Negative electrode of lead-carbon battery and preparation and application thereof

A lead-carbon battery and negative electrode technology, which is applied in the field of electrochemical power supply, can solve the problems of affecting the service life of lead-acid batteries and the decrease of battery capacity, so as to enhance charge acceptance and low-temperature starting performance, reduce water loss, and avoid uneven mixing problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

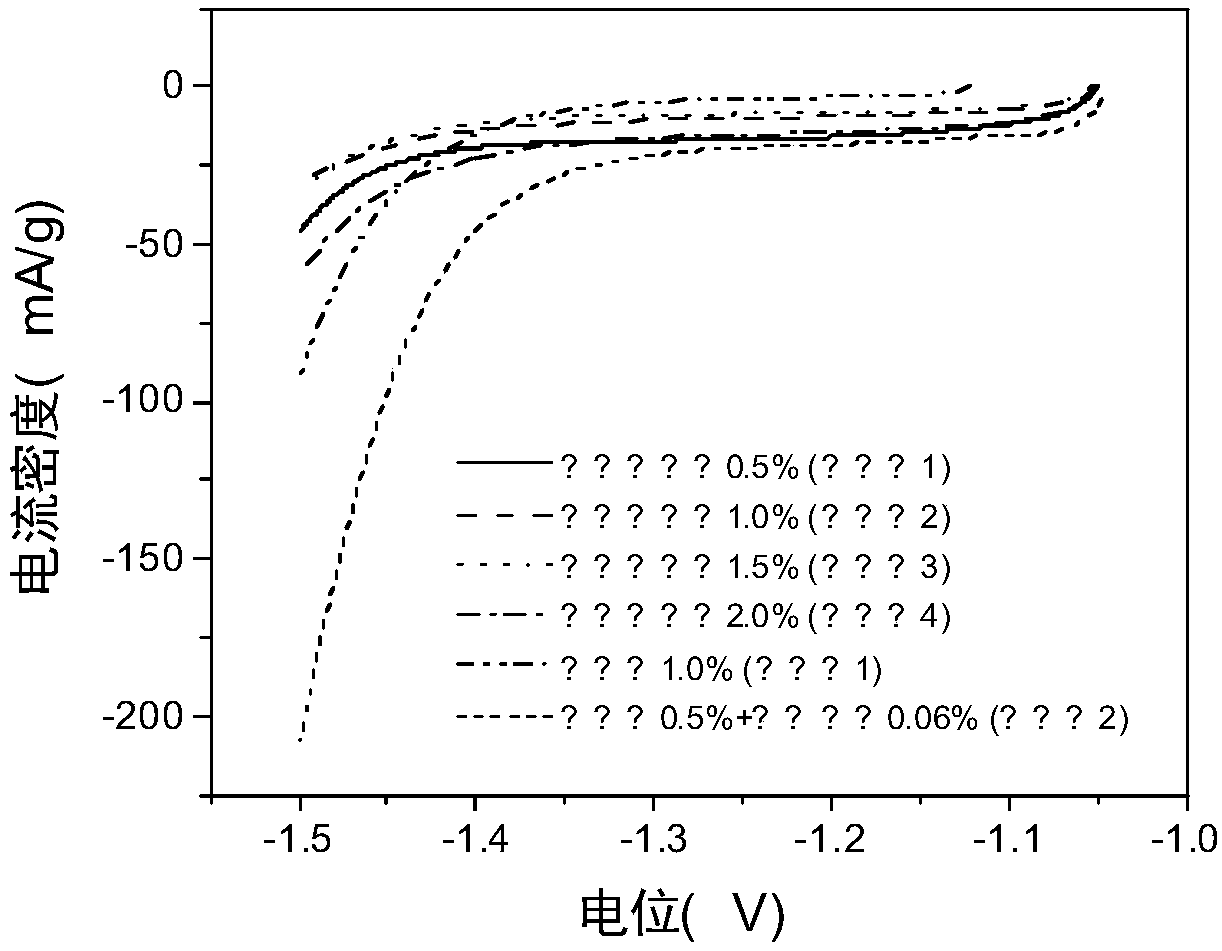

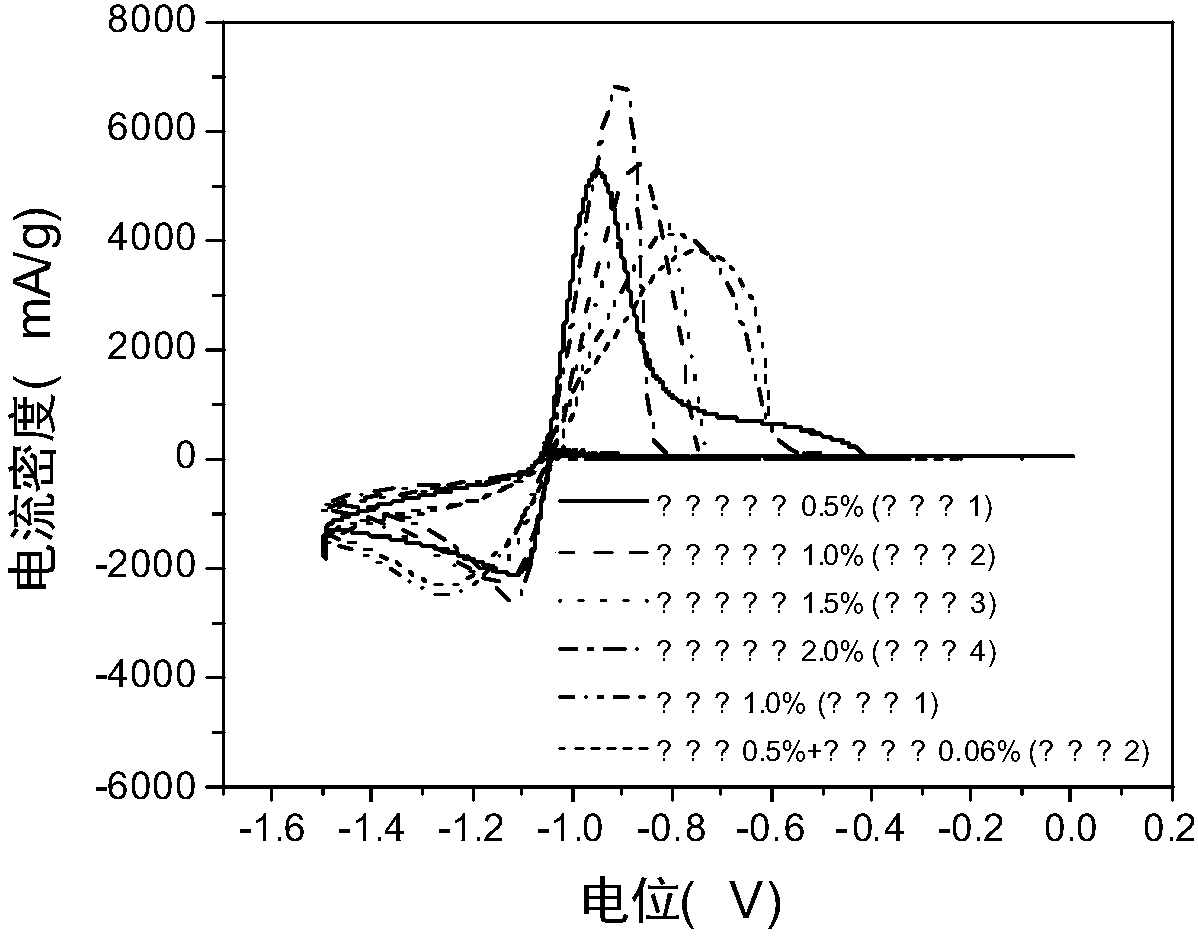

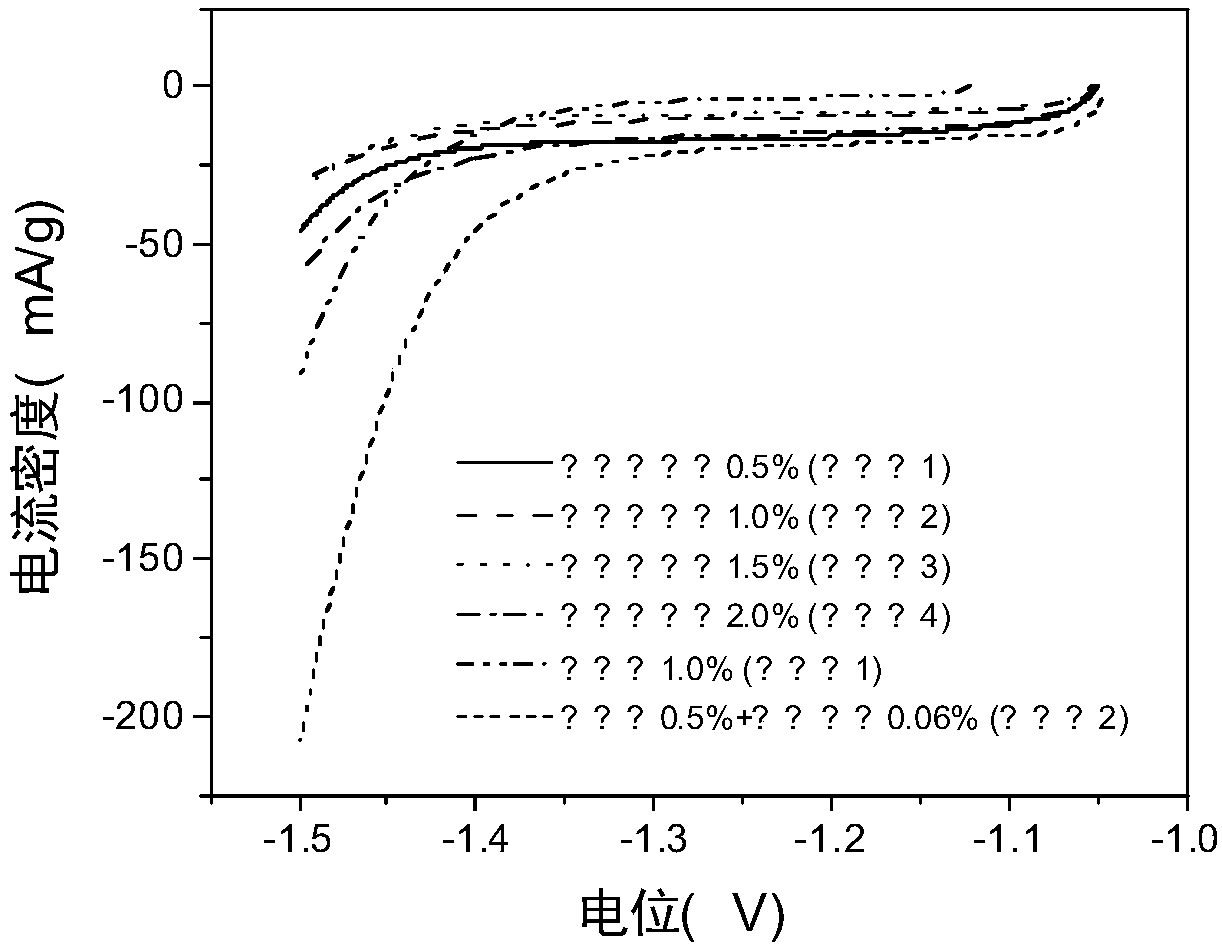

Embodiment 1

[0024] Put 10g of carbon fiber into CO 2 Burn in a gas furnace at 800°C for 6 hours; then mix the activated carbon fibers with 0.2g of lead nitrate evenly, and then undergo poisoning treatment at 300°C for 1 hour under an inert atmosphere to obtain poisoned carbon fibers. Weigh 100g of lead powder, additives (1.2g of barium sulfate, 0.2g of lignin), and 0.5g of modified carbon fiber, and pour them into the container of a paste machine for 5 minutes, so that all components are fully mixed to obtain a mixture. Add 10g deionized water to the mixed powder, stir for 5 minutes, then slowly add the density 1.2g / cm 3 10g of sulfuric acid was stirred evenly to obtain negative electrode lead paste. The obtained lead-carbon battery negative electrode paste is directly coated on the negative electrode grid, rolled and acid-leached, and then placed in a humidity-controllable high-low temperature box for curing and drying procedures, and cured at 45°C and 95% relative humidity for 36 hours...

Embodiment 2

[0026] Put 10g of carbon fiber into CO 2 Burn in a gas furnace at 800°C for 6 hours; then mix the activated carbon fibers with 0.2g of lead nitrate evenly, and then undergo poisoning treatment at 300°C for 1 hour under an inert atmosphere to obtain poisoned carbon fibers. Weigh 100 g of lead powder, additives (1.2 g of barium sulfate, 0.2 g of lignin), and 1.0 g of modified carbon fiber and pour them into the container of a paste machine and dry mix them for 5 minutes to fully mix the components to obtain a mixture. Add 10g deionized water to the mixed powder, stir for 5 minutes, then slowly add the density 1.2g / cm 3 10g of sulfuric acid was stirred evenly to obtain negative electrode lead paste. The obtained lead-carbon battery negative electrode paste is directly coated on the negative electrode grid, rolled and acid-leached, and then placed in a humidity-controllable high-low temperature box for curing and drying procedures, and cured at 45°C and 95% relative humidity for ...

Embodiment 3

[0028] Put 10g of carbon fiber into CO 2 Burn in a gas furnace at 800°C for 6 hours; then mix the activated carbon fibers with 0.2g of lead nitrate evenly, and then undergo poisoning treatment at 300°C for 1 hour under an inert atmosphere to obtain poisoned carbon fibers. Weigh 100 g of lead powder, additives (1.2 g of barium sulfate, 0.2 g of lignin), and 1.5 g of modified carbon fiber and pour them into a paste machine container for 5 minutes to dry mix each component thoroughly to obtain a mixture. Add 10g deionized water to the mixed powder, stir for 5 minutes, then slowly add the density 1.2g / cm 3 10g of sulfuric acid was stirred evenly to obtain negative electrode lead paste. The obtained lead-carbon battery negative electrode paste is directly coated on the negative electrode grid, rolled and acid-leached, and then placed in a humidity-controllable high-low temperature box for curing and drying procedures, and cured at 45°C and 95% relative humidity for 36 hours , dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com