An electrolytic bath reaction chamber used for in-situ XRD tests and a testing method

A technology of reaction chamber and electrolytic cell, which is applied in the field of electrochemistry, can solve the problems of cumbersome assembly process, low signal-to-noise ratio of the spectrum, uneven current density, etc., and achieve the effects of simple preparation method, accurate test potential and uniform current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

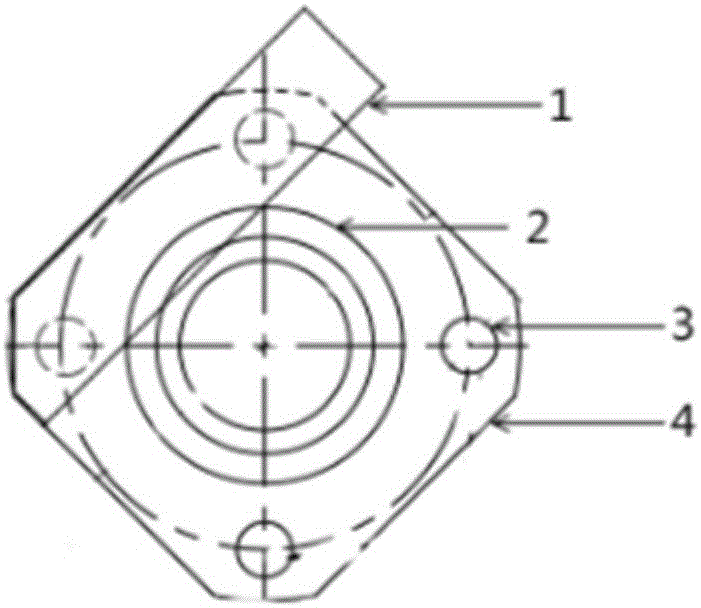

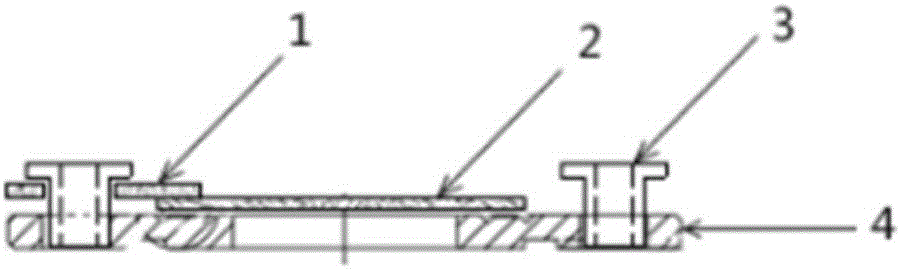

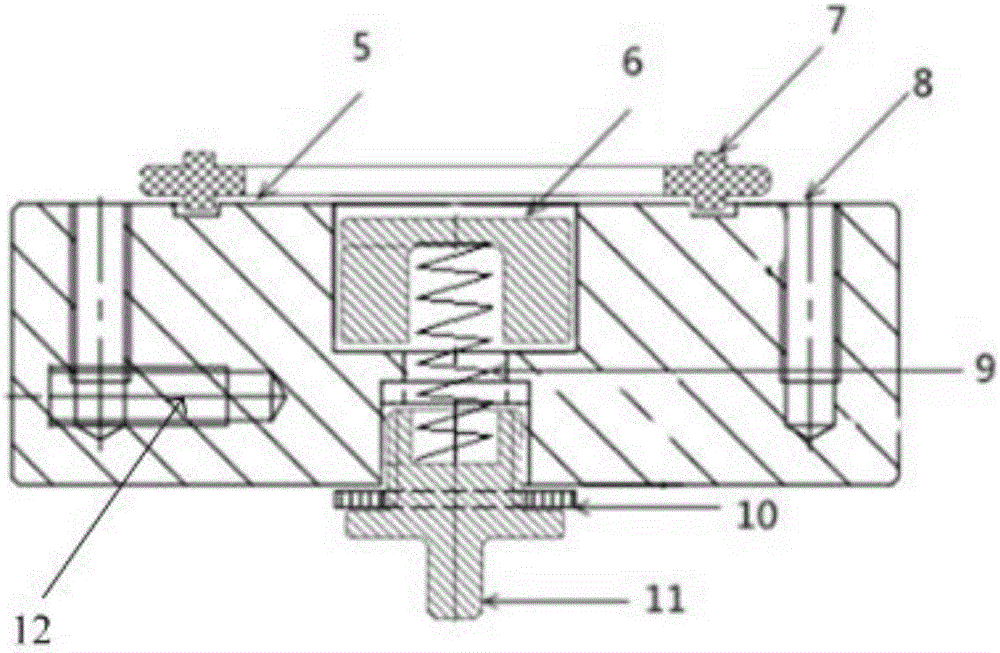

[0070] A kind of electrolytic cell reaction chamber (such as Figure 4 shown), the reaction chamber of the electrolytic cell includes the working electrode cover from top to bottom (such as Figure 1a and Figure 1b shown), the opposite electrode holder (such as figure 2 shown) and the base to fix the counter electrode holder (such as image 3 shown);

[0071] The working electrode cover includes a cover body 4, a test window 2 and a first copper sheet 1. The cover body 4 is provided with a test hole; the test window 2 completely covers the test hole, and the test window 2 is connected to the test hole by welding, bonding or pressing. Sealed connection; the test window 2 is sealed and connected to the test hole, the first copper sheet 1 is connected to the test window 2 by lamination or welding, and is located outside the test hole area; the material of the test window 2 is high X-ray transmission High-rate conductive material, and its characteristic peaks do not overlap o...

Embodiment 2

[0087] Utilize the electrolytic cell reaction chamber described in embodiment 1 to carry out the in-situ XRD test, wherein, the test window 2 is sealed and connected with the test hole by welding, and the test window 2 is a beryllium sheet; the first copper sheet 1 is laminated with the test hole. The test window 2 is connected, and the thickness of the test window 2 is 0.5 mm; there are four first connecting holes 3, second connecting holes 8 and bolts 13; the height of the reaction chamber of the electrolytic cell is 3.0 cm.

[0088] Described test method comprises the steps:

[0089] Step 1) Blend the graphite negative electrode material and binder to make a slurry, apply it directly on the inner side of the test window of the beryllium sheet, wipe off the part exceeding the area of the electrode sheet of the counter electrode, and dry it at 60°C for later use;

[0090] Step 2) In the glove box (argon atmosphere), assemble the counter electrode seat, the sealing screw 11 ...

Embodiment 3

[0097] Utilize the electrolytic cell reaction chamber described in embodiment 1 to carry out the in-situ XRD test, wherein, the test window 2 is sealed and connected with the test hole by bonding, and the test window 2 is a beryllium sheet; the first copper sheet 1 is connected with the test hole by welding. The test window 2 is connected, and the thickness of the test window 2 is 0.05 mm; there are four first connecting holes 3, second connecting holes 8 and bolts 13; the height of the reaction chamber of the electrolytic cell is 1.0 cm.

[0098] Described test method comprises the steps:

[0099] Step 1) Blend the NCA positive electrode material and binder to make a slurry, coat it on the aluminum foil, dry it, roll it, punch it into a circular pole piece according to the size of the counter electrode, and stick it on the inner side of the test window 2, spare;

[0100] Step 2) In the glove box (argon atmosphere), assemble the counter electrode seat, the sealing screw 11 ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com