Testing apparatus for straw cutting performance and testing method thereof

A cutting performance and testing device technology, which is applied in the direction of measuring devices, mechanical devices, devices using optical methods, etc., can solve the problems of cumbersome operation, low efficiency, and low degree of automation of the straw cutting test bench, so as to improve efficiency and operate The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

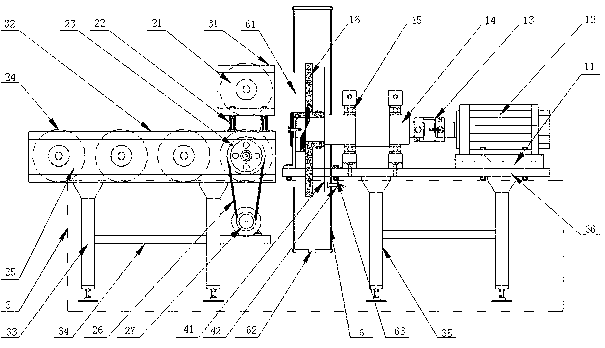

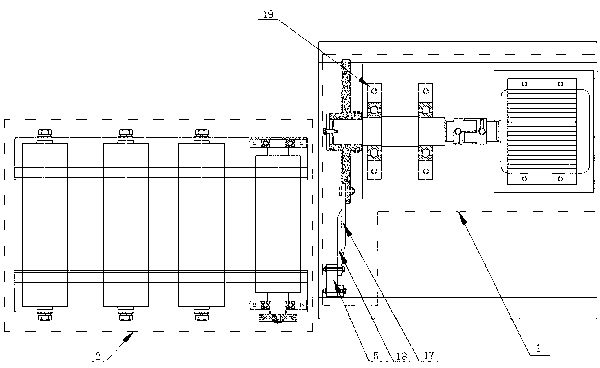

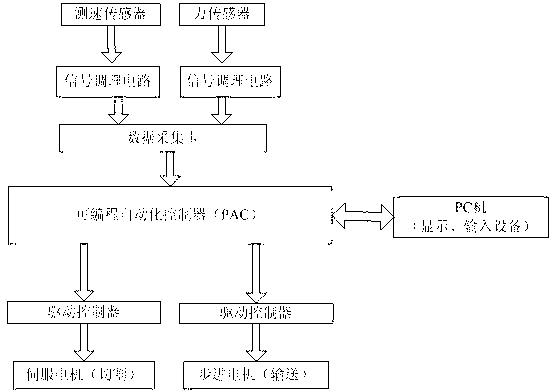

[0040] Such as figure 1 with figure 2 As shown, the straw cutting performance test device of the present invention consists of two parts: a mechanical system and a measurement and control system. The mechanical system includes a frame 3, a cutting device 1 and a conveying device 2. The frame 3 is provided with a compression wheel The support 31, the driven wheel support 32, the conveying device legs 33, the stepping motor support plate 34, the cutting device legs 35 and the cutting table 36, the cutting device 1 includes a servo motor support 11, a servo motor 12, The coupling 13, the rotating shaft 14, the bearing 15, the cutter head 16, the movable knife 17, the fixed knife 18, the bearing support 19 and the protective cover 6. The conveying device 2 includes a compression wheel 21, a pre-tensioning spring 22, a drive Wheel 23, driven wheel 24, chain 25, synchronous toothed conveyor belt 26, stepping motor 27; the cutting device 1 is on the right of the conveying device 2, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com