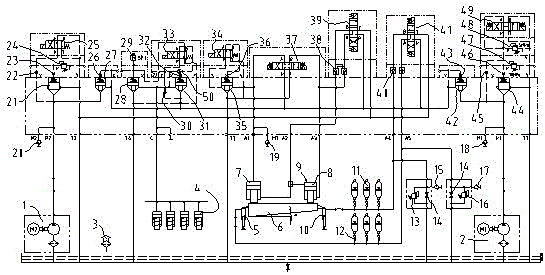

A hydraulic system of a large gate shearing machine

A technology of hydraulic system and shearing machine, which is applied in the field of hydraulic machine to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. according to figure 1 , the pressure control plug-in I21 included in the hydraulic system is connected to the power unit I1, and is connected to the oil tank through the T2 oil port, and forms a pressure control circuit with the damper I22, the electromagnetic reversing valve II33, the overflow valve III24, and the electromagnetic reversing valve I25. Electromagnetic reversing valve I25 can control the pressure building and unloading of power unit I1. The one-way valve formed by the direction control plug-in I27 and the damper III26 prevents the power unit II2 from affecting the power unit I1, which is particularly important in the failure state of the power unit I1. The pressure control plug-in Ⅱ44 is connected to the power unit Ⅱ2, and connected to the oil tank through the T1 oil port, and forms a pressure control circuit with the damper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com