Cathode for lithium-containing batteries and solvent-free method for the production thereof

A lithium battery and process technology, applied in battery electrodes, lithium batteries, electrode extrusion, etc., can solve problems such as toxicity, complicated dispersion steps, and complicated drying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The following dry, solvent-free starting components are provided:

[0082] 0.450g of activated carbon (YP50F, Kuraray Chemical Co., Ltd.) as porous, conductive carbon material,

[0083] 0.450 g of sulfur as electrochemically active cathode material,

[0084] 0.050g of conductive carbon black (Super C65, Te Mi Gao Co., Ltd.) as conductive carbon material,

[0085] 0.050 g polytetrafluoroethylene.

[0086] The above materials were added to the steel mortar mixer (ie to provide a dry, solvent-free composition). The fiberization of the above-mentioned polytetrafluoroethylene was obtained by grinding for 2 minutes under the condition of both the horizontal pressure and the vertical pressure of 20 kg. A fibrous composition is obtained. The composition was calendered in a calender at 155° C. to a thickness of 150 μm. A self-supporting or independent cathode foil is obtained.

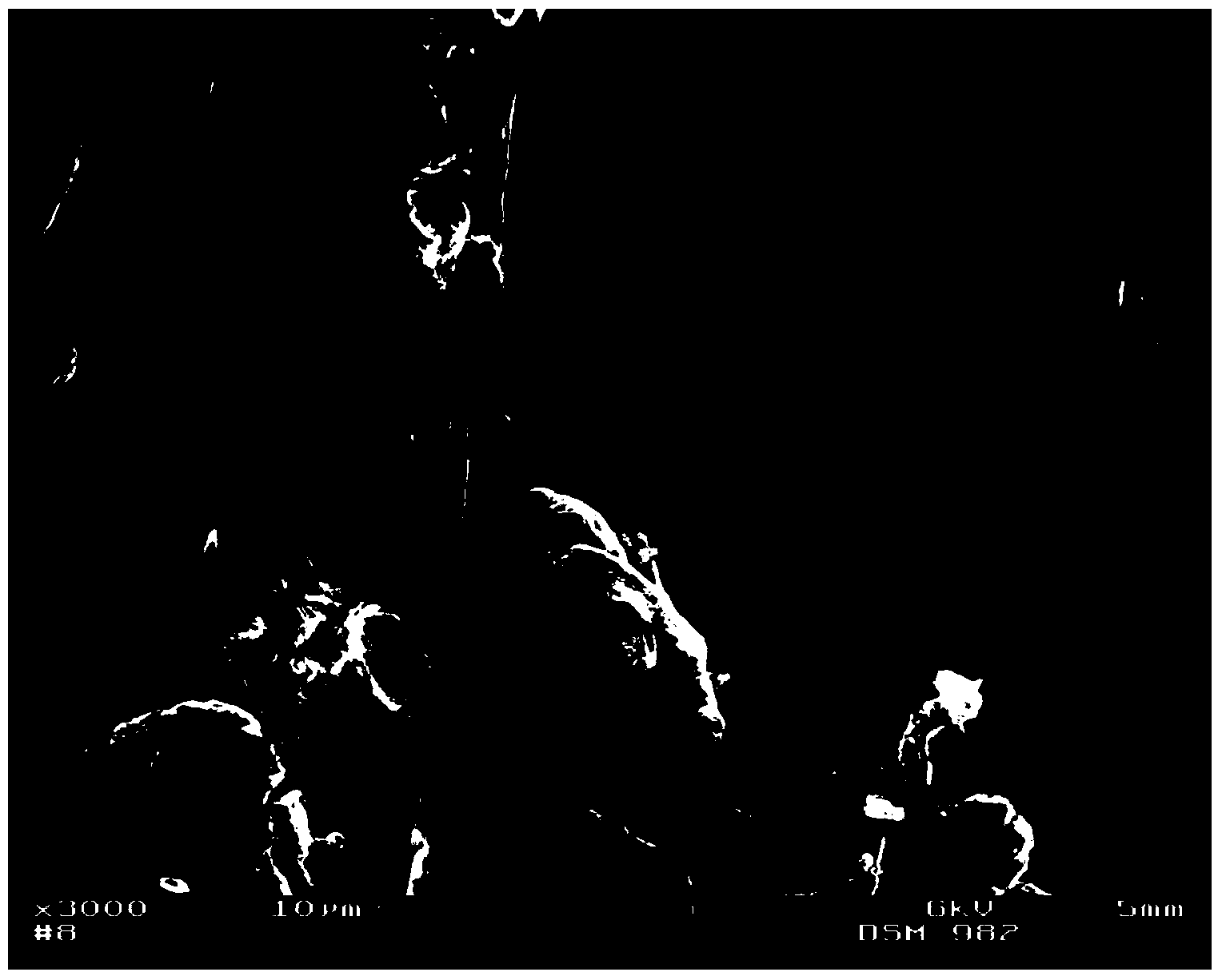

[0087] The self-supporting foil has good mechanical properties and, moreover, it can actually b...

Embodiment 2

[0089] The following dry, solvent-free starting components are provided:

[0090] 0.300g spherical carbon (TV 505, Blücher Adsor-Tech Co., Ltd.) as porous, conductive carbon material,

[0091] 0.600 g of sulfur as electrochemically active cathode material,

[0092] 0.050g of conductive carbon black (Super C65, Te Mi Gao Co., Ltd.) as conductive carbon material,

[0093] 0.050 g polytetrafluoroethylene.

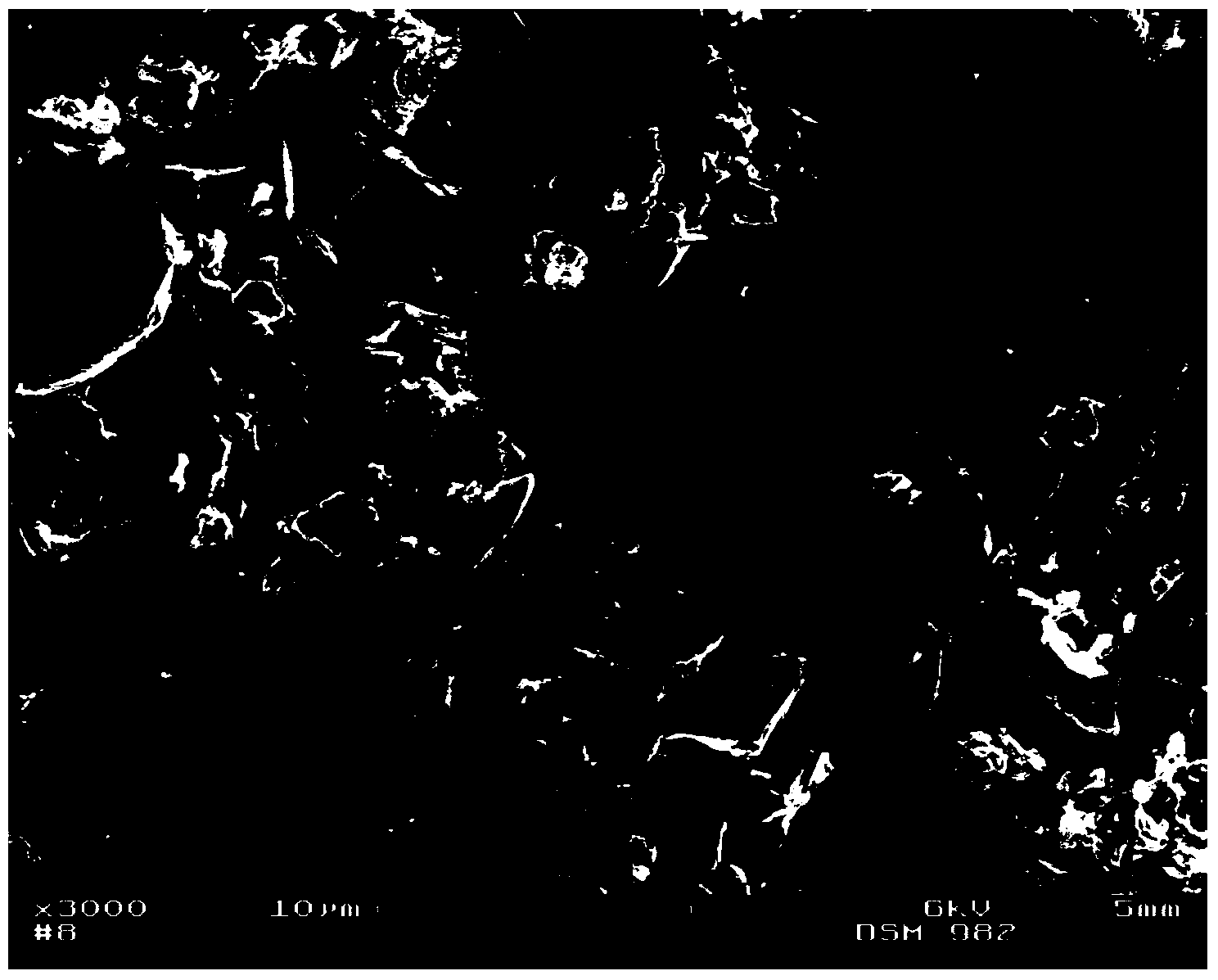

[0094] The aforementioned self-supporting cathode foil with a thickness of 150 μm was produced using a similar process step as in Example 1.

Embodiment 3

[0096] The following dry, solvent-free starting components are provided:

[0097] 0.250 g spherical carbon (TV 505, Blücher Adsor-Tech AG) as porous, conductive carbon material,

[0098] 0.500 g of sulfur as electrochemically active cathode material,

[0099] 0.200g of carbon nanotubes (NC7000, Nanocyl) as conductive carbon material,

[0100] 0.050 g polytetrafluoroethylene.

[0101] The aforementioned self-supporting cathode foil with a thickness of 150 μm was produced using a similar process step as in Example 1.

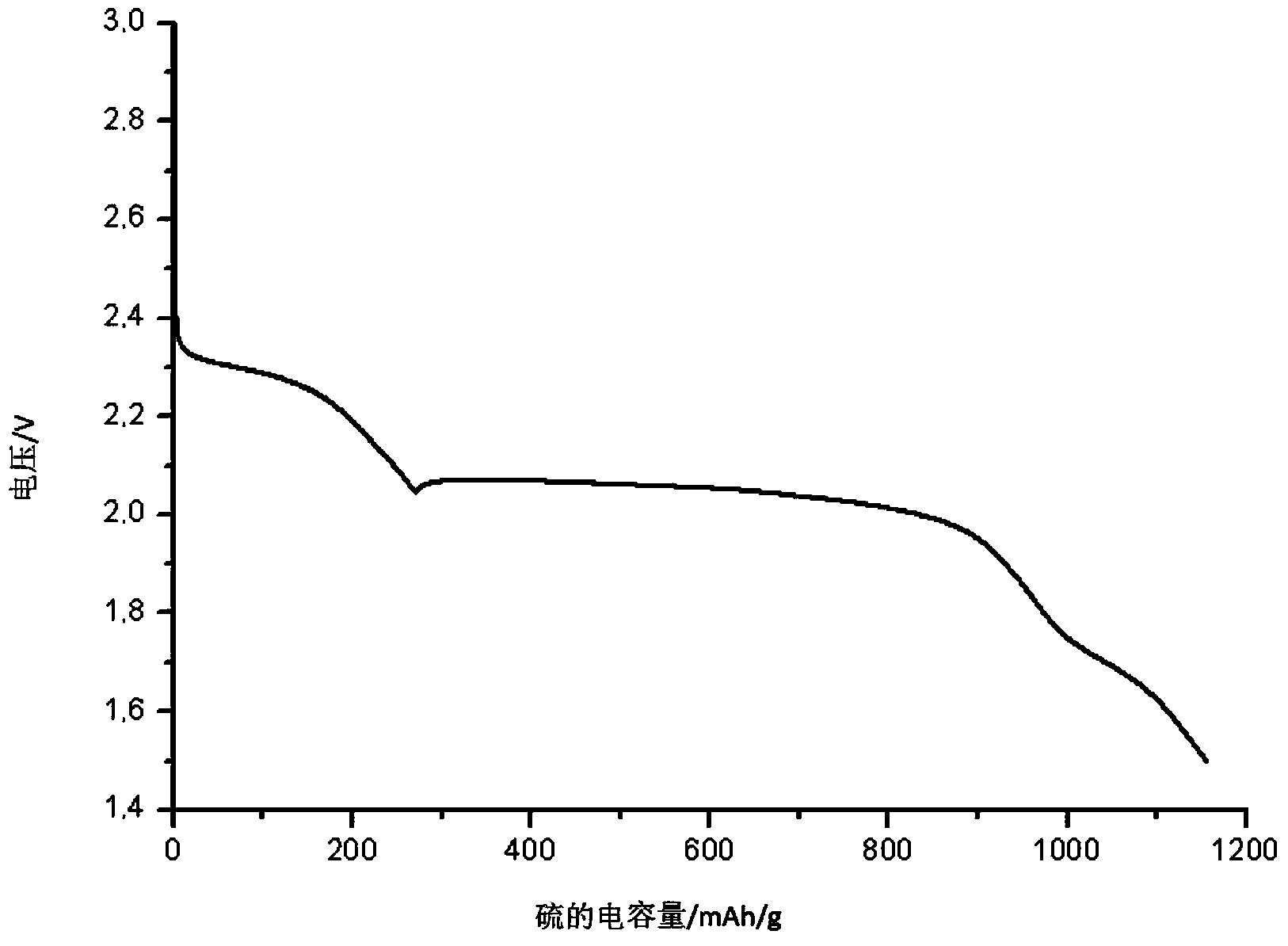

[0102] Using the self-supporting cathode foil produced in Example 3, the discharge curve of the first cycle of the lithium-sulfur battery was determined. This shows up in image 3middle. The discharge capacity of sulfur can be determined as high as 1150 mAh / g. This is almost comparable to the value of the lithium-sulfur battery in the prior art eg US 6,569,573.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com