A tape-sticking and cutting mechanism

A belt cutting and cutting knife technology, which is applied to the parts and packaging of the strapping machine, can solve the problems that the strapping cannot be completely cut off at one time, affects the stability of the strapping machine, and the cutting surface of the strapping is not smooth. Stable and reliable ironing, smooth incision and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

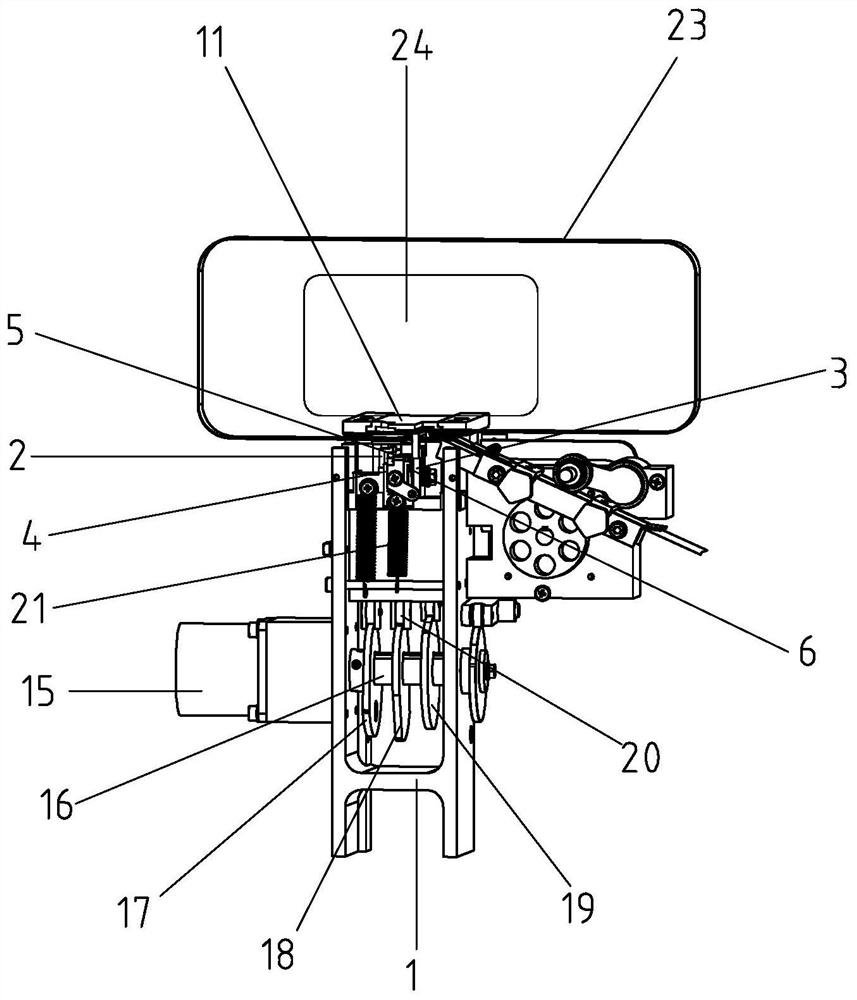

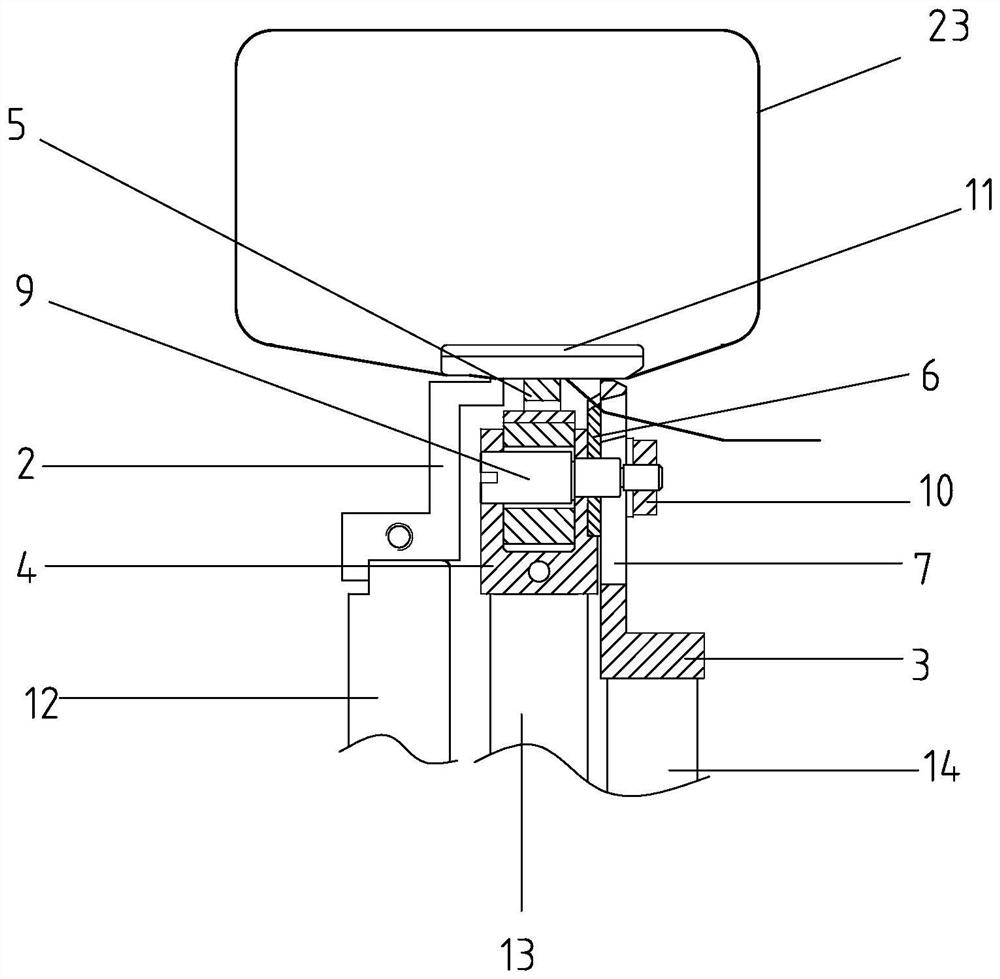

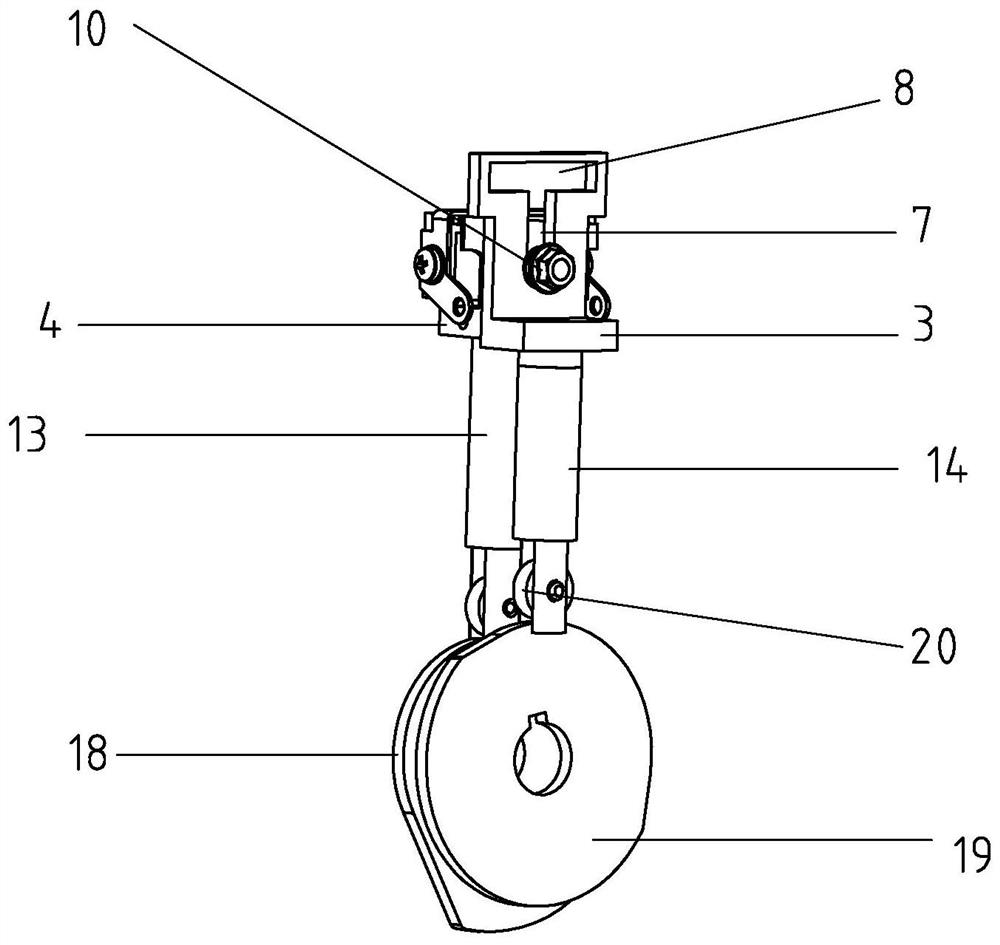

[0023] like figure 1 , figure 2 , image 3 , Figure 4 A hot sticking and cutting tape mechanism shown is arranged on the core frame 1, and includes a left limit seat 2, a right limit seat 3, a cutter seat 4 located between the left limit seat and the right limit seat, A perm assembly 5 is arranged in the cutter seat, a cutter 6 is provided on the right side of the cutter seat 4, a vertical slot 7 is arranged on the right limiting seat 3, and the right limiting seat 3 is located on the upper side of the vertical slot A threading groove 8 is provided, a connecting piece 9 is provided on the cutter seat 4, a cutter positioning hole 60 is provided on the cutter 6, and the end of the connecting piece 9 passes through the cutter positioning hole 60 and the vertical groove 7 successively. Connect with the fastener 10, the connector is slidingly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com