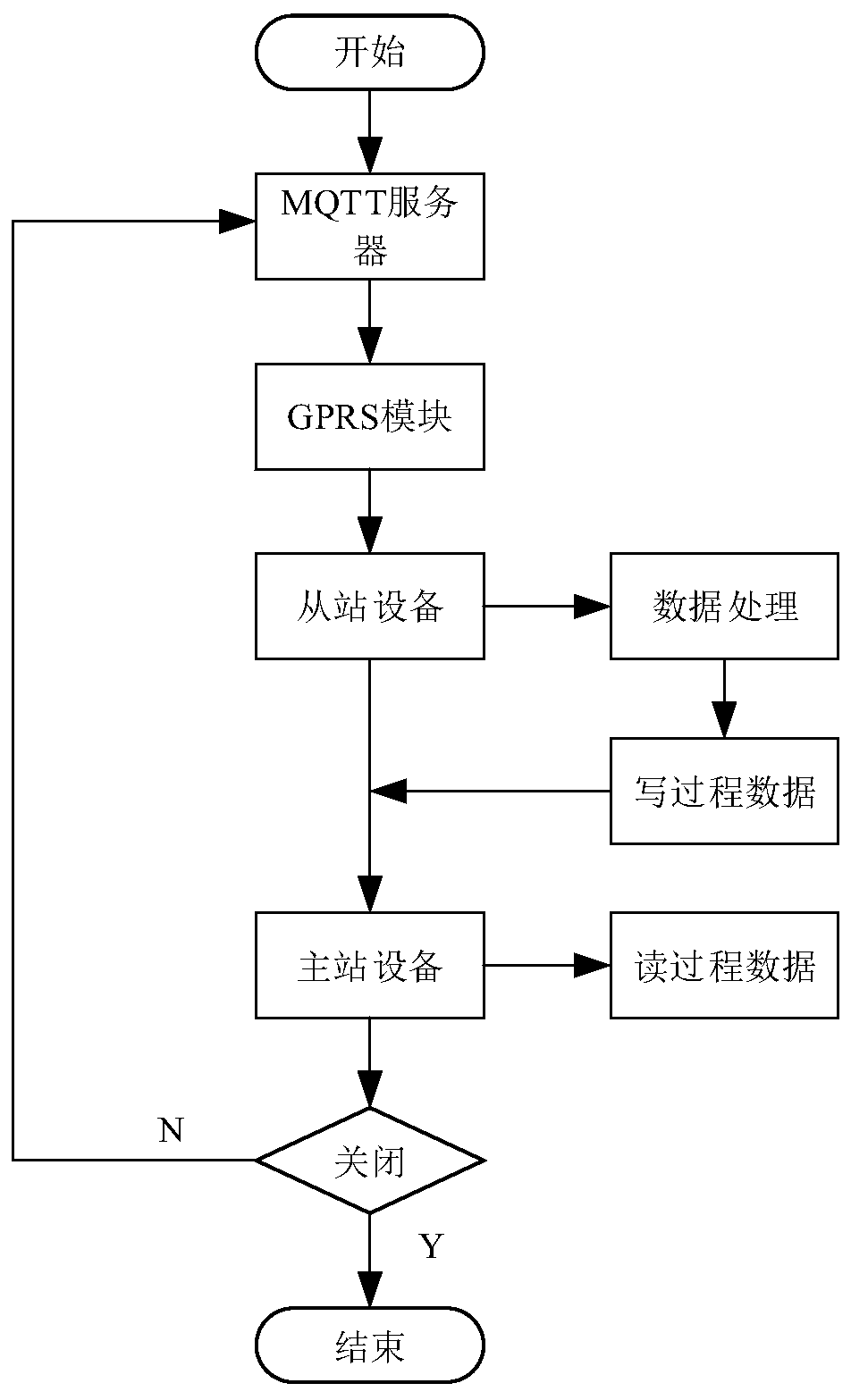

Message queuing telemetry transport (MQTT) protocol-based automatic proxy configuration (PAC) cloud operation and maintenance system

ActiveCN110320875ASolve the problem of not being able to connect to the InternetSolve the problem that data cannot be uploaded to the cloud platformTechnology managementTotal factory controlGeneral Packet Radio ServiceArea network

The invention belongs to the technical field related to industrial control automation and discloses a message queuing telemetry transport (MQTT) protocol-based automatic proxy configuration (PAC) cloud operation and maintenance system. The system includes a programmable automation controller, a cloud platform and a monitoring client. The programmable automation controller is used for monitoring and acquiring state information of a field industrial device and transmitting acquired data to the cloud platform. The cloud platform is used for interacting information with the programmable automationcontroller and the monitoring client respectively. The monitoring client is used for acquiring data from the cloud platform and monitoring the field industrial device based on the data. The programmable automation controller includes a master station module and a slave station module. The master station module and the slave station module communicate via a controller area network open (CANopen) bus. The slave station module includes a slave station and a general packet radio service (GPRS) module. The GPRS module is used for providing a network connection function for the slave station. The MQTT protocol-based PAC cloud operation and maintenance system lowers the cost and improves the efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for dynamically judging precision exception of winding drum of reeling machine

InactiveCN102615143ATimely replacementAvoid product quality accidentsMetal working apparatusPower flowMan machine

A method for dynamically judging precision exception of a winding drum of a reeling machine aims to find out a degradation phenomenon of the winding drum of the reeling machine timely. The method comprises the steps as follows: starting a wrapper roller of the reeling machine, and listening whether the winding drum makes a periodic sound; observing the monitoring picture of a man-machine interface of an operating board of the reeling machine; during the zero-calibration process, listening to the contact sound of the wrapper roller and the winding drum of the reeling machine on site; after the zero-calibration process, starting the wrapper roller of the reeling machine quickly, adjusting the roll bite of the wrapper roller capable of programming an automatic controller to minus 1 mm, and listening to the contact sound of the winding drum and the wrapper roller; after the zero-calibration process, starting the wrapper roller of the reeling machine quickly, adjusting the roll bite of the wrapper roller capable of programming an automatic controller to 2 mm, listening to the contact sound of the winding drum and the wrapper roller, and observing the current intensity of the winding drum picture; judging the dynamic accuracy of the winding drum according to a velocity curve of the winding drum of the reeling machine, and reeling up the head part of a steel coil for a range of 30 m to observe the feedback speed of the winding drum and to judge whether the precision of the winding drum of the reeling machine is normal or not, and then an accident of product quality can be avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Automobile intelligent beauty service system

InactiveCN106891862AEasy to cleanAchieve waxing and polishing workCleaning apparatus for vehicle exteriorsVehicle servicing/repairingProgrammable automationService system

The invention discloses an automobile intelligent beauty service system, which comprises a vehicle berth, a circular track arranged around the vehicle berth, a mobile car running along the circular track, a mechanical arm fixed to the mobile car, cleaning and beauty tools, 3D scanner, programmable automation controller and cloud database that store vehicle characteristics and corresponding cleaning and beauty procedures. The robotic arm picks up the 3D scanner and scans the vehicle after the vehicle parks in the parking lot to obtain vehicle position and shape information and send it to programmable automation The programmable automation controller compares the vehicle shape information with the vehicle features in the cloud database to obtain a corresponding vehicle cleaning and beautifying program, and the mechanical arm picks up a cleaning and beautifying tool to clean and beautify the vehicle according to the vehicle cleaning and beautifying program. The car intelligent beauty service system can perform corresponding cleaning and beautifying actions according to different models, and can better fit the vehicle surface to complete the cleaning action and improve the cleaning and beautifying effect.

Owner:美牙仕口腔医疗科技(苏州)有限公司

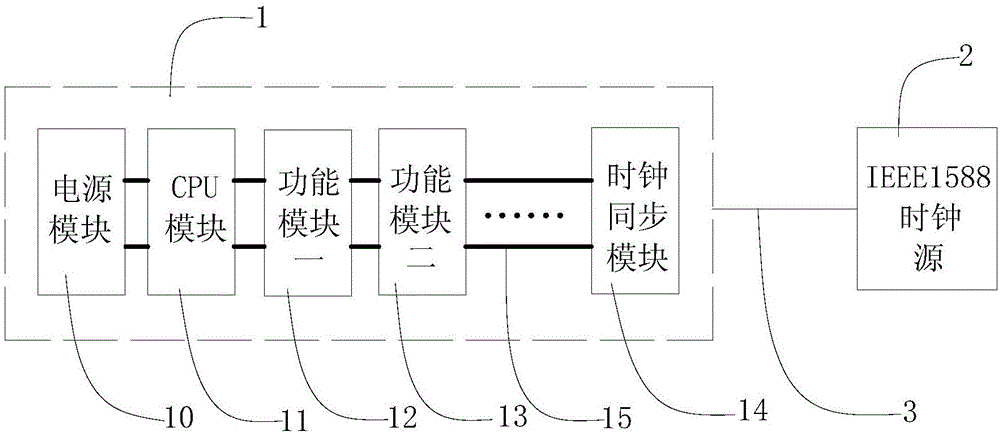

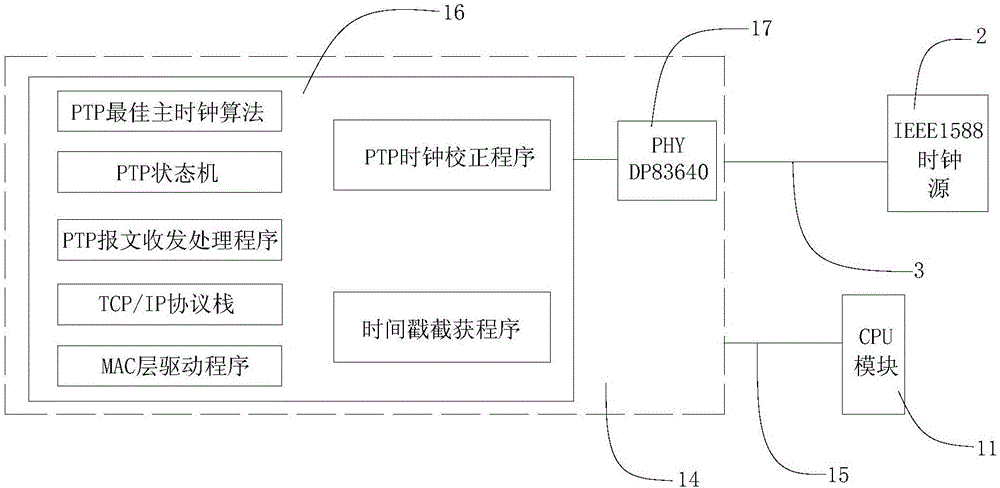

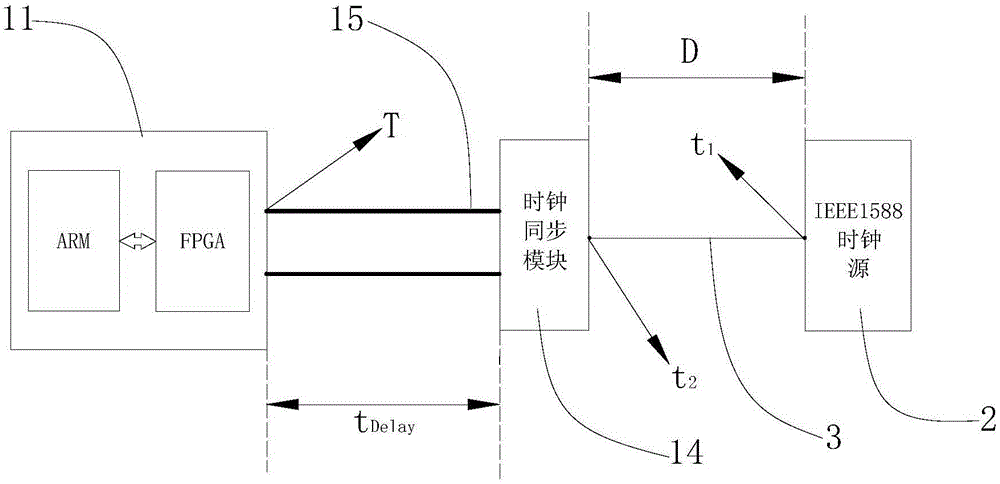

IEEE1588 time synchronization method and device based on PAC (Programmable Automation Controller)

ActiveCN106130711AClock synchronizationHigh precisionTime-division multiplexSynchronising arrangementClock correctionStructure of Management Information

The invention discloses an IEEE1588 time synchronization method and device based on a PAC (Programmable Automation Controller). The method comprises the following steps that: a clock synchronization module synchronizes with an IEEE1588 clock source; a CPU (Central Processing Unit) module reads a clock deviation value; the CPU module performs clock correction; the PAC is connected with the IEEE1588 clock source through a data cable; a power supply module, the CPU module, a functional module I, a functional module II and the clock synchronization module are connected through a backplane bus; the CPU module is used for communicating with the clock synchronization module and outputting a control command; and the clock synchronization module is used for finishing clock synchronization with the IEEE1588 clock source. The method and the device have the technical effects of simple structure and convenience in use. Moreover, high-performance hardware in the PAC is utilized fully; accurate time synchronization of the IEEE1588 is realized; extra hardware does not need to be added; and the hardware cost is reduced.

Owner:THREE GORGES NENGSHIDA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com