Patents

Literature

198results about "Electrode extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

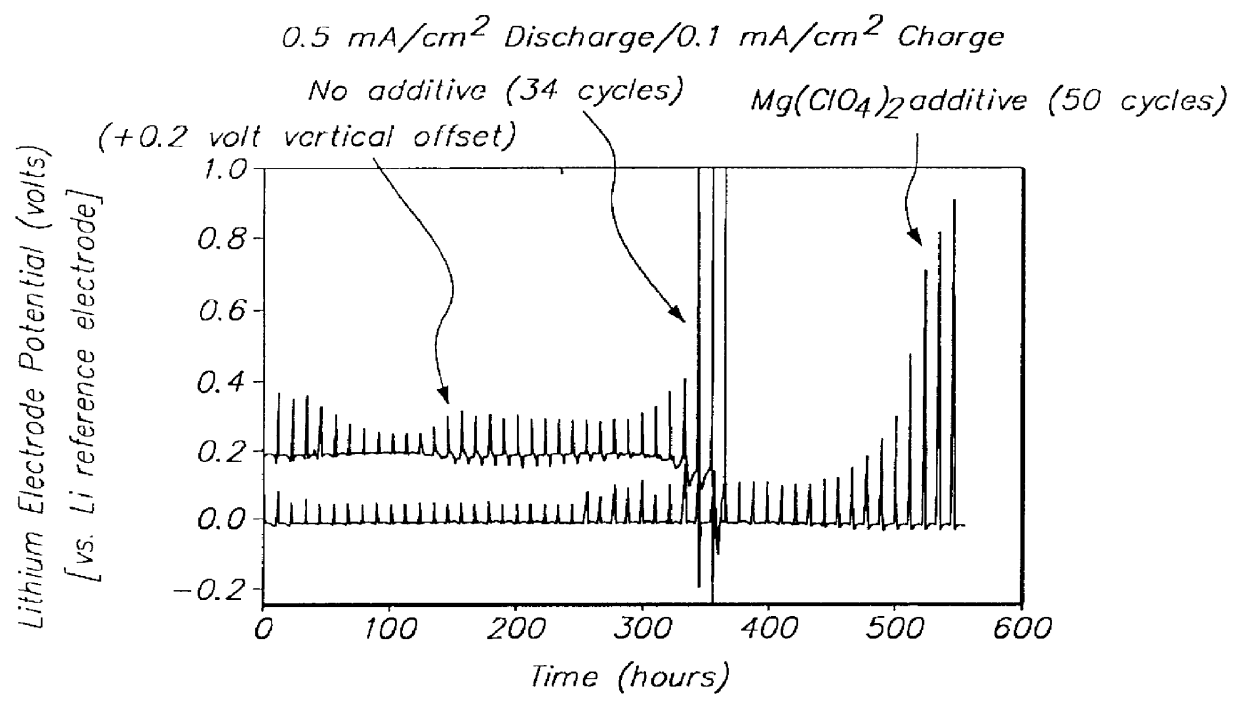

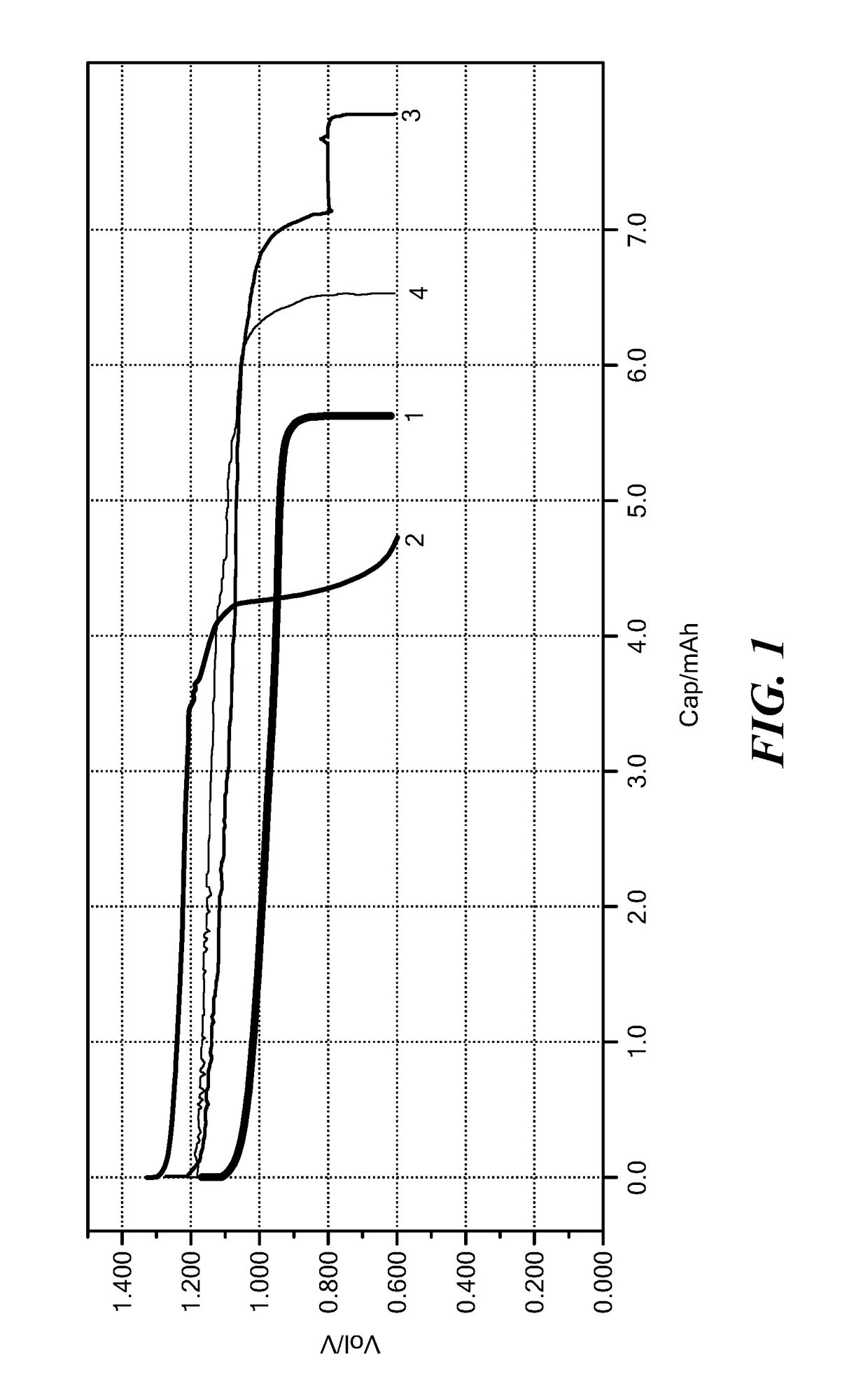

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

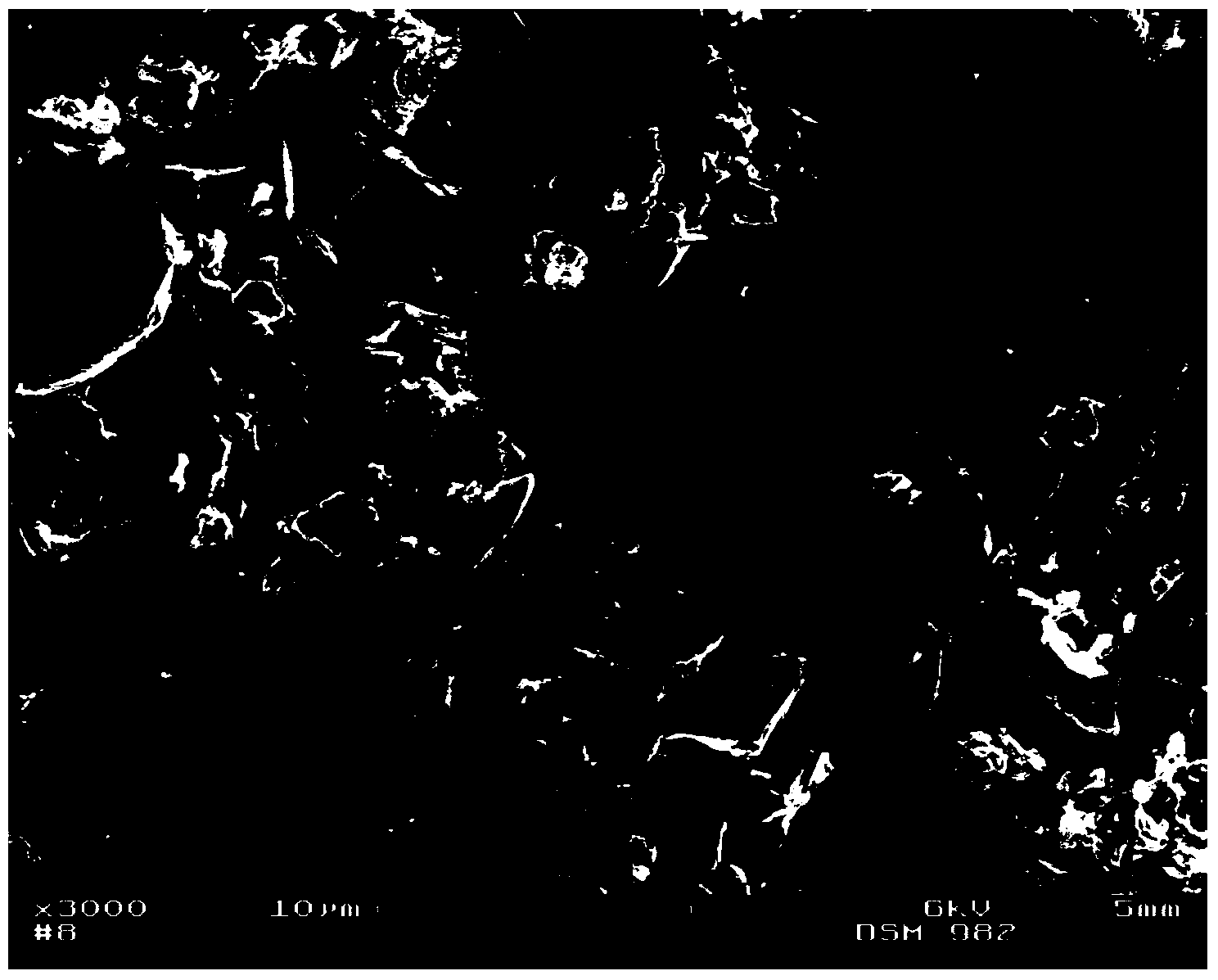

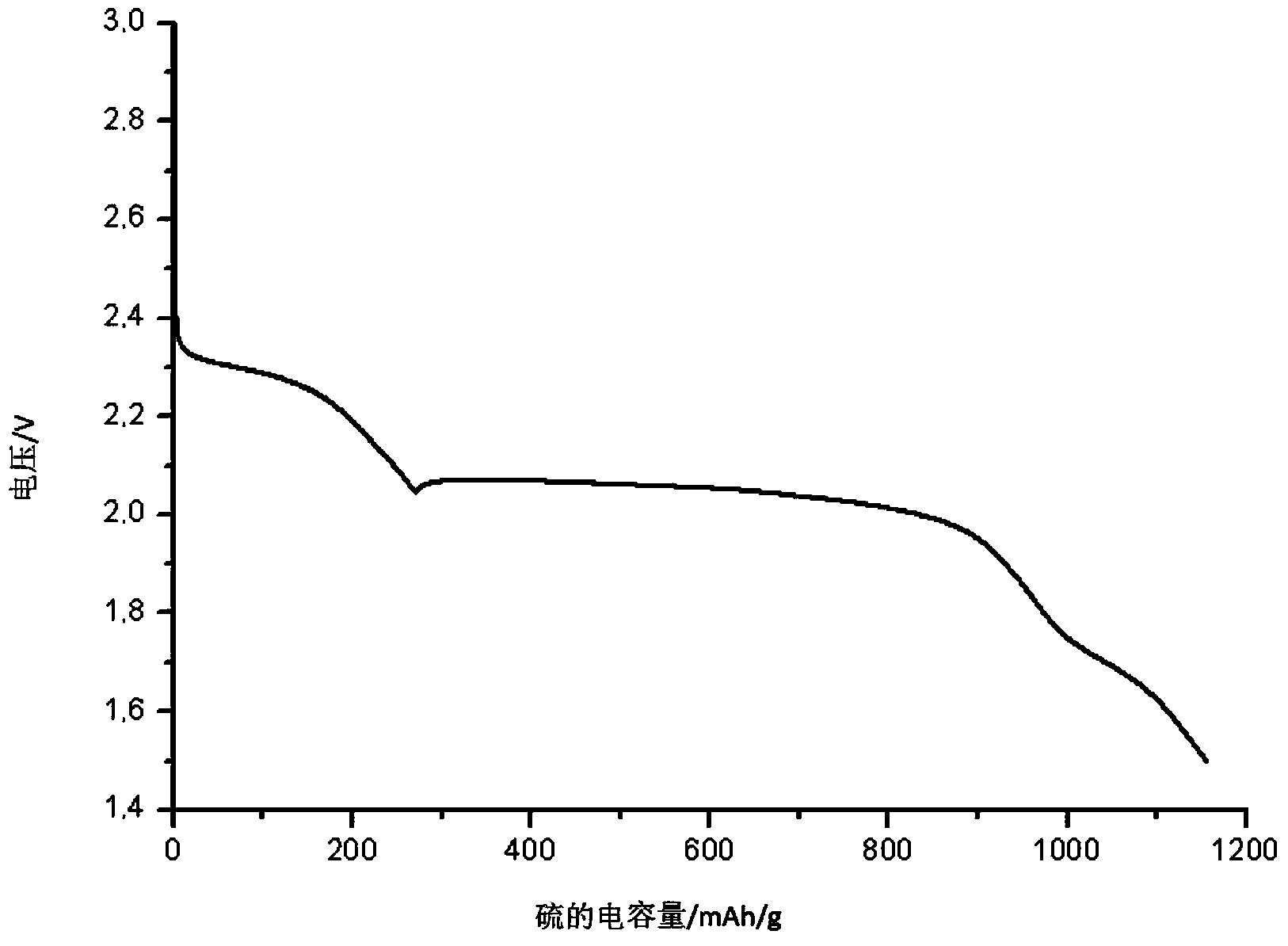

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

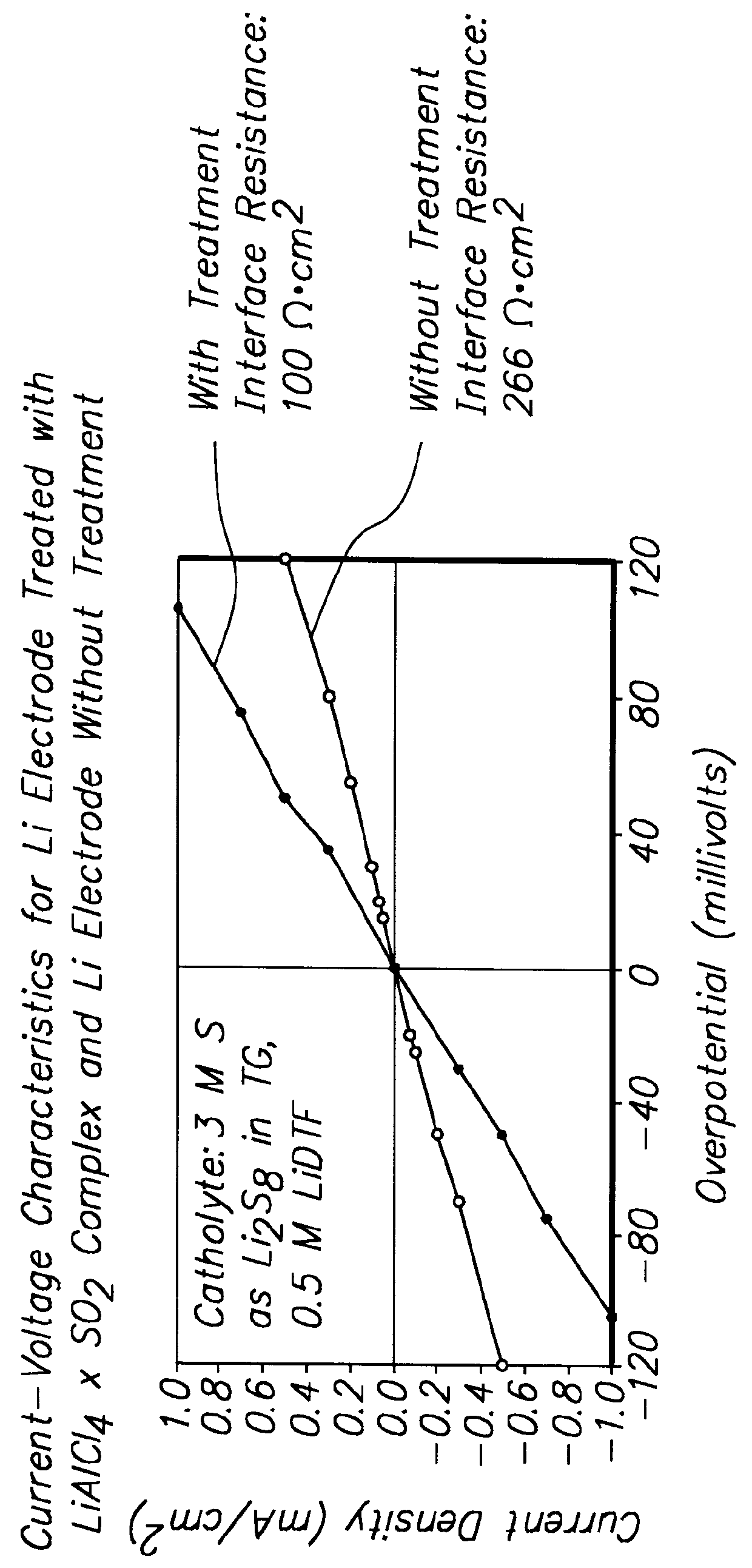

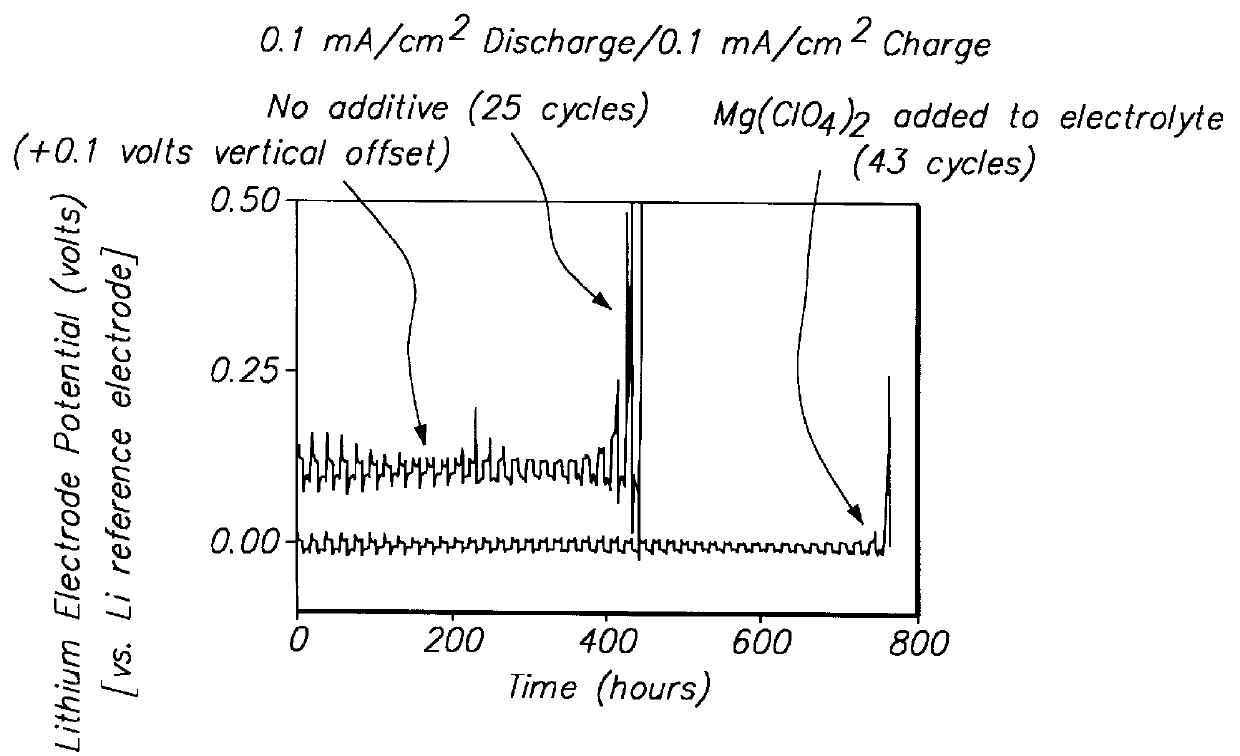

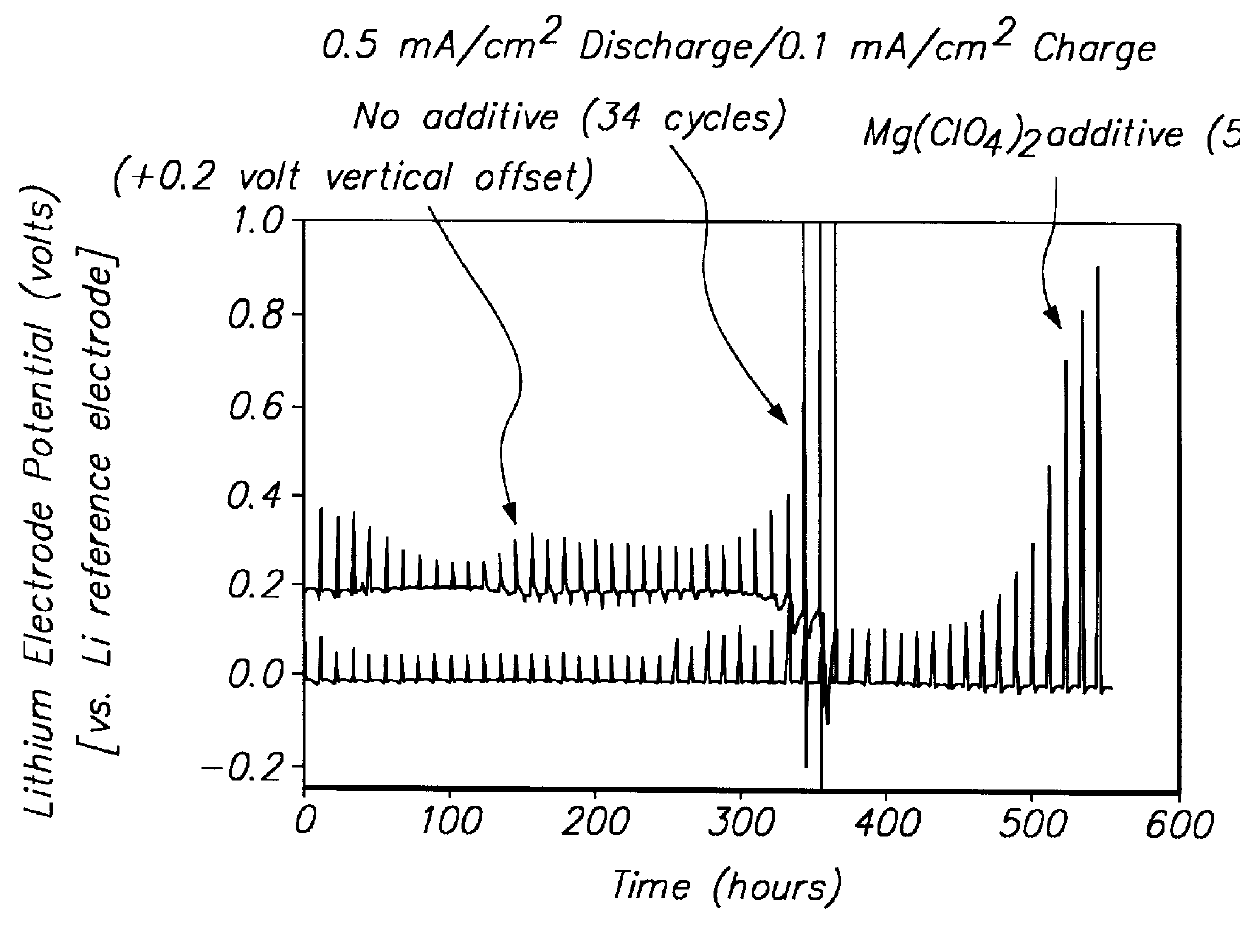

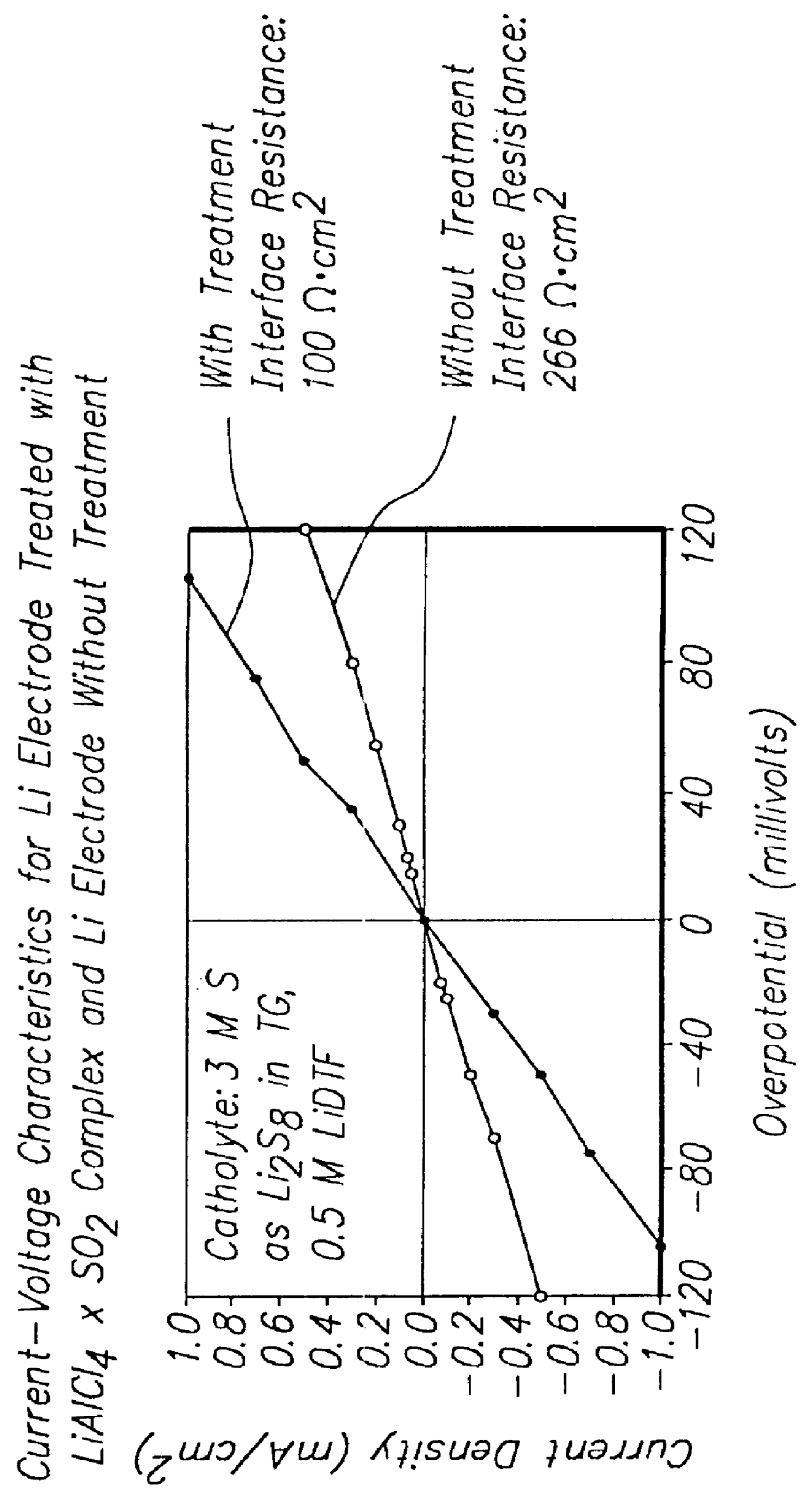

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

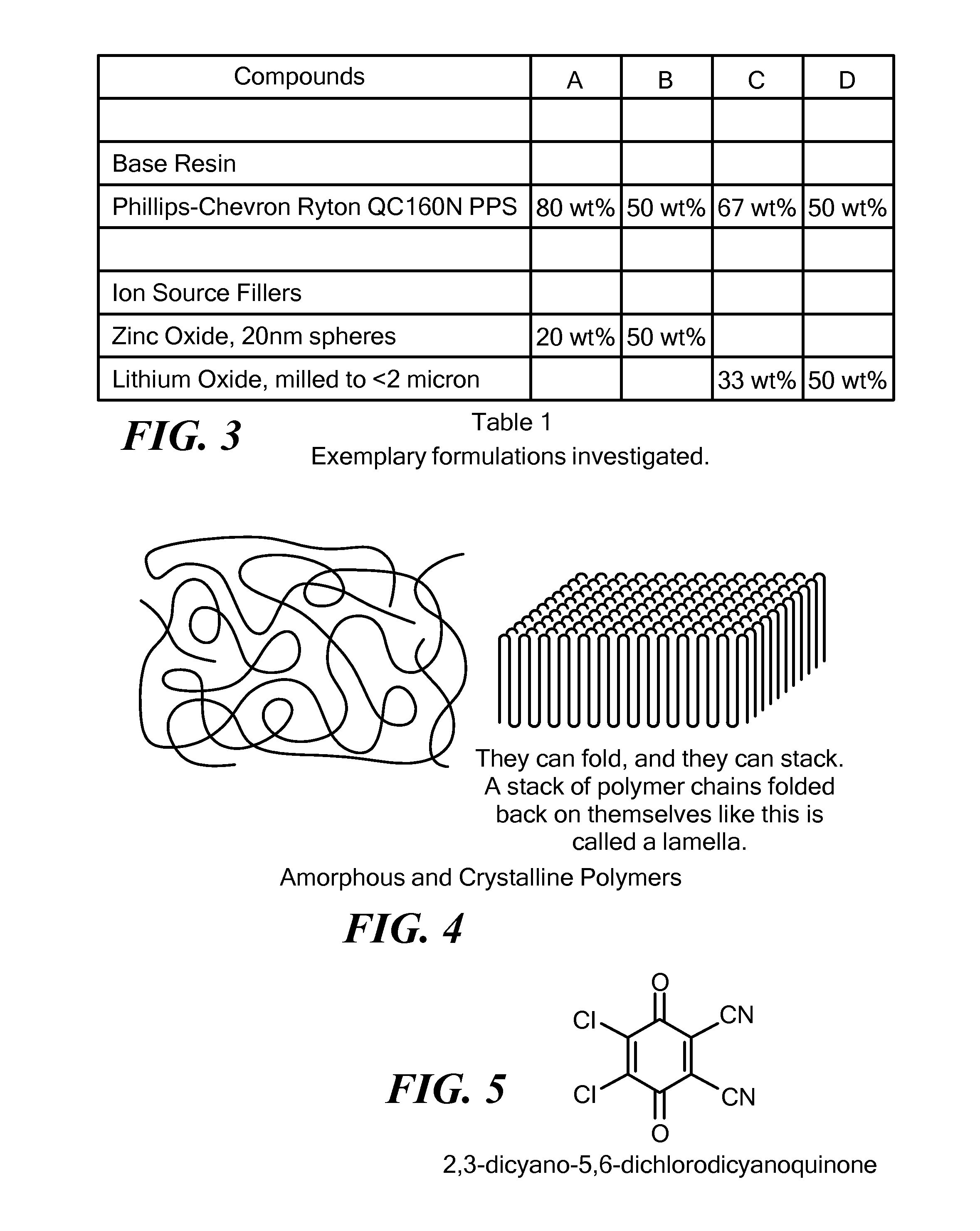

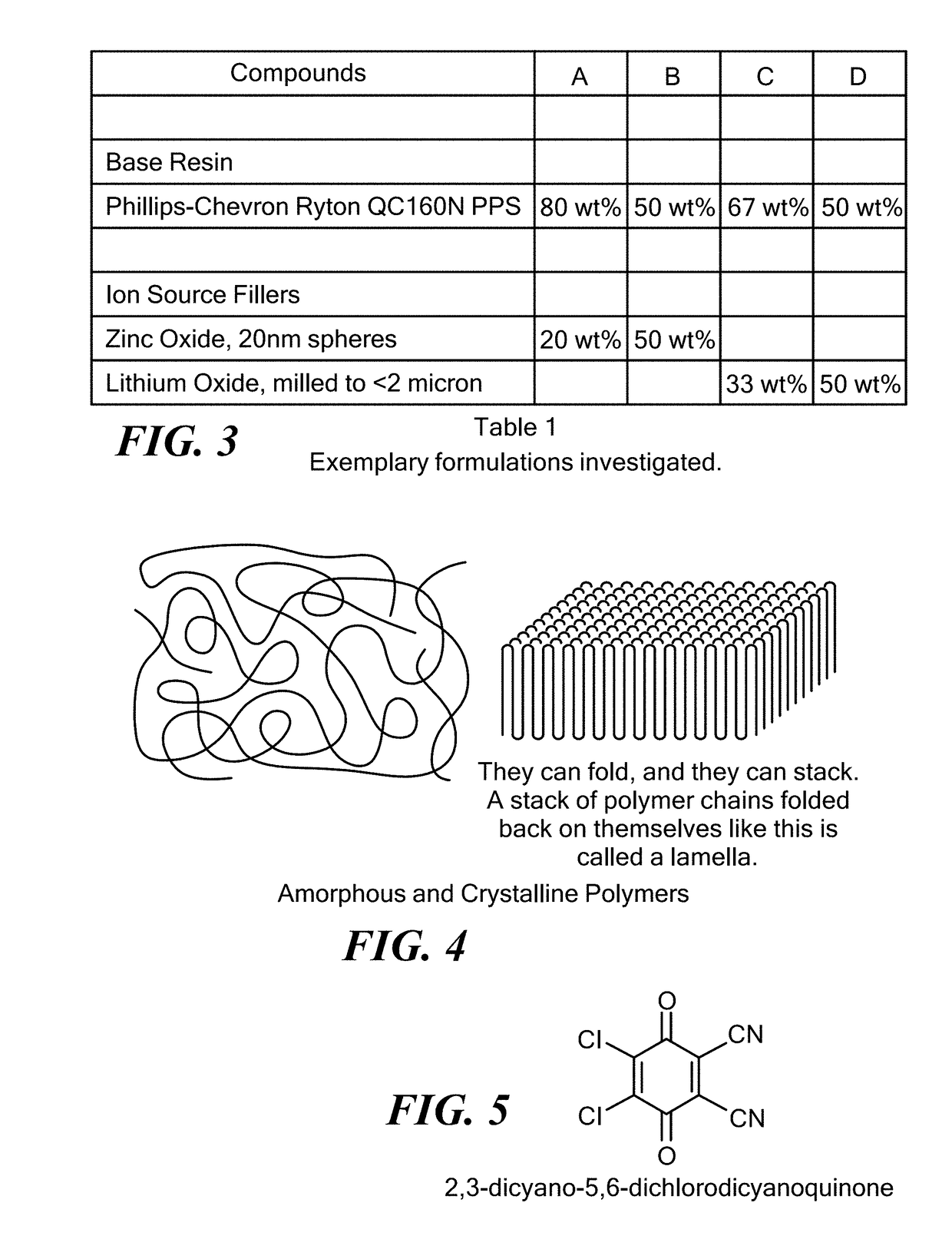

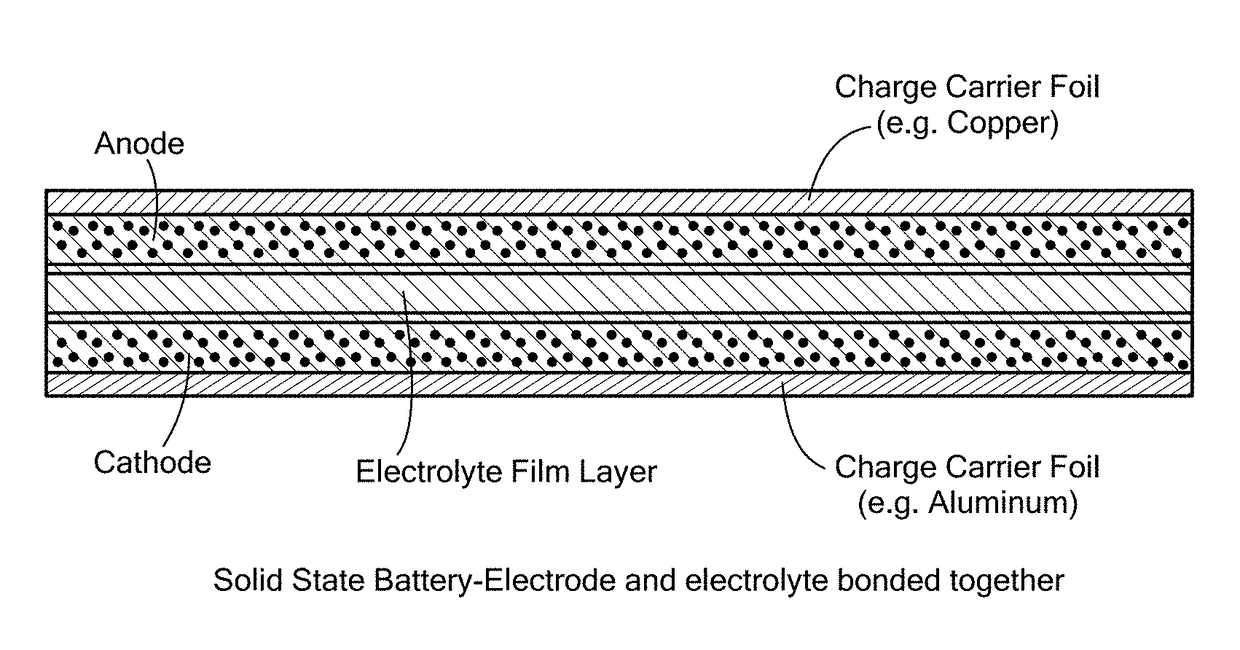

Solid, ionically conducting polymer material, and methods and applications for same

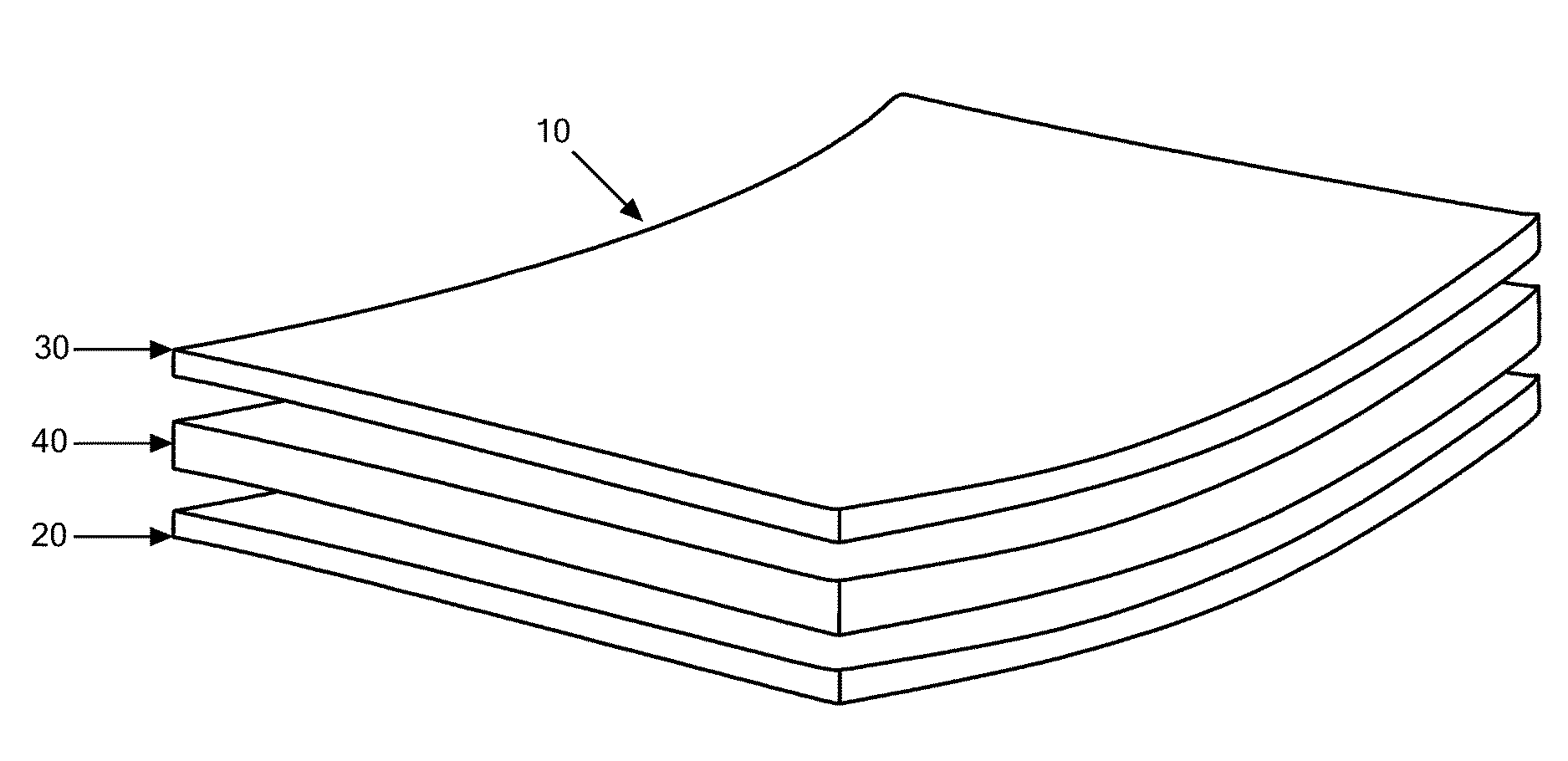

ActiveUS20150155559A1Low effective aqueous porosityLarge specific surface areaSolid electrolytesAlkaline accumulatorsPolymer sciencePolymer

The invention features a rechargeable alkaline battery comprising an anode; a cathode; and an electrolyte; wherein at least one of anode, the cathode and the electrolyte includes a solid, ionically conducting polymer material, and methods for the manufacture of same.

Owner:IONIC MATERIALS INC

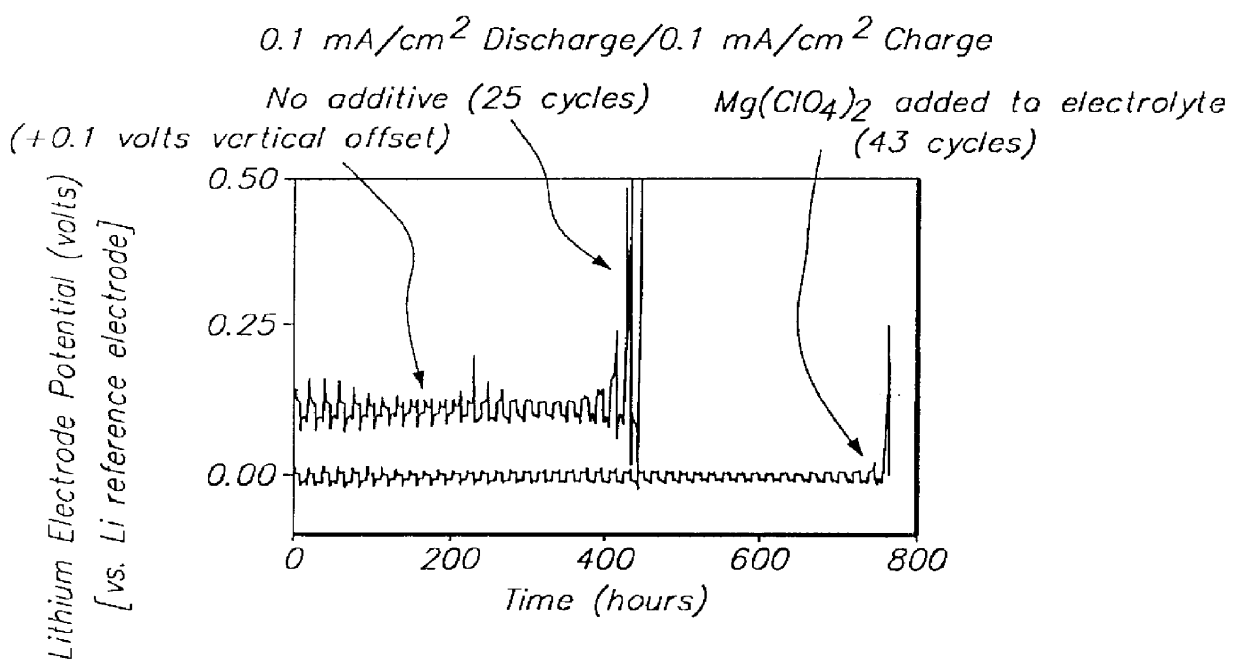

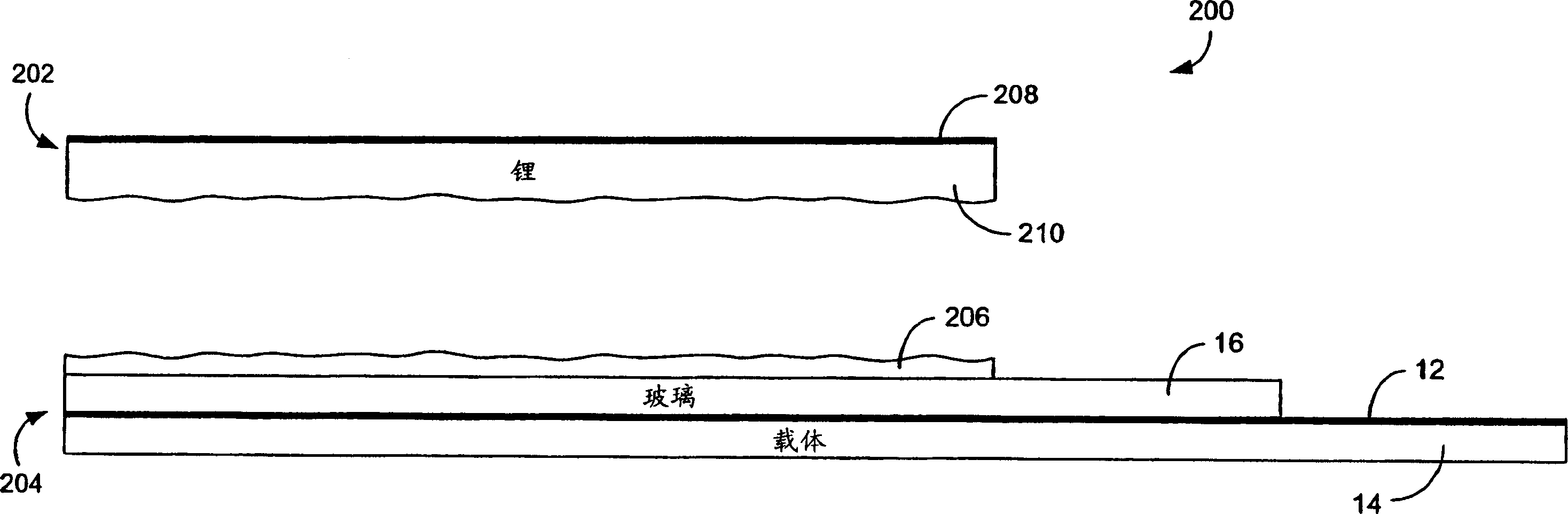

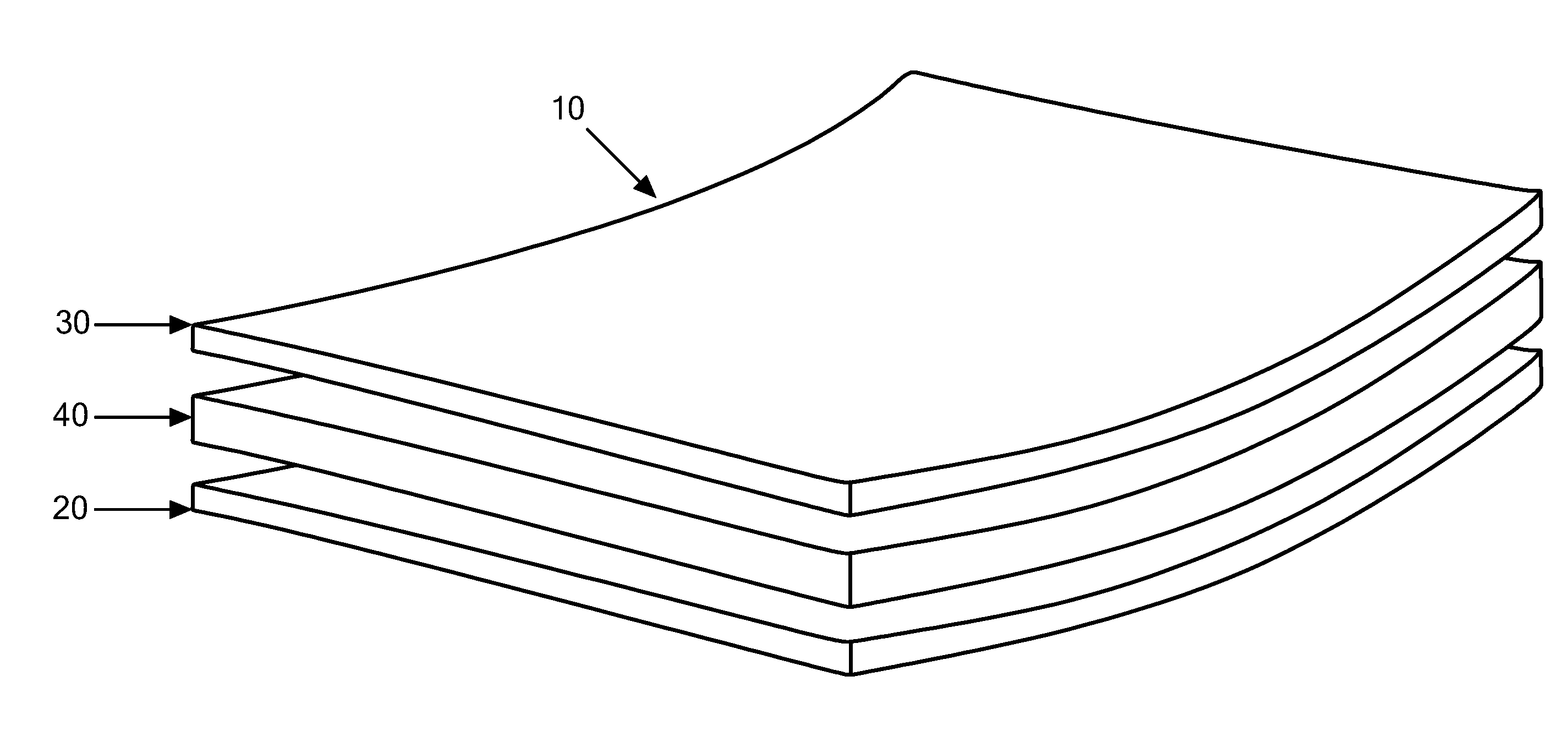

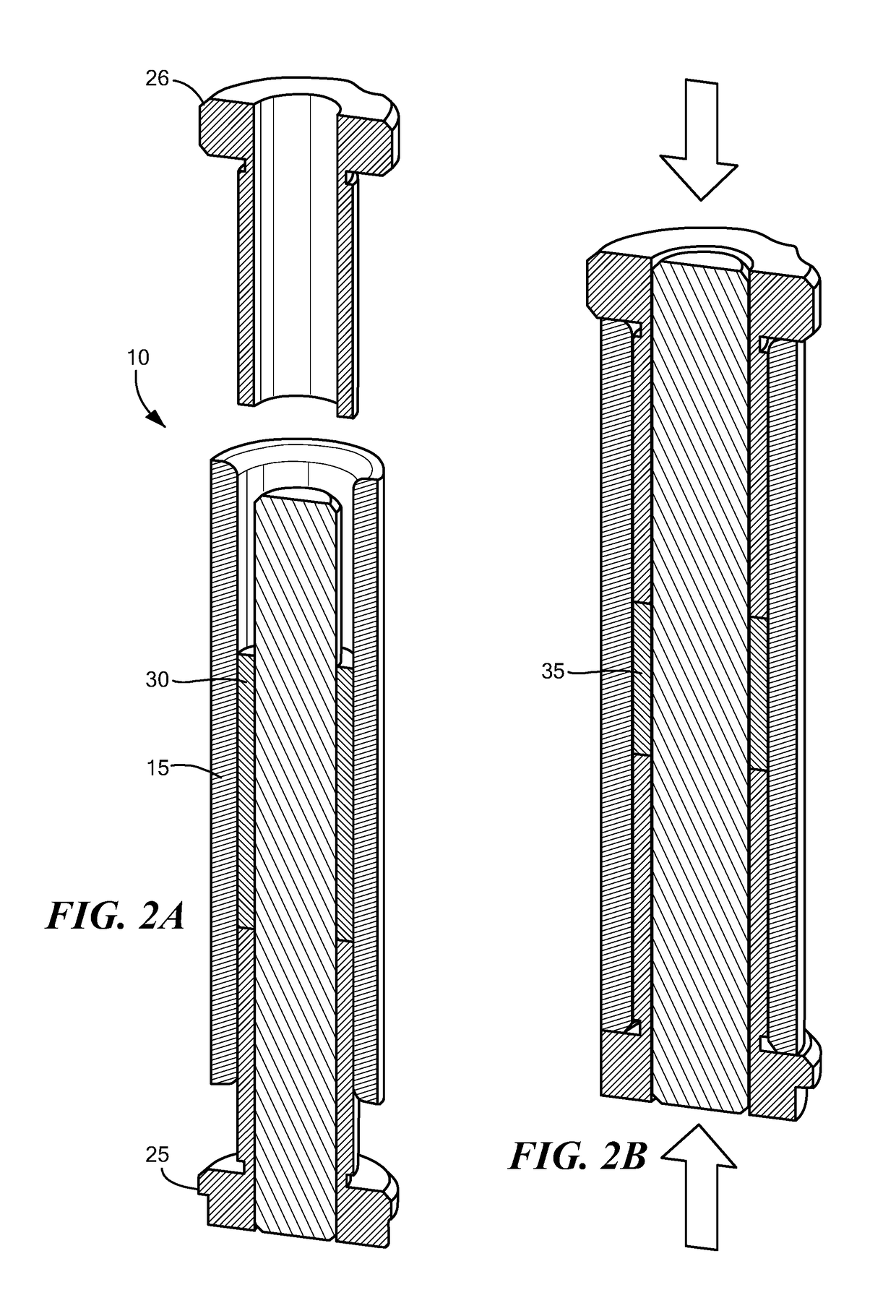

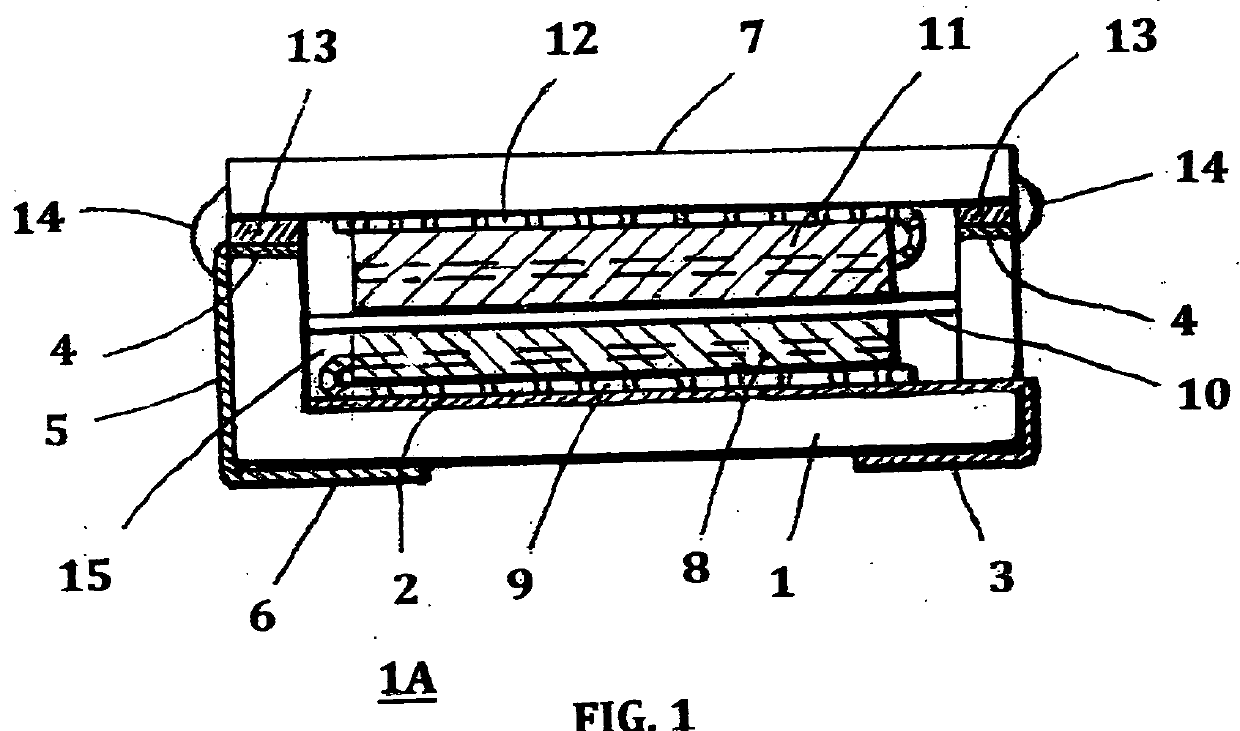

Layered arrangements of lithium cells

InactiveCN1415124ANon-aqueous electrolyte accumulatorsElectrode carriers/collectorsMetal electrodesMaterials science

A method employing a bonding layer is used to form active metal electrodes having barrier layers. Active metals such as lithium are highly reactive in ambient conditions. The method involves fabricating a lithium electrode or other active metal electrode without depositing the barrier layer on a layer of metal. Rather a smooth barrier layer is formed on a smooth substrate such as a web carrier or polymeric electrolyte. A bonding or alloying layer is formed on top of the barrier layer. Lithium or other active material is then attached to the bonding layer to form the active metal electrode. A current collector may also be attached to the lithium or active metal during the process.

Owner:POLYPLUS BATTERY CO INC

Additives for lubricating agents used in the lamination of lithium sheets into thin films

InactiveUS6019801AReduce water contentQuality improvementElectrode rolling/calenderingPrimary cellsLithiumPolymer science

These additives are represented by the following general formula:L-Y-Sin which L designates a hydrocarbon radical which serves as lubricating segment; S designates an oligomer segment which serves as solvating segment of metallic salts and Y designates a chemical bond which joins the hydrocarbon radical and the oligomer segment. With these additives there is no more need to subsequently wash the surface of laminated lithium.

Owner:BATHIUM CANADA

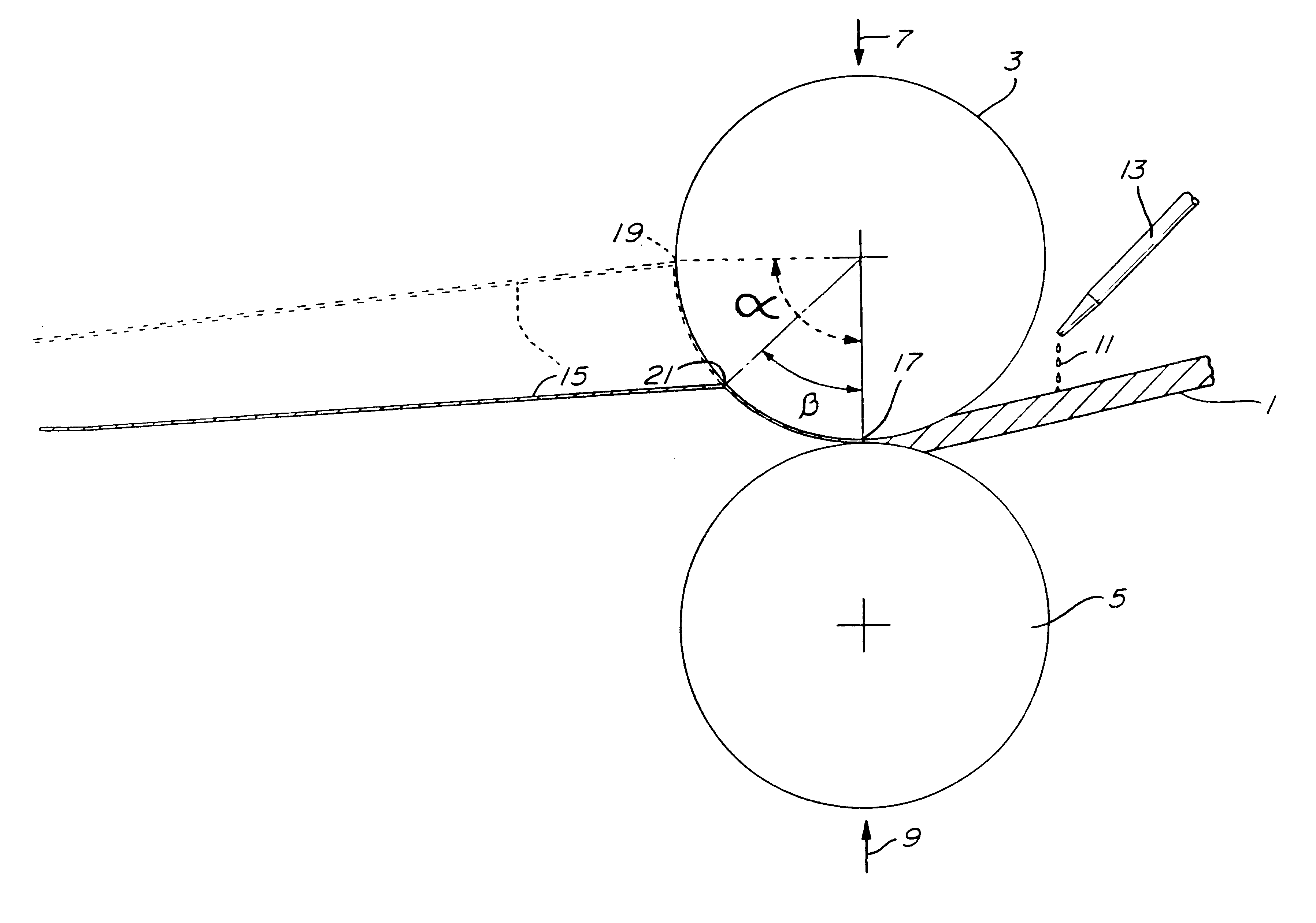

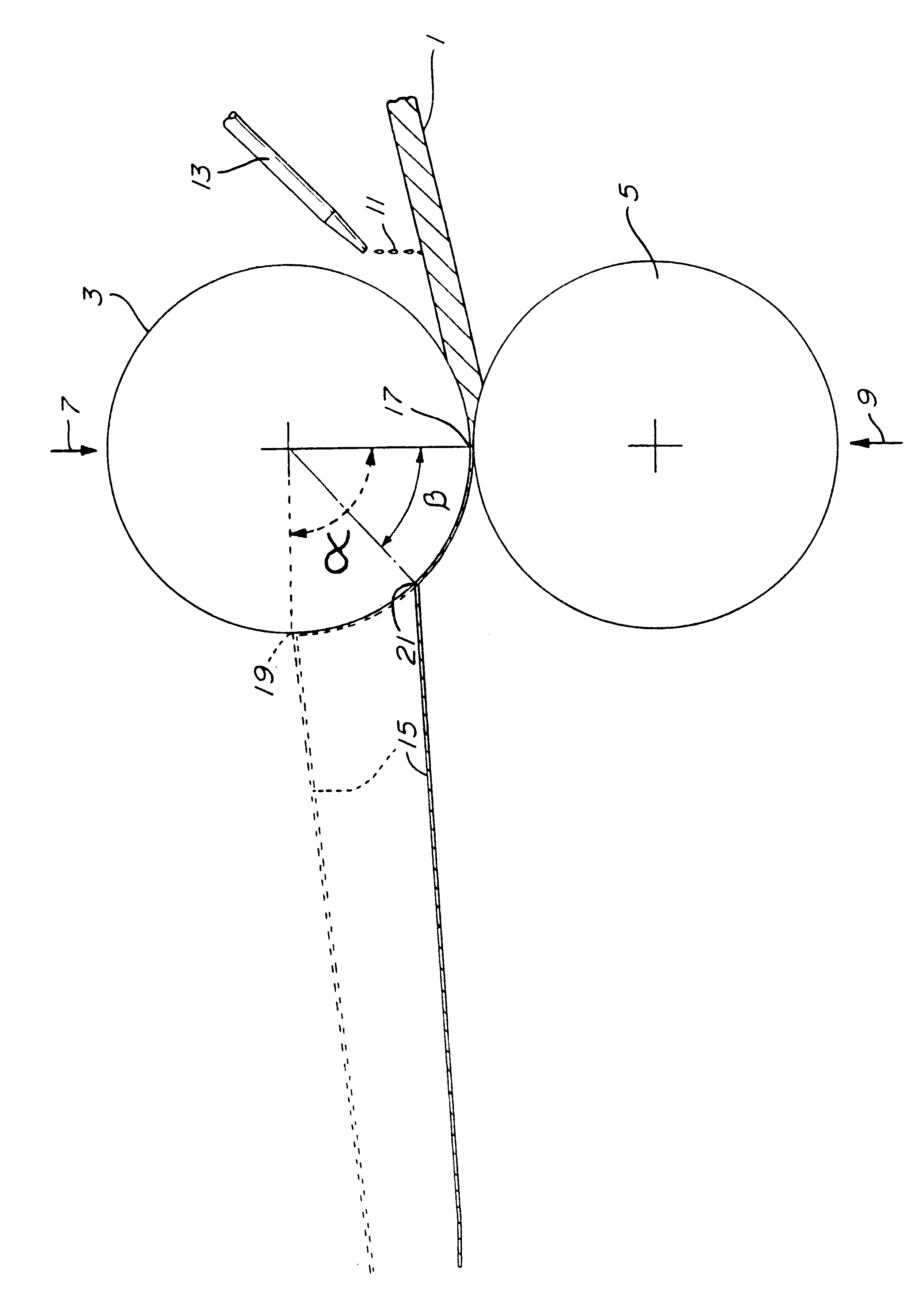

Method and apparatus for making positive electrode films for polymer batteries

InactiveUS20050236732A1Avoid separationElectrode rolling/calenderingSecondary cellsSolid contentPolymer chemistry

Owner:BATHIUM CANADA

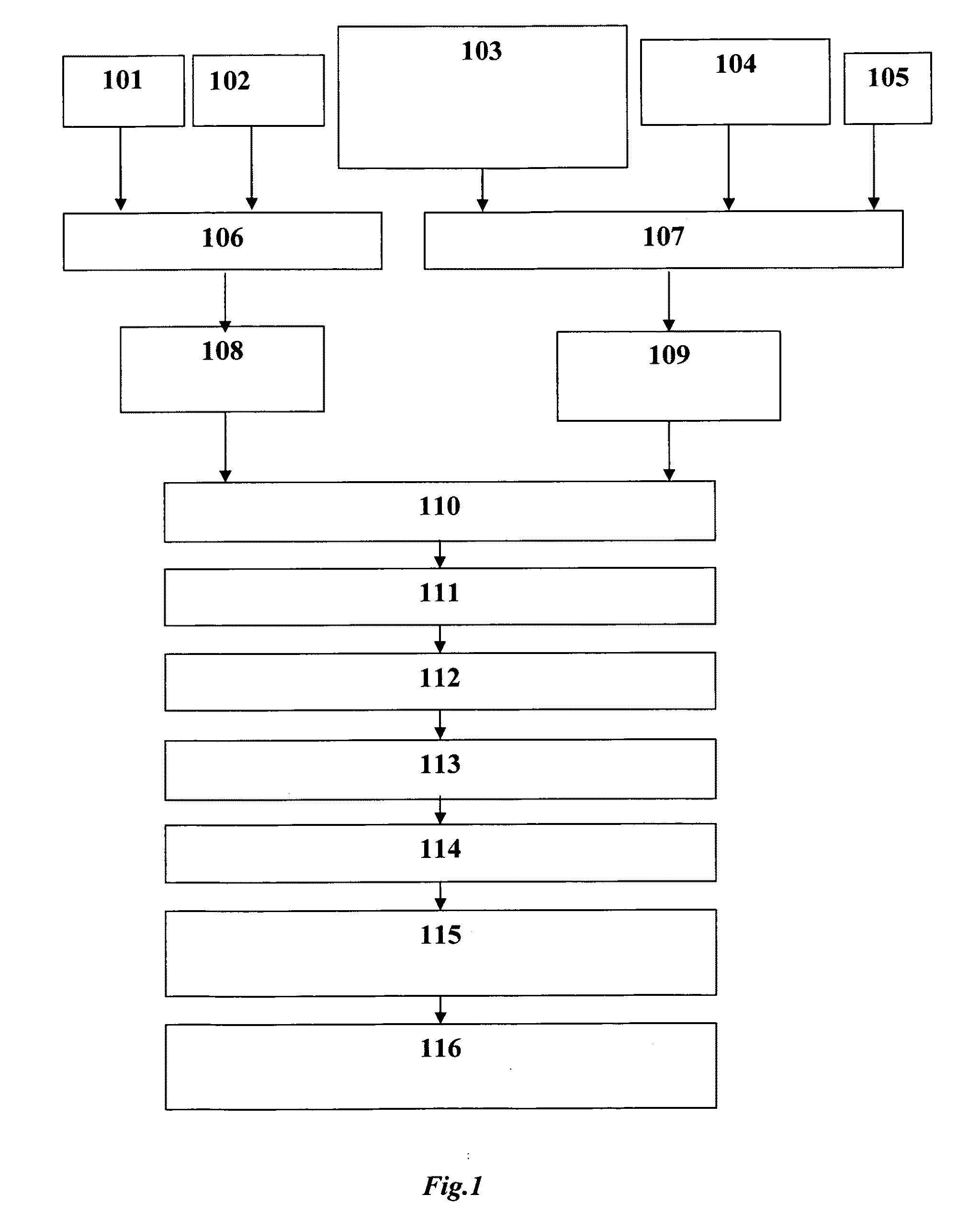

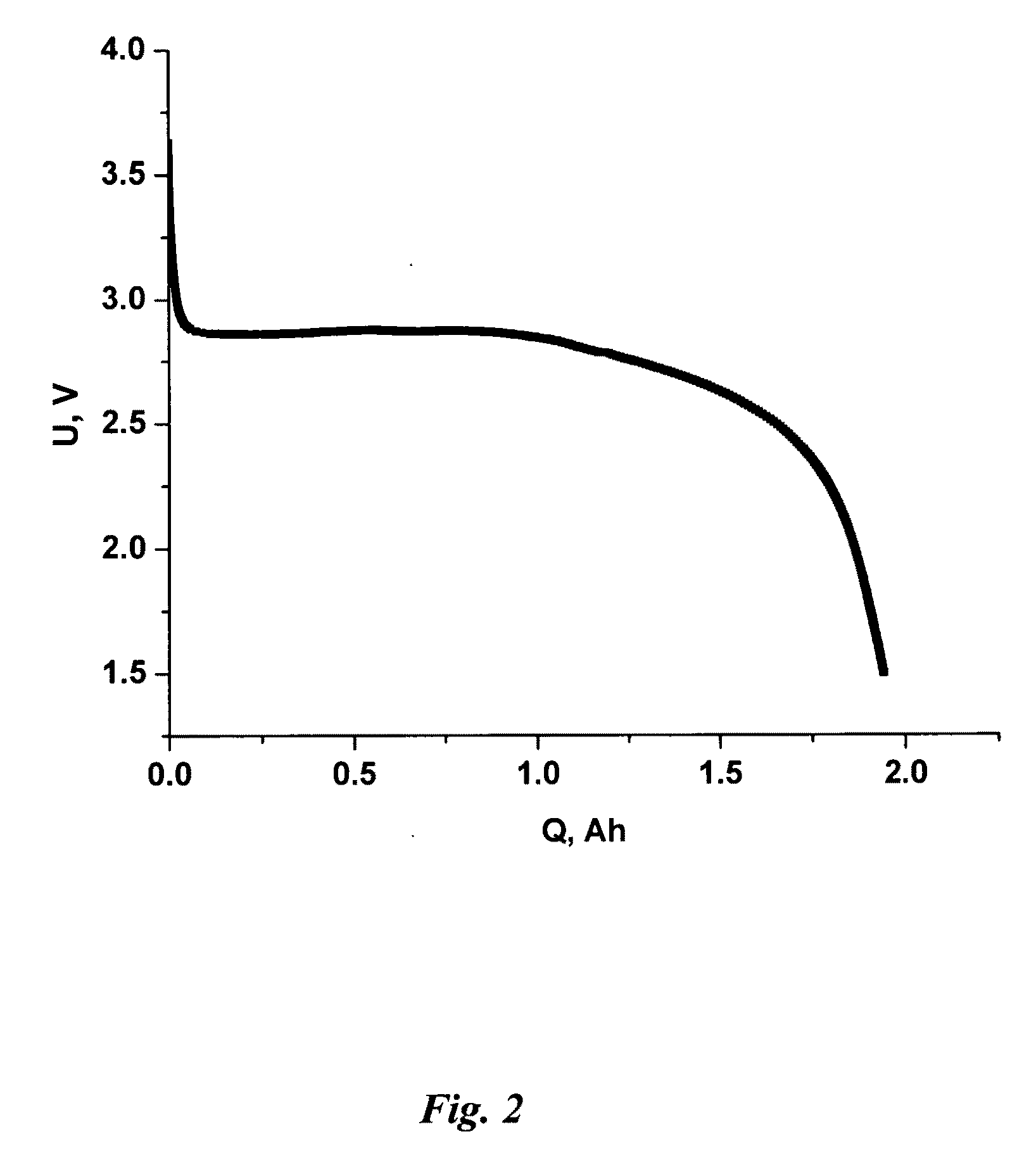

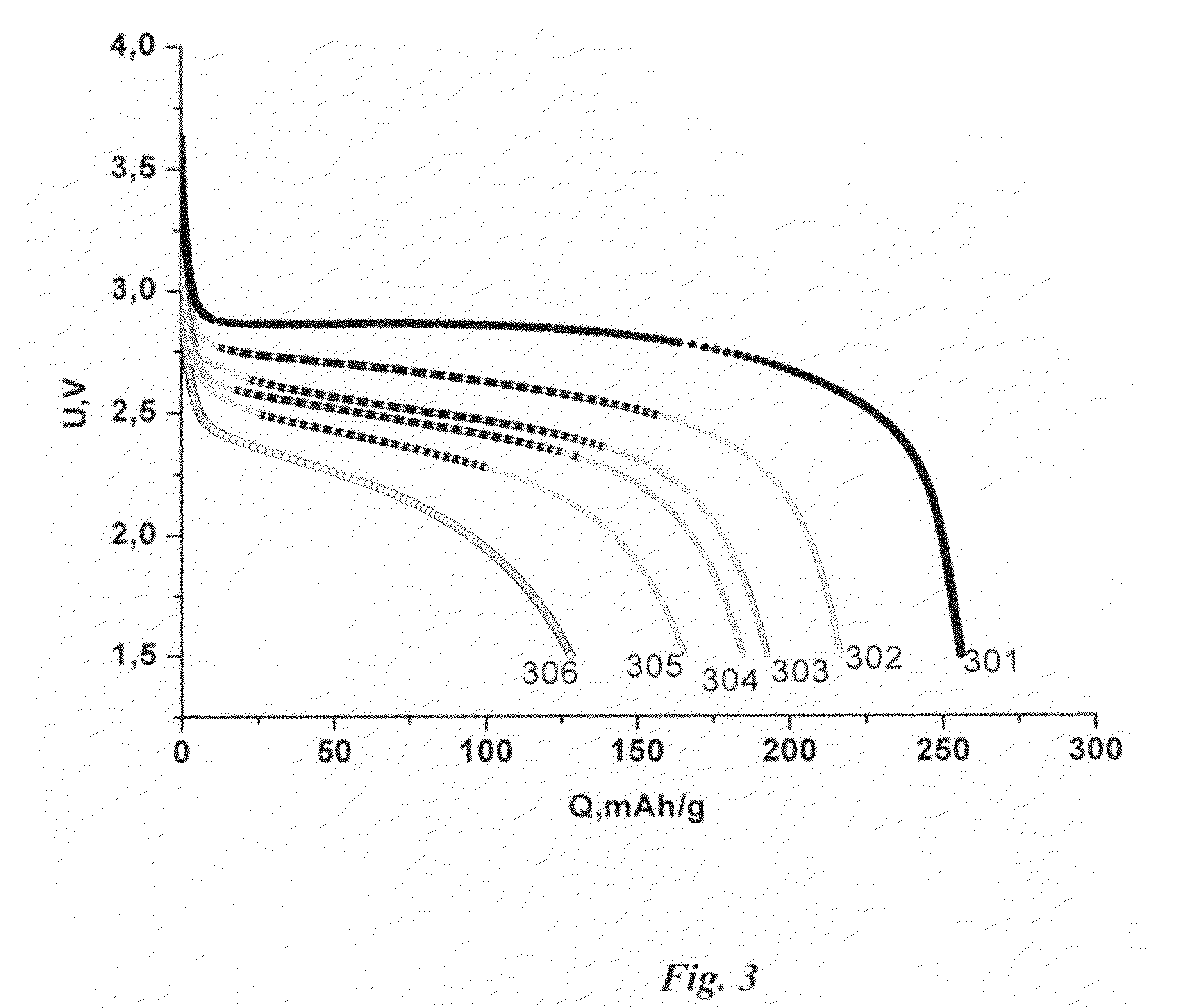

Electrode for lithium primary and secondary (rechargeable) batteries and the method of its production

InactiveUS20090117461A1Improve efficiencyWide operating temperature rangeElectrolytic capacitorsNon-aqueous electrolyte cellsElectrical resistance and conductanceLithium

The present invention relates to a method for production of electrodes for Li-primary and Li-ion batteries based of using two types of binder. The first binder is soluble in organic solvent and second binder is insoluble in organic solvent during the process of slurry preparation. Combination of the slurry composition and conditions of the electrode temperature treatment decrease the cathode production complexity, improve electrochemical characteristics of the electrode, increase adhesion properties and flexibility of coating, and reduce the interface resistance between the current collector and electrode mass.

Owner:ENERIZE CORP

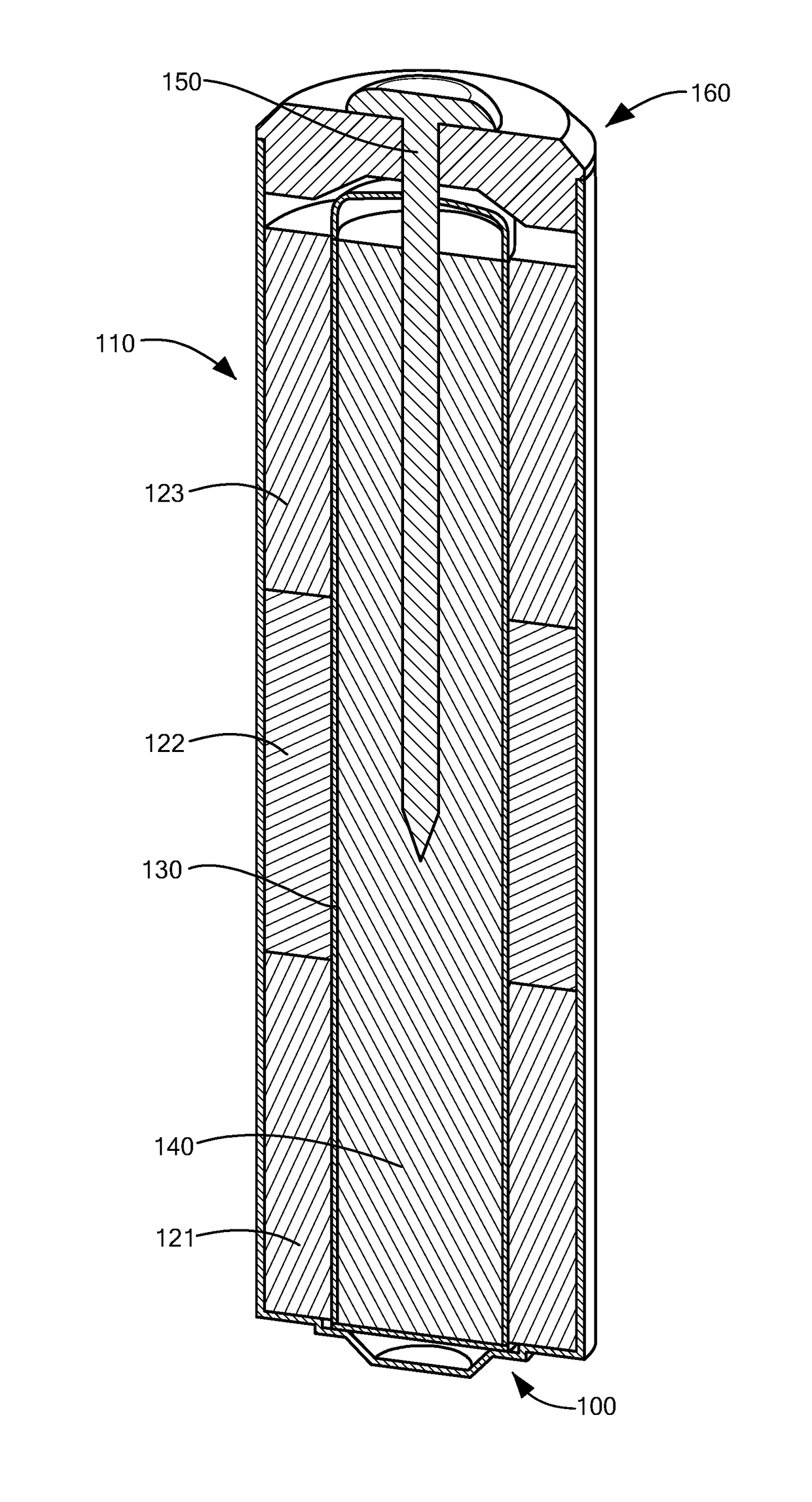

Lithium anodes for electrochemical cells

InactiveCN1415123ACell seperators/membranes/diaphragms/spacersFinal product manufactureLithium metalAlloy

The present invention provides a lithium positive electrode for an electrochemical cell, wherein the positive active layer has a first layer containing metallic lithium and a second layer of a temporary protective metal, wherein the temporary protective metal is capable of forming an alloy with lithium metal Or a metal capable of diffusing into lithium metal. The invention also provides a method of manufacturing such a positive electrode, an electrochemical cell comprising such a positive electrode, and a method of manufacturing such a battery.

Owner:SION POWER CORP

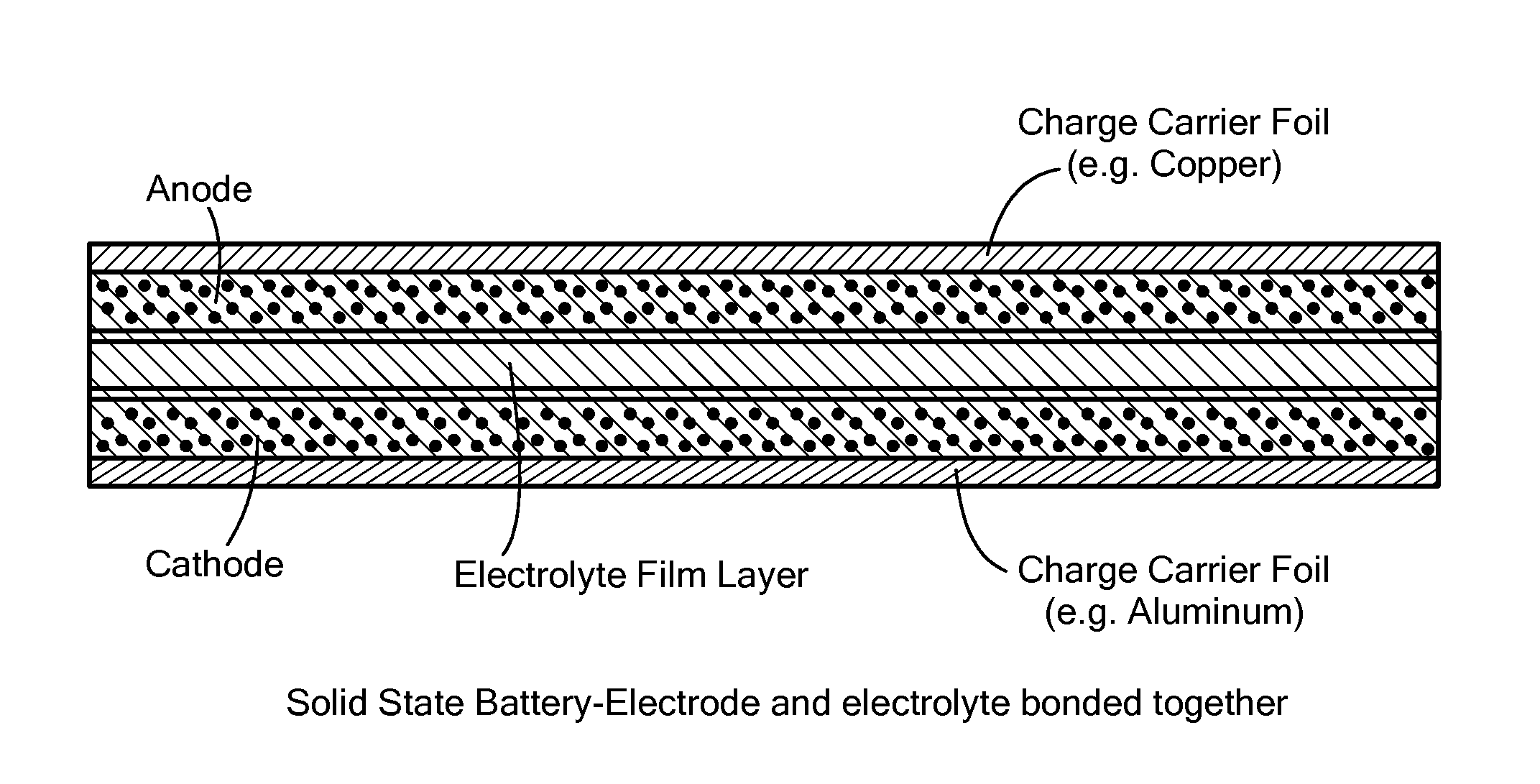

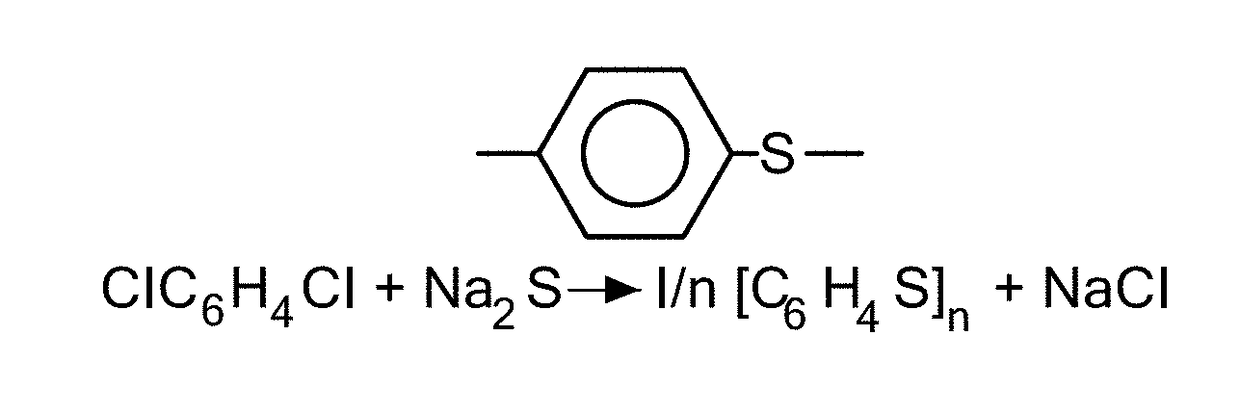

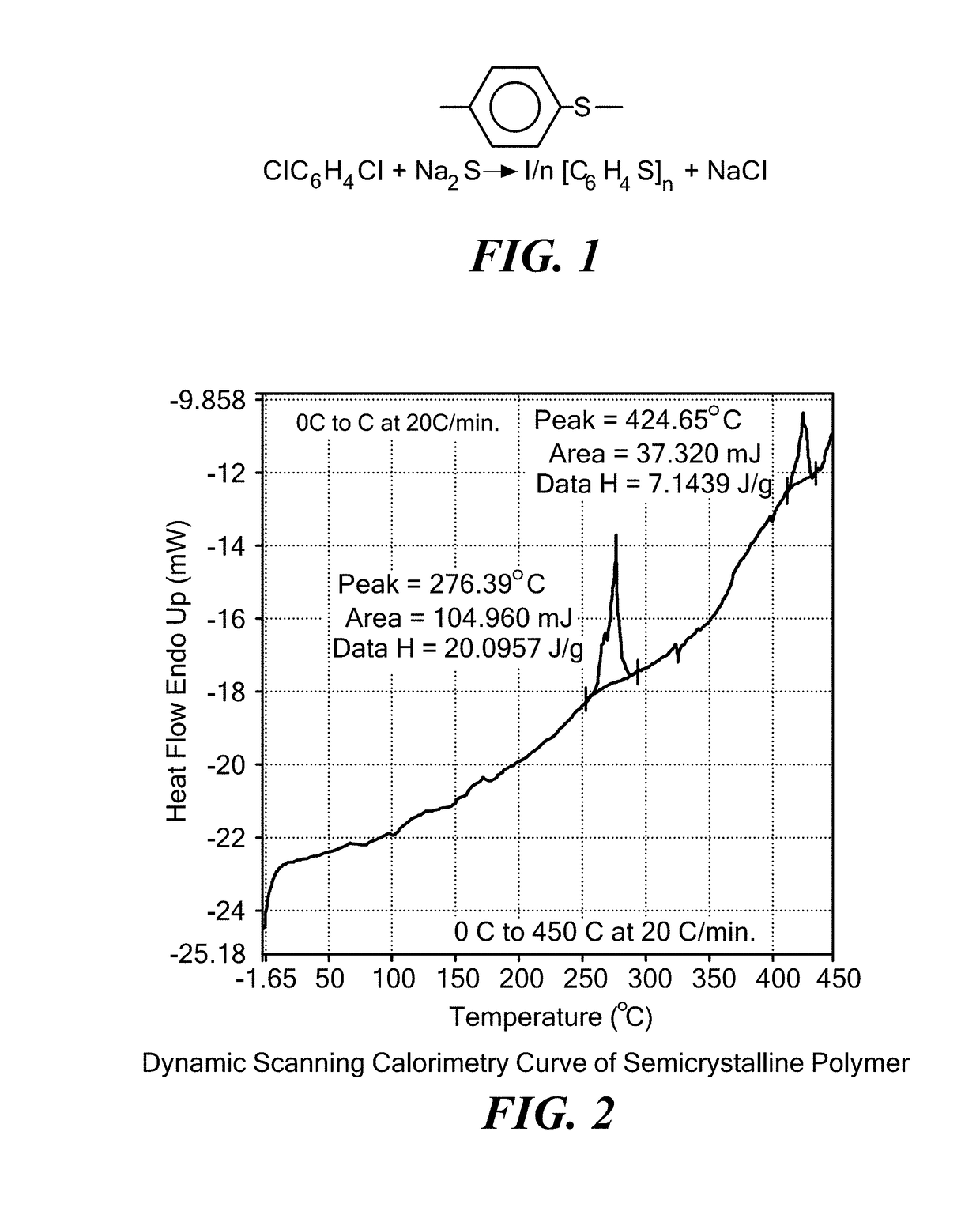

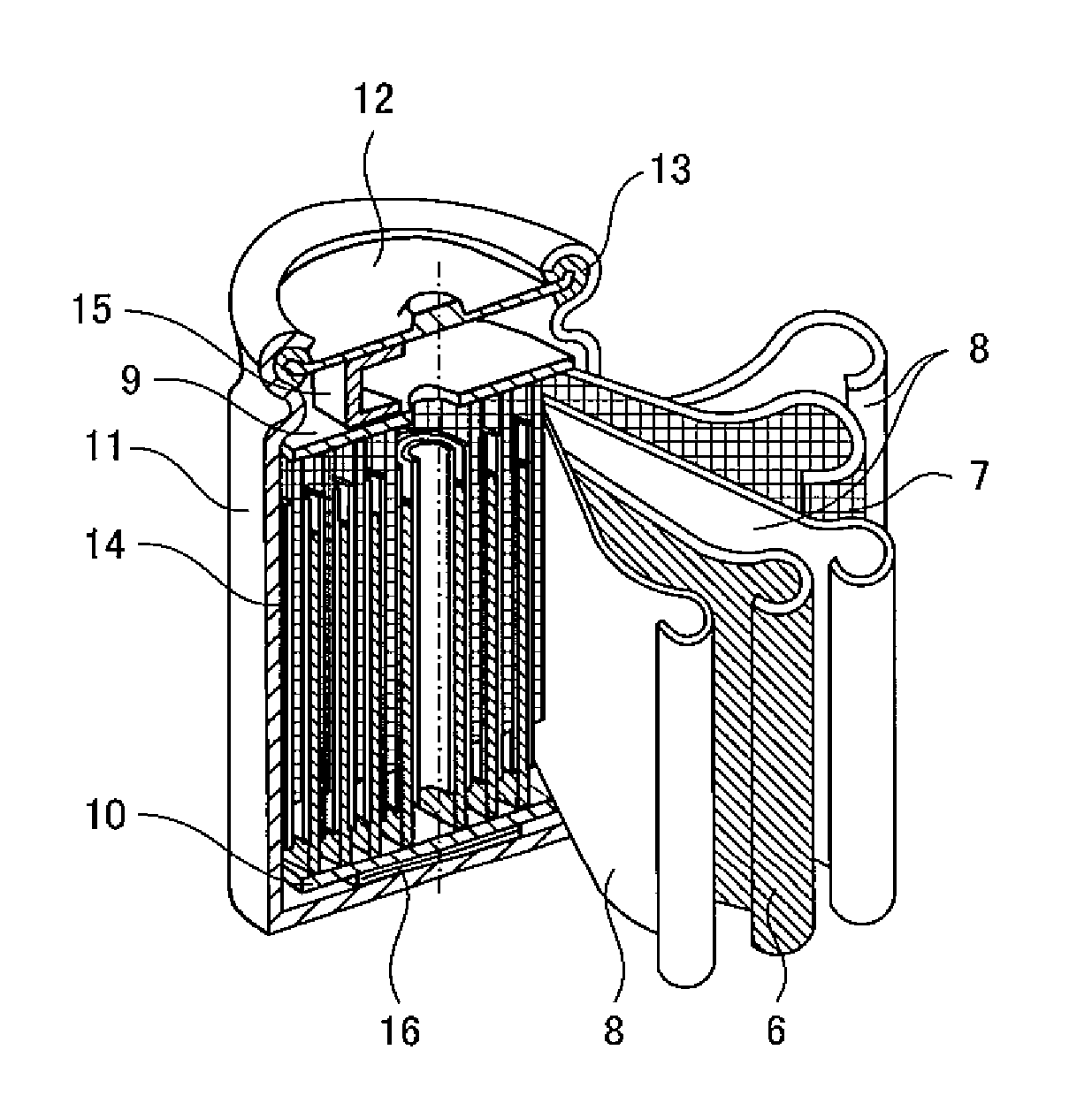

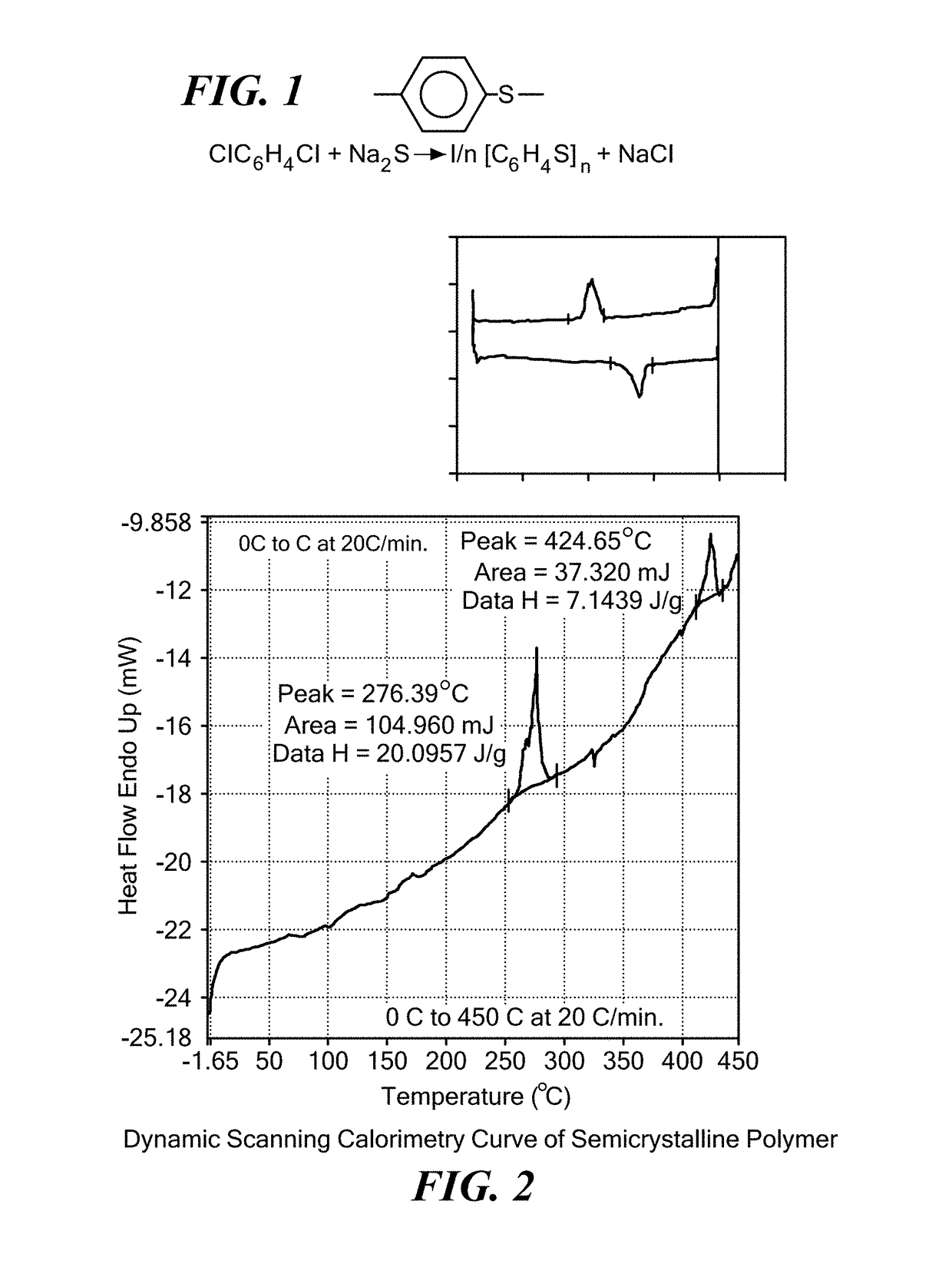

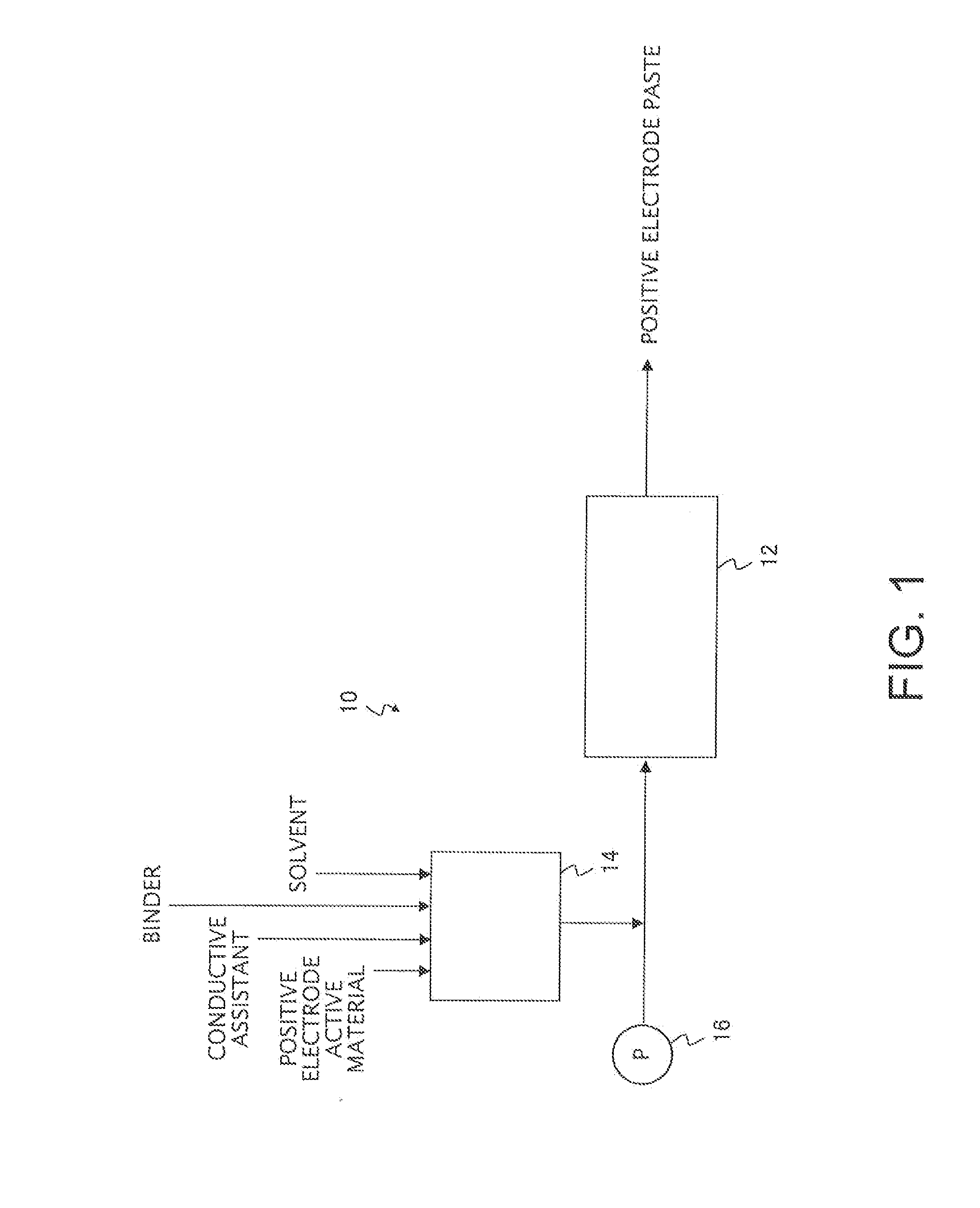

Solid ionically conducting polymer material

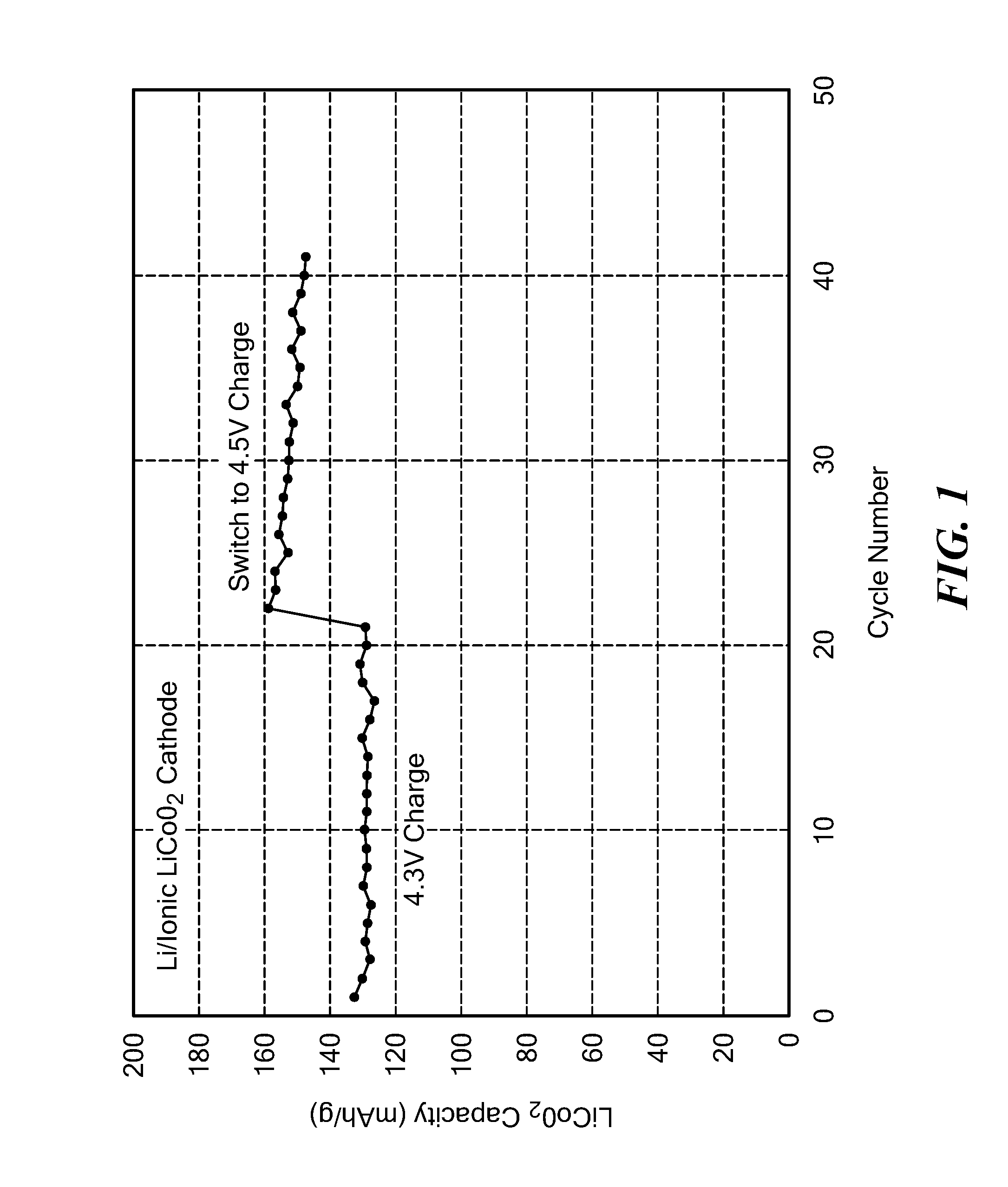

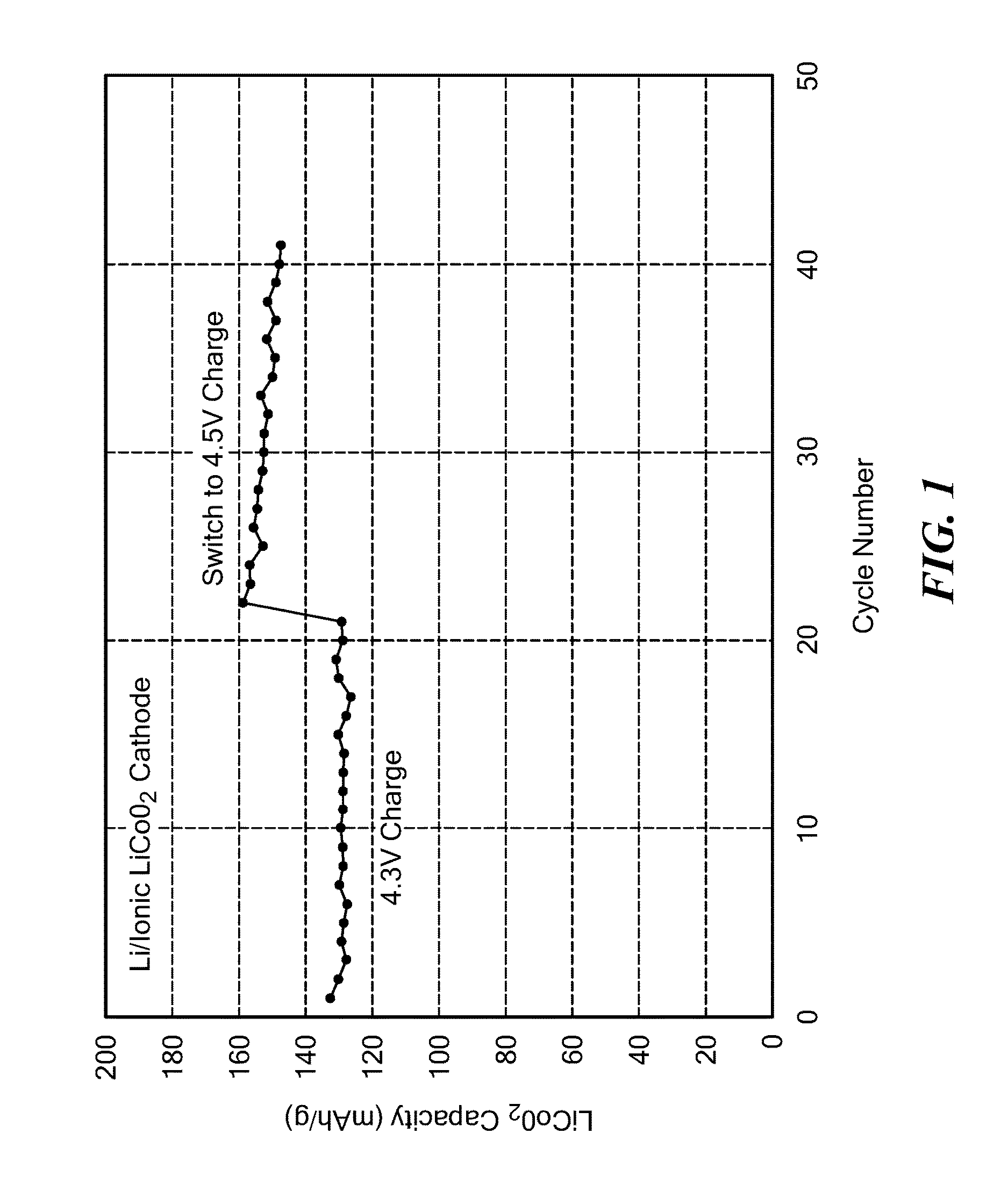

ActiveUS20170005356A1Increase capacityImprove cycle lifeIon-exchange process apparatusSolid electrolytesConductive polymerCrystallinity

A solid, ionically conductive, polymer material with a crystallinity greater than 30%; a glassy state; and both at least one cationic and anionic diffusing ion, wherein each diffusing ion is mobile in the glassy state.

Owner:IONIC MATERIALS INC

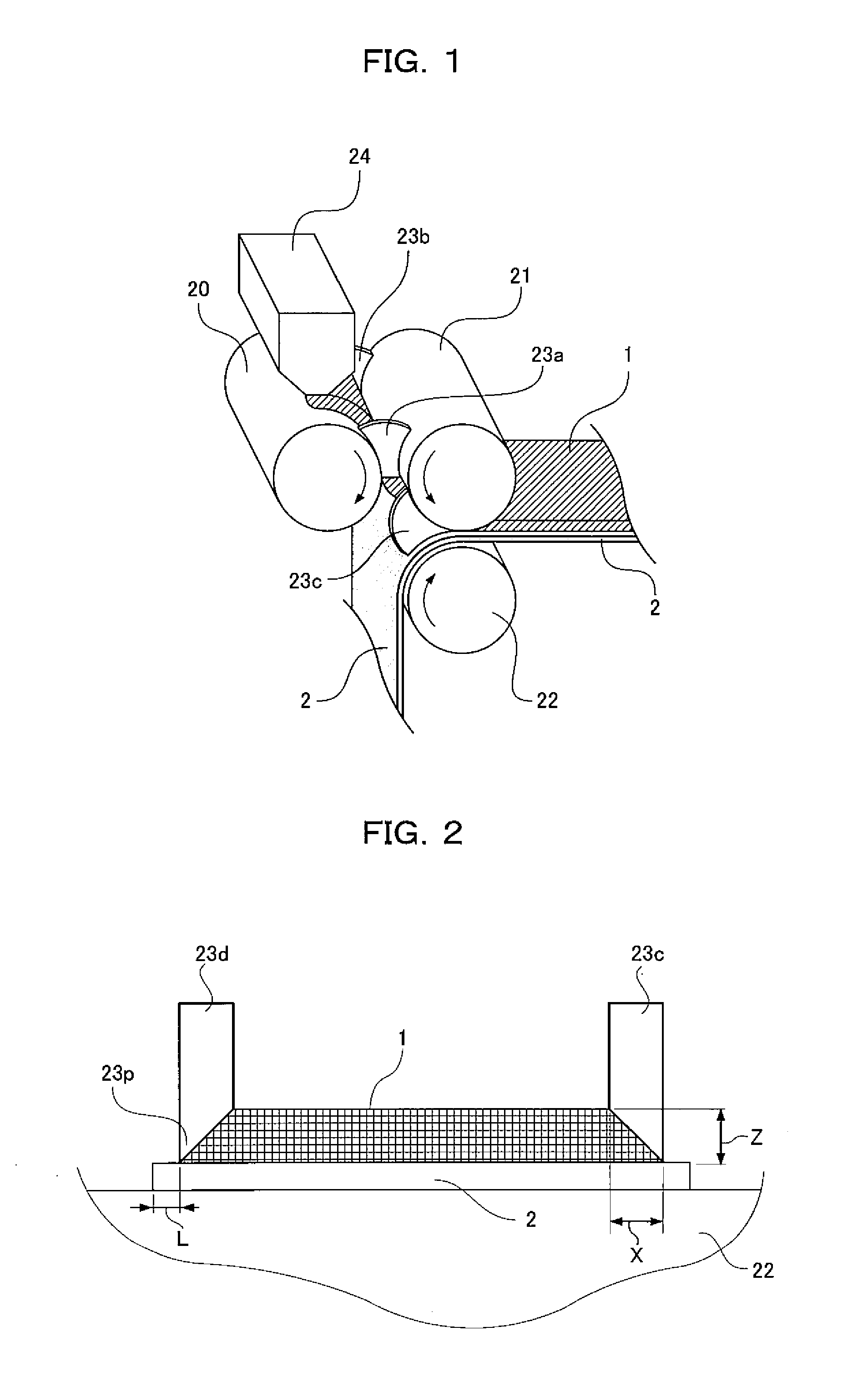

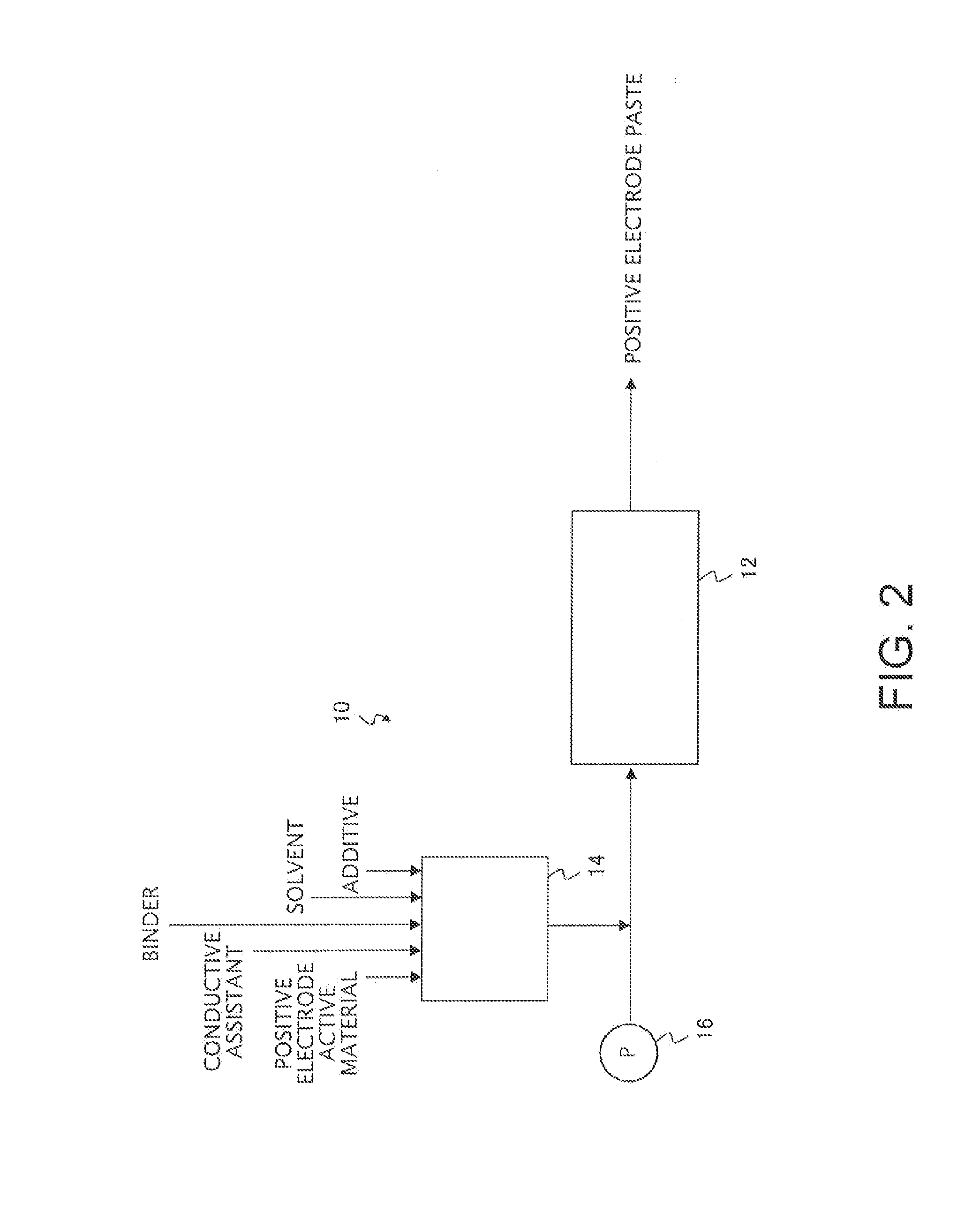

Solid ionically conducting polymer material

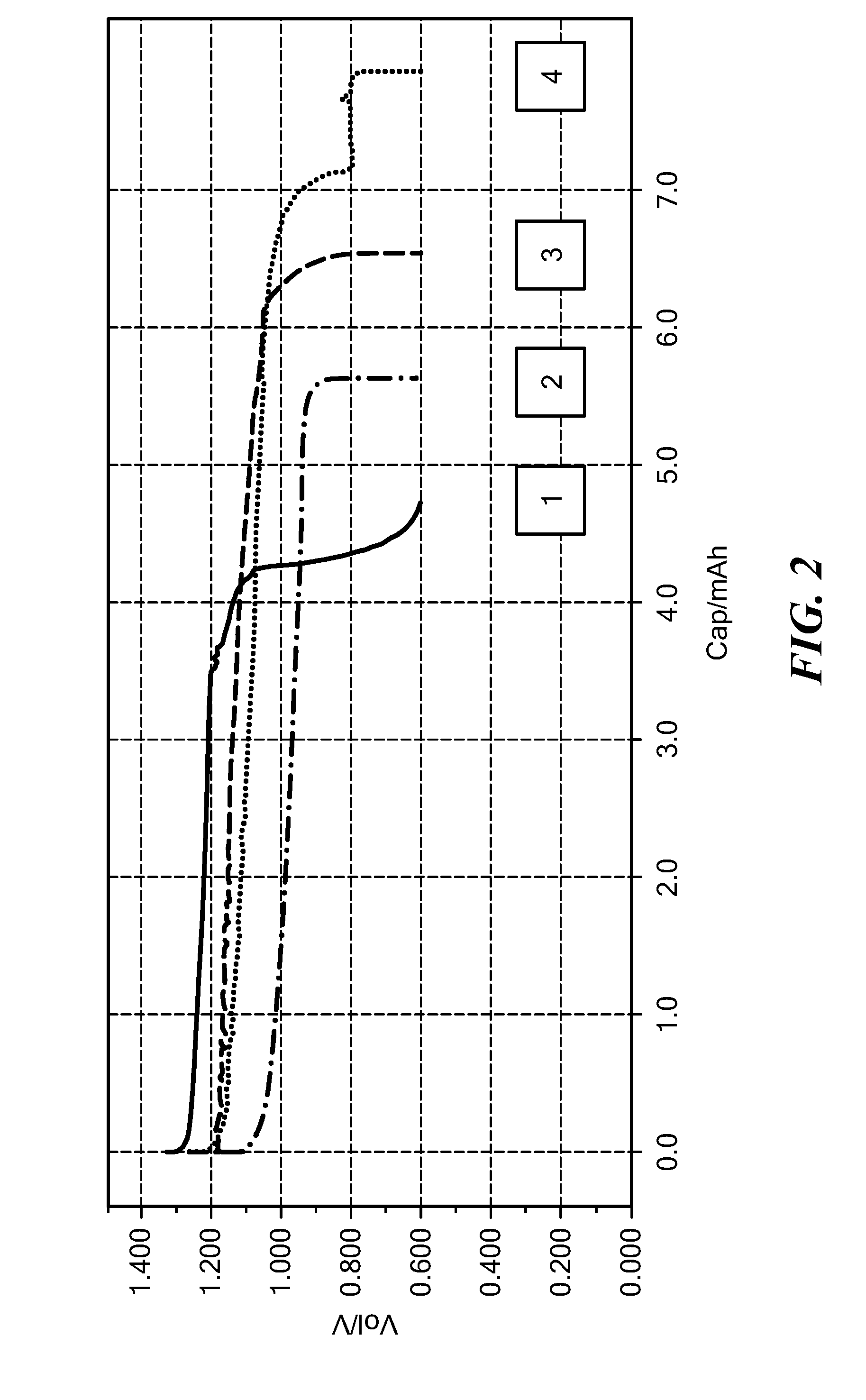

ActiveUS20170018781A1Increase capacityProlong lifeSolid electrolytesAlkaline accumulatorsCharge-transfer complexConductive polymer

A solid, ionically conductive, non-electrically conducting polymer material with a plurality of monomers and a plurality of charge transfer complexes, wherein each charge transfer complex is positioned on a monomer.

Owner:IONIC MATERIALS INC

Process for producing heat-expandable microspheres and application thereof

ActiveUS20160310924A1Good dispersionSmall particle sizeTransportation and packagingElectrode carriers/collectorsColloidal silicaLithium

A process for producing heat-expandable microspheres including a thermoplastic resin shell and a blowing agent encapsulated therein. The process includes the steps of dispersing a polymerizable component and the blowing agent in an aqueous dispersion medium having a pH of 7 or less and containing a fine-particle metal compound having a mean particle size ranging from 1.0 to 10 nm, and polymerizing the polymerizable component. The amount of the fine-particle metal compound ranges from 0.15 to 20 parts by weight to 100 parts by weight of the total amount of the polymerizable component and the blowing agent. Also disclosed are heat-expandable microspheres produced by dispersing a polymerizable component and a blowing agent in an aqueous dispersion medium containing colloidal silica and polymerizing the polymerizable component. Also disclosed is a composition containing the heat-expandable microspheres and a base component, a formed product, a slurry composition for use in forming a negative electrode of a lithium-ion secondary battery and a negative electrode.

Owner:MATSUMOTO YUSHI SEIYAKU

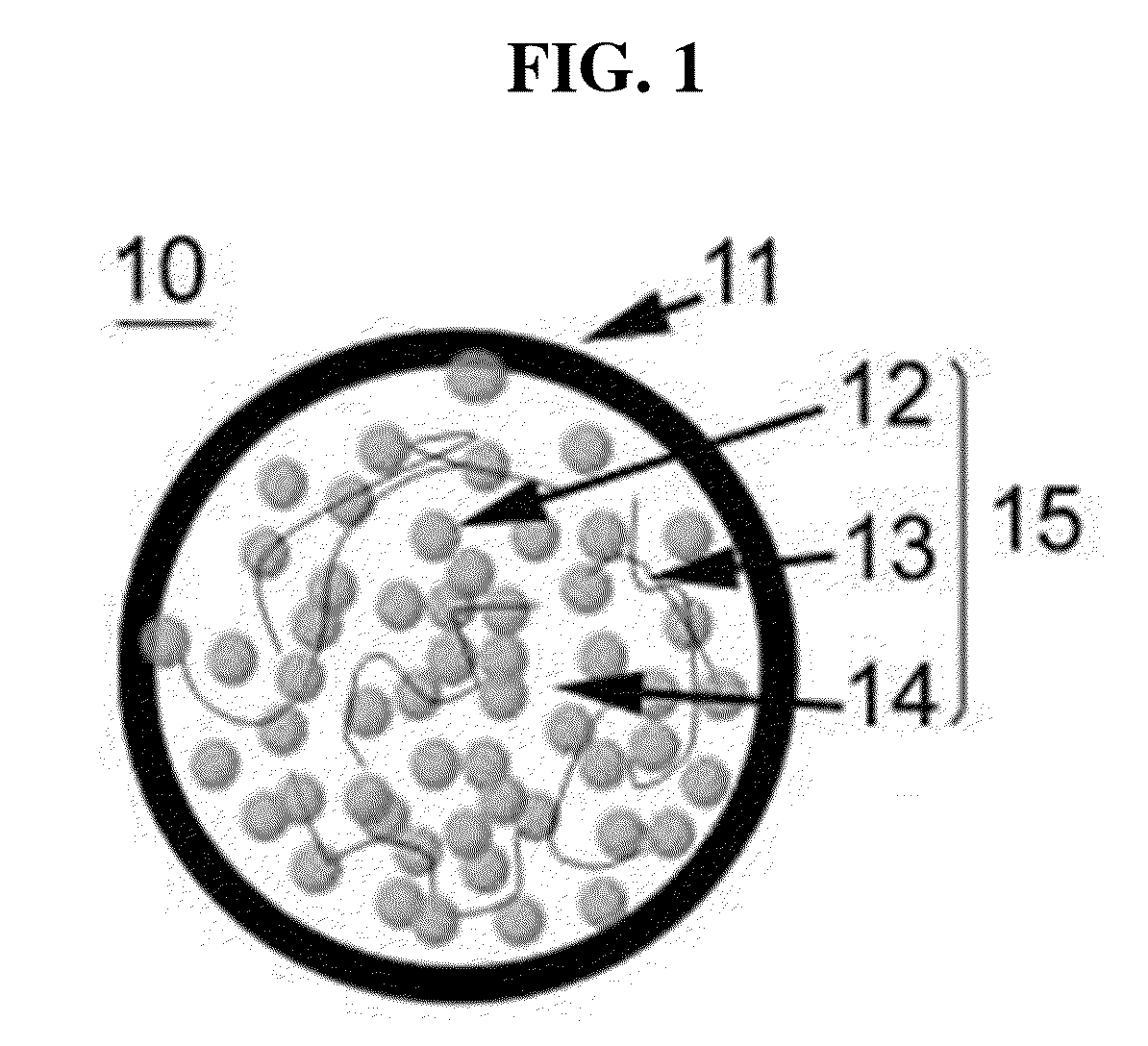

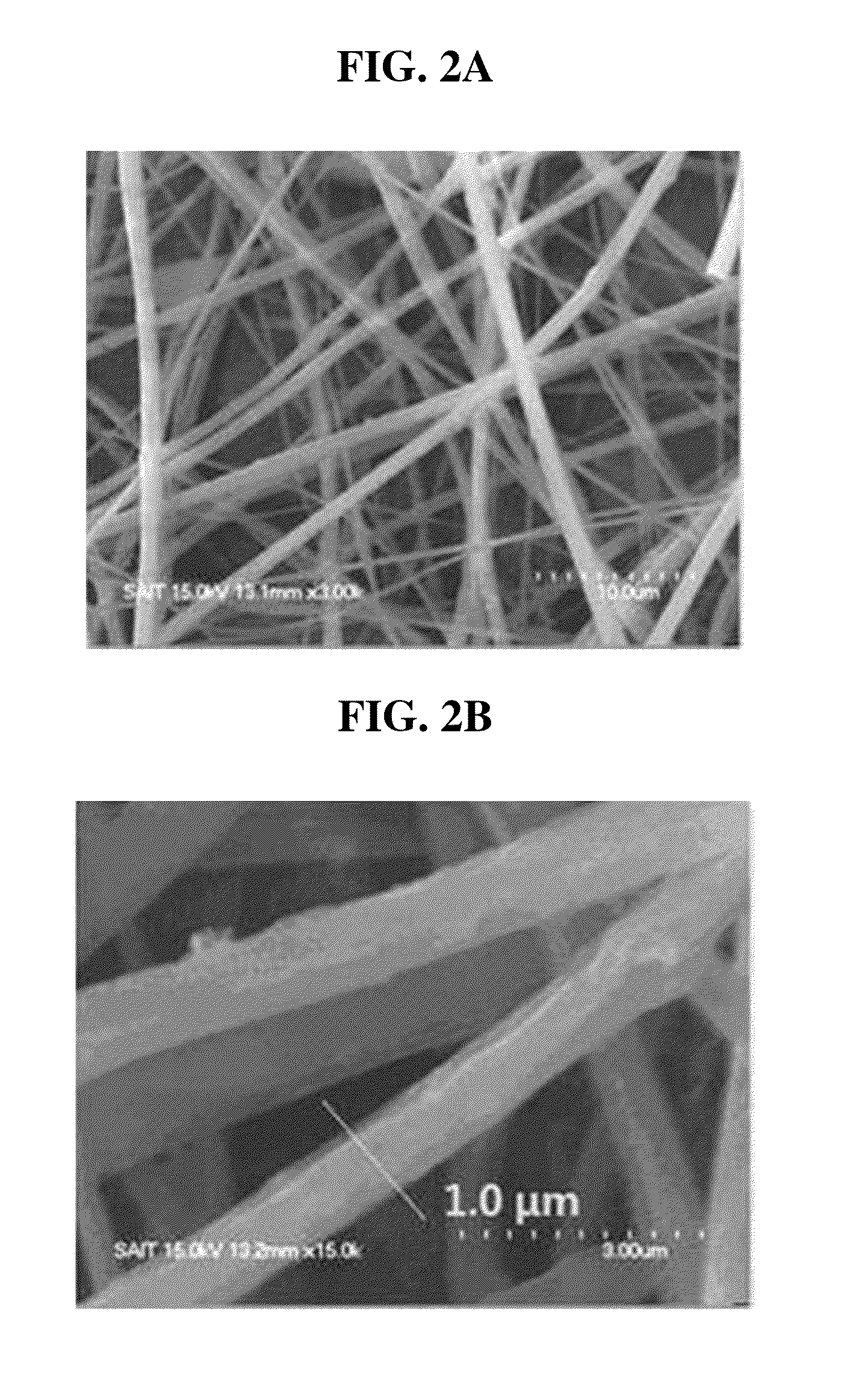

Composite anode active material, anode and lithium battery each including the composite anode active material, method of preparing the composite anode active material

ActiveUS20140087255A1Increase capacityImprove featuresSilver accumulatorsMicroscopic fiber electrodesFiberCarbon fibers

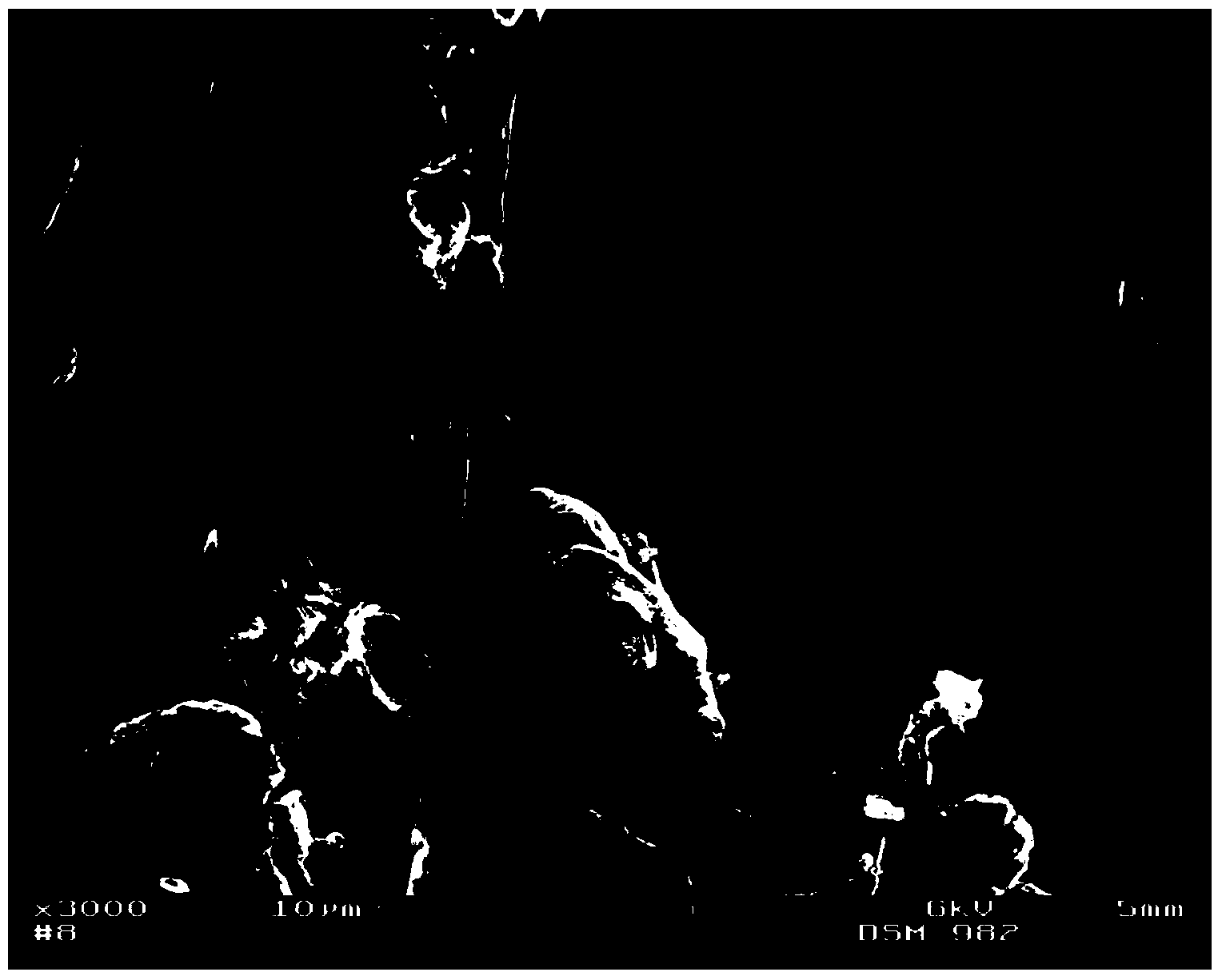

A composite anode active material, an anode including the composite anode active material, a lithium battery including the anode, and a method of preparing the composite anode active material. The composite anode active material includes: a shell including a hollow carbon fiber; and a core disposed in a hollow of the hollow carbon fiber, wherein the core includes a first metal nanostructure and a conducting agent.

Owner:SAMSUNG ELECTRONICS CO LTD

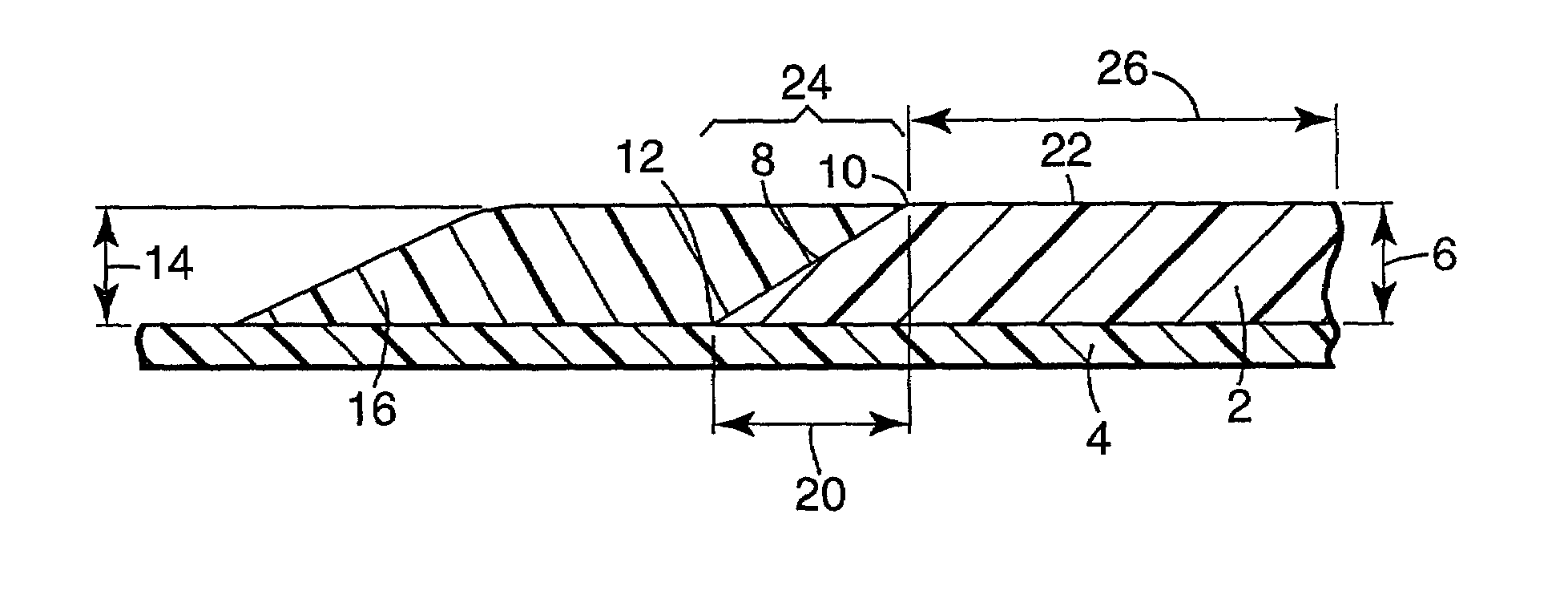

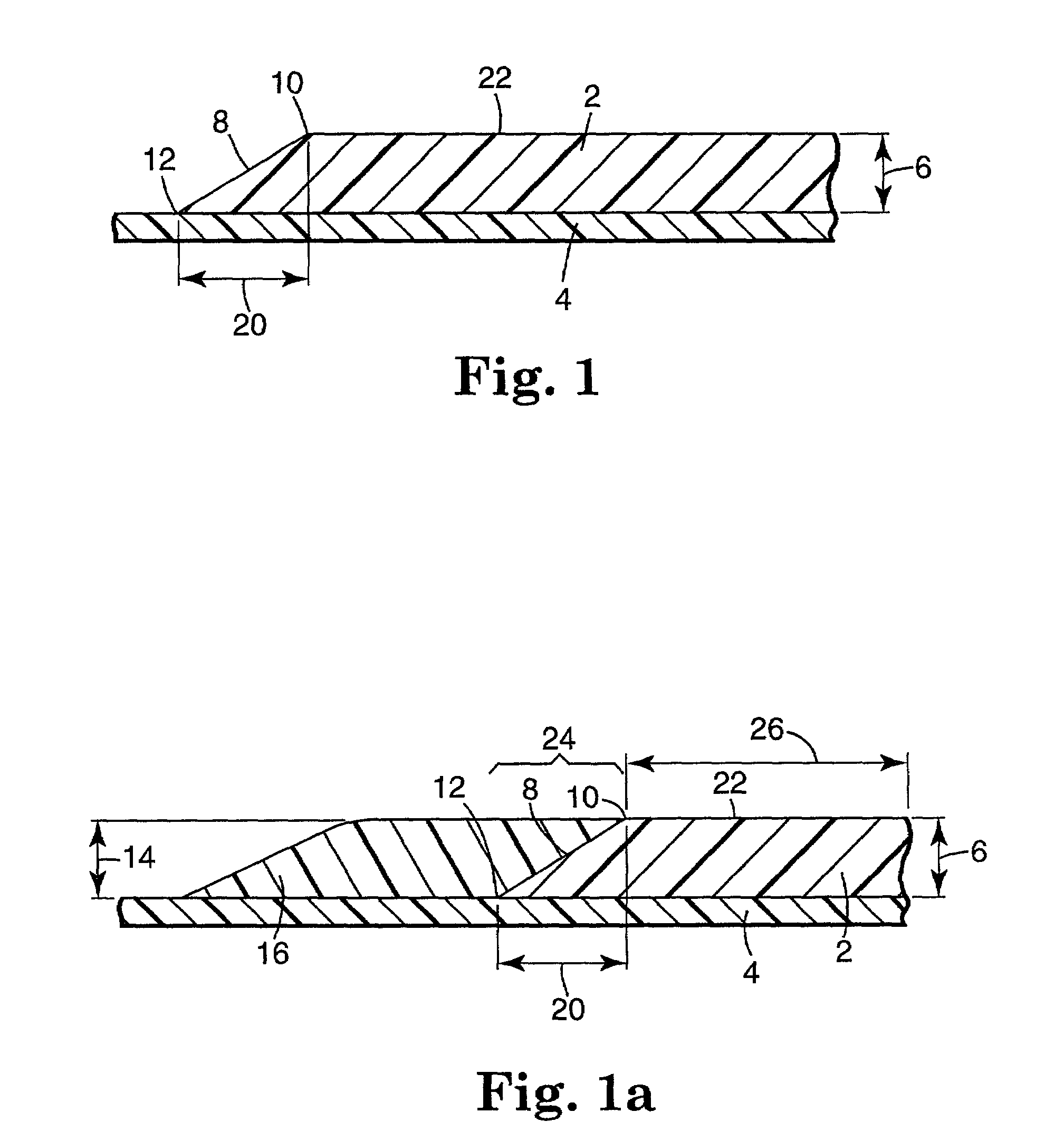

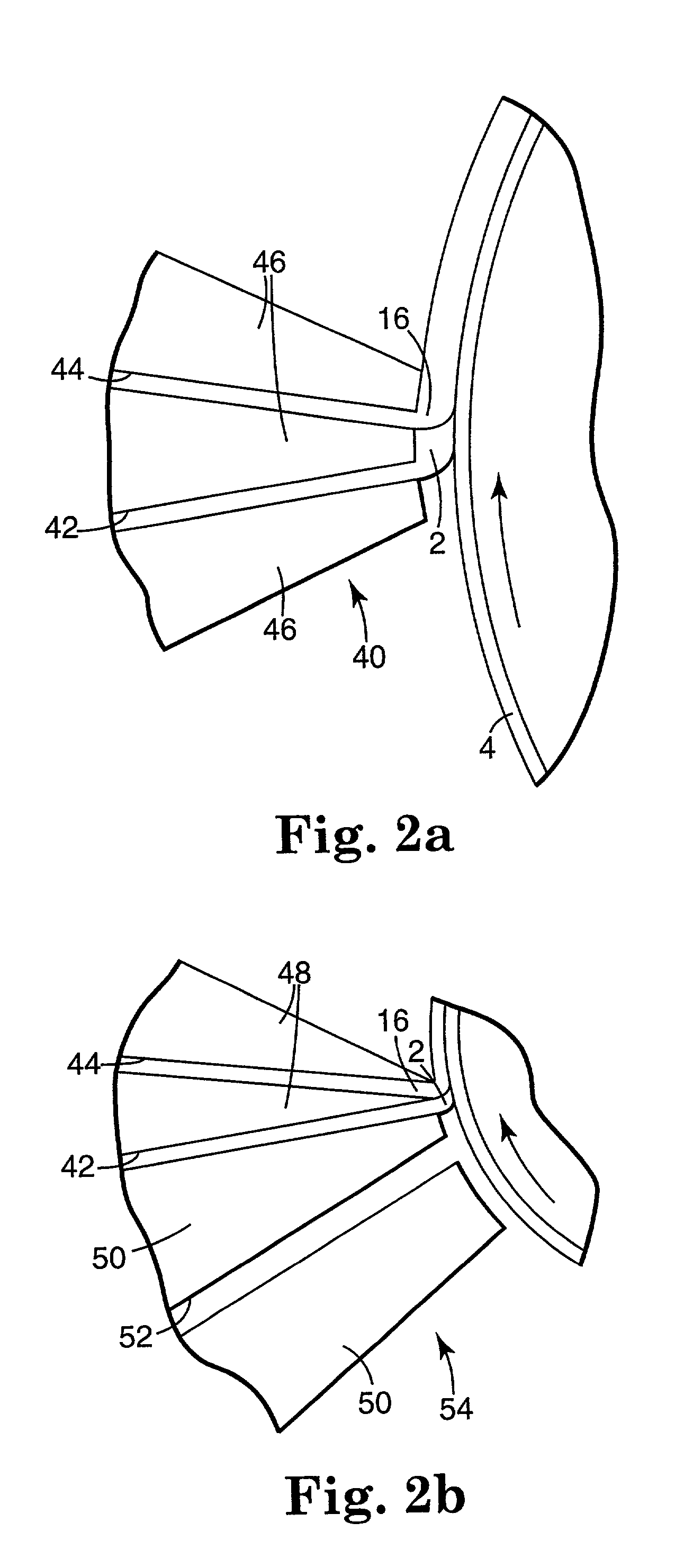

Coating edge control

InactiveUS7097673B2Efficient preparationEasy to shapeElectrode rolling/calenderingFinal product manufactureElectrochemical cellCoating materials

Described are methods and products prepared from the methods, each of which include methods of coating certain materials onto a substrate, including coating a coating material and an edge material onto the substrate in a manner which may provide an improved thickness profile of the overall coating, and that may do so by using the edge material to augment the thickness of the coating material edge, or that may do so by improving the coating material edge by using the edge material to affect the shape of the coating material edge, the products being useful, for example, in electrochemical cells.

Owner:3M INNOVATIVE PROPERTIES CO

Electrochemical cell having solid ionically conducting polymer material

ActiveUS20180006308A1Low effective aqueous porosityLarge specific surface areaSolid electrolytesAlkaline accumulatorsConductive polymerElectrochemical cell

Owner:IONIC MATERIALS INC

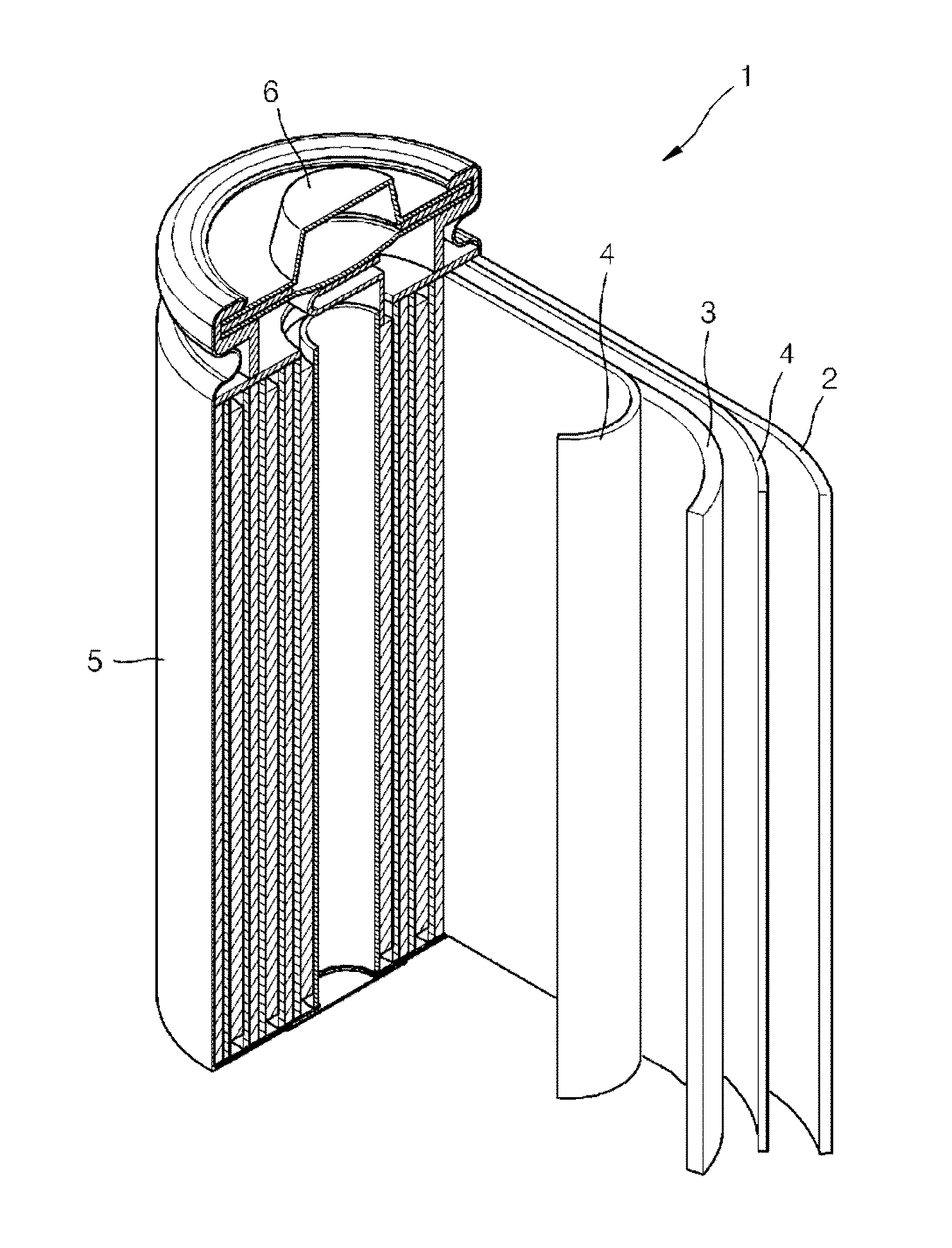

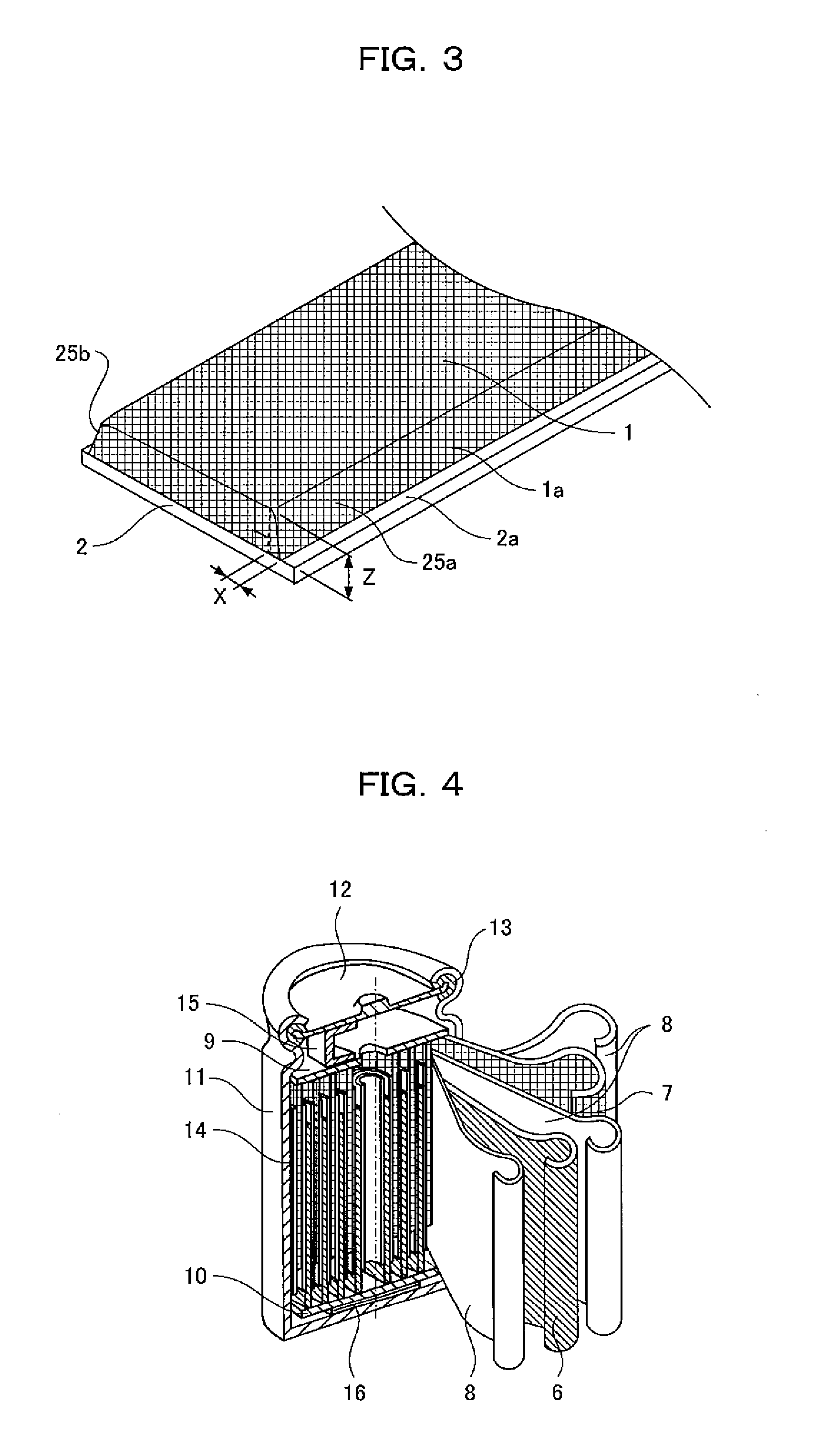

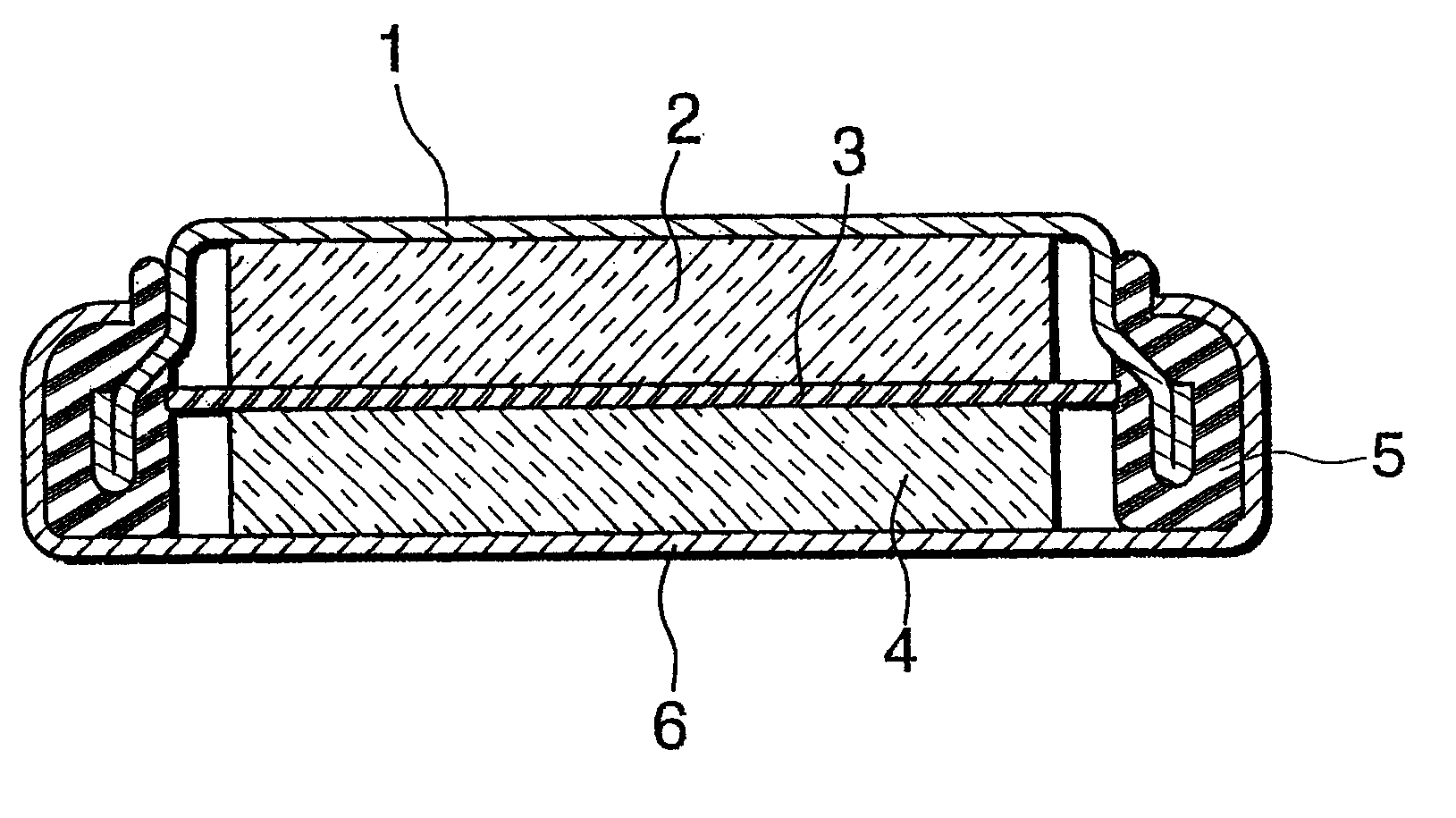

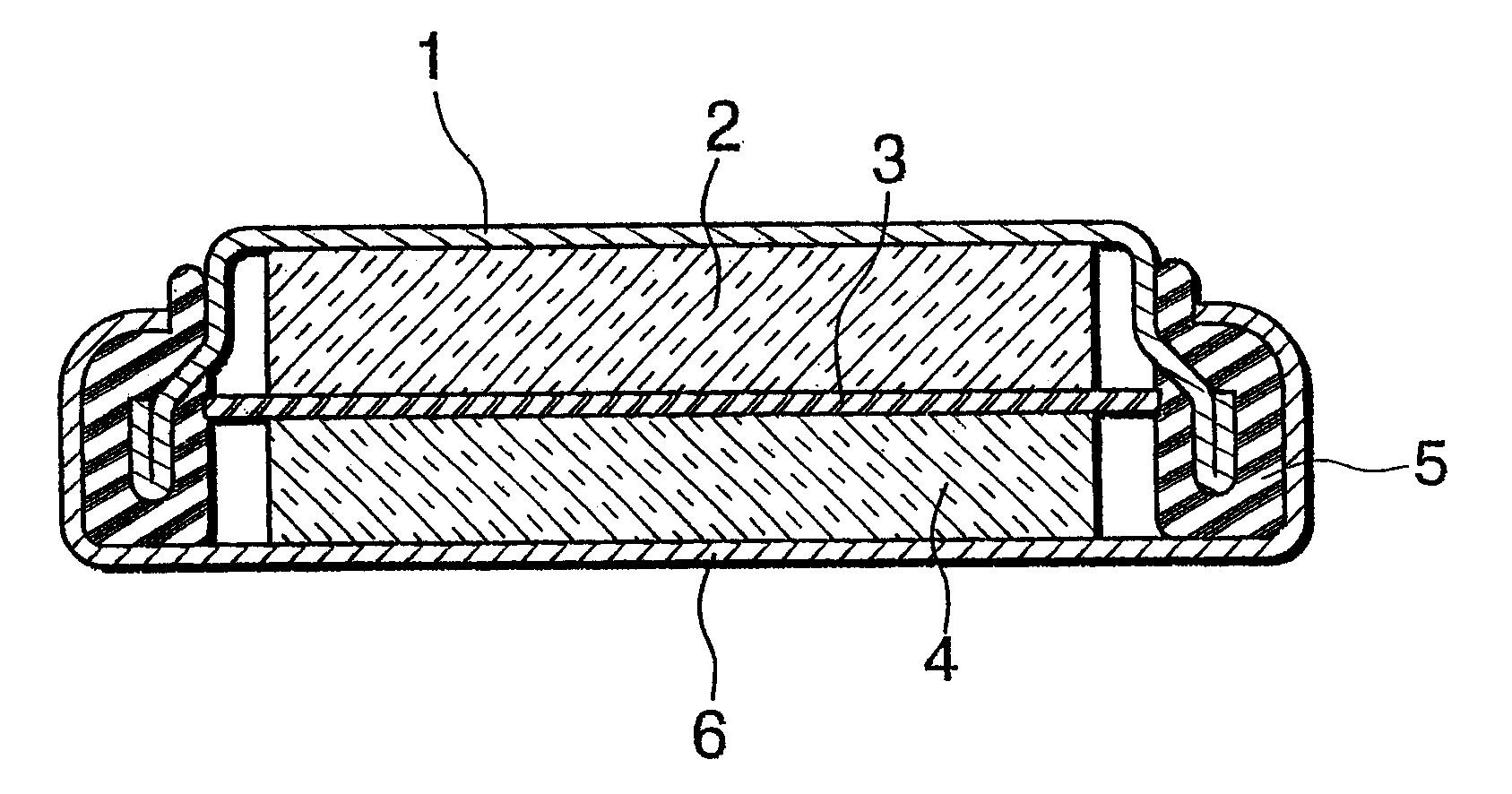

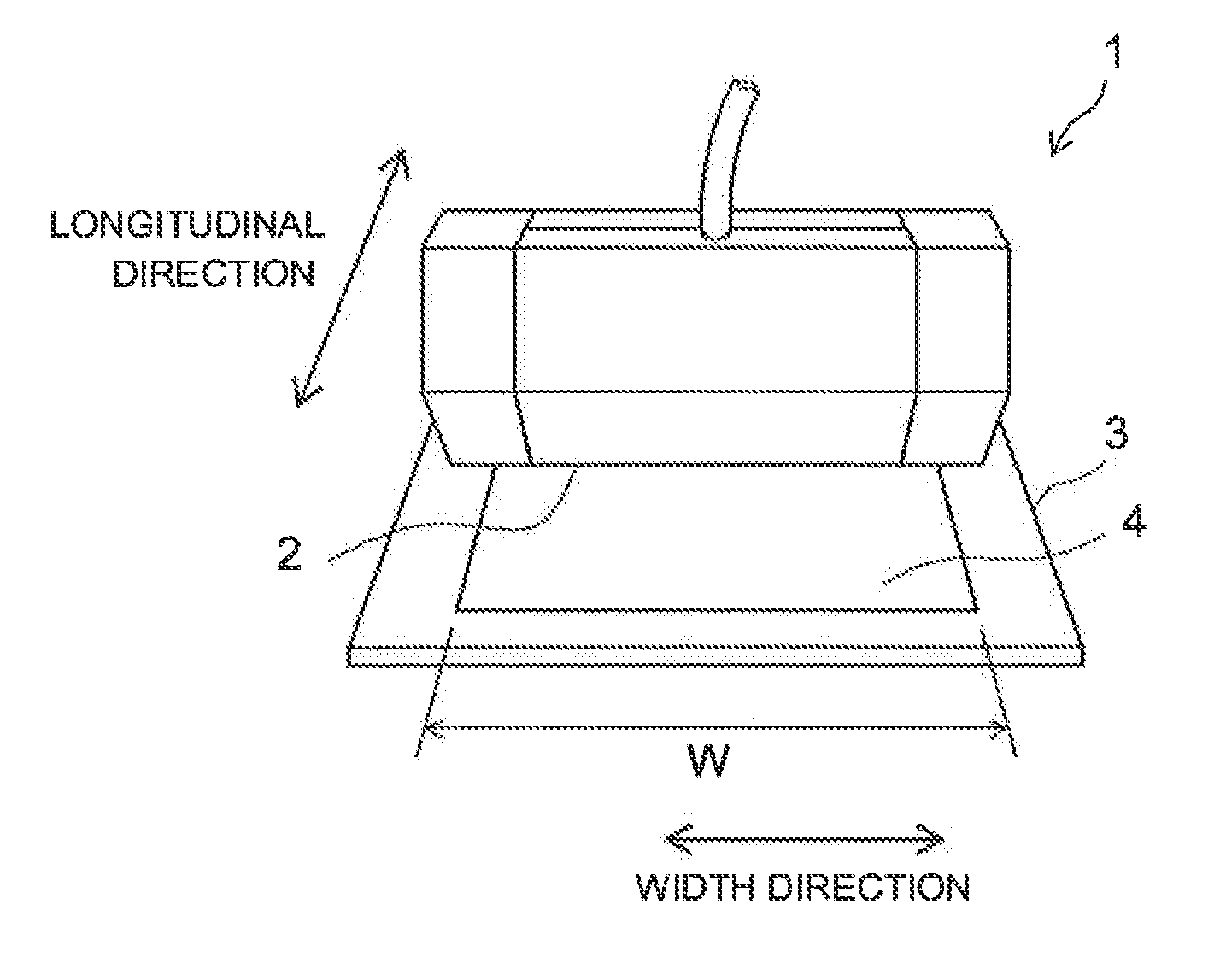

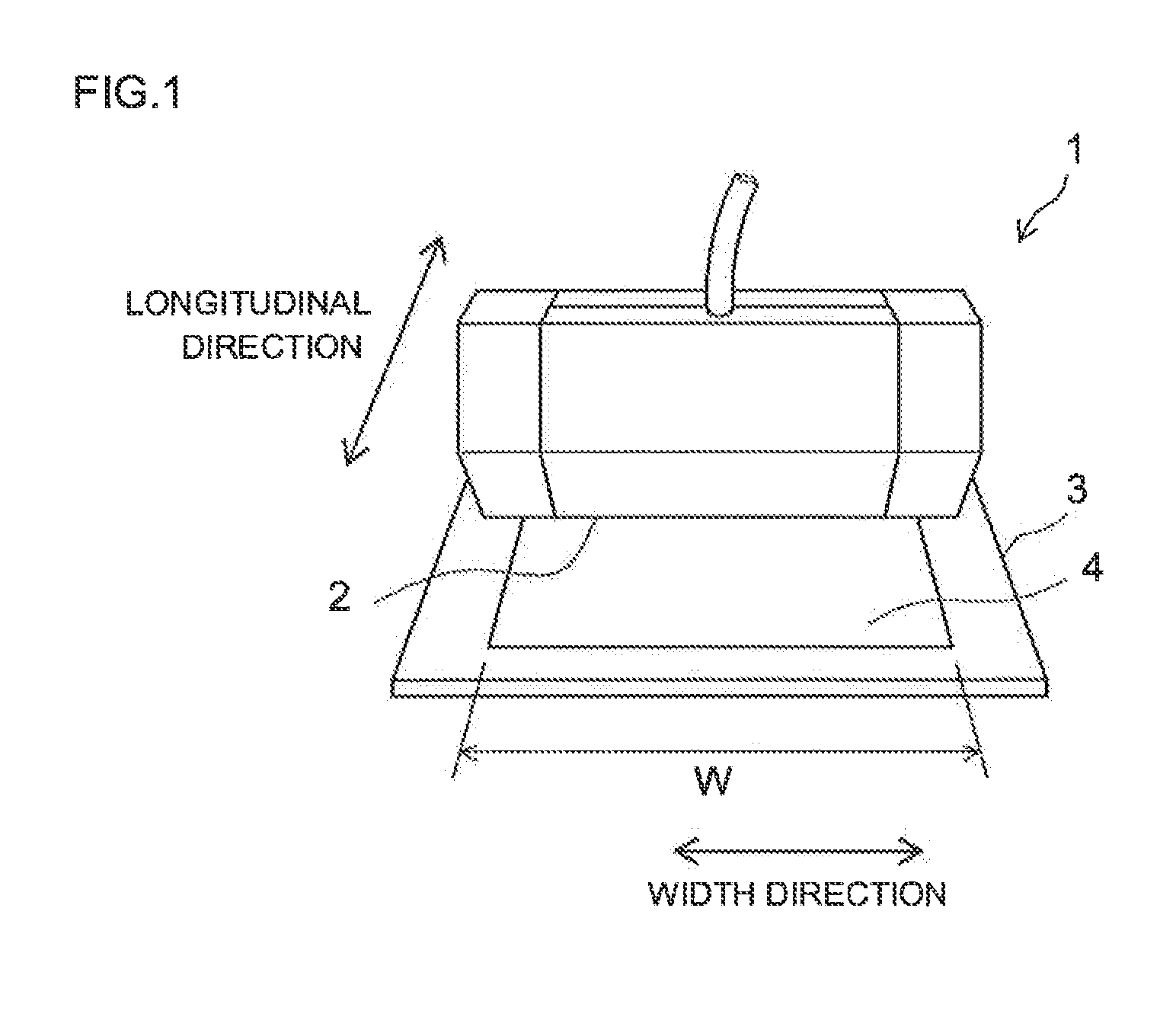

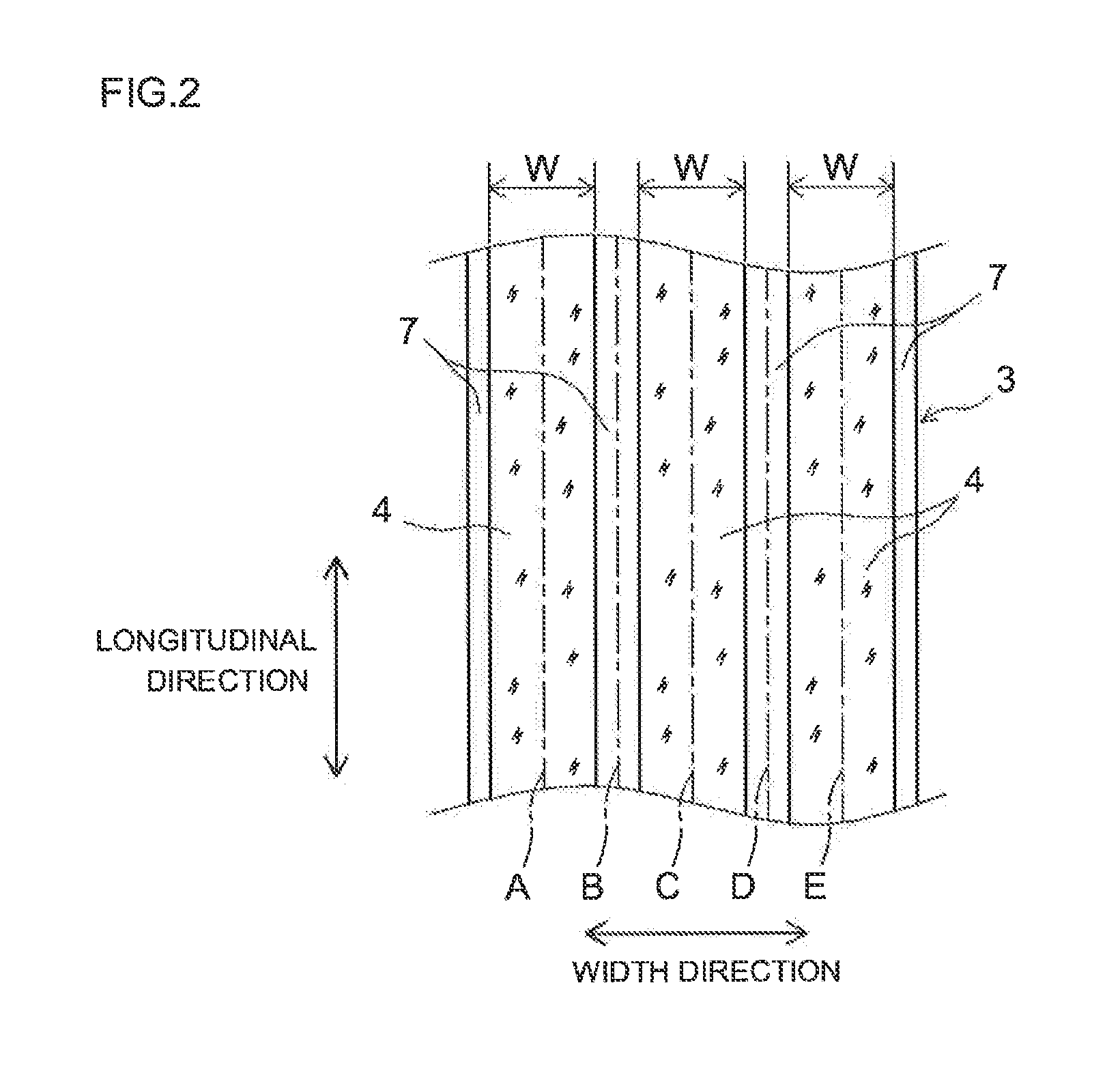

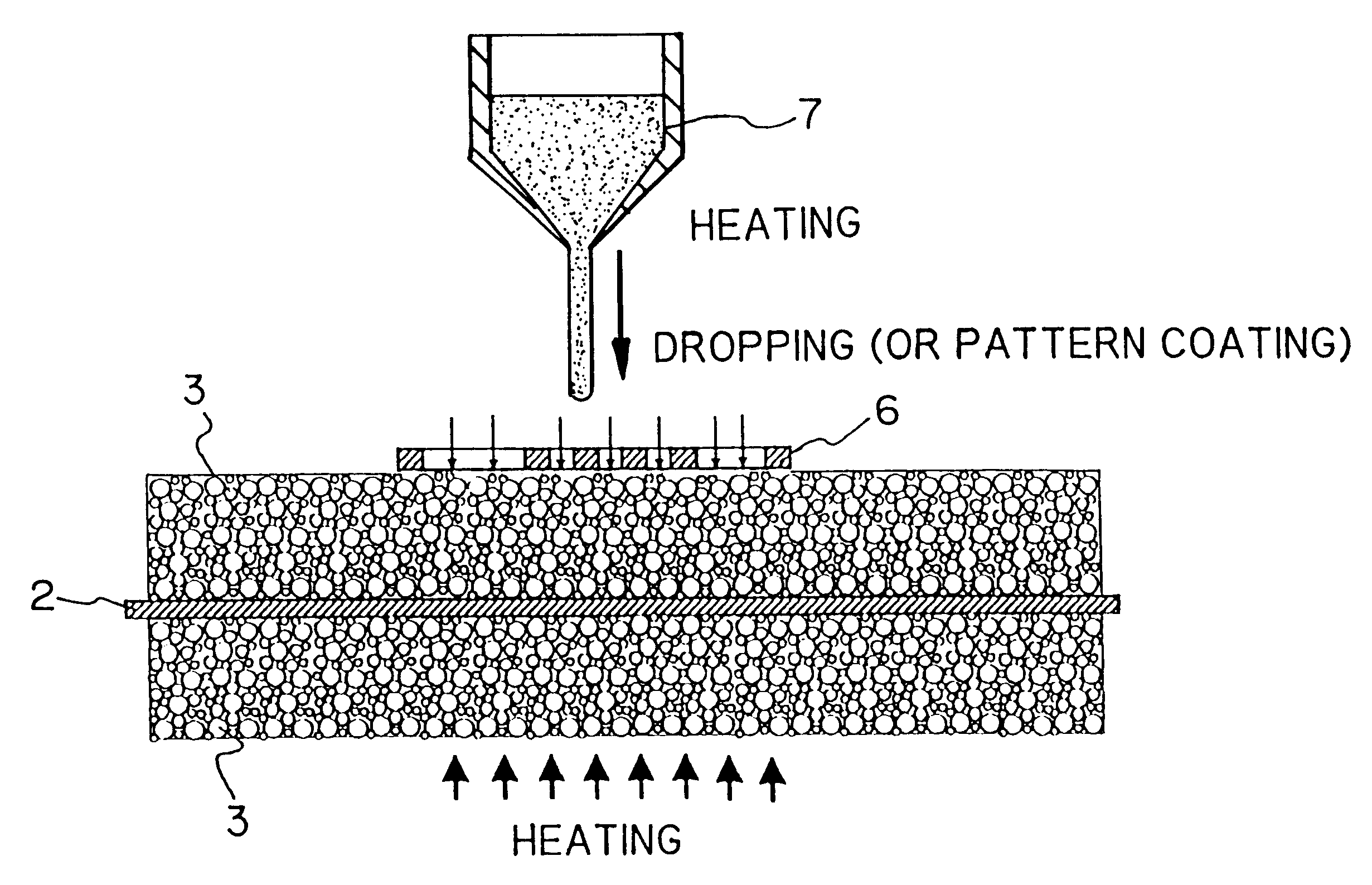

Battery, method of manufacturing the same and non-aqueous secondary battery using the same

InactiveUS20110052954A1Uniform thicknessLarge capacityElectrode rolling/calenderingFinal product manufactureElectrical batteryLaminated composites

To provide an electrode plate capable of retaining a larger amount of active material and having a composite material layer uniform in thickness, a positive electrode plate (6) or a negative electrode plate (7) is formed by laminating a composite material layer (1) of the active material on a surface of a current collector plate (2) in strip form. A slope in a thickness direction (X / Z) of the end surfaces of the composite material layer (1) along the longer sides of the current collector plate (2) is “0<(X / Z)≦1”.

Owner:PANASONIC CORP

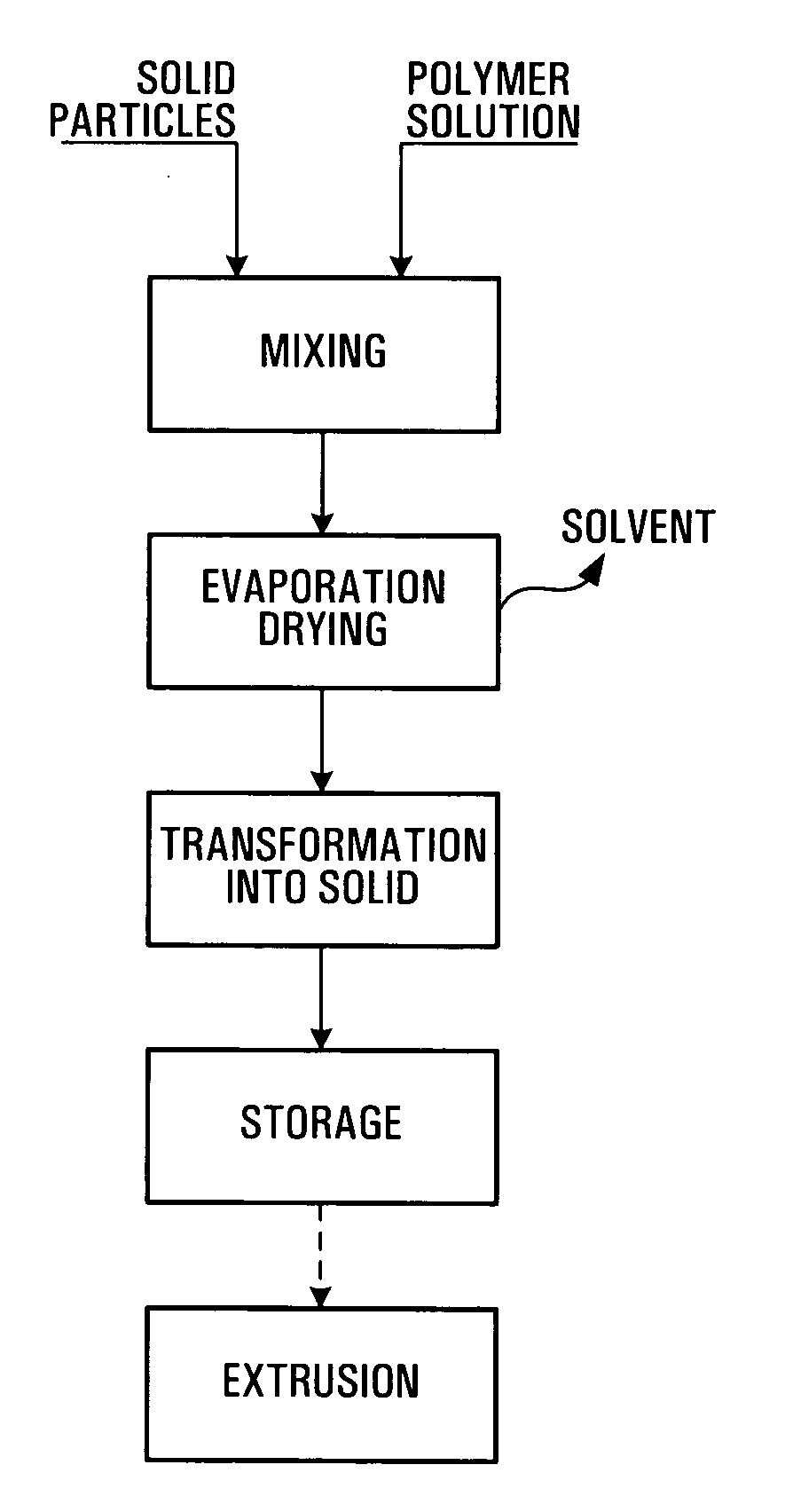

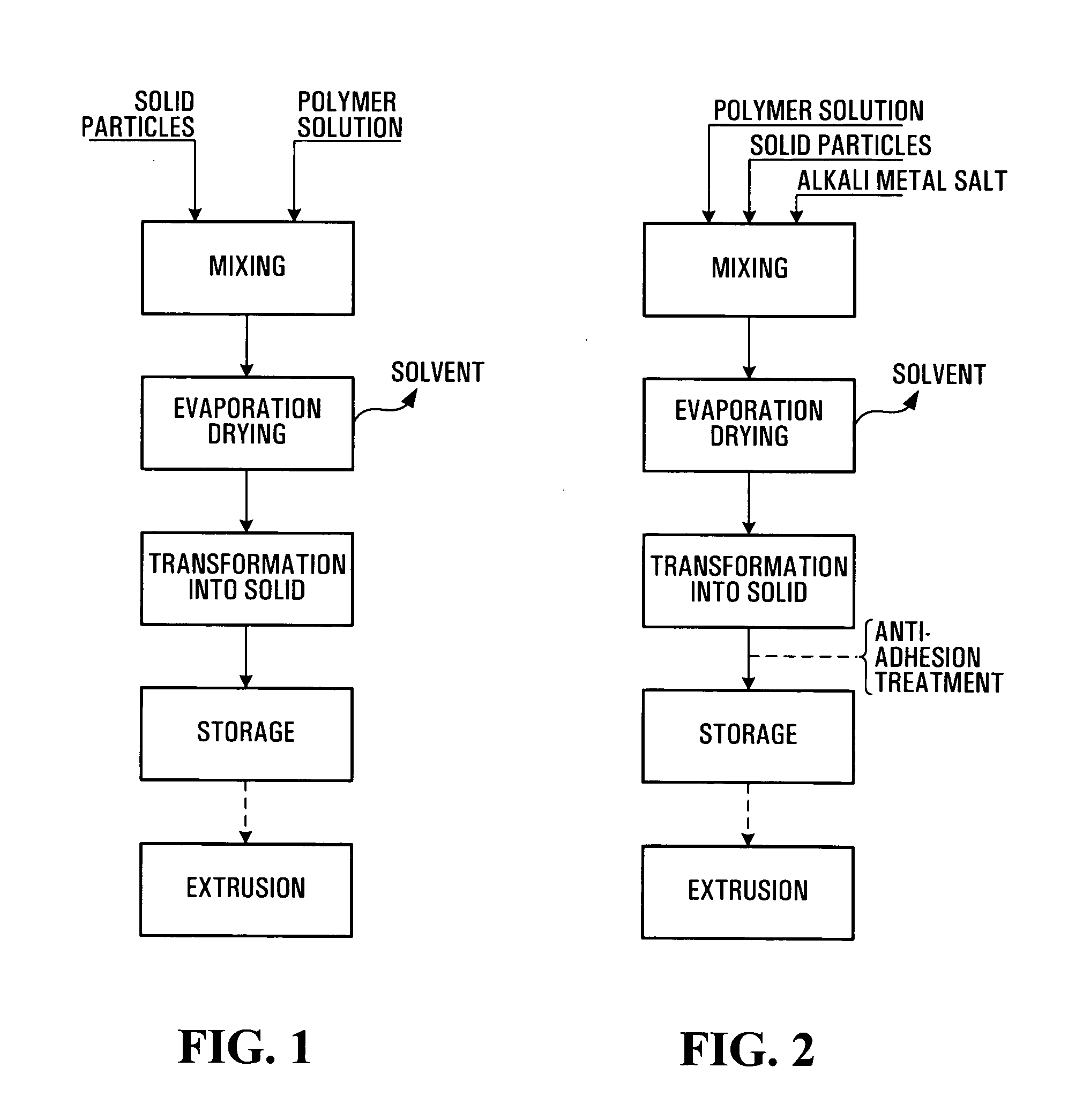

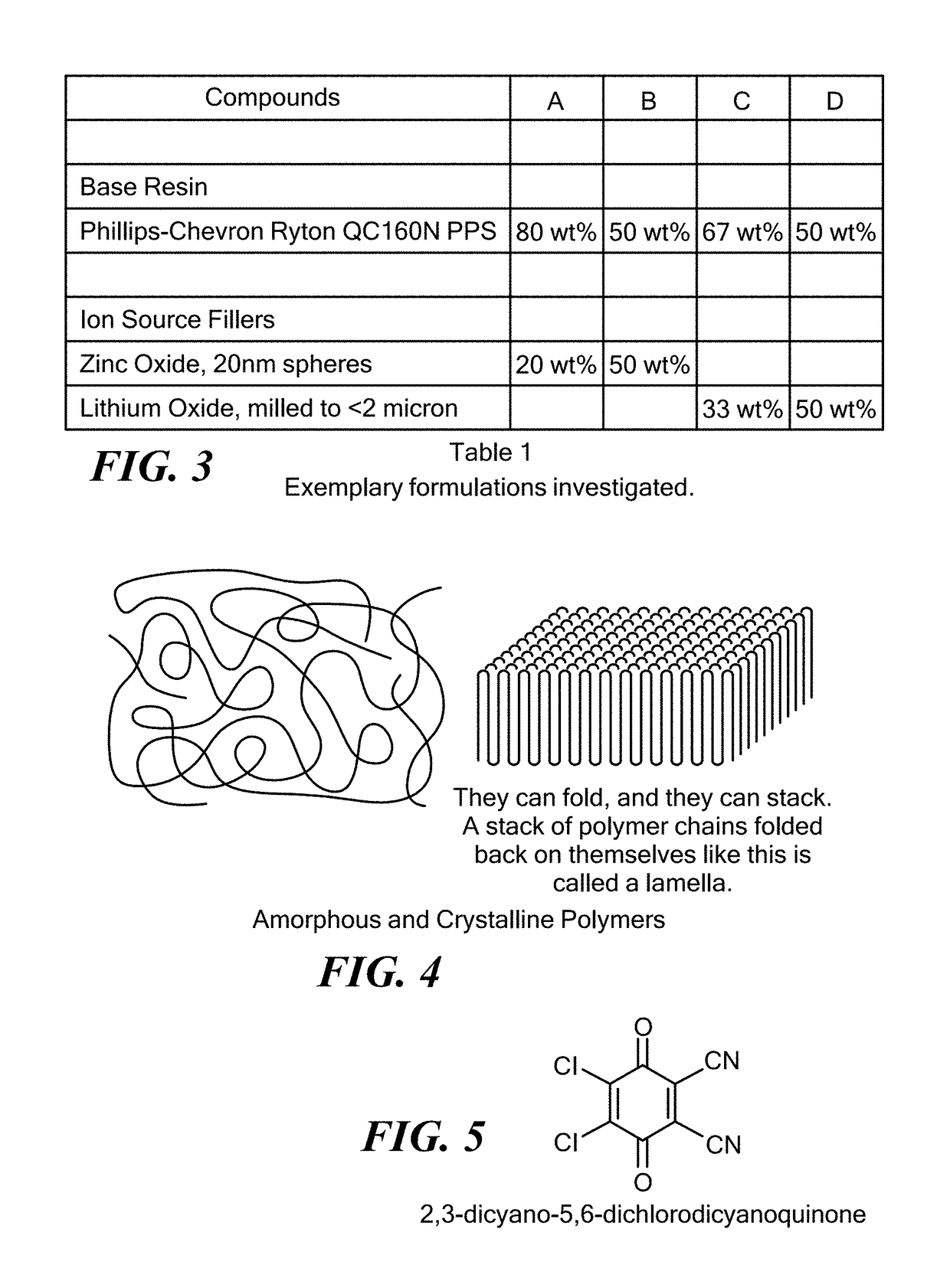

Cathode material for polymer batteries and method of preparing same

The invention provides a pre-mix of positive electrode material in transportable solid form comprising polymer and solid particles of electrochemically active material and / or electronically conductive additives and a process for preparing a pre-mix positive electrode in transportable solid form. The pre-mix positive electrode material may also comprise an alkali metal salt either dissolved or dispersed in the mixture. The invention also provides making a cathode film from the transportable solid pre-mix of positive electrode material.

Owner:BATHIUM CANADA

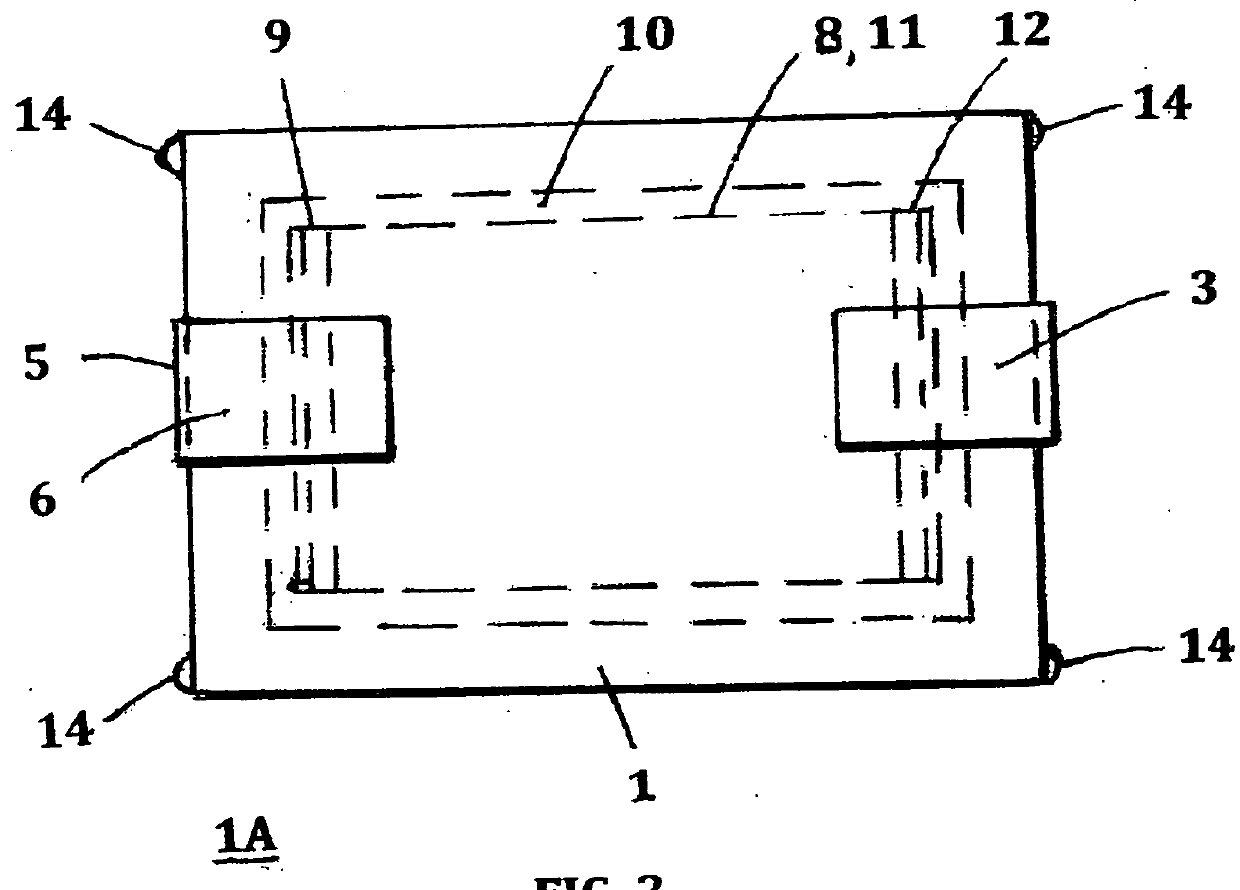

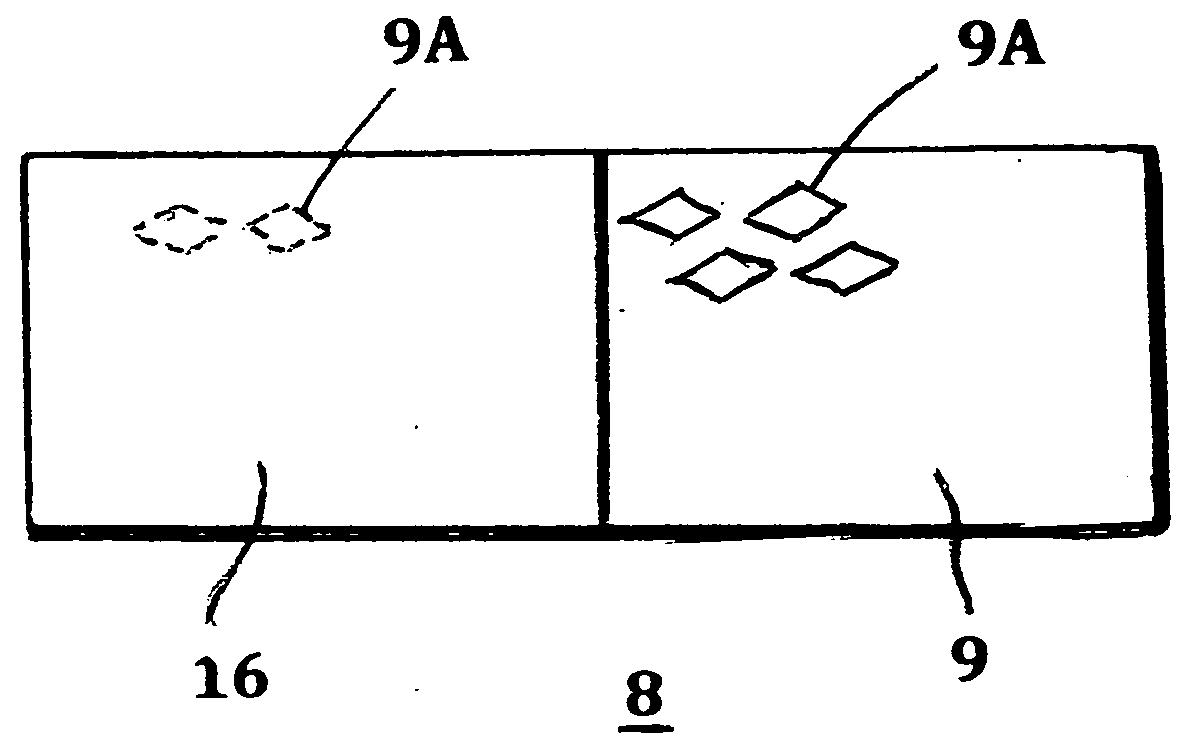

Electrode plate for secondary battery with nonaqueous electrolyte

InactiveUS6051338AElectrode rolling/calenderingElectrode melt handlingEngineeringElectrical and Electronics engineering

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and said electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

Additives for lubricating agents used in the lamination of lithium sheets into thin films

InactiveUS6517590B1Lower impedanceEasy to controlElectrode rolling/calenderingPrimary cellsLithiumOligomer

These additives are represented by the following general formula:in which L designates a hydrocarbon radical which serves as lubricating segment; S designates an oligomer segment which serves as solvating segment of metallic salts and Y designates a chemical bond which joins the hydrocarbon radical and the oligomer segment. With these additives there is no more need to subsequently wash the surface of laminated lithium.

Owner:BATHIUM CANADA

Alkaline metal-air battery cathode

ActiveUS20170092958A1Reduce oxygenIon-exchange process apparatusFuel and primary cellsConductive polymerEngineering

A metal-air battery and a component air cathode including a solid ionically conductive polymer material.

Owner:IONIC MATERIALS INC

Method of Assembly of Electrochemical Cells for High Temperature Applications

InactiveUS20180108496A1Easy constructionImprove conductivityElectrolytic capacitorsFinal product manufactureElectrical batteryEngineering

Heat resistant, highly conductive electrochemical cells for high temperature applications and methods of their assembly are described herein. The cells have at least two electrodes and at least one separator enclosed in heat resistant ceramic enclosure with metalized terminals on its bottom. Methods of the electrodes' tabs welding to inside connectors and the electrodes' coating are also disclosed. The resulting cells are solderable to circuit boards or various circuits.

Owner:VENKATESWARAN SAGAR +1

Solid, ionically conducting polymer material, and methods and applications for same

ActiveUS9742008B2Efficient porosityLow orSolid electrolytesAlkaline accumulatorsPolymer sciencePolymer

A rechargeable alkaline battery including an anode; a cathode; and an electrolyte is described. At least one of the anode, the cathode and the electrolyte includes a solid, ionically conducting polymer material. Methods for the manufacture of same are also described.

Owner:IONIC MATERIALS INC

Electrode paste production method

ActiveUS20160099461A1Efficient use ofLow-viscosity electrodeRotary stirring mixersSecondary cellsSolid fractionSolvent

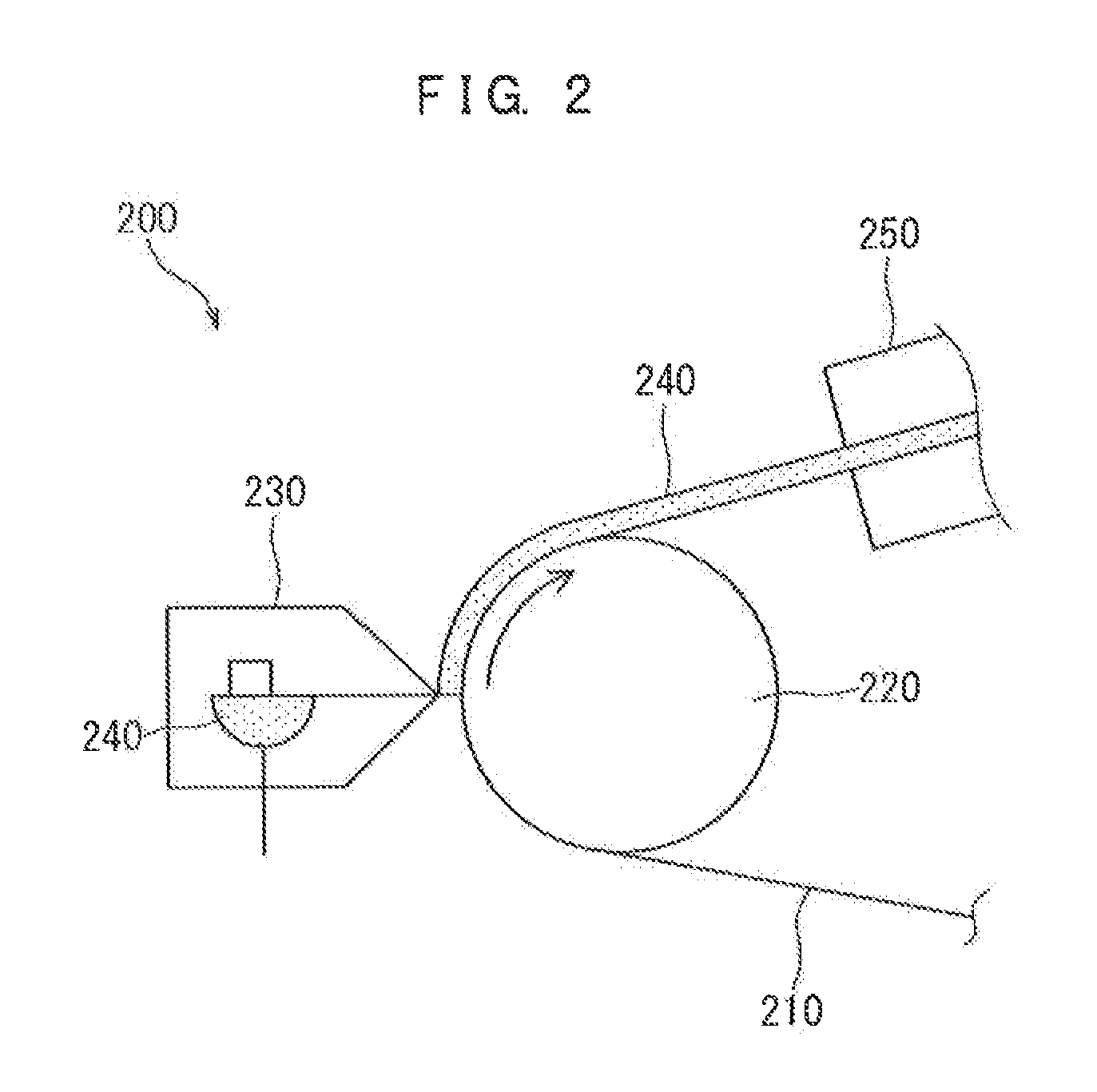

Provided is an electrode paste production method that can produce a low-viscosity electrode paste which can be readily applied even if the solid content concentration is high, for example in excess of 65% by mass. The electrode paste production method, in which the paste contains an active material and a solvent, includes a micromixing treatment step in which a mixture of a solid fraction containing an active material blended at a high solid content concentration and a solvent is kneaded using a micromixer.

Owner:TOYOTA JIDOSHA KK

Battery manufacturing method (as amended)

ActiveUS20130202781A1Good adhesivenessImprove quality stabilityFinal product manufactureSecondary cellsSolventAqueous solution

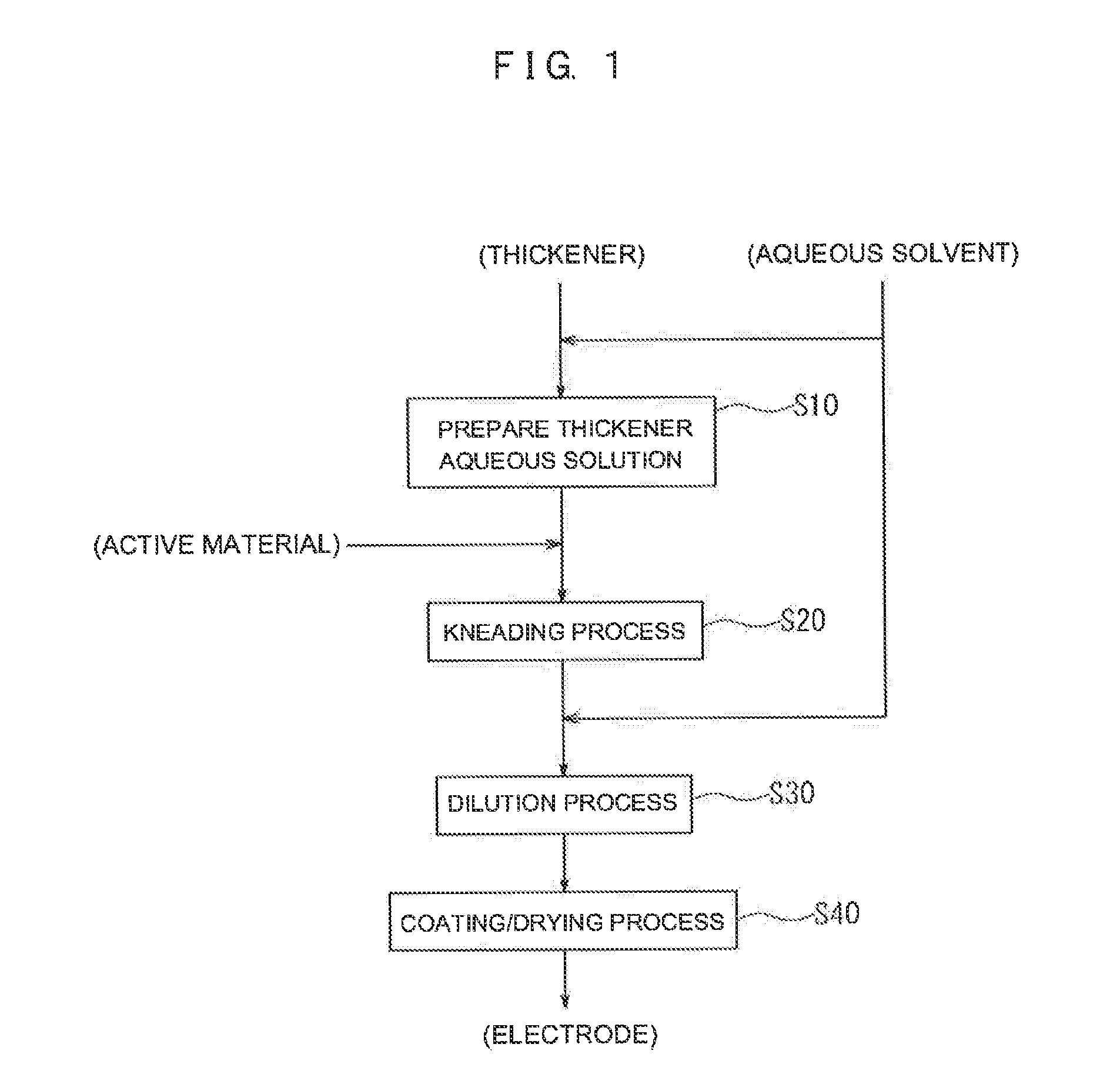

The present invention provides a battery manufacturing method including: a step of preparing a thickener aqueous solution by dissolving a thickener in an aqueous solvent (S10); a kneading step of introducing an active material into the prepared thickener aqueous solution and kneading a result (S20); a diluting step of adding an aqueous solvent to a kneaded material resulting from the kneading step such that the kneaded material is diluted, whereby an active material layer forming paste is obtained from the kneaded material (S30); and a step of obtaining an electrode in which an active material layer is formed on a current collector by coating the current collector with the active material layer forming paste and then drying the paste (S40).

Owner:TOYOTA JIDOSHA KK

Cathode for lithium-containing batteries and solvent-free method for the production thereof

InactiveCN104170125ASufficient shear forceReduce contentFinal product manufactureLi-accumulatorsSolvent freeSolvent

The present invention relates to a method for producing a cathode film for a lithium-containing battery, comprising the following steps: (i) providing a dry, solvent-free composition comprising polytetrafluoroethylene, an electrically conductive, electrochemically inactive carbon material and an electrochemically active cathode material; (ii) forming at least partially fibrillated polytetrafluoroethylene by the acting of shearing forces on the dry, solvent-free composition and obtaining a fibrillated composition; (iii) shaping the fibrillated composition into a cathode film.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method of producing an electrode for non-aqueous electrolyte battery

InactiveUS6361822B1Eliminate effect produced by moistureReduce capacityElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsMetallurgyMoisture

Owner:TDK CORPARATION

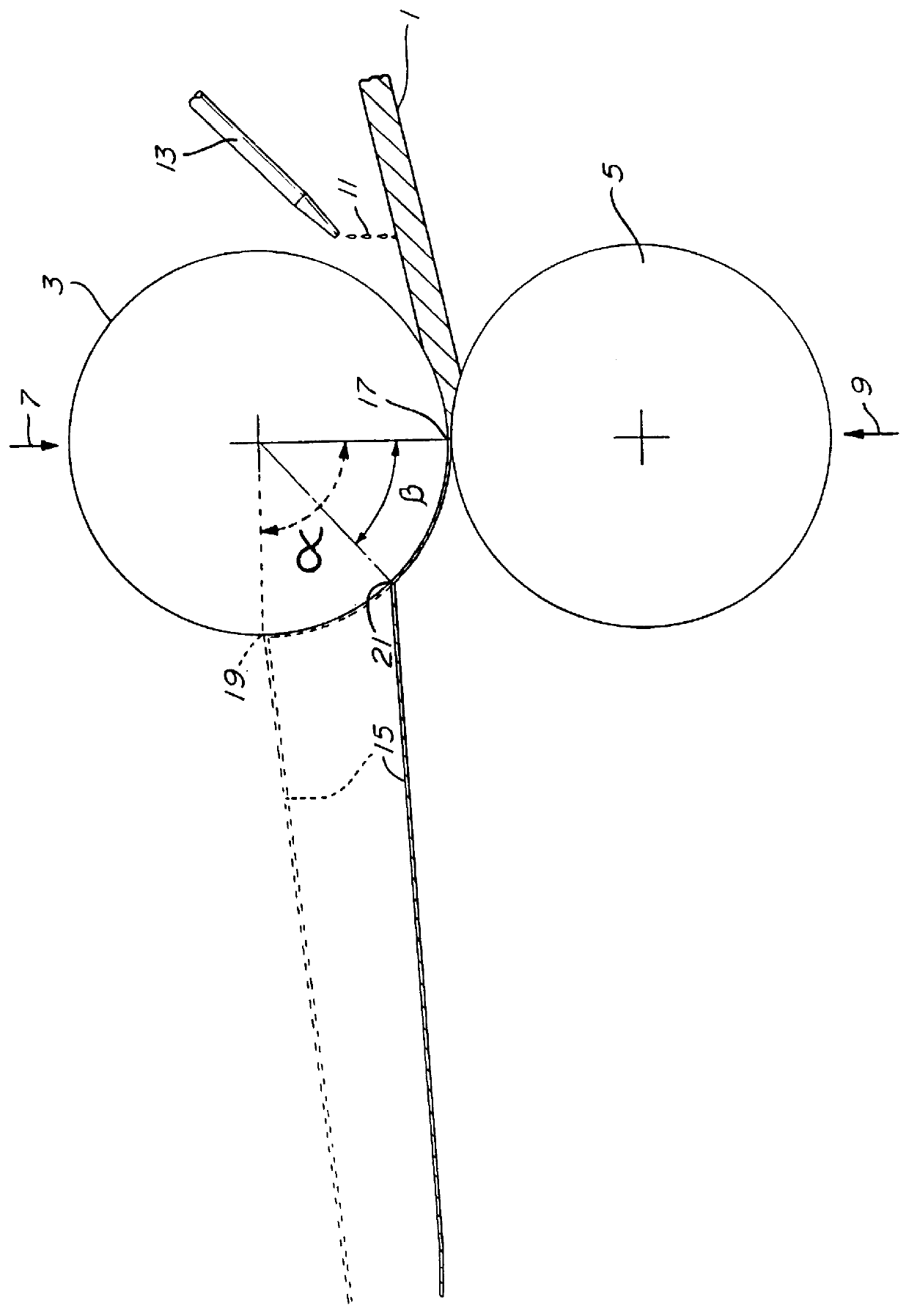

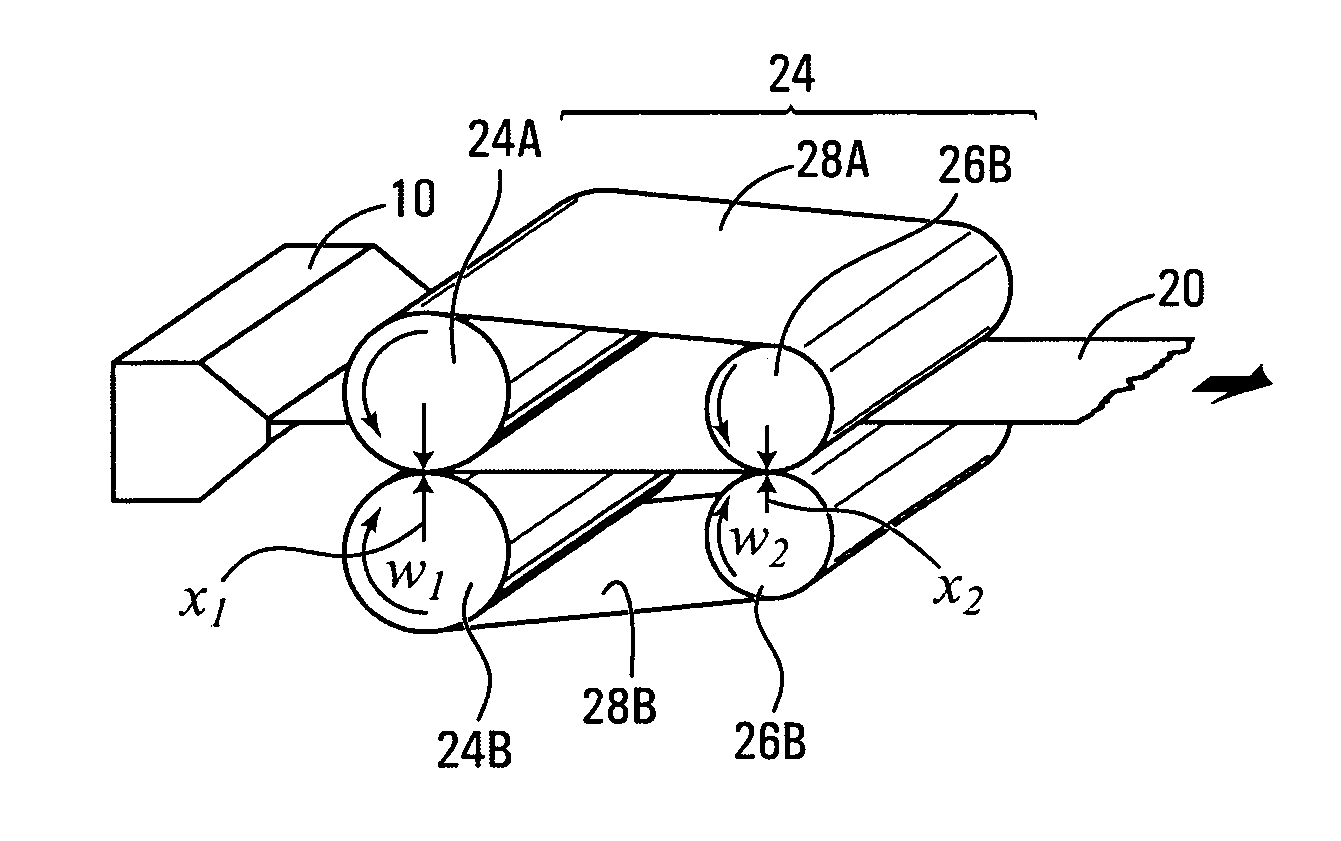

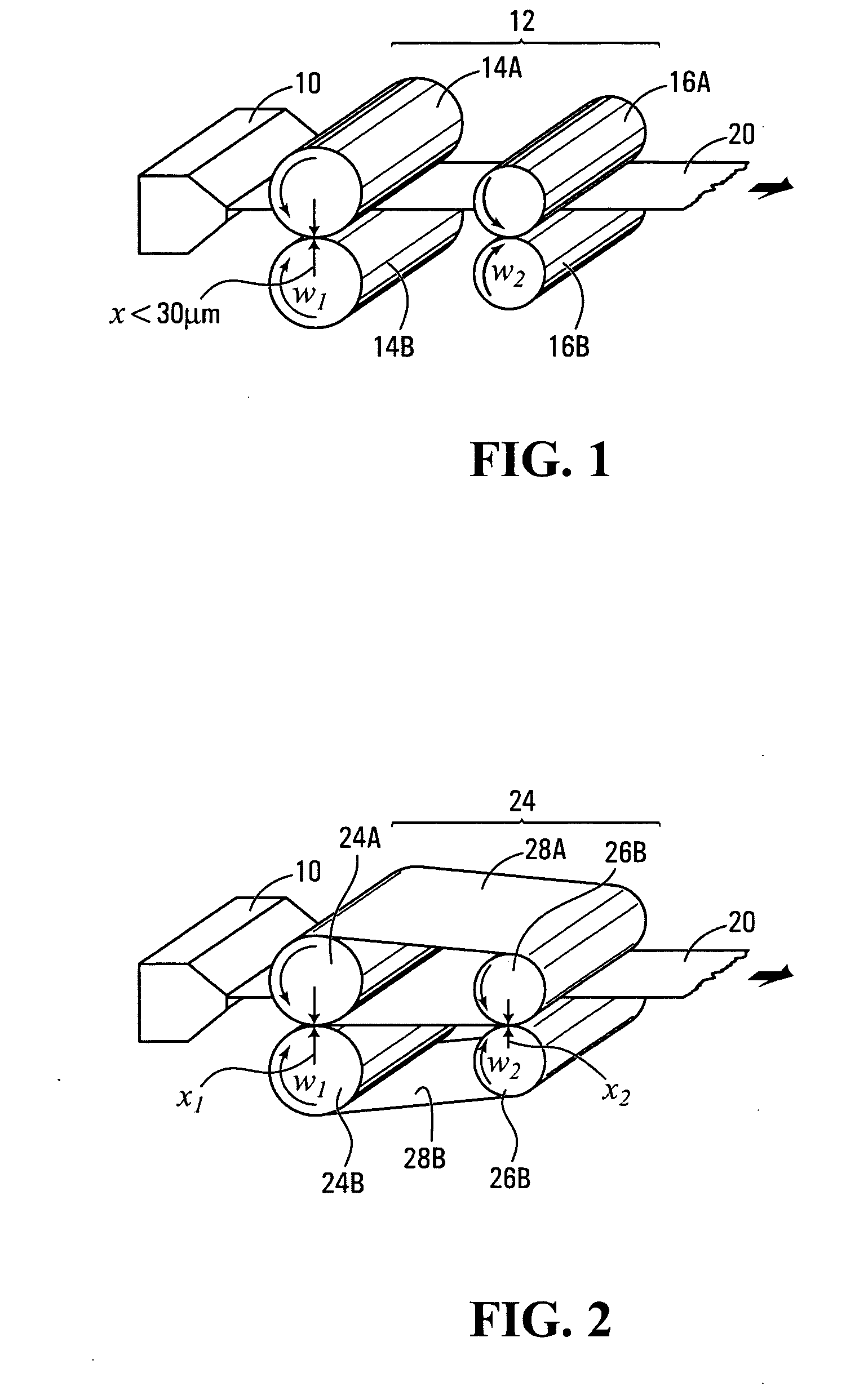

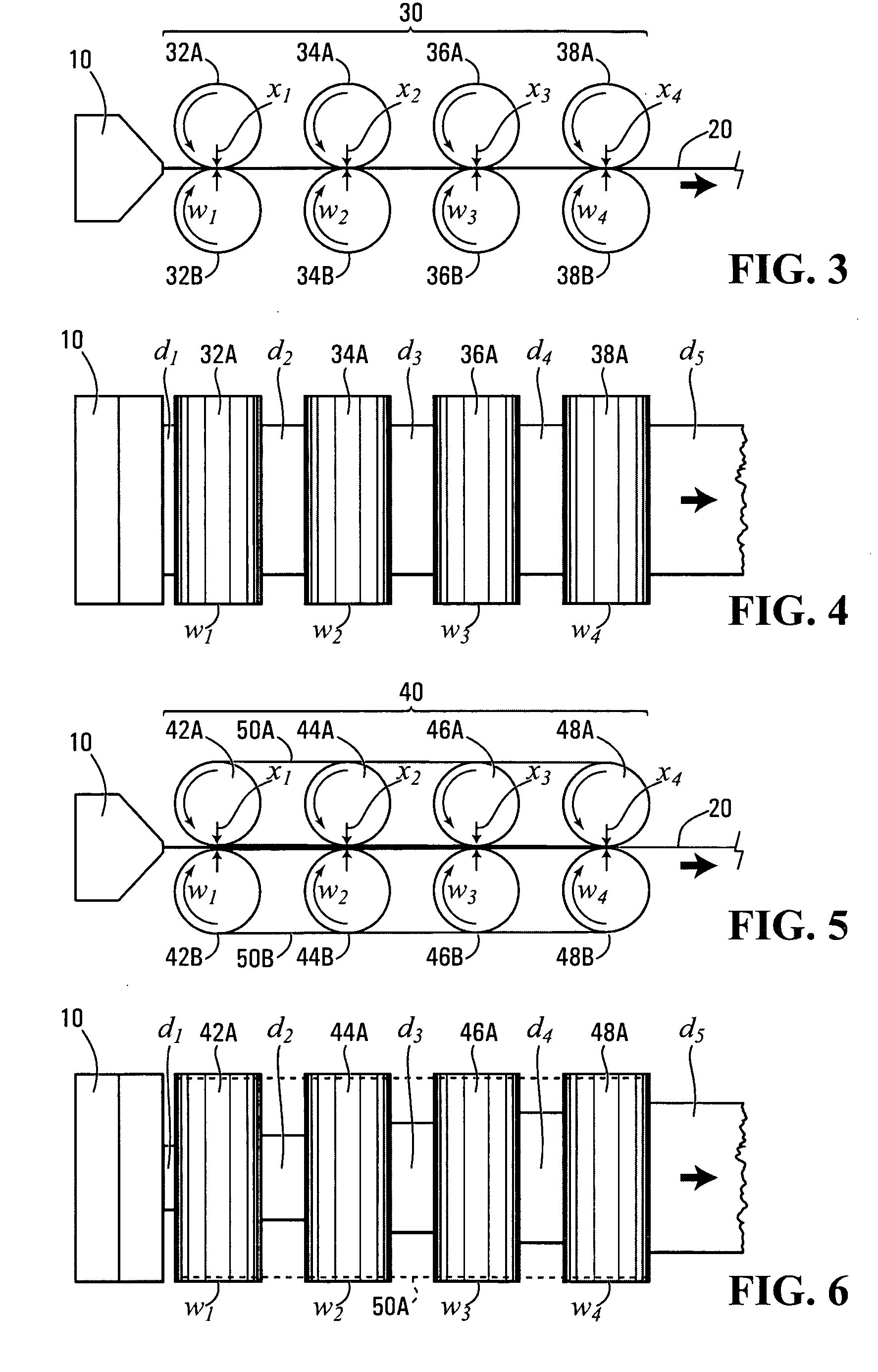

Coating method and coating apparatus

InactiveUS20130230641A1Increase productionUniform widthElectrode collector coatingElectrode extrusionMaterials scienceViscosity measurement

In a coating apparatus 100 provided by the present invention an electrode material paste 12 is coated onto an elongated collector 10, to form thereby a coating film 14 of predetermined width in the longitudinal direction of the collector. The coating apparatus 100 includes: a discharge nozzle 20 that discharges the paste 12 onto the collector 10, Which is an object to be coated; a transport pipe 30 that transports the paste 12 up to the discharge nozzle 20; a viscosity measurement unit 40 that measures the viscosity of the paste 12 that is transported within the transport pipe 30; and a gap control unit 50 that modifies a size H of the clearance between the discharge nozzle 20 and the collector 10 on the basis of the viscosity measured by the viscosity measurement unit 40.

Owner:TOYOTA JIDOSHA KK

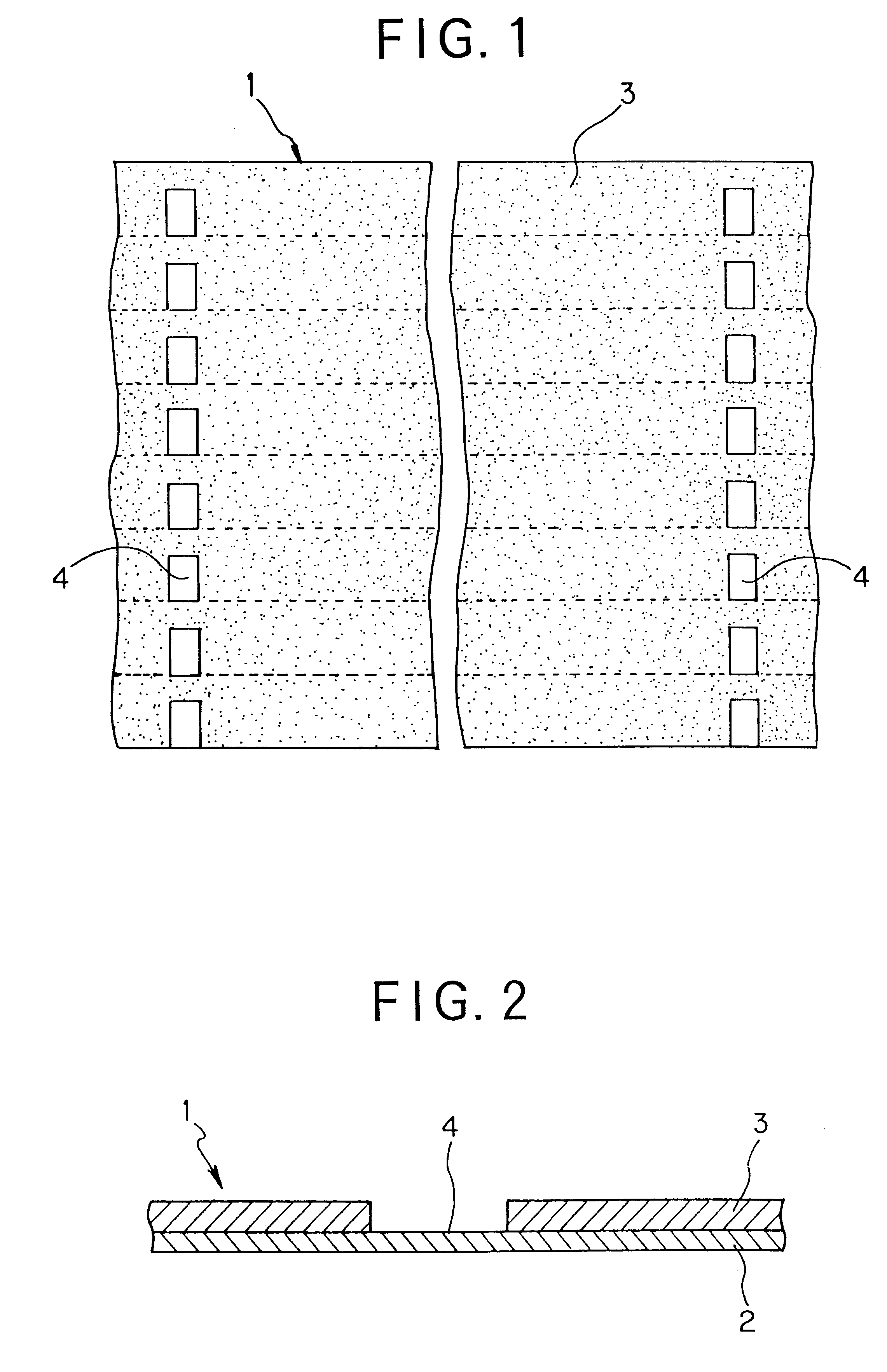

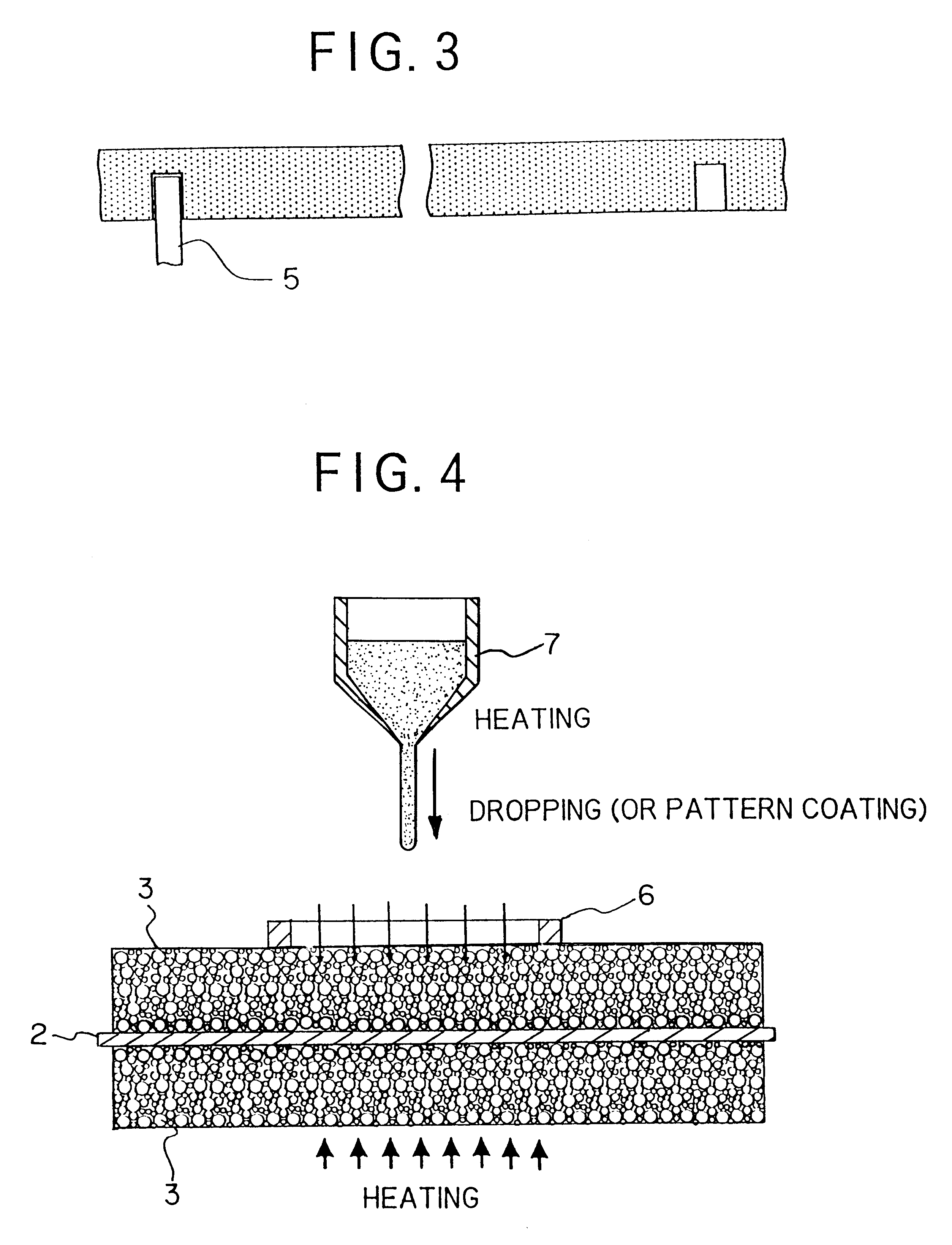

Process for producing an electrode plate with a terminal mounting portion and/or an identification mark

InactiveUS6315801B1Electrode rolling/calenderingPrimary cellsElectrical and Electronics engineeringCurrent collector

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and the electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

Battery electrodes with enlarged surfaces and method for production thereof

According to the invention, a method for the production of battery electrodes and battery electrodes produced with this method are provided, whereby the method comprises the production of compositions of the electrode materials for cathode or anode material and, if required, a separator material, and the extrusion of the electrode material to form the anode or cathode from the electrode material, and is characterized in that the electrode material comprises isocyanate and an aqueous dispersion of a polymer binder which react with one another to form porous structures. By means of the method according to the invention, extremely elastic and, at the same time, mechanically stable battery electrodes are generated that may be utilized in lithium secondary batteries.

Owner:GAIA AKKUMULATORENWERKE

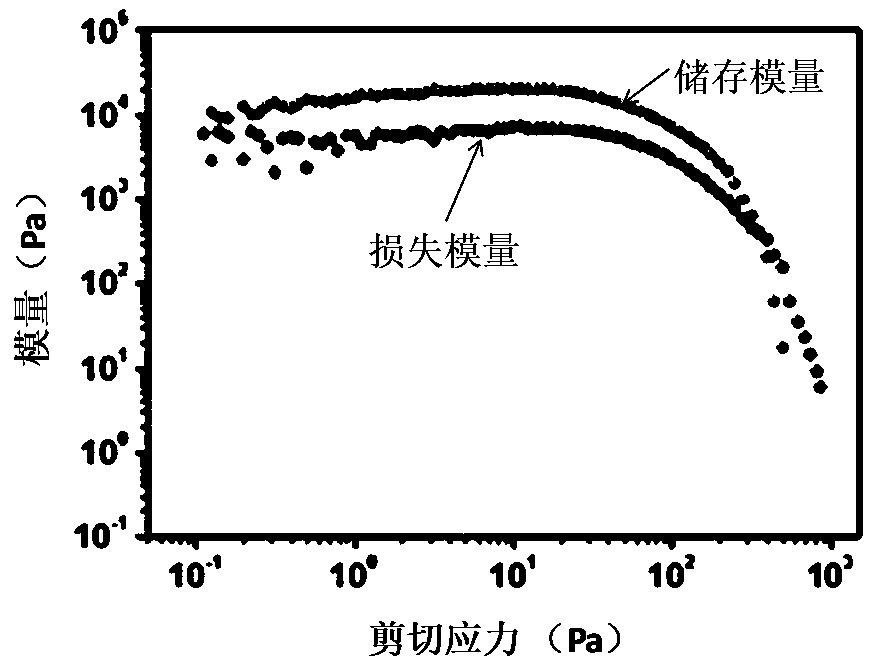

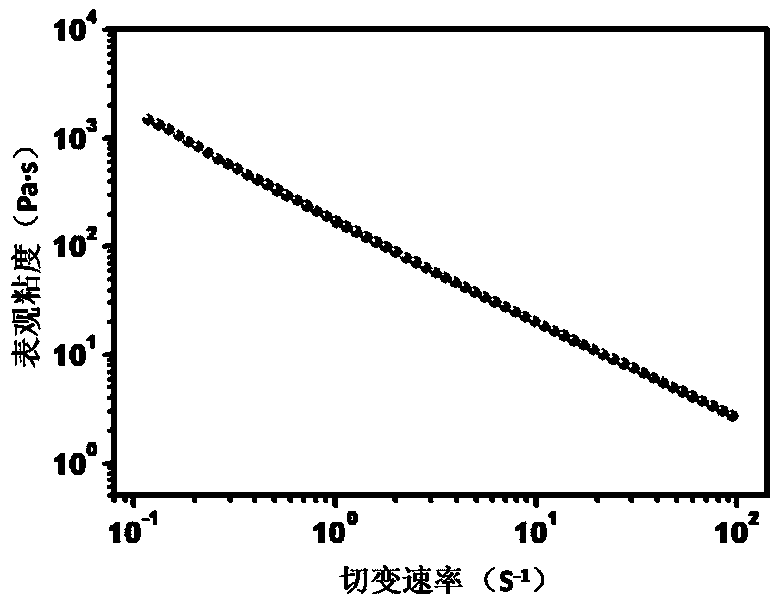

Lithium metal electrode prepared through 3D printing technology and preparation method thereof

ActiveCN110635109APromote circulationExcellent rate performanceAdditive manufacturing apparatusElectrode carriers/collectorsArray data structureRegular pattern

The invention discloses a lithium metal electrode prepared through the 3D printing technology and a preparation method thereof. The lithium metal electrode comprises a printing skeleton, wherein the printing skeleton is of a network structure with regular patterns and comprises a grid structure, an array structure, a honeycomb structure, a concentric circle structure or a spiral structure; and lithium metal, which is deposited on the surface of the printing framework and / or is filled in gaps of the printing skeleton. The invention further discloses printing slurry suitable for the method for preparing the lithium metal electrode through the 3D printing technology. According to the method for preparing the lithium metal electrode through the 3D printing technology, by applying the 3D printing technology to preparation of the lithium metal battery, the problem of preparation of microstructure materials which are difficult to industrially manufacture is solved, and the prepared lithium metal electrode shows excellent cycle performance, good rate capability, excellent deep charging and deep discharging performance and high coulombic efficiency; and after multiple times of charging anddischarging, the surface is smooth, and no obvious dendritic crystal is formed.

Owner:BEIHANG UNIV

Method for producing hybrid negative plate for lead-acid storage battery and lead-acid storage battery

ActiveUS20120263977A1Improve work efficiencyImprove productivityHybrid capacitor electrodesElectrolytic capacitorsProduction rateCapacitance

There is provided a method for producing a hybrid negative plate for a lead-acid storage battery which is improved in the production working efficiency and the productivity and enhances the quick charge and discharge characteristics and the discharge characteristics at a low temperature under PSOC of a lead-acid storage battery.A carbon mixture sheet produced by such a way that a carbon mixture prepared by mixing two types of carbon materials consisting of a first carbon material having electroconductivity and a second carbon material having capacitor capacitance and / or pseudocapacitor capacitance, and at least a binder, is adhered by pressure to the surface of a negative plate in a wet state, so that a hybrid negative plate is produced. The lead-acid storage battery provided with the hybrid negative plate is improved in the discharge characteristics.

Owner:THE FURUKAWA BATTERY CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com