Patents

Literature

99results about How to "Increase the hydrogen evolution overpotential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium ion redox flow battery electrolyte, preparation method thereof and battery thereof

ActiveCN101635363ASimple production processReduce lossesRegenerative fuel cellsFuel cell detailsManufacturing technologyVanadyl sulfate

The invention provides vanadium ion redox flow battery electrolyte, comprising vandic salt, sulphuric acid, additive, deionized water and metal salt can be dissolved in a sulphuric acid system. The electrolyte can greatly improve the cathode system evolution overpotential of the vanadium battery and anode system evolution overpotential, greatly reduce the ratio of gas evolution in the electrolyte caused by various polarizations in the process of operating the vanadium battery, and improve the stability of the electrolyte in the process of charge and discharge. The invention further provides a preparation method of the vanadium ion redox flow battery electrolyte, which eliminates a step of electrolyzing the obtained vanadyl sulfate solution to obtain 50% of trivalent vanadium and 50% of tetravalent vanadium, greatly simplifies the manufacture technology of the vanadium electrolyte which can be directly used for charging and discharging, reduces the lose of the vanadium in the process of preparation, and reduces the preparation cost of the electrolyte.

Owner:BYD CO LTD

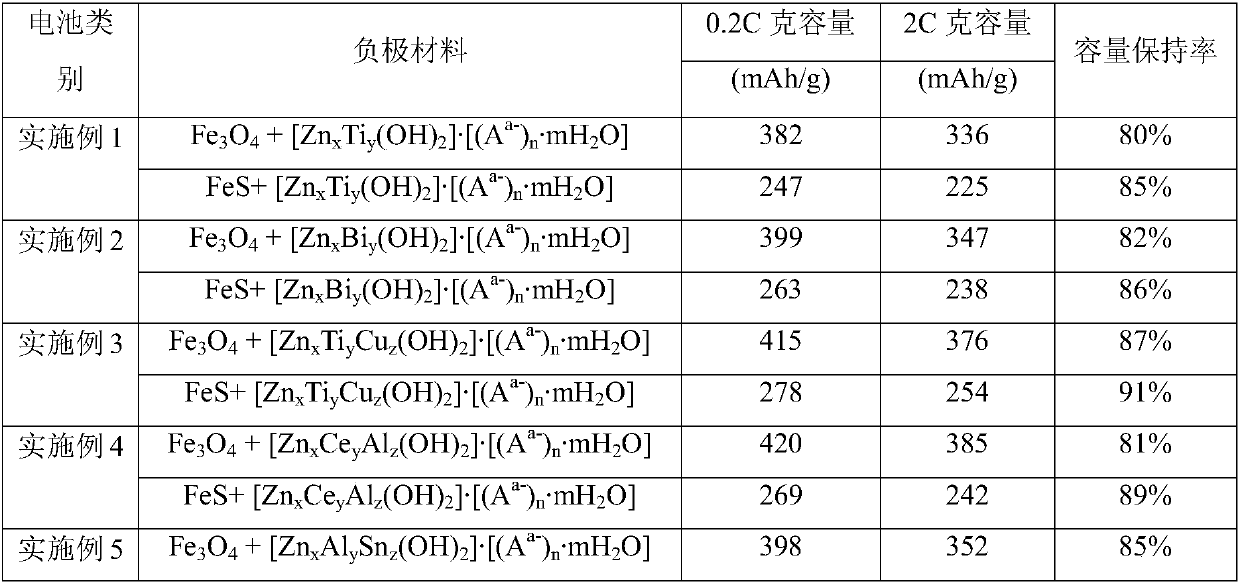

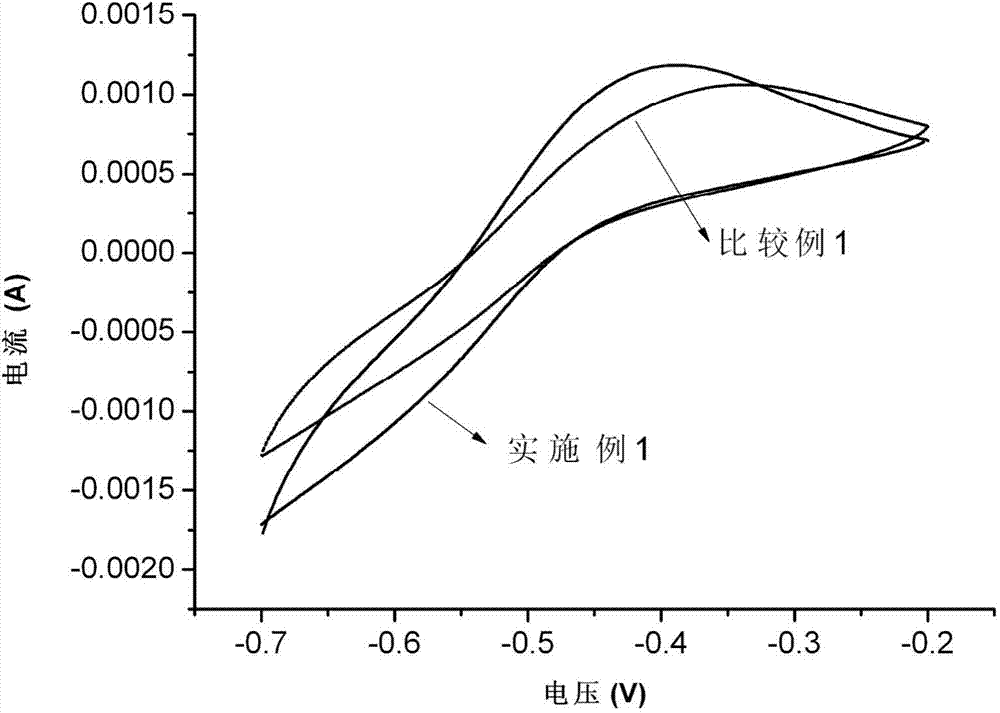

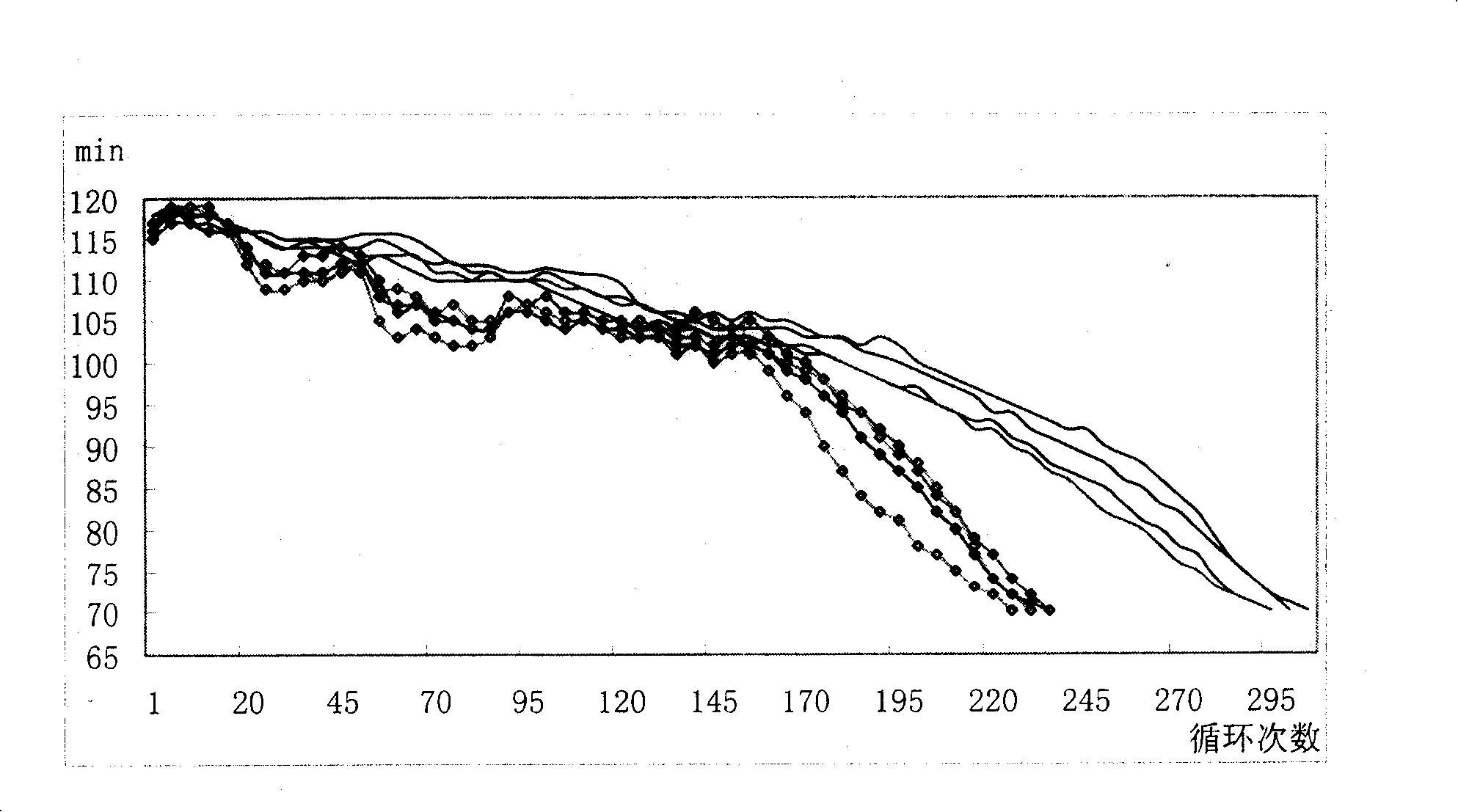

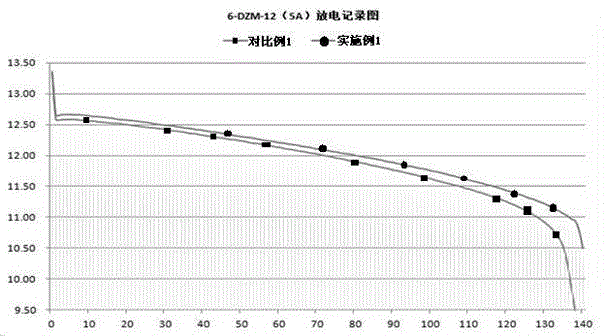

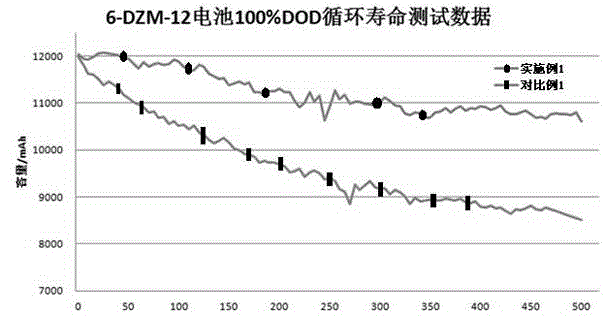

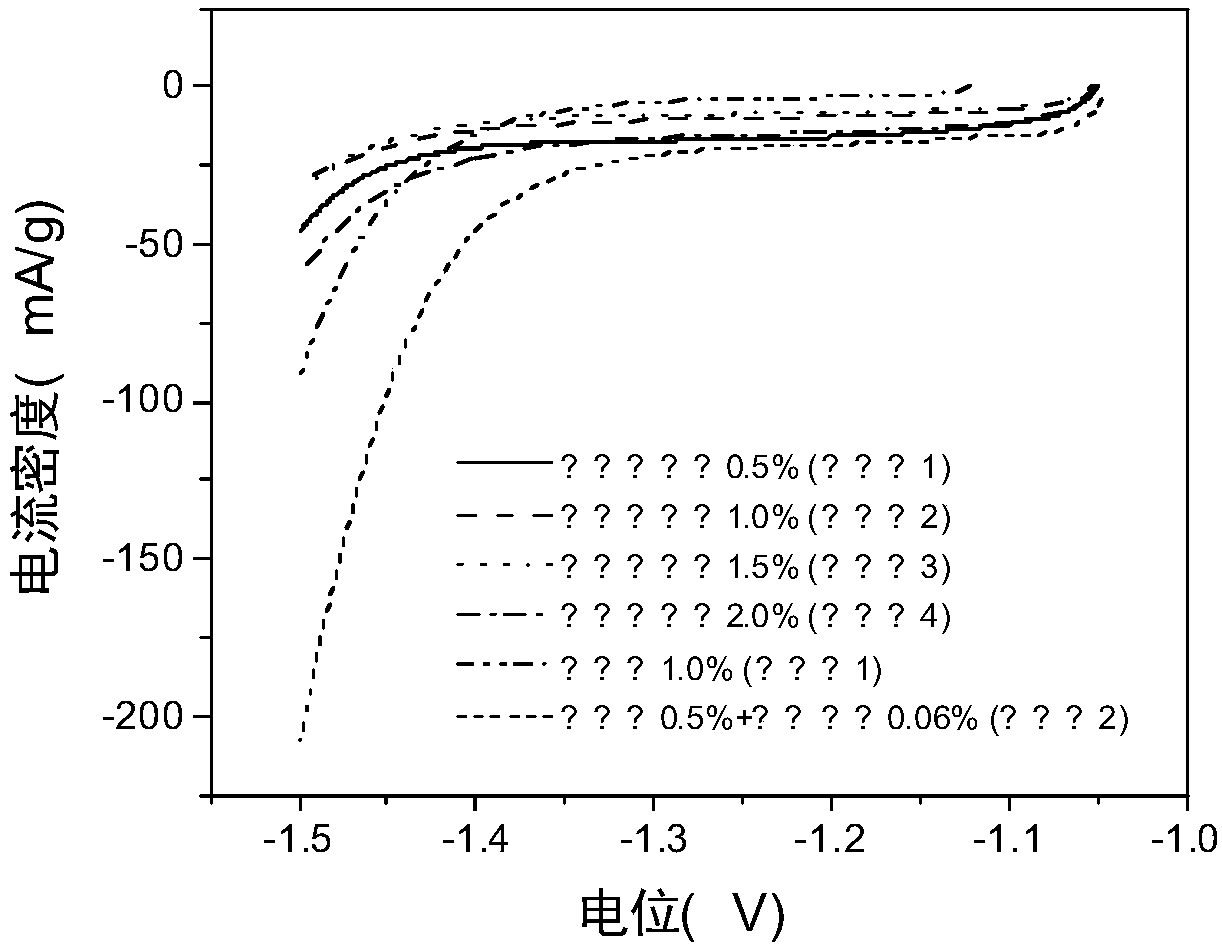

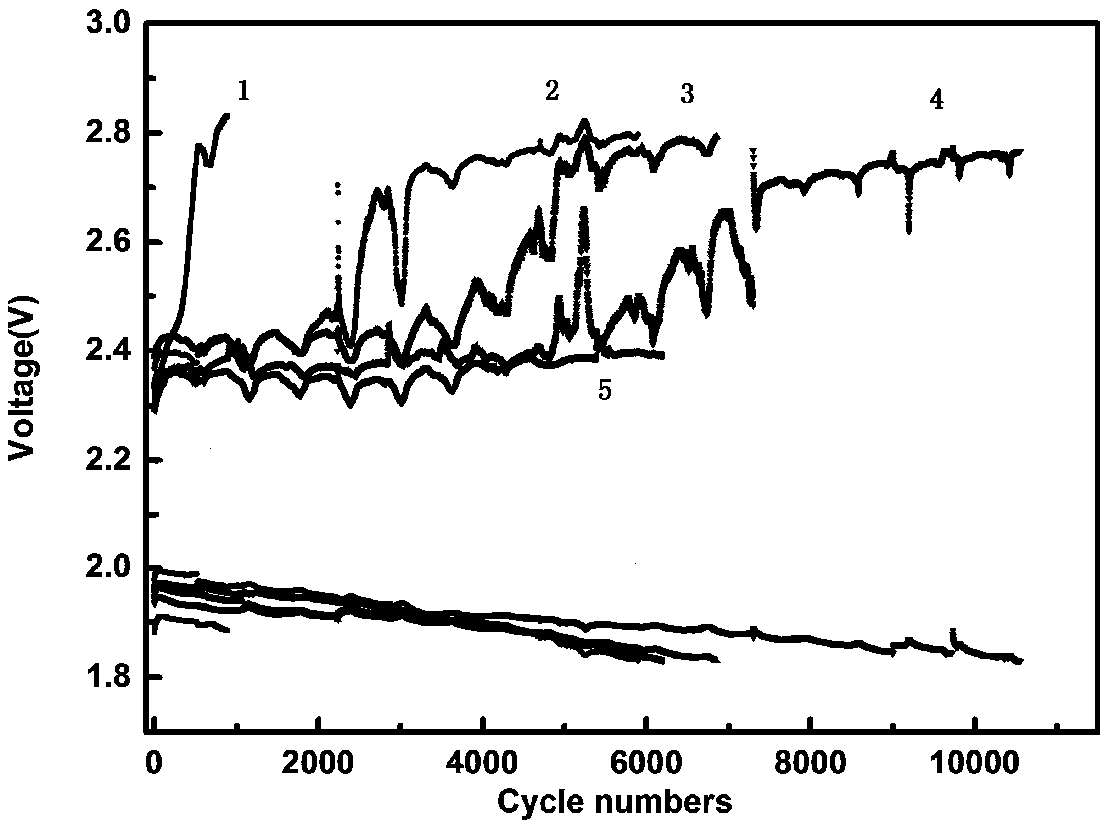

Negative plate of secondary nickel-iron battery, preparation method of negative plate and secondary nickel-iron battery of using negative plate

InactiveCN107681118AExcellent rate performanceImprove cycle performanceCell electrodesNickel accumulatorsEngineeringZinc

The invention discloses a negative plate of a secondary nickel-iron battery, a preparation method of the negative plate and a secondary nickel-iron battery of using the negative plate and belongs to the technical field of negative electrode materials for secondary nickel-iron batteries. According to the main points of the technical scheme, a negative active material in the negative plate of the secondary nickel-iron battery comprises an additive zinc-based multilayered hydroxide [ZnxMyM'z(OH)2].[(A<a->)n.mH2O]. The invention further particularly discloses a preparation method of the negative plate of the secondary nickel-iron battery and the secondary nickel-iron battery of using the negative plate. By adopting the novel negative plate of the secondary nickel-iron battery, the energy density and the rate capability of the secondary nickel-iron battery can be greatly improved and the cycle life of the secondary nickel-iron battery can be greatly prolonged.

Owner:HENAN NORMAL UNIV

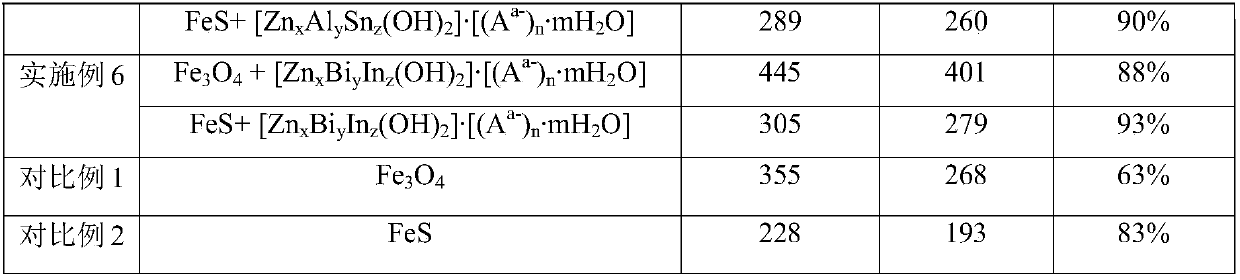

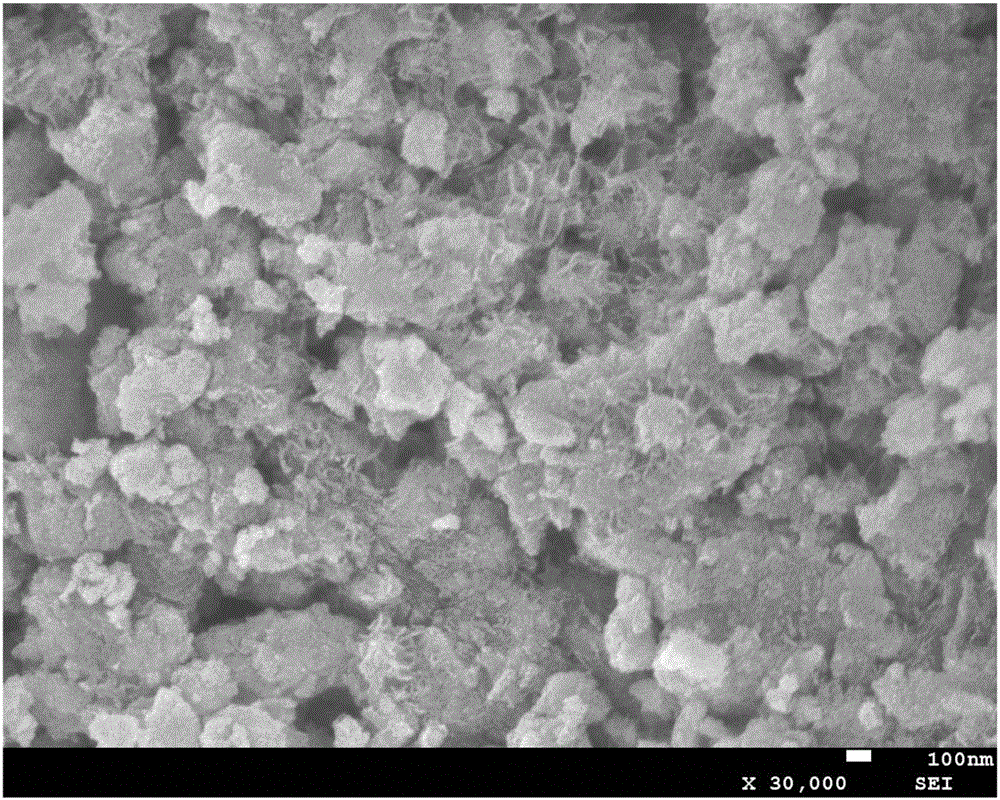

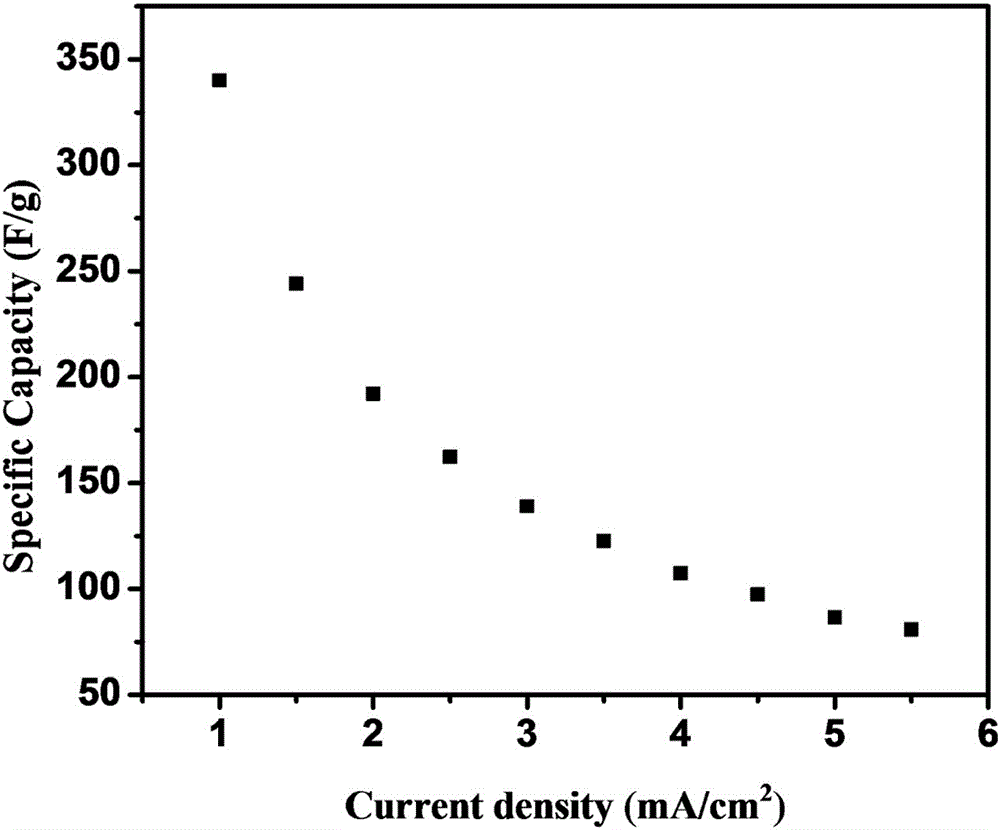

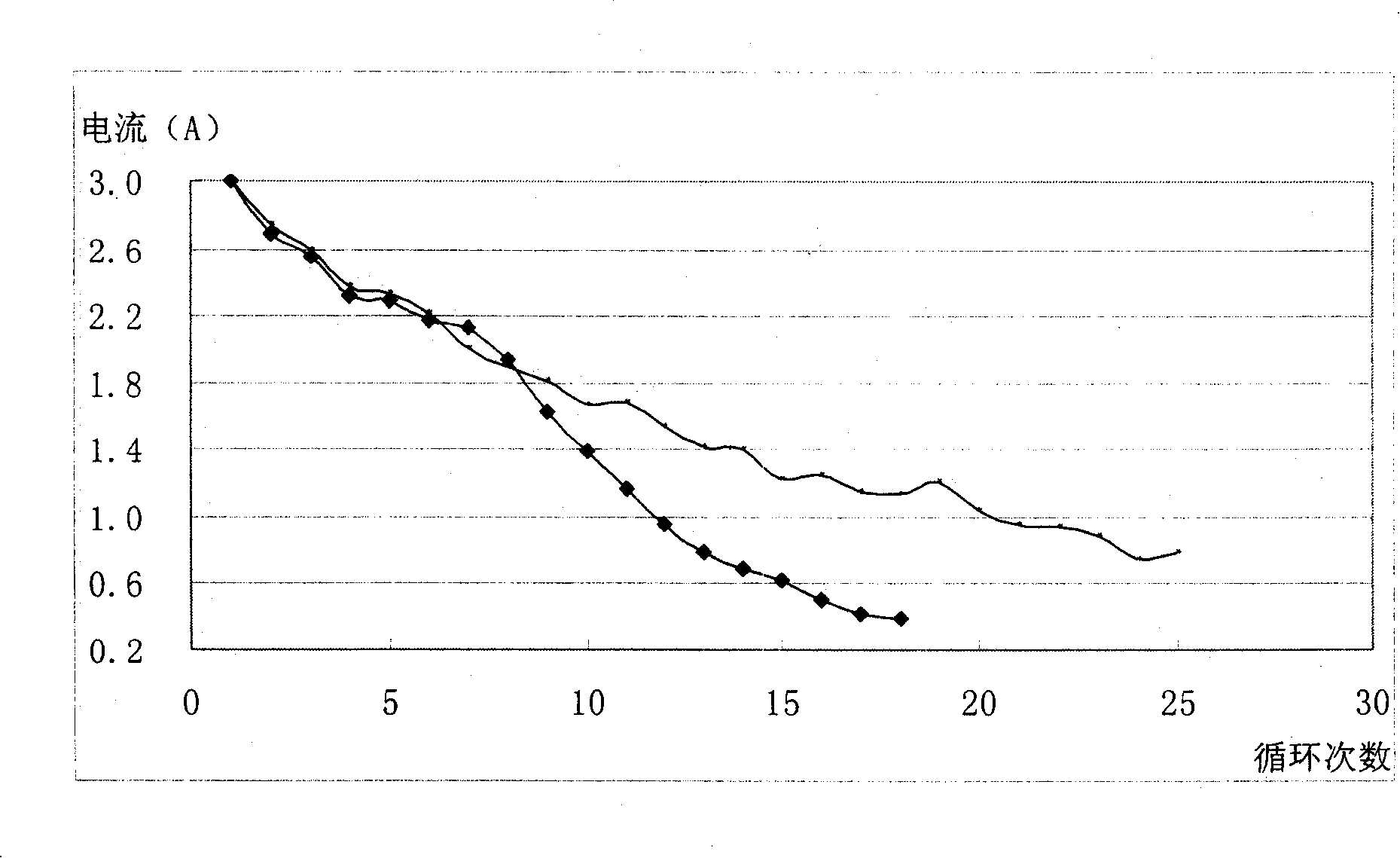

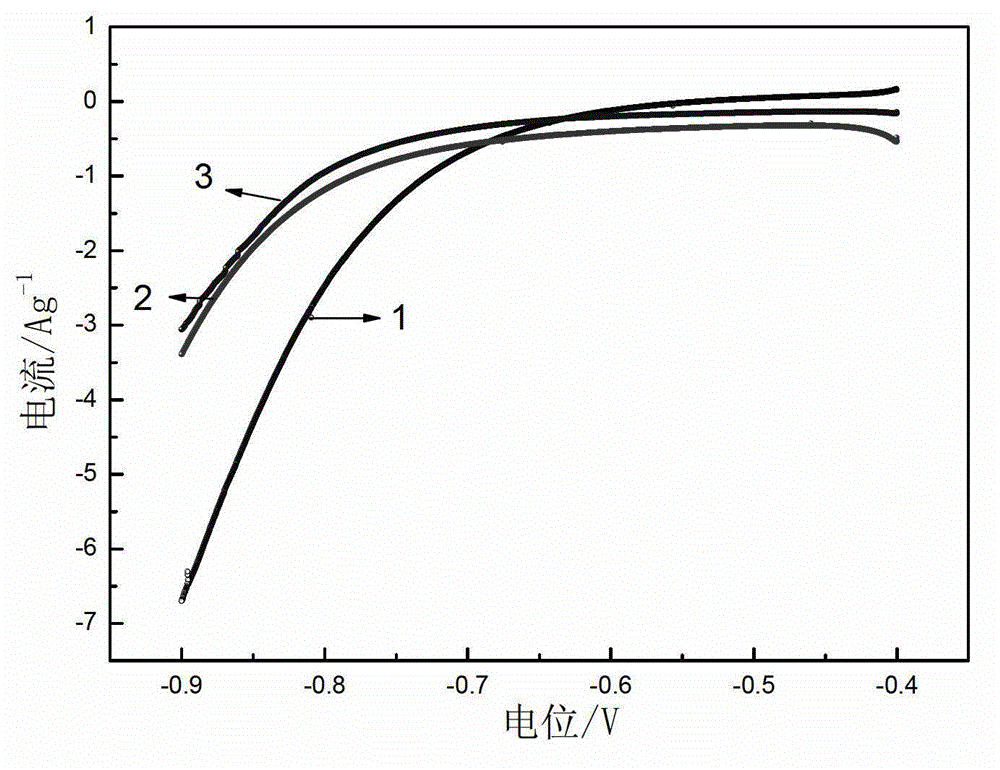

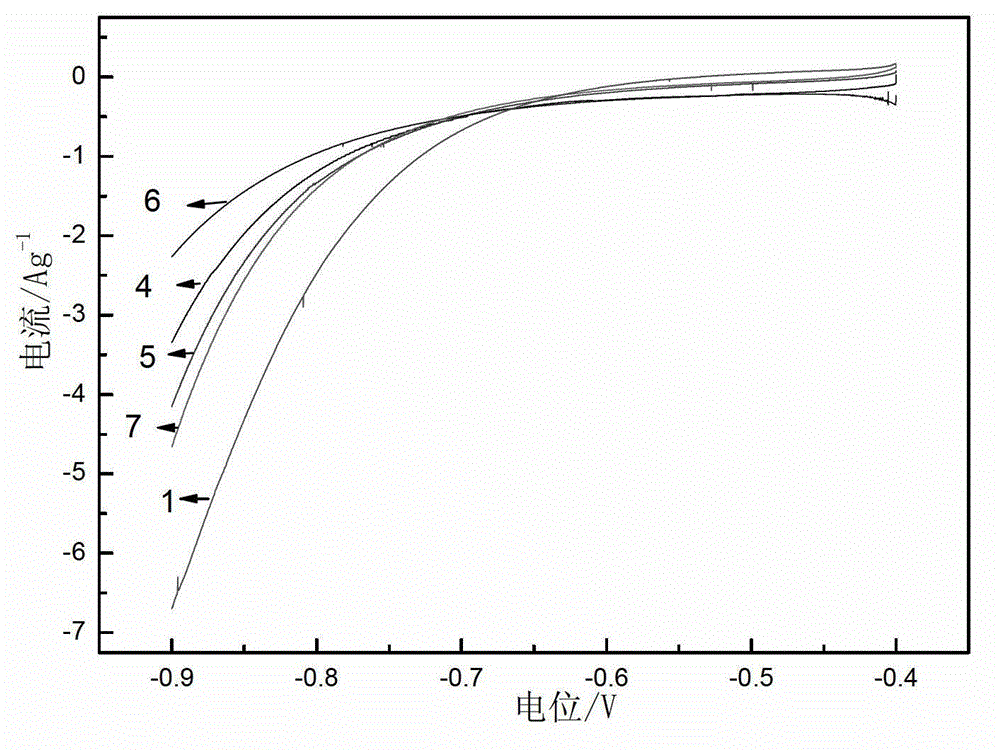

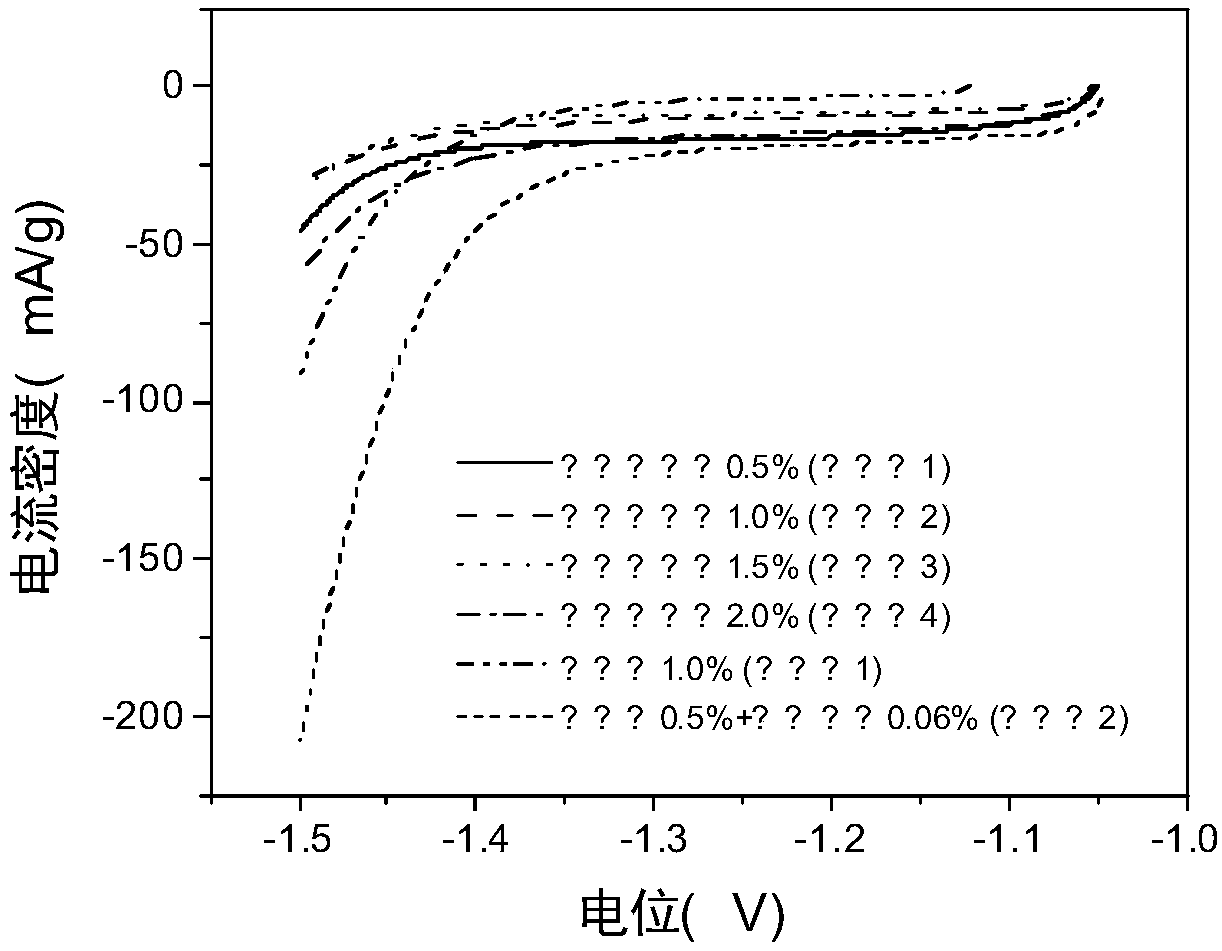

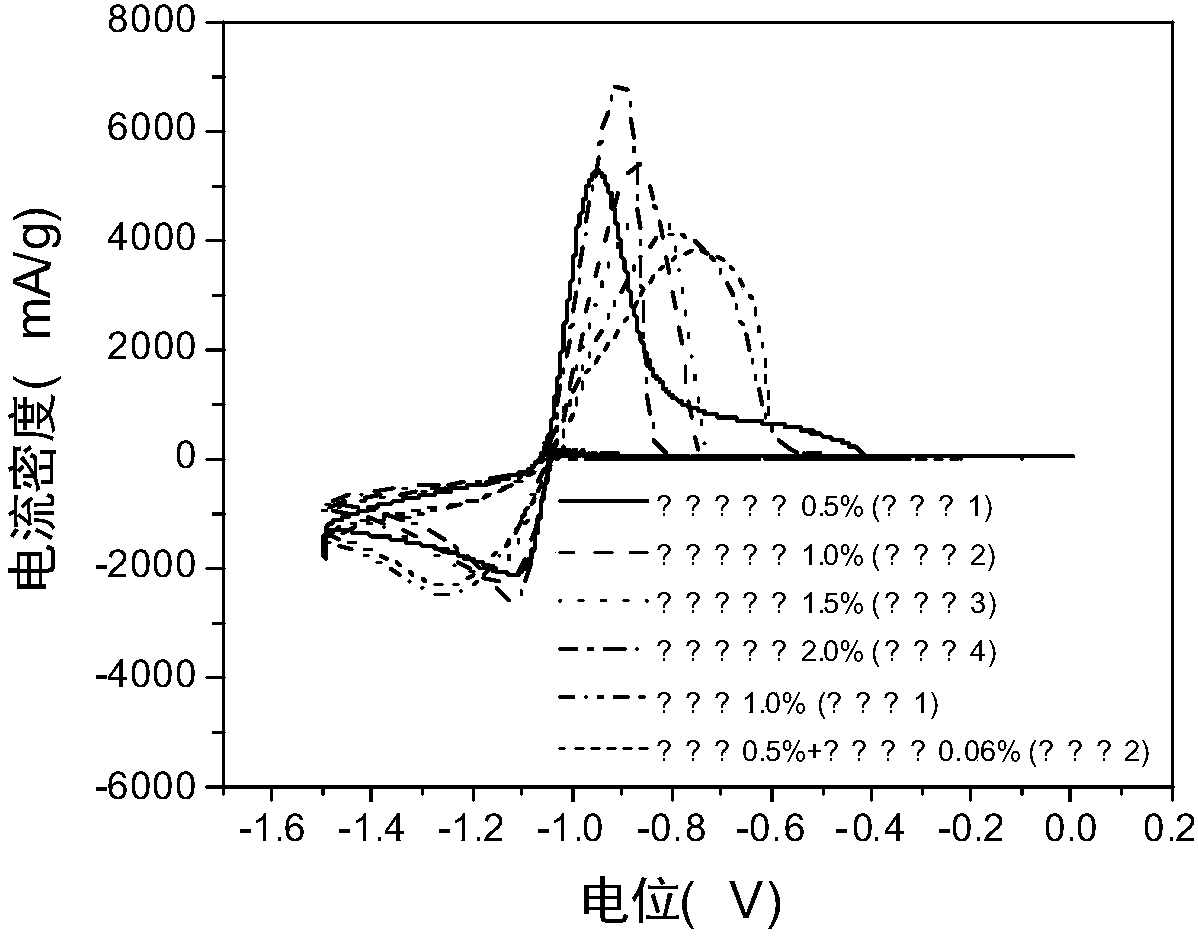

Vulcanized modification method for Ni-Fe LDH electrode material

InactiveCN106601500AIncrease capacityEasy transferHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceVulcanization

The invention discloses a vulcanized modification method for a Ni-Fe LDH electrode material. Urea is used as a precipitant and ferrous chloride is used as an iron source. Ni-Fe LDH grows on a nickel net substrate; and with a solvothermal method, vulcanization is carried out on the Ni-Fe LDH by using thiourea, sodium sulphide, or thioacetamide as a vulcanizing agent to obtain Ni-Fe LDH-S growing uniformly on the surface of the nickel net based on a cellular structure. Electrochemical performance evaluation is carried out on the Ni-Fe LDH-S in a 1M KOH electrolyte; and a potential window range is stabilized to be -1.1 to 0V. When constant-current charging and discharging are carried out in the potential window, the specific capacitance of the Ni-Fe LDH-S can reach 340 F / g, wherein the specific capacitance of the sample being Ni-Fe LDH without second-step vulcanization is only 45F / g. The result demonstrates that the specific capacity of the Ni-Fe LDH can be improved substantially.

Owner:CHINA THREE GORGES UNIV

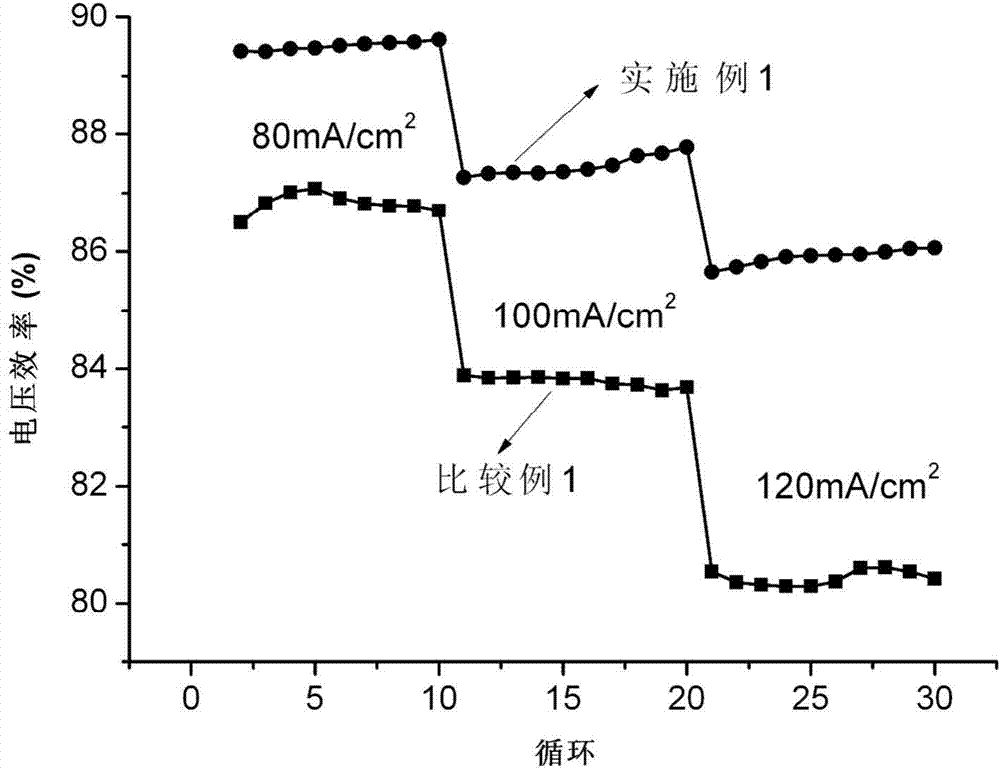

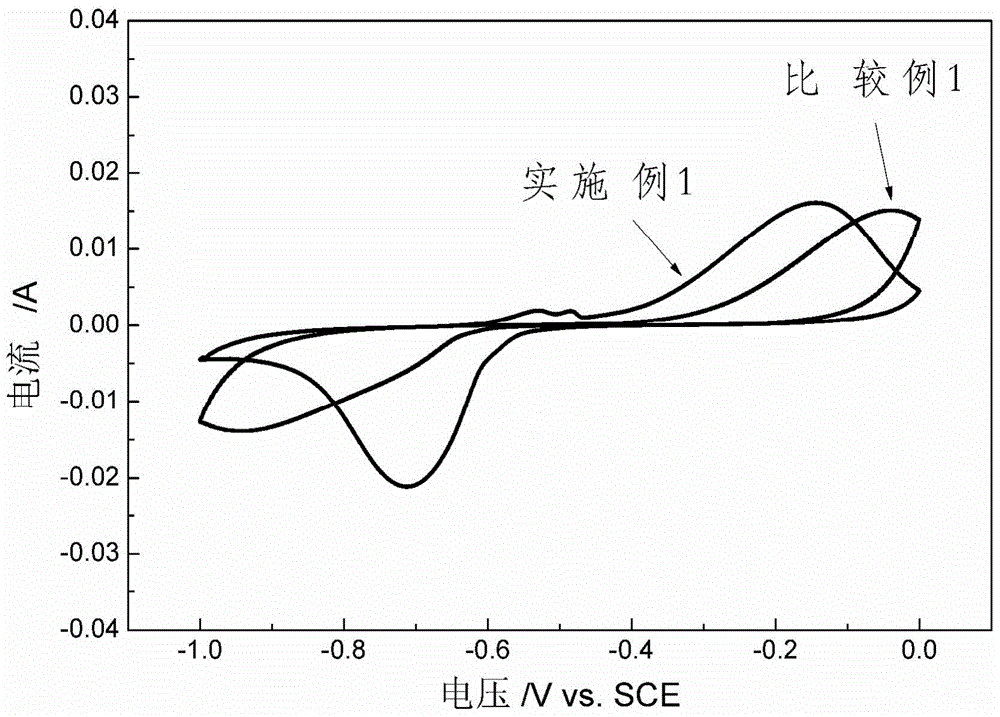

Double-function negative electrode and applications of double-function negative electrode as all-vanadium flow battery negative electrode

ActiveCN104518221AReduces electrochemical polarizationIncrease working current densityMaterial nanotechnologyCell electrodesFormateCharge transfer resistance

The invention relates to an all-vanadium flow battery double-function negative electrode, wherein a carbon material is adopted as a substrate, a Bi-containing electro-catalyst is modified on the surface of the substrate, the Bi-containing electro-catalyst is one or more than two selected from a Bi elementary substance, Bi2O3, a Bi halide and a Bi metal salt, the Bi halide is bismuth fluoride, bismuth trichloride, bismuth bromide, or bismuth iodide, and the Bi metal salt is bismuth sulfate, bismuth nitrate, bismuth phosphate, bismuth formate or bismuth acetate. According to the present invention, the electrode is suitable for the negative electrode of the all-vanadium flow battery, the electrocatalysis activity and the electrochemical reversibility of the electrode material on the V<2+> / V<3+> oxidation reduction reaction can be substantially improved, and the charge transfer resistance can be reduced; and the high hydrogen evolution overpotential is provided so as to inhibit the occurrence of the hydrogen evolution reaction and prolong the service life of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

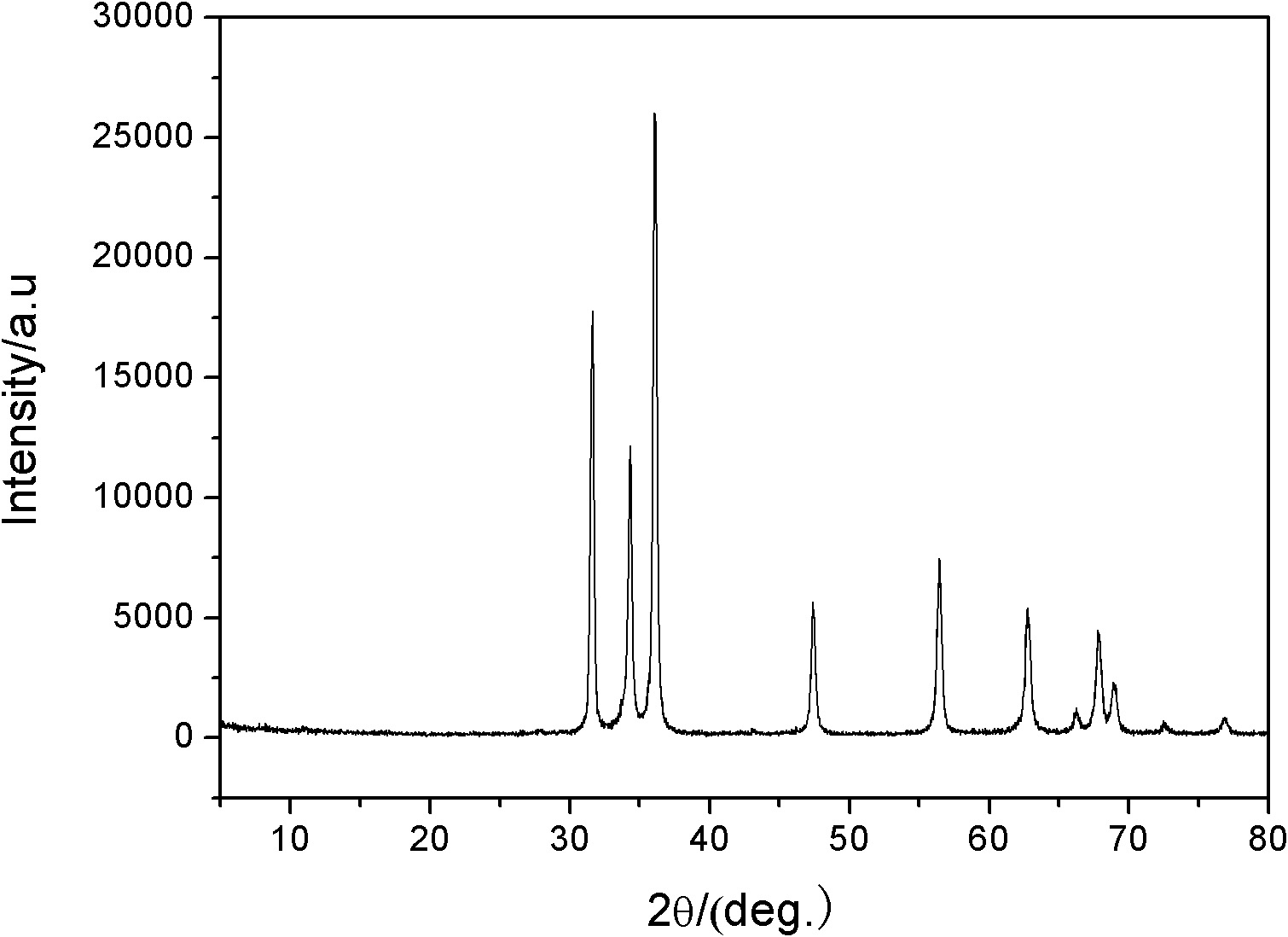

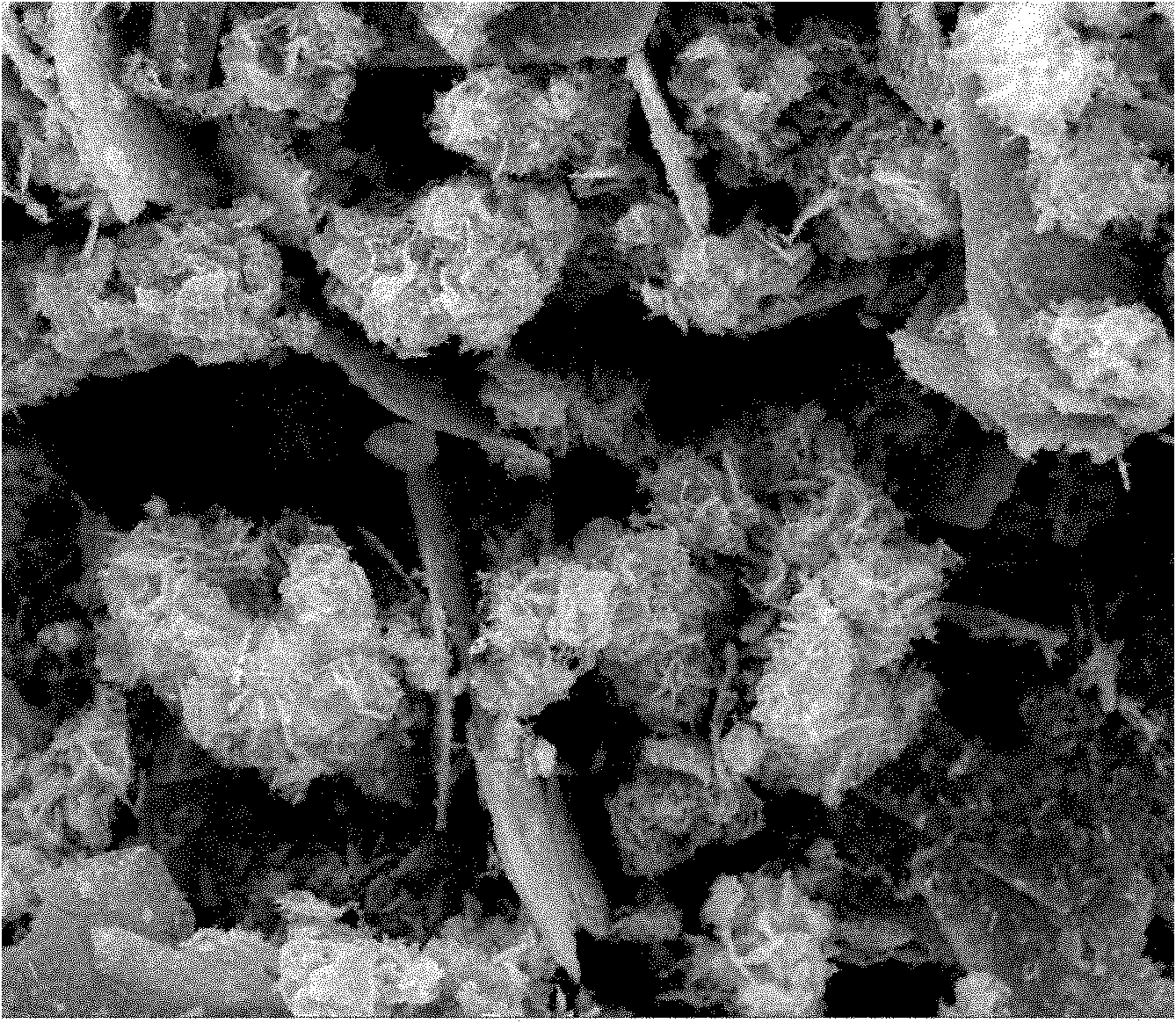

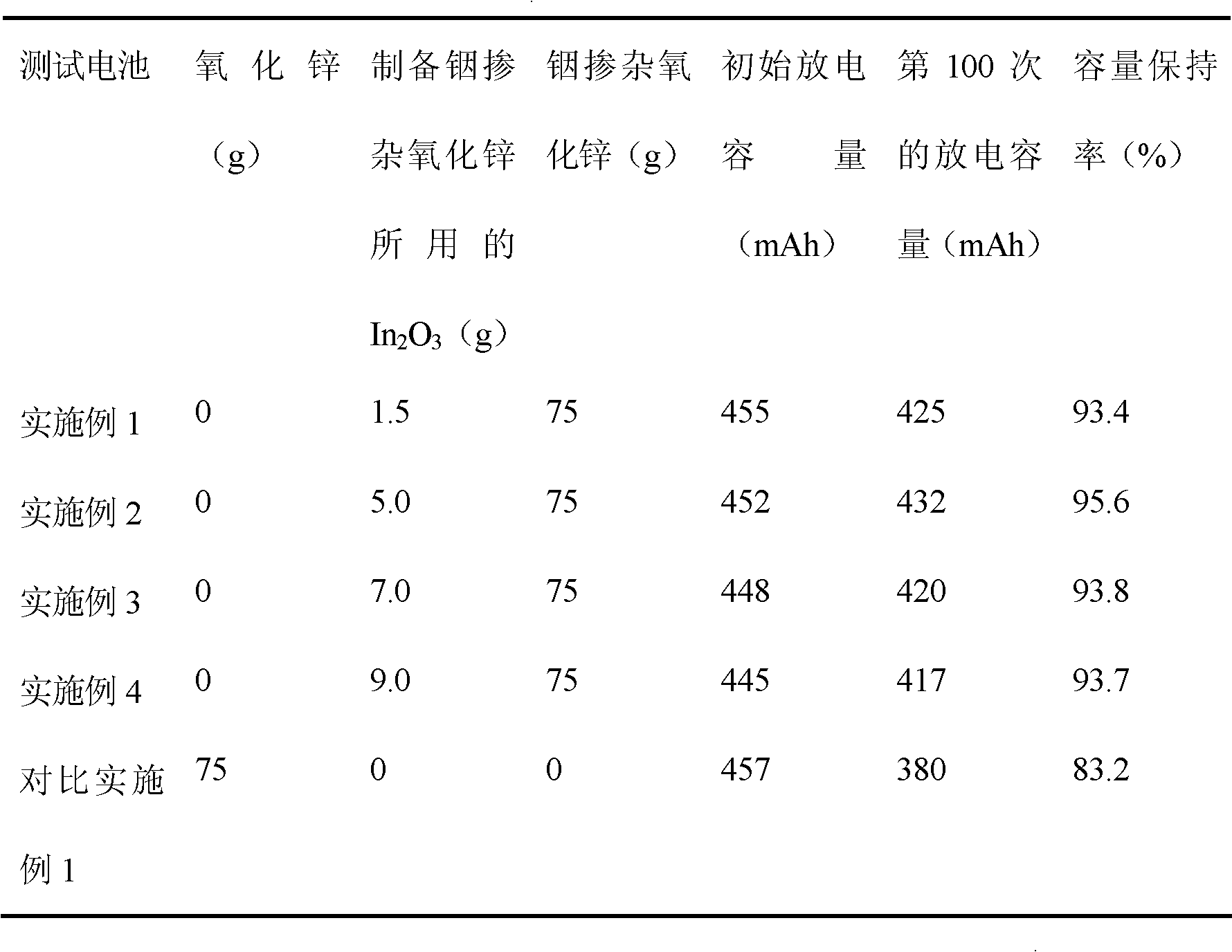

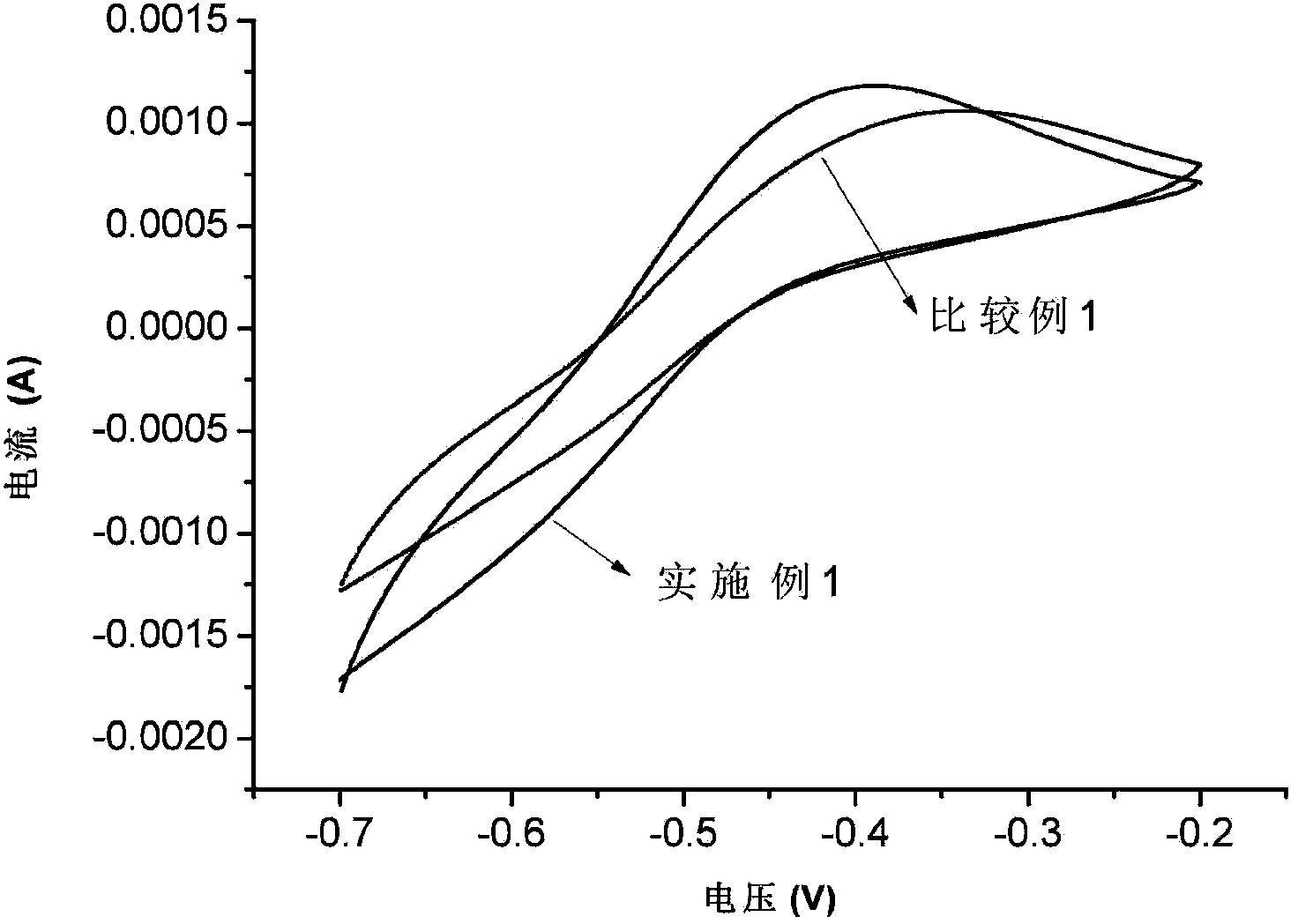

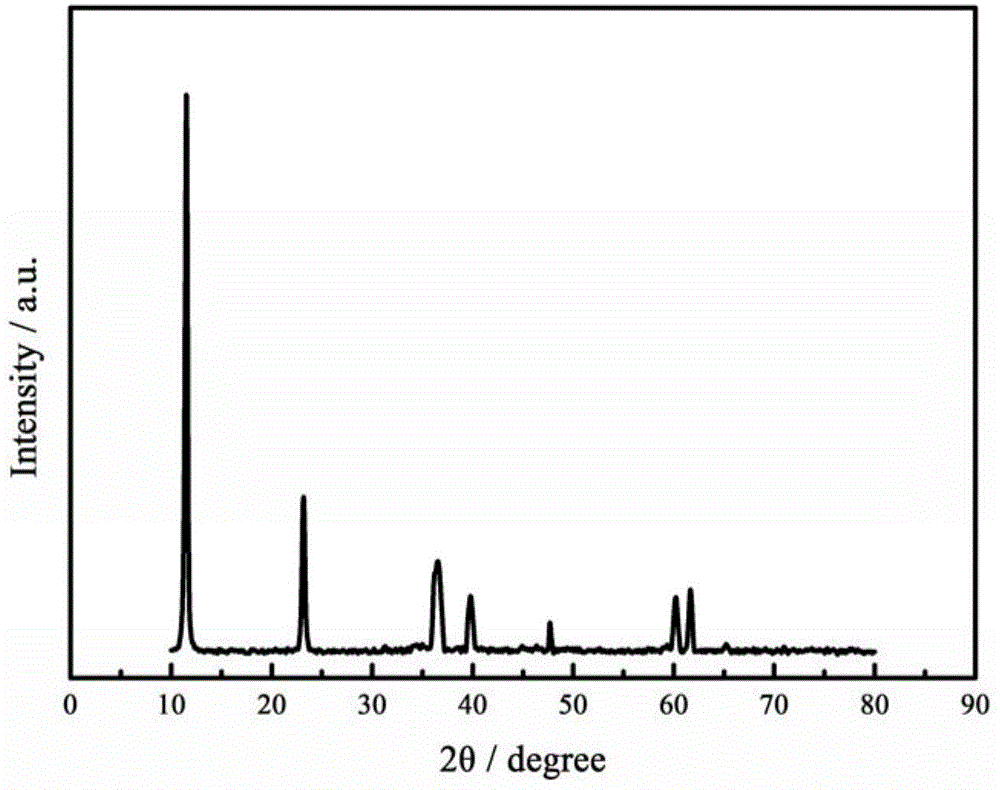

Zinc cathode active substance of zinc-nickel secondary battery and preparation method and application method thereof

InactiveCN102044669APromote migrationIncrease the hydrogen evolution overpotentialAlkaline accumulator electrodesIndiumDissolution

The invention discloses a zinc cathode active substance of a zinc-nickel secondary battery and a preparation method and application method thereof. The preparation method of the active substance comprises the following steps: (1) dissolving In2O3 in concentrated hydrochloric acid; (2) dissolving ZnCl2 in deionized water and adding dispersant; (3) mixing the two solutions and diluting with deionized water; (4) adding ammonia water dropwise into the mixed dilute solution to regulate pH while strongly stirring mechanically, then stirring and aging; (5) performing ultrasonic dispersion on the aged liquid, transferring to a hydro-thermal reaction kettle and putting the reaction kettle in an oven for heat preservation; and (6) filtering, washing and drying the precipitate, and calcining at certain temperature to obtain indium-doped zinc oxide. The active substance can reduce the deformation of the zinc cathode, suppress the dissolution of the active substance of the zinc cathode and prolong the cyclic service life of the zinc-nickel secondary battery.

Owner:CENT SOUTH UNIV

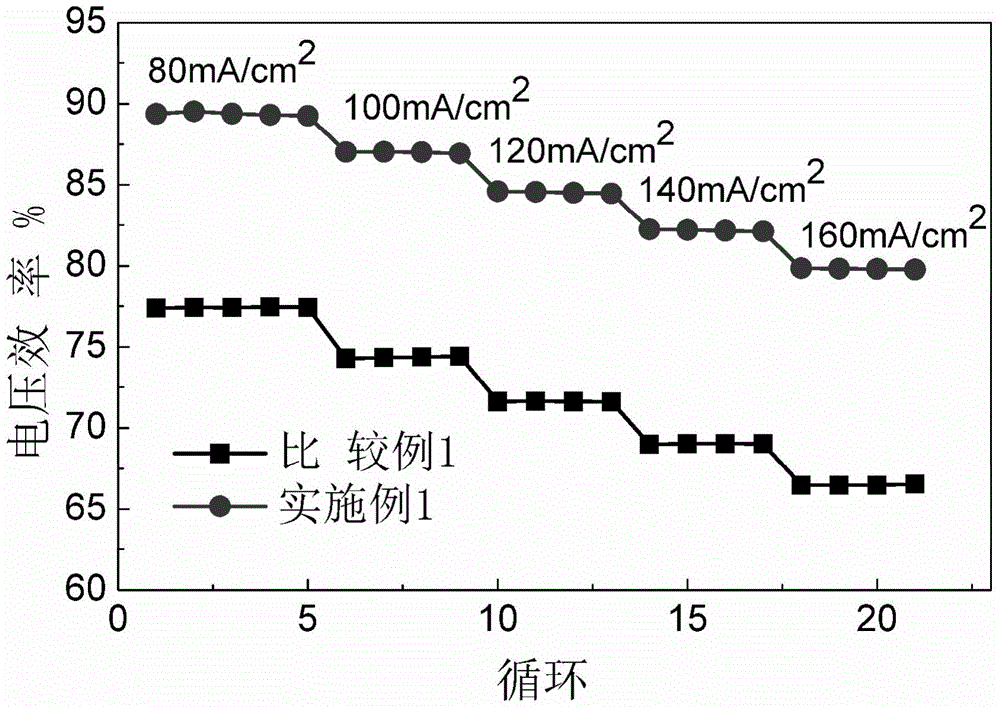

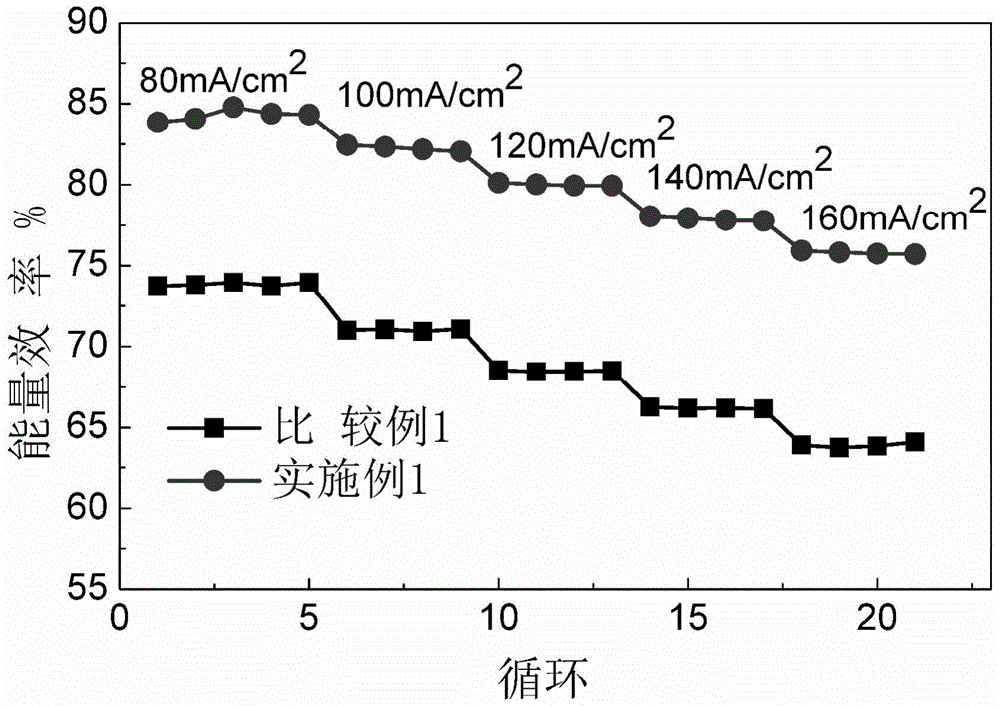

Difunctional negative electrode and its application as all-vanadium redox energy storage battery negative electrode

ActiveCN104218248AExtend working lifeIncrease the hydrogen evolution overpotentialCell electrodesFuel cellsCharge transfer resistanceOverpotential

A difunctional negative electrode for an all-vanadium redox energy storage battery negative electrode includes a carbon matrix material and a Bi-containing electro-catalyst modifying the surface of the carbon matrix material. The negative electrode is suitable for being used as the negative electrode of the all-vanadium redox energy storage battery, can greatly improve the electrocatalytic activity and electrochemical reversibility of an electrode material on a V<2+> / V<3+> redox reaction, and decreases the charge transfer resistance; and the negative electrode has high hydrogen evolution overpotential, can inhibit a hydrogen evolution reaction, and prolongs the work life of the battery. The difunctional negative electrode improves the voltage efficiency and energy efficiency of the all-vanadium redox energy storage battery, so the working current density of the battery is improved, and the weight, the size and the cost of the battery with same output power are greatly reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

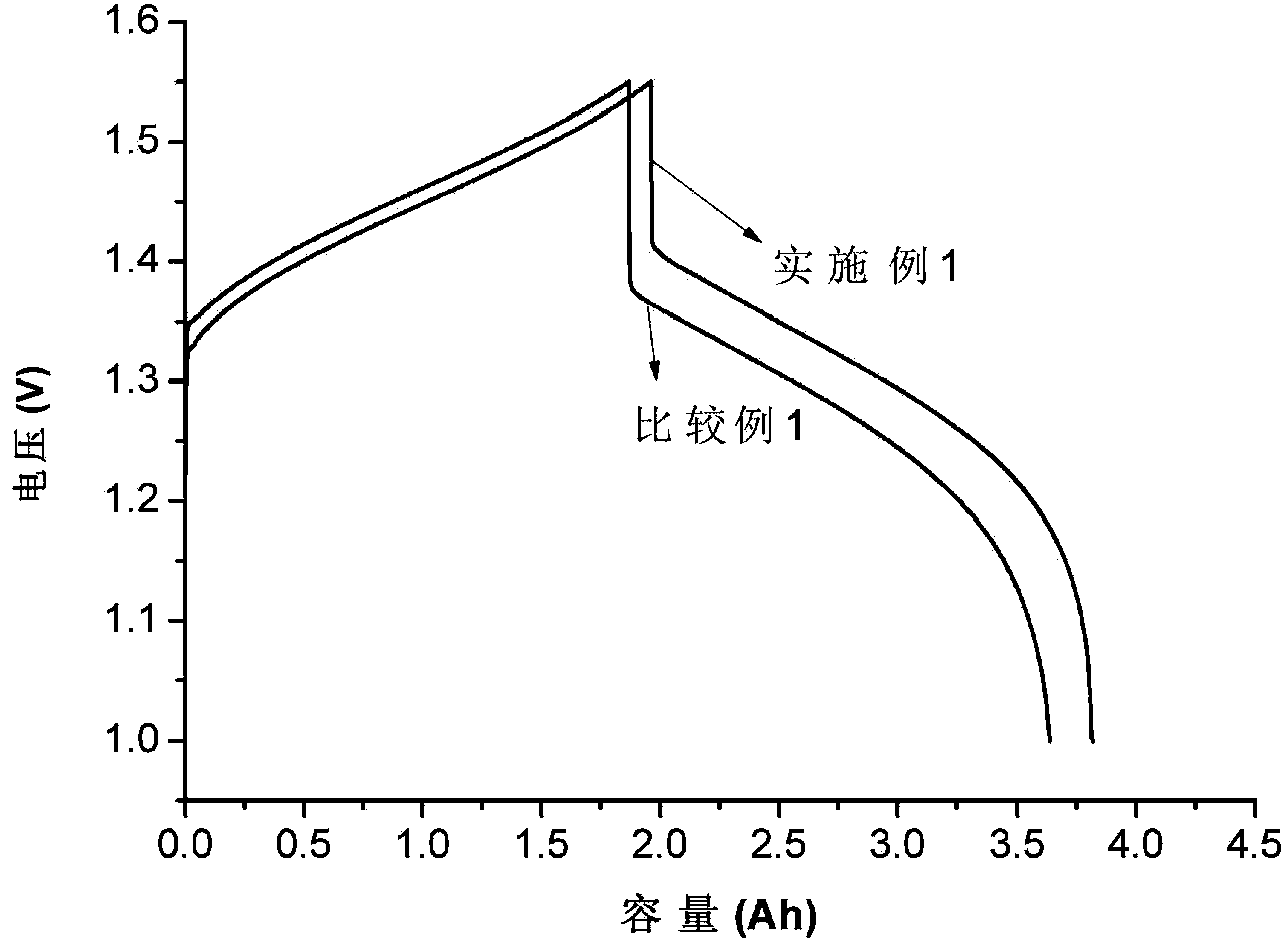

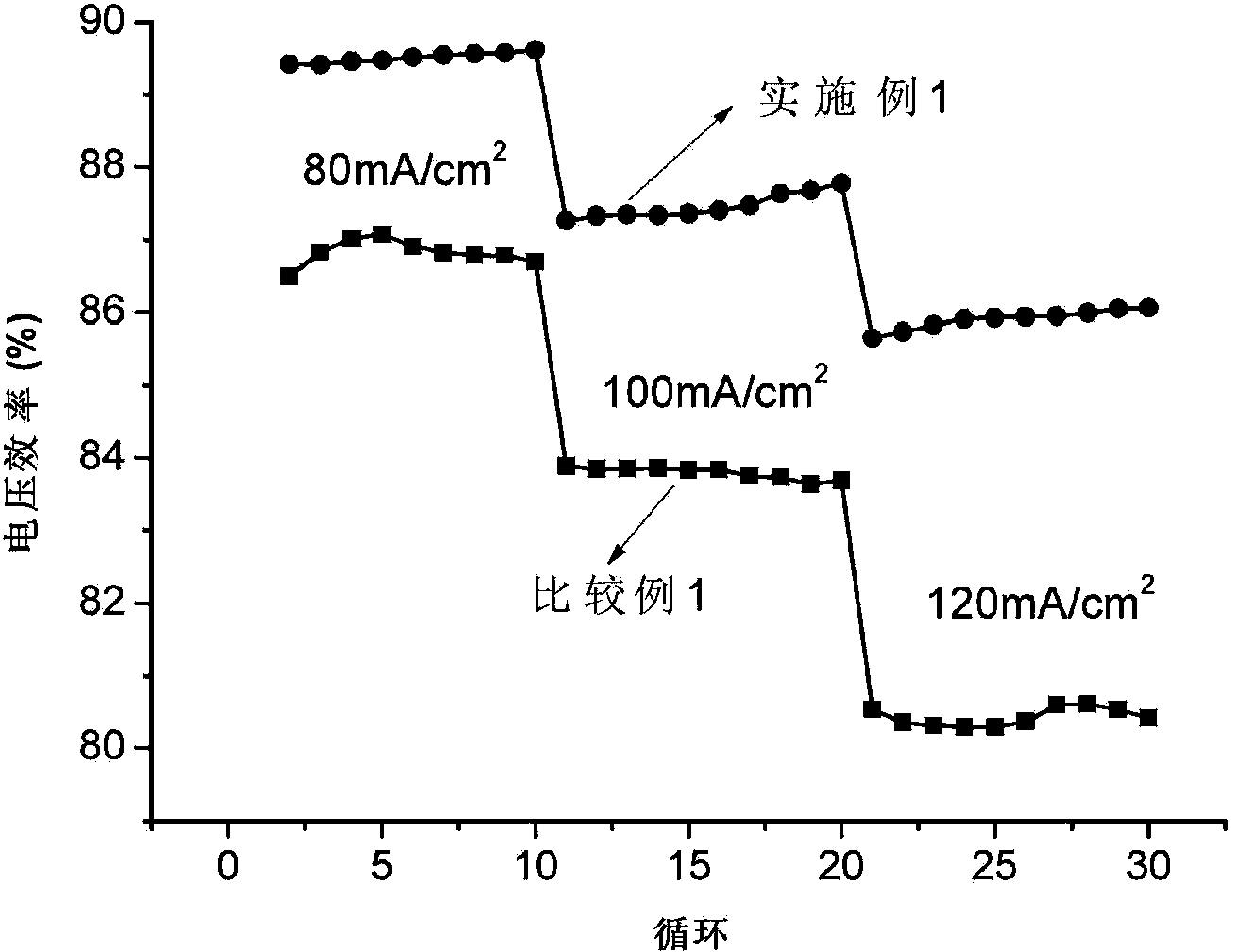

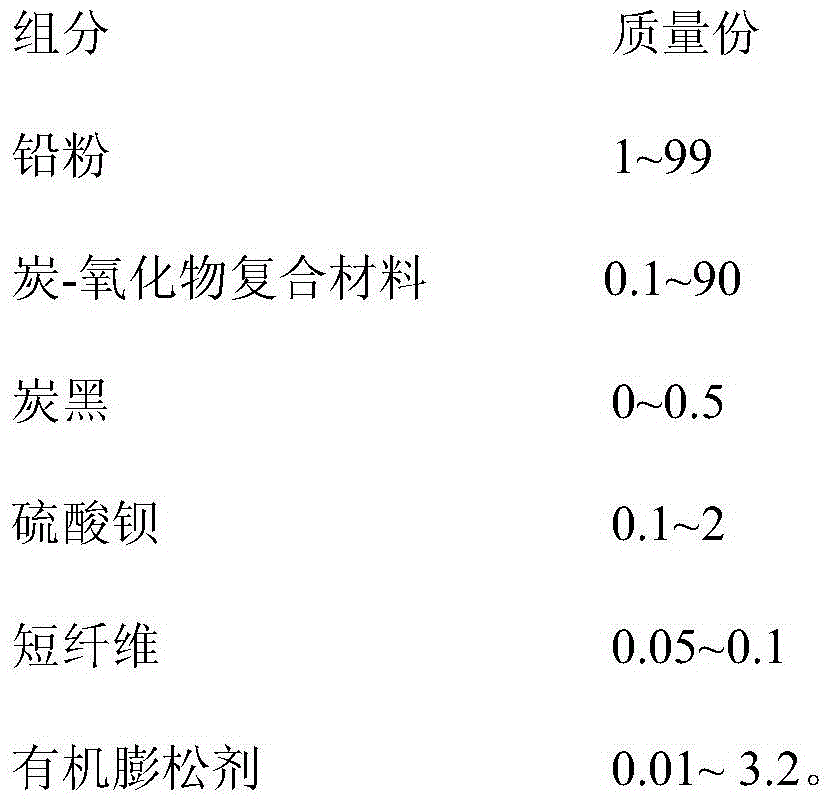

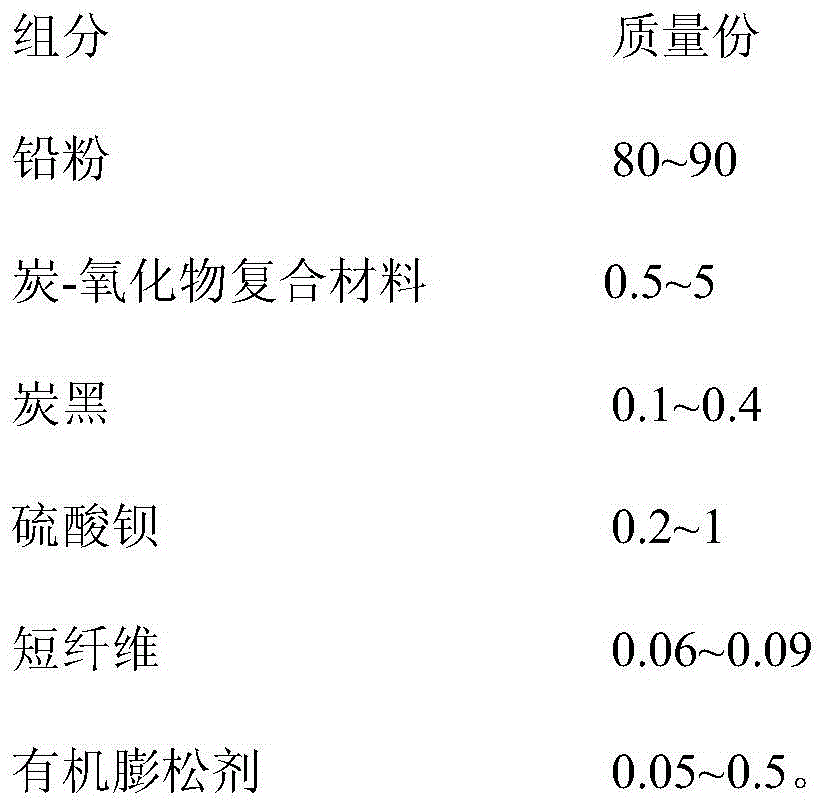

Negative lead paste for lead-carbon battery

ActiveCN105489887ALarge specific surface areaDelayed softening and sheddingFinal product manufactureCell electrodesFiberCapacitance

The invention provides a negative lead paste for a lead-carbon battery. The negative lead paste is prepared from the following components in parts by weight: 1-99 parts of lead powder, 0.1-90 parts of a carbon-oxide composite material, 0-0.5 part of carbon black, 0.1-2 parts of barium sulfate, 0.05-0.1 part of a short fiber and 0.01-3.2 parts of an organic swelling agent. Oxides on the surface and in holes of the carbon material of the lead paste are tightly adsorbed to the periphery of the carbon material in an ionic form, and are recombined on the surface and in the holes of the carbon material in curing and drying processes; and a tiny oxide film is evenly attached to the active surface and the holes of the carbon material by 'dissolving and recombination', so that the bonding degree of the carbon material and the oxides is greatly improved; the conduction characteristics and the capacitance characteristics of the carbon material are put into a fully play; and hydrogen evolution on the surface of the carbon material is limited.

Owner:CHINA ELECTRIC POWER RES INST +3

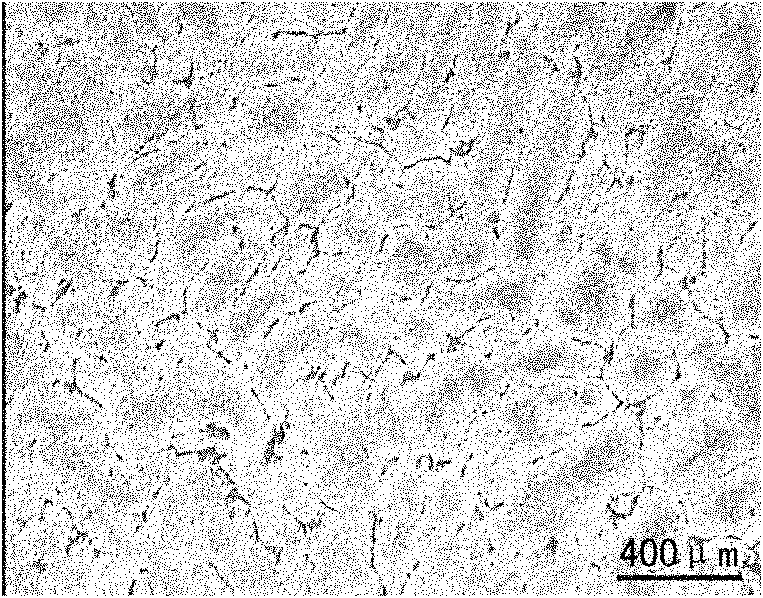

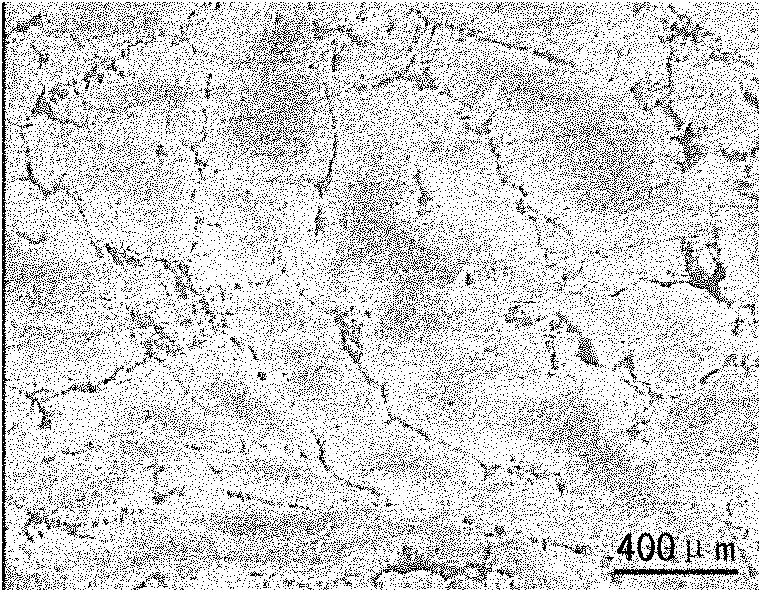

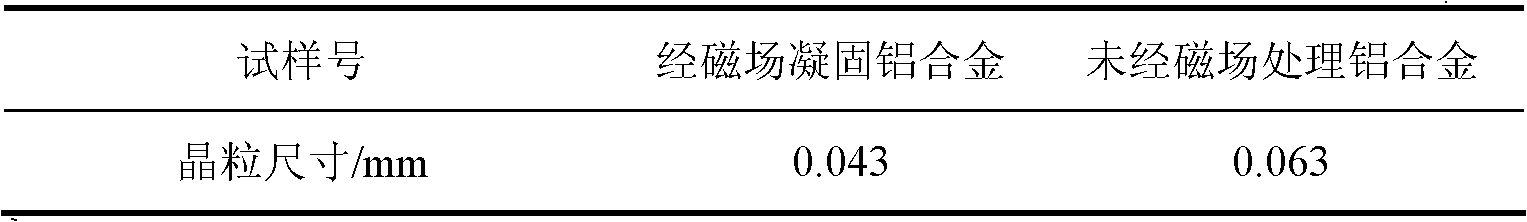

Method for preparing rare-earth aluminum alloy electrode material

The invention provides a method for preparing a rare-earth aluminum alloy electrode material. Aluminum (CP level) with purity of more than or equal to 99.9 percent, serving as a raw material, is added with the following elements in percentage by mass: 0.05 to 49 percent of Zn, 0.05 to 0.15 percent of Ga, 0.05 to 0.20 percent of In, 0.01 to 0.10 percent of Pb, 0.05 to 0.30 percent of Mn, 0.05 to 0.30 percent of Sn and 0.20 to 0.50 percent of Re; and the mass content of impurities is less than or equal to 0.01 percent. According to the method, the rare-earth aluminum alloy electrode material is prepared by adopting doping of rare-earth elements, and the rare-earth aluminum alloy electrode material with excellent performance is obtained by solidification treatment of an external magnetic field so as to provide material support for practical application of an aluminum fuel cell. By the solidification treatment of the external magnetic field for the rare-earth aluminum alloy electrode material, the polarization performance of aluminum alloy electrodes can be improved, hydrogen evolution corrosion can be inhibited, the utilization rate of an anode is improved, and the working potential is increased.

Owner:CENT SOUTH UNIV

Multi-element alloy for making lead acid accumulator plate grid

The present invention discloses a multi-component alloy for manufacturing lead-acid battery grids. The alloy contains elements of lead, calcium, tin, aluminum and bismuth, and the mass percentages of the components in the total amount of the alloy are that: calcium accounts for 0.06-0.12 percent, tin accounts for 0.08-1.5 percent, aluminum accounts for 0.017-0.034 percent, bismuth accounts for 0.084-0.13 percent; the rest is electrolytic lead. The alloy is high in hydrogen evolution potential and high in corrosion resistance. When the alloy is used for manufacturing lead-acid battery grids, the recombination efficiency of a cathode to oxygen inside batteries can be improved; the charge acceptance and overdischarge resistance of an anode in the process of deep discharge recycling use can be increased; the cycle life span of made-up lead-acid batteries is remarkably increased, and the increase rate is about 20 percent.

Owner:JIANGSU SHUANGDENG GROUP

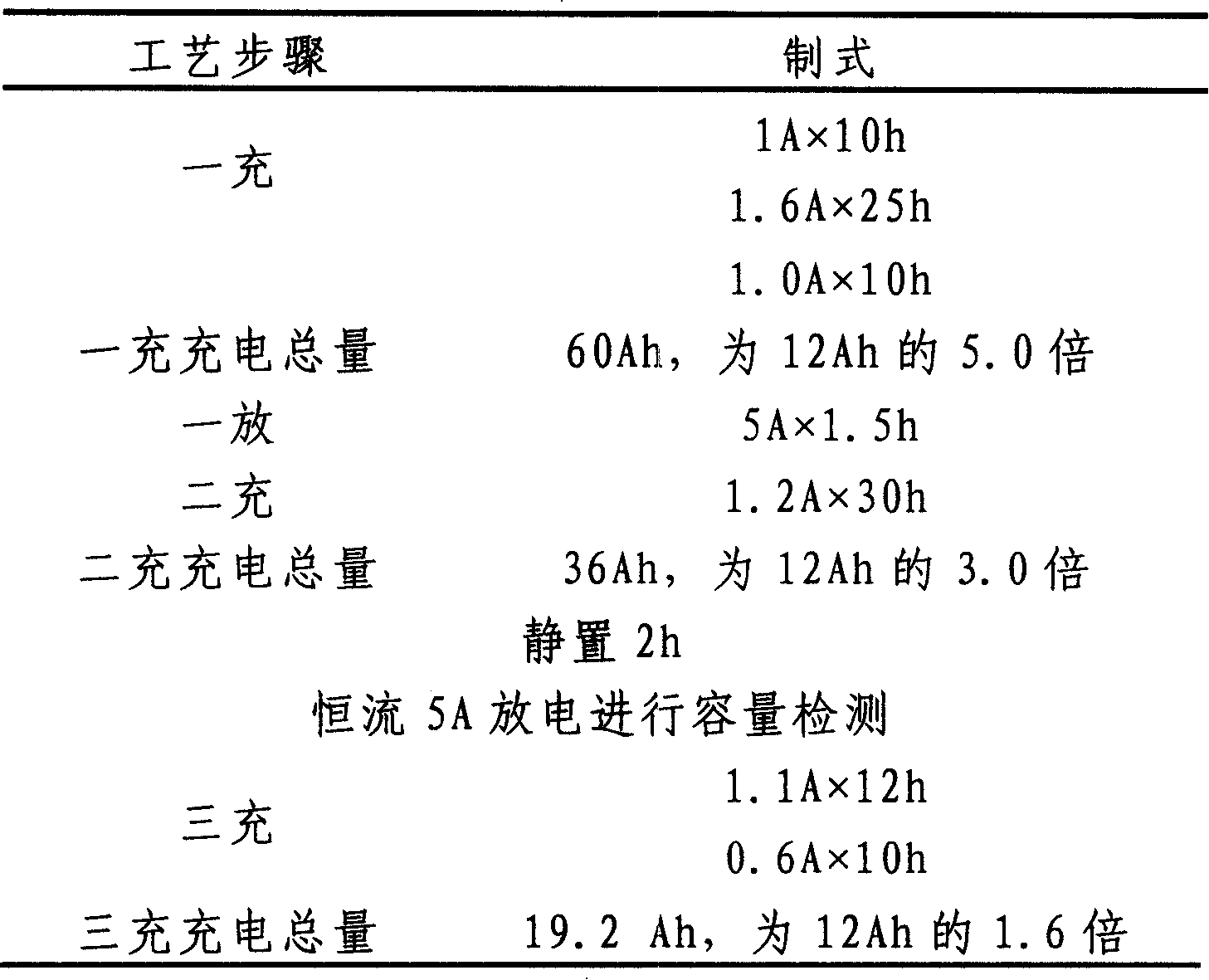

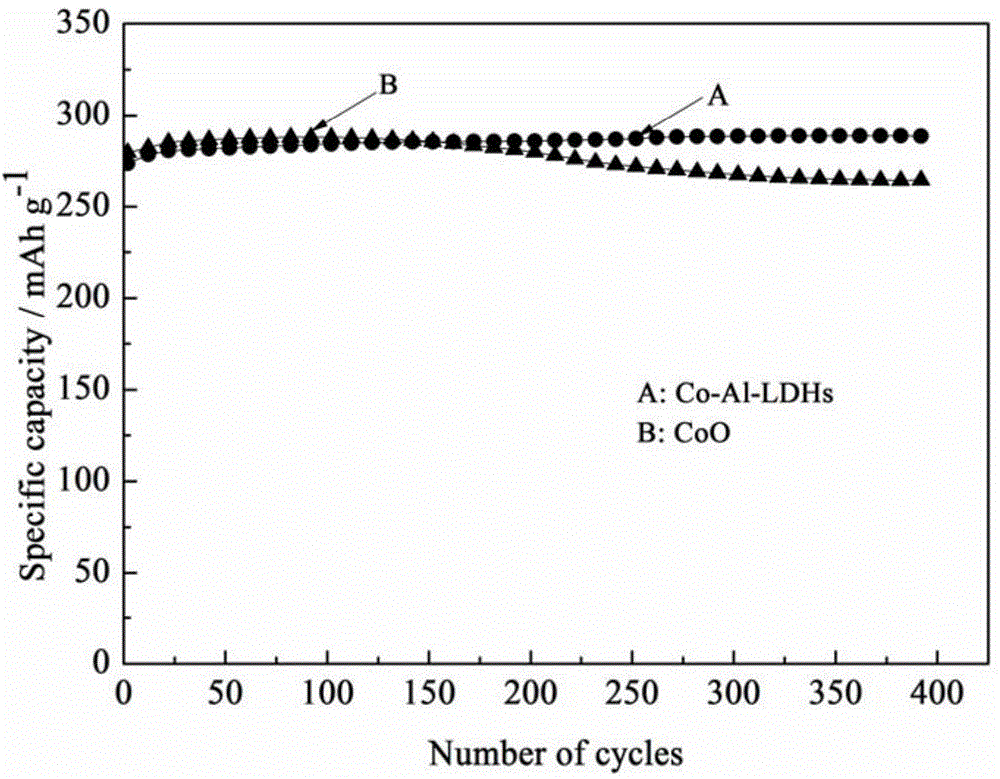

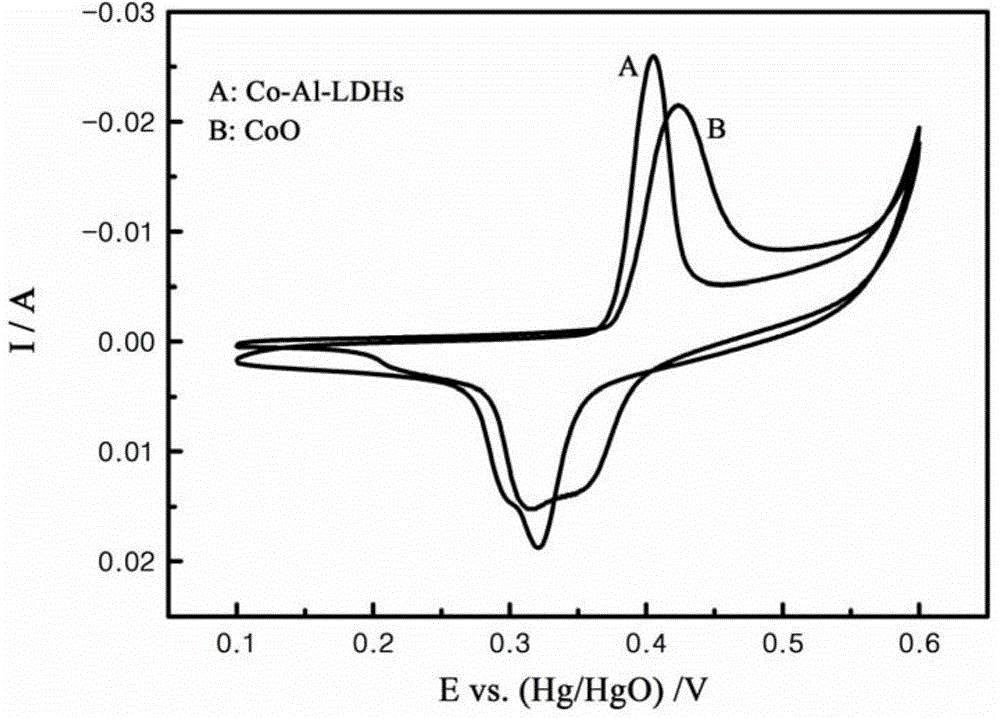

Method for preparing nickel positive electrode of nickel-metal hydride secondary battery by using cobalt-aluminum hydrotalcite and application thereof

InactiveCN104466122AThe synthesis process is simpleMild conditionsAlkaline accumulator electrodesNickel accumulatorsAdhesiveNickel oxide hydroxide

The invention discloses a method for preparing a nickel positive electrode of a nickel-metal hydride secondary battery by using cobalt-aluminum hydrotalcite. The method is characterized by comprising the following steps: a, mechanically mixing 30-40 parts by weight of cobalt-aluminum hydrotalcite, 50-60 parts by weight of nickelous hydroxide, 5-10 parts by weight of conductive agents to obtain a nickel-metal hydride battery positive electrode material mixture; b, adding dispersing agent solutions into the positive electrode material mixture in the step (a); ball-milling and adding adhesives for performing ball-milling for 3-5 hours to obtain a nickel positive electrode material with uniform mixing; and c, uniformly tabletting the nickel positive electrode material in the step (b) on current collector foam nickel and drying at the temperature of 60-200 DEG C, and cutting to obtain nickel positive electrode pole pieces. According to the nickel electrode of the nickel-metal hydride secondary battery, cobalt-aluminum hydrotalcite is used as an additive, the performance of the battery can be obviously improved, the capacity density and the power density of the battery can be improved, the charging / discharging cycle life of the battery is prolonged, the over-charging resistance capability is improved, and the self-discharging is reduced.

Owner:付春平

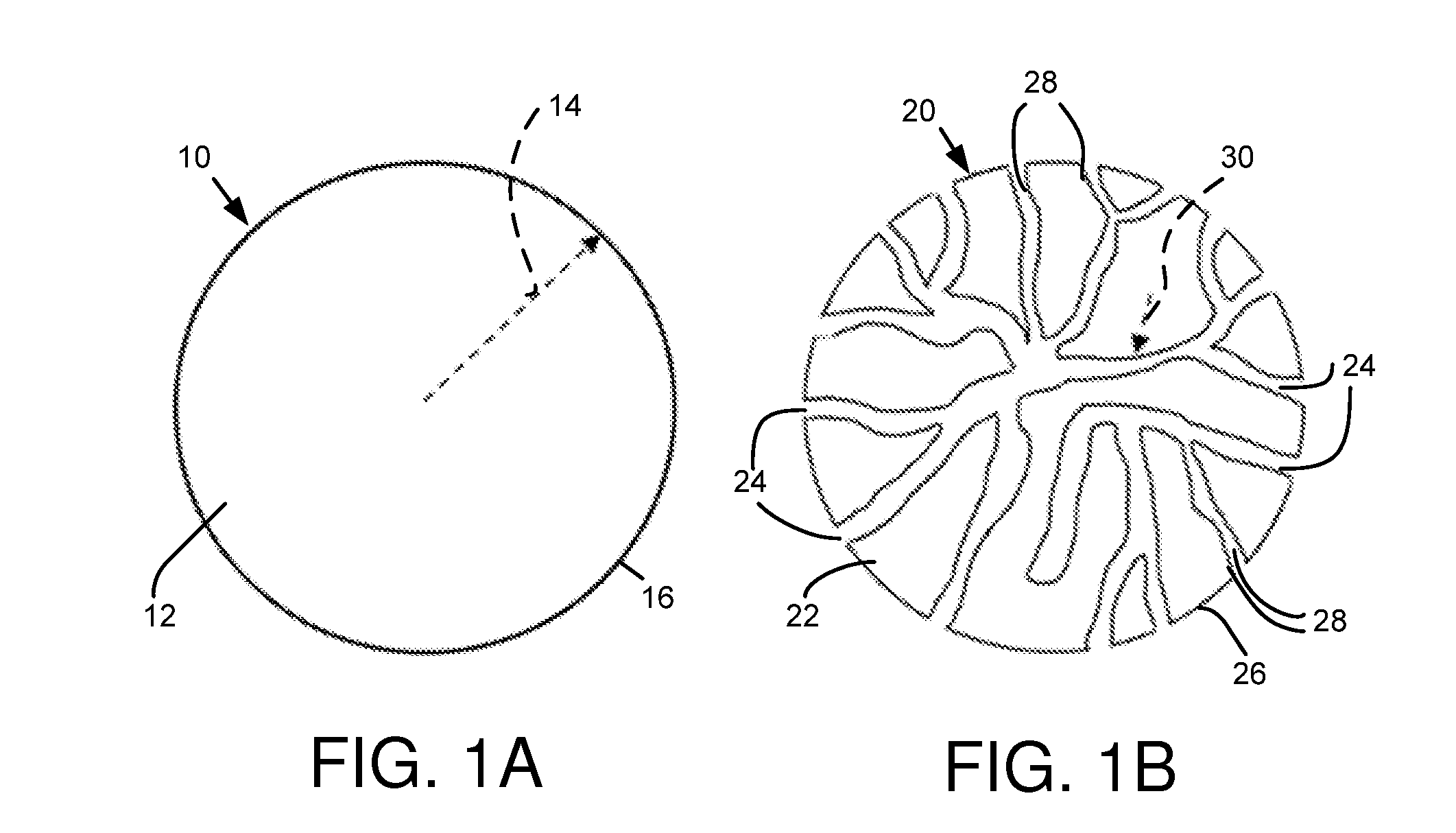

Composite battery separator

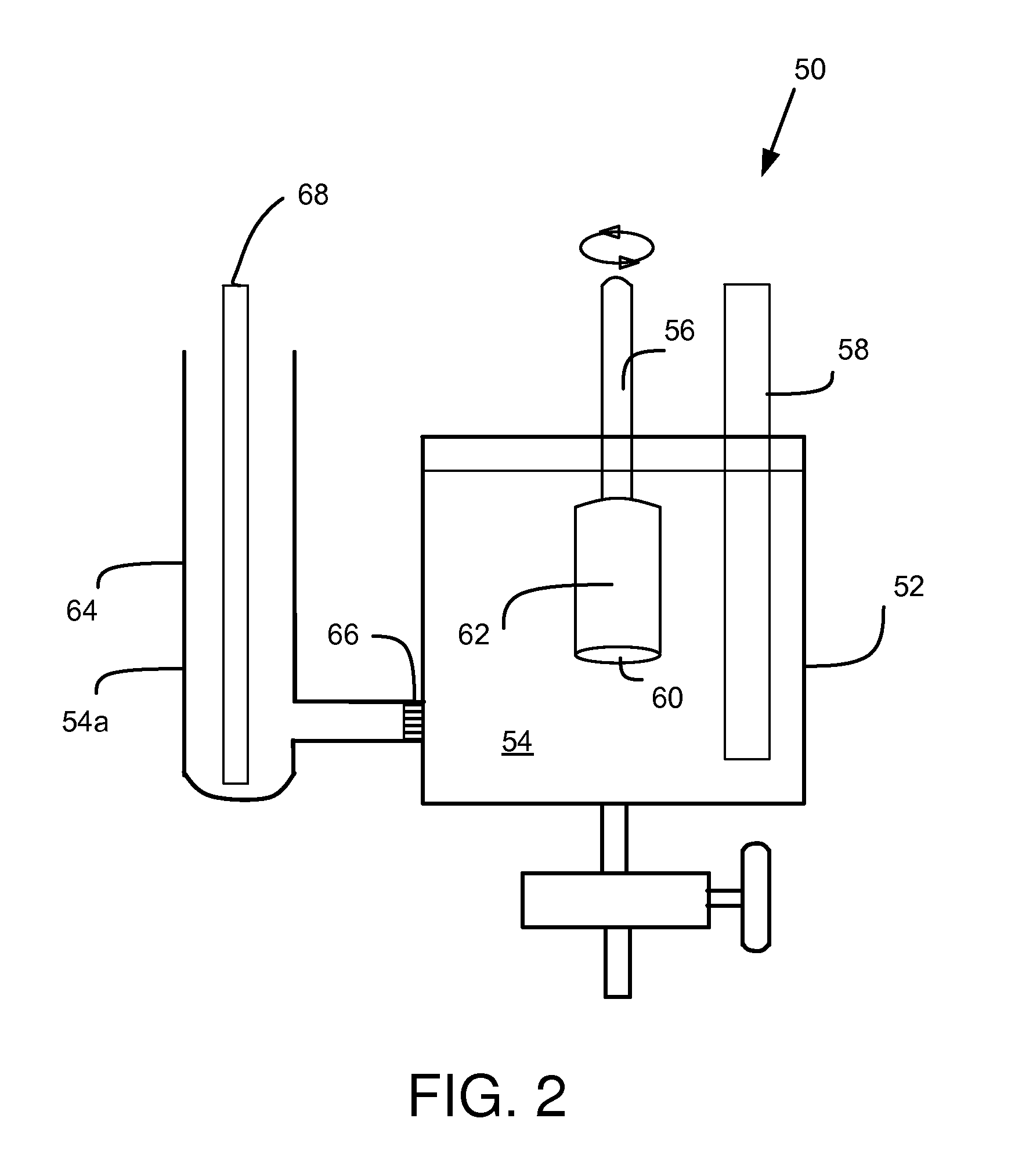

ActiveUS20120270110A1Increase resistanceDifficult and costly to produceCell seperators/membranes/diaphragms/spacersAcid electrolytesPorosityPolyolefin

A microporous silica-filled polyolefin separator (80) has a material composition that includes a fraction of cured rubber powder exhibiting low or no porosity. The cured rubber powder is a material derived from one or both of passenger and truck tires. The cured rubber powders exhibit the properties of increasing hydrogen evolution overpotential on the negative lead electrode and of decreasing the effect of antimony deposited on the negative electrode of the lead-acid battery. Incorporation of these cured rubber powders into the formulation of a microporous silica-filled polyethylene separator results in improved electrochemical properties in deep-cycle lead-acid batteries.

Owner:AMTEK RES INT

Preparation method of titanium/tilox black/lead composite substrate

ActiveCN104218245AImprove electronic conductivityImprove bindingLead-acid accumulatorsElectrode carriers/collectorsMetallurgyComposite substrate

The invention discloses a preparation method of a titanium / tilox black / lead composite substrate. The preparation method comprises the following steps of carrying out coarsening treatment on the surface of a titanium plate before lead electroplating, carrying out sintering to obtain a tilox black layer, and electroplating a lead layer on the surface by use of conductivity of tilox black so that the titanium / tilox black / lead composite substrate for a bipolar lead acid battery is obtained. The sintered tilox black layer is formed on the surface of the titanium plate so that adhesion of the electroplated lead layer and the titanium plate is improved, the electroplated lead layer is used for improvement of oxygen evolution and hydrogen evolution overpotential and increasing of strength of bonding with the active substance, and lead and the active substance form a firmly combined interface in pole plate curing. The titanium / tilox black / lead composite substrate has good electronic conductivity, is stable in the lead storage battery environment, can firmly bond with the active substance thereby forming a good electronic conductive interface, has high oxygen evolution and hydrogen evolution overpotential and high mechanical strength and is suitable as a substrate of a bipolar lead acid battery.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV +1

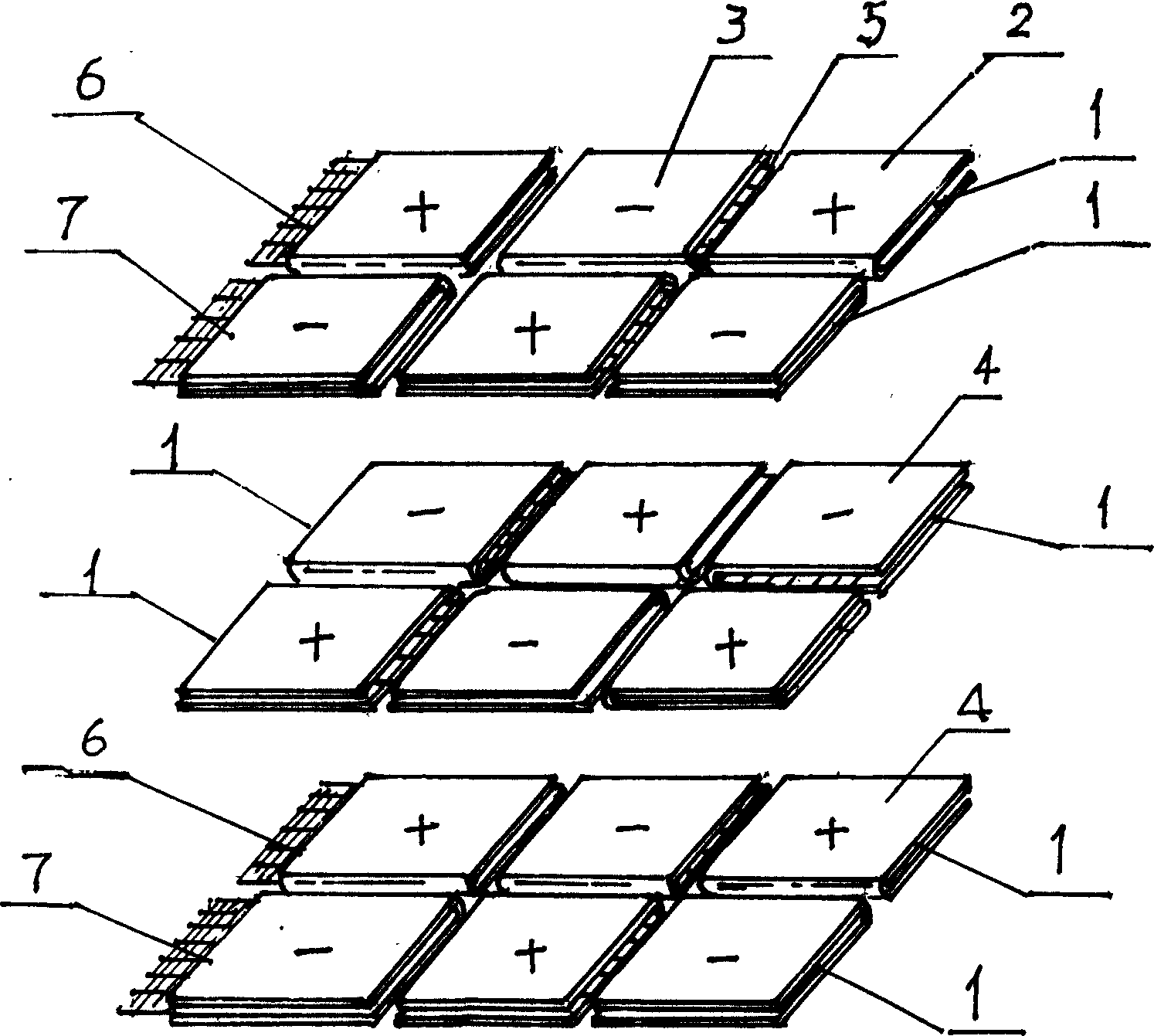

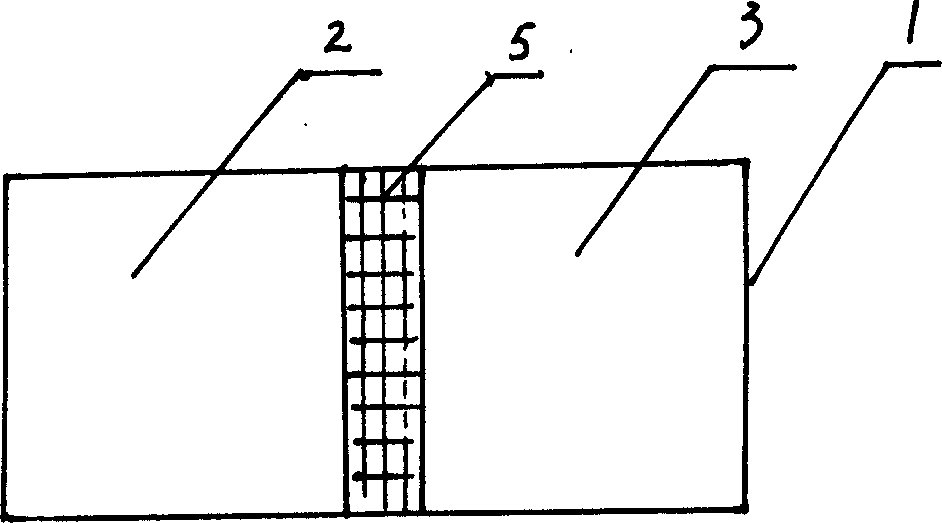

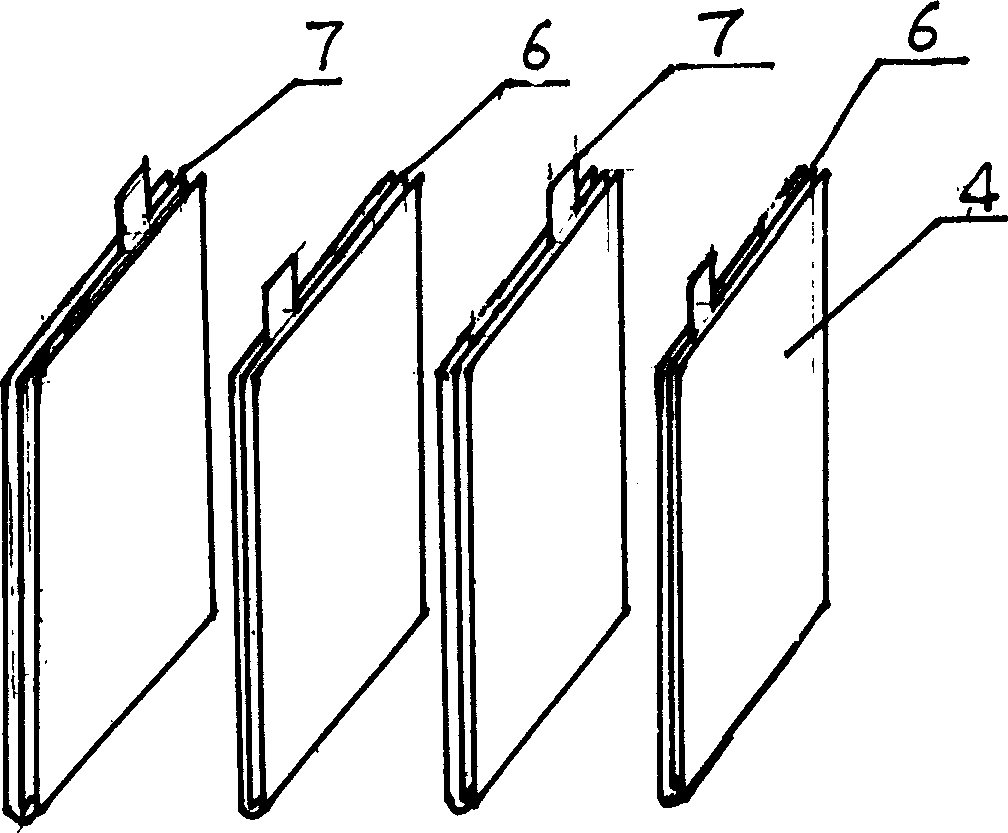

Method for making a lead fabric battery using novel lead fabric as polar plate grid

InactiveCN1501533AHigh tensile strengthSurface density error is smallFinal product manufactureElectrode carriers/collectorsMultiple formsGlass fiber

The invention discloses a process for making lead fabric battery using new pattern lead fabric material as pole plate slab lattice, wherein a physical vapour deposition or electrically-conducting paint coating - electrodeposition -heat treatment combination process is applied, in the production, the lead fabric material may be used in various forms, e.g. double pole plates, the two ends of the lead fabric are coated with positive, negative electrode lead grease, the central portion is coated with macromolecular insulation acid resisting paint, the bipolar pole plates' positive and negative electrodes are placed horizontally in an overlapping mode, a glass fiber baffle plate is arranged in the center. The structural pattern of the invention can take various types, the advantages of the invention are small internal impedance and great current charging and discharging.

Owner:钟发平

Recycling and treating method for pickling waste water of iron and steel

ActiveCN106222681AIncrease the hydrogen evolution overpotentialHigh iron recoveryPhotography auxillary processesProcess efficiency improvementIron powderWastewater

The invention discloses a recycling and treating method for pickling waste water of iron and steel. The recycling and treating method comprises the following steps of adding a cationic surfactant in the pickling waste water of the iron and the steel to obtain an electrolyzed mixed solution; electrolyzing the electrolyzed mixed solution in a diaphragm electrolytic cell, separating out high-purity iron at a cathode, and regenerating waste acid at an anode; breaking, annealing and reducing the separated high-purity iron to obtain high-purity iron powder; and enabling the waste acid regenerated at the anode to return to a pickling step of the iron and the steel for recycling. The recycling and treating method for the pickling waste water of the iron and the steel is simple in technique and high in iron recovery rate; the high-purity iron can be obtained and no secondary pollution is caused; after recycling and treatment, the acidity of the waste water is not reduced, and the pickling waste water can be regenerated for recycling; and in addition, the recycling and treating method is suitable for treating the pickling waste water of which the pH value is smaller than 2 of the iron and the steel.

Owner:ZHUZHOU SMELTER GRP

Electrolyte for super lead acid battery

InactiveCN102945981AThe hydrogen suppression modification process is simpleEfficient use ofLead-acid accumulatorsHydrogenOrganic matter

The invention provides an electrolyte formula for a super lead acid battery. The electrolyte for the super lead acid battery comprises sulfuric acid solution, hydrogen evolution inhibitor and additives, wherein the hydrogen evolution inhibitor is a mixture of one or more of metal salts, metal-ion complexes and organic matters which are capable of blocking hydrogen ions from discharging on the carbon negative electrode, raising the hydrogen evolution over potentiality of the carbon negative electrode surface of the super lead acid battery. The advantage of the electrolyte is that the hydrogen evolution inhibitor can block hydrogen ions from discharging on the carbon negative electrode, thus the hydrogen evolution over potentiality of the carbon negative electrode material of the super lead acid battery is raised, the problem of serious hydrogen evolution of the carbon negative electrode surface of the super lead acid battery is solved, and simultaneously the specific capacity of the carbon negative electrode is increased. The electrolyte disclosed herein is suitable for industrial application.

Owner:JIANGXI YONGFANG POWER CO LTD

A kind of carbon paste electrode and preparation method thereof

ActiveCN102269730AIncrease the hydrogen evolution overpotentialGood reproducibilityMaterial electrochemical variablesHydrogenCarbon paste electrode

The invention provides a carbon paste electrode. The carbon paste electrode comprises an electrode tube shell, a carbon paste filled in the electrode tube shell, and an electrode lead contacted with the carbon paste and led out from the electrode tube shell, wherein the carbon paste comprises graphite and a DNOP (di-n-octyl phthalate). The carbon paste electrode provided by the invention is low in residue current, simple in preparation method, non-toxic, easy to update the surface, low in price and wide in potential use range; the hydrogen overpotential is 200 mV higher than the carbon paste mixed by silicone oil and graphite powder and the reproducibility is good. The invention further provides a preparation method of the carbon paste electrode.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

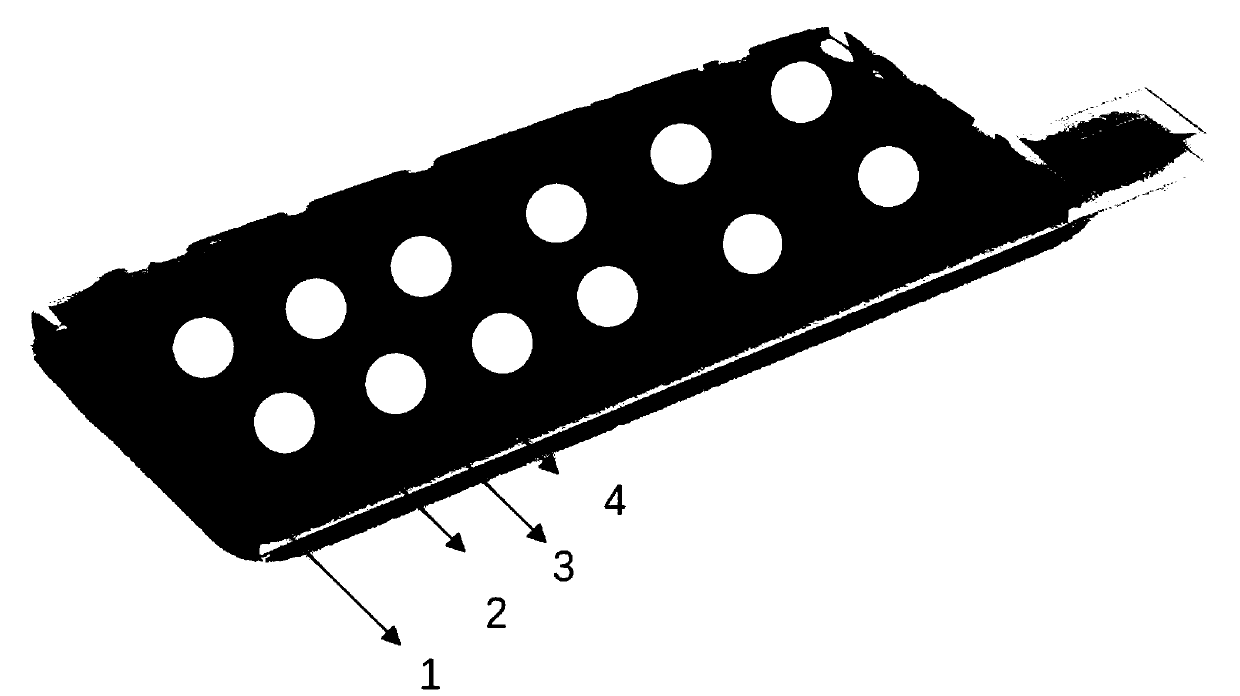

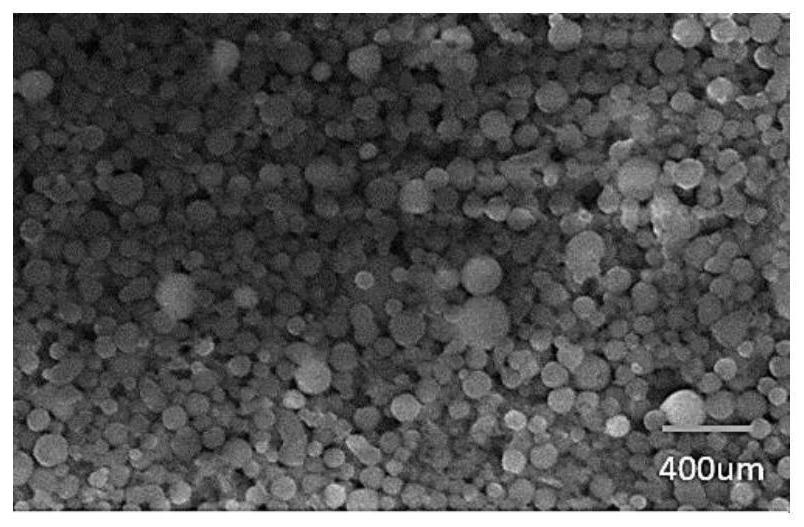

Structure of network-shaped lightweight metal zinc electrode and preparation method thereof

InactiveCN110148704AImprove cycle performanceIncrease energy densityElectrode manufacturing processesActive material electrodesFiberMass ratio

The invention relates to a structure of a network-shaped lightweight metal zinc electrode. The structure comprises a zinc base layer and a highly active layer on the base layer. The zinc base layer isat least one in the group consisting of foam zinc, a zinc mesh, a grid-shaped zinc plate, a punched zinc band or a zinc fiber fabric and has the thickness of 0.1 micrometer to 10 millimeters. The highly active layer on the base layer comprises zinc powder, conductive carbon material, additives and binders with the mass ratio of (20 to 70%): (60 to 25%): (15 to 4%): (5 to 1%) in the highly activelayer, and the thickness of the highly active layer is between 100 nanometers to 400 micrometers. The zinc powder has a spherical shape and a particle diameter of 10 nanometers to 50 micrometers, andthe mass of the zinc powder accounts for 20 to 70% of the total mass of the highly active layer. The structure has the advantages that a zinc material is used as a matrix, the self-limitation of the non-ideal complete reversibility of the zinc dissolution-deposition can be improved, therefore, a sufficient active material is provided during the large-capacity long-term circulation of a battery, and the cycle performance of the battery is improved.

Owner:浙江浙能中科储能科技有限公司

Electrolyte additive for inhibiting hydrogen evolution of negative plate for lead-acid storage battery

InactiveCN104505538ASolve the problem of increased water consumptionIncrease the hydrogen evolution overpotentialLead-acid accumulatorsHydrogenRare earth

The invention discloses an electrolyte additive for inhibiting hydrogen evolution of a negative plate for a lead-acid storage battery and a using method and application of the electrolyte additive. The additive is one or two of a rare earth compound and a fluorine-containing polymer, and the adding amount of the additive is 0.01-0.1 percent of the mass of a sulfuric acid solution. According to the electrolyte additive, the hydrogen evolution overpotential of the negative plate of different carbon-containing materials can be effectively improved, the hydrogen evolution rate is reduced, and the water loss of the battery is decreased, so that the performance of the lead-acid storage battery is improved, and the service life of the battery is prolonged. The electrolyte additive is suitable for a valve control type lead-acid storage battery and a flooded lead-acid storage battery which are produced by adopting a large quantity of carbon negative plates.

Owner:FUZHOU UNIV

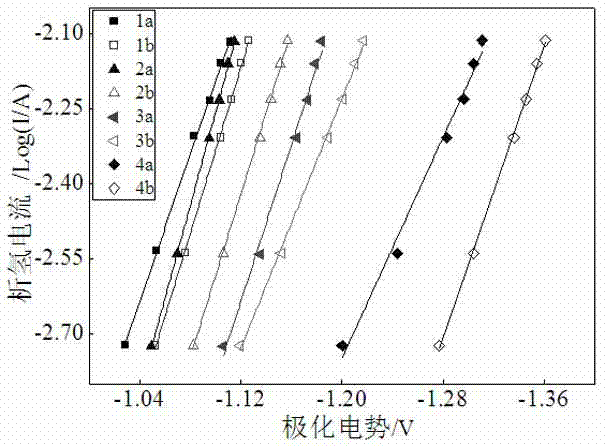

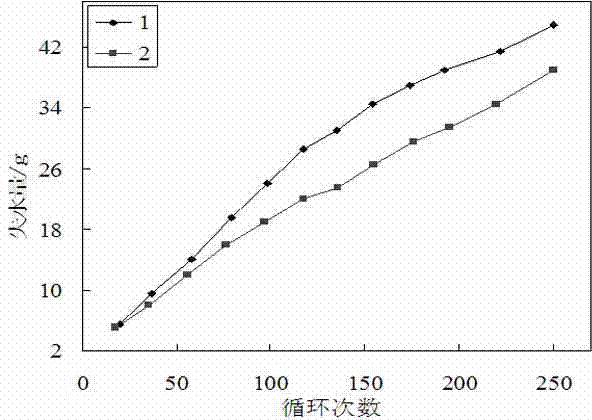

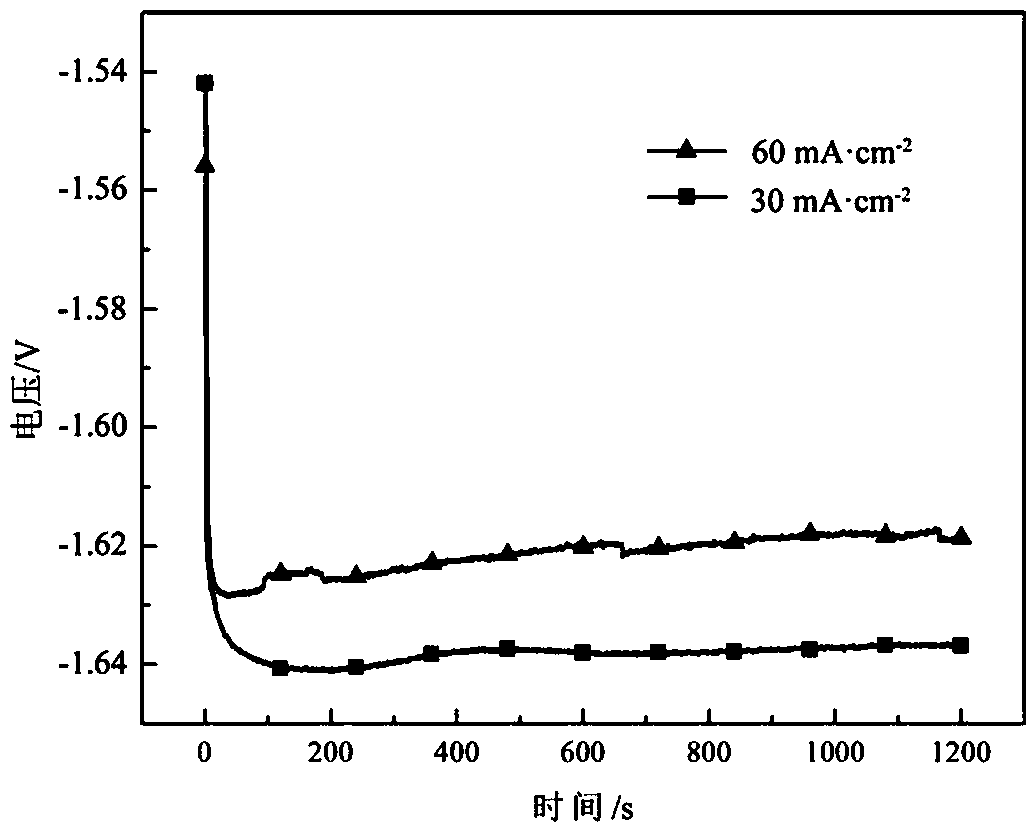

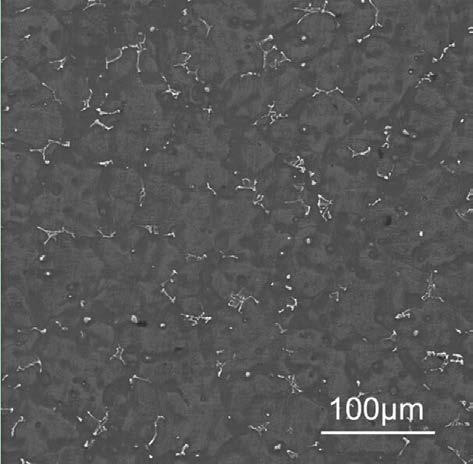

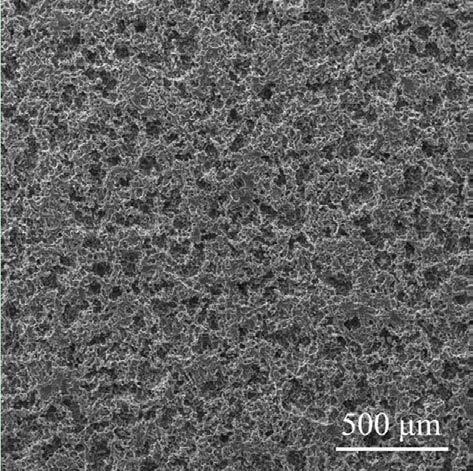

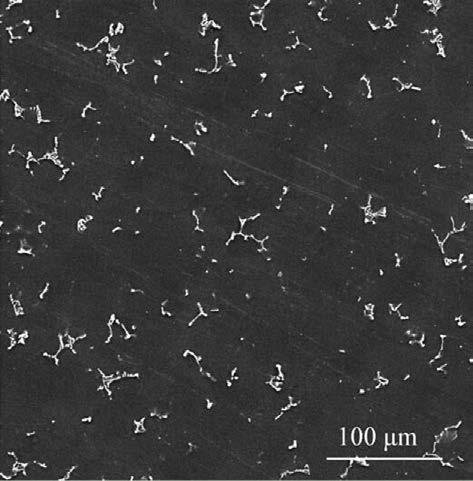

Preparation method and application of as-cast magnesium alloy anode material

InactiveCN110004340AGood casting performanceImprove mechanical propertiesFuel and primary cellsCell electrodesDischarge efficiencyElectrical battery

The invention relates to the field of anode materials of magnesium-air batteries, in particular relates to a preparation method and application of an as-cast magnesium alloy anode material. The preparation method comprises the following steps that (1) a magnesium ingot and an aluminum ingot are pre-treated separately; (2) germanium particles are pre-treated; (3) the pre-treated magnesium ingot andthe pre-treated aluminum ingot are molten; (4) the germanium particles are added after the magnesium ingot and the aluminum ingot to obtain melt, and heat preserving is conducted; and (5) the melt iscast, and cast ingots are naturally cooling to room temperature so as to obtain the as-cast magnesium alloy anode material, wherein the as-cast magnesium alloy anode material is composed of the following components of, by weight, 1-9% of Al, 1-6% of Ge and the balance magnesium. According to the magnesium alloy anode material, the anode material of the air battery with excellent comprehensive discharge performance is obtained by virtue of the synergistic effect of the alloy elements Al and Ge; and the magnesium alloy anode material has discharge potential of minus 1.589-minus 1.608V and the discharge efficiency of 64.2%-67.8% when the current density is 60 mA.cm<-2>.

Owner:TAIYUAN UNIV OF TECH

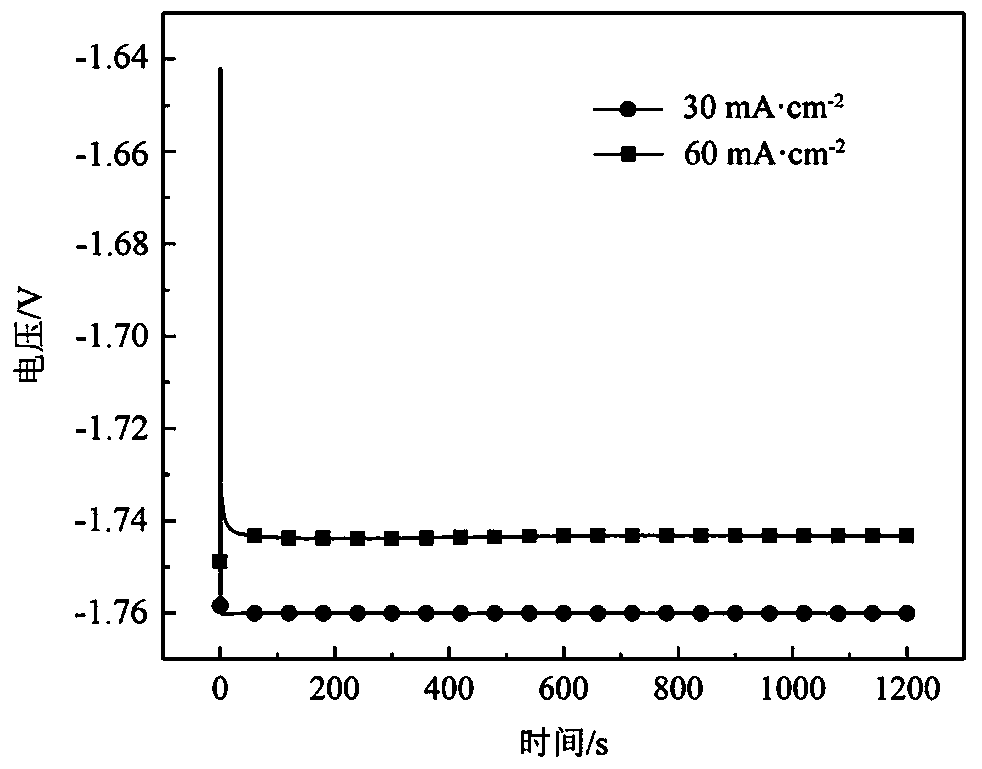

Magnesium alloy anode material and preparation method and application thereof

InactiveCN109930042AIncrease the active siteImprove discharge activityFuel and primary cellsPrimary cell electrodesDischarge efficiencySolution treatment

The invention relates to the field of magnesium alloy anode materials for magnesium air batteries, in particular to a magnesium alloy anode material and a preparation method and application thereof. The alloy anode material is composed of, by weight, 1%-9% of Al, 1%-6% of Ge and the balance magnesium. According to the magnesium alloy anode material, the air battery anode material with the excellent comprehensive discharge performance is obtained through the synergistic effect of the alloy elements including Al and Ge and solution treatment. Under the electric current density of 60 mA.cm<-2>, the average discharge potential measured through a timing potential method is between -1.726 V and -1.752 V, and the discharging efficiency reaches 70.9%-74.1%.

Owner:TAIYUAN UNIV OF TECH

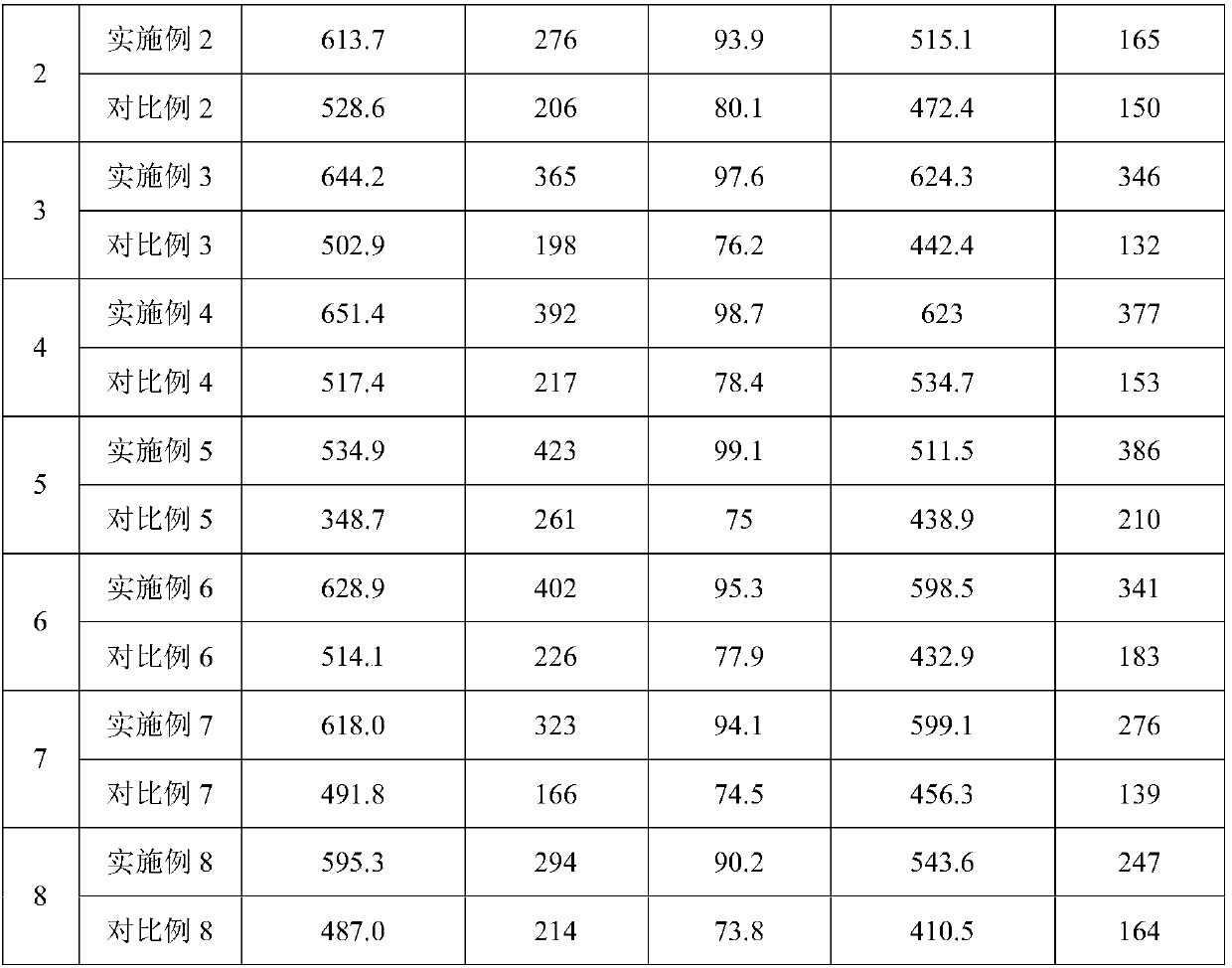

Nano composite material as well as preparation method and application thereof

ActiveCN108777293AIncrease the hydrogen evolution overpotentialReduce corrosion rateMaterial nanotechnologyCell electrodesSolventNano zinc oxide

The invention in particular relates to a nano composite material as well as a preparation method and application thereof. The nano composite material is prepared from nano zinc oxide with the granularity of 200 to 600nm and other metal nano oxide with the granularity of 10 to 30nm; in a mixture composed of the nano zinc oxide and the other metal nano oxide, the mass percent content of the nano zinc oxide is 70 percent to 95 percent, and the mass percent content of the other metal nano oxide is 5 percent to 30 percent. The preparation method of the nano composite material comprises the following steps: adding a reducing agent, and combining a solvothermal method with a rapid cooling technology to obtain a product. According to the nano composite material, a preparation technology is simple;after the obtained product is assembled to form a battery, the average specific capacity is 625mAh g<-1> after the battery is circulated for 120 circles under the multiplying power of 1C, and the coulombic efficiency reaches 94.8 percent; the product has good anticorrosion performance. By adopting the nano composite material, the anticorrosion performance of a zinc negative electrode can be improved and the marketization of zinc-based secondary batteries is facilitated.

Owner:CENT SOUTH UNIV

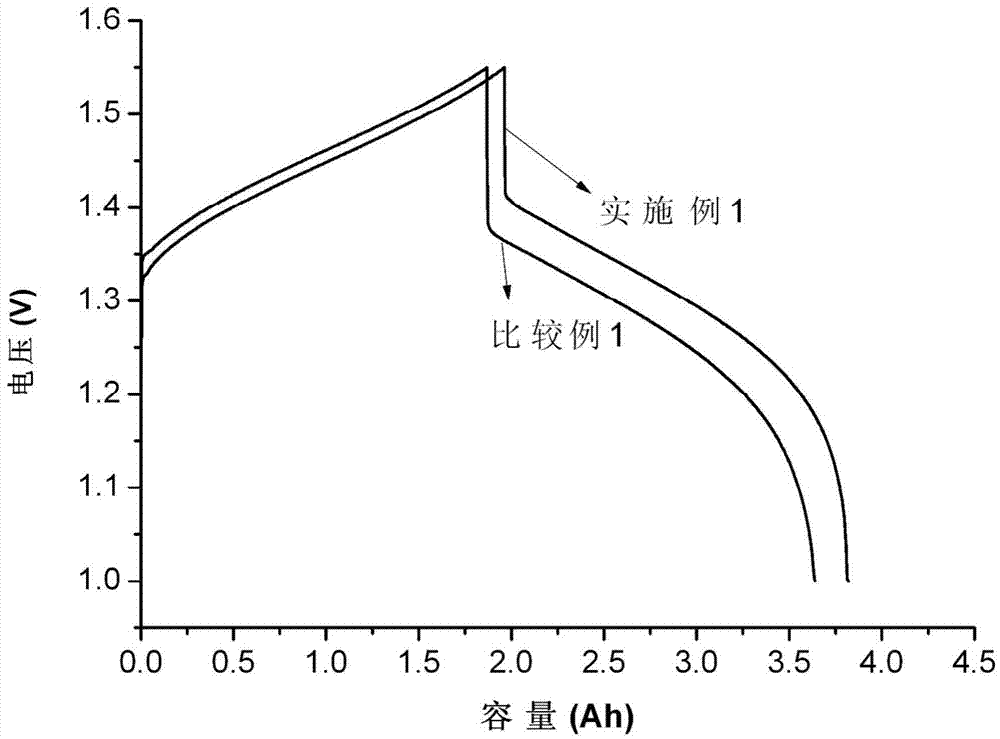

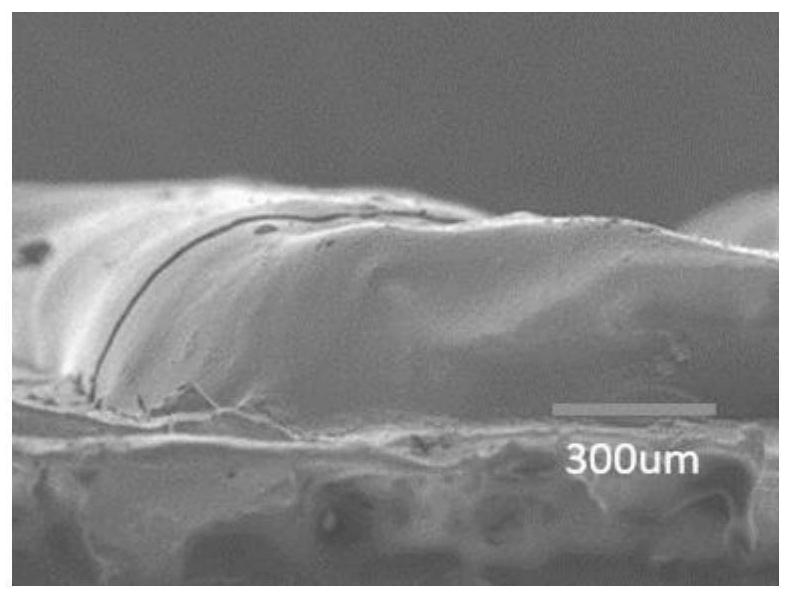

Composite negative plate of cerium and zinc redox flow cell and preparation method of plate

InactiveCN103259024AImprove conductivitySaves deposition preparation timeCell electrodesIndiumCerium

The invention provides a composite negative plate of a cerium and zinc redox flow cell and a preparation method of the plate, and belongs to the field of electrochemical cells. The composite negative plate comprises a metallic titanium plate and a surface active layer, wherein the surface active layer comprises a binding agent, an activating agent and an additive; polyvinylidene fluoride or polytetrafluoroethylene is used as the binding agent; the mixture of zinc powder and conducting material is used as the activating agent; and one or more of indium oxide, tin oxide, bismuth oxide, titanium oxide or cerium oxide is / are used as the additive; and the ratio of the binding agent to the activating agent to the additive is (5 to 15):(50 to 90):(5 to 50) in weight part. The invention also discloses a preparation method of the composite negative plate of the cerium and zinc redox flow cell. The cell assembled by the composite negative plate is subjected to charge-discharge testing through 100mA current, the number of cycles of the cell reaches more than 550, the average voltage efficiency of the cell is 88.4 percent, the average coulomb efficiency is 96.4 percent, and the average energy efficiency is 82.9 percent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

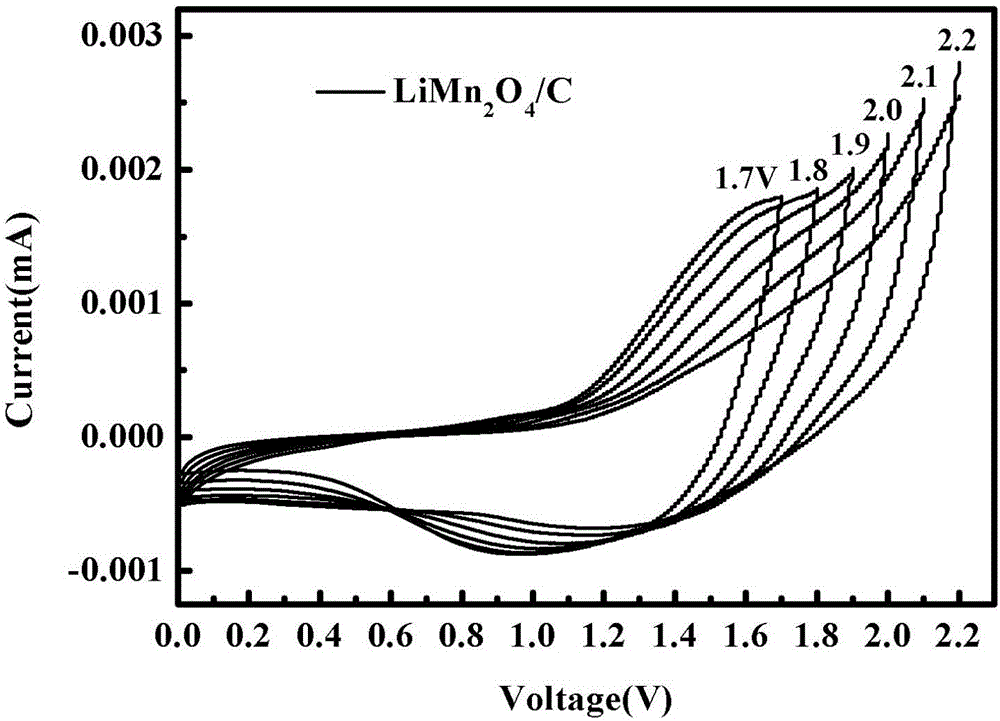

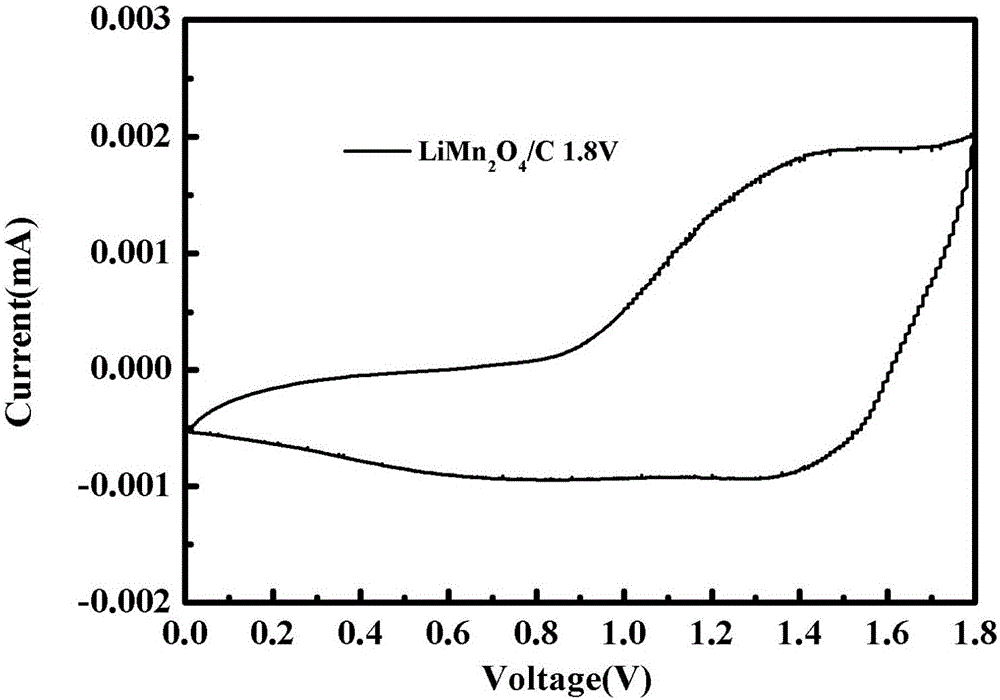

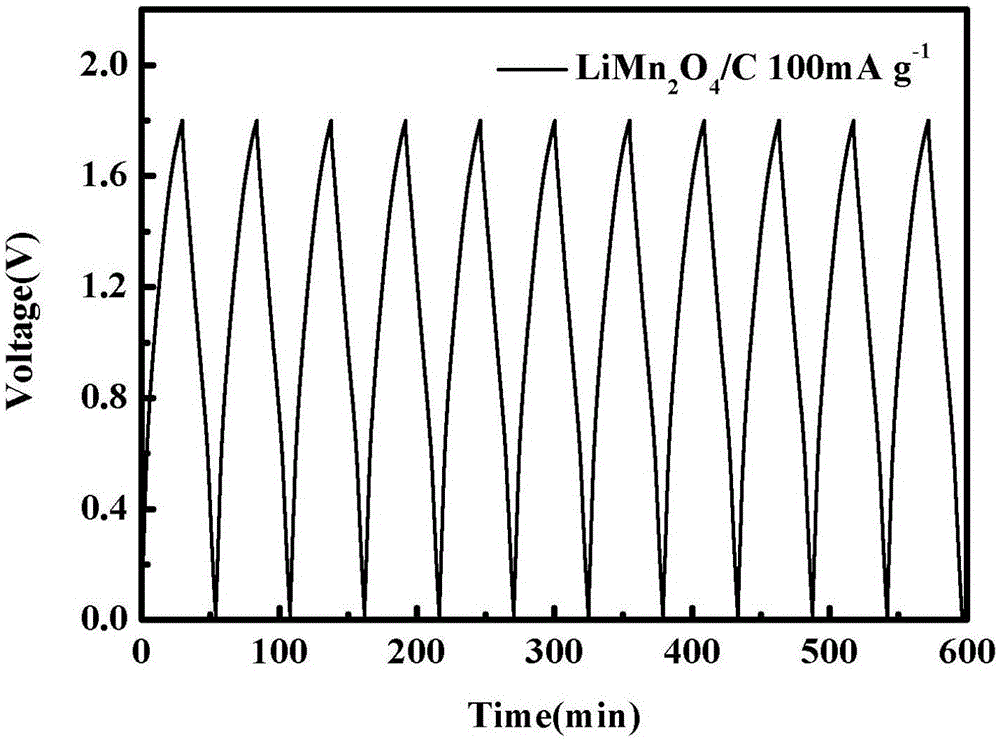

Aqueous hybrid supercapacitor and preparation method thereof

InactiveCN106206063ASolve the problems of complex structure and cumbersome preparation methodsSimple and practical structureHybrid capacitor electrodesHybrid/EDL manufactureSupporting electrolyteCopper foil

The invention provides an aqueous hybrid supercapacitor and a preparation method thereof, belongs to the technical field of energy and power electronic components, and aims at solving the problems that an existing aqueous hybrid supercapacitor is heavy and complicated in structure and the preparation method is fussy. The aqueous hybrid supercapacitor comprises a positive plate, a negative plate, a membrane between the positive plate and the negative plate and an electrolyte, wherein the positive plate is a nickel foam plate or an aluminum foil plate coated with a mixture of a lithium-containing composite metal oxide LiMxOy, a conductive agent, a binder and an oxygen inhibiting additive; the negative plate is the nickel foam plate, copper foil or a tinned steel mesh coated with another mixture of activated carbon, the conductive agent, the binder and the oxygen inhibiting additive; the membrane is a modified non-woven fabric membrane; the electrolyte is a lithium-containing neutral aqueous solution and a conductive support electrolyte; and the conductive support electrolyte is a potassium ion-containing neutral aqueous solution. The structure and the components of the aqueous hybrid supercapacitor are simple and practical; and the preparation method is simple and easy, and is suitable for preparation of the aqueous hybrid supercapacitor.

Owner:代相臣

Electrolyte additive for hydrogen evolution suppression of lead-acid storage battery and preparation method for electrolyte additive

ActiveCN104064816AIncrease the hydrogen evolution overpotentialIncrease the negative electrode hydrogen evolution overpotentialLead-acid accumulatorsPolyaspartic acidSulfuric acid

The invention relates to an electrolyte additive for hydrogen evolution suppression of a lead-acid storage battery. The additive contains polyaspartic acid, sulfate, succinic acid and ethylenediamine tetraacetic acid disodium; each liter of electrolyte of the lead-acid storage battery contains 1,500-2,000mg / L of polyaspartic acid, 1,000-1,200mg / L of sulfate, 1,500-2,000mg / L of succinic acid, 3,000-6,000mg / L of ethylenediamine tetraacetic acid disodium and the rest of a sulfuric acid. The succinic acid and the polyaspartic acid are mixed according to a certain ratio to form a sulfuric acid electrolyte additive; under the adsorption action of the succinic acid and the crystal refining action of the polyaspartic acid, the negative electrode hydrogen evolution overpotential of the lead-acid storage battery is increased, the electrochemical performance of the battery is improved, and the cycle service life of the battery is prolonged.

Owner:ANHUI YONGHENG STORAGE BATTERY

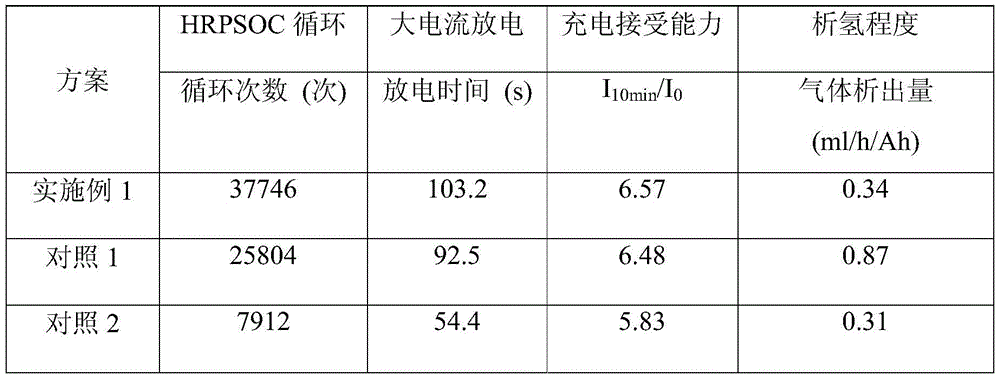

Negative electrode of lead-carbon battery and preparation and application thereof

InactiveCN109841833ALow costLower internal resistanceLead-acid accumulatorsLead-acid accumulator electrodesFiberBattery charge

The invention relates to a negative electrode of a lead-carbon battery. The negative electrode contains 0.1-50wt% of modified carbon fibers, and the modified carbon fibers are obtained by activating and then poisoning carbon fibers. The cost of the lead-carbon battery is reduced, the internal resistance of the battery is reduced by a conductive network structure in a negative plate, the sulfationof the battery is effectively inhibited, the water loss during the cycle life process of the lead-carbon battery is reduced, the hydrogen evolution overpotential is improved, the high-rate partial state of charge (HRPSOC) of the lead-carbon battery in some nuclear power states is extended, and the battery charge acceptance ability and low temperature start performance are enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Modified zinc oxide and preparation method and application thereof

The invention relates to modified zinc oxide and a preparation method and application thereof, in particular to a zinc negative electrode material for an alkaline zinc-air secondary battery, and belongs to the field of an air battery. The modified zinc oxide comprises a zinc oxide inner core, a first coating layer and a second coating layer, wherein the first coating layer is coated on the zinc oxide inner core, the second coating layer is coated on the first coating layer, the material of the first coating layer is C, and the material of the second coating layer is a titanium sub-oxide. The preparation method of the modified zinc oxide comprises the steps of growing a layer of phenolic resin on a surface of zinc oxide in an in-situ way; coating a layer of titanium-based organic-inorganicmixed gel; and performing reaction at 760-880 DEG C to obtain the product with the designed structure. When the product is used as a zinc negative active material of the alkaline zinc-air secondary battery, the product shows excellent electrochemical performance. The material is reasonable in structural design, the preparation process is simple, the obtained product has favorable performance, andindustrial application on a large scale is convenient.

Owner:CENT SOUTH UNIV

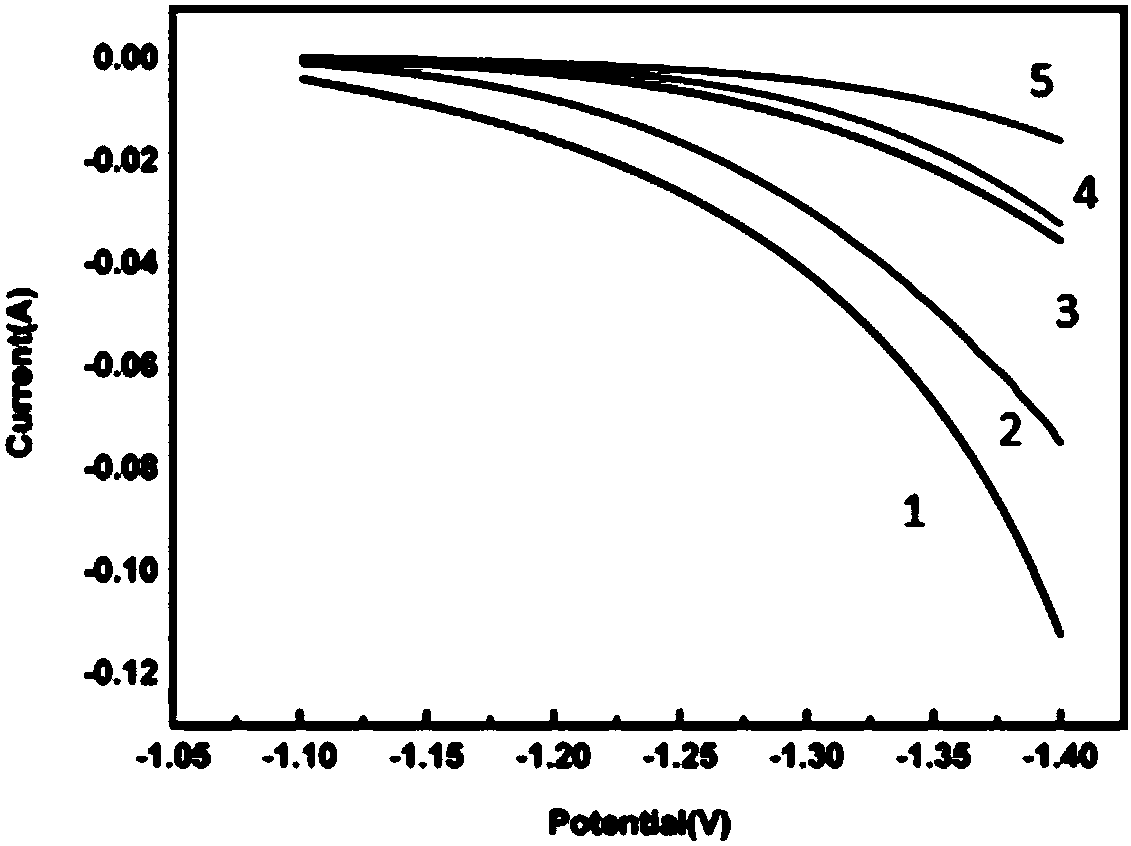

Preparation method of carbon-based additive used for lead-carbon negative electrode

ActiveCN107742696AIncrease the hydrogen evolution overpotentialInhibition of hydrogen evolution reactionFinal product manufactureLead-acid accumulator electrodesHigh rateState of charge

The invention discloses a preparation method of a carbon-based additive used for a lead-carbon negative electrode, and belongs to the technical field of lead-carbon battery manufacturing. A lead layeron the surface of the carbon-based additive used for the lead-carbon negative electrode prepared through carbon material sensitization, activation and chemical lead plating is uniform and compact indistribution, the hydrogen evolution overpotential of carbon material can be obviously improved, and the hydrogen evolution reaction of the negative electrode of a lead acid battery is inhibited; andthe compatibility of carbon material and lead is promoted, so that a good lead and carbon connecting structure is constructed. The high rate part state-of-charge (HRPSoC) simulation test charge-discharge cycles of the lead acid battery with the negative electrode containing the carbon-based additive used for the lead-carbon negative electrode can reach 10555 circles, and is 11 times of that of a contrast lead acid battery. According to the preparation method, sulfation of the negative electrode of the part state-of-charge (PSoC) can be inhibited obviously, and the cycle life of the lead acid battery is prolonged.

Owner:吉林省凯禹电化学储能技术发展有限公司

Multifunctional negative material and application thereof in all-vanadium redox flow battery

InactiveCN105322194AExtend working lifeIncrease the hydrogen evolution overpotentialCell electrodesRegenerative fuel cellsOver potentialElectrical battery

The invention discloses a multifunctional negative material. A carbon material is taken as a matrix; the surface of the material is modified by an electrocatalyst containing Pb; the electrocatalyst containing the Pb is one / two or more of a Pb simple substance, PbO<2> or lead sulfate; and the deposit rate of the electrocatalyst containing the Pb on the matrix is 0.05wt% to 80wt% of that of the multifunctional negative material. The electrode is applicable to a negative electrode of an all-vanadium redox flow battery; the electrocatalytic activity and the electrochemical reversibility of the electrode material on a V<2+> / V<3+> redox reaction can be improved; the charge transfer resistance is reduced; the multifunctional negative material has high hydrogen evolution over-potential; a hydrogen evolution reaction can be inhibited; the service lifetime of the battery is prolonged; and the charge and discharge capacity of the battery can also be improved. According to the multifunctional negative material, the voltage efficiency and the energy efficiency of the all-vanadium redox flow battery are improved, so that the working current density of the all-vanadium redox flow battery is improved; and the weight, the size and the cost of the battery with the same output power are greatly reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

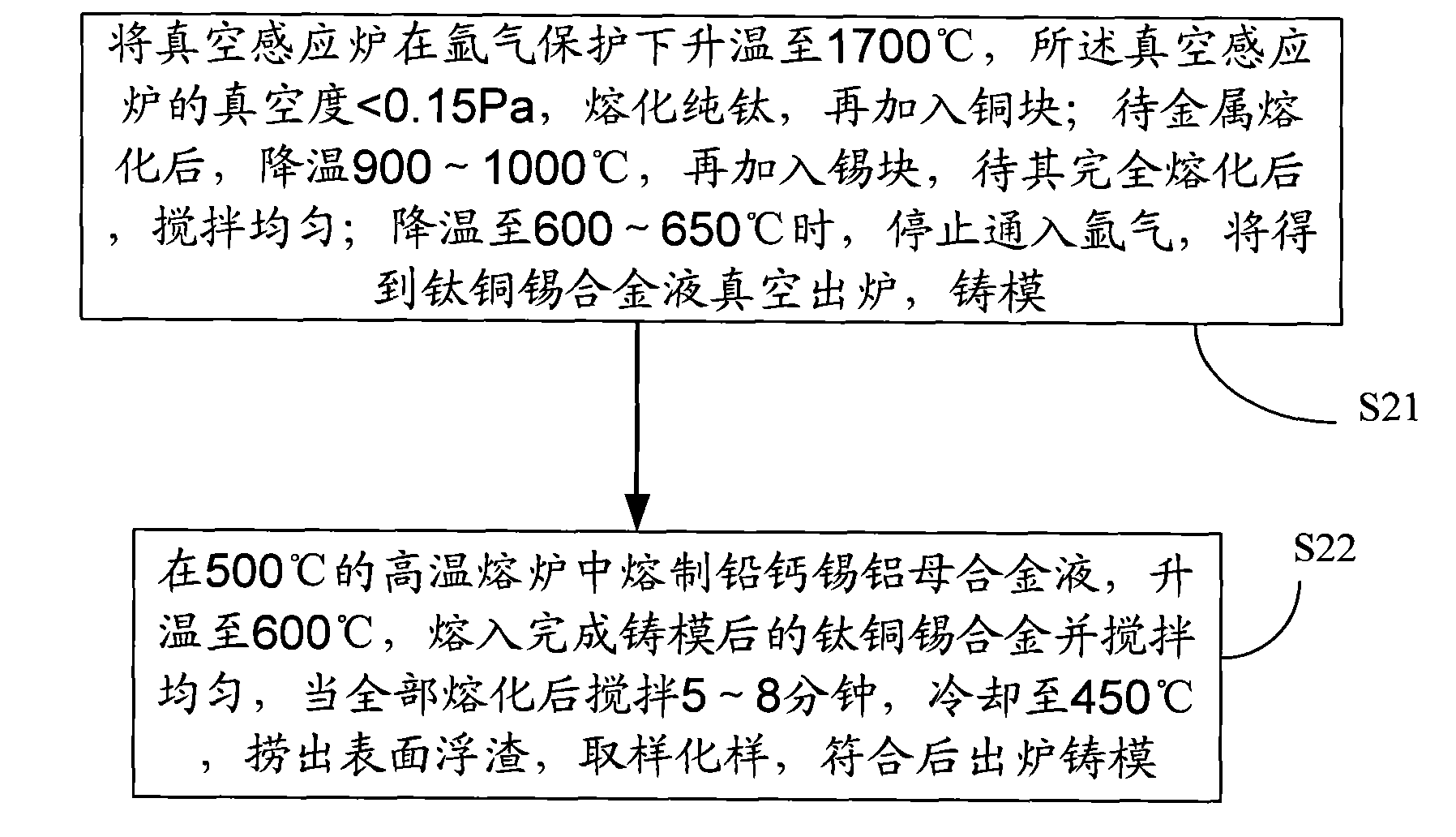

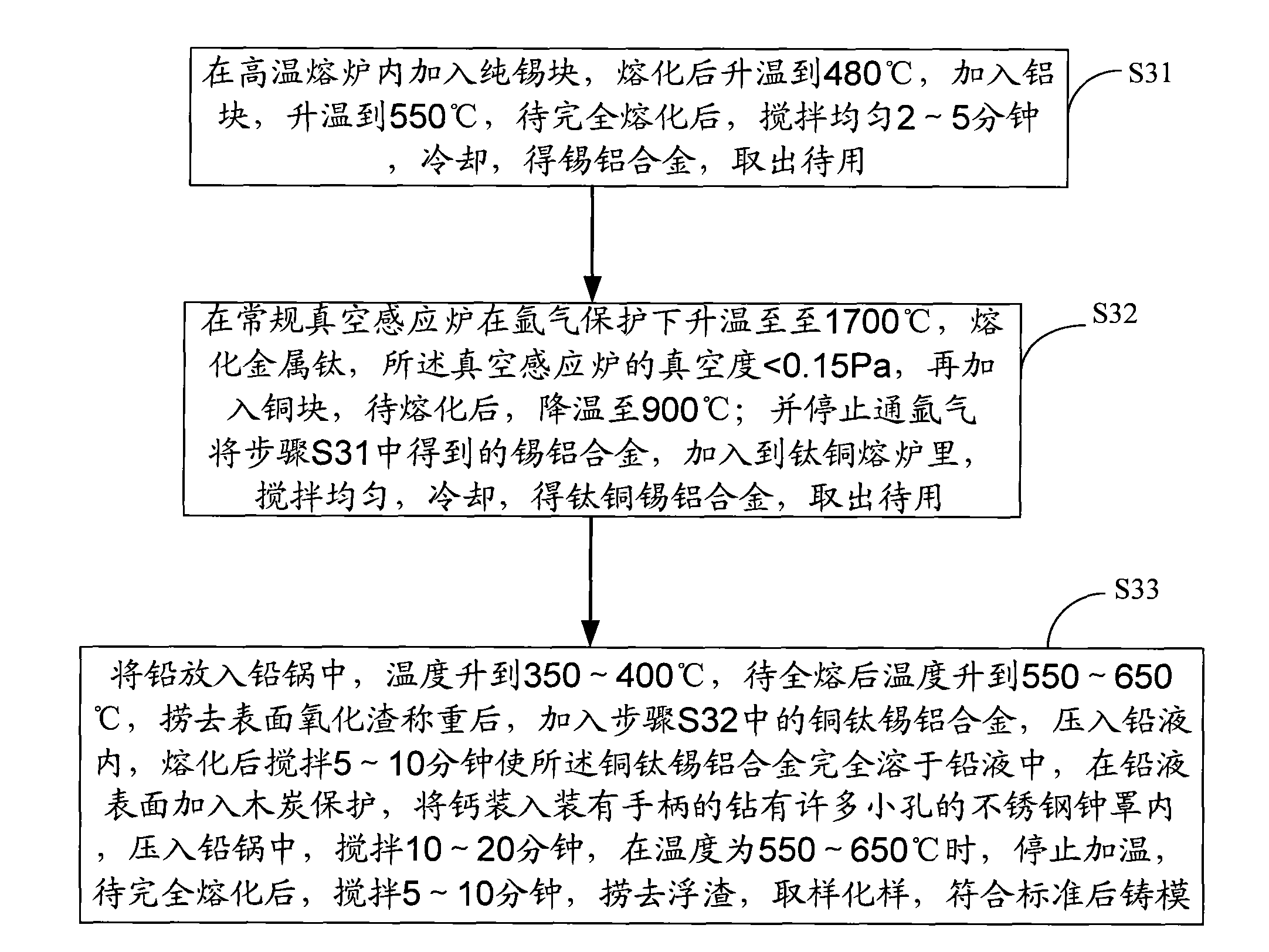

Grid alloy and manufacturing method and applications thereof

InactiveCN101662027AImprove corrosion resistanceIncrease the hydrogen evolution overpotentialLead-acid accumulatorsElectrode carriers/collectorsGrid alloyTitanium

The invention provides a grid alloy and a manufacturing method and applications thereof, the alloy comprises lead (Pb), calcium (Ca), tin (Sn), aluminum (Al), titanium (Ti) and copper (Cu), and the contents thereof by weight percent are as follows: Ca: 0.06-0.09%, Sn: 0.05-0.9%, Al: 0.005-0.053%, Ti: 0.00225-0.068%, Cu: 0.0045-0.176%, Pb: the balance, the purity of the Ti is 99.9%, and the sum ofthe weight percent of all the parts is 100%. The invention provides the titanium-containing grid alloy and the manufacturing method and the applications thereof, and the grid alloy has the advantagesof good corrosion resistance and very high hydrogen overpotential.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Aluminum air battery aluminum anode slurry for 3D printing and preparation method and application thereof

InactiveCN112820875AHigh porosityIncrease the hydrogen evolution overpotentialFuel and primary cellsAdditive manufacturing apparatusAluminum anodeAlcohol

The invention discloses aluminum air battery aluminum anode slurry for 3D printing and a preparation method and application thereof. The slurry comprises metal mixed powder and slurry, the ratio of the metal mixed powder to the slurry is 1g:(0.3-1.2) mL, the slurry comprises an antioxidant, a dispersing agent, an organic solvent and an organic adhesive, the metal mixed powder comprises Sn, In, Mg and the balance Al with the purity larger than or equal to 99.99%, and the metal mixed powder comprises Al with the purity larger than or equal to 99.99%. The viscosity of the slurry is 1-100 Pa.s; and the preparation method of the slurry comprises the following steps: (1) taking metal powder, and mixing and ball-milling the metal powder and absolute ethyl alcohol; (2) drying the ball-milled mixed solution until the alcohol is completely volatilized to obtain dried metal mixed powder; and (3) adding an antioxidant, a dispersing agent, an organic solvent and an organic adhesive into the dried metal mixed powder for ball milling, and obtaining slurry. The slurry can be applied to an aluminum anode of a 3D printing aluminum air battery. The slurry can increase the porosity of the anode, reduces the self-corrosion of the aluminum anode, is stable in performance, and improves the utilization rate of the anode.

Owner:南京信息工程大学滨江学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com