Patents

Literature

218 results about "Continuous testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous testing was originally proposed as a way of reducing waiting time for feedback to developers by introducing development environment-triggered tests as well as more traditional developer/tester-triggered tests. Continuous testing is the process of executing automated tests as part of the software delivery pipeline to obtain immediate feedback on the business risks associated with a software release candidate.

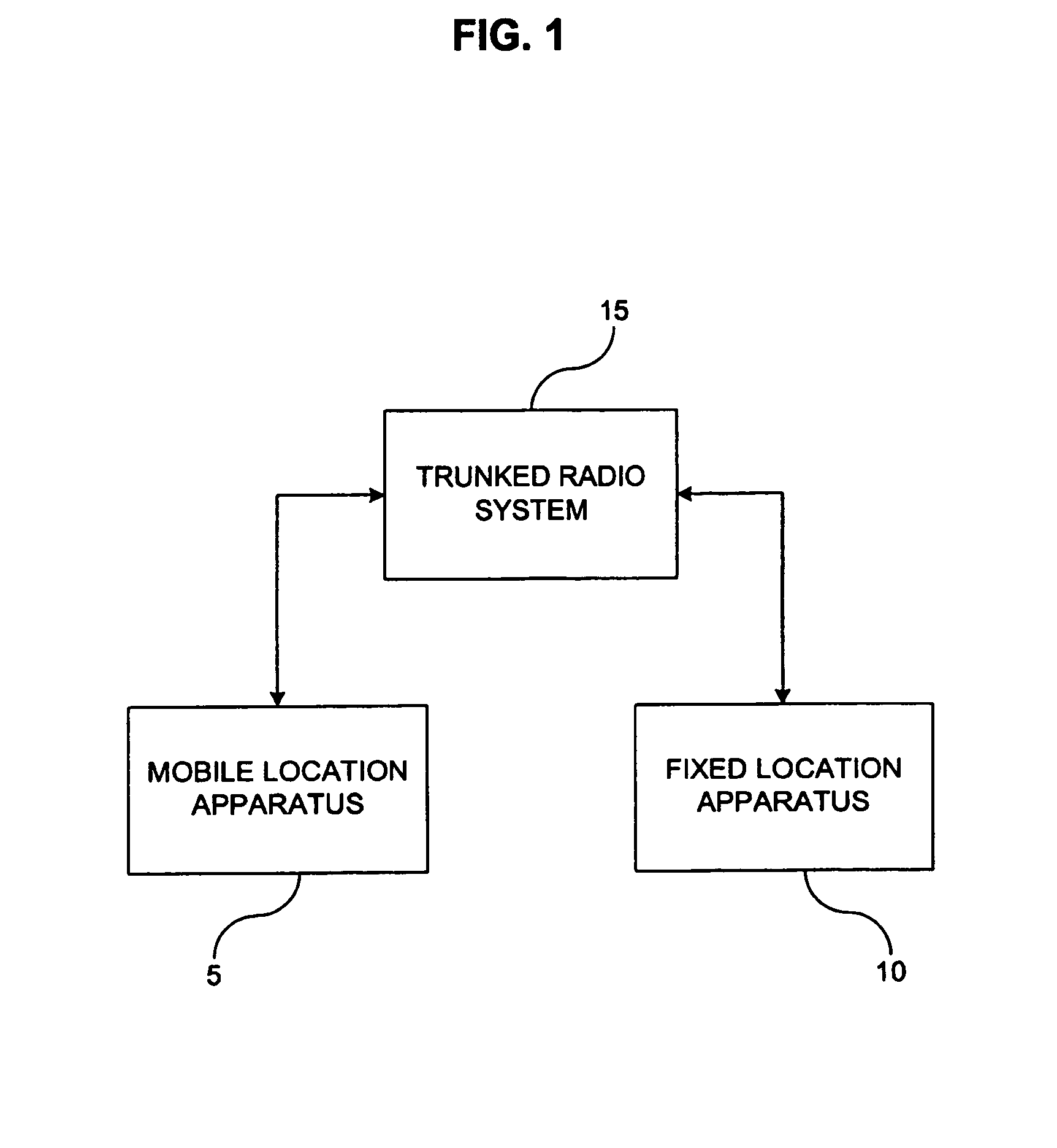

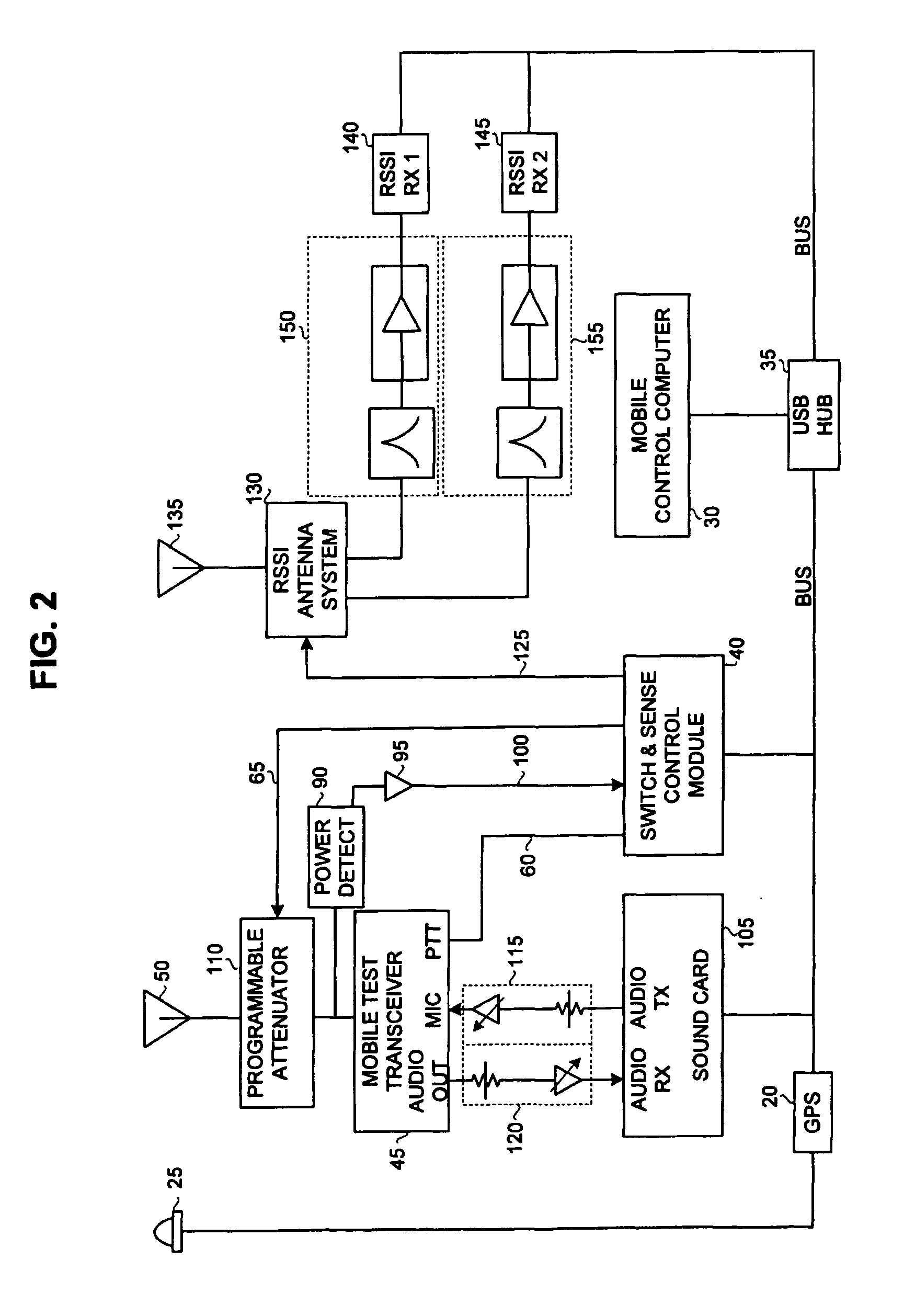

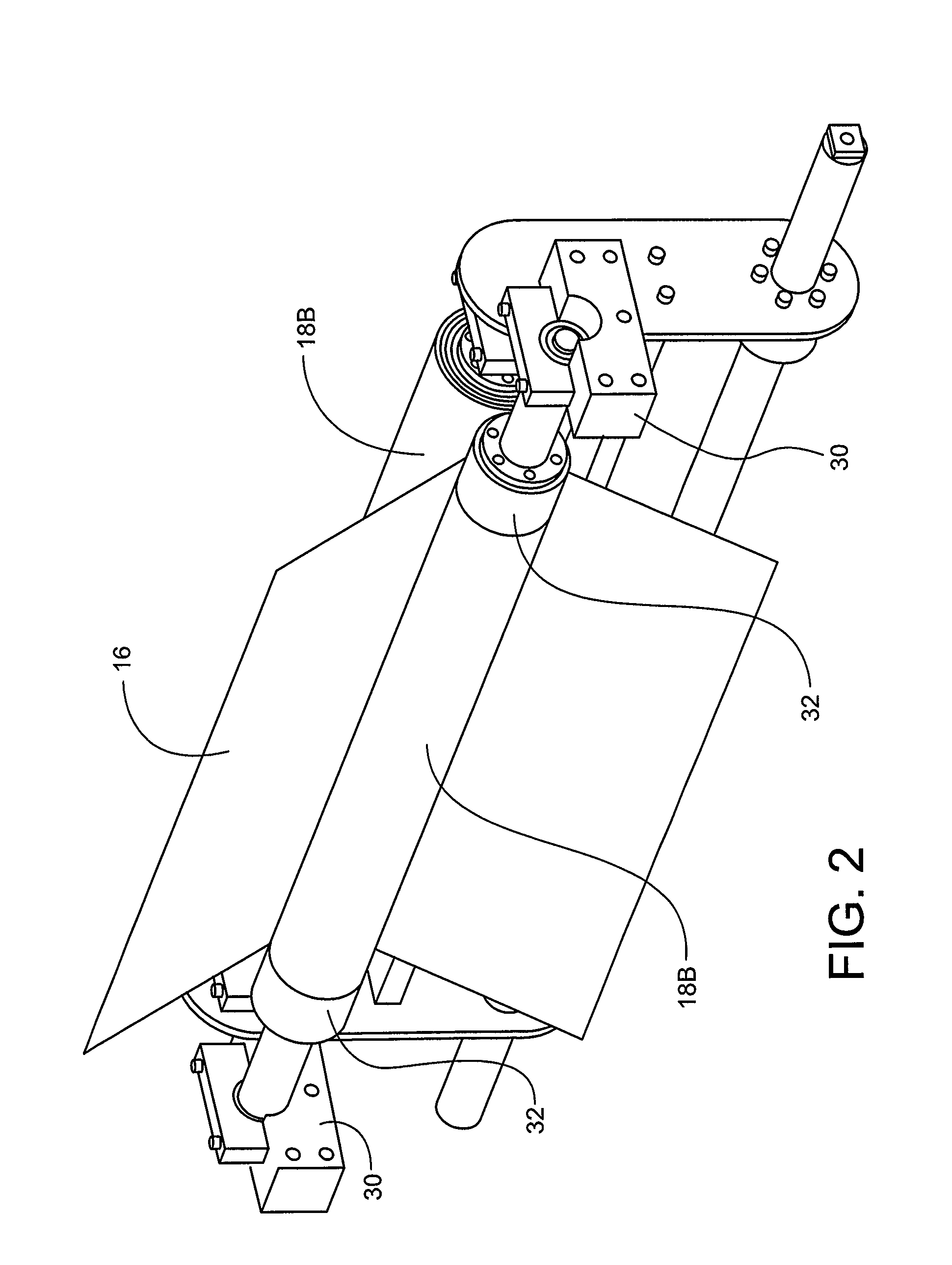

Method and System for Evaluating Radio Coverage

InactiveUS20070010241A1Speech analysisRadio/inductive link selection arrangementsRadio coverageEngineering

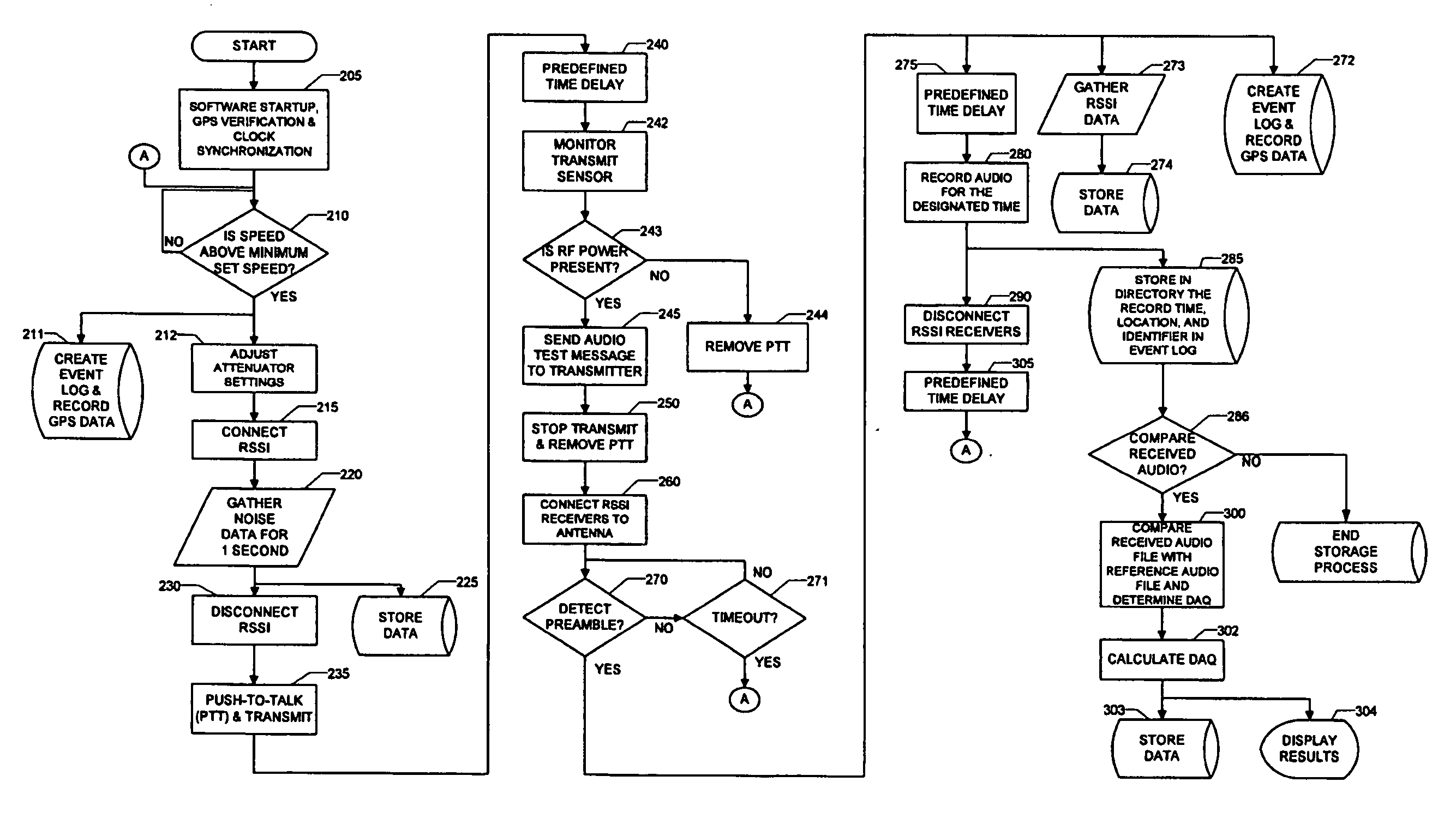

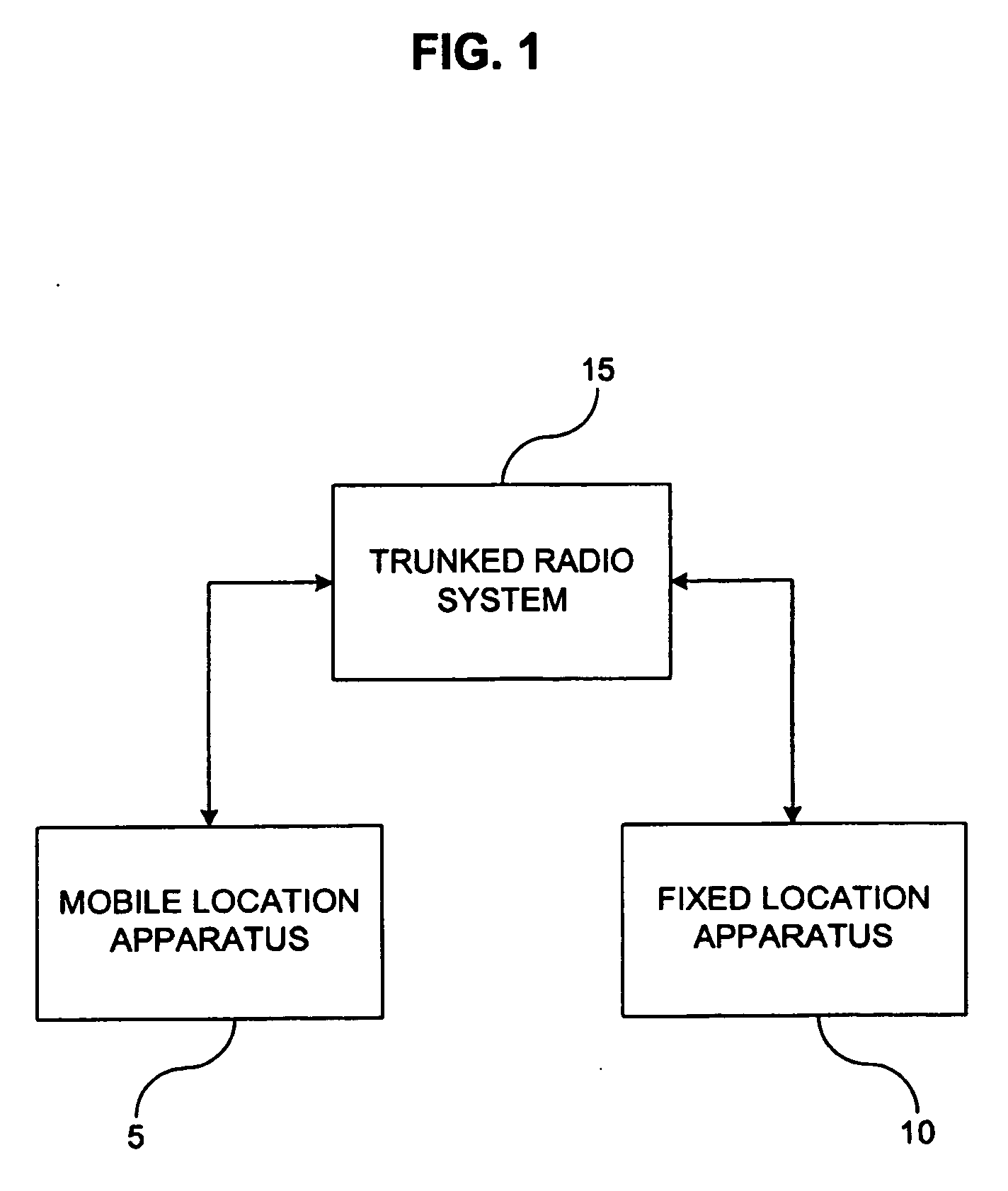

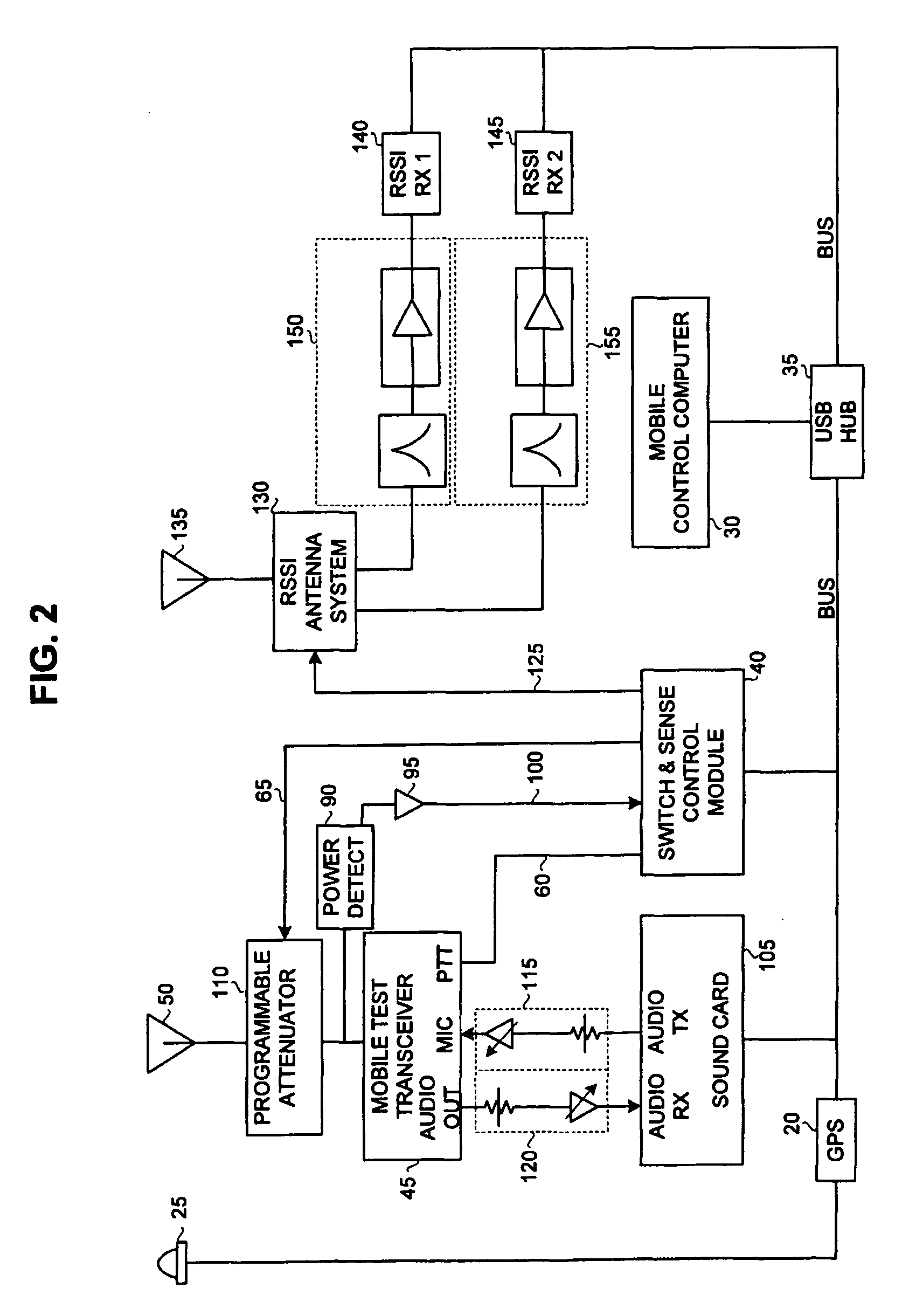

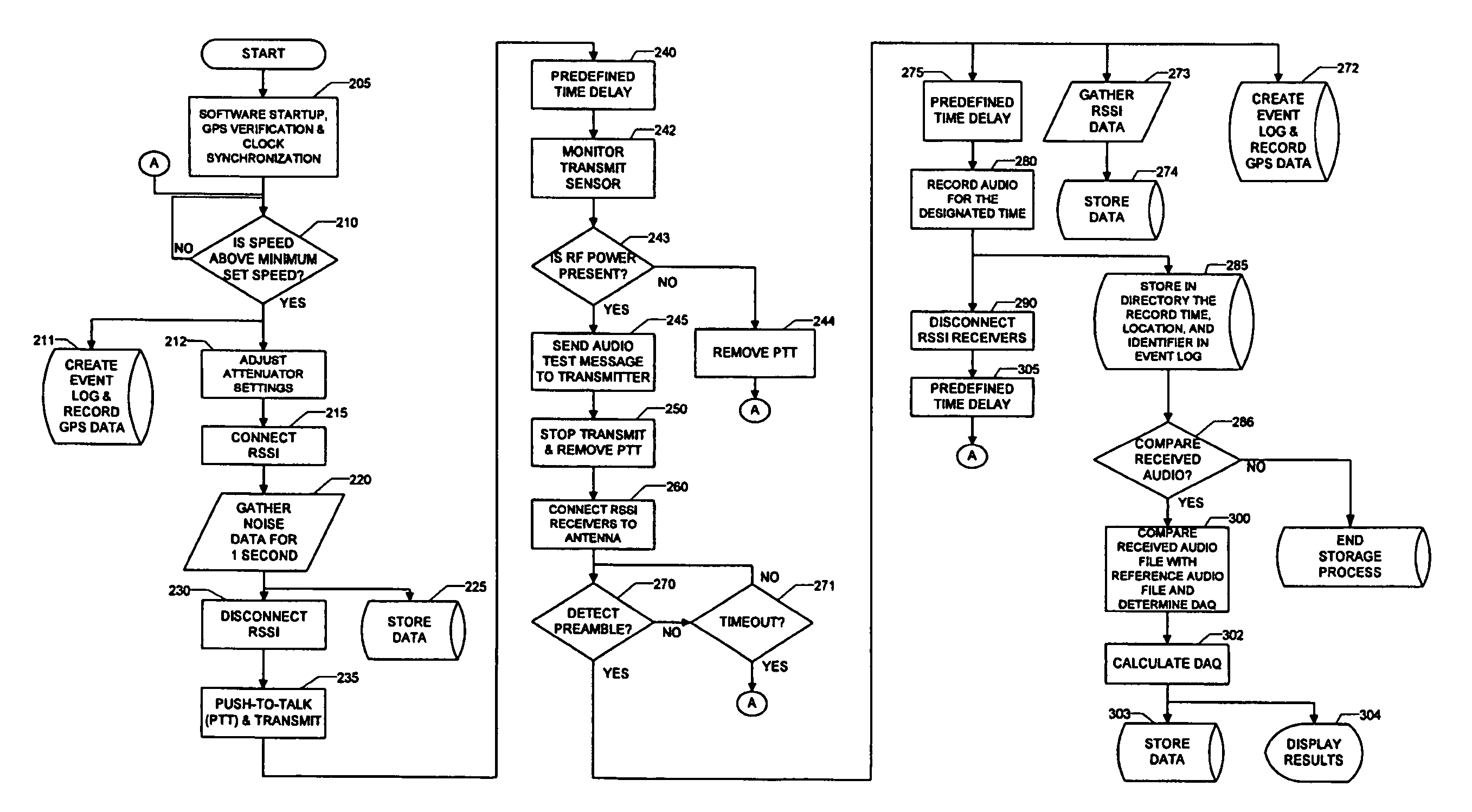

A system and method for testing radio coverage of a land mobile radio system. The system configuration generally employs a fixed unit, a mobile unit and the two-way radio system (not part of the invention) subject to testing. The test system and method are compatible with any land-mobile radio system (conventional, trunked, using proprietary or standards-based protocols, FDMA or TDMA) operating in any frequency band. One of three methods may be selected to perform testing at any one time: continuous testing, grid testing or receive-only testing. In the continuous and grid modes, both the talk-out and talk-in paths are measured. Test results are recorded in a computer file after being converted to a digital format, and are compared to an original “reference file” via the Perceptual Evaluation of Speech Quality (PESQ) algorithm as defined by ITU-T standard P.862. The PESQ output is then converted to a Delivered Audio Quality (DAQ) score by application of an empirical set of weighting factors to certain of the PESQ parameters.

Owner:CTA COMM

Method and System for Evaluating Radio Coverage

A system and method for testing radio coverage of a land mobile radio system. The system configuration generally employs a fixed unit, a mobile unit and the two-way radio system (not part of the invention) subject to testing. The test system and method are compatible with any land-mobile radio system (conventional, trunked, using proprietary or standards-based protocols, FDMA or TDMA) operating in any frequency band. One of three methods may be selected to perform testing at any one time: continuous testing, grid testing or receive-only testing. In the continuous and grid modes, both the talk-out and talk-in paths are measured. Test results are recorded in a computer file after being converted to a digital format, and are compared to an original “reference file” via the Perceptual Evaluation of Speech Quality (PESQ) algorithm as defined by ITU-T standard P.862. The PESQ output is then converted to a Delivered Audio Quality (DAQ) score by application of an empirical set of weighting factors to certain of the PESQ parameters.

Owner:CTA COMM

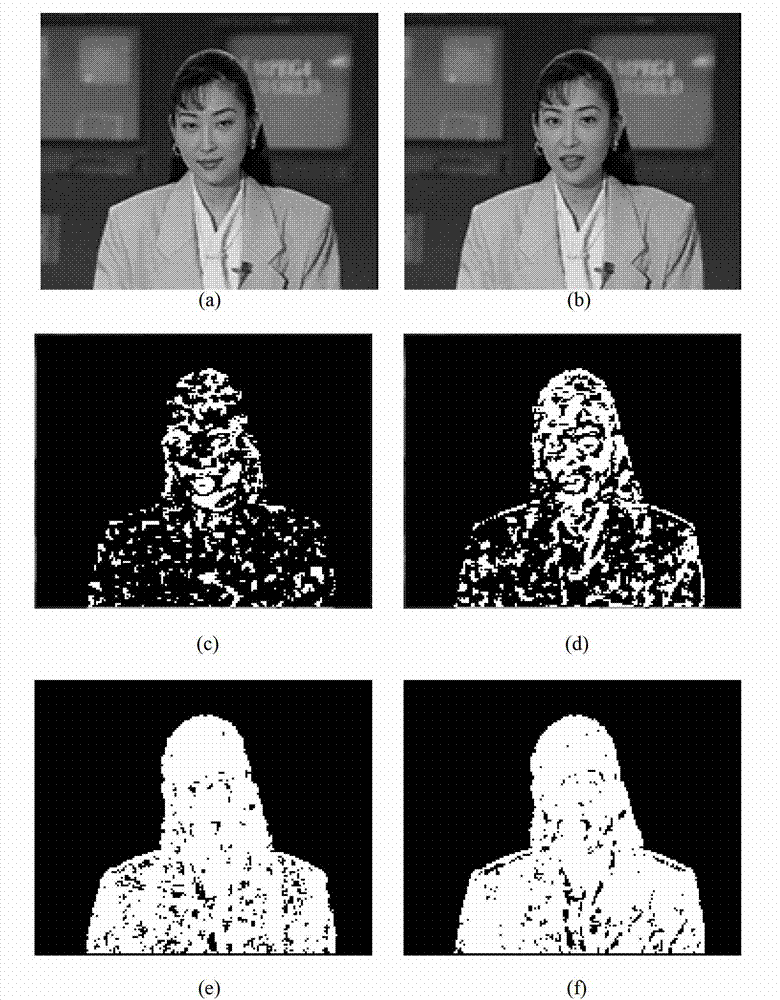

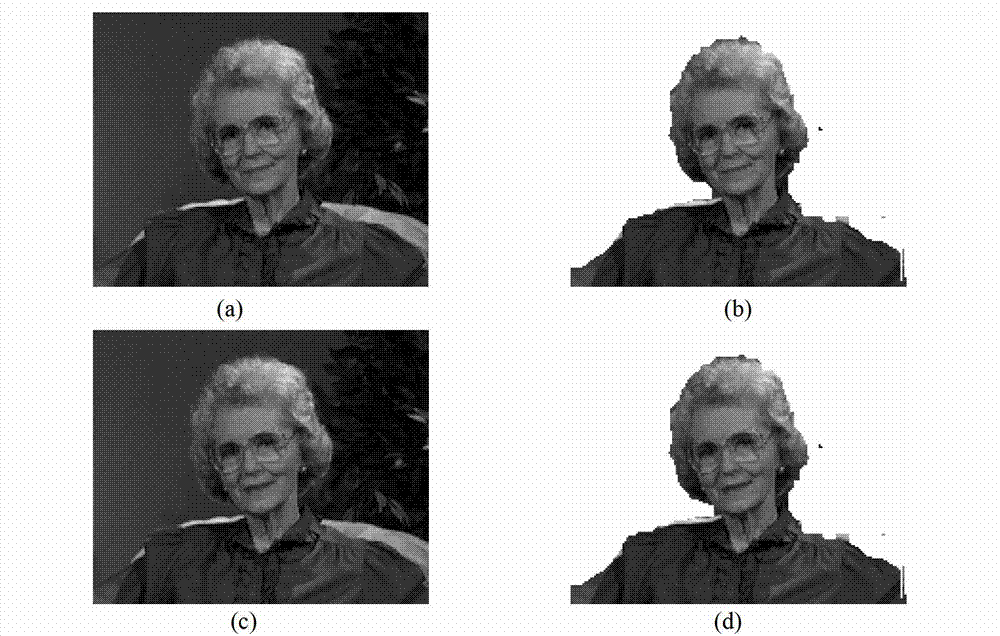

Video object division method based on change detection and frame difference accumulation

ActiveCN102970528AAvoid estimationInhibition effectImage enhancementImage analysisFrame differencePattern recognition

The invention discloses a video object division method based on change detection and frame difference accumulation. The video object division method includes: interframe changes of symmetrical frames with the interval to be k frames are tested through t significance testing, a detected initial motion and variation area is subjected to time domain fixed interval time domain calculating, and a memory mask is formed through further integrating; a threshold value is adjusted through image edge continuous testing by aid of a Kirsch edge testing operator based on discontinuous testing to obtain all connected edge information in the current frame; a semantics video object plane is obtained through a space-time filter; and video object division is achieved through selective application filling and morphological processing operations. The video object division method based on change detection and frame difference accumulation is novel, effectively solves the problems of video object internal lack and background exposing which are caused by irregular object movements frequently happening in the video object division method, and is greatly improved in division speed, division effect, application range and portability.

Owner:深圳鑫想科技有限责任公司

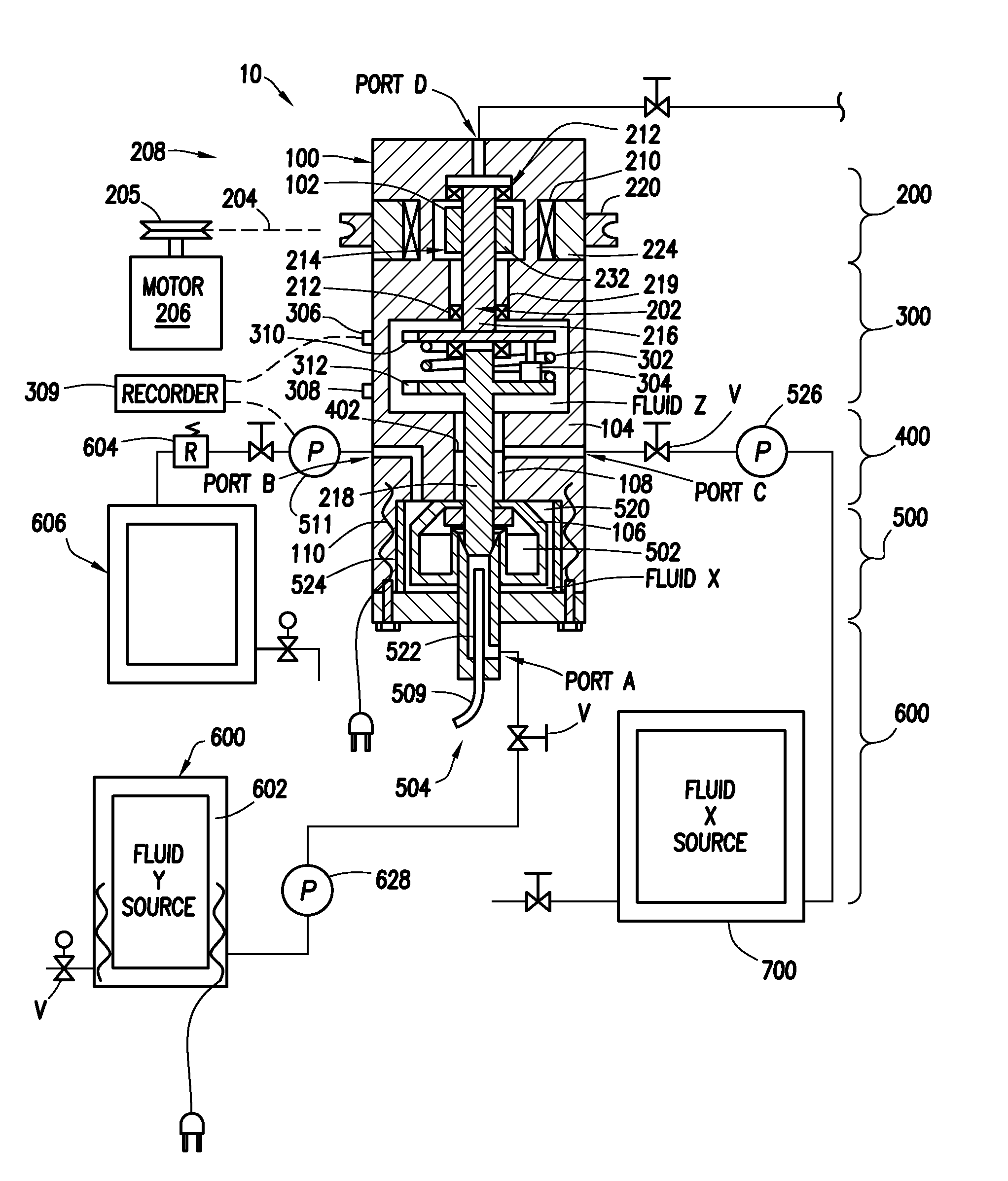

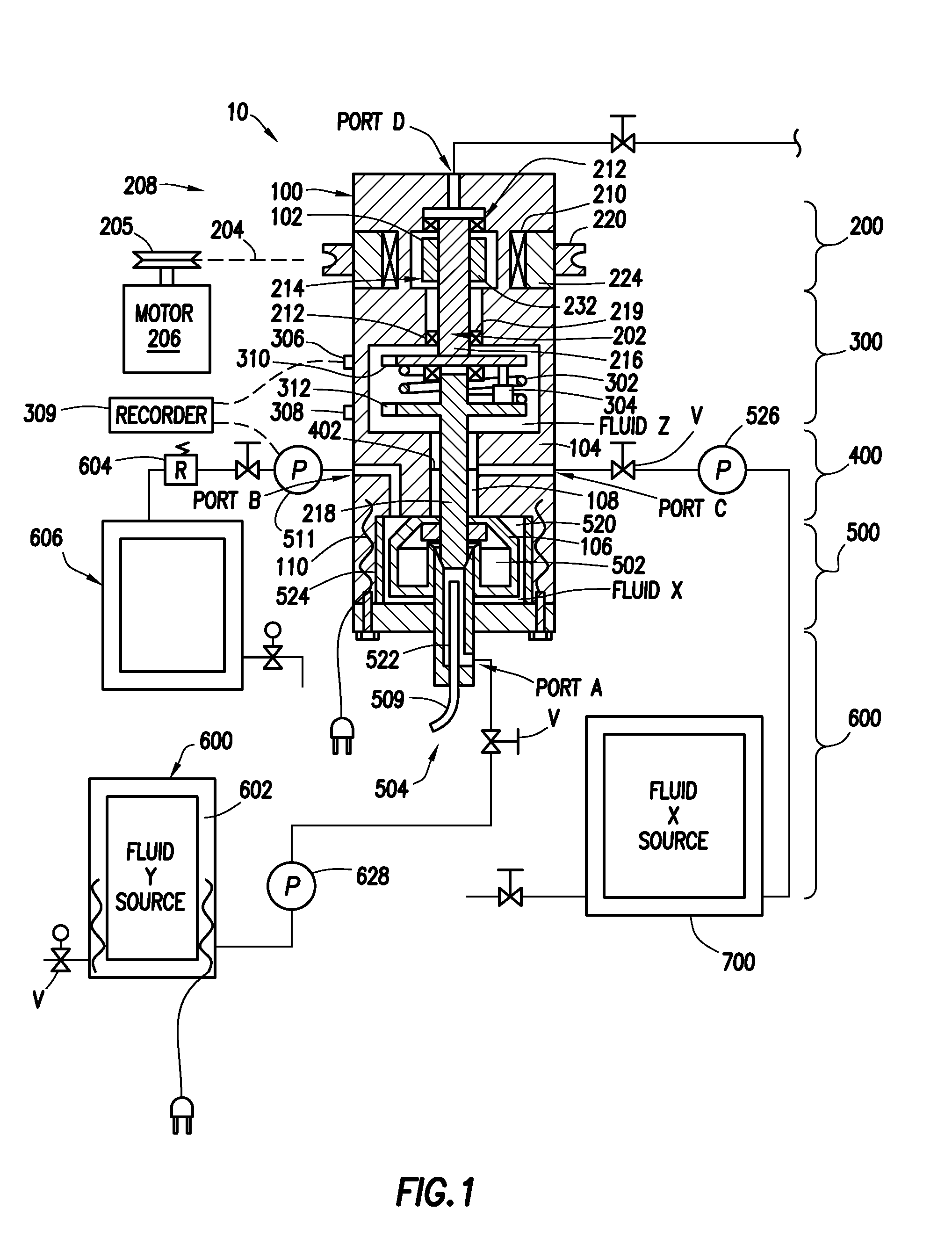

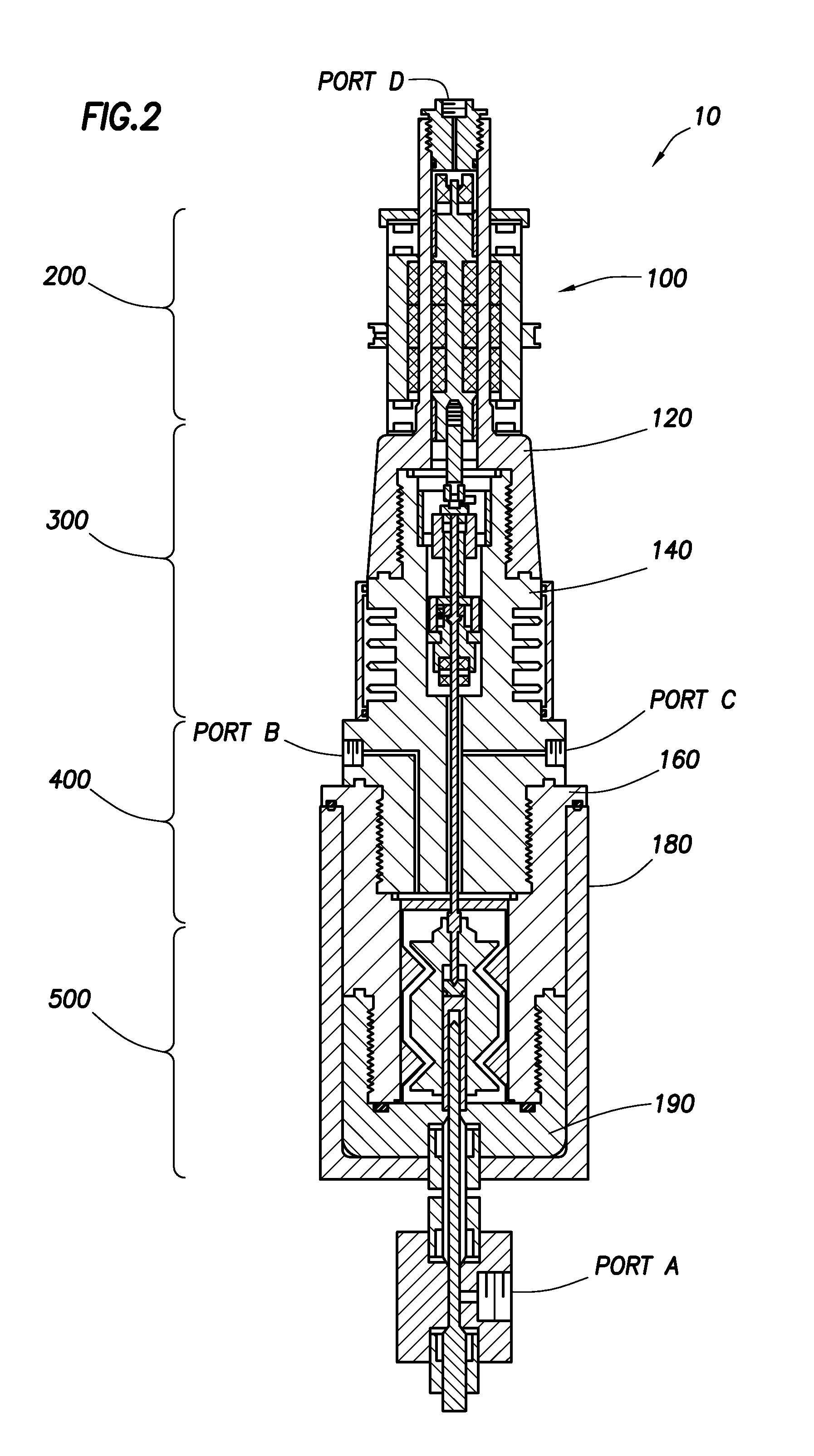

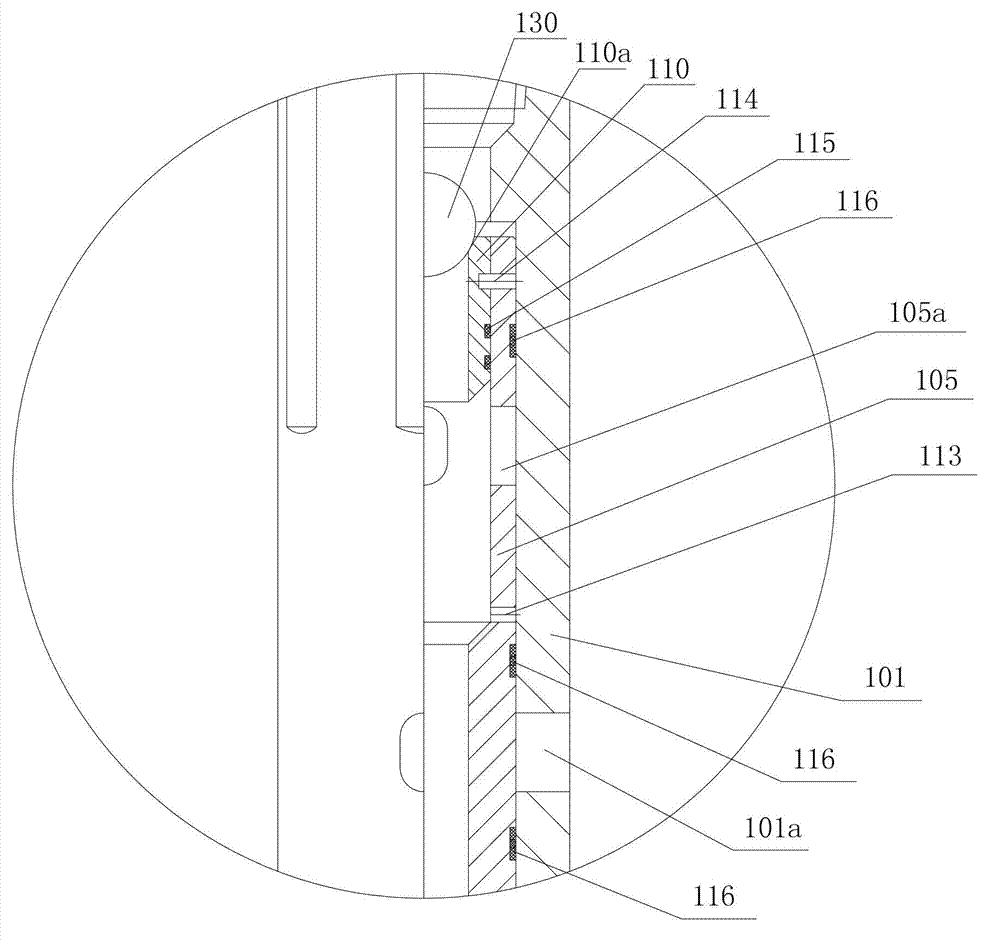

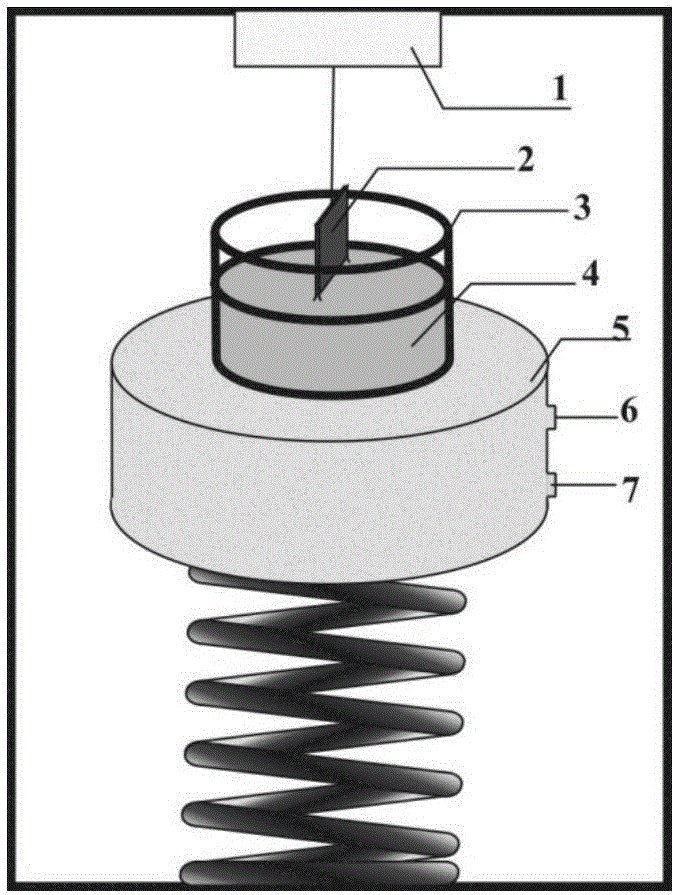

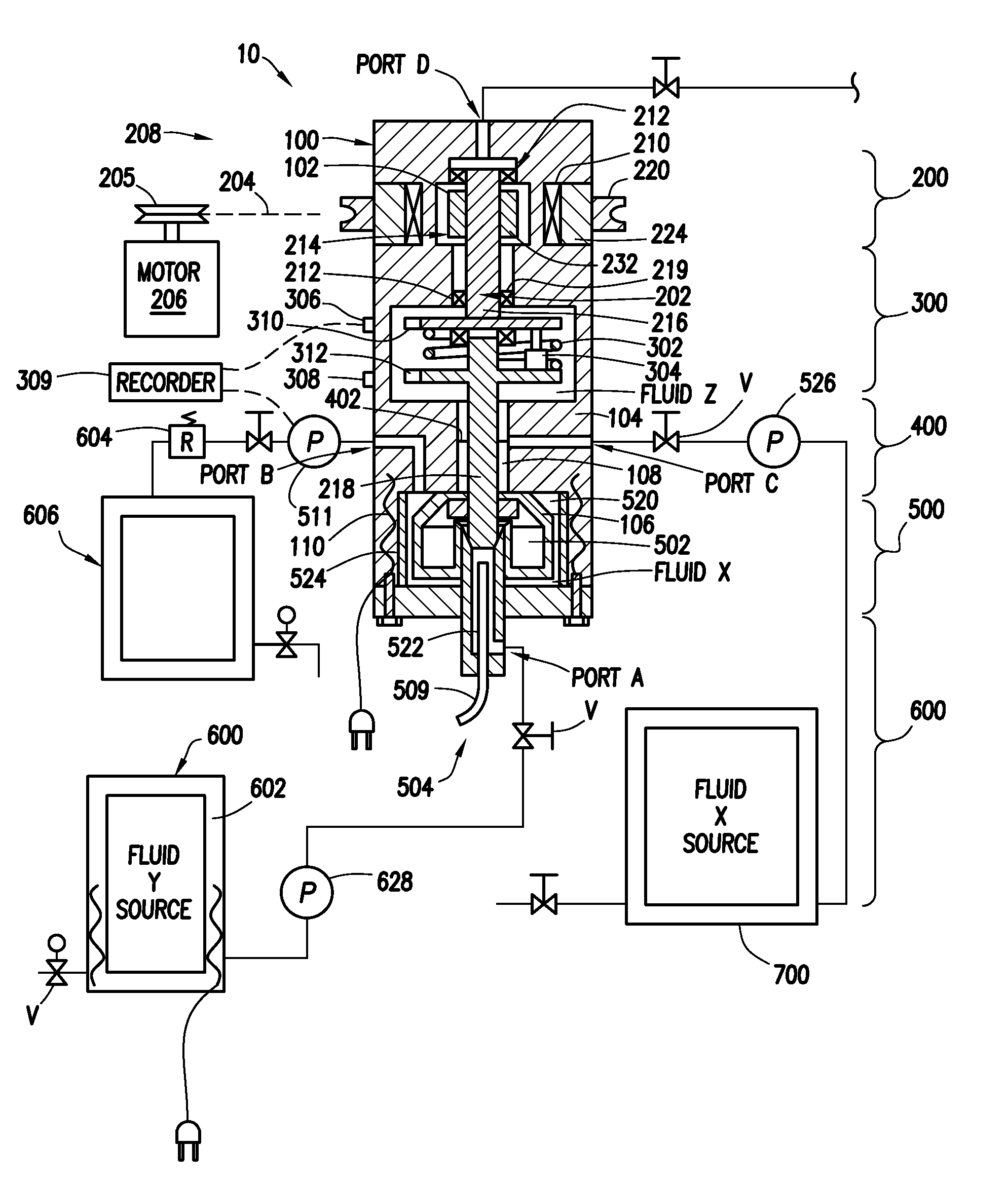

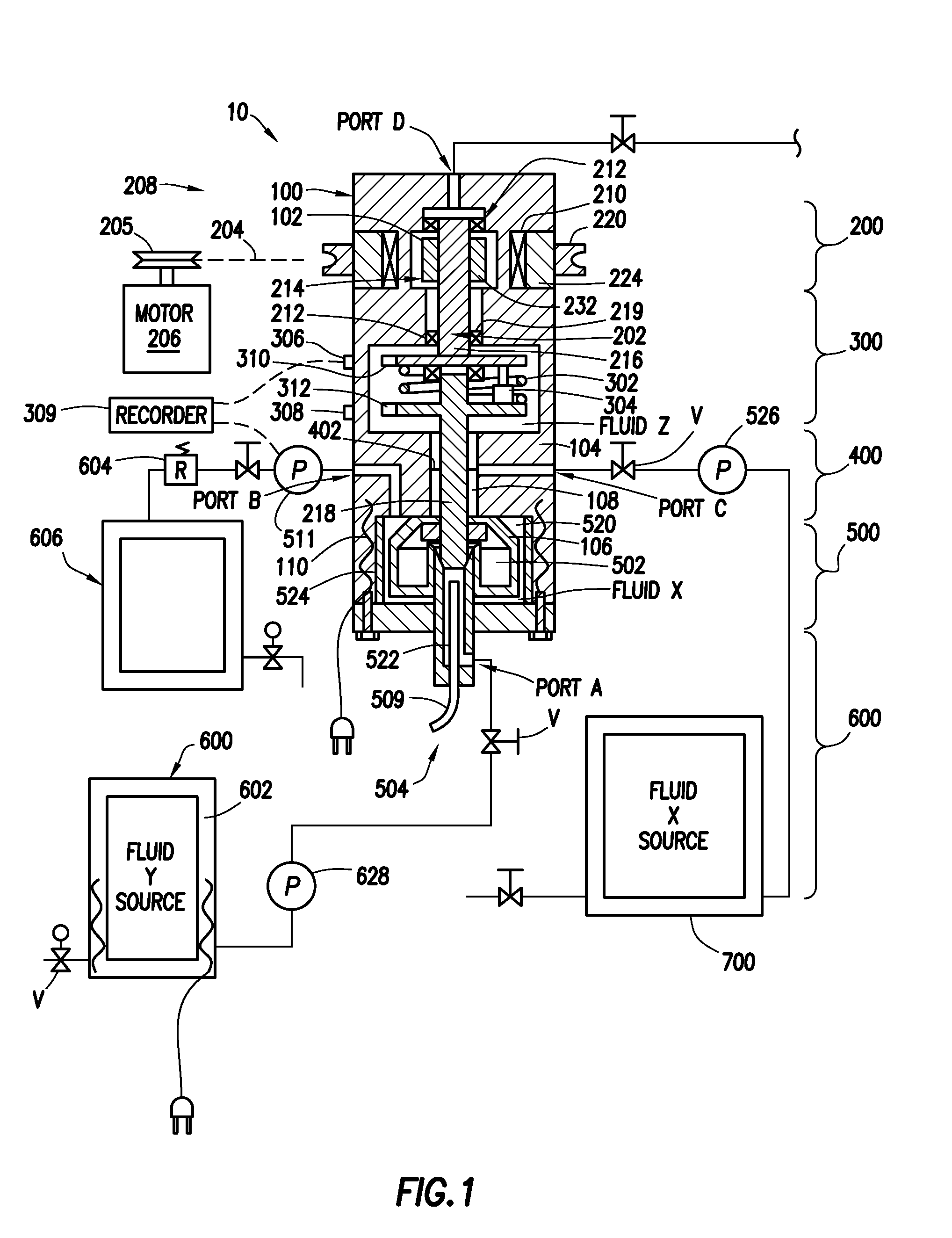

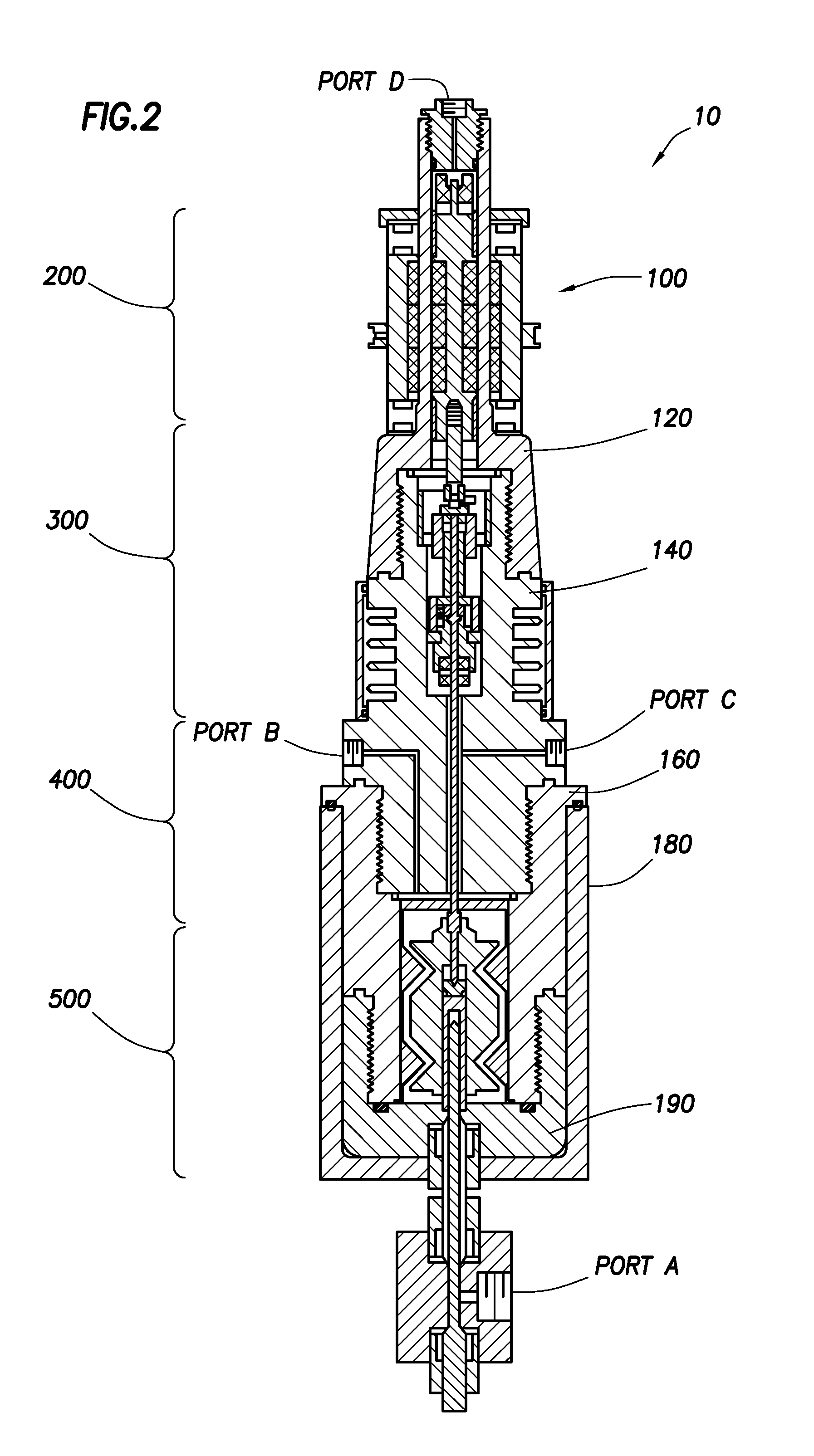

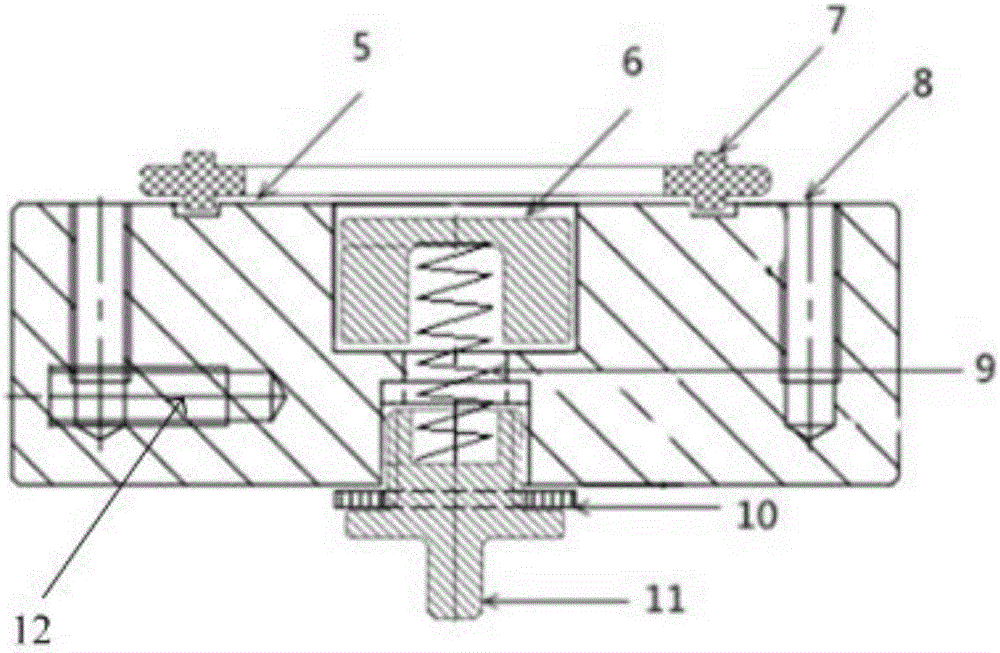

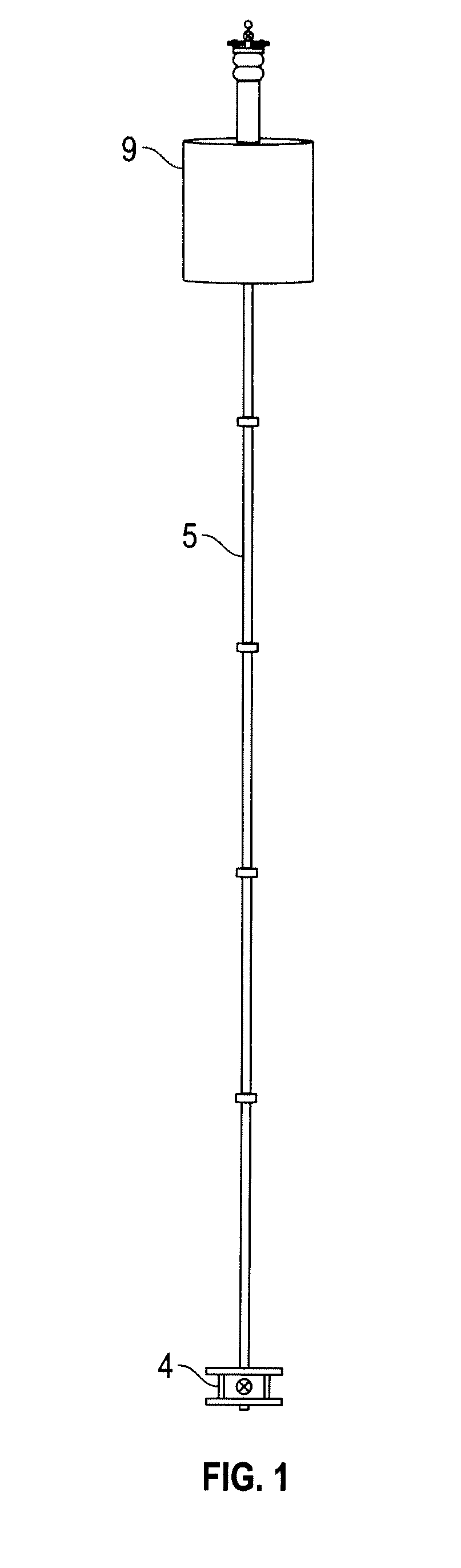

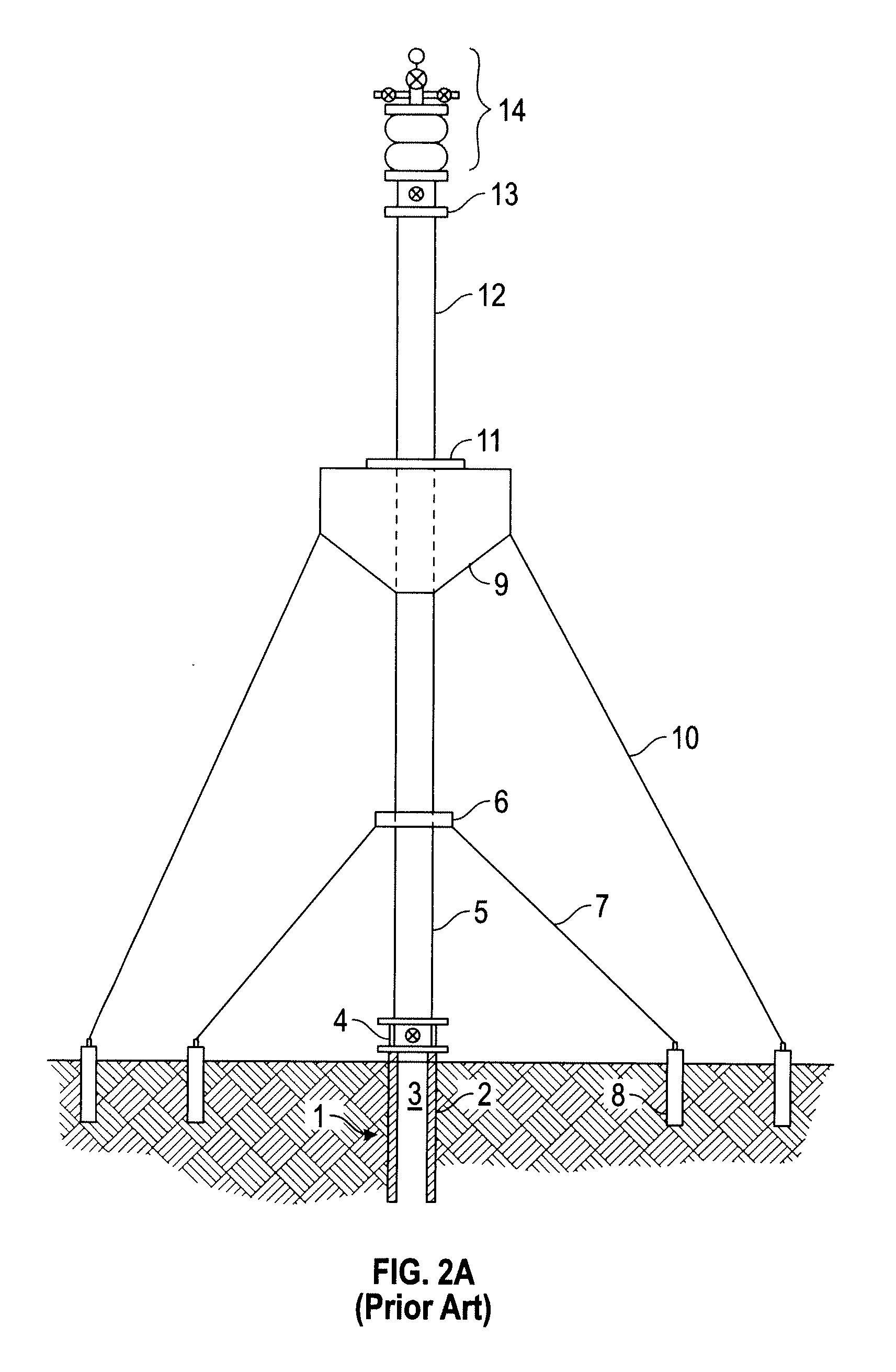

Apparatus and methods for continuous compatibility testing of subterranean fluids and their compositions under wellbore conditions

Disclosed is a fluid testing device which utilizes a small, cross-section fluid interface to separate a test fluid chamber from a drive and measuring chamber. The test fluid chamber contains the test fluid and a paddle-type fluid test assembly. The drive and measuring chamber contains a second fluid and assemblies for moving the paddle and for determining the resistance movement. The two chambers are connected together by a narrow cross-section passageway allowing for continuous testing while test fluids are flowed through the test chamber and for successive testing of different samples without breaking down the device between tests. A pair of coaxial shafts extends between the test fluid chamber and the drive and measuring chamber. The shafts are connected together by a spring located in the drive chamber whereby the resistance to movement is determined by measuring the deflection in the spring. The shafts are magnetically coupled to a motor to rotate the shafts.

Owner:HALLIBURTON ENERGY SERVICES INC

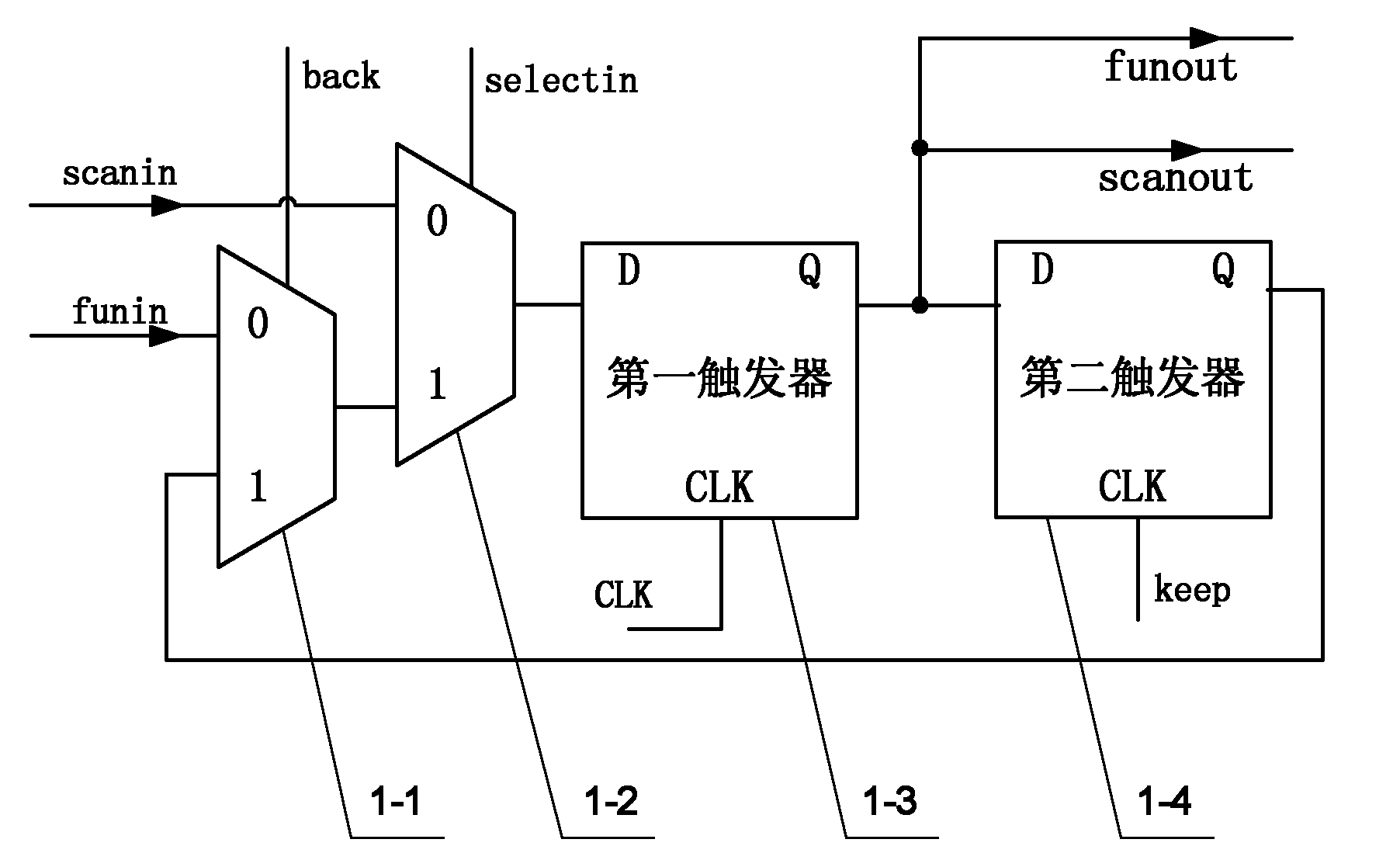

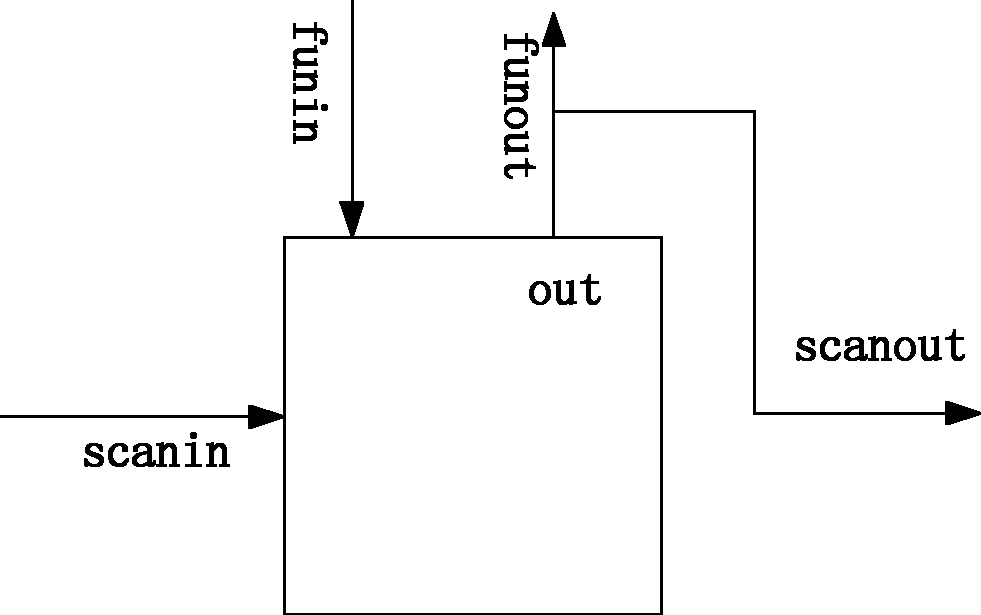

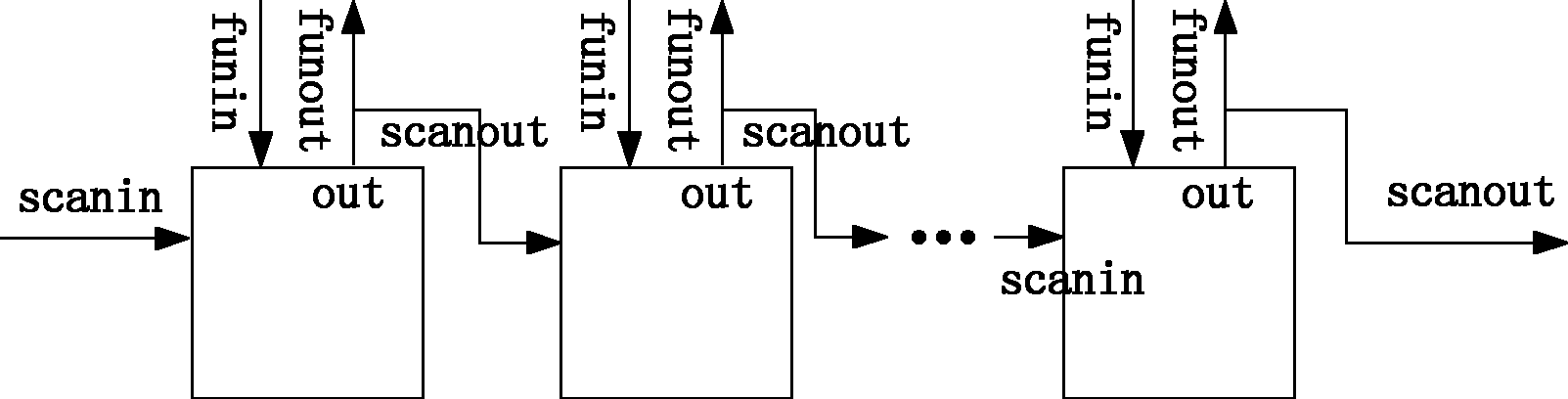

Improved scan chain unit and non-concurrent testing method based on same

InactiveCN102043122ASimple timing controlImprove test efficiencyDigital circuit testingSystem testingMultiplexer

The invention relates to an improved scan chain unit and a non-concurrent testing method based on the same, which belongs to the filed of on-chip system testing and aims at solving the problems that the existing scan chain-based non-concurrent on-line testing method has strict requirements for time sequences, is difficult to control and can not realize the one-step import of multiple groups of test vectors. The improved scan chain unit is used for replacing a D trigger in an on-chip system, and the unit contains two triggers and two selectors, wherein a first trigger is a basic unit which composes the original circuit scan chain and is used for realizing the function same with that of the original D trigger, and a second trigger is introduced for saving data in the testing process; and the two data selectors control the flow direction of data by means of enable ends, a first selector is used for controlling whether data in the second trigger can be transmitted to the first trigger, and a second selector is used for controlling the working state or the scanning state of the first trigger. Thus, multiple groups of test vectors can be input to the unit for continuous testing, and therunning state of the circuit is not changed before and after the test.

Owner:HARBIN INST OF TECH

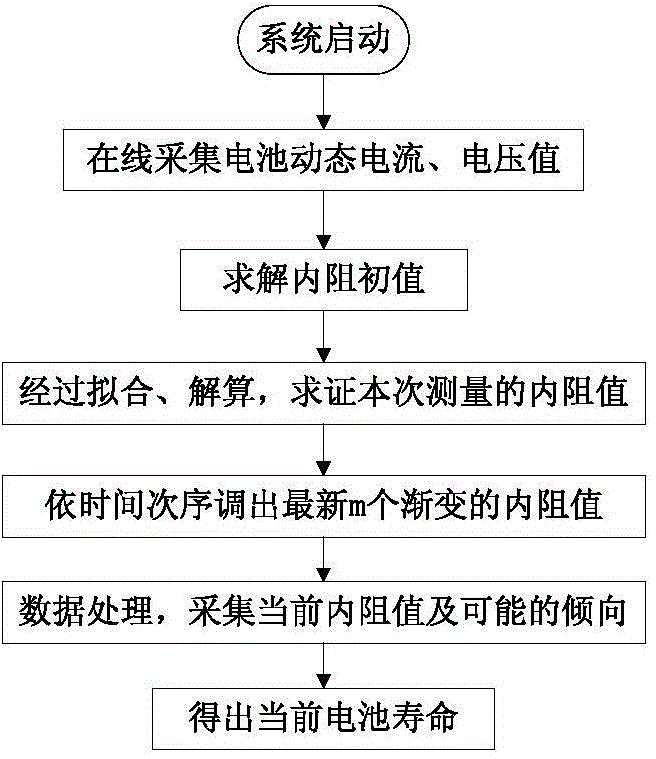

Power battery service life monitoring method based on on-line internal resistance testing

ActiveCN104678320AImprove accuracyOvercoming the disadvantages of "false value"Resistance/reactance/impedenceElectrical testingStart timeInternal resistance

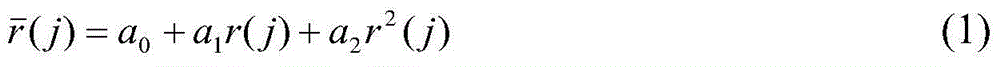

The invention discloses a power battery service life monitoring method based on on-line internal resistance testing, and aims to solve the technical problem that the conventional power battery service life testing method is poor in practicability. According to the technical scheme, the power battery service life monitoring method comprises the following steps: under the condition of rated load, testing a voltage-primary discharge current value of a power battery, thereby obtaining a present operation state value of the power battery; on the basis of continuous testing, calculating a primary value of the internal resistance of the power battery; subsequently, meeting optimization target which meets 'minimum square error' by using a least square fit method, and working out a primary tested value R (i) of the internal resistance of the power battery; testing for multiple times, thereby obtaining as string of progressive charge sequence {R(i)} i=1, 2, ..., m which can reflect the change rule of the internal resistance of the power battery within a relatively long period; finally, with the combination of historical records such as the service starting time and the utilization rate of the power battery, implementing data processing so as to obtain the present service life state of the power battery, and predicting the change and the available degree of the service life of the power battery in a future period. The power battery service life monitoring method is simple and practical, and avoids off-line measurement.

Owner:西安正中德信息科技有限公司

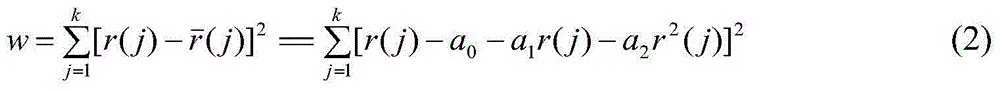

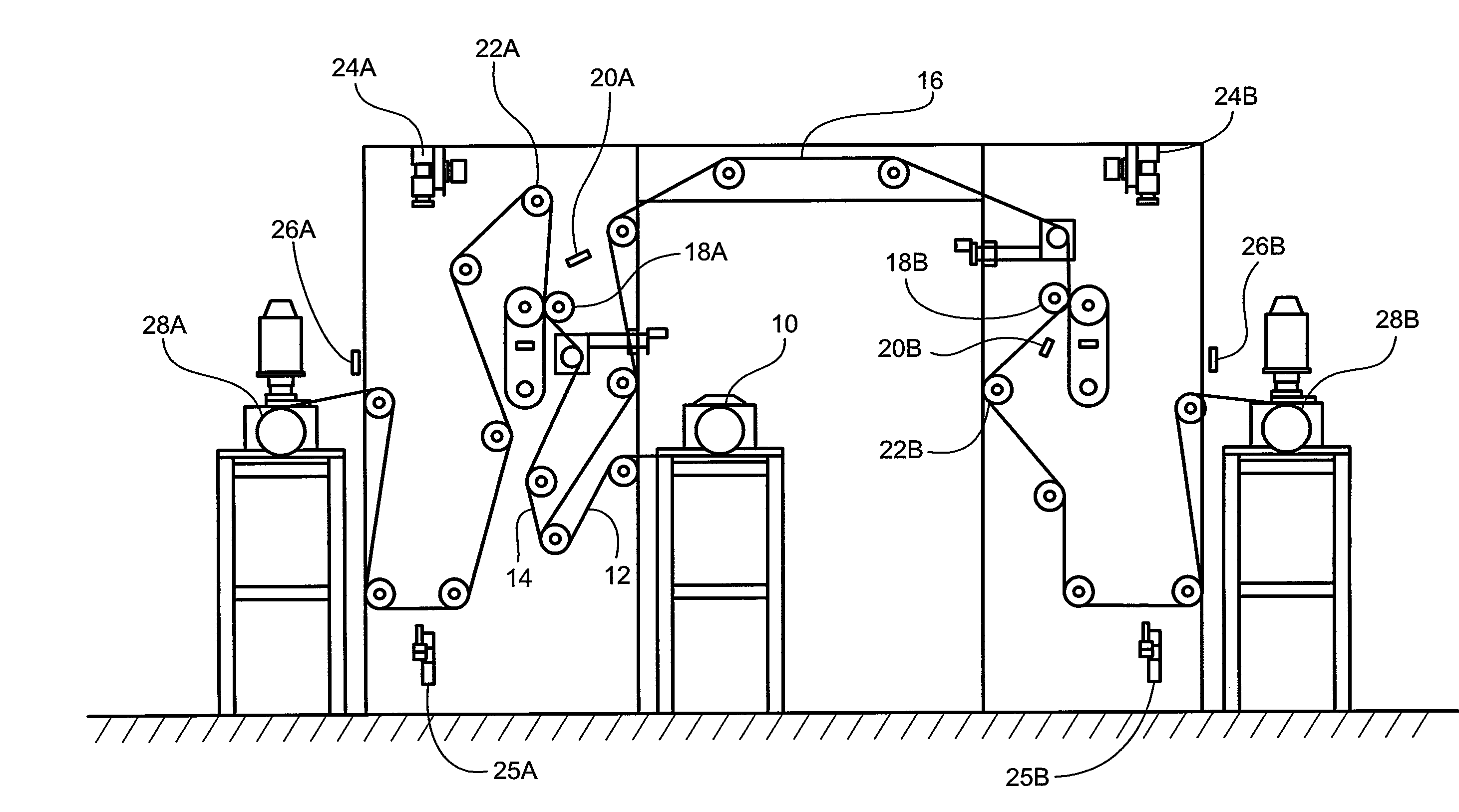

Continuous web inline testing apparatus, defect mapping system and related methods

InactiveUS20150115976A1Wide applicationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansConductive polymerEngineering

In at least selected embodiments, an industrial size continuous Hipot testing system has defect mapping capability capable of finding pinholes, weak spots, and / or embedded conductive particles in non-conductive sheet materials. Continuous testing is made possible through a pair of uniquely designed rollers, such as conductive polymer rollers. Automatic defect mapping is also incorporated into the system through the integration of the Hipot testing and line scan camera systems. The unit potentially has wide applications in many industries, such as, for example, semi-conductors and electronics, medical, high end packaging, and so forth.

Owner:CELGARD LLC

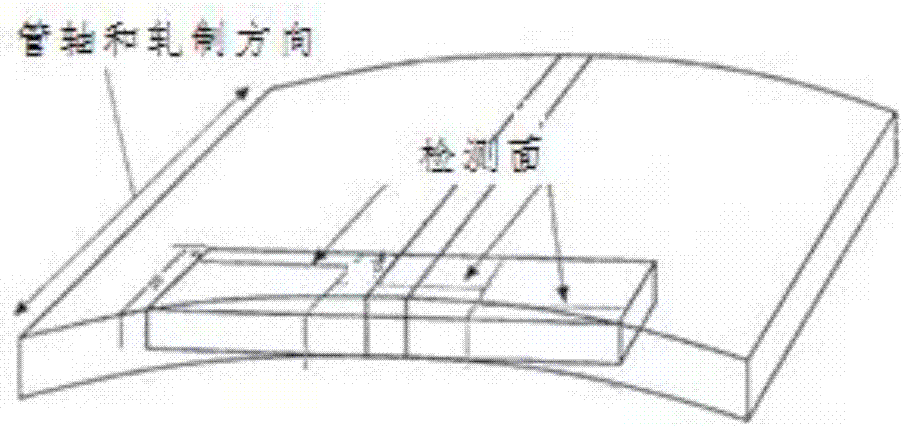

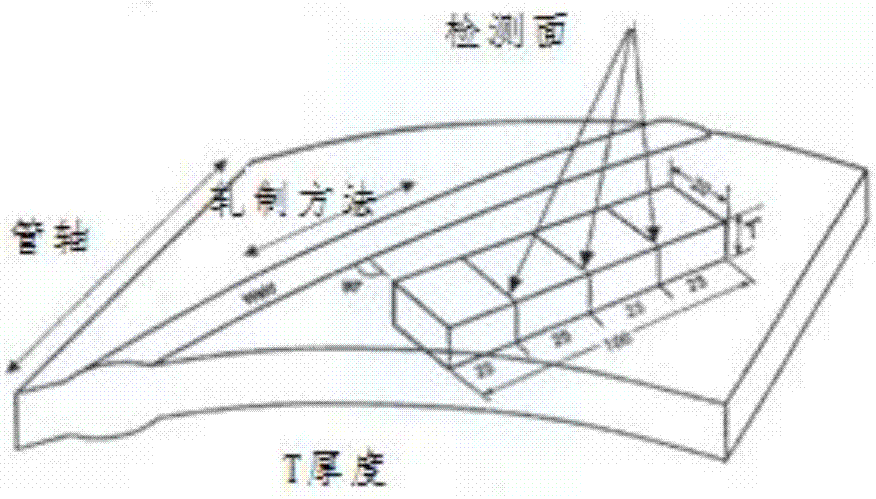

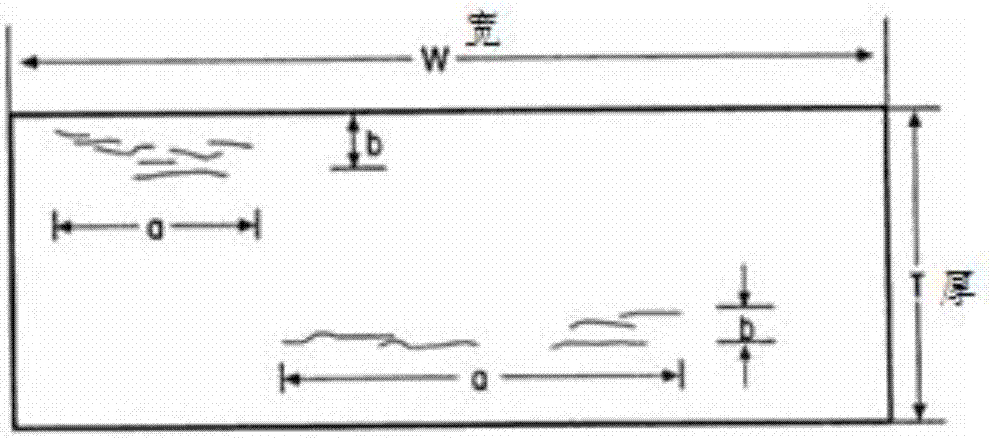

Reliable method for inspecting and researching HIC (hydrogen-induced cracking) sample cracks

ActiveCN107991455AIn-depth studyObserve the characteristicsPreparing sample for investigationTesting metalsHydrogenDirect observation

The invention relates to a reliable method for inspecting and researching HIC (hydrogen-induced cracking) sample cracks. The method comprises the main experiment procedures as follows: (1) processingof an HIC sample; (2) cleaning and storage of the sample; (3) sample soaking; (4) oxygen removal and H2S introduction; (5) pH value determination; (6) continuous testing for 96 h in an H2S saturated state; (7) taking out of the sample; (8) nondestructive testing; (9) sample cutting; (10) grinding, polishing and sample section cutting; (11) evaluation of the sample; (12) selection of an auxiliary welding part; (13) welding; (14) snapping; (15) removal of an auxiliary part; (16) cleaning of the cracked sample and measurement of the depth and width of the cracking surfaces under a metallurgic microscope; (17) deep research of the section. The morphology of the cracking surfaces, including cracking and extension processes, can be directly observed. Dyeing of primary cracking surfaces can be realized through the heating process in a welding technology, and primary cracking surfaces and secondary cracking surfaces can be distinguished. All cracking surfaces can be displayed, missing detection of cracks is avoided, and the morphology and size of the cracking surfaces can be reflected completely.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

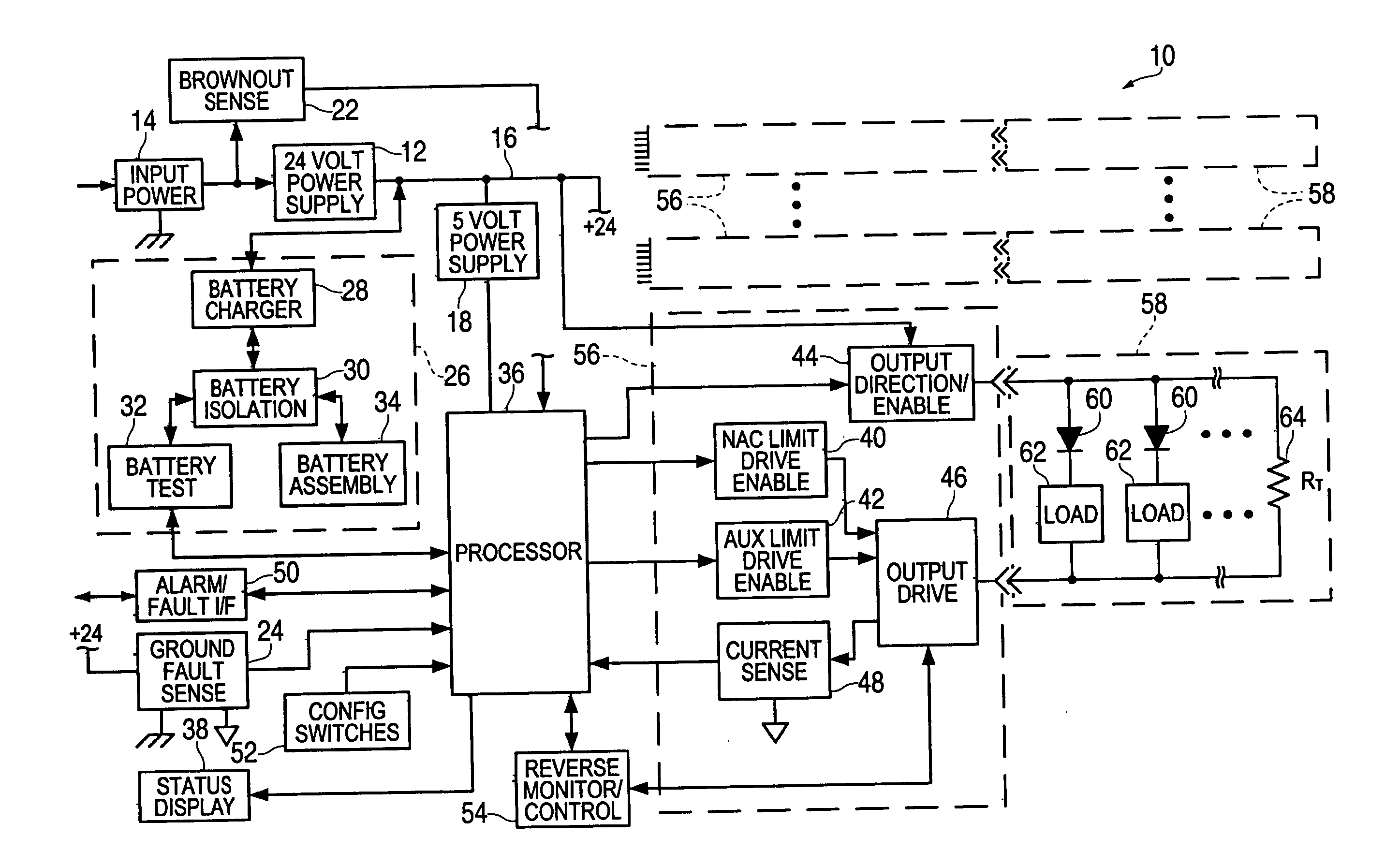

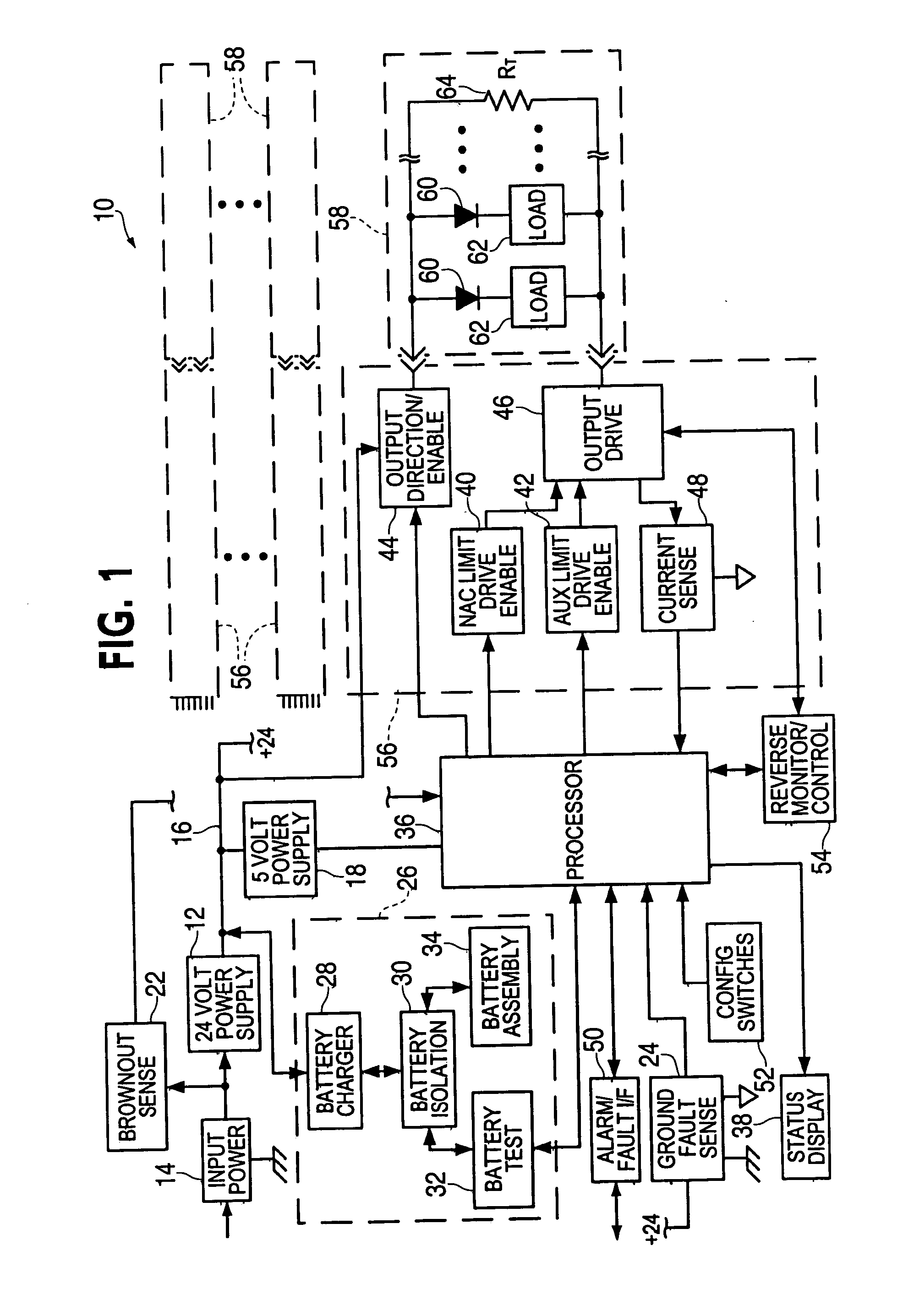

Fire alarm notification power supply with configurable notification appliance circuits and auxiliary power circuits apparatus and method

A power supply for providing excitation to notification appliance circuits (NACs) in fire alarm applications meets revised national and international requirements for both NAC drive and auxiliary load drive tasks with a single circuit configuration. The requirements stipulate ability to tolerate inrush when activating strobe lights and horns of ten times the nominal output, while limiting short-circuit drive in AUX mode to eight amperes after five seconds. The novel power supply improves on the requirements, first by continuously testing for overcurrent NAC status and signaling faults in real time, and second by shutting off AUX drive in event of a short and retrying periodically without a requirement for manual reset. Thus testing for wiring errors is rendered safer and nondestructive, and correction of a wiring error can be quicker.

Owner:GE SECURITY INC

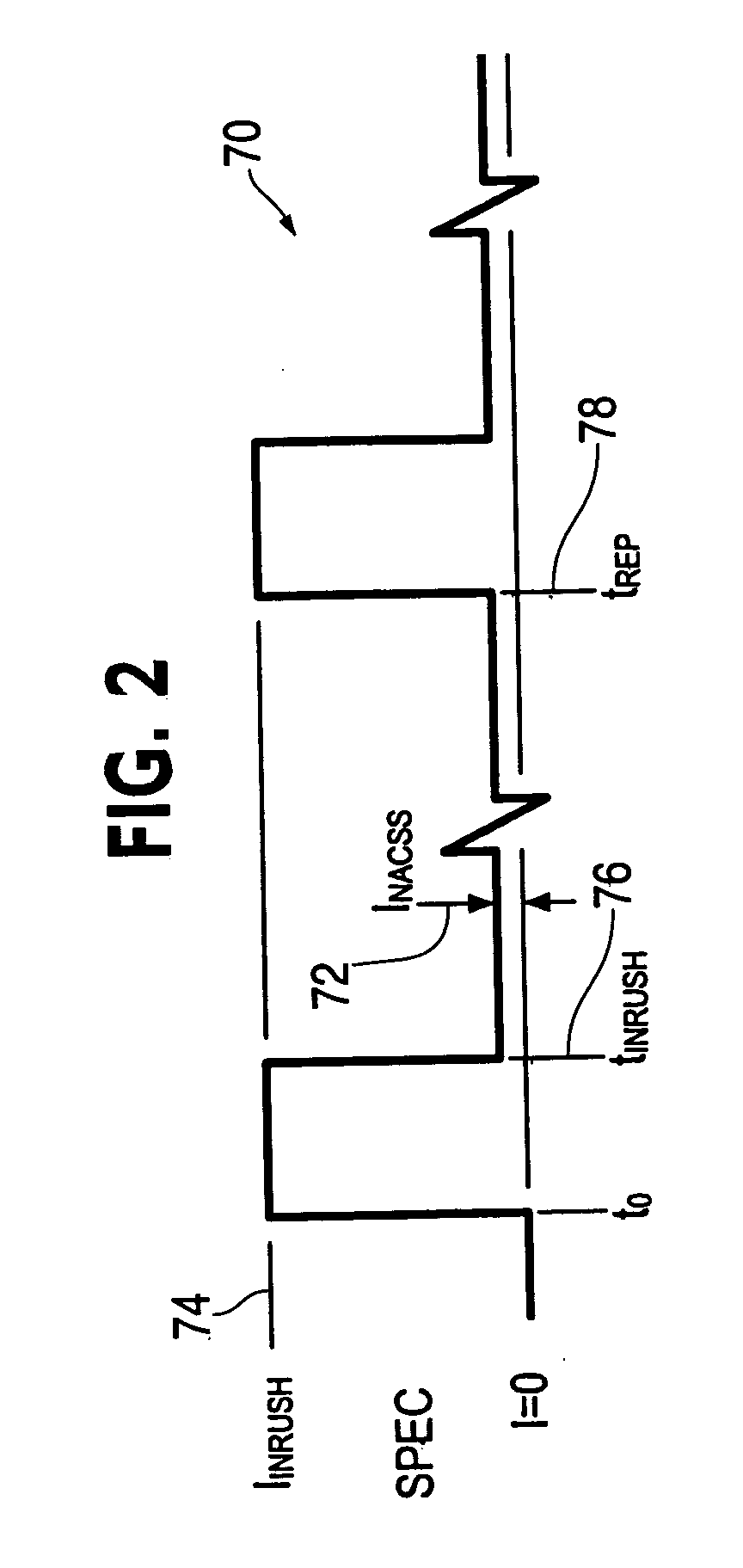

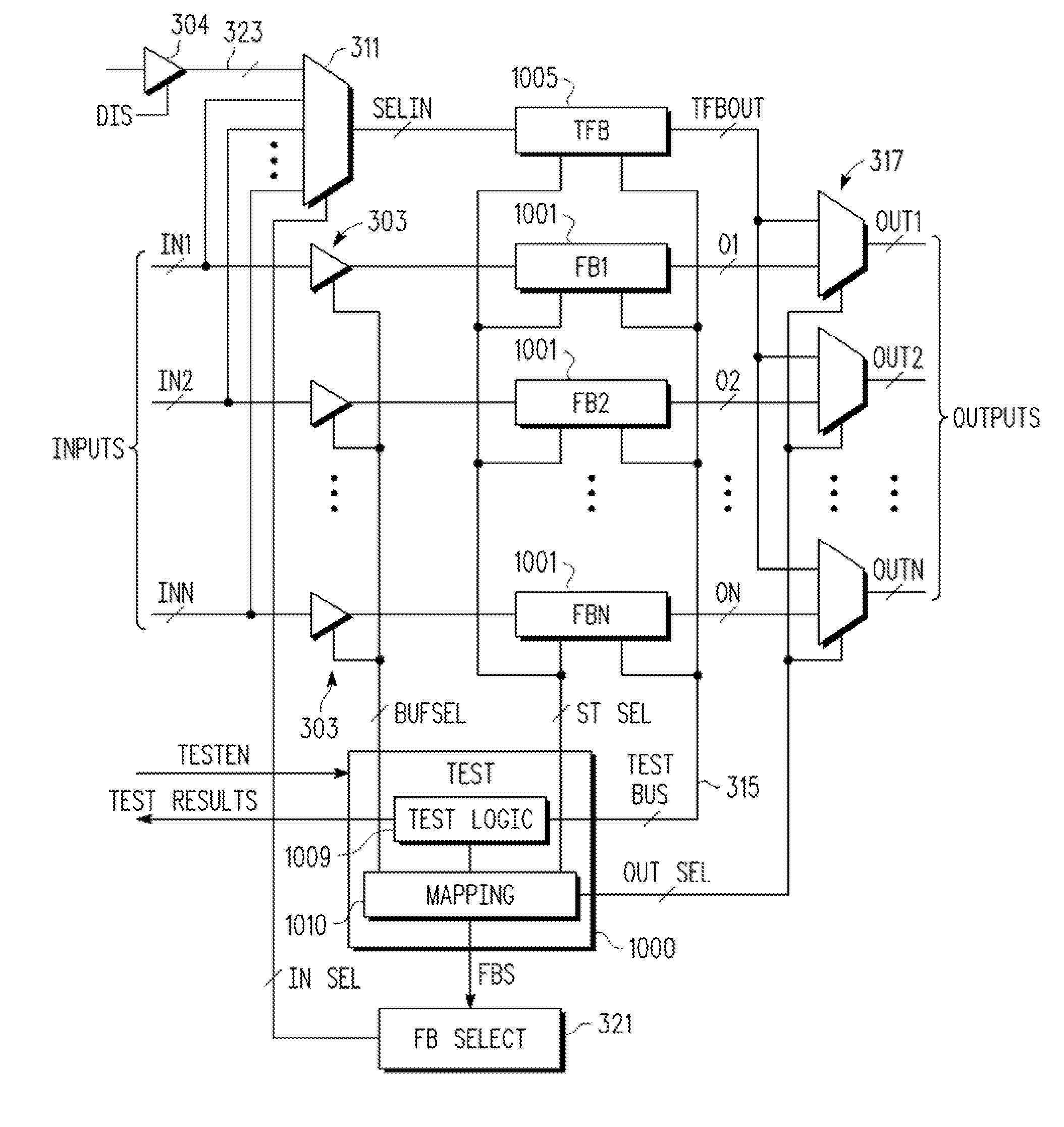

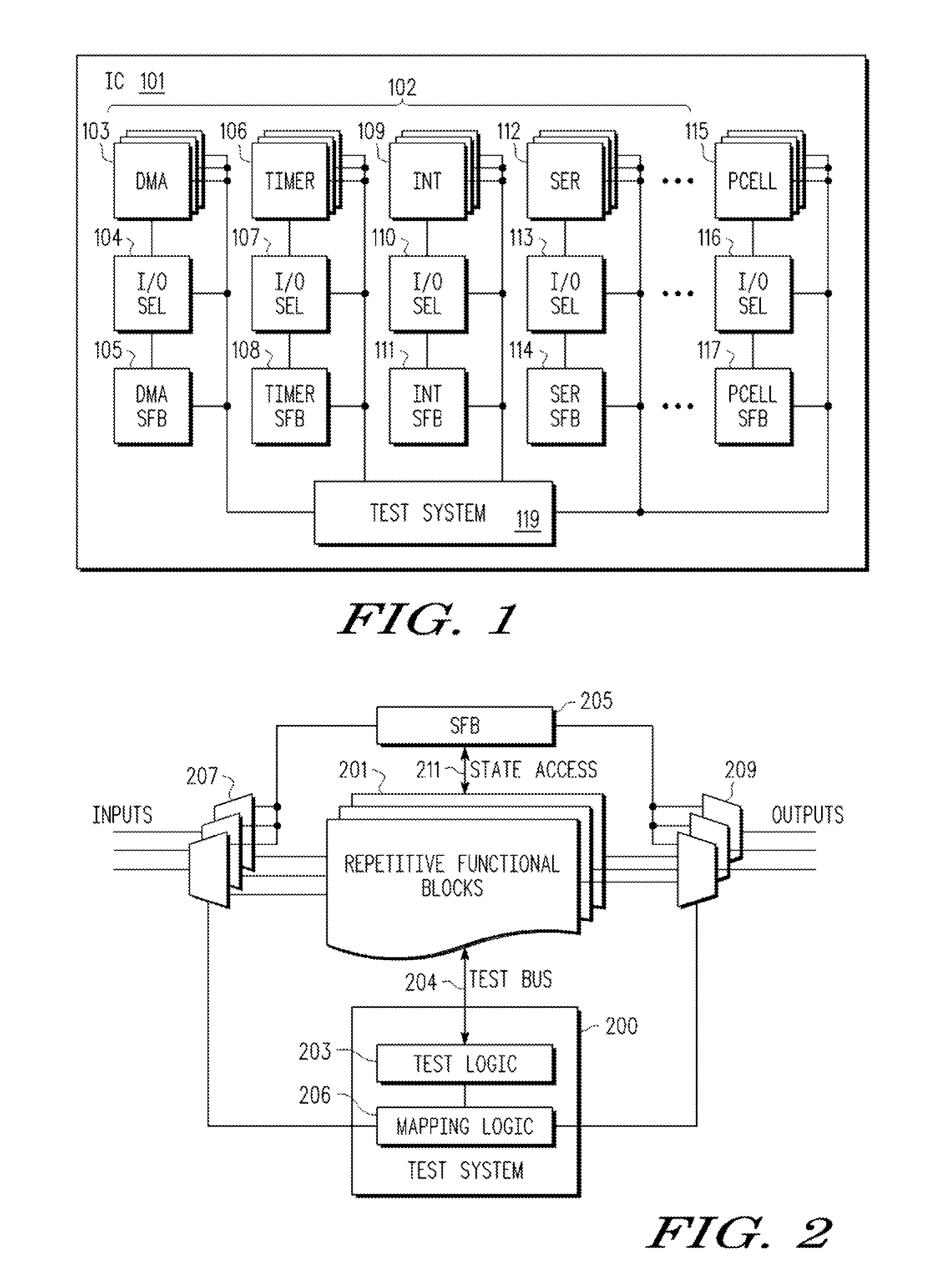

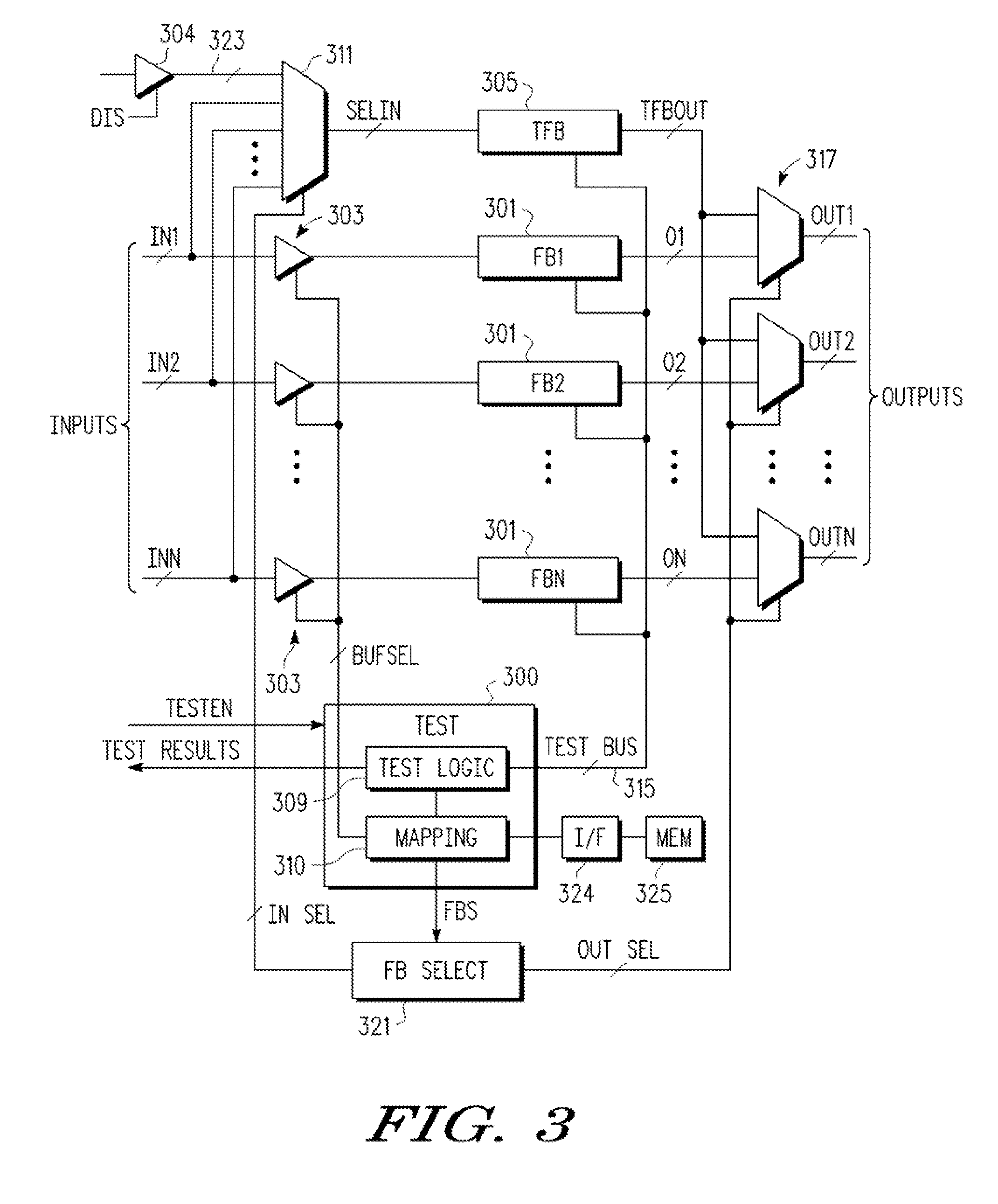

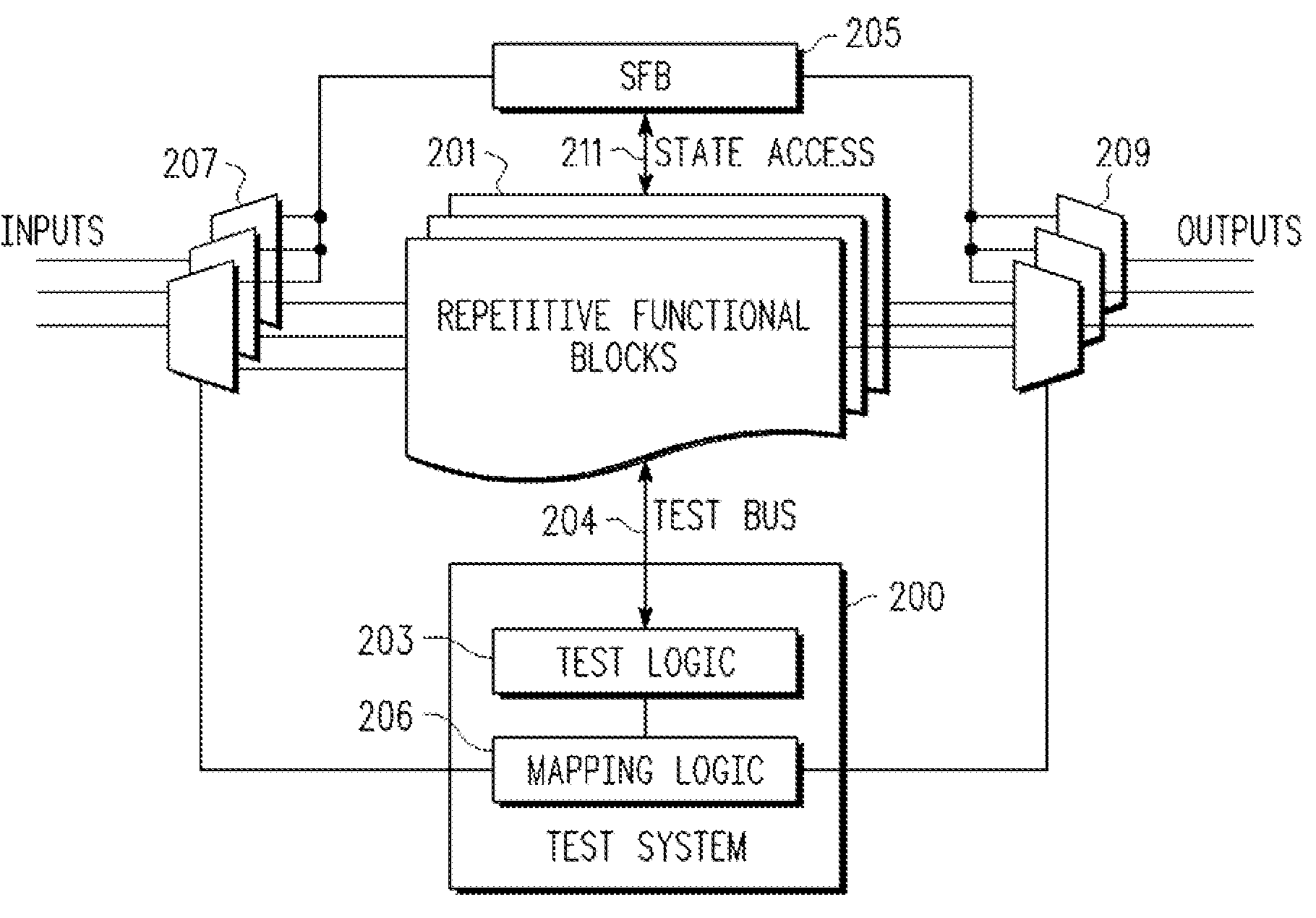

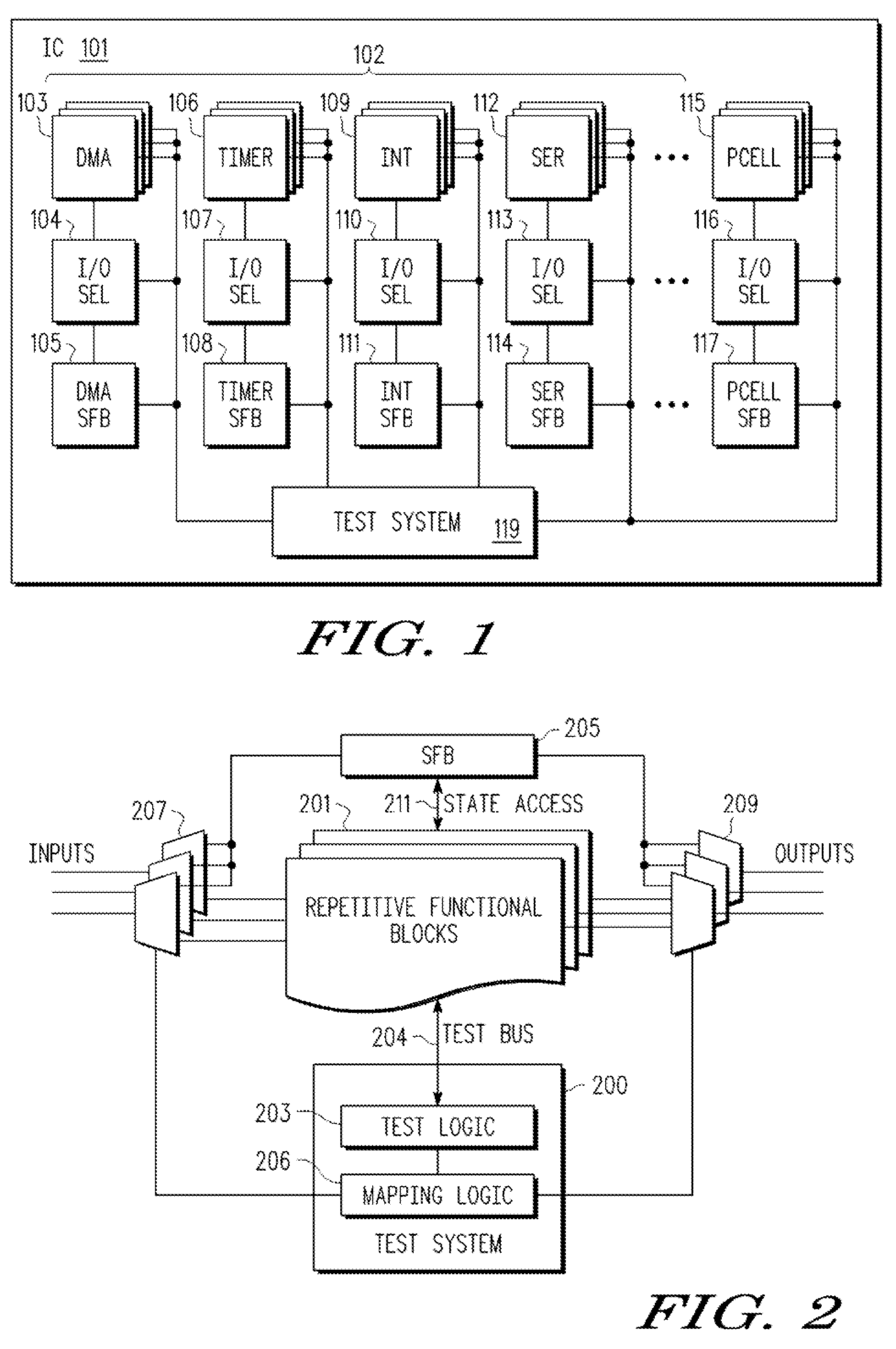

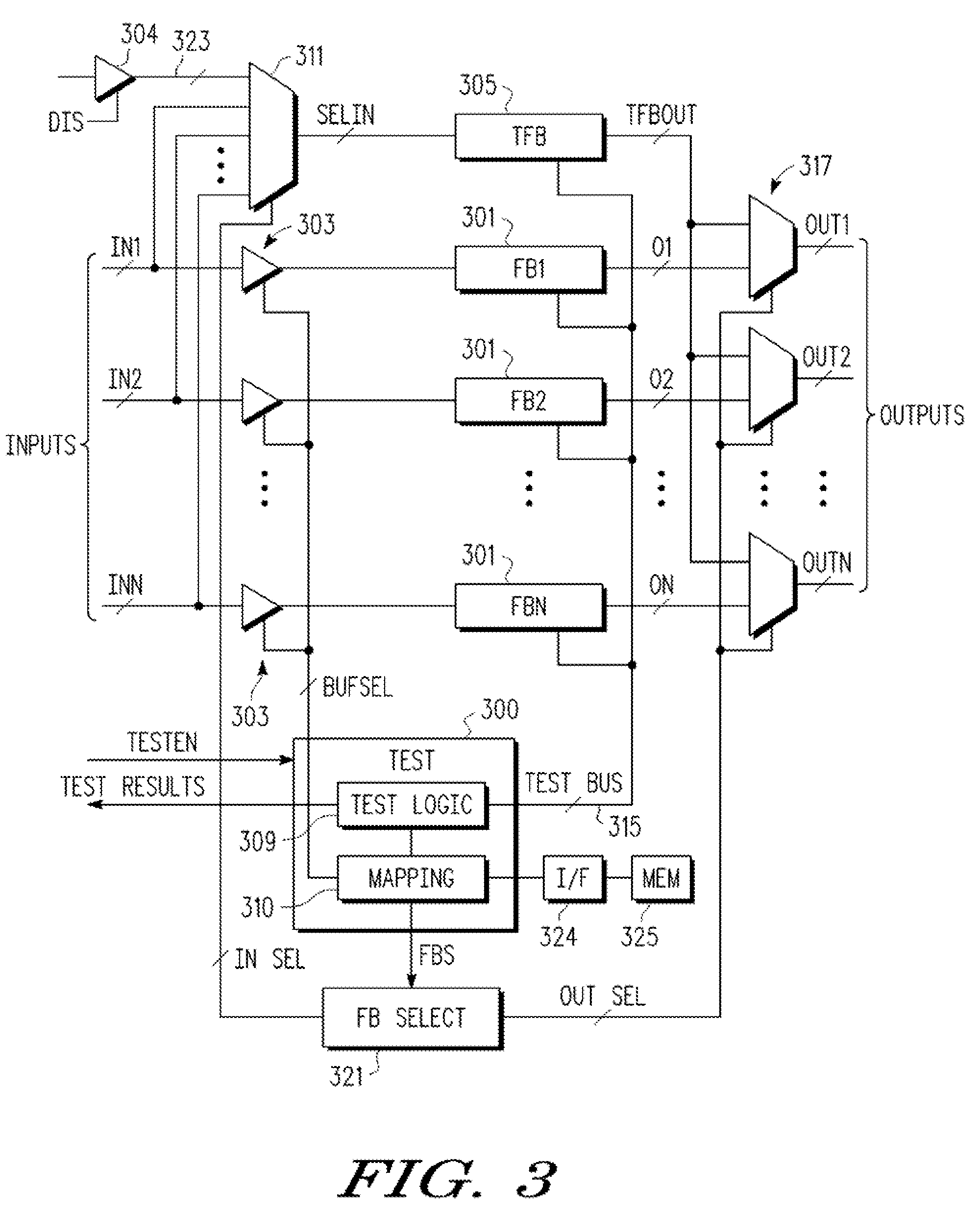

Integrated circuit with continuous testing of repetitive functional blocks

A method of continuous testing of repetitive functional blocks provided on an integrated circuit (IC) which includes selecting one of the repetitive functional blocks at a time for testing, substituting a test repetitive functional block for a selected repetitive functional block, and testing the selected repetitive functional block during normal functional mode of the IC. An IC which includes repetitive functional blocks for performing corresponding functional block operations during normal functional mode of the IC, and a test system which performs continuous testing of each repetitive functional block while the functional block operations are performed during normal functional mode of the IC. One block may be tested during normal operation for each IC reset event without transferring or copying state information. Multiple blocks may be tested one at a time during normal operation by transferring state information between a selected block and a test block.

Owner:NXP USA INC

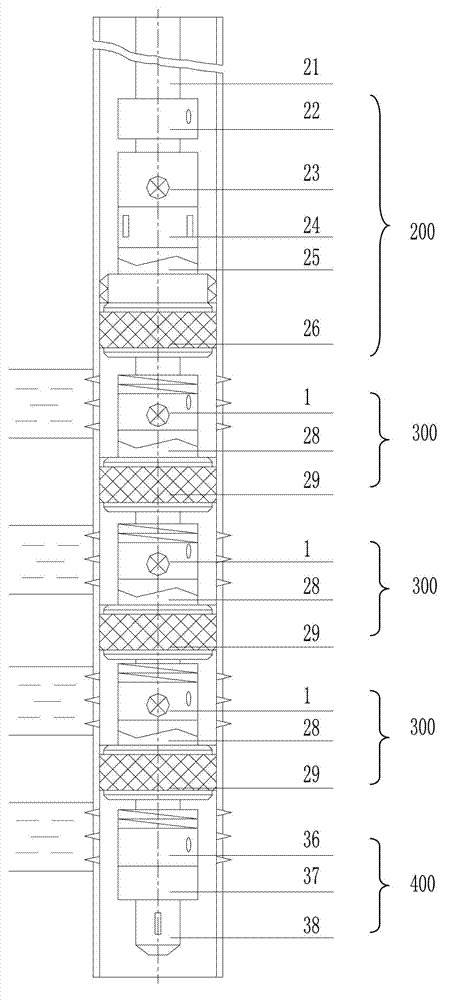

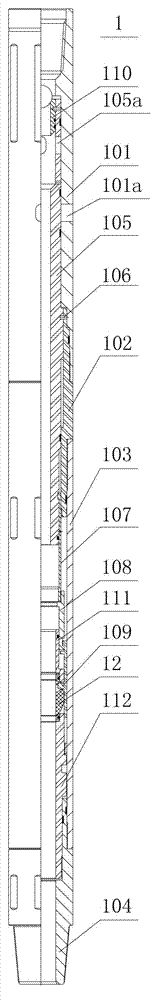

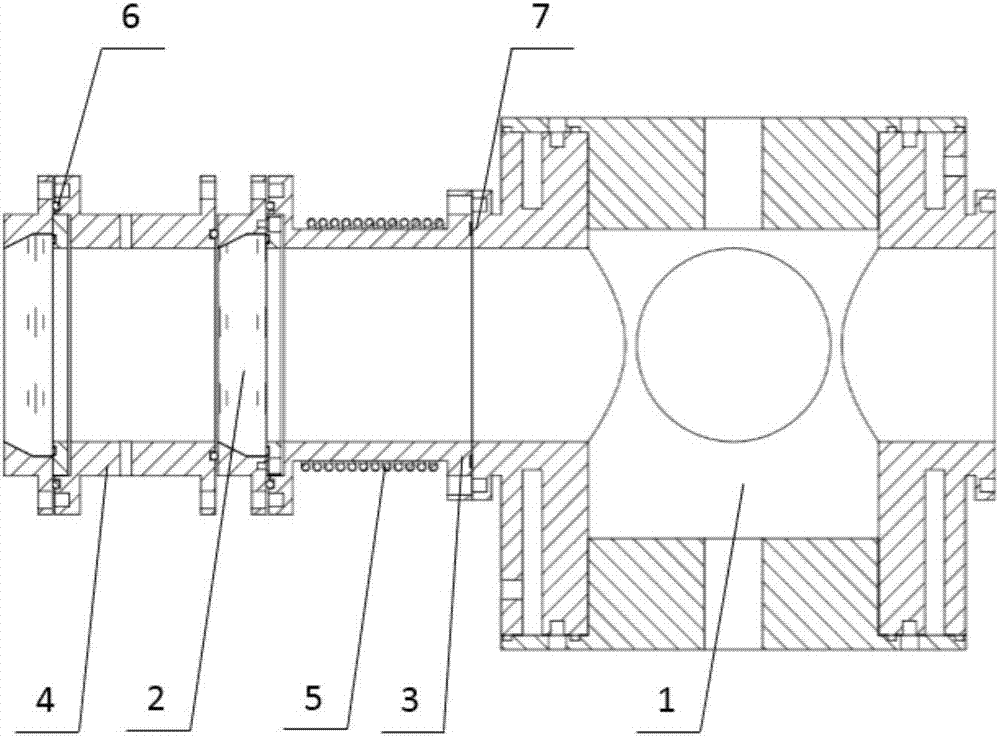

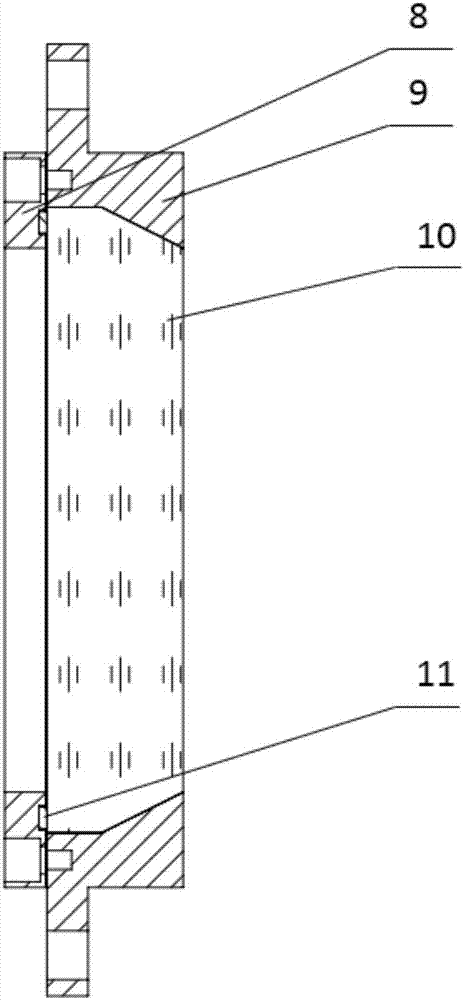

Multi-layer multi-section continuous oil testing system without lifting tubular column and operation method thereof

ActiveCN103114843ACompact and reasonable structureShort cycleSurveyFluid removalHierarchical testEngineering

The invention relates to a multi-layer multi-section continuous oil testing system without lifting a tubular column. The system is connected on the downhole testing tubular column in series and comprises an upper sub-system, a plurality of layered testing systems and a lower sub-system which are sequentially connected in series along the axial direction of the tubular column, wherein the upper sub-system comprises a manifold circulating valve, a main testing valve, a full-bore pressure gage support barrel, a safe connector and a top hydraulic packer which are sequentially connected in series along the axial direction of the tubular column. The plurality of layered testing systems are sequentially connected on the tubular column in series along the axial direction of the tubular column, each layered testing system corresponds to one oil layer, and each layered testing system comprises a hydraulic switching valve, a safe connector and a layered hydraulic packer. The lower sub-system comprises a hydraulic sliding sleeve, a pressure transmitting connector and a monitoring pressure gage which are sequentially connected in series along the axial direction of the tubular column. By means of the system, multi-layer and multi-section continuous testing, capacity increasing revamp, liquid discharging and a series of downhole operation processes can be completed without lifting the tubular column, and the system has the advantages of being simple in construction operation, convenient to assemble, short in construction period and the like.

Owner:PETROCHINA CO LTD

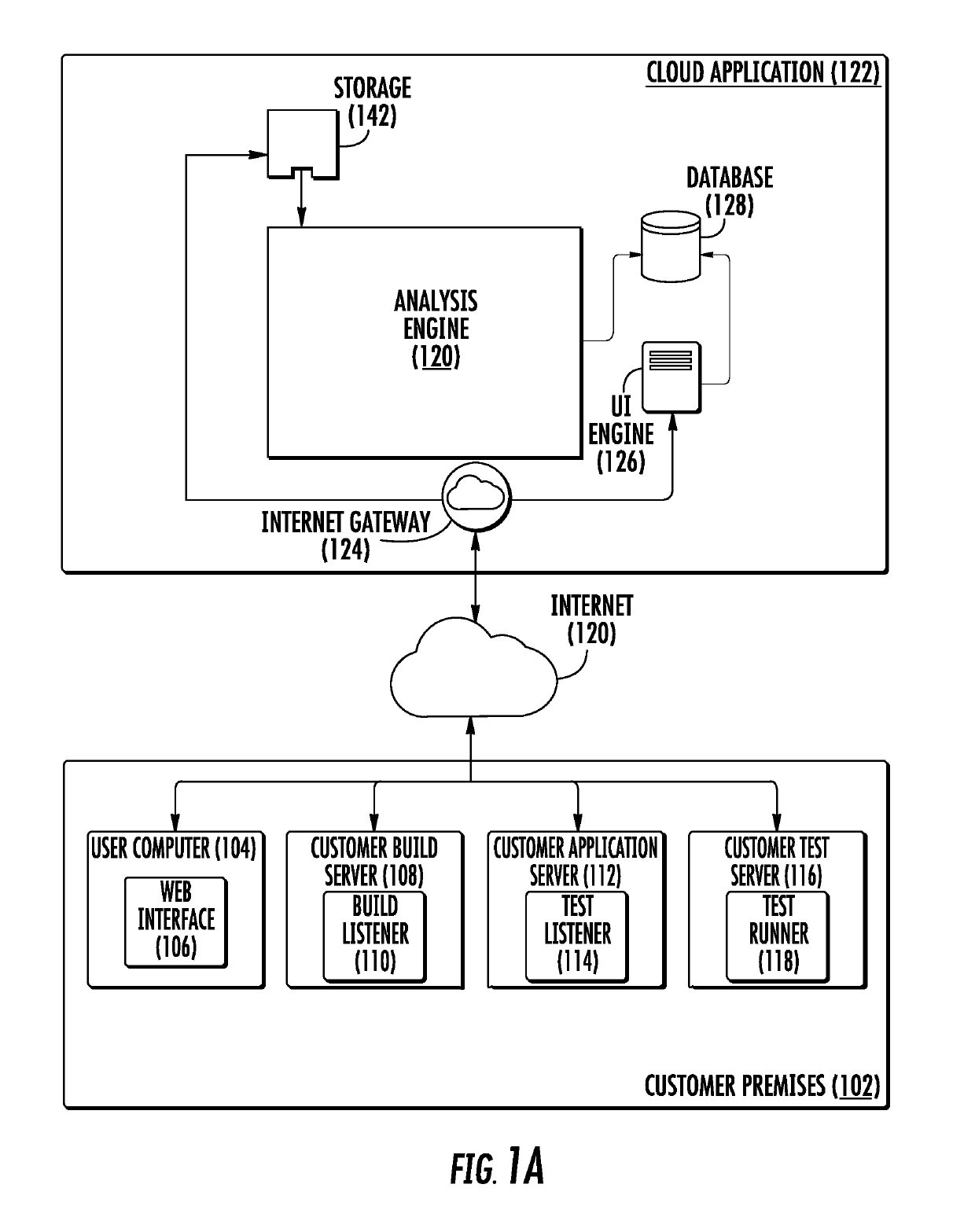

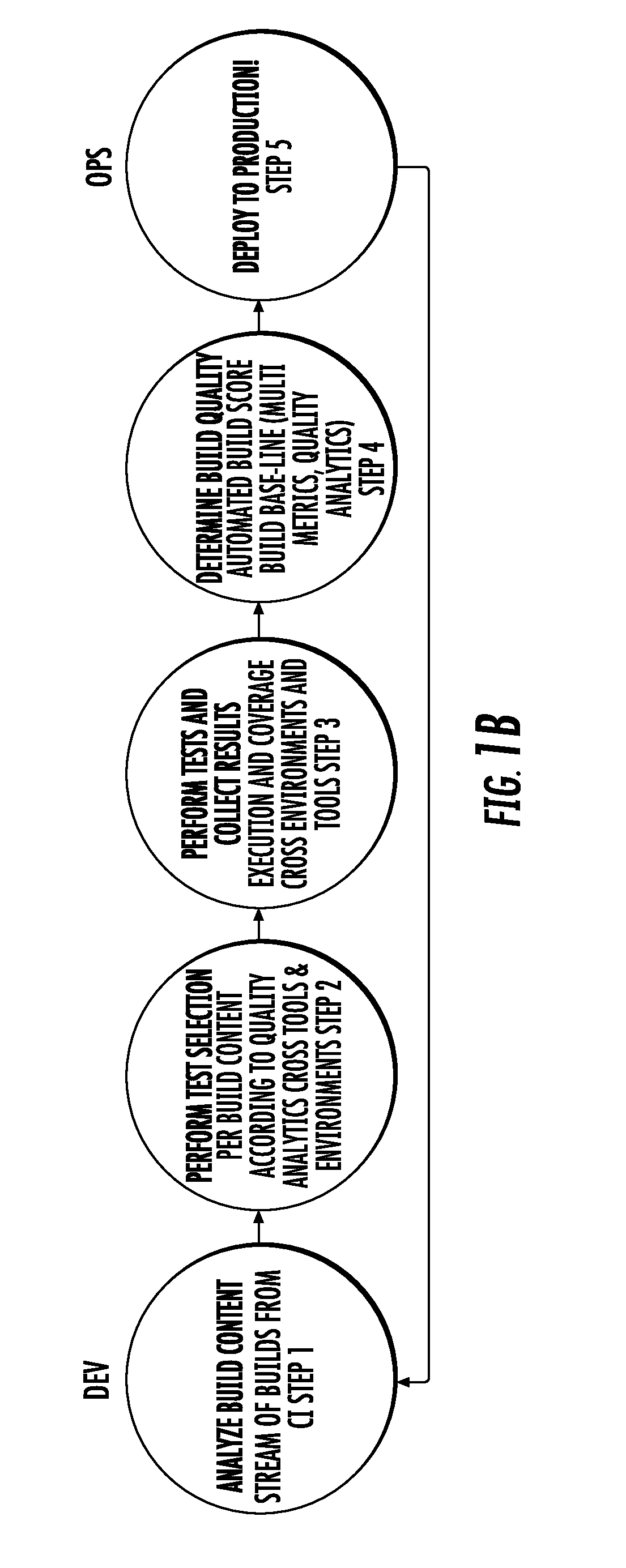

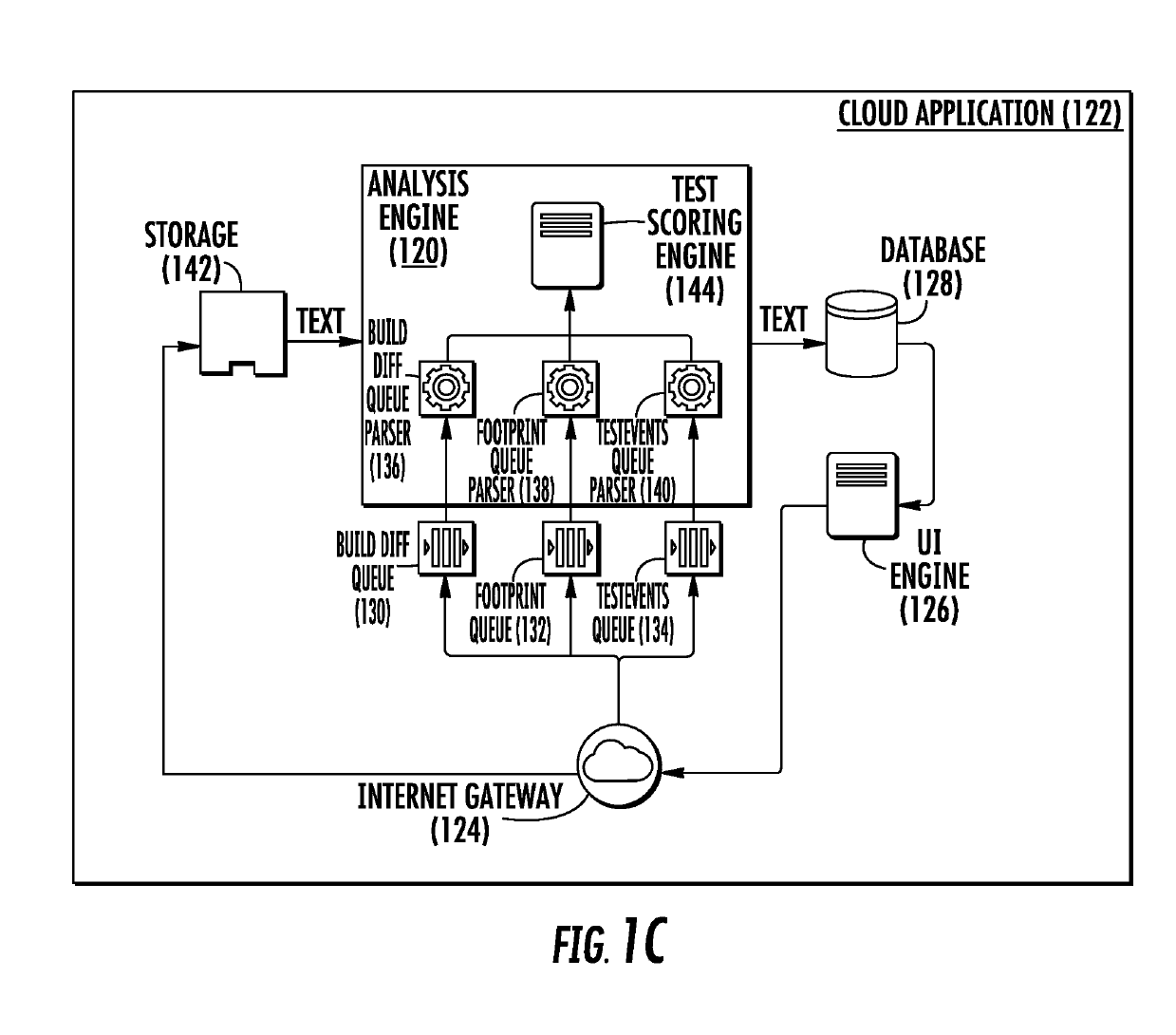

System and method for continuous testing and delivery of software

ActiveUS20190171550A1Automatic detectionRaise priorityVersion controlReverse engineeringContinuous integrationCode development

A system and method for CI / CT / CD, which is continuous integration / continuous testing / continuous delivery, in which testing is fully integrated to the needs of rapid code development and delivery. The system is determining test coverage of a plurality of tests, comprising a code builder for providing code, a code tester for testing the code with said plurality of tests, and a code test analyzer for analyzing results of said plurality of tests to determine coverage of said code by said plurality of tests.

Owner:SEALIGHTS TECH LTD

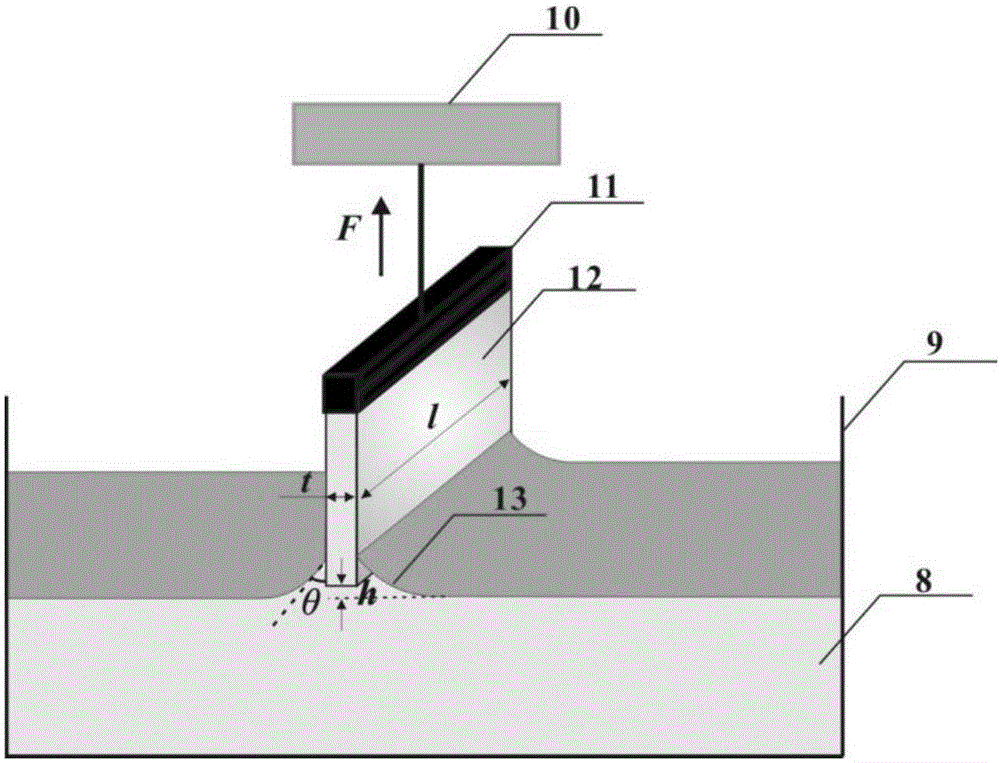

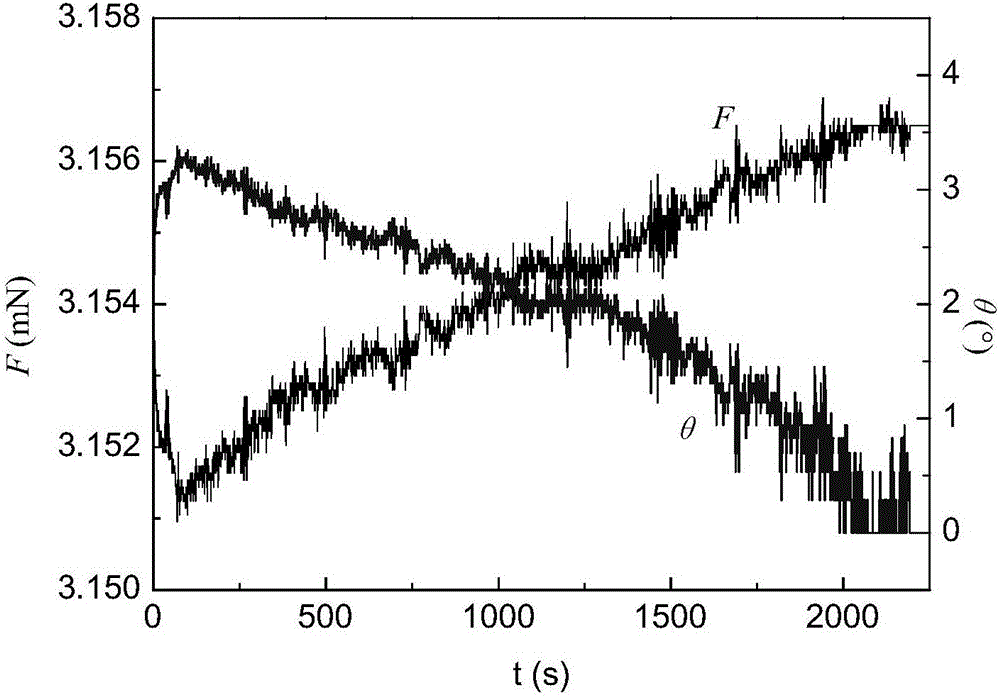

Testing method for rock surface static contact angle and rock surface wettability dynamic change testing method utilizing testing method for rock surface static contact angle

ActiveCN106596348AEasy to understandHigh sensitivitySurface tension analysisSurface stressGeophysics

The invention particularly relates to a testing method for a rock surface static contact angle and a rock surface wettability dynamic change testing method utilizing the testing method for the rock surface static contact angle. The testing method for the rock surface static contact angle includes the steps that the surface of a rock slice is cleaned and dried for use; by means of a surface / tension meter, a sample cell capable of ascending and descending is filled with to-be-tested liquid, and the rock slice for use is clamped and suspended below a micro balance; testing is carried out by means of an 'Interfacial tension' mode, the sample cell slowly ascends during testing till the liquid level just makes contact with the lower surface of the rock slice, reading numbers displayed by the micro balance are recorded, and the stress magnitude (F) of the rock slice is calculated; the contact angle (theta) of the to-be-tested liquid on the surface of rock is deduced and obtained according to the stress magnitude (F) of the rock slice, wherein theta is shown as the formula shown in the specification. The testing method is high in sensitivity, the micro balance can capture the micro change of surface stress of the rock slice, and the small contact angle and the micro change of the contact angle can be tested; the continuous testing time is long, and the rock surface wettability dynamic change rule can be recorded.

Owner:CHINA NAT OFFSHORE OIL CORP +1

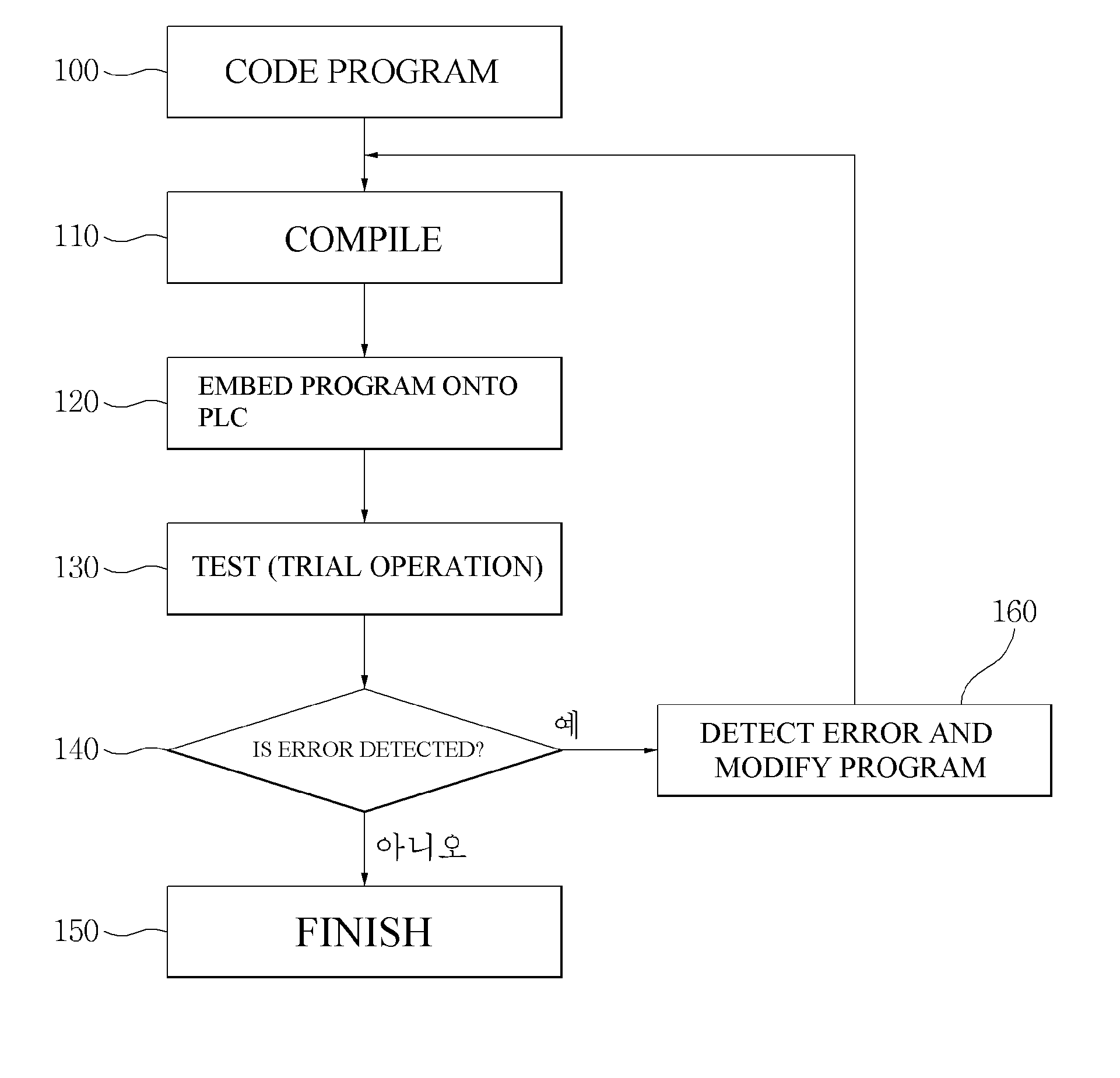

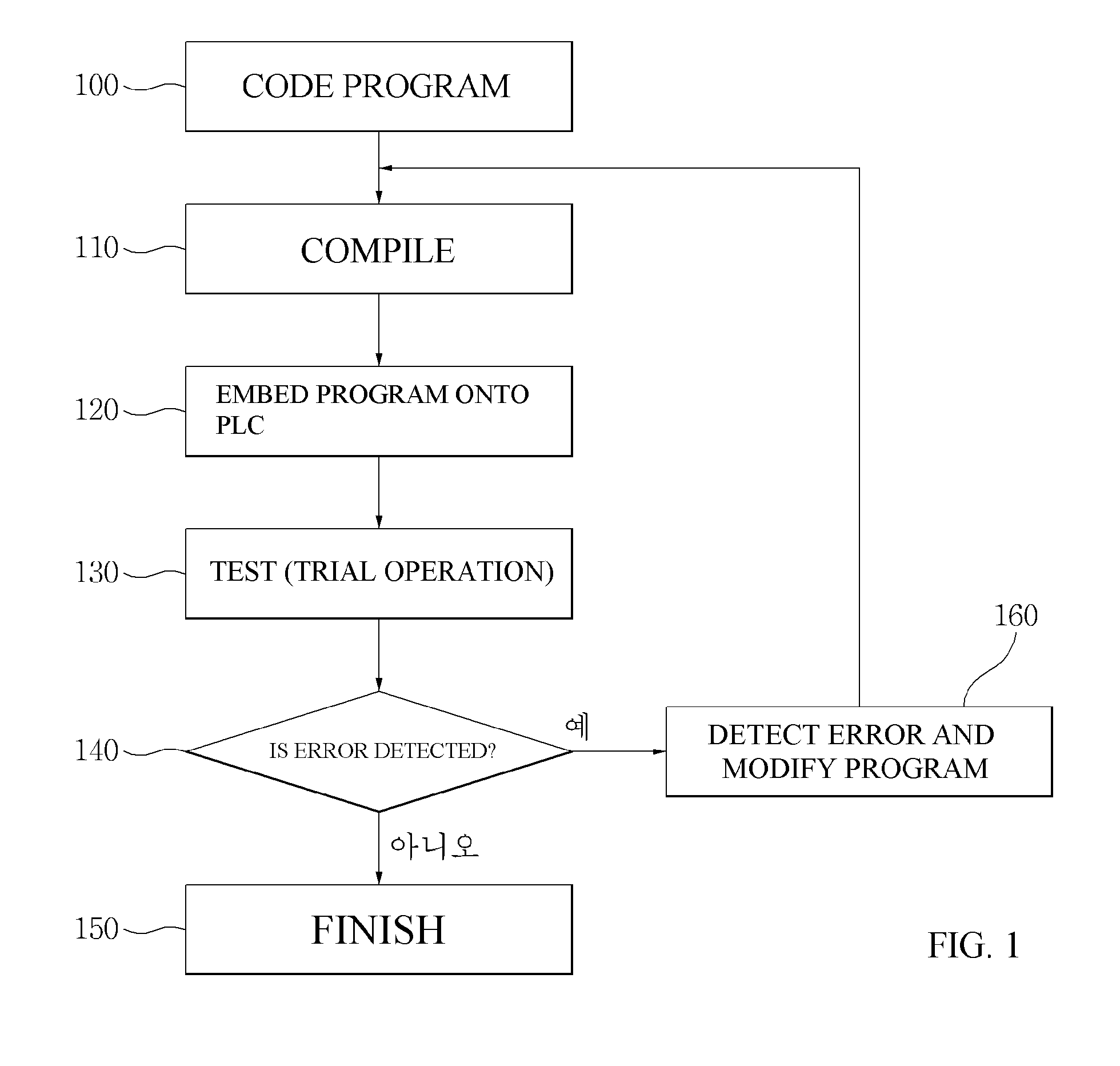

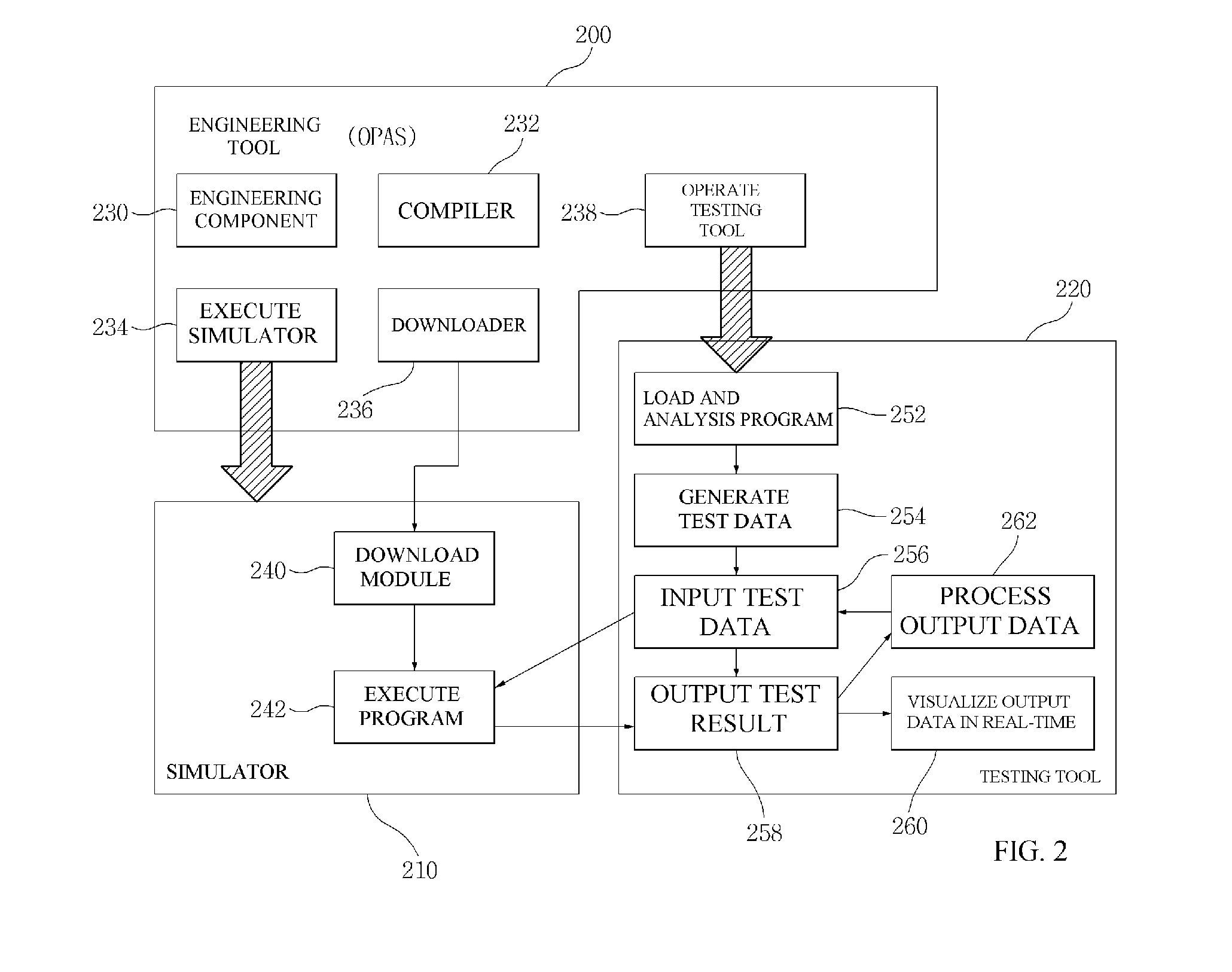

Method and system for testing sofware for industrial machine

ActiveUS20110099540A1Shorten the timeImprove accuracyResistance/reactance/impedenceComputer controlIndustrial machineTesting software

There are provided a method and system for testing software for an industrial machine with continuous test values reflecting actual environmental factors, using a simulator before the software for the industrial machine is embedded into an actual industrial machine. A method for testing software for an industrial machine, the method comprising the steps of: coding a program for a diagram through which the industrial machine is driven; compiling the program into an instruction with which the industrial machine is driven; downloading the compiled program onto a simulator for implementing a programming interface provided by the industrial machine; executing the compiled program in the simulator: generating a first data for testing the compiled program: transmitting the first test data to the simulator having the downloaded program from a testing tool; and outputting a result data obtained after executing the program having the transmitted first test data and then transmitting the result data to the testing tool. Accordingly, it is possible to reduce a time taken for testing, to improve the accuracy and efficiency of the testing and to save cost required in the testing.

Owner:SURESOFT TECH +1

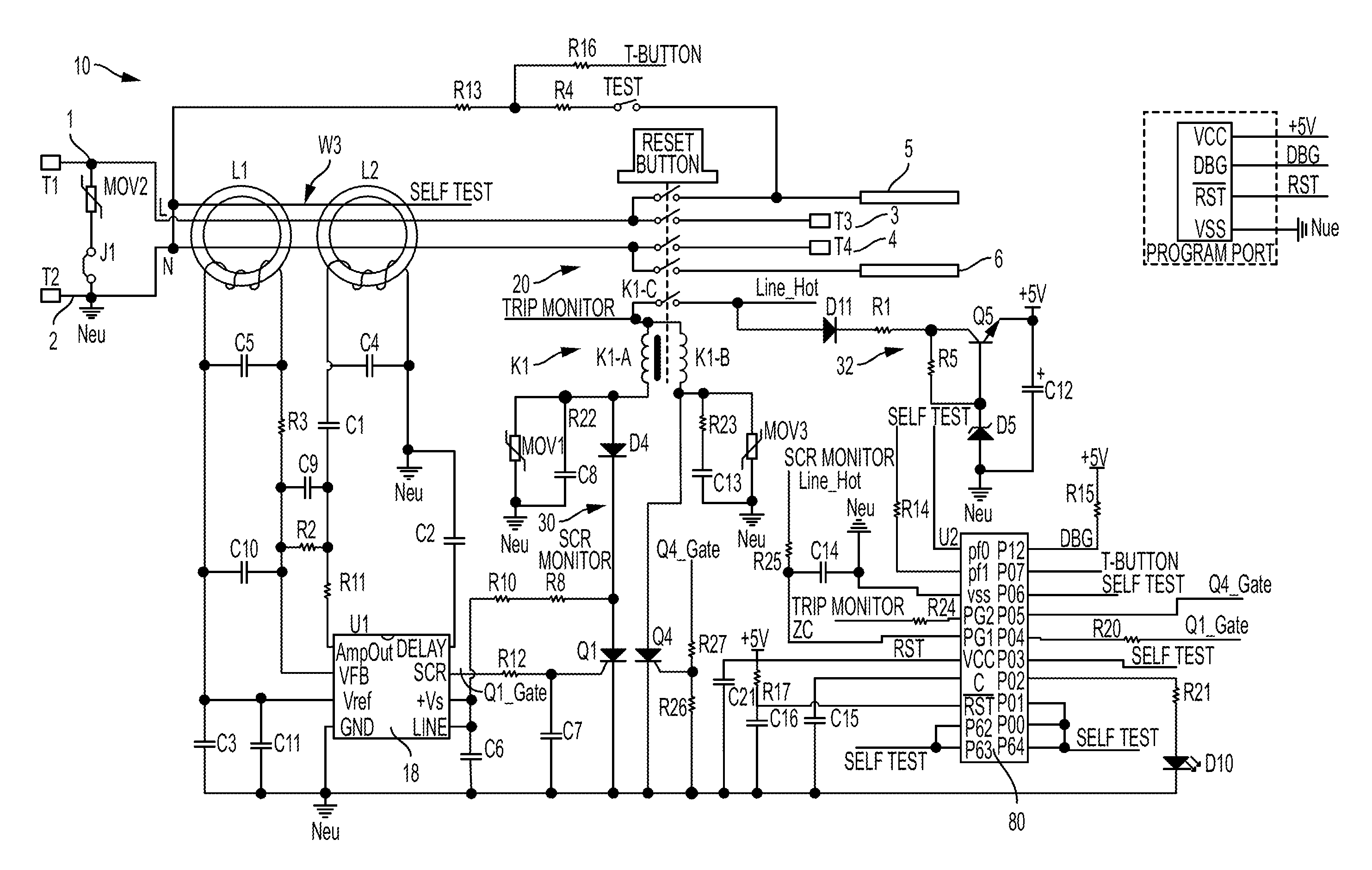

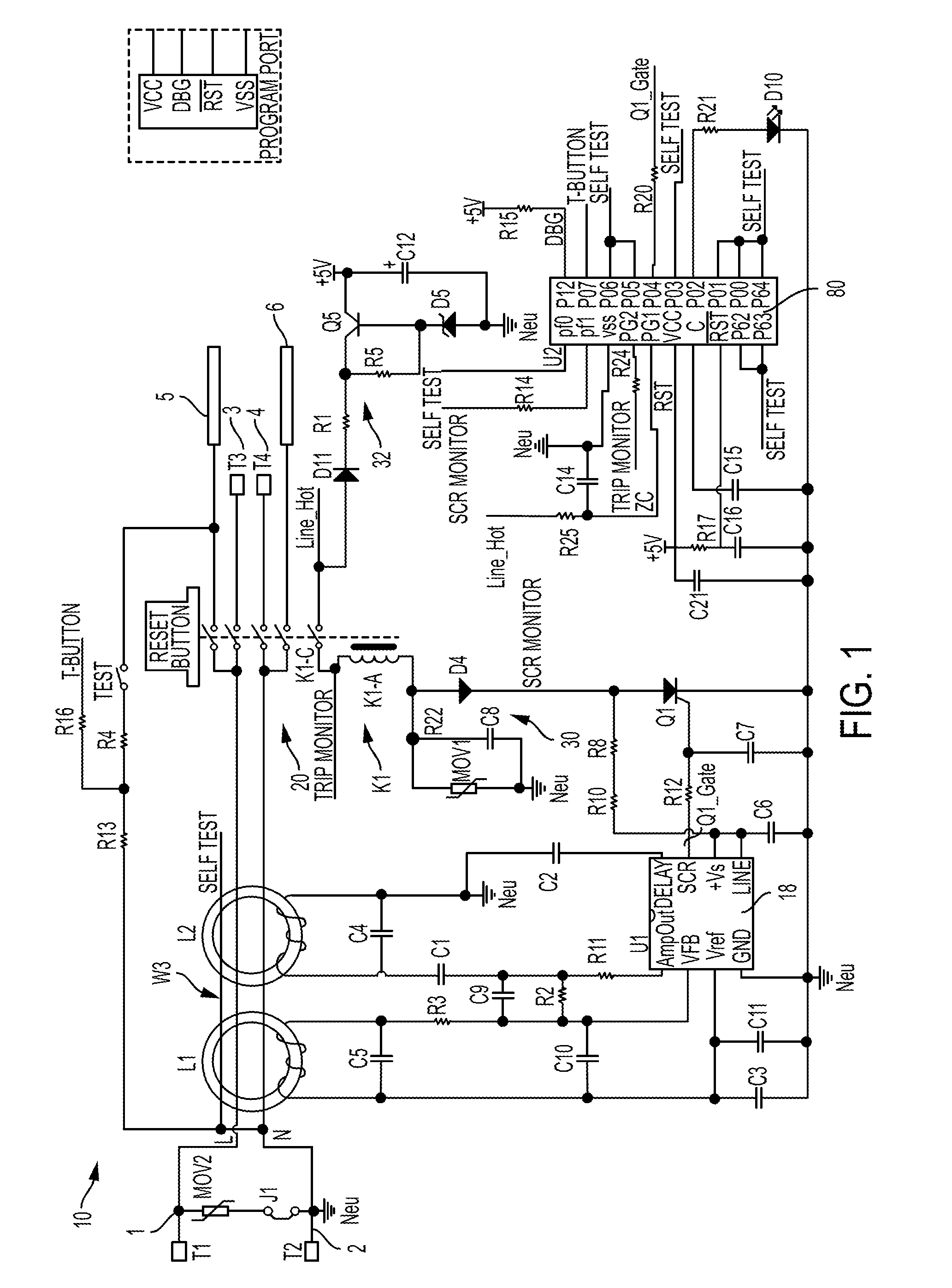

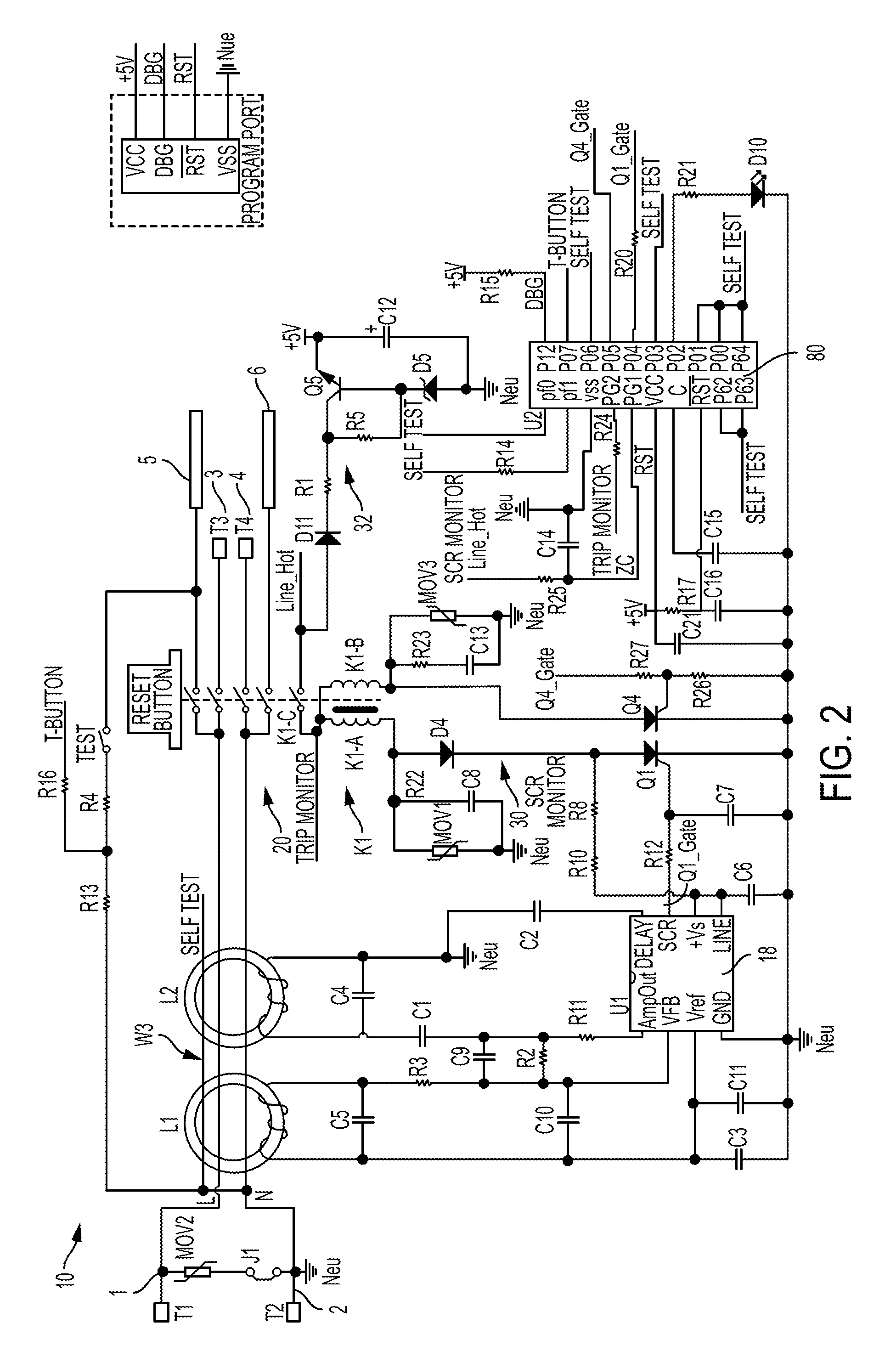

Protective Device with Self-Test

ActiveUS20170025846A1Emergency protective arrangements for limiting excess voltage/currentArrangements resposive to fault currentElectricityEngineering

A protective electrical wiring device includes a protective assembly including a sensor portion, a fault detection portion and a switch portion. A control circuit is configured to automatically perform a test cycle from time to time, each test cycle including a series of tests that determine the operational state of the protective assembly. At least one successive test in the test cycle is configured to test at least a portion of the protective assembly tested by a predecessor test in the test cycle. The control circuit is configured to establish a test result for each test in the series of tests, with each test result being stored in a test result table. The control circuit is configured to effect or not effect an end-of-life state by evaluating at least a portion of the test results in the test result table in accordance with a predetermined voting scheme.

Owner:PASS SEYMOUR

Apparatus and methods for continuous compatibility testing of subterranean fluids and their compositions under wellbore conditions

Owner:HALLIBURTON ENERGY SERVICES INC

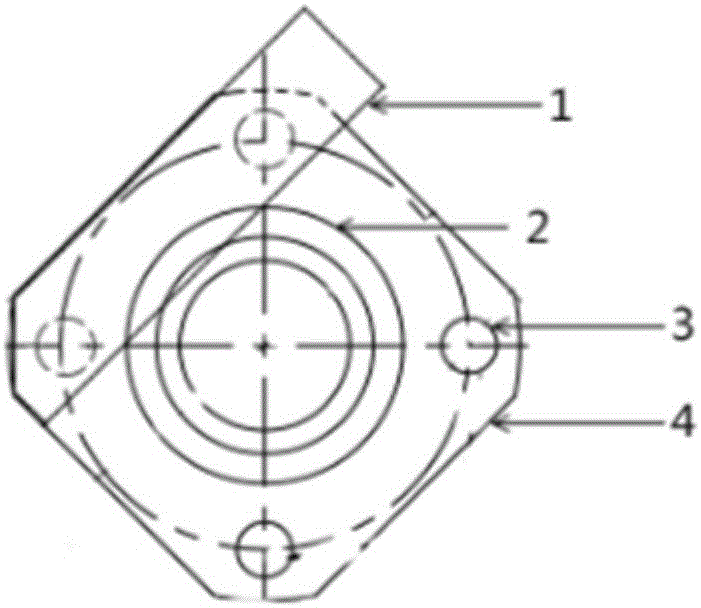

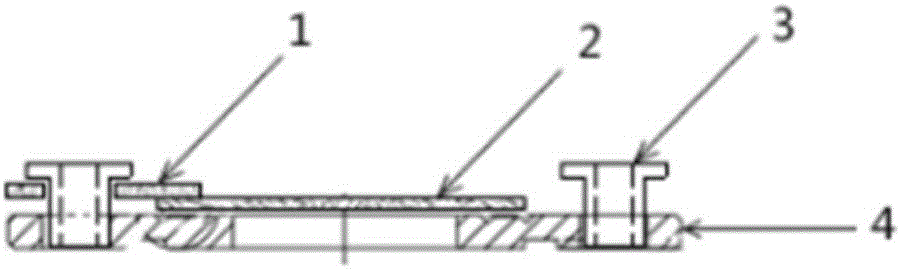

An electrolytic bath reaction chamber used for in-situ XRD tests and a testing method

ActiveCN106645240AImprove sealingImprove cycle performanceMaterial analysis using wave/particle radiationSignal-to-noise ratio (imaging)Power flow

An electrolytic bath reaction chamber used for in-situ XRD tests and a testing method are provided. The electrolytic bath reaction chamber includes a working electrode cover, a counter electrode base and an optional pedestal fixing the counter electrode base in order from top to bottom. The working electrode cover and the counter electrode base are sealed and connected in an insulating manner. The working electrode cover includes a cover body, a testing window and an optional first electric conductor. The counter electrode base includes a base body, a sliding block, a mobile device and an optional second electric conductor. The mobile device is connected to the sliding block and is used for moving the sliding block to allow the sliding block to be adjacent to the testing window. The electrolytic bath reaction chamber when being used for in-situ XRD tests has advantages of a simple and rapid working electrode preparing method, capability of continuous testing on one electrode sheet, few components, convenient assembling, a compact structure, a small size, good equipment universality and capability of being repeatedly used, and has characteristics of a high signal-to-noise ratio, a small off-axis error and no impurity-phase peak interference of obtained spectrums, uniform electric current density of the working electrode, accurate potential testing, high capacity retention rates in long circulation, and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

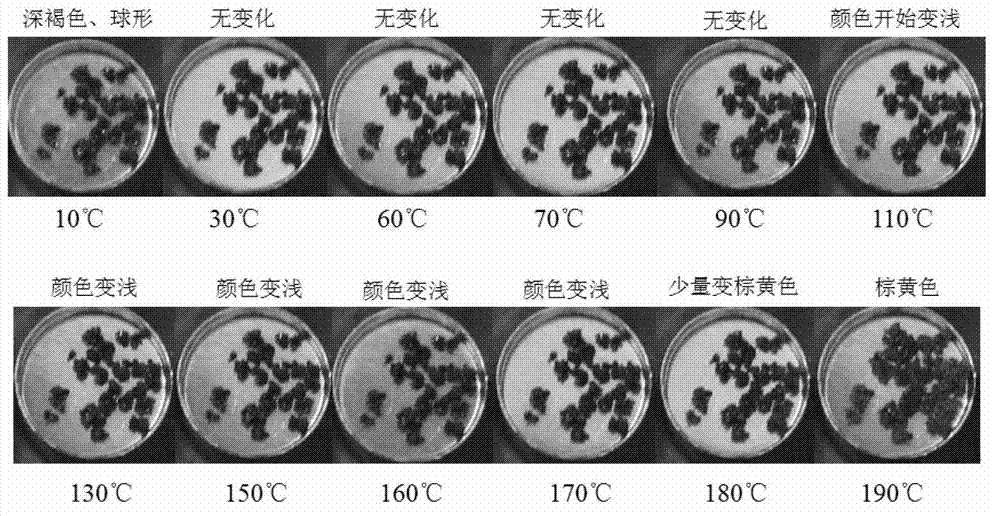

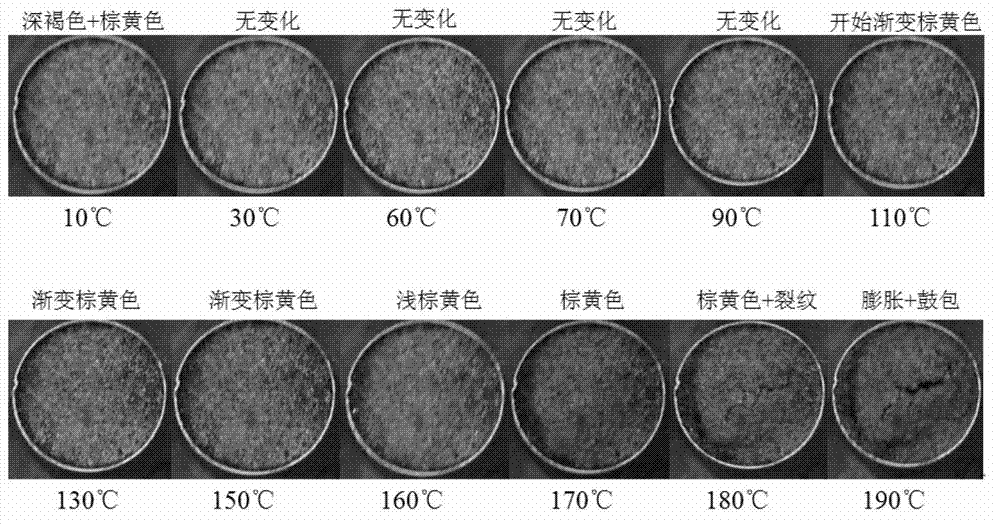

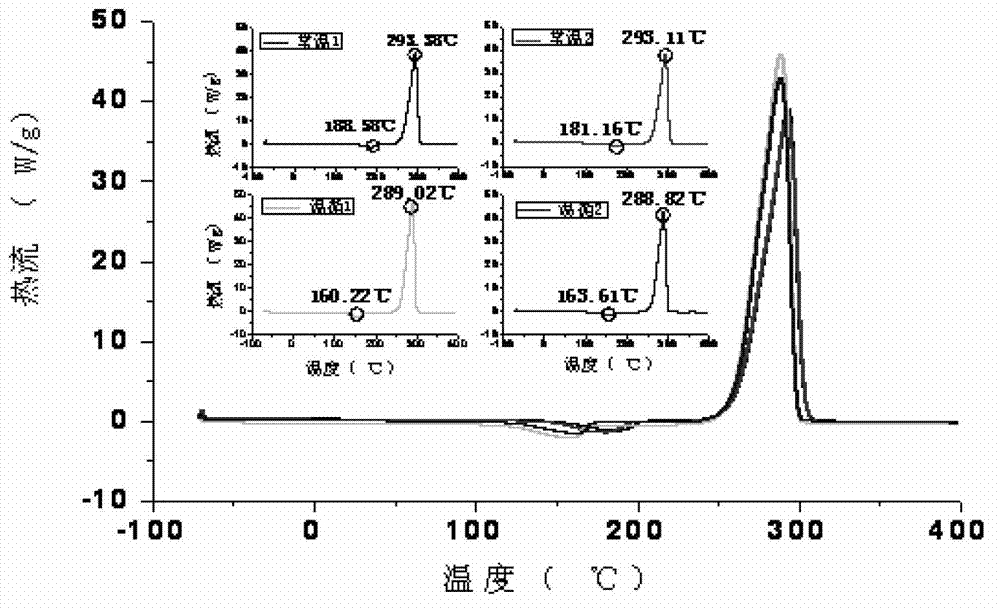

Method for testing performances of initiating explosive material changing with temperature

ActiveCN103196910AComprehensive change analysisEasy to operateMaterial heat developmentMaterial analysis by optical meansTest performanceCrucible

The invention discloses a method for testing the performances of an initiating explosive material changing with temperature. According to the invention, a method of combined usage of a high-definition digital camera and a differential scanning calorimeter is employed; a cover of the differential scanning calorimeter is opened, and a small amount of an initiating explosive material sample is placed in a crucible; the differential scanning calorimeter is continuously heated or cooled from a normal temperature at a certain temperature varying rate; the high-definition digital camera is used to shoot pictures to record physical appearance of the sample, and thus, continuous testing of physical changes of the initiating explosive material with temperature is realized. With the method provided by the invention, analysis of changes of chemical performances of initiating explosive materials with temperature can be realized, and analysis of changes of physical performances of loose or compact initiating explosive materials with temperature can also be realized; the method has the characteristic of easy and safe operation, can realize more comprehensive analysis of changes of the initiating explosive material with temperature, is applicable to both analysis of changes of a variety of initiating explosive materials with temperature and analysis of changes of other reagent samples with temperature and has good versatility.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

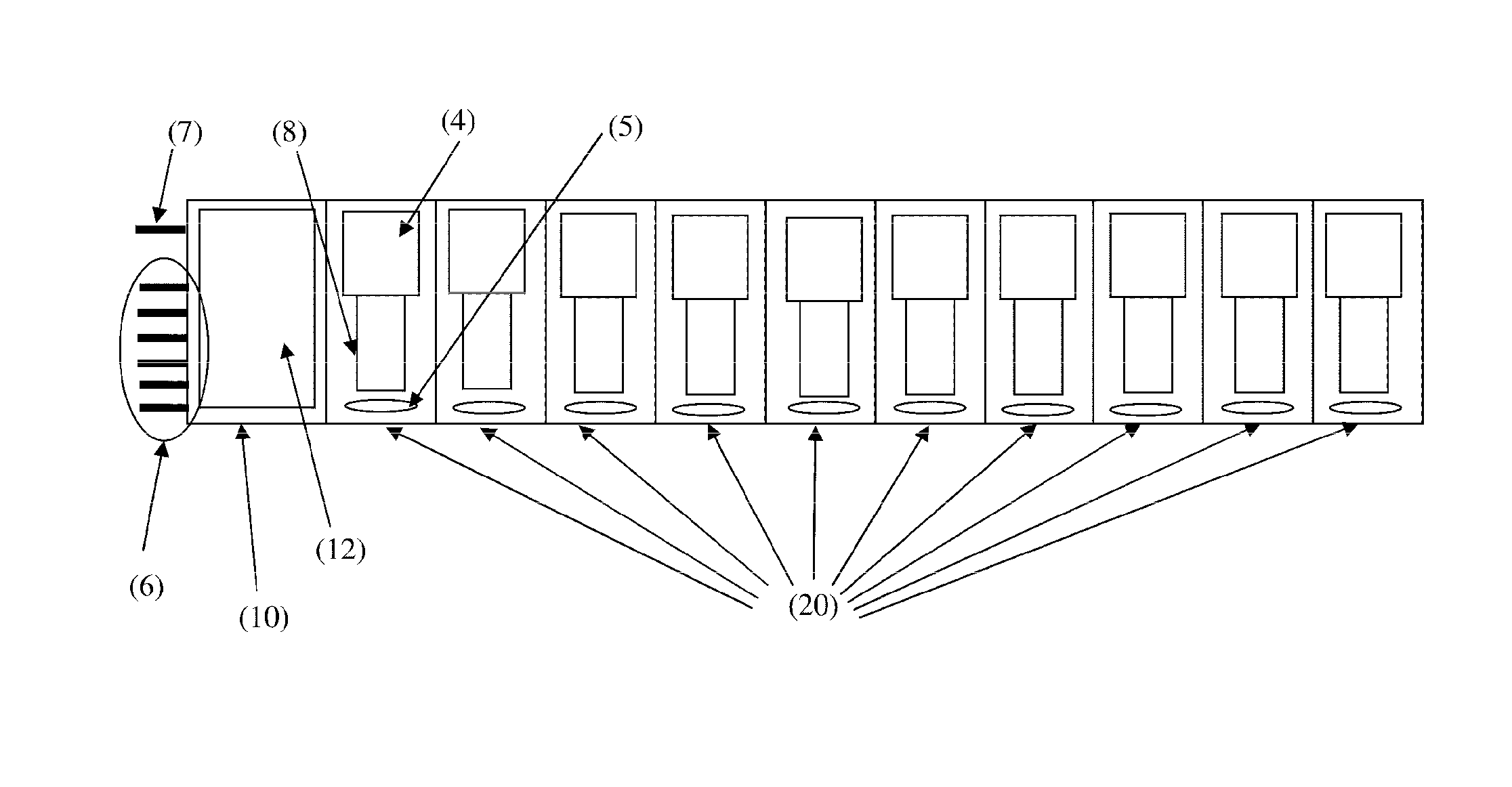

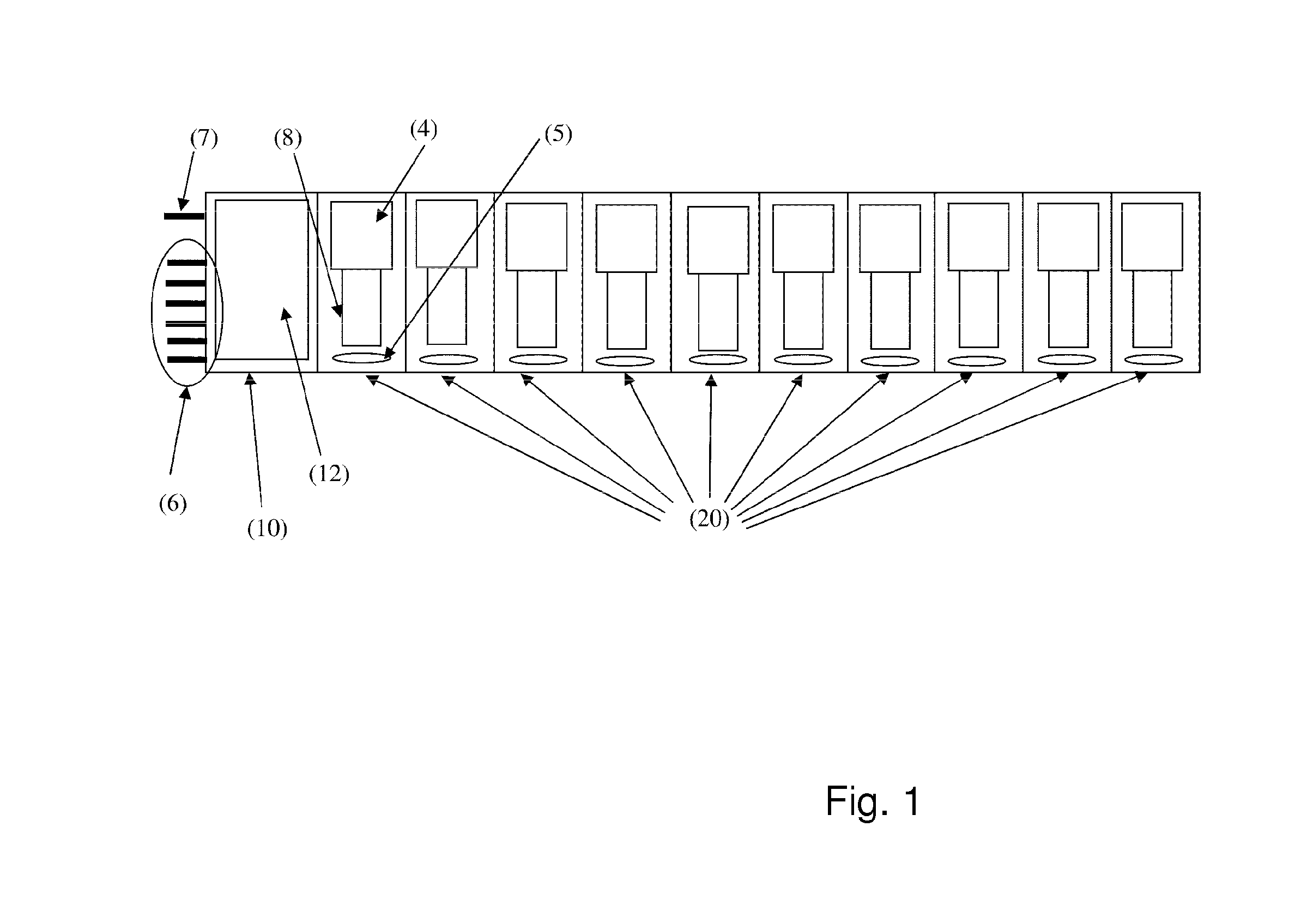

Test station for portable gas measuring devices

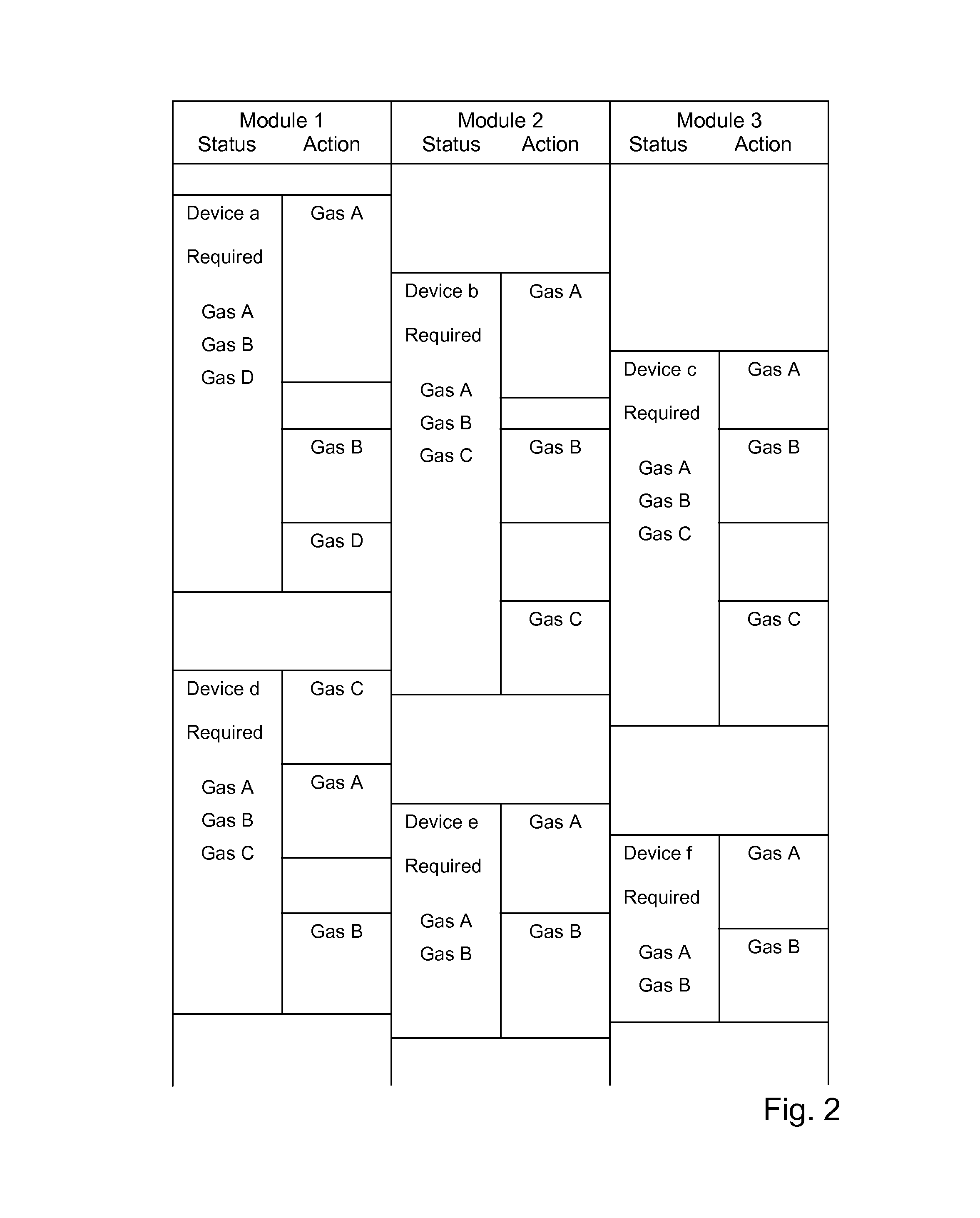

ActiveUS9128067B2Carry-out quicklyReduce testingMaterial analysis by optical meansGas analyser calibrationDevice typeControl set

A test station for a plurality of test gases, includes a main unit (10) with a control (12) and test modules (20), each for a gas measurement device, that exchange data to register a type of gas measurement device and test gas(es) required for the device type. The control sets a schedule for a test using a test gas, or for a plurality of successive tests each with different test gases and carries out the specific test planned according to the schedule, in parallel with tests for all of the test modules for a test gas and determines, as an additional gas measurement device is inserted, based on the particular device type of the additional gas measurement device, whether the currently-running test with the current test gas is suitable for the inserted test module; and if the test gas is suitable, to start the test for this test module.

Owner:DRAGER SAFETY

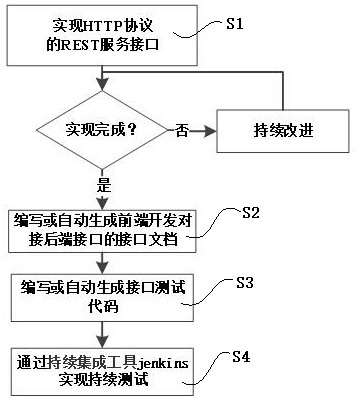

Method and system for quickly and automatically testing based on swagger

ActiveCN111930635AHigh speedImprove work efficiencySoftware testing/debuggingCreation/generation of source codeContinuous integrationLogisim

The invention provides a rapid and automatic test method and system based on a swagger. The method and system for quickly and automatically testing based on swagger comprises the following steps: S1,compiling and designing an REST service interface of an HTTP protocol according to service logic; s2, compiling or automatically generating an interface document of a front-end development docking rear-end interface; s3, compiling or automatically generating an interface test code for testing whether the interface function logic conforms to the business process or not; s4, achieving continuous testing through a continuous integration tool jenkins, and then achieving automation of the interface testing code process. According to the method, the swagger-editior is adopted to automatically generate the interface test code, so that the interface document can be quickly updated, the software quality is guaranteed, the professional requirements on developers are reduced, the interface test speedis increased, the work efficiency is improved, and convenience and quickness are achieved.

Owner:深圳微品致远信息科技有限公司

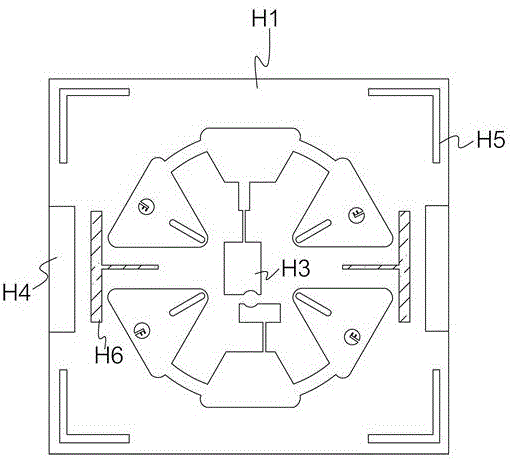

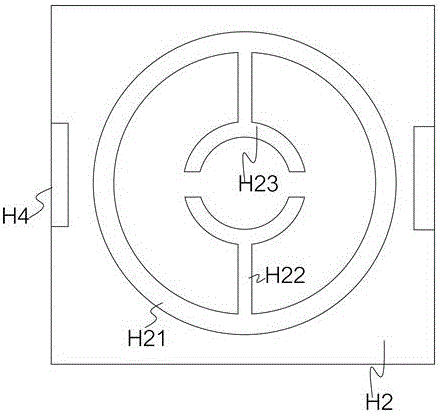

Micro-strip double-layer antenna

ActiveCN106207425AImprove performanceHigh gainRadiating elements structural formsAntennas earthing switches associationWidebandImpedance bandwidth

The invention discloses a micro-strip double-layer antenna. The micro-strip double-layer antenna comprises a first PCB and a second PCB which are laminated together; a first micro-strip unit is arranged on the top surface of the first PCB; the first micro-strip unit comprises two micro-strip vibration sets which are same in shape and arranged symmetrically; a second micro-strip unit is arranged on the top surface of the second PCB; and when the first PCB and the second PCB are laminated, the second micro-strip unit is located at the top surface of the second PCB and the bottom surface of the first PCB. Excellent performances and gain of the antenna with a relatively good front-to-rear ratio are realized through excellent double-layer structure design as well as continuous testing and parameter adjustment. The antenna has the characteristics of low profile, broad band and high gain; the antenna 10dB has the impedance bandwidth of 28.4%; and the average gain of a single antenna is 8.2 dBi.

Owner:佛山市佳昇通讯设备有限公司

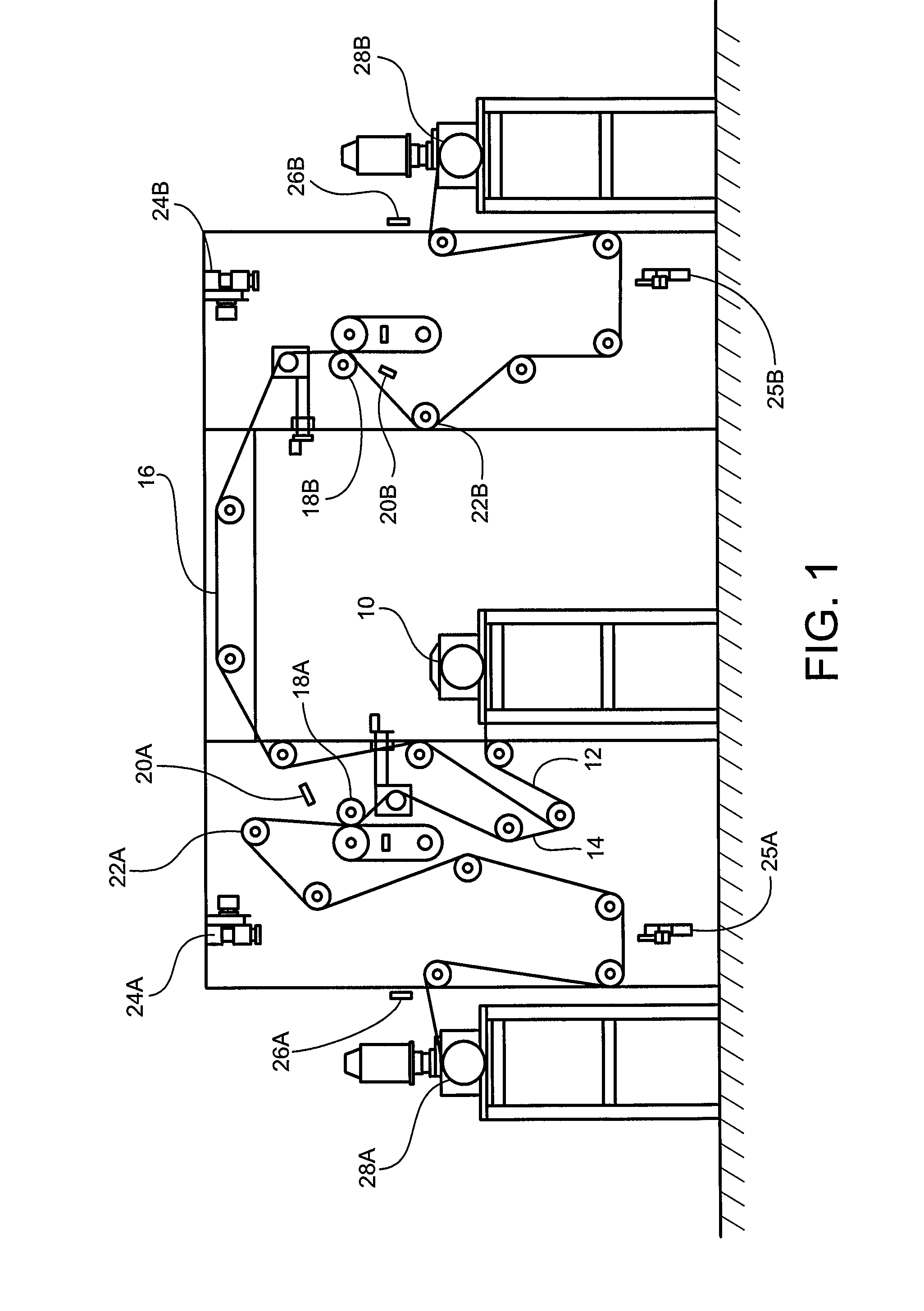

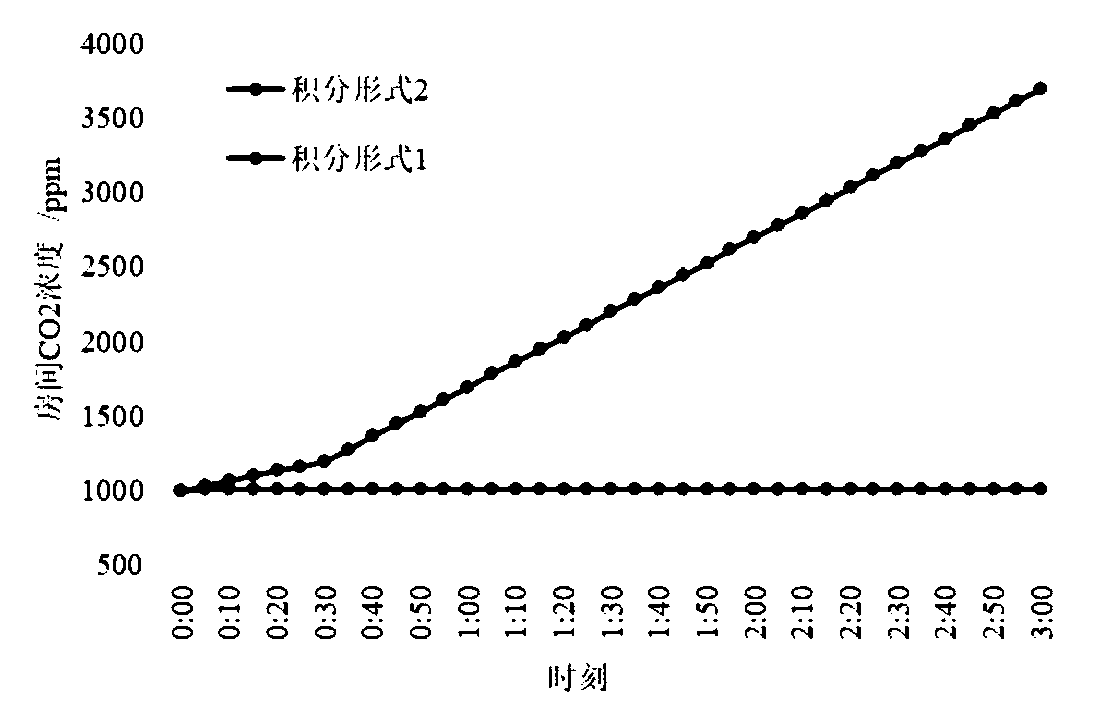

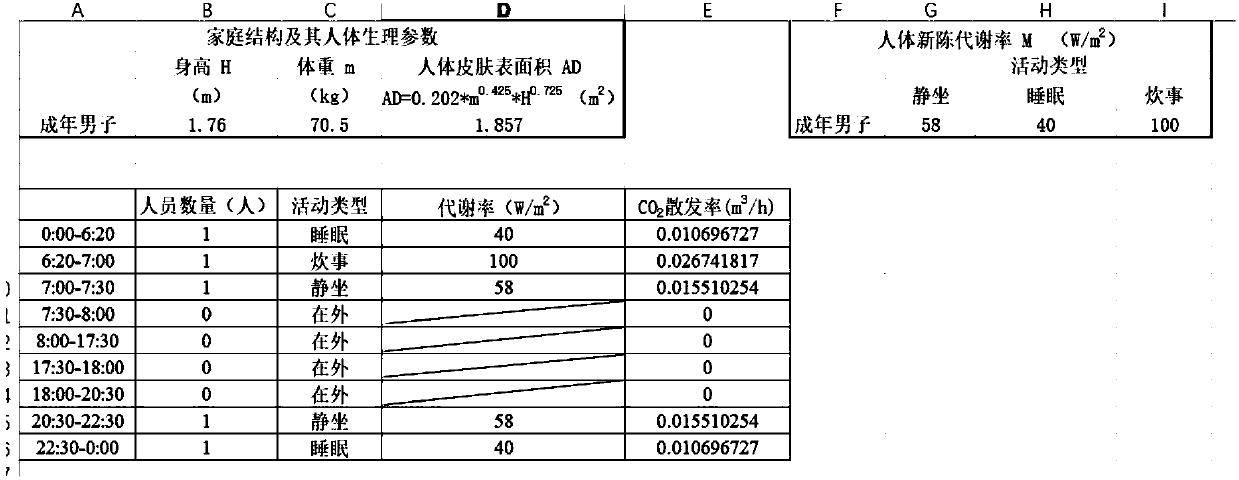

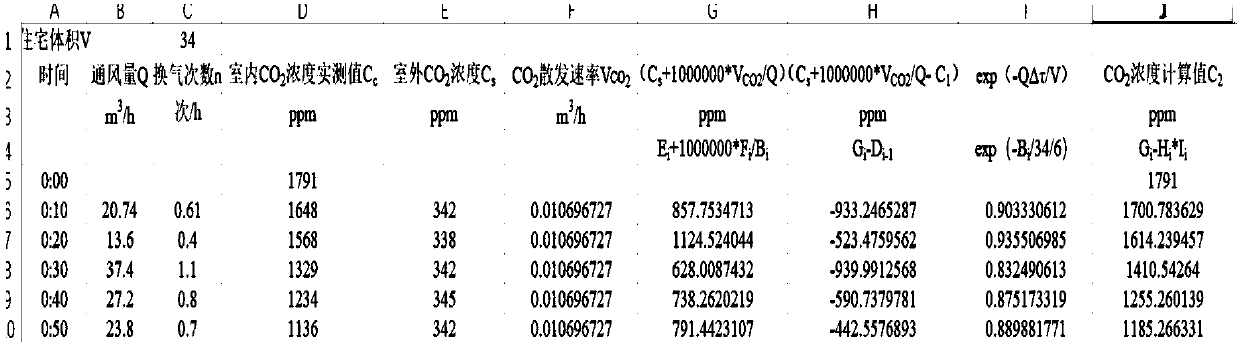

Dynamic measurement methods of room ventilation and air exchange quantity

ActiveCN108446443ASimplify workloadReduce testing costsDesign optimisation/simulationSpecial data processing applicationsHuman bodyAir exchange

The invention discloses a dynamic measurement method of room ventilation and air exchange quantity. A measurement manner of using CO2 emitted by human bodies as tracer gas is adopted, a mutual relationship of room CO2 concentration and the room ventilation and air exchange quantity is established according to a basic principle of mass balancing, and at the same time, the dynamically changing roomventilation and air exchange quantity is calculated and determined on the basis of an error analysis result according to continuous test data of the room CO2 concentration. By adopting the technical solution of the invention, all limits on emission status of room human-body CO2 can be removed, the room ventilation and air exchange quantity in each time interval can be conveniently and quickly calculated and obtained on the basis of the actually measured data of the room CO2 concentration, and thus dynamic changes of the room ventilation and air exchange quantity can be truly reflected.

Owner:BEIJING UNIV OF TECH

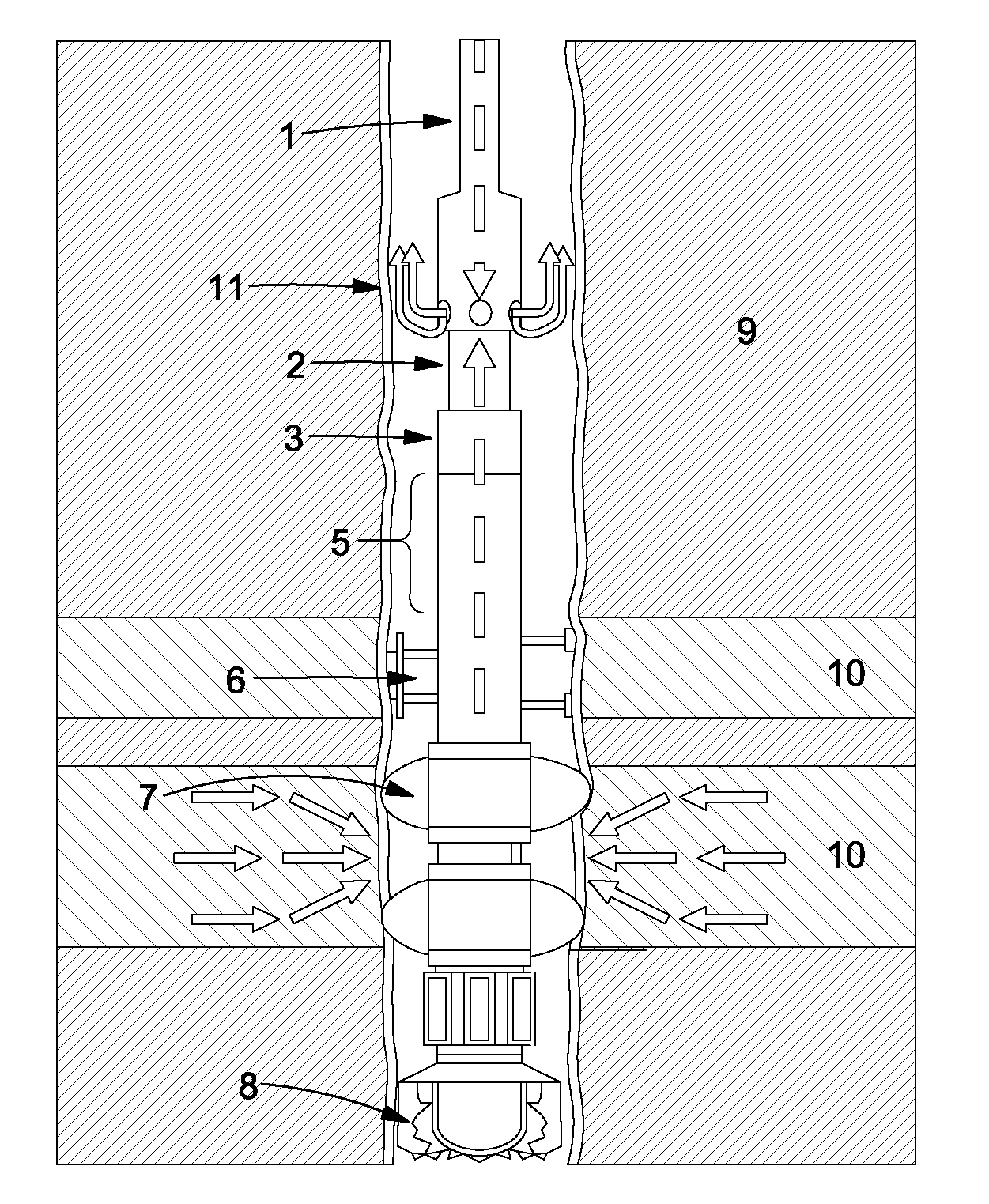

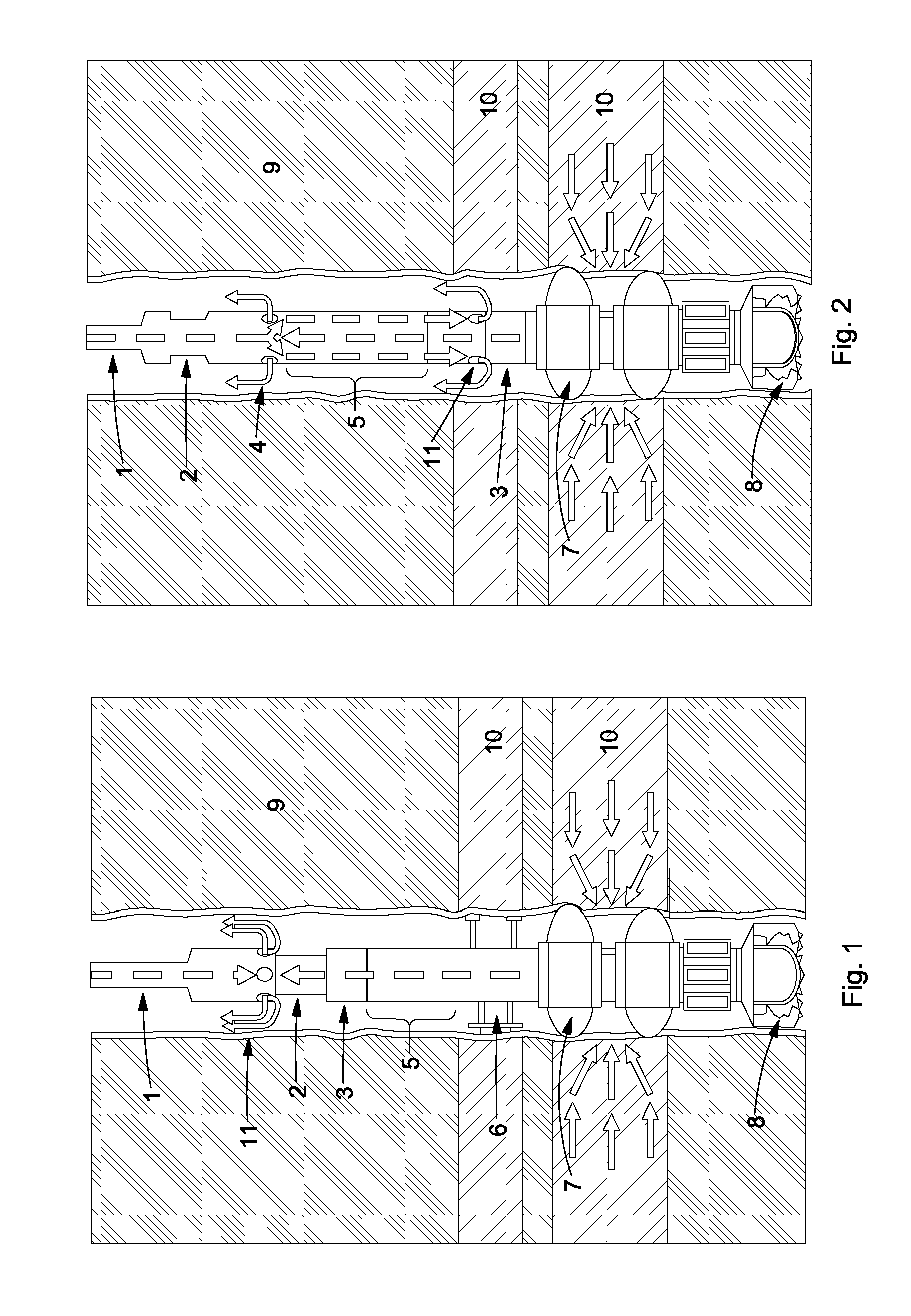

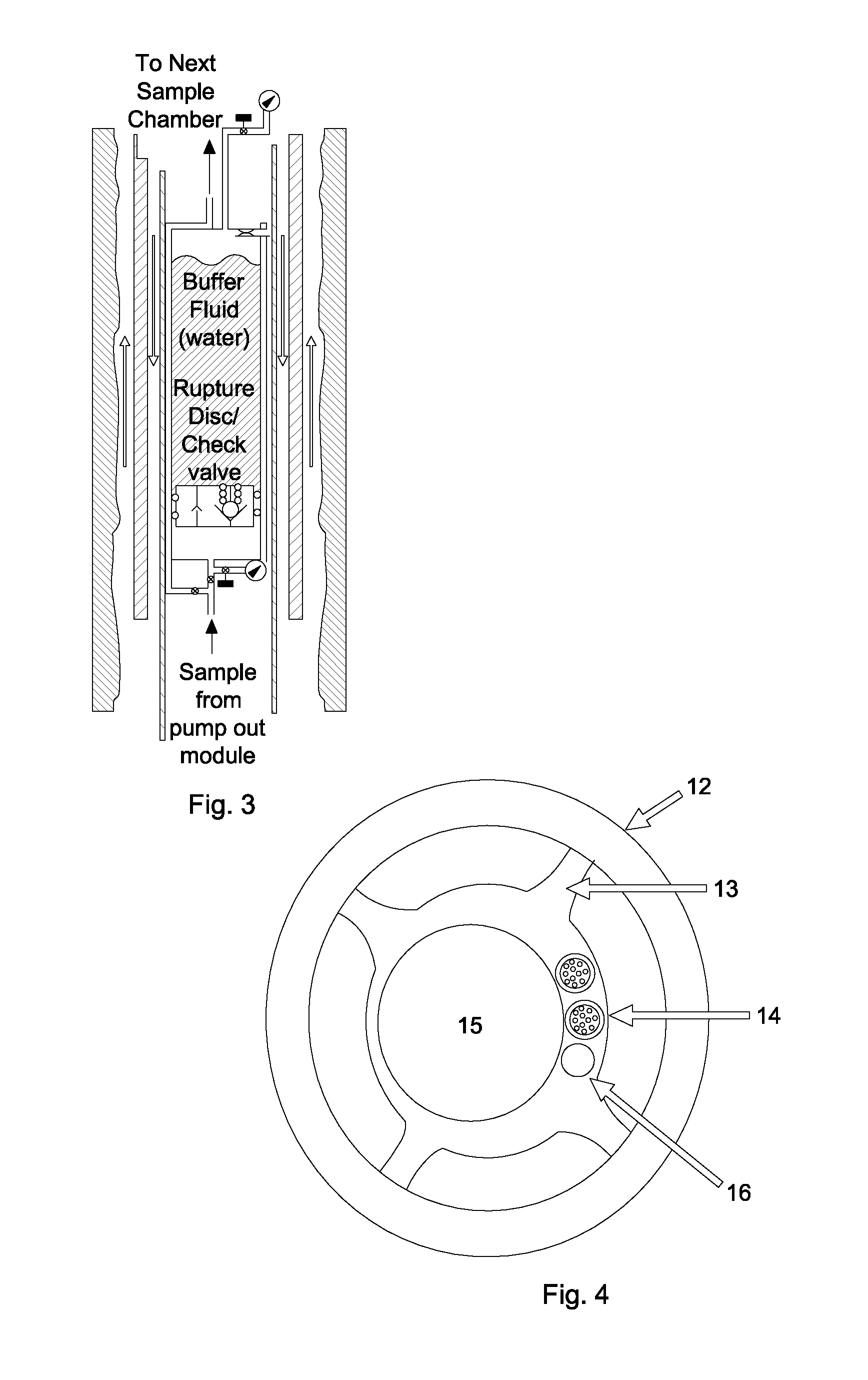

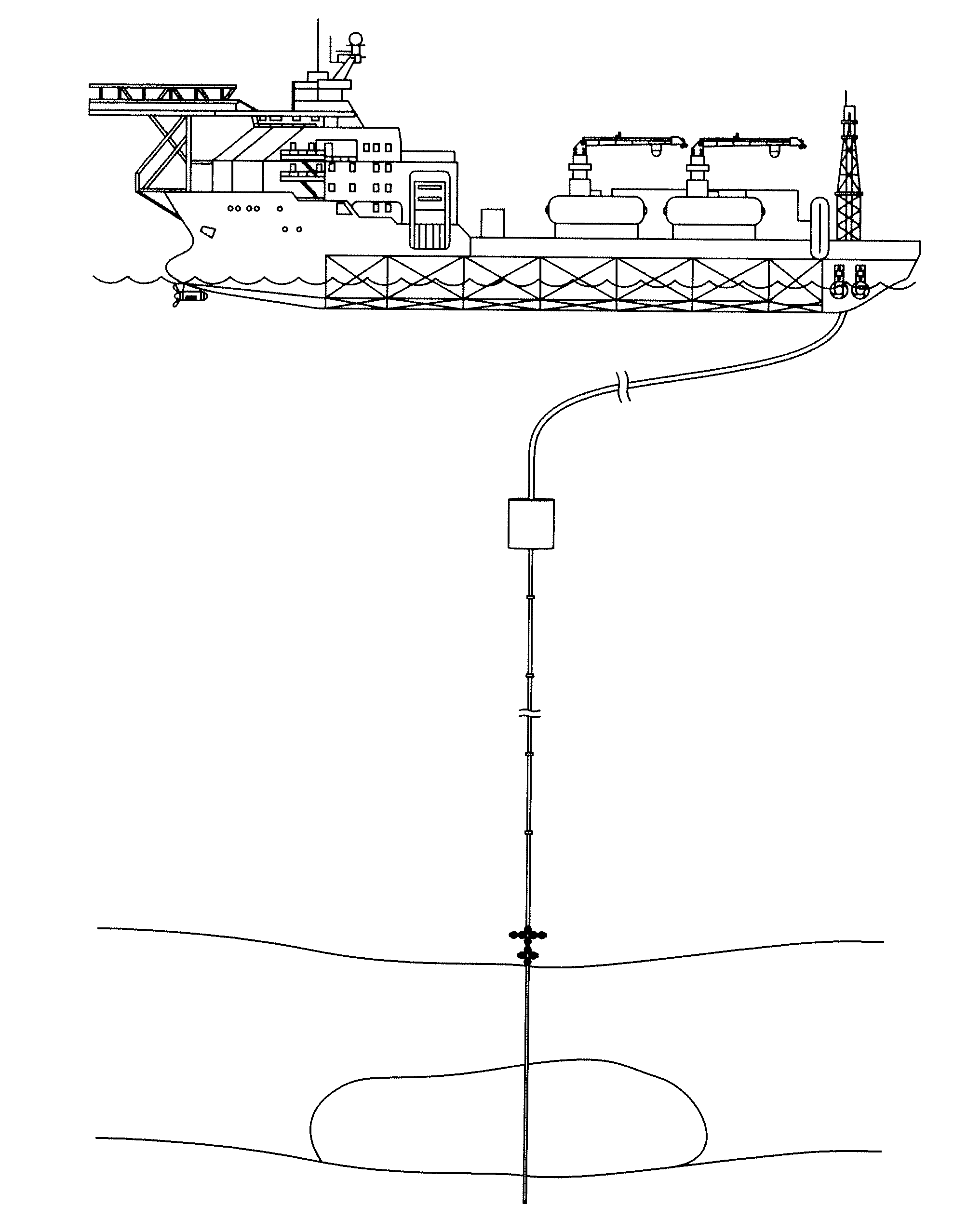

Assembly and method for transient and continuous testing of an open portion of a well bore

An assembly for transient and continuous testing of an open portion of a well bore arranged in a lower part of a drill string includes at least two packers fixed outside of the drill string, which are expandable for isolating a reservoir interval. The assembly includes a down-hole pump, sample chamber, sensors, closing valve, sensors and telemetry for measuring and realtime transmission of flow rate, pressure and temperature of fluid flow from the reservoir interval, from the down-hole pump, in the drill string and in an annulus above the packers, a mud driven turbine or electric cable, and a circulation unit. The circulation unit, independent of the circulation rate for mud to the annulus, can feed formation fluid from the reservoir interval into the annulus, so that at any time a well can be kept in over balance and the mud can solve the formation fluid from the reservoir interval.

Owner:STATOIL ASA PETRO SA (NO)

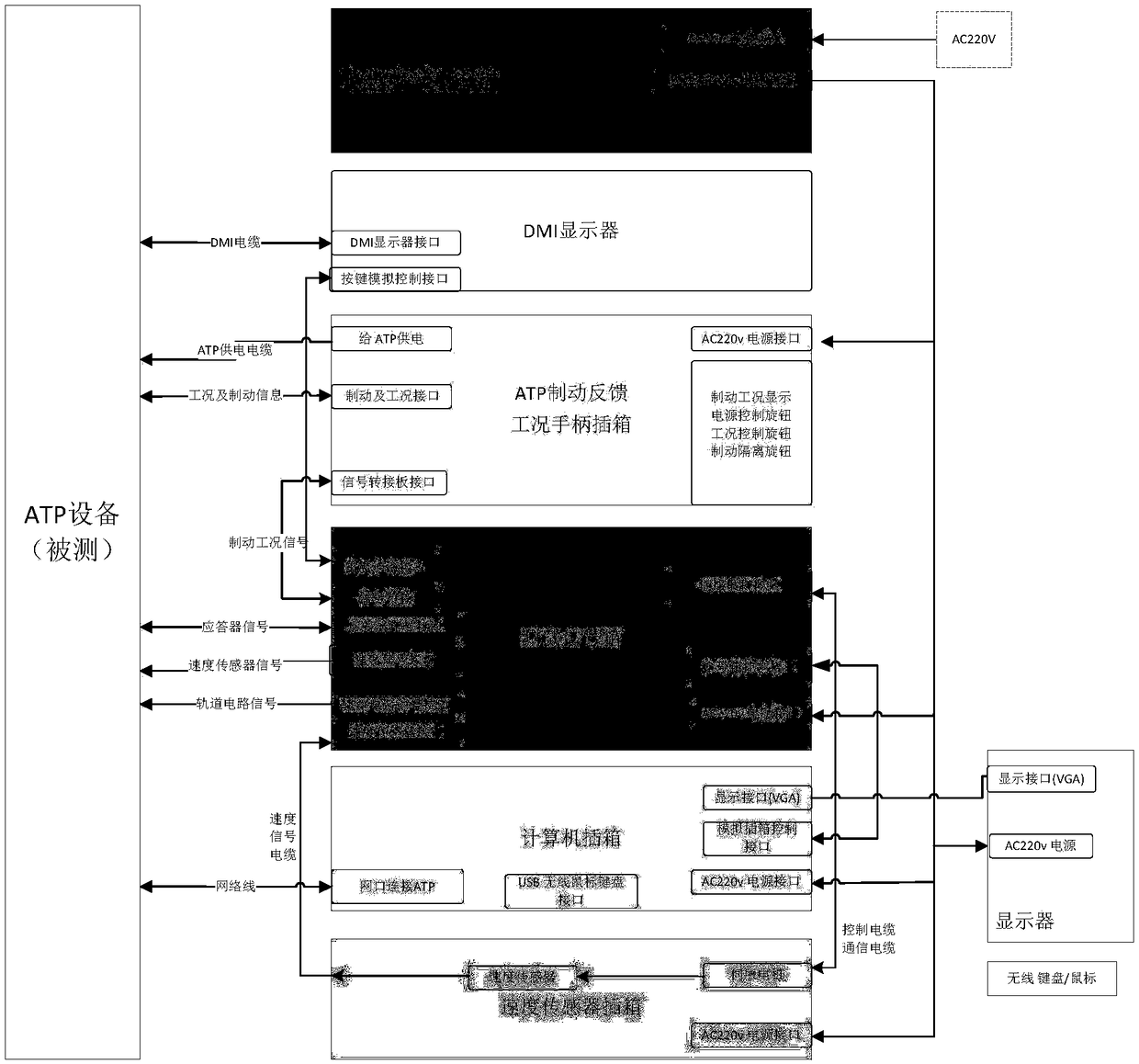

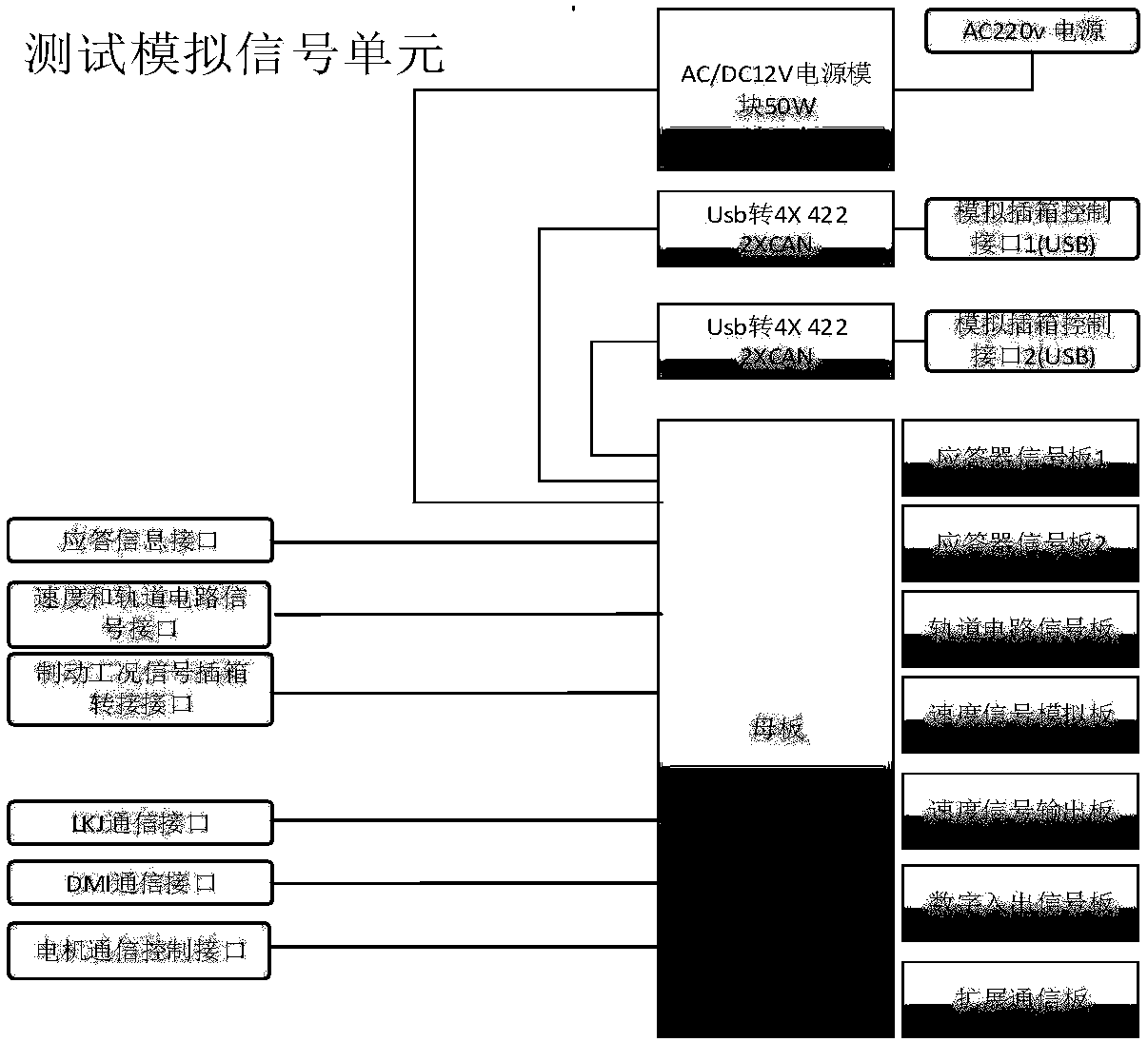

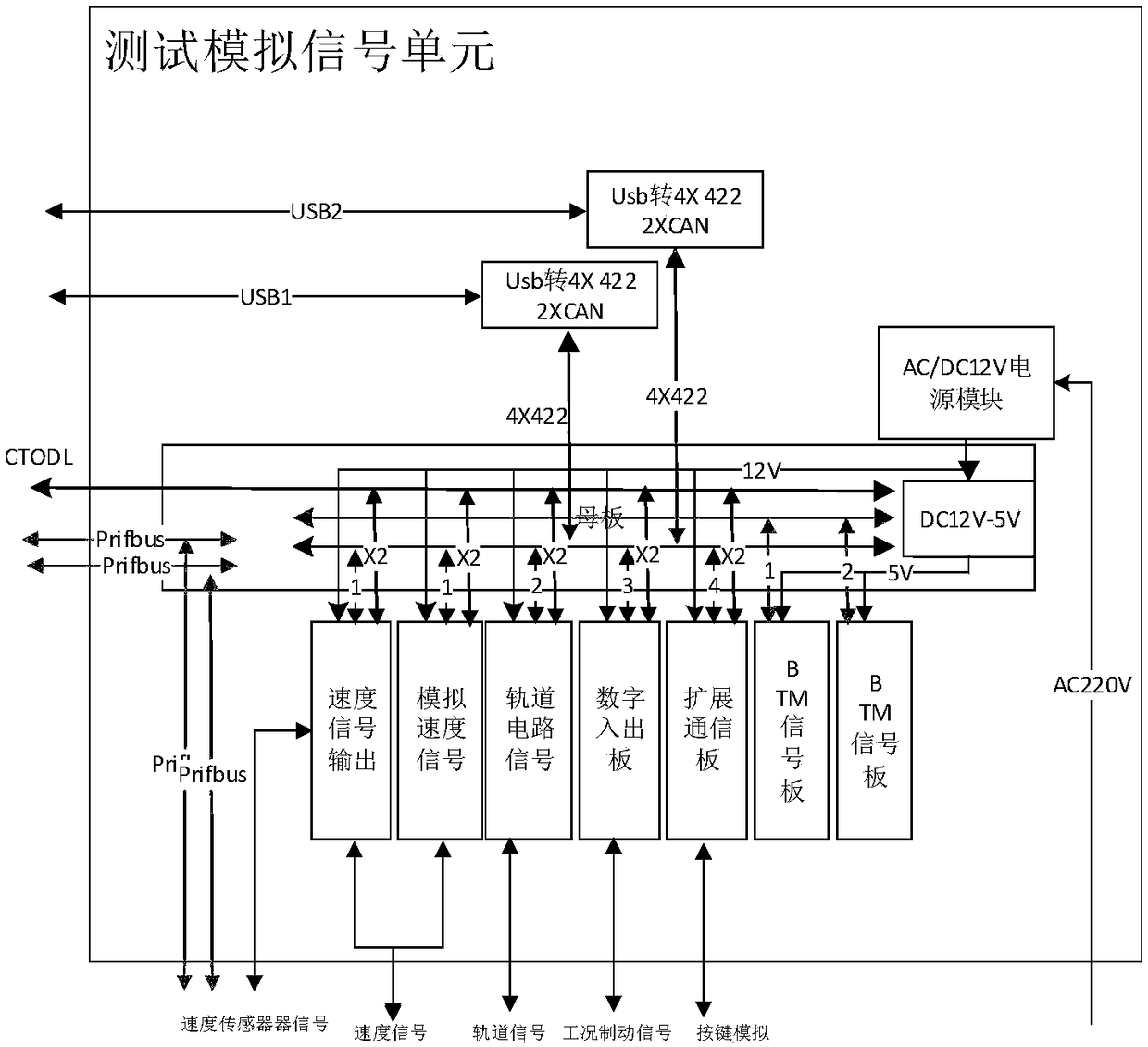

CTCS2-200C type train control on-board equipment automatic simulation test platform

ActiveCN108227519AHighly integratedEasy to set upSimulator controlElectric testing/monitoringTest efficiencyTest script

The invention discloses a CTCS2-200C type train control on-board equipment automatic simulation test platform, wherein the involved test equipment has a high integration level and facilitates the establishment and change of a test scene; a verification process is automatically handled by the machine, thereby solving the problem of careless omission caused by manual watching and control during a long-time and large-scale continuous test; the test process is completely automatic and has a high test efficiency which is particularly remarkable in a full-functional and large-scale integration test;multiple test scripts can be included in a test list, and all test scripts in the list are automatically implemented one by one; and the tested equipment is rebooted automatically between in each test script, and the rebooting interval can be configured, so as to finally realize an unattended and continuous test.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

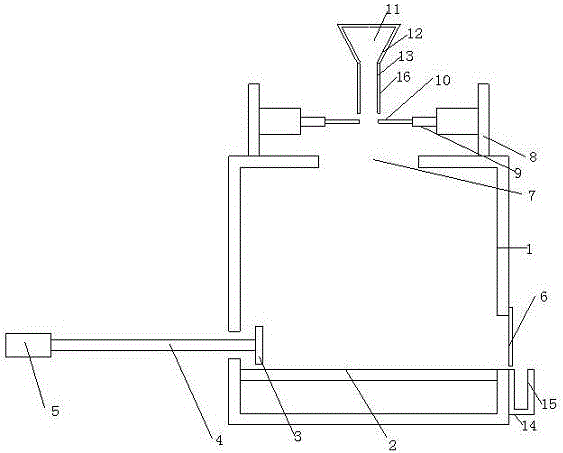

Electronic equipment product drop test device

InactiveCN106289703AImprove test efficiencyEnable continuous testingShock testingTest efficiencyDrop tests

The invention relates to an electronic equipment product drop test device. The electronic equipment product drop test device comprises a box body; the lower end of the box body is provided with an impact stage; one side of the lower end of the box body is provided with a push plate; one side of the push plate is connected with a push-pull cylinder through a connection rod, wherein the push-pull cylinder passes through one side of the box body; the other side of the lower end of the box body is provided with a sliding door which is connected through a hinge; an opening is arranged at the upper end of the box body; the left side and right side of the upper end of the box body are provided with a fixing plate respectively; the fixing plates are provided with a material discharging cylinder respectively; each material discharging cylinder is connected with a material plate; hoppers are arranged on the material plates; material tubes are arranged below the hoppers; and the lower end of one side of the sliding door is provided with a storage box. With the electronic equipment product drop test device of the invention adopted, continuous testing of products can be realized, testing efficiency can be improved, manual feeding is not required, and time and labor can be saved.

Owner:安徽云图信息技术有限公司

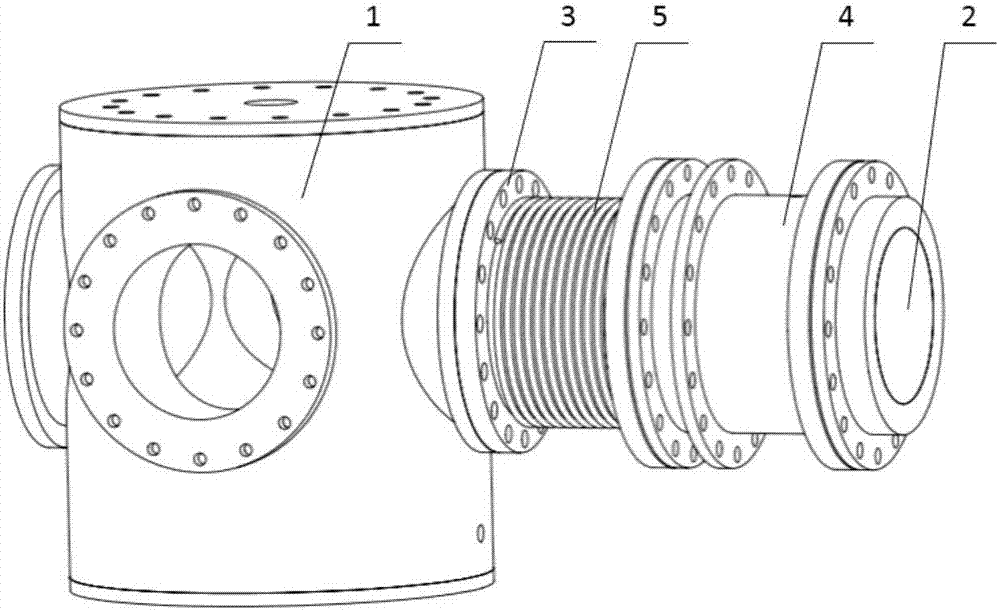

Visualized high temperature and high pressure combustion device

ActiveCN107084848AReduce the use temperatureIncrease the maximum working pressureGas-turbine engine testingJet-propulsion engine testingCyclic processCombustion chamber

The invention discloses a visualized high temperature and high pressure combustion device which comprises an incendiary bomb body, a glass assembly body, a high temperature switching section, a constant voltage switching section and a cooling copper pipe. The high temperature switching section and the constant voltage switching section are used together, and the pressure of a main combustion chamber is shared on two ways of glass. The use temperature of the glass is reduced. The maximum use pressure of the combustion device and the visualized window area are improved. According to the invention, the modular design of an optical window is used; the demolition frequency and the installation time of the optical glass are reduced; the service life of the optical glass is effectively improved; the replacement frequency of a sealing gasket is reduced; all sealing parts are non-cooled sealing; the construction is simple; the processing and installation are convenient; continuous testing under high temperature and high pressure conditions are realized; engine combustion and exhaust gas recirculation processes can be simulated, and visualized research is carried out; and a schlieren method, a laser absorption and scattering method, laser induced fluorescence and other test methods are carried out on air-fuel mixture, evaporation, combustion, soot generation and the like.

Owner:SHANGHAI JIAO TONG UNIV

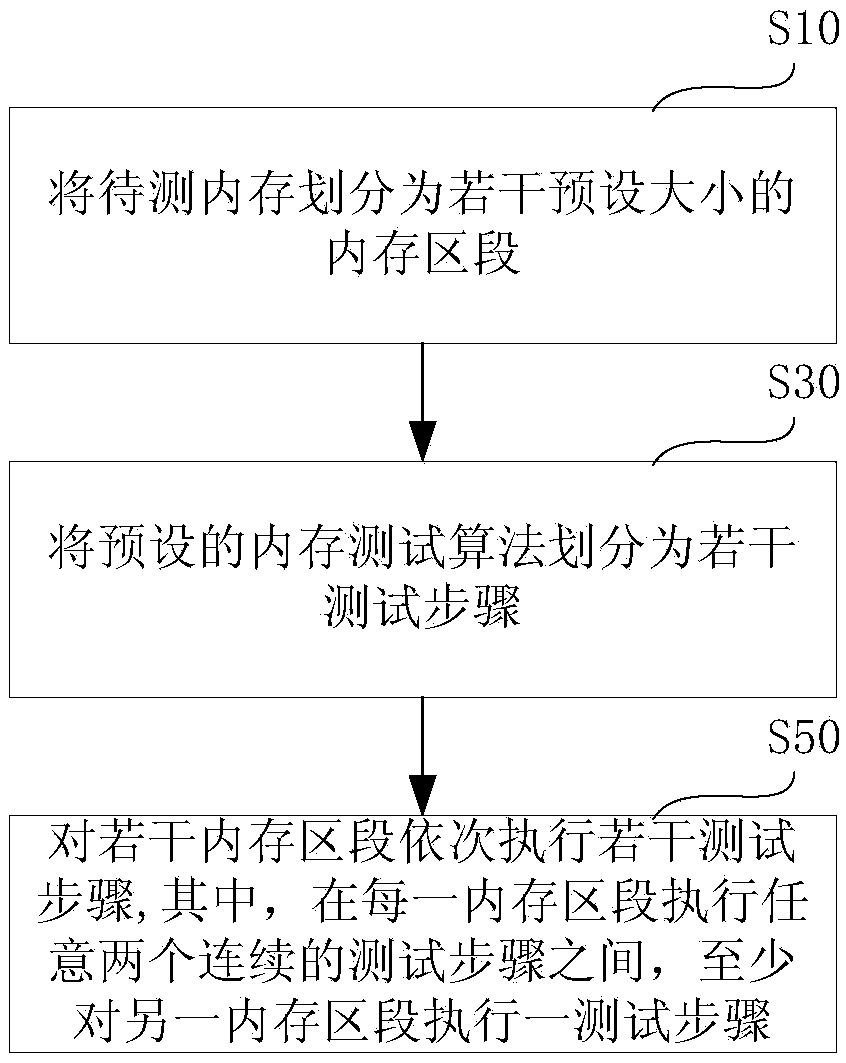

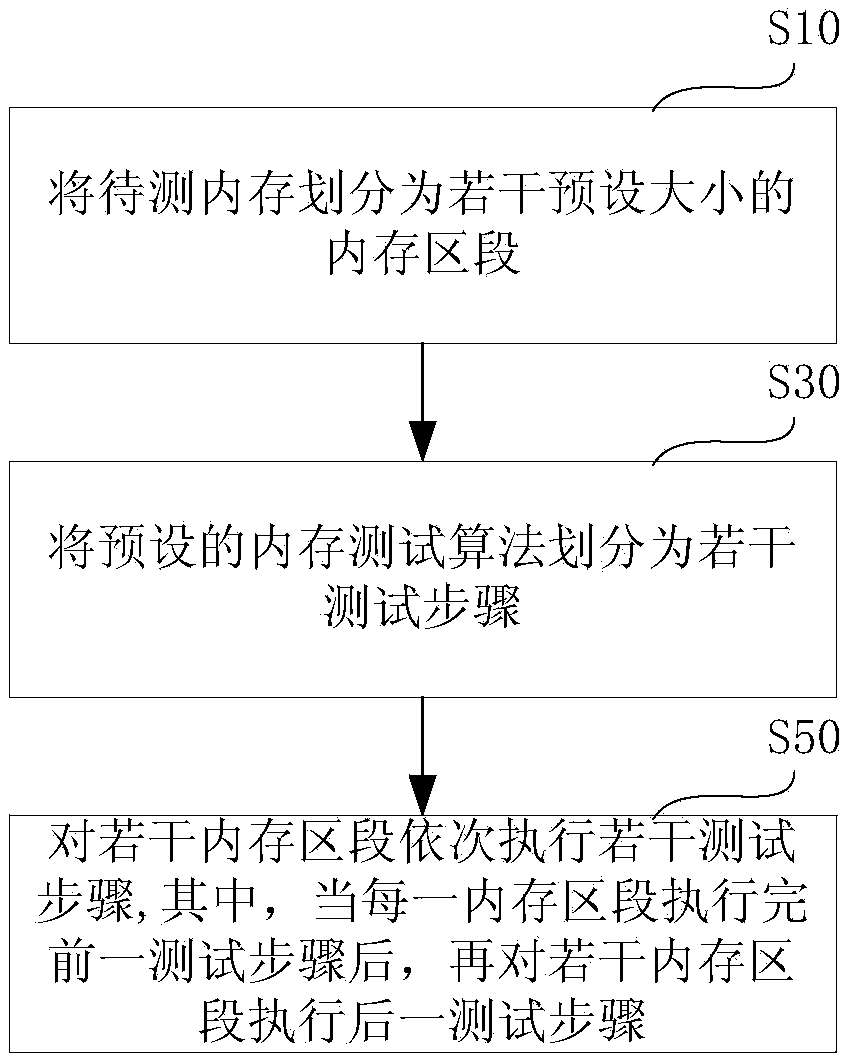

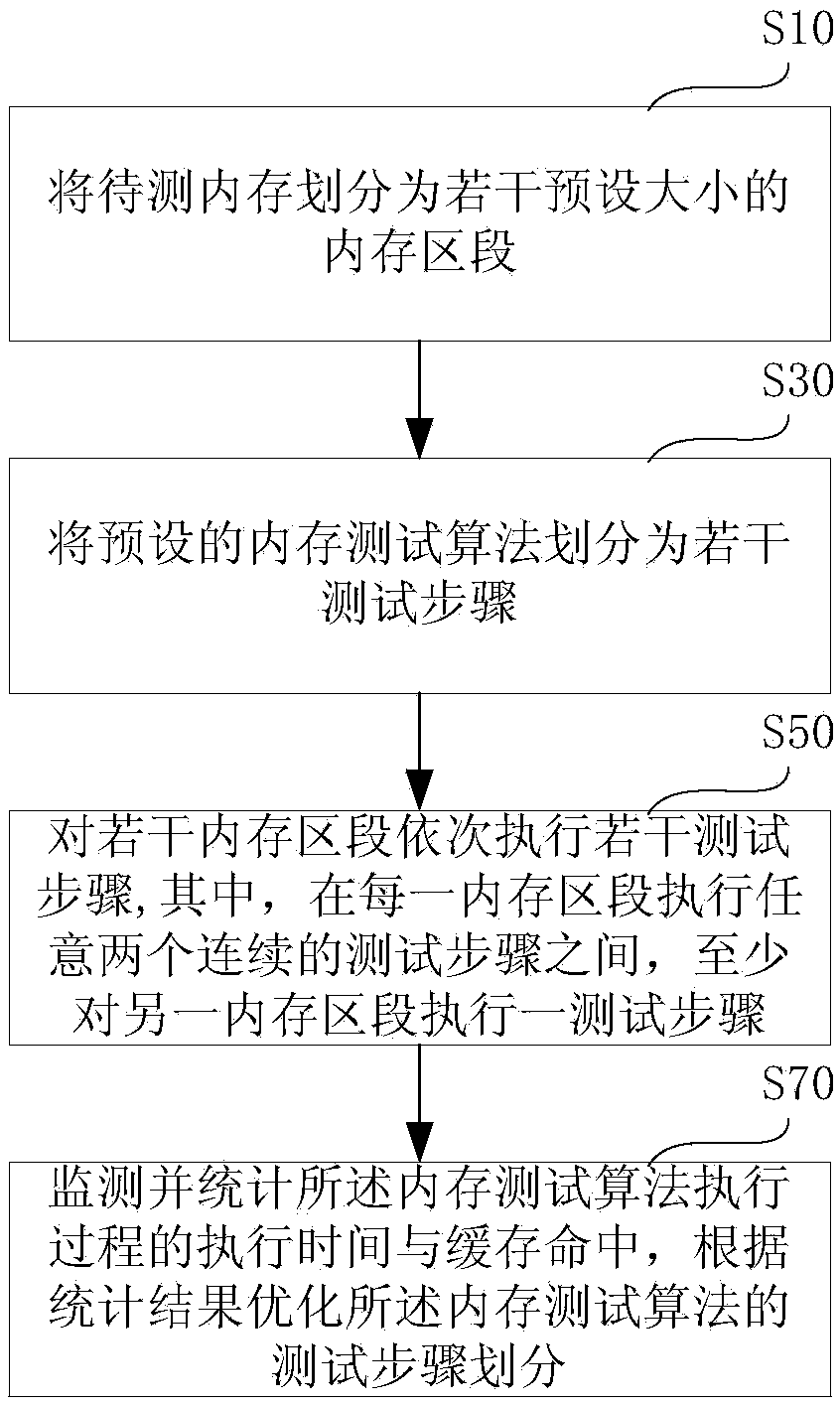

Memory testing method for reducing cache hit rate

ActiveCN105373456AImprove effectivenessReduce hit rateFunctional testingParallel computingTest algorithm

The invention provides a memory testing method for reducing a cache hit rate. The method comprises: dividing a to-be-tested memory into a plurality of memory sections of preset sizes; dividing a preset memory testing algorithm into a plurality of testing steps; and performing the testing steps on the memory sections in sequence, wherein one testing step is performed on another memory section between any two continuous testing steps performed on each memory section. According to the method, the testing steps are performed on different memory sections in sequence, so that a cache cannot continuously form effective concerned sections, the cache is always in a shake state, the cache hit rate is reduced, and the validity of memory testing is improved; and further, execution time and cache hit of an execution process of the memory testing algorithm are subjected to monitoring and statistics, and testing step division of the memory testing algorithm is optimized according to a statistic result, so that the efficiency and validity of memory testing are both considered and the memory testing method is optimized.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Integrated circuit with continuous testing of repetitive functional blocks

A method of continuous testing of repetitive functional blocks provided on an integrated circuit (IC) which includes selecting one of the repetitive functional blocks at a time for testing, substituting a test repetitive functional block for a selected repetitive functional block, and testing the selected repetitive functional block during normal functional mode of the IC. An IC which includes repetitive functional blocks for performing corresponding functional block operations during normal functional mode of the IC, and a test system which performs continuous testing of each repetitive functional block while the functional block operations are performed during normal functional mode of the IC. One block may be tested during normal operation for each IC reset event without transferring or copying state information. Multiple blocks may be tested one at a time during normal operation by transferring state information between a selected block and a test block.

Owner:NXP USA INC

Modular Exploration and Production System Including an Extended Well Testing Service Vessel

A modular exploration and production system combined with an oil well testing and service vessel is provided, the vessel comprising equipment for separating hydrocarbons and / or associated fluids and solids by means of a processing plant. The vessel is equipped with suitable equipment packages for all required functionality, so fluid received from wells, piping and installations at sea or inland waters is processed for the separation, control and ecological handling of the mixture (crude oil, gas, solids, chemicals and oily or production water) in a plurality of phases such as exploration, drilling, finishing, repair, stimulation, production, and production measurement. In an extended combination of such technologies, a single well test service vessel is used in conjunction with a field of neighboring self-standing riser systems to serially test well and production processes, resulting in project-scaled synergies between drilling and testing assets that lead to cleaner, more cost-effective recovery of higher quality yields.

Owner:ATLANTIS OFFSHORE HLDG

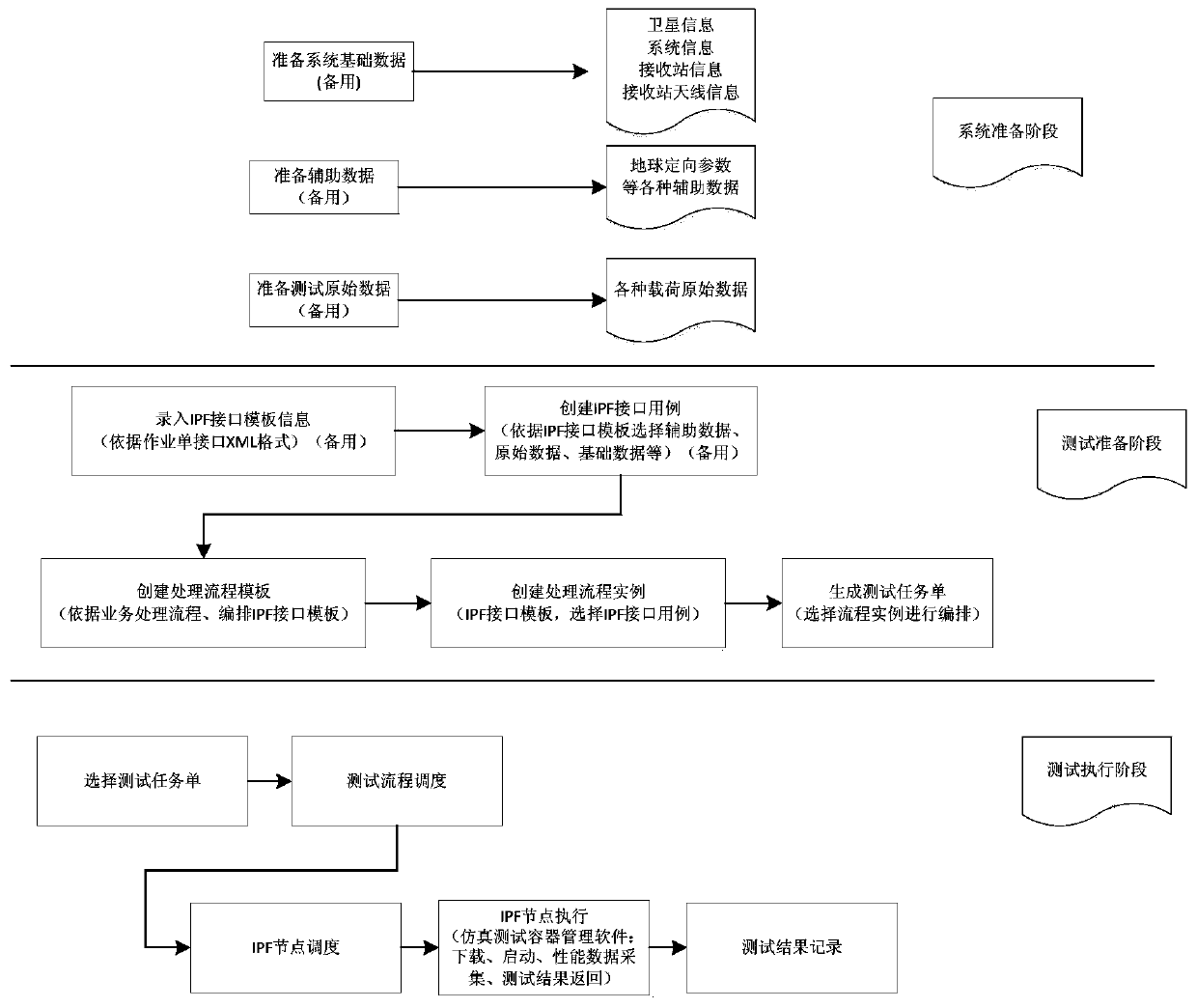

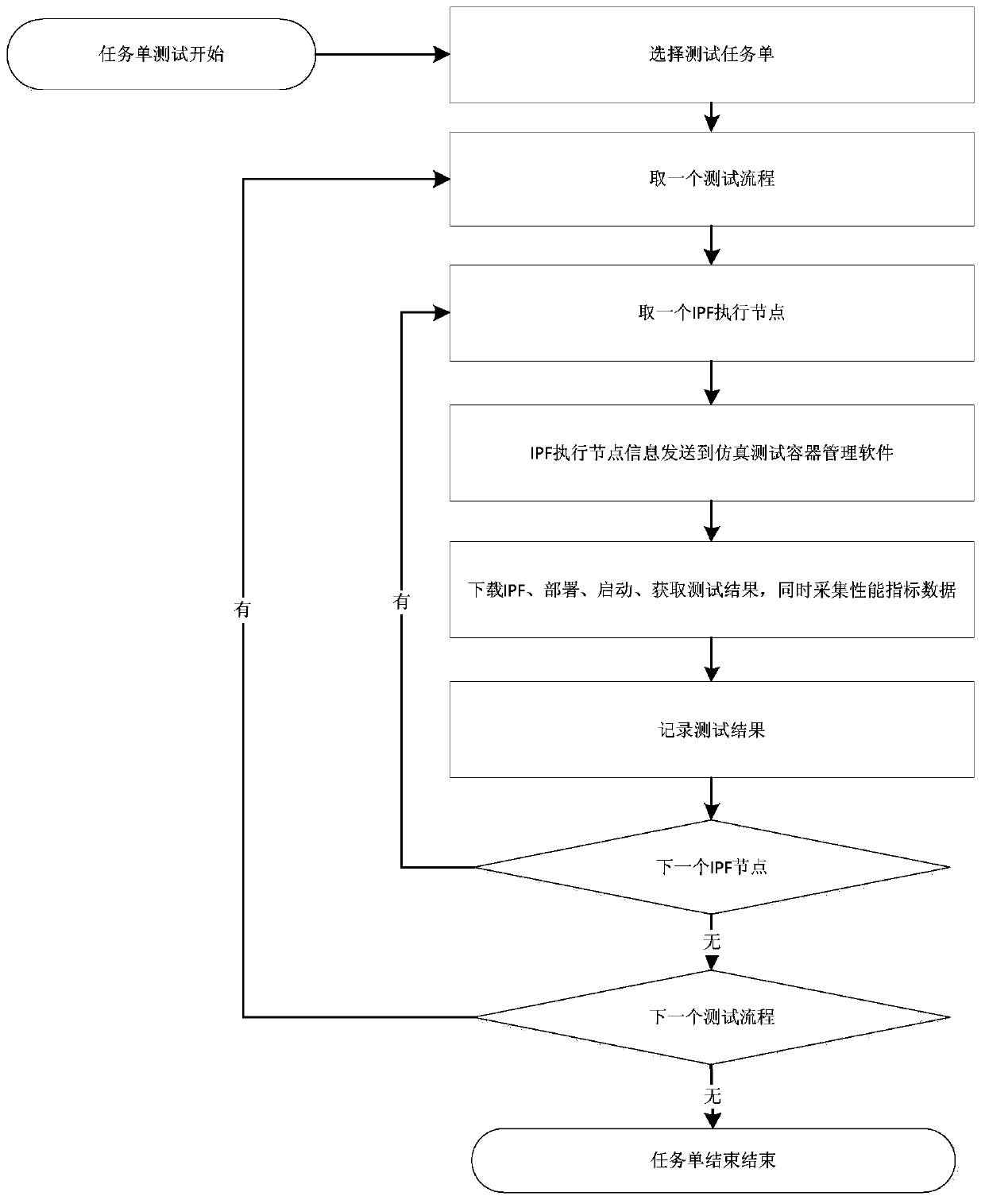

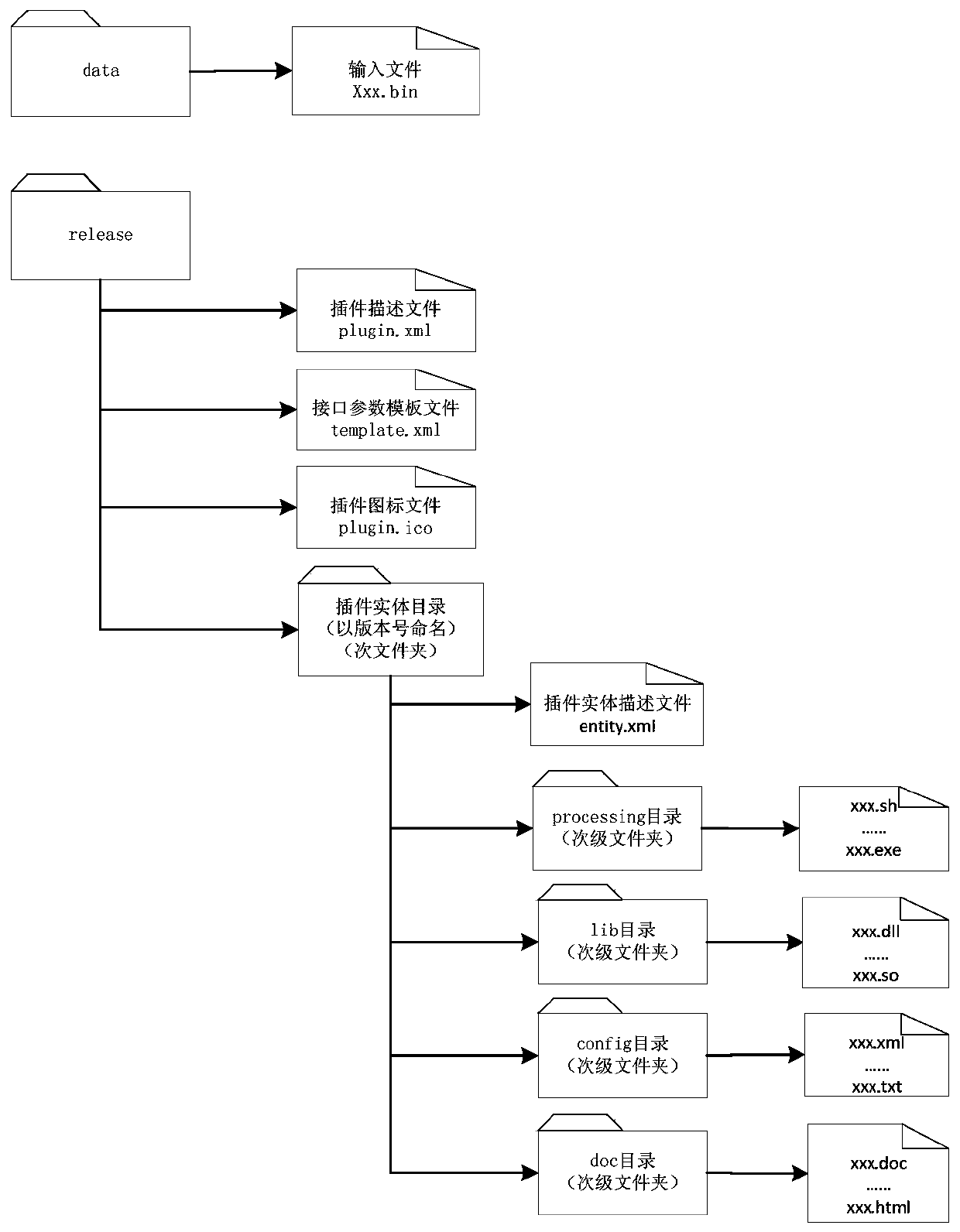

Interface testing method of ground data processing system

ActiveCN109753430AImprove continuityRealize monitoringSoftware testing/debuggingData processing systemControl system

The invention relates to an interface testing method of a ground data processing system, which is suitable for maintenance, upgrading and fault judgment of the satellite ground data processing system,in particular to operation maintenance management of the satellite ground data processing system in the field of spaceflight. According to the method, each data processing system is commanded and dispatched by a simulated satellite operation and control system according to a real process. The method comprises the following steps of: arranging an execution process, configuring operation parametersfor each processing system, preparing to input a processing file, monitoring a data processing operation process of the processing system in real time, and finally obtaining scientific evaluation according to each parameter and performance index in the process, thereby realizing automatic continuous testing and monitoring, outputting technical indexes without interruption, and continuously tracking the condition of a tested system. Through the trend, scientific basis is provided for system operation, maintenance, fault early warning and the like, the system reliability is improved, and the service life is prolonged.

Owner:莱诺斯科技(北京)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com