Preparation method of carbon-based additive used for lead-carbon negative electrode

An additive and carbon-based technology, applied in lead-acid battery electrodes, battery electrodes, lead-acid batteries, etc., can solve the problems of severe hydrogen evolution reaction, uneven lead-carbon materials and pastes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

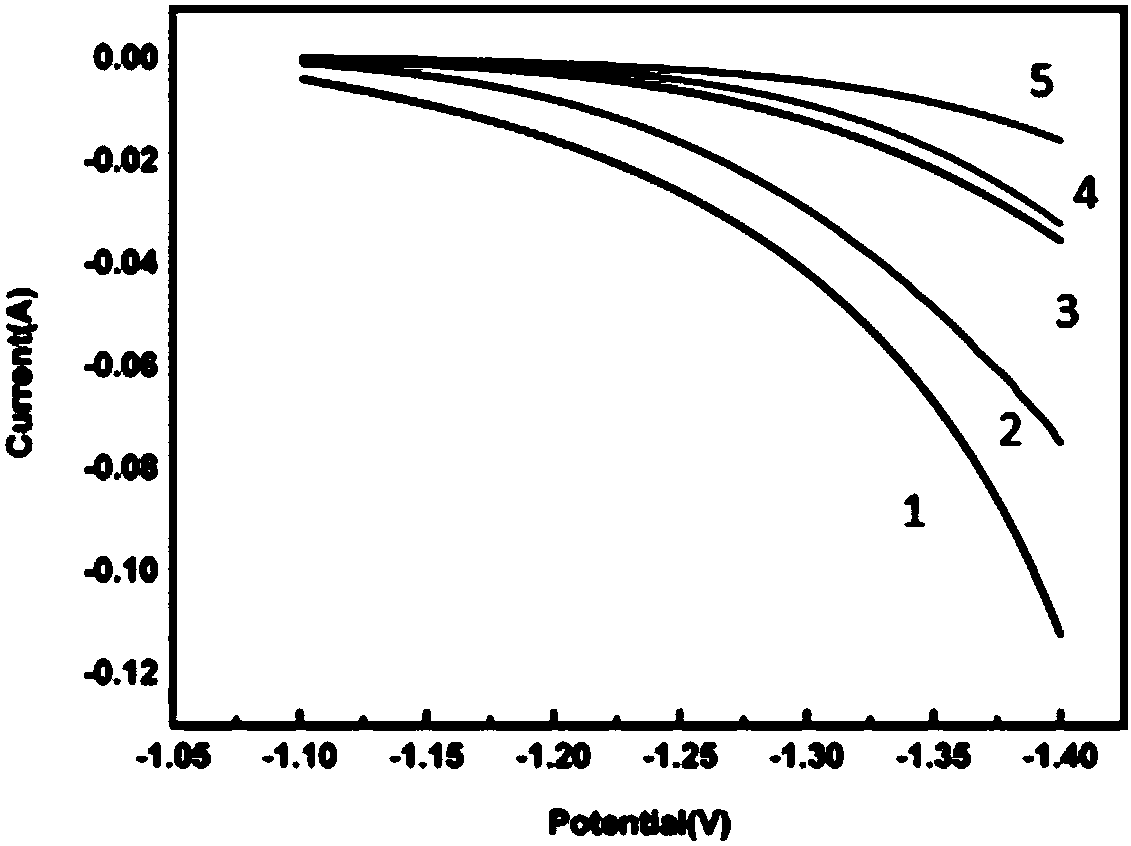

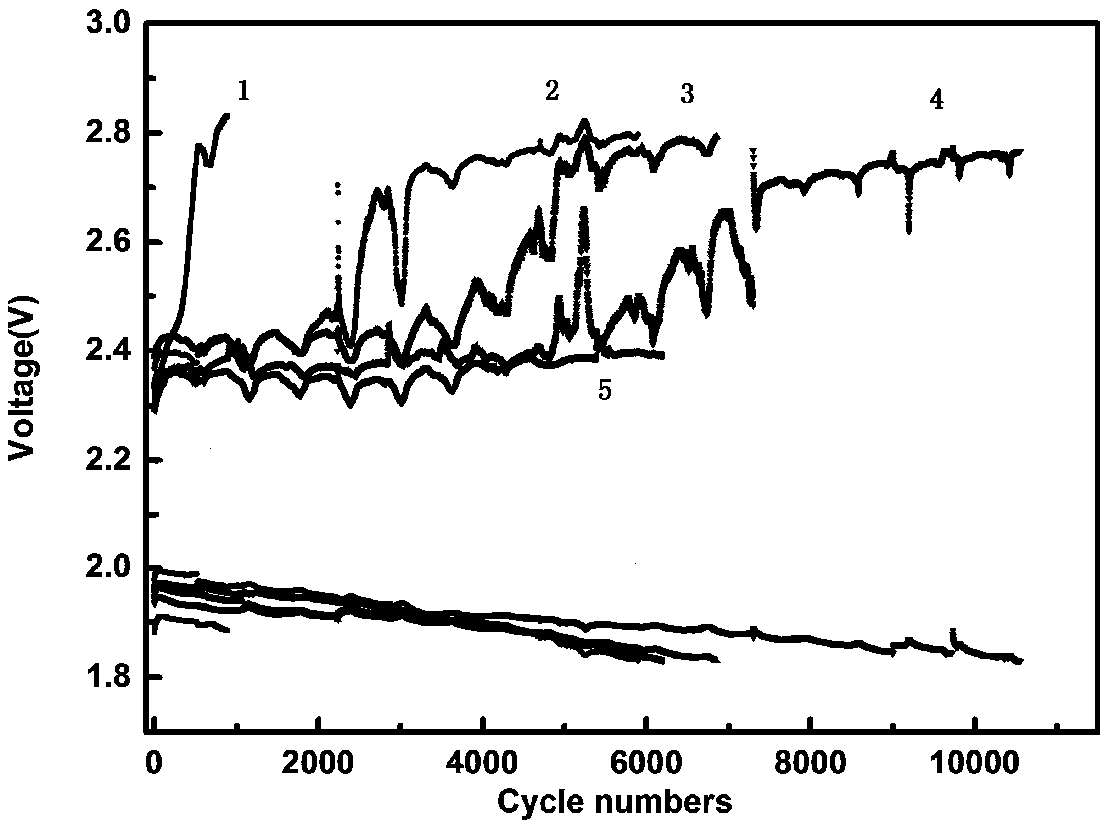

[0025] Take 3g of activated carbon, infiltrate in 20mL, 10wt.% sulfuric acid, wash and filter, then infiltrate, wash and filter with deionized water. Add 20mL of the treated carbon material, 5wt.% tin protochloride solution, stir for 1 hour, wash and filter, add 10mL, 0.0625wt.% palladium chloride solution, stir for 1 hour, wash, filter, and the treated The carbon material was put into 20mL DMSO solution containing 1.1g of thiourea and 4.8g of lead nitrate, and reacted at 60°C for 2 hours. Filter and dry overnight at 80°C to obtain a lead-carbon negative electrode carbon-based additive with a lead plating amount of 1.17wt.%.

[0026] Weigh 1Kg of lead powder, 1.3g of short fiber, 10g of barium sulfate, 2g of humic acid, 2g of sodium lignosulfonate, 3g of acetylene black and 20g of lead-carbon negative electrode carbon-based additives, dry mix for 30min, and then quickly add primary water 120mL, stirred for 10min, slowly added 58.86mL of 1.41g / mL sulfuric acid and stirred for ...

Embodiment 2

[0030] Take 3g of graphite, infiltrate in 20mL, 10wt.% sulfuric acid, wash and filter, then infiltrate, wash and filter with deionized water. Add 20mL of treated carbon material, 8wt.% stannous chloride solution, stir for 1 hour, wash and filter, add 10mL, 0.0725wt.% palladium chloride solution, stir for 1 hour, wash and filter, and the treated The carbon material was put into 20mL DMSO solution containing 2.2g thiourea and 9.6g lead nitrate, and reacted at 60°C for 2 hours. Filter and dry overnight at 80°C to obtain a lead-carbon negative electrode carbon-based additive with a lead plating amount of 2.11wt.%.

[0031]Weigh 1Kg of lead powder, 1.3g of short fiber, 10g of barium sulfate, 2g of humic acid, 2g of sodium lignosulfonate, 3.5g of acetylene black and 20g of lead-carbon negative electrode carbon-based additives, dry mix for 30min, and then quickly add a 120mL of water, stirred for 10min, slowly added 58.86mL of 1.41g / mL sulfuric acid and stirred for 30min, coated the...

Embodiment 3

[0035] Take 3g of activated carbon, infiltrate in 20mL, 10wt.% sulfuric acid, wash and filter, then infiltrate, wash and filter with deionized water. Add 20mL of the treated carbon material, 10wt.% tin protochloride solution, stir for 1 hour, wash and filter, add 10mL, 1wt.% palladium chloride solution, stir for 1 hour, wash and filter, and the treated carbon The material was put into 20mL DMSO solution containing 3.3g thiourea and 14.4g lead nitrate, and reacted at 60°C for 2 hours. Filter and dry overnight at 80°C to obtain a lead-carbon negative electrode carbon-based additive with a lead plating amount of 2.93wt.%.

[0036] Weigh 1Kg of lead powder, 1.3g of short fiber, 10g of barium sulfate, 2g of humic acid, 2g of sodium lignosulfonate, 4g of acetylene black and 20g of lead-carbon negative electrode carbon-based additives, dry mix for 30min, and then quickly add primary water 125mL, stirred for 10min, slowly added 58.86mL of 1.41g / mL sulfuric acid and stirred for 30min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com