Multifunctional negative material and application thereof in all-vanadium redox flow battery

An all-vanadium redox flow battery and negative electrode material technology, which is applied in the direction of regenerative fuel cells, battery electrodes, circuits, etc., can solve the problems of being unsuitable for large-scale applications, reducing hydrogen evolution, and high electrode costs, so as to improve electrocatalytic activity and electrochemical performance. Effects of reversibility, suppression of hydrogen evolution, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A certain size of graphite felt was impregnated in 0.02MPb(NO 3 ) 2 HNO 3 solution, after ultrasonic dispersion for 30 min, take it out, put it in a drying oven at 105 ° C for 10 h, and then put the loaded Pb(NO 3 ) 3 The graphite felt was heated to 600°C in a nitrogen atmosphere, and H 2 Constant temperature reaction 1h, Pb 2+ It was reduced to Pb, then cooled to room temperature under a nitrogen atmosphere, and weighed using an electronic balance to determine that the mass ratio of Pb loading was 2%.

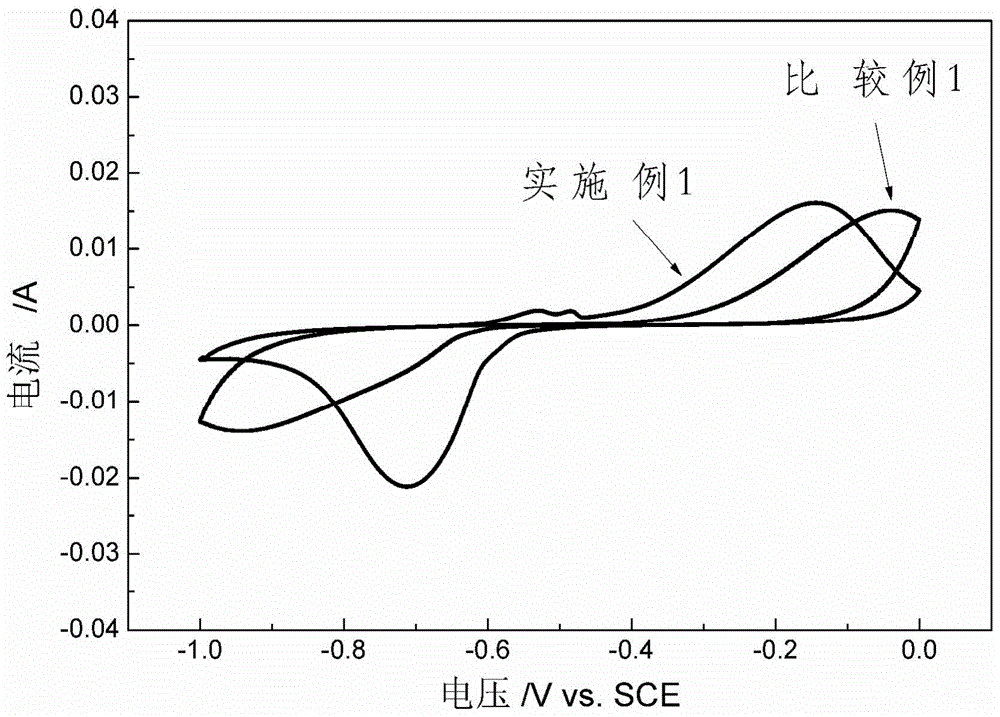

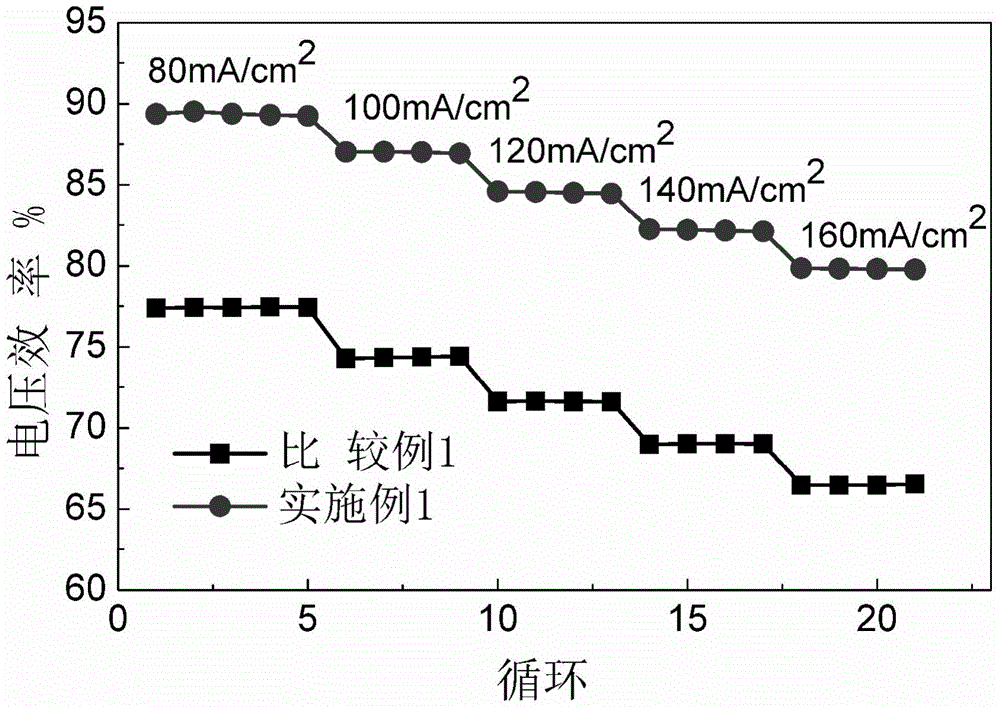

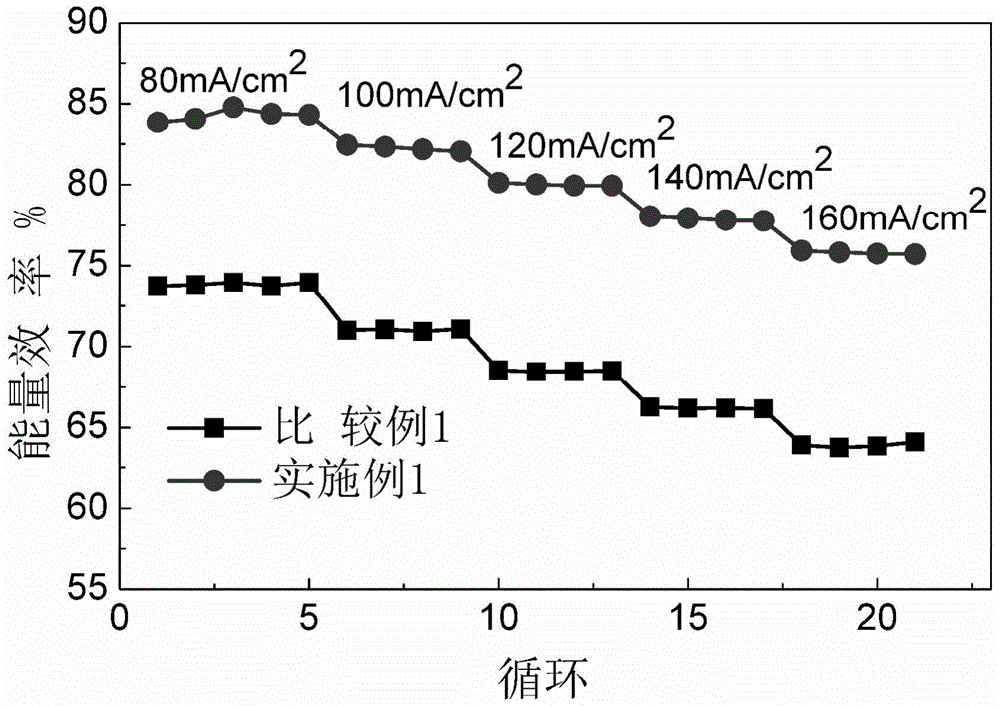

[0040] In order to test the electrochemical activity of the vanadium ion redox couple on the surface of the Pb-modified graphite felt, a cyclic voltammetry test was carried out on the Pb-modified graphite felt prepared in Example 1. Pb-modified graphite felt was used as the working electrode, a non-porous graphite plate was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. The electrochemical testing instrument us...

Embodiment 2

[0045] Immerse a certain size of carbon felt in a 0.05M lead acetate aqueous solution, ultrasonically disperse it for 30 minutes, take it out, put it in a drying oven at 100°C and dry it for 10 hours, then raise the temperature of the carbon felt loaded with lead acetate to 600°C in a nitrogen atmosphere, pass Enter H 2 Constant temperature reaction 2h, Pb 2+ It was reduced to Pb, then cooled to room temperature under a nitrogen atmosphere, and weighed using an electronic balance to determine that the mass ratio of Pb loading was 5%. The negative electrode material not only has high electrocatalytic activity, can reduce the electrochemical polarization of the liquid flow energy storage battery, increase the working current density of the battery, but also improve the charge and discharge capacity of the battery.

[0046] The single cell assembly evaluation conditions are the same as in Example 1, and the difference from Example 1 is that the all-vanadium redox flow battery us...

Embodiment 3

[0048] A certain size of carbon paper was impregnated in 0.1MPb(NO 3 ) 2 HNO 3 solution, after ultrasonic dispersion for 30 min, take it out, put it in a drying oven at 105 ° C for 10 h, and then put the loaded Pb(NO 3 ) 2 The carbon paper was heated to 600°C in a nitrogen atmosphere, and H 2 Constant temperature reaction for 1h, so that Pb(NO 3 ) 2 It was decomposed and reduced to Pb, then cooled to room temperature, and weighed using an electronic balance to determine that the mass ratio of Pb loading was 10%. The negative electrode material not only has high electrocatalytic activity, can reduce the electrochemical polarization of the liquid flow energy storage battery, increase the working current density of the battery, but also improve the charge and discharge capacity of the battery.

[0049] The single cell assembly evaluation conditions are the same as in Example 1, and the difference from Example 1 is that the all-vanadium redox flow battery using Pb-modified c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com