Modified zinc oxide and preparation method and application thereof

A zinc oxide and modified technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of large electrochemical polarization of the metal layer, large electrode polarization, and deterioration of electrode polarization. The preparation method is simple and convenient, the hydrogen evolution overpotential is improved, and the electrode internal resistance is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

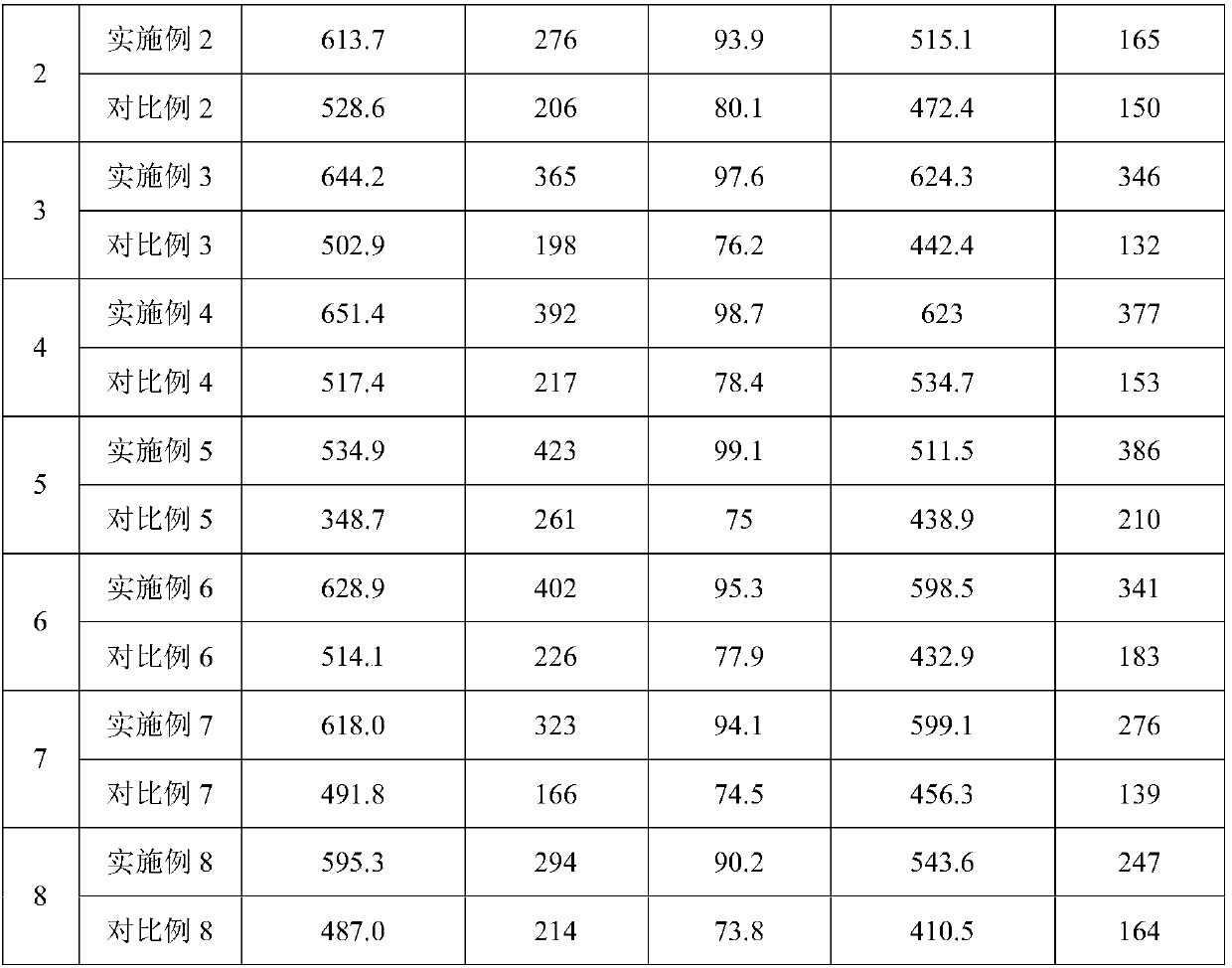

Examples

Embodiment 1

[0052] Preparation of modified zinc oxide:

[0053] (1) Evenly disperse 1.6g of zinc oxide powder (with a particle size of 2 to 3 microns) into 250mL of a solution containing 4.2mmol / L resorcinol and 1g of cetyltrimethylammonium bromide (water: ethanol v / v=2), add concentrated ammonia water while stirring, adjust the pH value to 9.8, after 30min, add formaldehyde (formaldehyde to phenol molar ratio: 2.5) at 35°C and react for 18h, then raise the temperature to 80°C to continue the reaction for 3h, and dissolve the product in water Wash with ethanol for 3 times to obtain zinc oxide coated with a phenolic resin layer with a thickness of 15 nm.

[0054] (2) Add 0.5 g of the product of step (1) to 120 mL of a solution in which 1.688 mmol / L isopropanol titanate is dissolved (ethanol: isopropanol v / v=1), stir and disperse for 30 min, and add 0.213 mL of ethyl titanate Diamine was reacted at 75°C. After 8 hours, the product was washed with ethanol three times, vacuum-dried for 10 h...

Embodiment 2

[0060] Preparation of modified zinc oxide:

[0061] (1) Evenly disperse 1g of zinc oxide powder (with a particle size of 2 to 3 microns) into a solution containing 250mL of 4.2mmol / L phenol and 0.8g of dodecyltrimethylammonium bromide (water:ethanol v / v=1 ), add 0.1mol / L potassium hydroxide solution while stirring, and adjust the pH value to 11.4. After 20 minutes, add glutaraldehyde (formaldehyde-phenol molar ratio: 1.5) at 40°C and react for 18 hours, then raise the temperature to 75°C to continue the reaction After 5 hours, the product was washed three times with water and ethanol in sequence to obtain zinc oxide coated with a phenolic resin layer with a thickness of 17 nm.

[0062] (2) Add 0.5g of the product of step (1) to 55mL solution (ethanol:isopropanol v / v=1.5) dissolved in 1.688mmol / L titanate n-propanol, stir and disperse for 60min, add 0.117mL ethylene The imine was reacted at 82°C. After 6 hours, the product was washed with ethanol three times, vacuum-dried for ...

Embodiment 3

[0066] Preparation of modified zinc oxide:

[0067] (1) Evenly disperse 1 g of zinc oxide powder (with a particle size of 2 to 3 microns) into a solution containing 250 mL of 6.3 mmol / L phenol and 0.9 g of dodecyltrimethylammonium chloride solution (water: ethanol v / v = 2), add concentrated ammonia water while stirring, adjust the pH value to 11.8, after 60 minutes, add formaldehyde (aldehyde, phenol molar ratio: 1.5) at 25°C and react for 10 hours, raise the temperature to 80°C and continue the reaction for 5 hours, and the product Filter and wash with water and ethanol three times to obtain zinc oxide coated with a phenolic resin layer with a thickness of 25 nm.

[0068] (2) Add 0.5 g of the product of step (1) to 100 mL of a solution in which 3.4 mmol / L isopropanol titanate is dissolved (ethanol: isopropanol v / v=1), stir and disperse for 30 min, and add 0.491 mL of ethyl alcohol Diamine was reacted at 75°C. After 8 hours, the product was washed with ethanol three times, va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com