Method and apparatus for making positive electrode films for polymer batteries

a technology of positive electrode material and polymer battery, which is applied in the field of polymer batteries, can solve the problems of inefficient process for mass production of cathode material, reduced density, and difficulty in extruding positive electrode material into thin films, and achieves high solid conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

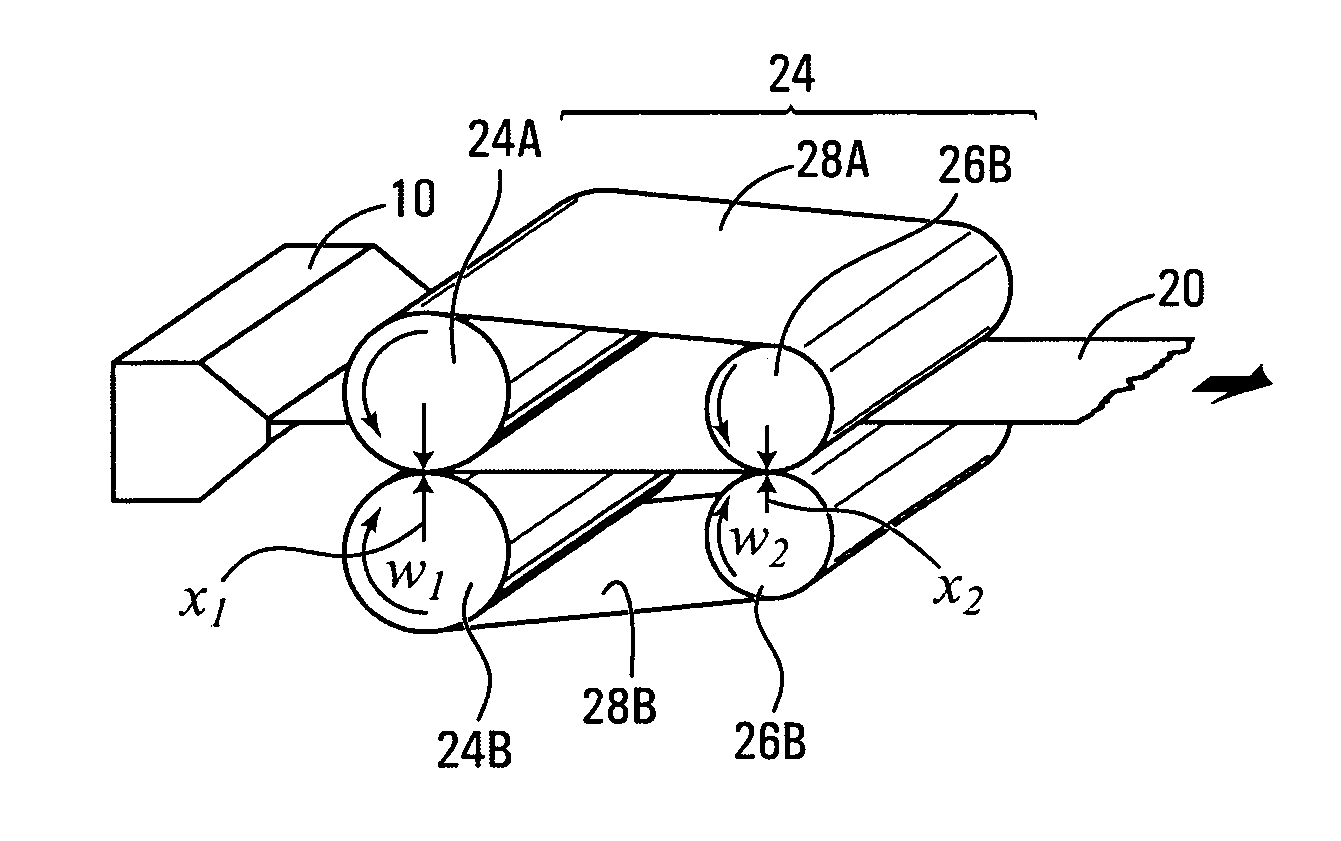

second embodiment

[0041] In FIG. 2, there is shown the invention in which a calendering apparatus 22 is juxtaposed to a sheet die 10 of a typical single or twin screw extruding machine (not shown). Calendering apparatus 22 comprises a first pair of cylindrical nip rollers 24A and 24B and a second pair of cylindrical nip rollers 26A and 26B. In this specific embodiment, nip rollers 24A and 26A are joined by a metallic belt 28A that remains in contact with the composite positive electrode sheet 20 as it is being calendered. Similarly, nip rollers 24B and 26B are joined by a metallic belt 28B that remains in contact with the composite positive electrode sheet 20 as it is being calendered. The metallic belts 28A and 28B impose that the rotational speeds of nip rollers 24A and 26A and of nip rollers 24B and 26B are equal such that ω1=ω2.

[0042] In one example of implementation, the distance x1 between nip rollers 24A and 24B is set at the final desired thickness of composite positive electrode sheet 20 of ...

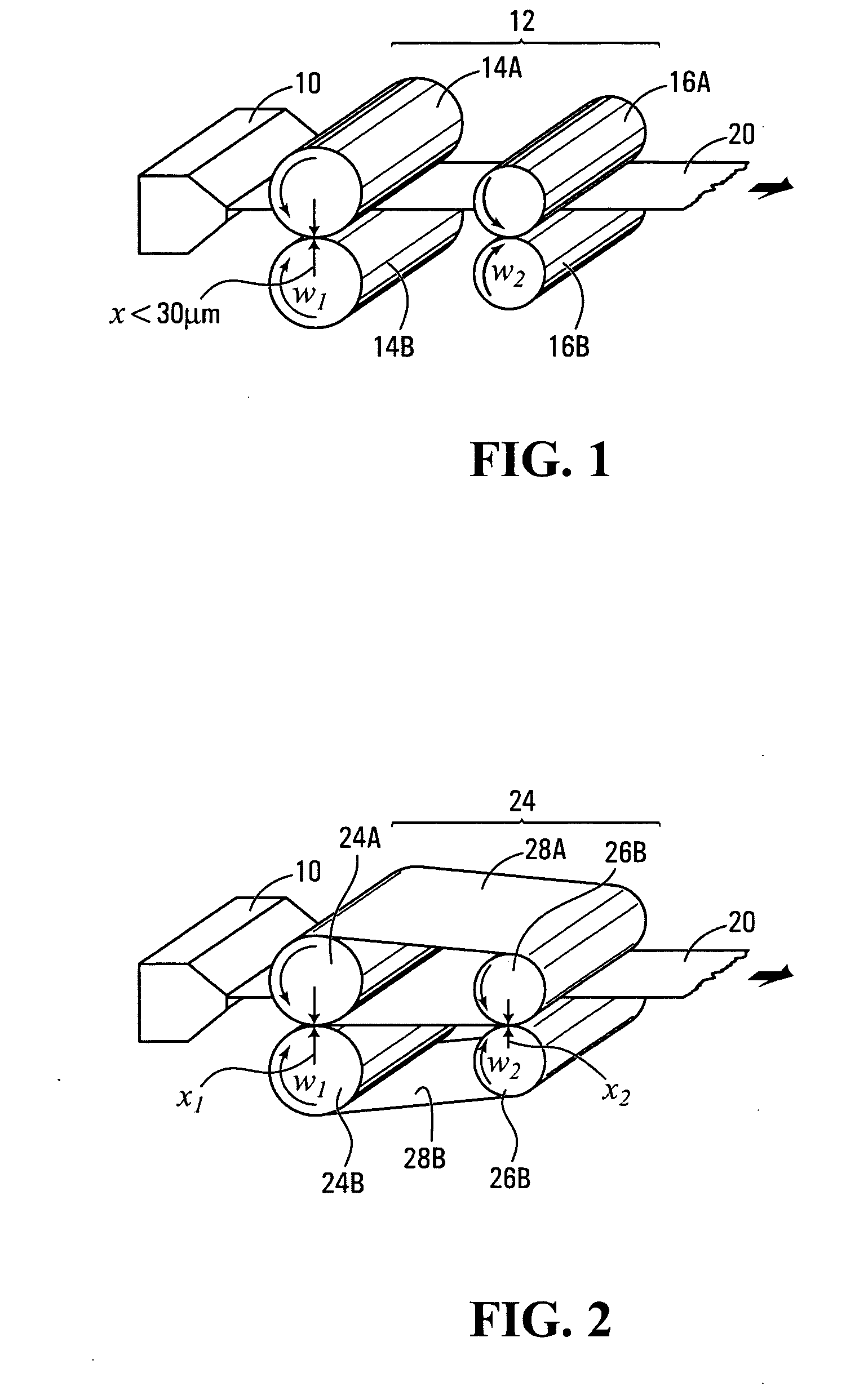

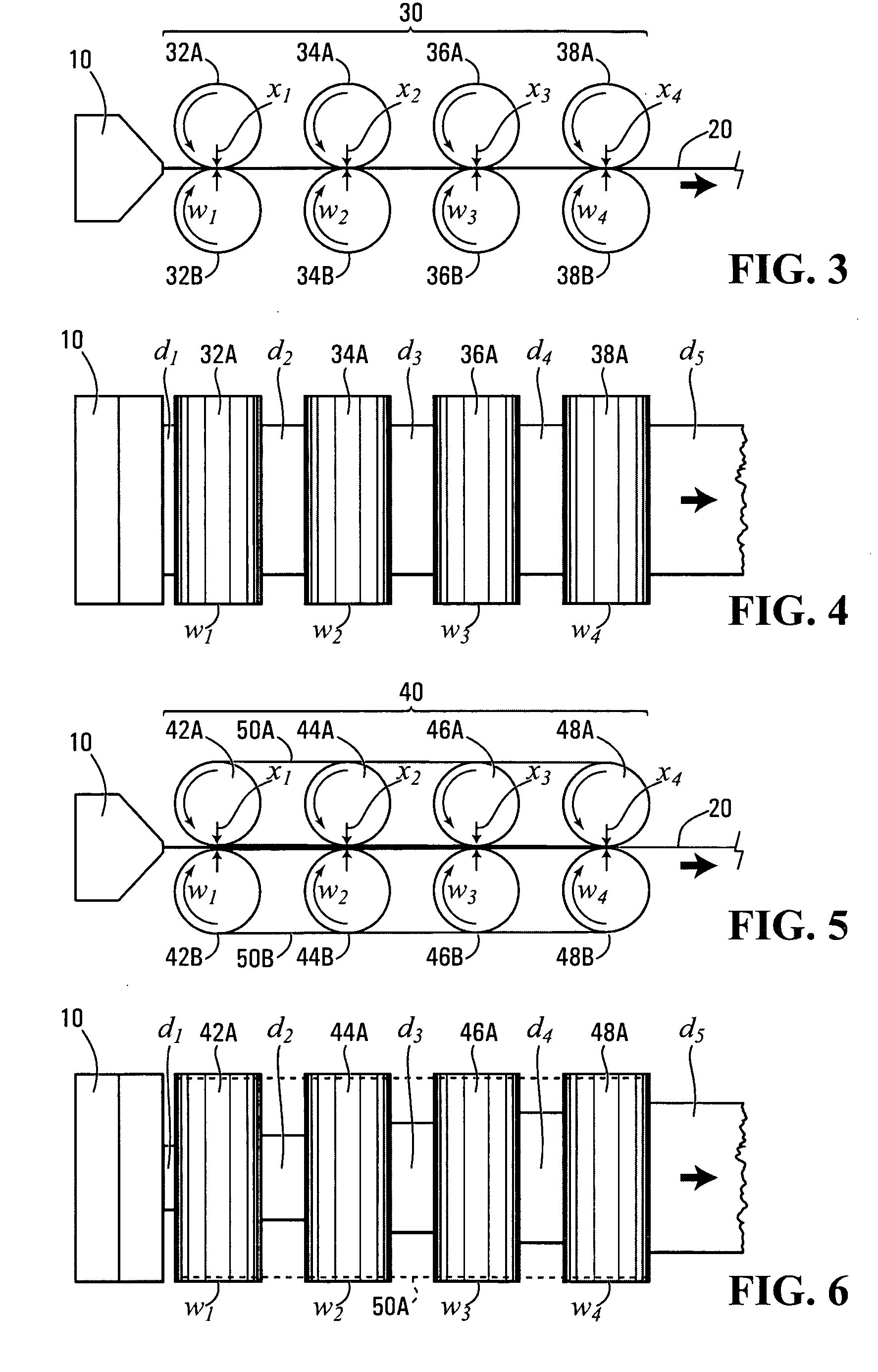

third embodiment

[0046] In FIGS. 3 and 4, there is shown respectively a side elevational view and a top plan view of the invention in which a calendering apparatus 30 is juxtaposed to a sheet die 10 of a typical single or twin screw extruding machine (not shown). Calendering apparatus 30 comprises a series of cylindrical nip rollers 32A, 32B, 34A, 34B, 36A, 36B, 38A and 38B arranged in pairs and adapted to progressively reduce the thickness of a composite positive electrode sheet 20 passing through the calendering apparatus 30. In this embodiment, the distances x1, x2 and x3 between the nip rollers 32A and 32B, 34A and 34B, and 36A and 36B, respectively, gradually decrease such that x1>x2>x3 and the thickness reduction, work performed on the composite positive electrode sheet 20 is also more gradual than in the previous embodiments shown in FIGS. 1 and 2. As an example only, the composite positive electrode sheet 20 may exit die 10 at a thickness of 75 μm, the distances x1, x2 and x3 between the nip...

fourth embodiment

[0049] In FIGS. 5 and 6, there is shown respectively a side elevational view and a top plan view of the invention in which a calendering apparatus 40 is juxtaposed to a sheet die 10 of a typical single or twin screw extruding machine (not shown). Calendering apparatus 40 comprises a series of pairs of cylindrical nip rollers 42A-42B, 44A-44B, 46A-46B, and 48A-48B, as well as two metallic belts 50A and 50B respectively circumscribing and joining together the two banks of nip rollers 42A-44A-46A-48A and 42B-44B-46B-48B. Calendering apparatus 40 is adapted to progressively reduce the thickness of a composite positive electrode sheet 20 passing through the calendering apparatus 40. In this embodiment, the distances x1, x2 and x3 between the nip rollers 42A and 42B, 44A and 44B, and 46A and 46B, respectively, gradually decrease such that x1>x2>x3 and the thickness reduction work performed on the composite positive electrode sheet 20 is also more gradual than in the previous embodiments s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com