Patents

Literature

136results about How to "Uniform current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

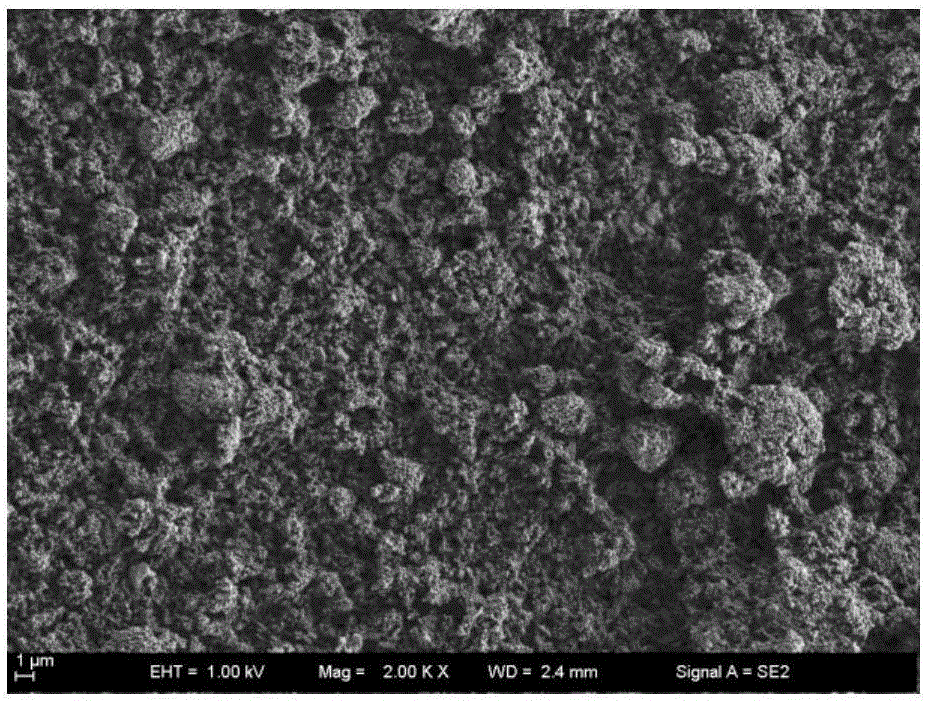

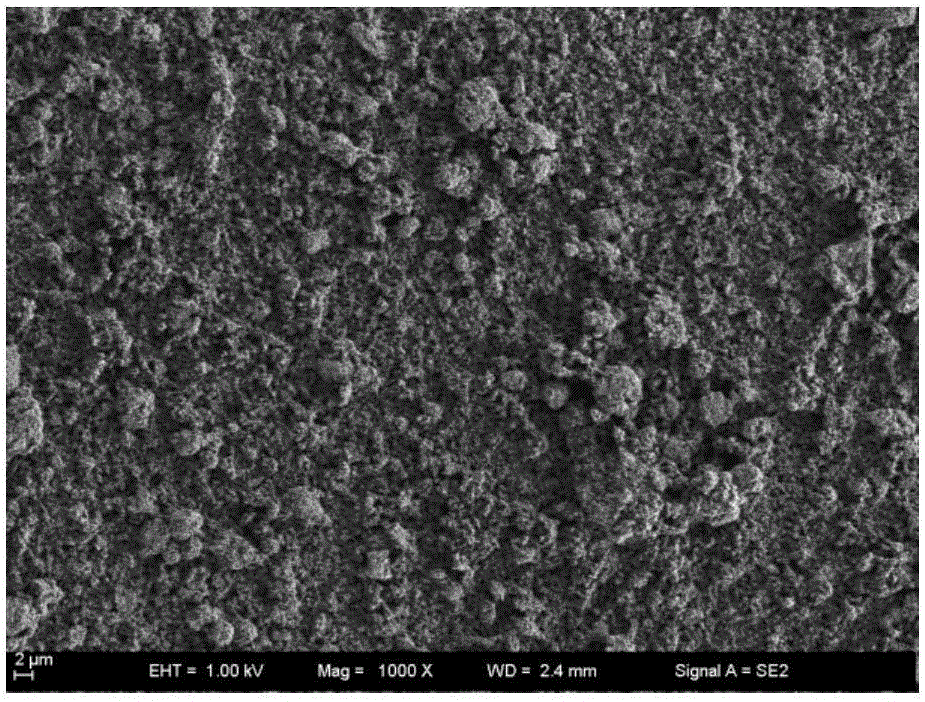

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

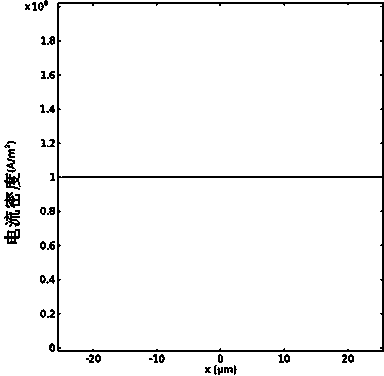

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

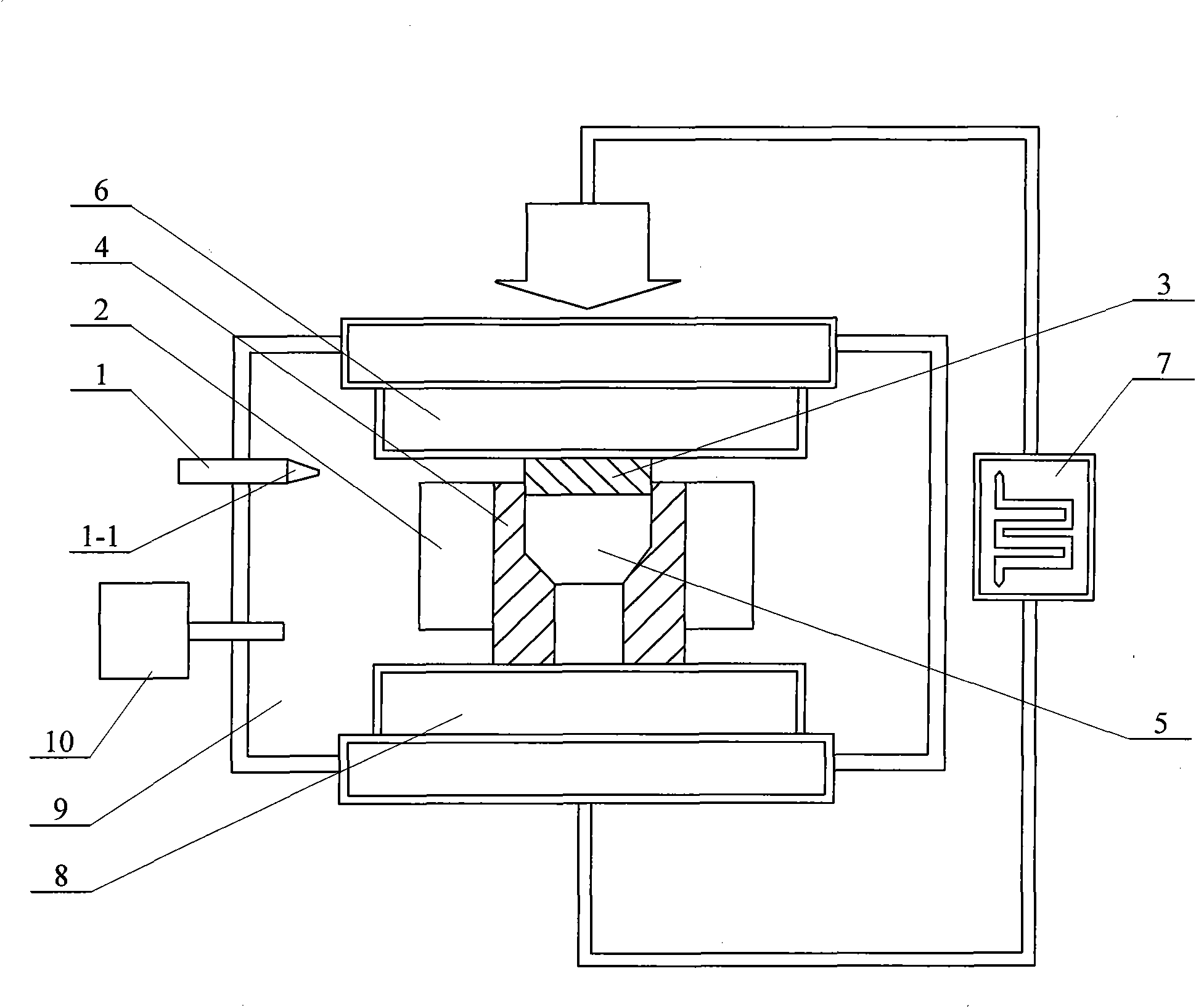

Pulse current assisted extrusion forming device and extrusion forming method

InactiveCN101670385AFast heatingImprove energy utilizationExtrusion diesExtrusion control devicesPressure rangePower flow

A pulse current assisted extrusion forming device and an extrusion forming method relate to an extrusion forming device and a method thereof. The invention solves the problems that the existing extrusion forming device is great in heat loss, and long in heating time, and the existing extrusion forming method is complicated in technical process flow, low in work efficiency and non-homogenous in distribution of density of the current produced inside the blank on the cross-section and easy to cause skin effect. A current-conducting female mold of the device is arranged in a mold cavity of an insulating outer film; a current-conducting male mold and the current-conducting female mold are used as electrodes and connected on a high frequency pulse power source; the pressure within the range of 5-200MPa is applied to the current-conducting male mold by an upper pressure head according to a yield strength value at the temperature selected by the blank to be formed so that the blank is extrudedto be a required shape by the mold after plastic extrusion deformation; the device has high heating speed and improves the work efficiency; and the method uses the heat effect of pulse current and the electro-plastic effect, thereby obviously improving the forming efficiency of the blank, increasing the material plasticity and saving the energy resource.

Owner:HARBIN INST OF TECH

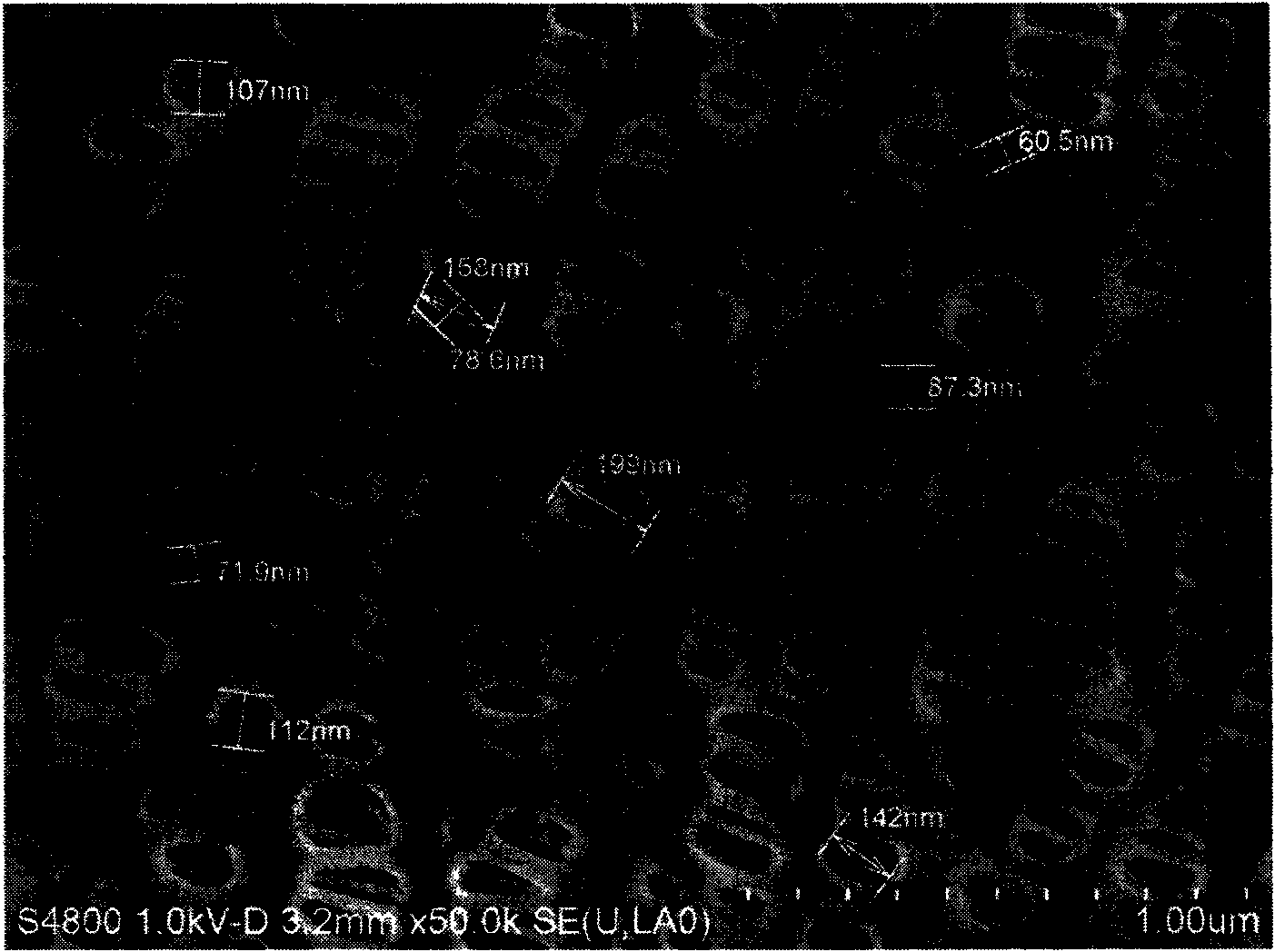

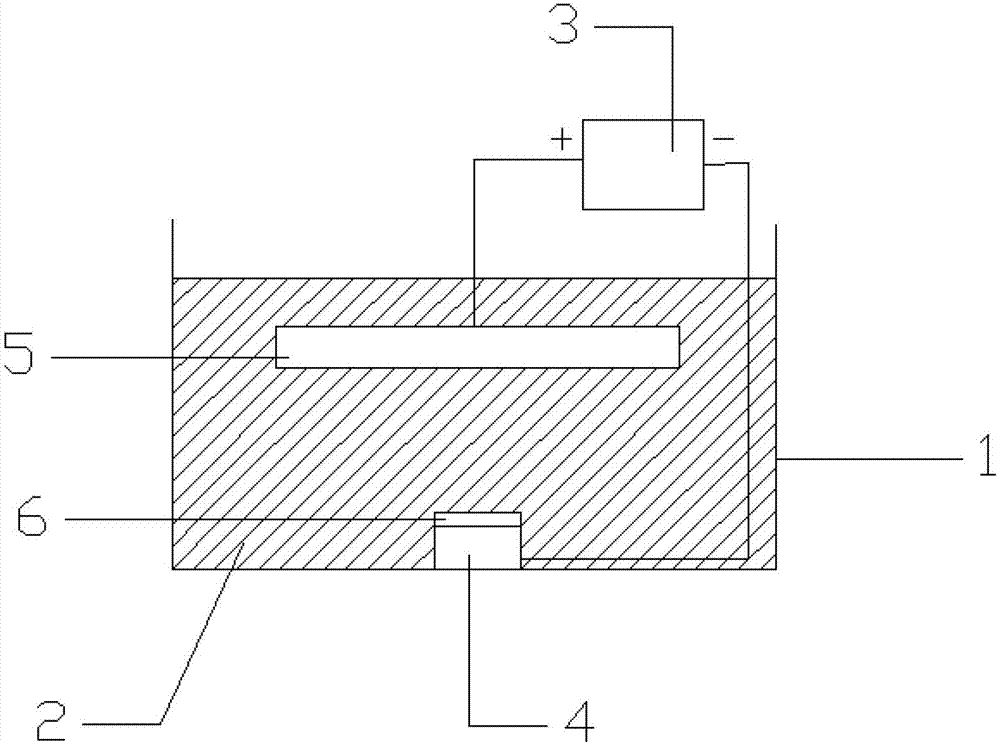

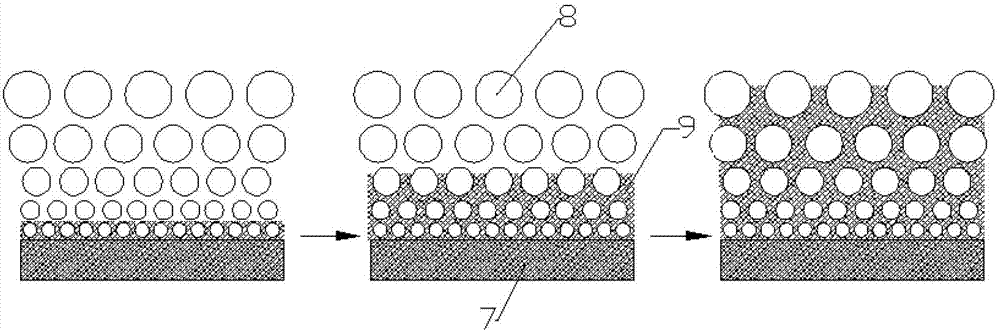

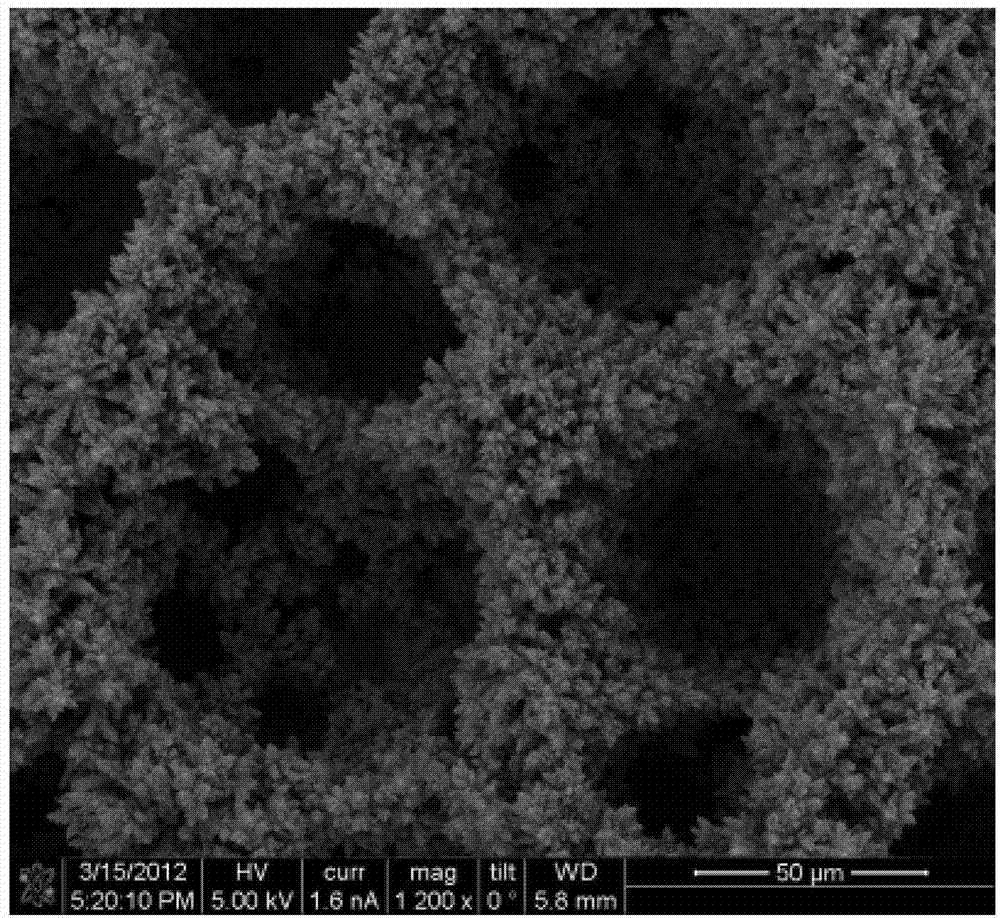

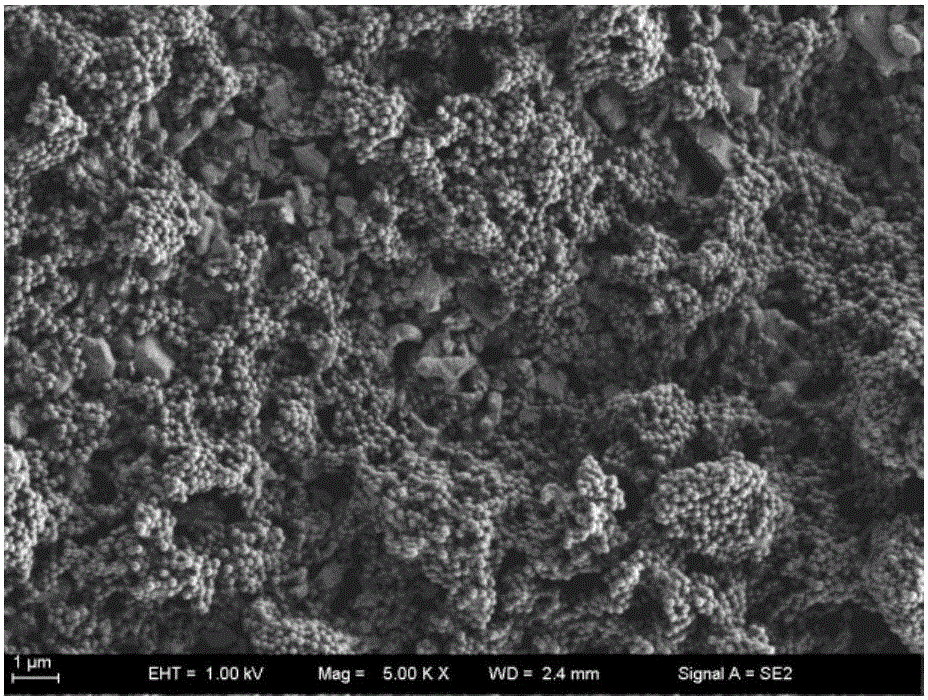

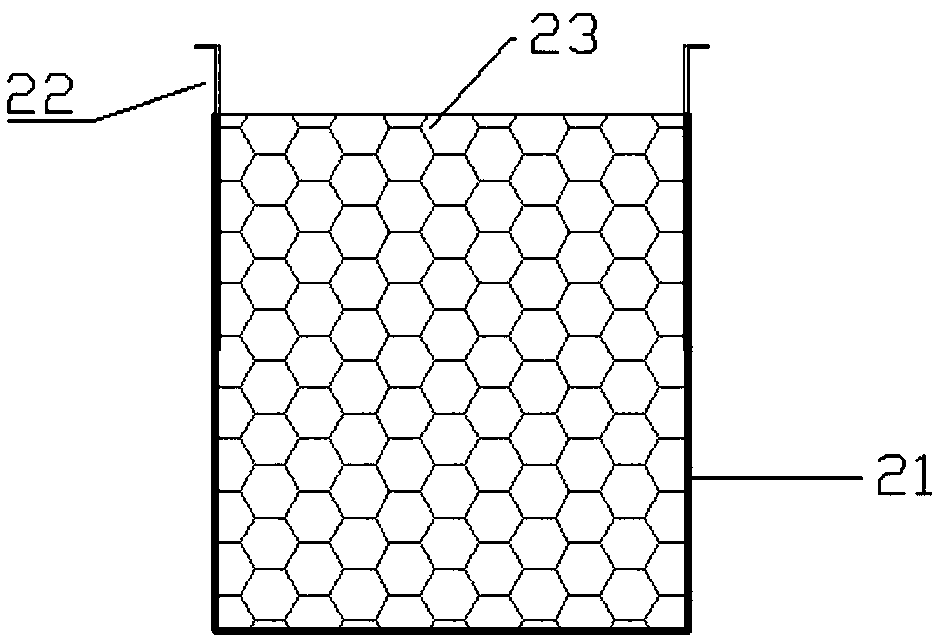

Micro-nano composite porous copper surface structure and preparation method and device thereof

ActiveCN103046088AEvenly distributedUniform detachmentMaterial nanotechnologyCellsMicro nanoHeat treated

The invention relates to the preparation of a porous surface, and discloses a micro-nano composite porous copper surface structure and a preparation method and a preparation device thereof. The preparation method for the micro-nano composite porous copper surface structure is a method for electro-deposition by a hydrogen template method, takes red copper as an anode and a cathode substrate, and includes: performing electro-deposition by taking red copper as an anode and a cathode substrate, and the mixture consisting of the H2SO4 and CuSO4 aqueous solution and additives as the electro-deposition solution to obtain an electro-deposition sample, soaking the electro-deposition sample with deionized water and ethanol and then drying to obtain the micro-nano composite porous copper surface structure; and thermally treating the obtained micro-nano composite porous copper surface structure to enhance the mechanical performance of the micro-nano composite porous copper surface structure. The device for preparing the micro-nano composite porous copper surface structure comprises an electro-deposition tank, an electro-deposition solution, a direct current power supply, a cathode substrate and an anode. The preparation method is simple to operate, and low in cost, and the micro-nano composite porous copper surface structure is controllable; and by the method, a micro-nano composite structure formed by superposing a micrometer scale aperture structure and a wall nano dendrites structure can be prepared, and the aperture of the structure is gradually increased and the structure is uniform.

Owner:SOUTH CHINA UNIV OF TECH

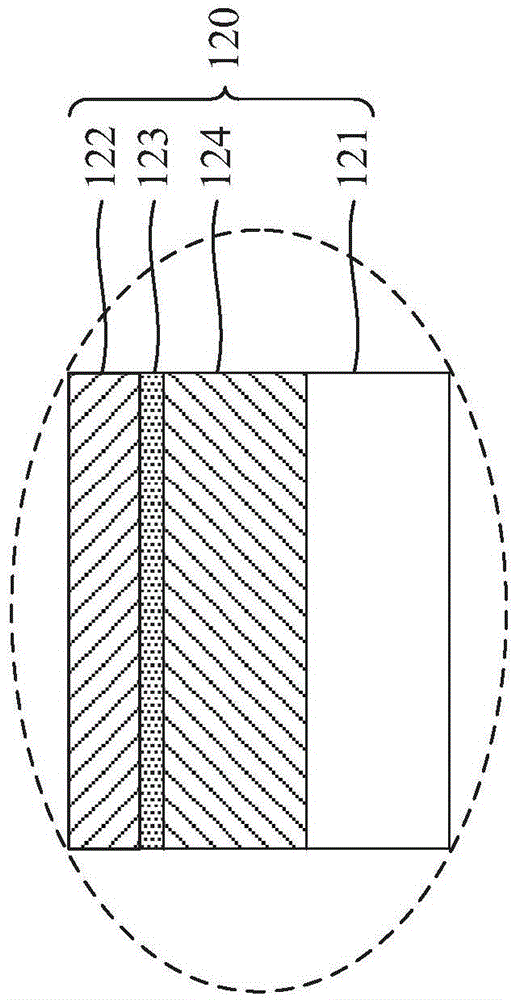

High-temperature-resisting lithium-ion battery membrane with plurality of types of coatings and preparation method of high-temperature-resisting lithium-ion battery membrane

The invention provides a high-temperature-resisting lithium-ion battery membrane with a plurality of types of coatings and belongs to the technical field of battery membranes. The high-temperature-resisting lithium-ion battery membrane is prepared from a coating membrane composed of a battery membrane with one surface or double surfaces coated with coating slurry; one surface or double surfaces of the coating membrane are coated with slurry additional layers; each slurry additional layer comprises at least one layer of coating composed of the coating slurry. The invention further provides a preparation method of the high-temperature-resisting lithium-ion battery membrane with the plurality of types of coatings; the battery membrane has the advantages that a coating membrane has relatively high safety on a battery; meanwhile, the battery membrane can also be used for resisting high temperature, reducing the shrinkage rate of the membrane under a high-temperature condition and prolonging the service life of the battery; the high-temperature-resisting lithium-ion battery membrane can be used for improving the affinity of the membrane and electrolyte and can guarantee that the membrane is sufficiently swollen through the electrolyte and the service life of the battery is prolonged.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

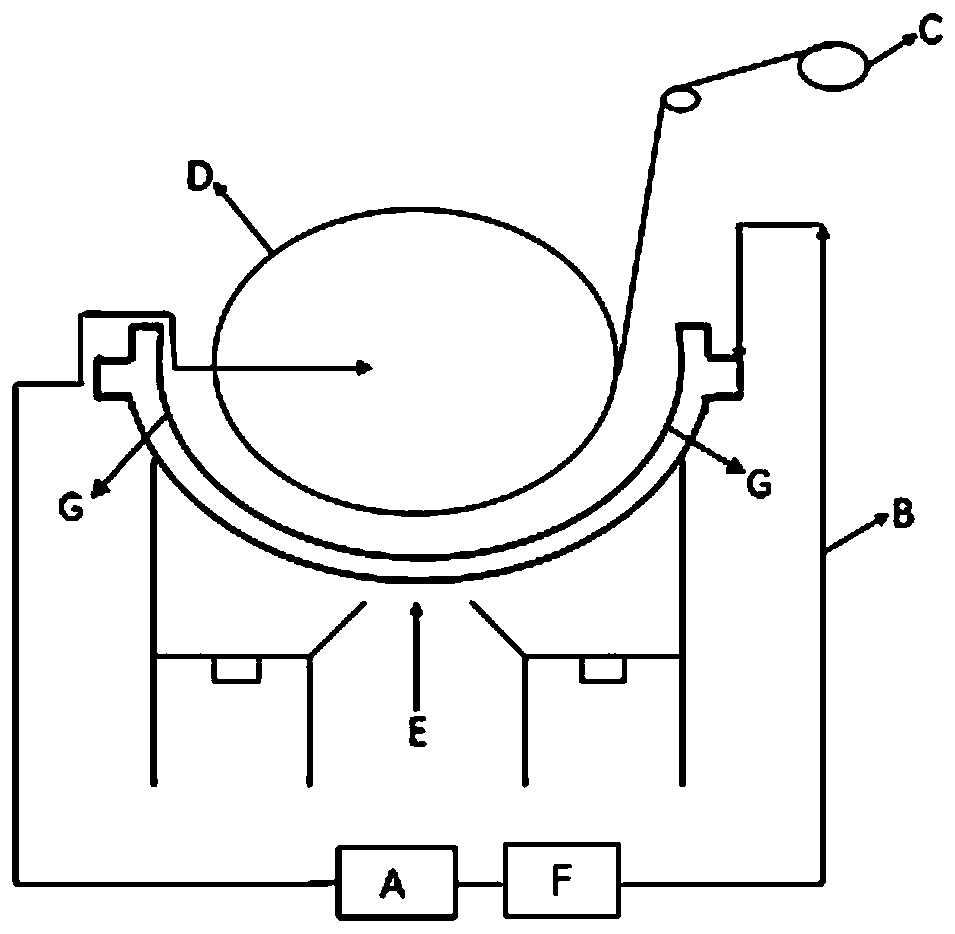

High temperature casting and forging continuous detection electromagnetic ultrasonic probe, flaw detection device and flaw detection method

ActiveCN110530978AGood heat insulationPower distribution is not affectedAnalysing solids using sonic/ultrasonic/infrasonic wavesCeramic coatingWater circulation

The invention discloses a high temperature casting and forging continuous detection electromagnetic ultrasonic probe, a flaw detection device and a flaw detection method. The casting and forging electromagnetic ultrasonic probe comprises a probe shell, a permanent magnet arranged in a cavity of the probe shell, and an exciting / receiving coil arranged at the lower side of the outer bottom of the probe shell, wherein the exciting / receiving coil is a spiral coil that is formed by a winding lead wire and parallel to the bottom of the probe shell, and the lead wire is formed by a plurality of silver wires uniformly painted with ceramic coating bound into a cluster; a magnetic base is arranged under the permanent magnet, and the central axis of the magnetic base is perpendicular to a plane wherethe exciting coil is located; a plurality of suction ports are formed, close to the bottom, of the side wall of the probe shell, a water inlet is formed in the top of the probe shell, and a water circulation and cooling channel is formed by a cavity among the probe shell, the permanent magnet and the magnetic base. Due to the three designs of the lead wire formed by the plurality of silver wiresuniformly painted with ceramic layers and the arrangement thereof, the magnetic base and water cooling, continuous detection on the 650 DEG C high-temperature castings and forgings can be achieved, energy conversion efficiency can be improved, lift-off sensitivity can be reduced, and a detection dead zone can be reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

Electrodeless gas discharge lamp

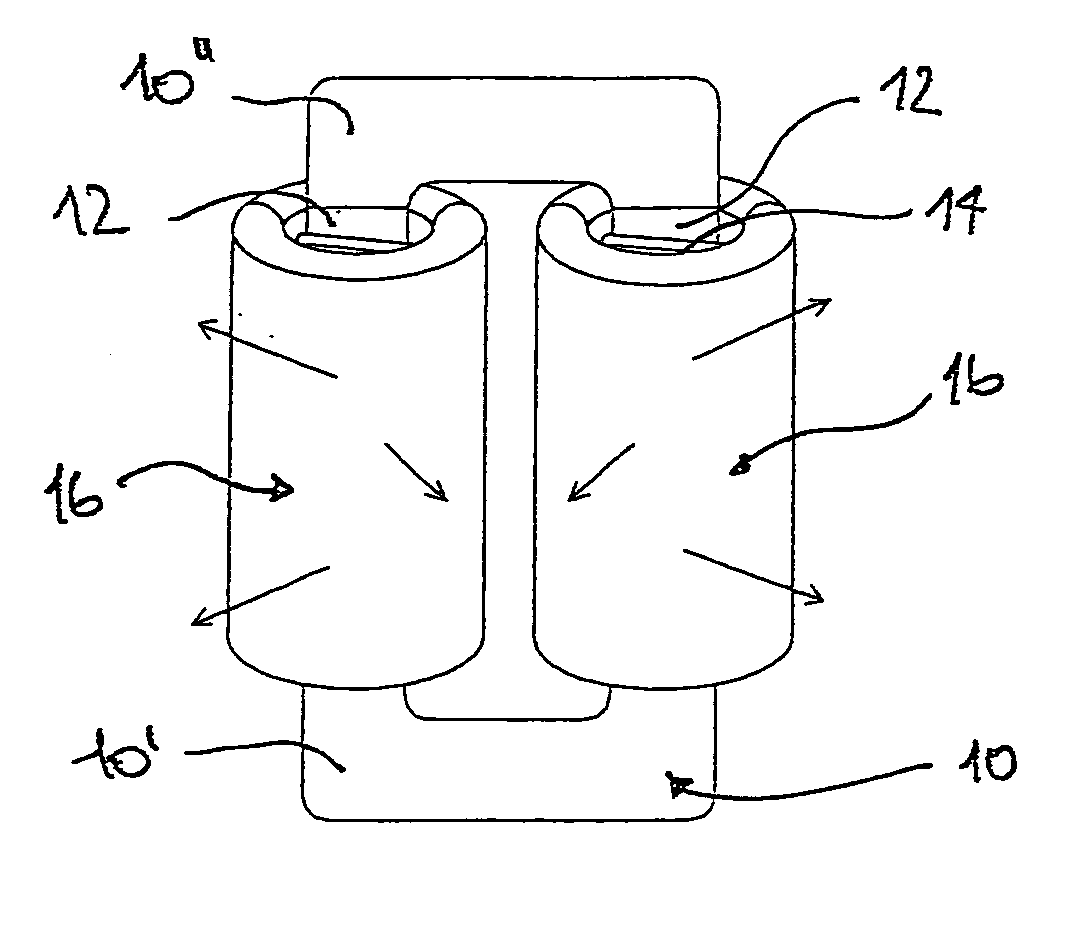

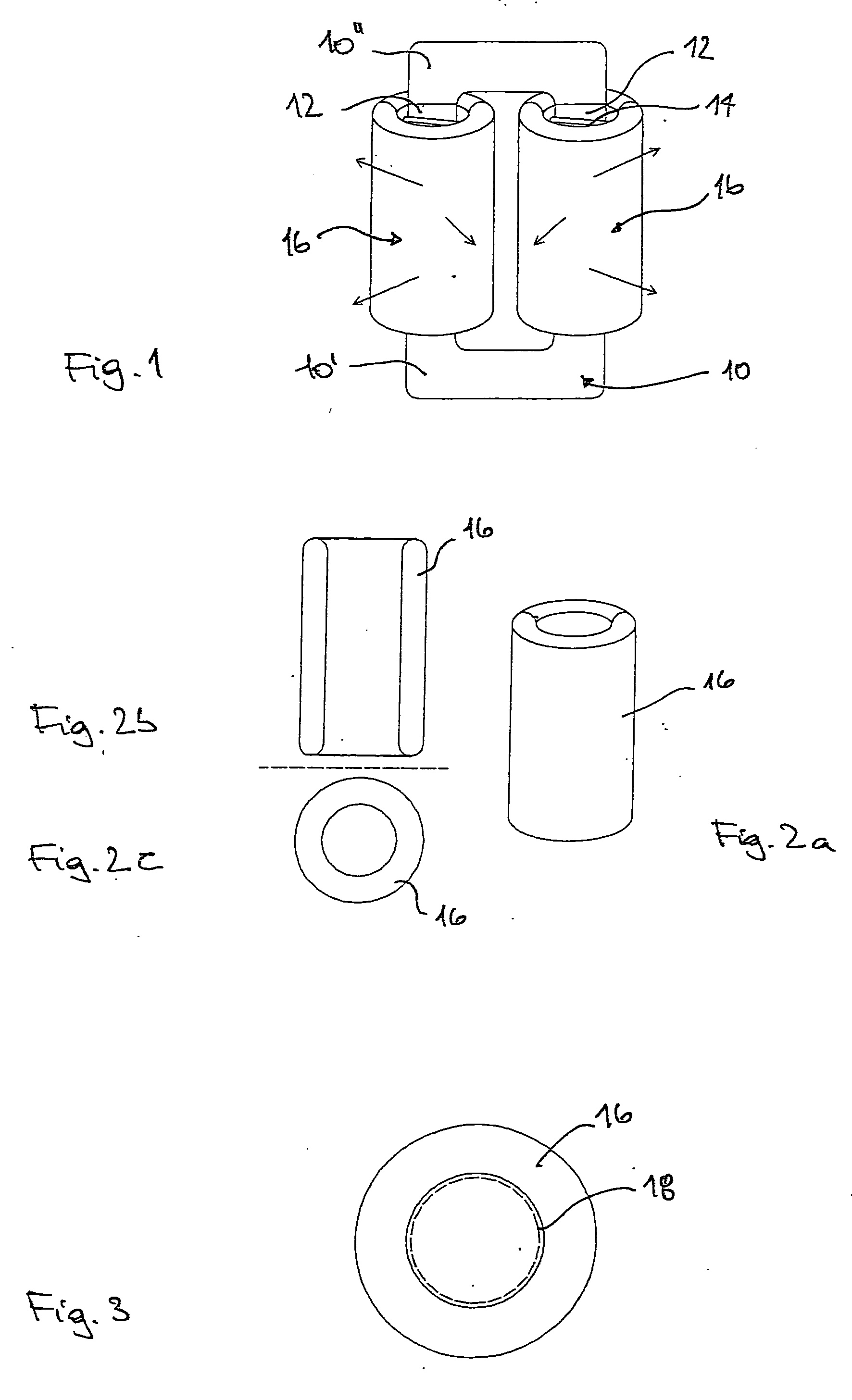

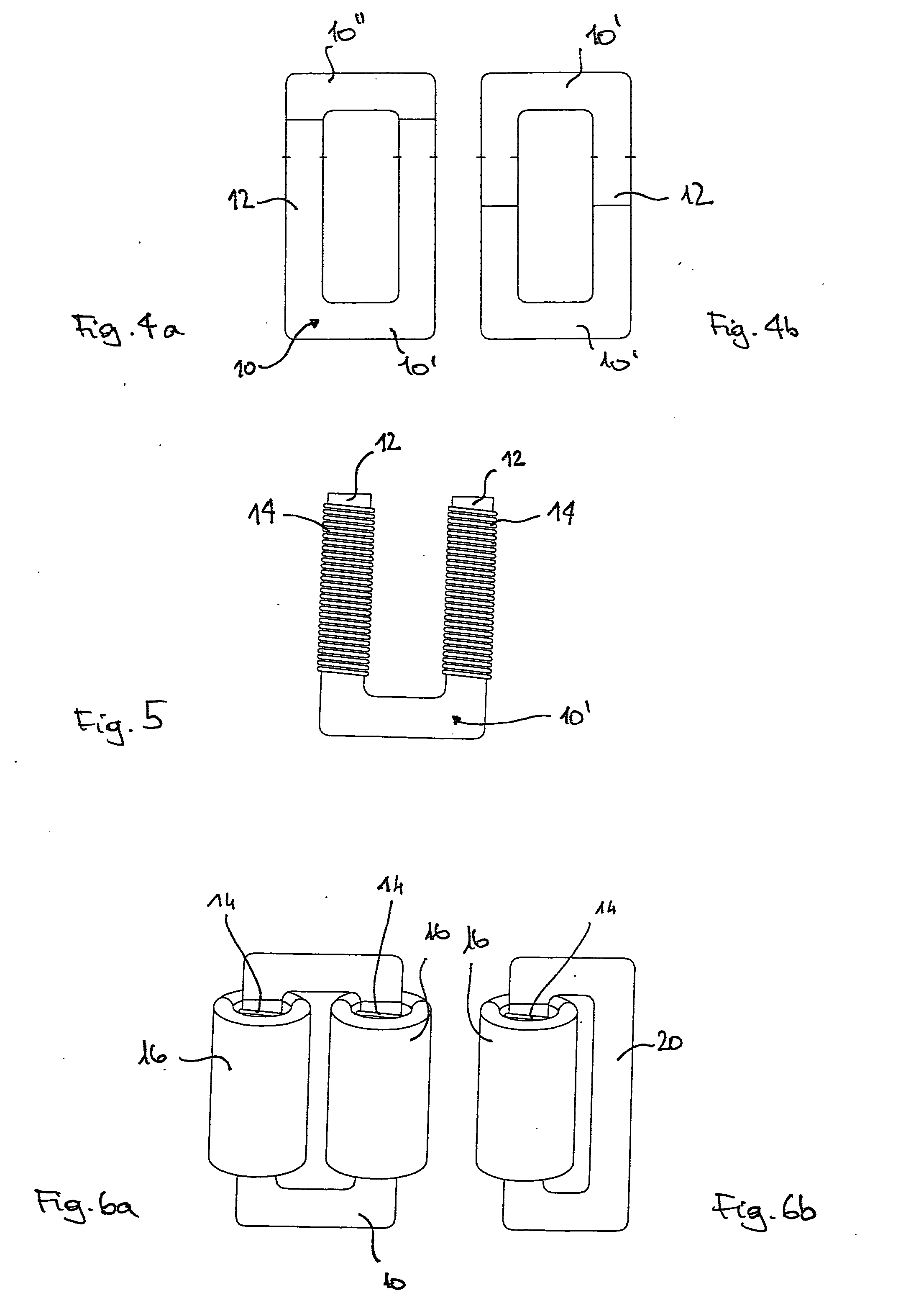

InactiveUS20070138927A1Uniform field intensityUniform current densityBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsEngineeringConductor Coil

The invention relates to an electrodeless high frequency gas discharge lamp according to the induction principle that, as a result of its design and construction, shows particularly low electromagnetic interference with a simultaneous increase in light efficiency. The gas discharge lamp according to the invention owes these advantageous properties on the one hand to the high coupling factor between the discharge current and the exciting current and, on the other hand, to the essentially homogeneous field conditions in the discharge vessel, which has been achieved by designing the discharge vessel to take the form of a hollow cylindrical ring which is seated directly over the exciter winding that extends over the entire length of the discharge vessel on a fully-closed, highly-permeable ferrite core.

Owner:MINEBEA CO LTD

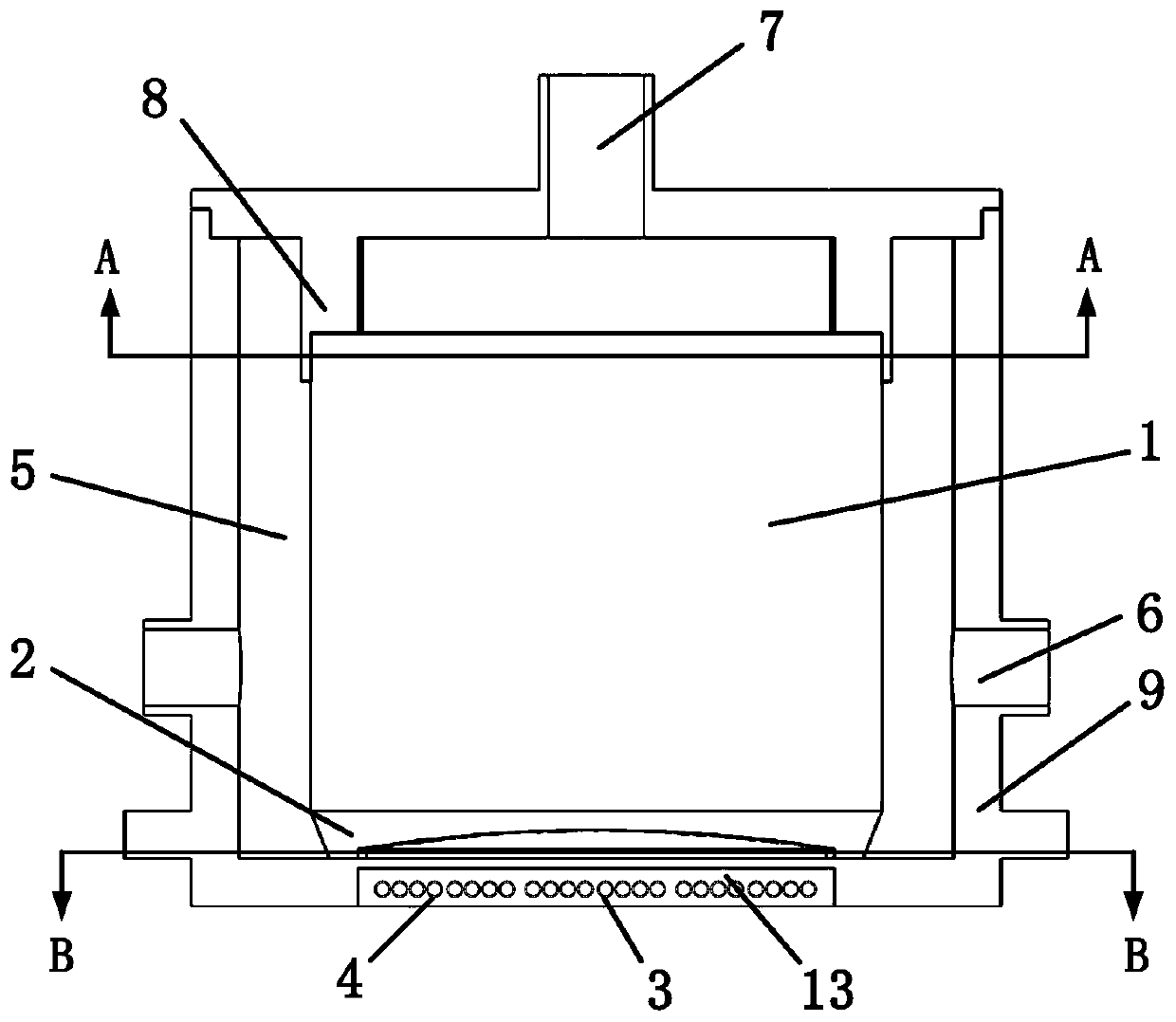

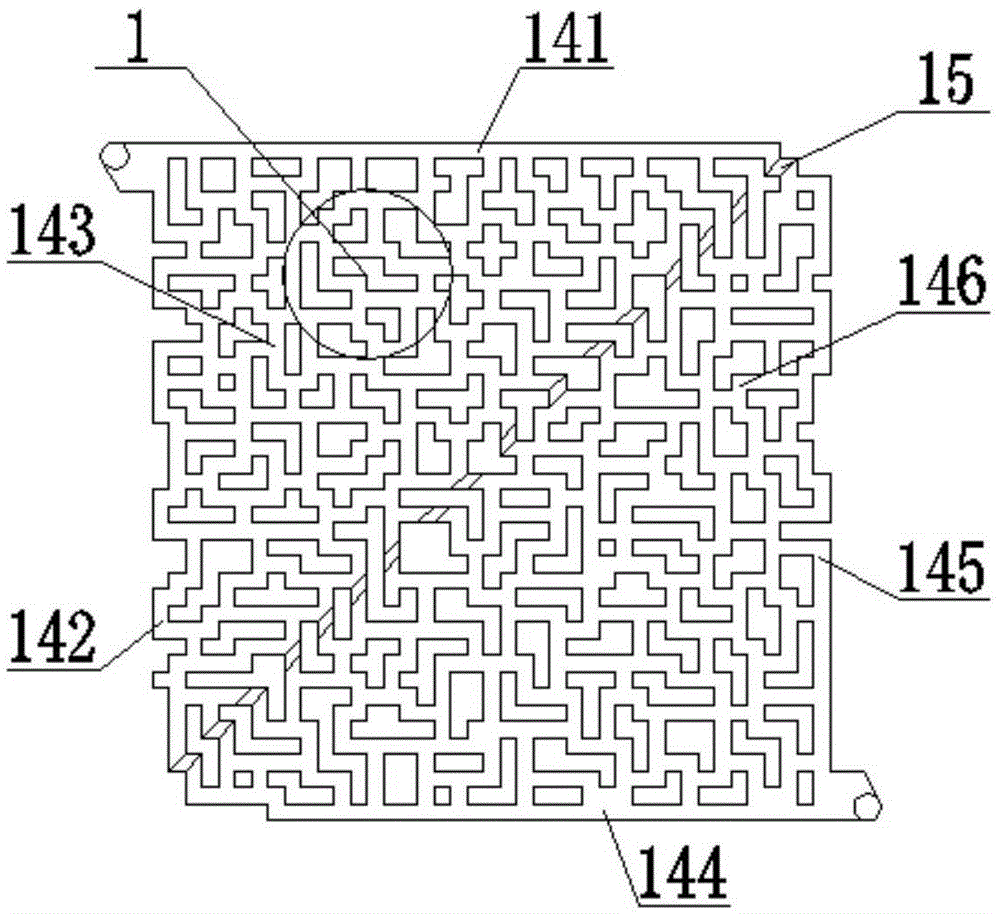

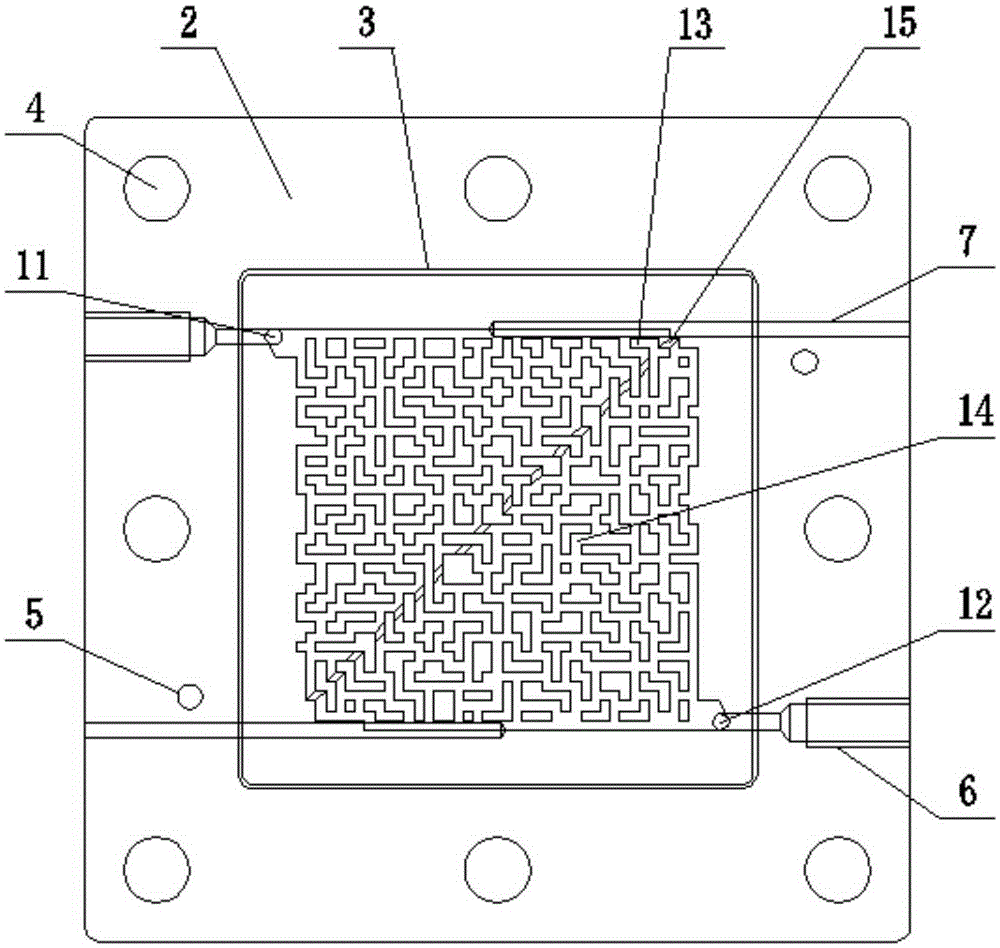

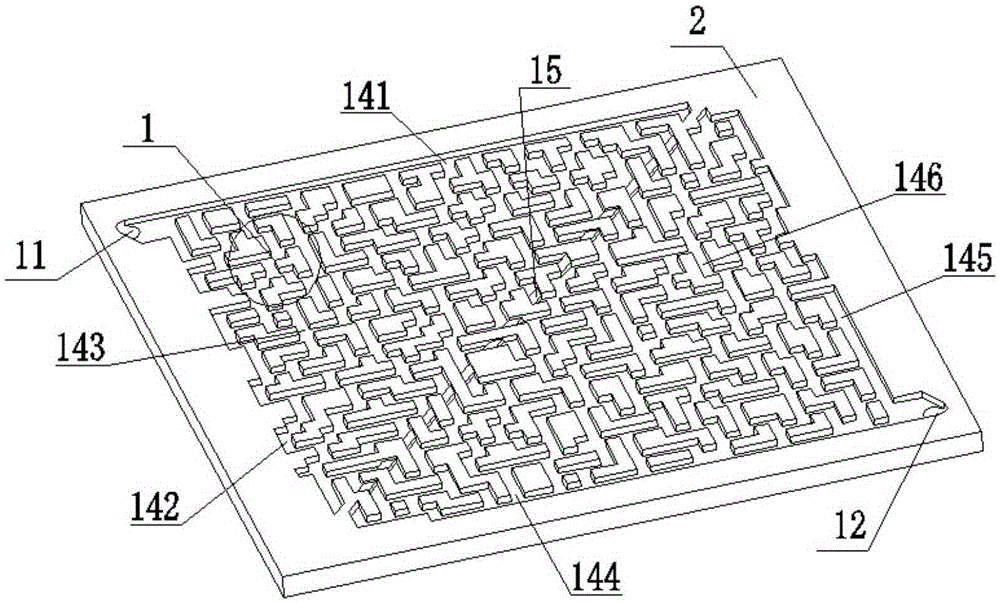

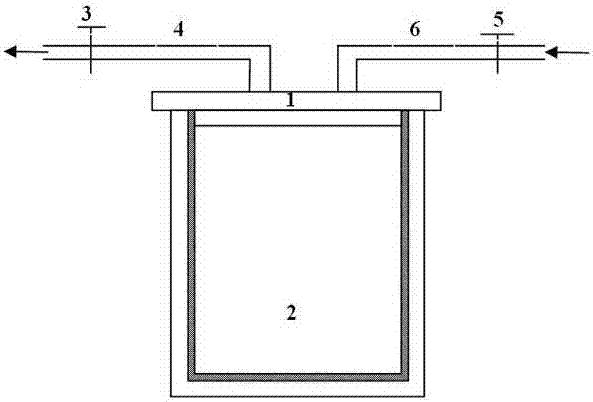

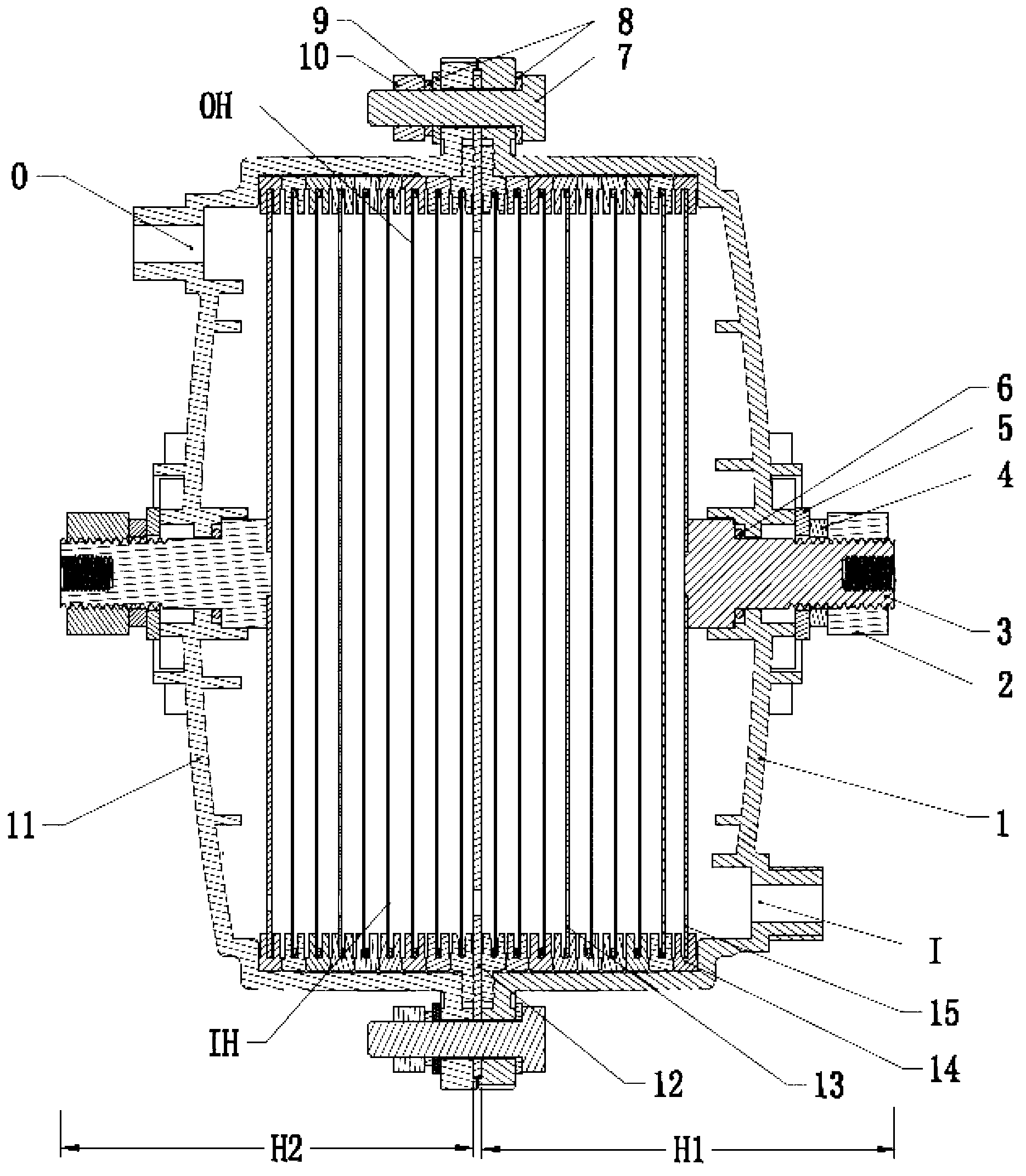

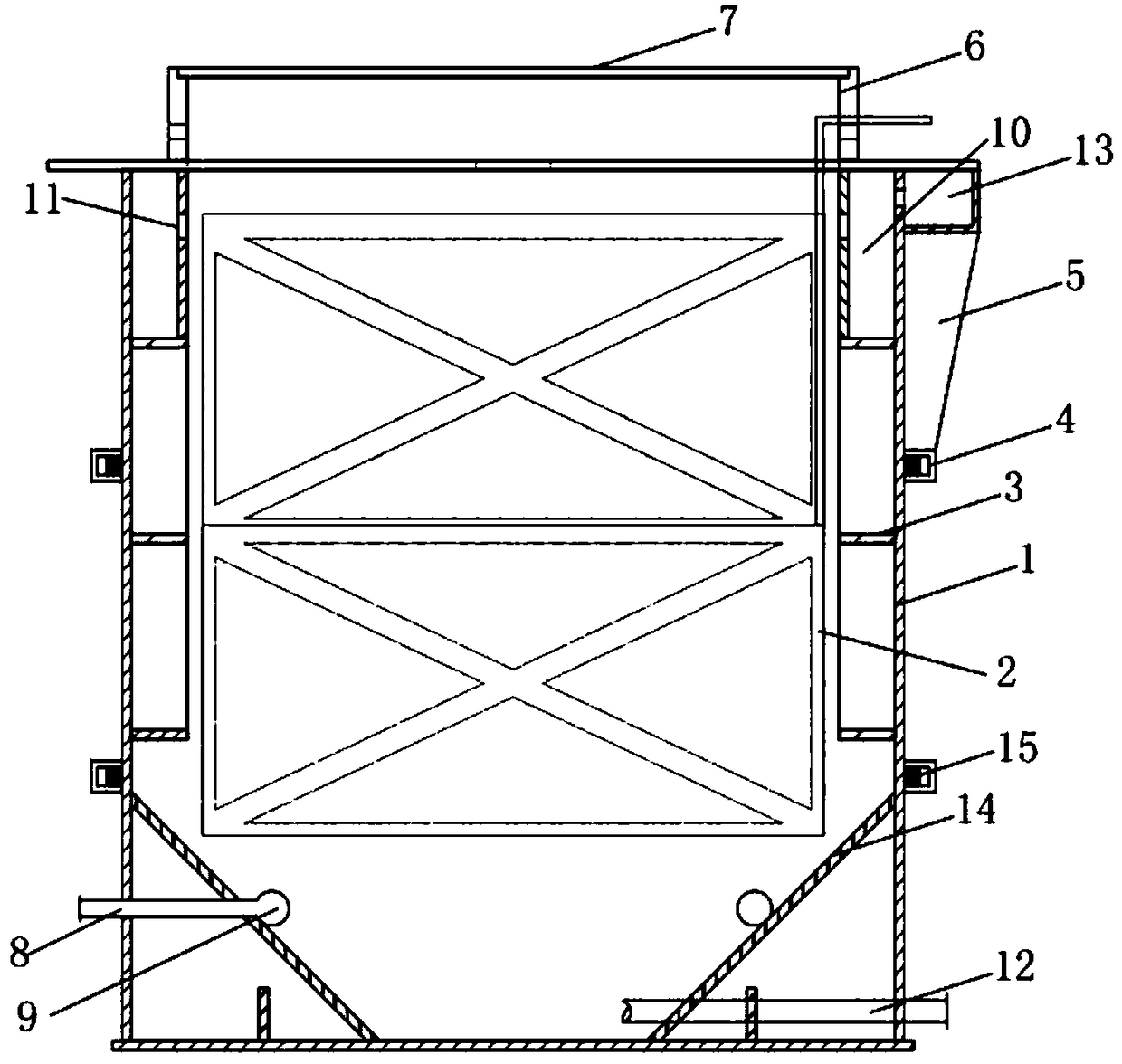

Proton exchange membrane fuel cell bipolar plate based on labyrinth-baffle-plate-structured flow field

ActiveCN106816610AEnhanced forced convectionImprove drainage capacityFuel cell heat exchangeWater management in fuel cellsElectrochemical responseWater discharge

The invention discloses a proton exchange membrane fuel cell bipolar plate based on a labyrinth-baffle-plate-structured flow field. The proton exchange membrane fuel cell bipolar plate includes a rectangular gas flow field (1), the reaction gas inlet (11) and the reaction gas outlet (12) of which are located at two ends of one diagonal of the gas flow field (1) in diagonal distribution. A plurality of ridges (13) with the same height and a plurality of baffle plates (15) are distributed in the gas flow field (1). The gas flow field (1) is internally divided by the ridges (13) into to a plurality of flow channels (14) with the same width, and all the baffle plates (15) arranged along the other diagonal of the gas flow field (1) and the ridges (13) located on the diagonal form a flow channel dam along the diagonal. The labyrinth-baffle-plate-structured flow field allows forced convection and water discharge capacity of the reaction gas to be improved, the gas is made to be uniformly distributed, and the electrochemical reaction efficiency of the cell is increased. The electric current density becomes uniform, and the electrochemical performance of the whole fuel cell is improved.

Owner:NANJING UNIV OF TECH

Contact type array tiny pit electrochemical machining method

ActiveCN104001997AConsistent strengthConsistent speedElectrochemical machining apparatusElectrolysisElectrical field strength

The invention provides a contact type array tiny pit electrochemical machining method and belongs to the technical field of electrochemical machining. The contact type array tiny pit electrochemical machining method comprises obtaining photoresist film patterns required to be performed electrolysis from a workpiece positive pole surface through a photographing masking mode; enabling a workpiece positive pole and a tool negative pole to be respectively connected with a positive pole and a negative pole of a power source; immersing the workpiece positive pole in the electrolyte; enabling the tool negative pole to be in contact with a photoresist film on the workpiece positive pole; switching on the power source to perform electrochemical machining. According to the contact type array tiny pit electrochemical machining method, the tool negative pole is in contact with the photoresist film on the workpiece positive pole, so that electric filed distribution in a machining area can be improved, the electric field intensity on the periphery and in the middle of the machining area tends to be consistent, and the array tiny pit electrochemical machining accuracy and locality are obviously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

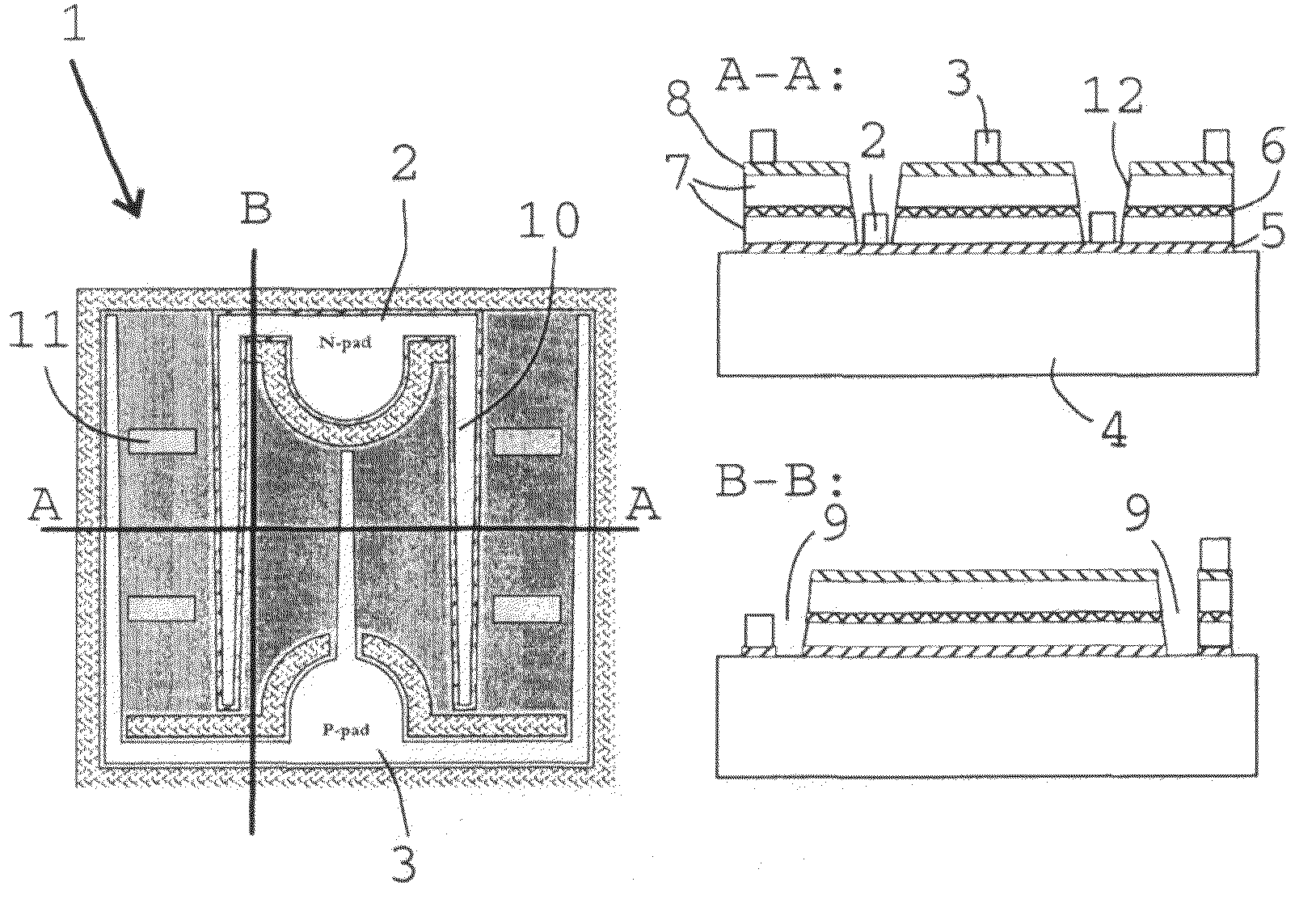

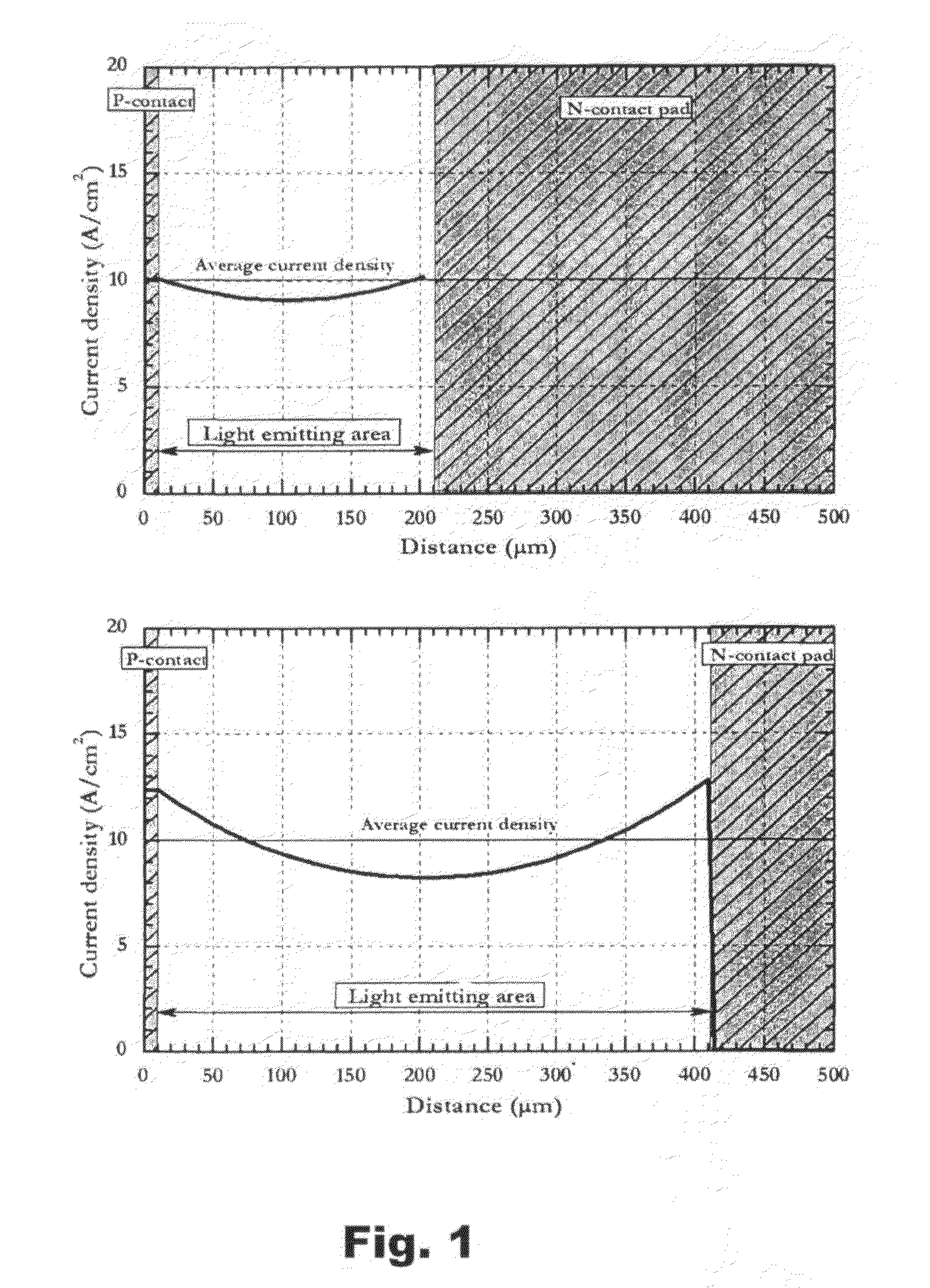

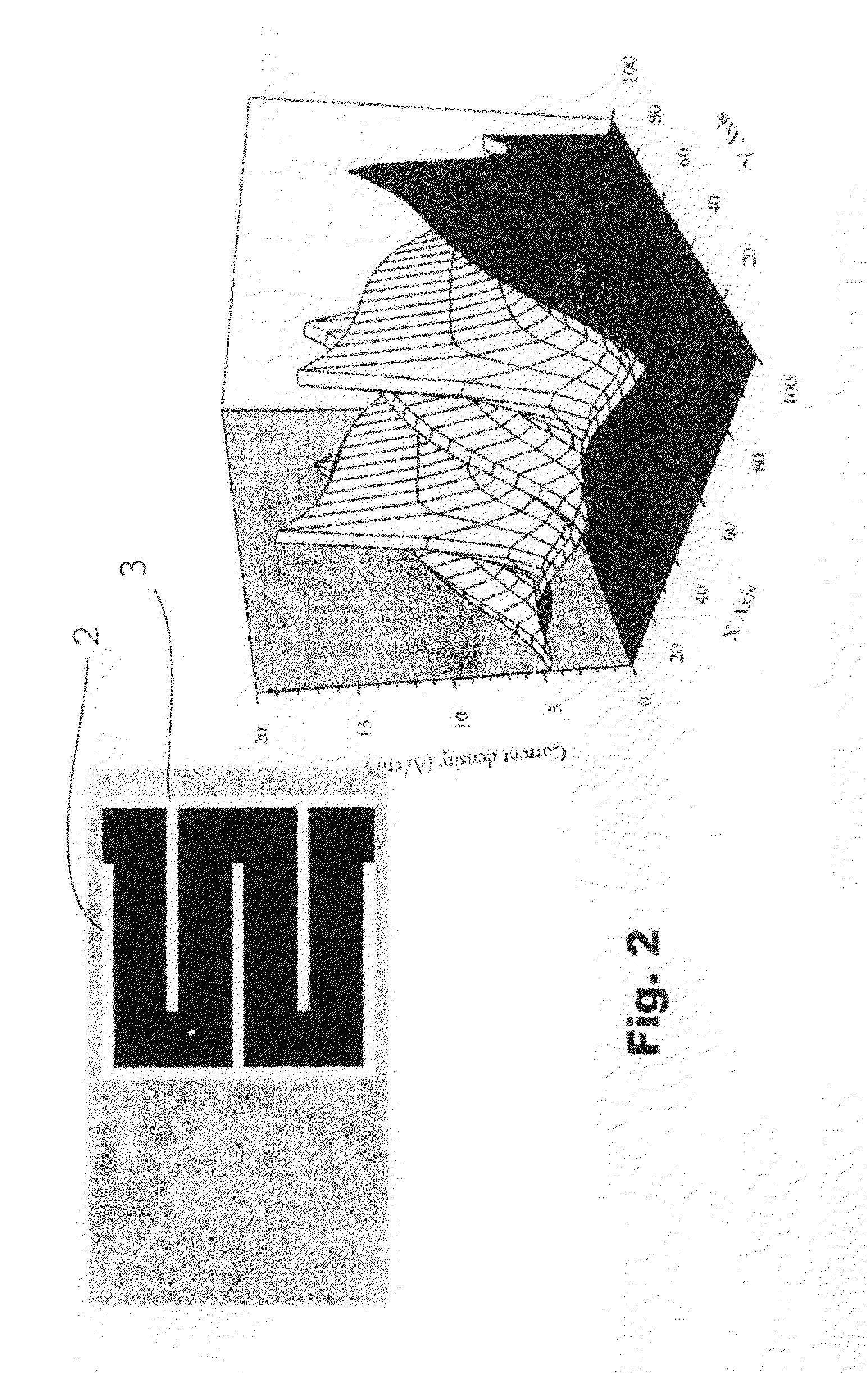

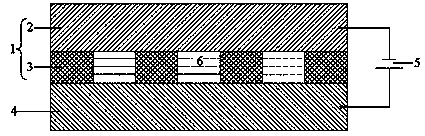

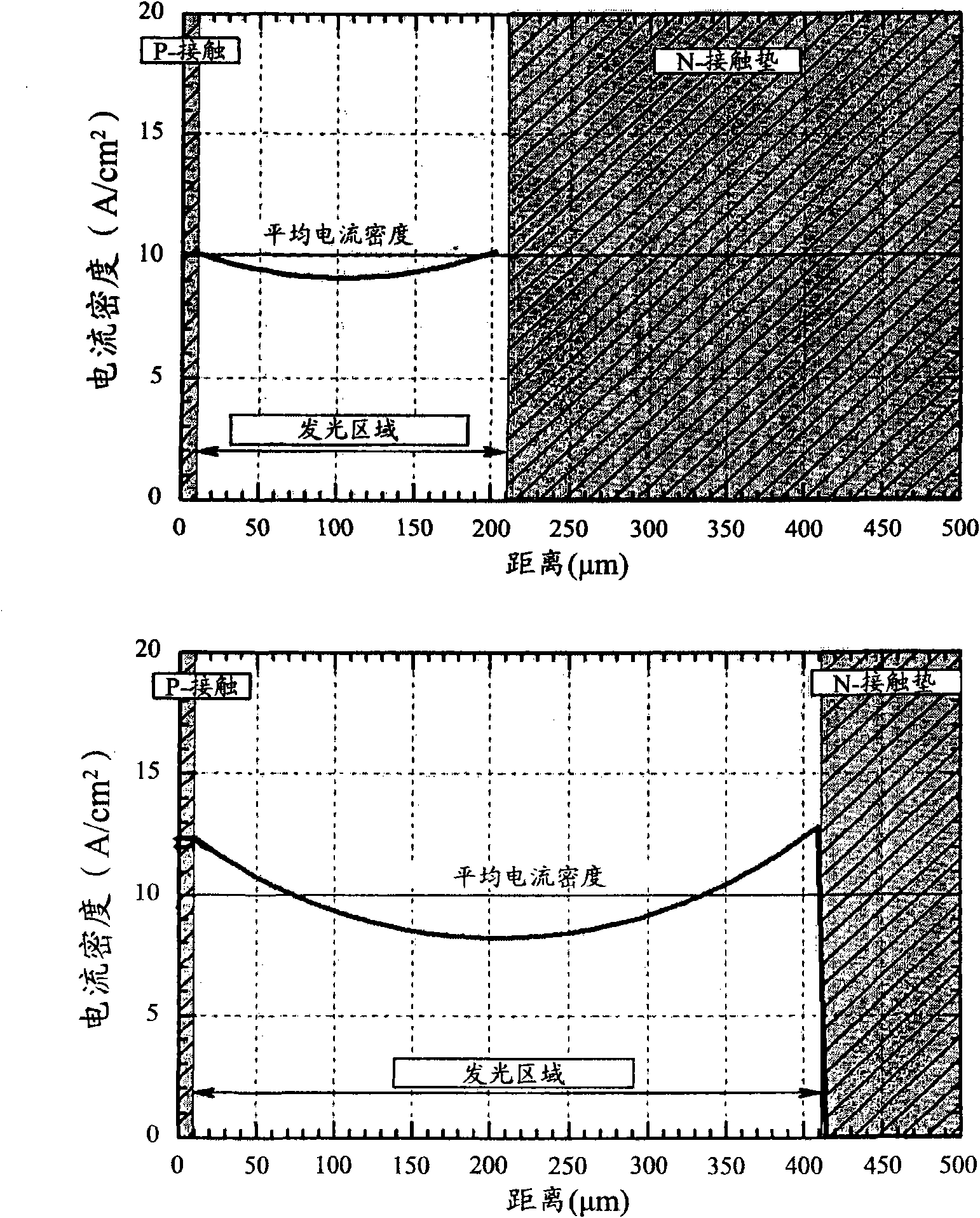

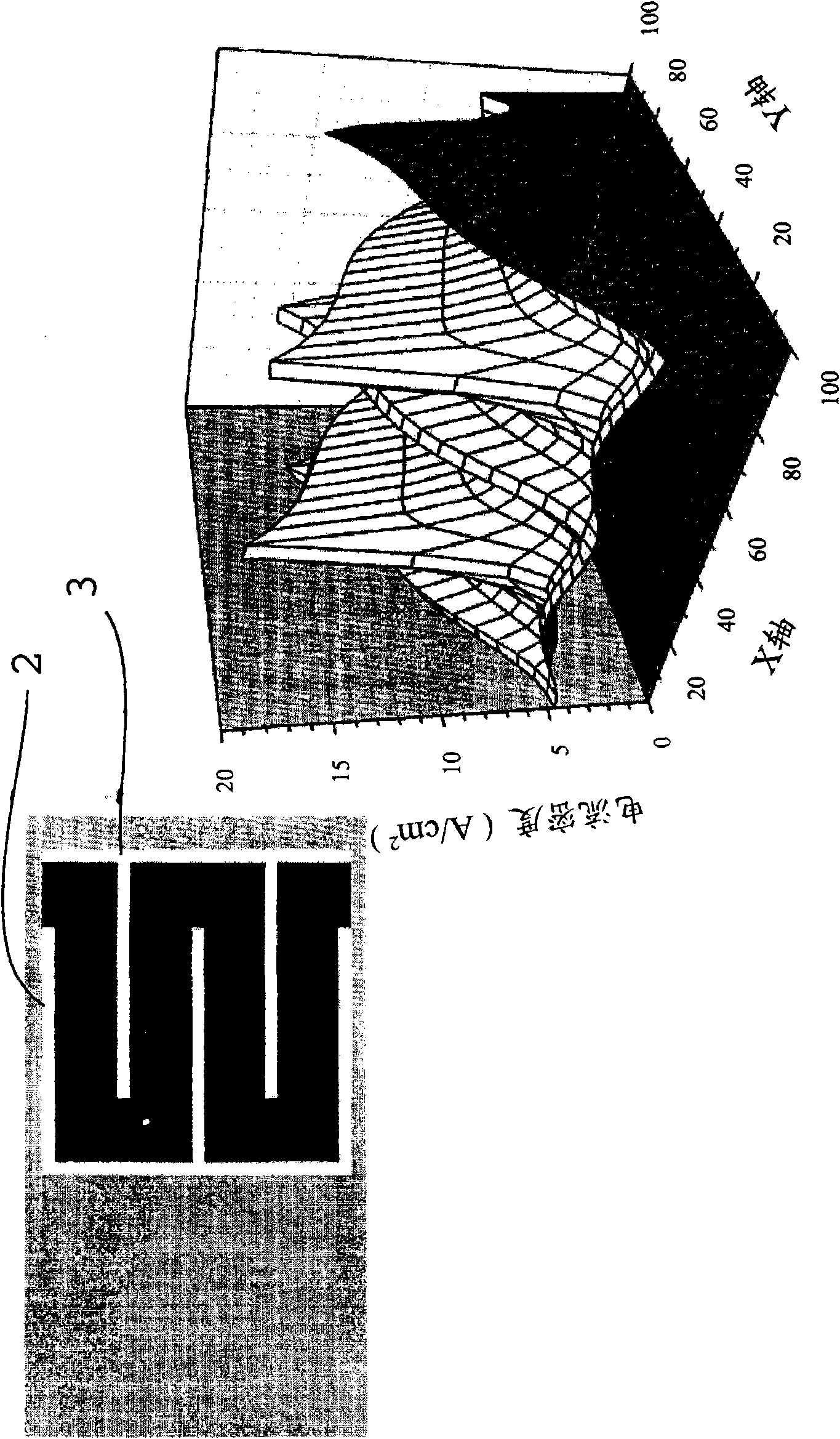

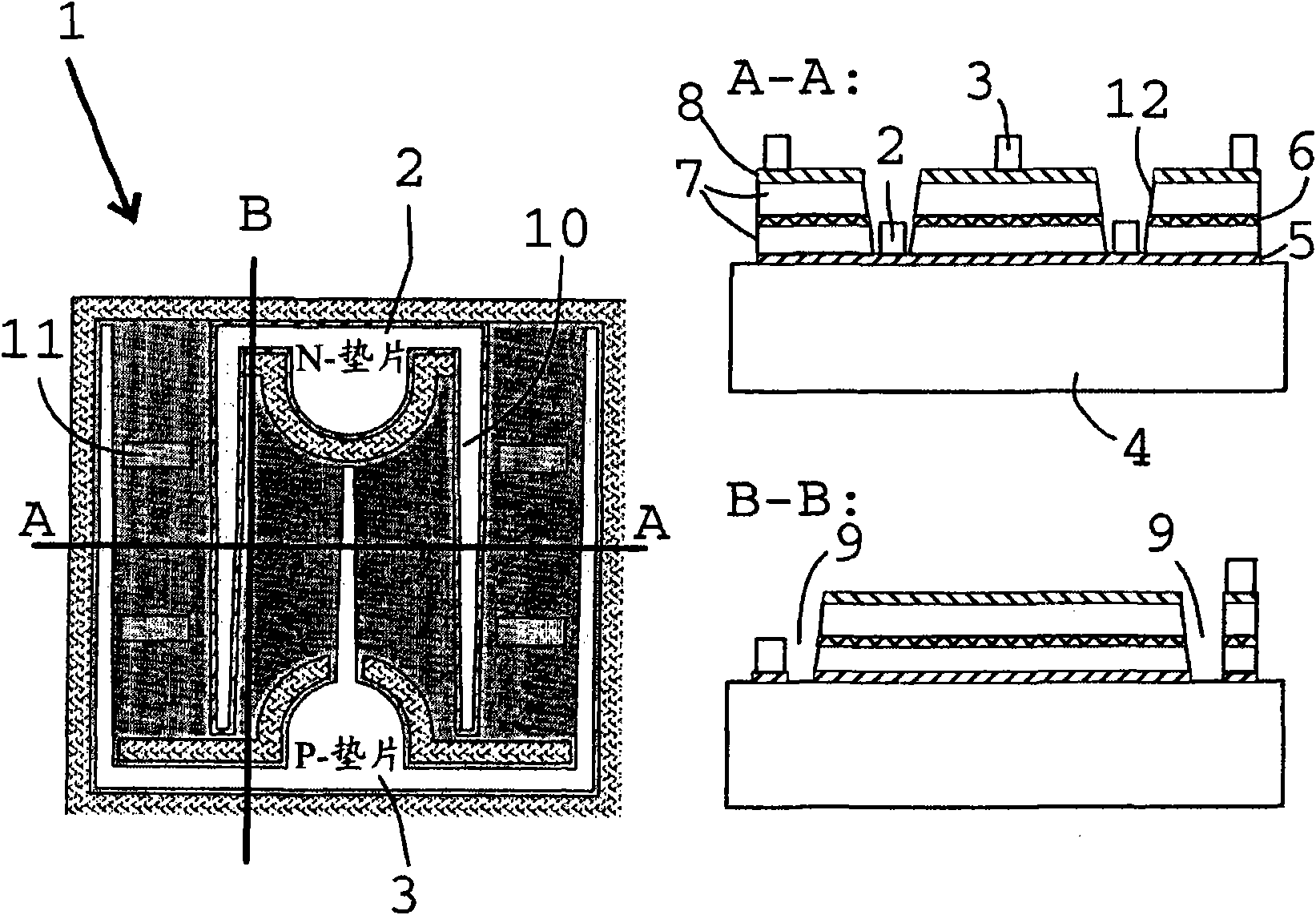

Light emitting diode

InactiveUS20100163910A1Uniform current densityIncrease overall perimeterSemiconductor devicesCurrent distributionElectric current flow

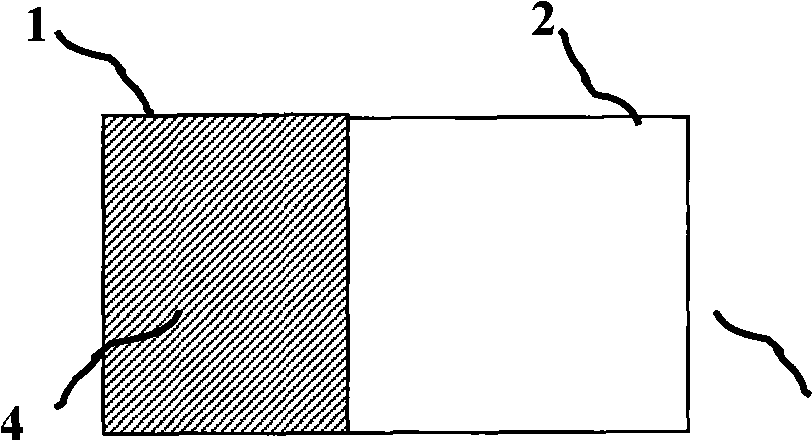

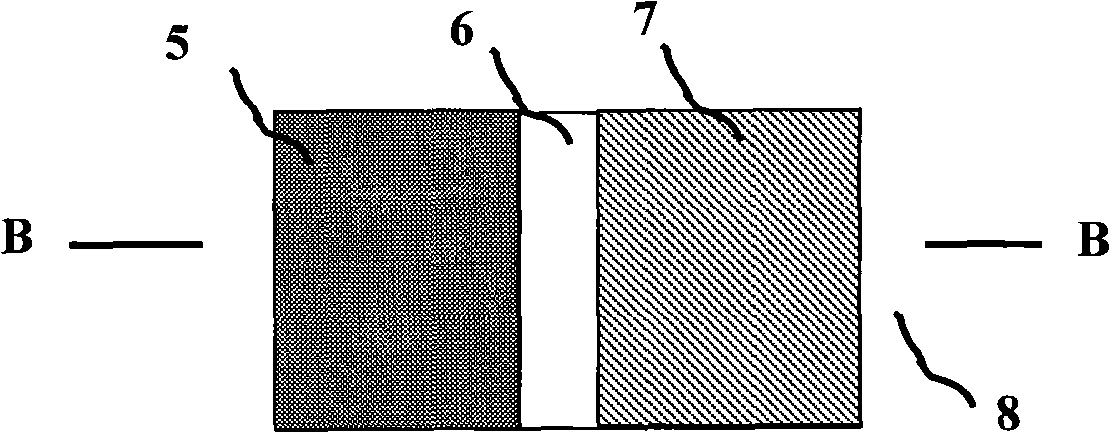

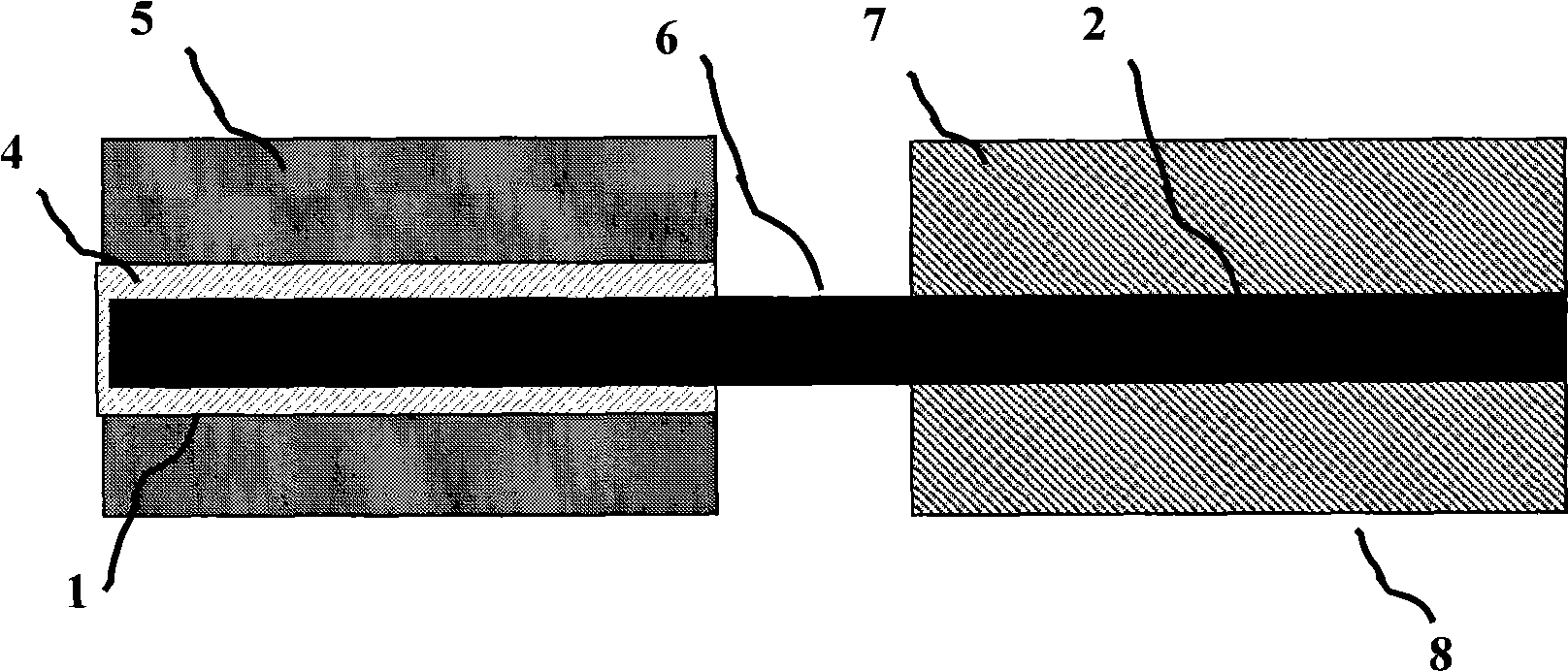

An LED chip (1) grown on an electrically insulating substrate (4) comprises a lower current-distributing layer (5) of a first conductivity type, a first electrode (2), a vertical layer structure (5, 6, 7), the last two being formed on the lower current-distributing layer horizontally separated from each other, the vertical layer structure comprising an active layer (6) and an upper current-distributing layer (8) of a second conductivity type above the active layer, and a second electrode (3) formed on the upper current-distributing layer, the geometry of the electrodes being adjusted to provide a horizontal distance between the electrodes lower than the current spreading length of the chip. According to the present invention, a vertical trench (9) is formed between the electrodes (2, 3), the trench extending through the chip (1), including the lower current-distributing layer (5), for controlling the horizontal current flow in order to achieve a uniform current density over the active layer (6).

Owner:OPTOGAN OY

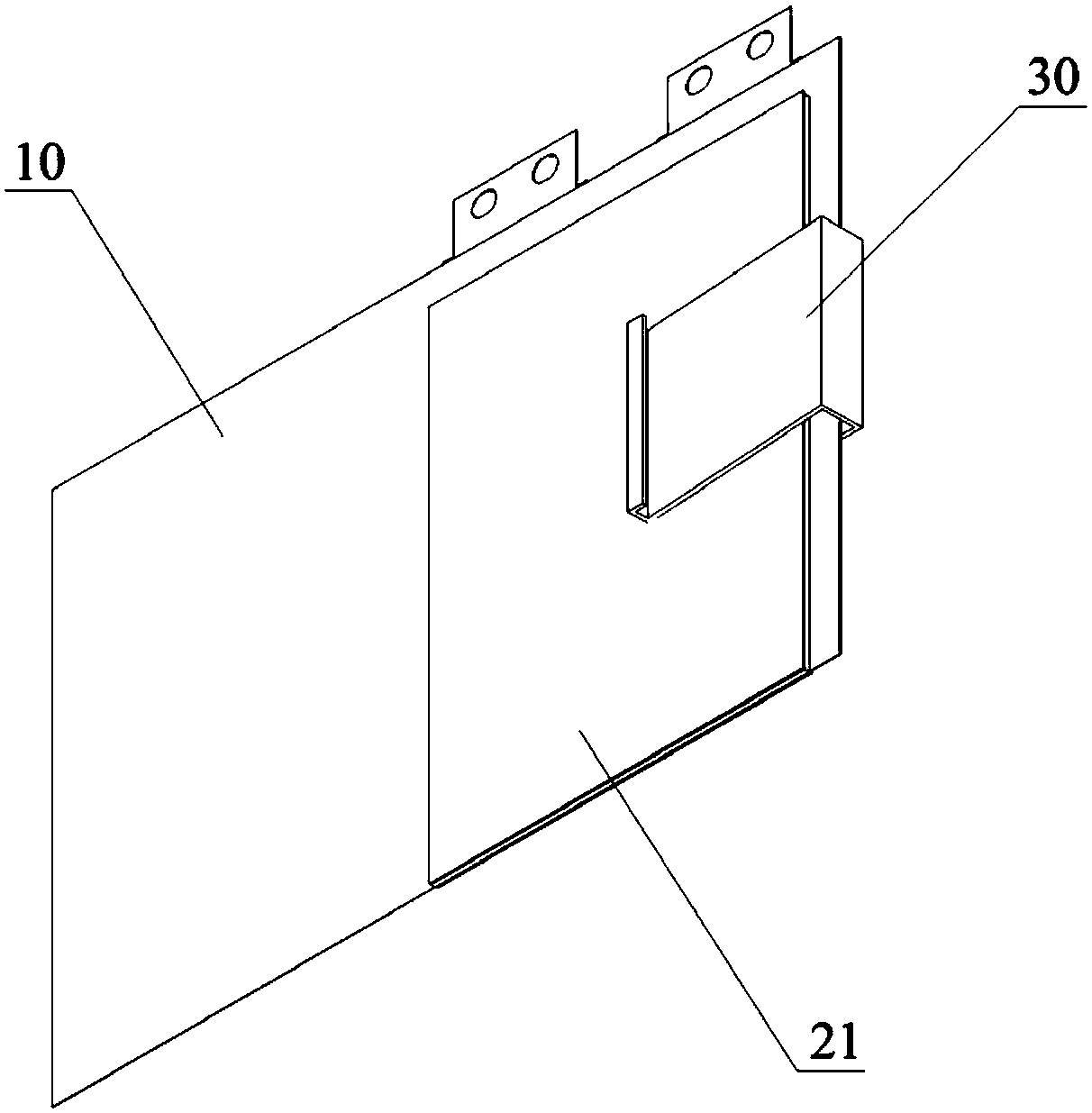

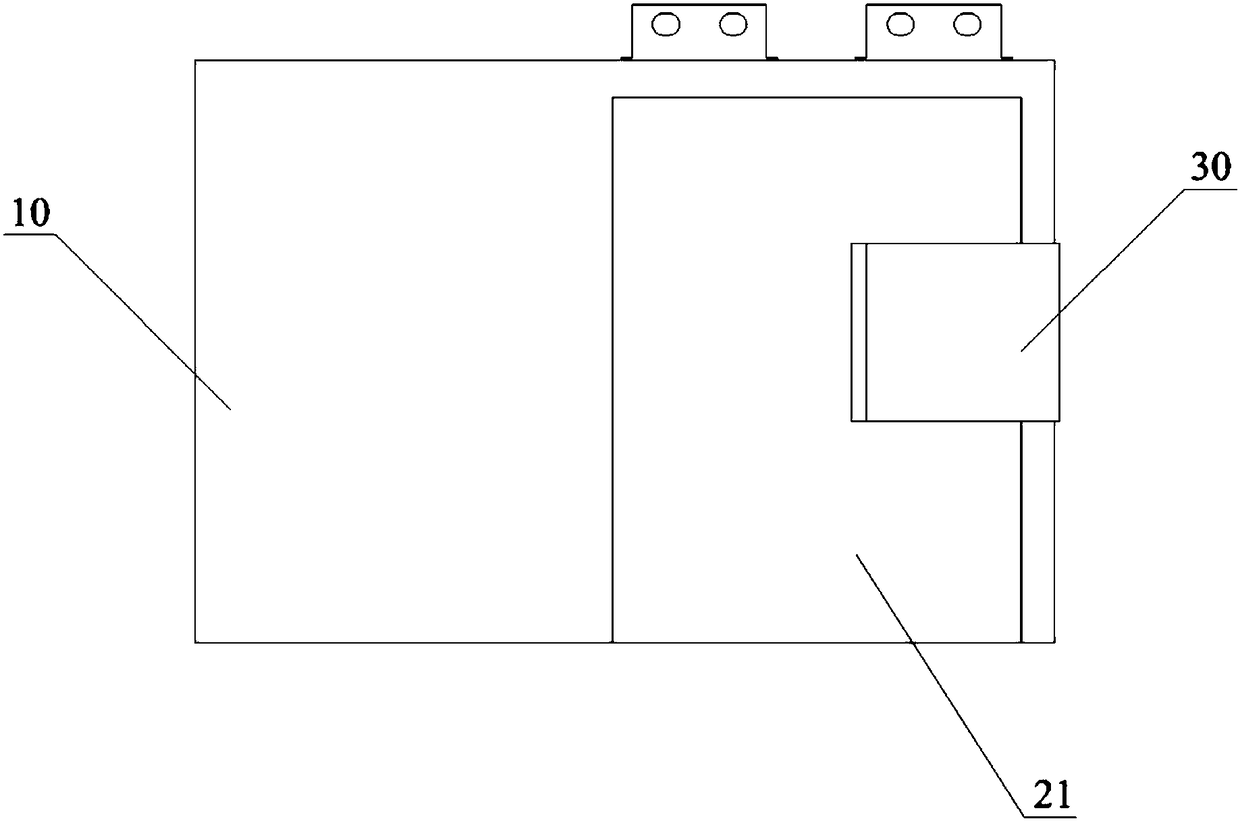

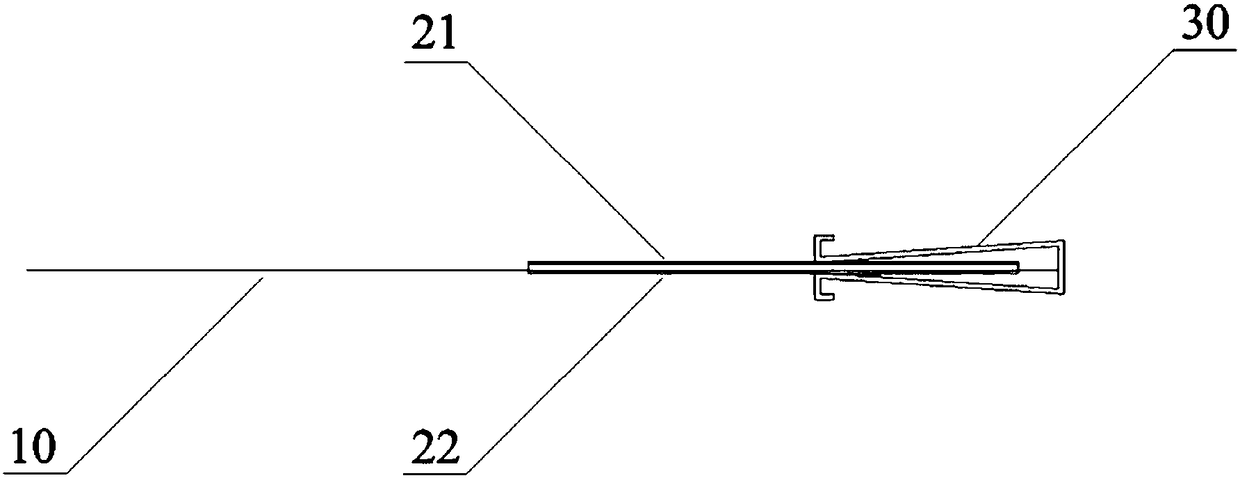

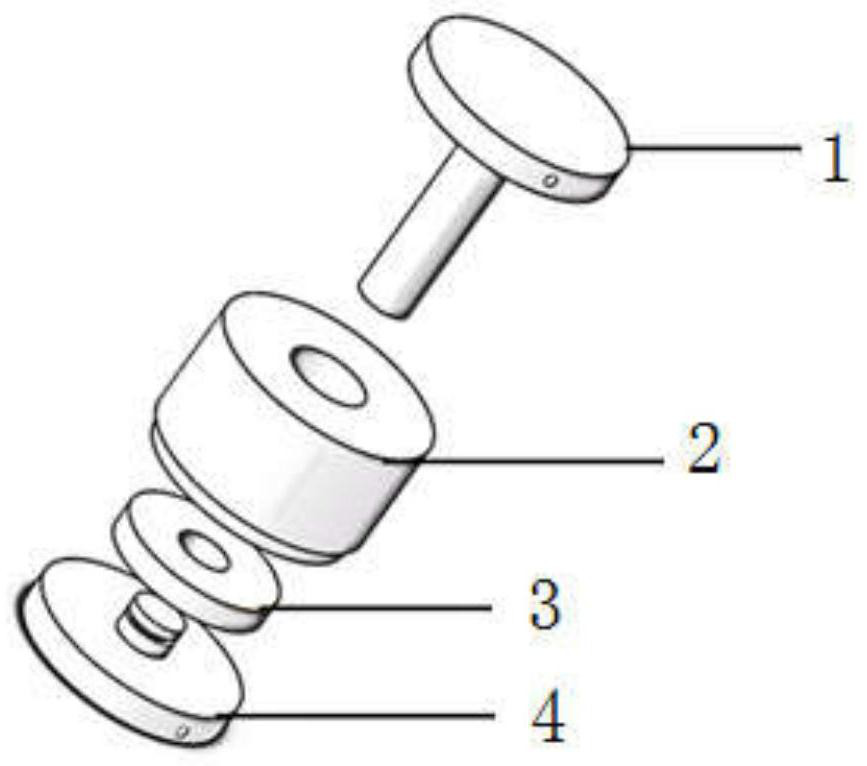

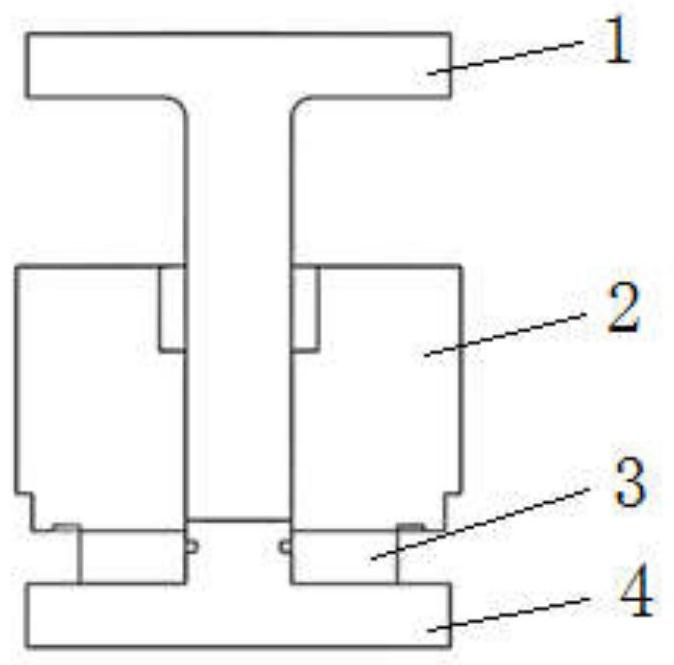

Formation method capable of prolonging cycle life of soft package power battery, battery formation clamp, applications and soft package power battery

PendingCN108306062AImprove cycle lifeFormation method to improve cycle lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPower batteryElectrical battery

The invention provides a formation method capable of prolonging the cycle life of a soft package power battery, a battery formation clamp, applications and the soft package power battery and relates to the technical field of soft package power batteries. The formation method comprises the steps of adopting multi-echelon vacuum standing and vacuum sealing treatment on the battery subject to liquidinjection, putting the vacuum sealed battery into the battery formation clamp for carrying out the steps of aging, precharge treatment and standing, wherein an immersion method of echelon vacuum standing is adopted after liquid injection, so that the absorption rate of an electrolyte can be reduced and the drainage time is shortened; pressure standing is adopted in the aging process, so that infiltration of the electrolyte can be fuller under certain pressure; and the battery formation clamp is adopted for precharge treatment, so that a positive plate and a negative plate of the battery can bein close contact, the formed SEI film is consistent in components, and the surface thickness is uniform and stable. The invention further provides the battery formation clamp. The clamp is simple instructure, convenient to use and suitable for industrial production.

Owner:BEIJING NAT BATTERY TECH

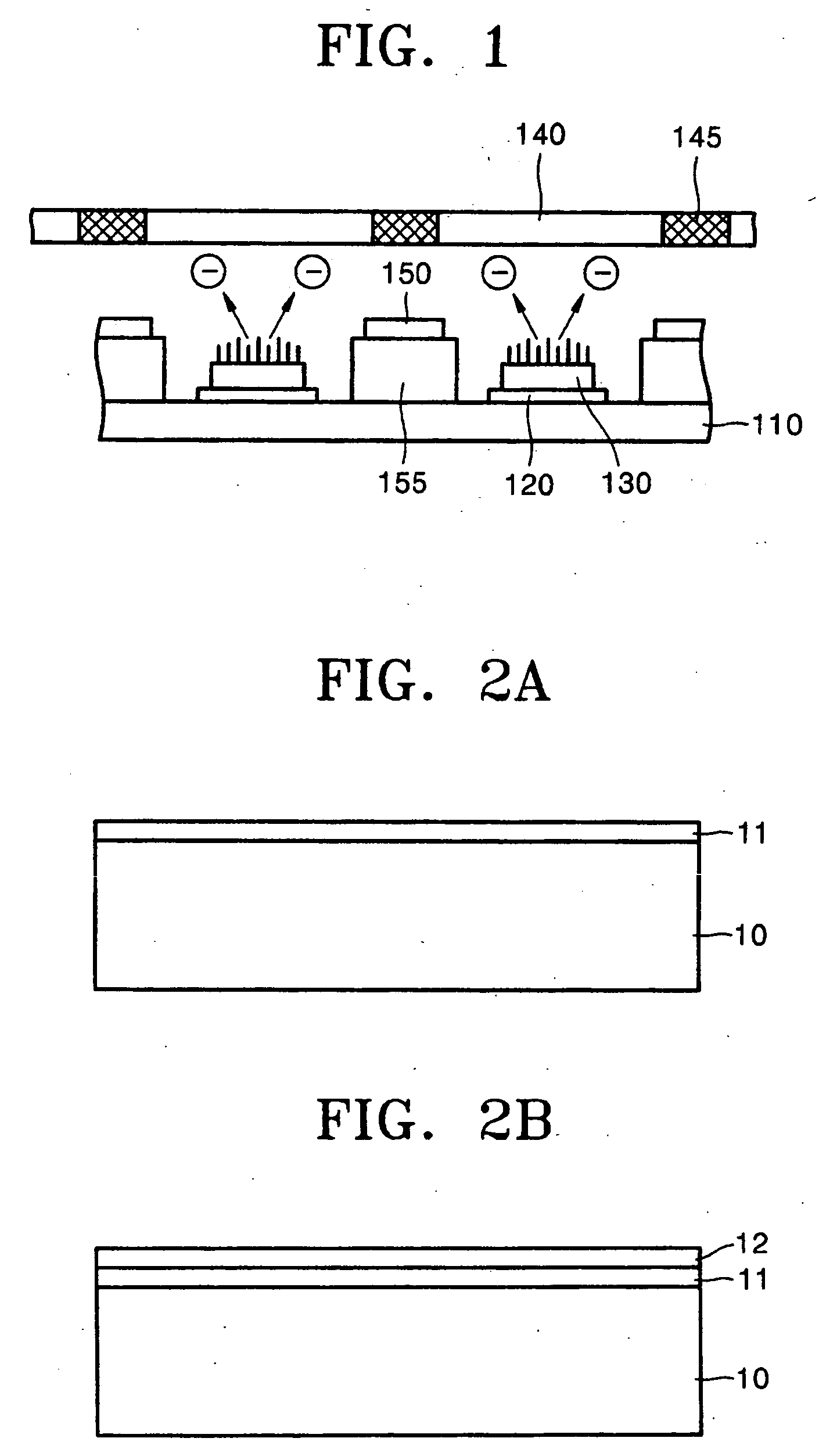

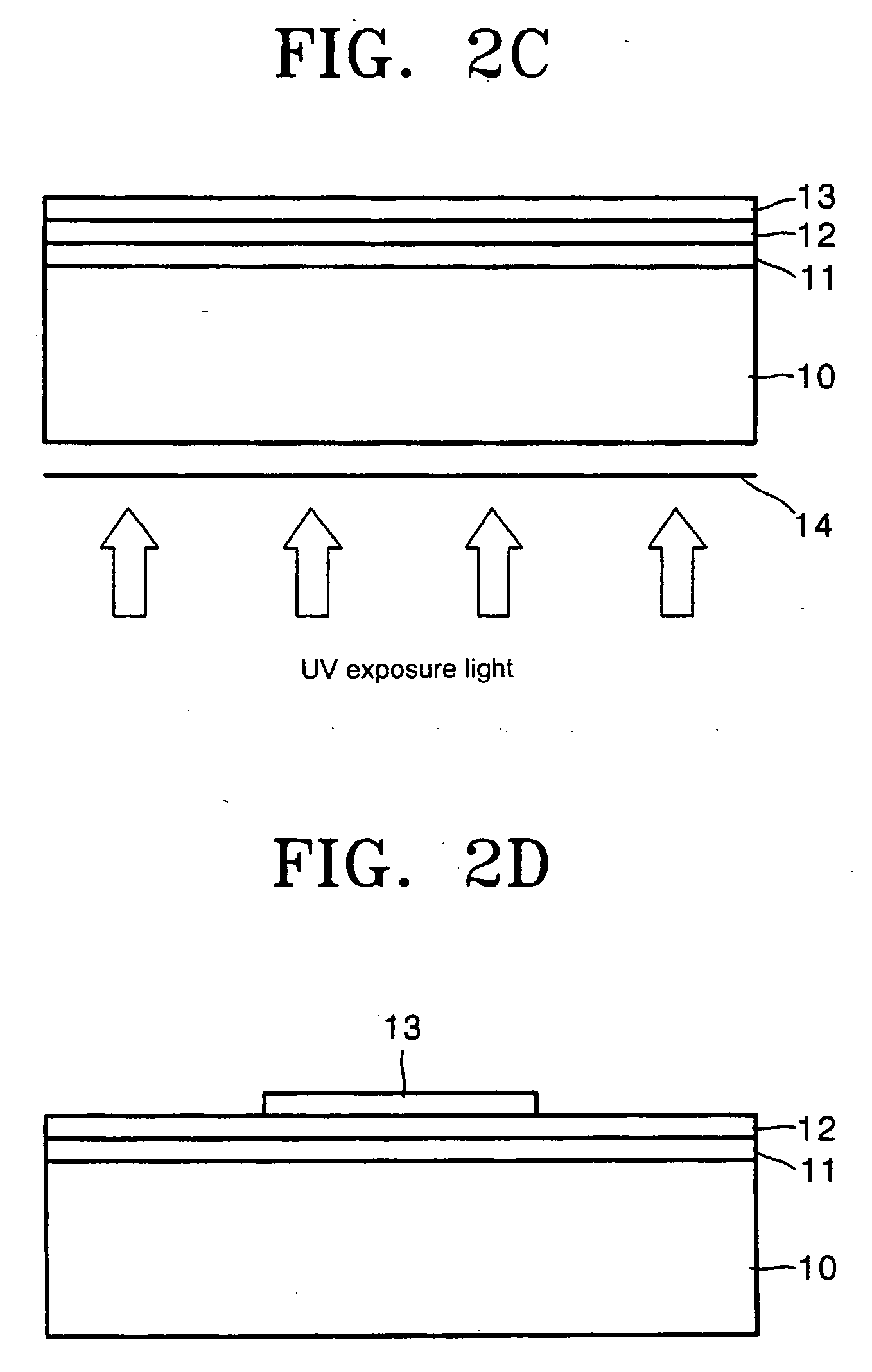

Long life-time field emitter for field emission device and method for fabricating the same

InactiveUS20050269928A1Uniform current densityLong life-timeDischarge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

An emitter for a field emission device (FED) designed to increase durability by interposing an ultraviolet (UV) transmissive resistive layer between a substrate and an emitter and a method for fabricating the same. The method includes depositing a transparent electrode on a transparent substrate, forming a resistive layer by stacking an ultraviolet (UV) transmissive resistive material on the transparent electrode, forming an emitter layer by stacking a carbon nanotube (CNT) on the UV transmissive resistive material, and patterning the emitter layer according to a predetermined emitter pattern.

Owner:SAMSUNG SDI CO LTD

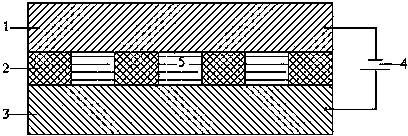

Common-current collector plate group with positive plates opposite to negative plates and common-current collector module battery

InactiveCN101556995AIncrease working temperatureImprove high temperature environment adaptabilityFinal product manufactureCell temperature controlEngineeringCharge discharge

The invention relates to a common-current collector plate group with positive plates opposite to a negative plates and a common-current collector module battery, belonging to the technical field of battery. One end of the positive plate of the common-current collector plate group with the positive plate opposite to the negative plate is provided with a naked section of conductive substrate and one end of the negative plate is provided with a naked section of conductive substrate; the naked sections of conductive substrates of all the positive plate are respectively connected with one side of a current collector, and the naked sections of all the conductive substrates of the negative plate are respectively connected with the other side of the current collector; the positive electrode of the module battery penetrates through a sealed shell and is connected with the positive plate group; the negative electrode of the module battery penetrates through a sealed shell and is connected with the negative plate group; all the positive plates are respectively wrapped by a membrane; the common-current collector plate group with the positive plates opposite to the negative plates is arranged between the positive plate group and the negative plate group in sequence; all the positive plates are respectively distributed between adjacent negative plates; and adjacent monomer batteries have a common current collector. The common-current collector plate group has simple structure and long service life, greatly improves large-current charging-discharging capability, charging-discharging efficiency, thermal environment adaptability and anti-vibration capability of the battery.

Owner:SHANGHAI JIAO TONG UNIV

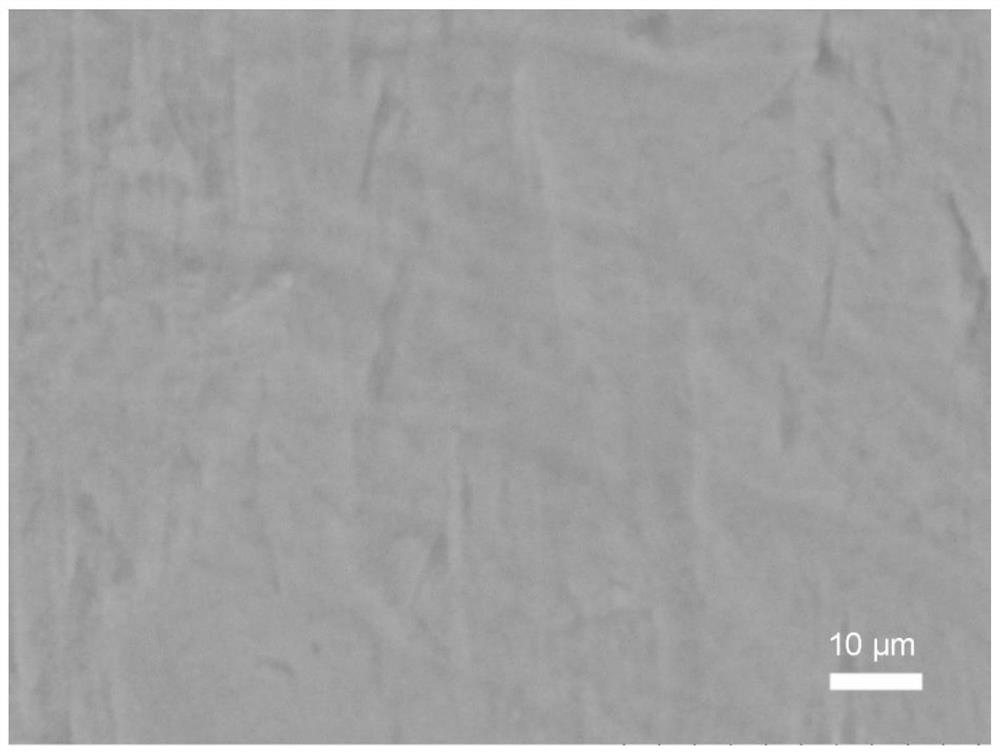

Fabrication method for surface electroplating coating layer of NdFeB rare-earth permanent magnet

ActiveCN107039168AIncreased vacuum handlingContains to avoidPermanent magnet manufactureVacuum pumpingMetallurgy

The invention belongs to the technical field of corrosion-prevention surface processing, and particularly relates to a fabrication method for a surface electroplating coating layer of an NdFeB rare-earth permanent magnet. The fabrication method comprises the steps of firstly, pre-processing a surface of the NdFeB rare-earth permanent magnet; secondly, performing vacuum pumping on the NdFeB rare-earth permanent magnet; and finally, electroplating by employing an ultrasonic wave electroplating groove. By the fabrication method, expansion and bubbles of a plating layer caused by a hydrogen evolution effect are prevented, the corrosion prevention performance of the surface coating layer of the NdFeB rare-earth permanent magnet is improved, an existing NdFeB electroplating corrosion-prevention technology is expected to be substituted, and thus, the fabrication method has a very wide application prospect.

Owner:凉山稀土产业技术研究院

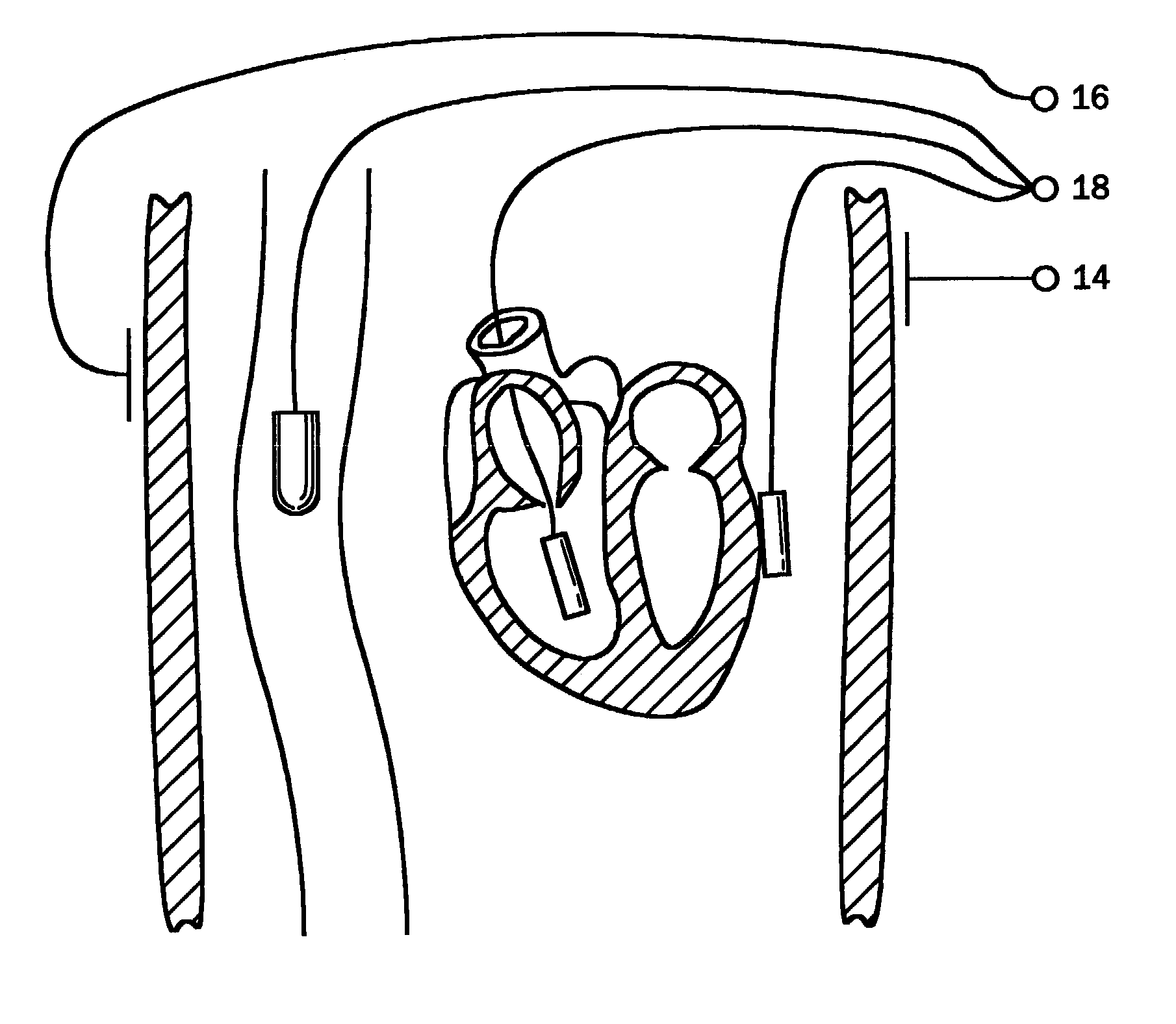

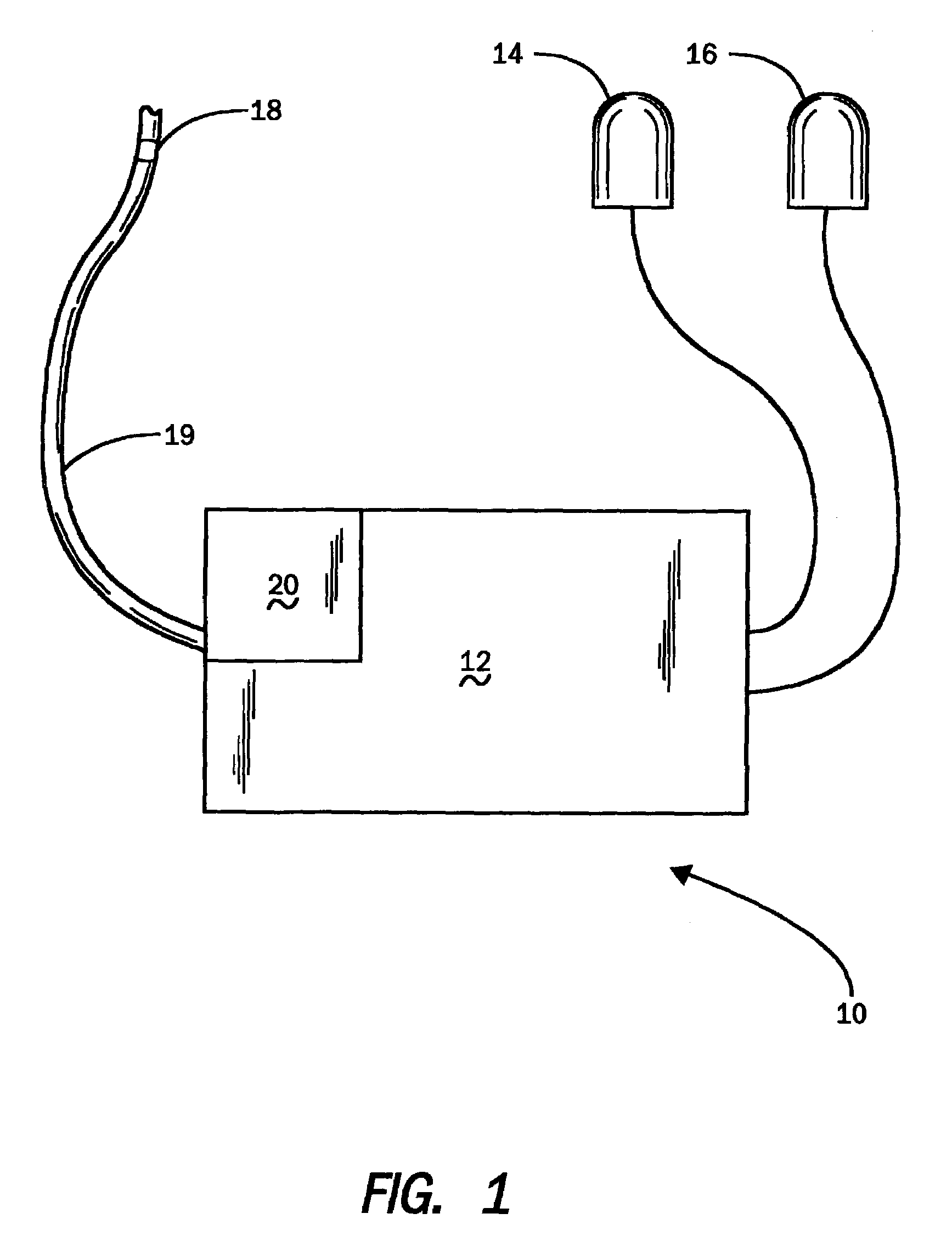

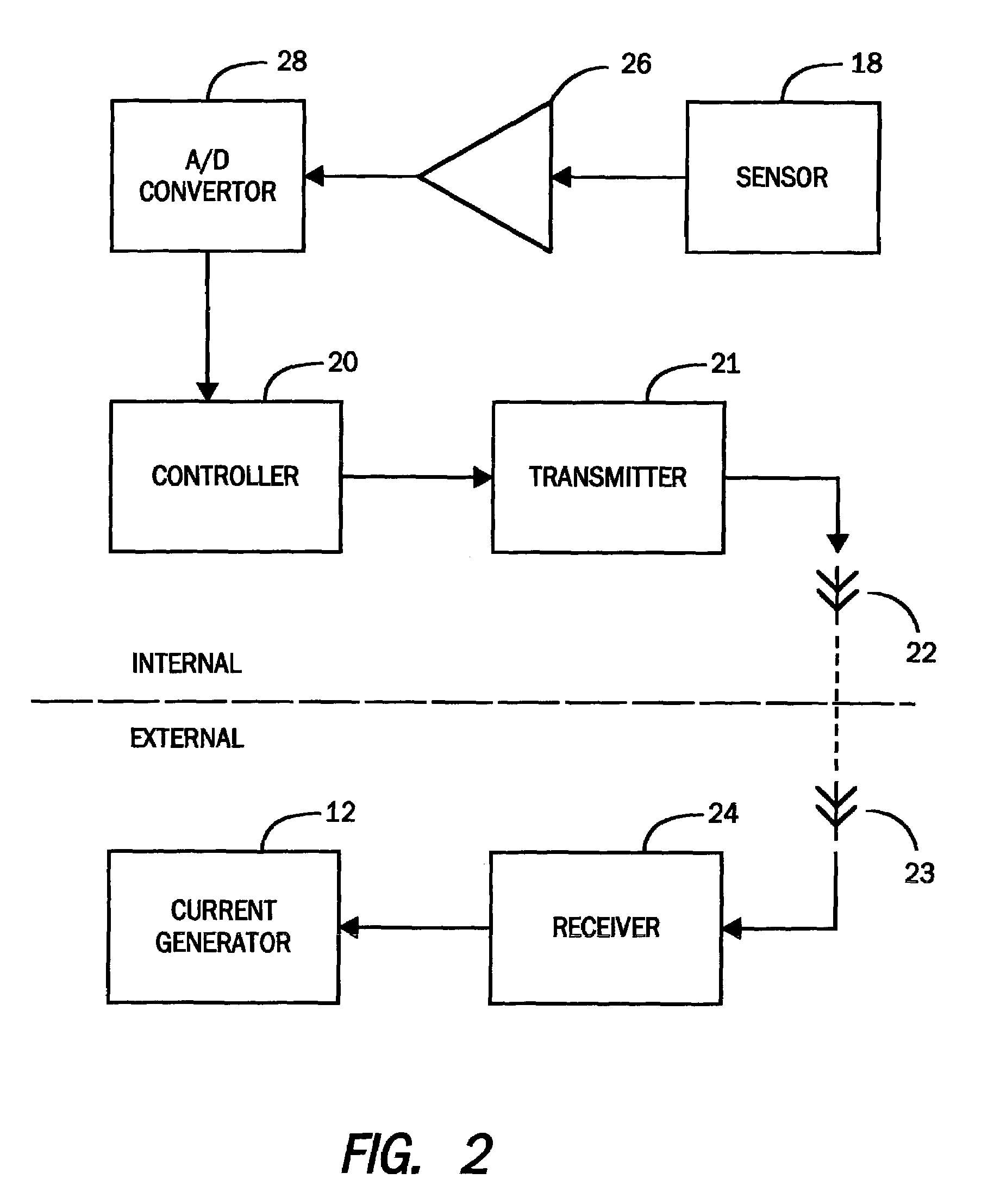

Therapeutic device and method for treating diseases of cardiac muscle

InactiveUS7113830B2Promote healingUniform current densityHeart stimulatorsArtificial respirationElectricityPower flow

An apparatus and method for conferring a therapeutic current on the heart and adjacent vasculature from externally positioned electrodes is provided. The apparatus includes a first electrode, a second electrode and a current generator. The method includes applying an electric stimulus to the heart and maintaining the timing and / or level of current to prevent unwanted depolarization.

Owner:MEDTRONIC PS MEDICAL

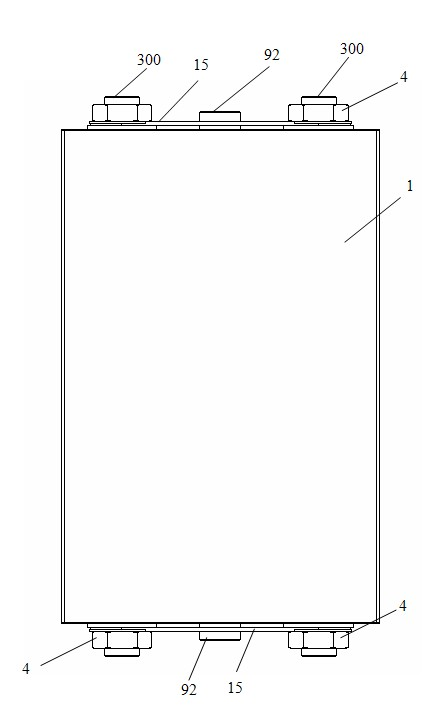

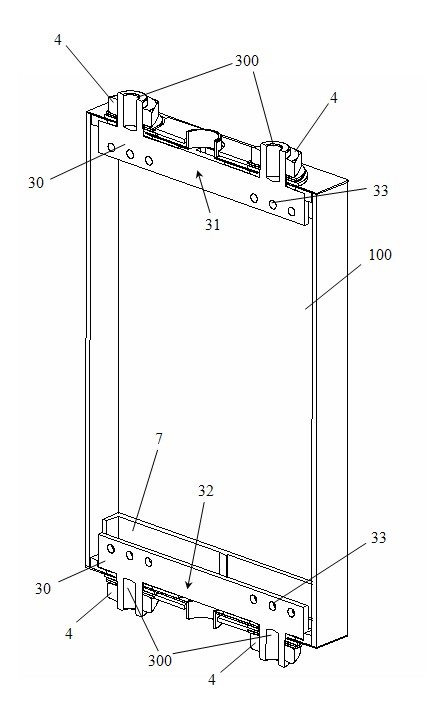

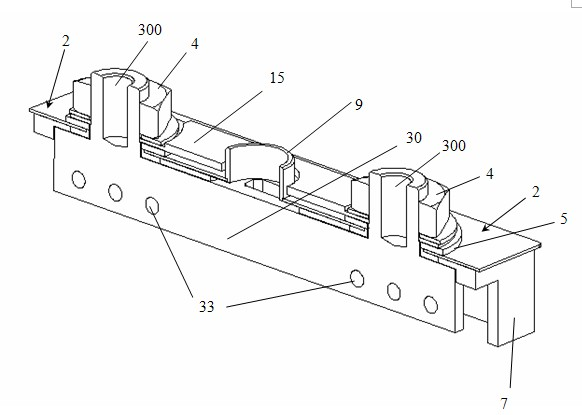

Lithium ion power battery with bidirectional current collectors

InactiveCN102013513AIncrease energy densityImprove rate discharge performanceElectrode carriers/collectorsSecondary cellsLithiumPower battery

The invention discloses a lithium ion power battery with bidirectional current collectors, which comprises a battery case (1). A battery core electrode group (100) is arranged in the battery case (1). An anode current collector (31) and a cathode current collector (32) are fixedly arranged at the upper and lower ends of the battery core electrode group (100) respectively. Cylindrical terminal posts (300) are arranged at the left and right ends of each of the anode current collector (31) and the cathode current collector (32) respectively. Battery covers (2) are arranged on the outer surfaces of the anode current collector (31) and the cathode current collector (32). The lithium ion power battery with the bidirectional current collectors adopts bidirectionally led-out external current collector structures, realizes a shortest current path and uniform current density, has increased energy density, improved rate discharge performance and relatively better current collection effect, and can be widely applied in the field of traffic and transportation.

Owner:TIANJIN LISHEN BATTERY

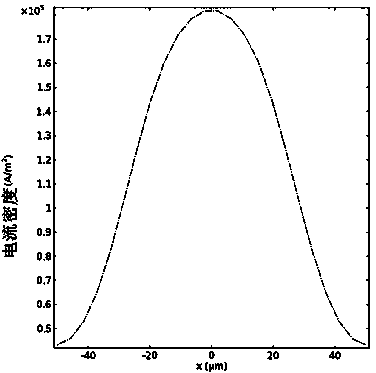

Micro-light-emitting diode

ActiveCN105552190AIncrease current densityUniform current densitySolid-state devicesSemiconductor devicesVertical projectionPower flow

The invention discloses a micro-light-emitting diode. The micro-light-emitting diode comprises a first-type semiconductor layer, a second-type semiconductor layer, a first current control layer, a first electrode and a second electrode. The second-type semiconductor layer is connected with the first-type semiconductor layer. The first current control layer is connected to the first-type semiconductor layer, and is provided with at least one opening in the first-type semiconductor layer. The first electrode is electrically coupled to the first-type semiconductor layer. The second electrode is electrically coupled to the second-type semiconductor layer. At least one of the first and second electrodes is provided with a light transmission part, vertical projection of the first current control layer on at least one of the first and second electrodes is partially overlapped with the light transmission portion, and the light transmission portion is transparent or semi-transparent. Thereby the micro-light-emitting diode is provided with a small light-emitting area, so the light-emitting area of the micro-light-emitting diode can be continue being shrinked, and the dimension of the micro-light-emitting diode is maintained.

Owner:MIKRO MESA TECH

Manufacturing method of high-capacity high-magnification high-safety lithium ion battery

InactiveCN103199262AUniform current densityIncrease capacityFinal product manufactureElectrode carriers/collectorsIonPolyvinylidene fluoride

The invention discloses a manufacturing method of a high-capacity high-magnification high-safety lithium ion battery. A positive pole material, a netty current collector, a negative pole material, a diaphragm and an electrolyte are adopted, and the positive pole material and the negative pole material are applied to the current collector to prepare a pole piece and prepare the battery. The preparation method of the current collector comprises the following steps of: (1) in an agitator kettle, dissolving PVDF (polyvinylidene fluoride) or PTFE (polytetrafluoroethylene) into NMP (N-methylpyrrolidone), or dissolving CMC into deionized water, then adding SBR (styrene butadiene rubber), stirring for 3-6hours, then adding a power mixture of one or more of silicon dioxide and aluminum oxide, with a concentration of 0.5-2%, and stirring so that powder is uniformly dispersed in the PVDF solution; and (2) applying a glue solution of the powder to the netty current collector by using a coater, and baking with an oven, so that the thickness of the powder on the current collector is 0.5-3mu m. The manufacturing method of the high-capacity high-magnification high-safety lithium ion battery has the beneficial effects of being simple in preparation, easy for production, and suitable for large-scale popularization and application.

Owner:SHANDONG REALFORCE ENTERPRISES

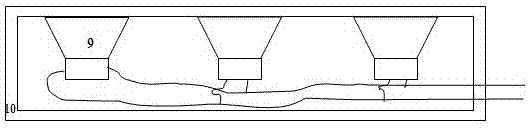

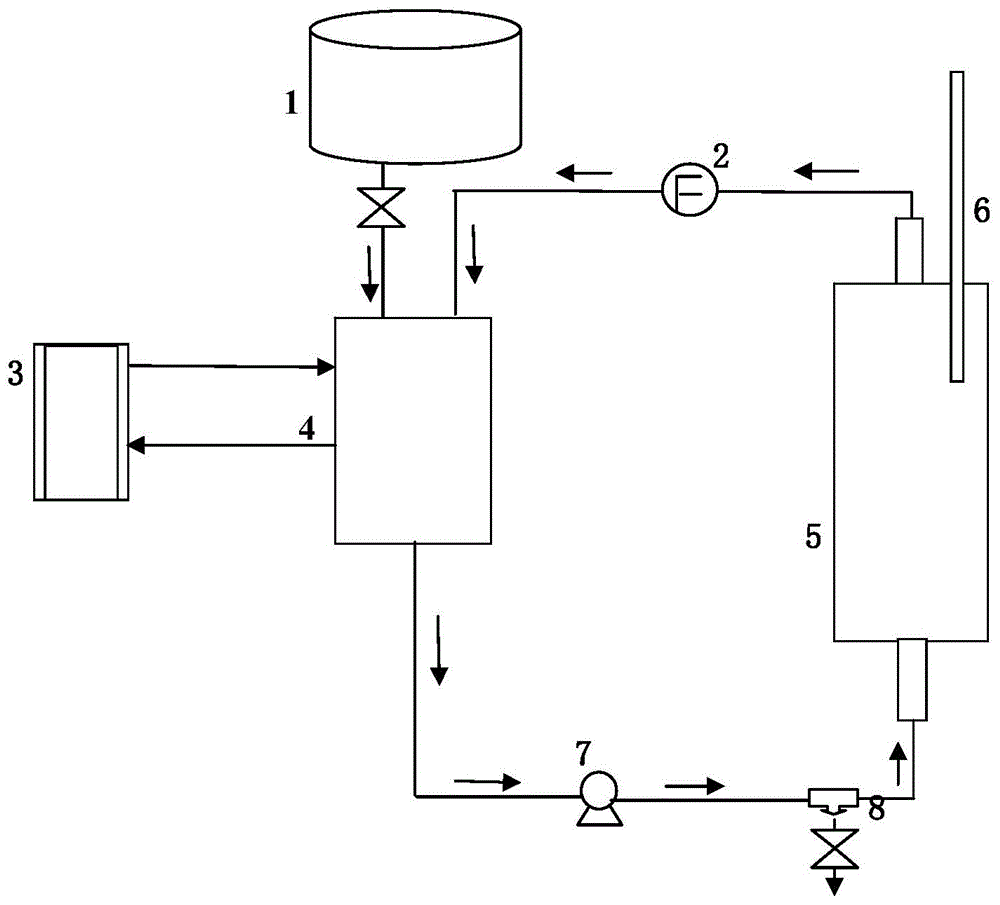

Method for electrolytic synthesis of butanedioic acid and fixed bed electrochemical reaction device

ActiveCN104947138AEasy to assembleAvoid emissionsElectrolysis componentsElectrolytic organic productionElectrolytic agentButanedioic acid

The invention provides a method for electrolytic synthesis of butanedioic acid and a fixed bed electrochemical reaction device. The method comprises the following steps: by taking a maleic anhydride solution with the mass concentration of 5-20% and a sulfuric acid solution with the mass concentration of 3-15% as an electrolyte, introducing the electrolyte into a circulating tank by virtue of a liquid storage tank; inputting the electrolyte into an electrolytic tank by virtue of a magnetic circulating pump; controlling the temperature of the electrolytic tank to be 30-80 DEG C and the current density to be 200-1000A / m<2>, and electrifying for electrolysis; after reaction, discharging the obtained reaction solution from a liquid outlet of a three-way valve, and performing cooling crystallization on the electrolyte, filtration and drying to obtain butanedioic acid; and recovering the filtrate after filtering out butanedioic acid, adding an appropriate amount of raw materials of maleic anhydride and concentrated sulfuric acid to re-prepare the filtrate into an electrolyte for cycle use. The device comprises the electrolytic tank, the liquid storage tank, the circulating tank, the heat exchanger and the magnetic circulating pump. The method and the device provided by the invention have the beneficial effects of improving the productivity and achieving energy conservation and high efficiency.

Owner:ZHEJIANG UNIV OF TECH

Improved zinc alloy zipper electroplating device

InactiveCN105755515AWon't wear outWill not depositSlide fastenersElectrodesZinc alloysElectroplating

The invention relates to an improved zinc alloy zipper electroplating device and belongs to the field of zipper electroplating devices.The improved zinc alloy zipper electroplating device comprises a plating tank, an anode device, a cathode device electrically in contact with a zipper and a zipper driving device for driving a zipper to move in the length direction of the plating tank, wherein the anode device comprises an anode plate, the anode plate is provided with a channel formed in the length direction of the anode plate, and the zipper penetrates through along the central axis of the channel.After the technical scheme is adopted, the zipper penetrates through the channel formed in the anode plate, zipper teeth on the zipper are electroplated when the zipper passes through the channel formed in the anode plate, the zipper teeth of the zipper in the channel do not produce friction with other devices in the electroplating process, and zipper tooth abrasion is not caused.The zipper located outside the channel cannot reach the deposition potential due to the fact that the current density is very small, so that a plating layer does not deposit basically.In addition, the zipper penetrates through along the central axis of the channel, the zipper teeth located in the channel are basically consistent in current density during electroplating, and it can be ensured that the plating layer is uniform during electroplating.

Owner:陈远婷

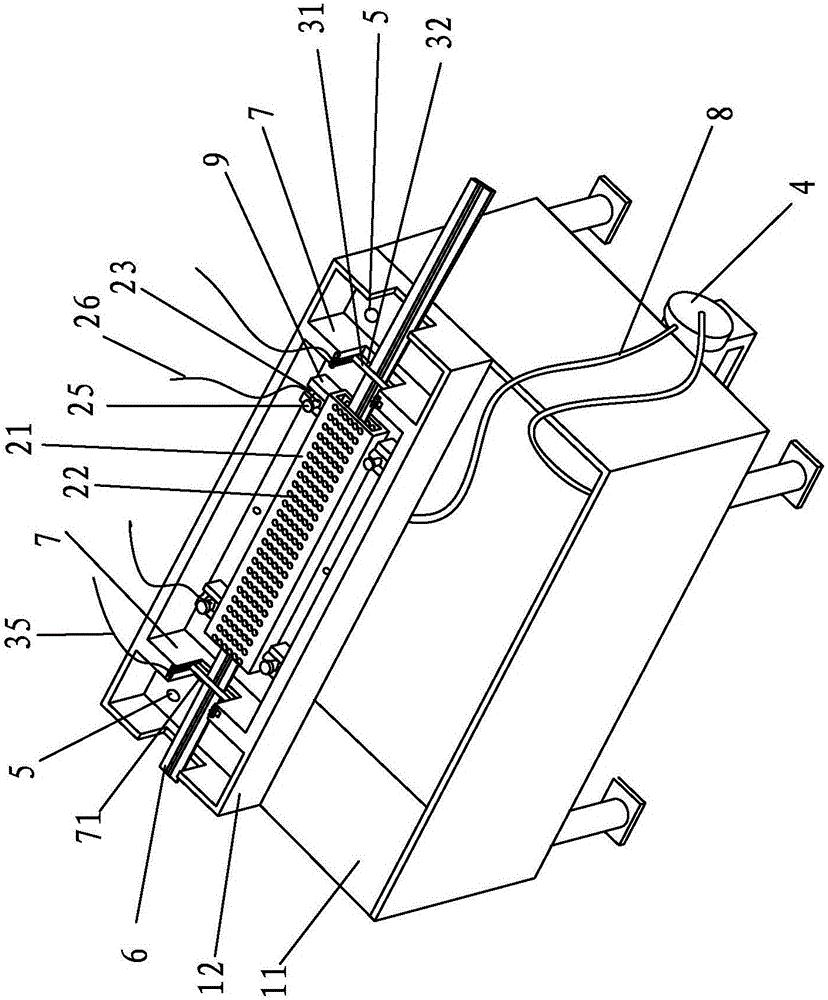

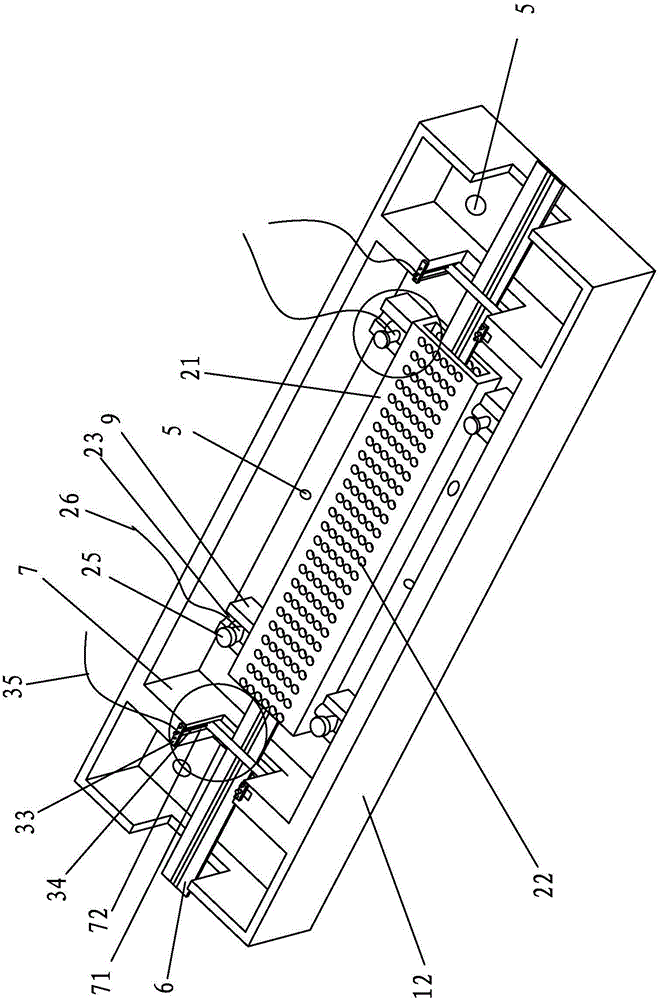

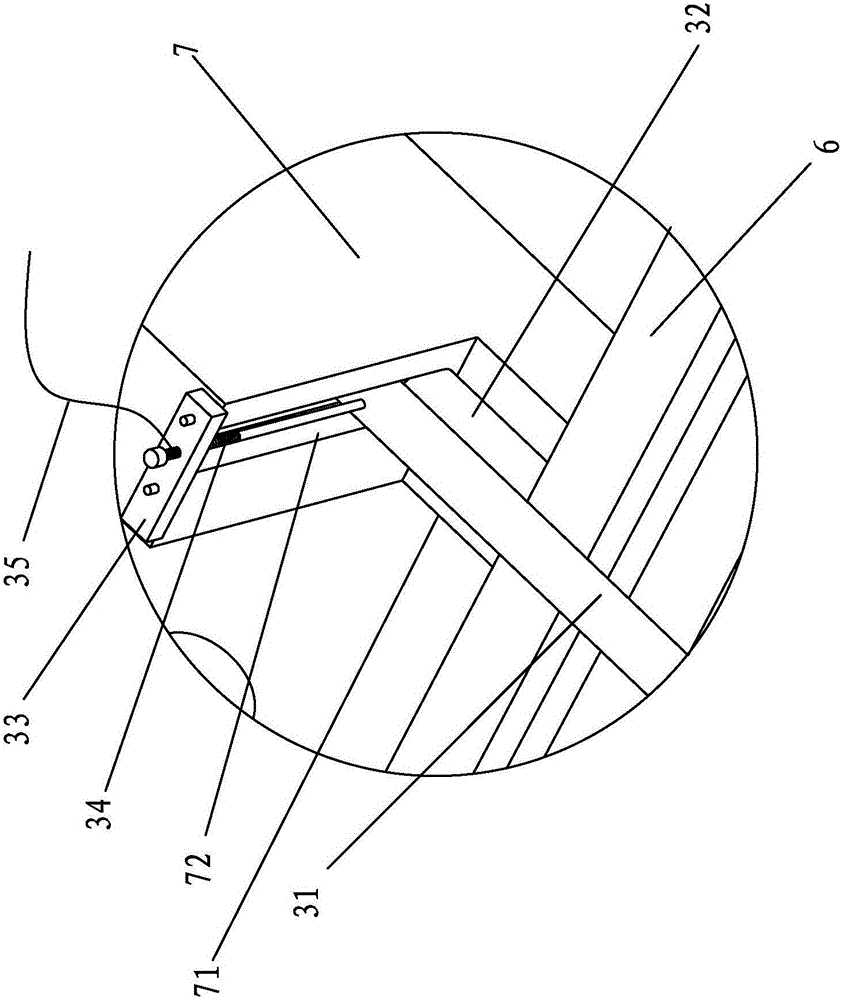

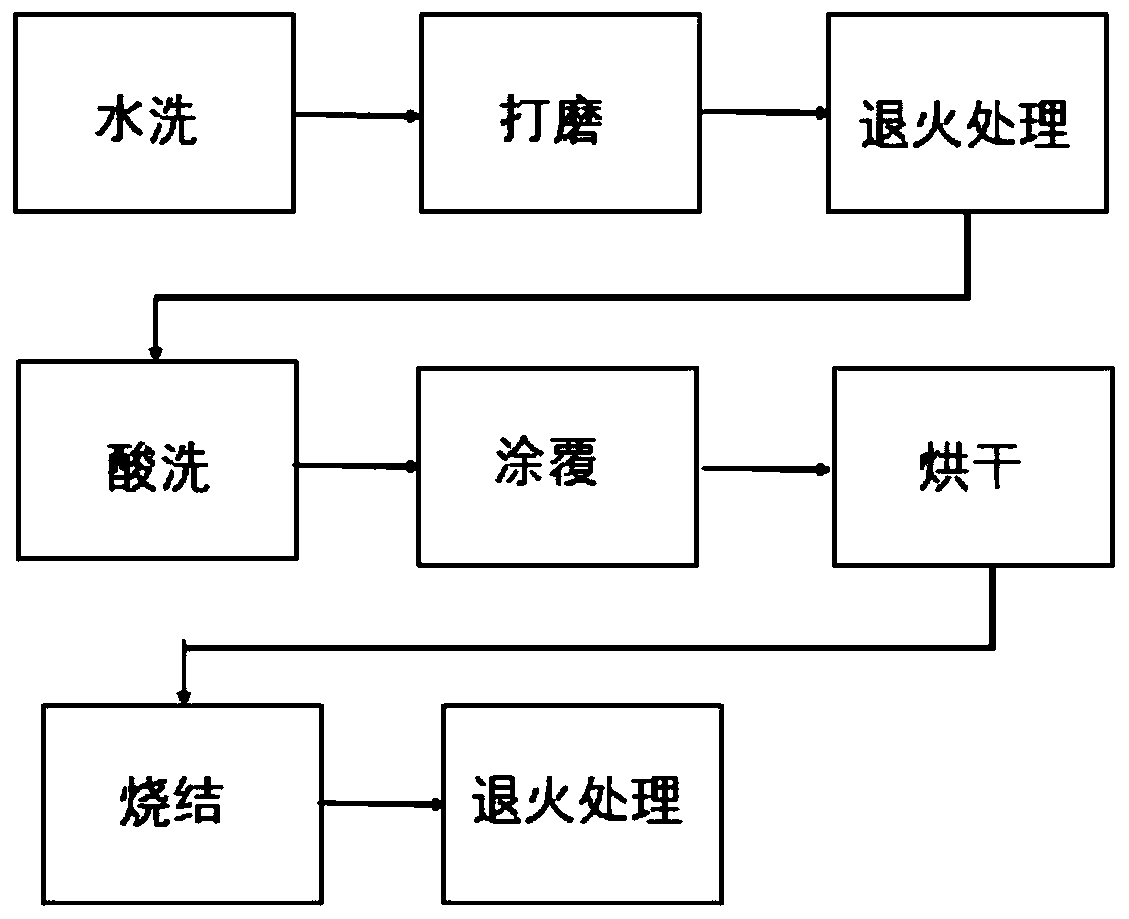

Back coating process of titanium anode plate for producing electrolytic copper foils

ActiveCN109989075AIncrease contact areaImprove work efficiencyPhotography auxillary processesLiquid/solution decomposition chemical coatingElectrolysisCopper foil

The invention provides a back coating process of a titanium anode plate for producing electrolytic copper foils, and belongs to the technical field of the electrolytic copper foils. The back coating process comprises the following steps of (1) selecting materials and carrying out annealing; (2) pickling; (3) coating; (4) drying and sintering; (5) cooling and annealing to obtain a titanium anode plate semi-finished product A with a back coating; (6) coating again, drying and sintering to obtain a titanium anode plate semi-finished product B with a back coating; and (7) repeating the step (6) one to ten times, and cooling to room temperature to obtain a finished product. According to the coating process, the generation of wave folding of the electrolytic copper foils is reduced, the currentdensity is uniform, the polarization reaction speed of each part of the titanium anode plate is uniform, the service life of the titanium anode plate is prolonged, the contact resistance of the titanium anode plate is reduced, the electricity is saved, and the energy consumption is reduced.

Owner:建滔(连州)铜箔有限公司

Slave type array micro pit electrolytic machining method

ActiveCN104014879AFast removalIncrease the electric field strengthElectrochemical machining apparatusElectrolysisCold cathode

The invention provides a slave type array micro pit electrolytic machining method, and belongs to the technical field of electrolytic machining. The method includes the steps that a tool cathode is manufactured and composed of a metal tool and a mask plate provided with a through hole group structure, a workpiece anode and the tool cathode are connected with the positive pole and the negative pole of a power supply respectively, the workpiece anode is immersed in electrolyte, the surface of the tool cathode and the surface of the workpiece anode are tightly attached, and electrolytic machining is carried out after the power supply is turned on; after primary electrolytic machining, the power supply is cut off, the tool cathode is lifted, the electrolyte on the surface of the workpiece anode is replaced, then the surface of the tool cathode and the surface of the workpiece anode are tightly attached, and the power supply is turned on for electrolytic machining. The tool cathode is lifted and falls periodically, and electrolytic machining is carried out. Due to the fact that the tool cathode and the workpiece anode are tightly attached, generated bubbles are accumulated on the side wall of a micro pit, stray corrosion around a machining area can be effectively reduced, and locality of electrolytic machining and micro machining are remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Contra-positioned bipolar battery

InactiveCN101499525AHigh precisionImprove securityFinal product manufactureActive material electrodesInternal resistanceEngineering

The invention relates to the technical field of batteries, in particular to an opposite bipolar plate and an opposite bipolar battery. The opposite bipolar plate is mainly characterized in that one end of a conductive substrate is provided with an anode plate, and the other end thereof is provided with a cathode plate. The opposite bipolar battery is mainly characterized in that the two ends thereof are respectively provided with a unipolar anode plate group and a unipolar cathode plate group; the opposite bipolar plate groups with the bipolarity are stacked in sequence between the unipolar anode plate group and the unipolar cathode plate group; the adjacent single batteries are internally connected in series as the opposite bipolar plate penetrates the separator; no single battery requires external connecting component; the structure is simple; the current density, working conditions and environmental conditions of heat and moisture for the polar plates are uniform; the internal resistance and the connection requirements are greatly reduced; the weight is greatly reduced; the reliability and security are substantially improved; the service life is long; and the cost is greatly reduced. The invention can greatly improve the power density and energy density of the battery, and simultaneously improves the high-current battery charge and discharge capacity, the charge-discharge efficiency, the adaptability to the thermal environment, the anti-vibration capability and the like.

Owner:SHANGHAI JIAO TONG UNIV

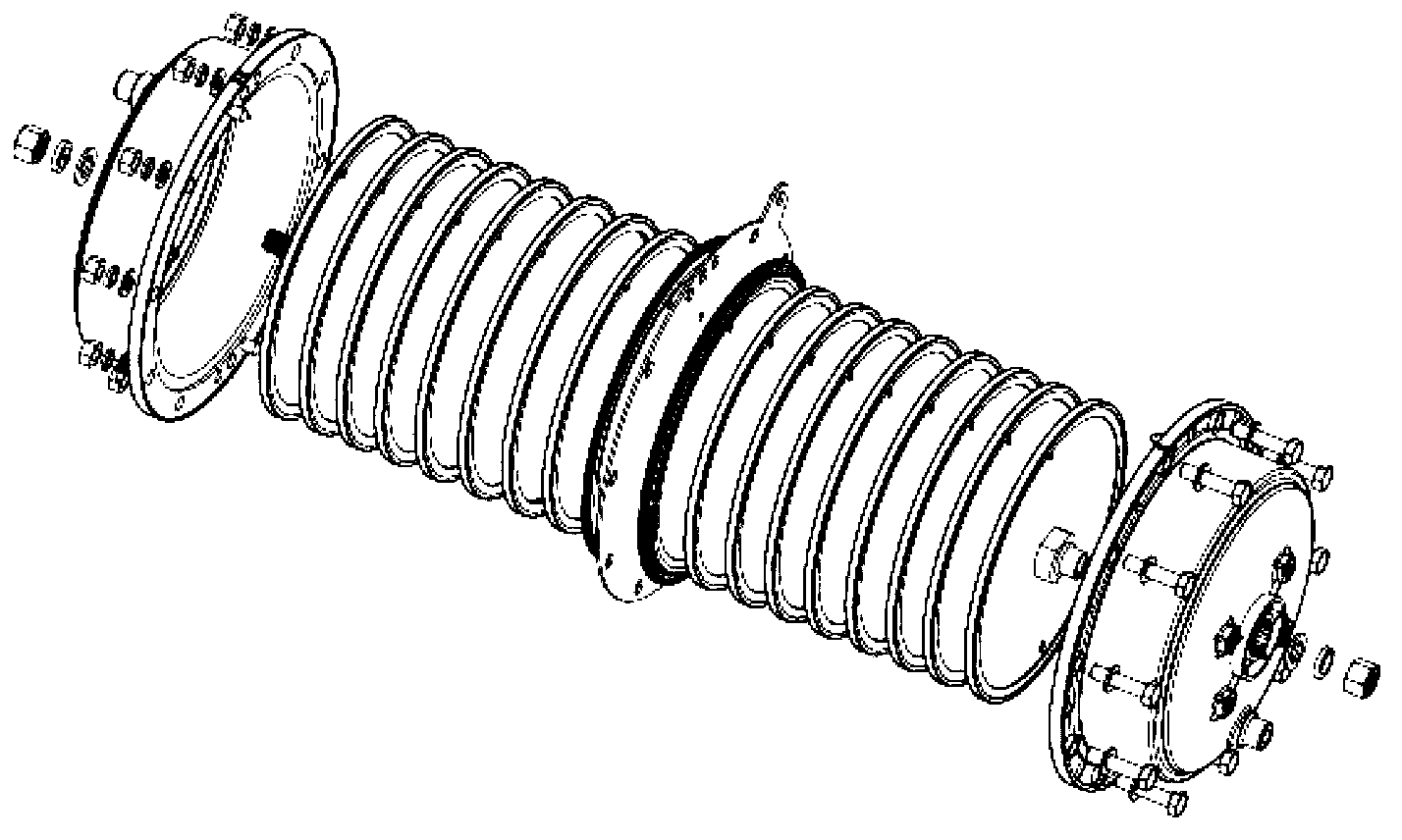

Series-parallel combined high-efficient hydrogen oxygen electrolytic bath

The invention relates to a series-parallel combined high-efficient hydrogen oxygen electrolytic bath. The structure is as follows: a negative plate on each end of the electrolytic bath is provided with an electrode post which is used as a negative binding post, a positive plate is installed on the junction between two semi-closed shells, and a positive binding post is guided out at a protruded position of the positive plate towards the outside of the electrolytic bath shell; a plurality of intermediate electrode plates are respectively symmetrically arranged on two sides inside the electrolytic bath shell from the positive plate, negative plates with negative binding posts are arranged on the leftmost end and the rightmost end of the electrolytic bath shell, the negative binding post is led out of the electrolytic bath shell, a pole piece inside a left shell of the electrolytic bath is serially connected with a pole piece inside a right shell of the electrolytic bath, a pole piece inside a left barrel of the electrolytic bath shell is serially connected with a pole piece inside a right barrel of the electrolytic bath shell, and the pole pieces share the intermediate positive plate, after a power supply wire is connected, the series-parallel combined electrolytic bath is formed. The pole pieces are connected together inside the electrolytic bath in series and parallel, two groups of parallel-connection pole pieces are designed in equal potential, the electrolytic bath provides electrolyte in an external cycling manner, so that the sealing is reliable, the leakage of the electrolyte can be avoided, the current utilization rate is high, and the convenience in assembling and dismantling can be realized.

Owner:武汉微氢科技有限公司

Electrolytic bath for copper displacement by iron

InactiveCN108866572AHigh recovery rateIncrease added valuePhotography auxillary processesProcess efficiency improvementAcid etchingElectrolysis

The invention discloses an electrolytic bath for copper displacement by iron. The electrolytic bath for copper displacement by iron is used for extracting metal copper from acid etching waste liquid.An anode titanium frame and a cathode copper / titanium sheet are alternately put inside the electrolytic bath; waste iron is put in the anode titanium frame; the anode titanium frame is connected witha direct current power supply positive electrode; the cathode copper / titanium sheet is connected with a direct current power supply negative electrode; the acid etching waste liquid is pumped from a bottom feeding pipe of the electrolytic bath for copper displacement by iron; under the effect of a direct current electric field, the anode titanium frame iron sheet is dissolved; the copper is separated out at the anode copper sheet / titanium sheet. The acid etching waste liquid after the electrolysis flows back to an external liquid inlet device through a built-in overflow groove for cyclic collection and then flows back into the electrolytic bath. When the concentration of the copper ion in the acid etching waste liquid is reduced to a certain concentration, the waste liquid is pumped intoan external storage device through a bottom discharge pipe of the electrolytic bath for copper displacement by iron, and is then pumped into the external electrolytic bath from the external storage device for byproduct recovery through electrolysis. The electrolytic bath for copper displacement by iron belongs to the electrolytic bath specially used for recovering copper in the acid etching wasteliquid through a process of inducting copper displacement by iron via the external electric field. The copper in the acid etching waste liquid can be effectively recovered.

Owner:苏碧云

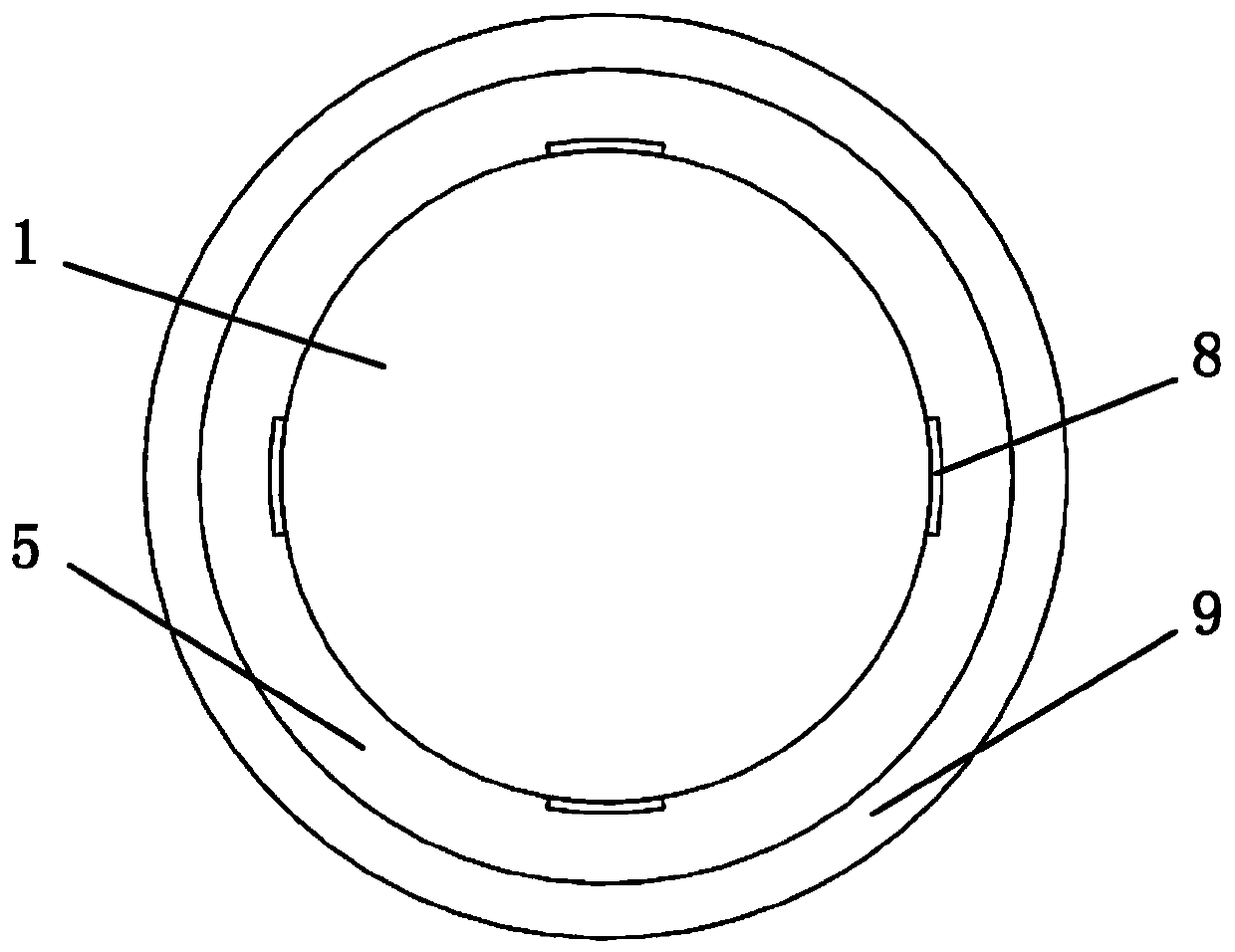

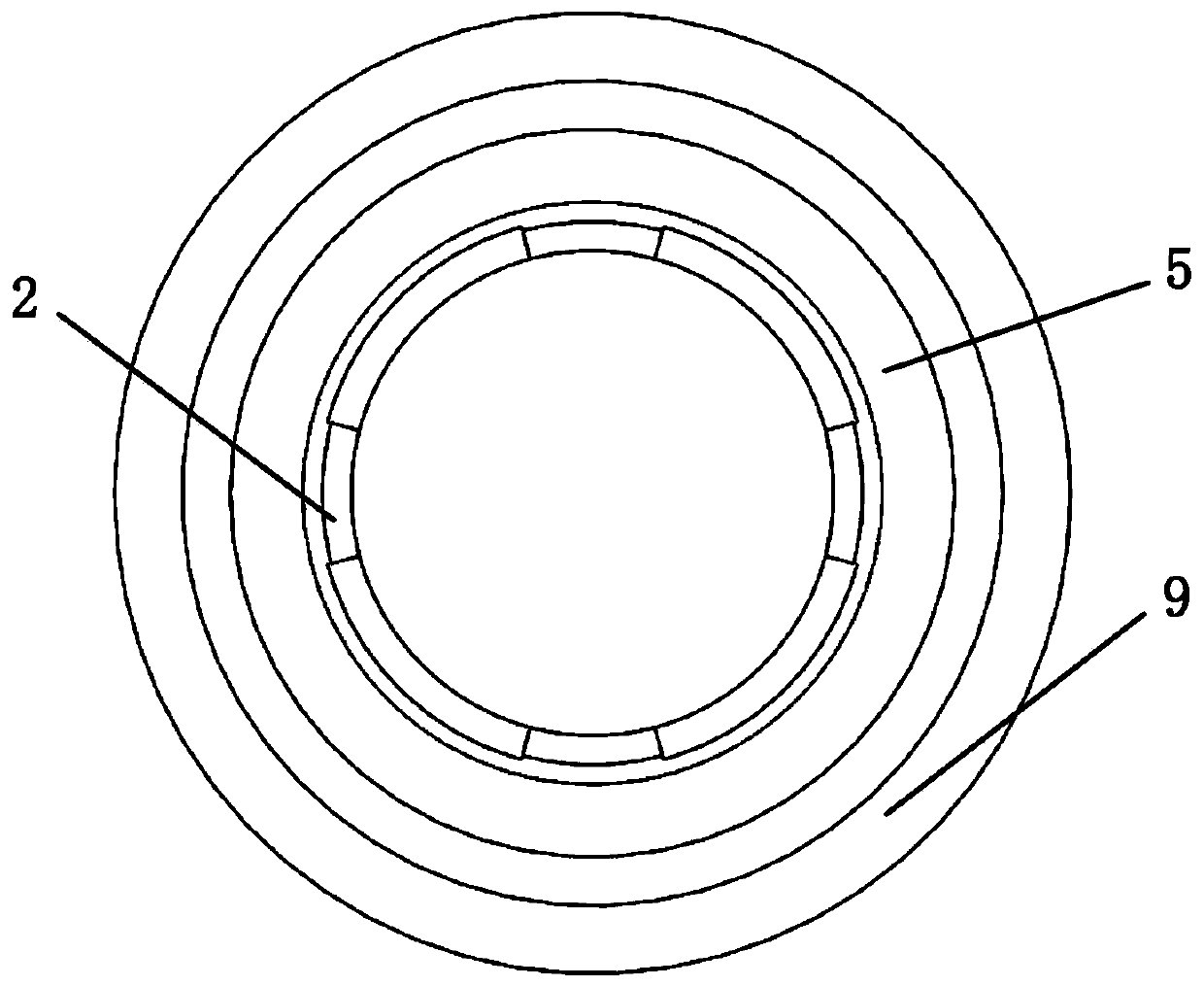

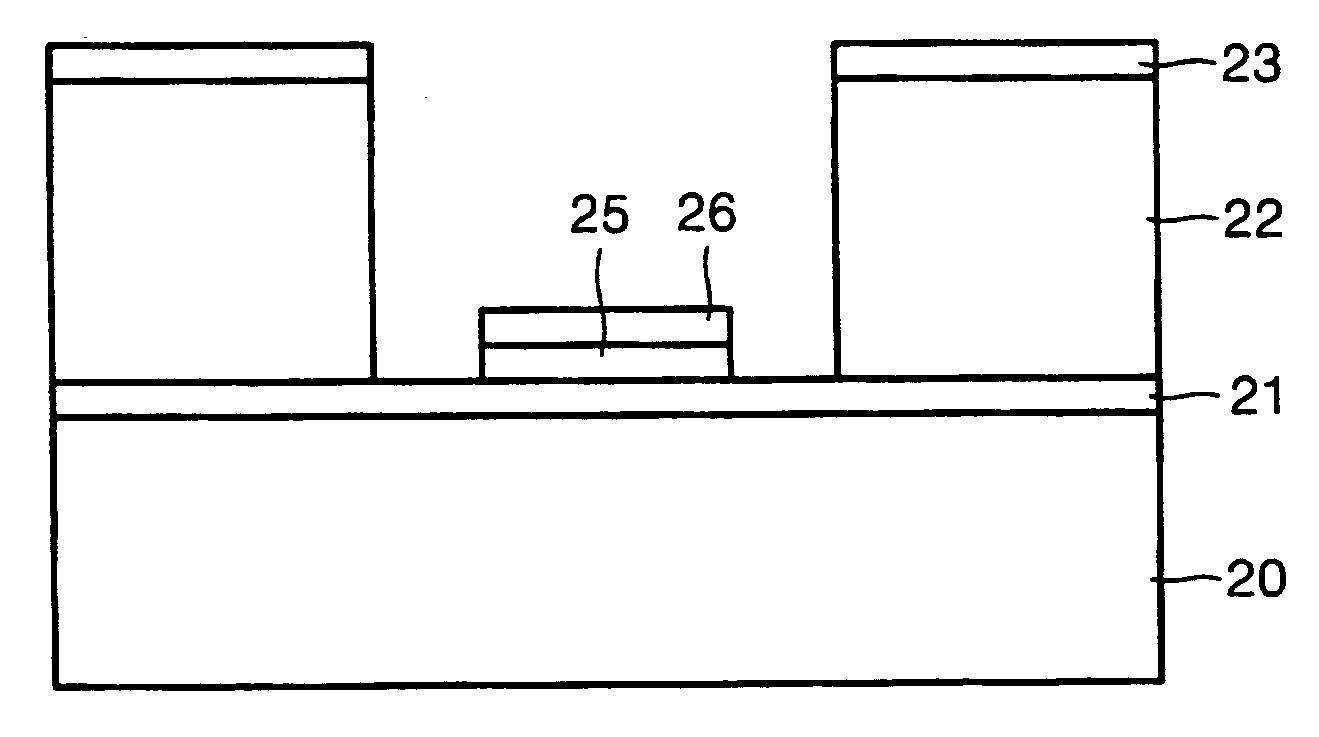

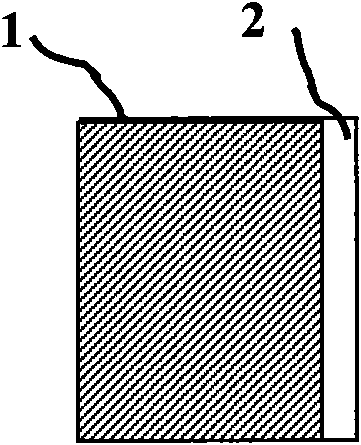

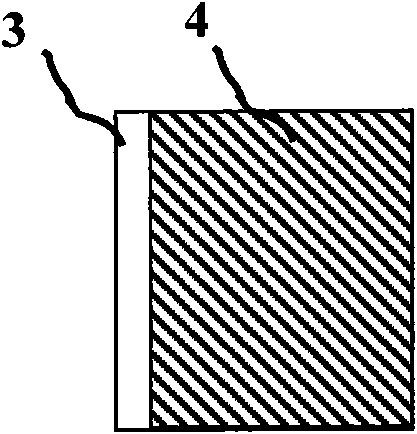

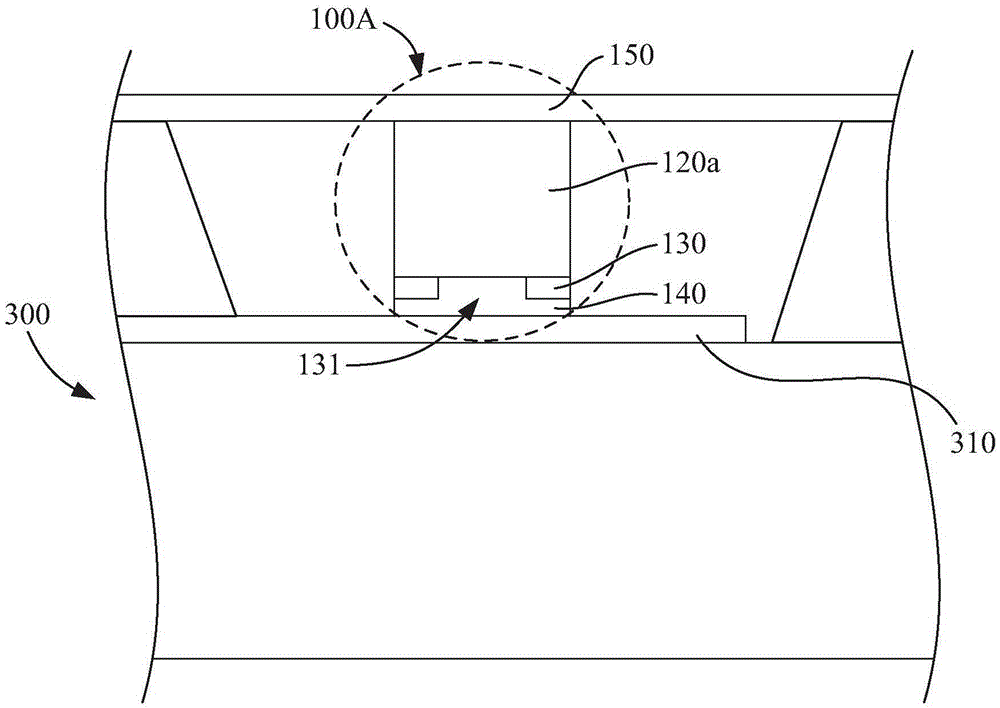

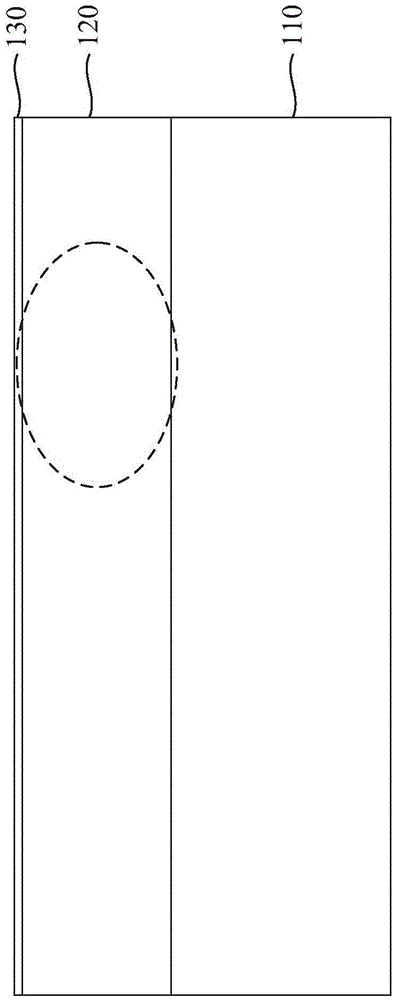

Light emitting diode

InactiveCN101681971AUniform current densityUniform densitySemiconductor devicesActive layerLight-emitting diode

An LED chip (1) grown on an electrically insulating substrate (4) comprises a lower current-distributing layer (5) of a first conductivity type, a first electrode (2), a vertical layer structure (5, 6, 7), the last two being formed on the lower current- distributing layer horizontally separated from each other, the vertical layer structure comprising an active layer (6) and an upper current-distributing layer (8) of a second conductivity type above the active layer, and a second electrode (3) formed on the upper current-distributing layer, the geometry of the electrodes being adjusted to provide a horizontal distance between the electrodes lower than the current spreading length of the chip. According to the present invention, a vertical trench (9) is formed between the electrodes (2, 3),the trench extending through the chip (1), including the lower current-distributing layer (5), for controlling the horizontal current flow in order to achieve a uniform current density over the activelayer (6).

Owner:OPTOGAN OY

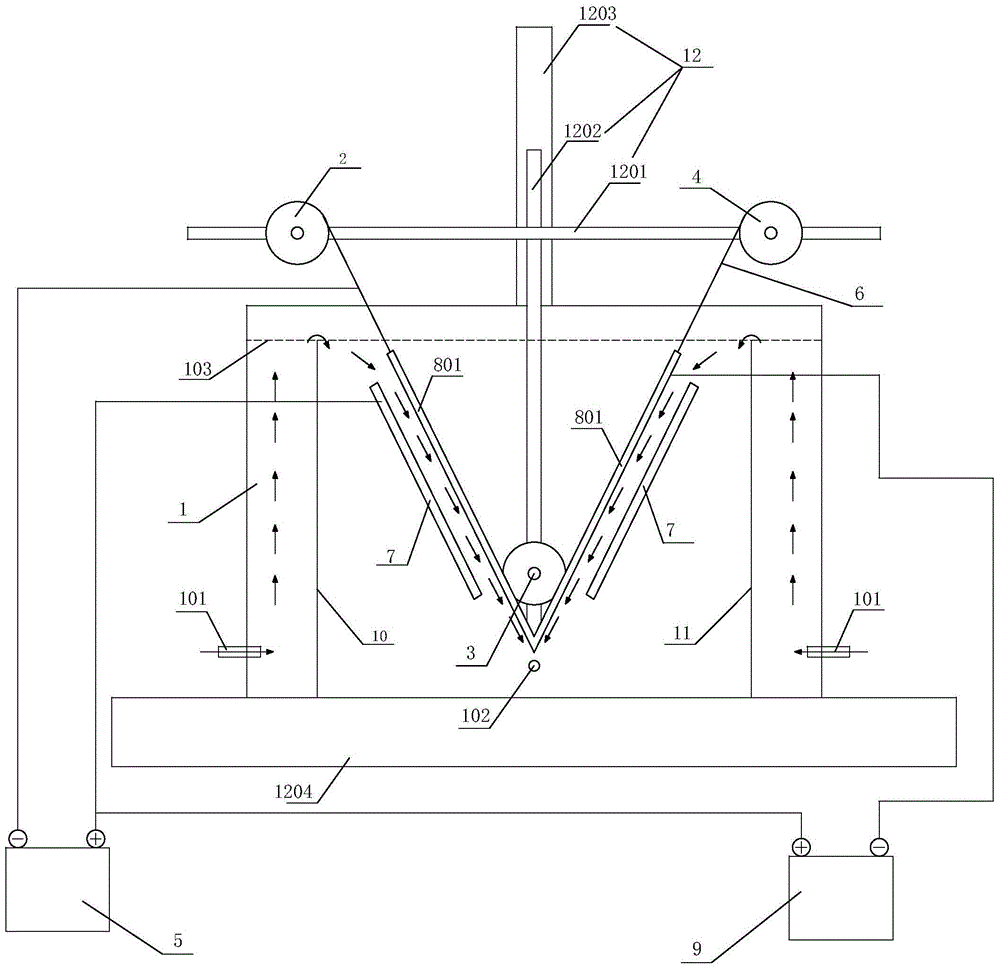

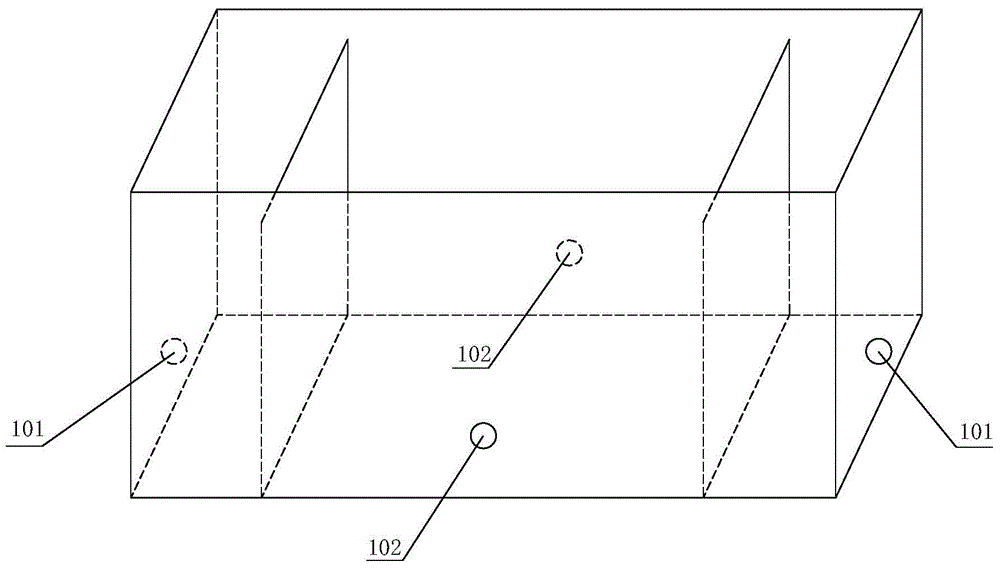

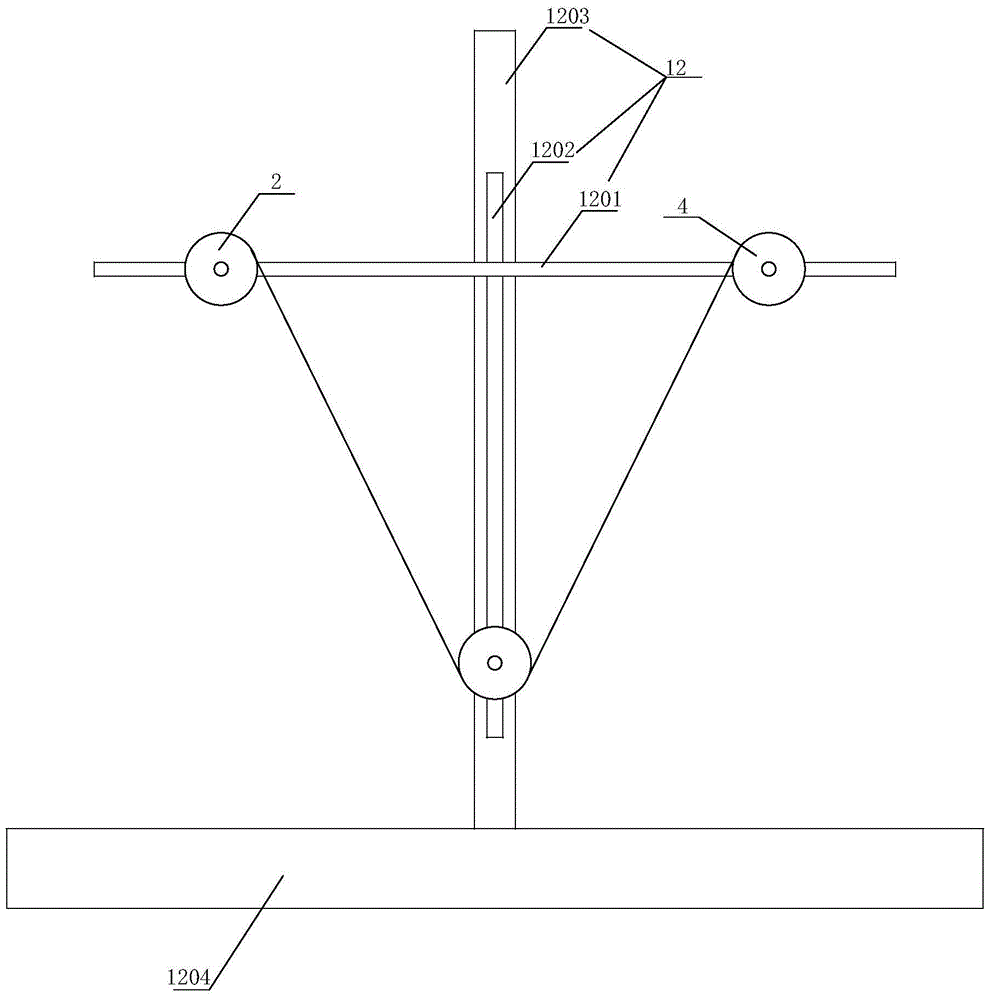

Copper foil electroplating testing machine

ActiveCN104988550ARealize the movement modeImprove the simulation effectElectrodesTemperature controlControl system

The invention discloses a copper foil electroplating testing machine which comprises an electroplating tank, copper foil which serves as an electroplating cathode, a left anode plate, a right anode plate, a power supply control system, a temperature control system, a recirculating filtration flow control system, a support frame, a left reeling machine, a right reeling machine, an immersed roller, a first baffle plate, a second baffle plate, two liquid inlets and two liquid outlets. According to the copper foil electroplating testing machine, the left reeling machine and the right reeling machine which are provided with electrical insulation reeling rollers are arranged to be matched with the immersed roller, an insulating tape can be driven to move left and right, and meanwhile the copper foil which serves as the electroplating cathode is detachably arranged on the lower surface of the insulating tape, winding movement of the insulating tape on the reeling rollers replaces the winding movement of the copper foil, the thickness of the copper foil is thinner, the copper foil is prone to cracking, and on one hand, the movement mode of the copper foil in the actual production is achieved; on the other hand, the problem that a test is interrupted due to the fact that the copper foil is prone to cracking is solved, and therefore the simulation capacity and the practicability of the electroplating testing machine are improved.

Owner:CNMC ALBETTER ALBRONZE

Method for oxidizing cultural relics in ironware

This invention describes a process for the dechlorination of iron antiquities, comprising the steps of: adding a cleaning agent and an amine inhibitor to an alkaline solution to prepare an alkaline dechlorination cleaning solution, and carrying out the cathode polarization dechlorination of iron antiquities in the said solution at a constant electric potential. This invention overcomes such problems as a certain degree of corrosion existing in the traditional dechlorination processes for iron antiquities or the damage to the intrinsic appearances of iron antiquities led by the abscission of the rusty layer resulting from hydrogen evolution caused by high local current in the electrochemical reduction method, and provides a rapid, effective and more protective process for the dechlorination of iron antiquities.

Owner:BEIJING UNIV OF CHEM TECH

Modified zinc oxide and preparation method and application thereof

The invention relates to modified zinc oxide and a preparation method and application thereof, in particular to a zinc negative electrode material for an alkaline zinc-air secondary battery, and belongs to the field of an air battery. The modified zinc oxide comprises a zinc oxide inner core, a first coating layer and a second coating layer, wherein the first coating layer is coated on the zinc oxide inner core, the second coating layer is coated on the first coating layer, the material of the first coating layer is C, and the material of the second coating layer is a titanium sub-oxide. The preparation method of the modified zinc oxide comprises the steps of growing a layer of phenolic resin on a surface of zinc oxide in an in-situ way; coating a layer of titanium-based organic-inorganicmixed gel; and performing reaction at 760-880 DEG C to obtain the product with the designed structure. When the product is used as a zinc negative active material of the alkaline zinc-air secondary battery, the product shows excellent electrochemical performance. The material is reasonable in structural design, the preparation process is simple, the obtained product has favorable performance, andindustrial application on a large scale is convenient.

Owner:CENT SOUTH UNIV

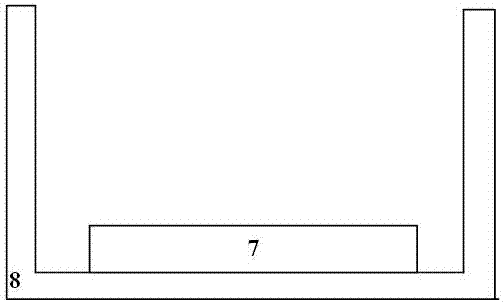

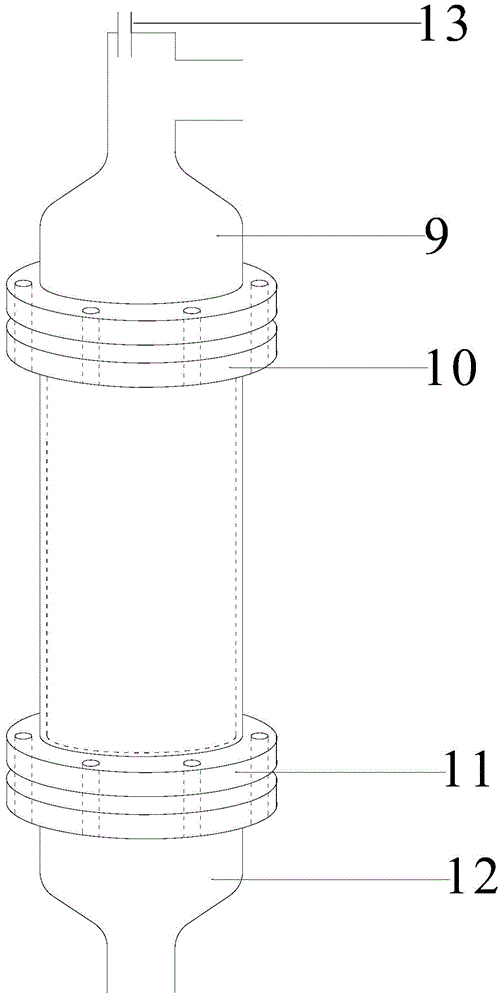

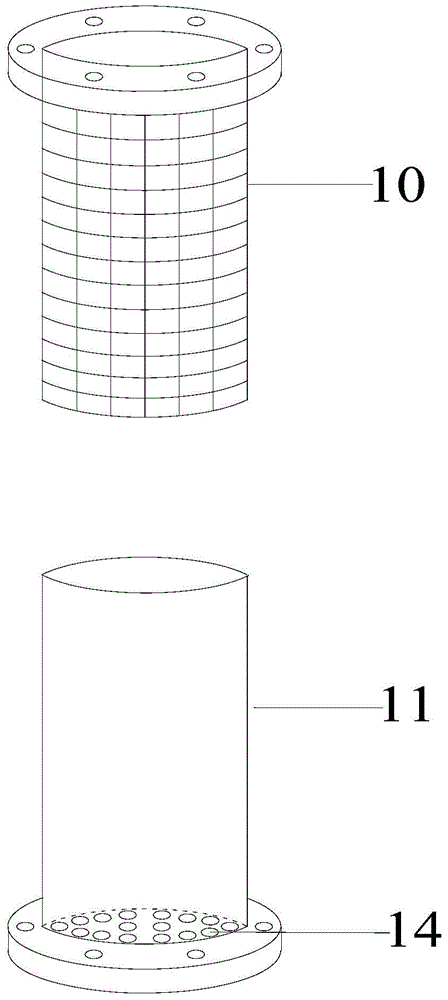

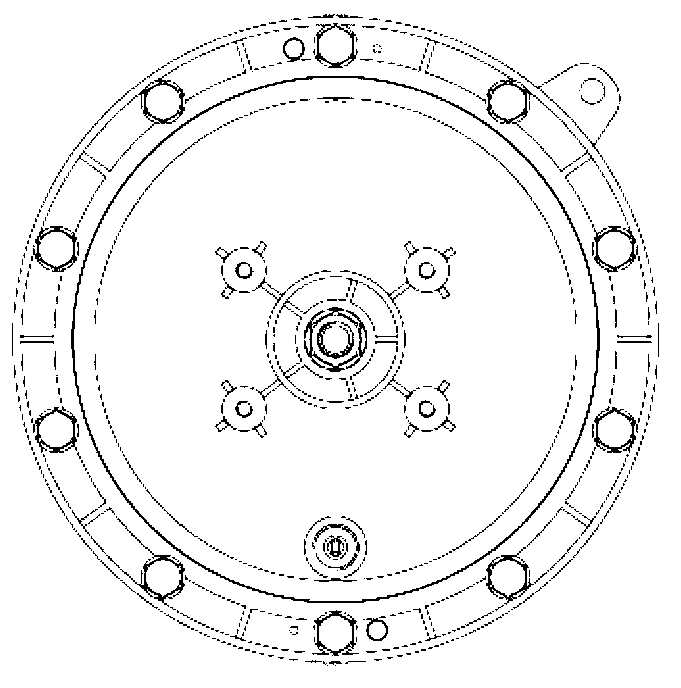

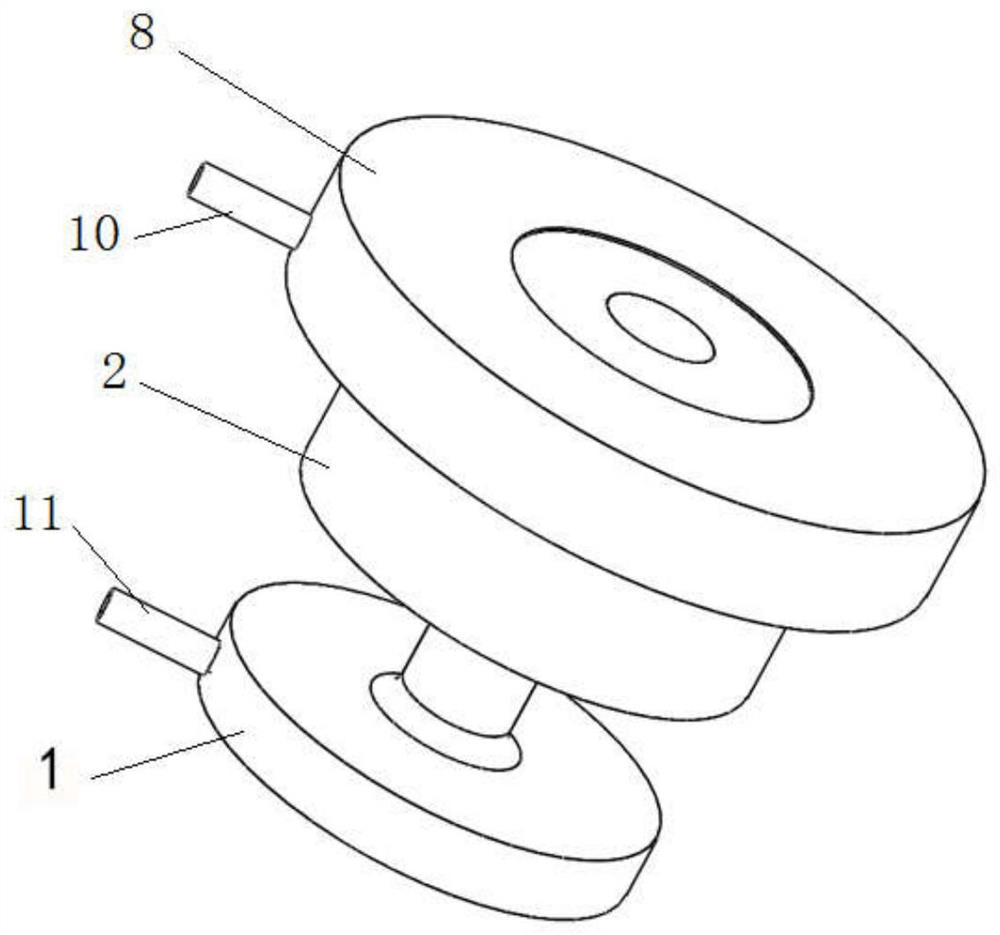

All-solid-state battery reaction chamber for in-situ XRD and Raman test and test method

PendingCN113030138ANo distractionUniform current densityMaterial analysis using wave/particle radiationAssembling battery machinesAll solid stateElectrical battery

The invention belongs to the technical field of batteries, and particularly relates to an all-solid-state battery reaction chamber for in-situ XRD and Raman test and a test method. The solid-state battery reaction chamber comprises a working electrode cover, a solid-state battery mold shell and a counter electrode holder which are sequentially connected from top to bottom; the working electrode cover comprises a cover body and a working electrode lead, the working electrode lead is connected with the cover body, and the cover body is provided with a test window for XRD test or Raman test; the solid-state battery mold shell is provided with a concave mold cavity, and a positive electrode, an electrolyte and a negative electrode of a solid-state battery can be assembled; and a metal rod matched with the concave mold cavity is arranged on the counter electrode holder, and an electrode outgoing line is arranged in the lower part of the counter electrode holder. The preparation method has the advantages of simplicity, rapidness, compact structure, small size, good equipment universality and reusability; and the obtained spectrum has the characteristics of high signal-to-noise ratio, low off-axis error, no impure phase peak interference, uniform working electrode current density, accurate test potential, high capacity retention ratio in long circulation and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

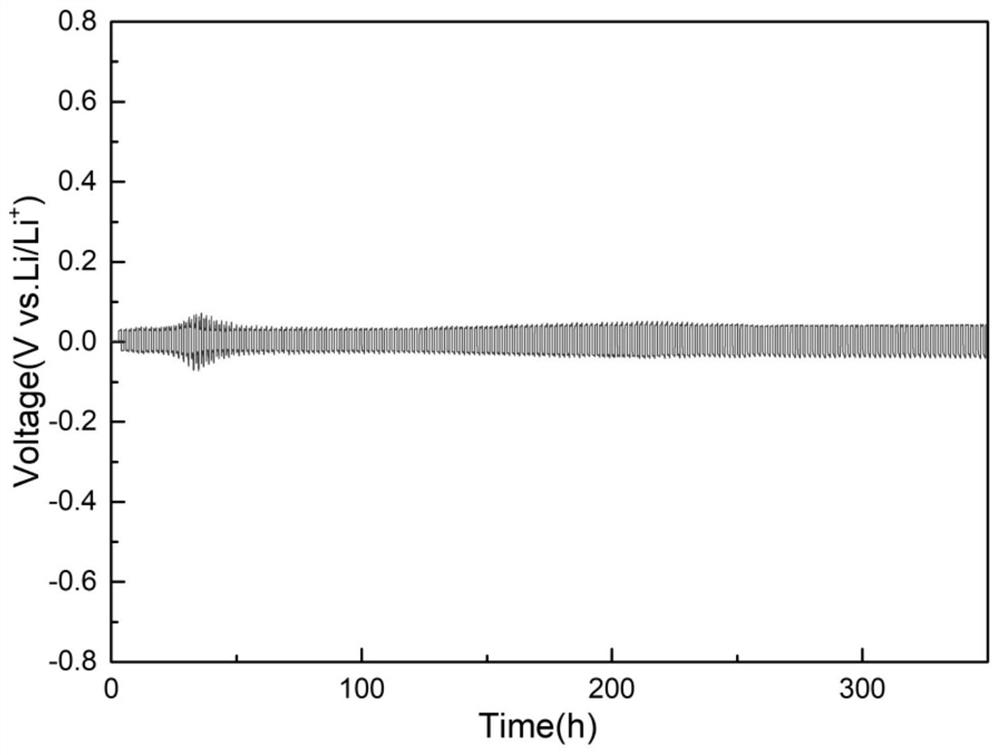

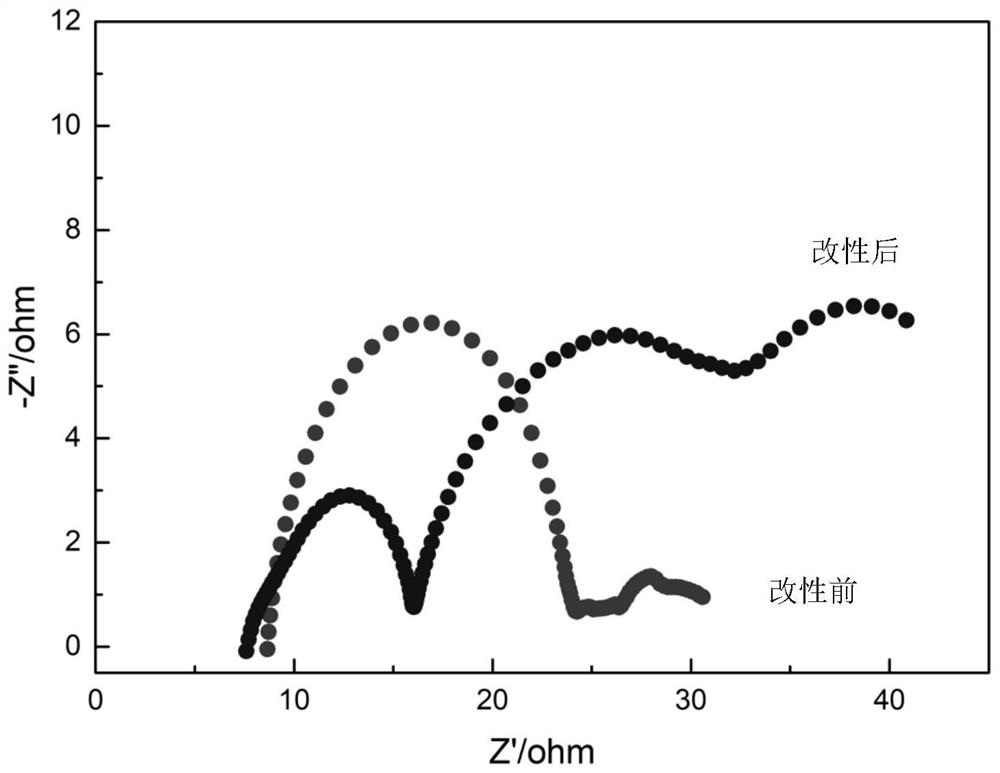

Lithium metal battery negative electrode surface modification method

ActiveCN112072076AImprove cycle performanceImprove electrochemical performanceElectrochemical processing of electrodesLi-accumulatorsElectrolytic agentLithium bromide

The invention discloses a lithium metal battery negative electrode surface modification method which is characterized by comprising the following steps: 1) weighing lithium bromide and lithium nitratein proportion, dissolving lithium bromide and lithium nitrate in a tetraethylene glycol dimethyl ether solvent, sealing the mouth with a preservative film, performing sealing at normal temperature, and uniformly performing stirring to prepare a clear and transparent polishing electrolyte; 2) assembling the lithium symmetric battery, adding the polishing electrolyte obtained in the step 1) into the lithium symmetric battery in the assembling process, and wetting a diaphragm; and 3) discharging the lithium symmetric battery assembled in the step 2) under set current density and discharge time,and polishing the surface of a negative electrode to obtain the modified lithium metal battery. The method has the advantages that the polished lithium surface is smooth and flat, the growth of lithium dendrites in the charging and discharging process of the lithium metal battery can be effectively inhibited, and the cycle performance of the lithium metal battery is improved.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com