Aluminum air battery aluminum anode slurry for 3D printing and preparation method and application thereof

An aluminum-air battery, 3D printing technology, applied in electrode manufacturing, battery electrodes, electrode extrusion, etc., can solve problems such as hydrogen precipitation, battery corrosion discharge, battery voltage drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

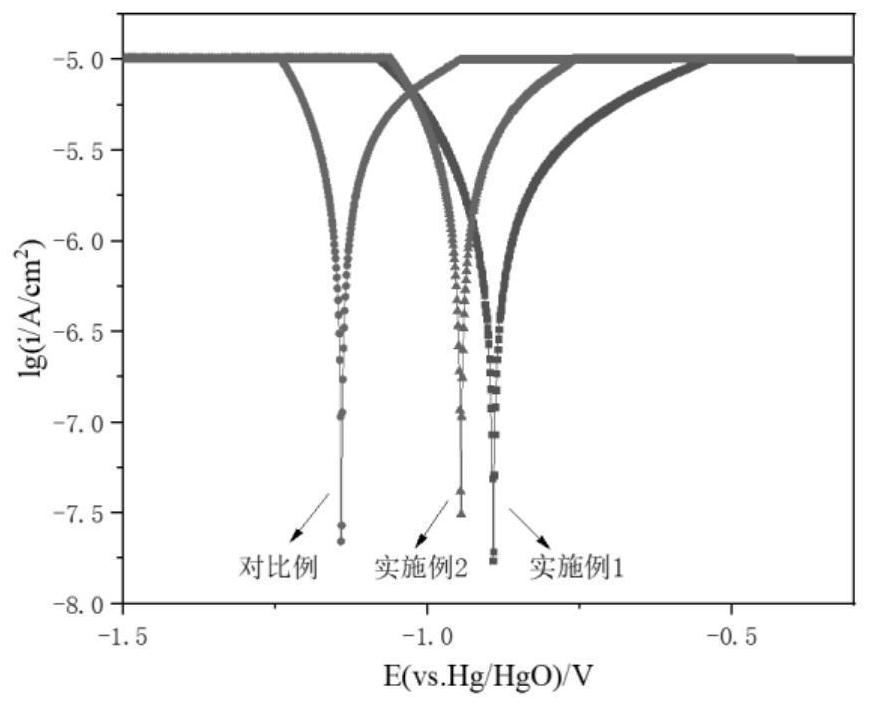

Embodiment 1

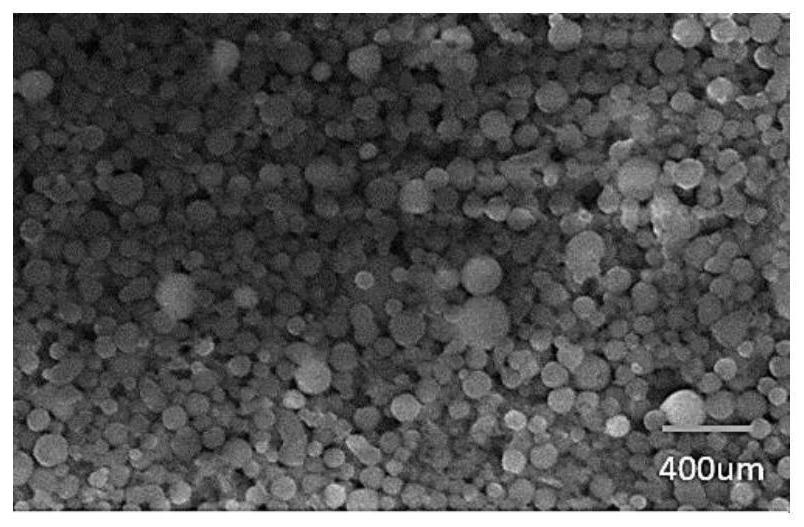

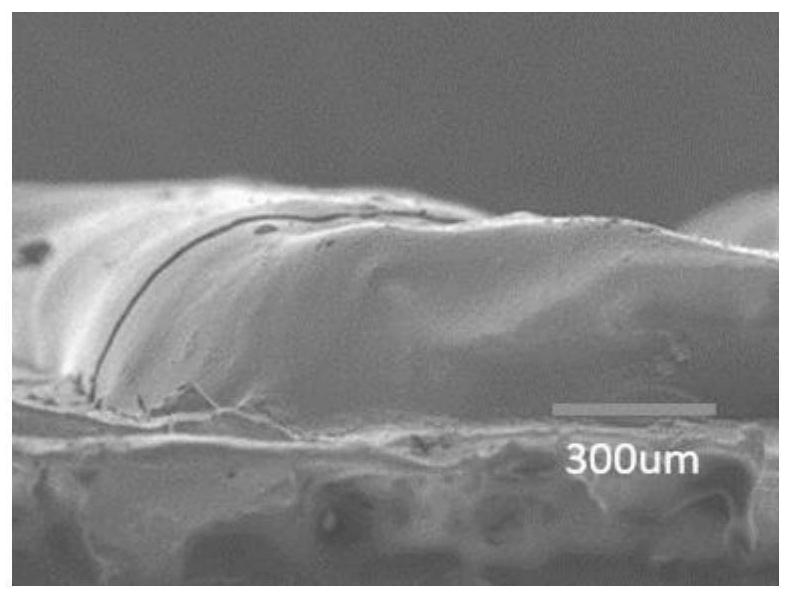

[0020] (1) Take a metal powder with a particle size of 50-100 μm and 1 kg, the mass percentages are as follows: 0.25% Sn, 0.25% In, 0.6% Mg, and the balance is Al with a purity of ≥99.99%, mix the metal powder with 1000 mL of absolute ethanol Mixed in a ball mill jar, using Si with a diameter of 10mm 3 N 4 balls, milled for 8h at a speed of 800r / min;

[0021] (2) placing the ball-milled mixed solution in a constant temperature water bath at 80°C and drying until the alcohol is completely volatilized to obtain dry metal mixed powder;

[0022] (3) Add 100 ml of tea polyphenols, 100 ml of polyethylene, 300 ml of benzene, and 100 ml of ethyl cellulose to the dry metal mixed powder, place the mixed solution in a ball mill, and place the mixed solution in a ball mill with a speed of 800 r / min and a diameter of 10 mm. 3 N 4 Under the condition of ball, ball mill for 8 hours to obtain a mixed slurry with a viscosity of 100 Pa.s. All of the above steps were done in a nitrogen-fille...

Embodiment 2

[0026] (1) Take a metal powder with a particle size of 20-40 μm and 1 kg, the mass percentages are as follows: 0.05% Sn, 0.05% In, 0.2% Mg, and the balance is Al with a purity of ≥99.99%, mix the metal powder with 600 mL of absolute ethanol Mixed and placed in a ball mill jar, using Si with a diameter of 6mm 3 N 4 Balls, milled for 4h at a speed of 400r / min;

[0027] (2) placing the ball-milled mixed solution in a constant temperature water bath at 60°C and drying until the alcohol is completely volatilized to obtain dry metal mixed powder;

[0028] (3) 40ml of dibutylhydroxytoluene, 40ml of polyethylene glycol, 60ml of acetone, and 60ml of ammonium methacrylate were added to the dry metal mixed powder, and the mixed solution was placed in a ball milling tank. 6mm Si 3 N 4 Under the condition of balls, ball milling was carried out for 4 hours to obtain a mixed slurry with a viscosity of 37 Pa.s. All of the above steps were done in a nitrogen-filled, sealed glove box. Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com