A household vertical noodle machine

A noodle machine, vertical technology, applied in the direction of dough extruder, mixing/kneading with vertical installation tools, dough forming machinery or equipment, etc., can solve the problem of dough or dough residue, poor customer experience, easy to Residual dough, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

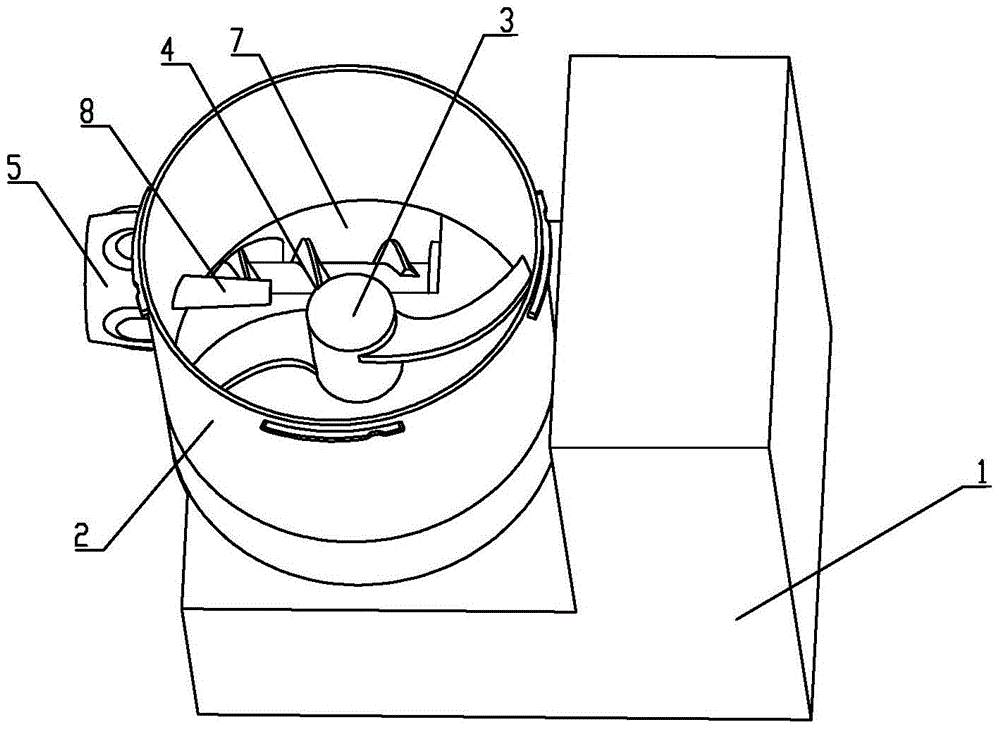

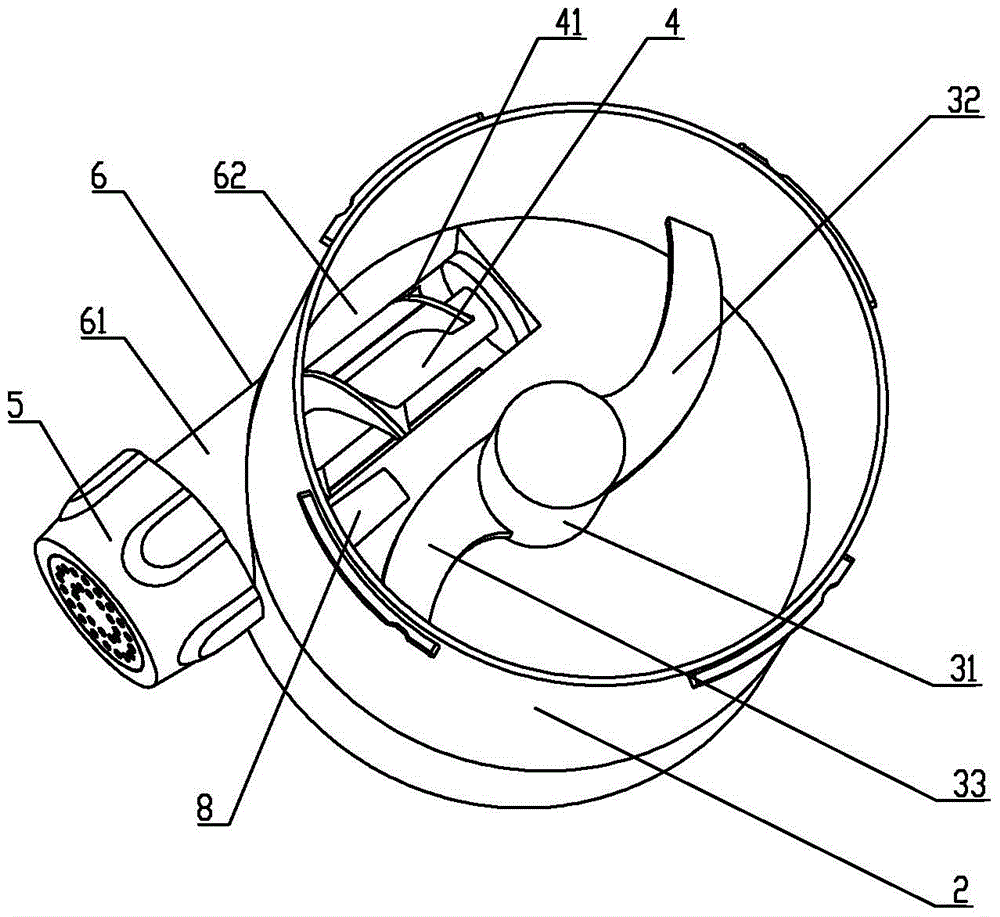

[0039] Such as figure 1 , 2 As shown, the household vertical noodle machine of the present invention includes a base 1, a stirring cup 2 connected to the base 1, a stirring rod 3, a noodle extruding cylinder 6, a screw 4, and a die head 5. A motor (not shown in the figure) and a control unit (not shown in the figure) electrically connected to the motor are provided, and the control unit includes a control circuit module and a circuit detection module.

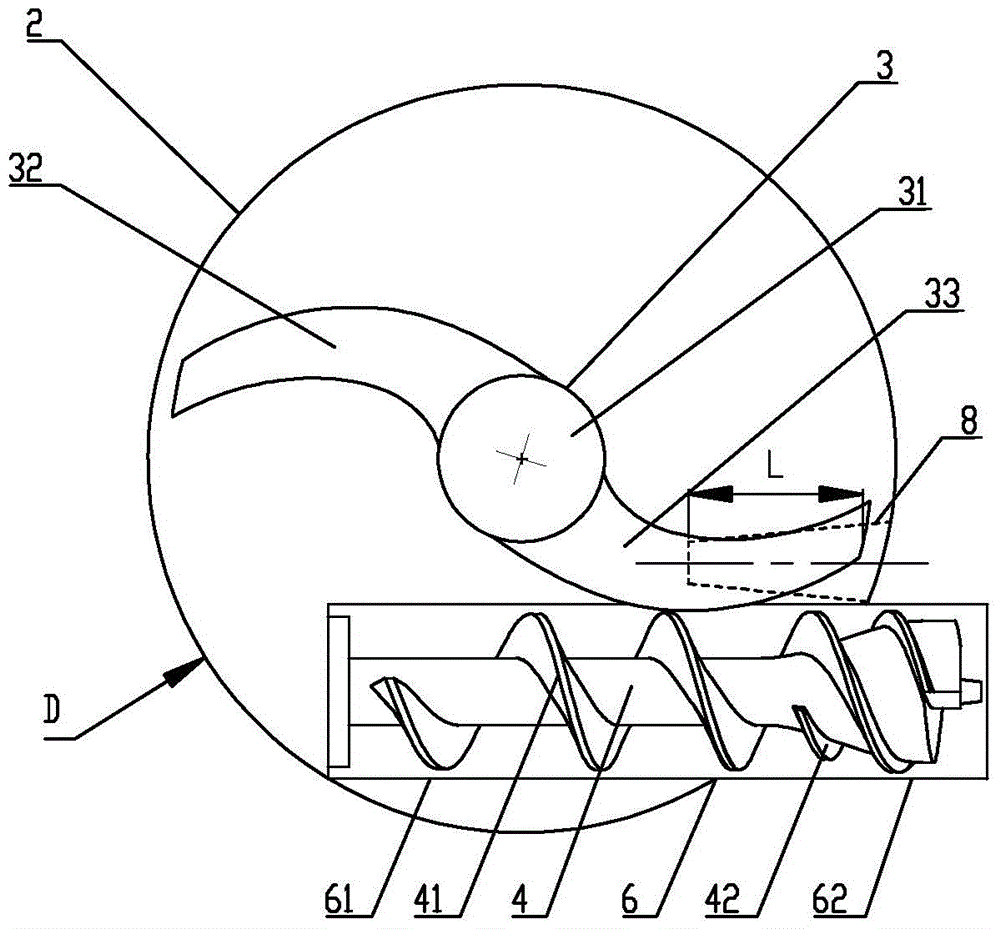

[0040] Such as image 3 As shown, the stirring cup 2 is circular, and the diameter of the stirring cup is D. This setting makes the inner wall of the mixing cup smooth, and the inner wall of the mixing cup will not form a dead corner of the dough when kneading the dough, so as to avoid remaining noodles in the mixing cup.

[0041] The stirring rod 3 is vertically arranged in the stirring cup 2, the stirring rod 3 includes a rod body 31 and an upper stirring tooth 32 and a lower stirring tooth 33 arranged on the rod body 31, ...

Embodiment 2

[0074] The difference between this embodiment and Embodiment 1 is that there are two motors, a first motor and a second motor, the first motor is connected to the stirring rod, and the second motor is connected to the screw.

[0075] The motor (not shown in the figure) includes a first motor (not shown in the figure) and a second motor (not shown in the figure), the first motor is in transmission connection with the stirring rod 3, and the second motor The first motor and the second motor independently drive the stirring rod 3 and the screw 4 to rotate and are independently controlled by the control unit.

[0076] The advantage of this embodiment is that two motors are used, and the screw and the stirring rod are controlled by separate motors, which is easy to control and accurate and reliable.

Embodiment 3

[0078] The difference between this embodiment and the first embodiment lies in that the stirring rod is different.

[0079] Such as Figure 8 As shown, there are two upper stirring teeth 32 located on the same horizontal plane, and the two upper stirring teeth 32 are symmetrically distributed relative to the rod body 31 . There are two lower stirring teeth 33 located on the same horizontal plane, and the two lower stirring teeth 33 are symmetrically distributed relative to the rod body 31 . The two upper stirring teeth 32 and the two lower stirring teeth 33 are integrally formed with the rod body 31 . Of course, they can also be fixed together by secondary injection molding or clamping or screwing or pasting.

[0080]The advantage of this embodiment is that the mixing rod can be cut four times with the dough cutting rod once it rotates, which further improves the dough mixing effect and improves the dough mixing efficiency; at the same time, the dough is cut smaller, making ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com